Page 1

AKD®-C and AKD®-N

EtherCAT Communication

Edition: J, October 2020

Valid for firmware version 1.20

Part Number 903-200023-00

Original Documentation

For safe and proper use, follow these

instructions. Keep for future use.

Page 2

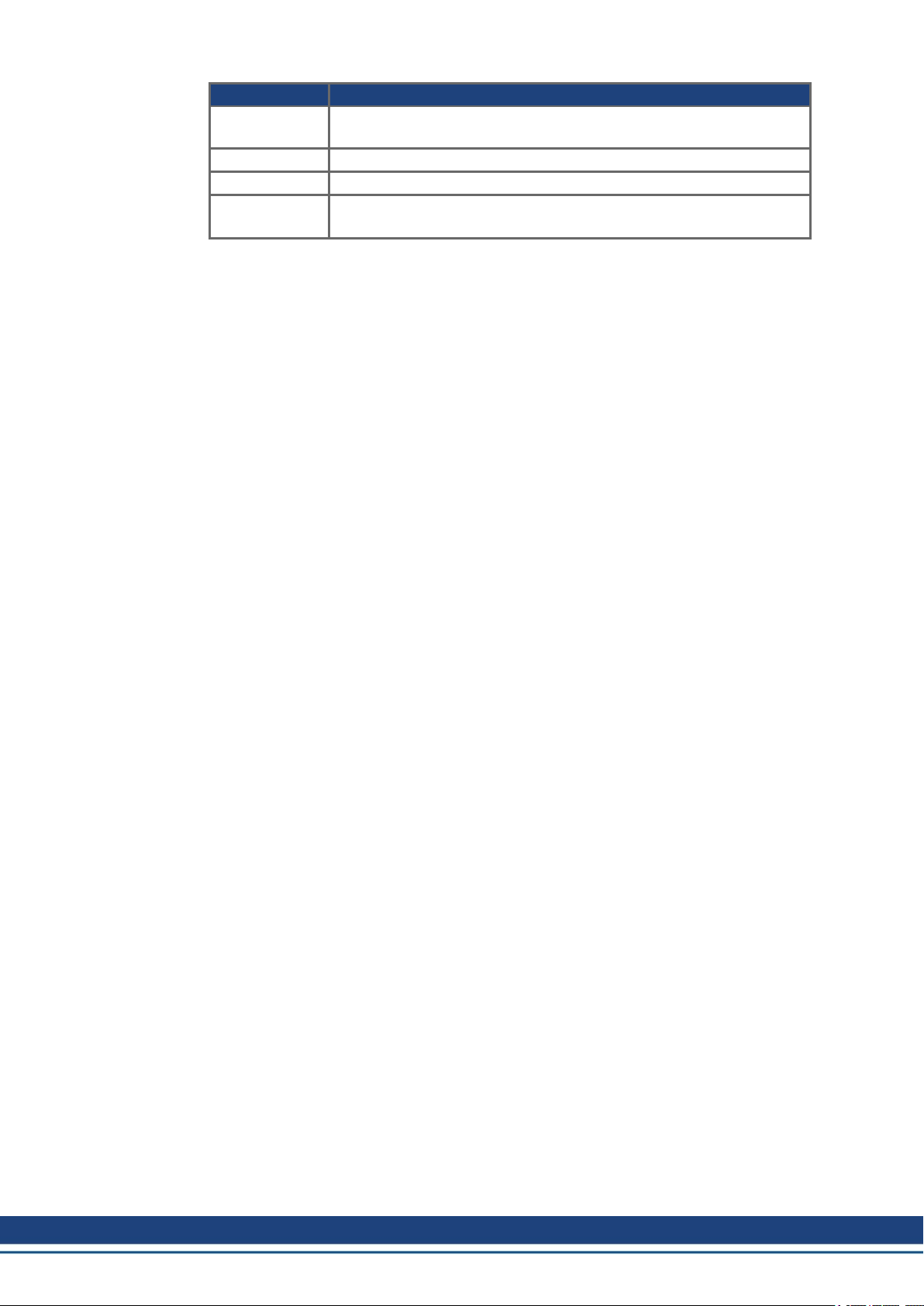

Record of Document Revisions

Revision Remarks

... Table with lifecycle information of this document see "Record of Docu-

G, 11/2018 Updated object information.

H, 11/2019 Added Emergency Messages

J, 10/2020 Added objects 34D1h, 547Ah, 547Bh and edited data types for objects

Trademarks

l AKD is a registered trademark of Kollmorgen Corporation

l SynqNet is a registered trademark of Motion Engineering Inc.

l EnDat is a registered trademark of Dr. Johannes Heidenhain GmbH

l EtherCAT is a registered trademark and patented technology, licensed by Beckhoff

Automation GmbH

l Ethernet/IP is a registered trademark of ODVA, Inc.

l Ethernet/IP Communication Stack: copyright (c) 2009, Rockwell Automation

l sercos

l HIPERFACE is a registered trademark of Max Stegmann GmbH

l PROFINET is a registered trademark of PROFIBUS and PROFINET International (PI)

l SIMATIC is a registered trademark of SIEMENS AG

l SpeedTec is a registered trademark of TE Connectivity Industrial GmbH

l Windows is a registered trademark of Microsoft Corporation

®

is a registered trademark of sercos®international e.V.

ment Revisions" (➜ p. 178)

2001h and 2012.

Current patents

l US Patent 8,154,228 (Dynamic Braking For Electric Motors)

l US Patent 8,214,063 (Auto-tune of a Control System Based on Frequency Response)

Technical changes which improve the performance of the device may be made without prior notice!

This document is the intellectual property of Kollmorgen. All rights reserved. No part of this work may be reproduced

in any form (by photocopying, microfilm or any other method) or stored, processed, copied or distributed by electronic

means without the written permission of Kollmorgen.

2 Kollmorgen | kdn.kollmorgen.com | October 2020

Page 3

AKD-C/N EtherCAT | Table of Contents

1 Table of Contents

1 Table of Contents 3

2 General 9

2.1 About this Manual 10

2.2 Target Group 10

2.3 Symbols Used 11

2.4 Abbreviations Used 12

3 Installation and Setup 13

3.1 Important Instructions 14

3.2 EtherCAT Onboard 15

3.2.1 LED functions 15

3.2.2 Connection technology 15

3.2.3 Network Connection Example 15

3.3 Guide to Setup 16

3.4 Important Configuration Parameters 17

3.5 Setting up Ethernet over EtherCAT (EoE) 19

3.5.1 EtherCATDevice Settings 19

3.5.2 Drive Settings 20

3.5.3 Connecting to the Drive 20

3.5.4 Performance Concerns 21

3.5.5 Restrictions 21

3.6 Setup via TwinCAT NC/PTP System Manager 21

3.6.1 Scan devices 22

3.6.2 Select the device 22

3.6.3 Scan for boxes 23

3.6.4 Add Slaves to NC tasks 23

3.6.5 Enable the network configuration 23

3.6.6 Enable the axis and move the axis 24

3.7 Setup WorkBench over TwinCAT 25

3.7.1 TwinCAT and WorkBench Configuration 25

3.7.2 Connecting to a Drive Using WorkBench 27

3.7.3 Configuring and Enabling a Drive 30

3.7.4 Download a Parameter File over TwinCAT 31

3.8 Setup via KAS IDE 32

4 EtherCAT Profile 33

4.1 Slave Register 34

4.2 AL Event (Interrupt Event) and Interrupt Enable 35

4.2.1 Interrupt Enable Register (Address 0x0204:0x0205) 35

4.2.2 AL Event Request (Address 0x0220:0x0221) 36

4.3 Phase Run-Up 37

4.3.1 AL Control (Address 0x0120:0x0121) 37

4.3.2 AL Status (Address 0x0130:0x0131) 37

4.3.3 AL Status Code (Address 0x0134:0x0135) 38

4.3.4 EtherCAT communication phases 38

Kollmorgen | kdn.kollmorgen.com | October 2020 3

Page 4

AKD-C/N EtherCAT | Table of Contents

4.4 CANopen over EtherCAT (CoE) State Machine 39

4.4.1 Status Description 39

4.4.2 Commands in the Control Word 40

4.4.3 State Machine Bits (status word) 41

4.5 Fixed PDO Mappings 41

4.6 Flexible PDO Mappings 44

4.6.1 Example: Flexible PDO Mapping 45

4.6.2 Example: Flexible PDOMapping with one byte gap in Rx-PDO 49

4.7 Supported Cyclical Setpoint and Actual Values 51

4.8 Supported Operation Modes 54

4.9 Adjusting EtherCAT Cycle Time 54

4.10 Maximum Cycle Times depending on operation mode 54

4.11 Synchronization 55

4.11.1 Synchronization behavior with distributed clocks (DC) enabled 55

4.11.2 Synchronization behavior with distributed clocks (DC) disabled 55

4.12 Latch Control Word and Latch Status Word 56

4.13 Mailbox Handling 57

4.13.1 Mailbox Output 58

4.13.2 Mailbox Input 59

4.13.3 Example: Mailbox Access 60

4.14 EEProm Content 61

5 Appendix 62

5.1 CANopen Emergency Messages and Error Codes 63

5.1.1 Error Codes for Drives 63

5.1.2 Error Codes for Power Supply 68

5.2 Object Dictionary AKD-C 69

5.3 Object Dictionary AKD-N 73

5.3.1 Float Scaling 73

5.3.2 Communication SDOs 73

5.3.3 Manufacturer specific SDOs 76

5.3.4 Profile Specific SDOs 94

5.4 Object Descriptions 98

5.4.1 Object 1000h: Device Type (DS301) 98

5.4.2 Object 1001h: Error register (DS301) 98

5.4.3 Object 1002h: Manufacturer Status Register (DS301) 99

5.4.4 Object 1003h: Predefined Error Field (DS301) 100

5.4.5 Object 1005h: COB-ID of the SYNC Message (DS301) 101

5.4.6 Object 1006h: Communication Cycle Period (DS301) 101

5.4.7 Object 1008h: Manufacturer Device Name (DS301) 102

5.4.8 Object 1009h: Manufacturer Hardware Version 102

5.4.9 Object 100Ah: Manufacturer Software Version (DS301) 102

5.4.10 Object 100Ch: Guard Time (DS301)Response monitoring 103

5.4.11 Object 100Dh: Lifetime Factor (DS301) 103

5.4.12 Object 1010h: Store Parameters (DS301) 104

5.4.13 Object 1011h: Restore Default Parameters DS301 105

5.4.14 Object 1012h: COB-ID of the Time Stamp (DS301) 106

4 Kollmorgen | kdn.kollmorgen.com | October 2020

Page 5

AKD-C/N EtherCAT | Table of Contents

5.4.15 Object 1014h: COB-ID for Emergency Message (DS301) 106

5.4.16 Object 1016h: Consumer Heartbeat Time 107

5.4.17 Object 1017h: Producer Heartbeat Time 108

5.4.18 Object 1018h: Identity Object (DS301) 108

5.4.19 Object 1026h: OS Prompt 110

5.4.20 Objects 1400-1403h: 1st - 4th RxPDO communication parameter (DS301) 111

5.4.21 Objects 1600-1603h: 1st - 4th RxPDO mapping parameter (DS301) 112

5.4.22 Objects 1800-1803h: 1st - 4th TxPDO communication parameter (DS301) 113

5.4.23 Objects 1A00-1A03h: 1st - 4th TxPDO mapping parameter (DS301) 115

5.4.24 Object 1C12h: RxPDO assign (DS301) 116

5.4.25 Object 1C13h: TxPDO assign (DS301) 117

5.4.26 Object 1C32h: SM output parameter (DS301, AKD-C) 118

5.4.27 Object 1C33h: SM input parameter (DS301, AKD-C) 120

5.4.28 Object 2000h: SystemWarnings 121

5.4.29 Object 2001h: SystemFaults 122

5.4.30 Object 2002h: Manufacturer status bytes 122

5.4.31 Object 2011h: DRV.RUNTIME in seconds 123

5.4.32 Object 2012h: Fault history: Fault numbers 123

5.4.33 Object 2013h: Fault history: Time stamps 124

5.4.34 Object 2014-2017h: 1st-4th Mask 1 to 4 for Transmit-PDO 125

5.4.35 Object 2018h: Firmware Version 126

5.4.36 Object 2026h: ASCII Channel 127

5.4.37 Object 204Ch: PV Scaling Factor 128

5.4.38 Object 2071h: Target Current 129

5.4.39 Object 2077h: Current ActualValue 129

5.4.40 Object 207Fh: Maximum Velocity 129

5.4.41 Object 2080h: Motion Task Select 130

5.4.42 Object 2081h: Active Motion Task 130

5.4.43 Object 20A0h: Latch position 1, positive edge 130

5.4.44 Object 20A1h: Latch position 1, negative edge 131

5.4.45 Object 20A2h: Latch position 2, positive edge 131

5.4.46 Object 20A3h: Latch position 2, negative edge 132

5.4.47 Object 20A4h: Latch Control Register 132

5.4.48 Object 20A5h: Latch Status Register 133

5.4.49 Object 20A6h: Latch position 1, positive or negative edge 133

5.4.50 Object 20A7h: Latch position 2, positive or negative edge 134

5.4.51 Object 20B8h: Reset of changed input information 134

5.4.52 Object 345Ah: Brake Control 135

5.4.53 Object 3474h: Parameters for digital inputs 137

5.4.54 Object 3475h: Parameters for digital outputs 138

5.4.55 Object 3496h: Fieldbus synchronization parameters 139

5.4.56 Object 34D1h: Legacy EtherCAT input handling 141

5.4.57 Object 6040h: Control word (DS402) 141

5.4.58 Object 6041h: Status word (DS402) 143

5.4.59 Object 605Ah: Quick stop option code (DS402) 145

5.4.60 Object 6060h: Modes of Operation (DS402) 146

Kollmorgen | kdn.kollmorgen.com | October 2020 5

Page 6

AKD-C/N EtherCAT | Table of Contents

5.4.61 Object 6061h: Modes of Operation Display (DS402) 147

5.4.62 Object 6063h: position actual value* (DS402) 147

5.4.63 Object 6064h: position actual value (DS402) 148

5.4.64 Object 6065h: Following error window 148

5.4.65 Object 606Ch: Velocity actual value (DS402) 148

5.4.66 Object 6071h: Target torque (DS402) 149

5.4.67 Object 6073h: Max current (DS402) 149

5.4.68 Object 6077h: Torque actual value (DS402) 149

5.4.69 Object 607Ah: Target position (DS402) 150

5.4.70 Object 607Ch: Homing offset (DS402) 150

5.4.71 Object 607Dh: Software position limit (DS402) 151

5.4.72 Object 6081h: Profile velocity (DS402) 152

5.4.73 Object 6083h: Profile acceleration (DS402) 152

5.4.74 Object 6084h: Profile deceleration (DS402) 152

5.4.75 Object 6087h Torque slope (DS402) 153

5.4.76 Object 608Fh: Position encoder resolution (DS402) 153

5.4.77 Object 6091h: Gear Ratio (DS402) 154

5.4.78 Object 6092h: Feed constant (DS402) 155

5.4.79 Object 6098h: Homing method (DS402) 156

5.4.80 Object 6099h: Homing speeds (DS402) 158

5.4.81 Object 609Ah: Homing acceleration (DS402) 158

5.4.82 Object 60B1h: Velocity Offset 159

5.4.83 Object 60B2h: Torque Offset 159

5.4.84 Object 60B8h: Touch probe function 160

5.4.85 Object 60B9h: Touch probe status 161

5.4.86 Object 60BAh: Touch probe 1 positive edge 162

5.4.87 Object 60BBh: Touch probe 1 negative edge 162

5.4.88 Object 60BCh: Touch probe 2 positive edge 162

5.4.89 Object 60BDh: Touch probe 2 negative edge 163

5.4.90 Object 60C0h: Interpolation sub mode select 163

5.4.91 Object 60C1h: Interpolation data record 164

5.4.92 Object 60C2h: Interpolation time period 165

5.4.93 Object 60C4h: Interpolation data configuration 166

5.4.94 Object 60D0h: Touch probe source 168

5.4.95 Object 60E0h: Positive Torque Limit Value 169

5.4.96 Object 60E1h: Negative Torque Limit Value 169

5.4.97 Object 60E4h: Additional position actual value 170

5.4.98 Object 60E8h: Additional gear ratio – motor shaft revolutions 171

5.4.99 Object 60E9h: Additional feed constant – feed 172

5.4.100 Object 60EDh: Additional gear ratio – driving shaft revolutions 173

5.4.101 Object 60EEh: Additional feed constant - driving shaft revolutions 174

5.4.102 Object 60F4h: Following error actual value (DS402) 175

5.4.103 Object 60FCh: Position demand internal value (DS402) 175

5.4.104 Object 60FDh: Digital inputs (DS402) 175

5.4.105 Object 60FEh: Digital outputs (DS402) 176

5.4.106 Object 60FFh: Target velocity (DS402) 177

6 Kollmorgen | kdn.kollmorgen.com | October 2020

Page 7

AKD-C/N EtherCAT | Table of Contents

5.4.107 Object 6502h: Supported drive modes (DS402) 177

6 Record of Document Revisions 178

7 Index 179

Kollmorgen | kdn.kollmorgen.com | October 2020 7

Page 8

AKD-C/N EtherCAT | Table of Contents

--- / ---

8 Kollmorgen | kdn.kollmorgen.com | October 2020

Page 9

AKD-C/N EtherCAT | 2 General

2 General

2.1 About this Manual 10

2.2 Target Group 10

2.3 Symbols Used 11

2.4 Abbreviations Used 12

Kollmorgen | kdn.kollmorgen.com | October 2020 9

Page 10

AKD-C/N EtherCAT | 2 General

2.1 About this Manual

This manual, AKD-C/N EtherCAT Communication, describes the installation, setup, range of

functions, and software protocol for the decentral drive system with AKD-C and AKD-N

devices.

A digital version of this manual (pdf format) is available on the DVD included with your

device. Document updates can be downloaded from the Kollmorgen website.

Related documents for the AKD-C/N series include:

AKD-C Installation Manual – This manual provides instructions for installation and device

setup.

AKD-N Installation Manual – This manual provides instructions for installation and drive

setup.

AKD User Guide – This manual describes how to use your drive in common applications.

It also provides tips for maximizing your system performance with the AKD. The User

Guide includes the Parameter and Command Reference Guide which provides doc-

umentation for the parameters and commands used to program the AKD-C and AKD-N.

Accessories Manual – This manual provides documentation for accessories like cables

and regen resistors used with AKD-C and AKD-N. Regional versions of this manual exist.

Additionally, an EtherCAT XML file, entitled AKD EtherCAT Device Description, describes

the drive SDO and PDO. This file is available on the Kollmorgen website (part of the firmware

zip archive).

2.2 Target Group

This manual addresses personnel with the following qualifications:

The qualified personnel must know and observe the following standards:

Installation: only by electrically qualified personnel.

