Esu Class 66, Class 77 Instruction Manual

En g i n E E r i n g Ed i t i o n

Instruction manual

1. Edition, September 2014

Class 66/77

2

Content

1. Declaration of Conformity

We, ESU electronic solutions ulm GmbH & Co. KG, Edisonallee 29, D-89231 Neu-Ulm, Germany, declare in sole responsibility that the product

„ESU H0-Diesellok Class 66/77“, part number: 31050, 31051, 31052, 31053, 31054, 31055, 31056, 31057, 31058, 31059, 31070, 31071,

31072, 31073, 31074, 31075, 31076, 31077, 31078, 31079 complies with all relevant regulations of the Directive for Electromagnetic Com-

patibility (2004/108/EG). The following harmonised standards have been applied:

EN 55014-1:2006 + A1:2009: Electromagnetic Compatibility - requirements for household appliances, electric tools, and similar apparatus - Part

1: Emission - Product

EN 55014-2:1997 + A1:2001 + A2:2008: Electromagnetic Compatibility - Requirements for household appliances, electric tools, and similar

apparatus - Part 2: Immunity - Product family standard.

1. Declaration of Conformity ........................................2

2. Prototype .................................................................3

3. Model .....................................................................6

3.1. Important remarks - please read this first ......... 6

3.2. Unpacking the model ...................................... 6

3.2.2. Mounting & removing the centre pick-up ..... 6

3.3. Outward appearance and special features ........ 7

4. The technology of the ESU model ............................8

4.1. Possible operating modes of the class 66/77 .... 8

4.1.1. Analogue mode ........................................... 8

4.1.2. Digital mode ................................................. 8

4.1.2.1. Digital operation with DCC systems .......... 8

4.1.2.2. DCC with RailComPlus®............................ 9

4.1.2.3. Prerequisites for RailCom® Plus ................. 9

4.1.2.4. M4 registration .......................................... 9

4.1.2.5. Digital operation with Märklin® Digital...... 9

4.2. Your first ride................................................... 9

4.2.1. Lighting functions ......................................... 9

4.2.2. Sound functions ......................................... 10

4.2.3. Curve and turnout sensors.......................... 10

4.2.4. Synchronised smoke generator ................... 10

4.2.4.1. Filling the smoke generator holding tank . 10

4.2.4.2. Operating the smoke generator ............... 11

4.2.5. PowerPack energy storage .......................... 11

5. Decoder Settings (Programming) ............................12

5.1. Configuration Variables (CVs) ........................ 12

5.1.1. Standardisation in the NMRA ...................... 12

5.1.2. Bits and Bytes ............................................. 12

5.2. Programming the decoder ............................. 12

5.2.1. Programming with DCC systems ................. 12

5.2.2. Programming with Märklin® 6021 ............ 12

5.2.2.1. Changing to the programming mode ...... 13

