Eswood CI-3B Equipment Manual

EQUIPMENT MANUAL

FOR

CI-3B COMPACT GLASS WASHER

JUNE 2011

T

ABLE OF CONTENTS

1. Important: Prior to Installation 3

2. General Description 4

3. Technical Specifications 5

4. Installation 6-7

5. Initial Start-up Procedure 8

6. Washing Operation 9

7. Shutdown and Maintenance 10

8. Trouble Shooting 11-12

9. CI-3B Export Model 13

10. Spare Parts 14-15

11. Wiring Diagram 16

12. Spare Parts & Service 17

PAGE No.

ESWOOD OPERATING MANUAL CI-3B June 2011

2

I

MPORTANT: PRIOR TO INSTALLATION

1

Installation must be carried out according to local regulations by

qualified trade persons. Isolating switch(es), shut-off valves etc must

be within easy reach of the machine for future service and

maintenance requirements. If in doubt call ESWOOD AUSTRALIA or

their representative for further information. No responsibility will be

accepted for defects or damages by improper installation, for changes

to the product not authorised by ESWOOD AUSTRALIA, or for

operation outside the technical specifications.

ESWOOD AUSTRALIA warrants their products to be free from defects

in material and workmanship under "normal use and service". This

does not include normal wear and tear of parts. ESWOOD

AUSTRALIA will repair or replace any parts, which in ESWOOD

AUSTRALIA’s sole judgement are defective in material or

workmanship, in accordance with the warranty offered.

This undertaking covers the provision for labour and parts for 12

months from the date of delivery to the purchaser. This undertaking

applies only to state capitals. Remote areas are not covered by this

commitment and special enquires should be made. (Note: Travel

time not covered by warranty)

In no event will ESWOOD AUSTRALIA be liable for loss of facilities or

other property and such things as, but not limited to, additional labour

costs, loss of revenue or anticipated profits, and other damages of any

kind whether direct, indirect, incidental or consequential.

Labour under warranty is supplied free of charge during normal

working hours, Monday to Friday. Should warranty work be requested

outside of our normal working hours a labour charge will be applied

equivalent to a normal hour rate without out of hours penalty rates.

(Refer to last page of this manual for your closest branch for Warranty

repair services)

Note: It is the responsibility of the owner to ensure the water feed to

Eswood Dish and Glass washers is of a quality that will not form

excessive build up of calcium and other dissolved minerals on the

heating elements. Premature failure of heating elements that exhibit

this cause of failure will not be covered under warranty, also if the filter

valve is discarded from the detergent tube warranty will be voided.

PLEASE ENSURE SUITABLE DETERGENT IS USED.

