Page 1

Chapter

Chapter

Chapter

CommuniCations

6

6

6

In This Chapter...

Communications: Capabilities ................................................................................... 6-3

Communication Ports ............................................................................................... 6-3

Communications: Connectivity ............................................................................... 6-11

Communication Ports ............................................................................................. 6-11

Communications ASCII and Custom Protocol Functionality .................................. 6-17

ASCII Instructions ................................................................................................... 6-17

Custom Protocol Instructions ................................................................................. 6-18

Communications: Ethernet ...................................................................................... 6-20

TCP and UDP Port Numbers .................................................................................. 6-20

IP Addressing and Subnetting ................................................................................ 6-20

PC Setup ................................................................................................................ 6-21

CPU Setup .............................................................................................................. 6-22

TCP Connection Behavior with Modbus TCP and Network Instructions ................. 6-23

Communications Modbus Functionality ................................................................. 6-24

Master/Client Function Code and Data Type Support ............................................ 6-24

Slave/Server Function Code and Data Type Support .............................................. 6-26

Assigning Modbus Addresses to Tags ..................................................................... 6-27

Modbus Options .................................................................................................... 6-30

Modbus Instructions ............................................................................................... 6-33

Network Instructions .............................................................................................. 6-35

Automatic Poll versus Manual Polling and Interlocking ........................................... 6-36

Message Queue ...................................................................................................... 6-38

EtherNet/IP for the Productivity Series ................................................................. 6-39

Terminology Definitions ......................................................................................... 6-39

Network Layer Chart .............................................................................................. 6-40

EtherNet/IP Data .................................................................................................... 6-40

Page 2

Chapter 6: Communications

Productivity

3000

Class 1 and Class 3 Connections ............................................................................ 6-41

Example Setup: Productivity3000® as EtherNet/IP Adapter ..................................... 6-41

Troubleshooting Tips: ............................................................................................. 6-47

Ethernet IP I/O Message Troubleshooting: .............................................................. 6-49

Ethernet IP Explicit Message Troubleshooting: ........................................................ 6-49

Communications: Remote I/O and GS-Drives ........................................................ 6-50

Things To Consider for the design of Remote I/O and GS-Drives ............................ 6-50

Configuration of Remote Slaves .............................................................................. 6-51

Configuration of GS-Drive Connections .................................................................. 6-54

Communications: Port Configuration ..................................................................... 6-58

Ethernet Configuration ........................................................................................... 6-58

External Ethernet Port Settings ............................................................................... 6-59

Local Ethernet Port Settings.................................................................................... 6-60

Remote Access Configuration ................................................................................. 6-60

Serial Configuration ................................................................................................ 6-61

RS-232 and RS-485 Port Settings ............................................................................ 6-61

Communications: Error Codes ................................................................................ 6-64

P3000 EtherNet/IP Error Codes ............................................................................. 6-65

ii

NOTE: The P3-RS module is discontinued as of 6/20. Please use P3-RX as a replacement.

Hardware User Manual, 4th Edition, Rev. M

Page 3

Productivity

3000

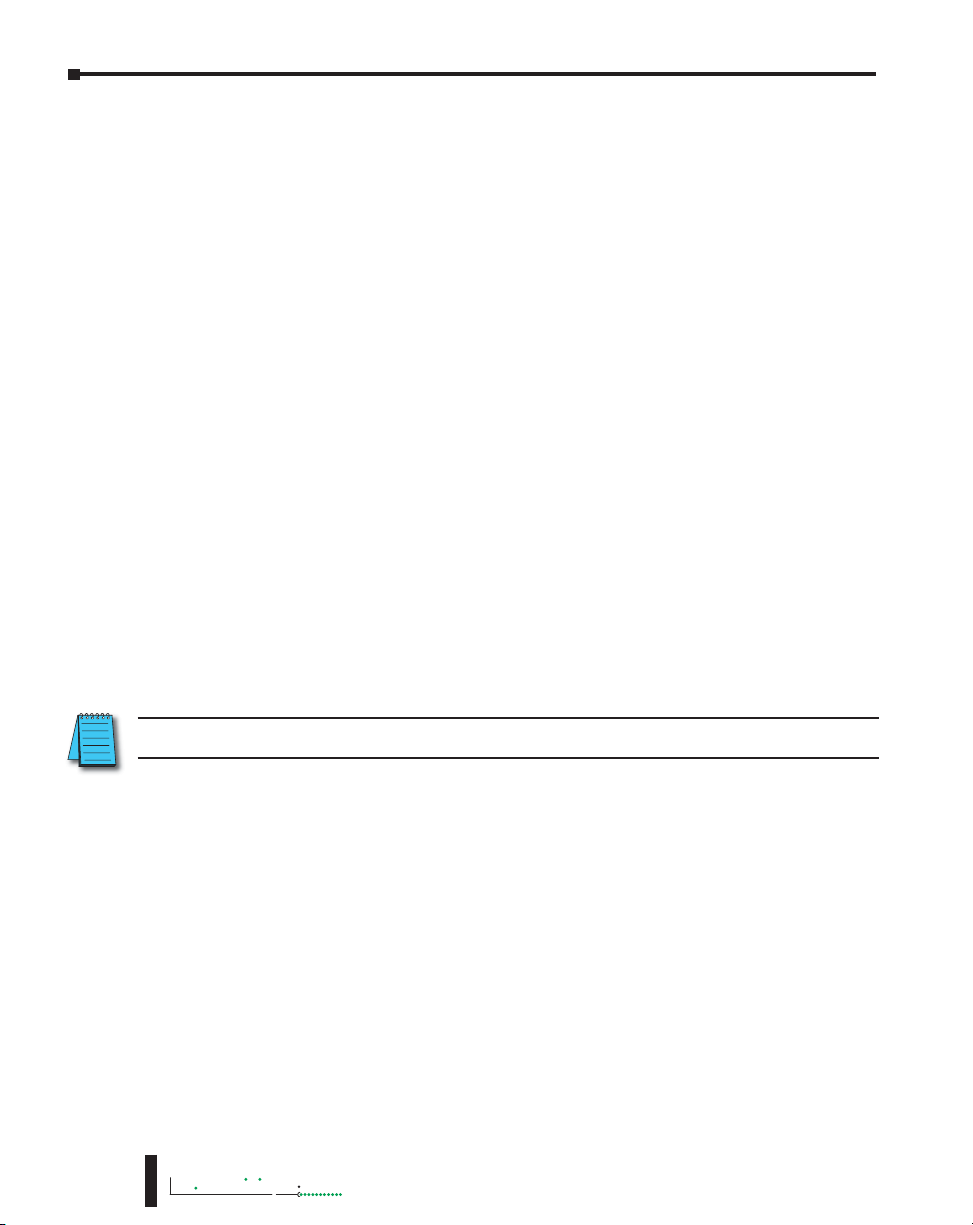

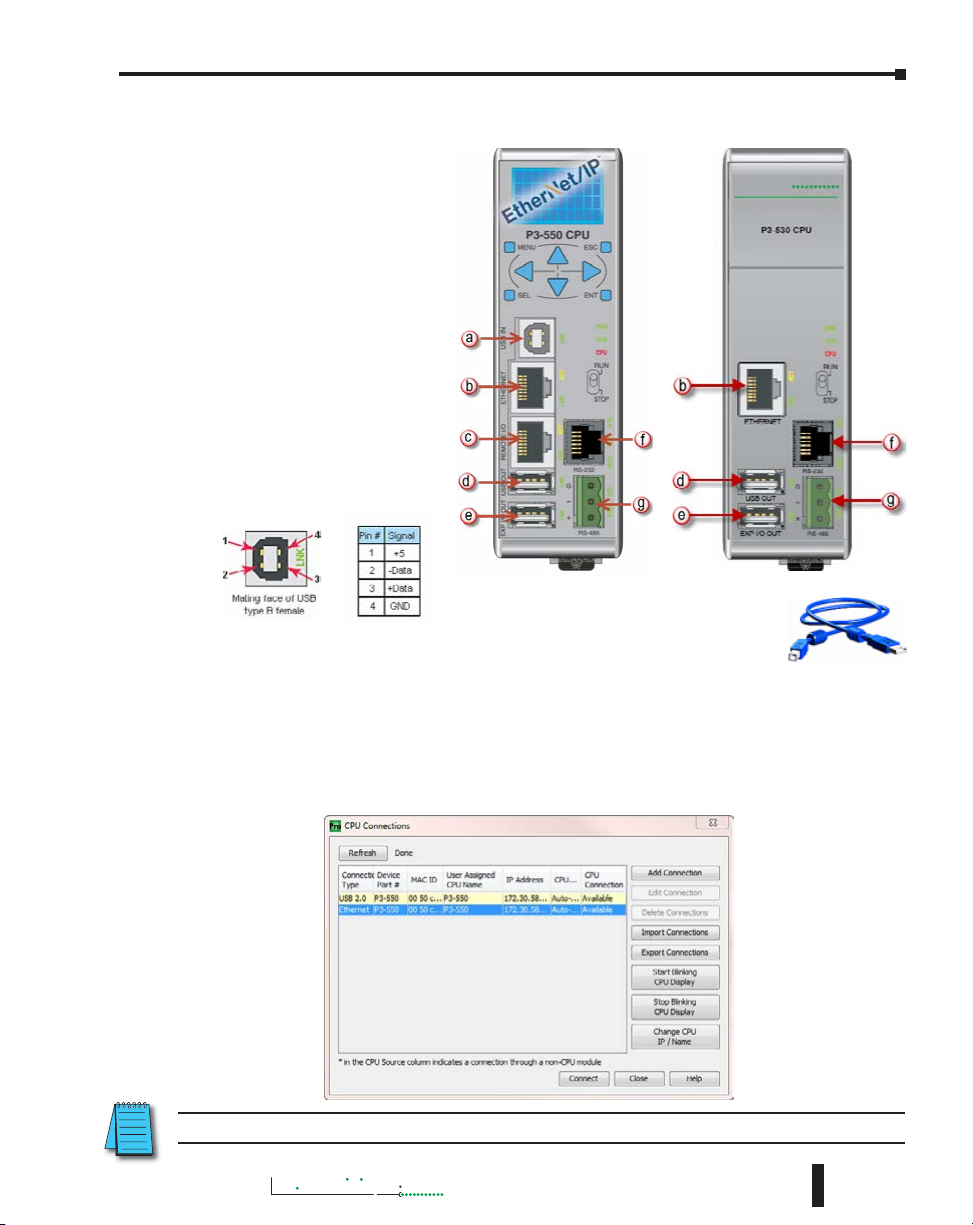

Communications: Capabilities

Communication Ports

The AutomationDirect P3000

CPUs are provided with several

Communications Ports. Each of

these ports are described in the

sections below.

a. USB IN: The USB IN

programming port is a USB

Type B style connector

located on the upper left

side of the CPU. It is used

exclusively for connecting to a

PC running the Productivity

Suite Programming

Software. Installing the

programming software will

install the USB driver as

well. See Communications:

Connectivity section for

connection information.

Chapter 6: Communications

NOTE: The USB IN port is NOT compatible with

older 1.0/1.1 full speed USB devices.

b. Ethernet: The Ethernet port is 10/100

Base-T Ethernet with an RJ-45 style

connector. It is used for:

• Connection to a PC running the

Productivity Suite programming

software.

• Modbus TCP Client connections

(Modbus requests sent from the

CPU).

• Modbus TCP Server connections

(Modbus requests received by the

CPU).

• Outgoing Email.

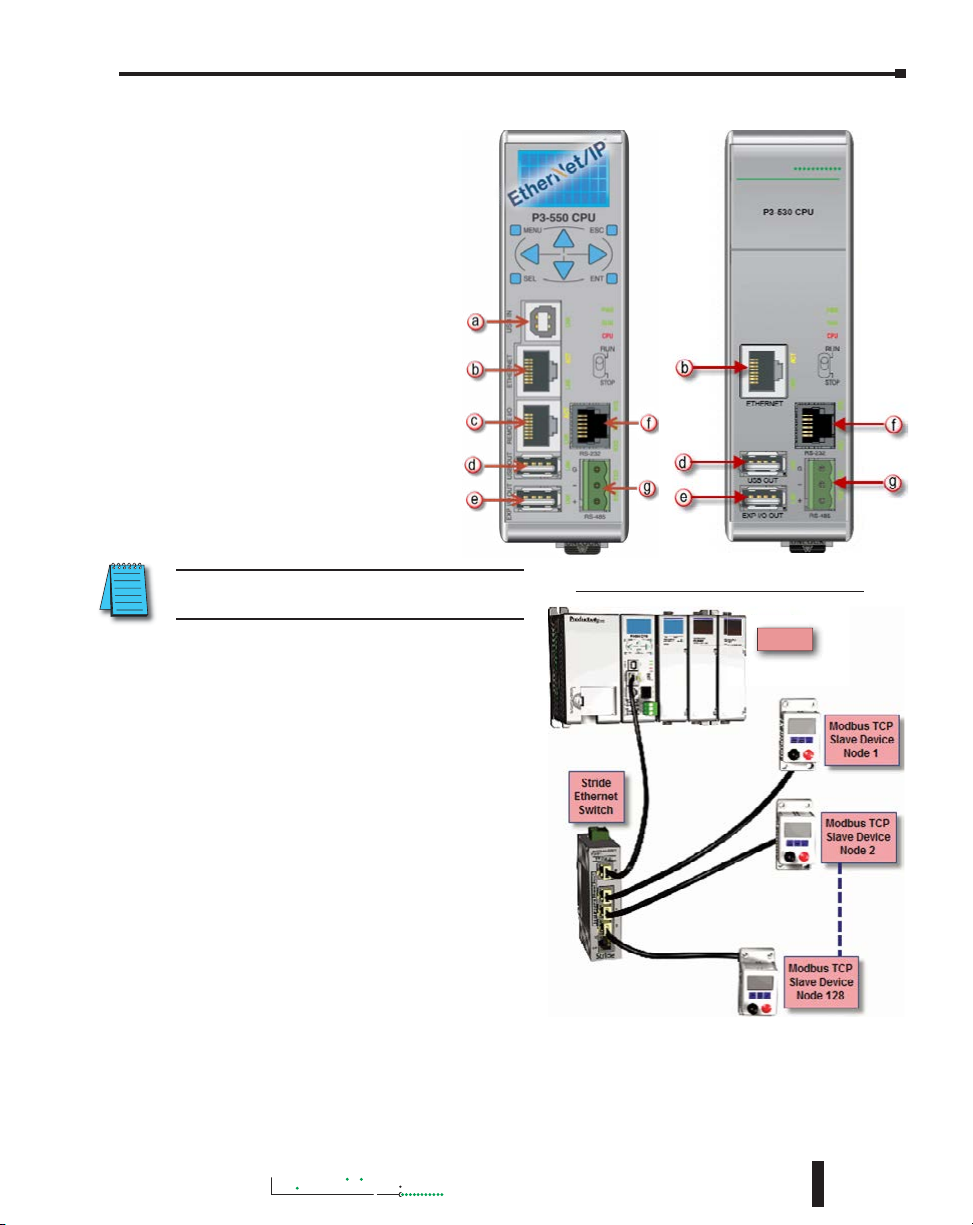

Modbus TCP Client connections: The

CPU can connect to 32 Modbus TCP

server devices concurrently by means

of communications instructions in the

ladder program (MRX, MWX, RX, WX).

It is possible to connect to more than

32 Modbus TCP server devices, but not

concurrently.

This is accomplished by having communications instructions for more than 32 devices in the

ladder program and controlling the enabling and disabling of the instructions so that only 32

devices are enabled at a given time. To connect to non Productivity3000

(Modbus Read) and MWX (Modbus Write) instructions. To connect to other P3000 CPU’s, use

the RX (Network Read) and WX (Network Write) instructions.

Modbus TCP Client (MRX-MWX)

P3-550(E)

®

devices, use the MRX

Hardware User Manual, 4th Edition, Rev. M

6-3

Page 4

Chapter 6: Communications

Productivity

The greatest difference between the RX and the MRX is the RX Tag Name in the target CPU

can be referenced directly and does not need a corresponding Modbus address. The way this

is accomplished is by mapping local and remote tagnames together within the local CPU’s

RX instruction. Once the instruction is set up to read a remote project, the “Tags of Remote

Project” or “Array Tags of Remote Project” drop down lists will be accessible. Map the Tag of

the Remote project to a Tag in the Local project to read this data.

Modbus TCP Server connections: The

CPU can serve data back to 32 Modbus

TCP Client devices concurrently. If

32 Modbus TCP Client devices are

connected to the CPU, then any new

TCP connection requests will be

denied until one of the existing 32

devices drops its connection. If the

Client device connecting to the CPU

is not a Productivity3000

a Modbus address must be assigned

to the tag that is being requested.

This is done in the Tag Database

window. If the device connecting to

the CPU is another P3000 CPU or

C-more panel, no Modbus address is

required. See Communications Port

Configuration for port configuration,

Communications: Connectivity section

for connection information and

Communications: Ethernet section for

Ethernet set up.

c. Remote I/O: The Remote I/O port

is 10/100Base-T Ethernet with an

RJ-45 style connector. It is used for

connecting to a Remote I/O network

consisting of P3-RS or P3-RX Remote

Slaves and/or GS-EDRV100 units with

GS-drives.

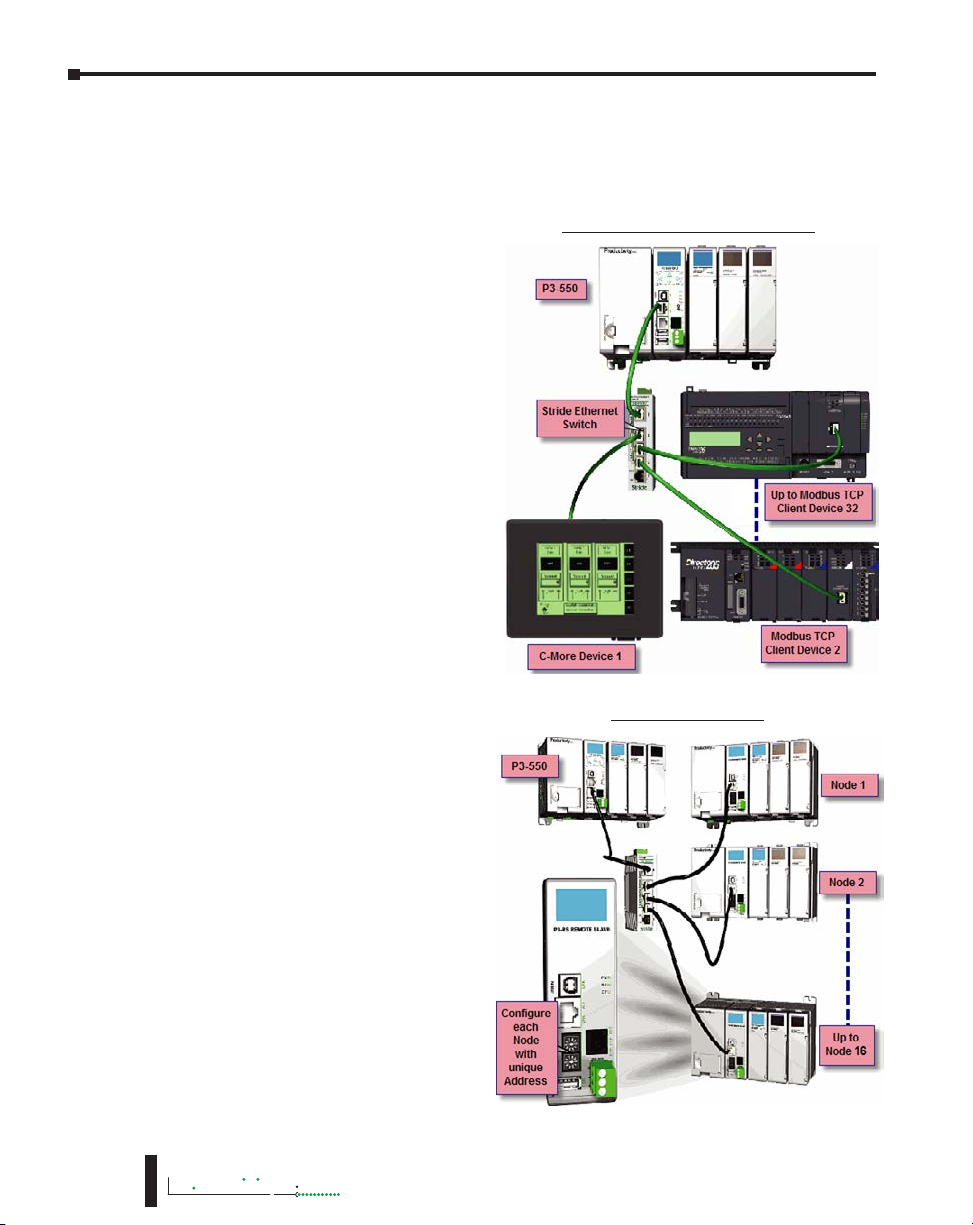

Remote Slaves: The P3-550(E) and

P3-550E CPUs can connect with up

to 16 P3-RS/RX Remote Slaves. The

P3-550(E)/E will auto detect all P3-RS/

RX units that are configured with

unique station addresses (by means

of two rotary switches on the front

of the module). The configuration

can be managed in the Hardware

Configuration in the Productivity

Suite Programming Software. See

Communications Remote I/O and GS

Drives for configuration information

and Communications: Connectivity

section for connection information.

