Estun pronet series User Manual

ProNet Series AC Servo User's Manual

(Version :V2.10)

Copyright © 2011 ESTUN AUTOMATION TECHNOLOGY CO., LTD

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any form, or

by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior written permission of ESTUN.

No patent liability is assumed with respect to the use of the information contained herein.

ProNet Series AC Servo User's Manual

- 1 -

About this manual

This manual describes the following information required for designing and maintaining ProNet series servo drives.

•Specification of the servo drives and servomotors.

•Procedures for installing the servo drives and servomotors.

•Procedures for wiring the servo drives and servomotors.

•Procedures for operating of the servo drives.

•Procedures for using the panel operator.

•Communication protocols.

•Ratings and characteristics.

Intended Audience:

•Those designing ProNet series servo drive systems.

•Those installing or wiring ProNet series servo drives.

•Those performing trial operation or adjustments of ProNet series servo drives.

•Those maintaining or inspecting ProNet series servo drives.

ProNet Series AC Servo User's Manual

- 2 -

Safety Precautions

■ Do not connect the servomotor directly to the local electrical network.

Failure to observe this may result in damage to servomotor.

■ Do not plug or unplug connectors from servo drive when power is on.

Failure to observe this may result in damage to servo drive and servomotor.

■Please note that even after power is removed, residual voltage still remains in the capacitor inside the servo drive. If

inspection is to be performed after power is removed, please wait 5 minutes to avoid risk of electrical shock.

■ Keep servo drives and other devices separated by at least 10mm.

The servo drive generates heat. Install the servo drive so that it can radiate heat freely. When installing servo drives

with other devices in a control panel, provide at least 10mm space between them and 50mm space above and below

them. Please install servo drives in an environment free from condensation, vibration and shock.

■ Perform noise reduction and grounding properly.

Please comply with the following instructions to avoid noise generated by signal lines.

1. Separate high-voltage cables from low-voltage cables.

2. Use cables as short as possible.

3. Single point grounding is required for the servomotor and servo drive (grounding resistance 100Ω or below).

4. Never use a line filter for the power supply in the circuit.

■ Conduct a voltage resistance test for the servo drive under the following conditions:

1. Input voltage: AC 1500Vrms, 1 minute

2. Braking current: 100mA

3. Frequency:50/60Hz

4. Voltage applied point: Between L1, L2,L3 terminals and frame ground.

■ Use a fast-response type ground-fault interrupter.

For a ground-fault interrupter, always use a fast-response type or one designed for PWM inverters. Do not use a

time-delay type.

■ Do not make any extreme adjustments or setting changes of parameters.

Failure to observe this caution may result in injury or damage to the product due to unstable operation.

■ The servomotor cannot be operated by turning the power on and off.

Frequently turning the power ON and OFF causes the internal circuit elements to deteriorate, resulting in unexpected

problems. Always start or stop the servomotor by using reference pulses.

ProNet Series AC Servo User's Manual

- 3 -

—Contents—

About this manual ........................................................................................................................................................... - 1 -

Safety Precautions .......................................................................................................................................................... - 2 -

Chapter 1 ........................................................................................................................................................................ - 7 -

Checking Products and Parts Names .............................................................................................................................. - 7 -

1.1 Checking Products on Delivery ......................................................................................................................... - 7 -

1.1.1 Servomotor ............................................................................................................................................ - 7 -

1.1.2 Servo drive ............................................................................................................................................ - 8 -

1.2 Part Names ..................................................................................................................................................... - 15 -

1.2.1 Servomotor .......................................................................................................................................... - 15 -

1.2.2 Servo drive .......................................................................................................................................... - 16 -

Chapter 2 ...................................................................................................................................................................... - 21 -

Installation ..................................................................................................................................................................... - 21 -

2.1 Servomotor ..................................................................................................................................................... - 21 -

2.1.1 Storage ................................................................................................................................................ - 21 -

2.1.2 Installation Sites .................................................................................................................................. - 21 -

2.1.3 Installation Alignment ........................................................................................................................... - 22 -

2.1.4 Installation Orientation ......................................................................................................................... - 22 -

2.1.5 Handling Oil and Water ........................................................................................................................ - 22 -

2.1.6 Cable Tension ...................................................................................................................................... - 23 -

2.1.7 Install to the Client ............................................................................................................................... - 23 -

2.2 Servo Drive ..................................................................................................................................................... - 23 -

2.2.1 Storage ................................................................................................................................................ - 23 -

2.2.2 Installation Sites .................................................................................................................................. - 23 -

2.2.3 Installation Orientation ......................................................................................................................... - 24 -

2.2.4 Installation Method .............................................................................................................................. - 24 -

Chapter 3 ...................................................................................................................................................................... - 26 -

Wiring ............................................................................................................................................................................ - 26 -

3.1 Main Circuit Wiring .......................................................................................................................................... - 26 -

3.1.1 Names and Functions of Main Circuit Terminals .................................................................................. - 26 -

