Esu LokSound Select, LokSound V4.0 Quick Start Manual

Quick Start Guide

LokSound Select

LokSound V4.0

Technical Data for LokSound Select and LokSound V4.0 Decoders

Operational modes

NMRA/DCC with 14, 28, 128 speed steps.

2-digit (short) and 4-digit (long) addresses.

Analog DC operation (de-selectable).

Automatic recognition of operational mode and DCC speed step selection.

Power

Runs all DC and coreless motors.

Silent, safe 31,25 kHz pulse width frequency BEMF

Motor output overload protection

8 pin and 21MTC decoders 1.10A continuous load / 2.00 A peak load

Next18 / Select Micro and V4.0 decoders 0.75A continuous load / 1.00 A peak load

Function outputs

8 pin Select and V4.0 decoders Up to 6 outputs (6 powered)

21MTC Select and V4.0 decoders Up to 8 outputs (4 powered, 4 logic)

Next18 / Select Micro and V4.0 decoders Up to 6 outputs (4 powered, 2 logic)

Sound

Audio amplifier: 2W @ 4 Ohm load

Speaker impedance 4 - 16 Ohms

Memory capacity 32 MBit

8 sound channels, all playable at once!

Over 20 different sounds!

Programming

Features

DCC Servicemode & DCC POM (Programming on Main).

RailCom® Feedback system. RailComPlus® automatic Registration.

CV Name Description Range

Default

1 Loco address Short (2 digit) address of locomotive 1 - 127 3

2 Start voltage Minimum speed of the locomotive 1 - 255 3

3 Acceleration This value multiplied by 0.25 is the time from stop to maximum speed 0 - 255 80

4 Deceleration This value multiplied by 0.25 is the time from maximum speed to stop 0 - 255 80

5 Maximum speed Maximum speed of the locomotive 0 - 255 255

6 Medium speed Medium speed of locomotive 0 - 255 88

8 Manufacturer‘s ID Manufacturers‘s ID ESU - Writing value 8 in this CV triggers a reset to

factory default values

151 -

17 & 18Long address of the loco Long address of engine ( see full manual online at www.loksound.com)

19 Consist Address Additional address for consist operation. Value 0 or 128 means: consist

address is disabled

1 – 127 consist address active, normal direction

129 – 255 consist address active reverse direction

0-255 0

27 Brake mode Allowed brake modes 28

Bit Function Value

0 ABC braking, voltage higher on the right hand side 1

1 ABC braking, voltage higher on the left hand side 2

2 ZIMO® HLU brakes active 4

3 Brake on DC, if polarity against driving direction 8

4 Brake on DC, if polarity like driving direction 16

7 Loco brakes with constant brake distance, if FS=0 128

28 RailCom® Configuration Settings for RailCom® 131

Bit Function Value

0 Channel 1 Address broadcast enabled 1

1 Data transmission allowed on Channel 2

7 RailCom® Plus automatic loco recognition active 128

29 Configuration register Calculated field. Add up the values you want to activate, then write this

number into CV 29.

12

Bit Function Value

0 Normal direction of travel

Reversed direction of travel

0

1

1 14 speed steps DCC

28 or 128 speed steps DCC

0

2

2 Disable analog operation

Enable analog operation

0

4

3 Disable RailCom®

Enable RailCom®

0

8

4 Speed curve through CV 2, 5, 6

Speed curve through CV 67 - 94

0

16

5 Short addresses (CV 1) in DCC mode

Long addresses (CV 17 + 18) in DCC mode

0

32

31 Index register H Should be either “0” or “16” for LokSound Decoders 16 16

CV Name Description Range

Default

32 Index register L CV 32=0 if accessing CVs 1- 255, CV 31=1,2,3 if accessing CVs 257-511 0 - 4 0

48 Master Sound Select Selects the prime mover sound (0, 16, 32, 64), the horn (0-15), the bell

(0,64), Brake Squeal Sound (0, 128) - add the numbers up for each selection to get the final value of CV 48. Will vary between sound files. Locate

the sound file description on our web site for valid values.

0 - 255

49 Extended

Configuration #1

0 Enable Load control (Back-EMF)

Disable Load control (Back-EMF)

100 - 255 19

1 DC Motor PWM frequency

20kHz motor pulse frequency

40 kHz motor pulse frequency

0

2

2 Reserved

0

0

3 Reserved 0

4 Automatic DCC speed step detection

Disable DCC speed step detection

Enable DCC speed step detection

0

16

5 LGB® function button mode

Disable LGB® function button mode

Enable LGB® function button mode

0

32

6 Reserved

0

64

7 Reserved

0

128

50 Analogue mode Selection of allowed analogue modes 0 - 3 3

Bit Description Value

0 AC Analogue Mode ( Only LokSound V4.0)

Disable AC Analog Mode

Enable AC Analog Mode

0

1

1 DC Analogue mode

Disable DC Analogue mode

Enable DC Analogue Mode

0

2

61 Random sound «min» Multiplied by 0.25 it is the time in seconds for the shortest random

sound interval. F

0 - 255 120

62 Random sound «max» Multiplied by 0.25 it is the time in seconds for the longest random sound

interval.