Setup: only by qualified personnel with extensive knowledge of electrical engineering

and drive technology.

Programming: software developers, project-planners.

ISO 12100, IEC 60364 and IEC 60664

National accident prevention regulations

10 Kollmorgen | kdn.kollmorgen.com | October 2020

Page 11

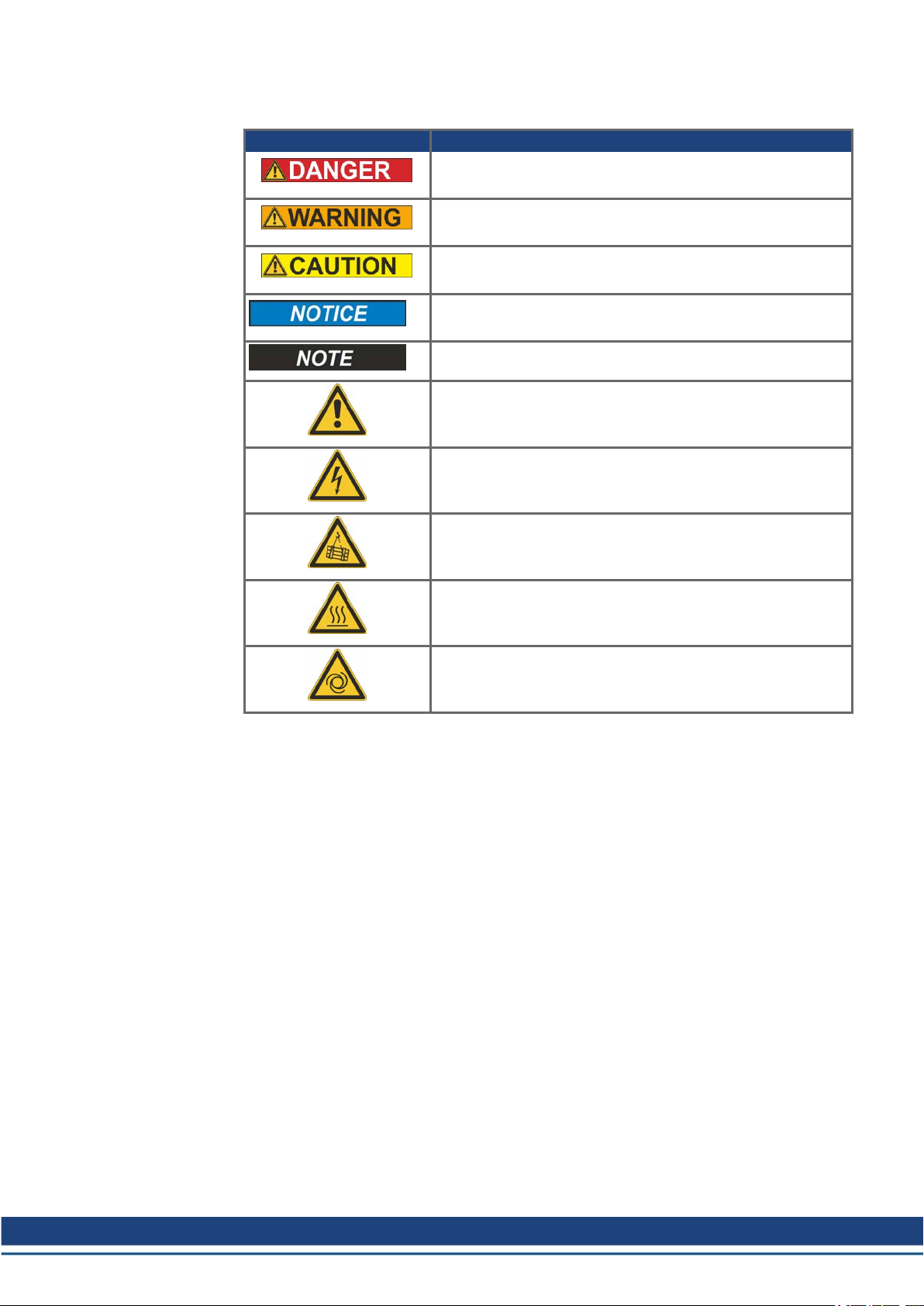

2.3 Symbols Used

Symbol Indication

AKD-C/N EtherCAT | 2 General

Indicates a hazardous situation which, if not avoided, will result in death or serious injury.

Indicates a hazardous situation which, if not avoided, could result in death or serious injury.

Indicates a hazardous situation which, if not avoided, could result in minor or moderate injury.

Indicates situations which, if not avoided, could result in property damage.

This symbol indicates important notes.

Warning of a danger (general). The type of danger is specified

by the text next to the symbol.

Warning of danger from electricity and its effects.

Warning of danger from suspended loads.

Warning of danger from high temperature.

Warning of danger from automatic start.

Kollmorgen | kdn.kollmorgen.com | October 2020 11

Page 12

AKD-C/N EtherCAT | 2 General

2.4 Abbreviations Used

Abbreviation Meaning

AL Application Layer: the protocol that directly used by the process entities.

Cat Category – classification for cables that is also used in Ethernet.

DC Distributed Clocks Mechanism to synchronize EtherCAT slaves and master

DL Data Link(=Layer 2). EtherCAT uses standardized Ethernet (IEEE 802.3)

ESC EtherCAT Slave Controller

FPGA Field Programmable Gate Array

FTP File Transfer Protocol

HW Hardware

ICMP Internet Control Message Protocol: Mechanisms for signaling IP errors.

IEC International Electrotechnical Commission: The international standards

IEEE Institute of Electrical and Electronics Engineers, Inc.

LLDP Link Layer Discovery Protocol

MAC Media Access Control

MII Media Independent Interface: Standardized interface Ethernet controller <-> routing

MDI Media Dependant Interface: Use of connector Pins and Signaling.

MDI-X Media Dependant Interface (crossed): Use of connector Pins and Signaling with

OSI Open System Interconnect

OUI Organizationally Unique Identifier – the first 3 Bytes of an Ethernet-Address, that

PDI Physical Device Interface: set of elements that allows access to ESC from the pro-

PDO Process Data Object

PDU Protocol Data Unit: Contains protocol information transferred from a protocol

PHY Physical interface that converts data from the Ethernet controller to electric or

PLL Phase Locked Loop

PTP Precision Time Protocol in accordance with IEEE 1588

RSTP Rapid Spanning Tree Protocol

RT Real-time, can be run in Ethernet controllers without special support.

RX Receive

RXPDO Receive PDO

SNMP Simple Network Management Protocol

SPI Serial Peripheral Interface

Src Addr Source Address: Source address of a message.

STP Shielded Twisted Pair

TCP Transmission Control Protocol

TX Transmit

TXPDO Transmit PDO

UDP User Datagram Protocol: Non-secure multicast/broadcast frame.

UTP Unshielded Twisted Pair

ZA ECAT Access mode EtherCAT

ZA Drive Acces mode drive

equipment.

crossed lines.

will be assign to companies or organizations and can be used for protocoll identifiers as well (e.g. LLDP)

cess side.

instance of transparent data to a subordinate level

optical signals.

12 Kollmorgen | kdn.kollmorgen.com | October 2020

Page 13

AKD-C/N EtherCAT | 3 Installation and Setup

3 Installation and Setup

3.1 Important Instructions 14

3.2 EtherCAT Onboard 15

3.3 Guide to Setup 16

3.4 Important Configuration Parameters 17

3.5 Setting up Ethernet over EtherCAT (EoE) 19

3.6 Setup via TwinCAT NC/PTP System Manager 21

3.7 Setup WorkBench over TwinCAT 25

3.8 Setup via KAS IDE 32

Kollmorgen | kdn.kollmorgen.com | October 2020 13

Page 14

AKD-C/N EtherCAT | 3 Installation and Setup

3.1 Important Instructions

There is a danger of serious personal injury or death by electrical shock or electrical arcing.

Capacitors can still have dangerous voltages present up to 7 minutes after switching off the

supply power. Control and power connections can still be live, even if the motor is not rotating.

Never remove electrical connections to the drive while it is live.

Wait at least seven minutes after disconnecting the drive from the main supply

power before touching potentially live sections of the equipment (e.g. contacts) or

undoing any connections.

To be sure, measure the voltage in the DC bus link and wait until it has fallen below

50 V.

Risk of death or serious injury for humans working in the machine. Drives with EtherCAT

are remote-controlled machines. They can start to move at any time without previous warning. The drive might restart automatically after power on, voltage dip or interruption of the

supply voltage, depending on the parameter setting.

Place a warning sign ("WARNING: Possible Automatic Start" or

similar) to the machine.

Ensure, that power on is not possible, while humans are in a

dangerous zone of the machine.

High Voltage up to 900 V!

Automatic Restart!

Install the drive as described in the Installation Manual. The wiring for the analog setpoint

input and the positioning interface, as shown in the wiring diagram in the Installation Manual,

is not required. Never break any of the electrical connections to the drive while it is live. This

action can result in destruction of the electronics.

The drive's status must be monitored by the PLC to acknowledge critical situations. Wire the

FAULT contact in series into the emergency stop circuit of the installation. The emergency

stop circuit must operate the supply contactor.

It is permissible to use the setup software to alter the settings of the drive. Any other alterations will invalidate the warranty. Because of the internal representation of the position-control parameters, the position controller can only be operated if the final limit speed of the drive

does not exceed:

rotary linear

at sinusoidal² commutation: 7500 rpm at sinusoidal² commutation: 4 m/s

at trapezoidal commutation: 12000 rpm. at trapezoidal commutation: 6.25 m/s

All the data on resolution, step size, positioning accuracy etc. refer to calculatory values.

Non-linearities in the mechanism (backlash, flexing, etc.) are not taken into account. If the

final limit speed of the motor must be altered, then all the parameters that were previously

entered for position control and motion blocks must be adapted.

14 Kollmorgen | kdn.kollmorgen.com | October 2020

Page 15

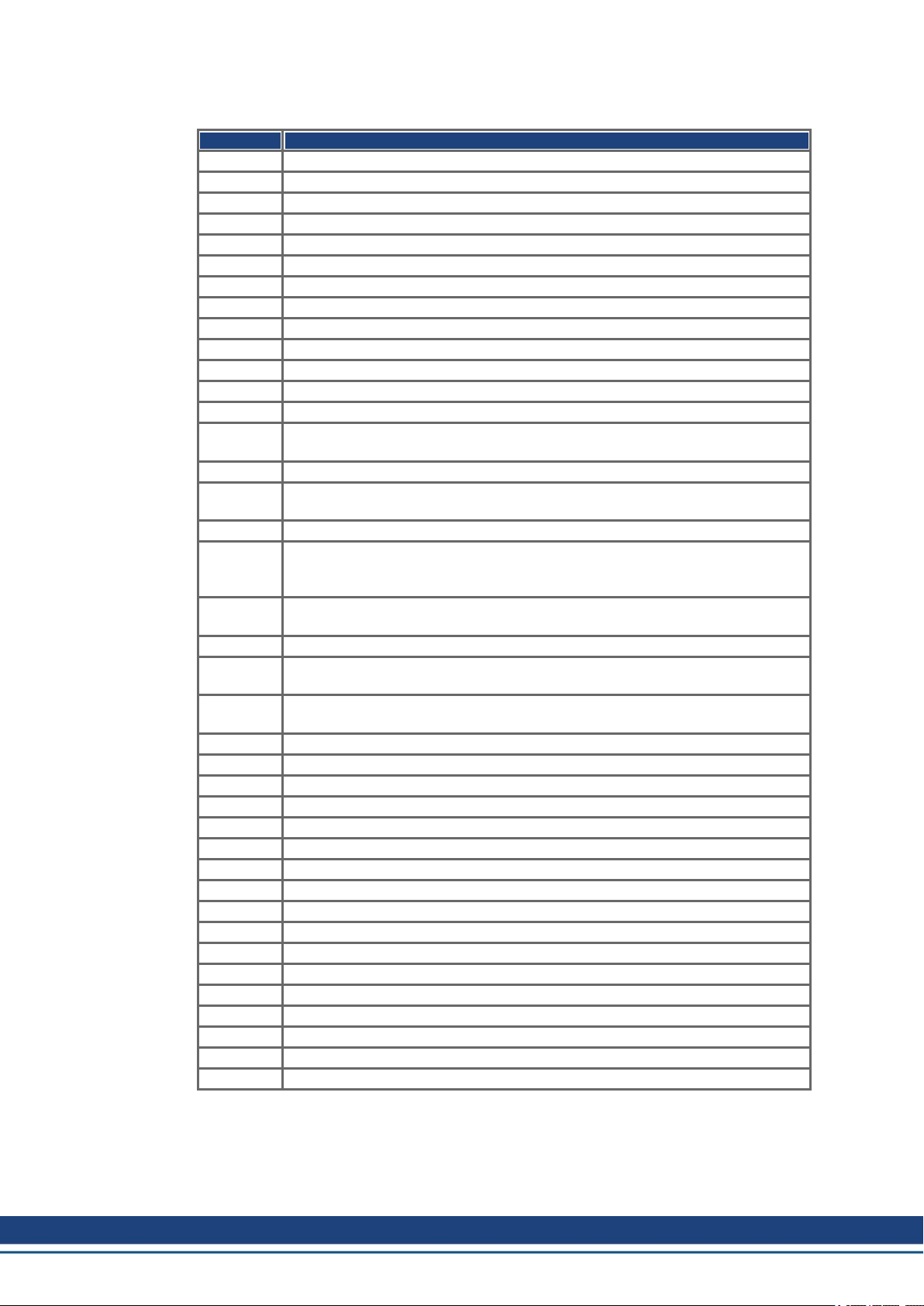

3.2 EtherCAT Onboard

Connection to the EtherCAT Network via X10 (in port) and X11 (out port).

3.2.1 LED functions

The communication status is indicated by the built-in LEDs.

Connector LED# Name Function

X10 LED1 IN port Link ON = active

X11 LED3 OUT port Link ON = active

AKD-C/N EtherCAT | 3 Installation and Setup

OFF= not active

LED2 RUN ON = running

OFF = not running

OFF = not active

LED4 - -

3.2.2 Connection technology

You can connect to the EtherCAT network using RJ-45 connectors.

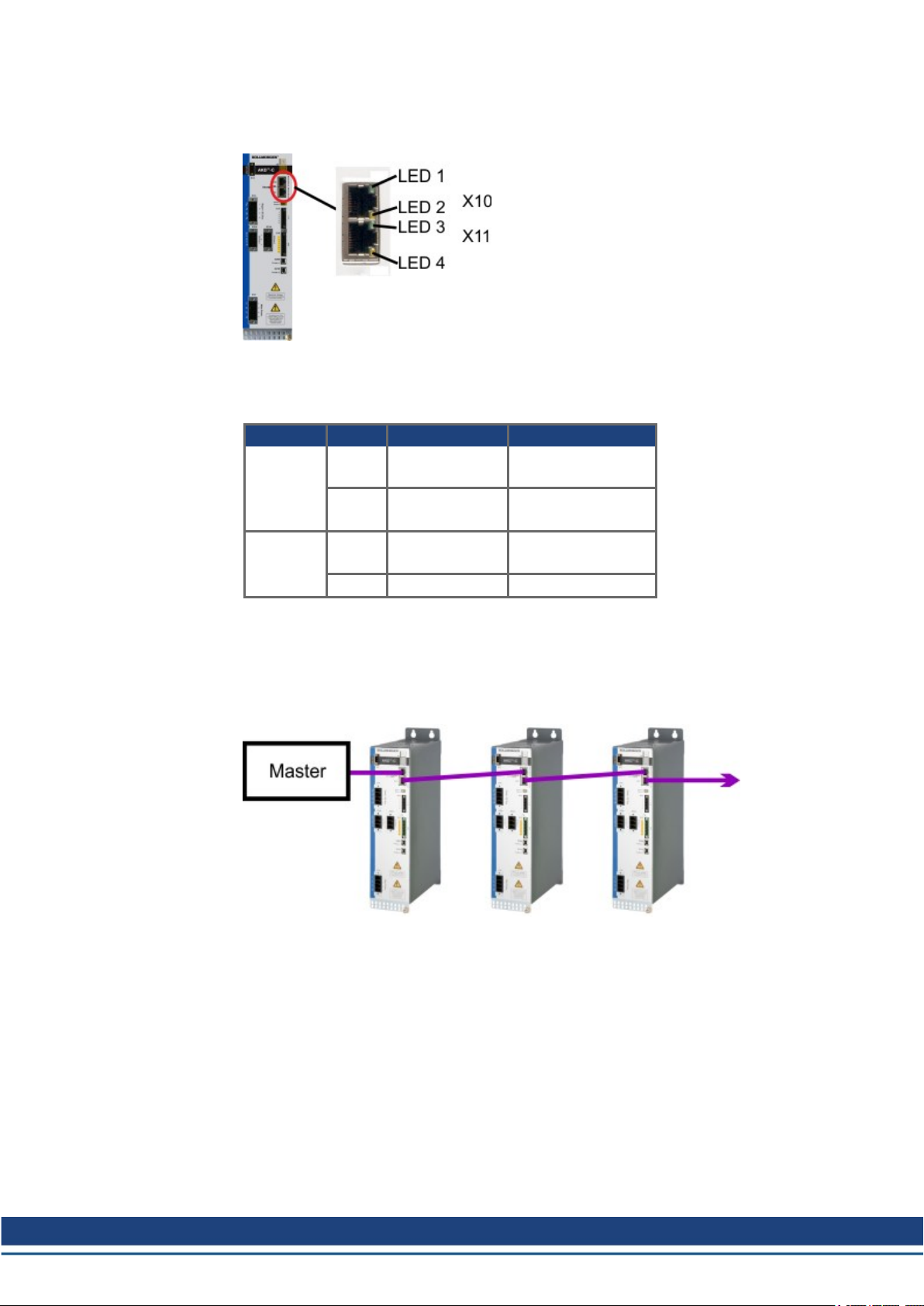

3.2.3 Network Connection Example

Kollmorgen | kdn.kollmorgen.com | October 2020 15

Page 16

AKD-C/N EtherCAT | 3 Installation and Setup

3.3 Guide to Setup

Only professional personnel with extensive knowledge of control and drive technology are

allowed to setup the drive.

Risk of death or serious injury for humans working in the machine. Drives with EtherCAT

are remote-controlled machines. They can start to move at any time without previous warning. The drive might restart automatically after power on, voltage dip or interruption of the

supply voltage, depending on the parameter setting.

Place a warning sign ("WARNING: Possible Automatic Start" or

similar) to the machine.

Ensure, that power on is not possible, while humans are in a

dangerous zone of the machine.

Refer to chapter "Important Configuration Parameters" (➜ p. 17) for fieldbus parameter setting (FBUS.PARAMx).

1. Check assembly/installation. Check that all the safety instructions in the product manual

for the drive and this manual have been observed and implemented. Check the setting for

the station address and baud rate.

