DSC2P 903 ver. F

Digital position controllers

Digital position controllers

DSCxx

HEADQUARTERS

SWITZERLAND

ETEL S.A.

Zone industrielle

CH-2112 Môtiers

Phone : +41 (0)32 862 01 23

Fax : +41 (0)32 862 01 01

E-mail : etel@etel.ch

http://www.etel.ch

Copyright ETEL SA. All rights reserved. Reproduction, adaptation or translation of this document is prohibited without prior written permission.

ETEL SA makes no warranty for the use of its products and assume no responsibility for any errors which may appear in this document.

Operation &

Software Manual

AMERICAS

ETEL Inc.

333 E. State Parkway,

US - Schaumburg

IL 60173-5337

Phone : +1 847 519 3380

Fax : +1 847 490 0151

E-mail : info@etelusa.com

SWITZERLAND

ETEL S.A.

Zone industrielle

CH-2112 Môtiers

Phone : +41 (0)32 862 01 33

Fax : +41 (0)32 862 04 12

E-mail : sales@etelsa.ch

ETEL SA retains the right to make any change to these specifications at any time, without notice.

FRANCE

ETEL S.A.

89 rue Henri Rochefort

FR-91025 Evry cedex

Phone : +33 (0)1 64 97 98 05

Fax : +33 (0)1 64 97 30 56

E-mail : etel@etel.fr

THE NETHERLANDS

ETEL B.V.

Copernicuslaan 34

NL-6716 BM Ede

Phone : +31 (0)318 495 200

Fax : +31 (0)318 495 210

E-mail : etel@etelbv.nl

GERMANY

ETEL GmbH

Schillgasse 14

DE-78661 Dietingen

Phone : +49 (0)741 17453-0

Fax : +49 (0)741 17453-99

E-mail : etel@etelgmbh.de

AUSTRIA (Sales rep)

I+L ELEKTRONIK GmbH

Vibrütteweg 9

AT-6840 Gotzis

Phone : +43 55 23 645 42

Fax : +43 55 23 645 424

E-mail : IUL@uta1002.at

ITALY

ETEL S.A.

Piazza della Repubblica 11

IT-28050 Pombia

Phone : +39 0321 958 965

Fax : +39 0321 957 651

E-mail : etel@etelsa.it

ISRAEL (Sales rep)

MEDITAL COMOTECH Ltd

7 Leshem St. - Ramat Siv

IL-49170 Petach tikva

Phone : +972 3 923 3323

Fax : +972 3 923 1666

E-mail : comotech@medital.co.il

THIS PAGE IS INTENTIONALLY LEFT BLANK

Operation & Software Manual

Direct Drives & Systems 3

Chapter A:

Internal functioning & architecture

1. The regulators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2. Current references generator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3. Set point generator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.1 Introduction to movements trajectories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.1.1 Movements trajectories used in the controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4. Controller timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4.1 STI (Slow Time Interrupt) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4.2 FTI (Fast Time Interrupt) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4.3 CTI (Current Time Interrupt) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5. Communication with the controller . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5.1 Single-axis configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5.1.1 Baud rate configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5.2 Multi-axis configuration with DSMAX or DSTEB . . . . . . . . . . . . . . . . . . . . . . . 24

