Page 1

Wall Mount, CE

Installation Manual

Revision D

Copyright © Electronic Theatre Controls, Inc.

All Rights reserved.

Product information and specifications subject to change.

Part Number:

7021M2130-GB

Released: 2014-01

Rev D

Page 2

Table of Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Using this Manual. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Product Variants. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Help from ETC Technical Services . . . . . . . . . . . . . . . . . . . . . . . . . .4

Prepare for Installation . . . . . . . . . . . . . . . . . . . . . . 5

Installation Environment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Electrical Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Cable Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Verify the Contents of the Shipping Carton . . . . . . . . . . . . . . . . .6

Additional Parts and Specialty Tools Required . . . . . . . . . . . . . .6

Cable Routing and Conduit Access . . . . . . . . . . . . . . . . . . . . . . .7

Installation Procedure . . . . . . . . . . . . . . . . . . . . . . 8

Install Mounting Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Mount the SmartPack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Rough-In Conduit and Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Connect Wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Power Supply Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Three-Phase Supply Connections . . . . . . . . . . . . . . . . . . . .10

Single-Phase Supply Connections (Europe) . . . . . . . . . . . .10

Load Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Earth/Ground Connections . . . . . . . . . . . . . . . . . . . . . . . . . .11

Neutral Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Connect Control Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Emergency/SmartLink . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Connect Emergency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Connect SmartLink . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Connect ESD Ground . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

DMX 512. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Connect DMX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Data Termination . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Guidelines for Data Termination: . . . . . . . . . . . . . . . . . . . . .15

Final Installation and Power Up . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Verify Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Final Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Test Loads via Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Select the operating language: . . . . . . . . . . . . . . . . . . . . . . .16

Set a level for a dimmer: . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Verify DMX512 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Troubleshooting SmartLink . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

LinkPower Supply Kit . . . . . . . . . . . . . . . . . . . . . . 19

Installation Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

ETC®, SmartPack™, SmartSwitch™ and SmartLink™ are either registered trademarks or trademarks of

Electronic Theatre Controls, Inc. in the United States and other countries. LonWorks® and LON® are registered trademarks of

the Echelon

®

Corporation. All other trademarks, both marked and not marked, are the property of their respective owners.

Page 3

Introduction

Congratulations on your purchase of the ETC® SmartPack™ Wall Mount dimming pack.

SmartPack continues ETC's tradition of providing the highest quality products for the

entertainment and architectural lighting market.

Using this Manual

Use this manual during the installation of the SmartPack Wall Mount unit. This manual

includes instructions for installing SmartPack units to operate together on a SmartLink™

control network. For user configuration and system operation instructions please refer to

the Wall Mount SmartPack User Manual.

The following symbols are used in this manual to alert you to danger or important

information.

Note:

CAUTION:

WARNING:

WARNING:

Please email comments about this manual to: TechComm@etcconnect.com

Provides important information about your installation.

A Caution statement indicates situations where there may be undefined or

unwanted consequences of an action, potential for data loss or an equipment

problem.

A Warning statement indicates situations where damage may occur, people

may be harmed, or there are serious or dangerous consequences of an

action.

RISK OF ELECTRIC SHOCK! This warning statement indicates situations

where there is a risk of electric shock.