®

device, then

Modbus TCP Client (RX-WX)

Remote I/O Slaves

6-4

3000

Hardware User Manual, 4th Edition, Rev. M

Page 5

Chapter 6: Communications

Productivity

3000

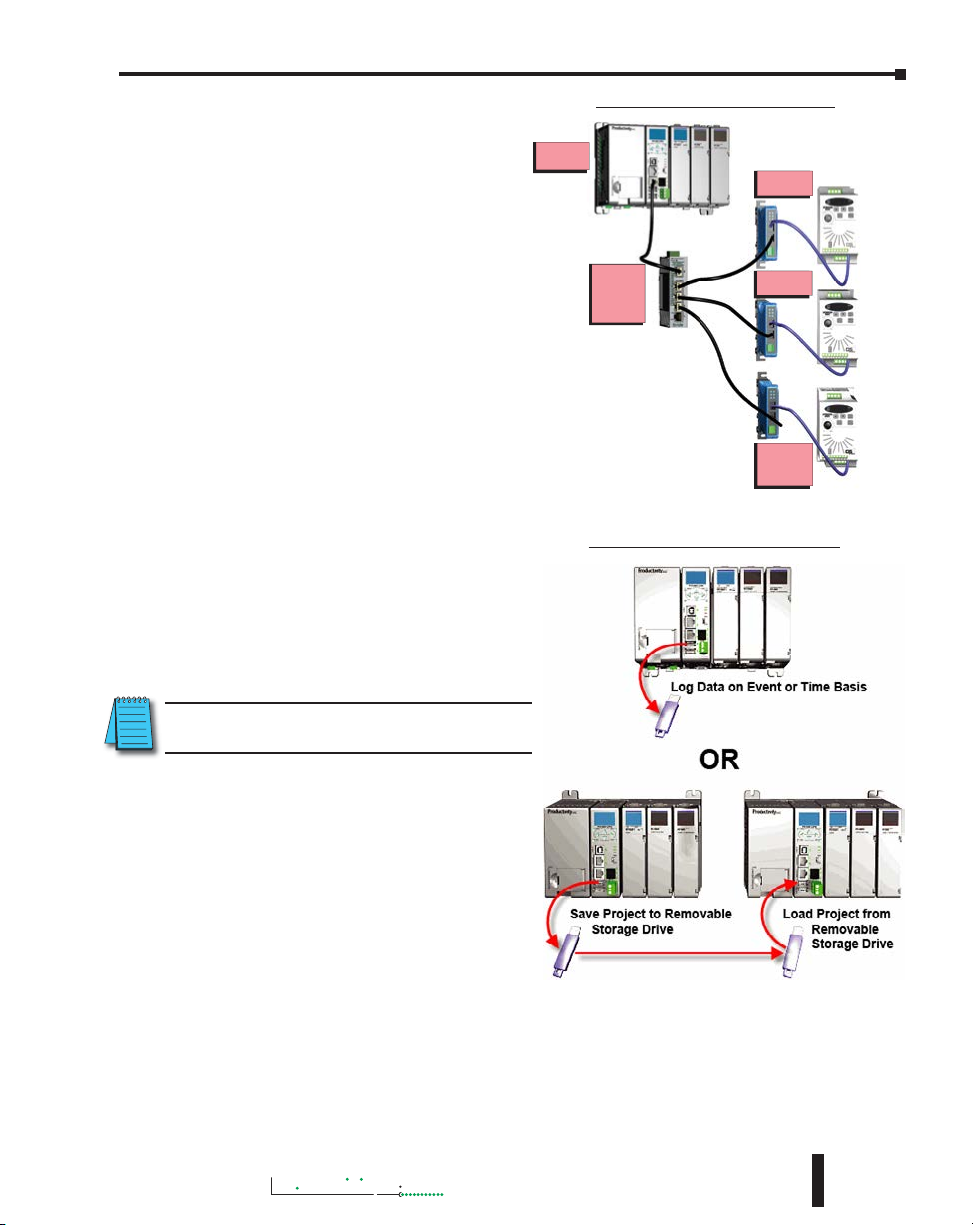

Remote GS1 (GS-EDRV100)

GS Drive Devices: The P3-550(E) CPU

can connect to up to 32 GS-EDRV100

Modules. The P3-550(E) will auto

detect all GS-EDRV100 modules that

have a unique address (configured by

the bank of dipswitches on the module).

The configuration can be managed

in the Hardware Configuration in

the Productivity Suite programming

software. See Communications:

Remote I/O and GS Drives section

for configuration information and

Communications: Connectivity section

for connection information.

d. USB OUT: The USB OUT data port

is the upper port of two USB 2.0 Type

A connectors on the CPU. The USB

OUT port uses a SDCZ4-2048-A10 Pen

Drive (may work with other pen drives)

for data logging only in the P3-530 or for

data logging and project transfers in the

P3-550(E).

NOTE: The USB OUT port is NOT compatible with

older 1.0/1.1 full speed USB devices.

P3-550

Stride

Ethernet

Switch

USB Removable Storage Drive

Node 1

Node 2

Up to

Node 32

Project Transfer (P3-550(E) only): For

security, this feature is disabled by default

when creating a new project. It can be

enabled in the Hardware Configuration

panel for the P3-550(E). Once enabled,

projects may be transferred between a

CPU and Removable Storage Device,

or between a Removable Storage Device

and PC. Files stored on the Removable

Storage Device by a P3-550(E) or the

Productivity Suite programming software

are stored under a default name, so only

one project may be handled at a time on a Removable Storage Device. Existing projects on the

Removable Storage Device will be overwritten without a prompt.

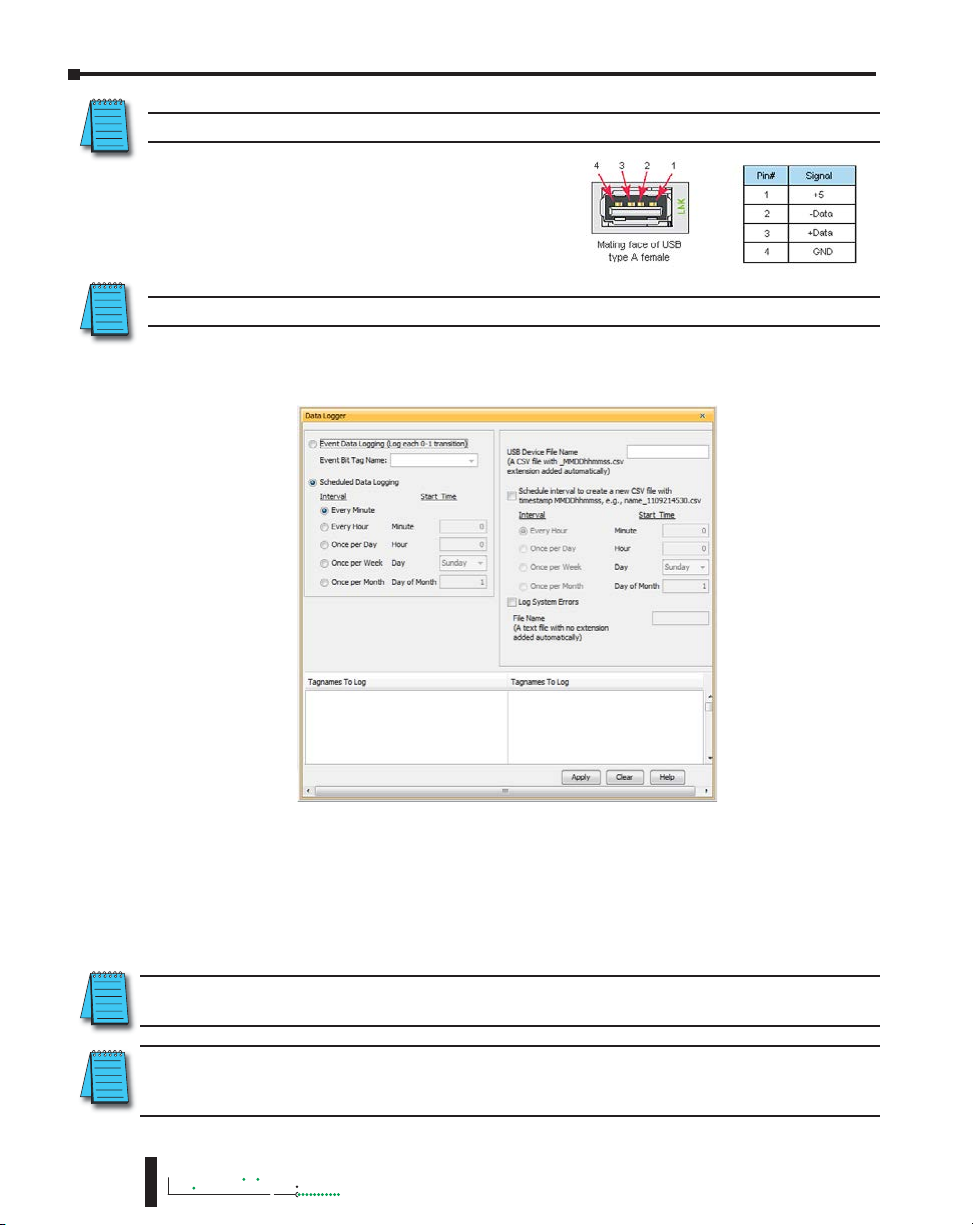

Data Logging: The Data Logger tool allows setup of periodic or event-based data logging of tag

and System Errors to the Removable Storage Drive. Data Logger setup is accessed under the

Monitor & Debug Menu. See Communications: Connectivity section for more information.

Hardware User Manual, 4th Edition, Rev. M

6-5

Page 6

Chapter 6: Communications

Productivity

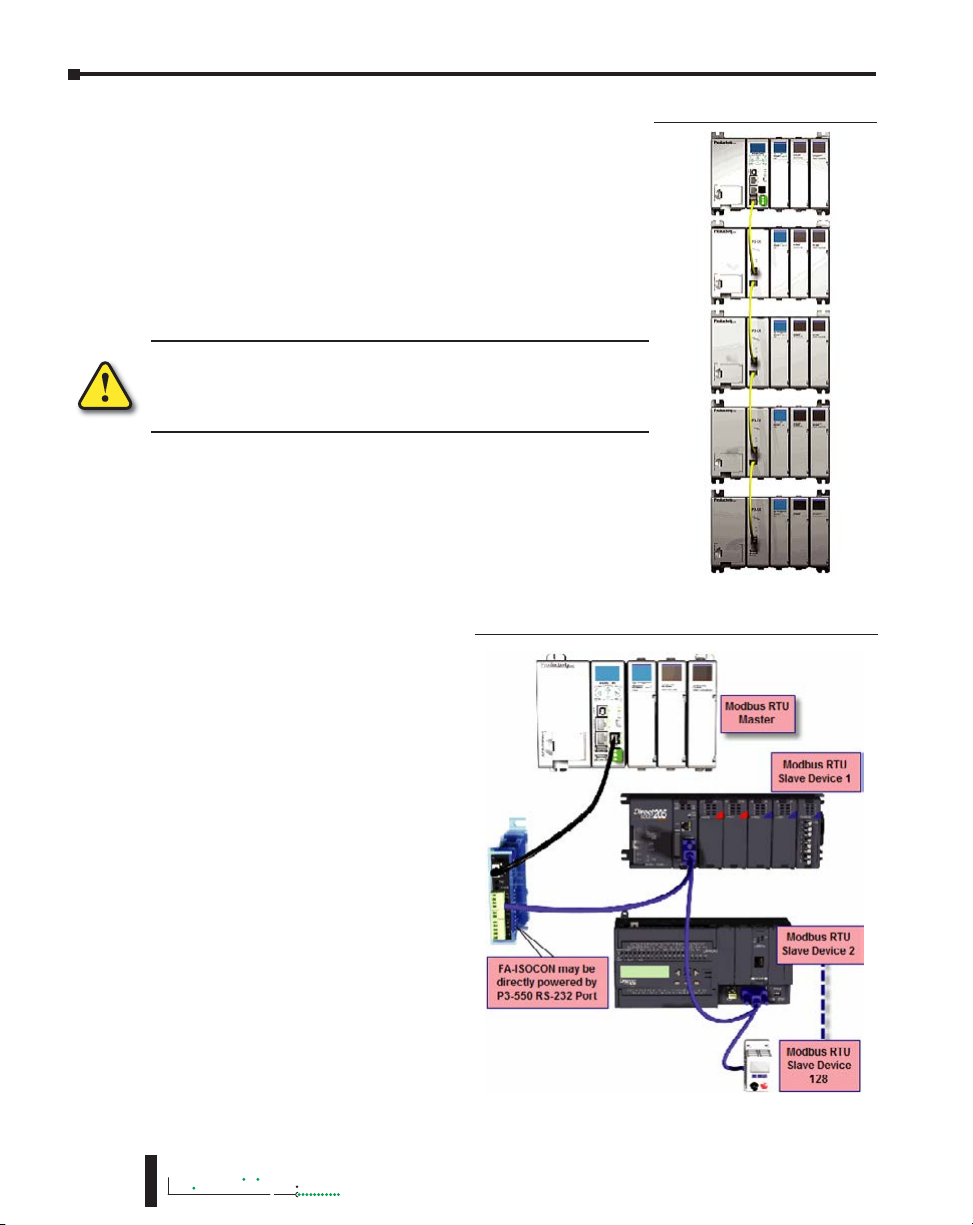

e. EXP I/O OUT: The Expansion I/O port is the lower port

of two USB 2.0 Type A connectors on the CPU. The EXP

I/O Out port is only used for connections to local P3-EX

modules in a Productivity3000

I/O is treated as local I/O by the CPU and is completely scansynchronous. The I/O is automatically detected on power up.

CAUTION: This port is ONLY for Expansion I/O. The signal pins on

this port are NOT standard USB. DO NOT USE A USB REPEATER

TO EXTEND THE RANGE OF THIS PORT. See Communications

Connectivity for more information.

®

base with I/O. Expansion

P3-EX Expansion Network

6-6

f. RS-232: The RS-232 port is an

RJ-12 connector located on the right

side of the CPU. This port can be

used for:

• Modbus RTU Master

connections.

• Modbus RTU Slave connections.

• ASCII Incoming and Outgoing

communications.

• Custom Protocol Incoming and

Outgoing communications.

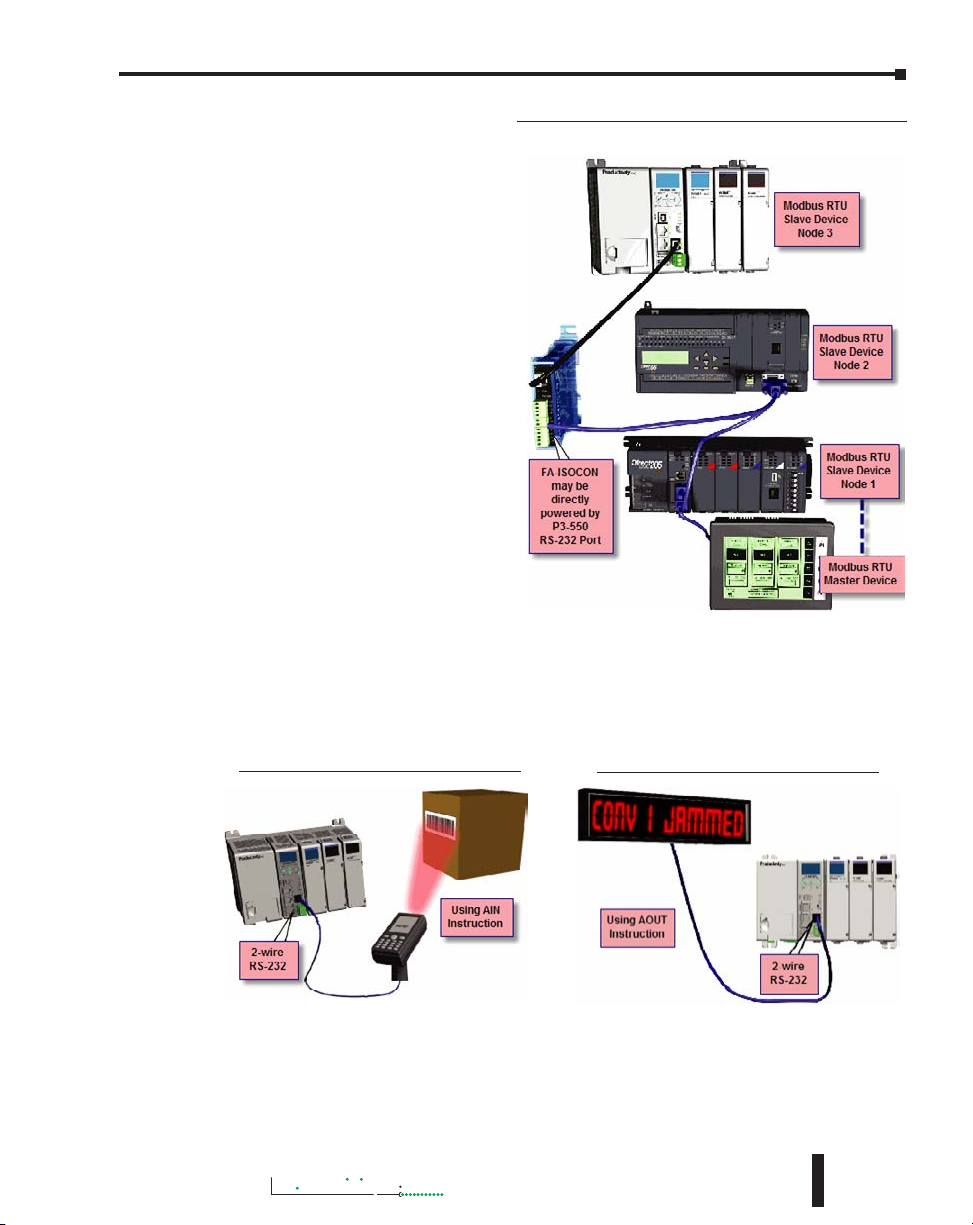

Modbus RTU Master connections:

The RS-232 port is intended to be

used for point-to-point connections

but it is possible to connect up to 128

devices on a network if a RS-232 to

RS-485/422 converter is connected

to the port (such as a FA-ISOCON).

This is accomplished by using the

communications instructions in the

ladder project (MRX, MWX, RX,

WX). If 4-wire RS-485 or RS-422

communications is needed, using

this port with an FA-ISOCON is the

best method. See Communications:

Connectivity section for more

information.

3000

Hardware User Manual, 4th Edition, Rev. M

RS-232 Modbus RTU Master Network Topology

Page 7

Productivity

3000

Modbus RTU Slave connections: The

RS-232 port is intended to be used

for point-to-point connections but

it is possible for the RS-232 port to

be used on a Modbus RTU network

by using a RS-232 to RS-485/422

converter. The port is addressable

in the Hardware Configuration in

the Productivity Suite programming

software. It is important to note that

the RS-232 port cannot be a Modbus

RTU master and slave concurrently.

If the port is set to Modbus RTU

and there are no communications

instructions (MRX, MWX, RX, WX) in

the project, the CPU will automatically

respond to Modbus requests from a

Modbus master. See Communications:

Connectivity section for more

information.