5.3 Multi-axis configuration with micro-master . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

6. Commands & registers syntax . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

6.1 Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

6.1.1 Sending commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

6.1.2 Accumulator operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

6.1.3 Sequence labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

6.2 Registers groups . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

6.2.1 Basic registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

6.2.2 Advanced registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

6.3 Register value attribution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

6.4 Register value reading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

6.5 Bit fields or numerical values for registers and commands . . . . . . . . . . . . . . 33

6.5.1 Bit fields . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

6.5.2 Examples of use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

ETEL Doc. - Operation & Software Manual # DSC2P 903 / Ver. F / 3/6/05

Operation & Software Manual

4

Direct Drives & Systems

Chapter B: System setup and tuning

7. Initial system installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

7.1 Controller connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

7.1.1 Stand-alone configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

7.1.2 Configuration with a DSMAX or a DSTEB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

7.2 Controller setup principle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

7.3 Install ETEL Tools software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

7.3.1 System requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

7.3.2 Installing ETT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

8. Controller setup with ETEL Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

8.1 Run ETT and set up the communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

8.2 Main Menu window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

8.2.1 Tools menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

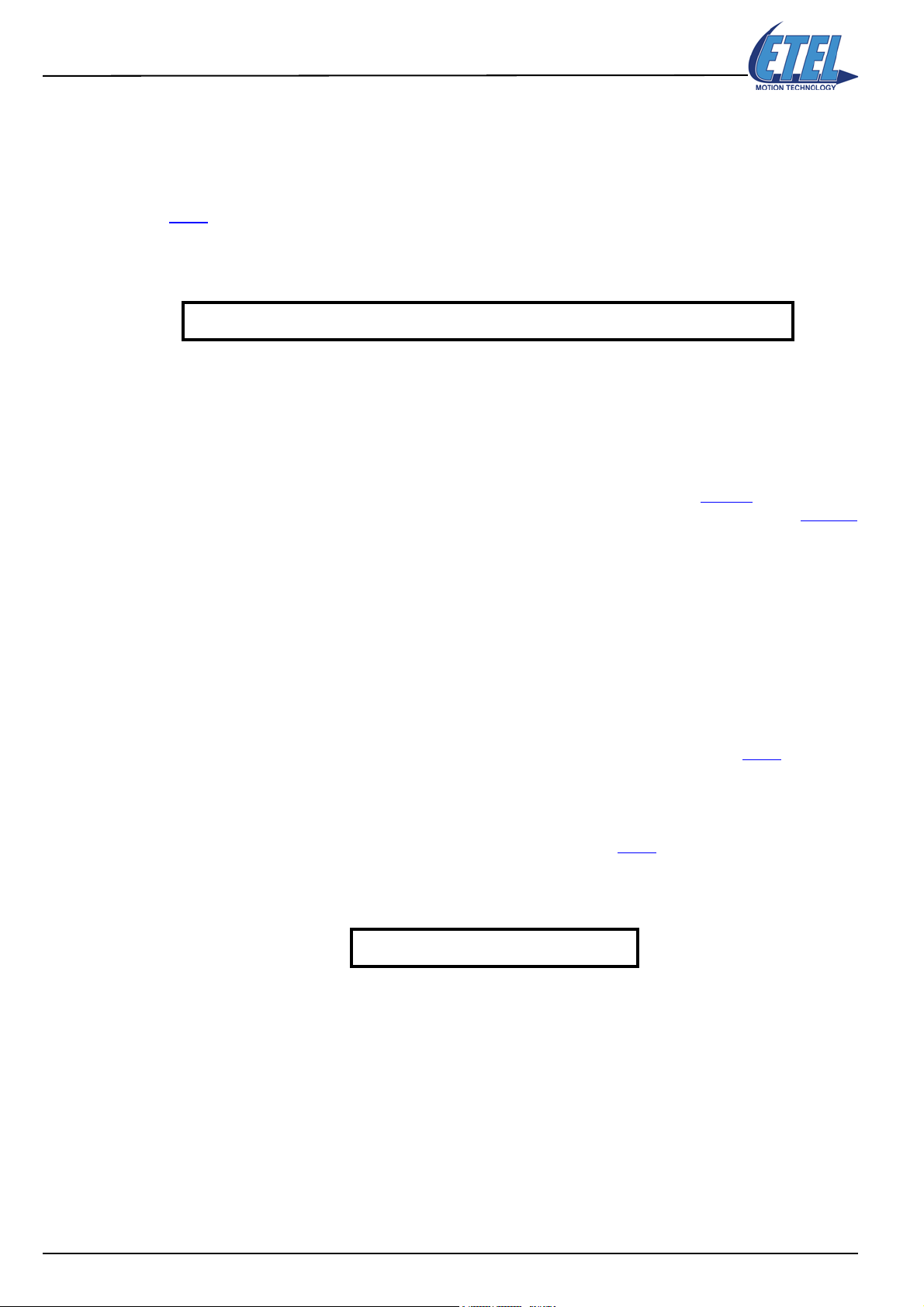

8.3 Drive Setting tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

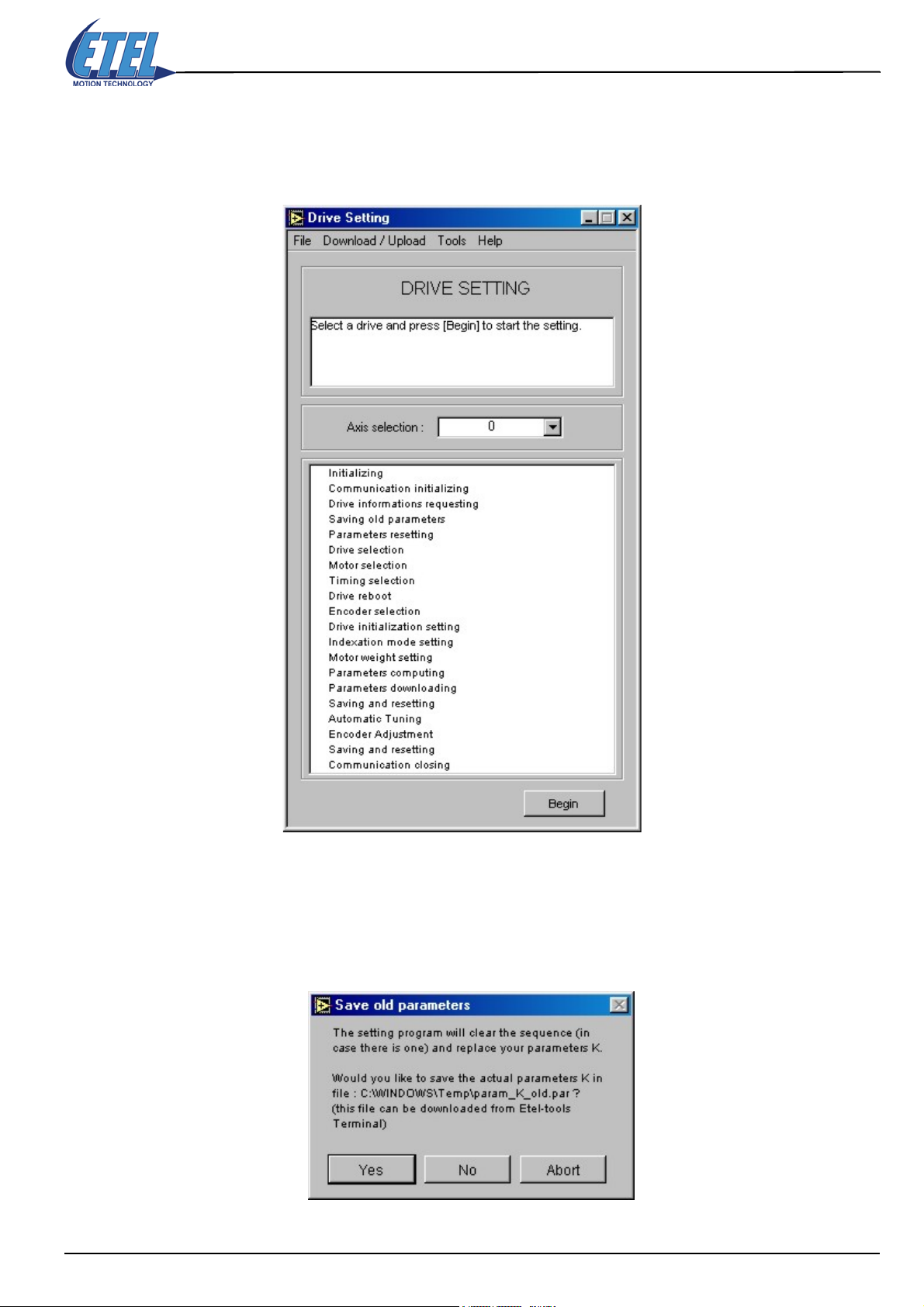

8.3.1 Drive selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

8.3.2 Motor selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

8.3.3 Encoder Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

8.3.4 Initialization mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

8.3.5 Homing mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

8.3.6 Mass or inertia . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

8.3.7 Automatic tuning options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

8.4 Scope tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

8.4.1 The icons bar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

8.4.2 Scope menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

8.4.3 Digital oscilloscope . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

8.4.4 Scope's Trigger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

8.4.5 Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

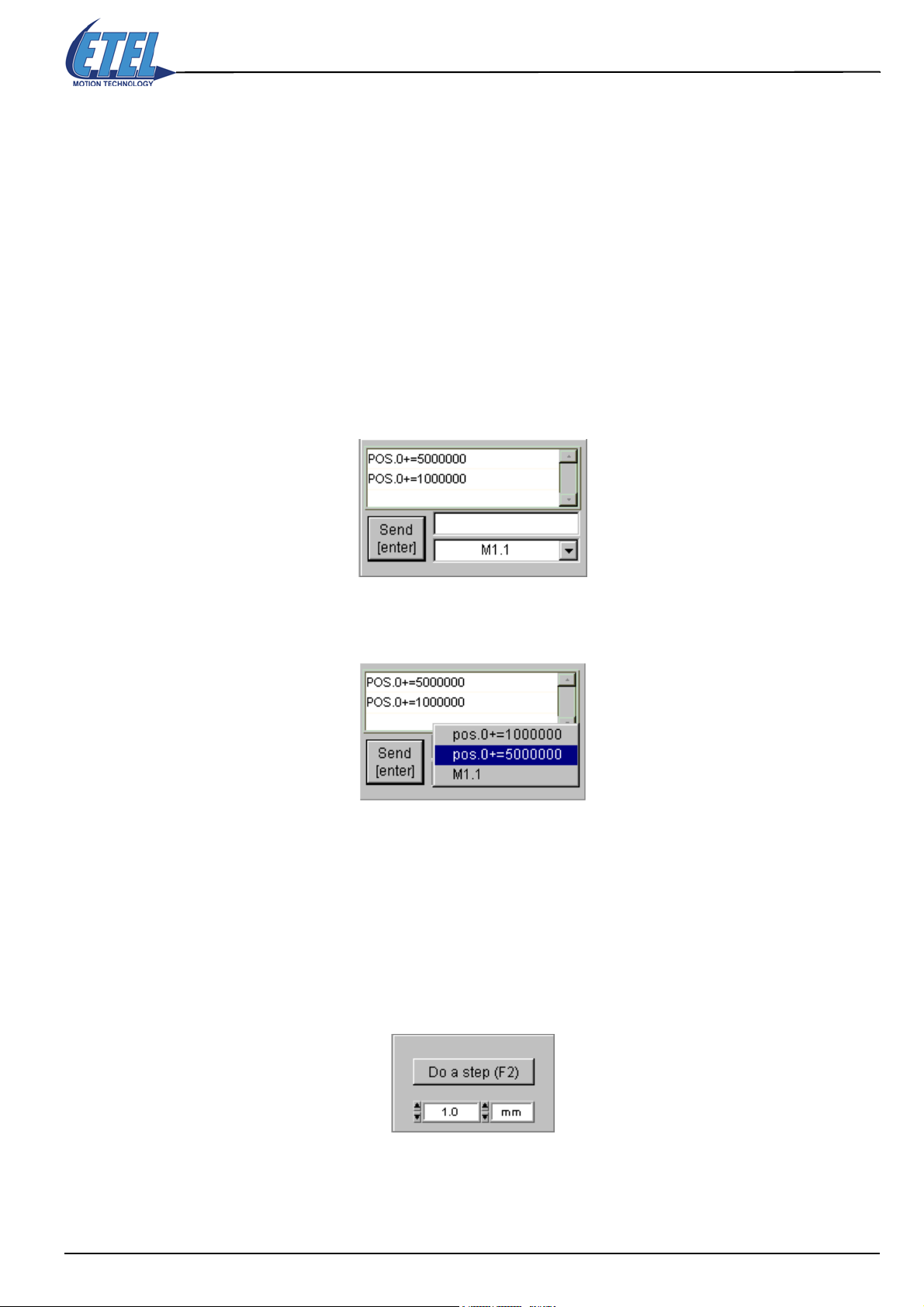

8.4.6 Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

8.4.7 Step movement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

8.4.8 System identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

8.5 Terminal tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

8.5.1 The icons bar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

8.5.2 Read / send registers and commands to the controller . . . . . . . . . . . . . . . . . . . . . . . . . . 64

8.5.3 Download sequence / registers into the controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

8.6 Editor tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

8.6.1 The icons bar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

8.6.2 Download (create, open, modify) sequences / registers . . . . . . . . . . . . . . . . . . . . . . . . . 67

8.6.3 Upload (create, open, modify) sequences / registers . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

ETEL Doc. - Operation & Software Manual # DSC2P 903 / Ver. F / 3/6/05

Operation & Software Manual

Direct Drives & Systems 5

8.7 Unit Converter tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

8.7.1 The icons Bar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

8.7.2 Unit conversion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

9. Simplified regulator's principle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

9.1 General diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

9.2 Parameters description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

9.2.1 Current regulator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

9.2.2 Position regulator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

10. Controller regulators tuning principle . . . . . . . . . . . . . . . . . . . . . . . . 76

ETEL Doc. - Operation & Software Manual # DSC2P 903 / Ver. F / 3/6/05

Operation & Software Manual

6

Direct Drives & Systems

Chapter C: System functions

11. Save the settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

12. Basic functions and settings (necessary to operate the controller) 82

12.1 Axis number selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

12.1.1 Selection with DIP switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

12.1.2 Selection with command AXI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

12.1.3 Serial number and firmware version . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

12.2 Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

12.3 Position encoder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

12.3.1 Analog encoders (K79=0) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

12.3.2 EnDat 2.1 encoders (K79=4) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

12.3.3 TTL encoders (K79=1 and K79=7) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

12.3.4 Stepper in open loop (K79=20, 21, 23 and 24) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

12.3.5 Macro modes (K79=100, 101 and 104) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

12.3.6 Position factors for DLLs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

12.3.7 Encoder monitorings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

12.4 Precaution parameters - IMPORTANT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

12.4.1 Movements limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

12.4.2 Current limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

12.4.3 Safety signals on DIN and DOUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

12.4.4 Motor temperature, TEB time-out and analog encoder error check . . . . . . . . . . . . . . . . 95

12.4.5 Vpower DC bus voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

12.4.6 Fuse check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

12.5 Errors and warnings handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

12.5.1 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

12.5.2 Reset errors: RST and RSD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

12.5.3 Clear errors: CPE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

12.5.4 Errors management with the m-master . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

12.5.5 Dynamic braking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

12.6 Basic reference mode (K61=1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

12.7 Initialization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

12.7.1 Phasing and homing basics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

12.7.2 Phasing processes (K90) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

12.8 Autosetting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

12.8.1 AUT command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

12.8.2 PWR command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

12.9 Homing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

12.9.1 K45 parameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

12.9.2 Homing modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

12.9.3 K40 parameter: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

ETEL Doc. - Operation & Software Manual # DSC2P 903 / Ver. F / 3/6/05

Operation & Software Manual

Direct Drives & Systems 7

12.10Basic movements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

12.10.1 SET command: zero machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

12.10.2 Linear or rotary movement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

