Etco IP-Mini Instruction Manual

www.etco.com

Old Values, New Ideas

Instruction Manual

IP-Mini Rear Feed Applicator

Thank you for purchasing

an ETCO product!

At ETCO we believe that old values and customer service

should still be the rule.

The mergers of today seem to have created companies that

operate as if their needs supersede those of the customers. At

ETCO no one will put you into voicemail unless you request it.

At ETCO you will not be put on hold for more then 15 seconds

without us checking back with you. At ETCO we won’t take an

order unless we can guarantee on time delivery and exact conformance to your requirements. At ETCO all managers are

accessible and will call you back.

The founders of ETCO had very basic values based on integrity.

Today we still live by those values. Please feel free to call us if

you have a question;

I promise you a human will answer.

David Dunn

Chairman

ETCO Incorporated, Tel: 401-467-2400 Fax: 401-467-9230 Web: www.etco.com

Instruction

Manual

ETCO IP-Mini

Rear Feed

Applicator

INSTALL AND SET-UP INSTRUCTIONS

CRIMP INSPECTION AND MEASUREMENT

MAINTENANCE SCHEDULES

TROUBLESHOOTING GUIDES

ASSEMBLY DRAWING and BILL OF MATERIALS

See pocket on the inside back cover of this manual.

TO CONTACT ETCO TECHNICAL SUPPORT.

TEL: 401-467-2400

FAX: 401-467-9230

EMAIL: applicator@etco.com

WEB: www.etco.com

Hours 8 am – 5 pm, Monday – Friday, Eastern US Time Zone

ETCO IP Mini Rear Feed Rev. 2

2

4

3

1

4

5

1

ALWAYS REMEMBER TO REPLACE

BOTH PRESS SAFETY GUARD AND

APPLICATOR SAFETY GUARD

BEFORE OPERATING PRESS.

(NOTE: THIS ALSO ACTIVATES

SAFETY INTERLOCK SYSTEM.)

