Page 1

Source 4

WRD

HPL to LED Retrofit

Installation and User Manual

Version 1.1.2

Part Number: 7067M1200-1.1.2 Rev: B

Released: 2018-12

Page 2

To view a list of ETC trademarks and patents, go to

etcconnect.com/ip

marked, are the property of their respective owners.

ETC intends this document, whether printed or electronic, to be

provided in its entirety. This product is intended for

professional use only. Read this entire document before using

this product.

This product is protected by one or more of the following

U.S. Patents: US 9,261,241 and 9,273,831.

. All other trademarks, both marked and not

Page 3

Table of Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . 1

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Sensor dimmer settings . . . . . . . . . . . . . . . . . . 5

Color rendering and quality . . . . . . . . . . . . . . 6

Contacting ETC . . . . . . . . . . . . . . . . . . . . . 7

Retrofit kit installation . . . . . . . . . . . . . . . 8

Wire the power connector (if needed). . . . . . 8

Remove incandescent lamp housing . . . . . . . 9

Install Source 4WRD retrofit . . . . . . . . . . . . . . 10

Fixture installation . . . . . . . . . . . . . . . . . 11

Attach C-clamp and safety cable . . . . . . . . . 11

Connect cables . . . . . . . . . . . . . . . . . . . . . . . . 12

DMX pinout . . . . . . . . . . . . . . . . . . . . . . . 13

User interface . . . . . . . . . . . . . . . . . . . . . 13

Error codes . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Focus the fixture . . . . . . . . . . . . . . . . . . . 14

