ETAS XETK-V2.0 Series, XETK-V2.0A, XETK-V2.0B, XETK-V2.0C User Manual

XETK-V2.0

Emulator Probe for MPC5600 and SPC5600 Family

User’s Guide

Copyright

The data in this document may not be altered or amended without special notification from ETAS GmbH. ETAS GmbH undertakes no further obligation in relation to this document. The software described in it can only be used if the

customer is in possession of a general license agreement or single license. Using

and copying is only allowed in concurrence with the specifications stipulated in

the contract.

Under no circumstances may any part of this document be copied, reproduced,

transmitted, stored in a retrieval system or translated into another language

without the express written permission of ETAS GmbH.

© Copyright 2018 ETAS GmbH, Stuttgart

The names and designations used in this document are trademarks or brands

belonging to the respective owners.

XETK-V2.0 - User’s Guide R11 EN - 12.2018

2

ETAS Contents

Contents

1 About this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.1 Identification of Safety Notices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.2 Presentation of Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.3 Scope of Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.4 Additional Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2 Basic Safety Notices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.1 General Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.2 Requirements for Users and Duties for Operators . . . . . . . . . . . . . . . . . . . . . 9

2.3 Intended Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.4 Identifications on the Product . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.5 Taking the Product Back and Recycling . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.6 CE marking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.7 RoHS Conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.7.1 European Union . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.7.2 China . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.8 Declarable Substances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.9 Use of Open Source Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.1 Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.2 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4 Hardware Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.1.1 XETK-V2.0 Variants . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.1.2 XETK-V2.0A/C VertiCal Interface Concept . . . . . . . . . . . . . . . . . . . 19

4.1.3 XETK-V2.0B Interface Concept . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.2 Architecture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.3 ECU Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

XETK-V2.0 - User’s Guide 3

ETAS Contents

4.4 Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4.5 XETK Ethernet Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4.6 Status LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4.7 Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4.8 Data Emulation Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4.8.1 Page Switching . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

4.8.2 XETK-V2.0A/C SRAM Characteristics & Data Retention . . . . . . . . . 28

4.8.3 Data Emulation Power Failures. . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

4.9 Nexus (JTAG) Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

4.9.1 XETK-V2.0A/C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

4.9.2 XETK-V2.0B. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

4.10 Watchdog Timer Disable / Tool Detect Interface . . . . . . . . . . . . . . . . . . . . . 31

4.10.1 XETK-V2.0A/C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

4.10.2 XETK-V2.0B. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

4.11 Startup and Triggering with DAI Pins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

4.11.1 XETK-V2.0A/C DAI Interface via BGA VertiCal Base Boards . . . . . . 33

4.11.2 XETK-V2.0A/C DAI Interface via QFP VertiCal Base Boards . . . . . . . 34

4.11.3 XETK-V2.0B DAI Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

4.11.4 Phases of the Startup Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

4.11.5 Triggering of Measurement Data Acquisition . . . . . . . . . . . . . . . . . 37

4.12 Pinless Startup and Triggering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

4.12.1 Startup Handshake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

4.12.2 Triggering of Measurement Data Acquisition . . . . . . . . . . . . . . . . . 39

4.13 Triggering with Timers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

4.14 Triggering with Trace . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

4.15 XETK-V2.0A/C Microcontroller EBI Voltage Supply . . . . . . . . . . . . . . . . . . . 40

4.16 XETK-V2.0A/C Nexus (JTAG) Debugger Interface . . . . . . . . . . . . . . . . . . . . 40

4.17 Braindead Flashing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

4.17.1 Braindead Flashing via Nexus (JTAG) Debug Interface . . . . . . . . . . 41

4.17.2 External Watchdog disable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

5 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

5.1 Connection to the ECU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

5.1.1 XETK-V2.0A/C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

5.1.2 XETK-V2.0B. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

5.2 Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

5.2.1 XETK Ethernet Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

5.2.2 Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

6 XETK Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

6.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

6.2 Configuration Parameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

7 Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

7.1 System Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

7.1.1 ETAS Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

7.1.2 Ethernet Interface of the PC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

7.1.3 Supported Microcontrollers and Software Versions . . . . . . . . . . . . 50

7.2 Environmental Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

7.3 Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

XETK-V2.0 - User’s Guide 4

ETAS Contents

7.3.1 XETK-V2.0A/C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

7.3.2 XETK-V2.0B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

7.4 Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

7.5 XETK Ethernet Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

7.6 ECU Interface Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

7.6.1 XETK-V2.0A/C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

7.6.2 XETK-V2.0B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

7.7 Test Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

7.8 Electrical Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

7.8.1 XETK-V2.0A/C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

7.8.2 XETK-V2.0B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

7.9 Switching Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

7.9.1 JTAG Timing Characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

7.9.2 Nexus Timing Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

7.9.3 XETK-V2.0A/C SRAM Read Timing. . . . . . . . . . . . . . . . . . . . . . . . . 66

7.9.4 XETK-V2.0A/C SRAM Write Timing . . . . . . . . . . . . . . . . . . . . . . . . 67

7.10 Mechanical Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

7.10.1 XETK-V2.0A/C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

7.10.2 XETK-V2.0B. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

7.11 Pin Assignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

7.11.1 XETK-V2.0A/C VertiCal Connector. . . . . . . . . . . . . . . . . . . . . . . . . 72

7.11.2 XETK-V2.0A/C Nexus (JTAG) Debugger Interface . . . . . . . . . . . . . . 77

7.11.3 XETK-V2.0B ECU Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

8 Cables and Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

8.1 ECU Adapter Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

8.1.1 CBAM230.1 Adapter Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

8.1.2 CBAM240.1 Adapter Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

8.2 PC Interface Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

8.2.1 CBE200-3 Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

8.2.2 CBAE200.2 Adapter Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

8.3 ETAS Module Interface Adapter Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

8.3.1 CBE230.1 Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

8.3.2 CBAE330.2 Adapter Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

8.4 Power Supply Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

8.4.1 Cable ETV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

8.4.2 Cable K70 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

8.4.3 Cable KA50. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

8.4.4 Cable CBM200 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

8.5 Adapters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

8.5.1 ETAH1 ECU Interface Adapter for XETK-V2.0B. . . . . . . . . . . . . . . . 86

8.5.2 ETAH2 Debugger Interface Adapter for XETK-V2.0A/C . . . . . . . . . 89

8.5.3 ETAH5 Debugger Interface Adapter for XETK-V2.0A/C . . . . . . . . . 91

8.5.4 ETAH4 ECU Interface Adapter for XETK-V2.0B. . . . . . . . . . . . . . . . 92

9 Ordering Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

9.1 XETK-V2.0 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

9.2 XETK-V2.0A/C - Debugger Adapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

9.3 XETK-V2.0B - ECU Adapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

XETK-V2.0 - User’s Guide 5

ETAS Contents

9.4 VertiCal Base Boards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

9.5 Sockets ECU - VertiCal Base Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

9.6 Connector XETK-V2.0B - ECU Adapter ETAH1 . . . . . . . . . . . . . . . . . . . . . . 95

9.7 Connector XETK-V2.0B - ECU Adapter ETAH4 . . . . . . . . . . . . . . . . . . . . . . 96

9.8 Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

9.8.1 ECU Adapter Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

9.8.2 Ethernet Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

9.8.3 Power Supply Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

9.9 Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

10 ETAS Contact Addresses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Figures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

XETK-V2.0 - User’s Guide 6

ETAS About this Manual

DANGER!

WARNING!

CAUTION!

1 About this Manual

This chapter contains information about the following topics:

• „Identification of Safety Notices“ on page 7

• „Presentation of Information“ on page 7

• „Scope of Supply“ on page 8

• „Additional Information“ on page 8

1.1 Identification of Safety Notices

The safety notices contained in this manual are identified with the danger symbol

shown below:

The safety notices shown below are used for this purpose. They provide notes to

extremely important information. Please read this information carefully.

indicates an immediate danger with a high risk of death or serious

injury, if not avoided.

indicates a possible danger with moderate risk of death or (serious)

injury, if not avoided.

identifies a hazard with low risk that could result in minor or medium

physical injuries or property damages if not avoided.

1.2 Presentation of Information

All activities to be performed by the user are presented in a "Use Case" format.

That is, the goal to be accomplished is briefly defined in the heading, and the

respective steps required for reaching this goal are then presented in a list. The

presentation looks as follows:

Goal definition:

any advance information...

•Step 1

Any explanation for step 1...

•Step 2

Any explanation for step 2...

•Step 3

Any explanation for step 3...

Any concluding comments...

XETK-V2.0 - User’s Guide 7

ETAS About this Manual

Note

Typographical Conventions

The following typographical conventions are used:

Bold Labels of the device

Italic Particularly important text passages

Important notes for the user are presented a

Important note for the user.

1.3 Scope of Supply

Prior to the initial commissioning of the module, please check whether the product was delivered with all required components and cables (see chapter "Ordering Information").

Additional cables and adapter

accessories and their order designation is available in this manual and at the

ETAS Home Page.

1.4 Additional Information

The configuration instructions for the product can be found in the corresponding

software documentation.

s follows:

s can be obtained separately from ETAS. A list of

XETK-V2.0 - User’s Guide 8

ETAS Basic Safety Notices

Note

2 Basic Safety Notices

This chapter contains information about the following topics:

• "General Safety In

• "Requirements for Users and Duties for Operators" on page 9

• "Intended Use" on page 9

• "Identifications on the Product" on page 12

• "Taking the Product Back and Recycling" on page 13

• "CE marking" on page 13

• "RoHS Conformity" on page 13

• "Declarable Substances" on page 14

• "Use of Open Source Software" on page 14

formation" on page 9

2.1 General Safety Information

Please observe the Product Safety Notices ("ETAS Safety Notice") and the following safety notices to avoid health issues or damage to the device.

Carefully read the documentation (Product Safety Advice and this User's Guide)

that belongs to the product prior to the startup.

ETAS GmbH does not assume any liability for damages resulting from improper

handling, unintended use or non-observance of the safety precautions.

2.2 Requirements for Users and Duties for Operators

The product may be assembled, operated and maintained only if you have the

necessary qualification and experience for this product. Incorrect operation or

operation by users without sufficient qualification may lead to injuries or death

or property damages.

General Safety at Work

The existing regulations for safety at work and accident prevention must be followed. All applicable regulations and st

strictly followed when using this product.

atutes regarding operation must be

2.3 Intended Use

An ETK is an electronic component that is installed in a vehicle control unit (ECU)

to read data from the ECU or write data to the ECU.

Application Area of the Product

This product was developed and approved for automotive applications. For use

in other application areas, please contact your ETAS contact partner.

Requirements for Operation

The following requirements are necessary for safe operation of the product:

XETK-V2.0 - User’s Guide 9

ETAS Basic Safety Notices

DANGER!

CAUTION!

• Use the product only according to the specifications in the corresponding

User's Guide. With any deviating operation, the product safety is longer

ensured.