0 - 255 200

63 Sound volume «Master» Master volume for all sounds. 0 - 192 192

64 Brake sound threshold

«Brake On»

If the actual loco speed step is smaller than or equals the value indicated

here, the brake sound is triggered.

0 - 255 100

65 Brake sound threshold

«Brake Off»

If the actual loco speed step is smaller than the one indicated here (up to

255), the brake sound will be switched off again. .

0 - 255 25

66 Forward Trim Divided by 128 is the factor used to multiply the motor voltage when

driving forward. The value 0 deactivates the trim.

0 - 255 128

67-94Speed table Defines motor voltage for speed steps. The values „in between“ will be

interpolated.

0 - 255 -

CV Name Description Range

Default

95 Reverse Trim Divided by 128 is the factor used to multiply the motor voltage when

driving backwards. Value 0 deactivates the trim.

0 - 255 128

113 Power Fail Bypass The time that the decoder bridges via the PowerPack after an interrup-

tion of voltage. Unit: A multiple of 0.016384 sec.

0 - 255 50

124 Extended Configura-

tion #2

Additional important settings for decoders - 24

Bit Description Value

0 Bi-directional bit: Enable driving direction when shifting

direction.

Disable driving direction.

1

0

1 Disable decoder lock with CV 15 / 16

Enable decoder lock with CV 15 / 16

0

2

2 Disable prime mover startup delay

Enable prime mover startup delay

0

4

3 Disable serial protocol for C-Sinus

Enable serial protocol for C-Sinus

0

8

4 Adaptive regulation frequency

Constant regulation frequency

0

16

5 Motor safety when blocking.

Motor is not switched off when blocked.

Motor is switched off for a few seconds when blocked to

avoid burnout

0

32

125 Starting voltage Analog

DC

0 - 255 30

126 Maximum speed Analog

DC

0 - 255 130

127 Starting voltage AC (ONLY for LokSound V4.0) 0 - 255 50

128 Maximum speed Analog AC(ONLY for LokSound V4.0) 0 - 255 150

134 ABC-Mode „Sensibility” Threshold, from which asymmentry on ABC shall be recognised. 4 - 32 12

See the full manual online at www.loksound.com

Warnings

• Do not expose to wet and humid conditions.

• Avoid mechanical force or pressure on the decoder.

• Only use the minimum amout of solder needed.

• Always disconnect power before handling the decoder.

• Never wrap the decoder in electrical tape, as this

may cause overheating.

• Make sure that neither the decoder nor any blank

wire ends may come into contact with the engine

chassis (risk of short circuit).

• Make sure that no wires are squeezed / cut when

reassembling the locomotive.

• Never operate a LokSound decoder unattended.

Requirements for Installation

The locomotive must be in perfect operating condition prior to the conversion: Only a locomotive

with faultless mechanical properties and smooth

running characteristics in analogue mode is worth

converting to digital. Check and replace all wear

and tear parts such as motor brushes, wheel contacts, light bulbs etc., if necessary.

Installing the Decoder

Locomotives with 8-pin interface

Some LokSound decoders are supplied with an

8-pin plug (refer to Fig 1). Remove the dummy

plug from the socket. Insert the plug of the decoder in such a way that pin 1 of the plug (this is the

side with the red / orange wires) sits next to the

corner of the socket that is usually marked with

*, +, • or “1”.

Do not rely on the assumption that the wires of the

harness have to face in a certain direction: the only

reliable reference is the marking of pin 1.

Locomotives with 21MTC interface

Some LokSound decoders are equipped with a

21MTC interface (fig. 2) You can insert the decoder in two ways: either the pins are put through

the decoder (most common); the socket of the

decoder remains visible after installation (mounting

on top) or the decoder is inserted in such a way that

the pins go straight into the socket. Which of the

two mounting positions is the correct one depends

solely on the locomotive. The position of the marker-pin is the crucial indicator. Plug the decoder into

the socket in such a way that the locomotive interface corresponds with the decoder. Do not apply

too much pressure when inserting the plug. The

decoder must go in without force.

