Page 1

Assembly Guide

Production Dates: September 2004 - Present

Copyright © Electronic Theatre Controls, Inc.

All Rights reserved.

Product information and specifications subject to change.

Part Number:

7062M2500-05.04

Released: April 2005

Rev A

Page 2

Table of Contents

Complete Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Complete Fixture Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Clean reflector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Lamp Socket Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Assemble lamp socket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Lens Holder Assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Cleaning 19°, 26°, 36°, and 50° glass lenses . . . . . . . . . . . . . . .8

Shutter Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

ETC®, Emphasis®, Expression®, Insight™, Imagine™, Focus™, Express™, Unison®, Obsession® II, ETCNet2™,

EDMX™, Source Four

of Electronic Theatre Controls, Inc. in the United States and other countries.

All other trademarks, both marked and not marked, are the property of their respective owners.

Table of Contents i

®

, Revolution®, Sensor®, and WYSILink™ are either registered trademarks or trademarks

Page 3

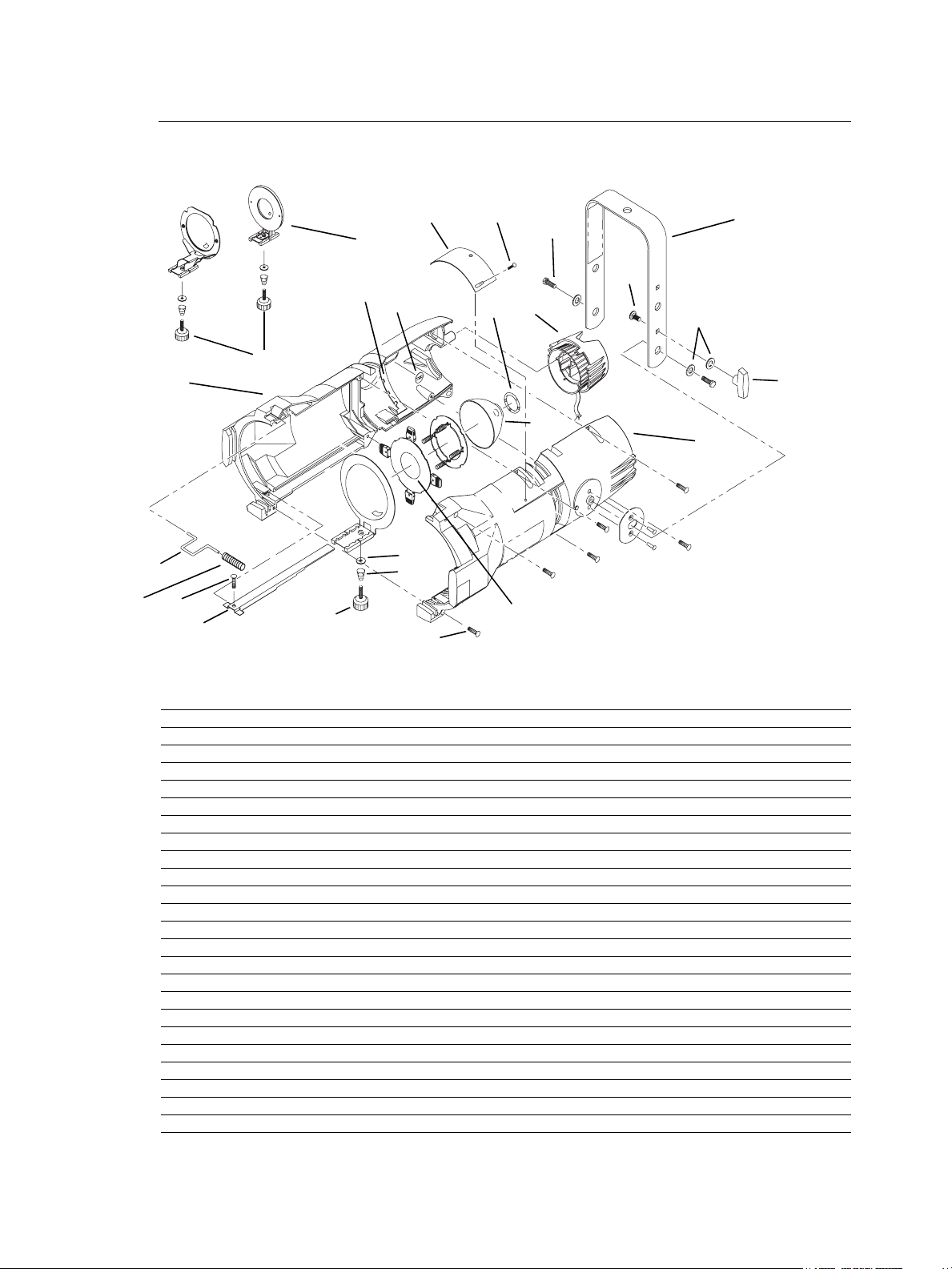

Complete Assembly

20

21

12

10

9

13

17

18

7

3

14

4

1

11

6

2

23

5

8

15

19

4

24

16

22

Reference

Number

1 7062A3002 Barrel, left casting 1

2 7062A3004 Barrel, right casting 1

3 7062A2008 Lamp burner assembly 1

4 HW8201 Knob, 10-32X.50LG male stud, black 1 or 2

5 7061A3005 Retainer, gel clip 1

6 7062A4010 Reflector, jr, glass 1

7 7062A3007 Spring, round 1

8 HW750 Spring, gel retainer 1

9 See page 7 Zoom Lens Holder Assembly (Source Four jr. Zoom only)

10 7062A3009 Yoke, jr 1

11 HW8144 Handle, yoke knob, 3092, 5/16-18, female 1

12 HW5193 Bolt, hex 5/16-18 x 1.0" black oxide (yoke) 2

13 HW5125 Bolt, carriage 5/16-18 1

14 HW5126 Washer, flat, 5/16, black oxide (yoke) 3

15 HW391 Screw, PHMS, 8-32 X 3/4 LG. 1

16 See page 9 Shutter assembly 1

17 7062A3013 Spring, reflector support 2

18 HW8200 Retainer, push on 2

19 7062A3014 Light baffle strip 1

20 7062A3015 Cover, iris slot 1

21 HW372 Screw, PhPHMS, 8-32 X 1/4 black oxide 2

22 HW3165 Screw, 8-32 x 1/2 PhPH taptite 6

23 HW4117 Nylon, washer flat, #10 1 or 2

24 HW779 Spring compression 1 or 2

Part

Number

Description Quantity

Required

Complete Assembly 1

Page 4

Complete Fixture Assembly

Tools Required:

• #2 Phillips screwdriver

Assemble Fixture