Set the Z-adjustment . . . . . . . . . . . . . . . . . . . 14

Adjust the yoke position . . . . . . . . . . . . . . . . 15

Change the height position. . . . . . . . . . . 15

Set the angle within the yoke . . . . . . . . . 15

Table of Contents i

Page 4

Shape the beam . . . . . . . . . . . . . . . . . . . . . . . 15

Use the color frame . . . . . . . . . . . . . . . . . 15

Use a pattern. . . . . . . . . . . . . . . . . . . . . . . 16

Cleaning and maintenance. . . . . . . . . . . 16

Clean the fixture. . . . . . . . . . . . . . . . . . . . . . . 16

Store the retrofit . . . . . . . . . . . . . . . . . . . . . . 17

Clean the lenses . . . . . . . . . . . . . . . . . . . . . . . 17

Clean the reflector . . . . . . . . . . . . . . . . . . . . . 18

Clean 5° and 10° polymer lenses . . . . . . . . . . 19

ii Table of Contents

Page 5

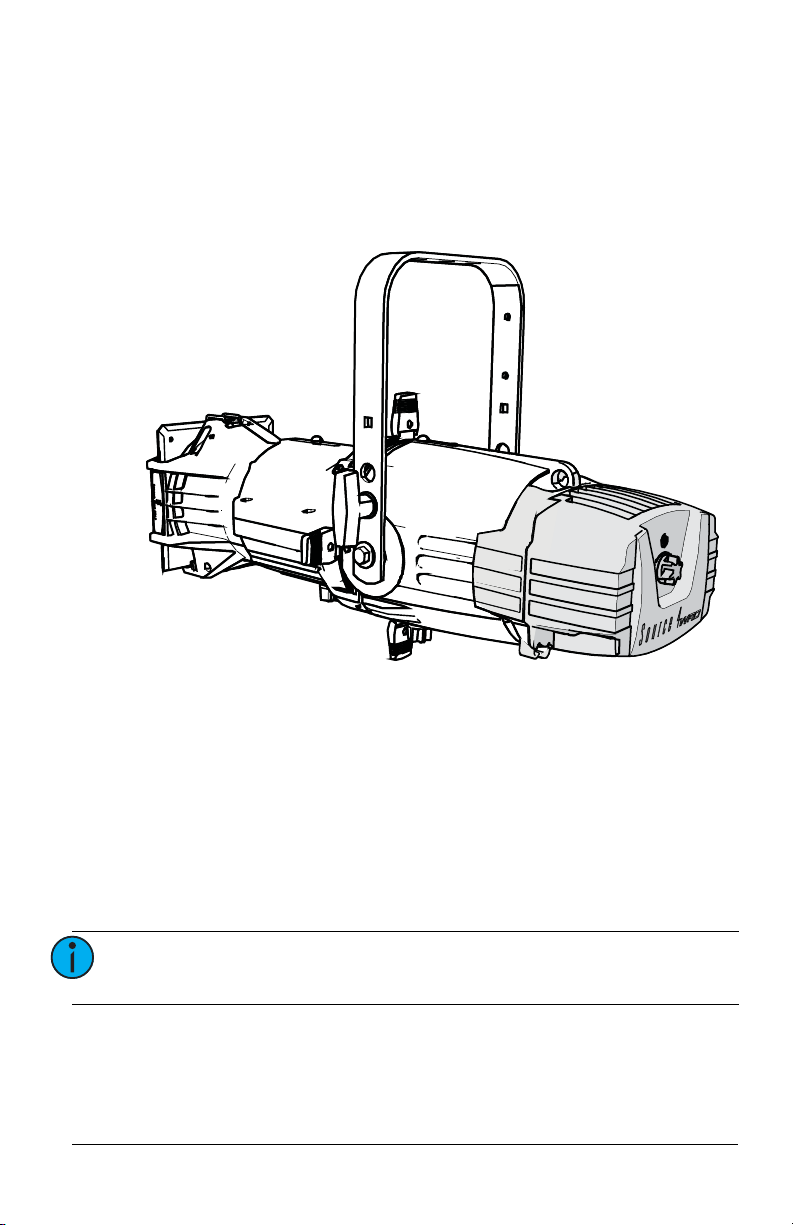

Introduction

Source 4WRD LED

retrofit kit shown

installed on a Source

Four fixture

Congratulations on your purchase of the ETC Source 4WRD LED retrofit kit.

Replacing your existing incandescent burner assembly with the Source 4WRD

LED brings a new tool to your lighting inventory. The Source 4

expands the options for existing Source Four fixtures and adds a new white

LED fixture to the ETC family.

WRD LED

The following Source 4

WRD options are available as 80 CRI, 90 CRI (Gallery),

and 90 CRI Daylight (Gallery) variants:

• Source 4

WRD LED retrofit kit: Used to modify an existing Source Four HPL

incandescent fixture to a white LED fixture. The Source 4WRD LED can

also be used with the Source 4WRD PAR or PARNel Fixture Body to create

a Source 4

WRD PAR or PARNel fixture. For more information, visit

etcconnect.com.

• Source 4WRD Light Engine: Combines the Source Four incandescent

fixture body with the Source 4

90 CRI (Gallery) variants.

Note:

Source 4

WRD

LED retrofit kit is not compatible with

WRD LED. Available only with 80 CRI and

Source Four LED, Fresnel, PAR, or jr fixtures.

User Manual 1

Page 6

Safety

The Source 4WRD fixture is intended for professional use only. Read the entire

manual before using this equipment.

WARNING:

Note the following safety warnings before use:

• Do not mount the Source 4

WRD

fixture on or near a

flammable surface.

• Do not use the Source 4

WRD

fixture below 5°C (41°F).

• Minimum storage temperature is 5°C (41°F). When the

fixture has been stored or transported in cold

temperatures, allow it to warm to room temperature for

a minimum of 1 hour before applying power. Applying

power to a cold fixture will cause damage to the fixture

and void the ETC warranty.

• Do not use this fixture with a damaged power lead. If

the power lead (cord set) is damaged, it must be

replaced.

• Do not use this fixture if glass lens is deeply scratched or

cracked. Damaged lenses must be replaced.

• To prevent wiring damage, or abrasion, do not expose

wiring to edges of sheet metal or other sharp objects.

• Use the Source 4

WRD

fixture in dry locations only, where

humidity does not exceed 90 percent (non-condensing).

These fixtures are not intended for outdoor use.

• Mount and support the fixture only by the primary

suspension holes in the yoke.

• Suspend the fixture from a suitable structure using only

hardware rated for the weight of the fixture.