Introduction 1

Page 4

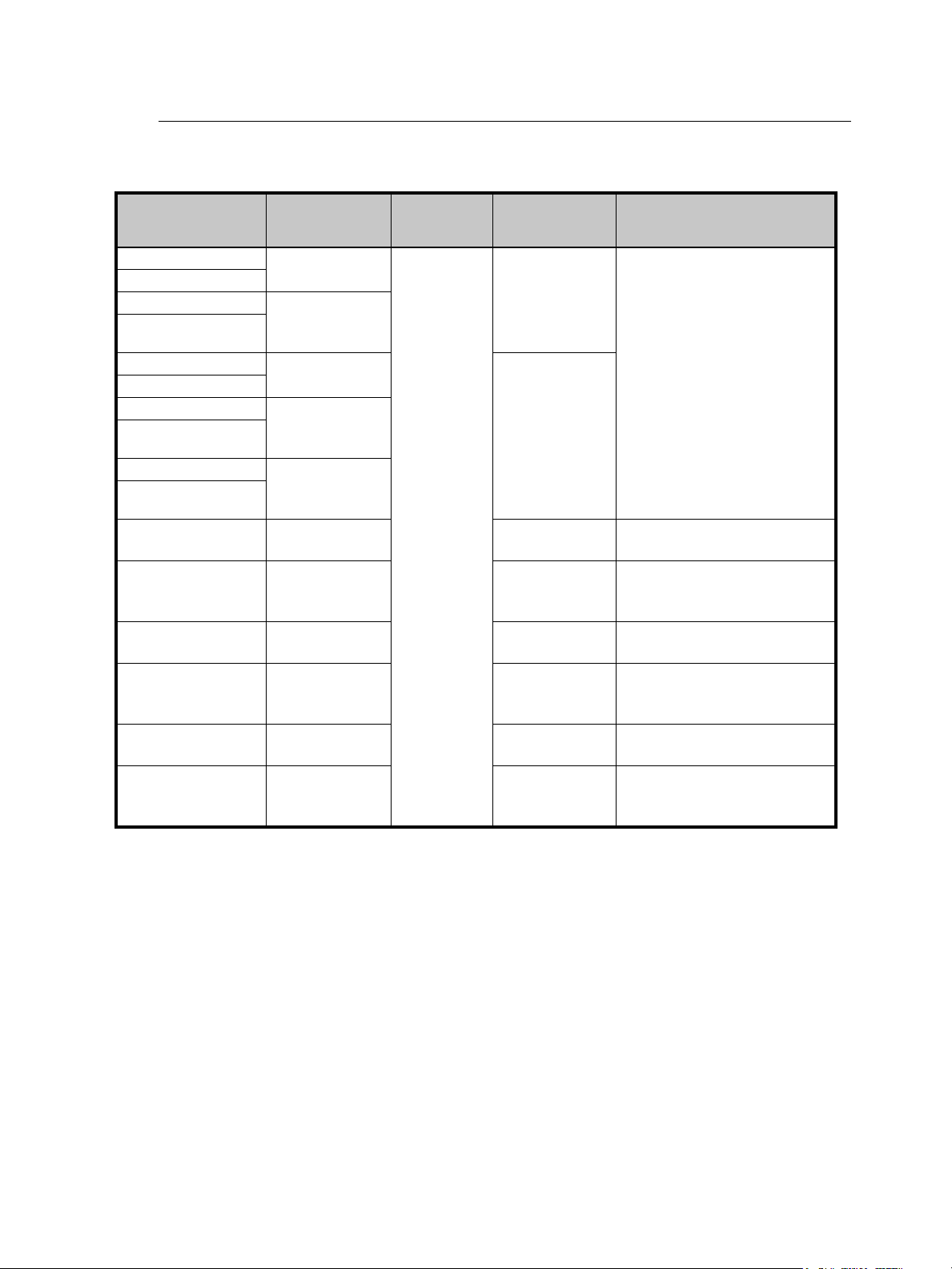

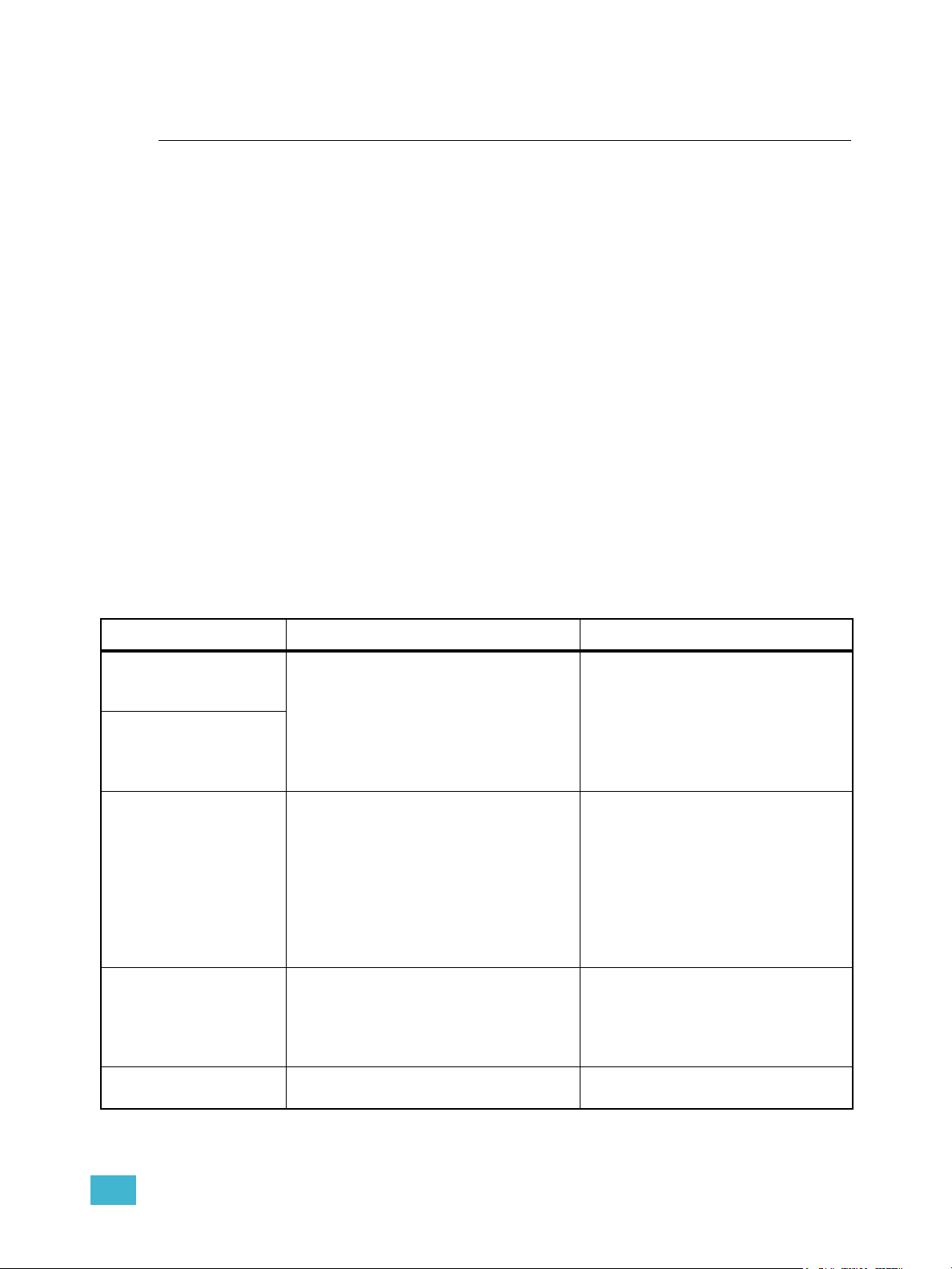

Product Variants

The instructions in this manual apply to the CE SmartPack Wall Mount dimming packs