5.2.2.2. Short mode ............................................. 13

5.2.2.3. Long mode .............................................. 13

5.2.3. Programming with the Märklin® Central

Station®............................................................... 13

5.2.4. Programming with ESU LokProgrammer ..... 14

5.3. Adress settings .............................................. 14

5.3.1. Short Addresses in DCC mode .................... 14

5.3.2. Long Addresses in DCC mode .................... 14

5.3.3. Motorola® address ..................................... 14

5.3.3.1 Consecutive addresses for more functions 14

5.4. Adapting the Driving Characteristics .............. 15

5.4.1. Acceleration and Deceleration .................... 15

5.4.1.1. Shunting mode ........................................ 15

5.4.2. Starting Voltage, Vmax ............................... 15

5.5. Break sectors ................................................. 15

5.5.1. DC break mode .......................................... 15

5.5.2. Märklin® brake mode ................................ 15

5.5.3. Lenz® ABC brake mode ............................. 16

5.6. Adjusting the volume .................................... 16

5.6.1. Overall sound volume ................................. 16

5.6.2. Adjust individual sounds ............................. 16

5.6.3. Motor sound .............................................. 16

5.6.4. Auxiliary sounds ......................................... 16

5.7. PowerPack ..................................................... 16

5.8. Decoder reset ................................................ 17

5.9. Adjusting the brightness of the lights ............ 17

5.10. Smoke generator ....................................... 17

5.10.1. Blower of the smoke generator ............... 17

5.10.2. Heating temperature ............................... 17

6. Maintenance..........................................................17

6.1. Removing the housing ................................... 17

6.2. Lubrication .................................................... 17

6.3. Replacing wheel sets ..................................... 17

6.4. Replacing traction tires .................................. 18

6.5. Installing a coupler ........................................ 18

7. Accessories supplied with the model ......................20

8. Technical support ...................................................20

9. Spare parts ............................................................20

10. List of all important CVs .......................................21

12. Warranty Certificate .............................................23

3

En g i n E E r i n g Ed i t i o n

Original

Prototype

2. Prototype

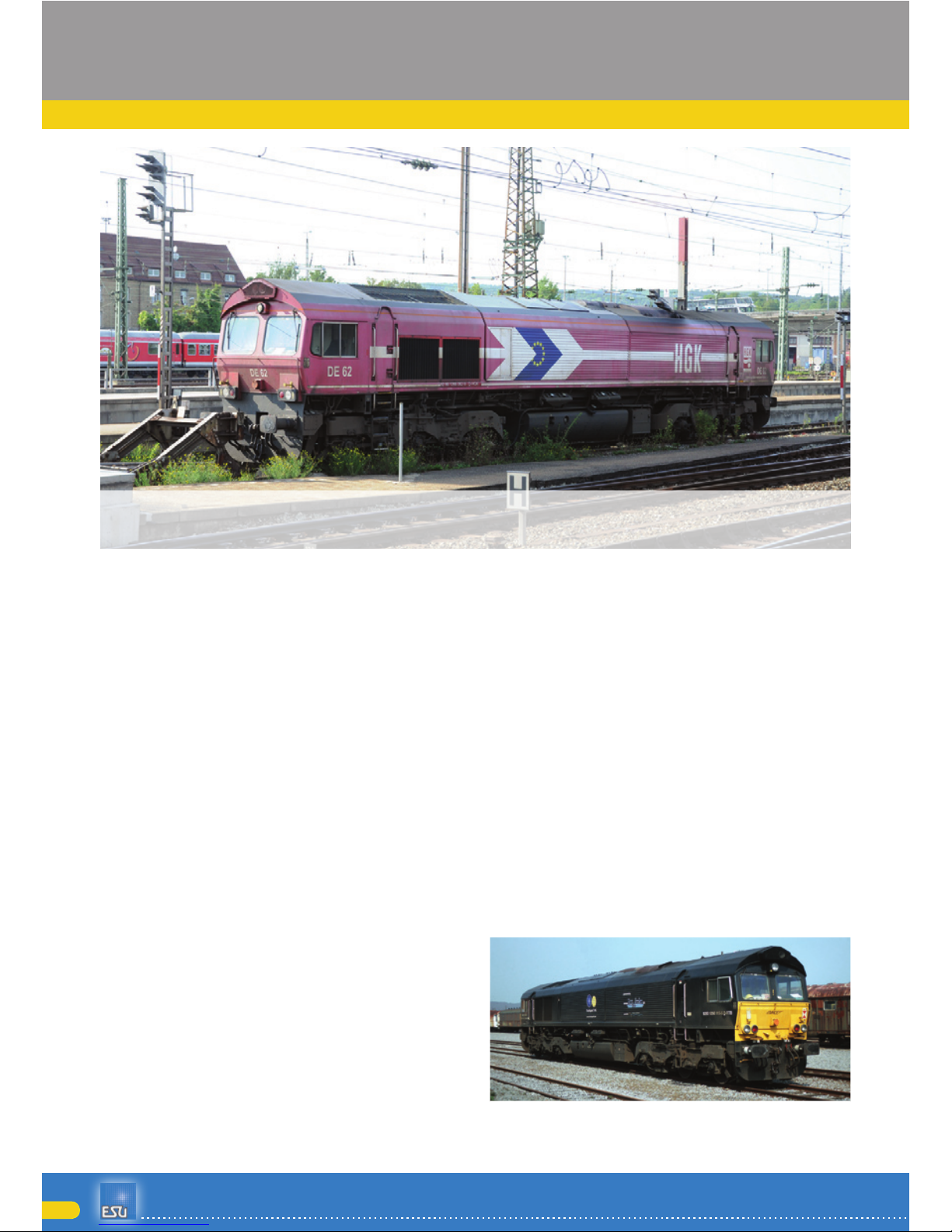

With the liberalisation of the international rail goods

traffic established in 2001 the newly founded rail

operators needed to procure motive power in order

to be able to handle the traffic they had fought so

hard to take away from the state owned railways.