• In addition to primary suspension, attach a safety cable

(ETC Model 400SC or other approved safety cable or

device) to the fixture housing. An appropriate

attachment point (hole) is provided in the protruding

tab on the fixture housing.

• Disconnect the unit from power and DMX and allow the

fixture to cool before removing or installing the shutter

barrel or other adapters, and for performing all cleaning

and maintenance.

2 Source 4

WRD

Page 7

WARNING:

The Source 4

WRD

LED is not user serviceable. Field

modification of the Source 4

warranty.

WRD

LED will void your ETC

Note:

• Maximum recommended ambient operating

temperature: Ta=50°C (122°F)

• Maximum anticipated external surface temperature:

Tmax=63°C (145°F) at Ta=50°C (122°F)

• External Temperature (steady state achieved) at

25°C (77°F) ambient: 38°C (100°F)

User Manual 3

Page 8

Specifications

Typical Power Consumption

Idle Power / Current DMX Mode: 1.2W/.046A; AC Mode: 0W

Full Intensity Power / Current 155.7W/1.35A

Physical

• Rugged die-cast aluminum construction

• Advanced thermal management systems for long LED life

• Ambient operating temperature: 5°C–50°C (41°F–122°F)

• Minimum storage temperature: 5°C (41°F)

•Weight:

- Source 4

WRD LED retrofit kit only: 3.65 lb (1.66 kg)

- Source 4WRD LED installed on 26° fixture with yoke and

C-clamp:14 lb (6.35 kg)

Electrical

• 114–125VAC 60Hz power input

• 155W draw at full (182W theoretical max. draw)

• Recommended two (2) fixtures per dimmed circuit

(D20 module)

• Max of 14 fixtures per non-dimmed circuit (R20 module)

• If using in DMX mode: Connect fixture to relay, constant

power, or dimmer with regulation off and parked at full

LEDs

• 4 CREE LED modules

• 30,000 hour estimated L70 rating (life-test in progress,

results pending)

Optical • Compatible with all ETC Source Four lens tubes

Control

• DMX512-A compliant

• DMX in and thru via two RJ45 connectors

• AC power for line-dimmed operation

• Simple seven-segment display and two-button user

interface includes local dimming control

Note:

4 Source 4

Connecting both power and data from a SmartBar 1 to a

Source 4

WRD

fixture may cause flickering.

WRD

Page 9

Sensor dimmer settings

The Source 4WRD fixture can be dimmed from a DMX source, an existing

dimmer, or locally on the fixture.

When powering a fixture with a CEM classic, CEM+, or CEM3 for DMX

dimming or AC level setting, set the parameters as shown below to ensure

that the dimmer is out of regulated mode.

The following tables apply to ETC Sensor control modules including CEM,

CEM+, and CEM3.

Note:

You may need to adjust dimmer settings for optimal

fixture control.

Note:

In CEM+, set Max Scale to 140V to guarantee that

regulation is off.