Part Number

7021A1103

7021A1103-LPS

7021A1105 12 channel /

7021A1105-LPS

7021A1106

7021A1106-LPS

7021A1107 6 channel /

7021A1107-LPS

7021A1110 3 channel /

7021A1110-LPS

7021A1111

7021A1112

7021A1113

7021A1114

7021A1115

7021A1116

Channel Count/

Breaker Type

12 channel /

10A breakers

10A (ND) 2 pole

breakers

6 channel /

15A breakers

15A (ND) 2 pole

breakers

25A (ND) 2 pole

breakers

12 channel /

10A breakers

12 channel /

10A (ND)

breakers

12 channel /

10A breakers

12 channel /

10A (ND)

breakers

12 channel /

10A breakers

12 channel /

10A (ND)

breakers

Operating

Voltage

230 VAC

47-63Hz

single or

three phase

Installed Weight

(loaded)

22Kg / 48lbs

A SmartPack with a “-LPS”

part number suffix includes a

LinkPower supply which is

factory installed for SmartLink

station power.

21Kg / 46lbs

28Kg / 61lbs ThruPower Switch

28Kg / 61lbs ThruPower Switch

28Kg / 61lbs ThruPower Relay

28Kg / 61lbs ThruPower Relay

24Kg / 53lbs Relay (only)

24Kg / 53lbs Relay (only)

Notes

2 SmartPack Wall Mount Installation Manual

Page 5

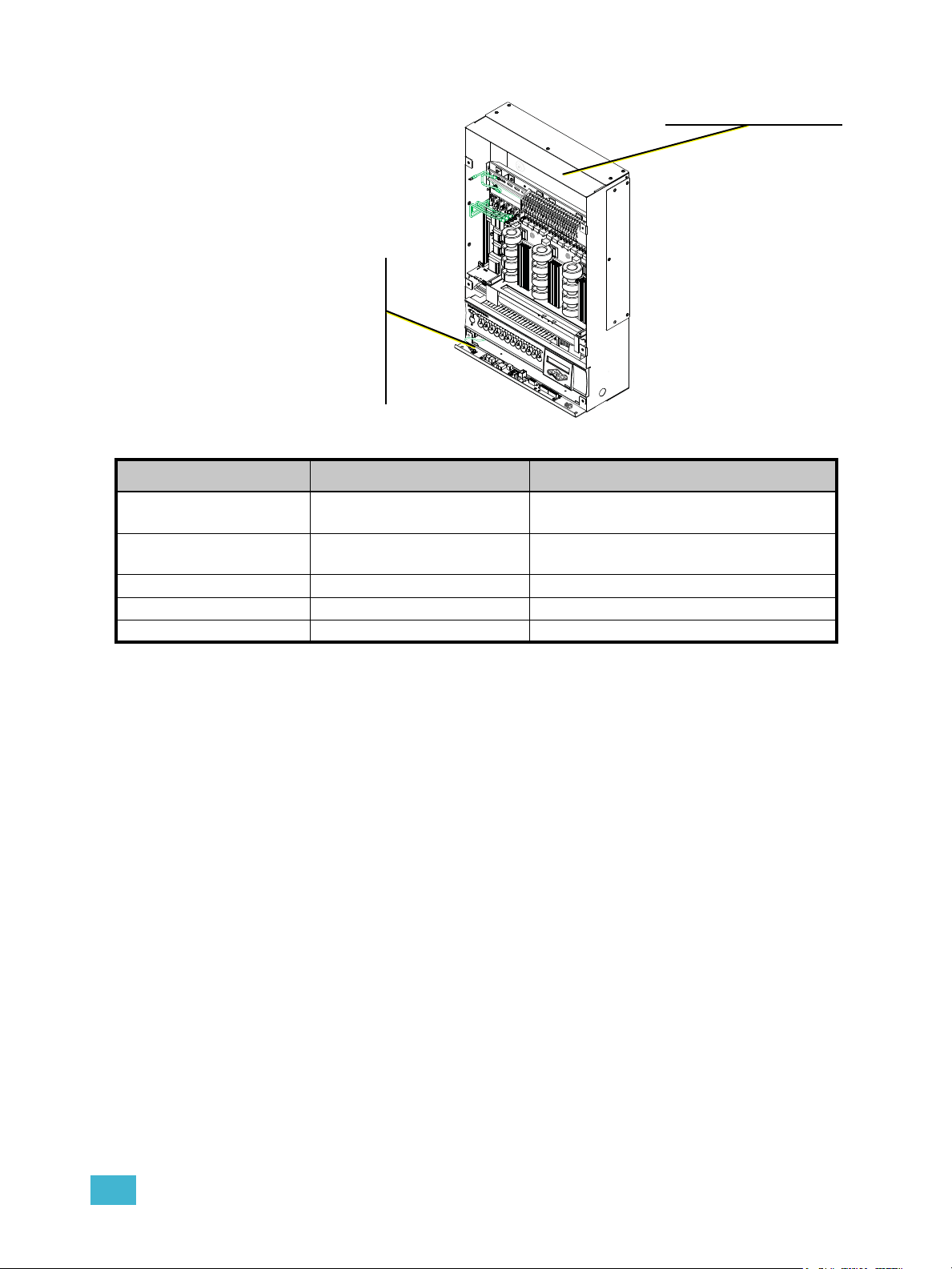

Option kits available for the SmartPack Wall Mount unit include:

I/O compartment

DMX512 In / DMX512 Thru

Emergency contact input

SmartLink™ enabled

Optional LinkPower supply

for wall station support.