Chapter 6: Communications

RS-232 Modbus RTU Slave Network Topology

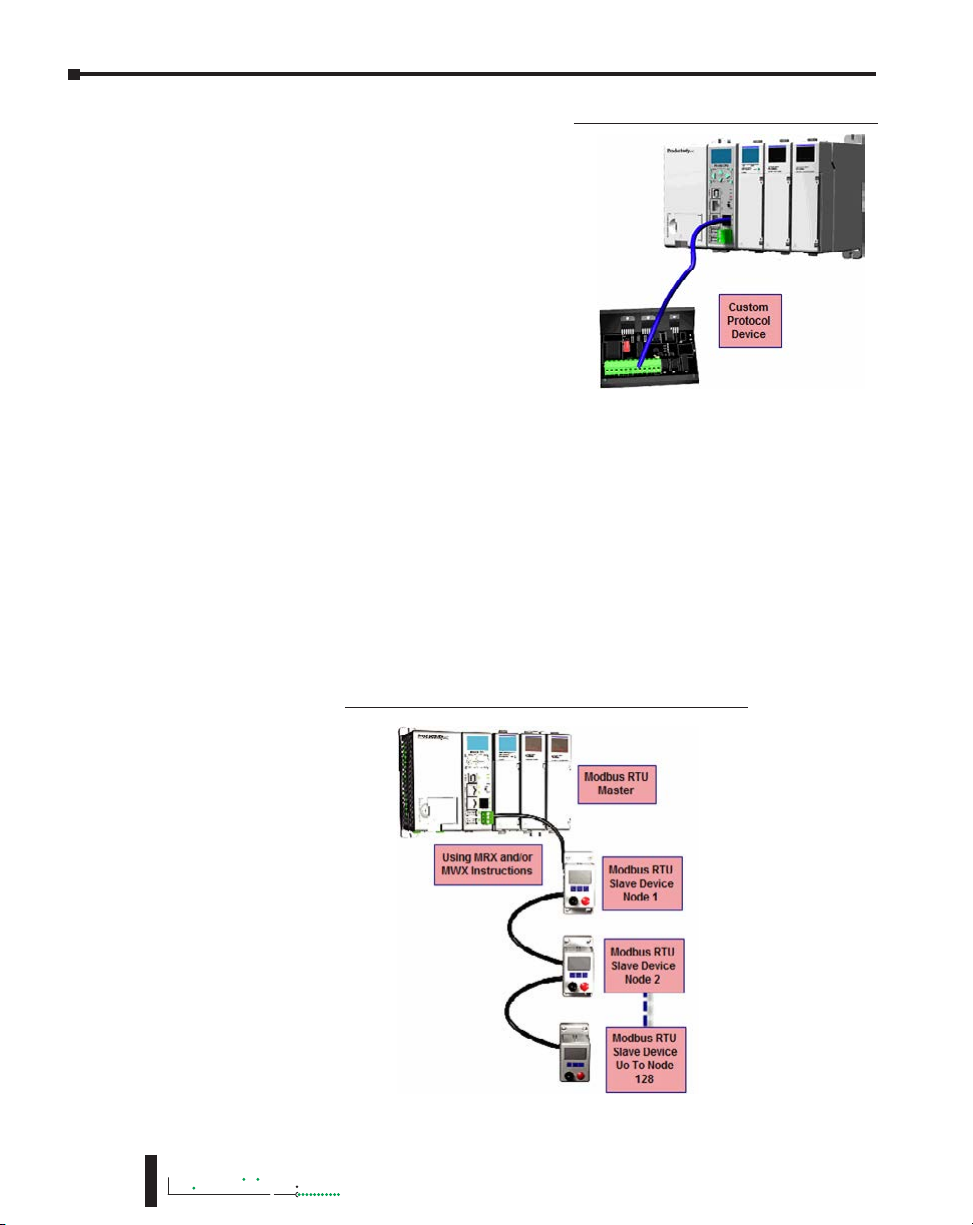

ASCII Incoming and Outgoing communications: The RS-232 port can be used for sending and

receiving non-sequenced String data. This feature is typically used for receiving bar code strings

from a scanner or sending statistical data to a terminal or serial printer using the ASCII IN and

ASCII OUT instructions. See Communications: Connectivity section for more information.

RS-232 ASCII In Communication

Hardware User Manual, 4th Edition, Rev. M

RS-232 ASCII In Communication

6-7

Page 8

Chapter 6: Communications

Productivity

Custom Protocol Incoming and Outgoing

communications: The RS-232 port can be used for

sending and receiving non-sequenced byte arrays

to various devices. This function is typically used

for communicating with devices that don’t support

the Modbus protocol but have another serial

communications protocol. This is accomplished by

using the Custom Protocol In and Custom Protocol

Out instructions. The RS-232 port is intended

to be used for point-to-point connections but it is

possible for the RS-232 port to be used on a multinode network by using a RS-232 to RS-485/422

converter. See Communications: Connectivity for

more information.

g. RS-485: The RS-485 port is a 3-pin removable terminal block. The RS-485 port can be used for:

• Modbus RTU Master connections.

• Modbus RTU Slave connections.

• ASCII Incoming and Outgoing communications.

• Custom Protocol Incoming and Outgoing communications.

Modbus RTU Master connections: The RS-485 network port is used for multi-node networks.

The CPU can connect to 128 Modbus RTU slave devices on a network. This is accomplished

by using the communications instructions in the ladder project (MRX, MWX, RX, WX). See

Communications: Connectivity section or more information.

RS-232 Custom Protocol In and Out

6-8

3000

RS-485 Modbus RTU Master Network Topology

Hardware User Manual, 4th Edition, Rev. M

Page 9

Chapter 6: Communications

Productivity

3000

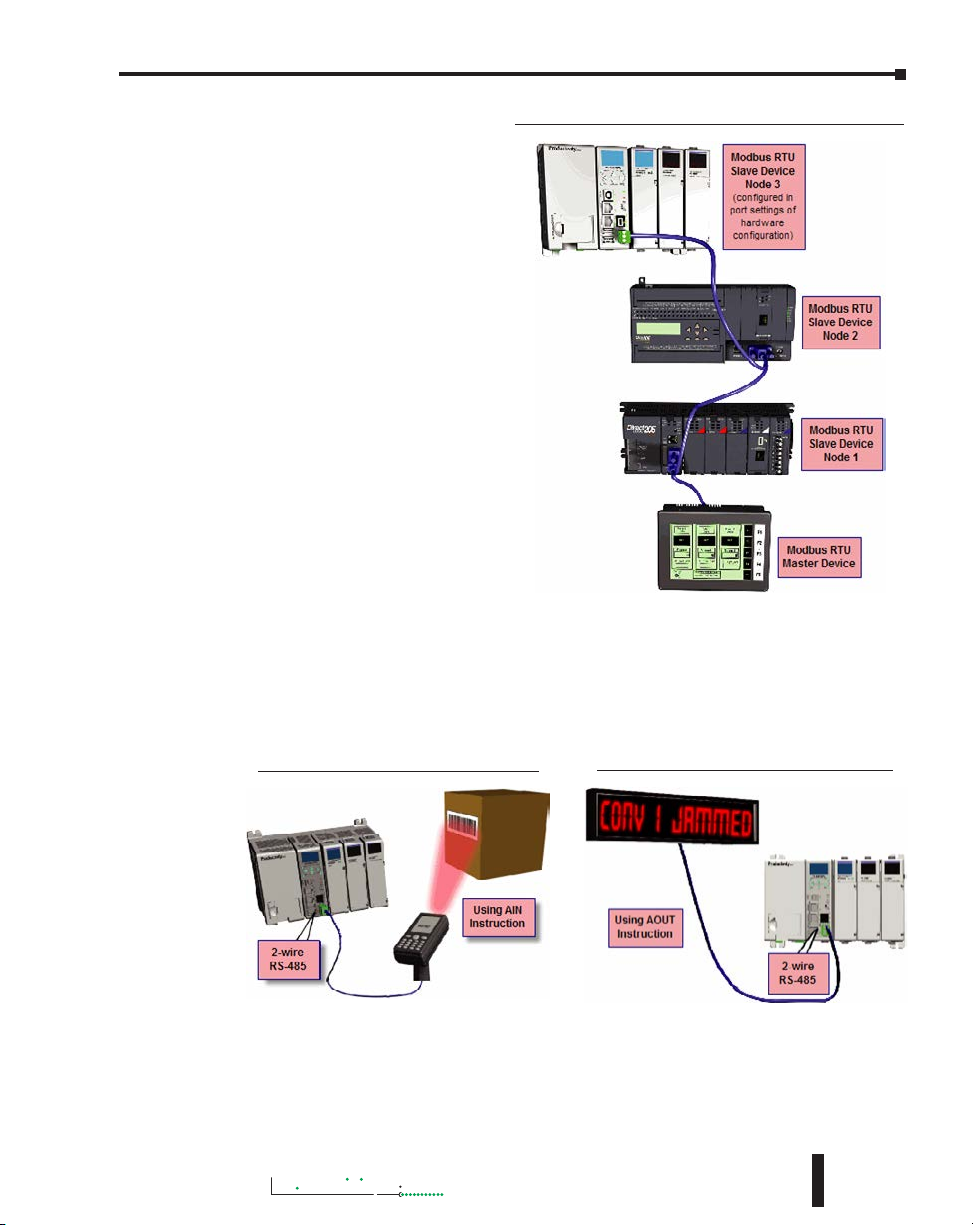

RS-485 Modbus RTU Slave Network Topology

Modbus RTU Slave connections:

The RS-485 network port is used

for multi-node networks. The

port is addressable in the Hardware

Configuration in the Productivity

Suite programming software. If

the port is set to Modbus RTU

and there are no communications

instructions (MRX, MWX, RX,

WX) in the project, the CPU will

automatically respond to Modbus

requests from a Modbus master. See

Communications Connectivity for

more information.

ASCII Incoming and Outgoing communications: The RS-485 port can be used for sending and

receiving non-sequenced String data. If long distances are required between the ASCII device

and the CPU, the RS-485 port is the better selection because of its increased distance support

(1,000 meters). ASCII communications are typically used for receiving bar code strings from a

scanner or sending statistical data to a terminal or serial printer using the ASCII IN and ASCII

OUT instructions. See Communications: Connectivity section for more information.

RS-485 ASCII In Communication

RS-485 ASCII Out Communication

Hardware User Manual, 4th Edition, Rev. M

6-9

Page 10

Chapter 6: Communications

Productivity

Custom Protocol Incoming and Outgoing communications: The RS-485 port can be used for

sending and receiving non-sequenced byte arrays to various devices. This function is typically

used for communicating with devices that don’t support the Modbus protocol but have another

serial communications protocol. If long distances are required between the device and the CPU,

the RS-485 port is the better selection because of its increased distance support (1,000 meters).

This feature is accomplished by using the Custom Protocol In and Custom Protocol Out

instructions. See Communications: Connectivity section for more information.

RS-485 Custom Protocol In and Out

6-10

3000

Hardware User Manual, 4th Edition, Rev. M

Page 11

Productivity

3000

Communications: Connectivity

Communication Ports

The AutomationDirect P3000

CPUs are designed with several

Communications Ports, seven

communications ports on the

P3-550, six on P3-550E, and five

communications ports on the

P3-530. The connectivity for

each of these ports is described

in the sections below. The

Communication Ports available

are:

a. USB IN Port (P3-550

only): Programming port

with a USB Type B female

connector.

This port requires a USB Type A-B cable

(such as the P3-EX-CBL6 cable).

Chapter 6: Communications

The USB Port is the simplest method of connecting the Productivity Suite programming

software to the P3-550 CPU. After the programming software has been installed, connect a

USB A to B cable from the PC to the CPU. Once the software has been opened, click on CPU

and select the “Choose CPU” option. The dialog shown below will appear.

Highlight the CPU listed in the dialog box and click on “Connect”. No configuration is

required.

NOTE: The USB IN port is NOT compatible with older 1.0/1.1 full speed USB devices.

Hardware User Manual, 4th Edition, Rev. M

6-11

Page 12

Chapter 6: Communications

Productivity

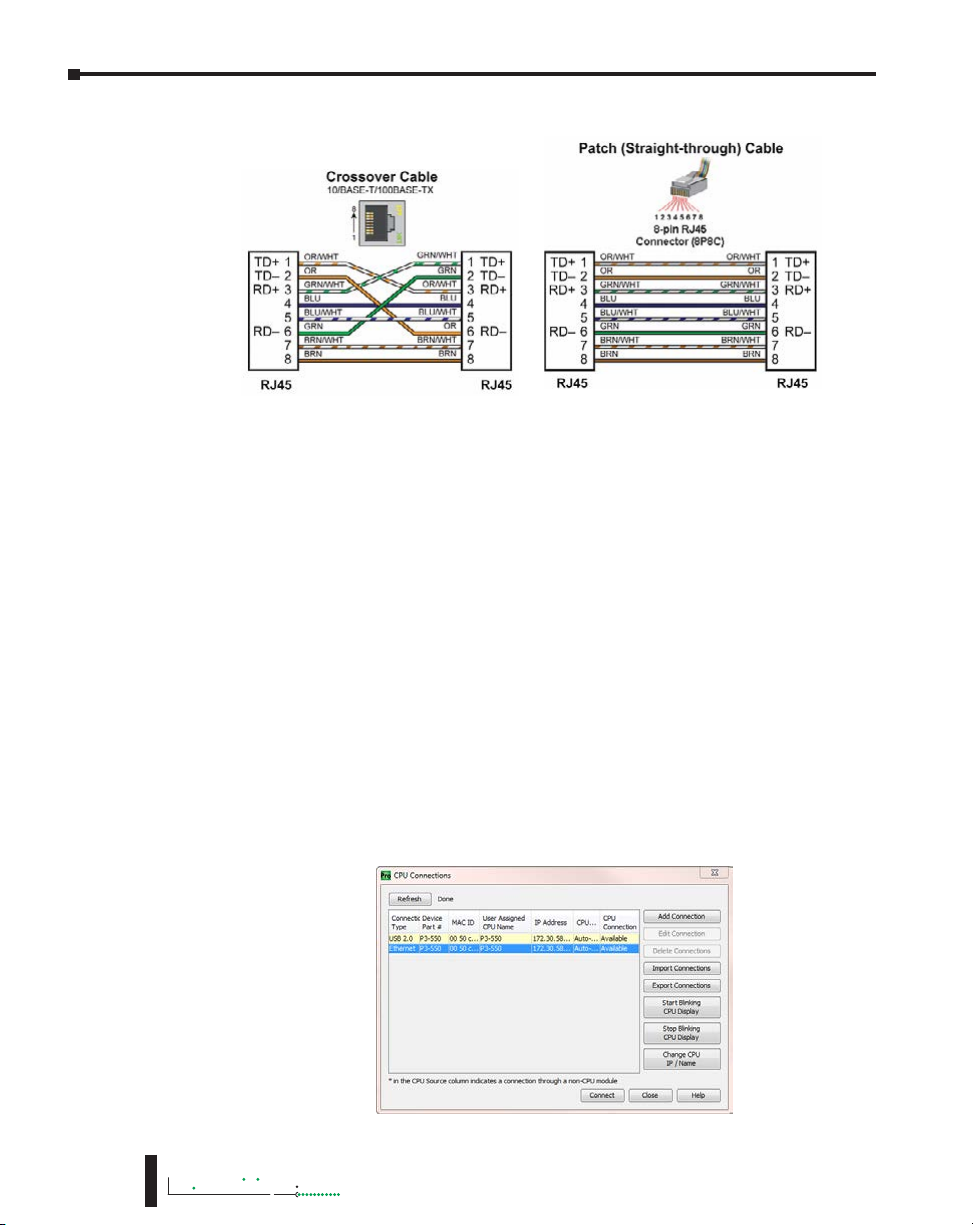

b. Ethernet Port: Programming and Modbus TCP Client/Server port with 10/100 Base-T

Ethernet RJ45 connector.

• General Information:

Crossover cables can be used to directly connect two endpoint Ethernet devices such as a

PC network interface card and the CPU. Patch (or Straight-through) cables are used to

connect an endpoint Ethernet device to an Ethernet switch.

The maximum distance for one cable or segment is 100 meters (328 feet). If the

distance required between 2 devices is greater than 100 meters, add an Ethernet switch to

extend the distance. An Ethernet switch can be added every 100 meters (or less) almost

indefinitely. Each Ethernet switch added will incur some latency (actual amount differs

between switches and manufacturers). So if a very long distance is needed between 2

Ethernet devices, it may be better to convert to fiber optics.

The External Ethernet Port can be used as a programming port, a Modbus TCP Client

port, a Modbus TCP Server port, or to communicate to other P3000 CPUs. The

External Ethernet Port can also be used to send emails using the EMAIL instruction.

• Create a Connection:

To communicate with the Productivity Suite programming software, connect a crossover

Ethernet cable from the PC to the CPU External Ethernet Port or connect a patch

(straight-through) Ethernet cable from the PC to an Ethernet switch and another patch

cable from the Ethernet switch to the External Ethernet Port. Once the software has been

opened, click on CPU and select the “Choose CPU” option. The dialog shown below will

appear.

6-12

3000

Hardware User Manual, 4th Edition, Rev. M

Page 13

Chapter 6: Communications

Productivity

3000

Highlight the CPU that you wish to connect to and press the “Connect” button. You may

see CPUs that are not on the same subnet as your PC within the CPU Connections dialog

box, but this does not mean you can connect to them. To connect to the CPU, you must

configure either your PC or your CPU to be in the same subnet. You can easily change the

Ethernet settings of the CPU by highlighting it and selecting the “Change CPU IP/Name”

button (shown below). Or if you prefer, the PC Setup section of this chapter contains

information on configuring the Ethernet settings of your PC.

c. Remote I/O Ethernet Port (P3-550(E) only): P3-RS/RX Remote Slave and/or

GS-EDRV100 Drive Ethernet RJ45 connector.

Crossover cables can be used to directly connect endpoint Ethernet devices and the CPU.

For example, connecting a P3-RS or P3-RX Remote Slave Module to the P3-550(E)

CPU. Patch (or Straight-through) cables are used to connect an endpoint Ethernet device

to an Ethernet switch.

The maximum distance for one cable or segment is 100 meters (328 feet). If the

distance required between 2 devices is greater than 100 meters, add an Ethernet switch to

extend the distance. An Ethernet switch can be added every 100 meters (or less) almost

indefinitely. Each Ethernet switch added will incur some latency (actual amount differs

between switches and manufacturers). So if a very long distance is needed between 2

Ethernet devices, it may be better to convert to fiber optics.

The Remote I/O Ethernet Port is used to communicate to the Remote I/O Network,

consisting of Remote Slave bases (P3-RS/RX modules) and GS Drives with a

GS-EDRV100 Ethernet module. It is highly recommended that the network attached to

this port be isolated from other networks and it is absolutely necessary that it be isolated

from other Remote I/O networks. See Remote I/O and GS Drives topic for details.

Hardware User Manual, 4th Edition, Rev. M

6-13

Page 14

Chapter 6: Communications

Productivity

NOTE: USB Project Transfers are NOT supported by the P3-530 CPU.

d. USB OUT Port: USB Port for Data logging or

project transfer with USB 2.0 Type A connector.

This Port serves two purposes: Data logging with

the P3-530 or data logging and project transfers

with the P3-550(E), require a SDCZ4-2048-A10

Removable Storage Device (may work with other

pen drives).

NOTE: The USB OUT port is NOT compatible with older 1.0/1.1 full speed USB devices.

Data logging is set up in the Productivity Suite Programming Software Data Logger

configuration window. See Data Logger Memory section of the previous chapter for setup

instructions.