Step 1: Place the left barrel casting (1) open side up on your work surface with the

colorframe end to your right.

Step 2: If necessary, place spring (17) over post in right and left castings (1 and 2).

Secure with clip (18).

Step 3: Set shutter assembly (see Shutter Assembly, page 9) into the shutter slot in left

casting (1) with the rounded side of the shutter handles facing right (gel opening

end of the fixture).

Step 4: Install the short end (without the flattened notch) of the gel retainer clip (5) in the

left casting (1).

Step 5: Position clip (5) in the forward, locked position, then install the retainer spring (8)

on the clip.

Step 6: Snap spring (7) onto reflector (6) and place assembly into left casting (1) so that

the front edge of the reflector is supported by spring (17). The spring (7) on the

back rests in the left casting rear supports.

Step 7: Gently set the right barrel casting (2) onto the left casting so that the gel clip

retainer, shutter assembly and reflector assembly fit into their respective

positions.

Step 8: Starting with the corner nearest the gel clip retainer, attach the right casting to

the left casting with screws (22). Do the right screws first, then the middle screws,

then the left screws.

Step 9: Install the iris slot cover (20) onto the barrel assembly with screws (21).

Step 10: With the colored dot on the lens facing out the barrel, slide the lens holder

assembly (or assemblies, if Zoom) into the lens holder track inside the barrel.

The assembly should slide smoothly in the track.

Step 11: Insert light baffle strip (19) through front of barrel assembly and through hole in

lens holder assembly. Slide strip (19) through supports in front of fixture and

install screw (15), spring (24), washer (23), and knob (4).

Step 12: Attach the lamp burner (3, see Lamp Socket Assembly, page 3) to the barrel

assembly with the knurled head screw.

Step 13: Attach yoke (10) to barrel assembly with bolts (12) and washers (14). Attach yoke

knob (11) with bolt (13) and washer (14) to side of fixture with clutch plate.

Step 14: Tighten bolts (12) to secure yoke to fixture. Tighten yoke knob (11) to secure

yoke in desired position.

Clean reflector

Remove dust with a blast of oil-free air or wipe with a clean, lint-free cloth using alcohol or

distilled water (alcohol is recommended).

WARNING:

2 Source Four jr / jr Zoom Assembly Guide

Do not use glass and window cleaners on the reflector. Chemicals in these

cleaners will stain the reflector.