3, 6, or 12 dimmer channels available

Variable speed cooling fan

Capable of dimming multiple load types

CE Compliant

32 built-in presets and a sequencer for

stand-alone operation.

Cover removed for clarity

Part Number Description Notes

7021K1010 LinkPower supply kit

7021K1000 19” Rack mount kit

7021K1004 RCD kit

7021K1008 RCD/40A Mains Breaker kit

7021K1006 RCD/63A Mains Breaker kit

optional - supplies power for up to four

SmartLink wall stations

requires 15 rack units of space (18 rack

units for ThruPower and relay models)

Introduction 3

Page 6

Help from ETC Technical Services

If you are having difficulties, your most convenient resources are the references given in

this manual. To search more widely, try the ETC web site at www.etcconnect.com

of these resources is sufficient, contact ETC Technical Services directly at one of the offices

identified below. Emergency service is available from all ETC offices outside of normal

business hours.

When calling for help, please have the following information handy:

• Model of SmartPack Wall Mount

• Other components in the system (if any) including other Smartlink host products,

LinkPower supply, quantity and type of SmartLink wall stations, etc.

• DMX control source used for system-wide control.

. If none

Americas

ETC International

Technical Services Department

3031 Pleasant View Road

Middleton, WI 53562

800-775-4382 (USA, toll-free)

+1-608 831-4116

service@etcconnect.com

Asia

ETC Asia, Ltd.

Technical Services Department

Room 1801, 18/F,

Tower I, Phase I, Enterprise Square

9 Sheung Yuet Road

Kowloon Bay, Kowloon, Hong Kong

+852 2799 1220

service@etcasia.com

United Kingdom

Electronic Theatre Controls, Ltd.

Technical Services Department

Unit 26-28 Victoria Industrial Estate

Victoria Road,

London W3 6UU, UK

+44 (0)20 8896 1000

service@etceurope.com

Germany

Electronic Theatre Controls, GmbH

Technical Services Department

Ohmstrasse 3

93607, Holzkirchen, Germany

+49 (80 24) 47 00-0

techserv-hoki@etcconnect.com

4 SmartPack Wall Mount Installation Manual

Page 7

Prepare for Installation

Installation Environment

• Dry room (30-95% humidity, non-condensing)

• 0-35°C (32-95°F) ambient temperature

• Dust free

• Wall-mounting location must support 23kg (50lbs)

• Minimum 25.4cm (10”) clearance in front of unit for airflow vents

Electrical Requirements

•50-60Hz

• 230/400 VAC, 3Ø+N+PE 40A per phase

• 230 VAC, 1Ø+N+PE 120A per phase

• For use on TN-C, TN-S, TN-CS and TT supplies

• Not suitable for use on Delta IT supplies

• This equipment must be connected to a suitable safety earth/ground.

Cable Specification

Purpose Cable Type/Description Note

AC Input - Three phase

230/400 VAC 3Ø+N+PE,

50-60Hz, 40A per phase

AC Input - Single phase

230 VAC, 1Ø+N+PE,

50-60Hz, 120A per

phase

DMX512

SmartLink™

Emergency

2

25mm

cable

Use only cables of size and rating

complying with local wiring regulations.

Recommended - Belden 9729

Alternatives

Carol - C0910

General -0E8990

Olfex - 9729

Omni - D62402

Quabbin - 8604

Olympic - 2998

Pro-Plex - PC224T

Belden 8471 plus 1 - 2.50mm

drain wire recommended (drain wire not

required if installed in grounded metal

conduit).

2 - 1.5mm

/ 2AWG maximum stranded

2

ESD

2

twisted

Supply gauge must be coordinated

with upstream protective switchgear.

CAT 5 cable is also approved for

DMX distribution if installed in

grounded metal conduit.

• For use of CAT 5 cable, you will

need to purchase a CAT 5

termination kit (ETC part number

4100A1013) from a local ETC

office or service provider.

For use with wall stations and

SmartLink pack to pack

synchronization. SmartLink is FTT10A topology-free and polarity

independent.

Contact input for emergency lighting

loads.

Prepare for Installation 5

Page 8

Compliance

CE Compliance

• EN55015, EN55022B, EN61000-6-2, EN60439-1

• Complies with CE Directives 336/83/EEC and 73/23/EEC

Verify the Contents of the Shipping Carton

• SmartPack unit with cover attached.

• Warning labels. If necessary replace the warning label on your SmartPack unit with the

label displaying the operational language of the installed location.

• SmartPack User Manual and Mounting Template.

• DMX Cable Preparation Kit with 8-pin connector (4100A1012).

Additional Parts and Specialty Tools Required

• 4 x 6-8mm (1/4” - 3/8”) bolts or screws, 50-100mm (2 - 4”) long, and suitable wall plugs,

are suggested. Mounting hardware and surface must support 23kg (50 lbs).

