Esu LokPilot V3.0, LokPilot V3.0 DCC, LokPilot V3.0 M4, LokPilot XL V3.0, LokPilot micro V3.0 User Manual

...

1

User manual

7. edition, November 2009

LokPilot V3.0

LokPilot V3.0 DCC

LokPilot V3.0 M4

LokPilot XL V3.0

LokPilot micro V3.0

LokPilot micro V3.0 DCC

LokPilot Fx V3.0

LokPilot Fx micro V3.0

LokPilot V3.0

P/N 51978

2

Contents

1.Declaration of conformity1.Declaration of conformity

1.Declaration of conformity1.Declaration of conformity

1.Declaration of conformity

......................................................................................

......................................................................................

...........................................

44

44

4

2. WEEE-Declaration (Eur2. WEEE-Declaration (Eur

2. WEEE-Declaration (Eur2. WEEE-Declaration (Eur

2. WEEE-Declaration (Eur

ope only)ope only)

ope only)ope only)

ope only)

..................................................................

..................................................................

.................................

44

44

4

3. Important Notes – Please r3. Important Notes – Please r

3. Important Notes – Please r3. Important Notes – Please r

3. Important Notes – Please r

ead this chapter firstead this chapter first

ead this chapter firstead this chapter first

ead this chapter first

....................

....................

..........

55

55

5

4. How this manual helps you4. How this manual helps you

4. How this manual helps you4. How this manual helps you

4. How this manual helps you

................................................................................

................................................................................

........................................

66

66

6

5. Intr5. Intr

5. Intr5. Intr

5. Intr

oduction – The LokPilot Familyoduction – The LokPilot Family

oduction – The LokPilot Familyoduction – The LokPilot Family

oduction – The LokPilot Family

..........................................................

..........................................................

.............................

66

66

6

5.1. The Members of the LokPilot Family ............................ 6

5.1.1. LokPilot V3.0 Decoders – an Overview ...................... 7

5.1.2. LokPilot V3.0 ............................................................. 7

5.1.3. LokPilot V3.0 DCC .................................................... 8

5.1.4. LokPilot V3.0 M4 ...................................................... 8

5.1.5. LokPilot XL V3.0

........................................................ 8

5.1.6. LokPilot micro V3.0 ................................................... 8

5.1.7. LokPilot micro V3.0 DCC .......................................... 8

5.1.8. LokPilot Fx V3.0 ........................................................ 8

5.1.9. LokPilot Fx micro V3.0 ............................................... 8

5.2. General Properties of all Decoders ............................... 8

5.2.1. Operating Modes ...................................................... 8

5.2.2. Motor Control ........................................................... 8

5.2.3. Analogue Mode ........................................................ 9

5.2.4. Functions .................................................................. 9

5.2.5. Programming ............................................................ 9

5.2.6. Operational Reliability ............................................... 9

5.2.7. Protection .................................................................. 9

5.2.8. Future included ......................................................... 9

6. Installing the Decoder6. Installing the Decoder

6. Installing the Decoder6. Installing the Decoder

6. Installing the Decoder

............................................................................................

............................................................................................

..............................................

1010

1010

10

6.1. Requirements for Installation ..................................... 10

6.2. Installing the Decoder ................................................ 10

6.3. Locomotives with 8-pole NEM 652-Interface .............. 10

6.4. Locomotives with 6-pole NEM 651-Interface ............. 11

6.5. Locomotives with 21MTC Interface ............................ 12

6.5.1. Connecting C-Sine motors („SoftDrive-Sinus“) ....... 12

6.6. Locomotives without Interface ................................... 12

6.6.1. Wiring Diagram for LokPilot or LokPilot micro ........ 13

6.6.2. Wiring Diagram for a LokPilot XL Decoder .............. 14

6.6.3. Colour Coding by Märklin® .................................... 15

6.6.4. Motor and Track Connections ................................. 15

6.6.4.1. Connecting DC and Coreless Motors ................... 15

6.6.4.2. Connecting Universal Motors ............................... 16

6.7. Connecting Functions ................................................ 16

6.7.1. Overload Protection of Function Outputs ................ 16

6.7.1.1. Suitable Light Bulbs ............................................. 16

6.7.2. Connecting the Light Outputs, AUX1 and AUX2 .... 16

6.7.3. Purpose of AUX3 and AUX4 ................................... 17

6.7.3.1. LokPilot with 21MTC Interface ............................. 17

6.7.3.2. LokPilot Fx V3.0 ................................................... 17

6.7.3.3. LokPilot Fx micro V3.0 .......................................... 17

6.7.4. Suitable Smoke Generators ..................................... 17

6.8. Connecting Capacitors ............................................... 18

6.8.1. All LokPilot H0 ........................................................ 18

6.8.2. Integral „PowerPack“ in LokPilot XL V3.0 ............... 18

7. Initial Operation7. Initial Operation

7. Initial Operation7. Initial Operation

7. Initial Operation

..............................................................................................................

..............................................................................................................

.......................................................

1919

1919

19

7.1. Factory Default Values ................................................ 19

7.2. Digital Operating Modes ............................................ 20

7.2.1. DCC Mode .............................................................. 20

7.2.1.1. DCC Speed Steps („flashing lights“) ................... 20

7.2.1.2. Auto-detection of DCC Speed Steps .................... 20

7.2.2. Motorola® Mode .................................................... 21

7.2.2.1. 28 Speed Steps .................................................... 21

7.2.2.2. Extended Motorola® Address Range ................... 21

7.2.3. Selectrix® Mode ..................................................... 21

7.2.4. M4, the mfx® Compatible Mode ............................ 21

7.3. Analogue Mode ......................................................... 22

7.3.1. Analogue DC operation .......................................... 22

7.3.2. Analogue AC Operation ......................................... 22

3

8. Decoder Settings (Programming) .............................. 22

8.1. Adjustable Properties of Decoders ............................. 22

8.1.1. Configuration Variables (CVs) ................................. 23

8.1.1.1. Standardisation in the NMRA ............................... 23

8.1.1.2. Bits and Bytes ...................................................... 23

8.1.2. M4 Configuration Range ........................................ 24

8.1.3. M4, the mfx® compatible protocol by ESU ............. 24

8.2. Programming with popular Digital Systems ............... 24

8.2.1. Programming with DCC Systems ............................ 24

8.2.2. Programming with the ESU ECoS ............................ 25

8.2.3. Programming with Märklin® 6021 ......................... 25

8.2.3.1. Changing the Programming Mode ...................... 26

8.2.3.2. The Short Mode ................................................... 26

8.2.3.3. Long mode ........................................................... 26

8.2.4. Programming with the Märklin® Mobile Station® . 27

8.2.5. Programming with the Märklin® Central Station .... 27

8.2.6. Programming with the ESU LokProgrammer ........... 28

9. Addr9. Addr

9. Addr9. Addr

9. Addr

ess Settingsess Settings

ess Settingsess Settings

ess Settings

............................................................................................................

............................................................................................................

......................................................

2828

2828

28

9.1. Short Addresses in DCC Mode ................................... 28

9.2. Long Addresses in DCC Mode ................................... 28

9.3. Motorola® Address .................................................... 29

9.4. Addresses in the M4-Mode ........................................ 29

10. Adapting the Driving Characteristics10. Adapting the Driving Characteristics

10. Adapting the Driving Characteristics10. Adapting the Driving Characteristics

10. Adapting the Driving Characteristics

............................................

............................................

......................

2929

2929

29

10.1. Acceleration and Deceleration ................................. 29

10.1.1. Switching Acceleration / Deceleration .................. 29

10.1.2. Shunting Mode ..................................................... 30

10.2. Starting Voltage, Maximum and Medium Speed ...... 30

10.3. Speed Curve ............................................................ 30

10.4. Changing between Operating Modes ...................... 31

10.4.1. Changing from Digital to Analogue DC ................ 31

10.4.2. Changing from Digital to Analogue AC ................ 31

10.4.3.

Changing from Analogue to Digital (directional bit) ....

31

10.4.4. Changing from Digital to Digital ........................... 31

10.4.5.

Changing modes with Analogue Mode turned off ....

32

10.5. Brake Sectors ........................................................... 32

10.5.1. DC Brake Mode .................................................... 32

10.5.2. Märklin® Brake Mode .......................................... 32

10.5.3. Selectrix® Diode Brake Sector .............................. 33

10.6. Constant Brake Distance .......................................... 33

10.6.1. Constant Linear Brake Distance ............................ 33

10.6.2. Linear Brake Distance ............................................ 33

10.7. Settings for Analogue Operation ............................. 33

10.7.1. DC Analogue Operation ....................................... 34

10.7.2. AC Analogue Operation ....................................... 34

11. Motor Contr11. Motor Contr

11. Motor Contr11. Motor Contr

11. Motor Contr

olol

olol

ol

..............................................................................................................

..............................................................................................................

.......................................................

3434

3434

34

11.1. Adjusting Load Compensation ................................. 34

11.1.1. Parameter for frequently used Motors ................... 34

11.1.2. Adjustments for other Motors / „Fine Tuning“ ...... 35

11.1.2.1. Parameter „K“ ................................................... 35

11.1.2.2. Parameter „I“ .................................................... 36

11.1.2.3. Reference Voltage .............................................. 36

11.2. Turning off Load Compensation ............................... 36

11.3. Adapting Load Control Frequency ............................ 36

11.4. Dynamic Drive Control: Up and Down the Hill ......... 37

11.5. Settings for the C-Sinus Motor ................................. 37

12. Function outputs12. Function outputs

12. Function outputs12. Function outputs

12. Function outputs

......................................................................................................

......................................................................................................

...................................................

3838

3838

38

12.1. Physical function outputs ......................................... 38

12.2. Allocation of Function Buttons (Function Mapping) . 38

12.3. Special Effects on Function Outputs ......................... 38

12.3.1. Switching on Outputs and Different Options ........ 38

12.3.2. Adjust Lamp Brightness ........................................ 39

12.3.3. Digital Couplers .................................................... 39

12.3.3.1. „Pulse“ Mode for Telex® ................................... 39

12.3.3.2. „Coupler“ Mode for Krois® and ROCO® .......... 39

4

1.Declaration of conformity

We, ESU electronic solutions ulm GmbH & Co KG, Industriestraße

5, D-89081 Ulm, declare in sole responsibility that the products

to which this declaration refers, namely

LokPilot V3.0, LokPilot V3.0 DCC, LokPilot V3.0 M4,

LokPilot micro V3.0, LokPilot micro V3.0 DCC,

LokPilot XL V3.0, LokPilot Fx V3.0,

are in compliance with the following standards:

EN 71 1-3: 1988 / 6: 1994 – EN 50088: 1996 – EN 55014, part 1

+ part 2: 1993

EN 61000-3-2: 1995 – EN 60742: 1995 – EN 61558-2-7: 1998

according to the directive

88 / 378 / EWG – 89 / 336 / EWG – 73 / 23 / EWG

2. WEEE-Declaration

Disposal of obsolete electrical and electronic equipment (as

practised in the European Union and other European countries

with dedicated collection systems).

This mark on the product, the packaging or the relevant

documentation indicates that this product must not

be treated like household waste. Instead this

product should be disposed of at a suitable

collection point for recycling of electrical and

electronic appliances. Thus you contribute to avoid

negative impact on the environment and people’s

health that could be caused by inappropriate

disposal. Recycling of materials contributes to preserve our natural resources. For more information regarding recycling of this

product, please contact your local administration, your waste

collection service or the dealer / shop where you purchased this

product.

Contents

12.3.3.3. Automatic „Coupler“ Function .......................... 39

12.3.4. Blinker lights ......................................................... 39

12.3.4.1. Period for Blinker Lights ..................................... 39

12.3.5. Examples for Typical Settings ................................ 42

12.4. Analogue Settings .................................................... 42

12.5. LGB® Pulse Sequence Mode .................................... 43

12.6. Swiss Headlight Mode ............................................. 43

13. Decoder Reset13. Decoder Reset

13. Decoder Reset13. Decoder Reset

13. Decoder Reset

................................................................................................................