• Observe the regulations applicable at the operating location concerning

electrical safety as well as the laws and regulations concerning work

safety!

• Do not apply any voltages to the connections of the product that do not

correspond to the specifications of the respective connection.

• Connect only current circuits with safety extra-low voltage in accordance

with EN 61140 (degree of protection III) to the connections of the prod

uct.

• The power supply for the product must be safely disconnected from the

supply voltage. For example, use a car battery or a suitable lab power sup

ply.

• Use only lab power supplies with double protection to the supply system.

• Ensure that the connections of the power supply are easily accessible.

• The module does not have an operating voltage switch.

– Switch on the product by connecting the power supply cable with the

power supply or by switching on the power supply.

– Switch off the product by disconnecting it from the power supply or by

switching off the power supply.

-

-

Connect the power cord only with a vehicle battery or with a

lab power supply! A connection to power outlets is prohibited.

- Route the power cord in such a way that it is protected against abrasion, damages, deformation and kinking. Do not place any objects on

the power cord.

- Never apply force to insert a plug into a socket. Ensure that there is

no contamination in and on the connection, that the plug fits the

socket, and that you correctly aligned the plugs with the connection.

- Do not use the product in a wet or damp environment.

- Do not use the product in potentially explosive atmospheres.

- Keep the surfaces of the product clean and dry.

Potential Equalization

Danger from inadvertent current flow!

Depending on the design, the shield of the Ethernet cables can be

connected with the housing of the module. Install the products only

on components with the same electrical potential or isolate the products from the components.

Requirements for the technical State of the Product

The product is designed in accordance with state-of-the-art technology and recognized safety rules. The product may be operated only in a technically flawless

condition and according to the intended purpose and with regard to safety and

XETK-V2.0 - User’s Guide 10

ETAS Basic Safety Notices

CAUTION!

CAUTION!

CAUTION!

CAUTION!

dangers as stated in the respective product documentation. If the product is not

used according to its intended purpose, the protection of the product may be

impaired.

Maintenance and Cleaning

The product is maintenance-free. Use a lightly moistened, soft, lint-free cloth for

cleaning the product. Ensure that no moisture can enter. Never spray cleaning

agents directly onto the product. Do not user any sprays, solvents or abrasive

cleaners which could damage the product.

Transport and Installation

The ETK can be damaged or destroyed!

Some components of the ETK board may be damaged or destroyed

by electrostatic discharges. Please keep the ETK in its storage package

until it is installed.

The board should only be taken from its package, configured, and

installed at a work place that is protected against static discharge.

During installation and removal, ECU and ETK must be in a de-eenergized state!

Risk of short circuiting the internal signals of the ETK!

When you mount the ETK to the ECU, you must ensure that the

screws and washers used will not penetrate the ETK printed circuit

board.

Differences in case ground potentials can cause high currents

to flow through the shields of the cables that connect various

system modules.

Ensure that the module mounting surfaces are at the same electrical

potential or insulate the modules from their mounting surfaces.

Cabling

Use exclusively ETAS cables at the connections of the product! Adhere to the

maximum permissible cable lengths! Observe the assignment of the cables to the

connectors! Detailed information about cabling is located in the ETK User's

Guides.

XETK-V2.0 - User’s Guide 11

ETAS Basic Safety Notices

Note

2.4 Identifications on the Product

Fig. 2-1 Adhesive Label (Example: Label for XETK-S14.0)

The following symbols are used for identifications of the product:

Symbol Description

The User's Guide must be read prior to the startup of the

product!

Symbol for WEEE, see chapter 2.5 on page 13

Symbol for CE conformity, see chapter 2.6 on page 13

Symbol for China RoHS, see chapter 2.7.2 on page 13

Symbol for China RoHS, see chapter 2.7.2 on page 13

Symbol for electrostatic sensitive components

XETK-S14.0A Product designation (example)

F 00K 110 722 Order number of the product (example)

SN: yyxxxxx Serial number (7-digit)

XXXX/YY Product version

ZZZZ Year of manufacture

ETAS GmbH,

PO Box 300220,

704

42 Stuttgart,

Germany

Manufacturer's address

For symbols and product information one or several adhesive labels can be

used.

XETK-V2.0 - User’s Guide 12

ETAS Basic Safety Notices

2.5 Taking the Product Back and Recycling

The European Union has passed a directive called Waste Electrical and Electronic

Equipment, or WEEE for short, to ensure that systems are setup throughout the

EU for the collection, treating and recycling of electronic waste.

This ensures that the devices are recycled in a resource-savi

no danger to health or the environment.

Fig. 2-2 WEEE-Symbol

The WEEE symbol (see Fig. 2-2 on page 13) on the product or its packaging

shows that the product must not be disposed of as residual garbage.

The user is obliged to collect the old devic

WEEE take-back system for recycling. The WEEE directive concerns all ETAS

devices but not external cables or batteries.

For more information on the ETAS GmbH Recycli

sales and service locations.

es separately and return them to the

ng software, contact the ETAS

ng way representing

2.6 CE marking

With the CE mark attached to the product or its packaging, ETAS confirms that

the product corresponds to the applicable product-specific European Directives.

The CE Declaration of Conformity for the product is available upon request.

2.7 RoHS Conformity

2.7.1 European Union

The EU Directive 2011/65/EU limits the use of certain dangerous materials for

electrical and electronic devices (RoHS conformity).

This product does not contain any of the restricted substances specified in the EU

Dir

ective 2011/65/EU or exceeds the maximum concentrations stipulated

therein. For individual electronic components used in our products, there are currently no equivalent alternative substanc

exceptions 7A and 7C-I in Annex III of this Directive.

ETAS confirms that the product corresponds

in the European Union.

2.7.2 China

ETAS confirms that the product meets the product-specific applicable guidelines

of the China RoHS (Management Methods for Controlling Pollution Caused by

Electronic Information Products Regulation) applicable in China with the China

RoHS marking affixed to the product or its packaging.

es, which is why we make use of the

to this directive which is applicable

XETK-V2.0 - User’s Guide 13

ETAS Basic Safety Notices

2.8 Declarable Substances

European Union

Some products from ETAS GmbH (e.g. modules, boards, cables) use components

with substances that are subject to declaration in accordance with the REACH

regulation (EU) no.1907/2006.

Detailed information is located in the ETAS download center in the customer

information "REACH Declaration" (

continuously being updated.

www.etas.com/Reach). This information is

2.9 Use of Open Source Software

The product uses Open Source Software (OSS). This software is installed in the

product at the time of delivery and does not have to be installed or updated by

the user. Reference shall be made to the use of the software in order to fulfill

OSS licensing terms. Additional information is available in the document "OSS

Attributions List" at the ETAS website www.etas.com.

XETK-V2.0 - User’s Guide 14

ETAS Introduction

Note

Note

3 Introduction

This section contains general safety instructions, information about the basic features and applications of the XETK-V2.0 Interface

Probe), hints to system requirements, and delivery scope.

Board (ETK = Emulator Test

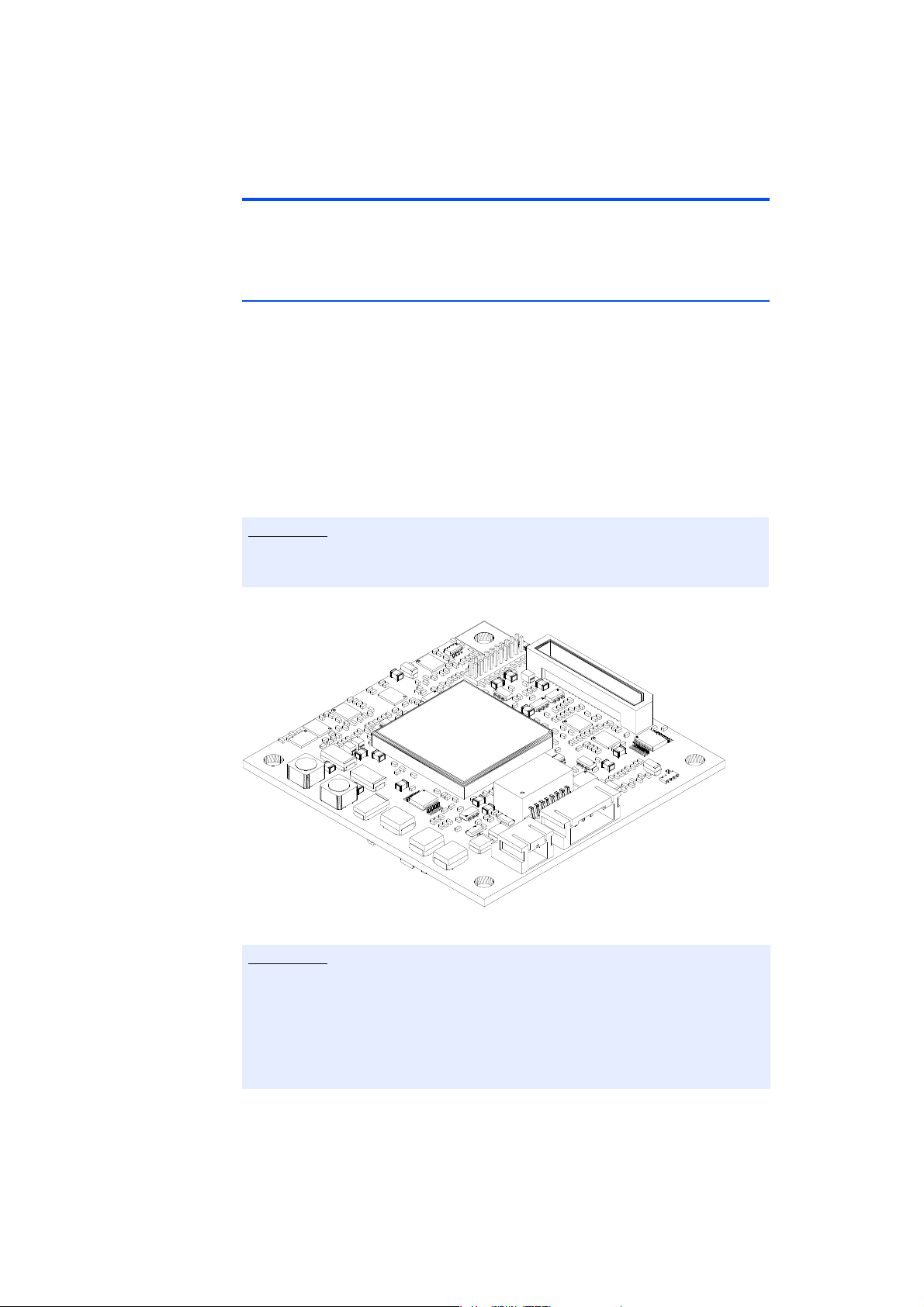

3.1 Applications

The XETK-V2.0 is an emulator probe for the Freescale MPC5600 microcontroller

family and ST SPC5600 microcontroller family using the Nexus debug interface

(IEEE/ISTO 5001). To cover the multiple microcontroller packaging options, the

XETK-V2.0 is available in three variants: the XETK-V2.0A, XETK-V2.0B, and

XETK-V2.0C.

