Page 1

Circuit Protection & Control

Flow Meter FC01-LQ

User handbook

M_FC01_LQ_0408_eM_FC01_LQ_0408_e

Page 2

Please follow these installation and adjustment instructions carefully. Failure to comply with

these instructions or misuse of this equipment will void your warranty coverage.

The instructions cover software version 1.00.

Equipment installation, connection and adjustment by qualified personnel only!

Page 3

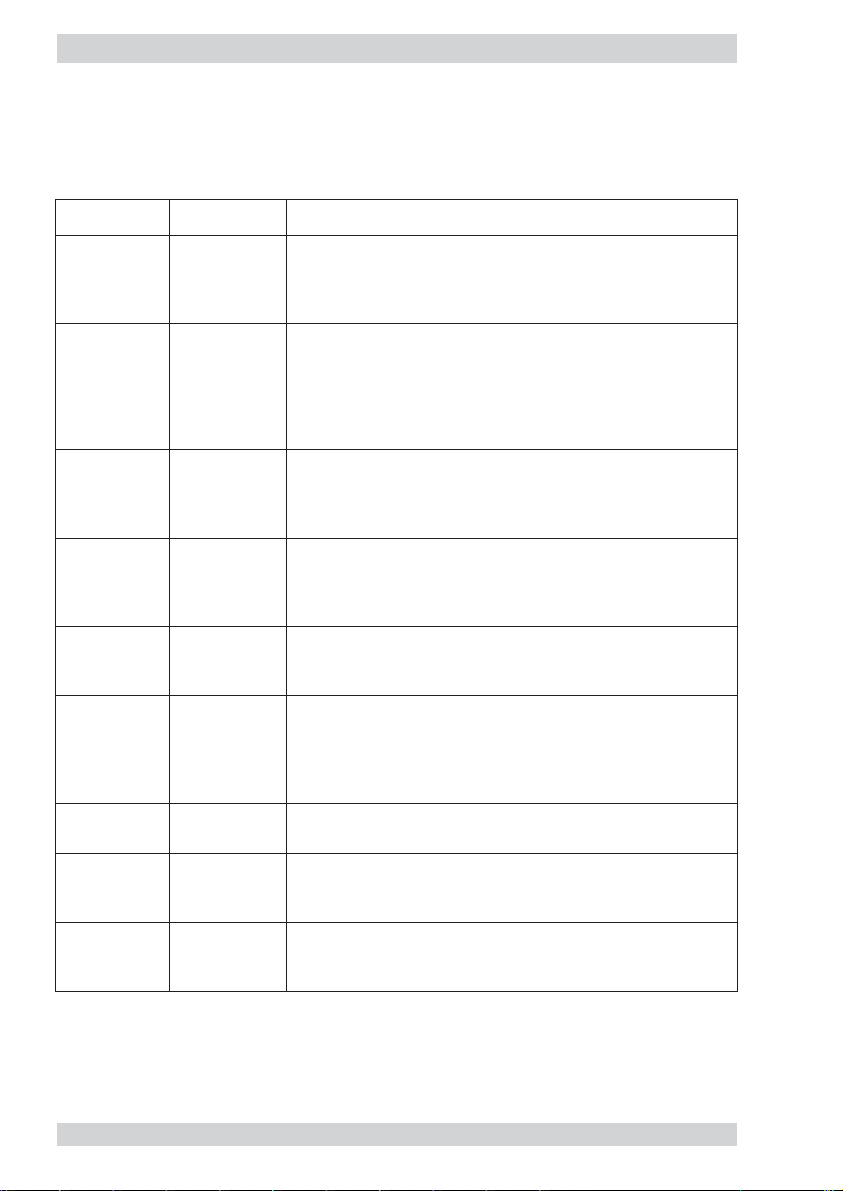

Table of content

1 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.1 Calorimetric monitoring procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.2 System description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.2.1 User interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.1 Selection of material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Stainless steel 1.4571 / AISI 316 Ti . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Nickel-based alloy (Hastelloy 2.4610) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.2 Installation of the monitoring heads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.2.1 Insertion head CSP-11 for sensor adapter TP-.. and ball valve BV-.. . . . . . . 7

2.2.1.1 Sensor adapter TP-.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.2.1.2 Mounting instructions for monitoring head CSP-.. with

sensor adapter TP-.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.2.1.3 Ball valve BV-.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.2.2 Monitoring head CSF-11 with adjustable immersion depth . . . . . . . . . . . . . 10

2.2.2.1 Mounting instructions for monitoring head CSF-11 . . . . . . . . . . . 11

2.2.3 Electrical connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.3 Installation of electronic control unit FC01-LQ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.3.1 Mechanical installation

2.3.1.1 Rail-mounted version FC01-LQ-U1... . . . . . . . . . . . . . . . . . . . . . . 14

2.3.1.2 Surface mounted version FC01-LQ-FH-U1... . . . . . . . . . . . . . . . . 15

2.3.1.3 Front panel mounted version FC01-LQ-ST-U1... . . . . . . . . . . . . . 16

2.3.2 Electrical connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2.3.2.1 Circuit diagram FC01-LQ 24 V (relay outputs) . . . . . . . . . . . . . . . 20

2.3.2.2 Circuit diagram FC01-LQ 24 V (transistor outputs) . . . . . . . . . . . 21

2.3.2.3 Electrical connection - frequency output

(version FC01-LQ-U1T4) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3 Operating system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Keypads MODE, UP and DOWN

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Menu paging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Calling a menu option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Entry of numerals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Transfer of entries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Deleting data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

M

▲

▼

Page 4

4 Operation and main menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4.1 Switch-on performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4.2 Measuring cycle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4.2.1 Operating data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

4.2.1.1 Measured value(s) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

4.2.1.2 Peak values (PEAK VALUE MIN / PEAK VALUE MAX.) . . . . . . . . . 28

4.2.1.3 Last error (LAST ERROR) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

4.2.1.4 Main menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

5 Configuration (CONFIGURATION) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

5.1 Selection of monitoring head (SENSOR SELECT) . . . . . . . . . . . . . . . . . . . . . . . . . . 30

5.2 Monitoring head data (SENSOR CODE) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

5.3 Limit switch combination (LIMIT SWITCHES) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

5.4 Flow rate unit (FLOW UNIT) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

5.5 Medium temperature unit (TEMP. UNIT) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

5.6 Display (DISPLAY SELECT) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

5.7 Bar graph (BARGRAPH) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

5.8 Pipe diameter (PIPE SIZE) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

5.9 Frequency output and totalizer (FREQUENCY OUTPUT) . . . . . . . . . . . . . . . . . . . . . 34

5.10 Analogue output - flow rate (ANA OUT FLOW) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

5.11 Analogue output - medium temperature (ANA OUT TEMP.) . . . . . . . . . . . . . . . . . . . 35

5.12 Quitting the configuration menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

5.13 Configuration menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

5.14 Configuration submenus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

6 Parameter selection (PARAMETERS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

6.1 Measuring time (MEAS. TIME) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

6.2 Limit switch 1 ON/OFF value (LS1 ON, LS1 OFF) . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

6.3 Limit switch 2 ON/OFF value (LS2 ON, LS2 OFF) . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

6.4 Scaling factor (FLOWSCALE) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

6.5 Quitting the parameter menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

6.6 Parameter selection menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

7 Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

7.1 Test and diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

7.1.1 Priority group I . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

7.1.2 Priority group II . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

7.1.3 Priority group III . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

7.2 Potential errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Page 5

8 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

8.1 Ambient conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

8.2 Electrical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

8.2.1 Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

8.2.1.1 DC voltage supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

8.3 Analogue outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

8.3.1 Voltage output V1 - 5 V FS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

8.3.2 Voltage output V2 - 10 V FS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

8.3.3 Current output C1 - 20 mA FS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

8.4 Signal outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

8.4.1 Relay outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

8.4.2 Transistor outputs (DC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

8.5 Metrological data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

8.5.1 Flow rate measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

8.5.1.1 Monitoring head CSP-11 - with sensor adapter type TP-.. . . . . . 53

8.5.1.2 Monitoring head CSF-11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

8.5.2 Temperature measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

8.5.3 Electronic control unit FC01-LQ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

8.6 Sensor interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

8.6.1 Electrical data of the terminal for calorimetric monitoring heads . . . . . . . . . 56

9 Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Index

Appendix

1 Performance of the digital and analogue outputs during the operating and error modes

2 Menu structure of the FC01-LQ (operator dialogue)

Page 6

Page 7

1 Description

The Flow Meter FC01-LQ is designed to detect flow speed, flow volume and medium temperature

of water (other liquids upon request).

These quantities are made available to the user as analogue electrical signals, physically isolated,

as current or voltage output and may be monitored by means of a limit monitor.

As relay outputs or transistor outputs the digital signals enable the user to integrate the FC01-LQ

into a control and monitoring system.

The transistor outputs enable the user to additionally process fault, status and volume pulse

indications in the control system.

The Flow Meter FC01-LQ may be used with calorimetric monitoring heads type CSx

(CSP, CSF).

Page 8

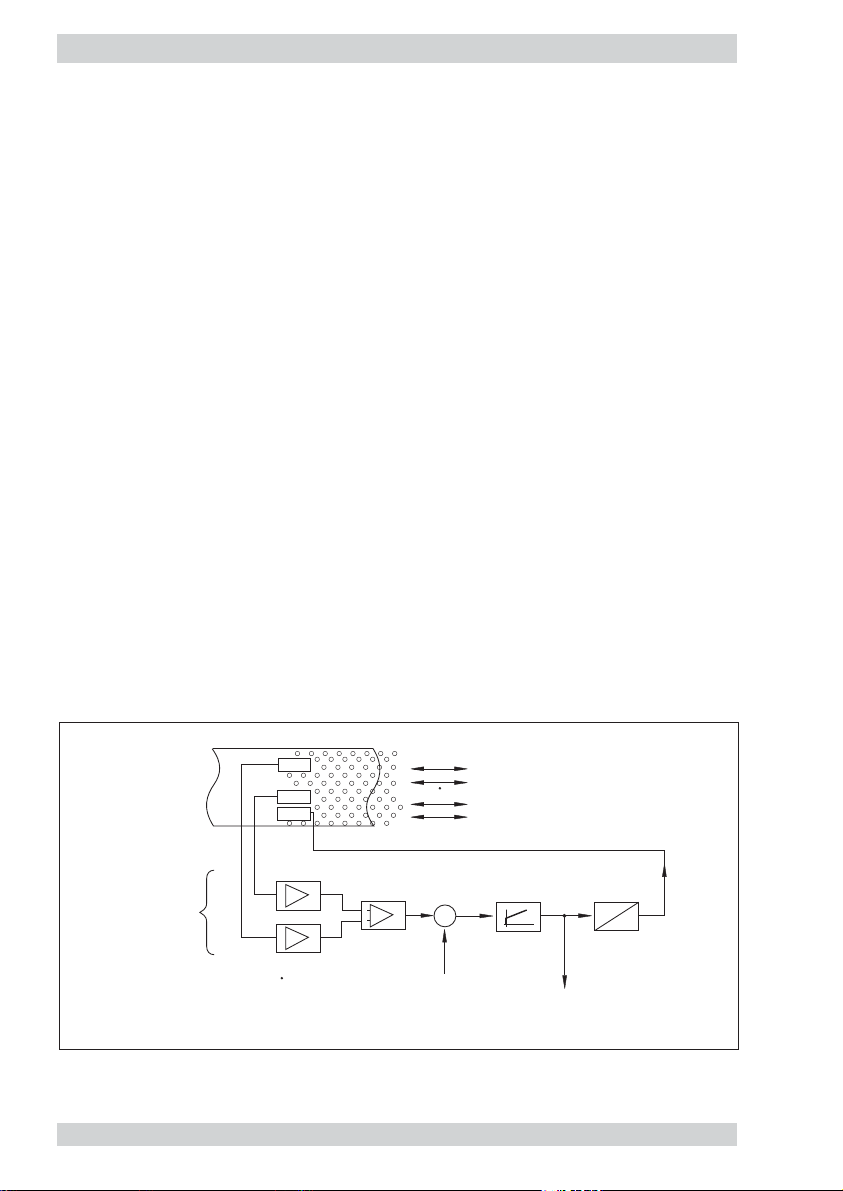

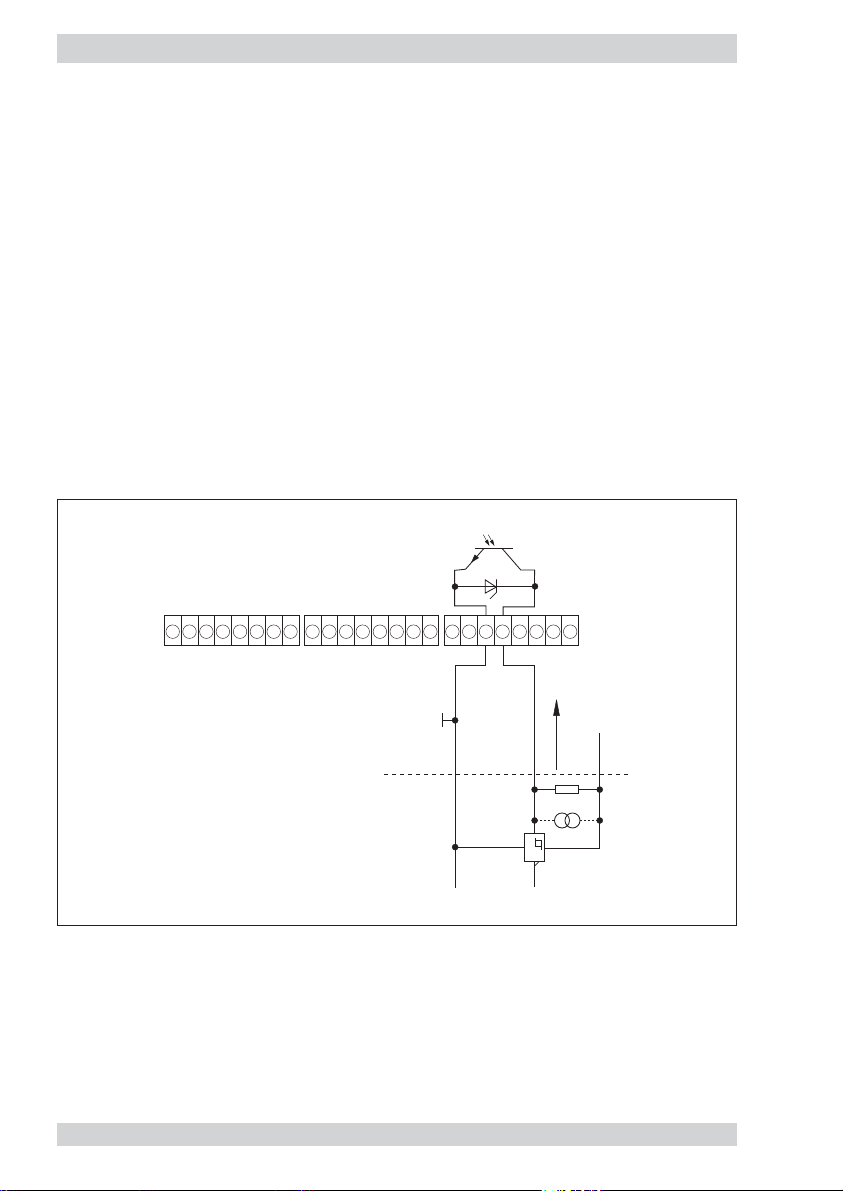

1.1 Calorimetric monitoring procedure

The calorimetric measuring procedure is based on the physics of heat dissipation.

A body with a temperature higher than its surroundings supplies a medium flowing past that

body with energy in the form of heat. The amount energy supplied is a function of temperature

difference ∆ϑ and mass flow.

The thermal measuring method CTD (Constant-Temperature-Difference) is based on following

principle:

The temperature difference ∆ϑ between the two sensors is kept constant and the mass flow is

determined by measuring the calorific power.

Fig. 1 is a schematic diagram of a CTD method based sensor.

Two temperature-sensitive resistors (sensor elements RS and RM) are immersed in the medium.

