Estyma Control M RS 420 Operation Manual

Operation manual for M RS 420 ESTYMA control unit

2

Contents

GENERAL INFORMATION .......................................................................................... 3

INTRODUCTION .........................................................................................................3

USE ............................................................................................................................4

SAFETY PRECAUTIONS ...............................................................................................6

DISPOSAL OF OLD EQUIPMENT .................................................................................7

APPLICABILITY OF THE MANUAL ................................................................................7

WIRING SYSTEM ....................................................................................................... 8

GENERAL REQUIREMENTS .........................................................................................8

LOCATION ..................................................................................................................8

ACCESSORIES .............................................................................................................9

ADDITIONAL CONTROL PANEL ..............................................................................9

ROOM TEMPEATURE REGULATOR .......................................................................9

OPERATING THE UNIT ............................................................................................. 10

MENU NAVIGATION ................................................................................................10

BOILER OPERATION MODES ....................................................................................12

WEATHER-COMPENSATED MODE WITH MIXER ACTUATOR CONTROL..............12

MANUAL MODE ..................................................................................................12

SUMMER MODE .................................................................................................13

BOILER TEMPERATURE SETTING..............................................................................13

CONTROL OF THE FOUR-WAY MIXING VALVE .........................................................14

HEATING CURVE SELECTION ....................................................................................15

AMOUNT OF AIR, LAMBDA SENSOR – POWER TEST MODE .....................................18

AIR DURING IGNITION .............................................................................................20

PUMPS .....................................................................................................................20

HOT TAP WATER ......................................................................................................20

HOT TAP WATER TEMPERATURE SETTING .........................................................20

HOT WATER PRIORITY ........................................................................................21

HOT TAP WATER HYSTERESIS .............................................................................21

HOT TAP WATER BOILER SETTING ......................................................................21

MENU LANGUAGE ...................................................................................................22

START UP .................................................................................................................22

FIRST BOILER IGNITION ............................................................................................23

ALARMS AND SAFEGUARDS ....................................................................................23

TECHNICAL DATA .....................................................................................................25

Operation manual for M RS 420 ESTYMA control unit

3

Thank you for choosing our product and congratulations on a good

decision. We will be grateful for comments concerning the unit’s

performance.