12.10.3Movement trajectory parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

12.10.4 Rotary S-Curve movement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .130

12.11Monitorings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

12.11.1 Monitoring registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

12.11.2 LCD display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

12.12Controller software characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

12.13Stepper in open loop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

13. Advanced functions (only for advanced users) . . . . . . . . . . . . . . . . . 137

13.1 Regulators in details - advanced tuning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

13.1.1 Regulators diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

13.1.2 Regulators parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

13.1.3 Monitorings diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

13.2 Advanced reference modes (K61¼1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

13.2.1 External reference modes (K61=0, 3, 4 or 36) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

13.3 Advanced movements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

13.3.1 Movements types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

13.3.2 Look-up table movements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .152

13.3.3 Infinite rotary movements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

13.3.4 Movement with predefined profile . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

13.3.5 Start movements: STA and STI commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

13.3.6 Concatenated movements: MMC command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

13.3.7 CAM command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

13.3.8 STE command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

13.3.9 BRK and STP commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 166

13.3.10 Parameters defining units scales . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 166

13.3.11 Movements equations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

13.4 Digital inputs / outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

13.4.1 Digital inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

13.4.2 Digital outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

13.5 Position capture on digital inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

13.5.1 Description of the position capture process on the digital inputs . . . . . . . . . . . . . . . . . 175

13.6 Analog input / output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 176

13.6.1 Analog input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 176

13.6.2 Analog outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

13.7 In-window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

13.8 RTI: Real-Time Interrupts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

13.8.1 RTI structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

ETEL Doc. - Operation & Software Manual # DSC2P 903 / Ver. F / 3/6/05

Operation & Software Manual

8

13.8.2 RTI elements description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 184

13.8.3 Controller parameters and commands for RTI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 186

13.8.4 RTI process chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

13.8.5 RTI types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 188

13.8.6 RTI programming examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 192

Direct Drives & Systems

13.9 Triggers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

13.9.1 Principle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

13.9.2 Mappings definition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

13.9.3 Triggers definition and structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195

13.9.4 Elements description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195

13.9.5 Masks, actions selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 198

13.9.6 Mappings activation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 199

13.9.7 Programming triggers example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 199

13.10Analog encoder interpolation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 202

13.11Status Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 203

13.11.1 M60 monitoring (SD1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 203

13.11.2 M61 monitoring (SD2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 204

13.11.3 M63 monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 204

13.12Advanced communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 206

13.12.1 Synchronization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 206

13.12.2 Real-time monitoring (RTM) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 207

13.13Encoder scaling and mapping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 210

13.13.1 Encoder scaling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 210

13.13.2 Encoder mapping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 211

13.13.3 Activation of the corrections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 212

13.13.4 Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 212

ETEL Doc. - Operation & Software Manual # DSC2P 903 / Ver. F / 3/6/05

Operation & Software Manual

Direct Drives & Systems 9

Chapter D: Programming

14. Basic programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 214

14.1 Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 214

14.1.1 Wait commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 214

14.1.2 Wait on bits: WBS and WBC commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 216

14.1.3 Wait on values: WPL, WSL, WPG and WSG commands . . . . . . . . . . . . . . . . . . . . . . . . . . 216

14.1.4 Controller busy: WTB command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 217

14.2 Tests and jumps to labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 219

14.2.1 Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 219

14.2.2 Unconditional jump: JMP command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 220

14.2.3 Conditional jump: TST, JEQ, JNE, JLT and JGT commands . . . . . . . . . . . . . . . . . . . . . . 221

14.2.4 Routine commands: CAL, RET and POP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 222

14.3 Accumulator functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 223

14.3.1 Set the accumulator: XAC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 223

14.3.2 Test XAC value: IEQ, INE, ILT, IGT, ILE, IGE, JBS and JBC . . . . . . . . . . . . . . . . . . . . . . . . 224

14.4 Sequences handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 225

14.4.1 Stop a sequence: HLT, HLB, HLO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 225

14.4.2 Group of axes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 225

14.4.3 Clear user variables: CLX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 226

14.4.4 End of sequence: END . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 226

14.5 Mathematical operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 227

14.5.1 Arithmetical operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 227

14.5.2 Logical operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 227

14.6 Float functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 229

14.6.1 Read / write F registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 229

ETEL Doc. - Operation & Software Manual # DSC2P 903 / Ver. F / 3/6/05

Operation & Software Manual

10

Direct Drives & Systems

Chapter E: Appendixes

15. Commands examples & reference list . . . . . . . . . . . . . . . . . . . . . . . . 232

15.1 AXI, SAV example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 232

15.2 BRK example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 233

15.3 CAL, RET, POP example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 234

15.4 CAM example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 235

15.5 CLX example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 236

15.6 DOUT example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 237

15.7 END example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 238

15.8 F registers (float) example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 239

15.9 HLT, HLB, HLO example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 240

15.10JBS, JBC example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 241

15.11JMP example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 242

15.12MMC example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 243

15.13MMD, LTN, LTI example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 244