Sensor RM assumes the temperature of the medium ϑ

M

whilst heater resistor RH heats element

RS to temperature ϑ

S

. As a function of the medium, the temperature differential ∆ϑ = ϑS- ϑMis

preselected as a reference variable by the CTD control and is kept constant. The r equir ed heater

current I

H

is a function of mass flow so that the control variable y of the control can be used for

evaluation.

Major benefits of this method are:

● Fast response, particularly to sudden flow standstill.

● Medium temperature measurement, providing optimum temperature compensation.

● Increased safety because the sensor cannot be overheated during flow standstill.

The flow rate is determined by mass flow.

fig. 1

control loop

RM

RS

RH

K

p

ϑ

S

K

p

K

p

m: mass flow

w: reference variable ( )

x : actual value (S-M)

−

+

ϑ

M

Δ

ϑ

ϑ

m

-x xd

w

xd: system deviation

y : control variable

ϑ

IH: heater current

medium

Kp,T

I

n

y

y

H

U

I

Page 9

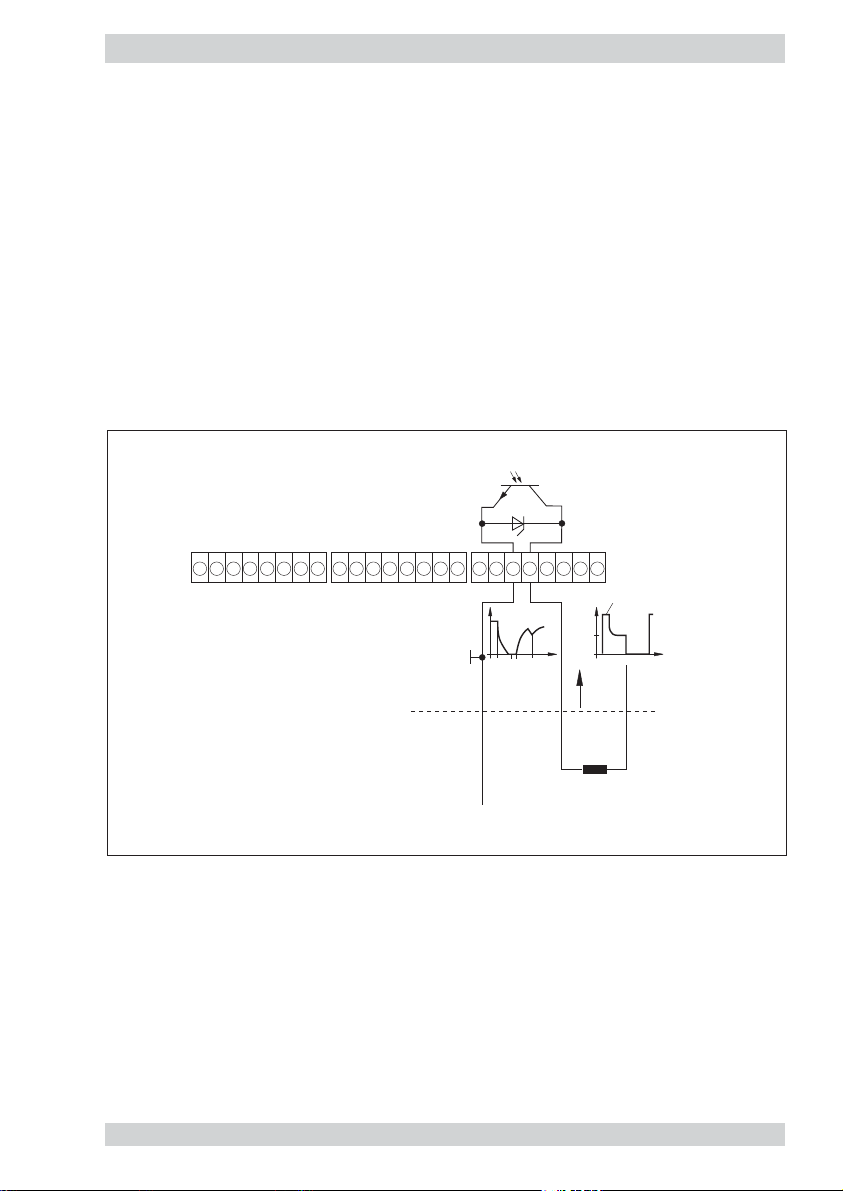

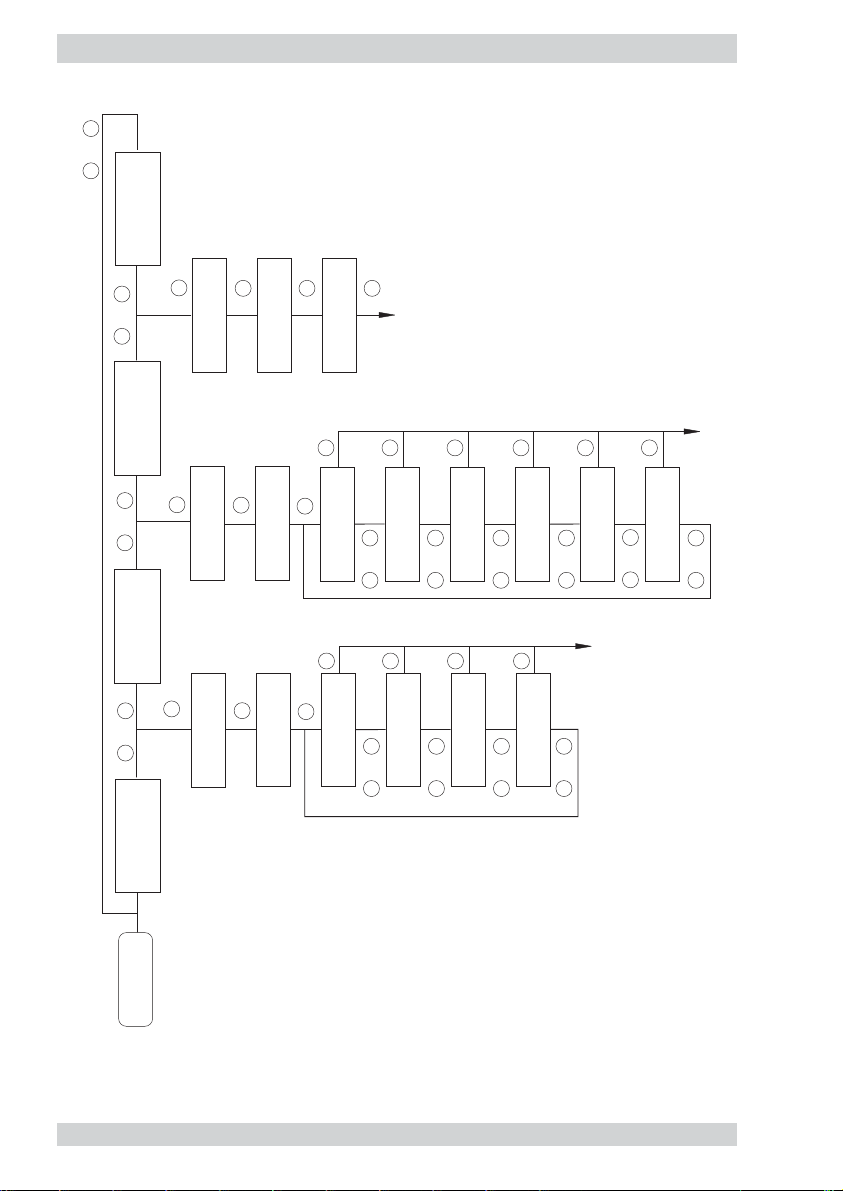

1.2 System description

The system comprises the following hardware functional modules:

1 Input voltage DC supply (terminal XV)

2 User interfaces: 2.1 signal outputs 2-way or 4-way signal outputs (terminal XAH)

2.2 analogue outputs 1 and 2 (terminal XAO)

3 Keyboard and display: keypads

liquid crystal display

4 Sensor interfaces: calorimetric monitoring had type CSx_ (terminal XSK)

5 Micro controller system: signal processing and monitoring

fig. 2

Power supply DC/DC

Sensorinterface

calorimetric

monitoring

head CSx_

4

1

Micro controller

system

5

Keyboard and Display

3

2.1

User

interface 1

User

interface 2

2.2

1 Input voltage:

2.1 User interface 1

2.2 User interface 2

3 Keyboard/Display:

4 Sensor interface

5 Controller system:

DC 19 … 32 V

relay outputs: 2 limit values

transistor outputs: 2 limit values +

analogue outputs

current or voltage

keypads

LC display

2 x 16 digits

calorimetric monitoring head type CSx_

signal processing

I/O - controlling

monitoring

parameter memory

1 error indication +

1 busy signal or

frequency output

(software selected)

Page 10

The power supply is physically isolated between power supply input and system power

supply output. This also applies to the analogue and signal outputs which are physically

isolated from each other as well as from the other electronics.

There is no electrical isolation between monitoring head and central electronic unit.

Connection of the monitoring heads is by means of precut cable links.

Cables and user interface connections are shown in para. 2.3.2 and circuit diagram 2.3.2.1/ 2.3.2.2.

System configuration and parameter setting are by means of the keyboard if default values

need to be changed. (paras. 5 and 6)

This mainly applies to monitoring head selection, signal outputs (switch point setting) and

analogue outputs (zero point setting and scaling).

1.2.1 User interfaces

Signal outputs: 1. R2 - Relays outputs (2 limit values)

(optional) Two-channel physical isolation, relay change over contact

The channels may be assigned in menu “CONFIGURATION”, either

individually or in pairs, to the physical quantities of temperature or

flow. The switch on and off values can be set as desired in menu

“PARAMETERS” (yet within the measuring range) for each contact.

Please see para. 8.4.1 for electrical connection.

2. T4 - Transistor outputs (2 setpoints + 2 status outputs or 2 setpoints +

1 status output + frequency output)

Four-channel physical isolation, transistor output - collector/emitter

(NPN) freely connectable

Channel 1: common error signal

Channel 2: busy signal or frequency output

Channels 3 and 4: Both channels may be assigned individually or in

pairs to the physical quantities of temperature or flow. The switch on

or off values of each transistor output can be set as desired.

Please see para. 8.4.2 for electrical connection.

Analogue outputs: Two-channel physical isolation, current or voltage output

(optional) Please see the ordering number to find out whether it is a current or

voltage output.

Output quantities: 0/1 - 5 V FS (option V1)

0/2 - 10 V FS (option V2)

0/4 - 20 mA FS (option C1)

These FS (full scale) output quantities apply to both channels (flow and

temperature) as standard.

20% zero elevation and FS value can be programmed. (See para. 5.11)

Shield connections are ungrounded.

The shields of the signal cables should be applied on one side only.

Page 11

Power supply: DC 24 V supply

Internal switch mode power supply with physical isolation of the

primary and secondary side.

Noise emission on the connection cable is limited by circuit design

and filter.

A PTC resistor provides protection from overcurrent. The element

automatically resets upon removal of the disturbance or after

disconnection of the supply voltage of the FC01-LQ for approx. 1 s

(e.g. remove terminal XV).

Please see para. 8.2.1 for technical characteristics.

Page 12

2 Installation

These are general directions for the application of calorimetric measuring heads which from

application to application should be reviewed by the user in accordance with individual

requirements.

2.1 Selection of material

Stainless steel 1.4571 / AISI 316 Ti

The standard monitoring head material is stainless steel 1.4571/AISI 316 Ti, an austenitic, acidresisting stainless steel that is commonly used throughout industry. Manufacturers claim it also

withstands oxidizing organic and anorganic acids, and partly even reductive media.

The resistance of this stainless steel should however be verified by the user, particularly when it

is used in medium mixtures that may from time to time be exchanged with cleansing agents. Its

chemical resistance also depends on temperature, flow rate and concentration of the medium.

Stainless steels owe their resistance to rust mainly to their alloy combination with chromium, the

formation of chromic oxide on the steel surface resulting in a passive state. Contamination,

deposits on the surface, or foreign rust may however neutralize the passivity. Therefore care

should be taken to keep the surfaces clean.

Stainless steel heads must not get in contact with steel parts other than stainless steel or with

chemically dissimilar metals, as this would cause electrolytic corrosion.

Nickel-based alloy (Hastelloy 2.4610)

Hastelloy 2.6410 is a material with a chemical resistance generally exceeding that of stainless

steel and copper-based alloys. They are particularly suitable for alkaline media (pH > 7). They

should however be examined for suitability for each specific application using resistance tables

and pragmatical values.

Page 13

2.2 Installation of the monitoring heads

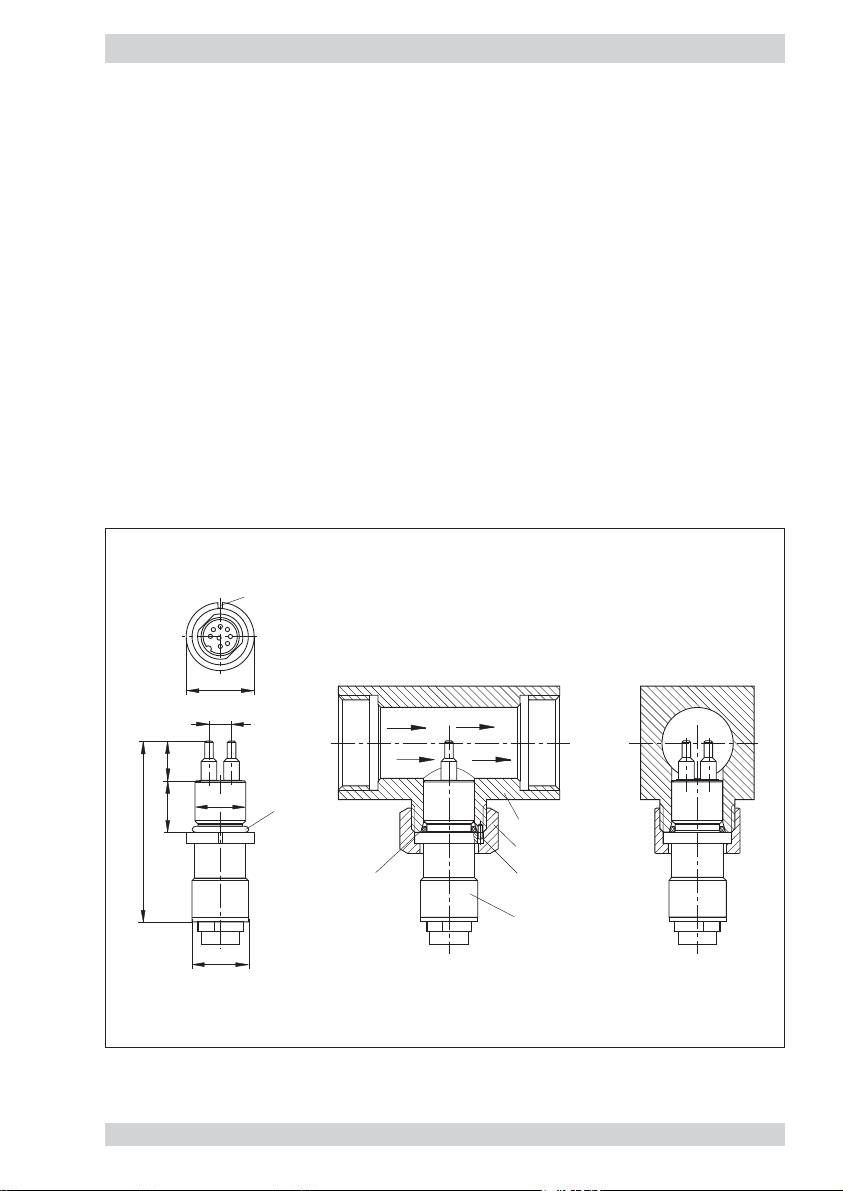

2.2.1 Insertion head CSP for sensor adapter TP-.. and ball valve BV-..

Application: general industry and installation

Style: insertion-type for sensor adapter and ball valve

Installation: sensor adapter TP-.. (fig. 4)

ball valve BV-.. (fig. 5)

Material of the area

exposed to medium: stainless steel 1.4571/AISI 316 Ti, electropolished

O ring viton

fig. 3

ø24

retention slot

8

14

ø18

18.2

64

ø20

O ring

O ring

sensor adapter TP-…

union nut

retention pin

monitoring head CSP-11..