ETCO Incorporated, Tel: 401-467-2400 Fax: 401-467-9230 Web: www.etco.com

11

SECTION 1

INSTALL AND SET-UP INSTRUCTIONS

ETCO IP MINI REAR FEED APPLICATOR – page 1

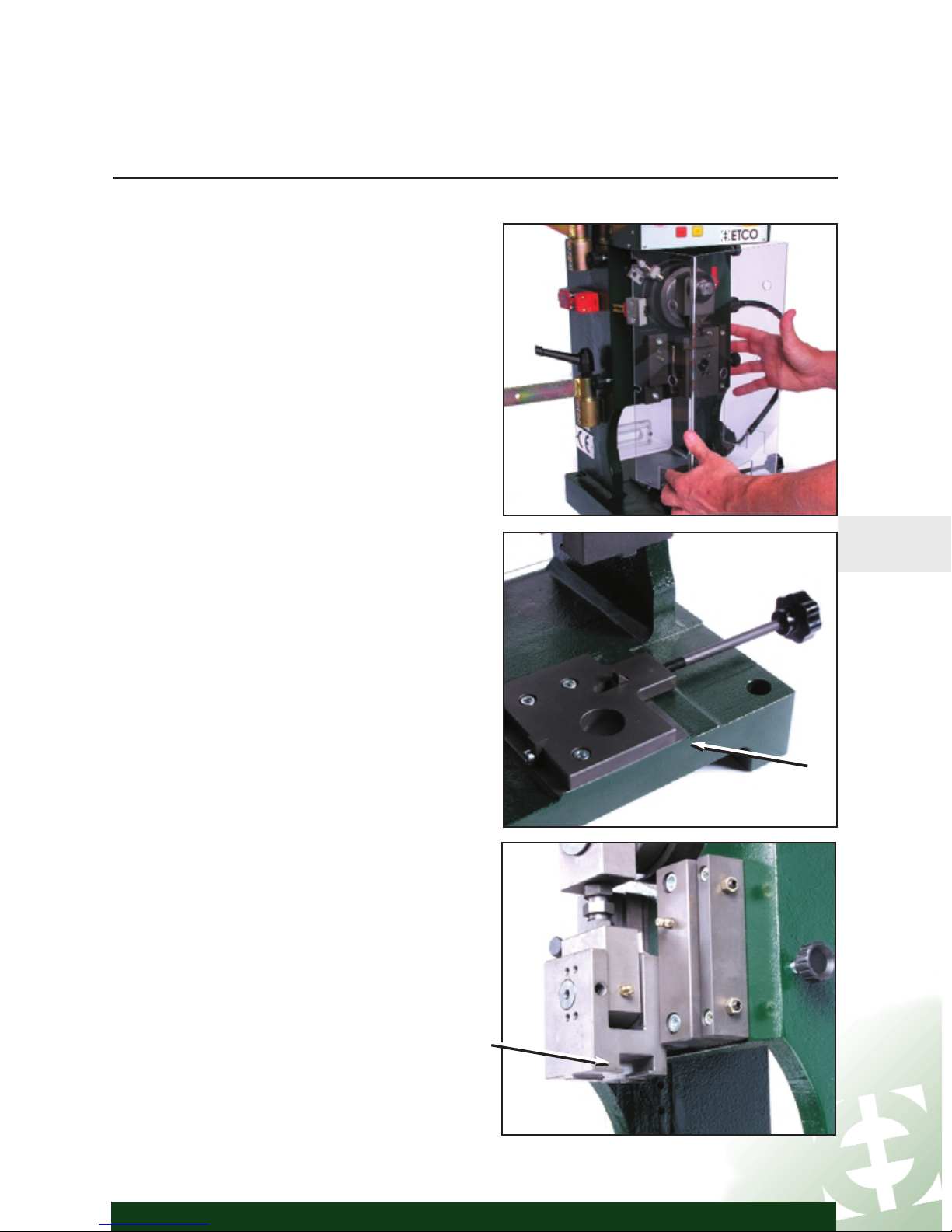

BEFORE INSTALLING APPLICATOR

1 Remove press Safety Guard.

Clean base plate on press.

2 Be sure press has Mini Die

Adapter Base Plate connected.

3 Be sure press has T-Slot

Connector installed.

Note: Contact

ETCO if Base Plate

or

T- Slot Connector are not

installed on your press.

