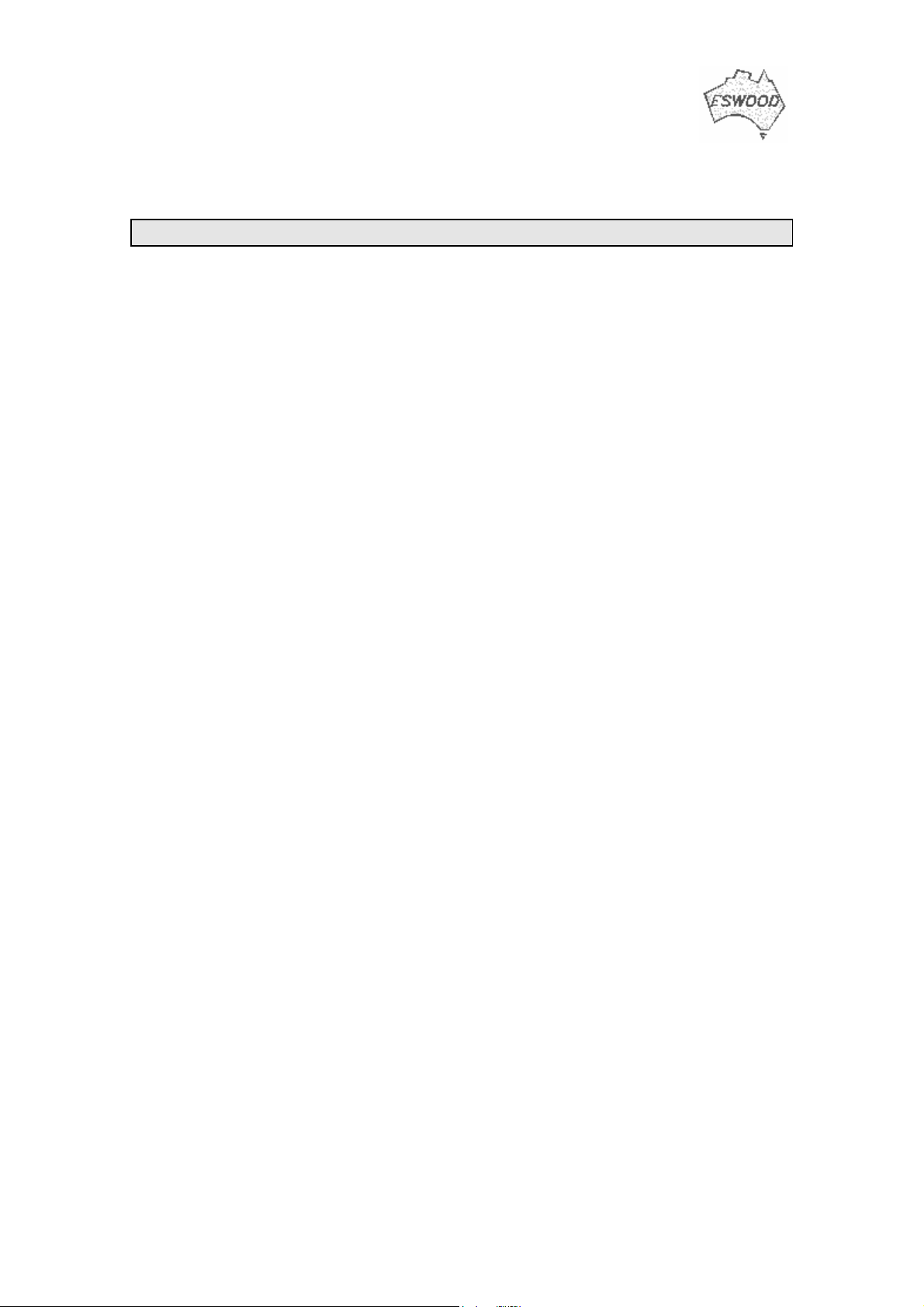

Eswood ES-100 Equipment Manual

EQUIPMENT MANUAL

FOR

ES-100 RACK CONVEYOR DISHWASHER

JUNE 2011

T

ABLE OF CONTENTS

1. Important: Prior to installation 3

2. Technical Specification 4

3. Installation 5

4. Installer-Initial Procedure 6-7

5. Washing Operation 8

6. Washing 9

7. Shutdown and Maintenance 10

8. Curtain Location 11

9. Trouble Shooting 12,13,14

10. Spare Parts 15

11. Spare parts & Service 16

ESWOOD OPERATING MANUAL ES-100 June 2011

2

I

MPORTANT: PRIOR TO INSTALLATION

1

Installation must be carried out according to local regulations by

qualified trade persons. Isolating switch(es), shut-off valves etc must

be within easy reach of the machine for future service and

maintenance requirements. If in doubt call ESWOOD AUSTRALIA or

their representative for further information. No responsibility will be

accepted for defects or damages by improper installation, for

changes to the product not authorised by ESWOOD AUSTRALIA, or

for operation outside the technical specifications.