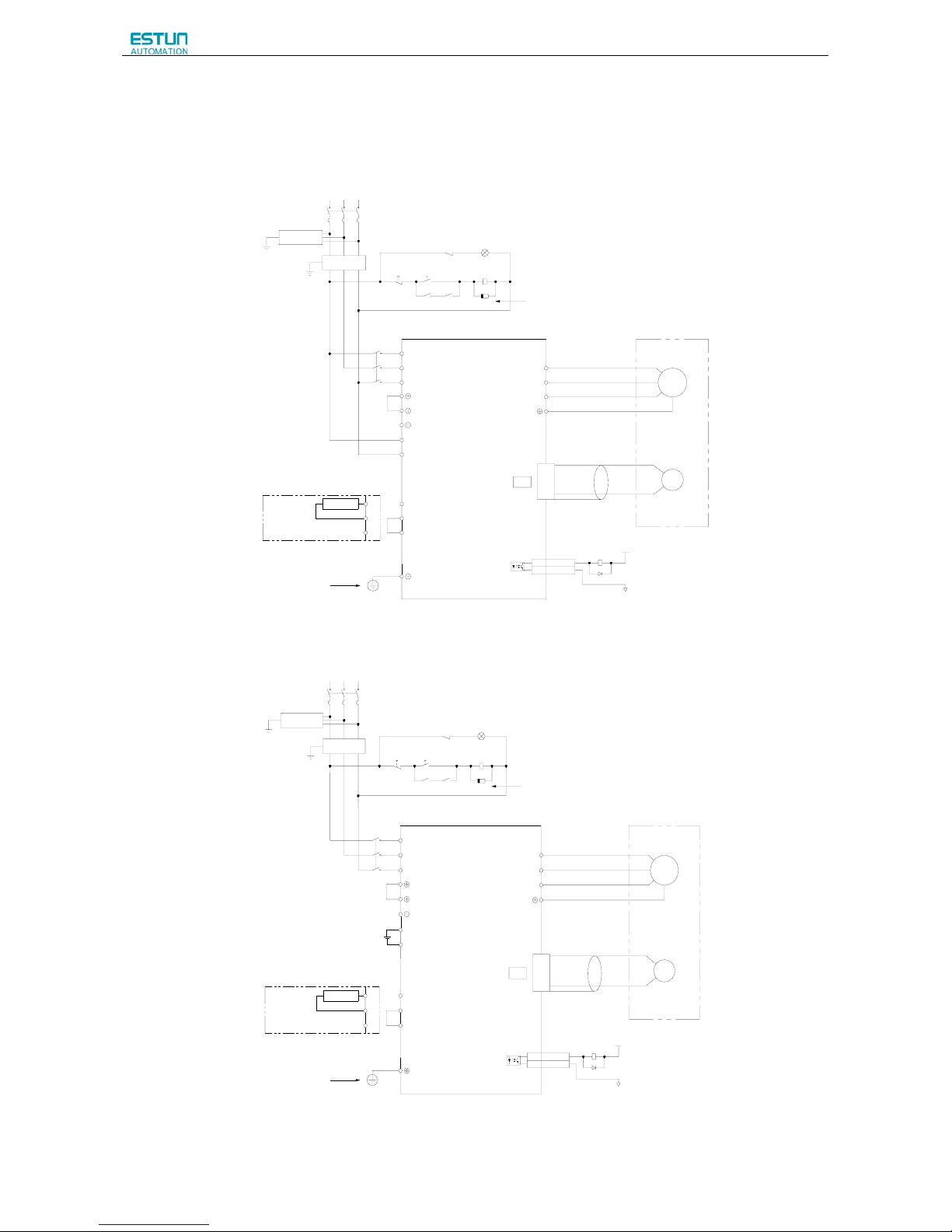

3.1.2 Typical Main Circuit Wiring Examples .................................................................................................. - 27 -

3.2 I/O Signals ...................................................................................................................................................... - 31 -

3.2.1 Examples of I/O Signal Connections ................................................................................................... - 31 -

3.2.2 I/O Signal Names and Functions ......................................................................................................... - 32 -

3.2.3 I/O Signal Connector (CN1) Terminal Layout ...................................................................................... - 34 -

3.2.4 Interface Circuit ................................................................................................................................... - 35 -

3.3 Wiring Encoders .............................................................................................................................................. - 36 -

3.3.1 Connecting an Encoder(CN2) .............................................................................................................. - 36 -

3.3.2 Encoder Connector(CN2) Terminal Layout ......................................................................................... - 38 -

3.4 Communication Connection ............................................................................................................................ - 38 -

3.4.1 Communication Connector(CN3) Terminal Layout .............................................................................. - 38 -

3.4.2 Communication Connector(CN4) Terminal Layout .............................................................................. - 39 -

3.5 Standard Wiring Examples .............................................................................................................................. - 40 -

3.5.1 Single-phase 200V ProNet-02A~04A/ProNet-E-02A~04A ............................................................... - 40 -