................................................................................................................

........................................................

4343

4343

43

13.1. With DCC Systems or 6020/6021 ............................ 43

13.2. With Märklin® systems (M4-decoders only) ............. 43

13.3. With the ESU LokProgrammer .................................. 43

14. Special Functions14. Special Functions

14. Special Functions14. Special Functions

14. Special Functions

......................................................................................................

......................................................................................................

...................................................

4444

4444

44

14.1. Directional Bit .......................................................... 44

14.2. Saving the Operating Status ..................................... 44

15. Multiple traction with LokSound Locomotives15. Multiple traction with LokSound Locomotives

15. Multiple traction with LokSound Locomotives15. Multiple traction with LokSound Locomotives

15. Multiple traction with LokSound Locomotives

................

................

........

4444

4444

44

16. RailCom®16. RailCom®

16. RailCom®16. RailCom®

16. RailCom®

............................................................................................................................

............................................................................................................................

..............................................................

4545

4545

45

17. Firmwar17. Firmwar

17. Firmwar17. Firmwar

17. Firmwar

e Updatee Update

e Updatee Update

e Update

......................................................................................................

......................................................................................................

...................................................

4545

4545

45

18. Accessories18. Accessories

18. Accessories18. Accessories

18. Accessories

........................................................................................................................

........................................................................................................................

............................................................

4646

4646

46

18.1. Change over skis ...................................................... 46

18.2. HAMO Magnets ....................................................... 46

18.3. Wire Harnesses with 8-pole or 6-pole Socket .......... 46

18.5. Mounting Adapter 21MTC ....................................... 46

19. Support and Assistance19. Support and Assistance

19. Support and Assistance19. Support and Assistance

19. Support and Assistance

....................................................................................

....................................................................................

..........................................

4646

4646

46

20. T20. T

20. T20. T

20. T

echnical Dataechnical Data

echnical Dataechnical Data

echnical Data

................................................................................................................

................................................................................................................

........................................................

4747

4747

47

21. List of all supported CVs21. List of all supported CVs

21. List of all supported CVs21. List of all supported CVs

21. List of all supported CVs

................................................................................

................................................................................

........................................

4848

4848

48

21.1. DCC Decoders ......................................................... 47

21.2. M4-Decoder ............................................................. 68

22. Appendix22. Appendix

22. Appendix22. Appendix

22. Appendix

..............................................................................................................................

..............................................................................................................................

...............................................................

7070

7070

70

22.1. How to programm long addresses ........................... 70

23. W23. W

23. W23. W

23. W

arrantyarranty

arrantyarranty

arranty

................................................................................................................................

................................................................................................................................

................................................................

7171

7171

71

5

Copyright 1998 - 2009 by ESU electronic solutions ulm GmbH & Co KG. Electrical

characteristics and dimensions are subject to change without prior notice. All rights reserved.

ESU might not be held responsible for any damage or consequential loss or damage

chaused by inappropriate use of the product, abnormal operating conditions, unauthorized

modifications to the products etc...Not suitable for children under 14 years of age.

Inappropriate use may result in injury due to sharp points and edges. Märklin® is a

registered trademark of the company Gebr.Märklin® and Cie. GmbH, Göppingen,

Germany. RailCom is a registered trademark of the company Lenz Elektronik GmbH,

Giessen, Germany.

All the other trade marks are owned by their respective right holders.

ESU electronic solutions ulm GmbH & Co. KG continues to develop the products according

to the company´s politics. Therefore, ESU reserves the right to carry out changes and

improvements on the products listed in this manual at any time and without any advanced

note.

Duplications and reproductions of this documentation are strictly forbidden and need to

be allowed by ESU in writing.

3. Important Notes – Please read this chapter first

We congratulate you to your purchase of an ESU LokPilot decoder.

This manual will guide you step by step through the features of

your LokPilot decoder.

Please read this manual carefully. Although the LokPilot has been

design as a robust device an incorrect connection may lead to

faults or even to the destruction of the device. Avoid any “costly”

experiments.

Important notes

•The LokPilot is exclusively intended for use with model train

layouts only. It may only be operated with the components listed

here. Any other use is not permitted.

•Any wiring has to be carried out while power is disconnected.

Please make sure that no voltage reaches the locomotive while

converting it, above all not accidently.

•Avoid mechanical force or pressure on the decoder.

•Do not remove the heat shrink sleeve on the decoder.

•Make sure that neither the LokPilot decoder nor any blank wire

ends may come into contact with the engine chassis (risk of

short circuit). Cover any blank ends of unused wires.

•Never solder on the circuit board, extend cables if necessary

•Never wrap the decoder in insulation tape, since this may cause

overheating

•Adhere to the wiring principles as outlined in this manual for

wiring any external components. Other circuitry may cause

damage to the LokPilot .

•Make sure that no wires are squeezed or cut by the model’s

transmission parts when reassembling the engine

•Any power supply must be protected by a fuse or circuit breaker

to avoid any potential hazards such as burning cables in case of

a short circuit. Only use transformers specifically designed for

model trains that bear the VDE/EN marks.

•Never operate the LokPilot unattended. The LokPilot is not a

(children’s) toy.

•Do not expose to wet and humid conditions

6

4. How this manual helps you

This manual is divided into several chapters that show you stepby-step how to install a LokPilot decoder.

Chapter 5 provides an overview over the characteristics of each

type of LokPilot decoder.

Chapter 6 describes installation of the decoder in detail. Please

make yourself familiar with the type of motor and the type of

interface installed in your locomotive prior to working through

chapters 6.2. to 6.5.

You can operate LokPilot Decoders with most commercially

available control systems for model trains.

Chapter 7 provides

an overview which digital and analogue systems can drive LokPilot

decoders and which special issues to consider.

You will find the factory default settings for the function buttons

in chapter 7.1.

You may adjust the default settings of your LokPilot decoder as

desired. Chapters

8 to 16 explain which parameters are adjustable

and how to do it.

We recommend, that you at least read chapters 8 and 9 regarding

address settings as well as chapter 11 concerning motor control

in order to be able to adapt your LokPilot decoder optimally to

your model locomotive.

Chapter 20 lists all technical data as well as supported CVs and

will assist you in case of questions.

If not stated otherwise all information refers to all types of the

LokPilot family. Should one particular decoder not support a

specific function, then this is clearly mentioned.

5. Introduction – The LokPilot Family

5.1. The Members of the LokPilot Family

Once more ESU introduced an even more advanced version of

the popular LokPilot decoder with its third generation LP (V3.0).

All LokPilot V3.0 decoders complement the excellent properties

of their predecessors and expand their capabilities by further

functions. These developments further improve the driving

characteristics, the operational reliability, and the flexibility of

the decoders.

The LokPilot decoder is the first choice for any sophisticated model

train enthusiast that places great value on excellent load control,

outstanding driving characteristics at low speed, and the utmost

flexibility due to adaptation to specific requirements. LokPilot

decoders automatically detect the operating mode and are

suitable for all commonly used motors. LokPilot decoders of the

third generation offer you flexibility and reliability that you would

expect from a state-of-the-art decoder. Future standards do not

represent a problem either: due to the flash technology, you can

update the decoder at any time.

In order to suit the different scales and the related current draw

of the model locomotives, all LokPilot V3.0 decoders come in

various options that we now would like to introduce to you.

5.1.2. LokPilot V3.0

The LokPilot V3.0 is a multi-protocol decoder. It supports the

Märklin® / Motorola® format, the DCC-format and Selectrix®.

It can also work on analogue DC or AC layouts. Thus, it is ideally

suitable for mixed Motorola® / DCC environments.

Due to its manifold lighting functions and its adaptability to different applications, it is the perfect all-rounder for your H0

locomotives.