The XETK-V2.0A/C combines a typical (X)ETK seria

and is based on the VertiCal interface concept from Freescale and ETAS. It can be

used with the above microcontrollers packaged with a Vertical Base Board.

The XETK-V2.0B is a typical (X)ETK serial interface and is suitable for the above

micr

ocontrollers in all packages.

l interface with a 32 bit SRAM

Refer to chapter 7.1.3 on page 50 for a list of supported microcontrollers and

the required software versions to use them.

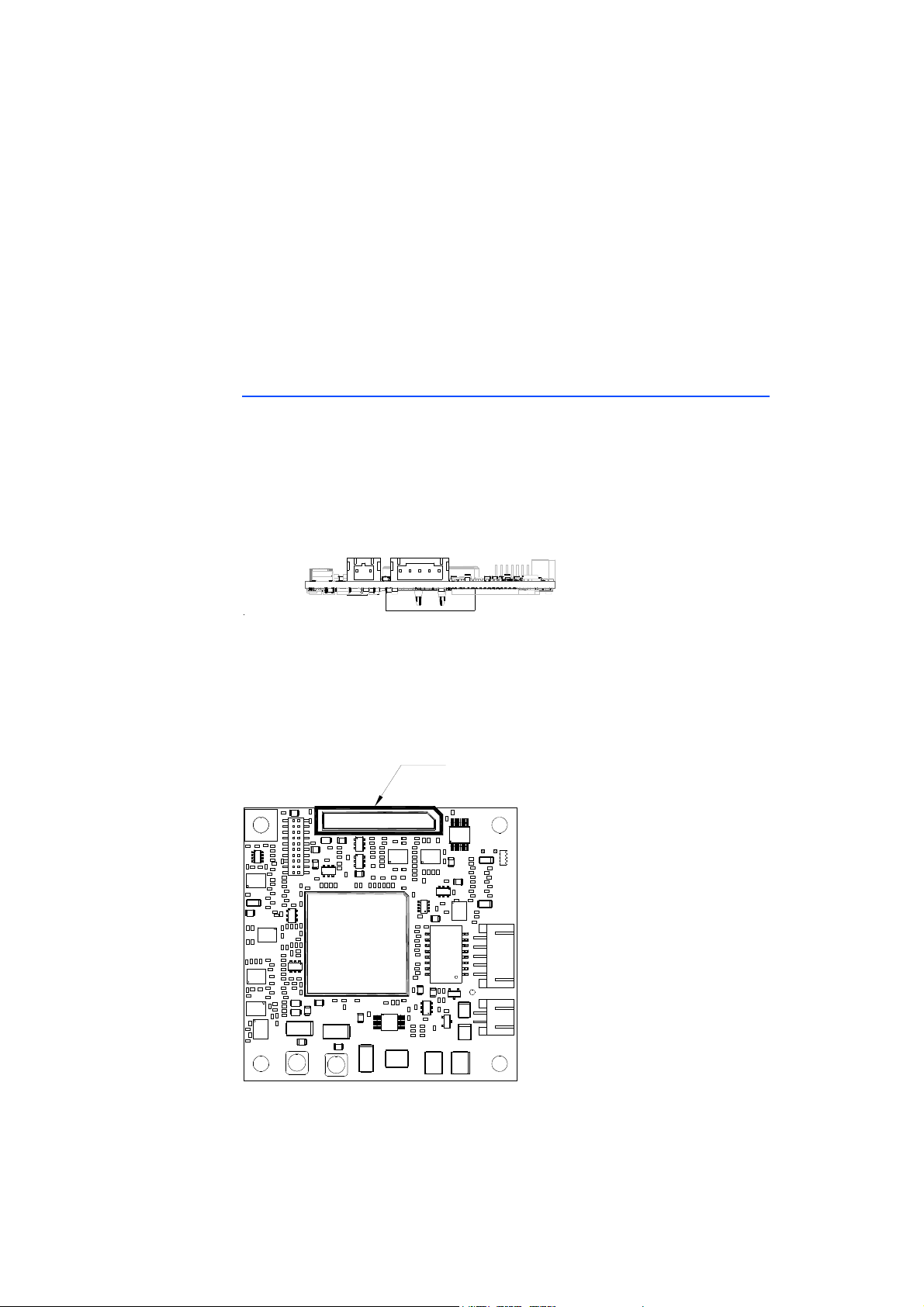

Fig. 3-1 XETK-V2.0 top view

The XETK-V2.0 can be ordered in three different functional and mechanical

variants: XETK-V2.0A, XETK-V2.0B, and XETK-V2.0C. Within the manual the

term "XETK-V2.0" describes features common to all variants. The term "XETKV2.0A/C" describes specific features common to the XETK-V2.0A and XETKV2.0C variants. The term "XETK-V2.0B" describe features specific to the XETKV2.0B variant.

XETK-V2.0 - User’s Guide 15

ETAS Introduction

The XETK-V2.0’s Nexus (JTAG) debug interface at 2.5 V or 3.3 V. The XETK-V2.0

performs measurement and calibration of variables as well as flashing via the

JTAG portion of the Nexus interface. Additionally the Nexus Auxiliary interface

can be used for high speed trace measurement.

The XETK-V2.0A/C provides a Synchronous RAM (SRAM) that can be used by the

ECU to store calibration or other ECU variables (XETK-V2.0A provides 2 MByte

SRAM, XETK-V2.0C provides 4 MByte SRAM). This SRAM is only accessible to the

XETK-V2.0A/C via the microcontroller’s Nexus (JTAG) debug interface. This inter

face operates at 2.5 V or 3.3 V.

The XETK-V2.0 supports the standard full duplex 100Base-T Ethernet interface

and be connected directly or via ES51x/ES59x/ES600 modules to the PC. No addi

tional ETAS modules are required for the access to the ECU. The XETK-V2.0 can

be used for rapid prototyping applications (bypass) as well as for measurement

and calibration applications.

3.2 Features

• Measurement Interface

– Nexus / JTAG interface (operates at 2.5 V or 3.3 V)

– Configurable JTAG interface clock speed: 20 MHz, 30 MHz, or

40

MHz

– Nexus Trace interface clock speed: up to 66 MHz

– Supports coldstart measurement mechanism

– Supports high speed measurement rasters with Nexus Trace (down to

10 μs)

– Hardware synchronization and time stamping

• Startup protocol for XETK / ECU synchronization

– DAI pins (all microcontrollers)

– Pinless via Nexus / JTAG

• Trigger interface

– 2 DAI triggers

– 32 Pinless triggers via Nexus / JTAG

– 4 triggers generated by internal timers

– 16 trace triggers

– 64 total measurement rasters

• Calibration interface

– XETK-V2.0A/C provides SRAM to be used for emulation data with a

configurable chip select

– XETK-V2.0A/C provides power for both the Microcontroller External

Bus Interface and the on board XETK RAM

– Microcontroller capability of re-mapping Flash to RAM emulation used

by ECU software

– Supports “Start on Working Page”

• Debugger interface

– XETK-V2.0 arbitration possible with "Lauterbach Power Trace"

-

-

XETK-V2.0 - User’s Guide 16

ETAS Introduction

– XETK-V2.0A/C provides additional Nexus (JTAG) compliant Samtec

connector for external debug hardware

– XETK-V2.0B hardware is prepared to be used simultaneously with a

debugger, but an additional external arbitration circuit and debugger

connection is required

• ECU flashing via XETK

– Braindead flashing under ProF control

• XETK-V2.0A/C VertiCal interface

– Small form factor

– Short signal lines for minimal impedance

– Applicable for multiplexed 32-bit microcontroller bus

– Supports 32-, 16- and 8-bit access to the provided memory

– VertiCal Shroud installed to aid in alignment during product installa-

tion

• Fast Ethernet interface

– Direct connection to PC

– Open XCP on Ethernet protocol

– Supports a variety of standard applications

• Firmware update (programming of the logic device) through service software "Hardware Service Pack" (HSP); removal of XETK or ECU not necessary

• Temperature range suitable for automotive application

• Permanent storage of configuration in EEPROM

For more technical data on the XETK-V2.0 consult the chapter "Technical Data"

on page 50.

XETK-V2.0 - User’s Guide 17

ETAS Hardware Description

Note

4 Hardware Description

In this chapter, the function blocks of the XETK-V2.0 are explained in detail.

The XETK-V2.0 can be ordered in three different functional and mechanical

variants: XETK-V2.0A, XETK-V2.0B, and XETK-V2.0C. Within the manual the

term "XETK-V2.0" describes features common to all variants. The term "XETKV2.0A/C" describes specific features common to the XETK-V2.0A and XETKV2.0C variants. The term "XETK-V2.0B" describe features specific to the XETKV2.0B variant.

4.1 Overview

4.1.1 XETK-V2.0 Variants

The XETK-V2.0 can be ordered in three different functional and mechanical variants: XETK-V2.0A, XETK-V2.0B, and XETK-V2.0C. The pri

between the XETK-V2.0 variants are described below.

mary differences

XETK-V2.0A/C XETK-V2.0B

ECU Connection 156 pin VertiCal 50 pin Samtec to ETAHx

Ad

apter:

ETAH1 - 38 pin Mictor

Calibration RAM 2 / 4 MByte SRAM pro-

Provided by ECU

1)

vided on XETK

Debugger Connection 50 pin Samtec None

Supported Microcontrol-

Vertical Base Board All Packages (e.g. Produc-

ler Packages

Installation Mounting VertiCal Base Board,

ad

ditionally 4 mounting

holes

JTAG / Nexus Interface Minimal signal condition-

ing on ECU (direct from

iCal Base Board)

Vert

Trigger Pin Connection Microcontroller GPIO via

D

AI circuit back to Verti-

Cal Base Board optional

3

ECU Switched Power

oring (Ignition /

Monit

ball locations

Built into VertiCal Base

Board

2)

tion Package or Vertical

ase Board)

B

Internal ECU housing or

ECU pcb using 4 mounting holes

Signal Conditioning

required on

ECU

microcontroller GPIO via

DAI circuit to XETK ECU

connector

Route signal to XETK ECU

connector

microcontroller power)

Standby Power Monitoring (Validity of Calibra-

Built into XETK Route signal to XETK ECU

conn

ector

tion RAM)

XETK-V2.0 - User’s Guide 18

ETAS Hardware Description

XETK-V2.0A/C XETK-V2.0B

Watchdog Timer Disable ECU circuit back to Verti-

Cal Base Board optional

ball location

3)

ECU circuit back to XETK

ECU connector

Dimension (H/W/D) 12 / 60 / 60 mm 9 / 60 / 60 mm

1)

: ECU application specific: internal or external RAM

2)

: XETK-V2.0B hardware is prepared to be used simultaneously with a debug-

ger (additional external arbitration circu

3)

: For ECUs with BGA adapters, VertiCal Base Boards with optional balls are

it and debugger connection is required).

required to use the DAI startup/ triggering and Watchdog Timer Disable features of the XETK-V2.0A/C.