ProNet Series AC Servo User's Manual

- 4 -

3.5.2 Three-phase 200V ProNet-08A~50A/ProNet-E-08A~50A ................................................................ - 41 -

3.5.3 Three-phase 400V ProNet-10D~75D/ProNet-E-10D~50D ............................................................... - 42 -

3.5.4 Three-phase 400V ProNet-1AD~2BD ................................................................................................ - 43 -

3.5.5 Single-phase 100V ProNet-02B/ProNet-E-02B ................................................................................... - 44 -

3.5.6 Single-phase 100V ProNet-04B /ProNet-E-04B .................................................................................. - 45 -

3.5.7 Three-phase 100V ProNet-08B/ ProNet-E-08B ................................................................................... - 46 -

3.5.8 Position Control Mode ......................................................................................................................... - 47 -

3.5.9 Speed Control Mode ............................................................................................................................ - 48 -

3.5.10 Torque Control Mode ......................................................................................................................... - 49 -

3.6 Wiring for Noise Control .................................................................................................................................. - 50 -

3.6.1 Noise Control ....................................................................................................................................... - 50 -

3.6.2 Precautions on Connecting Noise Filter .............................................................................................. - 51 -

3.7 Installation Conditions of EMC Directives ....................................................................................................... - 53 -

3.8 Using More than One Servo Drive .................................................................................................................. - 55 -

3.9 Connecting DC Bus ........................................................................................................................................ - 57 -

Chapter 4 ...................................................................................................................................................................... - 58 -

Operation ...................................................................................................................................................................... - 58 -

4.1 Trial Operation ................................................................................................................................................ - 58 -

4.1.1 Trial Operation for Servomotor Without Load ...................................................................................... - 61 -

4.1.2 Trial Operation for Servomotor without Load from Host Reference ..................................................... - 63 -

4.1.3 Trial Operation with the Servomotor Connected to the Machine .......................................................... - 67 -

4.1.4 Trial Operation for Servomotor with Brakes ......................................................................................... - 68 -

4.1.5 Position Control by Host Controller ...................................................................................................... - 68 -

4.2 Control Mode Selection ................................................................................................................................... - 68 -

4.3 Setting Common Basic Functions ................................................................................................................... - 70 -

4.3.1 Setting the Servo ON Signal ................................................................................................................ - 70 -

4.3.2 Switching the Servomotor Rotation Direction ...................................................................................... - 71 -

4.3.3 Setting the Overtravel Limit Function ................................................................................................... - 72 -

4.3.4 Setting for Holding Brakes ................................................................................................................... - 75 -

4.3.5 Instantaneous Power Loss Settings..................................................................................................... - 78 -

4.4 Absolute Encoders .......................................................................................................................................... - 79 -

4.4.1 Selecting an Absolute Encoder ............................................................................................................ - 79 -

4.4.2 Handling Battery .................................................................................................................................. - 80 -

4.4.3 Replacing Battery ................................................................................................................................ - 81 -

4.4.4 Absolute Encoder Setup(Fn010、Fn011) ............................................................................................ - 81 -

4.5 Operating Using Speed Control with Analog Reference.................................................................................. - 82 -

4.5.1 Setting Parameters .............................................................................................................................. - 82 -

4.5.2 Setting Input Signals ............................................................................................................................ - 83 -

4.5.3 Adjusting Reference Offset .................................................................................................................. - 84 -

4.5.4 Soft Start .............................................................................................................................................. - 87 -

4.5.5 Speed Reference Filter Time Constant ................................................................................................ - 87 -

4.5.6 S-curve Risetime ................................................................................................................................. - 88 -

4.5.7 Using the Zero Clamp Function ........................................................................................................... - 88 -

4.5.8 Encoder Signal Output ........................................................................................................................ - 90 -

4.5.9 Speed coincidence output ................................................................................................................... - 91 -

4.6 Operating Using Position Control .................................................................................................................... - 92 -

ProNet Series AC Servo User's Manual

- 5 -

4.6.1 Basic Setting in Position Control .......................................................................................................... - 92 -

4.6.2 Setting the Clear Signal ....................................................................................................................... - 96 -

4.6.3 Setting the Electronic Gear .................................................................................................................. - 96 -

4.6.4 Smoothing ........................................................................................................................................... - 99 -

4.6.5 Low Frequency Vibration Suppression .............................................................................................. - 100 -

4.6.6 Positioning Completion Output Signal ............................................................................................... - 102 -

4.6.7 Reference Pulse Inhibit Function (INHIBIT) ....................................................................................... - 103 -

4.6.8 Position Control (contact reference) ................................................................................................. - 104 -

4.6.9 Position Homing Control (Homing Function)...................................................................................... - 107 -

4.7 Operating Using Torque Control .................................................................................................................... - 110 -

4.7.1 Setting Parameters ............................................................................................................................ - 110 -

4.7.2 Torque Reference Input ..................................................................................................................... - 111 -

4.7.3 Adjusting the Reference Offset .......................................................................................................... - 112 -

