Et HP 036., HP 037. Operating Instructions Manual

Operating

Instructions

Pneumohydraulic controller

HP 036./HP 037.

en

BEA--206006-EN-04

1. Safey 2

2. Function 3

3. Variants 5

4. Mounting 7

5. Installation 9

6. Commissioning 10

7. Maintenance 14

8. Spare Parts 15

9. Technical Data 16

Pneumohydraulic controller HP 036./HP 037.

Page 2/16 BEA--206006-EN-04

1. Safey

1.1 Approved applications

1.2 Operating instructions

1.3 Mounting

The E+L controller HP 03.. must only be used to operate a hydraulic

positioning device.

Only use the controller

- if it is in perfect condition technically

- in accordance with its intended usage

- with an awareness of safety and risk factors and in compliance

with the operating instructions.

Any jobs regarding controller operation, gearing to production requirements, conversion, setting, its safety-related mechanisms, servi-

cing, maintenance and repair must be performed by qualied personnel only. Please observe the switching on/o procedure laid out in the

operating instructions.

Look after these operating instructions carefully and make sure they

are available to personnel at all times.

The operating instructions are part of the package and should be

read carefully prior to mounting, operation and maintenance work.

Please observe the locally applicable and customary safety and accident prevention regulations.

Hydraulic and pneumatic lines should be installed so that they do not

present any risk. There should be no bending (minimum bending radius 50 mm for lines supplied by E+L).

Operating elements that are a potential risk when pressure is reduced, e.g. bursting of the hose or motor standstill, should be appropriately safeguarded by the user.

Please ensure that:

- electrical components without enclosures such as switch panels

or operating devices are protected according to the locally applicable safety regulations, e.g. VDE 0100

- when laying electrical leads the customer shall ensure that the insulation is not damaged and that leads are correctly secured and

screened

- controller power is switched on along with the main machine system switch

- the controller is integrated into the machine control in such a way

as to prevent it starting up independently after a machine standstill

or an emergency OFF device reset.

The controller should be operated by qualied persons or suitably instructed personnel only.

1.5 Operation

Main switch on

your machine

L 1

1-pole illustration

Controller

HP 03.. electric

control

1.4 Installation

BEA--206006-EN-04 Page 3/16

Pneumohydraulic controller HP 036./HP 037.

The HP 03.. controller is used to position actuators in web guiding

systems or in unwinding/rewinding stations. The controller is designed for systems guiding by the web edge with a pneumatic sensor

FL2.. .