6-14

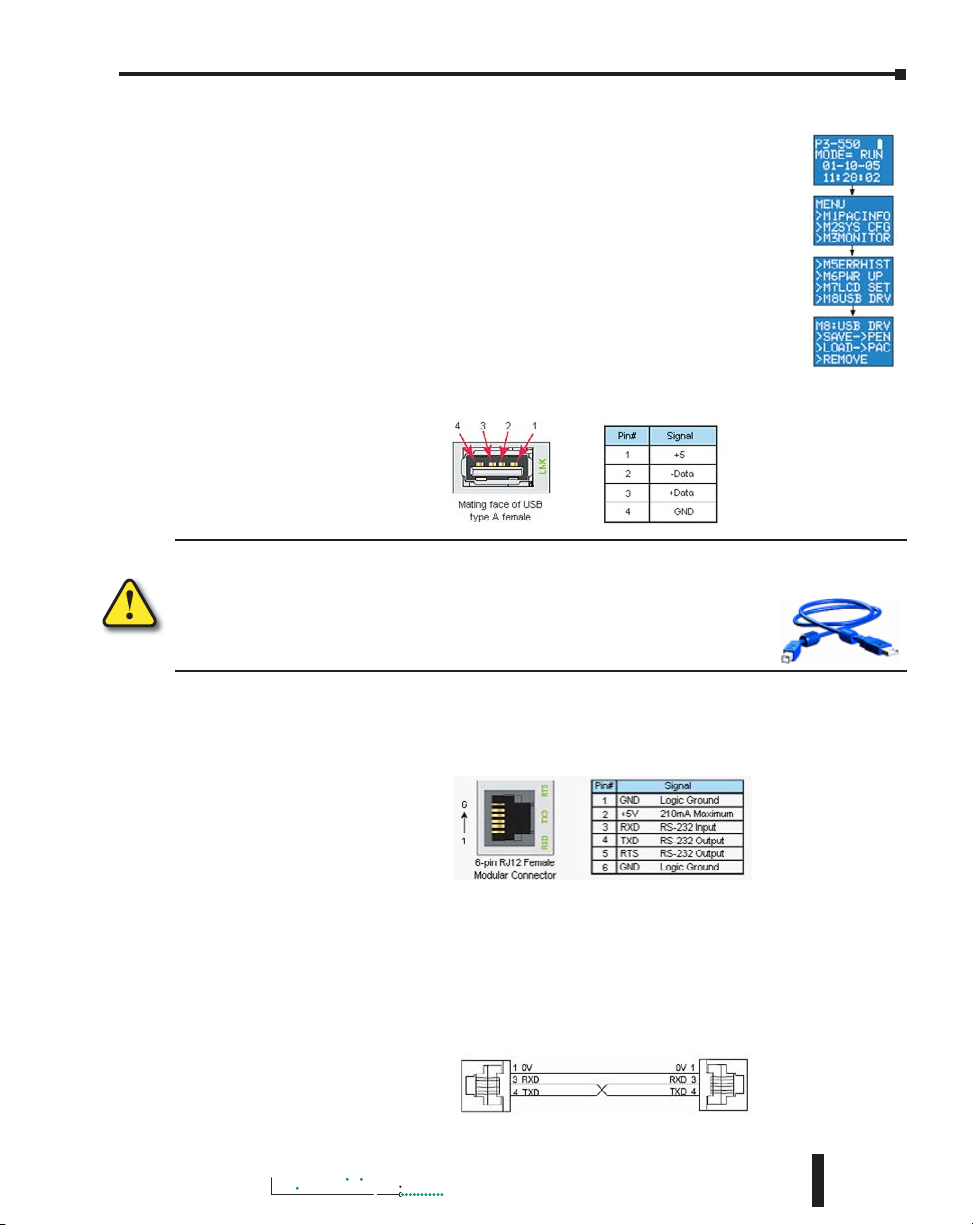

Project Transfer to and from a USB drive can be accomplished several different ways:

• Transfer project to USB Drive from PC programming software.

• Transfer project from USB Drive to PC programming software.

• Transfer project from USB Drive to P3-550(E) CPU.

• Transfer project from P3-550(E) CPU to USB Drive.

NOTE: You must first select the “Enable project transfer to/from USB drive” checkbox in the P3-550(E)

CPU Module Configuration.

NOTE: Before transferring a project to the CPU via USB pen drive, ensure that you are NOT connected

with the programming software either by USB or Ethernet. If you attempt the transfer with the software

connected via USB or Ethernet, a PACCON Error will appear on the LCD of the P3-550(E).

3000

Hardware User Manual, 4th Edition, Rev. M

Page 15

Chapter 6: Communications

Productivity

3000

To transfer a project to or from a USB Drive from the PC programming

software, insert the USB Drive into a USB Port on the PC. Go to File and

Transfer Project and select To USB Drive or From USB Drive.

To transfer a project to or from a USB Drive on the P3-550(E) CPU, press

Menu on the CPU display LCD and scroll down to the M8USB DRV option

as seen on right.

Select “>SAVE->PEN” to load the project that is currently on the CPU down

to the connected USB Drive.

Select “>LOAD->CPU” to load the project that is currently on the USB Drive

to the CPU.

e. Expansion I/O OUT Port: Expansion I/O Port with USB 2.0 Type A connector.

CAUTION: The Expansion I/O Port is ONLY for connecting to other Productivity3000® I/O bases with a

P3-EX module in the CPU slot. This port is not a standard USB A port. Note that in the diagram above,

pin 1 is used for the System Reset signal and is not the typical +5VDC VBUS signal

on most USB A ports. DO NOT USE EXTENDERS, CONVERTERS OR HUBS OF ANY

SORT ON THIS PORT. A P3-EX-CBL6 cable ships with each P3-EX Module. It is not

recommended to use any cable other than the one supplied.

After this connection is made, power cycle the system and the CPU will automatically detect the

expansion I/O units. They can be used once the Hardware Configuration has been read into

the programming software. Up to 4 expansion I/O bases may be added to a CPU.

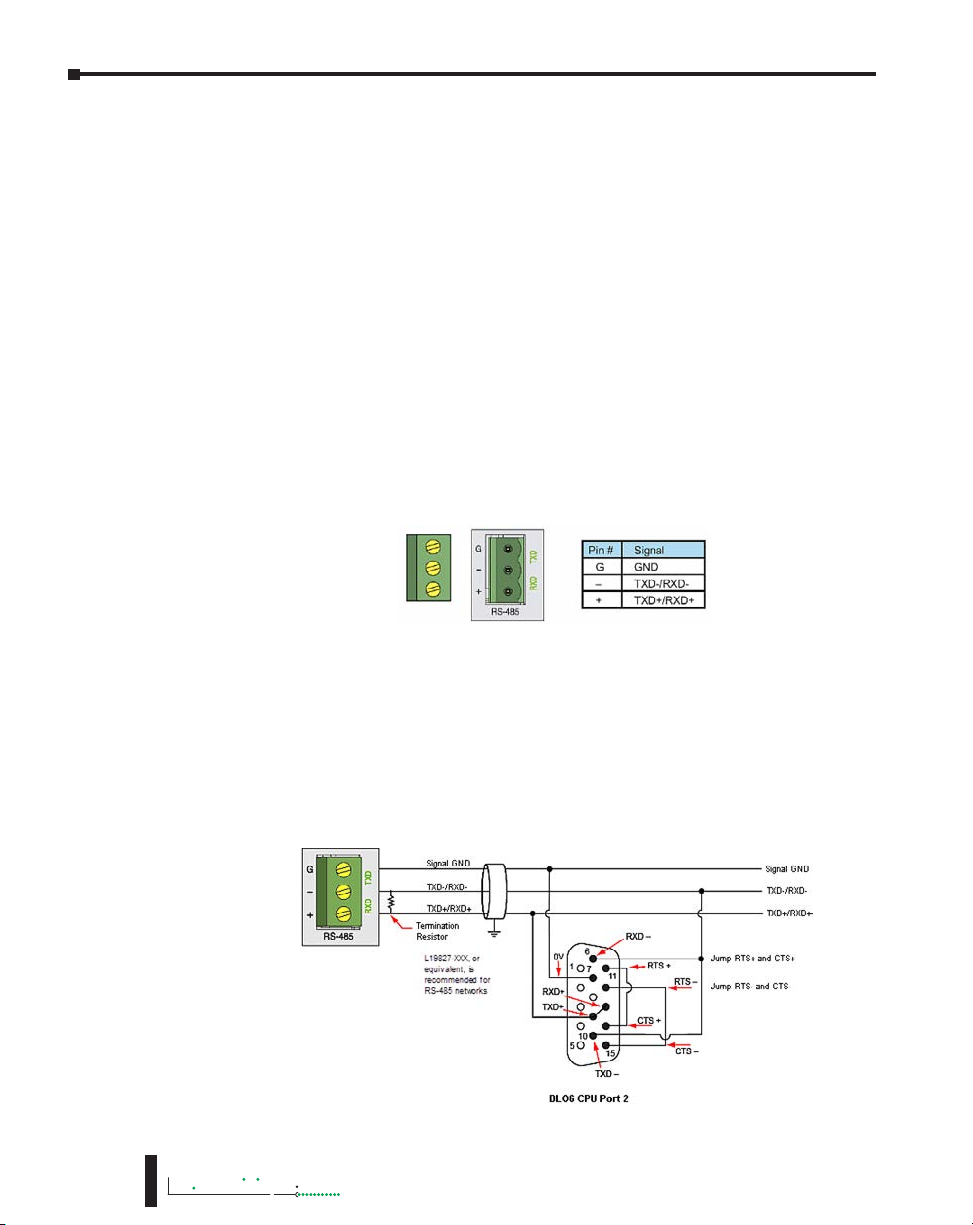

f. RS-232 Port: Serial RS-232 multipurpose communications port with RJ12 connector.

The RS-232 Port can be connected to Modbus RTU master or slave devices, as well as devices

that output non-sequenced ASCII strings or characters. The manner in which these devices

are wired to the CPU depends whether the device is considered to be DTE (Data Terminal

Equipment) or DCE (Data Communications Equipment).

If two DTE devices are connected together, the RX and TX signals should cross or the RX of one

device should go to the TX of the other device and the TX of one device should go to the RX of the

other device (as shown below).

Hardware User Manual, 4th Edition, Rev. M

6-15

Page 16

Chapter 6: Communications

Productivity

The CPU is considered a DTE device. Most Modbus or ASCII devices being connected to the

CPU will also be considered a DTE device and will need to swap TX and RX, but you should

always consult the documentation of that device to verify. If a communication device, such as

a Modem, is placed between the CPU and another Modbus or ASCII device it will most likely

require connecting the signals straight across (TX to TX and RX to RX). Again, this can differ

from manufacturer to manufacturer so always consult the documentation before wiring the

devices together.

The RTS signal on pin 5 of the RS-232 Port will turn on when the TX signal is turned on and

the RTS signal will turn off when the TX signal turns off. The amount of time that the RTS

signal turns on before the TX signal turns on and the amount of time that the RTS signal waits

before turning off after the TX signal turns off is adjustable in the P3-550(E) or P3-530 CPU

Module Configuration for the RS-232 Port. The RTS signal is very often required for media

converters, such as a RS-232 to RS-422/485 converter (much like the FA-ISOCON).

The RTS signal is sometimes required for use with Radio modems as well (Key on and off

control).

There is also +5VDC @ 210mA on pin 2 available for powering an external device such as the

C-more Micro panel.

g. RS-485 Port: Serial RS-485 multipurpose communications port with removable 3-pin

connector.

6-16

The RS-485 Port is useful for connecting multiple Modbus and ASCII devices on one network

and/or connecting devices to the CPU at distances greater than 50 feet (RS-232 limit). The

RS-485 standard supports distances of up to 1000 meters without requiring a repeater. The

RS-485 Port on the CPU can support up to 50 devices, depending on each device’s load (this

assumes a 19K Ohm load for each device). This number can be increased by placing an RS-485

repeater on the network, if necessary.

This port only supports RS-485 2-wire connections. For 4-wire RS-485 or RS-422, a converter,

such as an FA-ISOCON, should be used with the RS-232 Port.

A 120 Ohm resistor is required at each end of the network for termination.

3000

Hardware User Manual, 4th Edition, Rev. M

Page 17

Chapter 6: Communications

Productivity

3000

Communications ASCII and Custom Protocol Functionality

Besides Modbus RTU, there are two additional functions supported on the serial ports in the

Productivity3000® system.

• The first function is the ability to send and receive text-based data with devices such as bar code

readers and serial printers.

• The second function is the ability to communicate serially with other devices that do not

support the Modbus protocol and lack a Productivity3000 driver.

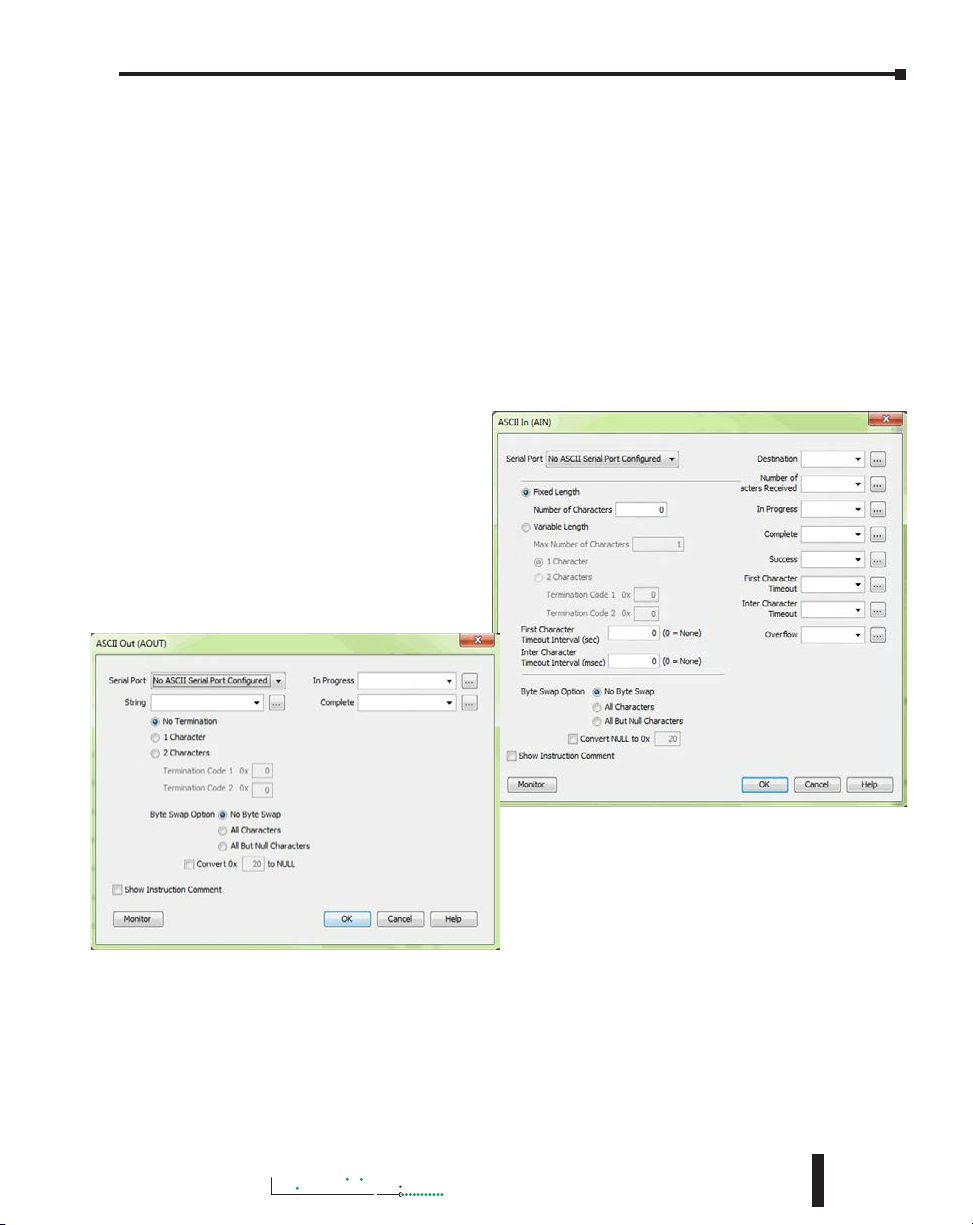

ASCII Instructions

The ASCII In/Out instructions use the String data type to send or receive text-based data

through the serial port. The String data type is only intended for use with the “printable

character set”. This can include numbers, letters or special characters.

With the ASCII In instruction,

the CPU can receive a fixed

length of characters or a variable

length of characters with a

termination code (an ‘end of

message’ character).

The ASCII Out instruction sends

text-based data out of the serial

port to various devices for control,

printing or display.

Hardware User Manual, 4th Edition, Rev. M

6-17

Page 18

Chapter 6: Communications

Productivity

Full duplex Mode (P3-550(E)/530)

1. RS232 can be set to FulDuplex node. Half Duplex is selected by default. This cna be changed in

the Hardware Configuration window for the CPU serial port.

2. AIN and AOUT instructions may be enabled at the same time.

3. AOUT may be enabled while AIN is already active, and vice versa.

4. The user may control treatment of buffered data before AIN is enabled using the checkbox

mentioned above.

5. RTS mode must be either always on or always off. Assert during transmit is not available.

Half duplex Mode [default] (P3-550(E)/530)

The ASCII instruction limitations are that it is not advisable to use the ASCII Out instruction to

send a String to a device that will respond (if the response is needed) and to use the ASCII IN (AIN)

instruction to try to receive this data.

1. AIN and AOUT cannot be enabled at the same time on the same serial port.

2. When the AOUT completes, the AIN cannot be enabled until the next logic scan.

3. The user may control treatment of buffered data before AIN is enabled using the checkbox

mentioned above.

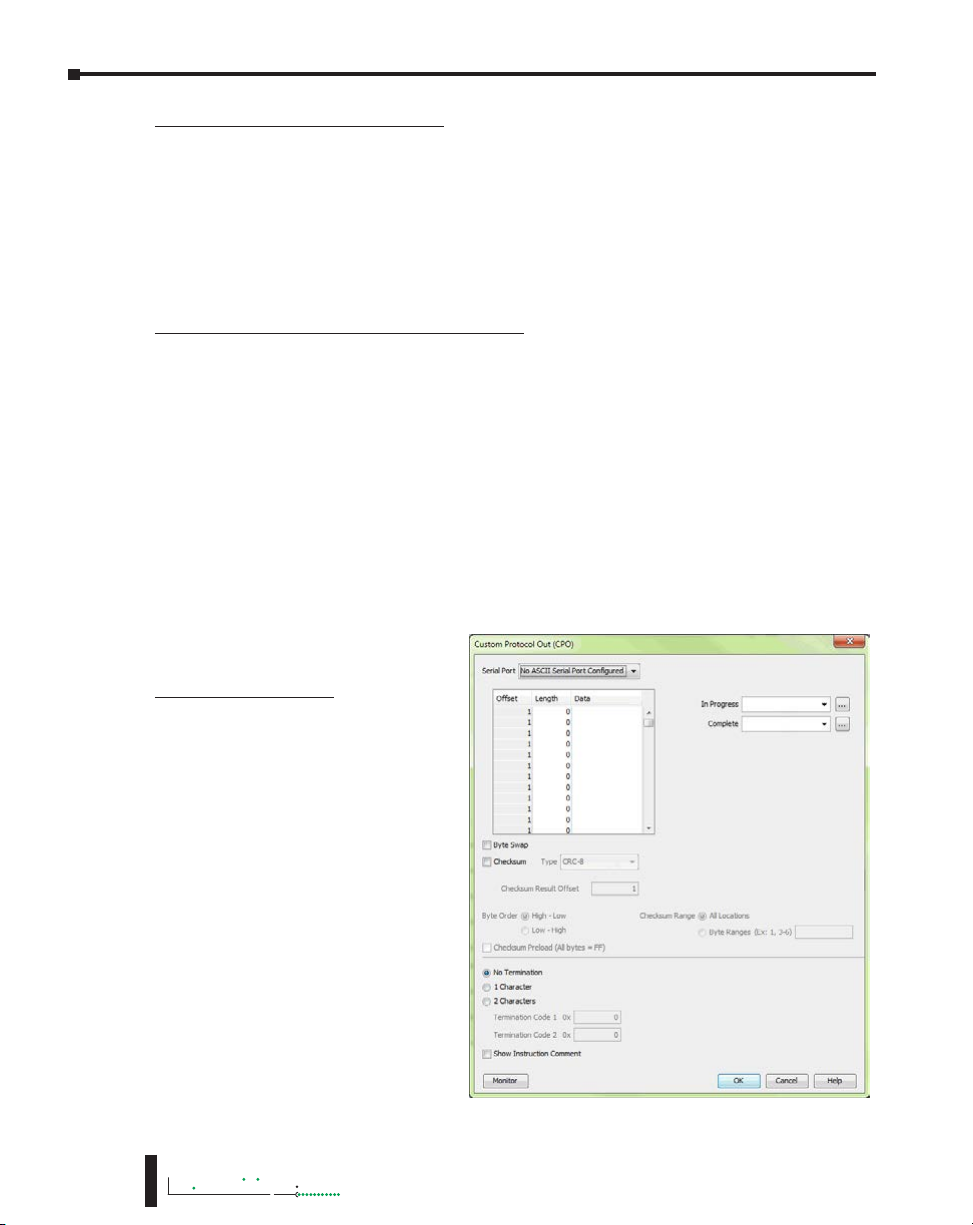

Custom Protocol Instructions

The Custom Protocol is a HEX based protocol used to communicate with devices that do

not have the standard Modbus RTU Protocol. There are two instructions used with Custom

Protocol communication:

• Custom Protocol Out (CPO)

• Custom Protocol In (CPI)

Custom Protocol Out

The Custom Protocol Out instruction

allows the user to send a ‘byte

formatted’ packet of data out of the

CPU serial port.