2. Connect PC,start WorkBench. Use the setup software WorkBench to set the parameters

for the drive.

3. Setup basic functions. Start up the basic functions of the drive and optimize the current,

speed and position controllers. This section of the setup is described in the in the online

help of the setup software.

4. Save parameters. When the parameters have been optimized, save them in the drive.

Automatic Restart!

16 Kollmorgen | kdn.kollmorgen.com | October 2020

Page 17

3.4 Important Configuration Parameters

The AKD holds several fieldbus-specific, general purpose parameters. Some of them contain

the following relevant data:

FBUS.PARAM01:

Sets the baud rate for the CANbus. Supported baud rates are 125, 250, 500 and 1000 kBaud.

On AKD-C, FBUS.PARAM01 sets and stores the EtherCAT station alias for the ESC (EtherCAT slave controller) of string 2.

FBUS.PARAM02:

This parameter activates the synchronization feature of the AKD. The DC feature must be

activated in order to allow the AKD to get synchronized with the master. Only works when

FBUS.TYPE= 3 (CANopen).

Drive internal PLL (phase locked loop) functionality: enabled (1),

Drive internal PLL functionality: disabled (0).

FBUS.PARAM03:

This parameter contains the Configured Station Alias address of the AKD. An EEPROM emulation write access to the Configured Station Alias address forces the AKD to store the drive

parameters automatically using the DRV.NVSAVE command. On AKD-C,

FBUS.PARAM03 sets and stores the EtherCAT station alias for the ESC (EtherCAT slave

controller) of string 1.

FBUS.PARAM04:

This parameter enables (1) or disables (0) the synchronization supervision of the CANOpen

or EtherCAT fieldbus.

Default values for this parameter are as follows:

CANopen drive: disabled (0)

EtherCAT drive: enabled (1)

Synchronization supervision is active when FBUS.PARAM 04 = 1 and the first CANOpen

Sync message or first EtherCAT frame is received. When more than three CANOpen sync

messages or seven EtherCAT frames have not been received and the drive is enabled, fault

F125 (“Synchronization lost“), occurs.

FBUS.PARAM05:

AKD-C/N EtherCAT | 3 Installation and Setup

Bit 0 1 Faults can only be reset using DS402 controlword bit 7.

0 The reset can also be done using Telnet or digital input and the DS402

state machine reflects this condition.

Bit 1 1 The state of the hardware enable does not change the state machine to

state Operation enable.

0 If the state Operation enable or Switched on is active, it falls back to the

state Switch on disabled, if the Hardware enable goes to 0.

Bit 2 1 WorkBench/Telnet cannot software enable the drive when

CANopen/EtherCAT are operational.

0 WorkBench/Telnet can software enable the drive.

During commissioning this bit should be set to 1 to

avoid influences to DS402 power stage state machine.

The fieldbus should not be in operation to avoid influence to test functions of WorkBench.

Bit 3 1 DS402 - state machine is not influenced if the software enable is taken

away using Telnet.

0 DS402 - state machine is influenced if the software enable is taken away

using Telnet.

Kollmorgen | kdn.kollmorgen.com | October 2020 17

Page 18

AKD-C/N EtherCAT | 3 Installation and Setup

Bit 4 1 Scaling is done using special DS402 - objects (independent on units)

0 Scaling for position, velocity and acceleration objects is done using UNIT

parameters.

Bit 5

1 FBUS.PARAM03 defines the station alias address if not 0. If

(EtherCAT

only)

FBUS.PARAM03 is set to 0, the address will be taken from rotary

switches if they are not 0. The EtherCAT master has the ability to use the

alias address selected by the drive or issue its own.

0 The rotary switches define the station alias address if not 0. If the rotary

switches are set to 0, the address is taken from FBUS.PARAM03 instead,

if it is not 0.

Bit 6 1 Bit 0 of parameter MT.CNTL (object 35B9 sub 0) can be accessed.

0 Bit 0 of parameter MT.CNTL (object 35B9 sub 0) is exclusively used for

DS402 controlword.

Bit 7 1 All capture objects (0x20A0-0x20A3, 0x20A6, 0x20A7, 0x60BA to

0x60BD) are scaled as object 0x6063.

0 All capture objects (0x20A0-0x20A3, 0x20A6, 0x20A7, 0x60BA to

0x60BD) are scaled as object 0x6064.

Bit 8 1 DS402 - state Switched on means power stage disabled.

0 DS402 - state Switched on means power stage enabled.

Bit 9 1 SDO content of object 0x6063 is the same as PDO content.

0 SDO content of object 0x6063 depends on AKD unit parameters.

Bit 10

(Bit 10 is act-

ive only,

if Bit 8 is set)

1 State Switched on can be reached without the high-level voltage being act-

ive.

0 State Switched on can only be reached when the high-level voltage is act-

ive; otherwise the drive stays in Ready to switch on.

Bit 11 1 No emergency messages over CANopen are triggered when a drive warn-

ing occurs.

0 Emergency messages over CANopen are triggered when a drive warning

occurs.

Bit 12 reserved

Bit 13

(EtherCAT

1 Downloaded parameter file is stored automatically to nonvolatile memory.

0 Downloaded parameter file is not stored automatically to nonvolatile

only)

memory.

Bit 14 1 If a warning occurs which limits a movement of the motor bit 11 in the

DS402 statusword is additionally set to bit 7.

0 Only bit 7 is set when any warning occurs.

Bit 15 1 The bit 10 of the statusword (target reached) is also set as a reaction to the

halt bit (bit 8) of the controlword when the motor velocity is below

CS.VTHRESH.

0 Bit 10 of the statusword is only set when the external setpoint value of a

movement is reached, e.g., target position in profile position mode.

Bit 16 1 The hardware enable input decides if the transitions between Switch on dis-

abled and Ready to switch on are taken.

0 The decision relies on the DS402 controlword.

FBUS.PARAM06 to FBUS.PARAM10:

Reserved.

18 Kollmorgen | kdn.kollmorgen.com | October 2020

Page 19

3.5 Setting up Ethernet over EtherCAT (EoE)

If you are using firmware version 1.16 or later and your EtherCATmaster supports Ethernet

over EtherCAT (EoE), a WorkBench connection to your drive can be established without connecting to the drive’s service port.

If the service port and EoE network interface are used in parallel, the service port network

interface shall be configured to be in a different subnet than the EoE network interface. Running both network interface in the same subnet is NOT supported.

The master will use the EtherCAT mailbox to forward the Ethernet traffic from your PC to the

drive, allowing you to access the drive as if it was connected over Ethernet.

The following walk through uses a TwinCAT master as an example.

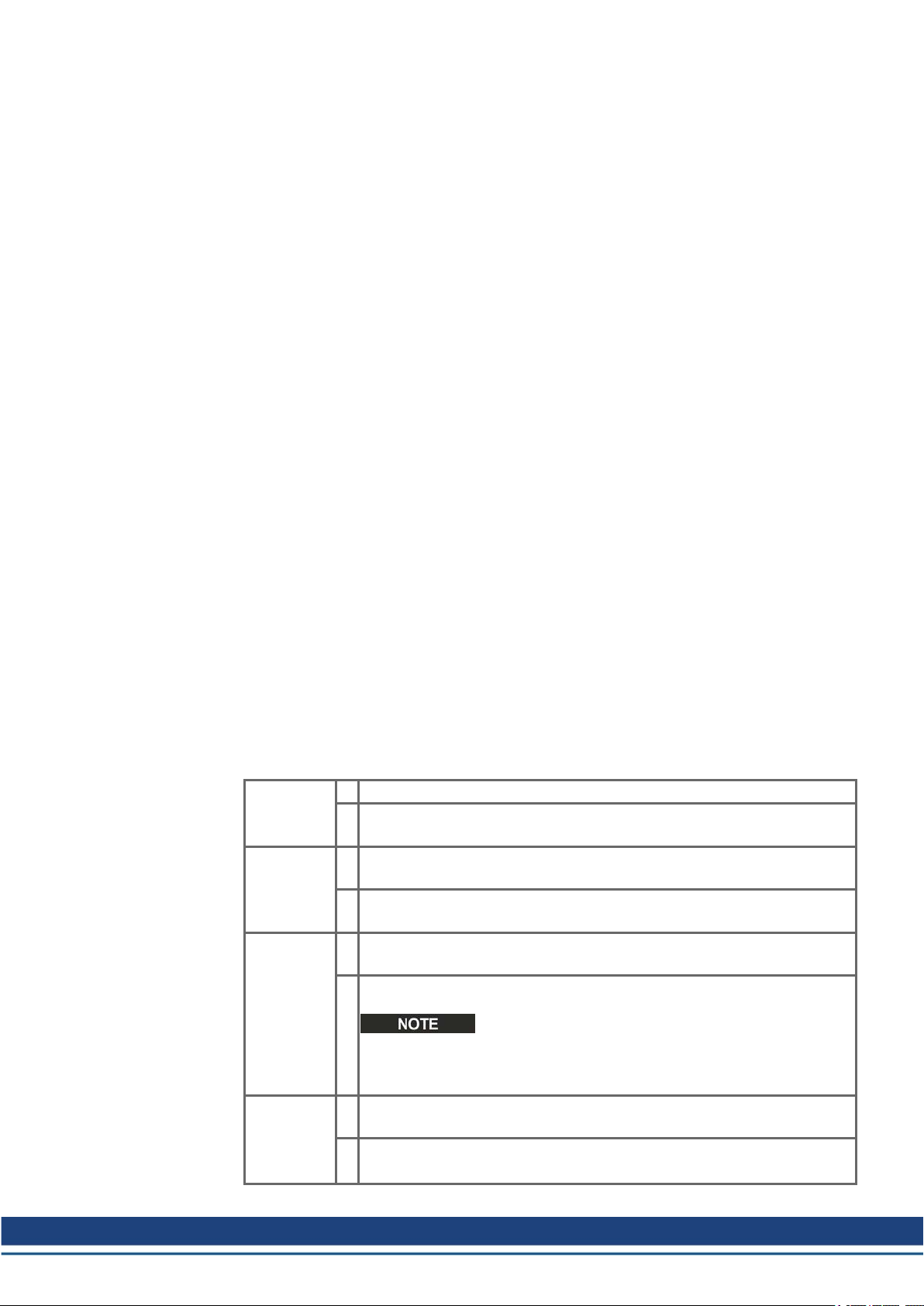

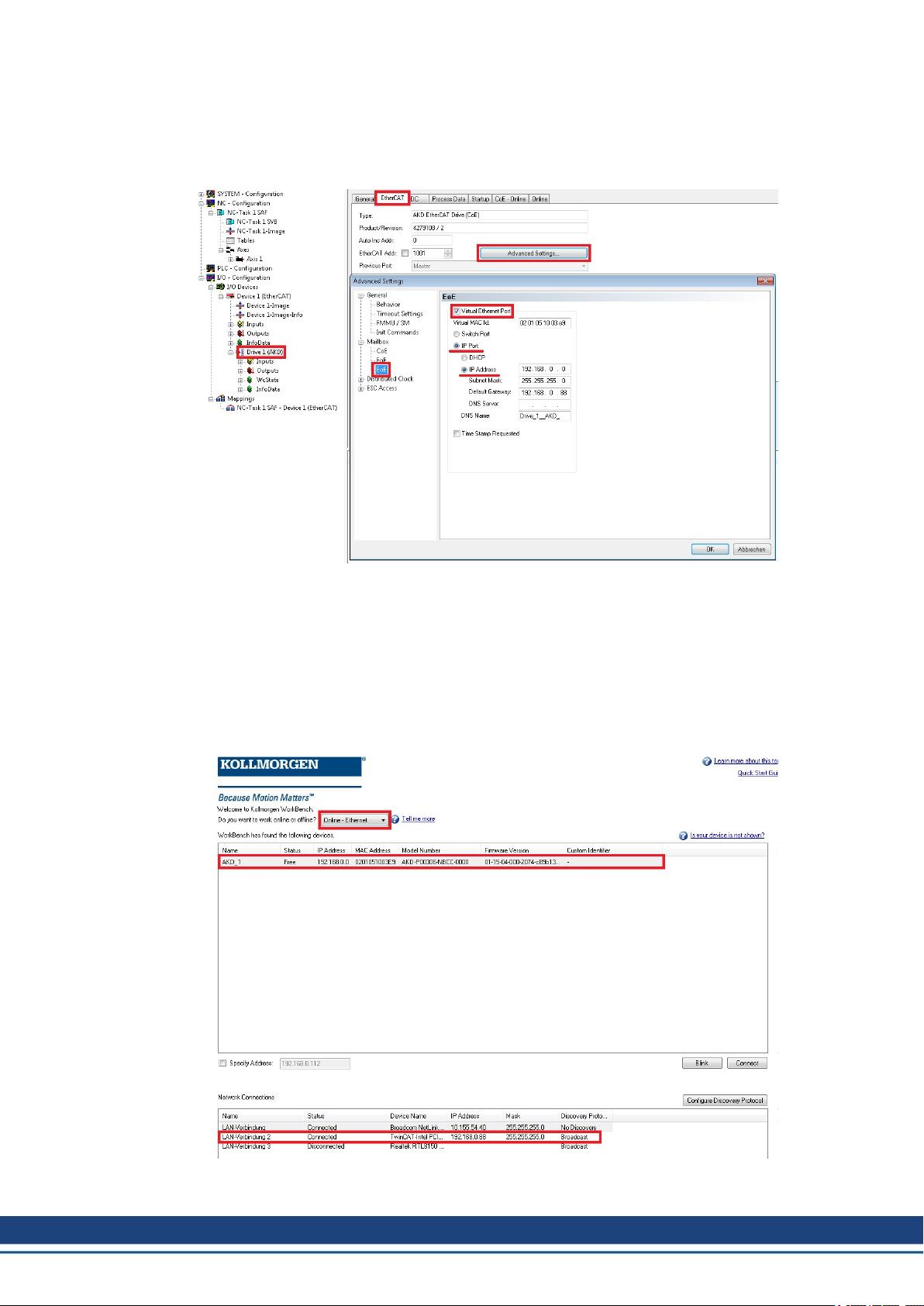

3.5.1 EtherCATDevice Settings

The first step is to make sure your EtherCAT device has EoE enabled. TwinCAT has a dedicated “EoE Support” page inside the EtherCAT device’s settings.

Enable "Virtual Ethernet Switch." Check the box "Connect to TCP/IP Stack."

AKD-C/N EtherCAT | 3 Installation and Setup

Kollmorgen | kdn.kollmorgen.com | October 2020 19

Page 20

AKD-C/N EtherCAT | 3 Installation and Setup

3.5.2 Drive Settings

After setting up the EtherCAT device, you must enable EoE for the drive. In TwinCAT there

is an EoE page within the Drive’s Mailbox settings. If the EoE page is not displayed, add the

drive to the EtherCAT network again, using the latest device description.

To enable EoE on your drive, check the “Virtual Ethernet Port” box, select “IP Port” and “IP

Address and enter at least a valid IP address and subnet mask.

3.5.3 Connecting to the Drive

You should now be able to access your drive over WorkBench using EoE.

Open WorkBench and make sure the discovery protocol is enabled for the network interface

that is in the subnet configured for your drive in the previous step. You can now connect to

your drive as if it were connected over the service port.

20 Kollmorgen | kdn.kollmorgen.com | October 2020

Page 21

3.5.4 Performance Concerns

Since EoE is very demanding on EtherCAT Mailbox communication, all measures to improve

Mailbox performance should be taken.

When releasing the EoE feature, the biggest allowed mailbox size has been increased from

512 to 1024 byte. A larger mailbox means fewer Mailbox transfers, resulting in a performance

increase.

Furthermore an additional Fieldbus Memory Management Unit (FMMU) has been added. This

allows the master to be notified of new data in the mailbox input without the need to poll the

mailbox, leading to a decrease in reaction time, thus improving performance. If your master

does not support this, you should at least try to decrease the period in which the master polls

the drive’s mailbox.

3.5.5 Restrictions

l Since a firmware download restarts the drive in the resident firmware, which does not sup-

port Ethernet over EtherCAT, downloading firmware via EoE is not possible. To update

your drive’s firmware use FoE instead.

l If your EtherCAT master uses the device description provided in the esi-file and you want

to automatically detect your drives, set the keyword ECAT.LEGACYREV to 0. The drive

will then report a different revision number and will be recognized by the master as a

device capable of Ethernet over Ethercat.

AKD-C/N EtherCAT | 3 Installation and Setup

3.6 Setup via TwinCAT NC/PTP System Manager

Before you set up the drive, make sure the following have been completed:

The AKD is configured with WorkBench and the servomotor is able to move

A correctly configured EtherCAT card is present in the master.

TwinCAT software from Beckhoff (NC/PTP-Mode setup) is installed. Install first the

TwinCAT System Manager, restart your PC, then install the option package NC/PTPMode.

The XML description of the drive is available (the XML file on the DVD or on the Kollmorgen website).

An AKD EtherCAT slave is connected to the EtherCAT master PC.

The TwinCAT system manager resides in Config-Mode. The current mode of the system

manager is displayed of the bottom right side of the TwinCAT main-screen window.

Copy the XML description of the drive to the TwinCAT system (usually to the folder

c:\TwinCAT\IO\EtherCAT) and restart the TwinCAT system since TwinCAT analyzes all

device description files during start-up.

The following example explains the automatic EtherCAT network setup. The network setup

can also be done manually; please refer to the TwinCAT manual for more details.