How this manual helps you

7

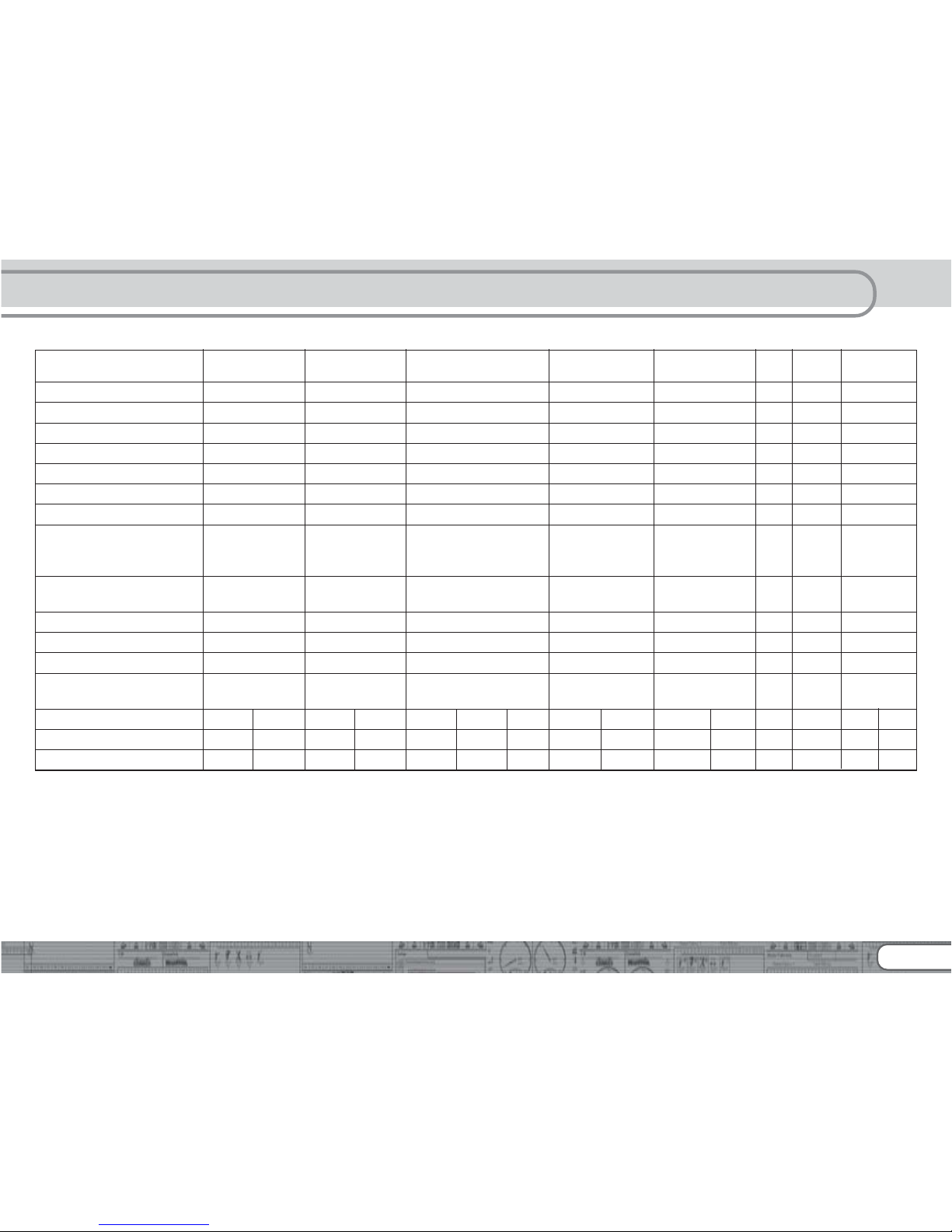

5.1.1. LokPilot V3.0 Decoders – an Overview

LokPilot micrLokPilot micr

LokPilot micrLokPilot micr

LokPilot micr

oo

oo

o

LokPilot micrLokPilot micr

LokPilot micrLokPilot micr

LokPilot micr

oo

oo

o

LokPilot V3.0LokPilot V3.0

LokPilot V3.0LokPilot V3.0

LokPilot V3.0

LokPilot V3.0LokPilot V3.0

LokPilot V3.0LokPilot V3.0

LokPilot V3.0

LokPilot V3.0 LokPilot V3.0

LokPilot V3.0 LokPilot V3.0

LokPilot V3.0

LokPilot LokPilot

LokPilot LokPilot

LokPilot

LokPilot LokPilot Fx LokPilot LokPilot Fx

LokPilot LokPilot Fx LokPilot LokPilot Fx

LokPilot LokPilot Fx

V3.0V3.0

V3.0V3.0

V3.0

V3.0 DCCV3.0 DCC

V3.0 DCCV3.0 DCC

V3.0 DCC

DCCDCC

DCCDCC

DCC

M4M4

M4M4

M4

XL V3.0 XL V3.0

XL V3.0 XL V3.0

XL V3.0

Fx micr Fx micr

Fx micr Fx micr

Fx micr

o V3.0o V3.0

o V3.0o V3.0

o V3.0

DCC Operation Ok Ok Ok Ok - Ok Ok Ok

Motorola Operation Ok - Ok - O k Ok Ok Ok

M4 Operation - - - - O k - - -

Selectrix Operation Ok Ok Ok - - - - -

Analogue DC Operation Ok O k Ok Ok Ok Ok Ok Ok

Analogue AC Operation - - O k - O k Ok Ok Ok

DCC programming modes Ok Ok Ok Ok - Ok Ok Ok

Motorola programming mode

using 6021, Mobile Station,

Central Station Ok - Ok - Ok Ok Ok Ok

M4 programming including

automatic recognition - - - - O k - - -

RailCom option Ok Ok Ok Ok - Ok Ok Ok

continuous motor current 0.75A 0.75A 1.1A 1.1A 1.1A 3.0A - -

function output current 2/140mA 2/140mA 4/250 mA 4/250mA 4/250mA

8/600mA

4/140mA 6/250mA

integrated PowerPack

buffer capacitor - - - - - - -

connection type 6 pin 6 pin 6 pin 6 pin 8 pin 6 pin 21MTC 8 pin 6 pin 8 pin 21MTC

screwing 6 pin 8 pin

21MTC

direct harness direct harness harness harness harness harness harness

terminal

harness harness

ESU item-number 52688 52687 52685 52684 52610 52612 52614 52611 52613 61600 61601 51702 52624 52620 52621

5.1.3. LokPilot V3.0 DCC

The LokPilot V3.0 DCC is a thoroughbred DCC decoder. Except

for the Motorola® and Selectrix® protocol, it supports all

functions of the LokPilot V3.0. In analogue mode, it can only

operate on DC powered layouts. The LokPilot V3.0 DCC is best

suited for the DCC purist who does not require multi-protocol

operation and does not want to pay for it either.

LokPilot V3.0 decoders - an overview

5.1.4. LokPilot V3.0 M4

The LokPilot V3.0 M4 is designed for the M4 data format. Besides

the new central units for Märklin systems with the mfx®-data

format, it is also suitable for the older models such as Delta or

control unit 6020 resp. 6021. Of course, you may also run it

with analogue alternating current. The LokPilot V3.0 M4

represents the first choice for all friends of the „new world“.

8

5.1.5. LokPilot XL V3.0

The LokPilot XL V3.0 is a powerful multi-protocol decoder for

Motorola® and DCC best suited for the larger scales: It can handle

a motor current of 3.0A and offers 8 function outputs. Furthermore, dirty tracks finally do not spoil your fun anymore due to

the integral „PowerPack“ energy buffer.

5.1.6. LokPilot micro V3.0

The LokPilot micro V3.0 is a real multi talent. Besides DCC and

Motorola® and Selectrix® and a maximum current draw of 0.75A,

it is ideal for the small scales with little room for decoders.

5.1.7. LokPilot micro V3.0 DCC

The LokPilot micro V3.0 DCC is a real power package: with a

permitted current draw of 0.75 A this DCC decoder with

RailCom® option offers the best solution for small locomotives

in N and TT-scale as well as small H0 locomotives with limited

room.

5.1.8. LokPilot Fx V3.0

The LokPilot Fx V3.0 is intended for vehicles without motors. It

has 6 function outputs. It supports the Motorola® as well as the

DCC format and is at home on analogue DC and AC layouts.

This LokPilot is ideal for using it in combination with another

LokPilot or LokSound decoder.

5.1.8. LokPilot Fx V3.0

The LokPilot micro FX V3.0 decoder is used for locos which are

too small for its „big brother“, the LokPilot Fx V3.0. It has four

function outputs and can be operated with the Motorola® and

the DCC format. It also proves it´s worth on analogue DCC

layouts.

5.2. General Properties of all Decoders

5.2.1. Operating Modes

All LokPilot V3.0 decoders (with the exception of the pure DCC

decoders) are true multi-protocol decoders with automatic

detection of the operating mode „on-the-fly.“ The decoder

analyses the track signal and filters out the part that is reserved

for it. Changing from digital to analogue and back represents

no problem whatsoever. This is important in case your storage

(fiddle) yard still works in analogue mode. Furthermore, all

LokPilot decoders support the relevant brake modes such as

ROCO®, Lenz® or Märklin® and stop as intended. LokPilot

decoders achieve the maximum compatibility with the operating

system in order to enable you to simulate even some unusual

operational requirements.

Provided the digital system supports them, then the LokPilot V3.0

supports and automatically detects the DCC protocol with 14,

28, or 128 speed steps. Of course, operation with the long 4digit addresses is possible as well.

Contrary to the original Märklin®-decoders, LokPilot V3.0

decoders support up to 255 addresses and 28 speed steps in

Motorola® mode. With the appropriate command station such

as for instance the ESU ECoS, you can expand the system limits

of the Motorola® system considerably.

Some LokPilot decoders also support the Selectrix® mode or M4

mode (mfx® compatible).

5.2.2. Motor Control

The most important function of digital decoders is motor control.

All LokPilot V3.0 decoders are designed for universal use and

therefore can control all commonly available DC motors,

regardless if they are by ROCO®, Fleischmann®, Brawa®,

Mehano®, Bemo®, LGB®, Hübner®, Märklin® or others.

Coreless motors (such as Faulhaber® or Maxon®) also work fine

with LokPilot. You may continue to use any universal motors

provided you replace the stator coils with a permanent magnet.

LokPilot V3.0 M4

9

You will find more info on this topic in chapter 6.6.4.2.

Fourth generation load compensation works with 16 resp. 32

kHz and assures extremely silent operation, particularly with

coreless motors. Due to 10-bit technology, your locomotives will

crawl at a snail’s pace if so desired. Load compensation is easily

adjustable to various motor and gear combinations (compare

with chapter 11).

With Dynamic Drive Control (DCC), you can limit the influence

of load control. Thus, you can control your locomotive in small

throttle notches for instance in the yard or on turnouts while the

locomotive responds like the prototype at high speed on the

main line (for instance when climbing a gradient). In other words,

if you do not change the throttle setting then the locomotive will

slow down up the hill, as does the prototype. There is more info

on this in chapter 11.4.

The minimum and maximum speed of the LokPilot V3.0 is

adjustable by setting three points or the speed table with 28

entries. The table is effective for all speed step ratings (14, 28,

and 128 speed steps); many decoders by others do not offer this

feature. Due to unique load compensation by ESU, there are no

visible jerks between speed steps – even in 14-speed-step-mode.

5.2.3. Analogue Mode

Quite a few LokPilot decoders replace analogue directional relays.

Therefore, you can not only set the starting speed and the

maximum speed as well as pre-select which functions should be

active in analogue mode: even load compensation works in

analogue mode! Therefore, LokPilot V3.0 decoders are ideal for

analogue locomotives: finally, you can slow down your older,

fast running locomotives.

5.2.4. Functions

Standard features for LokPilot V3.0 decoders include the following

features: acceleration and brake times can be separately adjusted

and switched, and of course, you can switch the shunting mode.

The brightness of all function outputs can be separately set and

allocated to the desired function buttons (function mapping).

There is a wide range of options: dimmer, flickering firebox, gyro-

light and mars-light, flash and double flash, blinker and alternate

blinker as well as switch functions with timers (e.g.: for Telex)

and a special coupler function for remote controlled couplers by

Krois® and ROCO®.

The unique ESU function mapping enables you to allocate every

function to the function buttons F1 to F15; even multiple

allocations are possible. You will find more info on this in chapter

12.

5.2.5. Programming

Where intended, LokPilot decoders support all programming

modes including POM (Programming-On-the-Main). You can use

any NMRA-DCC compatible command station for this purpose.

Even with the Märklin® central units 6020®, 6021®, Mobile

Station® and Central Station® all settings are adjusted

electronically. Most LokPilot V3.0 decoders support a simple-touse programming procedure. Owners of the ESU ECoS enjoy an

even more comfortable method of programming: you can read

all possible settings in plain text on the large display and easily

adjust them – even during operation!

5.2.6. Operational Reliability

LokPilot decoders store the current operating status. Thanks to

this data storage, the decoder will start again as quickly as

possible after a service interruption. Some decoders also have

an integral „PowerPack“ that assures continuous power even in

case of poor electrical contact.

5.2.7. Protection

All function outputs as well as the motor output have protection

against overload and short circuit. We want you to enjoy your

LokPilot decoders for a long time.

5.2.8. Future included

All LokPilot V3.0 decoders are suitable for firmware updates due

to the flash memory. You may add new software functions at a

later stage.

General Properties of all Decoders

10

6. Installing the Decoder

6.1. Requirements for Installation

The locomotive must be in perfect technical condition prior to

the conversion: Only a locomotive with faultless mechanical

properties and smooth running characteristics in analogue mode

is worth converting to digital. Check and replace all wear and

tear parts such as motor brushes, wheel contacts, light bulbs

etc., if necessary.

Please take note of the remarks in chapter 3 in order to prevent

possible damage of the decoder during installation!

6.2. Installing the Decoder

The components on the decoder must under no circumstances

touch any metal parts of the locomotive since this could lead to

short circuits and damage or even destruction of the decoder.

Therefore, all LokPilot decoders (with the exception of the ones

with the 21MTC-interface) come with a protective shrink sleeve.

Never wrap the decoder in insulating tape. Should there be no

ventilation around the decoder, then this may lead to a heat

build-up and ultimately to the destruction of the decoder. Rather apply the insulating tape to the metal parts of the locomotive.

Mount the decoder at a suitable location. In most model

locomotives, there is a dedicated space for the decoder. To hold

the decoder in place use double sided adhesive tape or some

(just a little) hot glue.