2. Function

2.1 Purpose

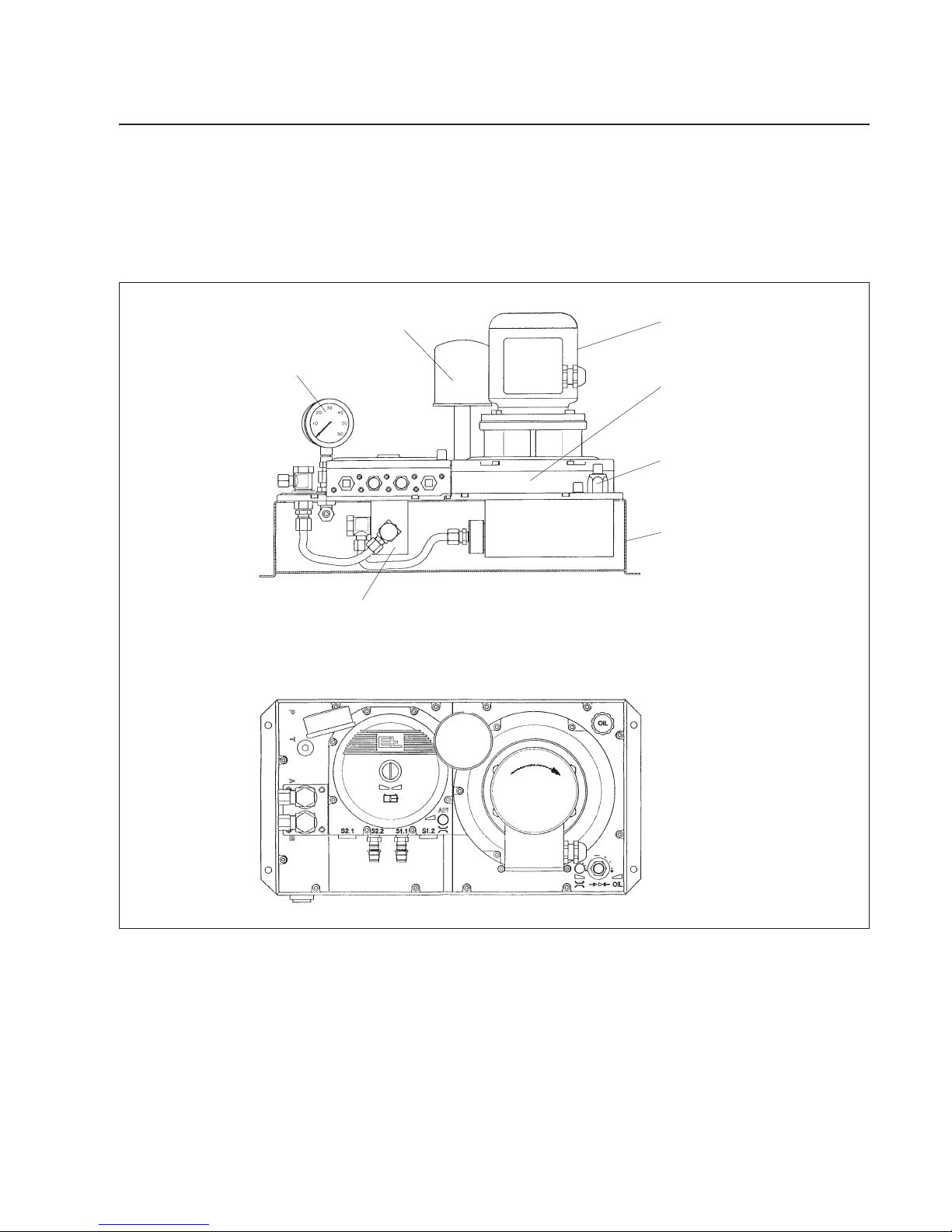

HP 03.. controller

2.2 Design

Side channel compressor

Air intake lter

Servo-valve

Pressure gauge

Fluid tank

Pressure relief valve

Three-phase a.c. motor

The HP 03.. controller is made up of the following components:

- three-phase a.c. motor

- side channel compressor

- air intake lter

- servo-valve

- pressure relief valve

- pressure gauge

- uid tank

Pneumohydraulic controller HP 036./HP 037.