15.14MMD=3 (calculated mvt.), SET example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 245

15.15PWR, IND, ACC, SPD, POS example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 246

15.16 REI: RTI example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 247

15.17RSD example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 248

15.18Special labels (79, 80) example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 249

15.19SLS example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 250

15.20STA example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 251

15.21STE example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 252

15.22STI example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 253

15.23STP example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 254

15.24TCL, TMK, TNB, TRS triggers example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 255

15.25TST, JGT, JEQ, JNE example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 256

15.26TST, JLT example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 257

15.27WBC, WBS example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 258

15.28WPG, WPL, WSG, WSL example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 259

15.29WTB example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 260

15.30WTM, WTT example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 261

15.31WTP example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 262

15.32WTW example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 263

15.33XAC, IEQ, ILT, IGT example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 264

15.34XAC, IGE, ILE example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 265

ETEL Doc. - Operation & Software Manual # DSC2P 903 / Ver. F / 3/6/05

Operation & Software Manual

Direct Drives & Systems 11

15.35XAC, INE example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 266

15.36Commands reference list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 267

16. Parameters K . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 277

16.1 Parameters K for DSC2P and DSC2V . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 277

16.2 Parameters K for DSCDP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 286

16.3 Parameters K for DSCDL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 295

16.4 Parameters K for DSCDM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 303

17. Monitorings M . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 312

17.1 Monitorings M for DSC2P and DSC2V . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 312

17.2 Monitorings M for DSCDP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 320

17.3 Monitorings M for DSCDL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 327

17.4 Monitorings M for DSCDM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 334

18. Warnings reference lists . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 341

18.1 Warnings for DSC2P and DSC2V . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 341

18.2 Warnings for DSCDP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 341

18.3 Warnings for DSCDL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 341

18.4 Warnings for DSCDM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 342

19. Errors reference lists . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 343

19.1 Errors for DSC2P and DSC2V . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 343

19.2 Errors for DSCDP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 347

19.3 Errors for DSCDL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 350

19.4 Errors for DSCDM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 353

20. Units conversion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 357

20.1 Cinematic quantities units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 357

20.1.1 Linear motors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 358

20.1.2 Rotary motors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 360

20.1.3 Resolution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 361

20.2 Current, force and torque units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 362

20.3 Time quantities units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 363

ETEL Doc. - Operation & Software Manual # DSC2P 903 / Ver. F / 3/6/05

12

Operation & Software Manual

Direct Drives & Systems

THIS PAGE IS INTENTIONALLY LEFT BLANK

ETEL Doc. - Operation & Software Manual # DSC2P 903 / Ver. F / 3/6/05

Operation & Software Manual

Direct Drives & Systems 13

Introduction

This document concerns the following ETEL digital position controllers: the DSC2P, DSC2V, DSCDP, DSCDL

and DSCDM also called 'position controller’ or simply ’controller’.

The purpose of this manual is to give details regarding the system's functioning, installation, tuning, functions

and programming possibilities. For electrical specifications, interfaces and hardware items, please refer to the

corresponding 'Hardware Manual'.

The information given in this manual is valid for:

• the DSC2P and DSC2V with a firmware from version 1.22 (firmware identical for both products)

• the DSCDP with a firmware from version 1.15

• the DSCDL with a firmware from version 1.06

• the DSCDM with a firmware from version 1.02

If a DSMAX motion controller is used, its firmware must be from version 1.20A for the DSMAX1 and

DSMAX2 and from version 1.10A for the DSMAX3.

If a DSTEB motion controller is used, the DLL used must be from version EDI2.13A (usable with

ETT4.11A or above).

All the functions described in this manual have not been implemented in all the controllers. This is why

a table is present at the beginning of all the paragraphs describing a function to indicate in which

product(s) this function is present.

Example:

DSC2P Function present in the DSC2P DSC2P Function not present in the DSC2P

Remark: If a part of a function is not present in a controller, the name of the corresponding controller will

be crossed out in the comment of the function (e.g: DSCDP

Remark: The updates between two successive versions are highlighted with a modification stroke in the

margin of the manual.

).

General operating conditions

The controllers are designed to operate in a non-aggressive and clean environment, with a humidity rate

ranging between 10% and 85%, an altitude < 2000m (6562 ft), and a temperature ranging between +15°C

(59°F) and +30°C (86°F) or +40°C (104°F) depending on the product (refer to the corresponding ’Hardware

Manual’ for more information). They must be connected to an electrical network of overvoltage category 2

(refer to EN 50178 and UL 840 standards for more information). The DSC2P, DSCDP and DSC2V are suitable

for use on a circuit capable of delivering not more than 5000 Arms, symmetrical amperes, 400 volts maximum.

The DSCDM must be connected to a power supply with SELV outputs. The electronics must be in an enclosure

respecting a pollution degree of 2 (refer to UL508C and EN 50178 standards for more information).

The controllers are not designed or intended for use in the on-line control of air traffic, aircraft navigation and

communications as well as critical components in life support systems or in the design, construction, operation

and maintenance of any nuclear facility.

Safety

Please, read all the safety precautions listed in this manual before handling the

controller:

Warning: Signals a danger of electrical shock to the operator.

Can be fatal for a person.

Caution: Signals a danger for the controller. Can be destructive for the material.

A danger for the operator can result from this.

ETEL Doc. - Operation & Software Manual # DSC2P 903 / Ver. F / 3/6/05 Introduction

14

Operation & Software Manual

Direct Drives & Systems

Caution: Indicates electrostatic discharges (ESD), dangerous for the controller.

The components must be handled in an ESD protected environment only.

• Before installing or operating the controller, all the corresponding documentations listed page 15 as well as

the one related to the motor(s) used with it.

• Never use the controller for purposes other than those described in this manual.

• A competent and trained technician must install and operate the controller, in accordance with all specific

regulations of the respective country concerning both safety and EMC aspects.

• Troubleshooting and servicing are permitted only for ETEL's technicians and agreed distributors.

• Operating the controller will make the motor move.

Keep away from all moving parts to avoid

injuries!

• High voltage may be present on the power and motor connectors.

• Before connecting or disconnecting a cable on one of these connectors or touching the controller, turn off

all the power supplies and wait 10 minutes (2min for the DSCDM) to allow the internal DC bus

capacitors to discharge.

• All the connector must be handled in an ESD protected environment, only.

• The safety symbols placed on the controller or written in the manuals must be respected.

• In the controller, the leakage current through the protective conductor to the GND is greater than a.c. 3.5

mA.

If the controller is integrated into a machine, the manufacturer of this machine must establish that it fulfils the

89/336/EEC directive on EMC before operating the controller.

How to use this manual

If you are not an experienced user, read first the Chapter A to catch the basis about the controller's internal

functioning and commands' syntax.

Then, follow step-by-step the Chapter B to successfully realize the first installation and setup of the

controller.

In Chapter C, §11.

details. Chapter C, §13.

specific applications.

Chapter D describes how to program the controller (movements sequences).

The appendixes in Chapter E include the registers and commands references lists (with commands

examples), as well as error and warning messages lists and units conversion formulas.

Remark: ETEL can provide its customers with training courses including theoretical presentation

and §12., all the basic functions necessary to operate the controller are described in

is reserved for experienced users and describes advanced functions only used in

and practice in real conditions, at our facilities in Môtiers (Switzerland).

Working principle

These digital position controllers have been designed for direct drive applications. They can work in

interpolated mode if they are mastered by a DSMAX motion controller (refer to the 'DSMAX User's Manual').

They can drive single-phase, two-phase and three-phase motors (two motors for the DSCDP, DSCDL and

DSCDM). You can obtain brushless torque and linear motors from ETEL as well as moving coils and moving

magnets. They can also drive brushless motors, DC motors, steppers (only if three-phase motors are starconnected). They must be implemented with analog (incremental or absolute (EnDat2.1)) or TTL encoders

available on the market.