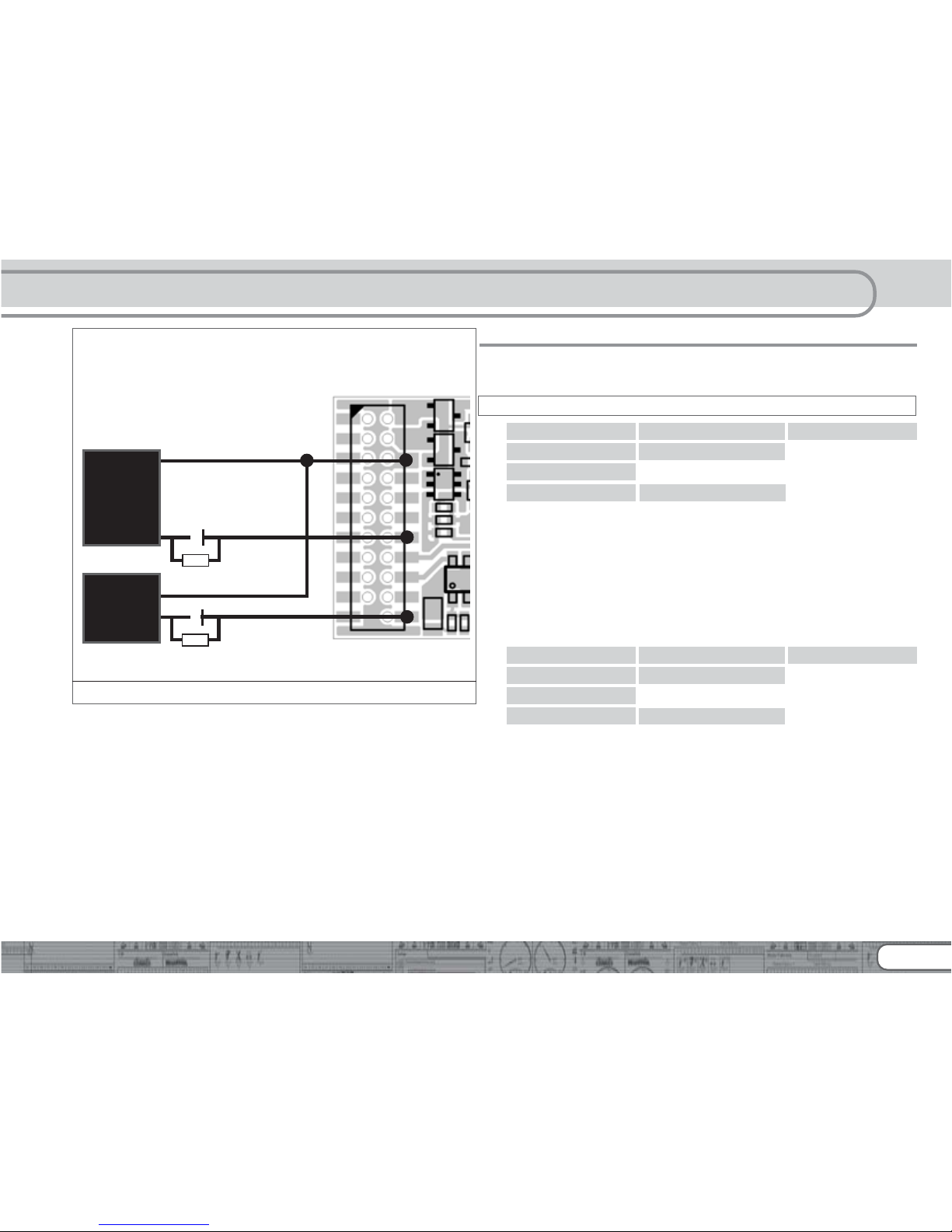

6.3. Locomotives with 8-pole NEM 652-Interface

Some LokPilot V3.0 decoders are supplied with an 8-pole interface

as per NEM 652 (refer to Fig 1). Installation in locomotives with

this interface is particularly easy:

•Remove the locomotive body. Please observe the instructions in

the manual of your locomotive!

•Remove the dummy plug from the socket and keep it in a suitable

place for later use.

Installing the Decoder

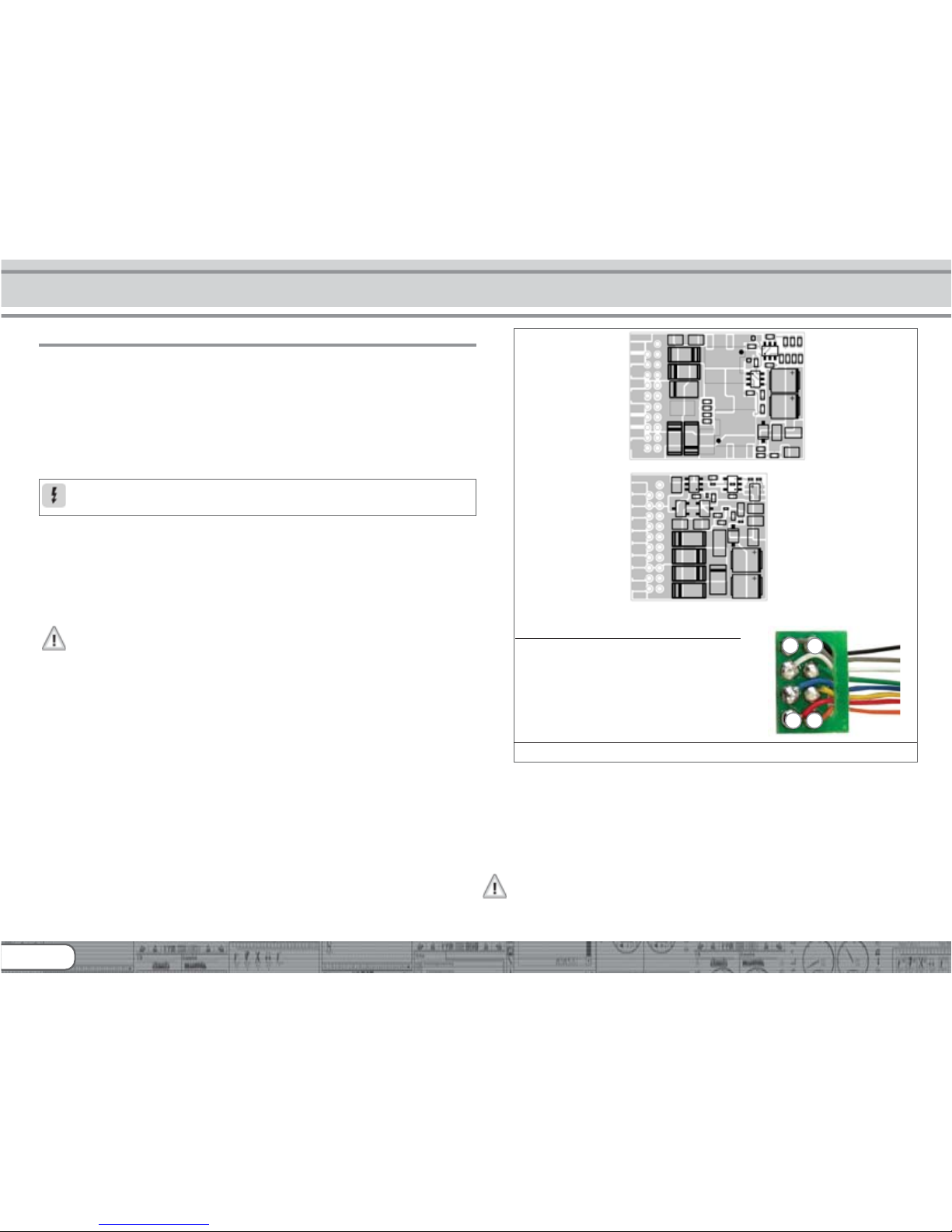

Figure 1: LokPilot V3.0 (DCC/M4), LokPilot Fx V3.0 - NEM652

•Insert the plug of the decoder in such a way that pin 1 of the

plug (this is the side with the red / orange wires) sits next to the

corner of the socket that is usually marked with *, +, • or 1.

Please make sure that the pins are straight when inserting the

plug.

Do not rely on the assumption that the wires of the harness have

to face in a certain direction: the only reliable reference is the

marking of pin 1.

52610 LokPilot V3.0

52611 LokPilot V3.0 DCC

61600 LokPilot V3.0 M4

52620 LokPilot Fx V3.0

AUX2

----

----

--

right motor terminal

----

----

--

right track connection

----

----

--

rearlight

----

----

--

common(+pole)

----

----

--

AUX1

----

----

--

headlight

----

----

--

left track connection

----

----

--

left motor terminal

----

----

--

AUX2

----

----

--

(orange) AUX3

----

----

--

right track connection

----

----

--

rearlight

----

----

--

common(+pole)

----

----

--

AUX1

----

----

--

headlight

----

----

--

left track connection

----

----

--

(gray) AUX4

----

----

--

Pin Description Color

1 right motor terminal orange

2 rear light yellow

3 output AUX1 green

4 left track connection black

5 left motor terminal gray

6 headlight white

7 common (+pole) blue

8 right track connection red

4

5

1

8

11

6.4. Locomotives with 6-pole NEM 651-Interface

Some LokPilot V3.0 decoders have a 6-pole NEM 651 plug (as

per Fig. 2). Installation in locomotives with this interface is

particularly easy:

•Remove the locomotive body. Please observe the instructions in

the manual of your locomotive!

•Remove the dummy plug from the socket and keep it in a suitable

place for later use.

•Insert the plug of the decoder in such a way that pin 1 of the

plug (this is the side with the red / orange wires) sits next to the

corner of the socket that is usually marked with *, +, • or 1.

Please make sure that the pins are straight when inserting the

plug.

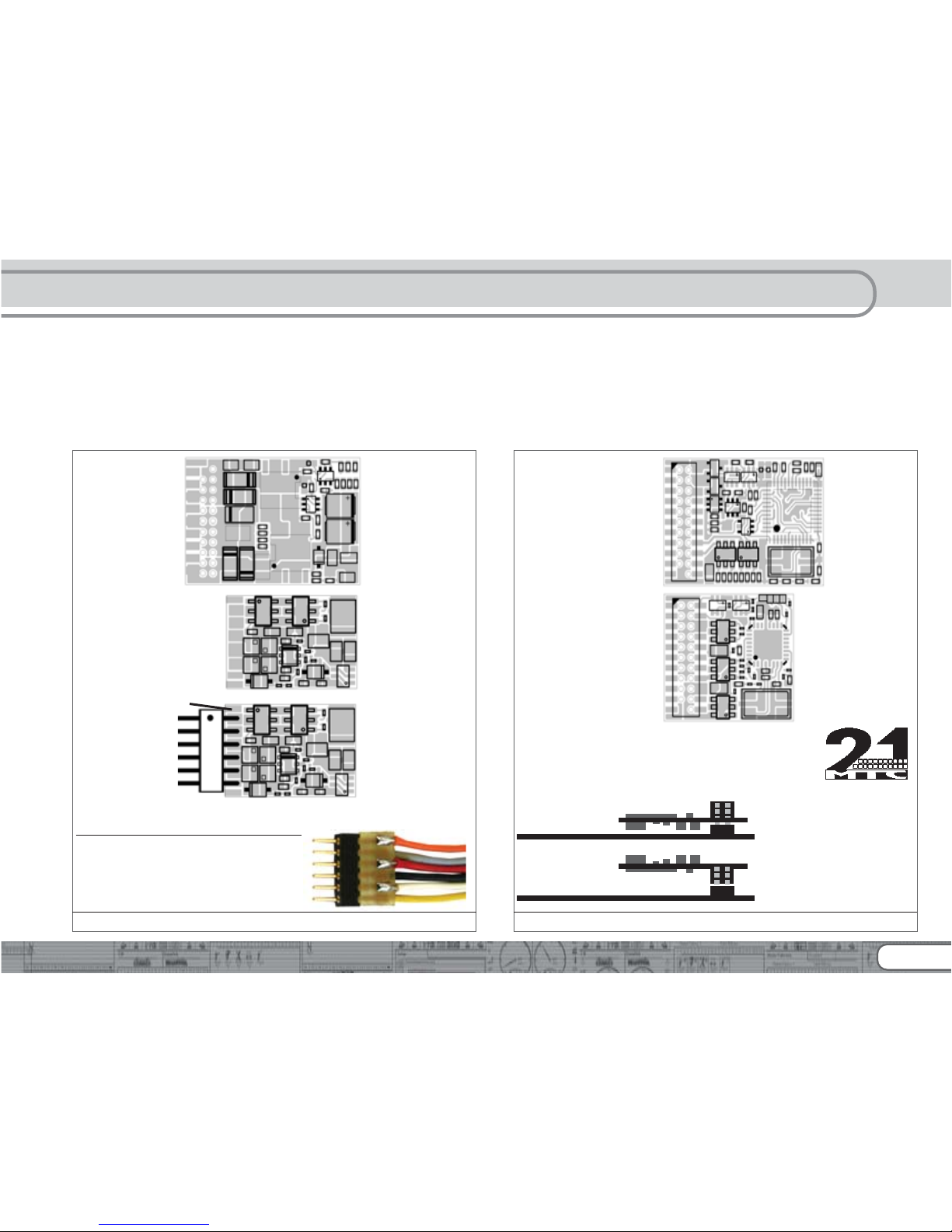

Figure 2: LokPilot V3.0 (DCC), LokPilot micro V3.0 - NEM651

52611 LokPilot V3.0

(violet) AUX2

----

----

--

right motor terminal

----

----

--

right track connection

----

----

--

rearlight

----

----

--

(blue) common(+pole)

----

----

--

(green) AUX1

----

----

--

headlight

----

----

--

left track connection

----

----

--

left motor terminal

----

----

--

Pin Description Color

1 right motor terminal orange

2 left motor terminal gray

3 right track connection red

4 left track connection black

5 headlight white

6 rear light yellow

52687 LokPilot micro V3.0

52684 LokPilot micro V3.0

(blue) common(+pole)

----

----

--

right motor terminal

----

----

--

left motor terminal

----

----

--

right track connection

----

----

--

left track connection

----

----

--

headlight

----

----

--

rearlight

----

----

--

soldering pad AUX1 (Logic level!)