Page 14

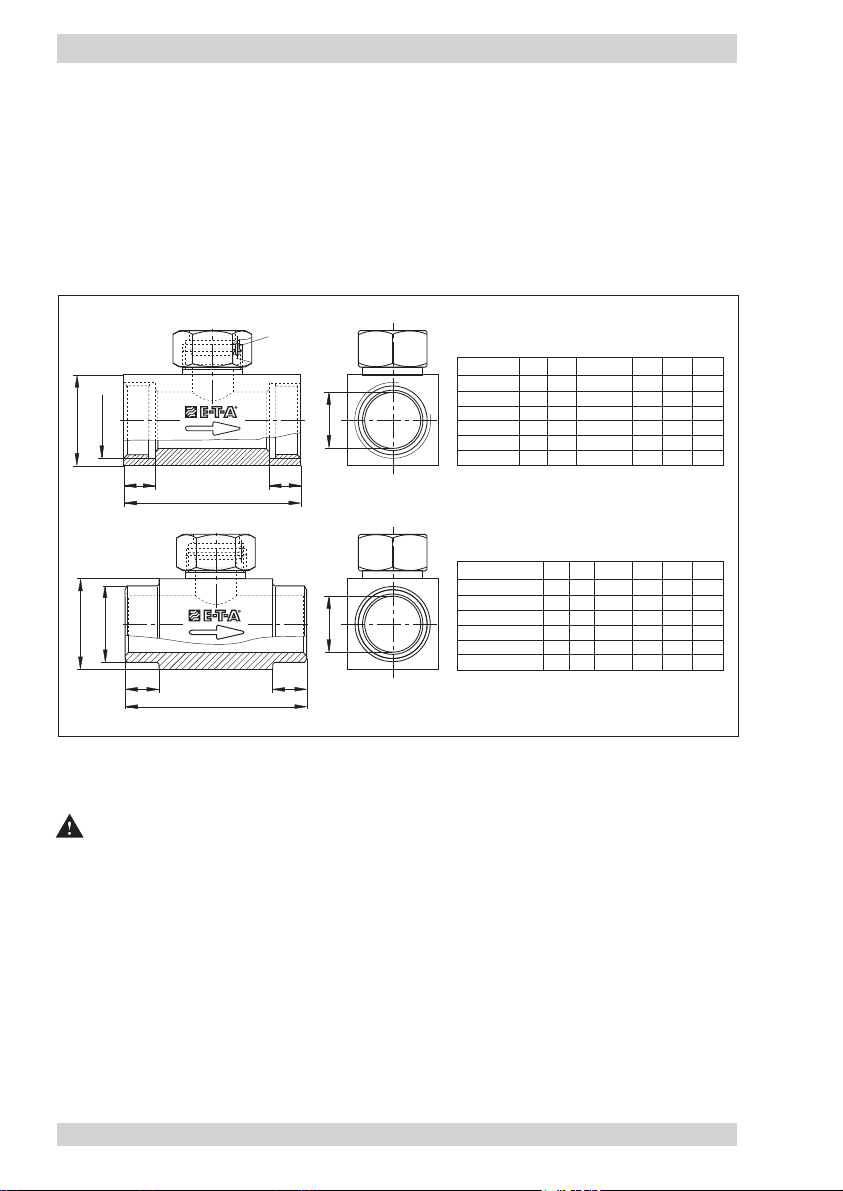

2.2.1.1 Sensoradapter TP-..

The sensor adapter TP-.. is available in 6 pipe diameters from 1/2" to 2".

Sensor adapter is available as screw-in (fig. 4 top) or welding type (fig. 4 bottom).

Material of the area exposed to medium:

- brass or

- stainless steel 1.4571/AISI 316 Ti

fig. 4

2.2.1.2 Mounting instructions (monitoring head CSP-.. with sensor adapter TP-.. )

Caution!

The monitoring head should only be installed or removed when the pipes are unpressurised.

To ensure the safety label is clearly visible, it should be affixed on to or close to the measuring point.

● Insert the monitoring head with the O ring into the sensor adapter and tighten the union

nut (observe correct retention).

The retention pin ensures correct alignment of the monitoring head after the union nut has

been tightened.

Correct immersion depth of the monitoring head is ensured by the stop provided.

Sealing of the monitoring head in the sensor adapter is by means of the O ring provided (fig. 3).

● Screw the sensor adapter into the pipe, using hemp or teflon tape for sealing.

retention pin

SW

Ty pe

DN

TP-01 …

TP-02 …

G

t

L

ødød

t

TP-03 …

TP-04 …

TP-05 …

TP-06 …

15

20

25

32

40

50

G

1/2"

16

3/4"

20

1"

25

11 /4"

32

11/2"

40

2"

50

SW

tød

L

27

50

11

32

64

12

40

78

14

50

94

15

55

110

15

70

138

19

SW

Ty pe

TP-01M1-SA

TP-02M1-SA

øD

t

L

t

TP-03M1-SA

TP-04M1-SA

TP-05M1-SA

TP-06M1-SA

DN

15

16

21.3

20

20

26.9

25

25

33.7

32

32

42.4

40

40

48.3

50

50

60.3

SW

tød

LøD

27

50

15

32

70

15

40

80

15

50

100

15

55

110

15

70

140

15

Page 15

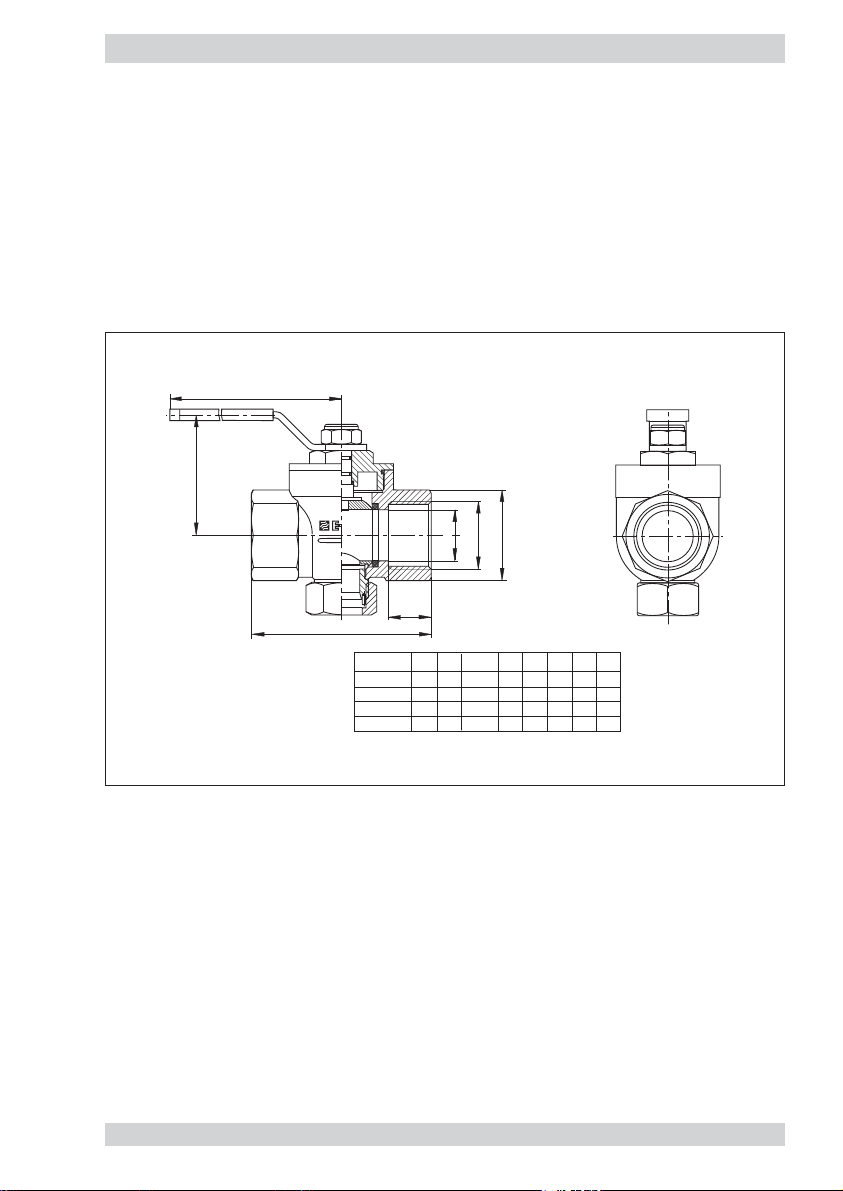

Ball valve BV-…

The ball valve of Postberg GmbH at D-63485 Bruchköbel is available in 4 nominal diameters

from 1" to 2". The ball valve ensures the sensors are fully immersed in the medium.

The monitoring head may also be replaced in pressurised pipe systems on duty.

Note:

❑ Please see the applicable drawing of Postberg GmbH for mounting instructions and

dimensions, if necessary.

fig. 5

A

H

G

ød

SW

L

BV-03M3

BV-04M3

BV-05M3

BV-06M3

Type

t

G

L

SW

1"

11/4"

11/2"

2"

tød

21

24

24

28

100

110

131

H

A

41

88

59

115

50

65

115

54

77

150

70

85

150

DN

25

25

32

32

40

40

50

50

Page 16

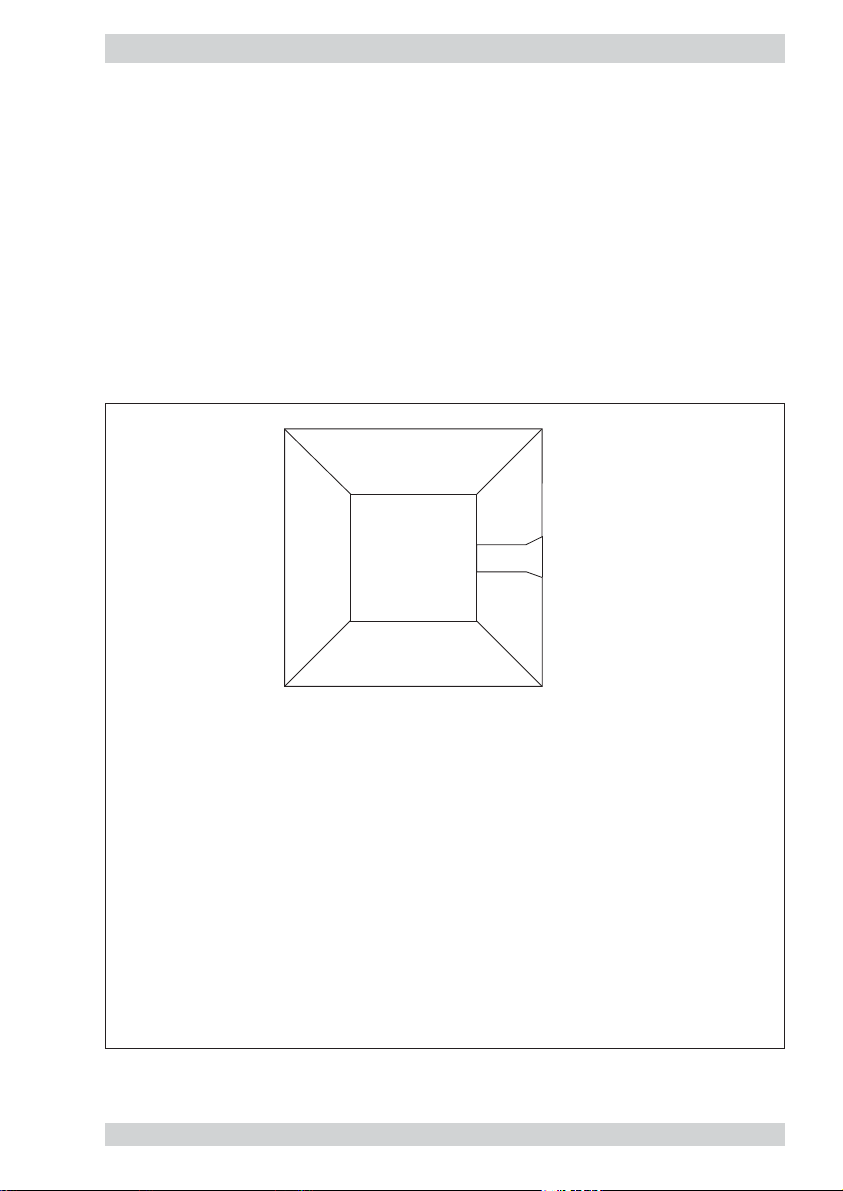

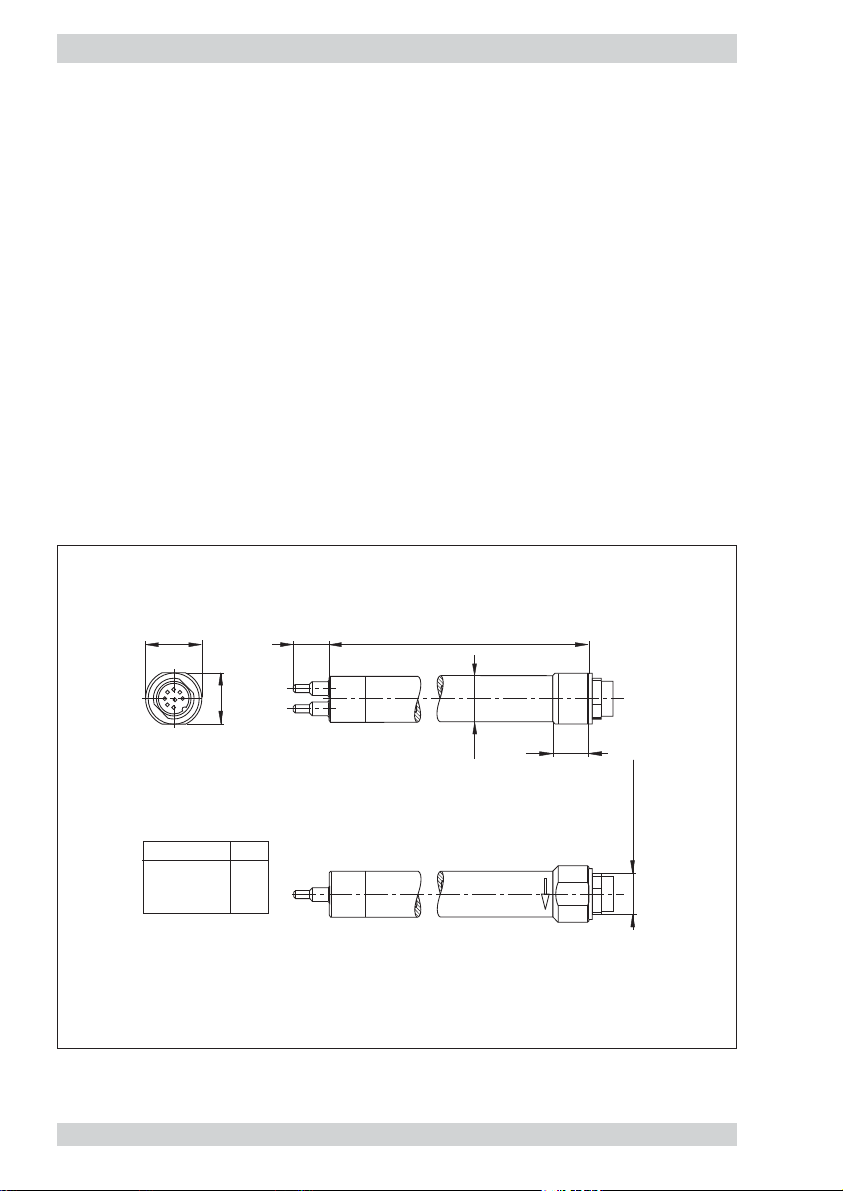

2.2.2 Monitoring head CSF-11 with adjustable immersion depth

Application: pipelines with nominal pipe diameters > DN50

Medium: liquids

Style: smooth shank, 18 mm dia., immersion depth adjustable within

the PG16 cable gland (accessory) or mounting in the stainless steel

cutting ring gland

Material of the area exposed to medium:

- M1 sensor and shank stainless steel 1.4571 /AISI 316 Ti (sensor)

- M7 sensor stainless steel 1.4571 /AISI 316 Ti, shank aluminium

Accessories:

- cable gland PG16 nickel-plated brass (see fig. 7)

- threaded installation bush stainless steel 316 (cutting ring) (see fig. 7)

fig. 6

ø22

SW20

Typ e

CSF-…L43… 190

CSF-…L30… 300

CSF-…L40… 400

14

L

L

ø18

monitoring head should be aligned

in direction of flow (see arrow)

14

16x0.75

M

ound connector

r

Page 17

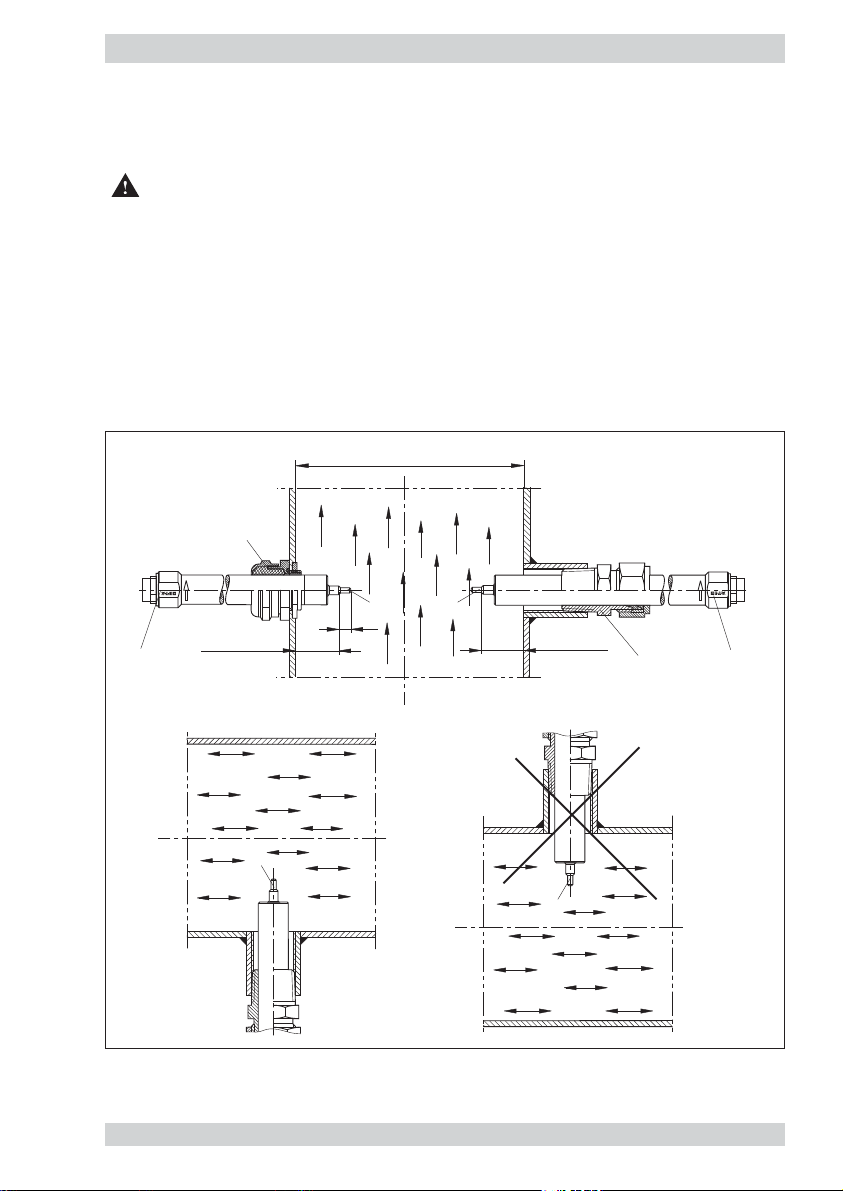

2.2.2.1 Mounting instructions for monitoring head CSF-11

Caution!

The two sensors (M) should be screwed into the pipeline far enough to ensure that they

are aligned side by side directly across the direction of flow. The sensors are correctly

positioned when the wrench flats (S) are aligned parallel with the pipeline.

The shoulder of the sensor (7 mm from the tip) must be at the position 1/8 from dia. i.

● In the case of vertical pipelines the monitoring head should be installed where the flow is

rising, if possible.

● For horizontal pipelines the monitoring head should be mounted on the underside of the

line (suspended).

V

fig. 7

ertical pipeline

PG16

(nickel-plated brass)

S

1/8 from dia.i

dia. i (internal pipe diameter)

M

7

M

monitoring head should be aligned

in direction of flow (see arrow)

1/8 from dia.i

threaded installation brush

(stainless steel-cutting ring)

S

Horizontal pipeline

M

M

Page 18

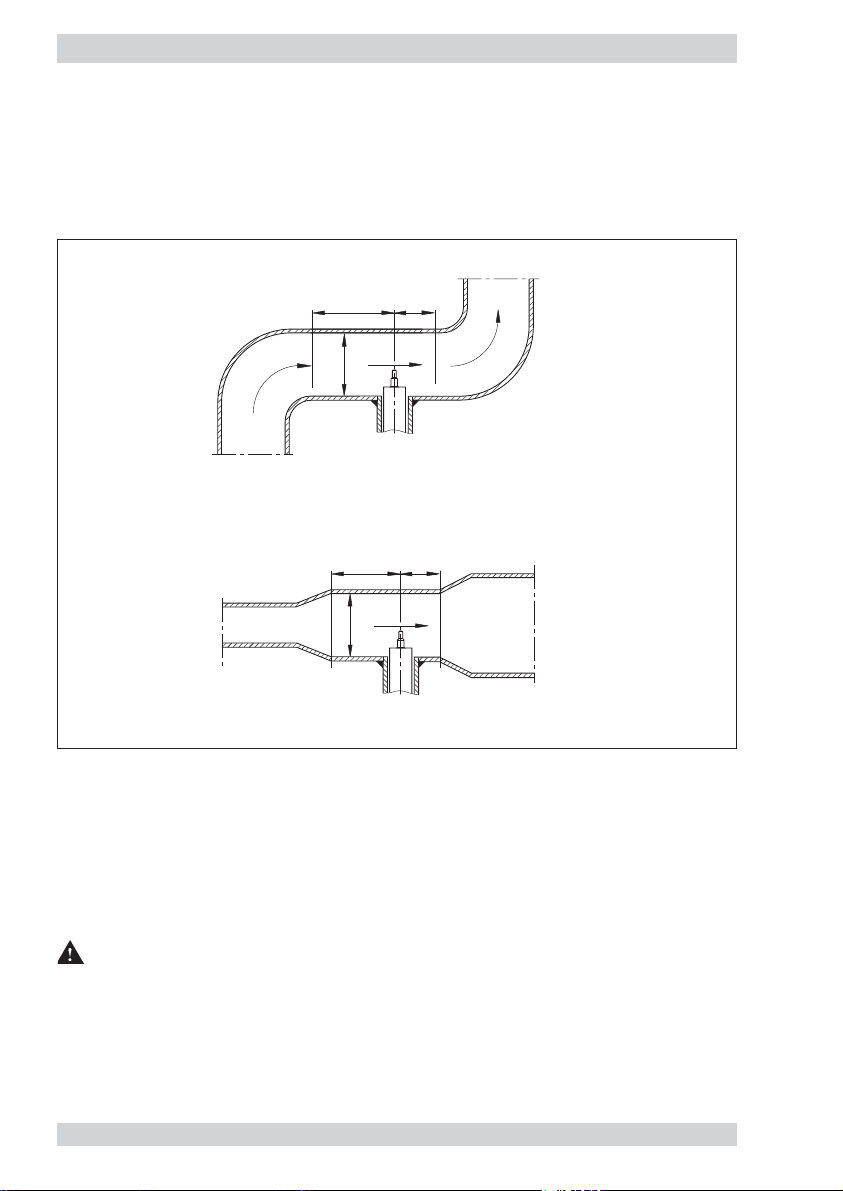

● The monitoring head should be installed only in a straight section of piping. There should be

a distance of at least 20 pipe diameters before the monitoring head, and 5 pipe diameters

after the monitoring head before or after bends and changes in pipe diameter, to avoid any

effects of turbulence.

fig. 8

● When installing the monitoring head, please observe that the arrow corresponds to the

flow direction.

● Fit monitoring head with locking set as follows (fig. 9):

- Fix first link of chain (1) into the clip (3) (tightening torque 10 Nm).

- Put chain catch (2) into link and fasten with the tight chain.

Caution!

Check locking system with regard to strength!

The locking chain must be mounted as tightly as possible.

5 x D20 x D

D

D = nominal pipe diameter

5 x D20 x D

D

D = nominal pipe diameter

Page 19

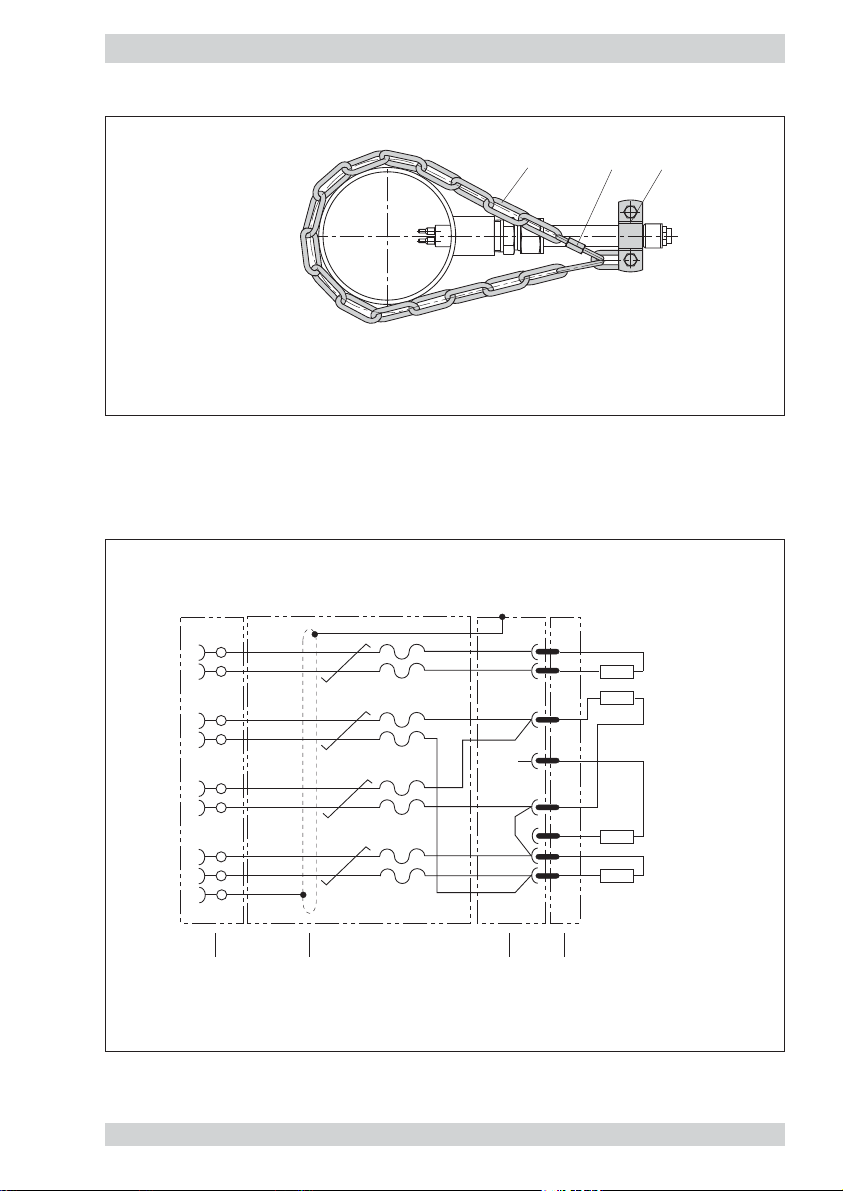

Locking set 01

2.2.3 Electrical connection2.2.3 Electrical connection

fig. 10

1 chain 4 x 32 DIN 5685 (approx. 1 m)

2 catch for chain NG 5

3 clip with screws and nuts DN15 to DIN 11850

(tightening torque 10 Nm)

Cable Do + Ka type xx

(depends on FC01-LQ version and sensor-type used - see figs. 15 and 16)

321

2

1

6

5

10

9

3

4

7/8

XSK

FC01-LQ

green

yellow

red

blue

pink

grey

brown

white

black

shield

cable

Kabel-Union

LifYCY 4 x 2 x 0,2 mm

or equivalent cable

green 7 7

yellow

3

red 4 4

pink

88

grey

1

5

6

brown

white

2

blue

round plug

2

X221 368 01

R(HEIZ)

3

R(Tdiff)

1

R(HEIZ)

5

6

2

R(Tref)

flange plug

X221 369 01

monitoring head

Page 20

2.3 Installation of electronic control unit FC01-LQ

2.3.1 Mechanical installation

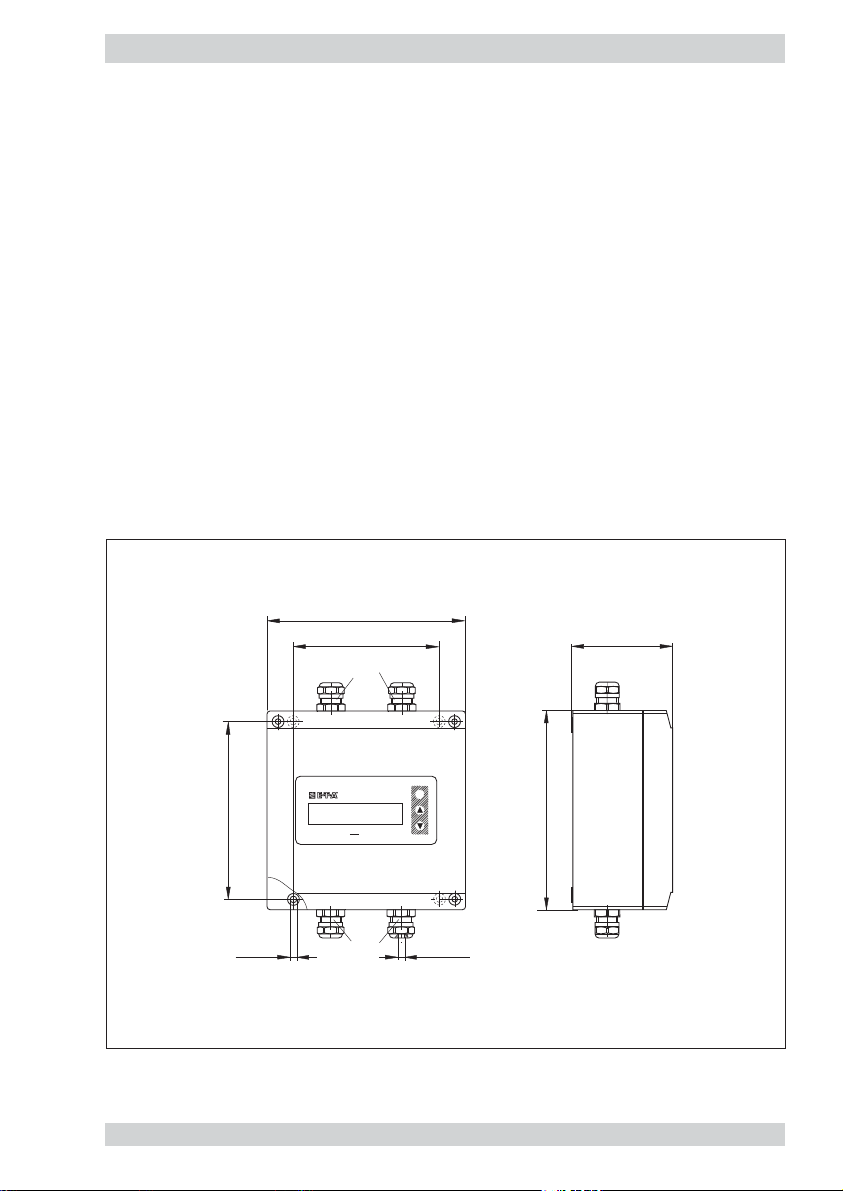

2.3.1.1 Rail-mounted version FC01-LQ-U1...

● The electronic housing is mounted on a symmetric rail to EN 50022.