Kollmorgen | kdn.kollmorgen.com | October 2020 21

Page 22

AKD-C/N EtherCAT | 3 Installation and Setup

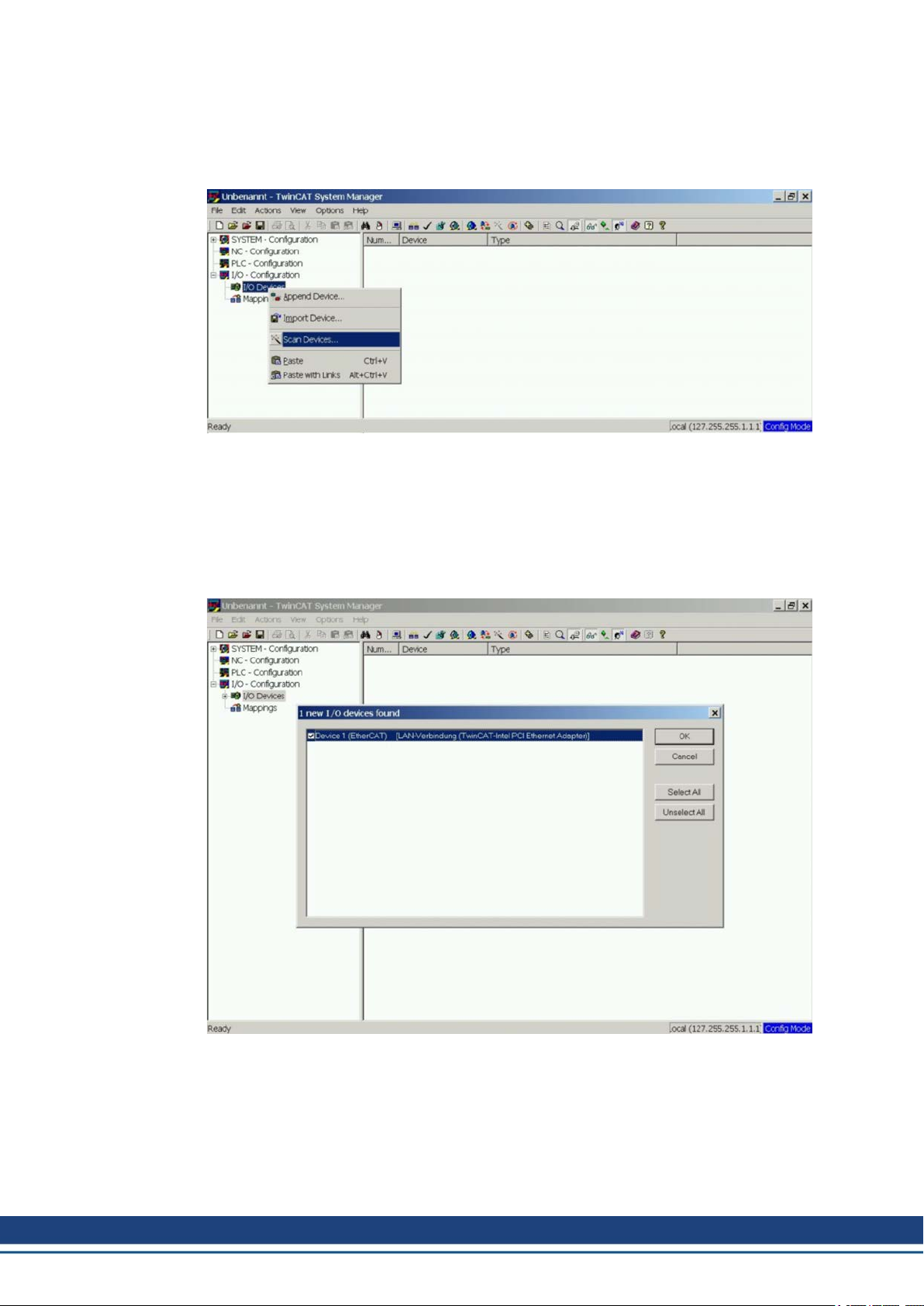

3.6.1 Scan devices

First ensure that the EtherCAT master is physically connected to the EtherCAT AKD. Create

a new (empty) project. Right click I/O Devices and scan for the devices. An example is

included in the EtherCAT network card, which is plugged into the PC.

A pop-up window informs you that not all devices can be detected by the TwinCAT software.

Click OK to continue.

3.6.2 Select the device

TwinCAT must be able to find the EtherCAT network card. An EtherCAT slave must be connected to the network card; otherwise TwinCAT will find a real-time EtherNET card instead of

the EtherCAT card. Press the OK button.

22 Kollmorgen | kdn.kollmorgen.com | October 2020

Page 23

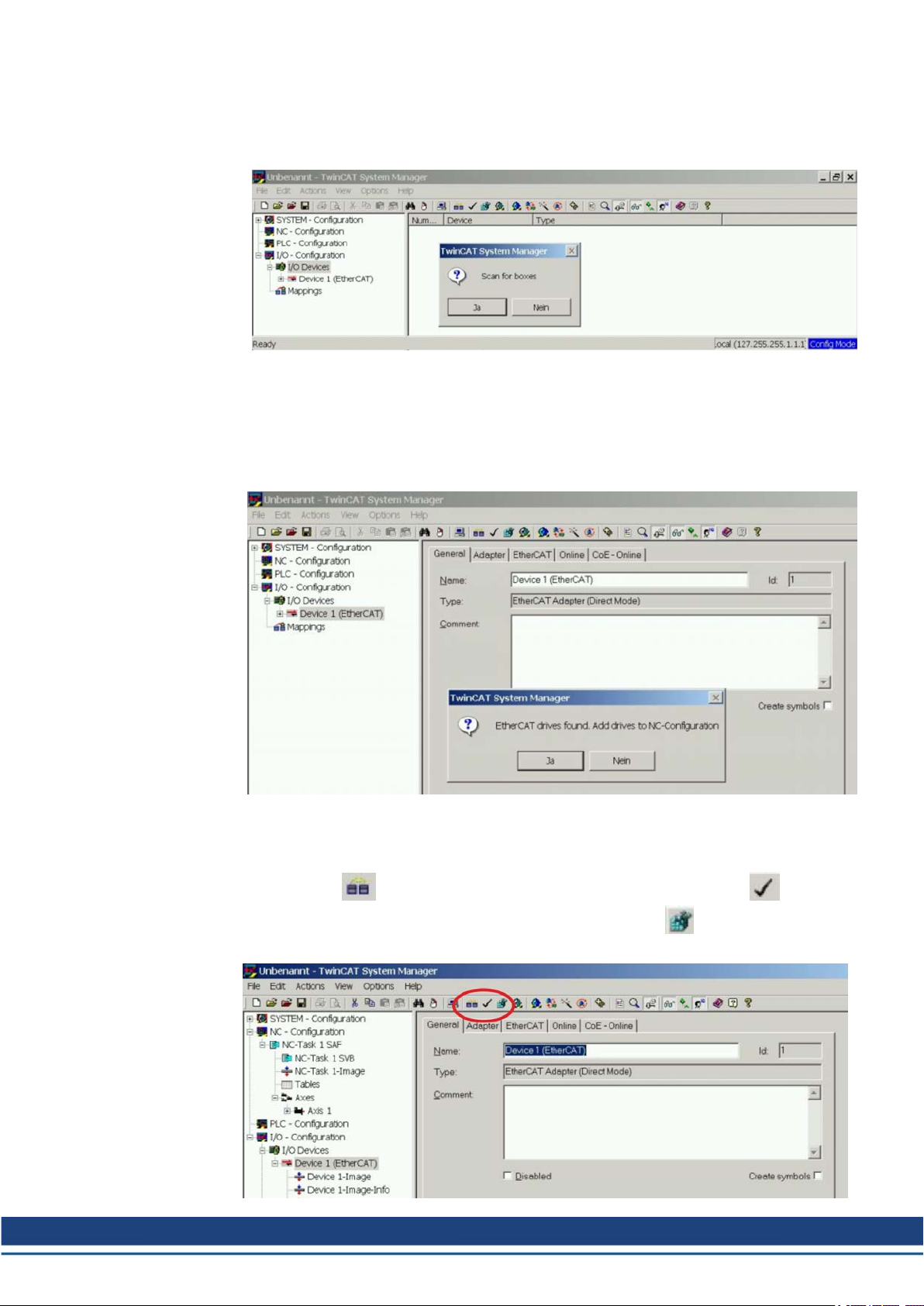

3.6.3 Scan for boxes

Click Yes to allow TwinCat to scan for boxes. A box is an alias for a slave device and is

always used in Beckhoff software products.

3.6.4 Add Slaves to NC tasks

TwinCAT should now have identified the AKD according to the Device Description file.

TwinCAT next asks if the slaves should be connected to NC tasks. Click Yes to continue.

An NC task can, for example, contain a PLC program, which can be programmed by the

user.

AKD-C/N EtherCAT | 3 Installation and Setup

3.6.5 Enable the network configuration

Confirm that the AKD appears in the device tree. Next, enable the network configuration.

First press the button in order to generate the mappings, then press the button in

order to let TwinCAT check the configuration and use finally the button in order to step

into run-mode. Confirm afterwards that TwinCAT is allowed to jump into run-mode.

Kollmorgen | kdn.kollmorgen.com | October 2020 23

Page 24

AKD-C/N EtherCAT | 3 Installation and Setup

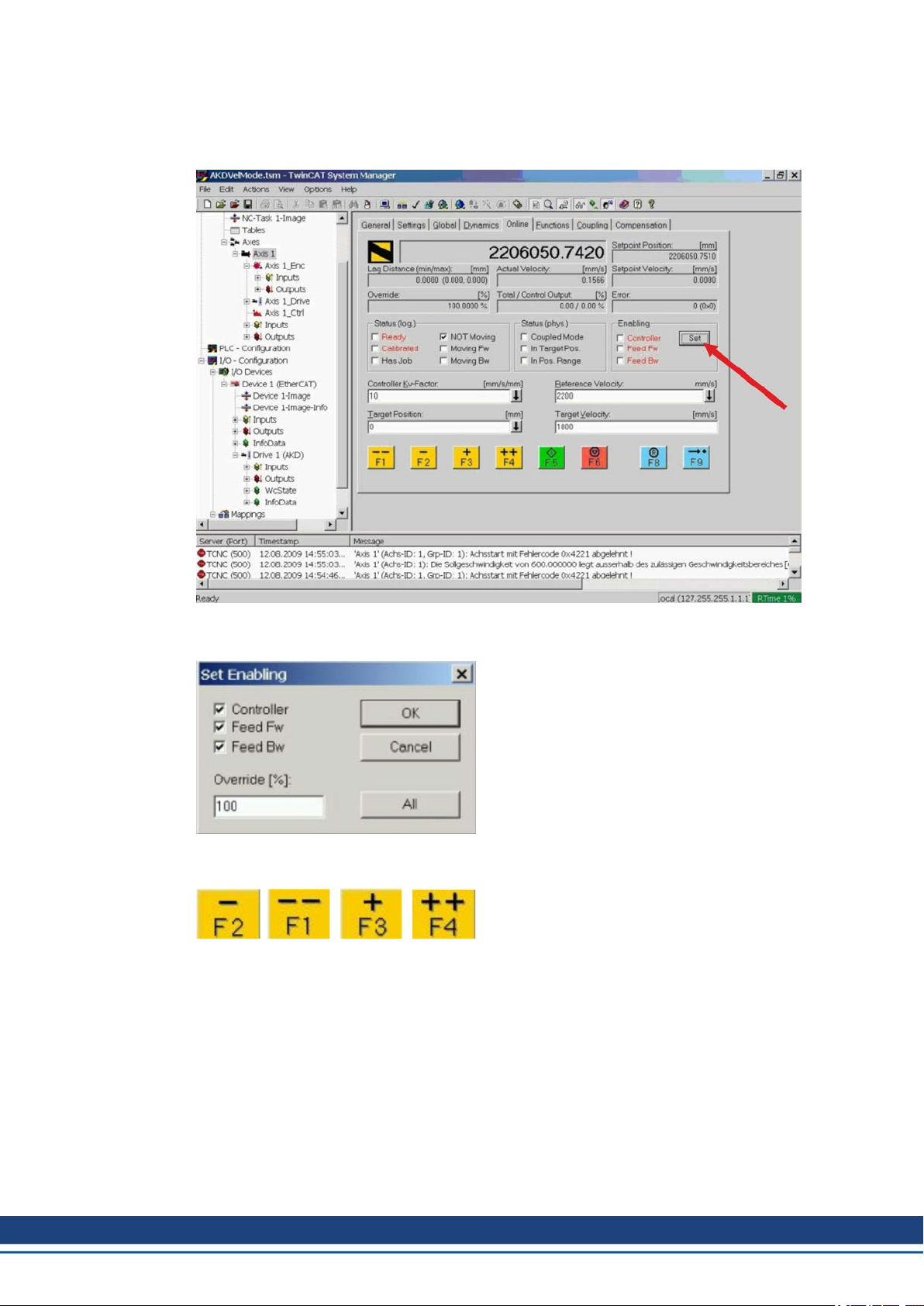

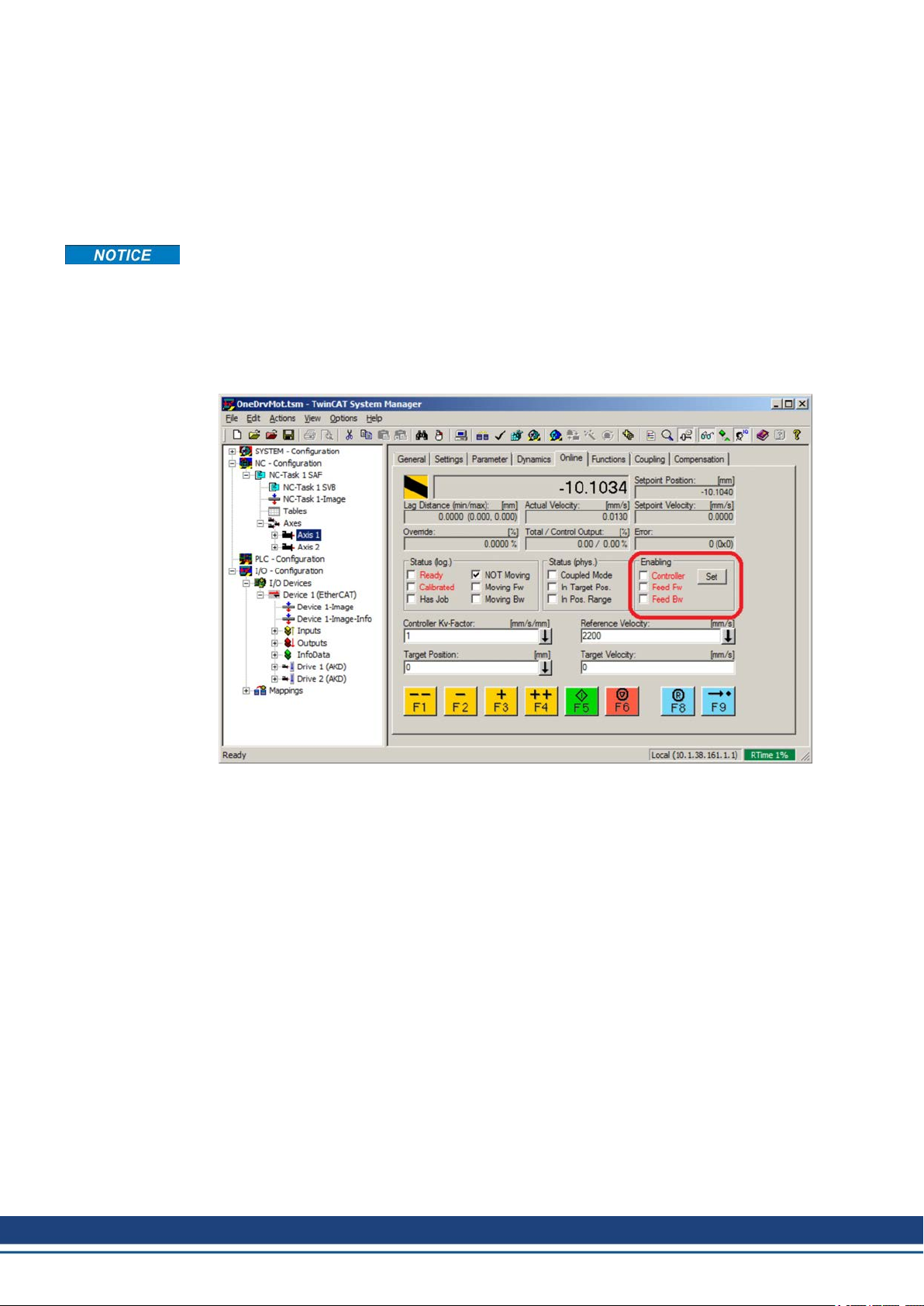

3.6.6 Enable the axis and move the axis

The Axis can be enabled by a mouse-click on the Set button within the Online window inside

of each Axis, see also the next picture.

Afterwards a pop-up window appears.

The following setting enables the drive and allows command values in both directions.

Afterwards the motor should move in positive or negative direction as soon as the clicks on

the following yellow buttons within the Online window:

24 Kollmorgen | kdn.kollmorgen.com | October 2020

Page 25

3.7 Setup WorkBench over TwinCAT

This chapter describes a quick start guide to setup a WorkBench over TwinCAT system and

make a motor spin under that system.

This chapter does not give specific details on TwinCAT system or WorkBench alone but is

giving guidelines and information on how TwinCAT master and WorkBench works together.

Main steps in configuring a WorkBench over TwinCAT system are:

TwinCAT and WorkBench configuration

Connecting to a drive using WorkBench

Configuring and enabling a drive

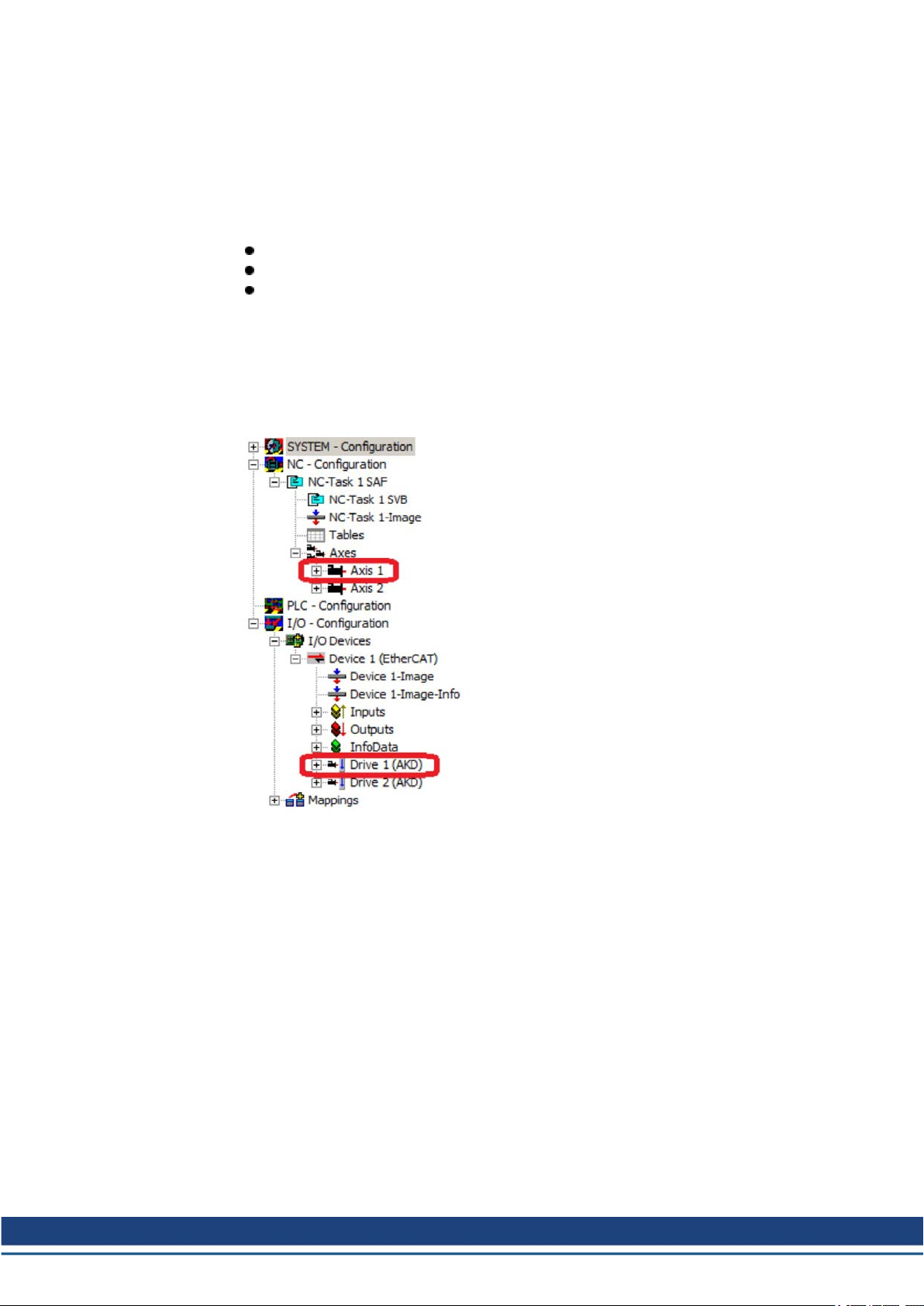

3.7.1 TwinCAT and WorkBench Configuration

The EtherCAT network must be setup and managed using TwinCAT System Manager. To be

able to connect to a drive and enable it, the drive must be loaded under the I/O Devices node

in TwinCAT System Manager and axis must be added to NC - Configuration as shown ➜ p.