Fig. 1: LokSoun with 8-pin interface

Pin Description Color

1 Right motor terminal orange

2 Rear light yellow

3 Output AUX1 green

4 Left track terminal black

5 Left motor terminal gray

6 Head light white

7 Common (+pole) blue

8 Right track terminal red

5 4

1

Wheel sensor 1

n.c. 2

AUX6 3

AUX4 4

ZBCLK 5

ZBDTA 6

Rearlight 7

Headlight 8

Loudsp. #1 9

Loudsp. #2 10

Index-pin 11

Figure 2: LokSound with 21MTC interface

22 Right track

21 Left track

20 GND

19 Right motor

18 Left motor

17 AUX5

16 Common (+)

15 AUX1

14 AUX2

13 AUX3

12 VCC

How to connect the decoder:

connector

to the top

Locomotive pcb

(Side view)

Locomotives without interface

All LokSound decoders have an interface (plug).

There is no “wires-only” version. Please remove

the plug at the end of the harness should hard

wiring become necessary.

First, please cut all wires installed in the locomotive. Take special care to remove any connections

to the chassis (ground): the motor leads must be

positively potential-free, in other words they may

not have any contact to the chassis or body or the

wheels and wheel contacts. Figure 3 and Figure 4

shows all connections.

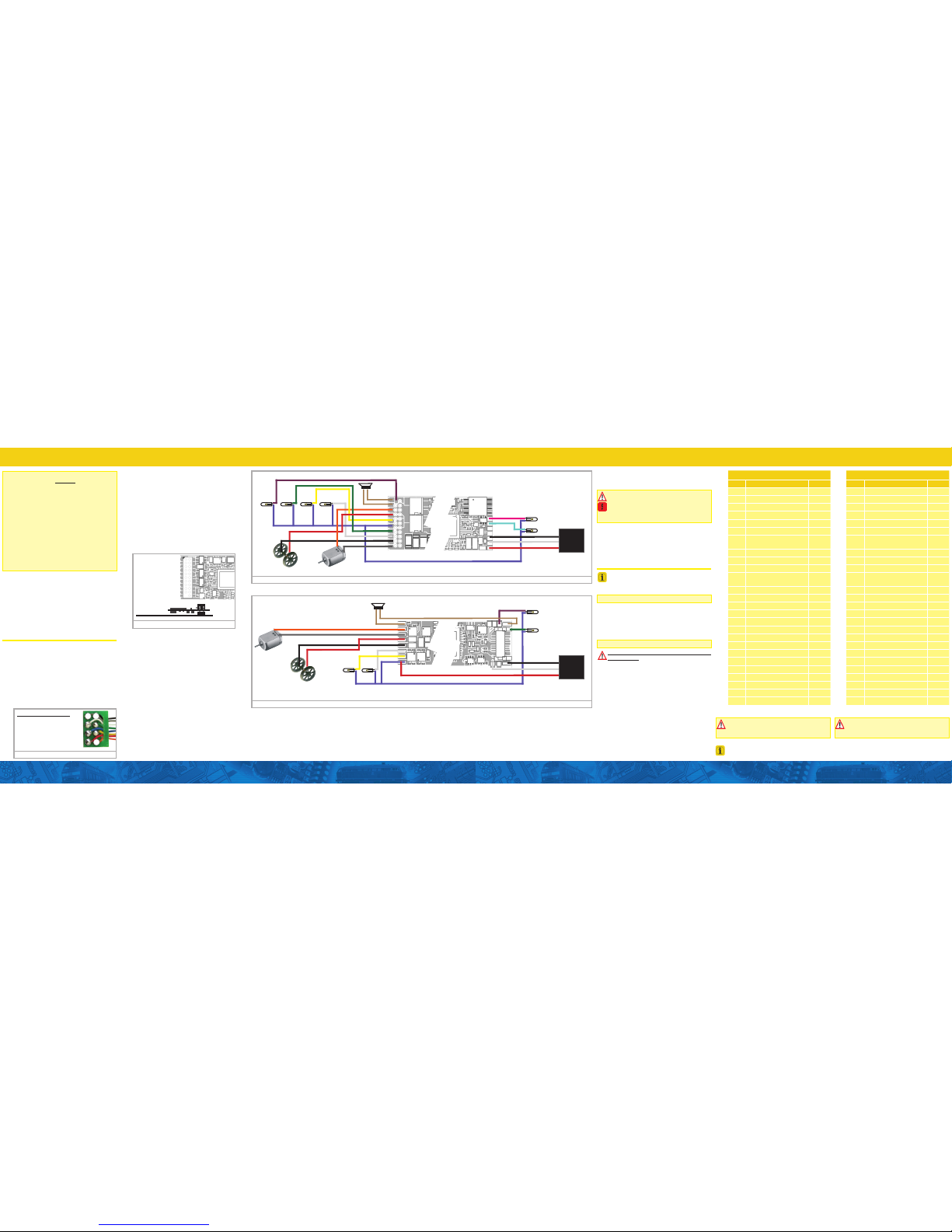

Figure 3: LokSound Decoder - Wiring Diagram

violet

DC motor

AUX2 AUX1

Rearlight

Head-

light

violet green yellow white

grey

orange

Left track

connection

Right track

connection

red

black

brown

brown

blue

blue

green

white

black

grey

yellow

red

orange

Loudspeaker

4~8 Ohms

Decoder FRONT Decoder BACK

blue (Decoder common)

pink

AUX3

AUX4

turquoise

U+

red

white Charge

GND

black

ESU

Power

Pack

Figure 4: LokSound micro Decoder - Wiring Diagram

DC motor

AUX2

AUX1

Head-

light

violet

green

yellow

white

grey

orange

Left track

connection

Right track

connection

red

black

brown

Loudspeaker

4~8 Ohms

brown

black

white

yellow

blue

red

grey

orange

Decoder FRONT

Decoder BACK

U+

Charge

GND

ESU

Power

Pack

blue (Decoder common)

Function outputs

You can wire all kind of loads to the function outputs.

Please make sure that the load does not exceed

the permitted maximum current and there are

no short circuits. The outputs of the LokSound

have protection but if an external voltage is

applied, the outputs may suffer damage or destruction.

Only install bulbs rated 16V or higher and with a

nominal current draw, that does not exceed 50

mA. If you like to use LEDs, a resistor with a rating

between 470 Ohms and 2.2 kOhms need to be