Constant values and/or Tag values

can be used as the source for data

transmitted. There are several

formatting options including Byte

Swap and Checksum.

6-18

3000

Hardware User Manual, 4th Edition, Rev. M

Page 19

Chapter 6: Communications

Productivity

3000

The Checksum option allows the user to select where in the packet the checksum should be

inserted, what type of Checksum (CRC-8 bit, CRC-16 bit, CRC-32 bit, XOR-8 bit, XOR-16

bit and XOR 32 bit), which bytes of the data source should be used in the calculation of the

checksum, what the byte order should be of the checksum (if greater than 8 bit) and how to

preload the checksum calculation.

If the device requires a different Checksum calculation, this can be done outside of the

instruction in other ladder code and the resulting Tag values can be inserted where appropriate

in the packet.

Termination characters can also be specified when needed.

The Custom Protocol Out instruction is for transmission only. If information needs to be

received from field devices, the Custom Protocol In instruction will have to be used. Unlike

ASCII, the Custom Protocol will buffer the received data. When the Custom Protocol In

instruction is executed, it will retrieve any data held in this buffer. Therefore, the lost responses

found with ASCII communication do not occur with Custom Protocol communication.

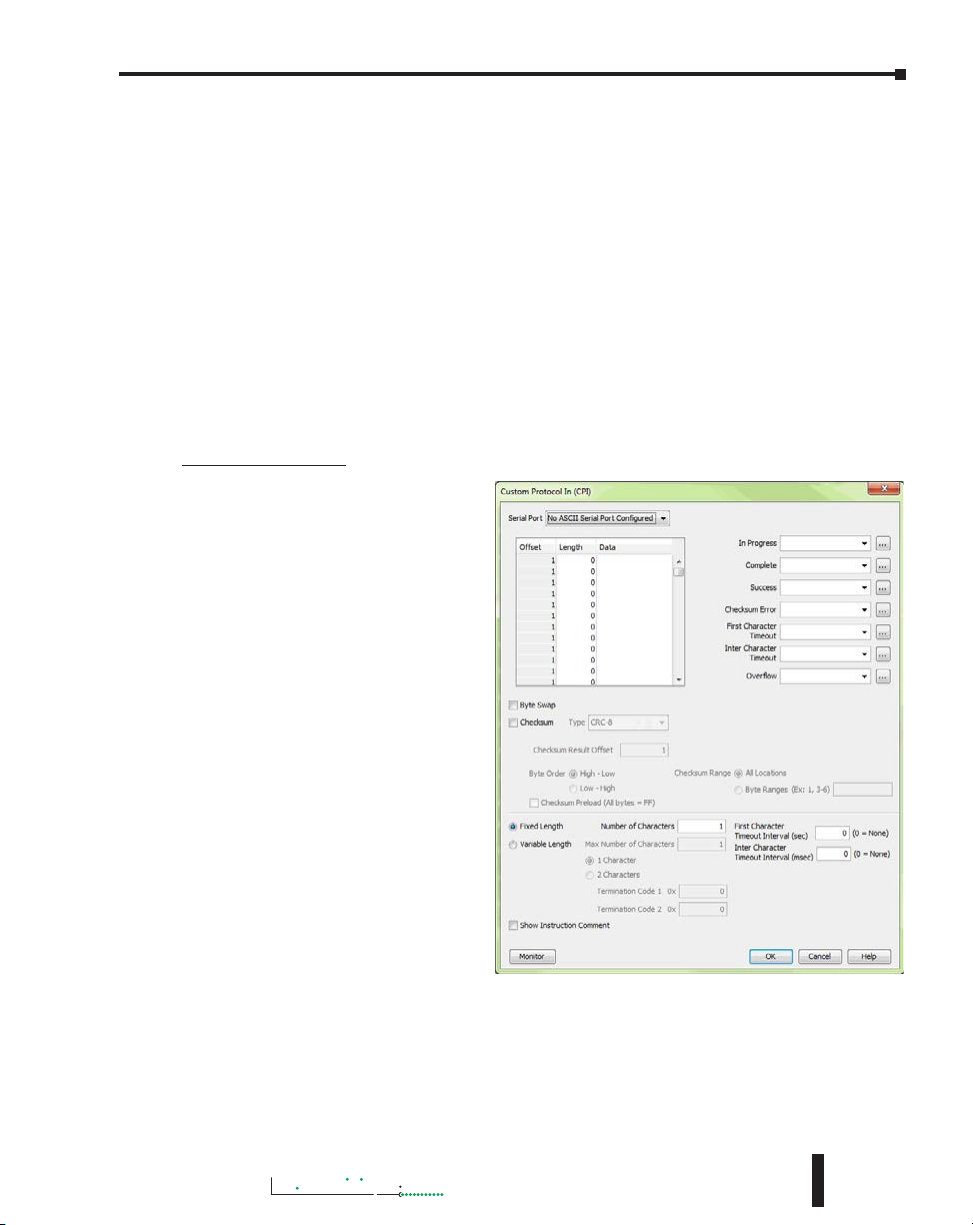

Custom Protocol In

The Custom Protocol In instruction

has similar formatting options to the

Custom Protocol Out instruction.

The Custom Protocol In instruction

will calculate the Checksum of the data

packet received based on the criteria

specified in the instruction and this

will determine the state of the status

bits assigned to the instruction. If the

Checksum calculation passes based on

the criteria specified in the instruction,

the “Success” status bit will become

true. If the Checksum calculation

fails, the “Checksum Error” status bit

will become true.

With the CPI instruction, the packet

termination must be specified, either

in terms of a termination character(s)

or a packet length. If a Checksum

is expected in the reply, be sure to

include this in the Fixed Length value

specified.

Hardware User Manual, 4th Edition, Rev. M

6-19

Page 20

Chapter 6: Communications

Productivity

Communications: Ethernet

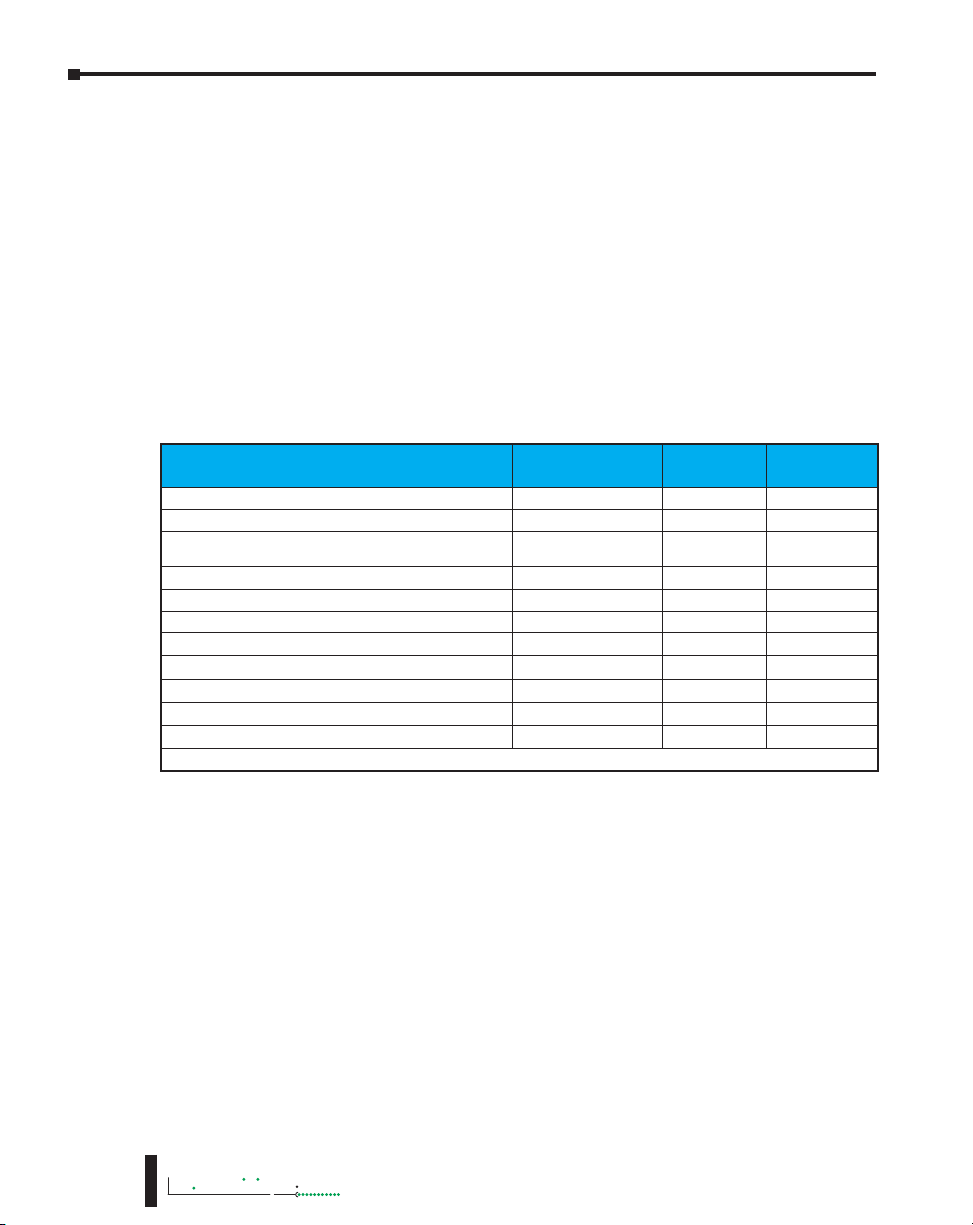

TCP and UDP Port Numbers

When doing TCP/IP and UDP/IP communications, there is a Source Port number

and Destination Port number for every message. The Client device must be aware of the

Destination Port Number(s) that the Server device is expecting to see and the Server device

must listen for this Destination Port number. After the Server device has received the message

with the Destination Port Number that it is listening on, it will formulate the return message

(if the applications require this) with the Source Port Number from the message sent as its

Destination Port Number.

It is important to understand a little about the Port numbering concept because many Ethernet

devices, such as routers with firewalls, will block messages with Destination Port numbers

that are not configured for that device. Listed below are the default Port Numbers used in

the Productivity3000

going through routers in many applications.

Programming Software CPU Discovery

Programming Software Connection and Project Transfer

Modbus Client Connections

(MRX, MWX, RX and WX instructions)

Modbus Server Connections

GS-Drive Discovery

GS-Drive Connection

Remote I/O Discovery

Remote I/O Connection

Email Instruction

Ethernet IP

Ethernet IP

* Adapters may choose to respond using another port number.

®

system. Some of these are configurable, allowing more flexibility when

Port

Port Number

(Decimal Format)

8888 UDP No

9999 UDP No

502 TCP Yes

502 TCP Yes

28784 UDP No

502 TCP No

8887 UDP No

8877 UDP No

25 TCP No

44818 TCP Yes

2222 UDP No*

TCP or UDP Configurable

6-20

IP Addressing and Subnetting

IP Addresses (used in conjunction with the Subnet Mask and Default Gateway address) are

used for network routing. This allows for easy and logical separation of networks.

It is outside of the scope of this help file to explain how IP Addresses and Subnet masks are

configured for actual usage. There are many books, documents and tools (Subnet calculators)

on the internet that provide this information. Each facility and network will incorporate their

own rules and guidelines for how their networks are to be configured.

3000

Hardware User Manual, 4th Edition, Rev. M

Page 21

Chapter 6: Communications

Productivity

3000

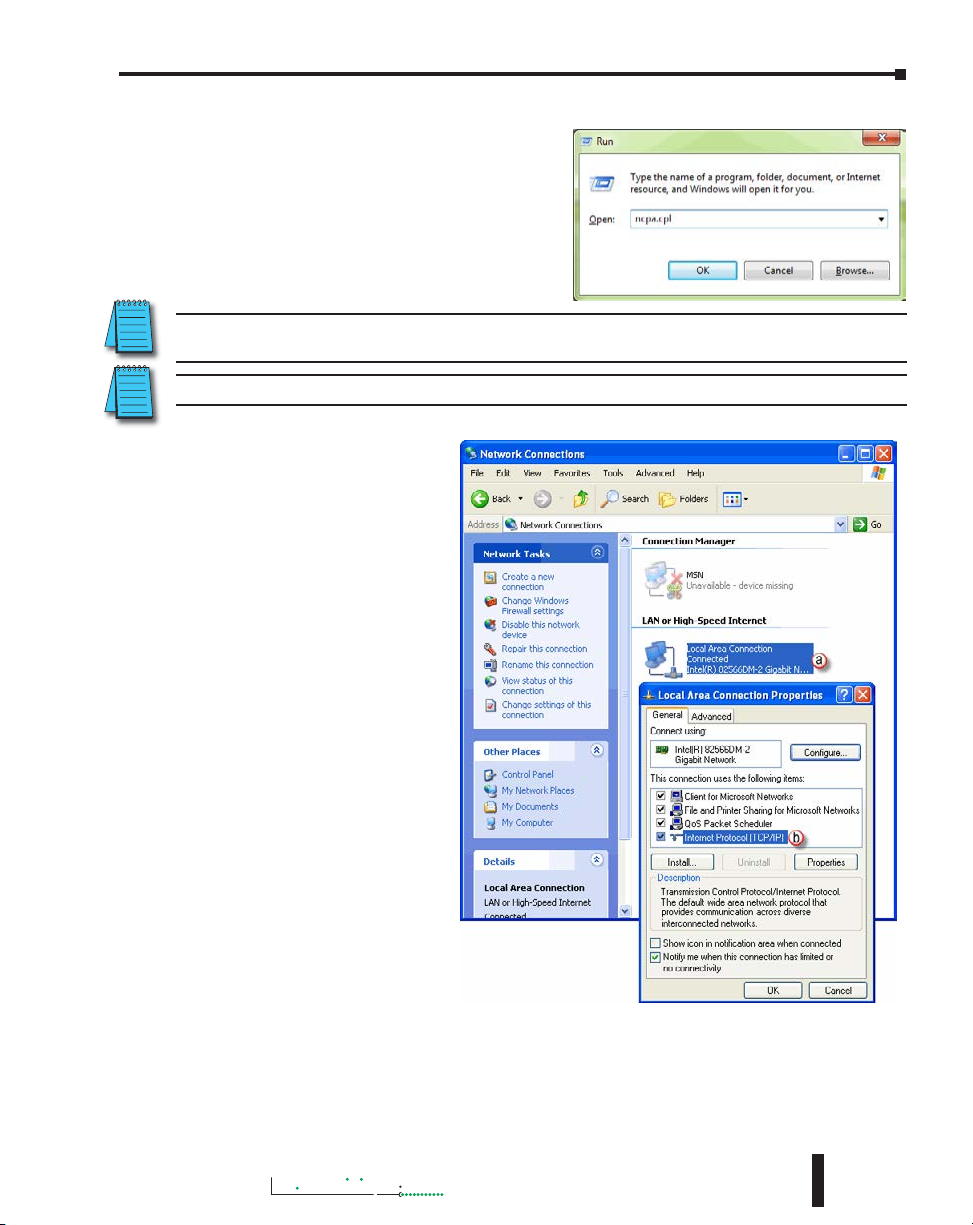

PC Setup

For testing and verification purpose, it is

recommended that the PC and the CPU be on

an isolated Ethernet switch. Configure the PC’s

network interface card setting as described below.

1. Go to Start, then Run, type ncpa.cpl in the

Open field and click on OK to bring up the

Network Connections dialog.

NOTE: Many system settings on your computer require Administrative privileges. Consult with your IT

department for necessary privileges and approvals.

NOTE: You should record initial settings prior to making any network configuration changes.

2. Network Connections

a. Right click on the

Network interface

shown in the Network

Connections dialog

and select Properties.

If there is more than

one Network Interface

on the PC, be sure

to choose the one

connected to the

Ethernet Switch with

the CPU on it.

b. From the Local Area

Connection Properties

window, highlight the

Internet Protocol(TCP/

IP) selection and click

on Properties.

Hardware User Manual, 4th Edition, Rev. M

6-21

Page 22

Chapter 6: Communications

Productivity

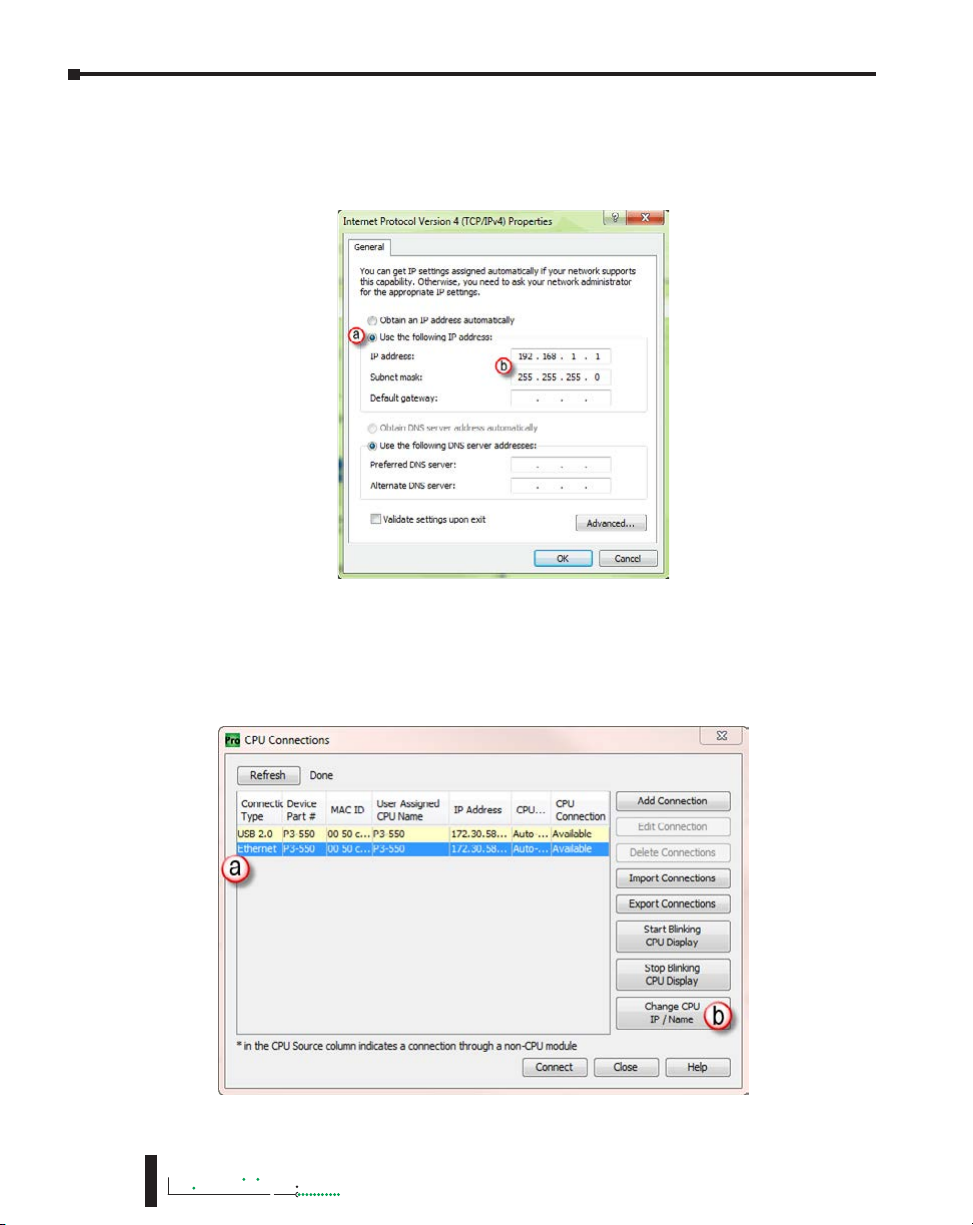

3. Internet Protocol (TCP/IP) Properties.

a. In the Properties window, select Use the following IP address.

b. Enter an IP Address of 192.168.1.1 and Subnet Mask 255.255.255.0 and select OK.