----

----

--

52686 LokPilot micro V3.0

52685 LokPilot micro V3.0

right motor terminal

left motor terminal

right track connection

left track connection

headlight

rearlight

(blue) common(+pole)

--

--

-

--

--

-

soldering pad AUX1 (Logic level!)

DCC

DCC

Figure 3: LokPilot V3.0, LokPilot V3.0 M4 - 21MTC

52614 LokPilot V3.0

22 right track

21 left track

20 GND

19 right motor

18 left motor

17 n.c.

16 common (+)

15 AUX1

14 AUX2

13 AUX3

12 VCC

n.c. 1

n.c. 2

n.c. 3

AUX4 4

n.c. 5

n.c. 6

rearlight 7

headlight 8

n.c. 9

n.c. 10

Index pin 11

22 right track

21 left track

20 GND

19 n.c.

18 n.c.

17 n.c.

16 common (+)

15 AUX1

14 AUX2

13 AUX3

12 VCC

n.c. 1

n.c. 2

n.c. 3

AUX4 4

n.c. 5

n.c. 6

rearlight 7

headlight 8

n.c. 9

n.c. 10

Indexpin 11

52621 LokPilot Fx V3.0

Insertion of decoder with

Connector to the top

(e.g.. Hobby trade, HAG, Märklin)

How to connect the decoder:

locomotive pcb

locomotive pcb

Insertion of decoder with

connector to the bottom

(e.g. Brawa)

12

6.5. Locomotives with 21MTC Interface

Some LokPilot decoders are available with a variant of the 21MTC

interface as per Fig. 3. Installation in locomotives with this

interface is particularly easy since the plug-socket connector

facilitates the mechanical fixing as well.

•Remove the locomotive body. Please observe the instructions in

the manual of your locomotive!

•Remove the dummy plug from the socket and keep it in a suitable

place for later use

•Search for the missing pin in the plug on the circuit board of the

locomotive. The missing pin serves as the marker. Memorise its

location.

•You can insert the decoder in two ways: either the pins are put

through the decoder; the socket of the decoder remains visible

after installation (mounting on top) or the decoder is inserted in

such a way that the pins go straight into the socket. Once the

decoder sits in the socket, the socket is hidden from view. This

method is common for Brawa locomotives.

•Which of the two mounting positions is the correct one depends

solely on the locomotive. The position of the marker-pin is the

crucial indicator.

•Plug the decoder into the socket in such a way that the locomotive

interface corresponds with the decoder.

•Do not apply too much pressure when inserting the plug. The

decoder must go in without force.

•Check if the decoder sits correctly.

6.5.1. Connecting C-Sine motors („SoftDrive-Sinus“)

The LokPilot decoder cannot drive the newer Märklin®-models

with C-Sine motors (also called „SoftDrive-Sinus“) directly. To

facilitate this, a circuit board supplied with the locomotive is

required. Märklin uses the 21MTC interface installed on this

circuit board and thus utilises the normal motor commands form

the decoder for the exchange of information.

Both the LokPilot V3.0 and the LokPilot V3.0 M4 with the 21MTC

interface are suitable for controlling the C-Sine control electronics

provided some parameters are set accordingly. Chapter 11.5.

explains the necessary steps.

Some Trix® locomotives have the same C-Sine motor; however,

the control electronics in Trix® locomotives communicate in a

different manner with the decoder. Currently it is not possible to

run such locomotives with LokPilot decoders even though they

have the same (mechanically identical) interface.

6.6. Locomotives without Interface

All LokPilot decoders have the interface (plug). There is no „wiresonly“ version. Please remove the plug at the end of the harness

should this become necessary.

Please do not extend any wires at the decoder end. If necessary

use an extension harness (also refer to chapter 18).

Installing the Decoder

13

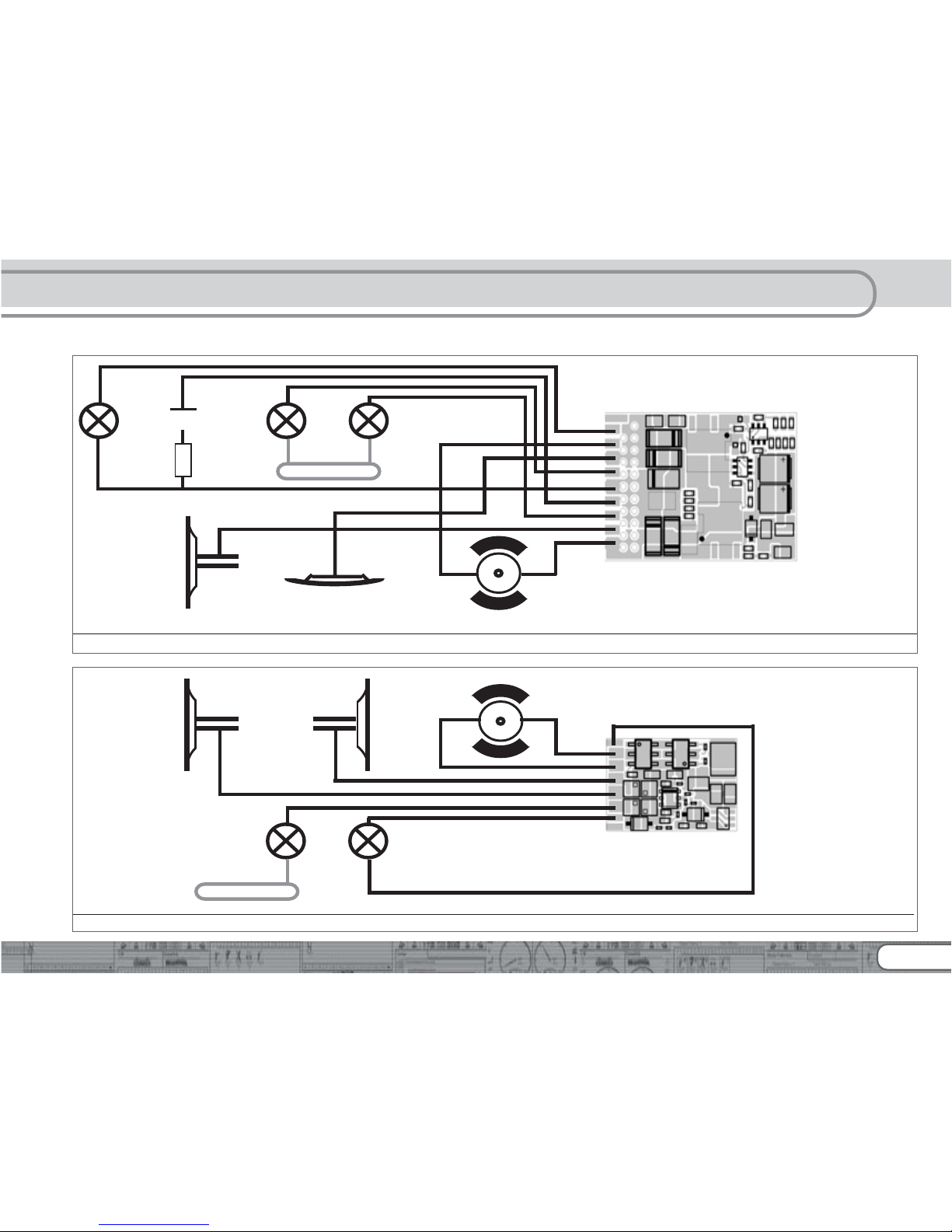

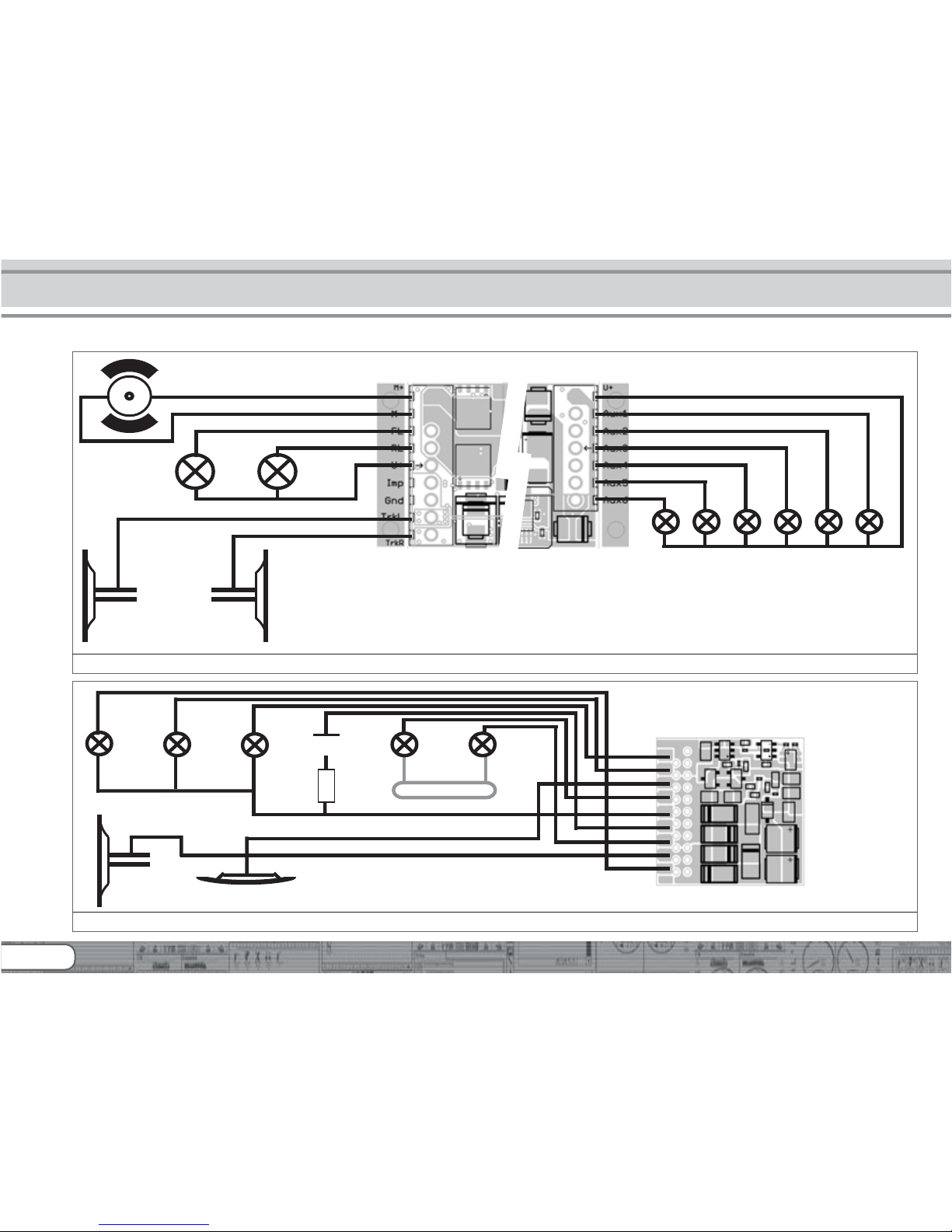

6.6.1. Wiring Diagram for LokPilot or LokPilot micro

Figure 5: Wiring Diagram for LokPilot micro V3.0, LokPilot micro V3.0 DCC (examples)

motor

52687 LokPilot micro V3.0

52684 LokPilot micro V3.0 DCC

orangegray

black red

wh ite yellow

Head

Lights

Rear

Lights

chassis

orange

gray

red

black

white

yellow

blue (optional, instead of chassis connection)

violet gr ee n yellow white

AUX2

AUX1 Rear

Light

Head

Light

gray

orange

motor

red

chassis

52610 LokPilot V3.0

52611 LokPilot V3.0 DCC

61600 LokPilot V3.0 M4

violet

orange

red

yellow

blue

green

white

black

gray

R

black

Figure 4: Wiring Diagram for LokPilot V3.0, LokPilot V3.0 DCC, LokPilot V3.0 M4 (examples)