• Conduit punch, Conduit or bushes 12.7mm (1/2”) diameter

• Slotted screwdriver for line terminals

• Phillips screwdriver

• 4.75mm (3/16”) wide slotted-style screwdriver for load terminals

• Jeweler’s screwdriver for data terminals

• Wire strippers

6 SmartPack Wall Mount Installation Manual

Page 9

Cable Routing and Conduit Access

1 N

1 L1

2 N

2 L1

3 N

3 L1

4 N

4 L1

5 N

5 L2

6 N

6 L2

1 L

7 N

7 L2

8 N

8 L2

9 N

9 L3

10 N

10 L3

11 N

11 L3

12 N

12 L3

2 L

3 L

4 L

5 L

6 L

7 L

8 L

9 L

10 L

11 L

12 L

Rear

Rear

Rear

Rear

Removable plates on top and bottom.

Remove appropriate plate to punch

conduit access as needed for AC Input

and load wiring. Remove plate

permanently if SmartPack is mounted

below another SmartPack or SmartSwitch.

Removable plates on either side.

Remove appropriate plate to punch

conduit access as needed for AC Input

and load wiring. Remove plate

permanently if SmartPack is mounted

to the side of another SmartPack.

Top

Bottom

Right Side

Left Side

Load Terminals

Access Holes for

mounting bolts or screws.

Earth/Ground BusAC Input Lugs

Knockouts in the lower side

panels accommodate conduit

or bushes for low voltage

control wiring to the

I/O compartment.

I/O Compartment - all lowvoltage (control terminations

conveniently located in the lower

panel.

CAUTION:

In order to maintain safety, proper air flow and cooling, do not leave any panels

removed unless facing an adjoined pack.

Prepare for Installation 7

Page 10

Installation Procedure

127mm

(5.0”)

305mm

(12.0”)

• SmartPack Wall Mount units may be

mounted up to two high by any width.

Allow clearances as described on

page 5

• Overall dimensions of the enclosure:

435mm x 157mm x 666mm

(17.2” x 6.2” x 26.2”)

or, for ThruPower or Relay racks:

435mm x 157mm x 741mm

(17.2” x 6.2” x 29.2”)

Install Mounting Hardware

Step 1: Affix the mounting template, if included in the shipping carton, to the wall to guide

the placement of the mounting bolts or screws. If the mounting template is not

provided, use the measurements below.

Step 2: Install the hardware required for mounting the SmartPack using the four

measured keyholes on the mounting template as a guide.

• Four 6-8mm (1/4” - 3/8”) bolts or screws, 50-100mm (2 - 4”) long, and

suitable wall plugs are suggested mounting hardware.

• Both the surface and the mounting hardware must support 23kg (50lbs).

• Expose at least 25mm (1”) of threads for mounting the SmartPack.

Note:

Access holes to tighten bolts / screws are shown in the Cable Routing and

Conduit Access graphic on page 7.

Mount the SmartPack

Step 1: Remove the four screws securing the cover to the SmartPack.

Step 2: Remove the cover assembly.

Note:

8 SmartPack Wall Mount Installation Manual

Step 3: Mount the SmartPack to the mounting bolts previously installed.

Step 4: Tighten the bolts securely.

The SmartPack Wall Mount unit ships with a debris shield to protect the

electronics during installation. Leave this shield in place during installation and

remove only after installation is complete and before energization.

• Check for a plumb installation and follow all local code restrictions.

Page 11

Rough-In Conduit and Cable

SmartPack Wall Mount dimmer packs have removable plates located on top, bottom and

both sides to accommodate conduit fittings for supply and load wiring. Additional wiring

space is provided at the top of the unit for contractor wiring convenience.

Two knockouts are provided, one on each lower side, specifically for low voltage (control)

wiring. See “Cable Routing and Conduit Access” on page 7.

Step 1: Install conduit for AC input power and load wiring to the panels in the appropriate

locations.

• The SmartPack dimmer pack is available with either 3, 6, or 12 dimmers.

Make certain conduit is sized appropriately for the required wire.

Step 2: Install conduit as required for low voltage (control) wiring.

Note:

Step 3: Pull AC input wiring and load wiring through the conduit previously installed.

CAUTION:

Step 4: Pull all low voltage control wiring through the conduit previously installed to the

Low voltage wiring must be routed separately from high voltage wiring.

a: All low voltage terminations are conveniently located in the I/O compartment

of the SmartPack. Two 12.7mm (1/2”) knockouts are provided for low voltage

control wiring.

a: Individual loads with earth ground and neutral connections.

b: Power supply wiring for predetermined three-phase or single phase

operation.

The SmartPack Wall Mount unit ships with a debris shield to protect the

electronics during installation. Leave this shield in place during installation and

remove only after installation is complete, before energization. If debris falls into

the fan or electronics remove the debris before applying power to the unit.

I/O compartment knockouts. Installation requirements for low voltage wiring may

include the following:

• DMX IN

• DMX PASS-THRU

devices.

• SmartLink

independent. Wiring may be bus, star, loop, home run (up to two home run

termination points available) or any combination of these.

• Emergency

lighting loads to full and all non-emergency lighting loads OFF. Contact ETC

for guidance on use with emergency lighting systems.

- required when SmartPack is to be controlled by a DMX source.