21 "Setup via TwinCATNC/PTPSystem Manager " in the EtherCATManual.

AKD-C/N EtherCAT | 3 Installation and Setup

In order to connect to the drives using WorkBench, the drives must be either in Pre-Op, SafeOp or Op state. State machine for a drive can be accessed from the Online tab for the corresponding drive under the I/O Configuration → I/O Devices → Device [x] → Drive [x] node

(see screenshot below).

Kollmorgen | kdn.kollmorgen.com | October 2020 25

Page 26

AKD-C/N EtherCAT | 3 Installation and Setup

Installation process for WorkBench is the same process as normal, except that it must be

installed on the same machine as TwinCAT. Communication to the drive is done thru

TwinCAT master and it's not possible to connect WorkBench to the master remotely.

26 Kollmorgen | kdn.kollmorgen.com | October 2020

Page 27

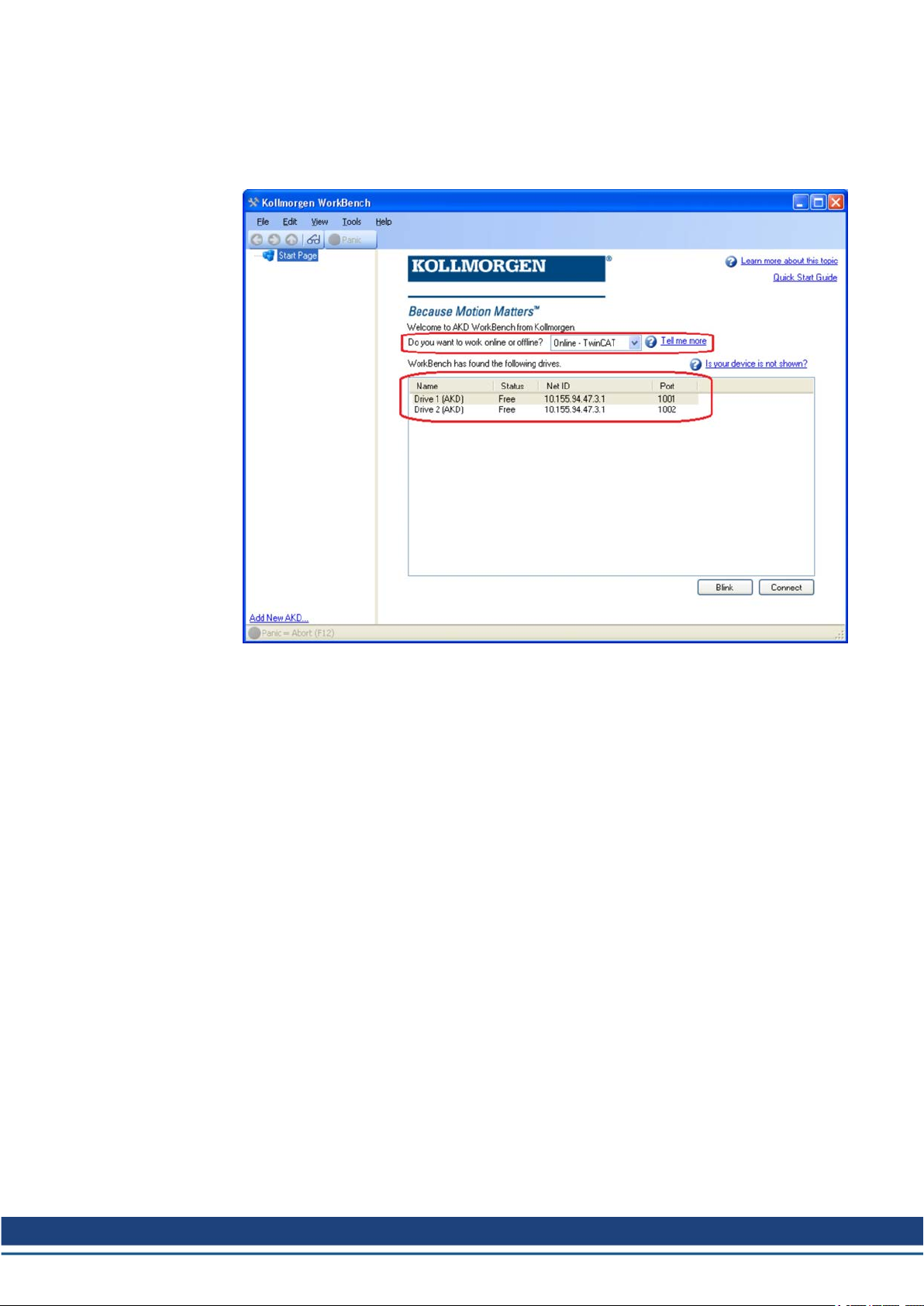

3.7.2 Connecting to a Drive Using WorkBench

In order to connect to a drive, a TwinCAT device must be added in WorkBench. The start

page of WorkBench can be used to do this. First, the type of drive (Online - TwinCAT) must

be specified. Then, a list of available drives will be provided.

AKD-C/N EtherCAT | 3 Installation and Setup

The information provided for a drive are it's name, status, Net ID and Port number. After

selecting a drive from the list, clicking on the "Connect" button will create a device in the left

frame of WorkBenchand connect the device.

Kollmorgen | kdn.kollmorgen.com | October 2020 27

Page 28

AKD-C/N EtherCAT | 3 Installation and Setup

The name, Net ID and port number are information comming from the TwinCAT master configuration file (the name may be different than the drive name returned by the DRV.NAME

command). While the status is an indicator that tells if there is already a device created within

WorkBench which is already connected to that particular drive.

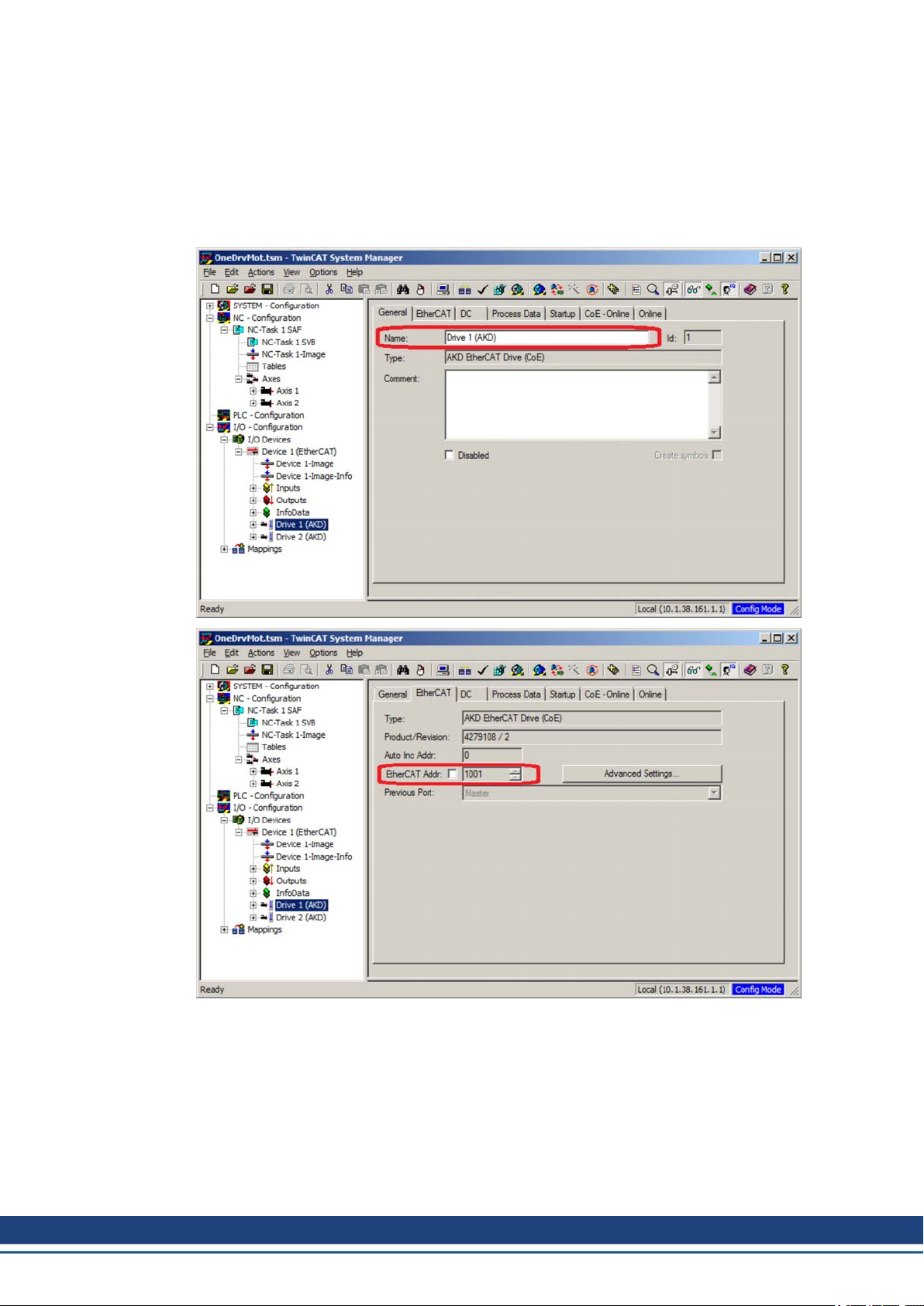

Using TwinCAT System Manager, the drive name and port number can be found in the General and EtherCAT tab respectively for the corresponding drive under the I/O Configuration →

I/O Devices → Device [x] → Drive [x] node.

28 Kollmorgen | kdn.kollmorgen.com | October 2020

Page 29

AKD-C/N EtherCAT | 3 Installation and Setup

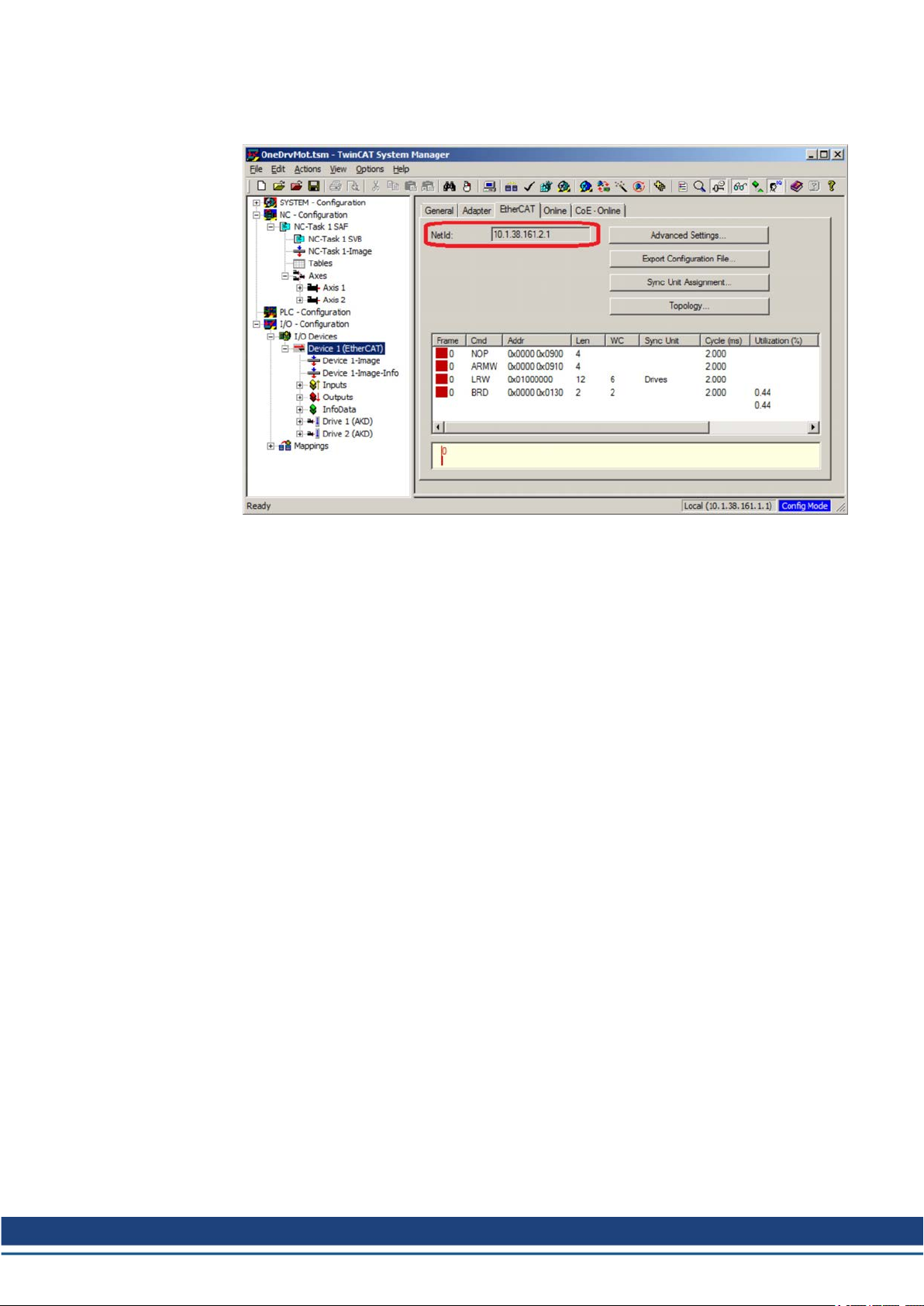

The Net ID can be found in the EtherCAT tab in the I/O Configuration → I/O Devices →

Device [x] node.

It is important to understand that thid information is coming from the TwinCAT master and it's

configuration file but not from the drive itself. Thus, if the TwinCAT configuration is not reflecting the actual network configuration, you may have a drive listed in WorkBench which is not

be powered up or even connected in the EtherCAT network, or you have a drive powered up

and connected to the TwinCAT network but not shown in the WorkBench list.

Kollmorgen | kdn.kollmorgen.com | October 2020 29

Page 30

AKD-C/N EtherCAT | 3 Installation and Setup

3.7.3 Configuring and Enabling a Drive

Once connected with WorkBench, a drive can be configured using all normal functionality of

WorkBench.

The only operation that is not possible to do using WorkBench over TwinCAT is the download

of a new firmware in the drive. Downloading a new firmware in the drive must be performed

using File over EtherCAT (FoE) feature of TwinCAT server.

If the cyclic communication of the TwinCAT master is enabled, it is possible that some commands sent by WorkBench using the ASCII channel are overwritten by the TwinCAT master.

Typically, the drive enable command will have no effect if sent from WorkBench because the

control word is usually mapped.

Using TwinCAT, enabling the drive can be done with the following procedure:

1. Under NC Configuration → Axes → Axis [x] node, choose the Online tab.

2. Press the Set button within the Enabling section.

3. In the pop-up dialog box, check the Controller checkbox to enable the drive (or un-check

to disable the drive) and press on the OK button.

30 Kollmorgen | kdn.kollmorgen.com | October 2020

Page 31

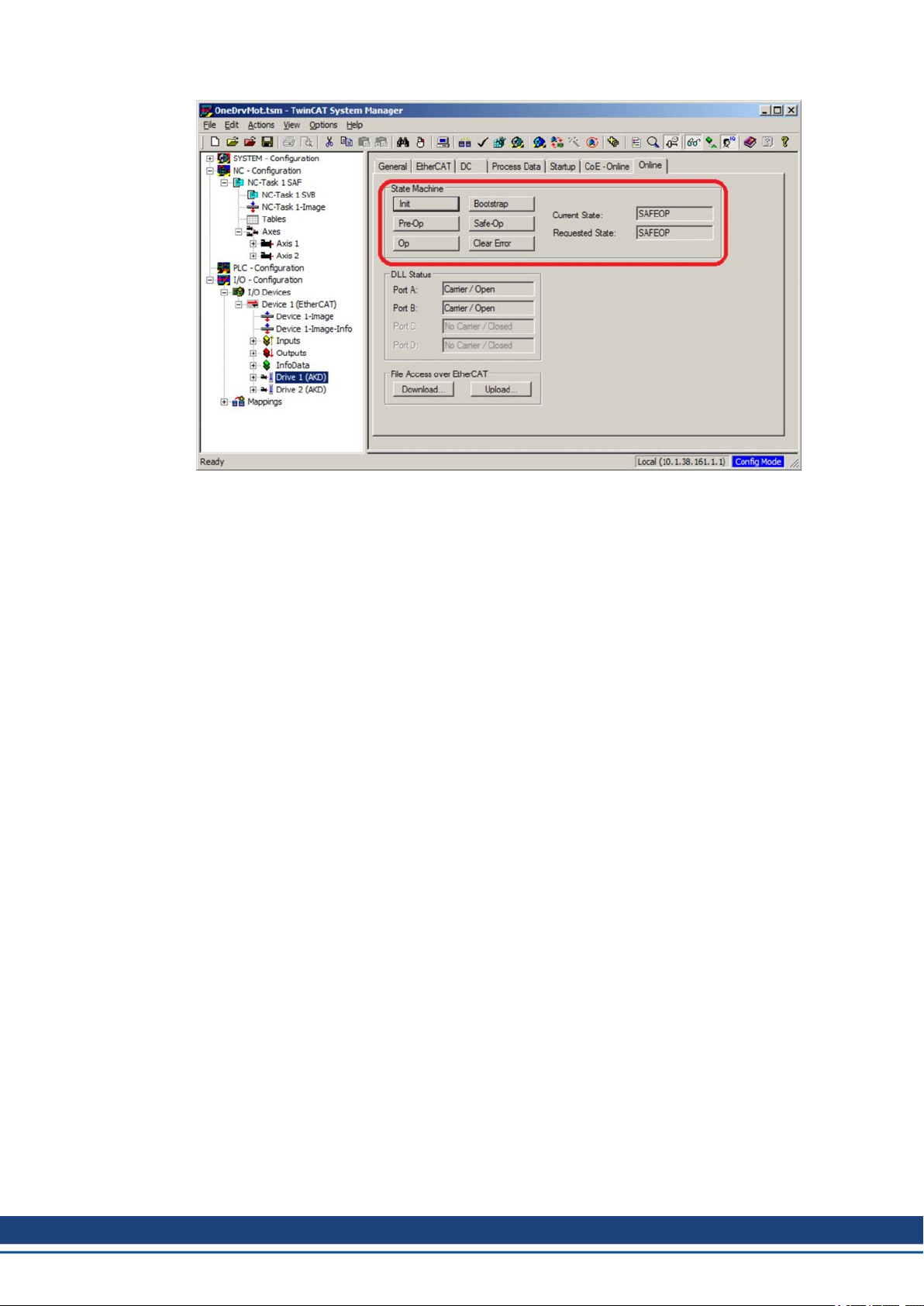

3.7.4 Download a Parameter File over TwinCAT

You can download a parameter file to the drive over EtherCAT. Before you start, make sure

that the drive is in INIT, PREOP, or SAFEOP state before trying to download the file.