ESTYMA electronics

Team

GENERAL INFORMATION

INTRODUCTION

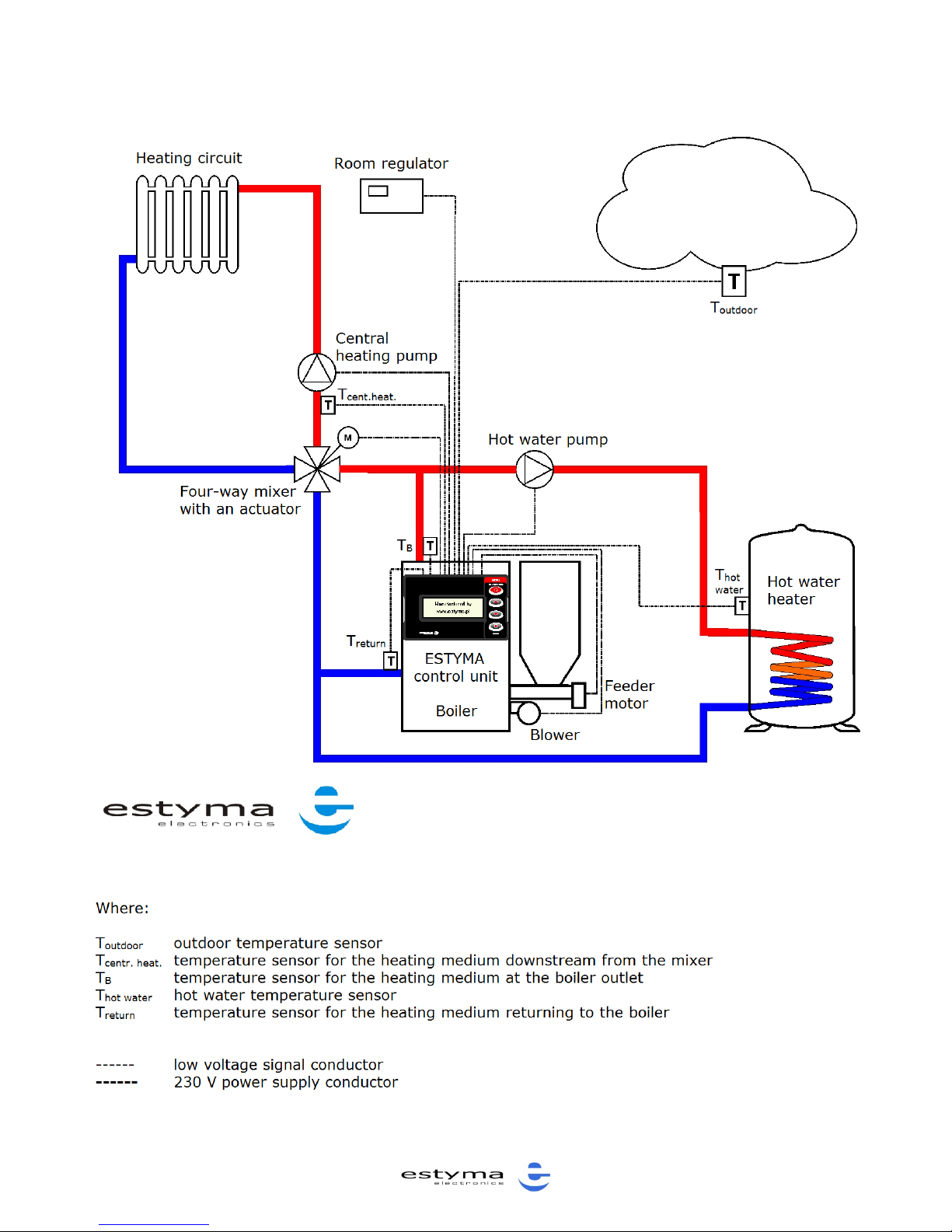

The boiler operation control unit ESTYMA control M RS is a modern

microprocessor system which controls not only the boiler, but also the central

heating system in weather-compensated and hot tap water modes.

The unit controls the amount of the fuel fed through on and off operation of the

motor of the fuel feeder, and the amount of the air supplied to the combustion

process. Thanks to solid state relays (SSRs), the blower has variable speed

control and the reliability of the unit controlling the feeder motor has been

greatly increased.

Automatic fuel ignition. The M RS ESTYMA control unit provides automatic

fuel ignition in the retort.

Measurement of waste gas temperature. The control unit measures waste

gas temperature which is an essential parameter in a boiler with automatic start

up. Waste gas temperature readouts are also very useful when inspecting the

boiler and adjusting its operation.

Weather-compensated control ensures highest thermal comfort because the

temperature of the heating medium is controlled depending on the outdoor

temperature. Control is effected through the mixing valve actuator.

Operation manual for M RS 420 ESTYMA control unit

4

Thanks to an advanced operation algorithm and the possibility of controlling

numerous parameters, the unit can be very flexibly adjusted to the needs of

the heating system.

The controller has an output testing function. The function is available in the

MAINTENANCE MODE and it allows to check the correctness of electrical

connections and the working order of the controlled equipment (pumps, blower,

feeder, mixing valve actuator) prior to starting the boiler.

A large alphanumeric display facilitates communication between the unit and

the user and the interface is very easy to use.

A new intuitive menu in several languages: Polish, English, German, French,

Lithuanian, Russian.

A Lambda sensor ensures optimum supply of air to the combustion process,

thereby simplifying the work of the operator; it also reduces fuel consumption

and improves combustion, reducing emissions of harmful substances to the

environment (optional boiler equipment).

The pneumatic fuel feeding control system allows the boiler to operate for long

periods of time without the need to add fuel.

The heat exchanger cleaning control system ensures that the boiler retains

high efficiency without the need to clean the exchanger.

USE

The figure below shows the operation flowchart of the M RS PID ESTYMA control

unit.

Operation manual for M RS 420 ESTYMA control unit

5

Operation manual for M RS 420 ESTYMA control unit

6

SAFETY PRECAUTIONS

Warning – risk of electric shock.

Before assembly or disassembly of the unit, disconnect the power supply in the

switchgear.

Read this operation manual carefully and thoroughly before using the unit.

Keep this operation manual and refer to it whenever you work with this unit in the

future.