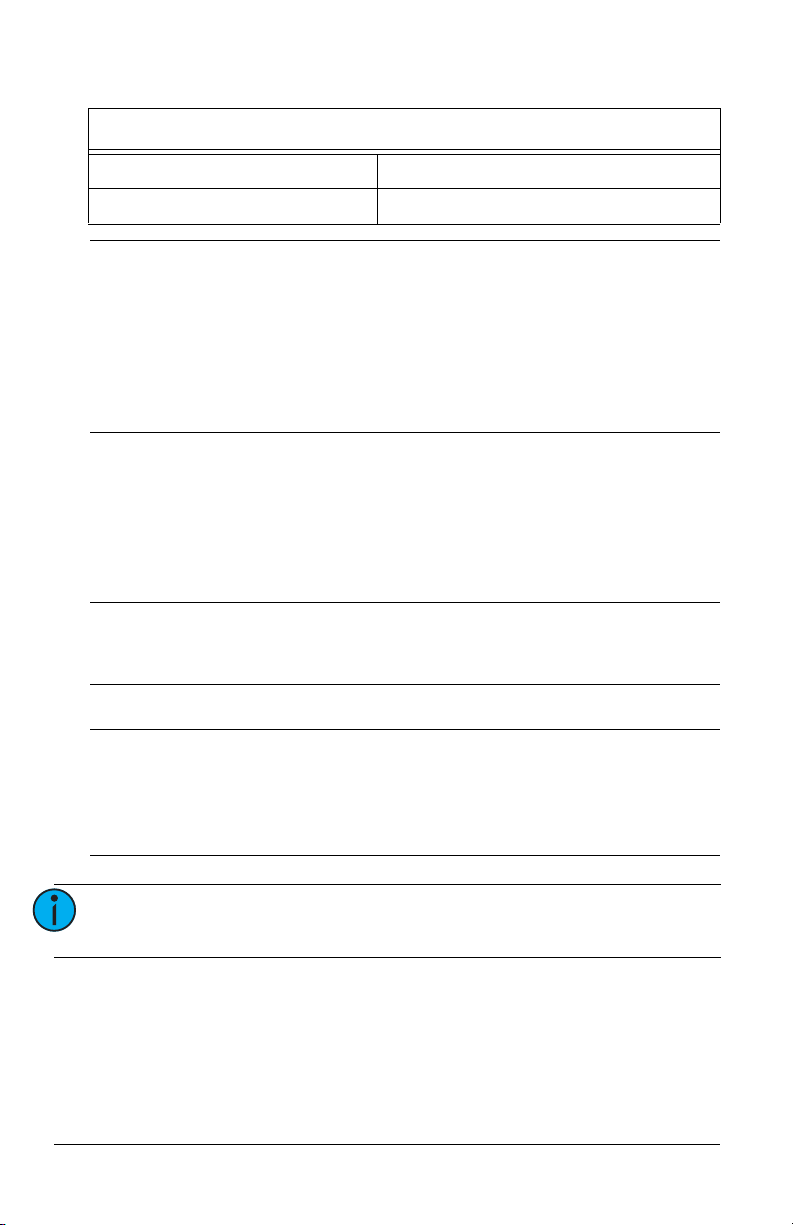

CEM+ and CEM3

Parameter Value

Curve Mod Square

Threshold 1%

Min Scale 6V

Max Scale 140V

Regulation OFF

Preheat Disabled

DC Prevent OFF

Inrush Protect OFF

Scale Load 100

CEM Classic v2.x CEM Classic v3.x

Parameter Value Parameter Value

Mode Normal Mode Normal

Boost 117 Curve Mod-Square

Scale 140

Threshold Normal

User Manual 5

Page 10

Note:

With AC dimming (line-dimmed) mode, performance

may vary based on the control settings of the dimmer

used. For this reason, ETC recommends using AC dimming

for level-setting or for architectural quality dimming

situations. ETC recommends testing the Source 4

fixture on all existing dimmers you wish to use.

Use DMX mode when high-performance, live, dynamic

dimming is required.

You may need to increase the SCR Off Time from the default setting. Contact

ETC for assistance in changing the SCR Off Time, or any other CEM classic,

CEM+, or CEM3 settings.

For the most current information on additional dimmer performance testing

for both ETC and non-ETC dimmers, please visit the ETC website:

https://support.etcconnect.com/ETC/Fixtures/Source_Four/

Source_4WRD%2F%2FSource_4WRD_PAR/

Dimmer_Settings_for_Use_with_Source_4WRD

Color rendering and quality

Source 4WRD fixtures are evaluated for Color Rendering Index (CRI) and Color

Quality Scale (CQS) performance using measured output spectrum. These

numbers may fluctuate slightly from fixture to fixture. This is a normal

characteristic of white LEDs, and this kind of variation is highly unlikely to be

apparent in most applications.

WRD

Fixture CRI

Source 4

(80 CRI) at 3000K

Source 4WRD LED Gallery

(90 CRI) at 3000K

Source 4

Gallery (90 CRI) at 5600K

6 Source 4

WRD LED

WRD LED Daylight

≥80 83 96 0.001

≥90 90 99 0.001

≥90 91 99 0.002

TM-30

(Rf)

TM-30

(Rg)

Duv

WRD

Page 11

Contacting ETC

If you are having difficulties, your most convenient resources are the

references given in this user manual. To search more widely, try the ETC

website at etcconnect.com. If none of these resources is sufficient, contact

ETC Technical Services directly at one of the offices identified below.