Introduction ETEL Doc. - Operation & Software Manual # DSC2P 903 / Ver. F / 3/6/05

Operation & Software Manual

Direct Drives & Systems 15

Record of revisions, document # DSC2P 903 x

Documents revisions

Issue (x) Date Modified

A 30.05.01 Operation & Software DSC2P, PRELIMINARY EDITION for firmware ver. 1.xx

B 06.11.01 Updated version with firmware from version 1.03

C 06.06.02 Updated version with firmware from version 1.10 for DSC2/6-P and with firmware from version 1.0 for DSCDP

D 03.03.03 Updated version with firmware from version 1.14 for DSC2P and with firmware from version 1.04 for DSCDP

Updated Version with firmware from version 1.17 for DSC2P and with firmware from version 1.07 for DSCDP

E 12.11.03

F 03.06.05

- Extended functions for K141 parameter (refer to §12.4.4

- Dynamic braking (refer to §12.5.5

- Extended functions for K32 parameter and new parameter K100 (refer to §12.9

- New homing modes: K40 = 34 to 39 (refer to §12.9.2

- New parameters and monitorings managing the analog I/O of the DSO-HIO optional board (refer to §13.6

- Real-time monitorings (refer to §13.12.2

- New mapping mode: the rotary mapping (refer to §13.13.2

Updated Version with firmware from version 1.22 for DSC2P/DSC2V, 1.15 for DSCDP, 1.06 for DSCDL and 1.02

for DSCDM.

- New interpolation mode: ITP = 2 (refer to §13.2.1.3

- New small movement phasing mode: K90 = 6 (refer to §12.7.2.4

- Stepper mode in open loop (refer to §12.13

- New monitorings: M110 (refer to §13.2.1.3

M146, M147, M148 and M149 (refer to §12.3.2

- Extended possibilities with the AUT command (refer to §12.8.1

- New command: INI (refer to §12.7.1.2

- Extended functions for K32 parameter (refer to §12.9

- Extended description of command WTW (refer to §14.1.1.3

- Digital Hall effect sensor available for DSCDP and DSCDM (refer to §12.7.2.3

- Increase of the triggers number and actions (refer to §13.9

)

)

)

), M239 and M241 (refer to §12.3), M240 (refer to §12.2) and M145,

)

)

)

)

)

)

)

)

)

)

)

)

)

)

Documentation concerning the position controllers:

• Operation & Software Manual (Controller's setup, use & programming) # DSC2P 903 F

• DSC2P Hardware Manual (Specifications & electrical interfaces) # DSC2P 904 x

• DSC2V Hardware Manual (Specifications & electrical interfaces) # DSC2V 904 x

• DSCDP Hardware Manual (Specifications & electrical interfaces) # DSCDP 904 x

• DSCDL Hardware Manual (Specifications & electrical interfaces) # DSCDL 904 x

• DSCDM Hardware Manual (Specifications & electrical interfaces) # DSCDM 904 x

• EBL2 communication Manual (EBL2 principal, messages mapping) # EBL2 908 x

• DSO-PWS User's Manual (Power module installation and specifications) # DSOPWS 902 x

• DSO-RAC2 Hardware Manual (DSO-RAC2 principal) # DSORAC2 904 x

ETEL Doc. - Operation & Software Manual # DSC2P 903 / Ver. F / 3/6/05 Introduction

16

Operation & Software Manual

Direct Drives & Systems

THIS PAGE IS INTENTIONALLY LEFT BLANK

Introduction ETEL Doc. - Operation & Software Manual # DSC2P 903 / Ver. F / 3/6/05

Operation & Software Manual

Direct Drives & Systems 17

Chapter A:

Internal functioning & architecture

ETEL Doc. - Operation & Software Manual # DSC2P 903 / Ver. F / 3/6/05 Chapter A: Internal functioning & architecture

18

1. The regulators

Two Digital Signal Processors (DSP, Sharc from Analog Devices) manage the controller. The first manages

the movements profiles and the second is used for the regulation loops. There are two regulation loops, a

position loop and a current loop, controlled by the second DSP. The position loop calculates the reference

force F

point generator. This force is afterwards sent to the current loop where the current reference generator

calculates the reference currents I

(proportional-integral) regulator which controls the current in the motor phase(s). The diagram below shows the

complete regulation process.

that the motor supplies to follow the position reference calculated in a separated generator, called set

c

User

a

max

v

max

x

final

Set point

generator

Operation & Software Manual

Direct Drives & Systems

for each motor phase. Those references are eventually sent to a PI

cx

x

c

V

c

a

c

State regulator

Position

control

F

c

Current

reference

generator

I

c

PI regulator

Current

control

Motor

I

x

F

Kt

Speed

V

estimator

x: Motor real position

V: Motor speed

F: Force supplied by the motor

I:Current in the motor

Kt : Motor force constant

Movement manager processor

Regulation (current & position) processor

x

x

: Position reference

c

V

: Speed reference

c

F

: Force reference

c

I

: Current reference in the motor

c

a

: Acceleration reference

c

The elements of this regulation general diagram are detailed in §9.1

users).

I

(for beginners) and in §13.1(for advanced

Chapter A: Internal functioning & architecture ETEL Doc. - Operation & Software Manual # DSC2P 903 / Ver. F / 3/6/05

Operation & Software Manual

Direct Drives & Systems 19

2. Current references generator

The motor has to deliver a force F = F

independently of its position with respect to the

magnets poles. All phases must then be fed with

sinusoidal type currents, in phase with the

magnetic field. For a three-phase motor, 3

sinusoidal currents must have a 120

(for a two-phase motor, it has to be a 90

o

phase-shift

o

phaseshift). Three phases motor will be considered, as it

is the most commonly used. The current

reference generator multiplies first the force

reference F

by the motor position on the sinusoid,

c

making out reference currents:

I

= sin (X + 0o) in phase 1, Ic2= sin (X + 120o) in

c1

phase 2 and I

= sin (X + 240o) in phase 3.

c3

The motor currents calculation is as follows:

Three pointers (1), with a 120° electrical phaseshift, point at in a table, according to the motor

position. This table, called commutation look-up

table (2), contains 2048 points (3) forming a

sinusoidal function period. Motor position sineforms are thus immediately read on the numbers of

the table. The force F

the two values giving I

is then multiplied by each of

c

and Ic3.

c1, Ic2

c

(1)

Motor

position

Current references generator

F

c

Sinusoid current shape 1

(2)

Sin. current shape 3

Sinusoid current shape 2

120 °

I

c1

I

c2

I

c3

(3)

Remark: When one of the pointers reaches the end of the table, it goes on from the other end.

Pointing at the right places in the table when powering on the motor is important, because its position with

respect to the magnets is not known at the beginning. The initialization procedure allows the user to know the

initial position.

ETEL Doc. - Operation & Software Manual # DSC2P 903 / Ver. F / 3/6/05 Chapter A: Internal functioning & architecture

Operation & Software Manual

20

Direct Drives & Systems

3. Set point generator

The set point generator calculates the motor position, speed and acceleration references. These references

are introduced in the position regulator. This calculation is made according to the type of requested movement,

the final position to reach, maximum authorized speed and acceleration. The set point generator carries out

one of the most important functions of the controller: the movement calculation.

3.1 Introduction to movements trajectories

Note: From the movements described below, the controller uses only the step movement (for

tuning) and the S-Curve movement (for motors movements in applications).

The users interested in the movements equations (order 0,1,2 and 3) can refer to Chapter C

(§13.3.11

A movement trajectory is a function which represents the position of a mobile in one direction versus time.

The first derivative of this function gives the speed trajectory of the movement (speed versus time). The

second derivative determines the acceleration trajectory of the movement (acceleration versus time). The

third derivative is called the jerk trajectory of the movement (jerk versus time).

).