4.7.4 Limiting Servomotor Speed During Torque Control ............................................................................ - 113 -

4.8 Operating Using Speed Control with an Internally Set Speed ....................................................................... - 114 -

4.8.1 Setting Parameters ............................................................................................................................ - 115 -

4.8.2 Input Signal Settings .......................................................................................................................... - 116 -

4.8.3 Operating Using an Internally Set Speed ........................................................................................... - 116 -

4.9 Limiting Torque .............................................................................................................................................. - 117 -

4.9.1 Internal Torque Limit .......................................................................................................................... - 117 -

4.9.2 External Torque Limit ......................................................................................................................... - 118 -

4.9.3 Torque Limiting Using an Analog Voltage Reference ........................................................................ - 119 -

4.10 Control Mode Selection ............................................................................................................................... - 120 -

4.10.1 Setting Parameters .......................................................................................................................... - 120 -

4.10.2 Switching the Control Mode ............................................................................................................. - 120 -

4.11 Other Output Signals ................................................................................................................................... - 121 -

4.11.1 Servo alarm output........................................................................................................................... - 121 -

4.11.2 Rotation Detection Output Signal (/TGON) ...................................................................................... - 122 -

4.11.3 Servo Ready (/S-RDY) Output ......................................................................................................... - 122 -

4.11.4 Encoder C Pluse Output (/PGC) ...................................................................................................... - 122 -

4.11.5 Over travel signal output (OT) .......................................................................................................... - 123 -

4.11.6 Servo Enabled Motor Excitation Output(/RD) .................................................................................. - 123 -

4.11.7 Torque Limit Detection Output (/CLT) ............................................................................................... - 123 -

4.11.8 Torque Detection Output (/TCR) ...................................................................................................... - 125 -

4.12 Online Autotuning ........................................................................................................................................ - 125 -

4.12.1 Online Autotuning ............................................................................................................................ - 125 -

4.12.2 Online Autotuning Procedure ........................................................................................................... - 126 -

4.12.3 Setting Online Autotuning ................................................................................................................ - 127 -

4.12.4 Machine Rigidity Setting for Online Autotuning ................................................................................ - 127 -

Chapter 5 .................................................................................................................................................................... - 128 -

Panel Operator ............................................................................................................................................................ - 128 -

5.1 Basic Operation ............................................................................................................................................ - 128 -

5.1.1 Functions on Panel Operator ............................................................................................................. - 128 -

5.1.2 Resetting Servo Alarms ..................................................................................................................... - 128 -

5.1.3 Basic Mode Selection ........................................................................................................................ - 129 -

5.1.4 Status Display Mode .......................................................................................................................... - 129 -

ProNet Series AC Servo User's Manual

- 6 -

5.1.5 Operation in Parameter Setting Mode ............................................................................................... - 131 -

5.1.6 Operation in Monitor Mode ................................................................................................................ - 132 -

5.2 Operation in Utility Function Mode ................................................................................................................ - 135 -

5.2.1 Alarm Traceback Data Display ........................................................................................................... - 135 -

5.2.2 Parameter Settings Initialization ........................................................................................................ - 136 -

5.2.3 Operation in JOG Mode ..................................................................................................................... - 137 -

5.2.4 Automatic Adjustment of the Speed Reference Offset ....................................................................... - 138 -

5.2.5 Manual Adjustment of the Speed Reference Offset ........................................................................... - 139 -

5.2.6 Offset-adjustment of Servomotor Current Detection Signal ............................................................... - 140 -

5.2.7 Software Version Display ................................................................................................................... - 142 -

5.2.8 Position Teaching Function ................................................................................................................ - 142 -

5.2.9 Static Inertia Detection ....................................................................................................................... - 142 -

5.2.10 Absolute Encoder Multiturn Data and Alarm Reset .......................................................................... - 143 -

5.2.11 Absolute Encoder Related Alarms Reset ......................................................................................... - 143 -

Chapter 6 .................................................................................................................................................................... - 144 -

MODBUS Communication ........................................................................................................................................... - 144 -

6.1 RS-485 Communication Wiring ..................................................................................................................... - 144 -

6.2 MODBUS Communication Related Parameters ........................................................................................... - 145 -

6.3 MODBUS Communication Protocol .............................................................................................................. - 146 -

6.3.1 Code Meaning ................................................................................................................................... - 146 -

6.3.2 Communication Error Disposal .......................................................................................................... - 152 -

6.3.3 Data Communication Address of Servo State .................................................................................... - 153 -

Chapter 7 .................................................................................................................................................................... - 156 -

Specifications and Characters ..................................................................................................................................... - 156 -

7.1 Servo drive Specifications and Models ......................................................................................................... - 156 -

7.2 Servo drive Dimensional Drawings ............................................................................................................... - 159 -

Appendix A .................................................................................................................................................................. - 162 -

Parameter ................................................................................................................................................................... - 162 -

A.1 Parameter List .............................................................................................................................................. - 162 -

A.2 Description of Parameter Type ..................................................................................................................... - 169 -

A.3 Parameters in detail ...................................................................................................................................... - 170 -

Appendix B .................................................................................................................................................................. - 188 -

Alarm Display .............................................................................................................................................................. - 188 -

ProNet Series AC Servo User's Manual

- 7 -

Chapter 1

Checking Products and Parts Names

1.1 Checking Products on Delivery

If any of the above items are faulty or incorrect, contact your ESTUN representative or the dealer from whom you

purchased the products.