Emergency service is available from all ETC offices outside of normal business

hours.

When calling for help, please have the following information handy:

• Product model

• Dimmer manufacturer and installation type

• Other components in your system (Unison, other consoles, etc.)

Americas United Kingdom

ETC, Inc. ETC Ltd

Technical Services Department Technical Services Department

3031 Pleasant View Road 26-28 Victoria Industrial Estate

Middleton, WI 53562 Victoria Road,

800-775-4382 (USA, toll-free) London W3 6UU England

+1-608 831-4116 +44 (0)20 8896 1000

service@etcconnect.com service@etceurope.com

Asia Germany

ETC Asia ETC GmbH

Technical Services Department Technical Services Department

Room 1801, 18/F Ohmstrasse 3

Tower 1, Phase 1 Enterprise Square 83607 Holzkirchen, Germany

9 Sheung Yuet Road +49 (80 24) 47 00-0

Kowloon Bay, Kowloon, Hong Kong techserv-hoki@etcconnect.com

+852 2799 1220

service@etcasia.com

User Manual 7

Page 12

Retrofit kit installation

LEDs

Up and down

navigation

RJ45 data in

and through

User interface

Source 4

WRD LED

Retrofit Kit

A #2 Phillips

screwdriver is

needed for kit

installation

WARNING:

Note:

RISK OF FIRE OR ELECTRIC SHOCK: Source 4

WRD

LED

retrofit kit installation requires knowledge of luminaire

electrical systems. If not qualified, do not attempt

installation. Contact a qualified electrician.

THE RETROFIT KIT IS ACCEPTABLE AS A COMPONENT OF

A LUMINAIRE WHERE THE SUITABILITY OF THE

COMBINATION SHALL BE DETERMINED BY AUTHORITIES

HAVING JURISDICTION.

Wire the power connector (if needed)

If you ordered a Source 4WRD retrofit without a power connector, wire the

connector in accordance with all national and local electrical codes:

• Brown = Line

• Blue = Neutral

• Green/Yellow = Ground

8 Source 4

WRD

Page 13

Remove incandescent lamp housing

1: Unplug the Source Four incandescent fixture and place it on a flat,

stable surface.

2: Loosen the brass thumb screw located above the beam adjustment

knob. The lamp housing is now loose and can be removed.

Note:

User Manual 9

The burner assembly is no longer needed. If you would

like ETC to recycle the burner assembly, contact ETC

Technical Services for more information. See Contacting

ETC on page 7.

Page 14

Install Source 4

Insert threaded

post here

Tighten

screw

Z-adjustment

knob

Source Four

fixture body

Lamp housing

hole

WRD

retrofit

WARNING:

RISK OF FIRE OR ELECTRIC SHOCK: Install this kit only

onto luminaires that have the construction features and

dimensions shown in the images in this document and

where the input rating of the retrofit kit does not exceed

the input rating of the luminaire.

WARNING:

Do not make or alter any open holes in an enclosure of

wiring or electrical components during kit installation.

CAUTION:

Do not touch or clean LED optic domes with anything

other than oil-free canned air.

1: Use oil-free canned air to clean the LED domes prior to installation.

2: With the fixture resting securely on a flat surface, attach the supplied

threaded post to the back end of the fixture body. Use a crescent

wrench to tighten the threaded post one-quarter turn past finger tight.

3: Gently slide the Source 4

WRD LED onto the fixture body and threaded

post while guiding the LED tower into the lamp housing hole, as shown

below. Take care to prevent contact between the LEDs and the

reflector.

4: Use a #2 Phillips screwdriver to tighten the screw located on the back

end of the Source 4

WRD LED, directly above the Z-adjustment knob.

5: Pull gently to verify secure attachment.

10 Source 4

WRD

Page 15

Fixture installation

Source 4WRD LED

Retrofit

Attached power lead

Adjustable yoke

Source Four lens tube

(not included)

Shutters (x4)

Yoke locking

knob

Cat5 cable

strain relief

The Source 4WRD Light Engine combines the classic form factor of the Source

Four incandescent fixture with an LED light source. The Source 4WRD Light

Engine includes an adjustable yoke, C-clamp, and attached power lead.