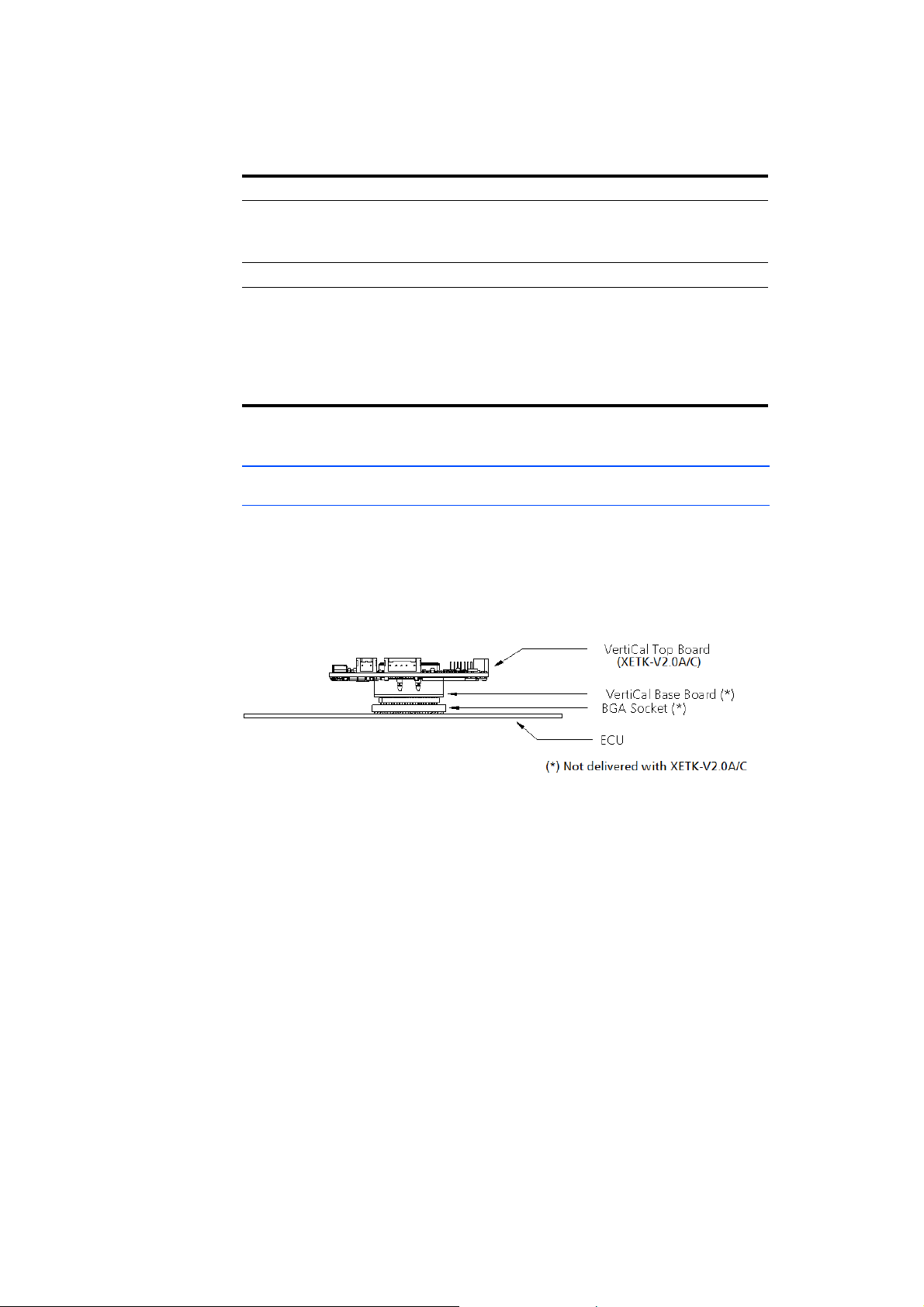

4.1.2 XETK-V2.0A/C VertiCal Interface Concept

Overview

The XETK-V2.0A/C uses the VertiCal interface concept to connect to the development ECU. The VertiCal Base Board uses a

age (CSP), which is fully compatible to

microcontroller in a chip scale pack-

the standard microcontroller.

With the VertiCal interface, the microcontroller of the ECU is not mounted on

t

he ECU or XETK, but on an additional board, the VertiCal Base Board.

Fig. 4-1 VertiCal Interface Concept (Side View)

The complete XETK-V2.0A/C VertiCal solution and its components are mounted

o

n two different boards:

• The VertiCal Base Board with

– a microcontroller in chip scale package (CSP)

– VertiCal connector (provides access to the ECU microcontroller adapter

and t

he VertiCal top board)

– a Pin Array / BGA / QFP Adapter to plug

the base board into the ECU

• The VertiCal Top Board (XETK-V2.0A/C) with

– Ethernet interface (converts microcontrolle

r signals into tool interface)

–2 MByte SRAM for XETK-V2.0A or 4 MByte for XETK-V2.0C

– Samtec connector with Nexus (JTAG) in

terface for a debugger

XETK-V2.0 - User’s Guide 19

ETAS Hardware Description

mкбенЙЗ=`бкЕмбн=_з~кЗ

sЙкнб`~д=`зееЙЕнзк

jбЕкзЕзенкзддЙк

mкбенЙЗ=`бкЕмбн=_з~кЗ

sЙкнб`~д=`зееЙЕнзк

máå=^êê~óL

_d^=^Ç~éíÉê

Note

Note

– VertiCal Shroud installed around the VertiCal connector to aid in align-

ment during product installation

For ECUs with BGA adapters VertiCal Base Boards with optional balls are

required to use the DAI startup/ triggering and Watchdog Timer Disable fea

-

tures of the XETK-V2.0A/C.

For ECUs with QFP adapters the DAI startup/triggering is already considered in

the VertiCal Base Board. The Watchdog Timer Disable feature of the XETKV2.0A/C is not available.

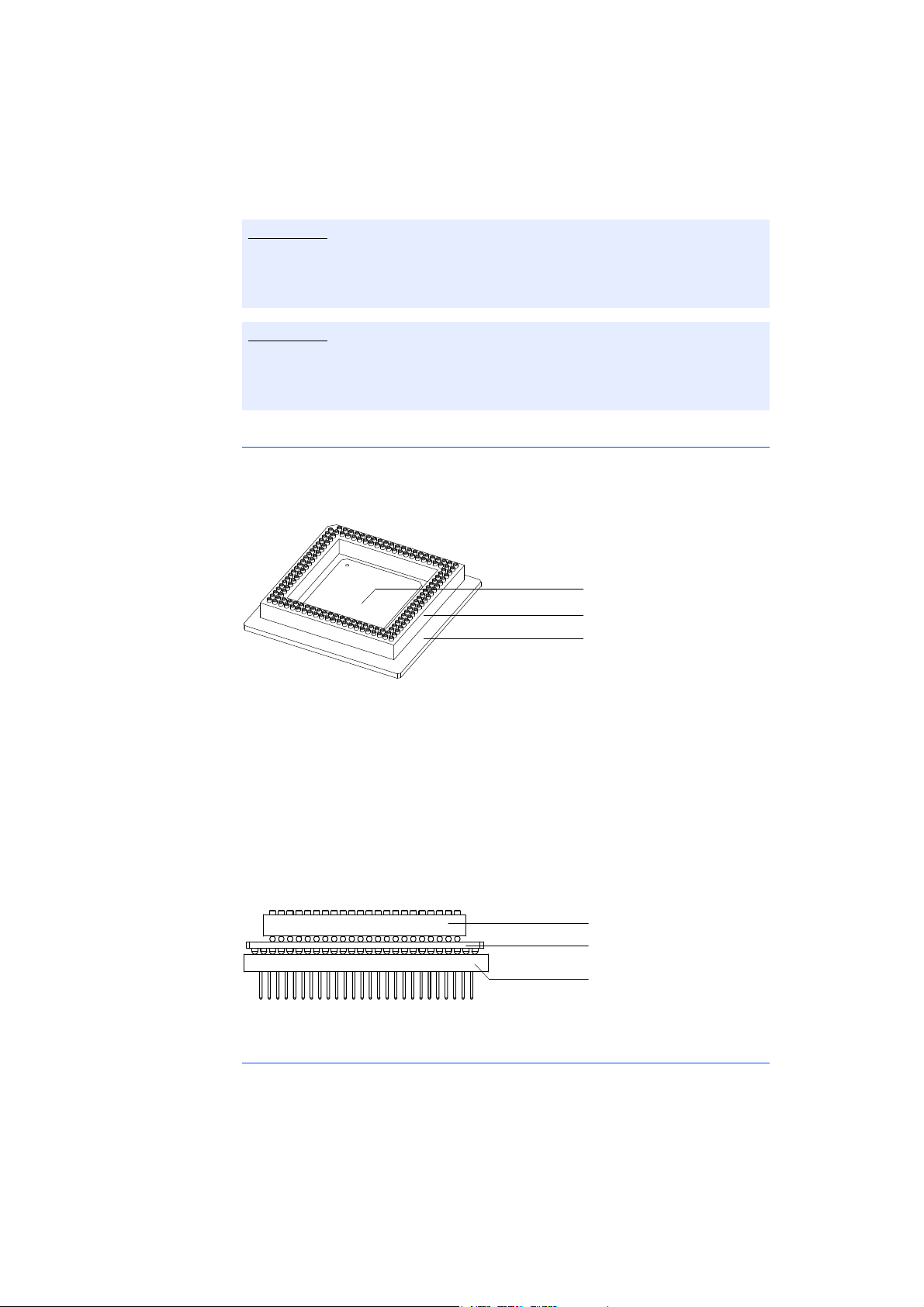

VertiCal Base Board

The printed circuit board (PCB), one of the VertiCal base board components, is

used as a base to mount the other components of the VertiCal Base Board.

Fig. 4-2 VertiCal Base Board

The upper side of the printed circuit board is assembled with

• the microcontroller device (packaged into the

specified CSP package),

• the VertiCal connector (standardized 156-way connector).

The lower side of the printed circuit board has a footprint similar to that used by

MPC5

600 family devices in standard production packages. It is populated with a

"BGA adapter" connector allowing connection and removal from an ECU development PCB which has been populated with

a compatible "BGA receiver"

socket (see Fig. 4-3).