Page 4/16 BEA--206006-EN-04

2.3 Mode of operation

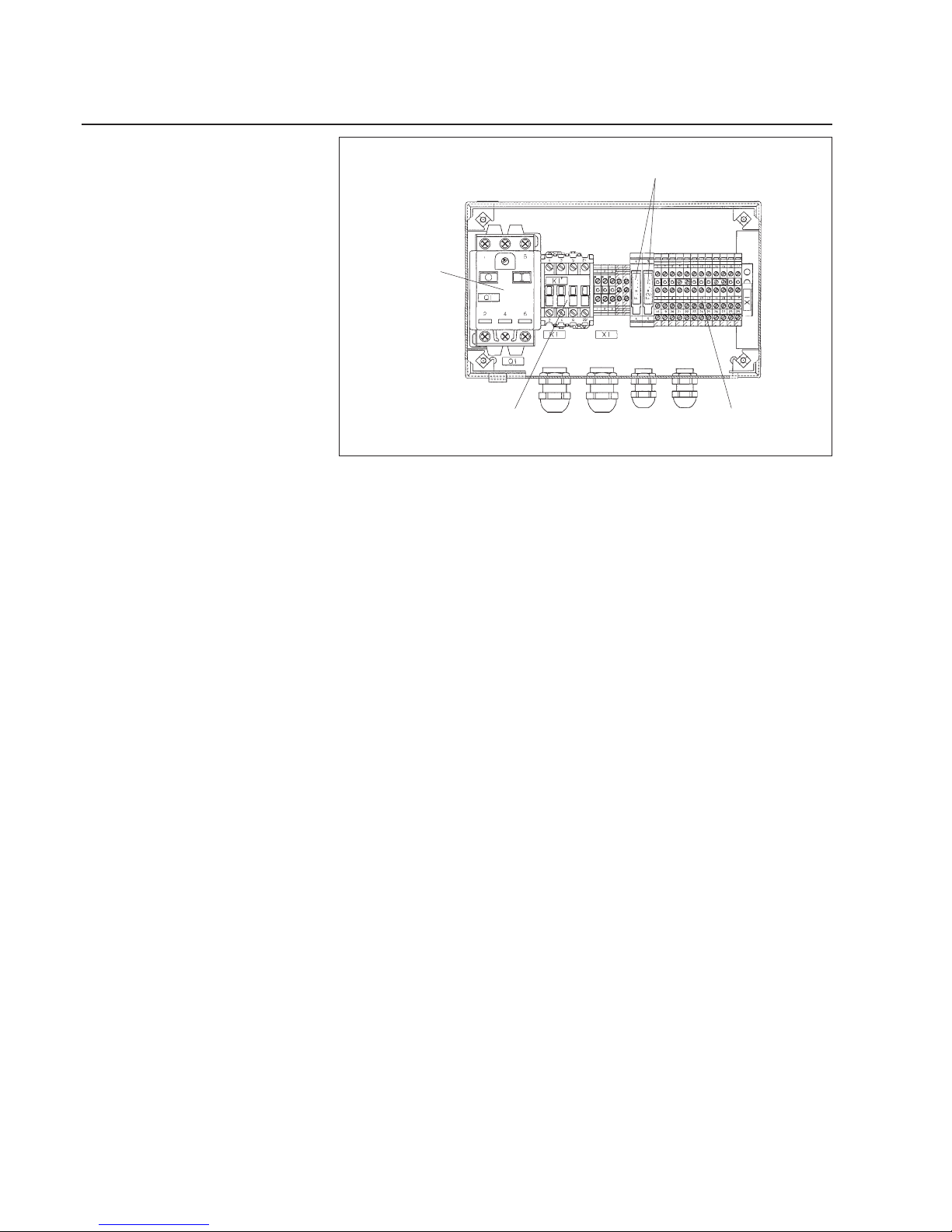

Motor protec-

tion switch

Contactor

Fuses

Switch panel SE 12521

Connection terminals

The HP 03.. controller is available in three dierent electrical versions.

- Switch panel SE 12521 with motor protection switch, three-phase

a.c. motor contactor and connection terminals for the valve wiring.

- Terminal box SZ 0921 with connecting terminals only for the threephase a.c. motor and valve wiring.

- No electrical wiring.

To generate the air required for sensing, ambient air is drawn into the

side channel compressor and fed to connection S 1 of the pneumatic

sensor. The level of the probing air pressure and thus the control

sensitivity for adjustment to dierent situations is set via a restrictor.

Some of the compressed air is sent to diaphragm D 1 (see pneumatic system plan on opposite page, at top). A pressure spring works

in the opposite direction to the dia grapm. If the sensor is covered appropriately, the diaphragm is maintained in the center and the system

in a zero position.

If the web moves away from the zero position, it changes the air cur-

rent which, in turn, inuences the diaphragm. The change to the diaphragm directly aects the servo-valve controlling the uid ow. The

uid ow changes the location of the positioning cylinder until the

web returns to its zero position.

BEA--206006-EN-04 Page 5/16

Pneumohydraulic controller HP 036./HP 037.