The procurement of technically sophisticated new

vehicles was often not possible due to budgetary

restraints. A more cost effective solution was offered by the American Electro Motive Division (EMD)

with the class 666 that had already been tested and

proven in Great Britain. The locomotives known as

the JT 42 CWR are based on the American SD40

and ongoing development culminating in the SD

40-2, which were found to be most reliable due to

their simple, but proven design.

The first railway institution employing the diesel

electric class 66 on German lines was the Harbour

and Freight Services AG in Cologne the so called

Häfen und Güterverkehr Köln AG (HGK). In 1999

this company purchased two units. Almost at the

same time the class 66 was introduced to other European countries. Rail traffic corporations having

purchased or leased class 66 locomotives can be

found in France, Belgium, the Netherlands, Luxembourg and Norway. So far about 650 units have

been delivered in two different version to European

customers. The somewhat long and slim outline

Class 66‘ predecessor is named JT 26 CW-66. The picture shows Deutsche Bahn 259 003 in Sed-

din on 28.9.1997

Picture: Rolf Wiemann

meets the clearance diagram of British Rail. The

square-edged design of the body and the chassis

with its massive boogies and quite a number of seemingly confusing pipes and cables give the class 66

an unmistakable appearance.

The General Motors twelve Cylinder Two Stroke

engine 12N-710G3B-EC can not only be heard but

also recognised due to its characteristic sound and

offers a power of 3194 HP (2350 kW). The starting

tractive effort amounts to 409 kN, the continuous

tractive effort is 260 kN. With a maximum speed of

120 km/h the class 66 locomotives can easily keep

pace with other trains using electric traction even

on mainlines. Due to the independence from centenary the client can, if need be, pick up the train

from the most remote spur or siding and take it

via DB mainlines right through to his own factory.

With their livery the class 66 locomotives form a

pleasant contrast to the standardized red livery of

the DB AG.

Since 1999 the HGK mainly handles block trains

with their class 66 locomotives albeit with varying

loads. Tank cars have been a standard load for HGK

class 66 locomotives taking the train over the entire

route to Braunschweig, Ingolstadt, Marktredwitz

and Aichstetten. But one can also find the locomo-

4

Prototype

tives from Cologne in central Germany whenever

they haul a train to Leuna or Berlin, amongst others.

We have chosen the DE671 built in 2003 and with

an extended concession issued in 2011 as the prototype for our model that bears white stripes on

the front.

The livery of the class 66 locomotives is accentuated

by the sharp contrast of black or grey sides with

the light green contrast patches leading around the

cabs. In Germany, Belgium and the Netherlands the

Captrain locomotives are mainly deployed hauling

container traffic, block trains consisting of tank

wagons or coal cars. They also display their power

ahead of block trains made up of cars with sliding

sides carrying parts for the automotive industry. In

Germany these six axle locomotives regularly travel

from the Rhine Ruhr region as far as Berlin.

As from 2010 CB rail, a renter of locomotives sent

their German and Luxembourg subsidiaries under

the name of Ascendos Rail Leasing GmbH into the

game of rail freight traffic. For operations on only

partly electrified lines Ascendos has a stable of 20

class 66 locomotives and an extra three class 77.

For Modeltrain enthusiasts these locomotives with

their green livery accentuated by the turquoise and

yellow contrast stripes are highly attractive since

they are not only deployed to haul block trains with

containers, tank cars, construction materials, coal,

motor vehicles or machine parts but make themselves useful in track maintenance service of for

transfers of other vehicles. Particularly in the area

of construction site logistics these locomotives are

often seen with only a handful of cars. Well known

companies renting these six axle locomotives have

been and are the HGK, Crossrail, ITL or the Ruhrtalbahn deploying them all over Germany, Belgium

and the Netherlands.