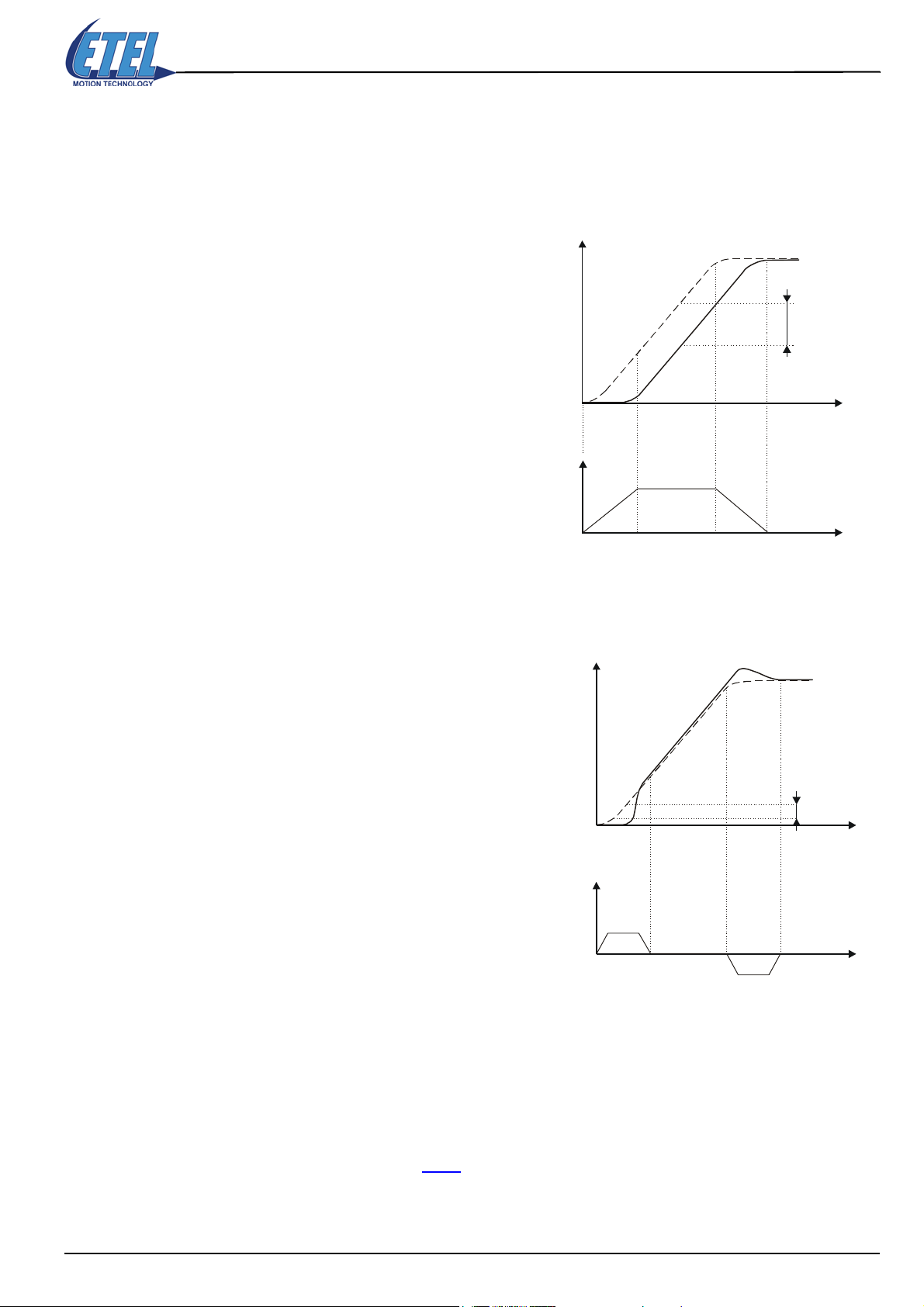

The step movement is a very abrupt movement in which the motor position changes instantaneously. The

rectangular movement whose speed trajectory is a rectangle, is a specific case of trapezoidal movement. The

trapezoidal movement is a movement whose speed trajectory is a trapezium and the S-Curve movement is

a movement which is a step ahead from the trapezoidal movement (trapezoidal acceleration), it is the smoother

movement, but for an identical maximum speed, the movement takes more time.

Step movement

(order 0)

Position Position Position Position

X

final

Speed Speed Speed Speed

Acceleration Acceleration Acceleration Acceleration

Rectangular movement

(order 1)

X

final

t ttt

V

max

t ttt

Trapezoidal movement

(order 2)

X

final

V

max

a

max

S-Curve movement

X

final

V

max

a

max

(order 3)

t ttt

Jerk Jerk Jerk Jerk

J

max

t ttt

Chapter A: Internal functioning & architecture ETEL Doc. - Operation & Software Manual # DSC2P 903 / Ver. F / 3/6/05

Operation & Software Manual

Direct Drives & Systems 21

3.1.1 Movements trajectories used in the controller

There are 8 types of movements trajectories available in the controller

Four of them are linear movements:

•Step movement

• S-Curve movement

• Look-up table movement (refer to §4.

• Calculated movements with predefined profiles

And four of them are rotary movements:

• Rotary S-Curve movement

• Infinite rotary movement

• Rotary look-up table movement (refer to §4.

• Rotary calculated movements with predefined profiles

)

)

The Step movement is used by ETEL Tools for the controller & system tuning only (refer to §10.

information).

The S-Curve and Rotary S-Curve movements are used in most applications (refer to §12.10

information).

The Look-up table, infinite rotary, rotary look-up table and calculated movements are used in some

specific applications, by advanced users only (refer to §13.3

3.1.1.1 Look-up table movement

The look-up table movements are movements whose trajectories are freely set by the user. It is possible to

save in the controller up to 8 different trajectories.

The look-up table movement's trajectory is kept in a table of 2000 points memorized in a controller, so its

name.

Position

. for more information).

pt 0

pt 1

pt 2

pt 3

for more

. for more

.......................

pt 1994

pt 1995

pt 1996

pt 1997

pt 1998

pt 2

0

ETEL Doc. - Operation & Software Manual # DSC2P 903 / Ver. F / 3/6/05 Chapter A: Internal functioning & architecture

pt 4

..........................

pt 6

pt 1996

pt 1999

Point

pt 1999

22

Operation & Software Manual

Direct Drives & Systems

For specific applications, the user himself may

create the movement trajectory he wishes to

use. It can be a complex movement, with back

and forth movements, where the controller is

used as an electronic cam. Software tools are

available to help to create complex movements.

When a look-up table movement is required,

only select the table with the requested

movement and the total time of the movement

t

movement

with LTN and LTI commands

respectively. Then the POS command selects

the trajectory final point position x

and starts

final

the movement. If a long movement is requested

during a very short lapse of time, speed and

acceleration may attain very high values, that

can even exceed the capacity of the system.

Position

X

final

X

initial

Example of complex movement

t

movement

t

3.1.1.2 Look-up table movement

Each sti (refer to §4.

), the controller takes a point

of the look-up table. The point depends on the

value of the execution time (LTI) of the look-up

table. If this value should fall between two points

of the table, it will be linearly interpolated between

the two adjacent points of the table (1).

Then the points read by the controller in the table

are interpolated a second time (2) every fti (refer

to §4.

). The trajectory is thus made of segments

of a sti (refer to §4.

). Refer to §13.3.2 for more

information about the LKT.

Position

Position

Theoretical

trajectory

166,7 µs0 µs

Example with a DSC2P

(2)

Points of

the LKT

333,3 µs

(1)

by the controller

500 µs

Trajectory

executed

time

666,7 µs

166,7 µs0 µs

Chapter A: Internal functioning & architecture ETEL Doc. - Operation & Software Manual # DSC2P 903 / Ver. F / 3/6/05

333,3 µs

Example with a DSC2P

666,7 µs500 µs

41µs (fti)

time

Operation & Software Manual

4. Controller timing

This explanation is for your global understanding of the controller. It is not a critical point to understand for the

controller operation.

The controller works on interrupts. Only the interrupts with an impact on the controller timing are explained

here:

4.1 STI (Slow Time Interrupt)

The STI is used for:

• Execution of commands coming from several sources: controller internal sequences, TEB communication,

optional boards (DSO-CAN, e.g.)