14

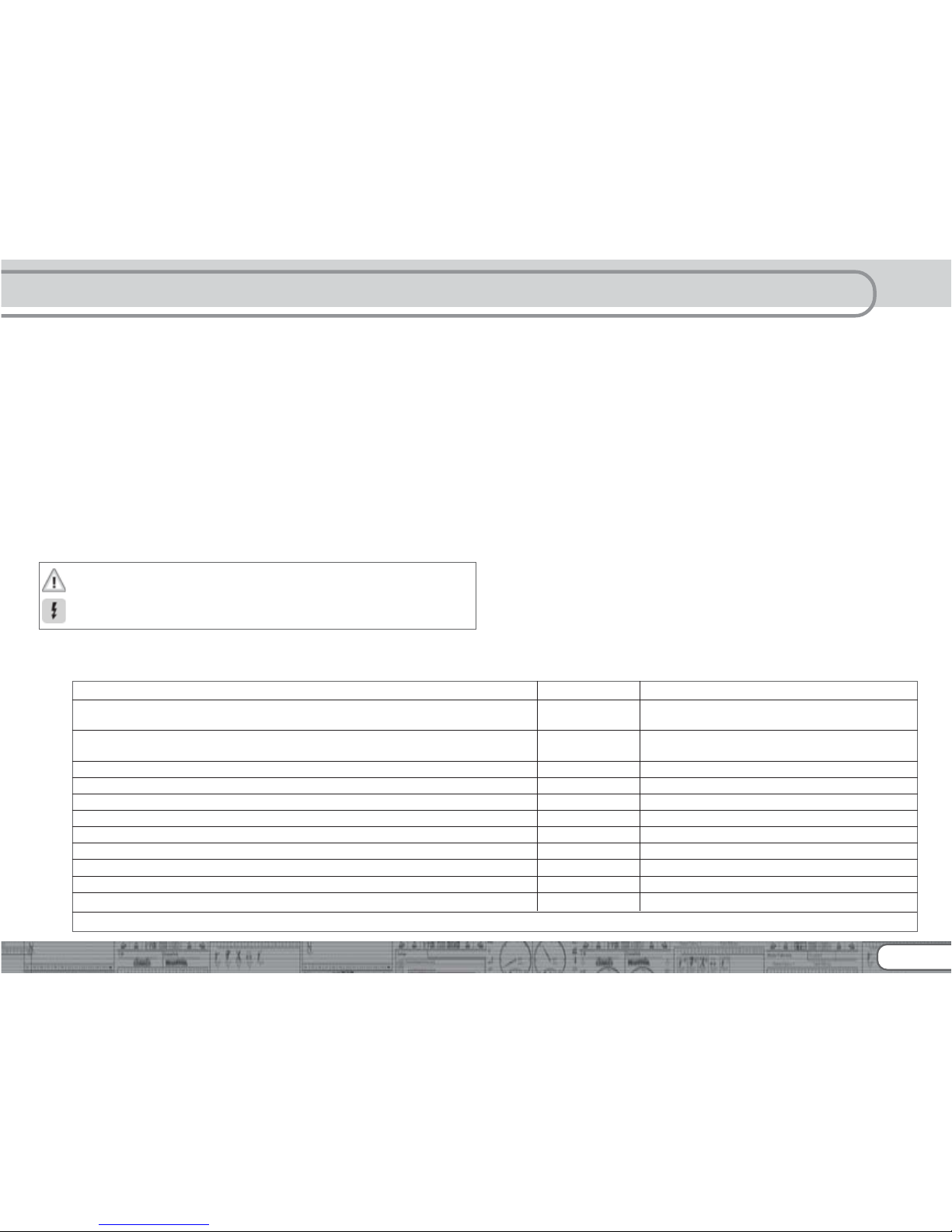

6.6.2. Wiring Diagram for a LokPilot XL Decoder

Installing the Decoder

Motor

Head

Lights

Rear

Lights

right motor terminal

left motor terminal

Figure 6: Wiring diagram for LokPilot XL V3.0 (wiring example)

left track connection

right track connection

Common (+Pole)

AUX6 AUX5 AUX4 AUX3 AUX2 AUX1

gre en yellow white

AUX1 Rear

Lights

Head

Lights

red

chassis

52620 LokPilot Fx V3.0

violet

orange

red

yellow

blue

green

white

black

gray

R

black

Figure 7: Wiring diagram for LokPilot Fx V3.0 (wiring example)

violet

AUX2

orange

AUX3

gray

AUX4

15

•Connect the red wire to the right rail pickup or the centre pick

up in AC models.

•Connect the black wire to the left rail pickup or the chassis in

AC models.

•Connect the orange wire with the motor terminal, which originally

lead to the right wheel pick up (centre pick up in AC models).

•The grey wire goes to the terminal, which originally connected

to the left rail (chassis for AC models).

6.6.4.1. Connecting DC and Coreless Motors

You may use all DC motors commonly used for model trains

provided they do not exceed the current limit of the decoder.

In some cases with the 5-pole High Performance Drive by

Märklin®, you may find three anti-interference capacitors:

the two capacitors connected directly to the motor leads and the

motor housing MUST be removed (also refer to Fig. 9 on the

following page).

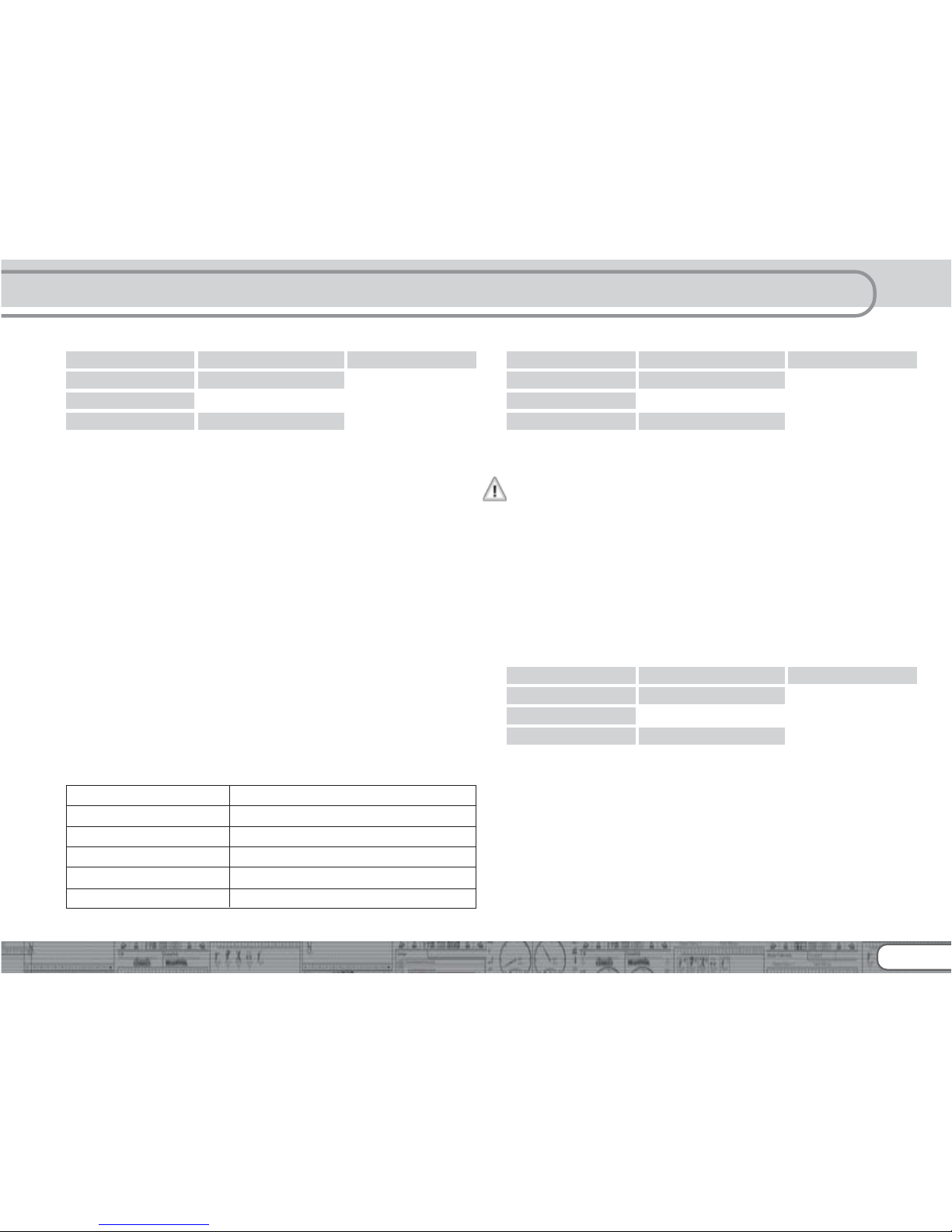

6.6.3. Colour Coding by Märklin®

Märklin® uses a different colour coding system compared to the

DCC colours. Please refer to Fig. 8 for more information.

6.6.4. Motor and Track Connections

Firstly, please cut all wires installed in the locomotive. Take special

care to remove any connections to the chassis: the motor leads

must be positively potential-free, in other words the may not

have any contact to the chassis or body or the wheels and wheel

contacts. It is particularly easy to overlook such connections in

Fleischmann® locomotives.

Make notes of which motor lead connects the motor with the

right and the left wheel contact. This avoids mistakes and assures

that your locomotive runs in the right direction.

Please check all connections with an Ohmmeter. Search for

short circuits, particularly between the motor leads and the wheel

contacts.

Figure 8: Colour coding by Märklin® in contrast to the DCC wiring code

Description Märklin color ESU color (following NMRA DCC standard)

AC: Power pickup show („Schleifer“) (Center Rail) red red

DC: right track connection

AC: Outside Rails brown black

DC: left track connection

left motor terminal blue orange

right motor terminal green gray

common (rectified track voltage) (+Pole) for function outputs orange blue

function output Rearlights yellow yellow

function output Headlights gray white

function output AUX1 brown/red green

function output AUX2 brown/green violet

function output AUX3 (logic level only occasionally, depending on decoder type) brown/yellow function output AUX4 (logic level only occasionally, depending on decoder type) brown/white -

16

6.6.4.2. Connecting Universal Motors with HAMO-Conversions

Do not wire universal motors installed in many older Märklin®

locomotives (also known as AC motors) directly to LokPilot

decoders. You must modify the motor by first installing permanent magnets – so called HAMO magnets. You may purchase

these magnets from your ESU dealer.

We supply three types of magnets. Please refer to chapter 18.2.

for more information regarding motor conversions with permanent magnets.

6.7. Connecting Additional Functions

You can wire any kind of load such as light bulbs, LEDs (light

emitting diodes), smoke generators or similar devices to the

function outputs provided the maximum current draw is less than

that of the decoder output.

The permitted maximum current draw per function output is listed

in chapter 20 under „Technical Data.“

Please make sure that the load does not exceed the permitted

maximum current and there are no short circuits. The outputs

of the LokPilot have protection but if an external voltage is

applied, the outputs may suffer damage or destruction.

6.7.1. Overload Protection of Function Outputs

The function outputs of LokPilot decoders have electronic

protection against overload and short circuit. The decoder keeps

checking the sum of all function output currents. If the current

is too high, the decoder will switch off the outputs. After about

1 second, the decoder tries to switch them on again. Should the

current still be too high – perhaps due to a short circuit – the

same procedure starts again.