1. First select the drive where you want to perform the download.

2. Change to the Online tab.

AKD-C/N EtherCAT | 3 Installation and Setup

3. Press the Download button.

4. Choose “All Files (*.*)” as file type to see the parameter files ending with “.akd”.

5. Select the file.

6. Press Open to start the download.

Downloading a parameter file over TwinCAT is supported by all drives from firmware

01.12.000.

Kollmorgen | kdn.kollmorgen.com | October 2020 31

Page 32

AKD-C/N EtherCAT | 3 Installation and Setup

3.8 Setup via KAS IDE

If you are using a Kollmorgen Automation Suite (KAS) system, the AKD setup is completely

integrated into the KAS Integrated Development Environment (IDE), as shown below:

For further information on the setup for a KASsystem, see the following sections in the KAS

documentation:

KAS IDE User Manual:See section 4.2.3 Add and Configure Drive.

KAS Online Help: See Using the KAS IDE> Creating a Project> Step 3 - Add and

Configure Drive.

32 Kollmorgen | kdn.kollmorgen.com | October 2020

Page 33

AKD-C/N EtherCAT | 4 EtherCAT Profile

4 EtherCAT Profile

4.1 Slave Register 34

4.2 AL Event (Interrupt Event) and Interrupt Enable 35

4.3 Phase Run-Up 37

4.4 CANopen over EtherCAT (CoE) State Machine 39

4.5 Fixed PDO Mappings 41

4.6 Flexible PDO Mappings 44

4.7 Supported Cyclical Setpoint and Actual Values 51

4.8 Supported Operation Modes 54

4.9 Adjusting EtherCAT Cycle Time 54

4.10 Maximum Cycle Times depending on operation mode 54

4.11 Synchronization 55

4.12 Latch Control Word and Latch Status Word 56

4.13 Mailbox Handling 57

4.14 EEProm Content 61

Kollmorgen | kdn.kollmorgen.com | October 2020 33

Page 34

AKD-C/N EtherCAT | 4 EtherCAT Profile

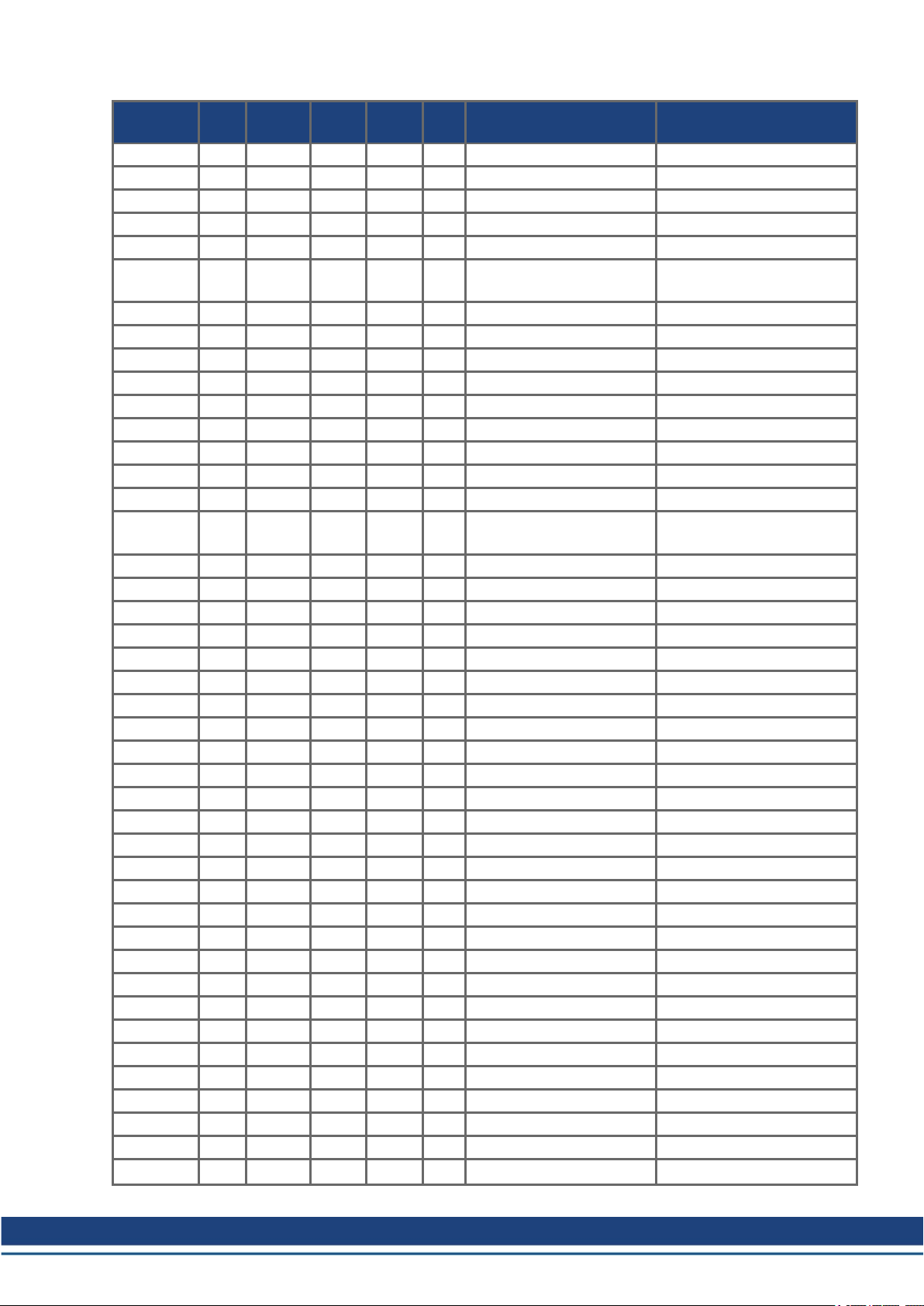

4.1 Slave Register

The table below gives the addresses of individual registers in the FPGA memory. The data is

provided in little-endian format, with the ’least significant byte’ occupying the lowest address.

A detailed description of all registers and FPGA memory locations is available in the “EtherCAT Slave Controller” description of the EtherCAT user organization (www.EtherCAT.org).

Address

0x0120 2 AL Control R/W R/O

0x0130 2 AL Status R/O R/W

0x0134 2 AL Status Code R/O R/W

0x0204 2 Interrupt Enable Register R/O R/W

0x0220 2 AL Event (IRQ Event) R/W R/O

0x0800 8 Sync Manager 0 (Mail Out Control Register) R/W R/O

0x0808 8 Sync Manager 1 (Mail In Control Register) R/W R/O

0x0810 8 Sync Manager 2 (Process data Output Con-

0x0818 8 Sync Manager 3 (Process data Input Control

0x0820 8 Sync Manager 4 R/W R/O

0x0828 8 Sync Manager 5 R/W R/O

0x0830 8 Sync Manager 6 R/W R/O

0x0838 8 Sync Manager 7 R/W R/O

0x0840 8 Sync Manager 8 R/W R/O

0x1100 Max. 64 ProOut Buffer (Process data Output, set-

0x1140 Max. 64 ProIn (Process data Input, act. values

0x1800 up to 512**

0x1C00 up to 512**

Length

(Byte)

up to 1024**

up to 1024**

Description

trol Register)

Register)

points ECAT)

ECAT)

Mail Out Buffer (Object Channel Buffer

ECAT, byte-length is specified in the device

description file)

Mail In Buffer (Object Channel Buffer Drive,

byte-length is specified in the device description file)

ZA

ECAT*ZADrive*

R/W R/O

R/W R/O

R/W R/O

R/O R/W

R/W R/O

R/O R/W

* ZA ECAT = Access mode EtherCAT

* ZA Drive = Access mode drive

** depends on firmware version and revision number

34 Kollmorgen | kdn.kollmorgen.com | October 2020

Page 35

4.2 AL Event (Interrupt Event) and Interrupt Enable

Communication between the drive and the EtherCAT FPGA can be interrupt-driven. The interrupt enable register and the AL event register are responsible for the EtherCAT interface interrupt functionality.

There are two events which lead also to a HW interrupt within the drive, the EEPROM emulation event and the SyncManager 2 event. The actual values of the drive (SyncManager 3

data) are written without any AL event request during each HW IRQ, e.g. triggered by a SyncManager 2 event. The Mailbox exchange between the master and the AKD is completely

handled by polling the AL event register within the background task of the drive.

The drive activates individual EtherCAT interface events when the corresponding bit of the

interrupt enable register is set to 1. When it is set to 0, the hardware interrupts for the specific

events are deactivated.

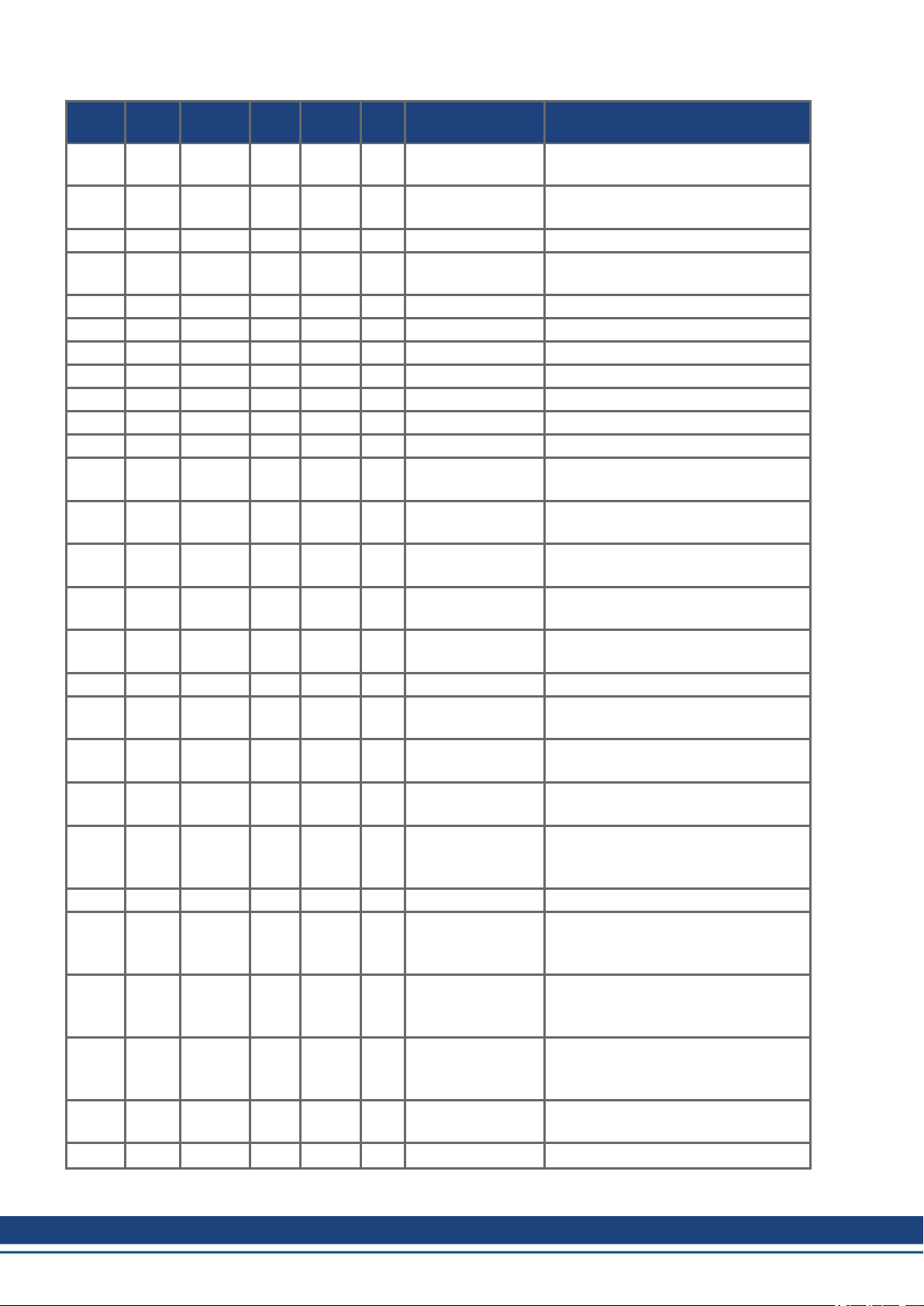

4.2.1 Interrupt Enable Register (Address 0x0204:0x0205)

AKD-C/N EtherCAT | 4 EtherCAT Profile

Parameter Address Bit

AL Control Event 0x204 0 R/W R/O Activation of AL control event for

- 0x204 1 R/W R/O Reserved

Sync0 DC Distributed

Clock

Sync1 DC Distributed

Clock

SyncManager activation

register change

EEPROM emulation

event

- 0x204 3 to 7 R/W R/O Reserved

Sync Manager 0 Event

(Mail Out Event)

Sync Manager 1 Event

(Mail In Event)

Sync Manager 2 Event

(Pro Out Event)

Sync Manager 3 Event

(Pro In Event)

- 0x205 4 to 7 R/W R/O Reserved

0x204 2 R/W R/O Activation of distributed clock

0x204 3 R/W R/O Activation of distributed clock

0x204 4 R/W R/O Activation of ‘SyncManager activ-

0x204 5 R/W R/O Activation of the EEPROM emu-

0x205 0 R/W R/O Activation of output event mail-

0x205 1 R/W R/O Activation of input event mailbox

0x205 2 R/W R/O Activation of output event pro-

0x205 3 R/W R/O Activation of input event process

ZA

DriveZAECAT

Description

phase run-up

(DC) sync 0 interrupts for entire

communication

(DC) sync 1 interrupts for entire

communication

ation register change’ IRQ.

lation interrupts.

box (SDO, Sync Manager 0) for

object channel.

(SDO, Sync Manager 1) for

object channel.

cess data (PDO, card's cyclical

setpoints)

data (PDO, drive's cyclical

actual values)

Kollmorgen | kdn.kollmorgen.com | October 2020 35

Page 36

AKD-C/N EtherCAT | 4 EtherCAT Profile

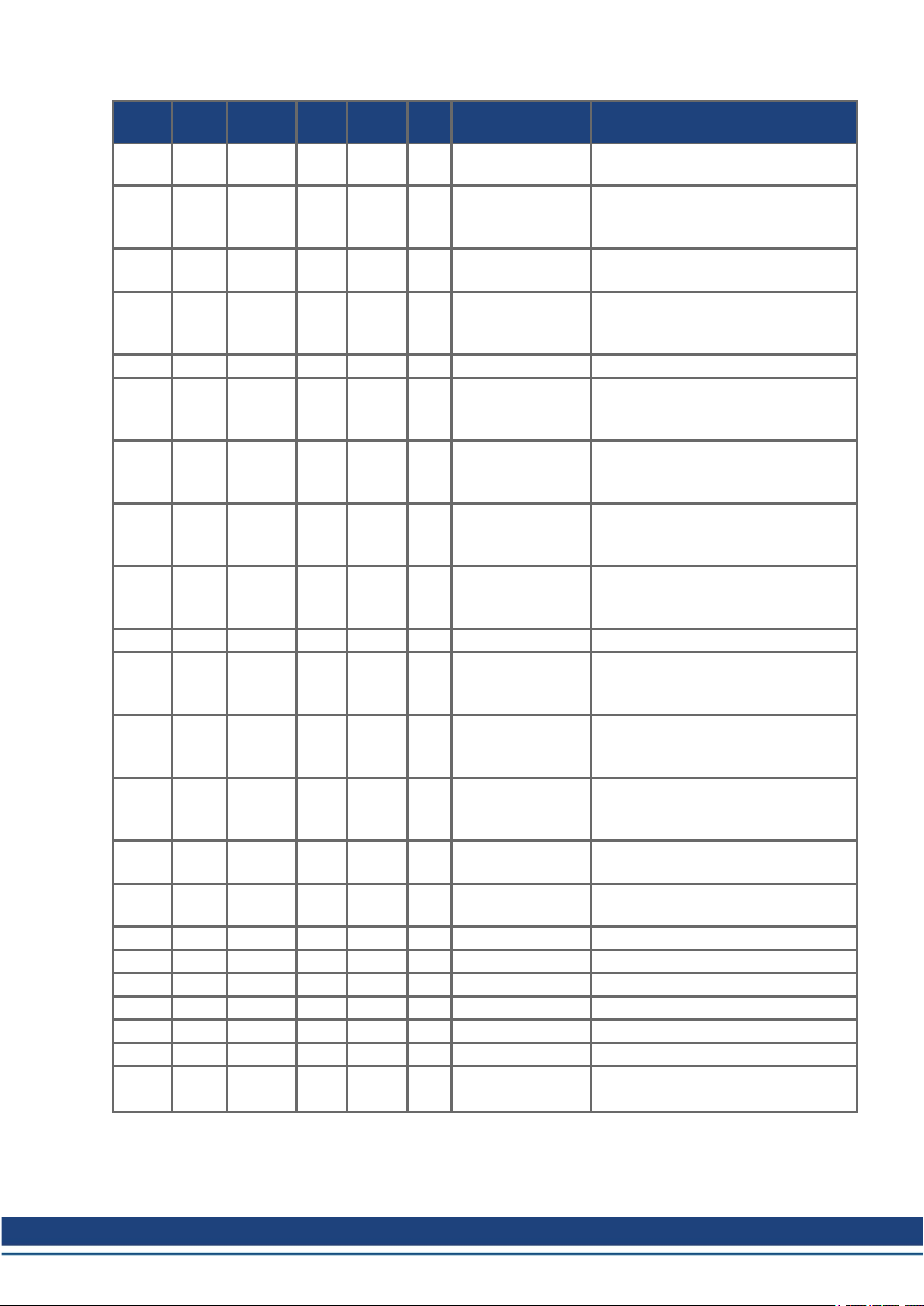

4.2.2 AL Event Request (Address 0x0220:0x0221)

When the relevant bit of the AL event request register is set to 1, the EtherCAT interface tells

the drive which event it should process by the AKD.