Select OK again on the Local Area Connection Properties window.

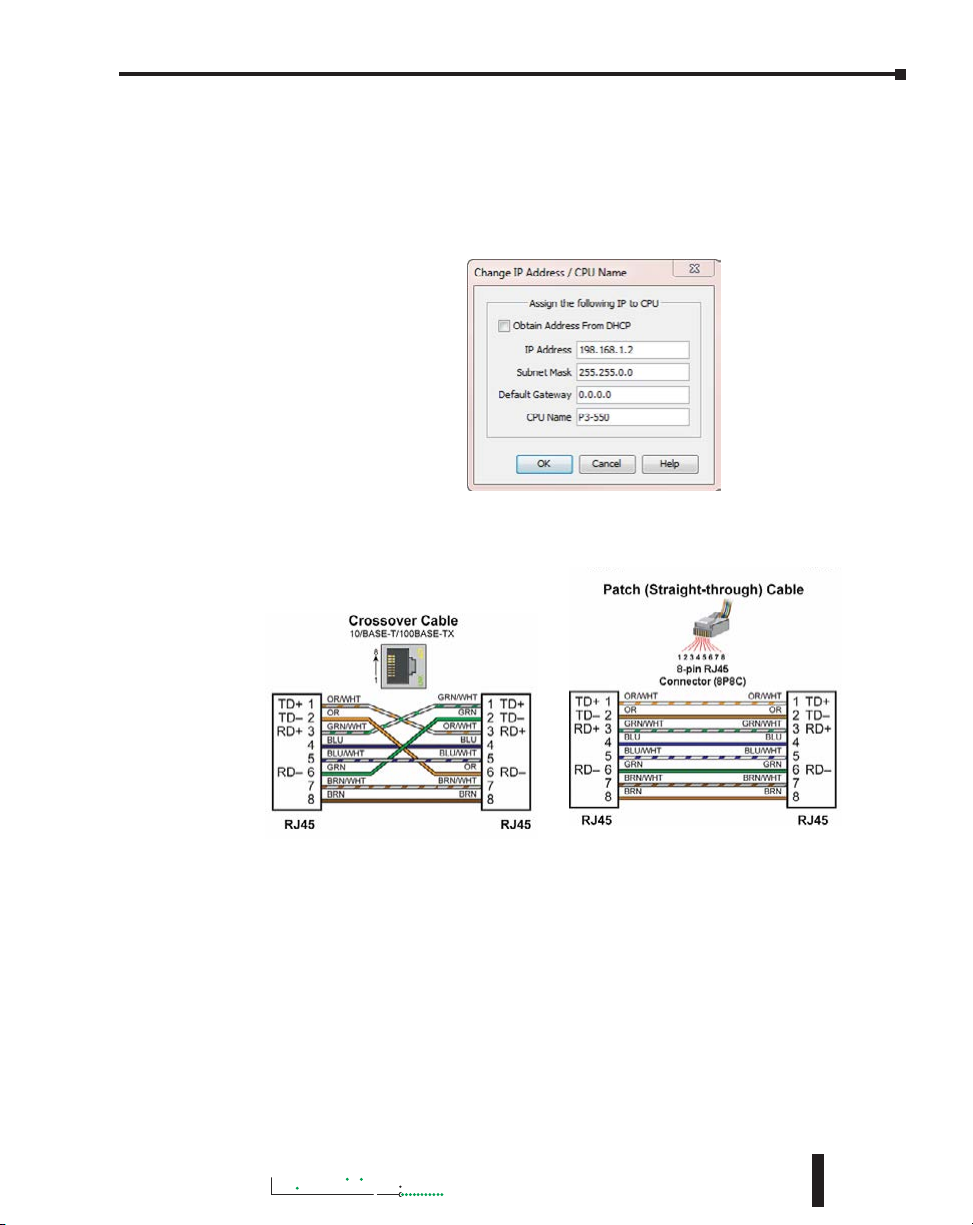

CPU Setup

Now configure the CPU’s network IP setting as shown below.

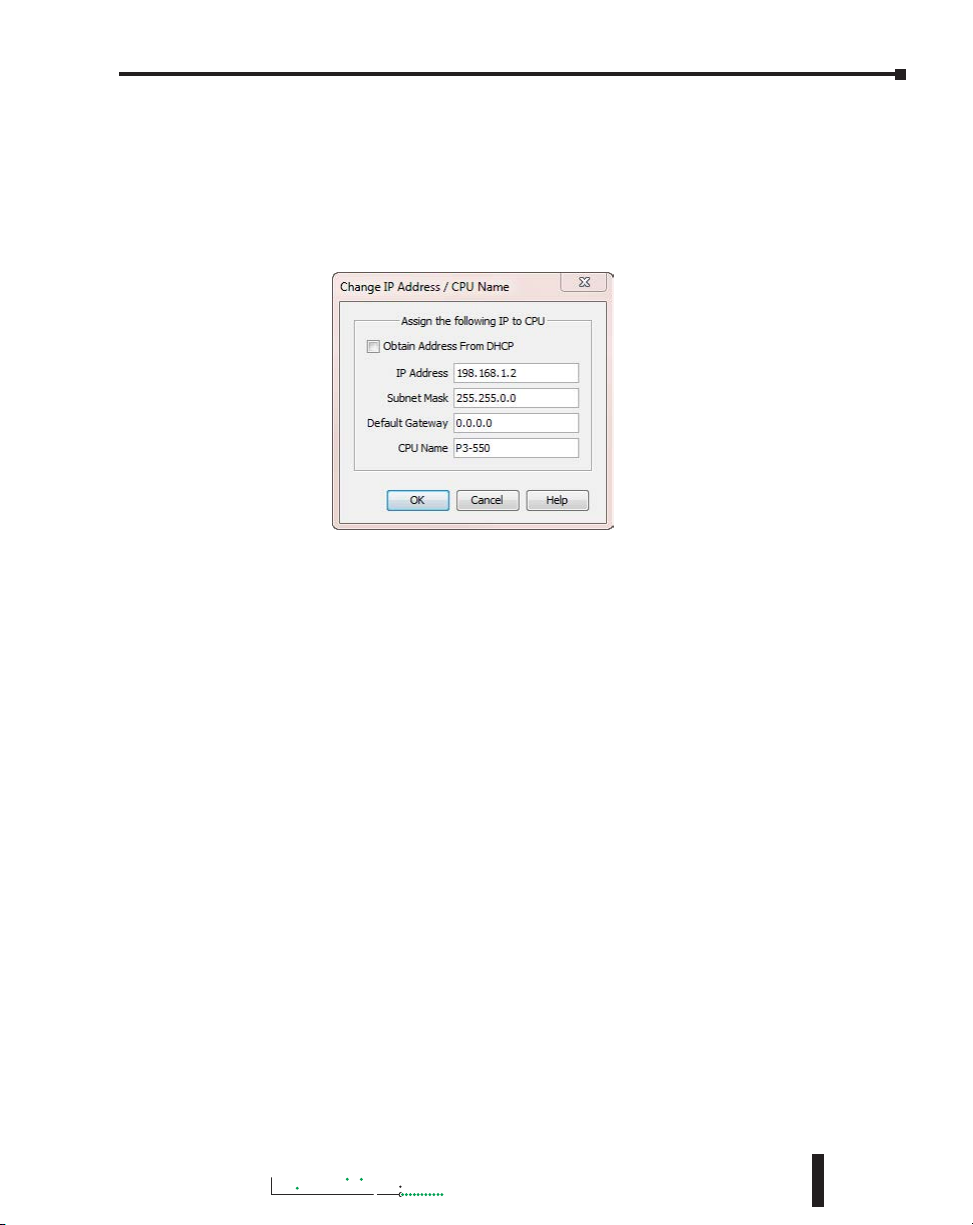

1. Select CPU from the Productivity3000® software Main Menu and then select Choose CPU

from the drop down menu.

2. The CPU Connections window will open as shown below.

6-22

3000

Hardware User Manual, 4th Edition, Rev. M

Page 23

Chapter 6: Communications

Productivity

3000

a. Click to highlight the CPU connected to the Ethernet switch.

b. Select the “Change CPU IP/Name” button.

3. The Change IP Address/CPU Name window will open as shown below.

a. Enter an IP Address of 192.168.1.2 and Subnet Mask 255.255.0.0 for the CPU’s network

IP setting and select OK.

The CPU is now configured with the correct IP Address for connectivity with the PC. The IP

Address and Subnet Mask settings will very likely differ from what will be used in the actual

application. Consult the Network Administrator of the facility where the CPU will be installed

to get the appropriate settings for that network.

TCP Connection Behavior with Modbus TCP and Network Instructions

When performing communications over TCP, a Connection must be established before the

applications can transfer data. The connection is typically maintained until the application

decides that the connection is no longer needed and then the connection will be severed.

Frequent connects and disconnects are not efficient for the Client or the Server and can add

unnecessary network traffic. But maintaining connections needlessly is also costly to the Client

and Server in terms of processing and memory so this should also be avoided.

The CPU allows user control of Client connections through enabling and disabling the rungs

containing Modbus and Network instructions. The MRX, MWX, RX and WX instructions

have two options for sending messages: Automatic Poll and Manual Poll.

Automatic Poll sends out messages at a specified rate. Enabling the instruction performs a TCP

connect with the Server device. Once the connection is established, the instruction messages

are sent at the rate entered in the poll rate field. This continues until the instruction is disabled.

The TCP connection will automatically be severed five seconds after the instruction is disabled.

Manual Poll sends out a message each time the instruction is enabled. Enabling the instruction

performs a TCP connect with the Server device and sends the message one time. The TCP

connection will automatically be severed five seconds after receiving the reply from the Server

device. If the instruction gets another positive edge enable within the five seconds, the message

will be sent and the disconnect of the TCP connection will be delayed by an additional five

seconds.

Hardware User Manual, 4th Edition, Rev. M

6-23

Page 24

Chapter 6: Communications

Productivity

Communications Modbus Functionality

Master/Client Function Code and Data Type Support

The following table lists the Modbus data type, the function code and the CPU source data

type that is supported when the CPU is the Client or Master on a Modbus TCP or serial

connection.

Modbus Client/Master Support (Using MRX and MWX Instructions)

Function

Function Name

Code

01 Read Coil Status 000000 - 065535 000001 - 065536

02 Read Coil Status 100000 - 165535 100001 - 165536

Read Holding

03

04

05 Write Single Coil 000000 - 065535 000001 - 065536

Registers

Read Input

Registers

Modbus 984 Addressing

(Zero Based)

400000 - 465535 400001 - 465536

300000 - 365535 300001 -365536

Modbus 984

Addressing

Productivity3000® Tag Types

(Data designation or source)

Discrete Output (DO)

Boolean (C )

Boolean System (SBRW)

Discrete Input (DI)

Boolean (C )

Boolean System (SBRW)

Integer 8 bit Unsigned (U8)

Integer 16 bit (S16)

Integer 16 bit Unsigned (U16)

Integer 16 bit BCD (B16)

Integer 32 bit (S32)

Integer 32 bit BCD (B32)

Integer 32 bit Float (F32)

Integer 16 bit System (SWRW)

Integer 8 bit Unsigned (U8)

Integer 16 bit (S16)

Integer 16 bit Unsigned (U16)

Integer 16 bit BCD (B16)

Integer 32 bit (S32)

Integer 32 bit BCD (B32)

Integer 32 bit Float (F32)

Integer 16 bit System (SWRW)

Discrete Input (DI)

Discrete Output (DO)

Boolean (C )

Boolean System (SBRW)

Boolean System Read Only (SBR)

6-24

3000

Hardware User Manual, 4th Edition, Rev. M

Page 25

Chapter 6: Communications

Productivity

3000

Modbus Client/Master Support (Using MRX and MWX Instructions) (continued)

Function

Code

06

15

16

Function Name

Write Single

Register

Write Multiple

Coils

Write Multiple

Registers

Modbus 984 Addressing

(Zero Based)

Modbus 984

Addressing

400000 - 465535 400001 - 465536

000000 - 065535 000001 - 065536

400000 - 465535 400001 - 465536

Productivity3000

(Data designation or source)

Integer 8 bit Unsigned (U8)

Integer 16 bit (S16)

Integer 16 bit Unsigned (U16)

Integer 16 bit BCD (B16)

Integer 32 bit (S32)

Integer 32 bit BCD (B32)

Integer 32 bit Float (F32)

Integer 16 bit System (SWRW)

Integer 16 bit System Read Only (SWR)

Discrete Input (DI)

Discrete Output (DO)

Boolean (C )

Boolean System (SBRW)

Boolean System Read Only (SBR)

Integer 8 bit Unsigned (U8)

Integer 16 bit (S16)

Integer 16 bit Unsigned (U16)

Integer 16 bit BCD (B16)

Integer 32 bit (S32)

Integer 32 bit BCD (B32)

Integer 32 bit Float (F32)

Integer 16 bit System (SWRW)

Integer 16 bit System Read Only (SWR)

®

Tag Types

Hardware User Manual, 4th Edition, Rev. M

6-25

Page 26

Chapter 6: Communications

Productivity

Slave/Server Function Code and Data Type Support

The following table lists the Modbus data type, the function code and the CPU source data type

that is supported when the CPU is the Server or Slave on a Modbus TCP or serial connection.

Modbus Server/Slave Support

Function Code Function Name Modbus 984 Addressing

01 Read Coil Status 000001 - 065536

02 Read Coil Status 100001 - 165536

03 Read Holding Registers 400001 - 465536

04 Read Input Registers 300001 -365536

05 Write Single Coil 000001 - 065536

06 Write Single Register 400001 - 465536

15 Write Multiple Coils 000001 - 065536

Productivity3000® Tag Types

(Data designation or source)

Discrete Output (DO)

Boolean (C )

Boolean System (SBRW)

Discrete Input (DI)

Boolean System Read Only (SBR)

Integer 8 bit Unsigned (U8)

Integer 16 bit (S16)

Integer 16 bit Unsigned (U16)

Integer 16 bit BCD (B16)

Integer 32 bit (S32)

Integer 32 bit BCD (B32)

Integer 32 bit Float (F32)

Integer 16 bit System (SWRW)

String

Analog Input, Integer 32 bit (AIS32)

Analog Input, Float 32 bit (AIF32)

Integer 16 bit System Read Only (SWR)

Discrete Output (DO)

Boolean (C)

Boolean System (SBRW)

Integer 8 bit Unsigned (U8)

Integer 16 bit (S16)

Integer 16 bit Unsigned (U16)

Integer 16 bit BCD (B16)

Integer 32 bit (S32)

Integer 32 bit BCD (B32)

Integer 32 bit Float (F32)

Integer 16 bit System (SWRW)

Integer 16 bit System Read Only (SBR)

String

Discrete Output (DO)

Boolean (C )

Boolean System (SBRW)

6-26

3000

Hardware User Manual, 4th Edition, Rev. M

Page 27

Chapter 6: Communications

Productivity

3000

Modbus Server/Slave Support (continued)

Function Code Function Name Modbus 984 Addressing

16 Write Multiple Registers 400001 - 465536

Productivity3000

(Data designation or source)

Integer 8 bit Unsigned (U8)

Integer 16 bit (S16)

Integer 16 bit Unsigned (U16)

Integer 16 bit BCD (B16)

Integer 32 bit (S32)

Integer 32 bit BCD (B32)

Integer 32 bit Float (F32)

Integer 16 bit System (SWRW)

Integer 16 bit System Read Only (SBR)

String

®

Tag Types

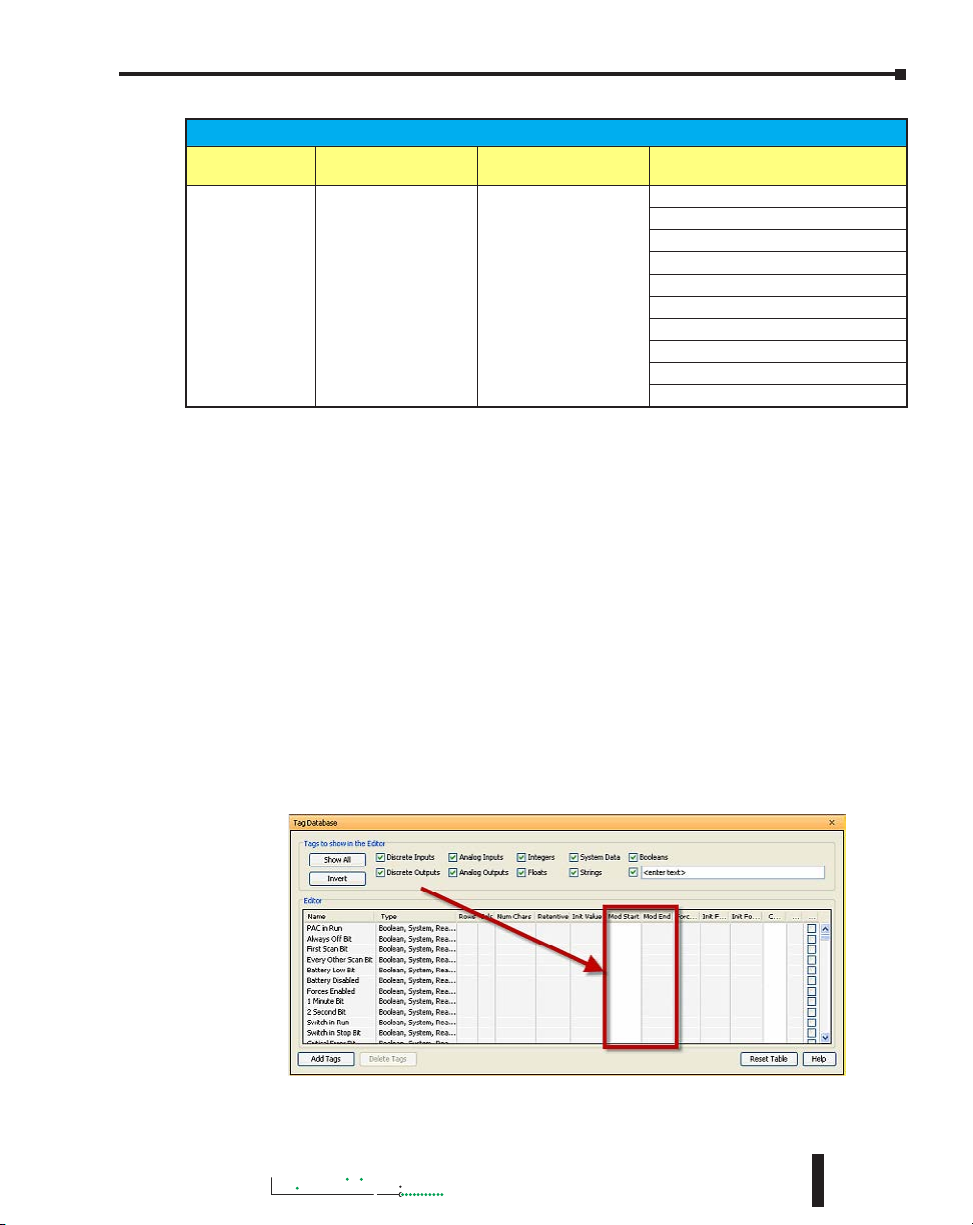

Assigning Modbus Addresses to Tags

There are many different data types in the CPU. Because of this, the Modbus addresses need

to be mapped to the various tag data types in the CPU.

There are two ways to map Modbus addresses to Tags in the Programming software:

• Modbus mapping in Tag Database window.

• Modbus mapping when creating Tags.

1. Modbus mapping in Tag Database window:

There are only two data sizes in the Modbus protocol: bits and words. In the CPU, there

are multiple size types, so it is sometimes necessary to map multiple Modbus addresses

to a single Tag entity. There are also array data structures in the CPU. When Modbus

addresses are mapped to arrays, they will be mapped as a contiguous block of addresses.

This is, in fact, the most efficient method to handle Modbus communications.