Attach C-clamp and safety cable

The C-clamp attaches the fixture to the mounting pipe and allows you to

adjust the position of the mounted fixture. ETC recommends using

1.5” schedule 40 pipe.

1: Tightly fasten the C-clamp to the yoke with the provided yoke bolt and

lock washer.

2: Place the C-clamp on mounting pipe, then tighten the pipe bolt to

secure it.

3: Loosen the C-clamp pan screw and rotate the yoke to the desired

position.

4: Tighten the pan screw to lock the fixture.

5: Connect the safety cable.

6: Tighten C-clamp pipe bolt to 15–20 ft lbs (20–27 Nm), approximately

finger tight plus up to one-quarter turn.

CAUTION:

7: Tighten the yoke pivot bolt to 5–10 ft lbs (6–7 Nm), approximately

finger tight plus up to one-eighth turn.

Do not exceed 25 ft lbs (33 Nm) while tightening the

C-clamp pipe bolt. Do not use excessive force.

CAUTION:

User Manual 11

Do not exceed 15 ft lbs (20 Nm) while tightening the yoke

pivot bolt. Do not use excessive force.

Page 16

Connect cables

The fixture can be controlled by AC power or DMX. The fixture responds to the

control method selected using the user interface. For more information, see

User interface

on

page 13

.

Note:

Make sure your dimmer is out of regulated mode for

optimum performance. See Sensor dimmer settings on

page 5 for recommended dimmer settings.

Note:

WARNING:

1: If using DMX control: Connect one RJ45 data cable for data-in and one

for data-thru, as needed.

• To order RJ45 to female XLR adapter, use ETC part number W6538.

• To order RJ45 to male XLR adapter, use ETC part number W6539.

2: When connecting data, consider the following:

• Two strain reliefs are built in to the bottom of the Source 4WRD

• When using DMX over Cat5, use Cat5e or better. Cable distance

• The Source 4

• Up to 32 fixtures can be connected together into a daisy chain.

Connecting both power and data from a SmartBar 1 to a

Source 4

Do not use or store the Source 4

5°C (41°F). When the fixture has been stored or

transported in cold temperatures, allow it to warm to

room temperature for a minimum of 1 hour before

applying power. Applying power to a cold fixture will

cause damage to the fixture and void ETC warranty.

fixture and should be used to support the fixture’s data cable.

must not exceed 300 m (1000 ft).

and should not be connected to a system network.

WRD

fixture may cause flickering.

WRD

fixture below

WRD fixture cannot be controlled via network protocols

Note:

The fixture is not self terminating. You must terminate

the last fixture in line with a 120 Ohm resistor. Please

contact your ETC customer service representative to

purchase ETC part number N4086.

3: Connect fixture to power source.

12 Source 4

WRD

Page 17

DMX pinout

User interface

Up and down

navigation buttons

RJ45 data

connections

Pin Description Pin Description

1 DMX + 5 Not Connected

2 DMX - 6 Not Connected

3 Not Connected 7 Iso Common (Shield)

4 Not Connected 8 Not Connected

User interface

The two-button, seven-segment display shows the DMX address, AC mode, or

the manually-set level.

• Set a DMX address: Use the up and down arrows to navigate to the

desired DMX address number (1–512).

• Set the fixture to AC mode: Use the down arrow to navigate one

number below DMX address 1. The display will read .

• Manually set a level: Use the down arrow to navigate one number

below . The display will read (Level = Full). Use the down arrow

to decrease the level to a percentage of full ( = 99%, = 98%,

etc.). You can set levels from 0%–100% (full).

User Manual 13

Page 18

Error codes

This shows an ideal beam

of uniform light

Adjust towards PEAK to

blend overlapped beams

Adjust towards FLAT to

improve sharp focus

Adjustment knob

The following error codes may be seen on the Source 4WRD user interface.

• indicates the fixture has gone into over-temperature protection.

Reset the fixture to clear the code.

- For DMX mode: Return the DMX control to 0.