Parameter Address Bit

AL Control Event 0x220 0 R/O R/W Processing of AL control event

Sync0 Distributed Clock

(DC) Event

Sync1 Distributed Clock

(DC) Event

SyncManager activation

register change

EEPROM emulation

event

- 0x220 6 to 7 R/O R/W Reserved

Sync Manager 0 Event 0x221 0 R/O R/W Mailbox request (SDO, Sync

Sync Manager 1 Event 0x221 1 R/O R/W Mailbox response (SDO, Sync

Sync Manager 2 Event 0x201 2 R/O R/W Process data output (PDO,

Sync Manager 3 Event 0x201 3 R/O R/W Process data input (PDO,

Sync Manager 4 –

Sync Manager 7 Event 0x221 4 to 7 R/O R/W Reserved

Sync Manager 8 –

Sync Manager 15 Event 0x222 0 to 7 R/O R/W Reserved

0x220 2 R/O R/W Processing of a distributed

0x220 3 R/O R/W Processing of a distributed

0x220 4 R/O R/W The content of the Syn-

0x220 5 R/O R/W Processing of an EEPROM

ZA

DriveZAECAT

Description

for phase run-up

clock (DC) event

clock (DC) event

cManager activation register

has been changed.

emulation event in order to

identify the AKD within the network.

Manager 0) for object channel.

Manager 1) for object channel.

card's cyclical setpoints)

drive's cyclical actual values)

36 Kollmorgen | kdn.kollmorgen.com | October 2020

Page 37

4.3 Phase Run-Up

The AL control, AL status and AL status code registers are responsible for communication

phase run-up (also referred to as EtherCAT status change), for current status display and for

any fault messages. The drive responds to every EtherCAT interface transition request made

by the AL control register via the AL Status and AL Status Code registers. Any fault messages are displayed in the AL status code register.

A status change within the AL control register is polled within the AKD, which means that an

AL control event does not lead to a HW interrupt within the drive.

4.3.1 AL Control (Address 0x0120:0x0121)

AKD-C/N EtherCAT | 4 EtherCAT Profile

Parameter Address Bit

Status 0x120 3 to 0 R/O W/O 0x01: Init Request

0x02: PreOperational

Request

0x03: Bootstrap Mode

Request

0x04: Safe Operational

Request

0x08: Operational

Request

Acknowledgement 0x120 4 R/O W/O 0x00: No fault acknowledgement

Reserved 0x120 7 to 5 R/O W/O -

Applic. specific 0x120 15 to 8 R/O W/O -

4.3.2 AL Status (Address 0x0130:0x0131)

Parameter Address Bit

Status 0x130 3 to 0 W/O R/O 0x01: Init

0x02: PreOperational

0x03: Bootstrap Mode

0x04: Safe Operational

0x08: Operational

Status change 0x130 4 W/O R/O 0x00: Acknowledgement

Reserved 0x130 7 to 5 W/O R/O -

Applic. specific 0x130 15 to 8 W/O R/O -

ZA

DriveZAECAT

ZA

DriveZAECAT

Description

0x01: Fault acknowledgement

(positive edge)

Description

0x01: Error, e.g. forbidden transition

Kollmorgen | kdn.kollmorgen.com | October 2020 37

Page 38

AKD-C/N EtherCAT | 4 EtherCAT Profile

4.3.3 AL Status Code (Address 0x0134:0x0135)

Parameter Address Bit ZA Drive ZA ECAT Description

Status 0x134 7 to 0 W/O R/O See table below

Status 0x135 7 to 0 W/O R/O See table below

Code Description

0x0000 No error All Current Status

0x0011 Invalid requested state change I -> S, I -> O, P -> O,

0x0017 Invalid sync manager configuration I -> P, P -> S Current Status + E

No other codes are supported.

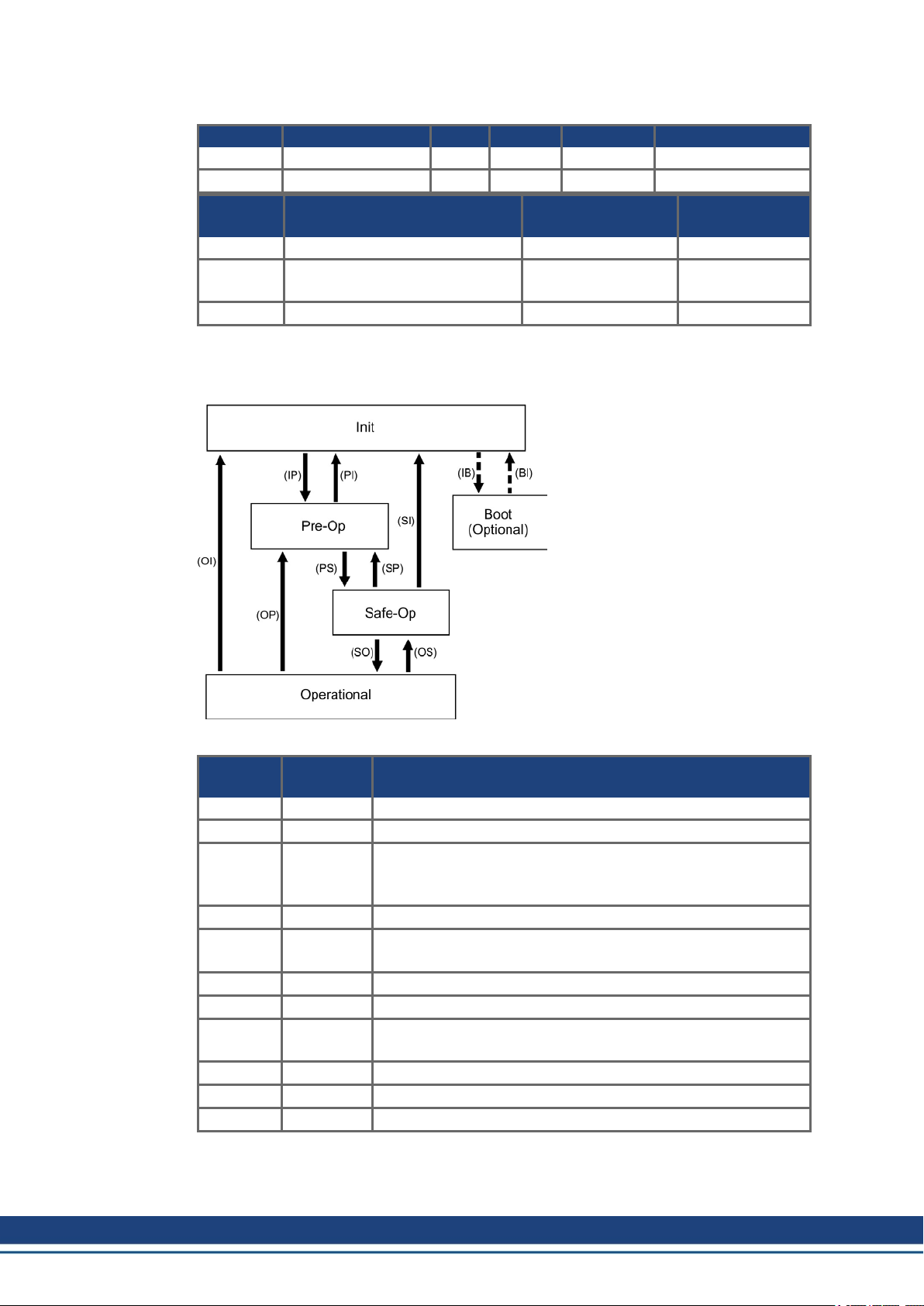

4.3.4 EtherCAT communication phases

Current Status

(Status change)

O -> B, S -> B, P -> B

INIT:

Initialization, no communication.

EEPROM emulation will be activated.

PRE-OP:

Mailbox active, slave parameterization

and startup parameters

Resulting Status

Current Status + E

SAVE-OP:

Cyclical actual values are transferred

and the drive tries to synchronize.

OPERATIONAL:

Cyclical setpoints are processed,

torque enable can be activated and the

drive must be synchronized.

Individual communication transitions

Transition

(IB) 0x03 -

(BI) - -

(IP) 0x02 AKD reads the SyncManager 0 & 1 configuration and verifies the

(PI) 0x01 -

(PS) 0x04 AKD reads the SyncManager 2 & 3 configuration and verifies the

(SP) 0x02 -

(SI) 0x01 -

(SO) 0x08 The SnycManager 2 hardware interrupt will be enabled by the

(OS) 0x04 Deactivation of SyncManager 2 hardware interrupt.

(OP) 0x02 Deactivation of SyncManager 2 hardware interrupt..

(OI) 0x01 Deactivation of SyncManager 2 hardware interrupt.

ALControl

(Bit 3 to 0)

Description

value of the start-address and the length. The AKD prepares

itself for handling SyncManager 0 events.

value of the start-address and the length.

drive.

38 Kollmorgen | kdn.kollmorgen.com | October 2020

Page 39

4.4 CANopen over EtherCAT (CoE) State Machine

AKD-C/N EtherCAT | 4 EtherCAT Profile

The state machine for the control and

status words corresponds to the

CANopen state machine in accordance

with DS402.

CANopen control and status words are

captured in every instance of fixed PDO

mapping (see chapter "Fixed PDO Mappings" (➜ p. 41)).

4.4.1 Status Description

Status Description

Not Ready to SwitchOnThe drive is not ready to switch on; the controller has not indicated

Switch On Disable In 'Switch On Disable' status, the amplifier cannot be enabled via

Ready to Switch On In 'Ready to Switch On' status, the drive can be enabled via the con-

Switched On In 'Switched On' status, the amplifier is enabled, but the setpoints of

Operation Enable In this status, the drive is enabled and setpoints are transferred from

Quick Stop Active The drive follows a quick stop ramp.

Fault Reaction Active The drive responds to a fault with an emergency stop ramp.

Fault A fault is pending, the drive is stopped and disabled.

readiness for service. The drive is still in the boot phase or in fault

status.

the EtherCAT interface, because (for example) there is no connection to a power source.

trol word.

the EtherCAT-interface are not yet transferred. The amplifier is idle,

and a positive edge in bit 3 of the control word activates setpoint

transfer (transition to 'Operation Enable' status).

the EtherCAT interface.

Kollmorgen | kdn.kollmorgen.com | October 2020 39

Page 40

AKD-C/N EtherCAT | 4 EtherCAT Profile

4.4.2 Commands in the Control Word

Bit assignment in the control word

Bit Name Bit Name

0 Switch on 8 Pause/halt

1 Disable Voltage 9 reserved

2 Quick Stop 10 reserved

3 Enable Operation 11 reserved

4 Operation mode specific 12 reserved

5 Operation mode specific 13 Manufacturer-specific

6 Operation mode specific 14 Manufacturer-specific

7 Reset Fault (only effective for faults) 15 Manufacturer-specific

Commands in the control word

Bit 7

Command

Shutdown X X 1 1 0 2, 6, 8

Switch on X X 1 1 1 3

Disable Voltage X X X 0 X 7, 9, 10, 12

Quick Stop X X 0 1 X 7, 10, 11

Disable Operation X 0 1 1 1 5

Enable Operation X 1 1 1 1 4, 16

Fault Reset 1 X X X X 15

Bits labeled X are irrelevant. 0 and 1 indicate the status of individual bits.

Mode-dependent bits in the control word

The following table shows the mode-dependent bits in the control word. Only manufacturerspecific modes are supported at present. The individual modes are set by Object 6060h

Modes of operation.

Operation mode No Bit 4 Bit 5 Bit 6

Profile Position Mode (pp) 01h new_setpoint change_set_

Profile Velocity Mode (pv) 03h reserved reserved reserved

Profile Torque Mode (tq) 04h reserved reserved reserved

Homing Mode (hm) 06h homing_operation_

Interpolated Position Mode (ip) 07h reserved reserved

Cyclic synchronous position

mode

Fault

Reset

Bit 3

Enable Oper-

ation

start

08h reserved reserved reserved

Bit 2

Quick

Stop

Bit 1

Disable

Voltage

immediately

reserved reserved

Bit 0

SwitchOnTransitions

absolute/relative

Description of the remaining bits in the control word

Bit 8: (Pause) If Bit 8 is set, then the drive halts (pauses) in all modes. The setpoints (speed

for homing or jogging, motion task number, setpoints for digital mode) for the individual

modes are retained.

Bit 9,10: These bits are reserved for the drive profile (DS402).

Bit 13, 14, 15: These bits are manufacturer-specific, and reserved at present.

40 Kollmorgen | kdn.kollmorgen.com | October 2020

Page 41

4.4.3 State Machine Bits (status word)

Bit assignment in the status word

Bit Name Bit Name

0 Ready to switch on 8 Manufacturer-specific (reserved)

1 Switched on 9 Remote (always 1)

2 Operation enable 10 Target reached

3 Fault 11 Internal limit active

4 Voltage enabled 12 Operation mode specific (reserved)

5 Quick stop 13 Operation mode specific (reserved)

6 Switch on disabled 14 Manufacturer-specific (reserved)

7 Warning 15 Manufacturer-specific (reserved)

States of the state machine

AKD-C/N EtherCAT | 4 EtherCAT Profile

Bit 6

State

Not ready to switch on 0 X 0 0 0 0

Switch on disabled 1 X 0 0 0 0

Ready to switch on 0 1 0 0 0 1

Switched on 0 1 0 0 1 1

Operation enabled 0 1 0 1 1 1

Fault 0 X 1 0 0 0

Fault reaction active 0 X 1 1 1 1

Quick stop active 0 0 0 1 1 1

Bits labeled X are irrelevant. 0 and 1 indicate the status of individual bits.

Description of the remaining bits in the status word

Bit 4: voltage_enabled The DC-link voltage is present if this bit is set.

Bit 7: warning There are several possible reasons for Bit 7 being set and this warning being

produced. The reason for this warning can be revealed by using the Object 2000h (system

warnings).

Bit 9: remote is always set to 1, i.e. the drive can always communicate and be influenced via

the RS232 - interface.

Bit 10: target_reached This is set when the drive has reached the target position.

Bit 11: internal_limit_active This bit specifies that a movement was or is limited. In different

modes, different warnings cause the bit to be set.

switch on

disable

Bit 5

quick

stop

Bit 3

fault

Bit 2

operation

enable

Bit 1

switched

on

Bit 0

ready to

switch

on

4.5 Fixed PDO Mappings

Various ready-to-use mappings can be selected for cyclic data exchange via SDO’s of the

object 0x1C12 and 0x1C13. Using object 0x1C12 subindex 1 (Sync Manager 2 assignment),

a fixed mapping for the cyclic command values can be set with the values 0x1701,

0x1702,0x1720 to 0x1725. Using object 0x1C13 subindex 1 (Sync Manager 3 assignment), a

fixed mapping for the cyclic actual values can be set via the data 0x1B01, 0x1B20 to

0x1B26.

Use the sequence below to select the fixed command value mapping 0x1701 via SDO’s:

1. SDO write access to object 0x1C12Sub0 Data:0x00

2. SDO write access to object 0x1C12Sub1 Data:0x1701

3. SDO write access to object 0x1C12Sub0 Data:0x01

Kollmorgen | kdn.kollmorgen.com | October 2020 41

Page 42

AKD-C/N EtherCAT | 4 EtherCAT Profile

Up to firmware version 1.8.x.x AKD.XML file, fixed mapping 0x1701 called out 0x6062sub0

as the “Position Command”. From AKD firmware release 1.8.5.0, the AKD.XML will be

changed to call out 0x60C1sub1 as the “Position Command” and an additional XML file called

“AKD_TwinCAT.XML” will be added to support TwinCat 2x and older. In reality, SDO

0x6062sub0 is not supported in the AKD firmware but was called in the fixed mapping to support a TwinCat issue.

Position interface, supported fixed mappings:

0x1701 Position command value (4 bytes), Control word (2 bytes), total (6 bytes)

0x1720 Control Word (2 bytes), Interpolated position command value (4 bytes), Latch

control word (2 bytes), Torque feed forward (2 bytes), Digital outputs (2 bytes)

0x1721 Interpolated position command value (4 bytes), Control Word (2 bytes), Torque

feed forward (2 bytes)

0x1722 Control word (2 byte), Interpolated position command value (4 bytes), Latch con-

trol word (2 bytes), Torque feed forward (2 bytes), Digital outputs (2 bytes), max.

torque (2 bytes)

0x1723 Control word (2 bytes), Interpolated position command value (4 bytes), Latch

control word (2 bytes), Torque feed forward (2 bytes), Digital outputs (2 bytes),

Reset of changed input information (2 bytes)

0x1724 Target position for cyclic synchronous position mode (4 bytes), Control word (2

byte), Torque feed forward (2 bytes)

0x1725 Controlword (2 bytes), Target position for cyclic synchronous position mode (4

bytes), Digital outputs (4 bytes), Torque feed forward (2 bytes), Analog output

value (2 bytes), Max torque (2 bytes)

0x1B01 Position actual value (4 bytes), Status word (2 bytes), total (6 bytes)

0x1B20 Position actual internal value (4 bytes), 2nd position feedback position (4 bytes),

velocity actual value (4 bytes), digital inputs (4 bytes), following error (4 bytes),

latch position positive (4 bytes), status word (2 bytes), torque actual value (2

bytes), latch status (2 bytes), analog input value (2 bytes)

0x1B21 Position Actual Internal Value (4 bytes), Status word (2 bytes)

0x1B22 Position actual internal value (4 bytes), 2nd position feedback position (4 bytes),

velocity actual value (4 bytes), digital inputs (4 bytes), following error (4 bytes),

latch position negative (4 bytes), status word (2 bytes), torque actual value (2

bytes), latch status (2 bytes), analog input value (2 bytes)

0x1B23 Position actual internal value (4 bytes), 2nd position feedback position (4 bytes),

velocity actual value (4 bytes), digital inputs (4 bytes), following error (4 bytes),

latch position positive / negative (4 bytes), status word (2 bytes), torque actual

value (2 bytes), latch status (2 bytes), analog input value (2 bytes)

0x1B24 Position actual value (4 bytes), status word (2 bytes)

0x1B25 Position actual internal value (4 bytes), 2nd position feedback position (4 bytes),

latch position 2 positive / negative (4 bytes), digital inputs (4 bytes), following

error (4 bytes), latch position 1 positive / negative (4 bytes), status word (2

bytes), torque actual value (2 bytes), latch status (2 bytes), analog input value (2

bytes)

0x1B26 Statusword (2 bytes), Position actual value (4 bytes), Analog input value (2

bytes), Digital inputs (4 bytes), Following error actual value (4 bytes)

42 Kollmorgen | kdn.kollmorgen.com | October 2020

Page 43

AKD-C/N EtherCAT | 4 EtherCAT Profile

Velocity interface, supported fixed mappings:

0x1702 Velocity command value (4 bytes), Control word (2 bytes), total (6 bytes)

The objects, which are mapped into the fixed PDOs can be read via the subindices 1 to n of

the above indices. The number of mapped entries is available by reading subindex 0 of the

above indices.