Page 5

Lamp Socket Assembly

1

13

6

3

20

5

22

23

2

14

22

21

12

8

19

10

7

18

11

16

9

15

4

Reference

Number

1 7060A3055 Housing, socket, casting, painted 1

2 7060A3057 Socket, light baffle casting, painted 1

3 7060A4007 Knob, X-Y, lamp set 1

4 7060A4008-02 Knob, Z, lamp set w/female insert 1

5 7060A4011 Bushing, cup 1

6 7060A3011 Hub, index, casting 1

7 7060A3012 Spring, lamp retainer 1

8 HW748 Spring, compression 1

9 7060B7019 Complete UL socket assembly 1

10 HW534 Nut, hex, 1/4-20, black zinc 1

11 7060A3025 Screw, 1/4-20 knurled head 1

12 HW746 Retaining ring, flat, Southco 1

13 HW5123 Nut, hex, 9/16-18, black zinc 1

14 HW747 Washer, wave 1

15 7060A3056 Clamp, strain relief, painted 1

16 HW3103 Screw, 8-32 x 5/8 PhFHMS, black zinc 2

17 HW5122 Bolt, 1/4-20 x 1.75, full thread, black zinc 1

18 HW8209 Clip Tinnerman 1

19 7060B7003

20 W6195 36" sleeve, fiberglass 1

21 HW749 Spring, ground 1

22 7060B7007

23 7060A3085 Source Four Lamp Retainer Wire 1

Part

Number

Description Quantity

48" W420 wire, 16 gauge, 200° C/300V, green UL 1180/CSA AWM

with lug J490T installed

4" W420 wire, 16 gauge, 200° C/300V, green, UL 1180/CSA AWM

with two J490T lugs installed

17

Figure 2

Required

1

1

Lamp Socket Assembly 3

Page 6

Assemble lamp socket

Tools Required:

• Open-end adjustable wrench or a 7/16” socket

• Needle-nose pliers

• #2 Phillips screwdriver

18

23

Figure 3

Step 15: Set the crossbar of the retainer clip (25) under the two hooks on the clip bracket

as shown in Figure 3.

Step 16: Place the Tinnerman clip (18) over the retainer clip crossbar between the two

hooks and press it down firmly until it snaps into place.

22

19

10

97

Step 17: Insert the bolt (17) through the light baffle socket casting (2). See Figure 4.

Step 18: Install the green ground wire assemblies (19 and 22) on the bolt (17) with the

prongs on the crimped connectors toward the casting. Run both wires through

the indent in the lip around the bolt hole. Secure with nut (10) and torque to 60

inch pounds.

Step 19: Place the socket assembly (9) into the light baffle socket casting (2). Be sure it is

well seated.

23

17

18

2

Figure 4

4 Source Four jr / jr Zoom Assembly Guide

Page 7

Step 20: Install the lamp retainer spring (7). The lamp retainer spring secures the socket.

Insert the spring one end at a time, making sure the rectangular slot in each side

of the spring seats on the corresponding tab in the casting.

Note:

Note:

If the spring does not seat correctly, coax it into place with a screwdriver or needlenose pliers.

6

5

13

14

1

3

Figure 5

Step 21: Install the bushing cup (5) into the housing socket casting (1) as shown in Figure

5. The cup should slide smoothly up and down, but not side to side.

Step 22: Insert the threaded end of the index hub (6) through the holes in the bushing cup

and the back of the housing socket casting (1).

Step 23: Slide the X-Y knob (3) over the exposed index hub bolt (6), then insert the wave

washer (14) on the bolt and secure with the 9/16 hex nut (13). Hand tighten the

X-Y knob (3).

Install the wave washer with the upward curve toward the hex nut.

4

Cable Clamp in

Housing

222112

8

1

Green

wires

11

16

White

wire

White

wire

15

Figure 6

Figure 7

Step 24: Insert the knurled head screw (11) through the housing socket casting (1) as

shown in Figure 6.

Step 25: Install the shorter green ground wire (22) onto the screw. The prongs on the

crimped connector should be toward the casting.

Step 26: Install the ground spring (21) onto the screw and secure it with the Southco flat

retaining ring (12). Install the Southco ring with its prongs away from the casting.

Lamp Socket Assembly 5

Page 8

Note:

Use pliers to straighten the Southco retaining ring (12) if it bends when you install

it on the bolt.

Step 27: Lay the leads in the bottom half of the cable clamp (located in the housing socket

casting [1]), making sure that the fiberglass sleeving extends slightly past the

screw holes in the housing socket casting. Install new sleeving if necessary.

Then, route the wires as shown in Figure 7.