When using light bulbs (incandescent lamps) please note the

following: they draw a very high „inrush current“ when they are

switched on, that becomes lower after a few moments. Therefore,

it can happen with 12V bulbs that the headlights „flash“ briefly

during switch-on and then extinguish due to the overload

protection of the decoder. It is important to install the correct

bulbs.

6.7.1.1. Suitable Light Bulbs

Only install bulbs rated 16V or higher and with a nominal current,

that does not exceed 50 mA.

Many older models by ROCO® and Fleischmann® have 12V bulbs

installed. They draw a high current, become very hot, and may

cause damage to the locomotive. Replace them with 16V bulbs.

6.7.2. Connecting the Light Outputs as well as AUX1 and AUX2

This procedure depends on the wiring of the lights and auxiliary

functions in the locomotive:

a) The

lamps / function outputs are insulated from the common

pole (ground) (i.e.: the locomotive chassis); therefore they are

potential free. Fig. 4 shows the correct wiring for the outputs

AUX1 and AUX2. The functions of the locomotive must be potential-free, in other words there may not be any other connection

to the function besides the wires from the decoder. The voltage

at these outputs is about 1.5V lower than the track voltage. The

blue wire is the „plus-pole“; the function output the „minuspole.“

If LEDs are installed (also refer to Fig. 4, output AUX1), then a

resistor must be wired in series with the LEDs. It should have a

Installing the Decoder

Figure 9: 5-pole Märklin® motor

greyorange

remove capacitors!

17

rating of between 470 Ohms and 2.2 kOhms. Running the LEDs

without this resistor will lead to their destruction!

b) The

lamps / function outputs are wired (together) against the

chassis of the locomotive (as in most locomotives by Märklin®

as well as in most older locomotives by Fleischmann® and

ROCO®). This scenario is illustrated for the light outputs in Fig.

4 (the headlights can of course also be wired as in „a)“). The

wiring is simpler but the available voltage is about half.

This type of connection is not suitable for multi-protocol

operation. Both M4 and Motorola® packets are asymmetrical.

Therefore, the function outputs do not have continuous power.

This leads to a rhythmic flicker of the headlights (pulsing) that

becomes particularly obvious with LEDs. Furthermore, the

headlights will only work in one direction in analogue DC mode.

Whether it will be the forward lights or the backup lights depends

on which way you have placed your locomotive on the track.

•Solder the backup lights to the yellow wire, the headlights to

the white one.

•The green wire connects to the function output AUX1.

•The purple wire goes to the function output AUX2.

If your locomotive is wired according to option b), then it is rea-

dy for use. Otherwise, you must connect the remaining wires of

all bulbs and functions together to the blue wire. This pole may

not have any connection to the chassis!

As shown in Fig. 4 it is possible to use both options in the same

locomotive.

6.7.3. Purpose of AUX3 and AUX4

6.7.3.1. LokPilot with 21MTC Interface

LokPilot decoders with 21MTC interface have two additional

outputs besides the 4 standard outputs, namely AUX3 and AUX4.

Since they are pure „logic-outputs,“ it is not possible to connect

any external loads directly. External power transistors are required.

Connect AUX3 and AUX4 via the interface; there are no wire

leads. In terms of their functionality, AUX3 and AUX4 are equal

to the other outputs.

6.7.3.2. LokPilot Fx V3.0

The LokPilot Fx V3.0 offers up to 6 function outputs (also refer to

Fig. 7). You can access the outputs AUX3 and AUX4 via the

orange resp. the grey wire.

For all other LokPilot decoders the orange and grey wires are the

motor leads. The LokPilot Fx V3.0 is an exception.

6.7.3.3. LokPilot Fx micro V3.0

The LokPilot Fx micro V3.0 offers up to 4 function outputs. You

can access the outputs AUX1 and AUX2 via the orange resp. the

grey wire.

For all other LokPilot decoders the orange and grey wires are the

motor leads. The LokPilot Fx V3.0 is an exception.

6.7.4. Suitable Smoke Generators

Unfortunately, it is not an easy task to find the right smoke

generator for each locomotive. The amount of smoke generated

depends on the following factors:

a) Track voltage

The track voltage varies depending on the command station.

Therefore, it is possible that a locomotive generates smoke

when driven by one digital system but does not generate any

smoke with another system. Even 1V variation makes a big

difference.

b) Type and tolerance of the Seuthe smoke generator and the

smoke distillate

Seuthe smoke generators have considerable production

tolerances. Therefore, it is possible that one unit works

perfectly well while another does not. Type of distillate and

filling level have an influence as well.

c) Setting the decoder output

For correct smoking action you should set the AUX output to

„Dimmer“ as well as full „Brightness.“ More info in chapter

12.

18

d) Connecting the smoke generator

Most smoke generators are wired against the chassis.

Therefore the smoke generator only receives current in every

second half cycle. How much power gets to the smoke

generator depends on your command station and the digital

protocol. Generally, Seuthe type 11 is recommended, but it

does not get enough power and therefore does not smoke

satisfactorily.

There are two options on how to solve this problem:

Solution 1: Using the Seuthe No. 10. This type is intended for

analogue operation and draws a relatively high current. Subject

to its tolerance levels, it may trigger the overload protection of

the decoder. In this case, you must wire a relay (ESU No. 51963)

into the circuit or you slightly reduce the „Brightness“ of the

output.

Solution 2: Using the Seuthe No. 11. Do not wire it against the

chassis but rather use the blue wire for the second pole („U+“).

This prevents the asymmetric track signal from interfering with

the smoke generator. It represents the best solution but is

sometimes a bit difficult in terms of wiring.

6.8. Connecting Capacitors

On many older layouts, current pick up of locomotives is not very

reliable. Therefore, power interruptions may cause a stop or

jerky movement when the locomotive travels over turnouts at

low speeds. This can be overcome with buffer capacitors (100

uF / 25V or higher show the desired results). If desired you may

connect them to the LokPilot decoders.

Soldering wires onto a decoder requires quality soldering

equipment and experience. Our warranty does not cover

damage caused by inappropriate soldering. Consider carefully

if you really need that capacitor.

6.8.1. All LokPilot H0

You can connect two larger capacitors as per the circuit in Fig.

11. One buffers the motor output, the smaler capacitor supports

the microcontroller of the decoder. The capacitor is charged via

a resistor (100 Ohms) thus preventing the digital system from

interpreting the charging current as short circuit at the time of

switch-on. The diode makes sure that the energy of the capacitor

is fully available when required.

However, you may not run this locomotive on AC layouts

anymore. Risk of destruction!

Disconnect / remove the capacitor prior to programming with

the ESU LokProgrammer!

6.8.2. Integral „PowerPack“ in LokPilot XL V3.0

The LokPilot XL V3.0 comes ex works with a particularly powerful

energy buffer. This „PowerPack“ allows your locomotive to keep

running for 2 seconds without power. The PowerPack does not

have to be configured, it simply works anytime. Please consider

the following aspects:

•The PowerPack only operates in digital mode. It automatically

turns off on analogue layouts.

•It may take up to two minutes to fully charge the capacitor

(„GoldCap“). Therefore, the time bridged with the energy buffer

depends on the current draw of your locomotive and the chargeup time.

•You may notice a certain reduction in the speed of a fast running

locomotive whenever the PowerPack provides power to the

locomotive. This is quite normal and does not represent faulty

behaviour.

•For safety reasons the PowerPack switches off the motor after

about 2 seconds even if there is still enough energy available.

Please also bear in mind that the locomotive may take up to 2

seconds before responding to the emergency stop button!

Installing the Decoder

19

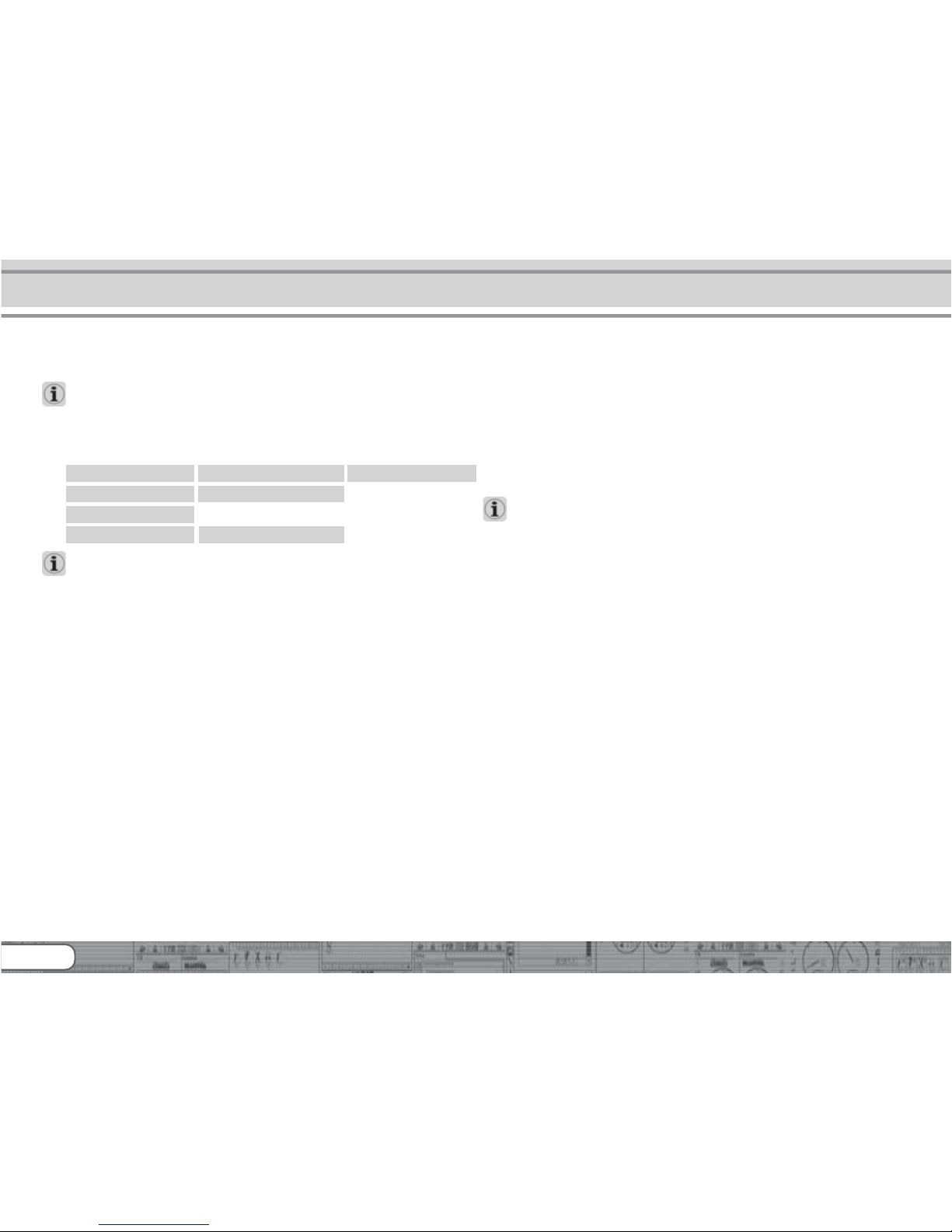

7. Initial Operation

7.1. Factory Default Values

The address is set to 03 with 14 speed steps.

LokPilot V3.0 LokPilot V3.0 DCC LokPilot V3.0 M4

LokPilot micro V3.0 LokPilot micro V3.0 DCC

LokPilot XL V3.0

LokPilot Fx micro V3.0

F1 switches output AUX1.

F2 switches output AUX2.

F3 switches the shunting mode on and off.

F4 switches the acceleration and deceleration on and off.

F5 switches output AUX3 (if available).

F6 switches output AUX4 (if available).

F7 switches output AUX5 (if available).

F8 switches output AUX6 (if available).

LokPilot Fx V3.0

F1 switches output AUX1.

F2 switches output AUX2.

F3 switches output AUX3.

F4 switches output AUX4.

•Does the locomotive move in both directions?