wired in series. Running the LED without resistor

will lead to their immediate destruction!

DCC Operation

The LokSound works with any DCC system.. Remove any capacitors that are wired into the track

feeders. This could impair the functionality of the

decoder.

The address is set to 03 with 28 speed steps.

Decoder Reset

You can reset the decoder to the default settings

at any time. In most cases POM programming will

not work to reset a decoder. Please use a separate

programming track.

Enter the value 08 into CV 08.

To complete the reset, power to the decoder must

be interrupted.

Volume Control

Master volume is controlled with CV 63. The range

is 0 - 192.

Individual volumes (CVs as shown) range from

0 - 128

Default Function Assignment - DIESEL

Function Effect Volume CV

F0 Directional Headlights -

F1 Bell 283

F2 Playable Airhorn 275

F3 Coupler 291

F4 Dynamic Brake 299

F5 AUX3 (Rotary Beacon) -

F6

AUX1 + AUX2 (Front

Ditchlights)

-

F7 Switching Mode -

F8 Sound (On / Off) 259

F9 Drive Hold -

F10

Locomotive (Independent)

Brake

-

F11 Radiator (Fan) Sound 315

F12 Dimmer (Headlights) -

F13 AUX4 (Rear Ditchlights) -

F14 - -

F15 Fast Spitter Valve 371

F16 Spitters on Shutdown -

F17 Brake Set / Brake Release -

F18 Sanding Valve 355

F19 Short Air Let Off 363

F20 Compressor 307

F21 Slow Spitter Valve 387

F22 Air Dryer 427

F23 - -

Random Sounds 461

Brake Squeal 459

Default Function Assignment - STEAM

Function Effect Volume CV

F0 Directional Headlights -

F1 Bell 283

F2 Whistle 275

F3 Coupler 291

F4 Coast Mode -

F5 AUX3 (Mars light) -

F6 AUX2 (Cab Light) -

F7 Manual Cylinder Cocks 427, 435

F8 Sound (On / Off) 259, 443

F9 Heavy Load Mode -

F10

Locomotive (Independent)

Brake

-

F11 Coal Shoveling 371

F12 Dimmer -

F13 AUX4 (Class Lights) -

F14 Air Pump Variable Speed 307

F15 Air Pump Slow 411

F16 Injector 323

F17 Auto Brake Set / Release Off -

F18 Ash Dump 355

F19 Blowdown 403

F20 Savety Valve 331

F21 Airhorn 419

F22 Grade Crossing Sequence 379

F23 Oil Headlights (No dynamo) -

Random Sounds 461

Brake Squeal 459

Make sure that Index CV 31 is set to 16 and

Index CV 32 is set to 1 before changing a

volume CV

Make sure that Index CV 31 is set to 16 and

Index CV 32 is set to 1 before changing a

volume CV

All function buttons are fully mappable. This allows you to customize your Function Assignments in any way

you wish. Please see our full manual for information on how to arrange this.

Loading...

Loading...