ETCO Incorporated, Tel: 401-467-2400 Fax: 401-467-9230 Web: www.etco.com

SECTION 1

UNPACK, INSTALL AND SET-UP INSTRUCTIONS

ETCO IP MINI REAR FEED APPLICATOR – page 2

1

BEFORE INSTALLING APPLICATOR

CONTINUED

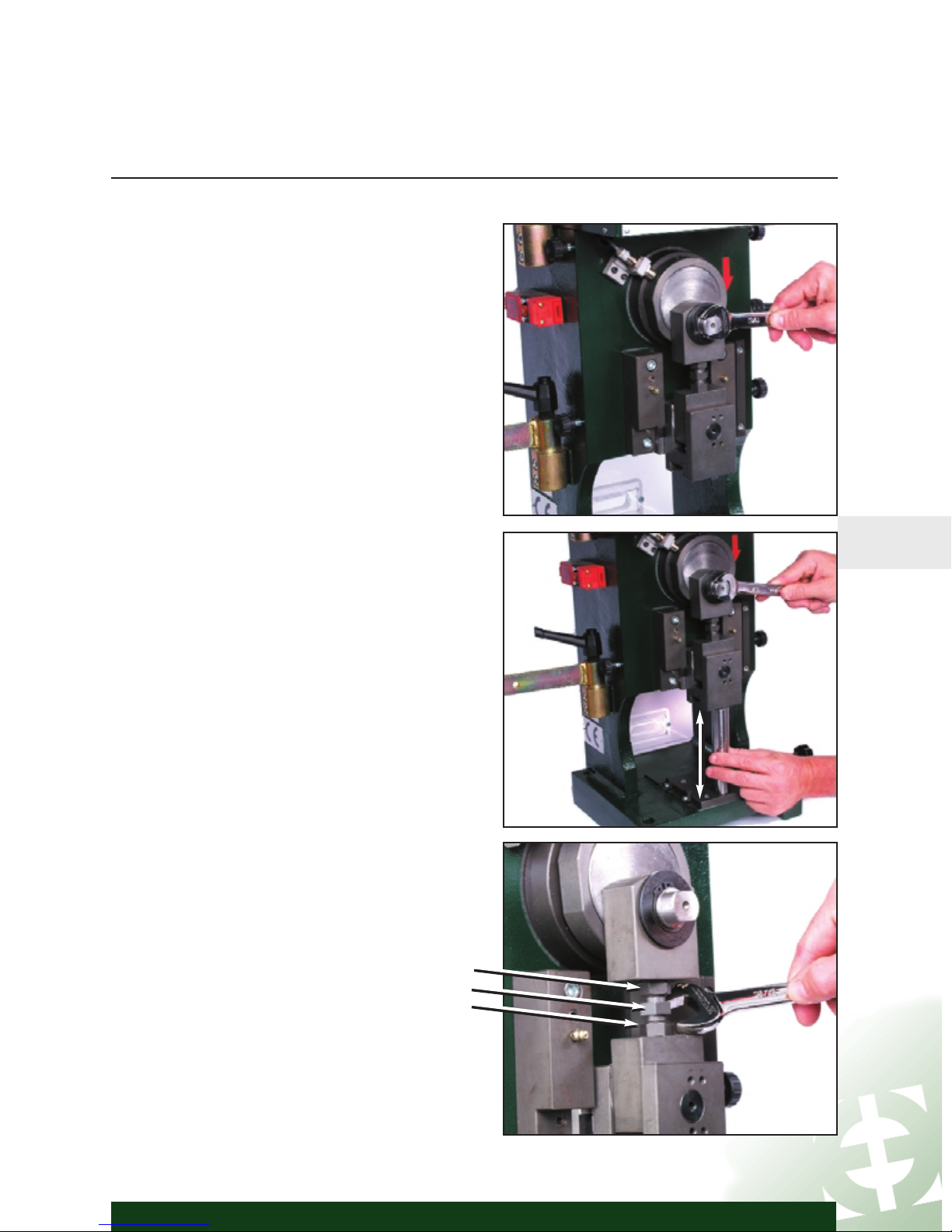

4 Using wrench on crankshaft

end, rotate crankshaft clockwise

to bottom dead center.

5 Measure shut height from

surface of Mini Die Adapter

Base Plate to pads on T-Slot

Connector. Shut height should

measure

5.346”.

6 If necessary, adjust shut height

by loosening the TWO locking

nuts (a, c) and rotating the ram

adjustment bolt (b) until proper

dimension is achieved.

Retighten the TWO locking

nuts.

Note: Turning ram adjustment bolt

(b) to the right will lower, and

turning it to the left will raise,

the shut height.