● For thermal reasons, the modules should be spaced by at least 10 mm.

● Removal is by releasing the spring catch.

fig. 11

FC01-LQ

Flow Controller

100

spring catch

M

75

56

60

Page 21

2.3.1.2 Surface mounted version FC01-LQ-FH-U1...

● Remove the cover of the housing.

● Install the housing in place using the 4 self-taping screws M4 (see fig. 12).

● Replace the cover and tighten the retaining screws.

fig. 12

140

103

M16

71

125

ø4.5

mounting holes

FC01-LQ-FH

Flow Controller

M16

M

140

ø5 to ø8

Page 22

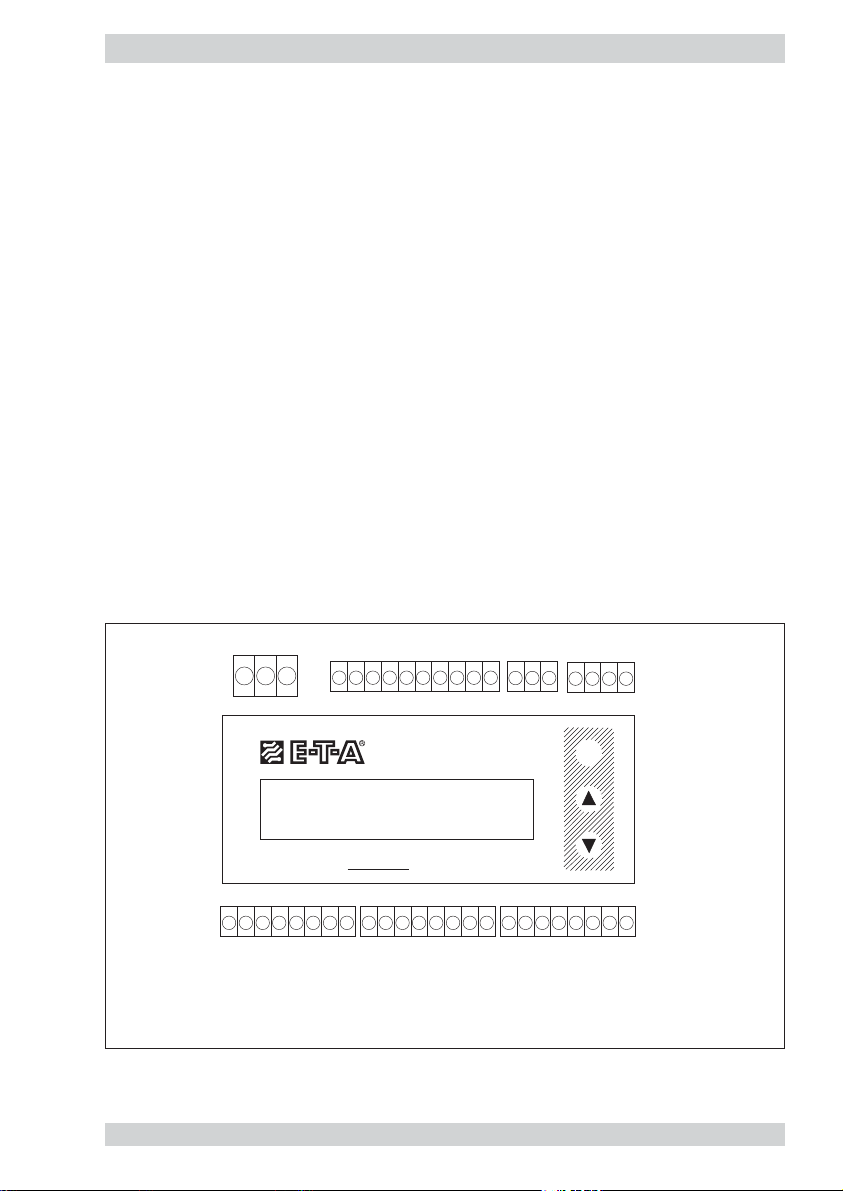

2.3.1.3 Front panel mounted housing FC01-LQ-ST-U1...

● Insert housing in the front of mounting hole and fix with 4 screws (see fig. 13) from the rear.

fig. 13

96

482

144

mounting hole

DIN 43700

M

92

140

Page 23

2.3.2 Electrical connection

Valid for all plug-in screw terminal strips:

Cable size: 0.14 mm

2

to 1.5 mm2, single or stranded conductor

Stripping length: 6.5 mm

Clamping screw: M2 (nickel-plated brass)

Contact material: pre-tinned tin bronze

XV - Power supply

Connection by 3 pole connector; max. 1.5 mm

2

; 3 x 0.75 mm2cable recommended

Pin No. Signal name Function

1 SGND general reference ground/shield ground

2+U

V

positive pole of supply voltage

3-U

V

negative pole of supply voltage

XTF - Keyboard release

Connection by 3 pole connector; factory-wired

Bridge 2-3 inserted = keyboard blocked

X

X

X

fig. 14

123

2345678910

123

1

XV XSK XTF

1234

M

FC01-LQ

(XAS) XAO XAH

8

7654321

V - power supply

SK - calorimetric monitoring head

TF - keyboard release

Flow Controller

8

7654321

(XAS) - nor released for user

XAO - analogue outputs

XAH - signal outputs

8

7654321

Page 24

XAO - - Analogue outputs

Connection by 8 pole connector; max. 1.5 mm

2

; LiYCY 2 x 0.25 mm2cable recommended

for each analogue output

Pin selection for analogue outputs (option: V1, V2, C1)

Pin No. Signal name Function

1 NC none

2 ANAO1 analogue output 1 - flow

3 ANA1GND reference potential for analogue output 1

4 SGNDA1 shield ground for analogue output 1 (ungrounded) *

5 SGNDA2 shield ground for analogue output 2 (ungrounded) *

6 ANAO2 analogue output 2 - temperature

7 ANA2GND reference potential for analogue output 2

8 NC none

* Apply shield on one side only.

XAH - Limit switch signal outputs - relay outputs - change over contacts

Connection by 8 pole connector; max. 1.5 mm

2

; LiYCY 3 x 0.38 mm2cable recommended

for each signal output

Pin No. Signal name Function

1 SGNDL1 shield ground 1

2 LIM1 non-inverted signal output 1 (N/O)

3 LIM1COM common change over input 1

4 /LIM1 inverted signal output 1 (N/C)

5 SGNDL2 shield ground 2

6 LIM2 non-inverted signal output 2 (N/O)

7 LIM2COM common change over input 2

8 /LIM2 inverted signal output 2 (N/C)

XAH - Limit switch signal outputs - transistor outputs NPN, freely connectable as emitter (-)

and collector (+) have been brought out separately.

Connection by 8 pole connector; max. 1.5 mm

2

; LifYCY 4 x 2 x 0.2 mm2 cable recommended

Pin No. Signal name Function

1 /ERROR E summarized error indication - emitter terminal

2 /ERROR C summarized error indication - collector terminal

3 /BUSY/PULSE E availability signal or frequency output -

emitter terminal

4 /BUSY/PULSE C availability signal or frequency output -

collector terminal

Page 25

5 LIM2 E limit value 2 - emitter terminal

6 LIM2 C limit value 2 - collector terminal

7 LIM1 E limit value 1 - emitter terminal

8 LIM1 C limit value 1 - collector terminal

XSK - Connection of calorimetric monitoring head type CS_x

Pre-sized connecting cable Do+Ka type 15 or Do+Ka type 18 with plug-in screw terminal strip

(see 2.2.3).

(XAS - secondary current supply)

Only for connection of cable shield (not released for user)

Pin No. Signal name Function

3 SGND /shield ground

Page 26

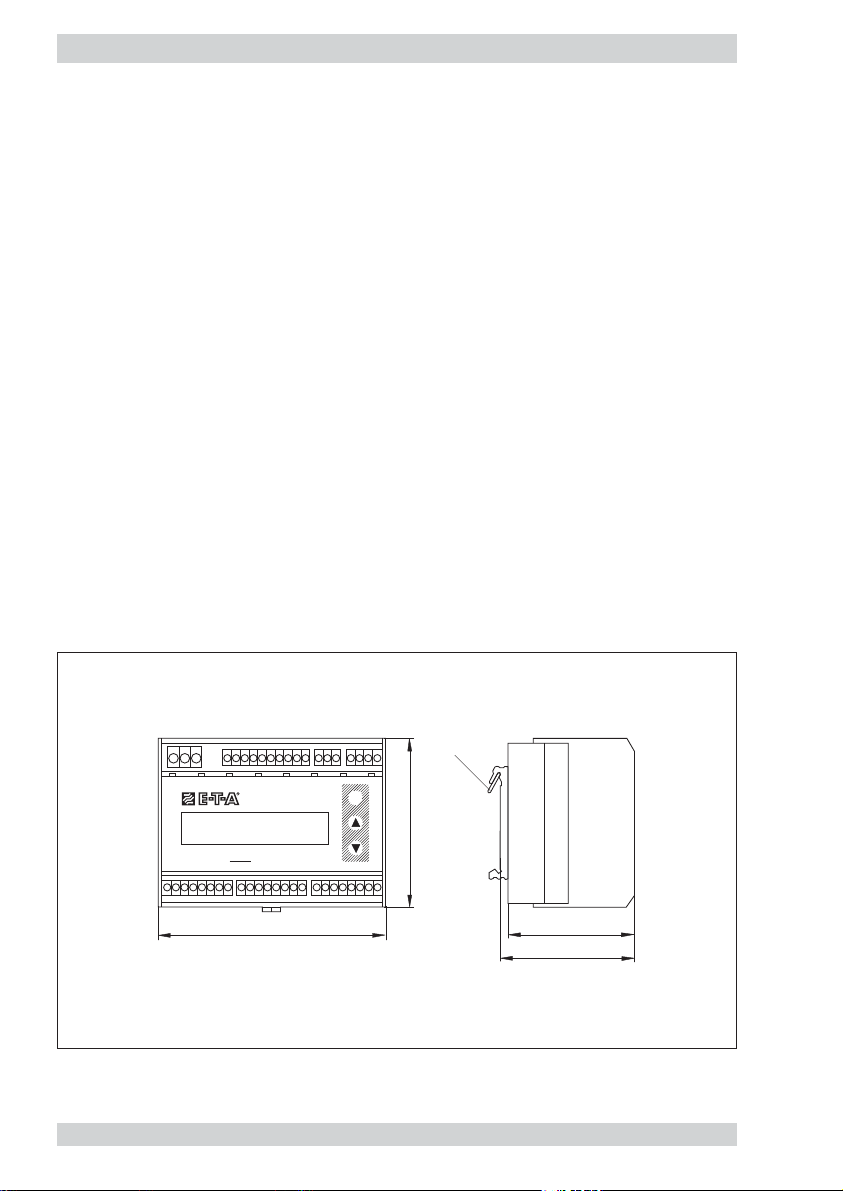

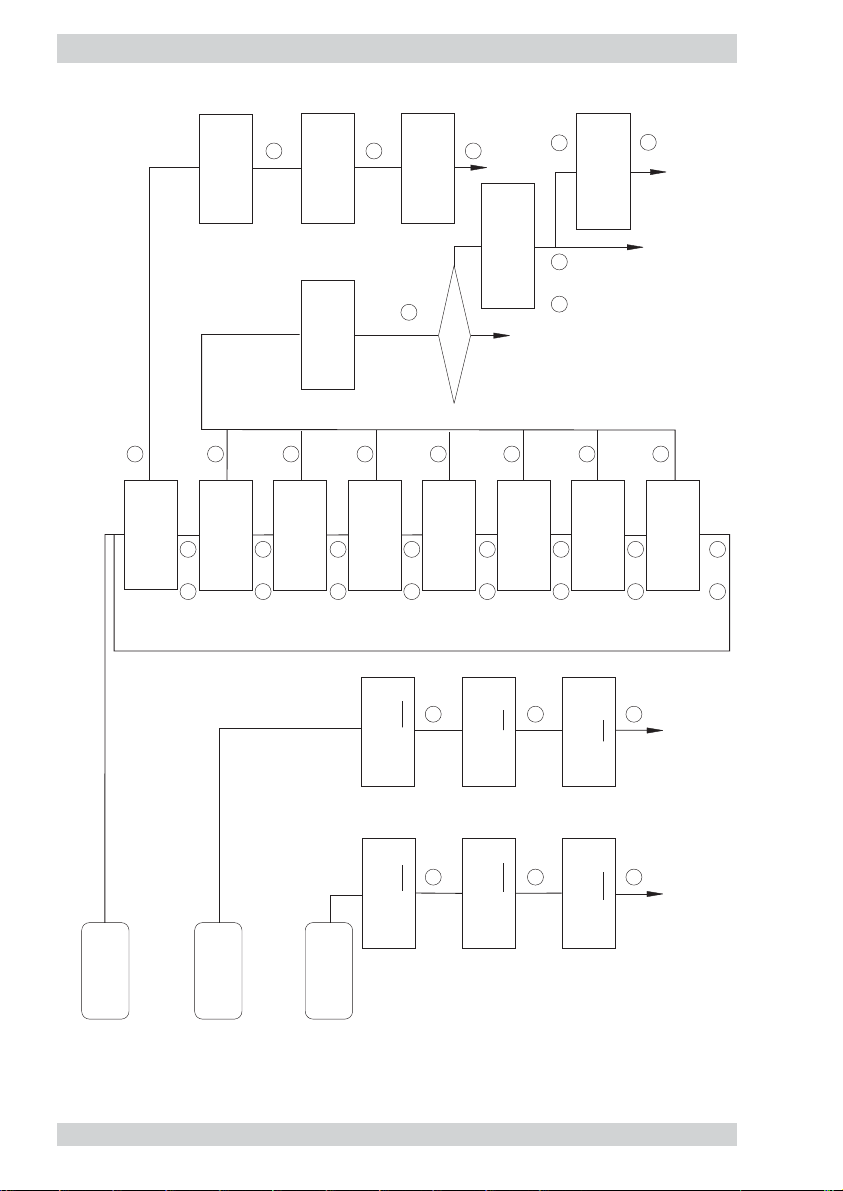

2.3.2.1 Circuit diagram FC01-LQ

Version: 24 V, relay outputs

fig. 15

recommended: 3x0.75 mm2LifYCY 4x 2x0.2 mm

power supply

0 V

+24 V

yellow/green

brown

blue

123

XV XSK XTF

2

calorimetric monitoring head

R(HEIZ) -LO

R(HEIZ) -HI

R(Tref) -HI

R(Tref) -LO

AGNDISSGND

yellow

green

brown

white

blue

red

1

2345678910

black

R(Tdiff)-LO

R(Tdiff)-HI

grey

pink

123

1234

M

* recommended

** SGNDA1

SGNDA2

ungrounded

}

Apply shield one side only.