The four units owned by the SNCF Benelux and regularly travelled through Belgium, the Netherlands

and Germany in their impressive and very elegant

blue silver livery. Initially it was quite easy to differentiate them due to their different design of the

contrast areas on the front and rear. They were

mainly hauling two axle hoppers, container trains

and tank car trains.

HKG‘s DE 62 still owns the british style headlights with outer position lamp in contrast to DE

61. Picture taken on 24.08.2011 in Ulm Hbf

Picture: Jochen Frickel

The prototype of the ESU model in Montzen

/ Belgium

Picture: Rolf Wiemann

5

En g i n E E r i n g Ed i t i o n

Original

Prototype

Section view of class 77 showing the components locationsFigure 1:

Drawing: ESU GmbH & Co. KG

DE61 of HGK is allowed to be used in ger-

many only

Picture: Jochen Frickel

Crossrail‘s class 77 DE 6311 in Neuwied train

station

Picture: Rolf Wiemann

6

Model

3. Model

3.1. Important remarks - please read this first

Congratulations to your purchase of the H0 diesel

locomotive class 66/77. Your H0 model offers various innovative functions. This manual provides a

step by step insight into the features of the class

66/77. Therefore we have one request:

Please read this manual prior to operating the model carefully. Although the model is quite robust,

inappropriate handling could lead to injury of the

operator or to damage of the locomotive. Do not

indulge in “costly” experiments.

This locomotive is not a toy and should only be •

operated under supervision.

Please make sure that the room has adequate •

ventilation when operating the smoke generator continuously!

Keep the smoke distillate away from children. It •

contains substances that may damage your health if consumed. In case of contact with your

eyes consult a doctor immediately.

Please return the pipette only into the packaging •

after you have emptied it completely. Otherwise

you may risk draining the smoke distillate.

Protect the model against wet conditions and •

humidity.

When working on the locomotive (maintenance) •

always make sure there is no power connected

to the model. Replace the housing on the chassis prior to operating the locomotive after maintenance work.

Make sure that no wires are squeezed or that no •

short circuit may occur.

Please note: All models shown here are pre-production samples. They may vary slightly from the series

production models!