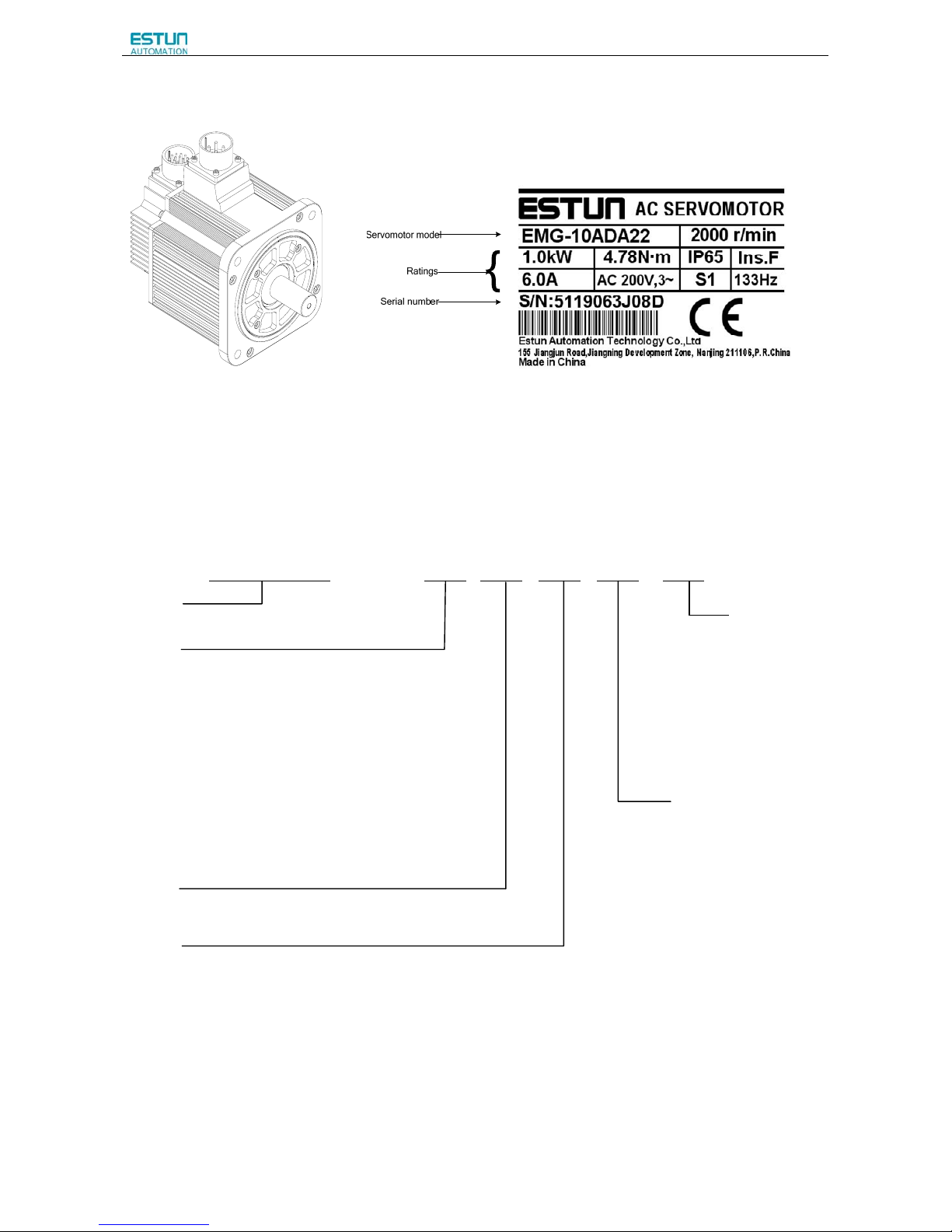

1.1.1 Servomotor

Servomotor Model Designation

EMG– 10 A D A 1 1

ESTUN Servomotor

【1+2】 【3】 【4】 【5】 【6】 【7】

EMG Model

【1+2】Rated Output

【4】Encoder

【7】Option

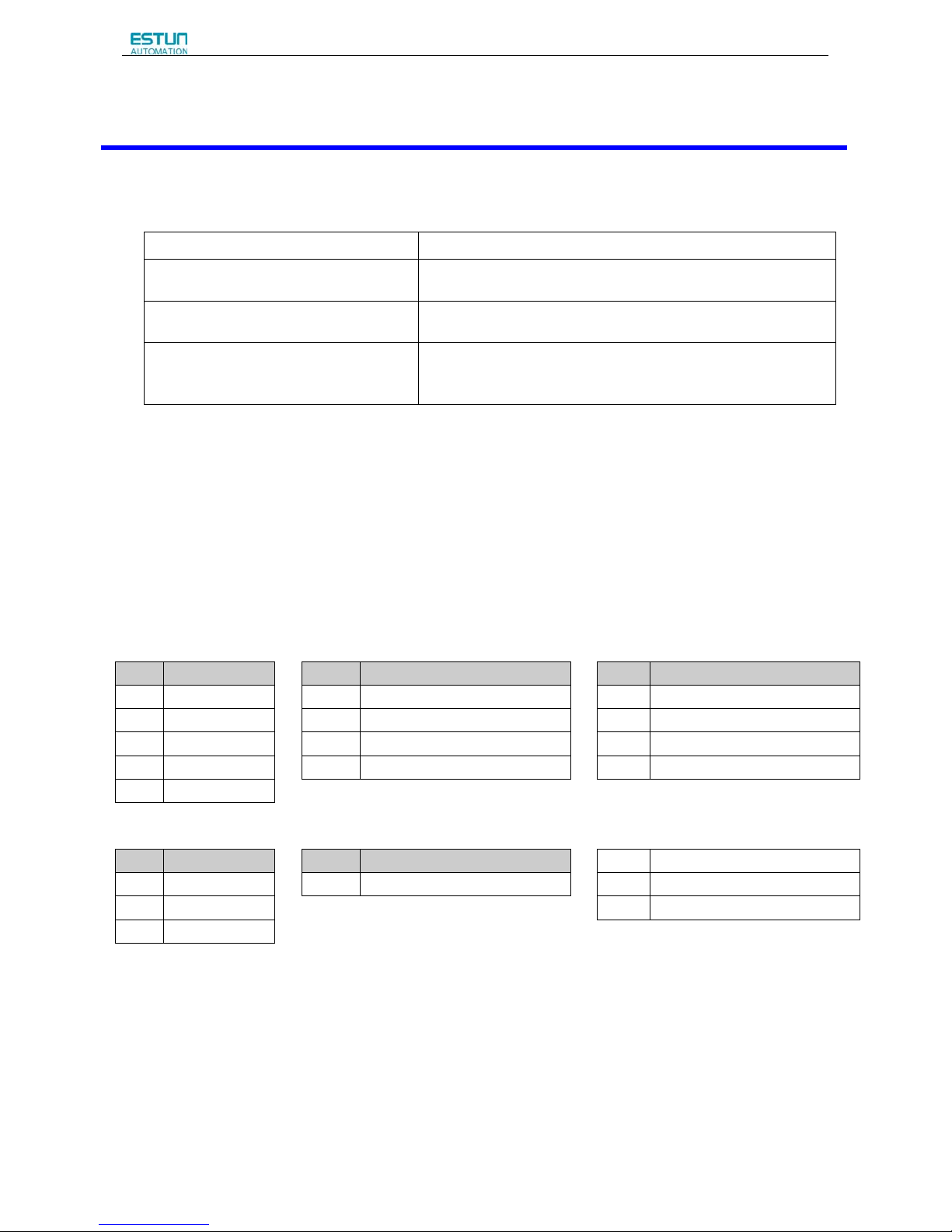

Code Rated Output Code Encoder Code Option

10 1.0kW D

Incremental encoder:131072P/R

1 None

15 1.5kW S

Absolute encoder:131072P/R

2 With oil seal

20 2.0kW R Resolver 3 With brake(DC 24V)

30 3.0kW P

Incremental Wire-saving Type:2500P/R

4 With oil seal and brake(DC 24V)

50 5.0kW

【3】Voltage

【5】Designing Sequence

【6】Shaft End

Code Voltage Code Designing Sequence Code Shaft End

A 200V AC A Designing sequence 1 Straight without key(Standard)

B 100VAC 2 Straight with key and tap

D 400VAC

Notes:

1. The EMG-30A□A□□, EMG-50A□A□□ servomotors are not mounted with an incremental encoder.

2. There is no brake mounted on the EMG-□□□DA□□ servomotor.

Check Items Comments

Are the delivered products the ones that

were ordered?

Check the model numbers marked on the nameplate on the

servomotor and servo drive.

Is there any damage?

Check the overall appearance, and check for damage or scratches

that may have occurred during shipping.

Does the servomotor shaft rotate smoothly?

If the servomotor shaft can be easily rotated by hand, then the motor

is working normally. However, if a brake is installed on the

servomotor, then it cannot be turned by hand.