FC01-LQ

Flow Controller

(XAS) XAO XAH

8

7654321

**

ANAO1

ANA1GND

SGNDA1

2 *

LiYCY 2x0.25 mm

}

C1, V1, V2

8

7654321

SGNDA2 **

ANAO2

ANA2GND

SGNDL1

2 *

LiYCY 2x0.25 mm

LIM1

LIM1COM

/LIM1

2 *

LiYCY 3x0.38 mm

}

signal outputsanalogue outputs **

8

7654321

SGNDL2

LIM2

LIM2COM

/LIM2

2 *

LiYCY 3x0.38 mm

Page 27

2.3.2.2 Circuit diagram FC01-LQ

Version: 24 V, transistor outputs (NPN)

fig. 16

2

2

yellow/green

123

E/ - emitter terminal

C/+ collector terminal

* recommended

** SGNDA1

SGNDA2

ungrounded

}

Apply shield one side only.

recommended: 3x0.75 mm

power supply

0 V

+24 V

R(HEIZ) -LO

brown

blue

yellow

1

LifYCY 4x 2x0.2 mm

calorimetric monitoring head

R(HEIZ) -HI

R(Tref) -HI

R(Tref) -LO

AGND

IS

SGND

R(Tdiff)-LO

green

brown

white

blue

red

black

grey

2345678910

R(Tdiff)-HI

pink

123

XV XSK XTF

FC01-LQ

Flow Monitor

(XAS) XAO XAH

8

SGND

7654321

**

ANAO1

ANA1GND

SGNDA1

*

2

}

LiYCY 2x0.25 mm

C1, V1, V2

8

7654321

E/ -

SGNDA2 **

ANAO2

ANA2GND

/ERROR

2 *

LiYCY 2x0.25 mm

C/+

/ERROR

signal outputsanalogue outputs **

1234

M

7654321

E/ -

C/ +

E/ -

C/ +

E/ -

/BUSY/PULSE

/BUSY/PULSE

LIM2

LIM2

LIM1

2 *

LifYCY 4x2x0.2 mm

8

C/ +

LIM1

Page 28

2.3.2.3 Electrical connection - frequency output (version FC01-LQ-U1T4)

The quantity-dependent pulse may be selected in the menu item “DISPLAY SELECT”. A square

pulse signal is available for driving a counter or a primary control at the plug XAH /BUSY E/- and

/BUSY C/+ (pins 3 and 4) (see fig. 16 - circuit diagram FC01-LQ - transistor outputs).

Signal ground shall be connected to pin 3 (BUSY E/-) and the driving load to pin 4 (BUSY C/+).

The pulse length is 50 ms (±1%) continuously.

Select cable size ≤1.5 mm

2

to make the connections.

The shield cables can be connected to connector XAS, pin 3.

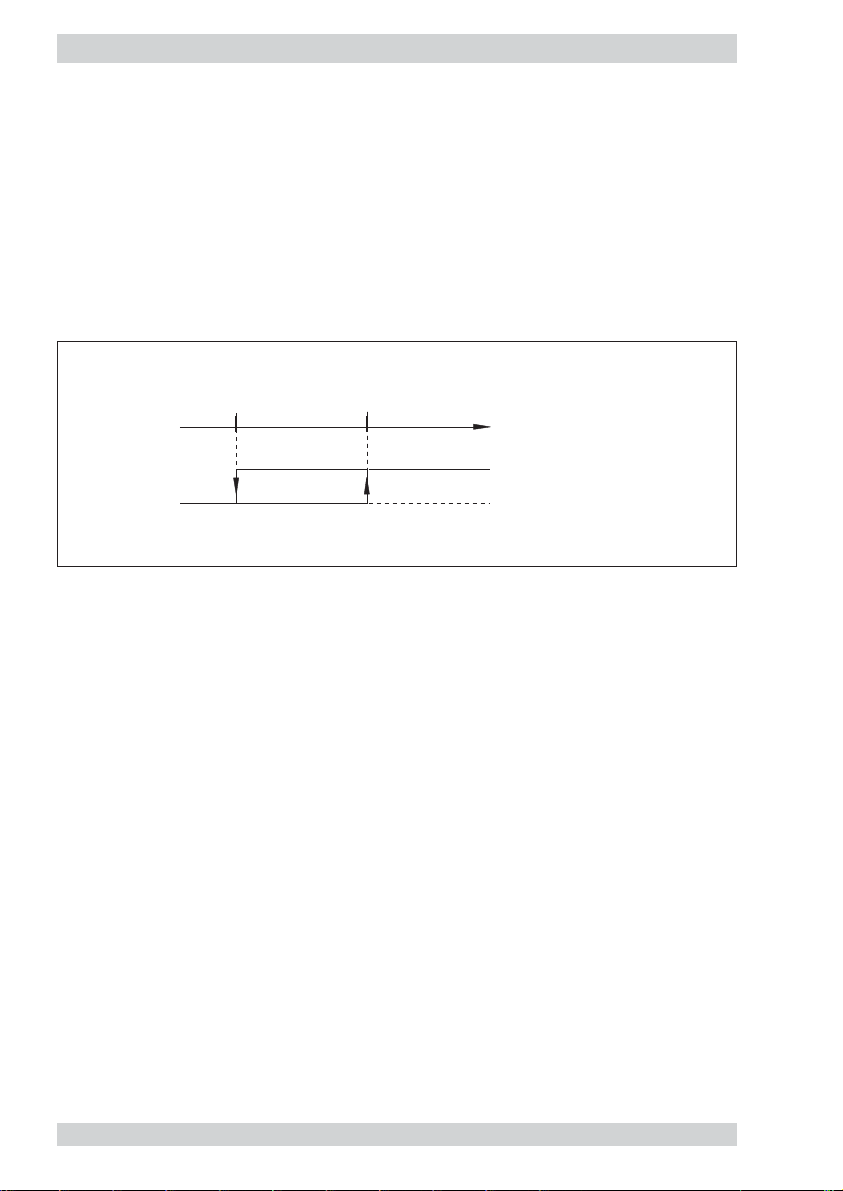

Electronic signal processing (fig. 17)

If the frequency output of the FC01-LQ is connected to an electronic counter, computer or PLC,

the load current should not exceed 10 mA so as to ensure low level is 0.8 V. The max. admissible

voltage level of 48 V is irrelevant in this connection.

Typical circuit (example 1)

fig. 17

XAS XAO

8

7654321

XAH

8

7654321

7654321

≤ 10 mA

L

i

8

V

U

CD

Page 29

Electromechanical pulse counter (fig. 18)

The FC01-LQ driver output comprises an integral safety circuit which when isolating the counter

operating coil will limit overvoltages caused by inductance and convert the energy stored.

The counter should be able of processing a counting frequency of ≥10 Hz, as the puls e length

is 50 ms (±0.1%) constinuously.

It should therefore be ensured that the counter can be increased by one during the time available.

If a separate relief network is preferred to the integral network, care should be taken when

processing the max. frequency of 10 Hz to ensure the energy stored in the operating coil has

dissipated by the time the counter output is reset. The time to do this should be below 40 ms,

making due consideration to switching times and pulse variations.

Typical circuit (example 2)

Note:

❑ As there will be a reset pulse available at the output in the moment the supply voltage of

the FC01-LQ is applied, make sure that the counter is switched on delayed or set to zero

after it has been switched on

fig. 18

XAS XAO

8

7654321

t

- switch-on time

ON

tL - time constent of switch-off current

8

7654321

i

C

tLtONt

XAH

8

7654321

zener voltage

U

C

U

V

C

U

<36 V

C

i

U

Inductance of the

counter drive

t

V

Page 30

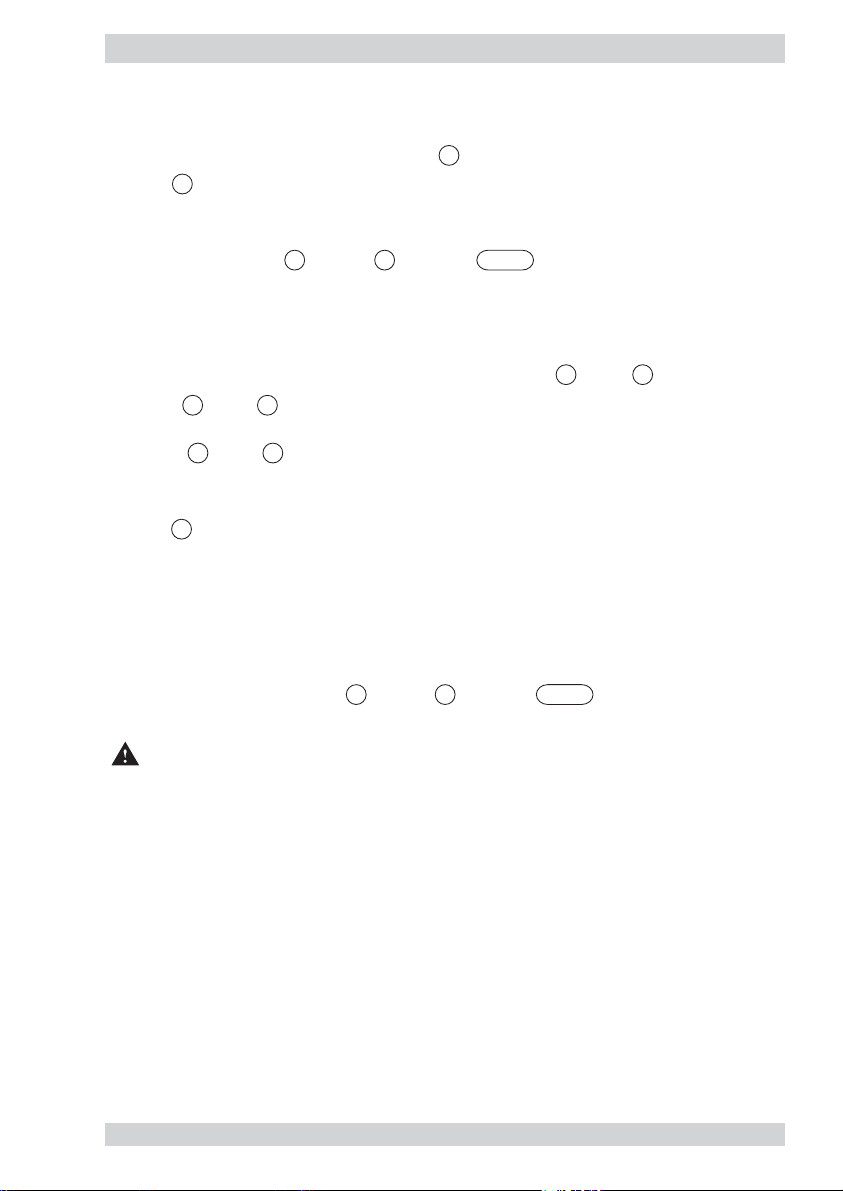

3 Operating system

Clear menu-driven control, via keyboard and display, enables easy definition of parameters and

configuration. This provides high system flexibility, making the FC01-LQ the optimum solution

for a wide variety of measuring, monitoring and display tasks.

All functions are distributed on the three following menu levels:

See Appendix 2 listing all functions available.

Keypads MODE, UP and DOWN

Setting and configuration is by means of three front keypads MODE, UP and DOWN.

It is also required for setting the unit to simultaneously press UP and DOWN =

.

Caution!

The FC01-LQ can only be set or operated when connector XTF (keyboard release) is

removed!

fig. 19

MAIN LEVEL (MENU)

CONFIGURATION LEVEL (MENU)

PARAMETER SELECTION (MENU)

M

▲

▼

M

▲

▲

▼

▼

▲ + ▼

MODE

M

UP

FC01-LQ

Flow Controller

DOWN

Page 31

Menu paging

The next menu option is selected by pressing MODE (forward paging)

.

Pressing MODE after the last menu option will cause skipping to the first option of the menu.

Calling a menu option

Simultaneously pressing UP and DOWN = calls the selected menu option, or

causes skipping to the selected submenu.

Entry of numerals

Some menu options require numerical values to be entered. After selecting the appropriate

menu option, the value indicated can be changed by pressing UP or DOWN.

Each time UP or DOWN are pressed, the value indicated will be increased and reduced

respectively, by one numeral skip.

The longer UP or DOWN are pressed, the faster the increase or reduction.

Transfer of entries

Pressing MODE transfers the set value or the selected menu option to a volatile memory.

A permanent transfer of settings and values is only effected when quitting the menu, after a

plausibility check of all entries.

Afterwards the data are still available even after switching the FC01-LQ repeatedly on and off.

Deleting data

Selected data such as MIN, MAX values, totalized quantity or LAST ERROR can be deleted or

reset by simultaneously pressing UP and DOWN = .

Caution!

After configuration and parameter selection re-connect plug XTF (keyboard release) to

protect the system against unauthorised access!

M

M

▲

▲

M

▲

▼

▼

▼

▲

▲ + ▼

▲

▼

▲ + ▼

▼

Page 32

4 Operation and main menu

4.1 Switch-on performance

Upon power application POWER ON TEST will be shown on the display for approx. 1 sec., with

the software version number being indicated in the second line.

During this period, the integral controller will conduct test routines (see para. 7.1, Test and diagnosis).

If during the test no error was found, the display will indicate HEATING UP. The FC01-LQ will

then be in the heating up period required for the measuring procedure.

4.2 Measuring cycle

Upon completion of the heating up period and availability of the first measured value, the display

will change to measuring cycle, and the user interfaces such as analogue outputs or limit

switches will be up-dated.

Note:

❒ It is not possible to configure or select parameters of the system during the measuring

operations!

All options of the main menu may be addressed without affecting the measuring and monitoring

function.

Menu option values

PEAK VALUE MIN

PEAK VALUE MAX

LAST ERROR

TOT ALISATOR

may be deleted simultaneously operating the UP and DOWN = switches without

affecting the measuring operations.

Over limits of the measuring range

Theoretically established measuring values will be used when the measuring range of

calorimetric monitoring heads is exceeded (0.05 … 3 m/s for water). The FM-LQ 1 can thus be

operated beyond the measuring values defined (up to 4 m/s for water).

This feature will not affect the accuracy specified for the measuring ranges defined whilst no

accuracy information can be given for conditions where the measuring ranges are exceeded.

Analogue output, limit switches etc. can be set beyond the measuring range. When per cent display

is selected, the defined measuring range will correspond to 0 ... 100% (>100% when the defined

range is exceeded).

The following operating data may be retrieved in the main menu during the measuring cycle: (see

para. 4.2.1).

▲

▼

▲ + ▼

Page 33

4.2.1 Operating data

4.2.1.1 Measured value(s)

Flow rate and medium temperature are indicated by the units selected in the upper line of the

LC display.

The lower line of the display will optionally show the switching condition of the limit switches and

an analogue bar with a 10-segment resolution, or the flow volume/time unit pertinent to the

indicated flow rate or the totalized flow volume (totalizer function).

The analogue bar has different meanings, depending on its configuration (see para. 5.7 - menu

option BARGRAPH).

fig. 20

flow rate temperature

Bar graph

indication

5.0 m/s -13.5 °C

TFF

Flow volume

indication

Flow volume

indication

Flow volume

indication

Totalizer

Totalizer

Totalizer

5.0 m/s -13.5 °C

1332.4 m3/h

5.0 m/s -13.5 °C

370.1 l/s

5.0 m/s -13.5 °C

22206.9 l/min

5.0 m/s -13.5 °C

F

37004567.9 l

5.0 m/s -13.5 °C

3704.6 m

5.0 m/s -13.5 °C

37044.9 m

TF

TF

TF

T

Temperature, active

(invers representation)

T

3

3

TF

TF

P

„switch-on condition“

Flow rate, passive

F

Frequency output selected

(invers representation)

P

„switch-on condition“

Page 34

The limit switches are identified according to their physical assignment, i.e. by F for flow rate and

T for medium temperature, at the first or last place of the second line on the display.

If F and T are shown reversed, the limit switch is in the switch-on condition.

Limit switches lying within the analogue bar range are also represented at the appropriate place

of the analogue bar (see para. 5.7).

The following figures show the display variants under menu option “Measured value(s)” (para. 5.6 -

menu option DISPLAY SELECT and 5.9 - menu option FREQUENCY OUTPUT).

4.2.1.2 Peak values (menu option: PEAK VALUE MIN / PEAK VALUE MAX)

The FC01-LQ comprises four specific measured-values memories.

They store the lowest and highest value of flow rate and medium temperature.

fig. 21

After switch-on or NOT-BUSY indication, the minimum and maximum values are deleted and will

be continuously updated (non-return pointer principle).

The peak values may be retrived in the main menu and are deleted by simultaneously pressing

UP and DOWN = .

Caution!

Power failure or disconnection of the power supply will delete the contents of the four

measured-values memories.

4.2.1.3 Last error (menu option: LAST ERROR)

The last main menu option to be called is the error memory.

This error memory comprises the number of the last error (see section 7). It may be very helpful

when commissioning the FC01-LQ.

Other than the peak value memories described above, the contents of this memory will be

retained even upon power failure.