a

b

c

ETCO Incorporated, Tel: 401-467-2400 Fax: 401-467-9230 Web: www.etco.com

SECTION 1

INSTALL AND SET-UP INSTRUCTIONS

ETCO IP MINI REAR FEED APPLICATOR – page 3

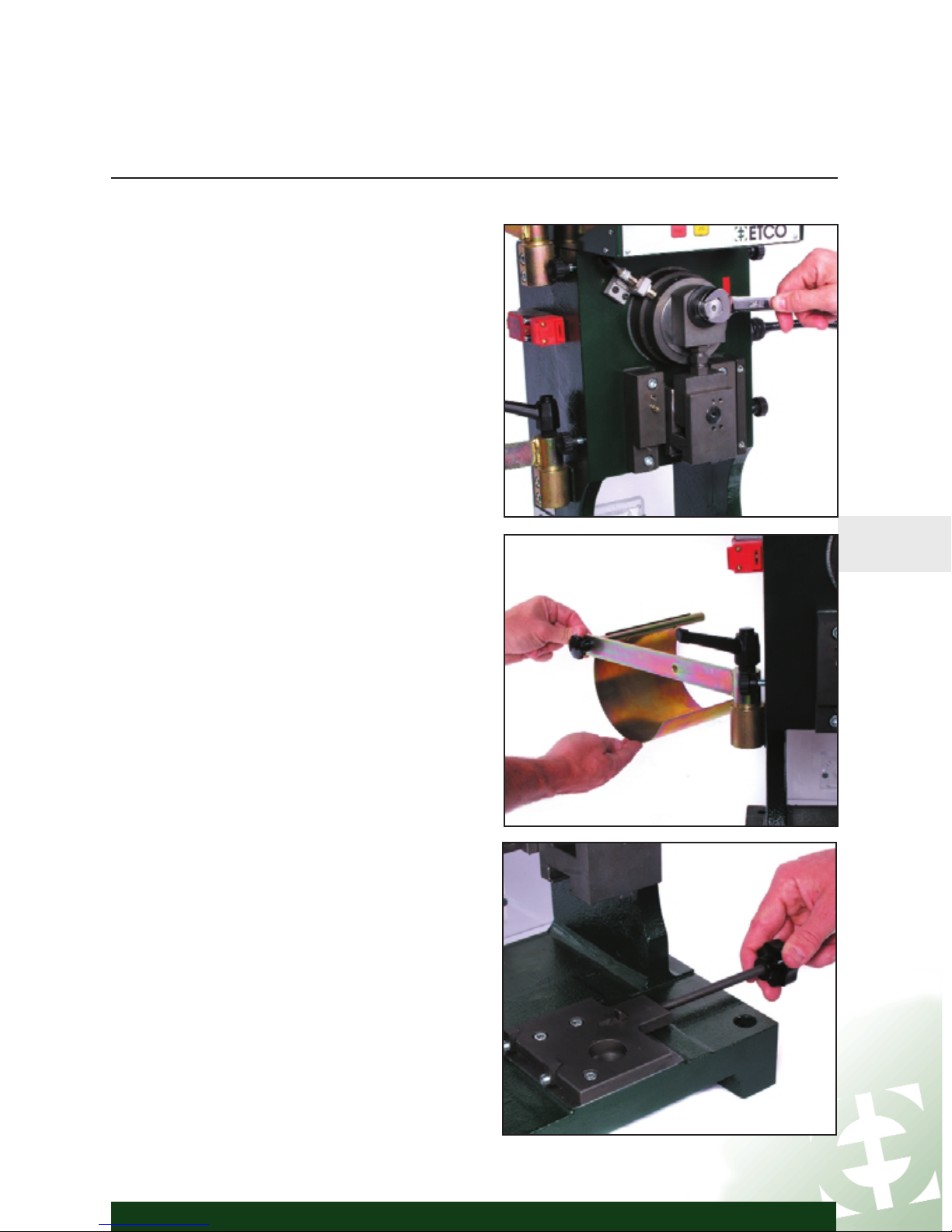

INSTALL APPLICATOR

7 Using wrench on crankshaft

end, rotate crankshaft clockwise

to top dead center.

8 Adjust position of Reel Arm

and Stock Chute.

9 Loosen Clamp Knob by

rotating counterclockwise.

1

ETCO Incorporated, Tel: 401-467-2400 Fax: 401-467-9230 Web: www.etco.com

11

INSTALL APPLICATOR CONTINUED

10 Remove applicator Safety Guard.

11 Slide Mounting Post on

Applicator into T-Slot from

left side of press.

12 With Mounting Post fully engaged

into T-Slot, pull Applicator body

down until Applicator Base Plate

is flat against Mini Die Adapter

Base Plate

SECTION 1

INSTALL AND SET-UP INSTRUCTIONS

ETCO IP MINI REAR FEED APPLICATOR – page 4

ETCO Incorporated, Tel: 401-467-2400 Fax: 401-467-9230 Web: www.etco.com

1

INSTALL APPLICATOR CONTINUED

13 Slide Applicator left until

Applicator Base Plate is

fully engaged in clamps.

14 Tighten right clamp by rotating

knob clockwise.

15 Using wrench on crankshaft,

cycle over by hand, one complete

revolution.

SECTION 1

INSTALL AND SET-UP INSTRUCTIONS

ETCO IP MINI REAR FEED APPLICATOR – page 5

Loading...

Loading...