In the Tag Database window, there are two columns named “Mod Start” and “Mod

End”. To map a Modbus address to a tag in the Tag Database window, simply doubleclick in the Mod Start field for the Tag.

Hardware User Manual, 4th Edition, Rev. M

6-27

Page 28

Chapter 6: Communications

Productivity

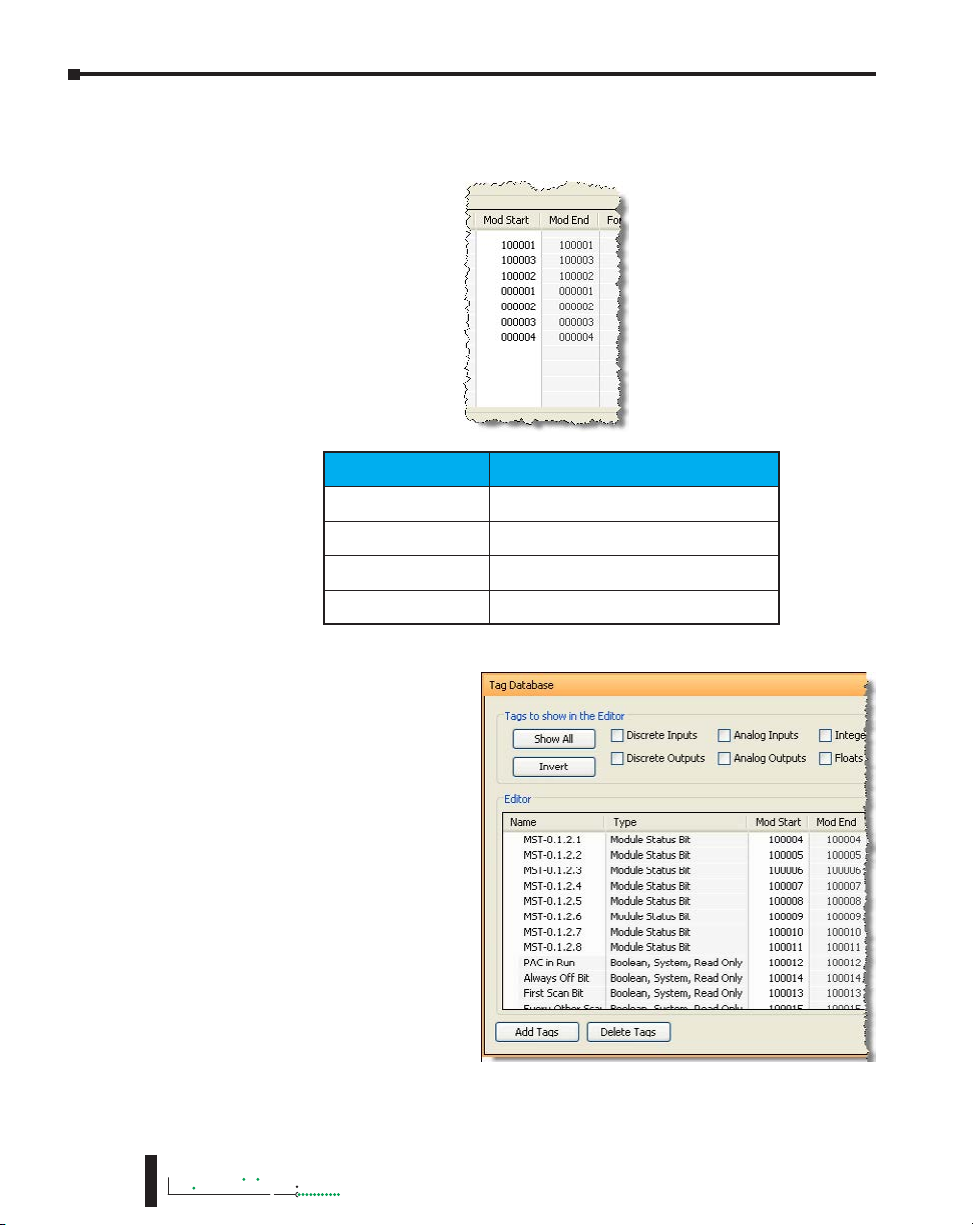

When you do this, you will see two values appear in the field. The left most value is

the Modbus data type. This is fixed based upon the tag data type. The chart below

indicates the four different Modbus data types in the 984 addressing scheme.

Address Identifier Modbus 984 Address Type

0xxxxx

1xxxxx

3xxxxx

4xxxxx

Coil (Read/Write bit)

Input (Read Only bit)

Input Register (Read Only 16 bit word)

Holding Register (Read/Write 16 bit word)

6-28

The right most value that you

see in the “Mod Start” field

is the address offset (range is

from 1 – 65535). You can

accept the value that is prefilled for you or the value can

be changed. The software

automatically pre-fills the

address offset with the next

available address.

3000

Hardware User Manual, 4th Edition, Rev. M

Page 29

Chapter 6: Communications

Productivity

3000

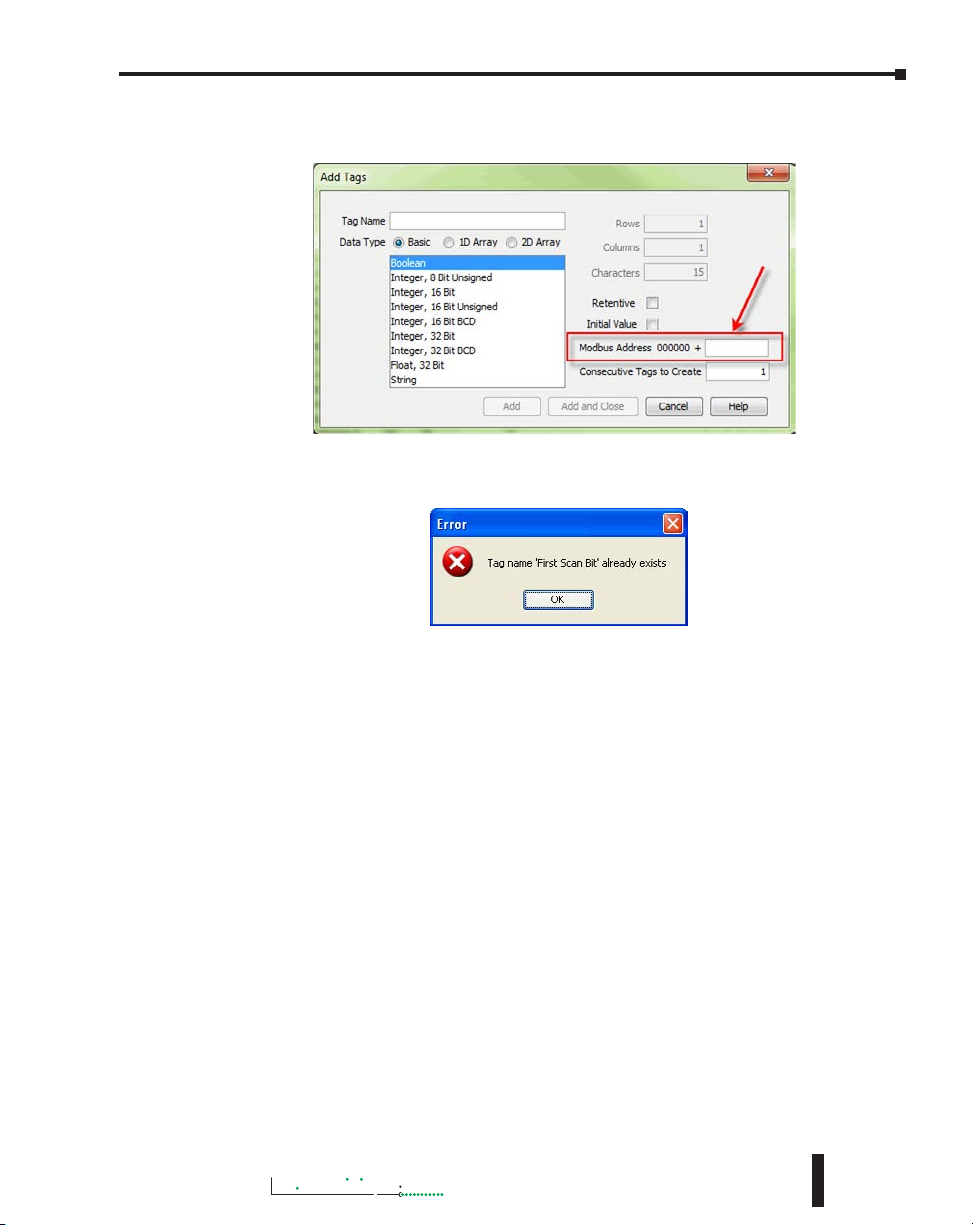

2. Modbus mapping when creating Tags:

Modbus addresses can be assigned to Tags as they are created in the Tag Database.

Type in the Modbus offset value when entering the Tag Name and Data Type. If the

address is already assigned, a warning message will appear.

Hardware User Manual, 4th Edition, Rev. M

6-29

Page 30

Chapter 6: Communications

Productivity

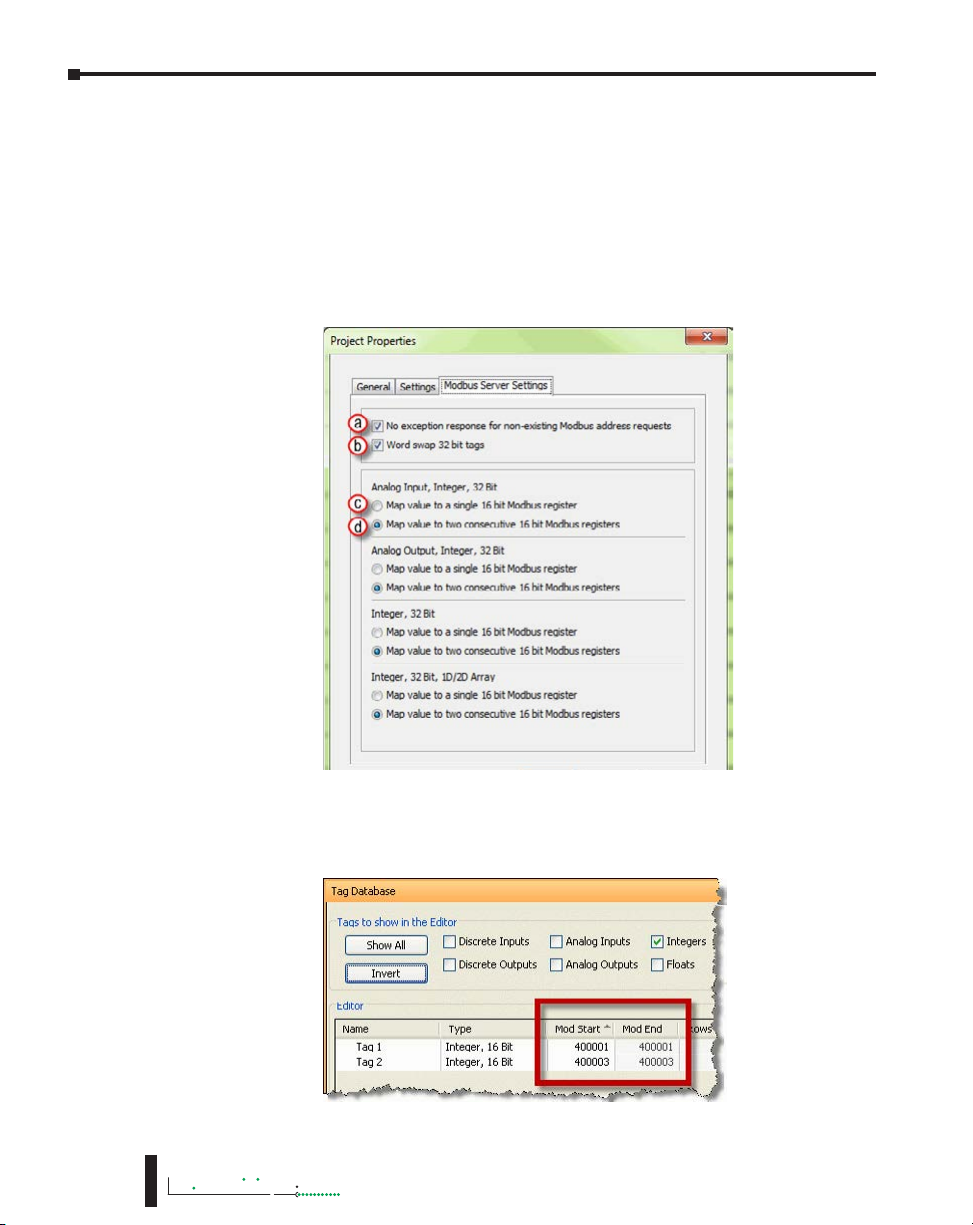

Modbus Options

The Modbus protocol does not have a specific method outlined for data types outside of bits

and 16-bit words. Most systems now have 32-bit data types. In order to transport 32-bit data

types across Modbus, they must be placed into two Modbus 16-bit registers. Unfortunately,

some devices do not support this and there are sometimes incompatibilities in the order of the

16-bit high word and low word handling between the devices.

In order to help alleviate this situation, there are some options for handling this in the

programming software. To find the Modbus Address options, go to File and click on Project

Properties and then click on the “Modbus Server Settings” tab.

6-30

a. No exception response for non-existing Modbus address requests: Because the Modbus addresses

can be manually assigned to tags, it is possible that gaps can occur in the Modbus address

mapping. For example: Tag1 has Modbus address 400001 assigned to it and Tag 2 has Modbus

address 400003 assigned to it.

3000

Hardware User Manual, 4th Edition, Rev. M

Page 31

Chapter 6: Communications

Productivity

3000

Most Modbus Master/Client devices will attempt to optimize their data requests to a Modbus

Slave/Server device by requesting blocks of data instead of individual registers. In the case

mentioned previously, most Modbus masters would send one read request starting at 400001

and a size of three instead of sending two read requests starting at 400001 with size one and

400003 with size one as shown below.

In the example shown above on left, a Modbus Slave/Server device should give an exception

response since there is no Modbus Address of 400002 in the device. This method can cause a

lot of inefficiencies. By selecting the “No exception response for non-existing Modbus address

requests” option, the CPU will not give an exception response to the request. Note that if

Modbus address 400002 by itself were requested it would give an exception response.

b. Word swap option (S-32, AIS-32, AOS-32, F-32, FI-32, FO-32):

Word swap allows the word order of 32-bit tags to be changed when sending the values across

Modbus. The default selection is on, which returns the data low word first.

Tag1 (Integer, 32-Bit) = 305,419,896 (hex = 0x12345678)

Tag1 Modbus address = 400001, 400002

Modbus reply for Tag1 (Word Swap ON ) = 01 03 04 56 78 12 34

Modbus reply for Tag1 (Word Swap OFF) = 01 03 04 12 34 56 78

Hardware User Manual, 4th Edition, Rev. M

Low

Word

First

High

Word

First

High

Word

Last

Low

Word

Last

6-31

Page 32

Chapter 6: Communications

Productivity

c. Map value to a single 16 bit Modbus register:

This option allows for compatibility with devices that do not support 32-bit Modbus

functionality. This option can be selected individually for the Analog Input and Output Signed

32 data types and the Internal Signed 32 data types, including the array form of these data types.

This function is only useful when the value contained in a 32-bit tag does not exceed a signed

15-bit value (32,765).

Tag1 (Integer, 32-Bit) = 22136 (hex = 0x00005678)

With “Map value to a single 16 bit Modbus register” turned OFF =

Tag1 Modbus address = 400001, 400002

Modbus reply for Tag1 (Word Swap ON) = 01 03 04 56 78 00 00

With “Map value to a single 16 bit Modbus register” turned ON =

Tag 1 Modbus address = 400001

Modbus reply for Tag1 = 01 03 02 56 78

d. Map value to two consecutive 16-bit Modbus registers: Allows for 32-bit data types to be

mapped to two consecutive 16-bit registers. This option is selected as default.

All of the options in the “Modbus Address” tab of the Project Properties only apply to the

Modbus Slave/Server functionality. Similar options are available for the Modbus Master/Client

functions as well and are available in the MRX and MWX Modbus instructions.

6-32

3000

Hardware User Manual, 4th Edition, Rev. M

Page 33

Chapter 6: Communications

Productivity

3000

Modbus Instructions

To read or set data in other Modbus Slave/Server devices, there are two instructions available

in the programming software, Modbus Read and Modbus Write.

• The Modbus Read (MRX) instruction is used to read data from other Modbus devices into

Tags of the CPU.

• The MRX instruction can be used for Modbus TCP or Modbus RTU. There are several

status bits that can be used to determine whether the read message was successful and if it

was not, the reason why.

Hardware User Manual, 4th Edition, Rev. M

6-33

Page 34

Chapter 6: Communications

Productivity

There is an “Automatic Polling” feature in the instruction to make it easier to read a device on a

pre-determined poll rate. There is also a “poll offset” field that can be used when simultaneous

instructions are enabled with the Automatic Polling feature to help stagger the flow of messages

being sent to the network.

• The Modbus Write (MWX) instruction is very similar in layout and configuration to the

MRX instruction. It is used to write values to a Modbus device from the tags in the CPU.

6-34

• The MWX operates very similarly to the MRX instruction. There are also many status bits

to indicate the success or reason of failure when sending a message.

• The Automatic Polling option is also available to the MWX instruction, although greater

care should be taken when using this feature in this instruction. This is explained in better

detail in the “Message Queue” section.

3000

Hardware User Manual, 4th Edition, Rev. M

Page 35

Chapter 6: Communications

Productivity

3000

Network Instructions

The Network Read (RX) and Network Write (WX) instructions are used to communicate to

other CPUs. They are very similar in operation to the MRX and MWX instructions but they

target Tag Names instead of Modbus addresses in the other CPU. There is also a significant

performance gain in using the RX and WX instructions when communicating to other CPUs

as opposed to using the MRX and MWX instructions.

The same status bits are available in the RX instruction as in the MRX instruction and operate

in the same manner. The greatest difference in the RX versus the MRX is that with the RX,

the Tag Name in the target CPU can be referenced directly and does not need a corresponding

Modbus address. The way this is accomplished is by mapping local and remote tag names

together within the local CPU’s RX instruction. Once the instruction is set up to read a remote

project, the “Tags of Remote Project” or “Array Tags of Remote Project” drop down lists will

be accessible. Map the Tag of the Remote project to a Tag in the Local project to read this

data.

Hardware User Manual, 4th Edition, Rev. M

6-35

Page 36

Chapter 6: Communications

Productivity

6-36

The WX instruction operates in the same manner except that the data from the Local tags will

be written into the Tags of the remote project. No Modbus mapping is required.

NOTE: The PC programming software project for the Remote CPU must be accessible by the PC running

the programming software for the Local project.

Automatic Poll versus Manual Polling and Interlocking

In many cases when performing multiple communications requests to other devices, the

message flow must be explicitly controlled in ladder code so that a message is not sent while

another one is in operation. This usually requires writing ‘interlocking’ code between the

instructions which typically involves the use of timers and shift registers, etc. Sometimes this

is necessary because of the application but in other cases where the CPU just wants to read

changing values from other devices and the frequency of that update is not critical it would be

much more efficient to skip the unnecessary code complexity of interlocking.

The desire to make it easier to communicate to other devices brought about the “Automatic

Polling” feature and the “Message Queue” in the CPU. The Automatic Polling feature allows

the user to choose the rate at which they desire to send messages without having to use a separate

timer and enable logic. The ‘Message Queue’ allows the user to stage the messages from the

ladder code to go out to each physical communications port without requiring interlocking logic.

3000

Hardware User Manual, 4th Edition, Rev. M

Page 37

Chapter 6: Communications

Productivity

3000

The implementation of how the message queue works is slightly different based on whether the

request is a read request or a write request.

Read Request Flowchart

Read or

Write?

Write

Read

Go to Write Request

Flowchart

Using

Automatic

Poll?

No

Request

Already in

Queue?

No

Add

Request to

Queue

Timer

Yes

Yes

Complete?

Yes

Discard

Request

No

Go to Next

Instruction

Write Request Flowchart

Read or

Write?

Write

Use

Automatic

Poll?

No

Add

Request to

Queue

Read

Yes

Go to Read Request

Flowchart

Timer

Complete?