Example:

A read access to object 1702 sub 0 gives a value of 2, a read on subindex 1 gives

0x60ff0020, on subindex 2 0x60400010. The meaning of these numbers can be seen in the

CANopen manual or the flexible-mapping example (➜ p. 46.).

Kollmorgen | kdn.kollmorgen.com | October 2020 43

Page 44

AKD-C/N EtherCAT | 4 EtherCAT Profile

4.6 Flexible PDO Mappings

In addition to the fixed PDO mapping the so-called flexible mapping of real-time objects is

possible.

Available objects for PDO mapping are listed in the object dictionaries ("Appendix" (➜ p.

62)). All objects with the entry "yes" in column "PDO map." can be used.

Restrictions of flexible mapping:

l An odd length PDO is not allowed.

In the Rx(=set-point)-direction the dummy-object 0x0002 sub 0 with a length of 8 bits

can be used to make the PDO-length even.

In the Tx(=actual value)-direction one sub-index of the manufacturer status object

0x2002 sub 1..4 can be used to guarantee the even length of the Tx-PDO.

These special mappings may be used if the objects 0x6060 and 0x6061 have to be

used in the mapping.

l The allowed PDOs have up to 32 bytes (Tx), 20 bytes for RX (FW version < 1.16) or 20

bytes for RX(FW > = 1.17). They are built from smaller PDO modules with a maximum

length of 8 bytes. These are built by using the mapping objects 0x1600 to 0x1603 and

0x1a00 to 0x1a03.

The configuration is similar to the described sequence for the fixed mappings:

1. The mapping selection is cleared (write 0 to object 0x1C12 sub 0 and 1C13 sub 0)

2. As the AKD - implementation is based on CANopen the real-time data are build from up to

4 PDOs with 8 bytes in both directions. These PDOs are built in the same way as in a

CAN-drive with the objects 0x1600 - 0x1603 and 0x1A00 - 0x1A03. Unused PDOs must

be cleared with writing 0 to the subindex 0.

3. SDO write access to object 0x1C12 sub 1 .. 4 with the PDOs (0x1600 .. 0x1603), that

should be used in receive direction of the AKD (set point values).

4. SDO write access to object 0x1C13 sub 1 .. 4 with the PDOs (0x1A00 .. 0x1A03), that

should be used in transmit direction of the AKD (actual values).

5. SDO write access to the objects 0x1C12 sub 0 and 0x1C13 sub 0 with the number of

mapped PDOs in this direction.

See an example in chapter "Flexible PDO Mappings" (➜ p. 44) .

The cyclically used data are visible in the PDO-assignment window for the Inputs and Outputs of the Sync Managers. Default setting are the fixed PDOs 0x1701 and 0x1B01 (visible

contents when selected in the PDO list).

44 Kollmorgen | kdn.kollmorgen.com | October 2020

Page 45

AKD-C/N EtherCAT | 4 EtherCAT Profile

If the flexible mapping is required, the PDO configuration check box must be changed.

4.6.1 Example: Flexible PDO Mapping

For the flexible mapping of the Outputs the fixed mapping 0x1701 has to be switched off and

up to 4 free-mappable PDOs (0x1600-0x1603) can be used instead. The maximum number of

bytes for each of these PDOs is 8.

After that the default mapping of e.g. the PDO 0x1600 can be extended:

==========>

Kollmorgen | kdn.kollmorgen.com | October 2020 45

Page 46

AKD-C/N EtherCAT | 4 EtherCAT Profile

A list of possible objects for the mapping will be shown and a new entry can be chosen.

In this case the setpoint for the interpolated

position mode is selected.

The same is valid for the Tx-PDO-direction.

Here the value of the actual internal position

is selected.

This results in the startup-SDO-list for this sample free-mapped-configuration.

The meaning of the data (for example 0x60410010 in the mapping of 0x1A00 sub 1) is as follows:

0x6041 is the index of the DS402 status word

0x00 is the subindex of the DS402 status word

0x10 is the number of bits for this entry, i. e. 16 bits or 2 bytes.

46 Kollmorgen | kdn.kollmorgen.com | October 2020

Page 47

AKD-C/N EtherCAT | 4 EtherCAT Profile

If this shall be used in the NC, the interpolation set point position has to be linked from the

axis to the NC-axis.

Kollmorgen | kdn.kollmorgen.com | October 2020 47

Page 48

AKD-C/N EtherCAT | 4 EtherCAT Profile

After doing this configuration the mapping can be activated as seen before in this document:

Now the NC-screen should show a position in the online window, which changes a bit in the

last digits.

After enabling the power stage with the All-button, the drive can be moved via the jog-buttons

or via the functions in the function menu.

48 Kollmorgen | kdn.kollmorgen.com | October 2020

Page 49

AKD-C/N EtherCAT | 4 EtherCAT Profile

4.6.2 Example: Flexible PDOMapping with one byte gap in Rx-PDO

The AKD needs an even number of bytes in a PDO so it can be necessary to fill a gap if a one

byte object like object 6060h sub 0 (mode of operation) is mapped to the Rx-PDO. This can

be done in the following sequence:

Rx-PDO Mapping with Controlword and 1st set-point.

Insert a one byte gap.

Kollmorgen | kdn.kollmorgen.com | October 2020 49

Page 50

AKD-C/N EtherCAT | 4 EtherCAT Profile

In CANopen over EtherCAT, a gap is programmed using index 0 sub 0 with the size of the

gap with one byte in the example.

Insert additional object 6060h sub 0 (mode of operation).

Result:

50 Kollmorgen | kdn.kollmorgen.com | October 2020

Page 51

View in the TwinCat I/O display.

AKD-C/N EtherCAT | 4 EtherCAT Profile

For Tx-PDOs, an even number of bytes is required. To fill a gap in the Tx-PDO mapping,

existing one byte objects like 2002h sub 1 (Manufacturer status byte 1) can be used.

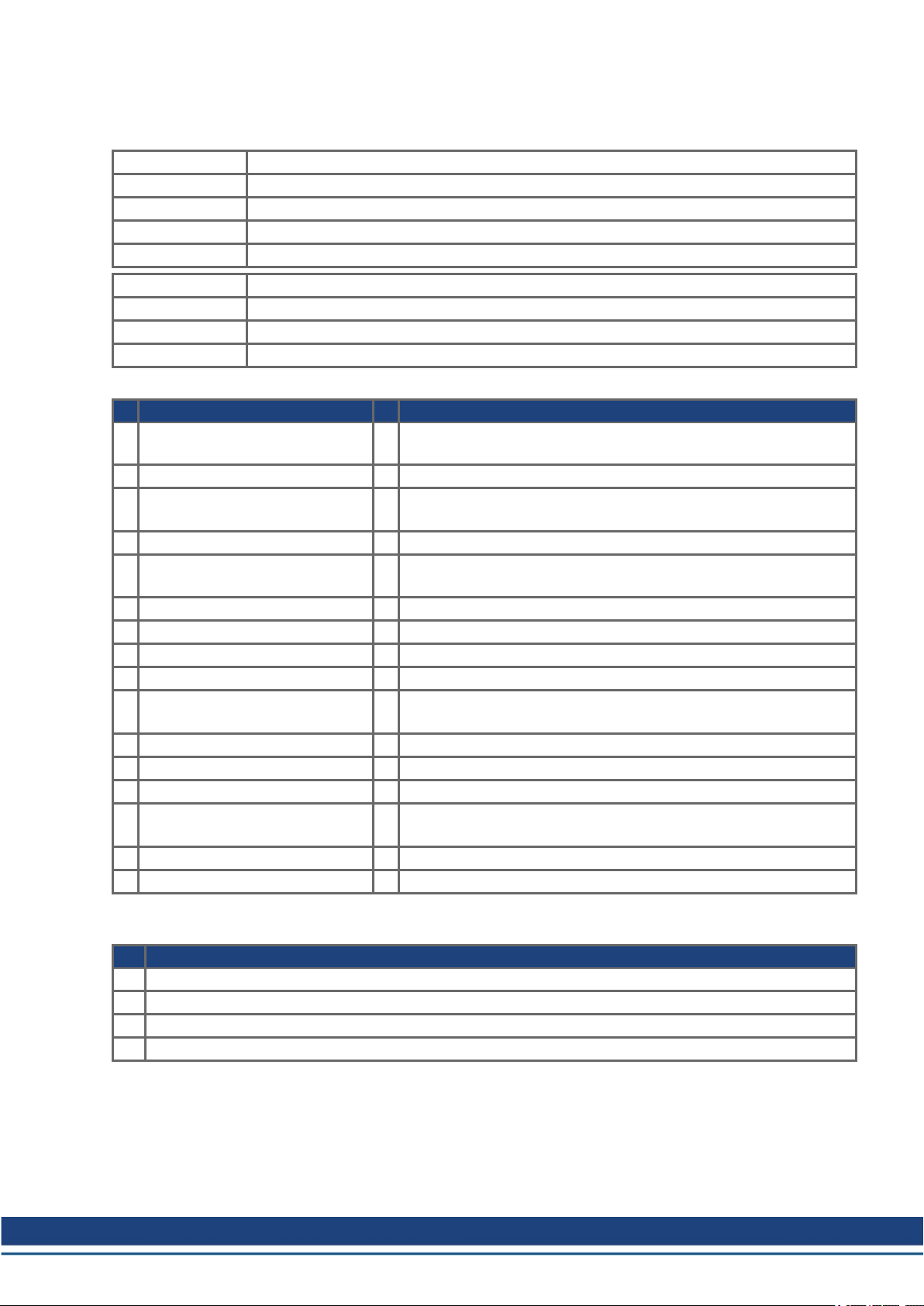

4.7 Supported Cyclical Setpoint and Actual Values

Supported cyclical setpoint values

Name

Target current 0x2071 sub 0 32 bit scaled in mA

Latch Control word 0x20A4 sub 0 UINT16

Clear digital Input Change Bit 0x20B8 16 bit

Analog output value 0x3470 sub 3 16 bit

External feedback position 0x3497 sub 0 32 bit

CANopen control-word 0x6040 sub 0 UINT16 CANopen control word.

Modes of Operation 0x6060 sub 0 8 bit DS402 opmode setpoint

Velocity Window 0x606D sub 0 16 bit

Velocity Window Time 0x606E sub 0 16 bit

Target Torque 0x6071 sub 0 16 bit 0.1% resolution

Maximum Torque 0x6072 sub 0 16 bit

CANopen

object

Data

type

Description

Kollmorgen | kdn.kollmorgen.com | October 2020 51

Page 52

AKD-C/N EtherCAT | 4 EtherCAT Profile

Name

CANopen

object

Data

type

Description

Target position 0x607A sub 0 INT32 Used in profile position mode / cyc-

lic synchronous position mode

Profile position target velocity 0x6081 sub 0 32 bit related to MT.V

Profile position target acc 0x6083 sub 0 32 bit related to MT.ACC

Profile position target dec 0x6084 sub 0 32 bit related to MT.DEC

Velocity feed forward 0x60B1 sub 0 32 bit

Torque feed forward 0x60B2 sub 0 INT16

Touch probe function 0x60B8 16 bit

Position command value 0x60C1 sub 1 INT32 Interpolation data record in IP-

mode

Digital outputs 0x60FE sub 1 UINT32

Velocity command value 0x60FF sub 0 INT32

52 Kollmorgen | kdn.kollmorgen.com | October 2020

Page 53

Supported cyclical actual values

AKD-C/N EtherCAT | 4 EtherCAT Profile

Name

CANopen

object

Data

type

Description

Position actual internal value 0x6063 sub 0 INT32

Velocity actual value 0x606C sub 0 INT32

CANopen status-word 0x6041 sub 0 UINT16 CANopen status word

Second position feedback 0x2050 sub 0 INT32

Digital inputs 0x60FD sub 0 UINT32

Following error actual value 0x60F4 sub 0 INT32

Latch position positive edge 0x20A0 sub 0 INT32

Torque actual value 0x6077 sub 0 INT16

Latch status 0x20A5 sub 0 UINT16

Actual Current 0x2077 sub 0 32 bit scaled in mA

Latch1 negative edge 0x20A1 sub 0 32 bit

Latch2 Positive 0x20A2 sub 0 32 bit

Latch2 Negative 0x20A3 sub 0 32 bit

Latch1 positive/negative edge 0x20A6 32 bit

Latch 2 positive/negative edge 0x20A7 32 bit

Modes of Operation 0x6061 8 bit DS402 opmode status

Position Actual Value 0x6064 sub 0 32 bit WB/ DS402 scale units

Touch probe status 0x60B9 sub 0 16 bit

Touch probe 1 positive edge pos 0x60BA sub 0 32 bit

Touch probe 1 negative edge pos 0x60BB sub 0 32 bit

Touch probe 2 positive edge pos 0x60BC sub 0 32 bit

Touch probe 2 negative edge pos 0x60BD sub 0 32 bit

Additional Pos actual value 0x60E4 sub 0 48 bit

Additional Pos actual value 0x60E4 sub 1 32 bit

Motor I2t 0x3427 sub 3 32 bit

Analog output value 0x3470 sub 2 16 bit

Analog Input value 0x3470 sub 4 16 bit

Manufacturer status register 0x1002 sub 0 32 bit

Kollmorgen | kdn.kollmorgen.com | October 2020 53

Page 54

AKD-C/N EtherCAT | 4 EtherCAT Profile

4.8 Supported Operation Modes

CANopen mode of

operation

Profile velocity DRV.OPMODE 1

Interpolated position DRV.OPMODE 2

Homing mode DRV.OPMODE 2

Profile Position DRV.OPMODE 2

Torque DRV.OPMODE 0

Cyclic Synchronous

Position

AKD mode of operation

DRV.CMDSOURCE 1

DRV.CMDSOURCE 1

DRV.CMDSOURCE 0

DRV.CMDSOURCE 0

DRV.CMDSOURCE 1

DRV.OPMODE 2

DRV.CMDSOURCE 1

Description

0x6060Sub0 Data: 3

In this mode, the EtherCAT master sends

cyclic velocity command values to the

AKD.

0x6060Sub0 Data: 7

In this mode of operation the EtherCAT master sends cyclic position command values

to the AKD. These command values are

interpolated by the AKD according to the

fieldbus sample rate.

0x6060 sub 0 data : 6

In this mode an AKD-internal homing can be

done.

0x6060sub0 Data: 1

Uses motion task 0 to execute a point to

point move

0x6060sub0 Data: 4

Commands torque in % of drive peak torque

0x6060sub0 Data: 8

Master calculates move profile and commands motion with position points

4.9 Adjusting EtherCAT Cycle Time

The cycle time to be used in the drive for the cyclical setpoints and actual values can either

be stored in the FBUS.SAMPLEPERIOD parameter in the amplifier or configured in the startup phase. This happens via SDO mailbox access to objects 60C2 subindex 1 and 2 for the

AKD-N. The setup for the AKD-C is done via Register writing to the appropriate ESC

registers 9A0h / 9A2h.

Subindex 2, known as the interpolation time index, defines the power of ten of the time value

(e.g. -3 means 10-3 or milliseconds) while subindex 1, known as interpolation time units,

gives the number of units (e.g. 4 means 4 units).

You can run a 2 ms cycle using various combinations. For example,

Index = -3, Units = 2 or

Index = -4, Units = 20 etc.

The FBUS.SAMPLEPERIOD parameter is counted in multiples of 62.5us microseconds

within the device. This means, for example that 2 ms equates to FBUS.SAMPLEPERIOD

value of 32.

4.10 Maximum Cycle Times depending on operation mode

The minimum cycle time for the drive is largely dependent on the drive configuration (second

actual position value encoder latch functionality enabled and so on)

Interface Cycle time AKD

Position ≥ 0.25 ms (≥ 250 µs)

Velocity ≥ 0.25 ms (≥ 250 µs)

Torque ≥ 0.25 ms (≥ 250 µs)

54 Kollmorgen | kdn.kollmorgen.com | October 2020

Page 55

AKD-C/N EtherCAT | 4 EtherCAT Profile

4.11 Synchronization

On all drives, the internal PLL is theoretically able to even out an average deviation of up to

4800 ppm in the cycle time provided by the master. The drive checks once per fieldbus cycle

a counter within the drive internal FPGA, which is cleared by a Sync0 (Distributed clock)

event. Depending of the counter value, the drive extends or decreases the 62.5 µs MTS signal within the drive by a maximum of 300 ns.

The theoretical maximum allowed deviation can be calculated by using the following formula:

The synchronization functionality within the drive can be enabled via setting bit 0 of the

FBUS.PARAM02 parameter to high. Therefore FBUS.PARAM02 must be set to the value of

1. Furthermore the distributed clock functionality must be enabled by the EtherCAT master in

order to activate cyclic Sync0 events.

4.11.1 Synchronization behavior with distributed clocks (DC) enabled

When the EtherCAT master enables distributed clocks, a distributed clock (DC) event is created in the AKD once per fieldbus cycle. An assigned 62.5 µs real-time task in the AKD monitors the elapsed time between the DC events and the AKD System time and extends or

reduces the 62.5 µs strobe to the CPU as necessary.

The following fieldbus parameters are used for the synchronization feature:

1. FBUS.SYNCDIST = Expected time delay of the AKD PLL-code to the DC event.

2. FBUS.SYNCACT = Actual time delay of the AKD PLL-code to the DC event.

3. FBUS.PLLTHRESH = Number of consecutive successful synchronized PLL cycles of

the AKD before the Drive is considered as synchronized.

4. FBUS.SYNCWND = Synchronization window in which the AKD is considered to be synchronized. The Drive is considered synchronized as long as the following statement is

true is true for FBUS.PLLTHRESH consecutive cycles:

FBUS.SYNCDIST-FBUS.SYNCWND < FBUS.SYNCACT <

FBUS.SYNCDIST+FBUS.SYNCWND

Example with a 4kHz fieldbus sample rate:

Explanation: The red-marked 62.5[µs] real-time task displays the AKD 62.5 µs real-time task

within one fieldbus cycle which is responsible for calling the AKD PLL-code. The time delay

(1) shows the actual delay to the previous DC event, which is ideally close to the adjusted

FBUS.SYNCDIST parameter. Depending on (1) the AKD slightly extends or reduce the 62.5

[µs] IRQ generation of the high-priority real-time task in order to either increase or decrease