The user may purposely delete the error memory in the condition selected by simultaneously

pressing UP and DOWN = .

▲

MIN VALUE

flow rate

MAX VALUE

flow rate

▲

▼

▲ + ▼

▼

▲ + ▼

MIN VALUE

medium temperature

MAX VALUE

medium temperature

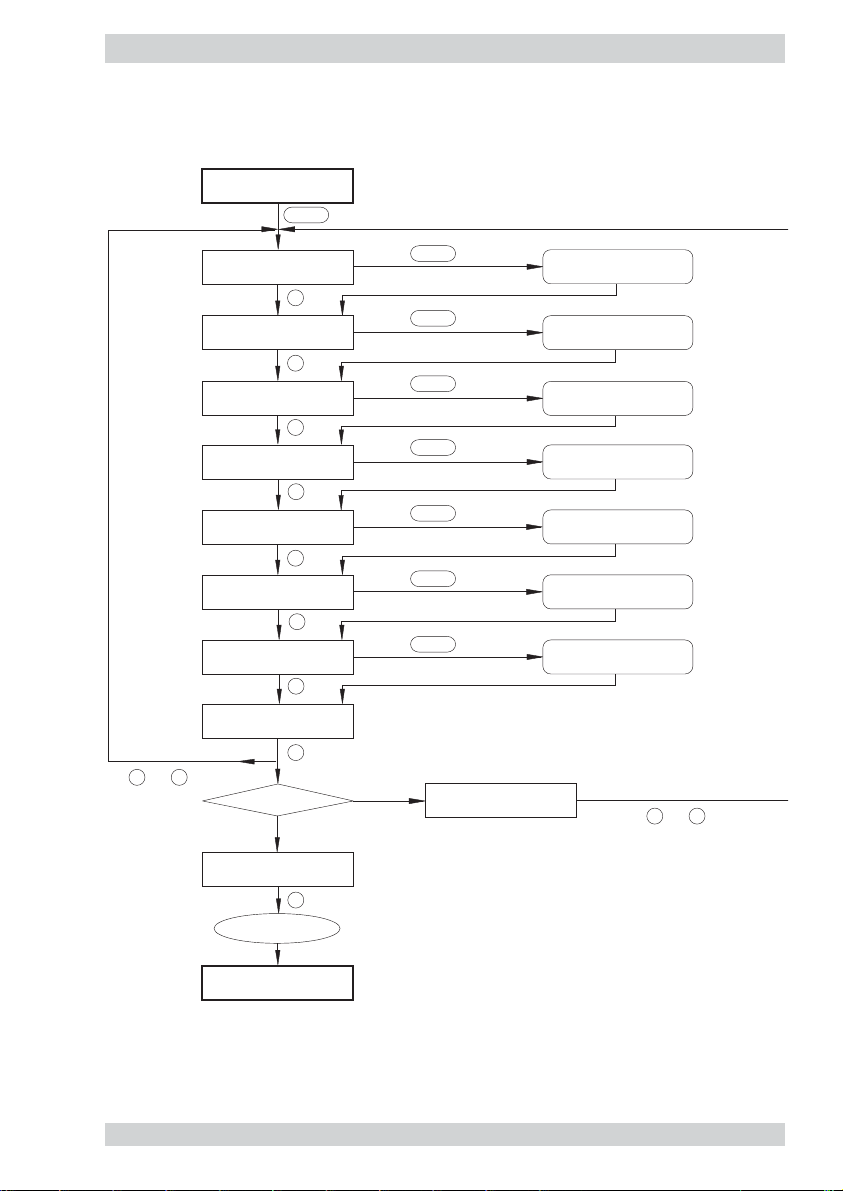

Page 35

power-on

HEATING UP *

12.5 m/s -13.5 °C *

M

TFF

TFF

See section 5

See section 6

10.8 m/s -19.5 °C *

PEAK VALUE MIN

M

14.8 m/s -105.6 °C *

PEAK VALUE MAX

M

12.5 m/s -13.5 °C *

CONFIGURATION

M

12.5 m/s -13.5 °C *

PARAMETERS

M

12.5 m/s -13.5 °C *

LAST ERROR 20

M

▲ + ▼

▲ + ▼

▲ + ▼

HEATING UP * PARAMETERS

▲ + ▼

HEATING UP * LAST ERROR

▲ + ▼

delete

minimum values

delete

maximum values

menu Configuration

menu Parameter Selection

delete errors

stored

* not available with turbine-type sensor

Page 36

5 Configuration (menu option: CONFIGURATION)

The CONFIGURATION menu serves to adjust the FC01-LQ to the application within the entire

system. During system configuration, measuring operations are not possible (see appendix 1).

Configuration possibilities are:

5.1 Selection of monitoring head (menu option: SENSOR SELECT)

This menu option comprises all monitoring heads that can be used with the FC01-LQ (issue 07.2003).

The appropriate sensor can be selected from the following menu (for type designation see type

label or CPI catalogue).

• TYPE CSP11WM1 (insertion head for water with sensor adapter TP-..)

• TYPE CSP11WM1BV (insertion head for water with ball valve BV-..)

• TYPE CSF11WM1 (monitoring head for water with adjustable immersion depth)

• TYPE S-No. xxx (custom designed monitoring head for special liquids)

The monitoring head programme is continuously extended - please enquire.

Caution!

Menu option SENSOR SELECT may influence data in the parameter selection menu (see

para. 5.12, Quitting the configuration menu).

5.2 Monitoring head data (menu option: SENSOR CODE)

To operate the FC01-LQ with a calorimetric monitoring head, it is necessary to set sensorspecific characteristics.

These characteristics are specified by the sensor code which together with the monitoring head

type number is marked on the monitoring head housing.

Enter the following characteristics when selecting a CSF monitoring head. The setting is menu

driven:

1. SENSOR CODE C value characteristics range: 700 … 1300

2. SENSOR CODE T value characteristics range: 01 … 99

Caution!

Take care to repeat these settings after replacing the monitoring head or electronic control

unit FC01-LQ, as the accuracy of measurements is determined by the sensor code.

Enter the following characteristics when selecting a CSP monitoring head:

1. SENSOR CODE C value characteristics range: 700 … 1300

2. SENSOR CODE value characteristics range: 01 … 99

The nominal diameter of the ball valve is selected in menu option BV SIZE SELECT.

Available sizes are:

• DN25 (1 in), DN32 (1 1/4 in), DN40 (1 1/2 in) und DN50 (2 in).

Page 37

Enter the following characteristics when selecting a CSP monitoring head with sensor adapter TP-..:

1. SENSOR CODE C value characteristics range: 700 … 1300

2. SENSOR CODE T value characteristics range: 01 … 99

The internal diameter of the sensor adapter is selcted in menu option TYPE SELECT.

Available sizes are:

• TP01 (1/2 in) • TP04 (1 1/4 in)

• TP02 (3/4 in) • TP05 (1 1/2 in)

• TP03 (1 in) • TP06 (2 in)

5.3 Limit switch combinations (menu option: LIMIT SWITCHES)

The FC01-LQ comprises two limit switches (LS1 and LS2) which are assigned to the physical

quantity/quantities to be monitored in submenu LIMIT SWITCHES.

The following combinations are available:

• LS1 F and LS2 F

limit switch 1 flow rate

limit switch 2 flow rate

• LS1 T and LS2 T

limit switch 1 medium temperature

limit switch 2 medium temperature

• LS1 F and LS2 T

limit switch 1 flow rate

limit switch 2 medium temperature

• LS1 T and LS2 F

limit switch 1 medium temperature

limit switch 2 flow rate

Mode of operation, limit value and hysteresis of the limit switches are set in menu PARAMETER

SELECTION.

Caution!

Menu option LIMIT SWITCHES may influence data in the parameter selection menu (see

para. 5.12, Quitting the configuration menu).

Page 38

5.4 Flow rate unit (menu option: FLOW UNIT)

At these point (1st line top left) the requested unit for the flow velocity will be set.

This menu option is used to set the desired flow rate unit:

• METRE/SEC [m/s] • FEET/SEC [FPS]

• PERCENT [%] • BLANK [no unit]

Any further entries relating to flow rate (e.g. limit value, analog ue output etc.), refer to that unit.

Standard percent is displayed when BLANK (no unit) is selected.

When the flow rate unit is changed, all configuration and parameter data relating flow rate will

automatically be converted!

5.5 Medium temperature unit (menu option: TEMP. UNIT)

This submenu is used to select the medium temperature unit (1st line top left).

Options are:

• GRAD CELSIUS [°C]

• GRAD FAHRENHEIT [°F]

• KELVIN [K]

All other entries relating to the medium temperature (limit value, analogue output, etc.) refer to

the unit selected there. When the temperature unit is changed, all configuration and parameter

data relating to medium temperature will automatically be converted.

5.6 Display (menu option: DISPLAY SELECT)

The FC01-LQ enables the user to define the 2nd line of the display 2 in certain points.

When the first line of the LC display in the main menu indicates the flow rate in the unit selected

as well as the medium temperature in °C, °F or K, it is possible to select the second line from

the following menu options (see para. 5.14).

• BARGRAPH Totalizer:

• LITRE/SECOND [l/s] • LITRE [l]

• LITRE/MINUTE [l/min] • METRE

3[m3

]

• METRE

3

/ HOUR [m3/h] • GALLONS° [° = US-GALLONS]

• GALLONS°/MINUTE

Where totalizer function has been selected, the totalizer will start at zero counting in the unit

selected (litre, m

3

or gallons).

When the display changes from m

3

to litre or gallons, or from litre or gallons to m3, the value

already counted will be converted.

The content of the totalizer is deleted by simultaneously pressing UP and DOWN =

, or when the max. display value (99999999.9 l, m

3

or gallons) is reached.

In both cases the totalizer will restart from zero.

▲ + ▼

▲

▼

Page 39

Caution!

The content of the totalizer is deleted in the event of power failure or disconnection of the

power supply!

Skipping to the submenu BARGRAPH or PIPE SIZE is effected depending on the selected menu

option.

5.7 Bar graph (menu option: BARGRAPH)

This menu option allows the user to set the bar graph as desired. The following settings should

be made:

• FLOW / TE MP = (bar graph assignment: flow rate/me dium temperature)

• ZERO = (initial value of the bar graph)

• FS = (final value of the bar graph)

Independent of its assignment, the bar graph has a constant resolution of 10 segments.

When entering the initial or final value, the user should observe reasonable resolution!

The bar graph also comprises the representation of the limit switch(es) as far as they can be

indicated in the bar range selected.

The representation of the limit switches in the bar graph depends on the switch-on value of the

limit switch.

For representation details see para. 4.2.1 (Operating data).

Example:

Limit switch assignment: LS1 F and LS2 T

Switch-on value LS2: 23 °C

Switch-off value LS2: 29 °C

Analogue bar graph assignment: medium temperature

Initial value - analogue bar graph: 20 °C

Final value - analogue bar graph: 30 °C

Instantaneuous temperature value: 25 °C

resulting in the analogue bar graph display shown below:

fig. 22

20 °C 21 °C 25 °C 29 °C 30 °C

23 °C

T T

LS2 ON

Page 40

5.8 Pipe diameter (menu option: PIPE SIZE)

If flow volume/time unit display has been selected, it is necessary to indicate the pipe diameter

to calculate mass flow.

This is provided by selecting the pipe diameter in menu option PIPE SIZE comprising pipe

diameters from 10.0 … 999.9 mm.

5.9 Frequency output (menu option: FREQUENCY OUTPUT)

The totalizer function of the FC01-LQ has been expanded by the output of proportional quantity

pulses. The function can only be displayed by version FC01-LQ-U1T4 (transistor outputs).

The proportional quantity pulses have been determined as follow:

Example: 1 pulse / 10.0 [litre]

The frequency output will supply 1 pulse per 10 litres (totalized quantity).

When the quantity-proportional pulses are assigned, the frequency of the frequency output must

no exceed 10 Hz. The limits that can be displayed are determined by the flow velocity range and

the pipe diameter.

Potential setting range of the frequency output: 1 pulse per 0.1 … 999.9 [litre], [m

3

], [gallons]

Behaviour of the frequency output when the max. frequency is exceeded

The max. frequency being exceeded will not cause the measurement to stop but will rather

cause the error output to signal error 60 on the display. This error is included in priority group III.

If a combination of priority III errors occurs simultaneously, they are indicated or stored in the

error memory observing the following sequence:

Error No. 20, 30, 60, 40, 41.

Behaviour of the frequency output when the measurement is stopped

When the measurement is stopped (as caused by priority II error and calling the configuration or

parameter selection menus), the pulses for the quantity already counted will be available.

Thereafter the output of pulses will be stopped, with the frequency output becoming highresistive until the measurement is restarted.

Behaviour of the frequency output when the content of the totalizer is deleted

The content of the totalizer may be deleted by simultaneously pressing UP and DOWN

= in the main menu.

As the frequency output refers to the content of the totalizer, although its operation is not

dependent on the content of the totalizer, a totalized quantity that is smaller than that set per

pulse will not be lost.

This means that only the content of the totalizer is deleted.

1 pulse / quantity (totalizer unit selected)

▲ + ▼

▲

▼

Page 41

5.10 Analogue output - flow rate (menu option: ANA OUT FLOW)

This menu option allows adjustment of the flow rate analogue output specifically to the

requirement of the entire system.

Options are:

• OFFSET = 0%/20% FS (0/4 … 20 mA, 0/1 … 5 V, 0/2 … 10 V)

• ZERO = (initial value 0(20) % corresponds to a flow rate of _ [m/s] [%] [FPS])

• FS = (final value 100% corresponds to a flow rate of _ [m/s] [%] [FPS])

When entering the initial or final value, the user should observe a reasonable resolution!

With a flow volume/time unit selected in menu DISPLAY SELECT and when setting the initial and

end values, the pertinent flow volumes will also be indicated.

5.11 Analogue output - medium temperature

(menu option: ANA OUT TEMP.)

In conformance with the configuration “Flow rate analogue output” it is possible to adjust the

medium temperature analogue output to the requirements of the entire system.

Options are:

• OFFSET = 0%/20% FS (0/4 … 20 mA, 0/1 … 5 V, 0/2 … 10 V)

• ZERO = (initial value 0(20) % corresponds to a medium temperature of … [°C] [°F] [K])

• FS = (final value 100% corr e sponds to a med ium te mperat ure o f … [°C] [°F] [K])

When entering the initial or final value, the user should observe a reasonable resolution!

5.12 Quitting the configuration menu

Upon configuration of the analogue outputs, the menu may be quitted or re-set to the start

(SENSOR SELECT).

To quit the configuration menu, the controller will check the data entered for plausibility.

“CONFIG. OK!” is indicated when the data are found correct. The menu may than be quitted by

pressing MODE.

Errors found during the plausibility check are indicated in the following sequence of priority.

Priority of entry errors in the CONFIGURATION menu:

• ERR. A-OUT FLOW OUT OF RANGE

(flow analogue output outside measuring range)

• ERR. A-OUT FLOW ZERO ≥ FS

(initial value ≥ final value with flow analogue output)

• ERR. A-OUT TEMP. OUT OF RANGE

(temperature analogue output outside measuring range)

• ERR. A-OUT TEMP. ZERO ≥ FS

(initial value ≥ final value with temperature analogue output)

M

Page 42

• ERR. BARGRAPH OUT OF RANGE

(bar value outside measuring range)

• ERR. BARGRAPH ZERO ≥ FS

(bar initial value ≥ bar final value)

The menu can only be quitted after correction of the error(s). To do this, return to the beginning

of the configuration menu by pressing UP or DOWN and select the menu option with

the incorrect entry for correction.

Caution!

If during the configuration data are affected which are accessible in the parameter

selection menu, (which may be the case for the options Sensor Selection, Medium

Selection and Limit Switch Assignment), the option “PARAMETERS” in the main menu will

be flashing.

In this event it is imperative to branch into parameter selection menu to set the data in

conformance with the desired application.

Example: Changing the limit switch assignment from LS1 → F / LS2 → T to

LS1 → F / LS2 → F

Effects on

parameter data: LS2 ON = 0.00

LS2 OFF = end of measuring range (depending on the medium selected)

Reason: Changing the physical assignment of limit switch 2 will adjust its switch-on and

switch-off values to the new assignment (flow rate).