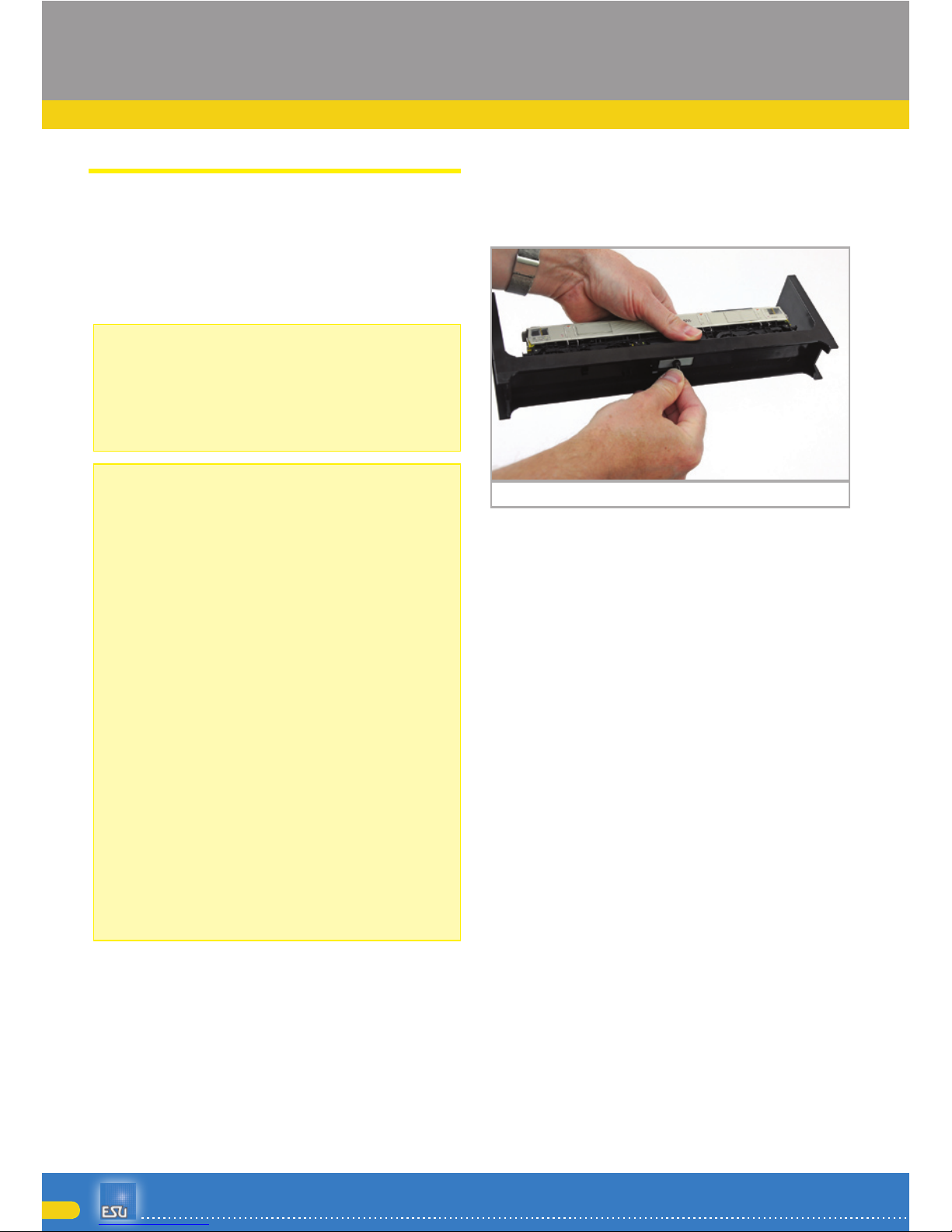

3.2. Unpacking the model

Pull the model screwed to the plastic holder with

both hands out of the foam insert. At the bottom of

the plastic holder you will find a hexagon spanner.

Now place the model on its side, hold the model

and the plastic holder with one hand and release

the hexagon bolt with the other hand.

For safe keeping of the spanner there are two retaining clips at the bottom of the plastic holder.

Please keep all parts of the packaging and this

manual for later use. Only the original packaging

guarantees proper protection against transport damage. Please fix the locomotive by means of the

hexagonal bolt to the plastic holder and place it into

the foam insert and put it into the carton and the

transport box prior to shipment.

Now you must adapt your class 66/77 to the control

mode of your layout. If you are a Märklin model

train enthusiast and therefore need a locomotive

with a centre pick-up you may simply place the locomotive onto the track, enter address 3 and you

are ready to run.

The centre pick-up clipped onto the locomotive serves not only for current pick-up but also activates

the electrical connection of both rails. Thus all 12

wheels pick-up current from the tracks.

If you operate a two-rail layout you must remove

the centre pick-up. How you do this is described in

chapter 3.2.2.

3.2.2. Mounting & removing the centre pick-up

Removal: Put the locomotive on its roof. Then you

apply the tool in such a way that the ends of the

four wire brackets fit into the four holes below the

base plate of the centre pick-up. Carefully(!) squeeze the tool and then lever the centre pick-up with a

slight tug from its position.

release of hexagon boltFigure 2:

7

En g i n E E r i n g Ed i t i o n

Model

Model

Mounting: For re-converting your locomotive to a

three-rail vehicle again hold the centre pick-up between thumb and index finger and place it in the

receptacle. Please note that the centre pick-up must

be attached to bogie “1”. Finally press the centre

pick-up until there is an audible “click”. That´s it!

3.3. Outward appearance and special features of

your class 66/77

With your new class 66/77 you can operate your

model trains prototypically like never before. There

are many separately applied detail parts on the metal housing as well as on the metal chassis. Of course, such details and modifications of the housing

are correct for the respective locomotive number.

All grab irons are made off sturdy plastic and are

separately applied. Separate plastic pipes are attached to the bogies.