ESWOOD OPERATING MANUAL CI-3B June 2011

3

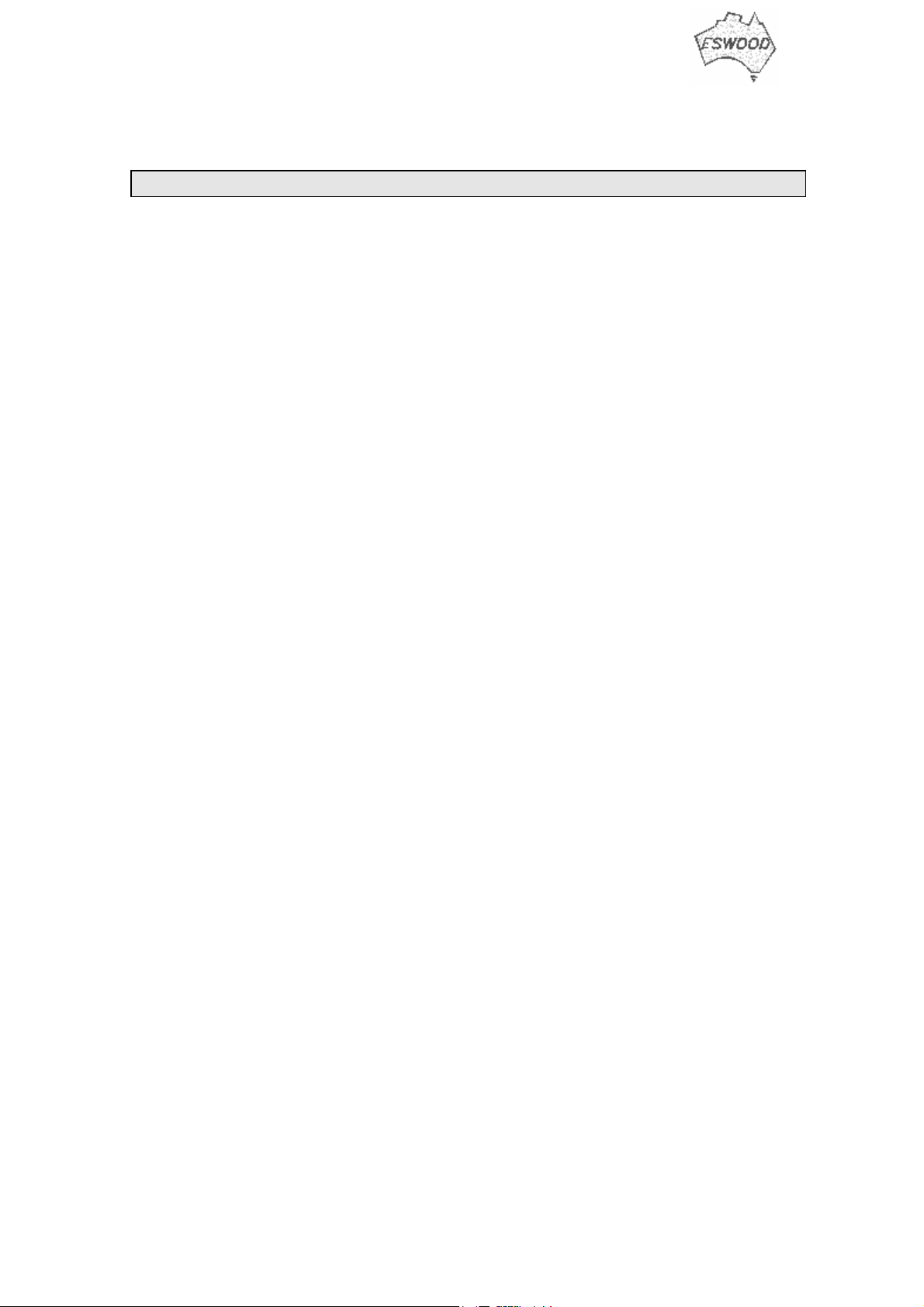

G

ENERAL DESCRIPTION

2

Performance to Match Your Needs: With a capacity to hygienically

wash 1800 glasses per hour, the CI-3B professional glass washer is

the perfect choice for your bar, cafe or coffee lounge. For the hustle

and bustle of a cocktail or lounge bar, the

CI-3B can be plumbed to provide a cold cycle after the final sanitising

rinse, and this would become a permanent part of the washing cycle.

Convenient Rack Size: The large wash chamber has been

designed to accept 430 x 360mm open wire glass racks which can

hold jugs or thirty 285ml (middy) glasses. An impact resistant 430 x

360mm nylon coated wire rack is supplied as standard.

Glass Cooling Cycle: This cycle is particularly useful for glasses

that are to be placed in a chillier, or can be used to cool down

glasses for a faster turn-around.

Convenient Design: The door is designed to provide a safe,

convenient and comfortable height for loading and unloading with

minimal bending. Safety is also assured thanks to a switch on the

door that prevents the machine from operating with the door open.

Wash System: Eswood’s wash system combines multiple jets on

rotating lower and upper wash and rinse arms, to produce a fast yet

spotless wash and rinse every time. The hygienic 82OC fresh water

wash/rinse is effectively directed from jets on the lower rotating arm,

and the cold final cycle is provided by the upper rotating arm.

Hot Water Booster Heater: Automatic water temperature monitoring

and a powerful booster heater ensure that correct water temperature

is maintained for hygiene and optimum cycle times during continuous

use.

Easy Low Cost Installation: Simply connect the hot water supply,

plug the cord into a 15 Amp power point, and connect the trap to the

drain outlet.

Quality, Reliability and Performance: Eswood has a reputation for

product reliability that is second to none. The finest of stainless steel

and durable synthetic materials are used, and all Eswood products

are fully guaranteed and backed by a national support network.

ESWOOD OPERATING MANUAL CI-3B June 2011

4

T

ECHNICAL SPECIFICATIONS

3

Machine Specifications

Net Weight 25kg

Washing Capacity 1800 glasses per hour

Cycle Time Red Button:- 19 second wash/rinse

Blue Button:- 15 second wash/rinse

- 15 second cooling.

Standard Equipment 430 x 360mm Open Wire Glass Rack

Rinse Cylinder and Element

Rinse Cylinder Capacity 91/2 Litres

Booster Element 3000 Watts

Water Input and Consumption

Hot Water Input 65OC @ 250 to 400 kPa

Cold Water Input 250 to 400 kPa

Drain Outlet 2” B.S.P. gravity fed

Hot Water only usage 8 Litres per cycle

Hot and Cold water usage 41/2 Litres hot water

3 Litres cold water

Wash/Rinse Temperature 82OC to 85OC

Final Cycle Temperature Cold: 20OC

Hot: 65OC

Electrical Usage

Electrical 240V, 50Hz, 1 phase, 12.5 Amps

ESWOOD OPERATING MANUAL CI-3B June 2011

5

I

NSTALLATION

4

1. Position on mounting brackets (already provided by others at

appropriate working height ) and remove the lower panel.

2. Connect the 2” B.S.P. gravity drain under the machine via a 2”

trap to the drain outlet.

3. Connect the hot water supply to the ¾” B.S.P. solenoid valve

labelled “HOT”. The hot water should be at a minimum of 65OC

and between 250 to 400 kPa. A pressure reducing valve should

be fitted for pressure above 400 kPa.

4. Connect the cold water supply to the ¾”B.S.P. solenoid valve

labelled “COLD”. The cold water supply should be between 250

to 400kPa. A pressure reducing valve must be fitted for

pressures above 400kPa.

If you do not require a permanent cooling cycle or your

glassware is sensitive to temperature changes then we suggest

that you do not use the cold water option and connect hot water

to this solenoid valve instead.

Do not make water or plumbing connections that will

prevent the machine from being removed from position, for

the purpose of servicing.

Note that all plumbing work is to be done in accordance with

local plumbing codes.

5. Ensure that the power switch is “OFF” and connect the three pin

plug lead to a 15 Amp, 240V, 50Hz, 1 phase power outlet.

Note that all electrical work is to be done in accordance with the

rating plate on the lower panel.

6. The CI-3B comes standard with a detergent injection system

already set up.

7. Purge the rinse cylinder of air by opening water supplies to the

machine, switching the machine on and putting it through three

or four cycles.

ESWOOD OPERATING MANUAL CI-3B June 2011

6

Loading...

Loading...