Apply all the rules and heed all the warnings included in the unit operation manual.

Make sure that the unit is not damaged. In case of any doubts, do not use the unit and

contact the supplier.

In case of any doubts concerning the safe operation of the unit, contact the supplier.

Pay special attention to all warning signs on the unit casing and its package.

Use the unit as intended.

The unit is not a toy. Do not allow children to play with it.

Under no circumstances children should be allowed to play with any parts of the

package of the unit.

Access to small parts such as clamping screws or bolts should be secured against

children. Such elements may be delivered with the unit and may result in choking when

swallowed by a child.

Do not make any mechanical or electrical changes to the unit. Such changes may cause

the unit to malfunction and fail to meet the relevant standards, leading to an adverse

impact on the performance of the unit.

Do not insert any objects into the unit through openings (e.g. ventilation grills), as this

may cause short circuiting, electric shock, fire or damage to the unit.

Do not allow water, humidity or dust to enter the unit, as this may cause short

circuiting, electric shock, fire or damage to the unit.

Provide adequate ventilation of the unit, do not cover or block the ventilation grills, and

ensure that there is free flow of air around the unit.

The unit should be installed indoors unless it is adapted for outdoor operation.

Do not expose the unit to mechanical impacts and vibrations.

When connecting the unit to power supply, make sure that the parameters of the

supply network are within the unit’s operating range.

In order to avoid the risk of electric shock, connect the unit to a socket with an

earthing pin. The socket must be properly earthed by a licensed electrician.

When connecting the unit, make sure that it does not overload the electrical circuit.

Avoid connecting the unit to one circuit with motors and other equipment that causes

impulse interference (e.g. washing machines, fridges, ...)

It is absolutely necessary to cut off power supply before connecting any cables or

peripherals to the unit.

Remove the plug from the socket in order to completely de-energize the unit, especially

if you do not intend to use the unit for a longer period of time.

Protect the power lead against damage; it should be laid in a way that ensures that

nobody treads on it; no objects should stand on the power lead.

All electrical connections must be as shown in the electrical assembly drawings and

must comply with national and/or local regulations concerning electrical connections.

Operation manual for M RS 420 ESTYMA control unit

7

This unit contains no parts that may be replaced by the user. All maintenance work

except for cleaning, fuse replacement (when the unit is de-energized), and function

setting, should be performed by an authorized service provider.

Before doing any maintenance work, you must cut off the power supply to the unit.

Do not clean the casing of the unit with petrol, solvents or any other chemicals that

may damage the casing of the unit. Using a soft cloth is recommended.

If the power lead is damaged, the unit must not be used. The damaged lead must be

replaced by a maintenance service provider, with a new one having the same

parameters as the original lead.

DISPOSAL OF OLD EQUIPMENT

This electronic equipment is made of materials which are partly

recyclable. Therefore, when the equipment has reached the end of

its service life, take it to an electrical and electronic equipment

recycling centre or to the manufacturer. The equipment must not

be disposed of with other household waste.

APPLICABILITY OF THE MANUAL

This instruction manual is applicable to M RS ESTYMA control units with software

versions up to 9.1. The software version is displayed in the welcome message

after connecting the unit to the power supply. Description of changes in higher

versions is available on the manufacturer’s website at: www.estyma.pl

Operation manual for M RS 420 ESTYMA control unit

8

WIRING SYSTEM

GENERAL REQUIREMENTS

Read this operation manual carefully and thoroughly before you start

using the unit.

The person installing the unit should have sufficient technical experience.

Copper wire connections should be designed to work in temperatures of

up to +75ºC .

All connections made must be as shown in the electrical wiring assembly

drawings and must be compliant with national and/or local regulations

concerning electrical connections.

LOCATION

The unit is intended for indoor installation only. After selecting the location, make

sure that it meets the following requirements:

The location must be free from excessive humidity and from flammable or

corrosive vapours.

The unit must not be installed near high power electrical equipment,

electrical machines or welding equipment.

The temperature in the location must not exceed 60ºC and should not be

lower than 0ºC. Humidity should be within the range from 5% to 95%,

with no vapour condensation taking place.

WARNING !!! The connections should be made while the unit is cut off from the

power supply (de-energized). The connections should be made by a licensed

professional.

Loading...

Loading...