• Trajectory calculation (Set point generator)

• RTI (Real Time Interrupts) and TRI (Triggers) management

Default value:

Direct Drives & Systems 23

DSC2P / DSC2V DSCDP / DSCDL / DSCDM

Slow Time Interrupt 1/6kHz = 166.67µs 1/2kHz = 500µs

To obtain the actual STI value in seconds, divide M245 by M242: STI [s] = M245 / M242

4.2 FTI (Fast Time Interrupt)

The FTI is used for:

• Linear interpolation between the trajectory points calculated by the STI

• Position loop regulation and position encoder interpolation.

Calculation of force reference (Fc) delivered to the current loop regulator.

• EBL2 communication, transmission/reception

Default value:

DSC2P / DSC2V DSCDP / DSCDL / DSCDM

Fast Time Interrupt 1/24kHz = 41.67µs 1/18kHz = 55.56µs

To obtain the actual FTI value in seconds, divide M244 by M242: FTI [s] = M244 / M242

4.3 CTI (Current Time Interrupt)

The CTI is used for:

• Current loop regulation

Default value:

DSC2P / DSC2V DSCDP / DSCDM DSCDL

Current Time Interrupt 1/24kHz = 41.67µs 1/18kHz = 55.56µs 1/72kHz = 13.89µs

To obtain the actual CTI value in seconds, divide M243 by M242: CTI [s] = M243 / M242

ETEL Doc. - Operation & Software Manual # DSC2P 903 / Ver. F / 3/6/05 Chapter A: Internal functioning & architecture

Operation & Software Manual

24

Direct Drives & Systems

5. Communication with the controller

The communication works with a PC. Three configurations are possible: either a single-axis configuration, or

a multi-axis one with DSMAX or DSTEB, or a multi-axis one with micro-master.

5.1 Single-axis configuration

In this configuration, the PC and the controller are linked through the ETEL-Bus-Lite2 (EBL2) protocol (serial

communication) whose default communication speed is 115'200 bps.

This protocol is open. Refer to the 'EBL2 Communication Manual' for more information.

5.1.1 Baud rate configuration

Available on DSC2P DSC2V DSCDP DSCDL DSCDM

The baud rate of the serial communication (EBL2) can be modified with parameter K195.

K Function Val ue Comment

Enables the selection of the ETEL-Bus-Lite2 rate. It is taken into account

only at the first switch on. If the user wants to change it, the value must

K195

be set in parameter K195, saved into the controller with SAV.<axis>=2

and then the controller must be switched off and on.

EBL2

Position

controller

slave

0 ETEL-Bus-Lite2 at 115200 Bps

9600 ETEL-Bus-Lite2 at 9600 Bps

19200 ETEL-Bus-Lite2 at 19200 Bps

38400 ETEL-Bus-Lite2 at 38400 Bps

57600 ETEL-Bus-Lite2 at 57600 Bps

115200 ETEL-Bus-Lite2 at 115200 Bps

Remark: On the DSCDM, parameter K195 must be saved with the same value on both axes.

5.2 Multi-axis configuration with DSMAX or DSTEB

In this configuration, the controllers are linked in daisy-chain. The master is a DSMAX or a DSTEB motion

controller, with whom the PC communicates via the PC ISA or PCI connector. The axes are called slaves. All

axes are linked together by the Turbo-ETEL-Bus also called TEB (ETEL proprietary protocol). One of the roles

of the master is to dispatch the orders he receives from the PC or (sent by itself) to the slaves. Each axis has

a personal number, and if several axes are chained, every number must be different from the others (from 0 to

30); the master will always have the number 31. It is then possible to link up to 31 axes.

Chapter A: Internal functioning & architecture ETEL Doc. - Operation & Software Manual # DSC2P 903 / Ver. F / 3/6/05

Example:

Operation & Software Manual

Direct Drives & Systems 25

ISA/PCI

port

ISA/PCI

port

DSMAX

or

DSTEB

in the PC

master

DSMAX

or

DSTEB

in the PC

master

TEB

TEB

DSC2P

axis 0

slave

DSCDP

Axis 0Axis

1

slave

TEB

Turbo-ETEL-Bus

TEB

Turbo-ETEL-Bus

Remark: All the position controllers (slave axes) can be connected together. The only rule to respect is to

have 31 slaves maximum.

5.3 Multi-axis configuration with micro-master

In this configuration, the controllers are also linked in daisy-chain. The master is a DSC2P or DSC2V called

micro-master (and written µ-master) with whom the PC communicates via the EBL2. The µ-master can also

have a sequence which send commands to other controllers. It always has the axis number 0. The other axes

are called slaves. All axes are linked together by the Turbo-ETEL-Bus also called TEB (ETEL proprietary

protocol). One of the roles of the master is to dispatch the orders he receives from the PC or (sent by itself) to

the slaves. Each axis has a personal number, and if several axes are chained, every number must be different

from the others (from 0 to 30). It is then possible to link up to 31 axes.

DSC2P

axis 1

slave

DSCDP

Axis Axis

2 3

slave

TEB

TEB

DSC2P

up to

31 axes

slave

DSCDP

up to

Axis Axis

28 29

slave

The µ-master is a DSC2P or a DSC2V.

The slaves can be any controller

EBL2

DSC2P

or DSC2V

axis 0

µmaster

TEB

Controller

axis 1

slave

Turbo-ETEL-Bus

TEB

Controller

axis 2

slave

TEB

Controller

up to

30 axes

slave

The functioning mode is chosen with the MDE command which is an alias of parameter K170 (only available

on the DSC2P and DSC2V)

K Alias Value Comment

0 Select slave mode (default mode)

K170 MDE

ETEL Doc. - Operation & Software Manual # DSC2P 903 / Ver. F / 3/6/05 Chapter A: Internal functioning & architecture

1

Select

µ-master mode

26

Operation & Software Manual

Direct Drives & Systems

This parameter is taken into account when the controller is switched on. Then, its value must be modified and

saved with the SAV command and the controller reset before using this parameter.

Remark: To check if the axis number 0 is in µ-master mode, all you need is to link the TEB IN with the TEB

OUT and the led besides 'TEB OK' must be lighted. You can also check the state of the bit# 6 of

the M60 monitoring (SD1). If the bit is equal to 0, the controller is in the slave mode and if it is equal

to 1, the controller is in the µ-master mode.

In the µ-master mode, the axis 0 can execute normal commands (record 20H), emergency commands (record

18H) and monitorings (record 12H) on all the axes present on the TEB. When the ETEL Tools is connected on

the µ-master, all the slaves present on the TEB are visible and can be questioned. The µ-master can execute

a sequence and receive normal commands, emergency commands or monitorings via the EBL2 at the same

time.

In the configuration with the µ-master you do not have a DSMAX or DSTEB board in the PC, then you do not

have access to the interpolation mode.

In the µ-master, monitoring M81 represents the mask of all the other axes present.

M Name Comment

M81 Mask of the axes Mask of all the axes present and given by the u-master only (axis 0)

Remark: The µ-master mode cannot be used with a field buses optional board.

Chapter A: Internal functioning & architecture ETEL Doc. - Operation & Software Manual # DSC2P 903 / Ver. F / 3/6/05

Operation & Software Manual

Direct Drives & Systems 27

6. Commands & registers syntax

6.1 Commands

6.1.1 Sending commands

Examples:

WTM.1 ;Command without parameter, sent to the axis 1.

AUT.2=1 ;Command with one parameter, sent to the axis 2.

TST.1=X1.1,10 ;Command with two parameters, sent to the axis 1.

Syntax:

All the commands which can be sent to the controller are given under the following format:

<cmd_name>.<axis> [=<p1>] [,<p2>]

Fields put in 'square brackets' (like: [=<p1>]) are optional. All commands do not use them.

<cmd_name> Command name. All controller's commands names have three letters.

.<axis> Axis or group of axis number which have to execute the command.

Possible values:

• Integer from 0 to 30 according to the number of axis if the command refers to

one single axis.

• Symbol ! if the command refers to all linked axes.

• Some selected axes numbers between commas (refer to §14.4.2

• Symbol % and the axes mask total number, to select some axes (refer to

§14.4.2

[=<p1>][,<p2>] The command can have zero, one or two parameters. If no value is defined, it is

automatically the value 0 by default which is selected for a command which needs

one or two parameters. (Note: the = link sign is needed only if at least one [<px>]

field is present).