- For AC mode: Remove the fixture from power for five seconds and

then restore power.

• indicates the fixture has gone into under-temperature protection.

Allow the fixture to warm to a minimum of 5°C (41°F).

• Flashing DMX address indicates loss of DMX.

• Dark screen indicates loss of power or fixture time-out. In the event of

time-out, press any button to wake the user interface.

Focus the fixture

Set the Z-adjustment

Use the Z-adjustment knob located on the rear of the Source 4WRD fixture to

adjust the field of the LED light for specific applications.

1: Turn on the Source 4WRD fixture and aim it at a flat surface.

2: Slide the fixture barrel towards or away from the Source 4

create a hard-edged beam of light.

3: Turn the knob toward PEAK or FLAT until the desired field is obtained.

14 Source 4

WRD LED to

WRD

Page 19

Adjust the yoke position

Low clearance

position

General use

position

Yoke locking

knob

Retaining

clip

Change the height position

1: Remove the yoke locking knobs,

washers, and hex bolts from either

side of the fixture.

2: Raise or lower the fixture to the

desired position within the yoke.

3: Reinstall the yoke’s hex bolts,

washers, and locking knobs.

4: Tighten the yoke knobs to secure in

position.

Set the angle within the yoke

1: Loosen the yoke locking knob.

Do not remove the knob.

2: Tilt the fixture to the desired

position.

3: Tighten the yoke locking knob

to secure in position.

Shape the beam

User Manual 15

You can shape the beam by using the

shutters, a pattern, an optional drop-in iris,

and by rotating the barrel.

Use the color frame

The color frame holder is equipped with a

spring-loaded retaining clip that prevents

color frames and accessories from falling out.

WARNING:

1: Release the retaining clip by pushing it sideways while gently pulling

2: Insert the color frame.

3: Lock the retaining clip by pushing sideways while gently pushing

backwards.

forward.

Make sure all color frame accessories are locked in

position with the retaining clip before hanging the

Source 4

WRD

fixture.

Page 20

Use a pattern

A-size pattern

holder: Holds 3”

diameter patterns

B-size pattern holder:

Holds 2.5” and 2.75”

diameter patterns

Fan and

fin stack

The pattern holder slot is on the top side of the barrel and in front of the

shutters. It accommodates A-size, B-size, and glass pattern holders.

Note:

3.12" Diameter

3.70"

Because the Source 4

2.75" Diameter

3.70"

WRD

aperture is 3 inches wide, ETC

recommends using A-size patterns for maximum pattern

effectiveness.

Cleaning and maintenance

Clean the fixture

• Use oil-free canned air to clean the

LED domes prior to installation and

prior to storage.

• Use oil-free canned air to clean the

fan and fin stack as part of regular

fixture maintenance.

• When not installed on the fixture,

store the Source 4

original packaging or in a dustresistant plastic bag.

CAUTION:

Do not touch or clean LED optic domes with anything

other than oil-free canned air.

WRD LED in its

16 Source 4

WRD

Page 21

Store the retrofit

Store with LED

dome up

• Store the Source 4WRD LED at temperatures of

5°C (41°F) or higher.

• If you must store the Source 4

5°C (41°F), make sure it is in an upright position as

shown to the right. Allow it to warm to room

temperature for a minimum of one hour before

applying power.

WRD LED below

Clean the lenses

Note:

After shipping or storing the Source 4

WRD

LED below

5°C (41°F), visually inspect the unit to ensure the low

temperatures have not caused cracking of the LED array.

WARNING:

Replace lenses if they contain visible damage (cracks or deep scratches) that

may impair their effectiveness.

Note:

Do not use ammonia-based or other harsh commercial

cleaners. Clean lens and reflector only as directed.

Commercially available glass cleaning agents should be

avoided as they may contain ammonia, other harsh

chemical detergents or abrasive agents. These cleaners

may damage the glass surface and the Anti-Reflective

coatings. Do not immerse or soak the glass in any

cleaning solution.

To clean the inside of lenses, you must remove the lenses

from the lens tube. For instructions on removing the

lenses, see the

Source Four Assembly Guide

, which is

available for download at etcconnect.com.