- allows pass-thru of the DMX signal to other DMX

- station wiring is FTT-10A, topology-free and polarity

- receives a contact input that switches selected emergency

Installation Procedure 9

Page 12

Connect Wiring

LOAD1

N1

N2

NL1L2L3EARTH

To Circuit Breakers

Input Wiring

Supply cable:

Lugs will accommodate

25mm

2

/ 3AWG maximum

stranded cable.

Important Note:

Supply cable gauge must be

coordinated with upstream protective

switchgear.

EarthL3L2L1N

LOAD1

N1

N2

NL1L2L3EARTH

To Circuit Breakers

Input Wiring

Important Note:

Jumper wires must match

specifications for incoming line wire.

Important Note:

For operation on single phase supplies

at full power, upstream switchgear,

such as RCD's or main breakers, must

be located separately outside the

enclosure. Please contact ETC

technical services for assistance.

Earth L1 N

L3 L2

Power Supply Connections

Three-Phase Supply Connections

Note:

If a DIN rail option kit is fitted with RCD and/or terminals, please follow the wiring

instructions supplied with the kit.

Single-Phase Supply Connections (Europe)

CAUTION:

The SmartPack Wall Mount unit ships with a debris shield to protect the

electronics during installation. Leave this shield in place during installation and

remove only after installation is complete and before energization. If debris falls

into the fan or electronics remove the debris before applying power to the unit.

10 SmartPack Wall Mount Installation Manual

Page 13

Load Connections

1 N

1 L1

2 N

2 L1

3 N

3 L1

4 N

4 L1

5 N

5 L2

6 N

6 L2

7 N

7 N2

8 N

8 L2

9 N

9 L3

10 N

10 L3

11 N

11 L3

12 N

12 L3

N

N

N

N

N

N

N

N

N

N

N

N

Incoming Load Wiring

Earth/Ground Bus

Insert load

conductors here.

These wires installed by

ETC prior to shipping the

unit.

Earth/Ground Connections

Connect the earth/ground conductor for each load to the Earth/Ground Bus.

Neutral Connections

Step 1: Prepare load conductors by stripping 6mm of insulation from the end.

Step 2: Insert the stripped end into the terminal and tighten the screw using a 4.75mm

(3/16”) wide slotted style screwdriver.

• Terminals accept wire between 1.5mm

• Take care not to tighten the load connection onto the wire insulation.

1 N

1 L1

2 N

2 L1

3 N

3 L1

4 N

4 L1

5 N

5 L2

6 N

N

N

2

/ 16AWG and 6mm2 / 8AWG.

6 L2

7 N

7 N2

8 N

8 L2

9 N

9 L3

Installation Procedure 11

Page 14

Connect Control Wiring

I/O panel to

chassis ground

Link Power supply

(optional)

Data to CPU

Emergency /SmartLink

DMX In

DMX Thru

ESD Ground

Presets, Sequence,

Sequence Timing

SmartPack

SmartPack

Unison DRd12

rack

LinkPower

supply

installed

Belden 8471 plus

12.5mm

2

ESD

drain

SmartLink

Stations

SmartPack

SmartLink

ATC

Emergency, SmartLink, DMX In and DMX Pass-Thru are connected in the

I/O compartment of the SmartPack Wall Mount unit. Each connection uses a pluggable

screw terminal which can be removed for easy wiring.

The RJ45 connection labeled J2 on the I/O board connects the I/O control board to the

control CPU board for data communication to the SmartPack. This connection is made at

the factory prior to shipment.

The LinkPower supply provides power for up to four SmartLink wall stations per system.

SmartPack Wall Mount is available with or without the LinkPower supply option. For field

installation of the LinkPower supply reference LinkPower Supply Kit, page 19.

Emergency/SmartLink

SmartLink is a control protocol that provides added functionality to the SmartPack dimming

pack for inter-connectivity and shared communication of specific data to other SmartLink

enabled host products. Reference the SmartPack User Manual for configuration details.

Recall

Up

Preset

Enter

Back

Down

Hold

Preset 1

Preset 2

Preset 3

Preset 1

Preset 6

Preset 4

Preset 2

Preset 7

Preset 5

Preset 3

12 SmartPack Wall Mount Installation Manual

Preset 8

Preset 1

Preset 9

Preset 4

Preset 2

Preset 5

Preset 10

Preset 3

Preset 4

Preset 5

Page 15

The six position pluggable screw terminal labeled J3 Panic/LON is provided as the

termination point for both Emergency and SmartLink control.

COM

Emergency

NET A

NET B

NET B

NET A

123456

Connect Emergency

Step 1: Strip 6.35mm (1/4”) of insulation from the ends of the two 1.5mm

Step 2: Remove the 6 position pluggable connector from J3 on the I/O PCB.

Step 3: Twist the two 1.5mm

Step 4: Insert the 1.5mm

Step 5: Tighten the screw firmly onto each wire.

Connect SmartLink

Termination is available for up to two separate SmartLink data runs and is FTT-10A

topology-free and polarity independent utilizing a LonWorks

SmartLink wall stations, ETC recommends terminating the station data run to the

SmartPack with the LinkPower supply installed and utilizing the second data bus for

SmartLink pack to pack synchronization. A clean, well organized wire installation assists

with troubleshooting efforts when needed.

Note:

J2

Control

LON1

LON2

1 2 3 4

DMX

NC

PAN

COM

NETA

NETB

NETB

NETA

2

wires.

2

wires together as close to the connector as possible.

2

into pins 5 and 6.