ESWOOD AUSTRALIA warrants their products to be free from

defects in material and workmanship under "normal use and

service". This does not include normal wear and tear of parts.

ESWOOD AUSTRALIA will repair or replace any parts, which in

ESWOOD AUSTRALIA's sole judgement are defective in material or

workmanship, in accordance with the warranty offered.

This undertaking covers the provision of labour and parts for 12

months from the date of delivery to the purchaser. This undertaking

applies only to state capitals. Remote areas are not covered by this

commitment and special enquires should be made. (Note: Travel

time not covered by warranty)

In no event will ESWOOD AUSTRALIA be liable for loss of facilities

or other property and such things as, but not limited to, additional

labour costs, loss of revenue or anticipated profits, and other

damages of any kind whether direct, indirect, incidental or

consequential.

Labour under warranty is supplied free of charge during normal

working hours, Monday to Friday. Should warranty work be

requested outside or our normal working hours a labour charge will

be applied equivalent to a normal hour rate without out of hours

penalty rates. (Refer to last page of this manual for your closest

branch for Warranty repair services)

Note: It is the responsibility of the owner to ensure the water feed to

Eswood Dish and Glass washers is of a quality that will not form

excessive build up of calcium and other dissolved minerals on the

heating elements. Premature failure of heating elements that exhibit

this cause of failure will not be covered under warranty.

ESWOOD OPERATING MANUAL ES-100 June 2011

3

T

ECHNICAL SPECIFICATION

2.

M

achine Specification:

Net Weight 202kg.

Washing Capacity 100 Racks per hour

Standard Equipment 3x U.K. Plate Racks

1x B.K. Cup/Cuttlery Rack

W

ash Pump, Tank and Element

Wash Pump 2.2 kW. wash pump 900

Lt/minute

Wash Tank Capacity 87 Litres

Wash Tank Heater 7,200 W.

Wash Temperature 60°C to 65°C

R

inse Cylinder and Element

Rinse Tank Capacity 6 Litres

Rinse Tank Heater 12,000 W

82°C minimum

Water Consumption 350 Litres per hour

D

rive Unit

0.18 kW.

E

lectrical and Water Connections:

Electrical Input 415/50/3N, 21.5 kW.

Water Input 65°C minimum @ 200-400 kPa

Hot Water Inlet 1/2” B.S.P. fitting

Drain Outlet 2” B.S.P. gravity fed

(with Dryer add 6.6 kW.)

ESWOOD OPERATING MANUAL ES-100 June 2011

4

I

NSTALLATION

3.

1. Drain Connections: 2” B.S.P. to be trapped in accordance with

local water authorities.

2. Hot Water Connection: Connect hot water at minimum 60°C,

pressure requirement 100 to 400 kPa to connection point.

3. Electrical Connection: Electrical connection should be made in

accordance with rating plate at side of control box and in

accordance with local electrical authority regulations. An

isolating switch should be mounted on wall near machine.

4. To install the machine remove lower panels, make sure

machine is level back to front and side to side by turning

adjustable feet then:

(a) Connect trap to drain outlet under main tank.

(b) Connect hot water to the filtered inlet situated under main

wash tank (isolating valve to be supplied by others).

(c) Electrical connection: Lift electrical cover panel and connect

the 3 Phase power L1,L2,L3 on the terminal block and the

earth wire connection to earth terminal, neutral wire to “N”.

(d) Attach benching to either end of machine with fall back

towards the machine to allow the water to drain back into the

machine.

5. Machine should be fitted with automatic detergent and rinse

agent feeding equipment. Check with detergent company for

the supply of equipment and proper commercial chemicals and

feed settings.

ESWOOD OPERATING MANUAL ES-100 June 2011

5

Loading...

Loading...