Possible values:

•Integer

• Value contained in any register, at any depth, [px] syntax is similar to a command

syntax:

Remark: An alias like POS, SPD, MMD... is a more user-friendly term representing a parameter K. Their

syntax is identical to the one of the corresponding register. Refer to §16.

alias.

).

<register>[:<depth>].<axis>

to know the list of the

).

Some commands calculate parameter values. For example AUT calculates K80, K56 and K53

value. Others use the value contained in the parameters when they are executed. For example

INI has a different action according to the value contained in parameter K90. In the commands

description which follows, the list of the calculated parameters and those of the read

parameters are given from case to case.

In this manual, only the axis 1 will be mentioned at, to make it simple; for commands explanations

all commands have compulsory axis number.

Exception: The STE command (ex: STE.1+=X4.1) uses + or - operators, with the following syntax:

<cmd_name>.<axis>[<operator>][=<p1>][,<p2>]

Remark: Refer to §8.5

ETEL Doc. - Operation & Software Manual # DSC2P 903 / Ver. F / 3/6/05 Chapter A: Internal functioning & architecture

to know how to send a command.

28

6.1.2 Accumulator operations

Example:

XAC.0=150/X23.0 ;In the accumulator, divide 150 by the value contained in the X23 variable.

Operation & Software Manual

Direct Drives & Systems

Refer to §14.3

Syntax:

Operations with the accumulator are given under the following format:

for more information about XAC command (functions with 2 operators).

XAC.<axis> = <p1> <operator> <p2>

.<axis> Axis or group of axis number which have to execute the command.

Possible values:

• Integer from 0 to 30 according to the number of axis if the command refers to

one single axis.

• Symbol! if the command refers to all linked axis.

• Some selected axes numbers between commas (refer to §14.4.2

•Symbol % and the axes mask total number to select some axes (refer to §14.4.2)

<p1> and <p2> Accumulator parameters. If no value is defined, the value 0 by default is

automatically selected.

Possible values:

•Integer

• Value contained in any register, at any depth, [px] syntax is similar to a command

syntax:

<register>[:<depth>].<axis>

).

<operator> Mathematical operator. Possible values:

6.1.3 Sequence labels

When programming a sequence in the controller, labels are used (refer to §14.2).

Example: :11.2

Syntax:

.<label_#> Label distinctive number, defining a part of the controller sequence

.<axis> Axis number that contains the sequence.

• Arithmetical and logical operators (+, -, &,...). Refer to §14.3

information.

: <label_#>.<axis>

Possible values:

• Integer from 0 to 511. Labels :79 and :80 are specific.

Possible values:

for more

• Integer from 0 to 30 depending on the axis used.

•Symbol % if the command refers to the axis (controller) where the sequence is

stored

Chapter A: Internal functioning & architecture ETEL Doc. - Operation & Software Manual # DSC2P 903 / Ver. F / 3/6/05

6.2 Registers groups

The registers are accessible to the user, they store all the controller’s internal values. Each register has an

identification number preceded by a letter corresponding to its group. To have the motor working correctly, it is

necessary to set the values of the registers belonging to the K group, called parameters. There are 6 main

types of registers, 3 are basic (always used) and 3 are advanced (for specific applications only):

6.2.1 Basic registers

K, for parameters Also called setting parameters. They define the motor, encoder, regulator gains and

M, for monitorings Also called monitoring variables. They are exclusively used to monitor the

X, for variables Also called user variables. They are variables that the user may freely use for

Operation & Software Manual

Direct Drives & Systems 29

the protections (maximum current, maximum position error, over-temperature, etc).

Each of them may be modified, by ETEL engineers and trained personal only.

controller’s internal values such as motor speed, acceleration, motor current, etc.

Note: They can only be read, and no value can be assigned.

programming. Each user variable function may be defined in a program, according

to the user's needs. Values can be stored in variables and read at any time.

Examples: Parameter K1 describes the proportional gain value of the position loop.

6.2.2 Advanced registers

R, for RTIs Also called real time interrupts (for advanced users only), they allow the execution

E, for triggers Also called triggers events (for advanced users only), they are used if the user's

F, for float Also called floating-point variables (float-32 registers), used by the controllers

L, for LKT Also called look-up table movement (for advanced users only), they allow the

T, for trace It allows the acquisition of the registers X, K, M and L of the controller according to

X13 variable describes the 14

M11 monitoring indicates the motor real speed.

of an immediate function. The sequence execution may jump to a defined label,

under some conditions. Refer to §13.8

sytem has to react specifically when the motor reaches some defined positions.

Refer to §13.9

mathematical functions (all other registers in the controller are integer). Refer to

§14.6

for more information.

execution of a movement with a user-defined trajectory. Refer to §3.1.1.1

§13.3.2

the time, used by the ’Scope’ of ETEL Tools. Refer to ’EBL2 Communication

Manual’ for more information.

for more information.

for more information.

th

user variable.

for more information.

and

S, for sequence It allows the user to write/read a user’s programmed sequence. A ’download/upload’

menu is available from each tool of ETEL Tools to use the sequence without using

the S registers (transparent for the customer). Refer to §8.5.3

ETEL Doc. - Operation & Software Manual # DSC2P 903 / Ver. F / 3/6/05 Chapter A: Internal functioning & architecture

for more information.

Operation & Software Manual

30

6.3 Register value attribution

Examples of registers definition:

K210:2.10=10000 ;Integer value attributed to parameter K210, sent to axis 10.

K211:3.2=X21.2 ;User variable X21 attributed to parameter K211, both from axis 2.

The syntax and operations described below are also valid for XAC value attribution (accumulator).

Syntax:

The syntax giving a value to a register is as follows:

<register> [:<depth>].<axis> [<operator>] = <p1>

Fields put in 'square brackets' (like: [<operator>]) are optional. They are not always used.

<register> Defines the register used; is made up of the register's type and number:

Type possible values:

Direct Drives & Systems

• K, X, R, E, S, T, L, F

Number possible values:

• Integer from 0 to 510 if the register type is K or X

Integer from 0 to 7 if the register type is R

Integer from 0 to 191 if the register type is E

Integer from 0 to 8190 if the register type is S

Integer from 0 to 999 if the register type is T

Integer from 0 to 1999 if the register type is L

Integer from 0 to 255 if the register type is F

•Y (indirect parameterization, refer to the 'EBL2 Communication Manual' for

more information)

[:<depth>] K parameters may contain up to 4 different values simultaneously. Each value is

stored at a different depth numbered 0, 1, 2,and 3. If no depth is defined, depth 0 is

automatically programmed by default.

For R and E, [:<depth>] is another RTI priority (R) or another trigger line (E).

Possible values:

• Integer from 0 to 3 if the register type is K or E

• Integer from 0 to 11 if the register type is R

• Integer from 0 to 1 if the register type is T

• Integer from 0 to 7 if the register type is L

•X and F = 0

.<axis> Axis or group of axis number whose registers need to be modified.

Possible values:

• Integer from 0 to 30 according to the number of axis if the command refers to

one single axis.

•Symbol ! if the command refers to all linked axes.

• Some selected axes numbers between commas (refer to §14.4.2

•Symbol % and the axes mask total number, to select some axes (refer to

§14.4.2

• Y (indirect parameterization, refer to the 'EBL2 Communication Manual' for

more information)

Chapter A: Internal functioning & architecture ETEL Doc. - Operation & Software Manual # DSC2P 903 / Ver. F / 3/6/05

).

).

Operation & Software Manual

Direct Drives & Systems 31

[<operator>] Mathematical sign for arithmetic and logical operations, only with K and X registers.

Possible values:

• + addition.

• - subtraction.

• * multiplication.

• / division.

• ~ logical not (not for F registers).

• & logical and (not for F registers).

• l logical or (not for F registers).

• &~ “logical and” and “logical not” (not for F registers).

• l~ “logical or” and “logical not” (not for F registers).

• >> Arithmetical shift to the right (not for F registers).