The large speaker powered by the LokSound V4.0

M4 decoder distributes its powerful sound through

the cut-through radiator grills. New is also the sen-

sor triggering the squealing noise in curves and on

turnouts.

The ESU 5-pole high performance motor with a virtually silent commutator and two flywheels assure

plenty of power and smooth running. All four axles

are powered.

Four traction tires assure considerable tractive effort. Model train enthusiasts who prefer to run their

locomotives without traction tires and rather enjoy

more prototypical wheels sets find a voucher for six

wheel sets (2-rail system) with RP 25 wheels (please

also refer to page 26!). In order to obtain these

wheel sets, simply send this voucher to ESU. In order to assure perfect driving dynamics and excellent

sound without interruptions due to dirty tracks the

locomotive is equipped with a “PowerPack“energy

storage module.

A coupler shaft as per NEM 362 with short coupler

kinematics provides close coupling between locomotive and train in any situation.

In terms of its lighting the class 66/77 is just as

prototypically versatile as its full scale counterpart.

Of course there is directional lighting generated by

warm white LEDs that can be turned off at one end,

wherever the train is coupled to the locomotive.

During shunting all three headlights at either end

are switched on. In addition there is directional cab

lighting as well as illuminated driver’s cab-control

panel. Since these locomotives are employed internationally one can also set the lighting according to

the Belgian, Dutch and French lighting rules.

pickup shoe removalFigure 3:

Assembly of pickup shoeFigure 4:

8

Technical functions

4. The technology of the ESU model

The new LokSound V4.0 M4 decoder is a central

part of your new class 66/77. Its circuitry is responsible for design and control of all running and sound

functions of the class 66/77:•

Driving forward and in reverse •

Lighting functions•

Sound functions•

Smoke generator•

Besides M4 the LokSound V4.0 M4 also supports

DCC with RailComPlus, Motorola® and Selectrix®

and also be operated on analogue layouts. Programming can be done either with DCC command

stations or with Märklin® central units, etc. the decoder automatically detects the mode of operation;

therefore you do not have to set anything in this

regard.

In case you wish to change any of the default settings of the locomotive (such as the address or the

sound volume) we recommend to first reading

chapter 5. This chapter lists all parameters of the

LokSound V4.0 M4 decoder and how to change

them with the various command stations available

on the market.

4.1. Possible operating modes of the class 66/77

4.1.1. Analogue mode

The class 66/77 may also be operated on conventional (=analogue) DC or AC model train layouts.

The number of available functions is, however, quite limited:

Driving forward and backwards•

Directional lighting•

Engine sounds (automatic)•

The smoke generator cannot be turned on in analogue mode. The engine sound sets in at about

6.5 V track voltage. At 8.5 V the locomotive slowly starts moving. Both DC transformers (throttles,

e.g.: ROCO®) and AC transformers (e.g.: Märklin®,

Titan) are suitable for analogue operation. Please

note, that due to the large number of different systems on the market you may not achieve troublefree operation with electronic throttles employing

PWM (pulse width modulation).

Attention: the class 66/77 must have come to a

complete standstill before you activate the changeof-direction command! Never switch to the opposite direction while the locomotive is moving.

4.1.2. Digital mode

For prototypical operation we recommend using

a digital command control system. The numerous

functions are only available in digital mode.

The default address (ex works) is “03” (DCC and

Märklin® Motorola®)

14 speed steps with Märklin® Motorola®.

In DCC mode the decoder automatically detects the

speed steps set in the command station.