CAUTION:

Step 28: Install the top half of the cable clamp (15) and secure it with the two screws (16).

Note:

Step 29: Using the four screws (24), attach the handle (23) to the lamp socket assembly.

Step 30: Place the compression spring (8) on the protrusion on the inside of the index hub

Step 31: Insert bolt (17) through spring (8) and through the index hub (6) of the housing

Step 32: Before proceeding, check again to make sure the wires are still positioned as

Step 33: Press the two castings together firmly so the bottom of the light baffle (2) sits on

You must follow the wire routing diagram to ensure that the socket leads do not

interfere with the lamp focus mechanism.

Tighten the screws alternately to ensure a solid connection.

To ensure that the clamp holds the cable tightly, flatten the cable, then fold over

the sleeving before you install the top half of the clamp. Make sure the top edge

of the cable clamp is even with the edge of the socket to prevent interference with

lamp focus movement. Make sure sleeving is not pinched.

See Figure 2.

(6).

socket (1), joining the two castings. Make sure wires are not pinched between

the two pieces.

indicated in Figure 6. Adjust if necessary.

top of the cable clamp (15), then install the X-Y lampset (3) and Z lamp knob (4).

Hand tighten the knob all the way to the right.

CAUTION:

6 Source Four jr / jr Zoom Assembly Guide

You must install Z knob as described above to ensure proper lamp focus travel.

Page 9

Lens Holder Assemblies

Fixed Field Angle Lens

18

19

20

Paint dot should

be situated on

this side of lens

and centered

above the bottom

clip.

1, 2, 3

17

21

6, 7, 8

Zoom Front Lens

4

15

Zoom Rear Lens

13

16

Figure 8

9

14

11

17

12

10

15

Orientation

marks to

5

this side

Reference

Number

1 7062A3005 Lens holder, 26° 1

2 7062A3017 Lens holder, 36° 1

3 7062A3018 Lens holder, 50° 1

4 7062A3019 Lens holder, Zoom, forward (Source Four jr. Zoom only) 1

5 7062A3020 Lens holder, Zoom, back (Source Four jr. Zoom only) 1

6 7062A4001 Lens, 26°, ”black dot” 1

7 7062A4002 Lens, 36°, “white dot” 1

8 7062A4003 Lens, 50°, “yellow dot” 1

9 7062A4008 Lens, Zoom, forward (Source Four jr. Zoom only) 1

10 7062A4009 Lens, Zoom, back, black (Source Four jr. Zoom only) 1

11 7062A3027 Lens cover, Zoom, front, 25º-50º (Source Four jr. Zoom only) 1

12 7062A3026 Lens cover, Zoom, rear, 25º-50º (Source Four jr. Zoom only) 1

13 7062A3029 Plate, secondary aperture (Source Four jr. Zoom only) 1

14 HW124 Screw 4-40 x 1/4 SPHMS, black Oxide 2

15 HW196 Nut 4-40 Keps 4

16 HW1127 Spacer (Source Four jr. Zoom only) 2

17 7060A4010 Bushing gate (fixed, front, or rear lens) 4

18 HW8209 Tinnerman clip 3

19 HW4117 Nylon washer, flat, #10 1 or 2

20 HW779 Spring, compression 1 or 2

21 HW8201 Lens knob, 10-32 x .50 LG male stud, black (Fixed or Zoom) 1 or 2

Part

Description Quantity

Number

7062A2001 Lens holder assembly, 26° (black dot) 1

7062A2003 Lens holder assembly, 36° (white dot) 1

7062A2004 Lens holder assembly, 50° (yellow dot) 1

7062A2005 Lens holder assembly, Zoom, forward 1

7062A2006 Lens holder assembly, Zoom, rear 1

Required

Lens Holder Assemblies 7

Page 10

Assemble Fixed Field Angle Lens:

Step 1: Place the lens on the lens holder between the tabs. The paint dot should be on

the side opposite the tabs.

Step 1: Position the lens by centering the paint dot above the bottom tab notch, as shown

in Figure 8. This will keep the paint dot visible after the fixture is fully assembled.

Step 2: Center one Tinnerman clip (18) on each tab, and press clip until it is fully seated.

If clips are in uneven positions, lens will be tilted or loose.

Step 3: Firmly press the clips down and then push the spine of each clip towards the

center of the lens. This will ensure that the clips contact the lens surface.

Step 4: Check lens and make sure the clips hold it securely.

Step 5: Snap the bushings (17) onto the lens holder assembly as shown.