Fig. 4-3 VertiCal Base Board (fitted with Pin Array/ BGA Adapter, Side View)

Typical Usage

The standard ECU microcontroller is replaced by the VertiCal base board with the

same dimensions and the same pinout.

The VertiCal base board connects the

ECU with the XETK-V2.0A/C.

XETK-V2.0 - User’s Guide 20

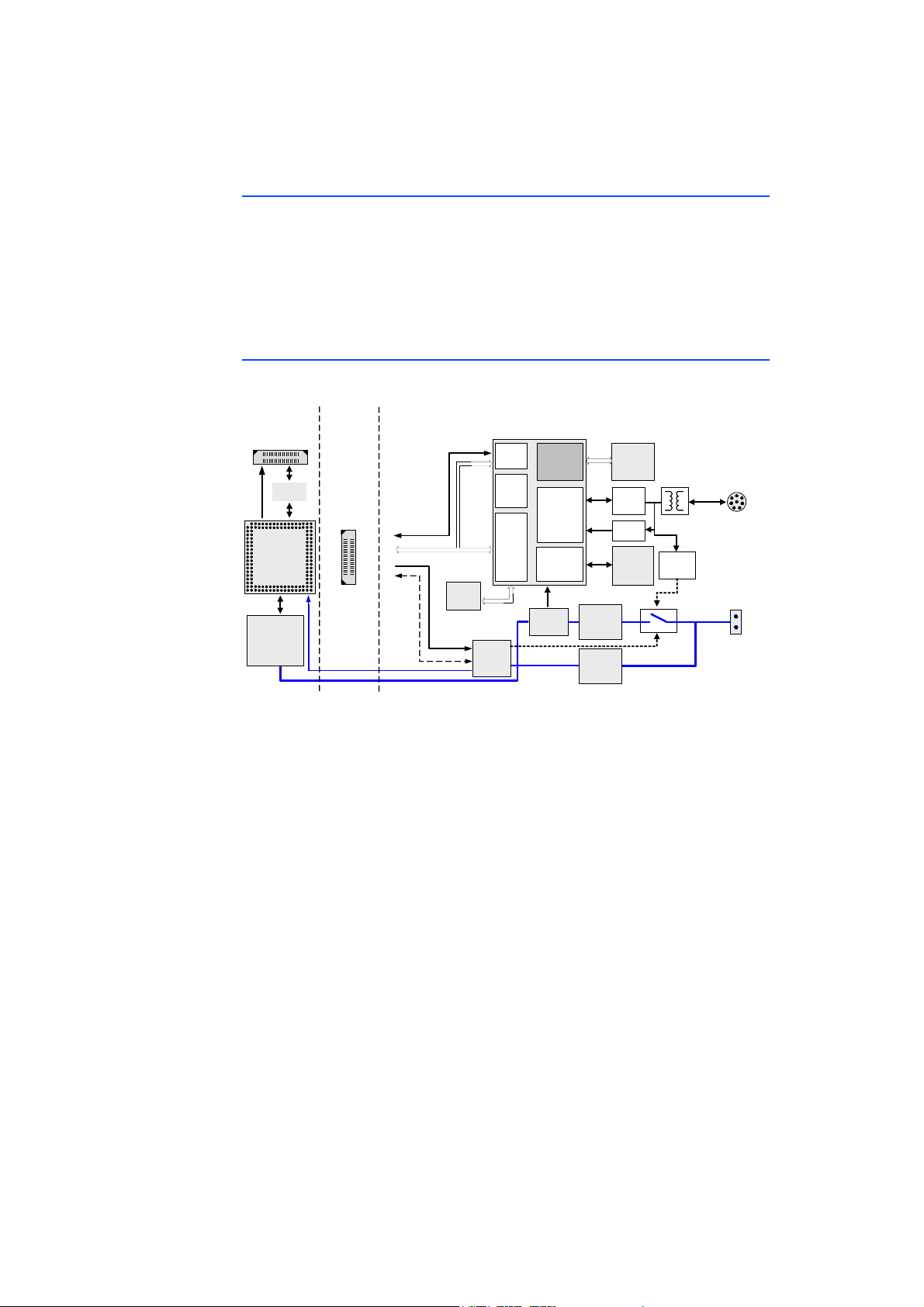

ETAS Hardware Description

XCP on

Ethernet Interface

SRAM

System

Functions

Trigger

Unit

100

MBit/s

Ethernet

Phyter

Ethernet

Phy

Automatic

Power On

Ethernet

Traffic

Detection

Ethernet

Traffic

Detection

Sense ECU

Power Supplies

ECU

Reset

Power

Supply

Monitoring

Standby Power Supply

ECU

Reset &

Power

Control

DMA

MCU

Core

Ethernet

MAC

Measurement &

Calibration

Unit

ECU

Access

Unit

Serial Flash

Configuration &

Manufacturing

Data

Time

Sync.

Trace

Functions

SRAM

Nexus / JTAG

DAI Pins

U- BattU- Batt

Power

Supply

4.3V...36V

Standby

Supply

4.3V...36V

Power

159

Pin

VertiCa

l

Connecto

r

VertiCal

Connector

(ECU Interface)

Nexus

Aux.

Nexus SAMTEC

Connector

(Debugger)

JTAG

Arbitration

SRAM

XETK-V2.0A – 2 MB

XETK-V2.0C – 4 MB

(Data Working Page

+ Measurement)

EBI Power Supply

XETK-V2.0

BA/C

Nexus SAMTEC

Connector

(ECU Interface)

4.1.3 XETK-V2.0B Interface Concept

The XETK-V2.0B connects to the ECU in a similar manner to other serial (X)ETKs,

using a cable with a standard debugging interface connector. The XETK-V2.0B is

equipped with a 50 pin Nexus Samtec connector and connects to the ECU using

an ETAHx ECU adapter cable.

The ETAH1 ECU adapter cable offers a connection to an EC

U equipped with a 38

pin Mictor connector. Other ETAHx variants are possible.

4.2 Architecture

Fig. 4-4 XETK-V2.0 Architecture

The XETK-V2.0’s primary interface to the

development ECU is the Nexus / JTAG

interface of the microcontroller. This interface is available at the VertiCal connector of the XETK-V2.0A/C or the Samtec co

face provides the XETK access to the same m

nnector of the XETK-V2.0B. This inter-

emories accessible to the

microcontroller, including both internal and/or external Flash and/or RAM. The

XETK-V2.0 can only access these memories while the microcontroller is powered

and out of reset.

The XETK-V2.0A/C provides a SRAM the developm

lation memory and/or as measuremen

t data memory. The XETK-V2.0A/C

ent ECU can use as data emu-

accesses this SRAM in the same way as other development ECU memories, via

the microcontroller’s Nexus /JTAG interface.

While the microcontroller accesses the program dat

a (not the program code) out

of the data emulation memory provided by either the XETK-V2.0A/C or the ECU,

the content of the data emulation memory can simultaneously be modified by

the calibration and development system through the XETK Ethernet interface.

This process enables adjustments of parameters, characteristic lines and maps

through the calibration and development system. Using an additional measurement data memory area, the ECU microcontroller can provide data to the calibration and development system by buffering the data (DISTAB13) and triggering

XETK to read the data via JTAG. The XETK then reads, buffers, processes and

the

sends this measured data to the PC.

XETK-V2.0 - User’s Guide 21

ETAS Hardware Description

`lkN

`lkO

ON R

N

`lkQ

`lkR

If no additional measurement data memory is available, the XETK-V2.0 can alternatively read the data to be measured directly from the microcontroller’s memory. This process is Triggered Direct M

The XETK-V2.0 can also receive the data to

easurement (TDM) with DISTAB13.

be measured via the Nexus Auxiliary

interface using data trace windows and trace triggering. The data trace can be

used with or without DISTAB13.

The 100 Mbit/s XETK Ethernet interface provides communication with the PC.

The power supply for the XETK-V2.0 is provided by a switch mode power supply,

to

minimize power dissipation.

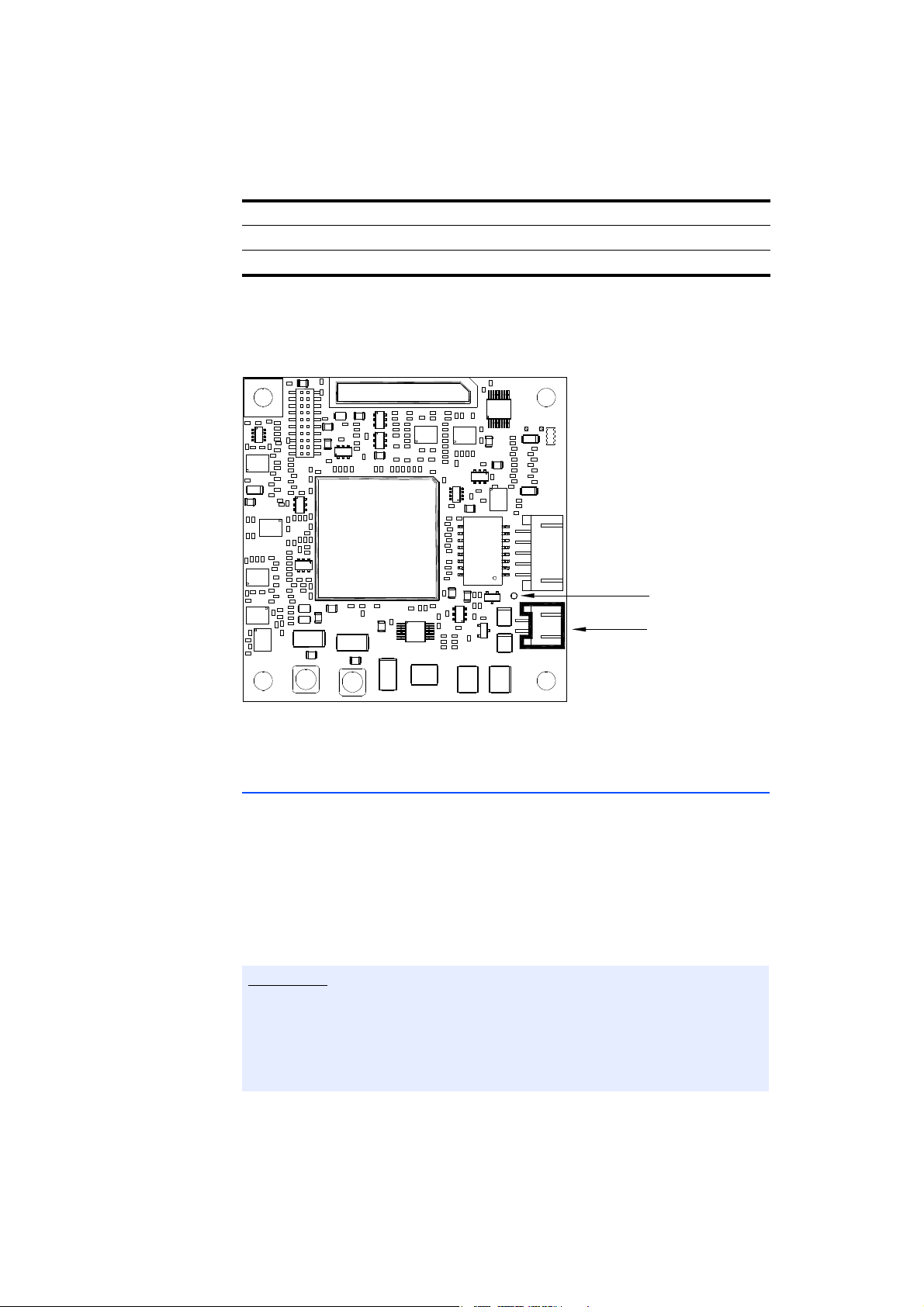

4.3 ECU Interface

The XETK-V2.0A/C and XETK-V2.0B utilize different connectors of the XETKV2.0 as the ECU interface.