®

network. For systems utilizing

One SmartLink host product (SmartPack, SmartSwitch, Unison DRd with

SmartLink or Sensor + with SmartLink) in the system must have a LinkPower

Supply or Station Power Module installed for wall station power. A SmartLink

LinkPower supply (7021K1010) is limited to powering four SmartLink stations.

Alternatively, you may power up to 16 SmartLink stations when using a SmartLink

Station Power Module (S-SPM). You may have up to four SmartLink host products

in a SmartLink system.

Step 1: Cut the Belden 8471 cable so that a 20cm (8”) tail extends from the edge of the

panel.

Step 2: Strip 18cm (7”) of the outer jacket off.

Step 3: If pulling two Belden 8471 cables, label each pair with data type and run

designation. Example: SL1 and SL2.

Step 4: Strip 6.35mm (1/4”) of insulation from the ends of the Belden 8471 wires.

Step 5: Insert the white wire from SL1 data run into pin 1 (NETB) terminal on the

pluggable connector. Tighten the screw firmly onto the wire.

Step 6: Insert the associated SL1 black wire into pin 2 (NETA) terminal on the pluggable

connector. Tighten the screw firmly onto the wire.

Step 7: Repeat steps 5-6 to terminate the second data run (SL2) if required to the

remaining pins 3 and 4 terminals on the connector. Tighten the screw firmly onto

each wire.

Step 8: Reinstall the 6 position pluggable connector to J3 on the I/O PCB.

Installation Procedure 13

Page 16

Connect ESD Ground

As shown with Belden 9729 color code

Pin 1 - Com

Pin 2 - DMX - (Black)

Pin 3 - DMX + (Red)

DMX In and Pass-Thru on the same pluggable

screw connector as shown.

For use with CAT 5 cable, contact ETC for a

CAT 5 termination and IDC connector kit (ETC

part number 4100A1013), sold separately.

For installations with SmartLink data runs (Belden 8471) installed in grounded metal

conduit there is no need to run or terminate an additional ESD drain wire. For installations

not installed in grounded metal conduit follow the instructions below for ESD

termination.

Step 1: Locate the grounding lug on the tray of the I/O panel, just to the right of the I/O

termination board.

Step 2: Loosen, but do not remove, the set screw on the grounding lug.

Step 3: Strip 6.35mm (1/4”) of insulation from the end of the 2.5mm

2

ESD drain wire(s)

and twist together.

Step 4: Insert the bare end into the grounding lug and secure with the set screw.

DMX 512

Two 8 position receptacles are provided on the I/O termination board, one for DMX In and

the other for DMX-Thru. Prior to connecting DMX, follow the instructions for Belden 9729

cable preparation as defined on the single sheet instructions packaged with the 8 position

pluggable screw connector. A cable preparation kit for installation of CAT 5 cable (ETC part

number 4100A1013) is available for purchase, contact ETC for details.

Connect DMX

(J4) DMX IN

n/c

n/c

n/c

DATA-

7021B5602

preliminary

n/c

678

DATA+

12345678

COM

DMX+

DMX-

(J5) DMX

PASS-THRU

n/c

n/c

n/c

DMX+

n/c

678

DATA-

DATA+

12345678

DMX-

ISOCOM

n/c

n/c

Step 1: For DMX In and DMX Pass-Thru using Belden 9729 as recommended, prepare

the Belden cable as described in the DMX Cable Preparation kit instructions.

Step 2: Using the 8 position pluggable screw connector provided in the cable preparation

kit, connect Shield (Com), DMX- and DMX+ as indicated in the graphic above.

Step 3: DMX Pass-Thru using Belden 9729 can utilize the same pluggable screw

connector as DMX In. Connect Shield (Com), DMX - and DMX + as indicated in

the graphic above.

14 SmartPack Wall Mount Installation Manual

Page 17

Data Termination

Switch UP= termination ON

Switch DOWN = termination OFF

The I/O board includes termination switches for both SmartLink data runs and DMX512.

Follow termination guidelines as indicated in the graphic below.

J2

Control

Guidelines for Data Termination:

For SmartLink (silk-screened as LON) data termination:

• For a single pack installation set switch 1 and 2 to the UP position.

• If multiple packs are installed, only one pack should terminate LON, switch 1 and 2 UP.

All other packs should have LON switches 1 and 2 set DOWN.

• If there are no SmartLink data runs set switch 1 and 2 DOWN.

For DMX 512 data termination:

• If the pack is the last or the only DMX device on the data run set switch 3 UP.

• If the pack is not the last DMX device on the data run set switch 3 DOWN.

DMX

LON

LON

1 2 3 4

NC

NETB

NETA

Installation Procedure 15

Page 18

Final Installation and Power Up

Verify Installation

• Is the SmartPack unit securely mounted with all mounting bolts tight?

• Is there sufficient clearance 254mm (10”) in front of the unit?

• Check wiring:

• Are all power supply and load cables landed and properly terminated?

• Are all emergency lighting circuits separated from normal circuits with a voltage

barrier?

• Are all unused cable access openings covered with plugs or removable plates?

• Do all control cables meet specifications?

• Are all low voltage connections terminated properly?

• Are all data terminations terminated?

• Remove all debris and the debris shield from the unit.

• The SmartPack Wall Mount unit ships with a debris shield to protect the electronics

during installation. Leave this shield in place during installation and remove only

after installation is complete and before energization. If debris falls into the fan or

electronics remove the debris before applying power to the unit.