An overview of the configuration menu and a summary of the measuring ranges and menus

available for the sensor type selected are shown on the following pages.

▲

▼

Page 43

5.13 Configuration menu

Config. plausible?

yes

submenu

temperature unit

submenu

LS combination

submenu

sensor select

END OF CONFIG.?

M→yes ▲ or ▼ → no

CONFIGURATION

ANA OUT TEMP.

CONFIGURATION

ANA OUT FLOW

CONFIGURATION

DISPLAY SELECT

CONFIGURATION

TEMP. UNIT

CONFIGURATION

FLOW UNIT

M

CONFIGURATION

LIMIT SWITCHES

CONFIGURATION

ERROR CONFIG.

CONFIG. OK!

PUSH M

M

CONFIGURATION

SENSOR SELECT

M

M

M

M

M

M

M

▲ + ▼

▲ + ▼

▲ + ▼

▲ + ▼

▲ + ▼

▲ + ▼

▲ + ▼

▲ + ▼

PARAMETERS

A

B

C

D

E

F

G

submenu

flow unit

submenu

display selection

submenu

analogue temperature

submenu

analogue flow

no

return to main menu

See:

or

▲

▼

or

▲

▼

Page 44

A

▼

or

▲

TYPE S-No. xxx

SENSOR SELECT

M

▼

or

▲

SENSOR SELECT

TYPE CSF-11WM1

▼

M

or

▲

SENSOR SELECT

TYPE CSP-11WM1

M

▼

or

▲

M

C xxx

SENSOR CODE

SENSOR CODE

SENSOR CODE

SENSOR CODE

M

C xxx

SENSOR CODE

M

C xxx

SENSOR CODE

T xxx

T xxx

T xxx

M

PIPE SIZE

DIAM. = xxx.x mm

M

M

TP01 (1/2 in)

TYPE SELECT

M

M

DN25 (1 in)

BV SIZE SELECT

M

Conf.

M

▼

TP02 (3/4 in)

TYPE SELECT

or

▲

M

▼

DN32 (1.1/4 in)

or

BV SIZE SELECT

▲

M

▼

TP03 (1 in)

TYPE SELECT

or

▲

M

▼

DN40 (1.1/2 in)

or

BV SIZE SELECT

▲

M

▼

TP04 (1.1/4 in)

TYPE SELECT

or

▲

M

▼

DN50 (2 in)

or

BV SIZE SELECT

▲

M

▼

TYPE SELECT

or

▲

▼

or

▲

M

▼

TP05 (1.1/2 in)

TYPE SELECT

or

▲

Conf.

Conf.

▼

TP06 (2 in)

or

▲

Conf.→ return to configuration menu

SENSOR SELECT

TYPE CSP-11WM1BV

submenu

sensor select

5.14 Configuration submenus

Page 45

Conf.

M

▼

or

▲

M

Conf.

▼

or

▲

Conf.

Conf.

Conf.

→ T LS2 → F

LIMIT SWITCHES

LS1

M

→ F LS2 → T

LIMIT SWITCHES

LS1

M

T

→

T LS2

→

LIMIT SWITCHES

LS1

M

F

→

F LS2

→

LIMIT SWITCHES

LS1

FLOW UNIT

BLANK (no unit)

▼

or

▲

▼

or

▲

▼

or

▲

M

Conf.

Conf.

Conf.

FLOW UNIT

M

FLOW UNIT

M

FLOW UNIT

▼

or

▲

FEET/SEC. (FPS)

▼

or

▲

PERCENT (%)

▼

or

▲

METRE/SEC (m/s)

Conf.

Conf.

Conf.

M

M

M

▼

or

▲

KELVIN (K)

TEMP. UNIT

▼

or

▲

TEMP. UNIT

FAHRENHEIT (°F)

▼

or

▲

°C)

TEMP. UNIT

CELSIUS (

Conf.→ return to configuration menu

Configuration submenus (cont’d)

submenu

limit switch

combination

B

flow unit

submenu

C

submenu

temperature unit

D

Page 46

submenu

display selection

Totalizer function?

or

▲

▼

FREQUENCY OUTPUT?

M → yes other → no

FREQUENCY OUTPUT

PULSE/..........(unit)

M

M

DISPLAY SELECT

METRE

3

/HOUR

DISPLAY SELECT

LITRE/SECOND

DISPLAY SELECT

GALLONS°/MINUTE

DISPLAY SELECT

BARGRAPH

ANA OUT FLOW

ZERO = 0.5 m/s

Conf.

M

M

M

M

DISPLAY SELECT

LITRE

DISPLAY SELECT

METRE

3

BARGRAPH

ZERO = 10.0 m/s

BARGRAPH

FS = 20.0 m/s

ANA OUT FLOW

OFFSET =

(FS)

ANA OUT TEMP.

OFFSET = (FS)

PIPE SIZE

52.5 mm

ANA OUT TEMP.

ZERO = -10.0

°

C

ANA OUT TEMP.

FS = 85.0 °C

M

M

Conf.

BARGRAPH

TYP=FLOW or TEMP

M

ANA OUT FLOW

FS = 3.5 m/s

M

DISPLAY SELECT

LITRE/MINUTE

M

M

M

M

M

DISPLAY SELECT

GALLONS

°

° US-GALLONS

Conf.

M

M

Conf.

Conf.

Conf.

M

MM

E

F

G

Conf.

→

return to configuration menu

or

▲

▼

or

▲

▼

or

▲

▼

or

▲

▼

no

yes

submenu

analogue flow

submenu

analogue

temperature

or

▲

▼

or

▲

▼

or

▲

▼

or

▲

▼

Page 47

6 Parameter selection (menu option: PARAMETERS)

After configuration of the FC01-LQ in conformance with its application (configuration menu), it

is possible to set parameters (e.g. limit values).

During parameter setting, measuring operations are not possible (see Appendix 1).

The following parameters may be set in the Parameter selection menu:

6.1 Measuring time (menu option: MEAS. TIME)

The measuring time may be set between 1 and 30 sec., referring both to flow rate and medium

temperature.

The effect of the measuring time may be compared to that of a filter; it is used to determine the

average of the last measured values (measuring time 100 ms) after each measurement.

The set measuring time does not influence the measuring rate and display up-date.

6.2 Limit switch 1 - switch-on value (menu option: LS1 ON = ......)

Limit switch 1 - switch-off value (menu option: LS1 OFF = ......)

Depending on the configuration (see configuration menu) limit value 1 may be set either for flow

rate or medium temperature.

The limit value may be set over the entire measuring range and is always related to the display

value.

Limit switch up-date is by measuring rate, independent of the set measuring time.

The hysteresis is determined by entering different switch-on and switch-off values. Its magnitude

should be reasonably adjusted to current operating conditions.

A specific definition of the operation (closed-current or open-circuit principle) may be dropped

by separately entering the switch-on and switch-off value of the limit switch, because the

definition is deducted from the switch-on and switch-off value..

fig. 23

Example 1: Switch-on value lower than switch-off value

switch-on value

0

ON

switch-off value

hysteresis

OFF

measured value

(flow/temperature)

∞

switching condition ON

switching condition OFF

Page 48

Example for ON:

FC01-LQ with relay outputs (option R2):

• LIM1 - LIM1COM = closed

/LIM1 - LIM1COM = open

FC01-LQ with transistor outputs (option T4):

• LIM1E - LIM1C = switched

Example 2: Switch-on value higher than switch-off value

Example for ON: as described in example 1 (fig. 23)

With limit switch 1 set for flow rate and a flow volume/time unit selected in menu DISPLAY

SELECT, and when setting the switch-on and switch-off value, the pertinent flow volumes will

also be indicated.

6.3 Limit switch 2 - switch-on value (menu option: LS2 ON = ......)

Limit switch 2 - switch-off value (menu option: LS2 OFF = ......)

See limit switch 1!

6.4 Scaling factor (menu option: FLOWSCALE)

The scaling factor influences flow rate indication.

The factor, which may be set between 0.01 and 9.99, allows flow rate indication changes

(increasing or reducing the measured value in the display).

For example, the scaling factor may be used to indicate the average flow rate in the pipeline

rather than that available at the sensor.

fig. 24

ON

OFF

switch-off value

0

hysteresis

switch-on value

measured value

(flow/temperature)

∞

switching condition ON

switching condition OFF

Page 49

6.5 Quitting the parameter selection menu

Before the parameter selection menu can be quitted, the controller will conduct a plausibility

check of the data entered.

“PARAMETERS OK!” is indicated when the data are found to be correct. The menu may then be

quitted by pressing MODE.

Errors found during the plausibility check are indicated in the following sequence of priority.

Priority of entry errors in the PARAMETER SELECTION menu:

• ERROR LS1 OUT OF RANGE

switch-on and/or switch-off value for limit switch 1 outside measuring range

• ERROR LS2 OUT OF RANGE

switch-on and/or switch-off value for limit switch 2 outside measuring range

• ERROR LS1 ON = OFF

switch-on value for limit switch 1 equals switch-off value for limit switch 1

• ERROR LS2 ON = OFF

switch-on value for limit switch 2 equals switch-off value for limit switch 2

The menu can only be quitted after correction of the error(s). To do this, return to the beginning

of the parameter selection menu by pressing UP or DOWN and select the menu option

with the incorrect entry for correction.

An overview of the parameter selection menu is shown on the following page.

M

▲

▼

Page 50

END OF PARAM.?

M→yes ▲ or ▼ → no

PARAMETERS OK!

PUSH M

no

return to main menu

yes

▲

▼

or

▲

▼

or

PARAMETERS

FLOWSCALE 1.12

PARAMETERS

LS2 OFF = 68.5 °C

PARAMETERS

LS2 ON = 73.0 °C

PARAMETERS

PARAMETERS

MEAS. TIME = 3 sec

ERROR PARAMET.

Paramet. plausible?

PARAMETERS

LS1 ON = 1.24 m/s

PARAMETERS

LS1 OFF = 1.50 m/s

▲ + ▼

LAST ERROR

MM

M

M

M

M

M

M

M

Page 51

7 Errors

7.1 Test and diagnosis

The FC01-LQ is provided with extensive test and diagnosis functions which may be classified

as follows:

7.1.1 Priority group I

Priority group I comprises the switch-on test routines (FC01-LQ self-test) which are carried out

when the system is switched on.

Their implementation is indicated.

Errors No. 1 to 5 do not allow system operation.

The test routines may be repeated by pressing any of the switches.

If even after several trials the switch-on test cannot be conducted without error indication, the

system should be returned to the supplier for rectification, indicating the error number.

Priority I errors cannot be rectified by the user!

7.1.2 Priority group II

These test functions are continuously carried out during operation. The occurrence of errors

No. 10 and 21 will cause measurements to stop, indicating the error and monitoring the source

of the error. Upon rectification of the error, the system will automatically return to measuring

operation.

7.1.3 Priority group III

These test routines are also continuously carried out during operation.

Other than the above priority groups, errors No. 20, 30, 60, 40 and 41 will not cause

measurements to stop; the error output will indicate and the number of the error will be shown

on the display.

Page 52

7.2 Potential errors

Independent of the priority group, all errors found are indicated with their relevant number.

In order to facilitate operation, the last error is stored in a non-volatile memory. The stored error

may be retrieved and deleted in the main menu.

If a combination of errors occurs simultaneously, they are indicated or stored in the error memory

observing the following sequence.

Priority group I

Error Cause Rectification

No. 1 No system parameter available Return to supplier.

No. 2 Incorrect test sum of parameter Return to supplier.

memory

No. 3 Incorrect test sum of program Return to supplier.

memory

No. 4 Incorrect test sum of data memory Return to supplier.

No. 5 Internal controller error Return to supplier.

Priority group II

Error Cause Rectification

No. 10 Sensor not connected; or cable Check cable or replace sensor.

between FC01-LQ and sensor

defective; or defective sensor

Sensor selected (configuration) Correct sensor selection in

differs from sensor connected configuration menu

No. 21 Medium temperature too high

Page 53

Priority group III

Error Cause Rectification

No. 20 Medium temperature too low

No. 30 Over limits of flow rate

No. 60 Assignment of quantity per pulse

too low *

No. 40 Controller error (oscillator-watchdog)

Admissible EMC levels may have

been exceeded

No. 41 Controller error (watchdog timer)

Admissible EMC levels may have

been exceeded

* Error No. 60 can only occur with version FC01-U1T4.

Page 54

8 Technical data

8.1 Ambient conditions

rail-mounted surface mounted front panel mounted

Storage temperature: -20 … +70 °C -20 … +70 °C -20 … +70 °C

Ambient temperature: * +10 … +50 °C ** +10 … +50 °C +10 … +50 °C

Degree of protection: IP20 IP65 IP65

* Only if the modules are spaced by at least 10 mm.

** The max. ambient temperature of +40 °C applies to all systems fitted with current output C1.

8.2 Electrical characteristics

8.2.1 Power supply

DC supply

Pin selection: Signal name Pin XV

shield 1

+U

V

2

-U

V

3

8.2.1.1 DC voltage supply

Supply voltage: U

VN

= DC 24 V *

Input voltage range: U

V

= DC 19 V to DC 32 V

(ripple incl.)

Admissible ripple: max. 20 % U

V

Rated current consumption: I

vnk

= 170 mA with zero flow

I

vnk

= 200 mA with max. flow (end of measuring range)

Power consumption may be up to 300 mA±10 % when analogue output C1 is fitted.

* DC 12 V possible if the FC01-LQ is used whithout option C1 (analogue outputs).

Page 55

Inrush current: Ip= typ. 3 A (20 µs)

Switch-off current: I

kipp

= typ. 0.75 A

Rated power consumption: P

n

= 4.1 W with zero flow, voltage outputs

P

n

= 4.8 W max. flow (end of measuring range),

voltage outputs

Insulation voltage: supply input - central electronic unit ≥ DC 500 V

8.3 Analogue outputs

The analogue outputs are physically isolated from each other as well as from the electronic

control unit FC01-LQ.

Pin selection for analogue outputs V1, V2 and C1

Signal name Pin XAO

NC 1

analogue output 1 - flow rate 2

reference ground 1 3

shield 1 * 4

shield 2 * 5

analogue output 2 - temperature 6

reference ground 2 7

NC 8

NC - not used

Analogue output 1 - ANA OUT FLOW (flow output)

Analogue output 2 - ANA OUT TEMP. (temperature output)

* Shield ungrounded - apply on one side only.

The output is reverse polarity protected.

Insulation voltage: analogue output - analogue output DC 500 V

analogue output - central electronic unit DC 500 V

Page 56

8.3.1 Voltage output V1 - 5 V FS

Signal voltage range: US= 0 V (1 V) to 5 V ±2% FS

Max. signal rippl: dU

S

= 5% FS

Min. admissible load resistance: R

l

= 1 kΩ

Max. admissible load capacity: C

l

= 1 nF

Max. admissible load inductance: L

l

= 100 nH

Short circuit proof: yes (XAO - between all terminals)

8.3.2 Voltage output V2 - 10 V FS

Signal voltage range: US= 0 V (2 V) to 10 V ±2% FS

Max. signal ripple: dU

S

= 5% FS

Min. admissible load resistance: R

l

= 1 kΩ

Max. admissible load capacity: C

l

= 1 nF

Max. admissible load inductance: L

l

= 100 nH

Short circuit proof: yes (XAO - between all terminals)

8.3.3 Current output C1 - 20 mA FS

Signal current range: IS= 0 mA (4 mA) to 20 mA ±2% FS

Max. signal ripple: dI

S

= 5% FS

Min. admissible load resistance: R

l

= 0Ω

Max. admissible load resistance: R

l

= 250Ω

8.4 Signal outputs

The signal outputs are physically isolated from each other as well as from the electronic

control unit FC01-LQ.

8.4.1 Relay outputs R2 (DC or AC)

Pin selection: Signal name Pin XAH

Limit Switch 1 / shield 1

Limit Switch 1 / N/O 2

Limit Switch 1 / common 3

Limit Switch 1 / N/C 4

Limit Switch 2 / Schirm 5