1: Remove the lens tube from the fixture barrel:

a: Remove the beam focus knob and retainer bolt from the top of the

barrel and set aside.

b: Slide the lens tube out of the barrel.

2: Remove any dust from inside the lens tube with a blast of oil-free air or

wipe with a clean, lint-free cloth. Isopropyl alcohol, distilled water, or a

50%-50% mixture of each can be used to clean the glass surface.

3: Slide the lens tube back into the barrel with the color frame retaining

clip on top. Reinstall the beam focus knob and retainer bolt.

User Manual 17

Page 22

Clean the reflector

WARNING:

To quickly clean the reflector, remove the lens tube and clean the dust from

the reflector with a blast of oil-free air. You may also wipe the reflector with a

clean lint-free cloth. If either method is not sufficient, follow these steps.

1: To protect the lamp housing during cleaning, remove the LED lamp

housing by loosening the attachment screw and pulling the housing

straight out. (See image on

2: Remove the barrel rotation knob located at the bottom of the barrel.

Use a Phillips screwdriver to remove the retainer bolt located on top of

the reflector housing.

3: Rotate the barrel 45° in either direction. Carefully remove the barrel

from the reflector housing.

4: Remove dust with a blast of oil-free air or wipe with a clean, lint-free

cloth. Isopropyl alcohol, distilled water, or a 50%-50% mixture of each

can be used to clean the glass surface.

5: Insert the barrel into the reflector housing with the iris/pattern slot on

top. Align the triangles on both parts.

6: While gently pressing in, rotate the barrel 45° clockwise until it sets into

position, then rotate the barrel counterclockwise 45°. The barrel should

be firmly attached and the triangles should be aligned.

7: Reinstall the barrel rotation knob and tighten the retainer bolt.

8: Reinstall the LED lamp housing and tighten the attachment screw. See

Install Source 4

Unplug the fixture before attempting to clean the

reflector.

WRD

retrofit

page 10

on

.)

page 10

.

18 Source 4

WRD

Page 23

Clean 5° and 10° polymer lenses

To quickly clean the lenses, remove dust with a blast of oil-free air. If this is not

sufficient, follow these steps.

CAUTION:

Handle polymer lenses by their edges only. Never rub

anything dry on a polymer lens.

1: Remove the beam focus knob at the bottom of the barrel. Remove the

lens tube from the barrel.

2: Use a Phillips screwdriver to remove the brackets that hold the lens in

place. Remove the lens from the tube.

3: Dip the lens in a clean isopropyl alcohol/water mixture (9 parts water to

1 part isopropyl alcohol).

4: Use a soft moistened nylon bristle brush to wash the smooth side of the

lens in a linear (non-circular) motion.

5: Use the same brush to lightly wash the ridged side of the lens by

following its ridges.

6: Dip the lens in a clean isopropyl alcohol/water mixture (9 parts water to

1 part isopropyl alcohol).

7: Dry the smooth and ridged surfaces with an air gun. Make sure the air

flow moves liquid away from you.

8: Inspect the lens for dirt. Repeat steps 3–7 if necessary.

9: Set the lens back in the lens tube with the ridged side facing the front

of the tube. Reinstall the lens brackets.

10: Slide the lens tube back into the barrel with gel frame retainer on top.

Reinstall beam focus knob.

User Manual 19

Page 24

Corporate Headquarters Middleton, Wisconsin, USA Tel +608 831 4116

Service (Americas) service@etcconnect.com

London, UK Tel +44 (0)20 8896 1000 Service: (UK) service@etceurope.com

Rome, IT Tel +39 (06) 32 111 683 Service: (UK) service@etceurope.com

Holzkirchen, DE Tel +49 (80 24) 47 00-0 Service: (DE) techserv-hoki@etcconnect.com

Hong Kong Tel +852 2799 1220 Service: (Asia) service@etcasia.com

Web: etcconnect.com Copyright © 2018 Electronic Theatre Controls, Inc. All Rights

Reserved. Product information and specifications subject to change. ETC intends this

document to be provided in its entirety.

7067M1200-1.1.2 Rev B Released 2018-12

Loading...

Loading...