The XETK-V2.0A/C interfaces to the microcontroller via the VertiCal connector,

CO

N1 (refer to Fig. 4-6 on page 22). The interface provides access to

controller’s external bus and Nexus (JTAG

) interface.

the micro-

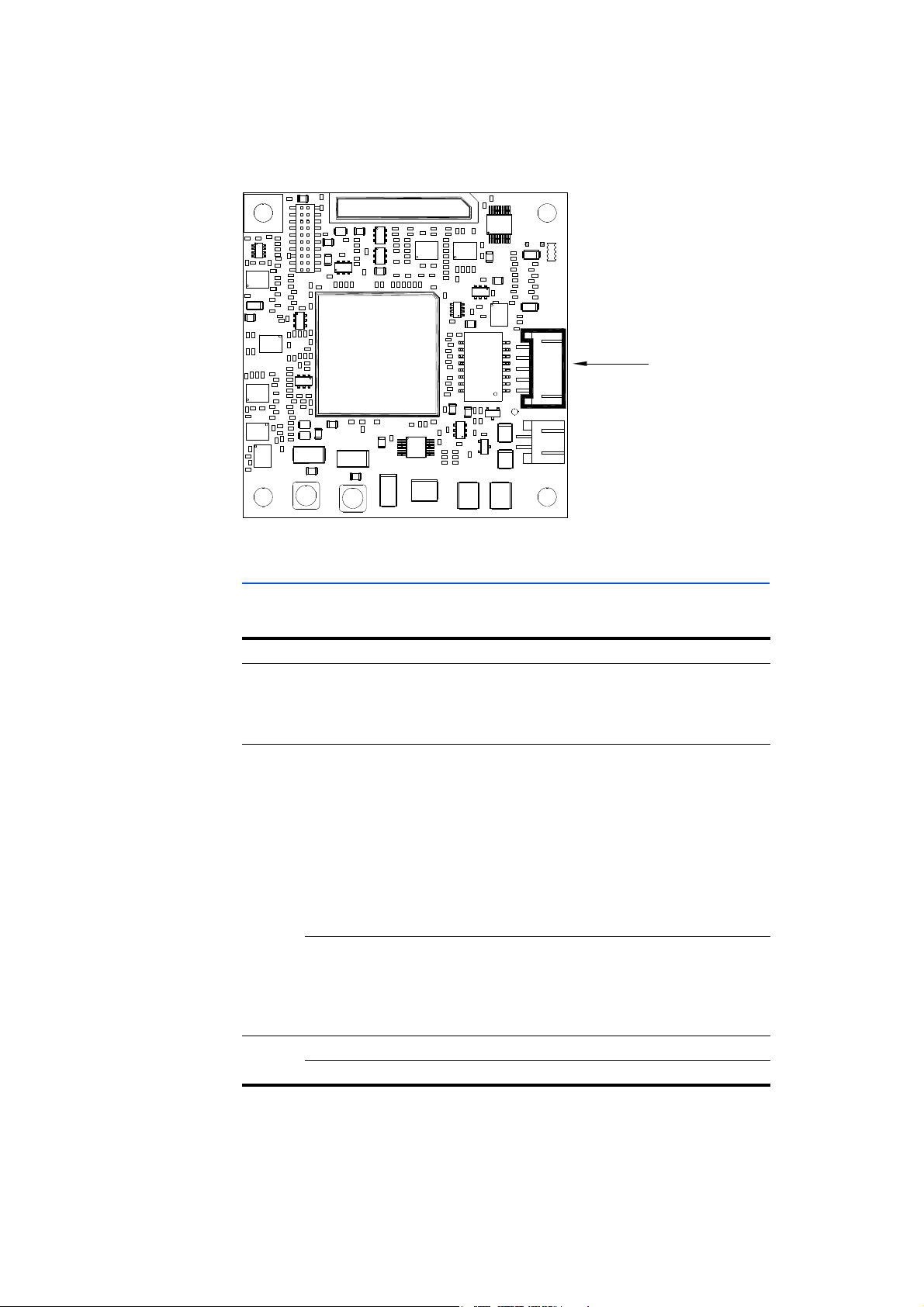

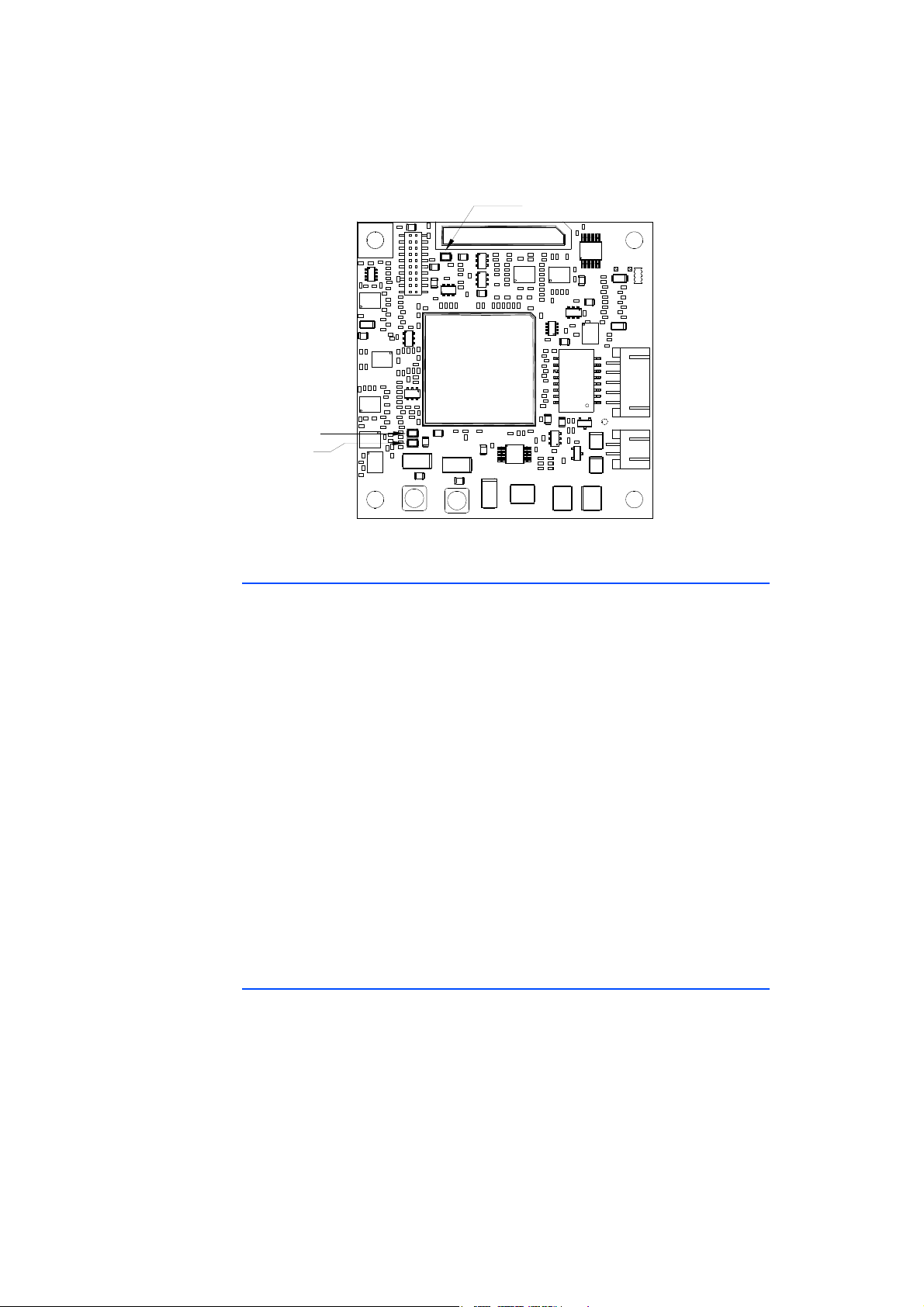

Fig. 4-5 XETK-V2.0A/C ECU Interface CON1

The XETK-V2.0B interfaces to the microcontroller via the Samtec connector,

CO

N5 (refer to Fig. 4-6 on page 22). The interface provides access to

the micro-

controller’s Nexus (JTAG) interface.

Fig. 4-6 XETK-V2.0B ECU Interface CON5

XETK-V2.0 - User’s Guide 22

ETAS Hardware Description

b`r=mçïÉê

pмййду

jáÅêçJ

ЕзенкзддЙк

bqh`~к=_~ннЙку

r_^qq s`` s``

b`r

`lkN

`lkO

ON R

N

`lkQ

`lkO

ON R

N

`lkQ

For a complete list of the pins of the XETK-V2.0A/C ECU interface refer to

section 7.11.1 on page 72 and to section 7.11.3 on page 79 for the XETK-V2.0B

ECU Interface. In general the interface of each device consists of:

• ECU voltage lines, which are not used for powering the XETK, but for

de

tecting the ECU status; therefore the power consumption on these lines

is negligible (refer to chapter 4.4 on page 23)

• Data Acquisition Interrupt lines (DAI

lines) which are used for XETK synchronization at startup and for Data Acquisition (refer to chapter 4.11.4

and 4.11.5)

• Reset lines which allow the XETK to bot

h monitor and control the system

reset of the ECU (refer to chapter 4.7 on page 26)

• JTAG Interface used as the measur

ement and calibration interface

between the XETK-V2.0 and the microcontroller (refer to chapter 4.9

on page 29)

• Nexus Auxiliary Interface used as an optional mea

surement interface

between the XETK-V2.0 and the microcontroller

4.4 Power Supply

The XETK-V2.0 needs a permanent power supply. It is powered directly from the

car battery. The input voltage may vary between 4.3 V and 36 V

Fig. 4-7 Power Supply monitoring

All necessary voltages required by the XETK

are created through switching power

supplies which minimizes heat build-up. The power supply of the ECU is not

affected by the XETK-V2.0. An automatic switch ensures that the power supply

of the XETK-V2.0 is automatically switched on and off. The ECU voltage VCC

(V_RESET for XETK-V2.0A/C and V_NEXUS for XETK-V2.0B) is monitored by the

XETK to recognize whether the ECU is switched on or off.