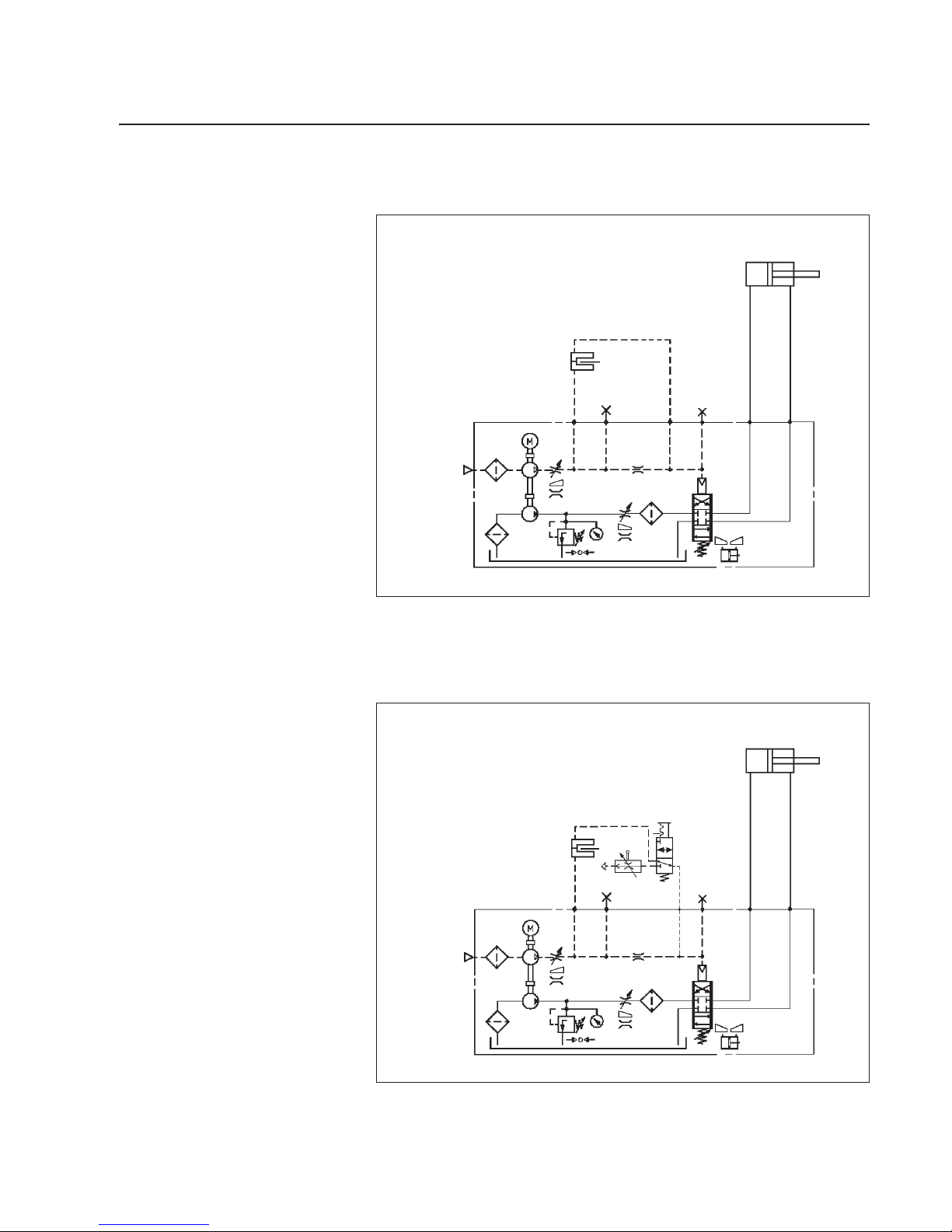

On the basic model HP 03.. without valve assembly, guiding by the

web edge only (automatic) is possible.

:S 1.1 :S 1.2

:S 2.1 :S 2.2

- HZ

:S 1

- FL

AIR

T

AP

T

P

OIL

HP 0360 20 bar

HP 0370 30 bar

B

:A :B

D 1

:S 2

FL = pneumatic sensor

HZ = positioning device

P

D 1

- FL

AIR

:S 2.2

OIL

- SC

T

:S 1

:S 2

:S 1.1 :S 1.2

:S 2.1

P

A

B

T

HP 0360 20 bar

HP 0370 30 bar

:A

:B

- HZ

- V 1

FL = pneumatic sensor

HZ = positioning device

SC = servo center actuator

V 1 = manually-actuated valve

Valve assembly 02 permits guiding by the web edge (automatic) or

servo center. Reversing is eected via a manually-actuated valve.

3. Variants

3.1 Basic model, system 1

3.2 Valve assembly 02,

system 2a

Loading...

Loading...