Assemble Zoom Front Lens:

Step 1: Position the lens (9) between the lens holder (4) and the lens cover (11) so that

the convex side of the lens faces the lens holder, as shown in Figure 8.

Step 2: Align the holes in the lens cover with the holes in the lens holder as shown.

Step 3: Secure the lens cover and the lens to the lens holder using screws (14) and

locking nuts (15). Tighten securely to ensure the lens cannot move.

Step 4: Snap the bushings (17) onto the lens holder (4) as shown.

Assemble Zoom Rear Lens:

Step 1: Slide spacers (16) over the PEM studs of the secondary aperture plate (13), as

shown in Figure 8.

Step 2: Insert the PEM studs on the secondary aperture plate (13) through the holes in

the lens holder (5).

Step 3: Position the lens (10) between the lens holder (5) and lens cover (12) as shown.

The blue orientation marks on the lens should face the lens holder.

Step 4: Insert the PEM studs of the secondary aperture plate (13) through the lens cover

(12).

Step 5: Secure the lens cover, lens, and aperture plate using nuts (15).

Step 6: Snap the bushings (17) onto the lens holder (5) as shown.

Cleaning 19°, 26°, 36°, and 50° glass lenses

Step 1: Dampen a clean, lint-free cloth with vinegar or household ammonia. You may

use water, but it leaves spots. You can remove the spots by polishing the lens

gently with a clean, dry cloth.

WARNING:

Step 2: Starting from the center, gently wipe the lens.

Never use glass and window cleaner or any abrasive material to clean the

lens. Glass and window cleaners will stain the lens surface. Abrasive

materials (such as steel wool) will damage the surface of the lens.

8 Source Four jr / jr Zoom Assembly Guide

Page 11

Shutter Assembly

1

3

2

Shutter Assembly: The bottom divider plate

(4) has four dimples punched into the surface;

the divider plate (2) has none. The middle

divider plate (3) has a slightly smaller diameter

hole than the other two.

Reference

Number

1 7062A2002 Shutter blade assembly 4

2 7062A3016 Plate, divider 1

3 7062A3010 Plate, Gate, middle 1

4 7062A3030 Plate, divider with dimples 1

5 7062A3031 Plate, spring support 1

6 HW754 Spring, shutter 4

Part

Number

Figure 13

4

5

6

Description Quantity

Required

Assemble Shutters:

Step 1: Place the divider plate (2) on a flat surface.

WARNING:

Step 2: Place two shutter blades (1) on top of plate (2). Handles should extend out past

Step 3: Place the middle divider plate (3) on top of the two shutter blades. The notches

Step 4: Place the two remaining shutter blades (1) on top of the middle divider plate.

Note:

Step 5: Place the top divider plate (4) on top of the third and fourth shutter blades. The

Step 6: Install the four springs (6) onto the nips on the spring support plate(5).

Step 7: Place the dimples of the plate divider (4) onto the open ends of the springs.

Divider plate edges may be sharp. Handle with caution!

the edge of the divider plate.

in the divider plates must line up.

The third and fourth shutter blade handles should be perpendicular to the previous

shutter handles.

Ensure that the rounded side of all shutter handles face the same direction,

raised dimples should point away from the shutters.

Carefully place assembly in fixture casting (See page 2, step 3).

Shutter Assembly 9

Page 12

Corporate Headquarters

London, UK

Rome, IT

Unit 5, Victoria Industrial Estate, Victoria Road, London W3 6UU, UK Tel +44 (0)20 8896 1000 Fax +44 (0)20 8896 2000

Via Ennio Quirino Visconti, 11, 00193 Rome, Italy Tel +39 (06) 32 111 683 Fax +39 (06) 32 656 990

Holzkirchen, DE

3031 Pleasant View Road, P.O. Box 620979, Middleton, Wisconsin 53562-0979 USA Tel +608 831 4116 Fax +608 836 1736

Ohmstrasse 3, 83607 Holzkirchen, Germany Tel +49 (80 24) 47 00-0 Fax +49 (80 24) 47 00-3 00

Hong Kong Room 605-606, Tower III Enterprise Square, 9 Sheung Yuet Road, Kowloon Bay, Kowloon, Hong Kong Tel +852 2799 1220 Fax +852 2799 9325

Service:

(Americas) service@etcconnect.com

Web:

www.etcconnect.com

7062M2500-05.04

Rev A Released 04/2005

Copyright © 2005 ETC. All Rights Reserved. Product information and specifications subject to change.

(UK) service@etceurope.com (DE) techserv-hoki@etcconnect.com

(Asia) service@etcasia.com

Loading...

Loading...