The XETK-V2.0 must be supplied with power through the 2-pin power supply

nector CON2 in Fig. 4-8 below.

con

Fig. 4-8 Power Supply Connector CON2 (left: XETK-V2.0A/C, right: XETK-

V2.0B)

XETK-V2.0 - User’s Guide 23

ETAS Hardware Description

`lkO

`lkP

Note

Pin CON2 Signal Description

1 U

2 GND Ground

Batt

Battery Supply Voltage for XETK

Additionally the through-hole solder pad CON3

supply U

Fig. 4-9 Power Supply Connectors CON2 and CON3

. The power supply on CON3 must use the GND of CON2.

Batt2

can be used to connect a power

4.5 XETK Ethernet Interface

The XETK Ethernet interface shown in Fig. 4-10 can be directly connected to the

PC. No additional ETAS module is r

The interface is a standard full duplex 10

XCP protocol. The XETK Ethernet interface is integrated in the ETAS IP world with

automatic IP management and supports the open automotive "Universal Measurement and Calibration" standard "XCP

open XCP on Ethernet interface allows for connecting to the XETK-V2.0 with

third party application software.

The XETK Ethernet interface is not compatible with the ETK interfaces in modules like e.g. ES910, ES590, ES591,

The XETK Ethernet interface is compatible with the ECU interface of the ES910

module and the Ethernet interfaces of the ES51x/ ES592/ ES593-D/ ES595/

ES600 modules.

The maximum length of the interface cable is specified for 30 m.

equired for the access to the ECU.

0Base-TX Ethernet interface using the

on Ethernet" (TCP/IP, UDP/IP). The

ES592, ES593-D, ES595, ES1232-A.

XETK-V2.0 - User’s Guide 24

`lkQ

ETAS Hardware Description

Fig. 4-10 Location of the Ethernet Interface CON4

4.6 Status LEDs

There are three LEDs displaying the operating status of the XETK-V2.0 (Fig. 4-11

on page 26).

LED State Meaning

Red On XETK-V2.0 is supplied with power and active (i.e. the ECU is

Green On Power supply has dropped under 4.3V (XETK-V2.0A/C) or

Off Working page may be different to

swit

ched on or the ETAS calibration and development sys-

tem is connected and ready to communicate with the XETK-

)

V2.0

th

e selected standby threshold (XETK-V2.0B):

- data retention of the calibration data in the XETK-V2.0A/C

RAM or the ECU RAM monitored by the XETK-V2.0B is no

S

longer ensured

- as soon as ECU switches on again, it should switch to the

nce Page.

Refere

Green LED stays lit until the calibration and development

em downloads data into the calibration data memory.

syst

Until then switching to the Working Page is not possible.

reference page. Calibra-

tion and development system has downloaded data since

he last power failure. Switching between the Reference

t

Page and Working Page is possible.

Yellow On 100 Mbit/s link to calibration system established

Flashing Communication active

XETK-V2.0 - User’s Guide 25

iba=êÉÇ

iba=уЙддзп

iba=ЦкЙЙе

ETAS Hardware Description

Fig. 4-11 Status LEDs

4.7 Reset

The requirement for XETK reset mechanism is to ensure that power-up and

power-down behavior of ECU is clean and to prevent corruption of data stored

in the XETK-V2.0A/C’s SRAM.

To accomplish this the XETK-V2.0 senses the microcontroller power supply at the

E

CU interface connection; V_RESET of the XETK-V2.0A/C and V_NEXUS of the

XETK-V2.0B. This allows the XETK to detect when the ECU is off and forward this

information to INCA. In addition, it allows the XETK to enter the power save

mode if the ECU is off and the PC is off or unplugged.

Furthermore, the XETK-V2.0 se

write protect signal for its memory. If configured, the /RSTOUT line can also be

used to sense the status of the ECU reset.

Finally, the XETK-V2.0 generates a reset signal

in reset while the XETK is in power save mode and to prevent the microcontroller

from starting until the XETK is ready to work.

The XETK is ready to work when it has finished

power save mode or after initial power-up. This feature allows it also to reset the

ECU under tool control (required for INCA and ProF) and to perform an emergency stop of the ECU in case of XETK failure.

4.8 Data Emulation Memory

The XETK-V2.0 is a serial XETK using JTAG / Nexus as its primary microcontroller

interface. Typical of all serial XETKs, the RAM used for data emulation and data

measurement is not accessible by the XETK until the microcontroller is powered

up and the startup handshake is performed. This includes the 2 MByte of SRAM

pr

As with parallel XETKs, serial XETKs have a

and a Working Page (ETAS two page XETK concept).

ovided on the XETK-V2.0A or the 4 MByte provided on the XETK-V2.0C.

nses the status of the /RESET line to generate a

by pulling /RESET to keep the ECU

its initialization after leaving

system consisting of both a Reference

XETK-V2.0 - User’s Guide 26

ETAS Hardware Description

Note

The Reference Page is located in the ECU flash and can not be modified by a

simple write access. All changes to the Reference Page must be done via Flash

programming. The INCA user can use ProF to invoke a customized flash programming algorithm.

When using the XETK-V2.0A/C, the Working Page should be located within the

ETK-V2.0A/C’s on board SRAM. The Working Page may be a portion of or the

X

entire size of this RAM. To make the Working Page accessible to the XETKV2.0A/C, the microcontroller software must configure the external bus interface

correctly.

When using the XETK-V2.0B, the Work

nal or external RAM of the ECU. It is recomm

powered.

Another important restriction is that no access to

the ECU is not running. To enable a cold start measurement in spite of this

restriction, a special procedure is defined to give the user the feeling of a parallel

XETK.

Because there is no write protection of the data emulation memory possible,

the user must be take care not to overwrite emulation data.

ing Page may be located in either a inter-

ended that this RAM is permanently

the memory is possible, while

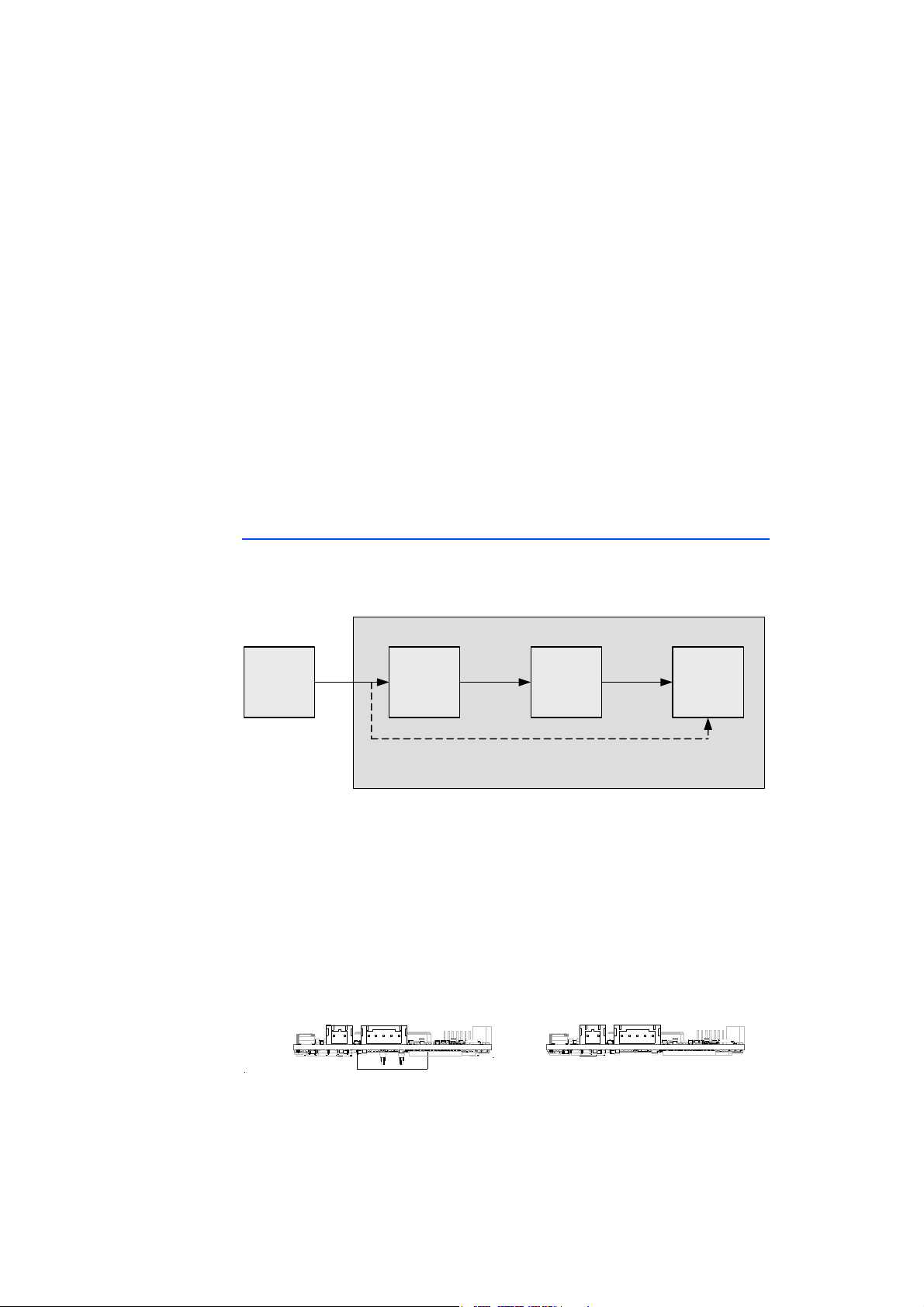

4.8.1 Page Switching

To enable calibration, the Working Page must be activated. The process of

switching from the Reference Page to the Working Page and vice versa is known

as page switching. The XETK-V2.0 supports two methods of page switching;

however, one method is only available for certain microcontrollers.

Regardless of which page switch method is used and which page is activated

rom the microcontroller’s point of view, both the Reference Page and Working

f

Page are accessible for standard operations using INCA such as upload or checksum calculations.

Protocol Based

The XETK-V2.0 supports Protocol Based page switching for all supported microcontrollers. Switching between Reference and Working Page is done in microcontroller software by re-directing accesses to calibration data between either

Flash (Reference Page) or the RAM (Working Page) using microcontroller

the

internal mechanisms. The XETK-V2.0 does not directly control the microcontroller mechanism used to do this re-direction. Instead the XETK-V2.0 and microcontroller software share a mailbox in RAM. The XETK use

and monitor page switching; the microcontroller is responsible to service this

mailbox and perform the page switches.