ProNet Series AC Servo User's Manual

- 8 -

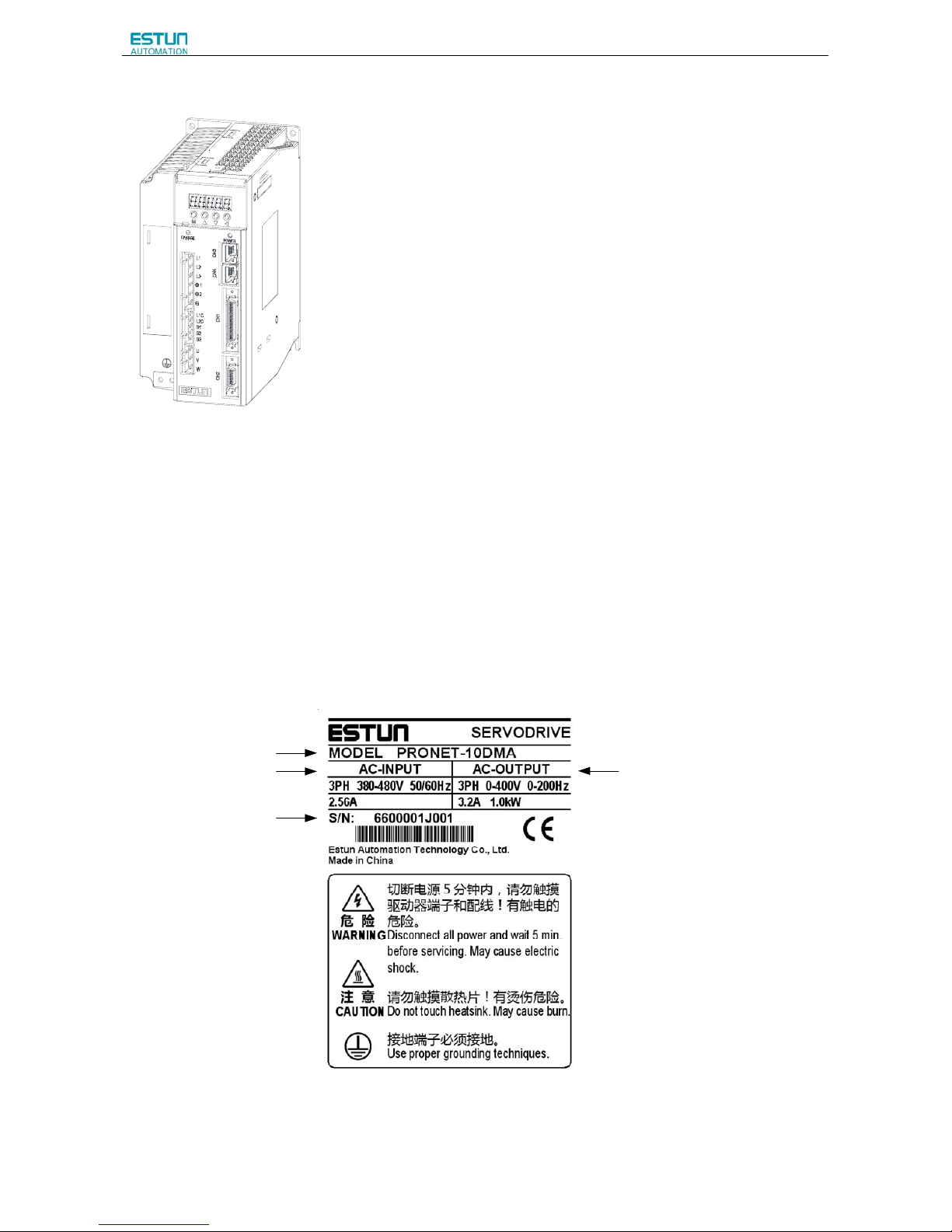

Appearance and Nameplate

1.1.2 Servo drive

ProNet Servo drive Model Designation

PRONET – 10 A E A -P

Note:

○

1

Resolver, with the feature of high reliability and long service life, is suitable for harsh environments and a wide range

of temperatures and humidity levels. The factory setting for the resolver precision used in the ESTUN servo drive is

4096.

○

2

ProNet-□□□E□ Supports AE100 model. ProNet-□□□M□ does not support extended module.

Rated Output

02 0.2kW

04 0.4 kW

08 0.75 kW

10 1.0 kW

15 1.5 kW

20 2.0 kW

30 3.0 kW

50 5.0 Kw

70 7.0kW

75 7.5 kW

1A 11 kW

1E 15 Kw

2B 22kW

Vol tag e

A 200VAC

B:100VAC

D 400VAC

Control Mode

M Speed control, torque control, position control

E Speed control, torque control, position control (support extended module)

Encoder Interface

A 17-bit serial encoder

Absolute Encoder

B Resolver

○

1

ProNet Model

Extended module type

-D DP100

-E EC100

-P PL100

ProNet Series AC Servo User's Manual

- 9 -

ProNet-E Servo drive Model Designation

PRONET–E – 10 A

Note:

○

1

ProNet-E is only available with the wire-saving incremental encoder (2500 P/R)

○2 ProNet-E does not support extended module.