Yes

No

Go to Next

Instruction

Write requests will fill the queue much faster than read requests. That’s why it is advisable to

carefully choose when doing write requests whether to use the “Automatic Poll” feature or to

manually send write requests only when needed (data to write has changed). When designing

a system, it is important to know the total time it takes to send a request and get a reply for

each target device. The Poll time should be longer than this time. The longer the poll time

can be, within tolerance of the application, the better the overall network performance. So for

efficiency in programming and for the best possible performance for the system, conservative

poll rates should be used when utilizing the “Automatic Poll” feature.

There is also a “Poll offset” field in the communications instructions. This helps prevent the

instructions from being queued all at the same time. When the CPU project starts, there is a

master timer that begins. The ladder scan will look to see if the instruction is enabled. If it is

enabled, it will begin the Automatic Poll timer at the specified poll offset value from the master

time clock.

Hardware User Manual, 4th Edition, Rev. M

6-37

Page 38

Chapter 6: Communications

Productivity

Message Queue

If the application requires more explicit, orderly control of each message sent to the devices,

turn off the “Automatic Poll” feature. Using the instruction’s status bits, logically control each

message as required.

All of the above explains how messages get into the “queue”. There are several factors involved

with how each queue (1 for each physical port) is emptied.

• Serial port queues: The serial port queues empty slower than the Ethernet port

queues, not just because of the hardware speed itself but because of the nature of serial

communications. Each request sent must wait for a response or a timeout (whichever

comes first). Once the reply is received for a request or a timeout has occurred, the next

item in the list can be sent. So the response time of the slave devices on the network will

largely affect the speed at which the queue fills and empties.

• Ethernet port queues: The Ethernet port queue can empty faster because when sending

requests to multiple devices, the CPU does not have to wait on a response from one device

before sending a request to another device due to the inherent nature of the Ethernet

hardware. However, sending multiple requests to the same Ethernet device does necessitate

that the CPU waits for a response from the first request before sending another request to

that same device.

Another difference in the Ethernet port queue versus the Serial port queue spawns from the

TCP ‘connection’ based behavior of Modbus TCP. If a TCP connection is lost to a device

and there are still requests in the queue for that device, those requests will be dropped from the

queue. There are three ways this can happen:

1. If a TCP timeout occurs (server device fails to respond within specified timeout value), the TCP

connection is lost.

2. If the server device closes the connection, then all of the requests will be dropped.

3. And, finally, if all rungs with communications instructions to a device are disabled for five

seconds, the CPU will drop the TCP connection for that device in order to free up valuable

resources that could be used elsewhere in the system.

This is another factor that should be considered when designing the system. If it is imperative

that no message be lost when communicating to a device, each instruction should be explicitly

handled one by one (interlocking logic).

6-38

3000

Hardware User Manual, 4th Edition, Rev. M

Page 39

Productivity

3000

EtherNet/IP for the Productivity Series

Terminology Definitions

A lot of terminology associated with EtherNet/IP is not always clear. Some of these terms are

listed below along with their respective definitions.

• Scanner: This is the term used to describe the device that initiates the EtherNet/IP sessions.

The Scanner is sometimes referred to as the “Originator” as well. In more standard Ethernet

terms, the Scanner would often be called the “Client”.

• Adapter: This is the device that responds to the EtherNet/IP communications that are initiated

by the Scanner. The Adapter is also known as the “Target” as well. Typically, the Adapter is an

Ethernet “Server”.

• Object: In EtherNet/IP, an Object is a representation of a defined set of Ethernet connections,

behaviors, services and data attributes. There are standard objects and there are custom defined

objects as well. See Object Modeling example below.

• Class: A Class is a set of Objects that are related in some fashion. See Object Modeling example

below.

• Instance: An Instance is an actual, usable manifestation of an Object. See Object Modeling

example below.

• Attributes: Attributes are the specific items within an Object Class. The category of Attributes

should be the same for all Instances of an Object but the actual Attribute itself might vary. See

Object Modeling example below.

• Connection Point: A Connection Point value is the “Class Code” reference for a data block.

This value is required for access to input and output data in IO Messaging. It is typically

defined for each input and output data block by the Adapter device manufacturer.

• IO Messaging: IO Messaging (also called “Implicit Messaging”) is a method of reading and

writing blocks of data without defining the Connection Point and size for each block transfer.

The Connection Point, size and transfer rate (RPI) are defined at the beginning and then the

data blocks are transferred at the specified intervals.

• Explicit Messaging: This method of reading or writing data requires that each message defines

the type of data and size of data needed for each request.

Chapter 6: Communications

Object Modeling Example:

Class ------- Definition of Automobile

Attributes -- Make, Model, etc…

Object ------ A Ford Mustang

Instance ----Sally’s Ford Mustang

Hardware User Manual, 4th Edition, Rev. M

6-39

Page 40

Chapter 6: Communications

Productivity

Network Layer Chart

The diagram above illustrates the OSI seven layer model and how EtherNet/IP fits into this

model. In general, there are three basic layers for sending and receiving data in the EtherNet/

IP protocol:

• EtherNet/IP layer (Register Session, etc…)

• CIP layer (CIP Forward Open, etc…)

• The uppermost layer,which contains several different types of messaging.

The ODVA specification defines many different types of messaging that reside on the CIP layer.

Two types of messaging supported in the phase 1 release of the Productivity3000® EtherNet/IP

protocol are IO Messaging and Explicit Messaging. IO Messaging is accomplished through a

Class 1 Connection and Explicit Messaging can be accomplished through a Class 3 Connection

or an Unconnected Message.

Tag Based Messaging (used for reading and writing values to Allen Bradley Control and

ComCPUtLogix PLCs) and PCCC (used for reading and writing values to Allen Bradley

MicroLogix and SLC PLCs) are planned for subsequent phases of this protocol.

6-40

EtherNet/IP Data

When doing IO Messaging, the data that is transported is defined as “Input” data and “Output”

data. Don’t confuse this type of data with what most PLCs define as Input data and Output

data. In most PLCs, Inputs are typically associated with an Input module that reads point from

real word devices. Outputs are typically associated with an Output module that turns off and

on real word devices.

In IO Messaging, Input data is data that is sent from the target device back to the Originator

or to multiple devices that are listening (multicast messages). Output data is data that is sent

from the Target device. This data may or may not be connected to real word devices. That

is completely dependent upon the Adapter device. For example: When the Productivity3000

is configured as an EtherNet/IP Adapter device, the Input data and Output data is defined in

internal data arrays and does not directly tie to any Input and Output point to the real world.

If it is desired to tie these array elements to real word devices, that must be accomplished in

code by Copy commands (or other instructions).

NOTE: The Scanner (originator) in the P3000 will only accept messages from an Adapter (target) device

that the Scanner has established a connection to.

NOTE: The Adapter (target) in the P3000 will respond back to a Scanner (originator) in the method

(Multicast or Unicast) that is sent in the forward open message from the Scanner (originator).

3000

Hardware User Manual, 4th Edition, Rev. M

Page 41

Chapter 6: Communications

Productivity

3000

Class 1 and Class 3 Connections

What are they and how are they best used?

• Class 1 Connection is the transport mechanism that IO Messaging uses to send data. The basic

concept is that data is sent in one direction: the Originator sends Output data in a Unicast UDP

message to the Target and the Target sends Input data in either a Unicast message back to the

Originator or Multicast UDP messages to multiple devices. The Input data and Output data

messages have no relationship to each other. This method works well for Remote I/O type data

and is very efficient due to little overhead and reduced handshaking messages on the wire. Class

3 Connection is one of the mechanisms that Explicit messaging uses. Class 3messaging uses

TCP messages unlike Class 1. Each Class 3 request has a header that defines the type of data

requested as well as the size requested. It allows for more flexibility in messaging but does create

additional overhead.

NOTE: Explicit messaging can be accomplished with unconnected messages as well for more infrequent

requests. Explicit messaging is a slower performing method of communications but it typically allows for

more flexibility and control when the situation requires it.

When can the P3000 CPU use Class 1 or Class 3 Connections?

• Class 1 and Class 3 Connections can be accomplished with the Productivity3000® CPU as an

Adapter or as a Scanner or both simultaneously.

How many connections can the P3000 support for Ethernet IP?

• 4 - TCP

• 4 - Ethernet IP

• 4 - CIP (Up to 4 CIP connections are allowed per Ethernet IP connection. Therefore, if one

device can support 4 CIP connections then you can have up to a total of 16 CIP connections

using 4 devices)

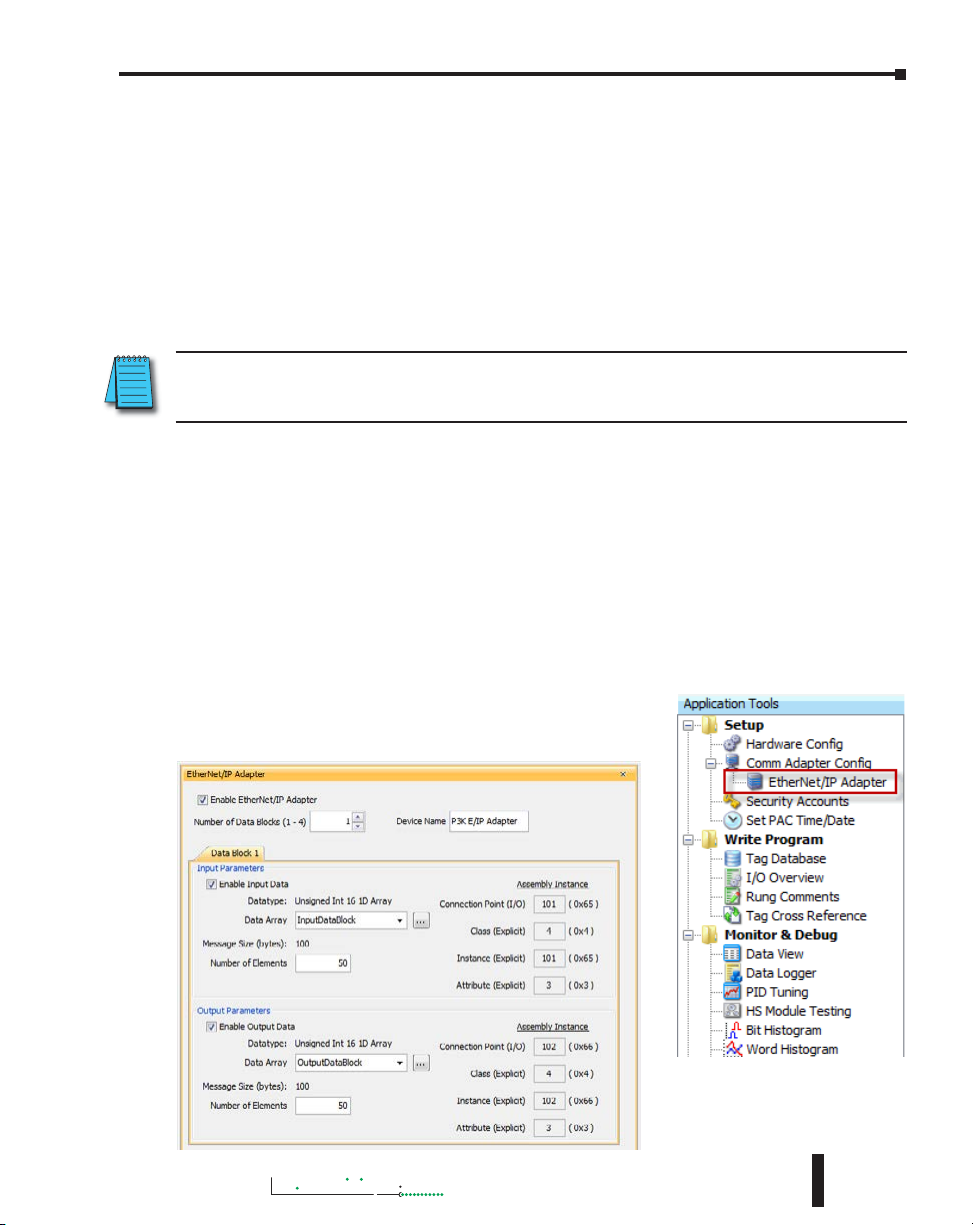

Example Setup: Productivity3000 as EtherNet/IP Adapter

The Adapter setup is accomplished through the EtherNet/IP

Adapter setup under the Comm Adapter Config section of the

Setup menu as seen on right.

Hardware User Manual, 4th Edition, Rev. M

When the EtherNet/IP Adapter

is selected from the menu the

window shown here will open.

6-41

Page 42

Chapter 6: Communications

Productivity

Fill in the required parameters and once configured these parameters will be used to configure

the Scanner side as shown in the examples below. The first example shows how to setup a

Class 1 IO Message connection from a 3rd party EtherNet/IP Scanner device (an Allen Bradley

PLC).

6-42

The following example shows how a Class 3 Explicit Message might be accomplished from a

3rd party device (Allen Bradley PLC). As you can see the Input Data must be retrieved in one

connection or message and the output data in another. Remember that Class 3 messaging is

not as efficient in protocol messaging as Class 1 but it does allow for granular control.

NOTE: In this example, size configuration is not shown on the Scanner side. The tag created for the

Destination must be large enough to contain the data requested (shown with dashed boxes).

3000

Hardware User Manual, 4th Edition, Rev. M

Page 43

Chapter 6: Communications

Productivity

3000

Hardware User Manual, 4th Edition, Rev. M

6-43

Page 44

Chapter 6: Communications

Productivity

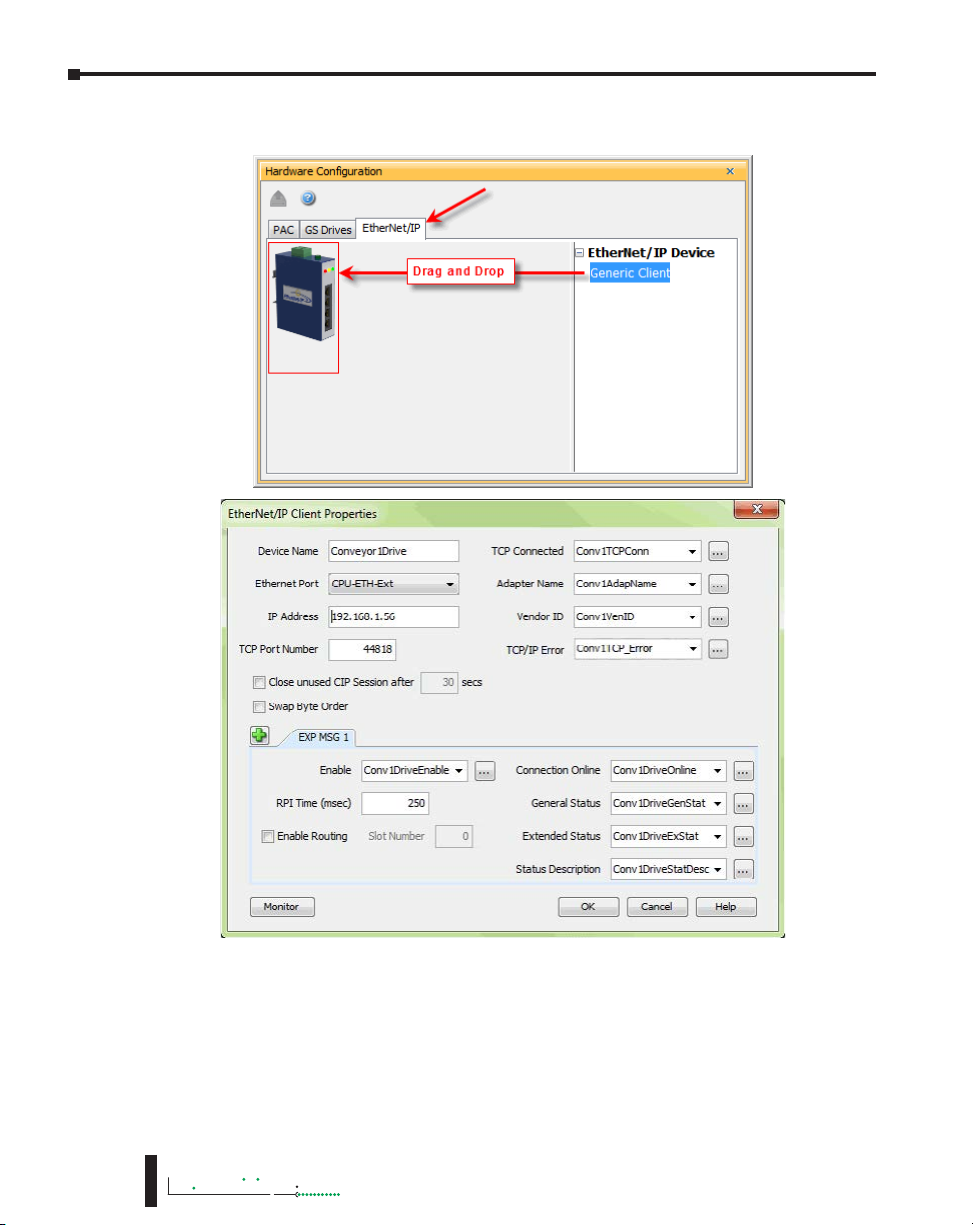

Example Setup: Productivity3000® as EtherNet/IP Scanner

This example shows how to connect the Productivity3000 Scanner function to an EtherNet/IP

adapter device using Class1 IO Messaging. First, create an EtherNet/IP device in the Hardware

Configuration as seen below:

Configure the parameters to match

the settings of the Adapter device.

The image on right shows the setup

of the Input data.

The size, in this case, is dynamic

to the configuration of the device.

For this particular example, we

configured the device in a manner

that allows it to publish 8 bytes

of data for Input. Many devices

will have a fixed configuration

that should be published in the

manufacturer’s documentation.

6-44

3000

Hardware User Manual, 4th Edition, Rev. M

Page 45

Productivity

3000

The Output data must also be

configured. Its data is also dynamic

based upon the configuration. In

our example, we configured the

device in a manner that caused it

to require 8 bytes of Output data.

Chapter 6: Communications

The image on left shows the setup for the

Configuration data. The Configuration data,

for most devices, is a fixed size. Some devices

will require that the Configuration data

Connection Point be included in the Forward

Open message (as shown on left) even if the

size is 0. Some devices will require that the

Configuration data Connection Point not be in

the Forward Open and the checkbox option in

the image below would need to be de-selected.

Hardware User Manual, 4th Edition, Rev. M

6-45

Page 46

Chapter 6: Communications

Productivity

The following example shows how to connect the Productivity3000® Scanner function to

an EtherNet/IP adapter device using Class 3 Explicit Messaging. As with IO Messaging, an

EtherNet/IP device must be created in the Hardware Configuration as seen below:

6-46

Explicit Messages can be performed in 2 ways: Unconnected or Connected (Class 3). The

advantage of using Unconnected messaging is it allows more discrete control of each request.

The disadvantage of Unconnected messaging is that Unconnected messages have a lower

priority and will take longer to get serviced on some devices. Connected messages get serviced

faster since there is a connection established to the device. If Connected messaging is desired,

create an Explicit Message tab as shown in the image above. If Unconnected messaging is

desired, do not create an Explicit Message tab. Only fill out the information in the upper

portion of the EtherNet/IP Client Properties window.

3000

Hardware User Manual, 4th Edition, Rev. M

Page 47

Chapter 6: Communications

Productivity

3000

Once the desired parameters have been entered, the device may now be referenced in the

Explicit Message Instruction. If Unconnected messaging has been selected, choose the

Unconnected MSG option in the Connection drop down box. If Connected messaging has

been selected, choose the Explicit Message that was configured in the EtherNet/IP Client

Properties window in the Connection drop down box. The rest of the settings should be

matched to the specifications documented by the manufacturer. An example for requesting

the Identity of a device is shown below. The data array configured for this function must be

sufficient in size to hold the returned data from the device for this object. Data can also be

written to the device if it supports an object for this purpose. If data is being written, enable the

Output selection and specify the data array and size required by that device’s object.

Troubleshooting Tips:

a. Use the diagnostic tags in the Hardware Configuration and Explicit Message Instruction:

As explained previously in the Network Layer Chart section, there are multiple layers

of messaging involved with EtherNet/IP. If it appears that the Productivity3000 is not

communicating with another EtherNet/IP device, there are diagnostic tags available to

narrow down which layer of the protocol is preventing successful communications.

Hardware User Manual, 4th Edition, Rev. M

6-47

Page 48

Chapter 6: Communications

Productivity