•Does the indicated direction of travel correspond with the actual

one? If not, are the motor leads swapped or is the 8-pole plug

inserted the wrong way round?

•Switch on the lights: do they work properly? If you have installed

a LokPilot with an 8-pole plug, check if the plug sits in the socket correctly.

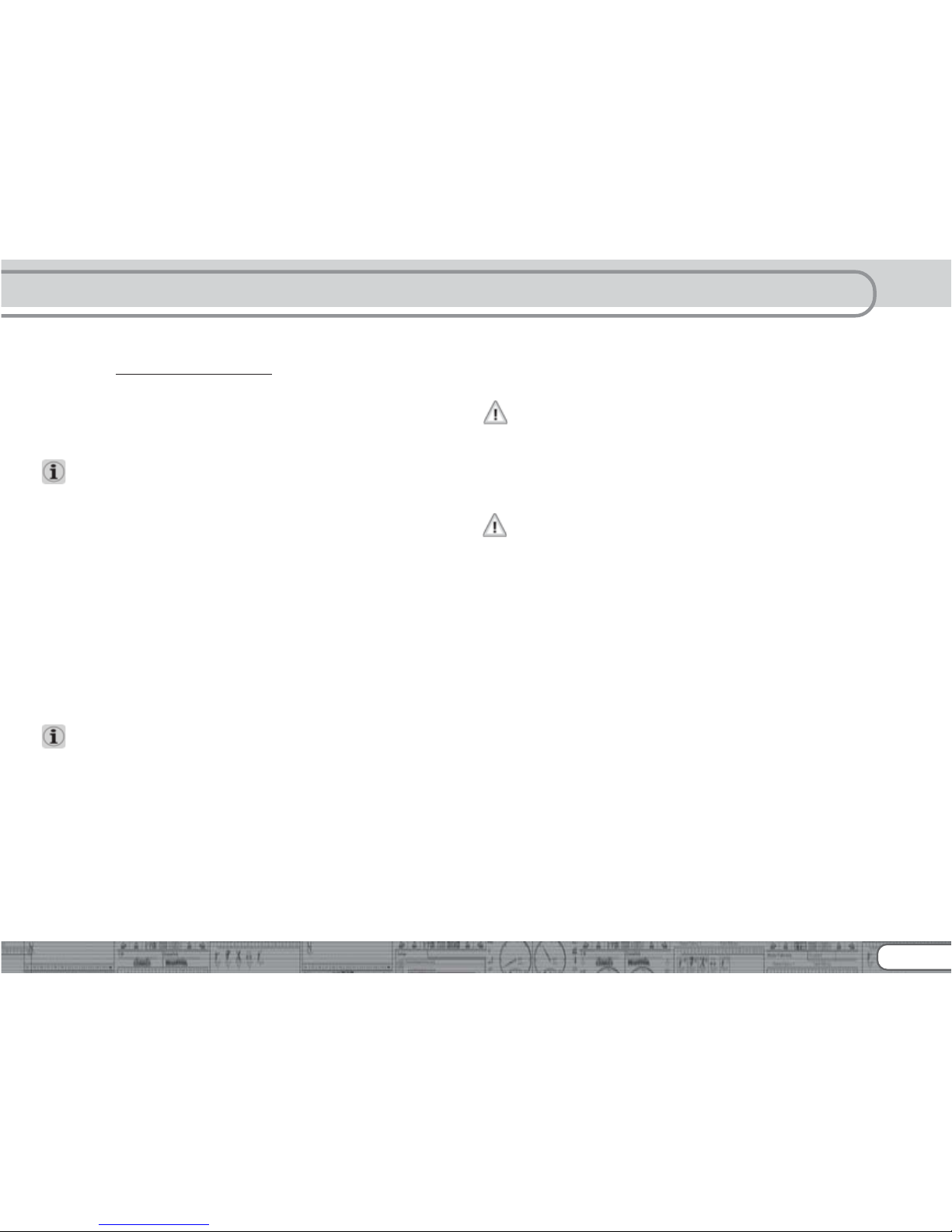

Figure 11: 2200µF + 470µF capacitor with LokPilot

GND

U+

(positive pole)

GND

U+

(positive pole)

1N4007

100Ω,1/4 Watt

470µF

6,3V

-

+

1N4007

100Ω,1/4 Watts

Initial Operation

-

+

2200µF

25V

52610 LokPilot V3.0

52611 LokPilot V3.0 DCC

61600 LokPilot V3.0 M4

20

7.2. Digital Operating Modes

In the following chapters, we describe operation of the LokPilot

with different digital systems.

Since not every LokPilot supports all digital systems, we state

which chapter is applicable for which type.

7.2.1. DCC Mode

LokPilot V3.0 LokPilot V3.0 DCC

LokPilot micro V3.0 LokPilot micro V3.0 DCC

LokPilot XL V3.0

LokPilot Fx V3.0 LokPilot Fx micro V3.0

Remove any capacitors that are wired into the track feeders (e.g.

ROCO® feeder track). This could impair the functionality of the

decoder.

The LokPilot works with any DCC system. Unfortunately, the

DCC protocol also brings some difficulties into the game. One

of them occurs so often that we deal with it right away.

7.2.1.1. DCC Speed Steps („flashing lights“)

„Lights do not work“ with DCC systems: DCC locomotives run

with 14, 28, or 128 speed steps. The decoder must „know“ the

speed step setting of the command station. The command station

must be able to operate with this mode and must be set

accordingly. If this is not the case, the following problems may

occur:

•You cannot switch the lights with F0 at all.

•The lights keep switching on and off dependent on the speed

step.

In this case, make sure that the speed step settings of decoder

and command station are the same.

7.2.1.2. Auto-detection of DCC Speed Steps

LokPilot decoders implement auto-detection to avoid the above

problem. We have tested this with the following systems:

• ESU ECoS®

• Bachmann E-Z-Command® Dynamis®

• ROCO® Lokmaus2 and Lokmaus3

• Uhlenbrock® Intellibox

• Lenz® Digital plus V2.3

• ZIMO® MX1

When operating with Lenz® digital plus V3.0 the auto-detect

feature does not work at 14 speed steps. Select 28 / 128 speed

steps instead.

The LokPilot tries to establish the speed step setting every time it

receives power (i.e.: after switching on the power on your layout

or the track sector where your locomotive is located) and the

lights are switched on. This process requires that you switch on

the lights and turn the throttle until the lights light up

continuously.

Should you change the speed step setting during operation then

you must interrupt the power to the decoder for a short moment

in order to activate the auto-detection.

This auto-detect feature can be turned off with bit 4 in CV 49

(also refer to the CV table in chapter 12.1). Then you have to set

the correct speed step with bit 5 in CV 29.

Initial operation

21

7.2.2. Motorola® Mode

LokPilot V3.0 LokPilot V3.0 M4

LokPilot micro V3.0

LokPilot XL V3.0

LokPilot Fx V3.0 LokPilot Fx micro V3.0

The LokPilot works with all Märklin® devices and compatible

systems that are in the market until now. The functions F1 to F4

can only be activated with the so-called „new Motorola® format.“

In order to activate this you must set the DIP-switch 2 on your

6021 to the upper position („On“).

LokPilot decoders support two special features in Motorola®

mode:

7.2.2.1. 28 Speed Steps

While the original Motorola® system used by the following central

units, namely Märklin® central unit 6021, Delta® and Mobile

Station®, only supports 14 speed steps, the LokPilot decoder

can also handle the 28-speed step mode. In conjunction with

suitable command stations (e.g.: ESU ECoS, in „Motorola® 28“

mode) this leads to smoother control of your locomotives. No

changes are required on the decoder.

7.2.2.2. Extended Motorola® Address Range

While the original Motorola® format only knows the addresses

from 01 to 80, the LokPilot offers the following range of

addresses:

LokPilot V3.0 01 - 255

LokPilot V3.0 M4 01 - 255

LokPilot XL V3.0 01 - 255

LokPilot micro V3.0 01 - 127

LokPilot Fx V3.0 01 - 127

LokPilot Fx micro V3.0 01 - 127

Chapter 9 explains how to set the address.

7.2.3. Selectrix® Mode

LokPilot V3.0

LokPilot micro V3.0

LokPilot XL V3.0

You may operate the LokPilot with any Selectrix® compatible

command station with access to the functions „lights“ and F1.

For programming any parameters, you must use the DCC

programming mode. It is not possible to program it with a „pure“

Selectrix® system. Any changes programmed in DCC are also

valid for operation with Selectrix® command stations.

As soon as a decoder receives commands in Motorola® or DCC

format (whenever it receives a signal packet with information

addressed to it), the Selectrix® receiver switches off automatically.

This allows trouble-free mixed operation with Selectrix® / DCC /

Motorola®. The Selectrix® receiver turns on again as soon as

the decoder detects a power interruption.

7.2.4. M4 Mode

LokPilot V3.0 M4

The LokPilot M4 is recognised and embedded into the system

automatically by the Märklin® systems devices Central Station®

and Mobile Station® immediately after placing the locomotive

onto the track. This process runs automatically and does not

require any specific decoder settings.

As soon as the decoder receives a valid M4 data packet (whenever

the decoder recognizes that it is run by an M4 capable central

unit) it will ignore Motorola® data packets. Only after interrupting

power to the decoder briefly or if it does not receive any M4 data

packets for about 4 seconds will it accept Motorola® data packets

again.

22

7.3. Analogue Mode

All LokPilot decoders are set ex factory to operate in analogue

mode as well.

Please take note of the remarks in chapter 10.4 if the decoder

should move repeatedly from analogue into digital sectors and

back.

7.3.1. Analogue DC operation

LokPilot V3.0 LokPilot V3.0 DCC

LokPilot micro V3.0 LokPilot micro V3.0 DCC

LokPilot XL V3.0

LokPilot Fx V3.0 LokPilot Fx micro V3.0

LokPilot decoders work on conventional DC layouts. Ex works,

load compensation is active. This provides smooth control of

your locomotives even at low speeds (in DC mode as well). Since

load compensation requires about 3 – 4 Volts as „base voltage“

you must turn the throttle further than normal (=locomotives

without decoder) before the locomotive starts moving.

7.3.2. Analogue AC Operation

LokPilot V3.0 LokPilot V3.0 M4

LokPilot XL V3.0

LokPilot Fx V3.0

Other LokPilot decoders than the ones mentioned above are

not suitable for analogue AC mode. AC will definitely lead to

the destruction of the decoder!

Where intended, LokPilot decoders support operation with AC

transformers. Therefore, the LokPilot decoder can simply replace

the old directional relay. Load compensation is active (similar to

DC mode) and provides smooth control and slow-speedperformance you have never seen before. The LokPilot V3.0

recognised the pulse for changing direction as usual. Just wait

until the locomotive has stopped prior to changing direction.

Never issue the „Change of Direction“ command to a moving

locomotive! This could lead to damaged gears!

We cannot recommend the use of the old (blue) Märklin®

transformers that where originally designed for 110/220 Volt.

Depending on their age and their tolerance range, the pulse for

changing direction could be too high in case of increased mains

voltage and therefore destroy the LokPilot decoder.

Do yourself and your locomotives a favour and purchase a suitable

Märklin® transformer (220V version = No. 6647, 110V version =

No. 6646) – your locomotives and decoders will thank you with

longer product life!

8. Decoder Settings (Programming)

Chapter 8 covers setting various parameters of the LokPilot

decoder. Should you not be familiar with the handling of CVs

please take the time to read these occasionally quite complex

instructions.

After an introduction into the world of parameters in chapter

8.1, we explain in the following section 8.2 how to change various

parameters in DCC mode and with Märklin® central units.

The chapters 9 to 16 explain which parameters have what kind

of influence on the behaviour of the LokPilot decoder.

8.1. Adjustable Properties of Decoders

The hardware determines some features such as the number of

function outputs as well as the maximum permitted current of

the motor output and therefore they are not programmable.

Nevertheless, there are plenty of possibilities to influence the

behaviour of the LokPilot decoder by adjusting software-governed

properties.

Initial Operation

Loading...

Loading...