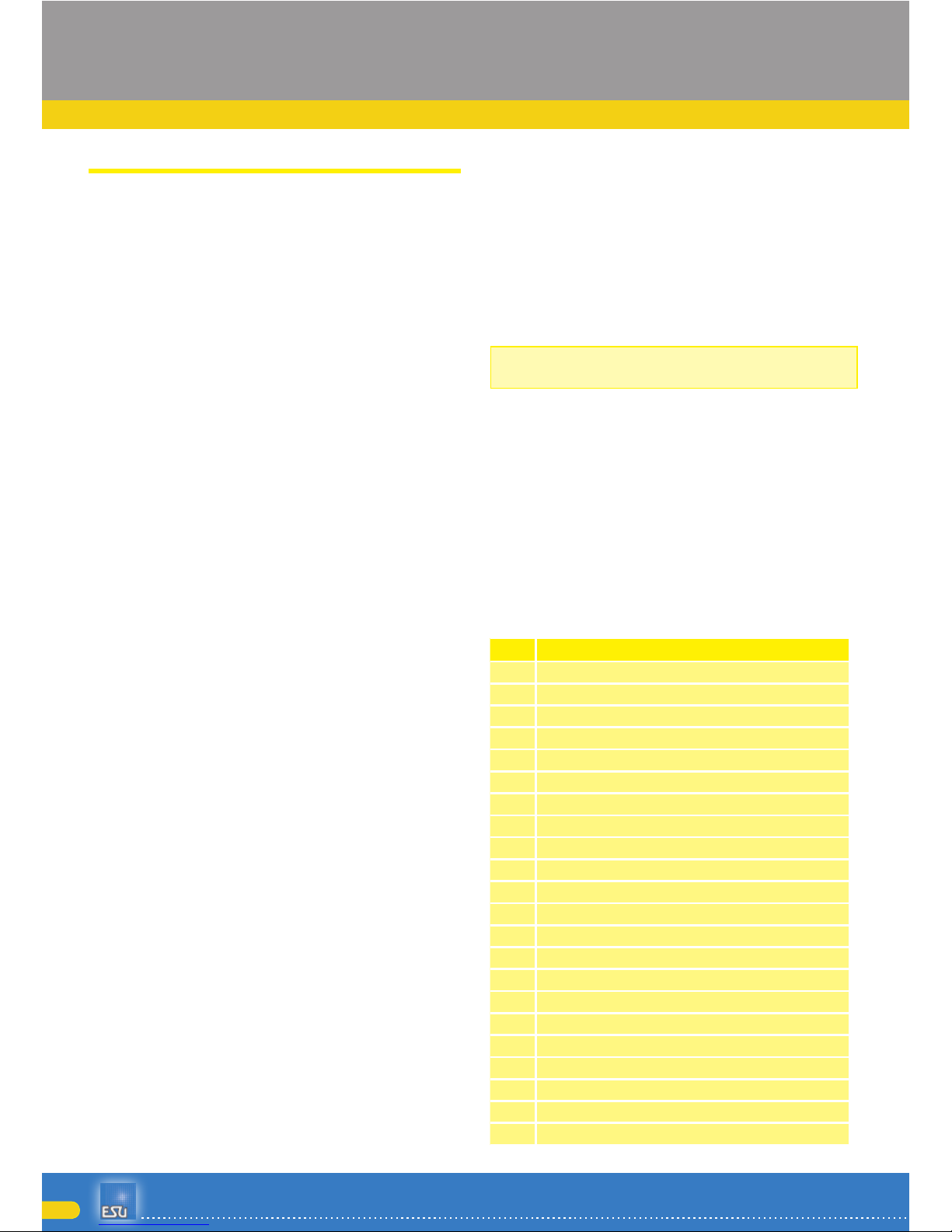

4.1.2.1. Digital operation with DCC systems

The class 66/77 can be operated with any DCC

compliant system. Sounds and other functions of

the class 66/77 can be triggered with the function

buttons F0 through F21.

Function mapping (ex works):

Functionmapping:

Button

Function

F0 Directional lighting

F1 Engine sound

F2 Horn (high)

F3 Smoke generator

F4 Cab lighting

F5 Headlights off at cab 1

F6 Headlights off at cab 2

F7

Headlights as per lighting rules in BE/FR (Third headlight off)

F8 shunting lights DE/FR/BE

F9 Horn (low)

F10 Emergency stop

F11 Platform announcement

F12 Turnout sensor off

F13 Coupler sound

F14 Illuminated driver’s cab-control panel

F15 Shunting lights as per NL

F16

Air compressor / exterior lights as per CNet,TGOJ, CLF

F17 Station announcement

F18 Short horn (high)

F19 Short horn (low)

F20 Sanding

F21 Shunting mode

Loading...

Loading...