Final Installation

Step 1: Attach the ground wire with the ring terminal from the chassis to the grounding

stud on the I/O panel and secure.

Step 2: Close the I/O panel and secure with two screws.

a: All wires should be dressed neatly.

b: Ensure the wires are not crimped in the I/O Panel while closing.

Step 3: Attach the ground wire with the spade connector to the front cover and secure

the front cover to the unit.

Step 4: Apply power to the unit.

Test Loads via Menu

After power is applied to the unit, select the operating language and test each load using

the TEST MENU.

Select the operating language:

Step 1: Apply power to the unit. Available languages for SmartPack will scroll in the

display at 3-second intervals.

Step 2: Press when the preferred language is displayed:

•Set Language - English

•Choisir la langue - Français

•Sprache auswählen - Deutsch

•Seleccionar idioma - Español

16 SmartPack Wall Mount Installation Manual

Page 19

Set a level for a dimmer:

Test Dimmer: [ All ]

T

Level: 100%

Step 1: Press to enter the Test menu.

Step 2: Use < or to scroll the selection of dimmers, choose one or [ALL] dimmers.

Step 3: Use + or - to set a level, press . The menu will progress to the next dimmer.

Step 4: Press . “Exit Test Mode” displays.

• Exit Test Mode and retain all Test levels, scroll to [Keep Test On] and

press .

• Exit Test menu, clearing all Test levels and return to the previous menu,

scroll to [Test: all off], press .

• Press < to return to the Test menu.

• Press << to exit the Test menu, clearing all Test levels, and return to the main

menu.

Verify DMX512 Operation

Test each load with DMX512 input using a controle console or DMX512 test device.

Troubleshooting SmartLink

After all SmartLink control stations are installed and connected to the SmartLink enabled

product, check for shorts and cross-connections with a digital voltmeter.

• Check the voltage between Net A and ground. This reading should be between 18

- 21 Volts.

• Check the voltage between Net B and ground. This reading also should be

between 18-21 Volts.

• Check the voltage between Net A and Net B. This reading should be between 3642 Volts.

Check that two LED indicators (located at CR1 and CR2) are illuminated on the LinkPower

supply board.

• If both are illuminated the data connections are good.

• If CR1 is illuminated but not CR2, Net A is shorted to ground.

• If CR2 is illuminated but not CR1, Net B is shorted to ground.

• If neither LED is illuminated, Net A and Net B are both shorted.

If you have any difficulties installing your system, please contact ETC Technical Services

at the office nearest you.

Installation Procedure 17

Page 20

18 SmartPack Wall Mount Installation Manual

Page 21

Appendix A

Step 4

Step 5

LinkPower

supply

I/O board

LinkPower Supply Kit

One SmartLink LinkPower Supply (S-LPS) powers up to four wall stations over the

SmartLink™ network.

Note:

You may have only one station power source on the SmartLink network. This

source may be either the LinkPower Supply (S-LPS) or a SmartLink Station Power

Module (S-SPM) which powers up to 16 SmartLink stations. As well, you may

have up to four SmartLink host products in a SmartLink system. One SmartLink

host product (SmartPack, SmartSwitch, Unison DRd with SmartLink or Sensor +

with SmartLink) in the system must have a LinkPower Supply or Station Power

Module installed for wall station power.

Installation Procedure

The LinkPower supply kit includes a LinkPower supply and four screws.

Step 1: Remove power from the control electronics by turning the Standby breaker off.

Step 2: Remove the two screws securing the I/O panel to the chassis.

Step 3: Fold the I/O panel down to reveal the control terminations.

Step 4: Angle the LinkPower supply board approximately 10° and insert the four pins as

found on the LinkPower supply into the receptacle on the I/O board.

Step 5: Align the LinkPower supply with the four screw mounts located on the I/O panel

and secure with the four screws provided. Do not over tighten the screws.

Step 6: Close the I/O panel and secure with the two screws.

Step 7: Re-apply power to the control electronics.

A LinkPower Supply Kit 19

Page 22

Page 23

Page 24

Corporate Headquarters

London, UK

Rome, IT

Unit 26-28, Victoria Industrial Estate, Victoria Road, London W3 6UU, UK Tel +44 (0)20 8896 1000 Fax +44 (0)20 8896 2000

Via Pieve Torina, 48, 00156 Rome, Italy Tel +39 (06) 32 111 683 Fax +44 (0) 20 8752 8486

Holzkirchen, DE

3031 Pleasant View Road, P.O. Box 620979, Middleton, Wisconsin 53562-0979 USA Tel +608 831 4116 Fax +608 836 1736

Ohmstrasse 3, 83607 Holzkirchen, Germany Tel +49 (80 24) 47 00-0 Fax +49 (80 24) 47 00-3 00

Hong Kong Rm 1801, 18/F, Tower 1 Phase 1, Enterprise Square, 9 Sheung Yuet Road, Kowloon Bay, Kowloon, Hong Kong Tel +852 2799 1220 Fax +852 2799 9325

Service:

(Americas) service@etcconnect.com

Web:

www.etcconnect.com

7021M2130-GB

Rev D Released 2014-01

Copyright © 2014 ETC. All Rights Reserved. Product information and specifications subject to change.

(UK) service@etceurope.com (DE) techserv-hoki@etcconnect.com

(Asia) service@etcasia.com

Loading...

Loading...