Direct Register Access

The XETK-V2.0 supports Direct Register Access page switching for microcontrollers which provide additional internal registers for page switching. Switching

etween Reference and Working Page is done in microcontroller hardware by re-

b

s this mailbox to request

XETK-V2.0 - User’s Guide 27

ETAS Hardware Description

Note

Note

Note

Note

directing accesses to calibration data between either the Flash (Reference Page)

or the RAM (Working Page) using microcontroller internal registers. The XETKV2.0 has direct access to control these registers.

To use Direct Register Access page switch

initialize the necessary registers; however, it must not change the values after the

XETK startup handshake has taken place.

The XETK-V2.0 can use the Direct Register Access page switch method with

the MPC5676R, MPC5644A, SPC564A80, and MPC5777C.

4.8.2 XETK-V2.0A/C SRAM Characteristics & Data Retention

The XETK-V2.0A’s SRAM is 2 MBytes, 32 x 512 kBytes. The XETK-V2.0C’s SRAM

is 4 MBytes, 32 x 1024 kBytes. It is a synchronous memor

VertiCal Base Board supporting 32 bit multiplexed mode or 16 bit non multiplexed mode using the configuration feature "Calibration Bus Data Width". The

16 bit non multiplexed mode setting can only be configured for microcontrollers

at do not support 32 bit multiplexed mode; otherwise 32 bit multiplexed mode

th

t be used.

mus

ing the microcontroller software must

y connected to the

In 16 bit mode, the XETK-V2.0A/C’s SRAM is only 1 MByte, 16 x 512 kBytes.

In multiplexed mode during the address cycle of a read or wr

Address pins are used as Address. The address is latched into the SRAM during

this cycle using CLKOUT and /TS. During the data cycle of a read or write access

the Address and Data pins both contain data to create the 32 bit data bus.

The XETK-V2.0A/C’s SRAM is powered by the same power that is supplied to the

ETK-V2.0A/C. To guarantee that data in the SRAM is preserved even when the

X

ignition is switched off, the XETK-V2.0A/C must be permanently supplied with

power from the car battery. If the ECU with XETK-V2.0A/C is disconnected from

the battery, all data in the SRAM is not guaranteed and may be lost.

The XETK-V2.0A/C’s SRAM content is not ba

Working Page data in the SRAM permanently to the ECU, the INCA user can use

ProF to invoke a customized flash programming algorithm to store the content

of the Working Page to the Reference Page in Flash.

To access the XETK-V2.0A/C’s SRAM the microcontroller software must configure the microcontroller’s external bus interface for either multiplexed or non

multiple

for 32 bit (multiplexed) accesses or for 16 bit (non multiplexed) accesses. Additionally the VertiCal Base Board may require configuration by hardware solder

br

xed mode. The chip select for the XETK-V2.0A/C must be configured

idges to select 32 bit (multiplexed) or for 16 bit (non multiplexed).

cked up in a data flash. To store the

ite access the

The XETK-V2.0A/C does not support burst accesses to this SRAM.

XETK-V2.0 - User’s Guide 28

ETAS Hardware Description

Microcontroller

(VertiCal Base Board)

TDO

TDO

/RDY

/RDY

/TRST

TDI

R >=100k

or Pullup

TDI

/TRST

TMS

TCK

TMS

1k 1k

TCK

ECU XETK

22

22

22

22

1k

V_NEXUS

XETK

System

Controller

MDO[15..0]

/MSEO[1..0]

/EVTO

MDO[15..0]

/MSEO[1..0]

/EVTO

/EVTI

/EVTI

22

MCKO

MCKO

VertiCal

Connector

Other ECU

JTAG / Nexus

Connectors

not present

not present

not present

not present

not present

not present

not present

not present

not present

Note

4.8.3 Data Emulation Power Failures

The XETK-V2.0 has a circuit which recognizes and stores power failures. The

XETK-V2.0 will notify the microcontroller software of the power failure using the

DAI pins and additionally will prevent the user from switching to the working

page until the PC software has downloaded a new Working Page data into the

data emulation memory.

The calibration feature "start on working page" or "start on last active page

with the last active page being the working page" is only possible when the

working page has been downloaded since the last power failure. Until a down

load occurs after a power failure the micro

controller software is informed of a

power failure by the DAI pins and is responsible to make the reference page

active.

4.9 Nexus (JTAG) Interface

-

4.9.1 XETK-V2.0A/C

Fig. 4-12 Equivalent Circuitry of the XETK-V2.0A/C Nexus (JTAG) Interface

The ECU part of the XETK-V2.0A/C Nexus (JTAG

Fig. 4-12. The XETK incorporates 22 Ohm series resistors for the TDI, /TRST, TCK,

and TMS lines on the ECU interface. Additional pull ups / downs are as shown.

XETK-V2.0 - User’s Guide 29

) interface is depicted in

ETAS Hardware Description

Micro -

controller

TDO

TDO

/RDY /RDY

/TRST

TDI

R >=100k

or Pullup

TDI

/TRST

TMS

TCK

TMS

1k 1k

TCK

ECU XETK

44

44

44

44

1k

V_NEXUS

XETK

System

Controller

MDO[15..0]

/MSEO[1..0]

/EVTO

MDO[15..0]

/MSEO[1..0]

/EVTO

/EVTI

/EVTI

22

MCKO MCKO

ECU Specific

ECU Specific

ECU Specific

ECU Specific

CAUTION!

The microcontroller is mounted directly on the VertiCal Base Board; therefore it

is not possible to add additional series resistors between the microcontroller and

XETK for TDO, /RDY, /EVTO, MCKO, MDOx, and /MSEOx.

When the ECU design incorporates JTAG /

Nexus connectors, additional circuitry

is required to ensure these connectors and the signal routing do not influence

the interface between the microcontroller and XETK. The ECU must incorporate

0 Ohm series resistors on every signal which goe

s to an additional JTAG / Nexus

connection. Additionally, the resistors must be placed as close to the microcontroller as possible; especially for TCK and MCKO. For proper operation of the

ETK-V2.0A/C it is mandatory to depopulate these resistors (e.g. not present), as

X

shown in Fig. 4-12. For ECUs used without the XETK-V2.0A/C, the resistors can

be populated to provide functional JTAG / Nexus connectors.

Risk of damaging the XETK due to short circuiting the JTAG

signals!

When the XETK-V2.0A/C is connected to the ECU, you must ensure

that no other device is actively driving the JTAG signals (TCK, TDI,

TMS) via another connector on the ECU (e.g. Lauterbach debugger

directly on ECU pcb). To use these other tools you must remove the

XETK-V2.0A/C or plug the other tools into the ECU via the XETKV2.0A/C’s NEXUS (JTAG) Debugger Connector.

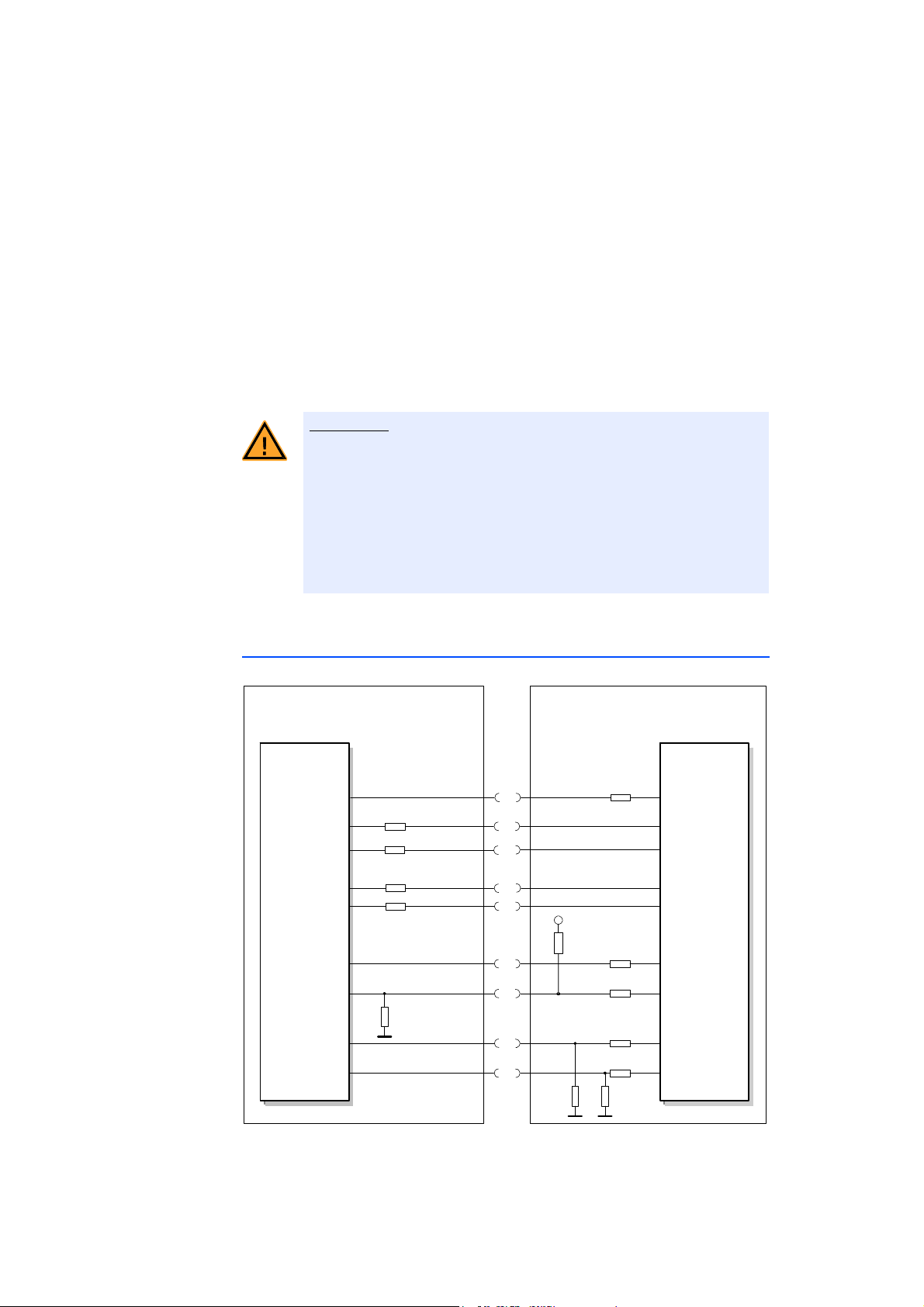

4.9.2 XETK-V2.0B

Fig. 4-13 Equivalent Circuitry of the XETK-V2.0B Nexus (JTAG) Interface

XETK-V2.0 - User’s Guide 30

Loading...

Loading...