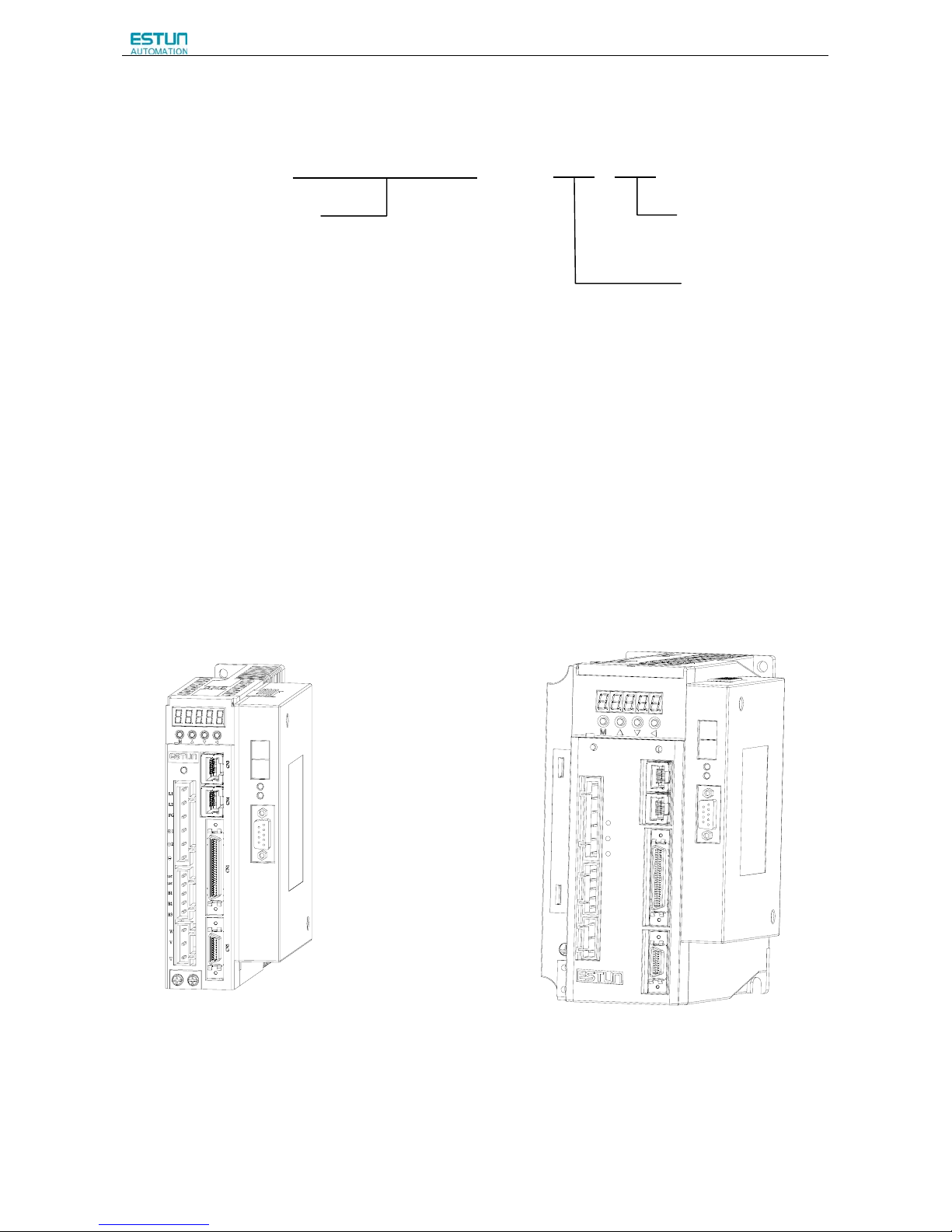

ProNet Servo Drive Appearance

ProNet-02A/04A ProNet-08A/10A

L1

L2

L3

CN3

CN4

CN1

CN2

L1C

L2C

B1

B2

B3

U

V

W

+

-

1

+2

CHARGE POWER

Rated Output

02 0.2kW

04 0.4 kW

08 0.75 kW

10 1.0 kW

15 1.5 kW

20 2.0 kW

30 3.0 kW

50 5.0 kW

Vol tag e

A:200VAC

B:100VAC

D

:400VAC

ProNet-E Model

ProNet Series AC Servo User's Manual

- 10 -

ProNet-15A/20A ProNet-10D/15D/20D

L1

L2

L3

CN3

CN4

CN1

CN2

L1C

L2C

B1

B2

B3

U

V

W

+

-

1

+

2

CHARGE POWER

L1

L2

L3

CN3

CN4

CN1

CN2

24V

B1

B2

B3

U

V

W

+

-

1

+

2

CHARGE

POWER

GND

ProNet-30A/50A ProNet-30D/50D/70D/75D

CN3

CN4

CN1

CN2

CHARGE

POWER

L1

L2

L3

L1C

L2C

B1

B2

B3

U

V

W

+

-

1

+

2

CN3

CN4

CN1

CN2

CHARGE

POWER

L1

L2

L3

24V

GND

B1

B2

B3

U

V

W

+

-

1

+

2

ProNet Series AC Servo User's Manual

- 11 -

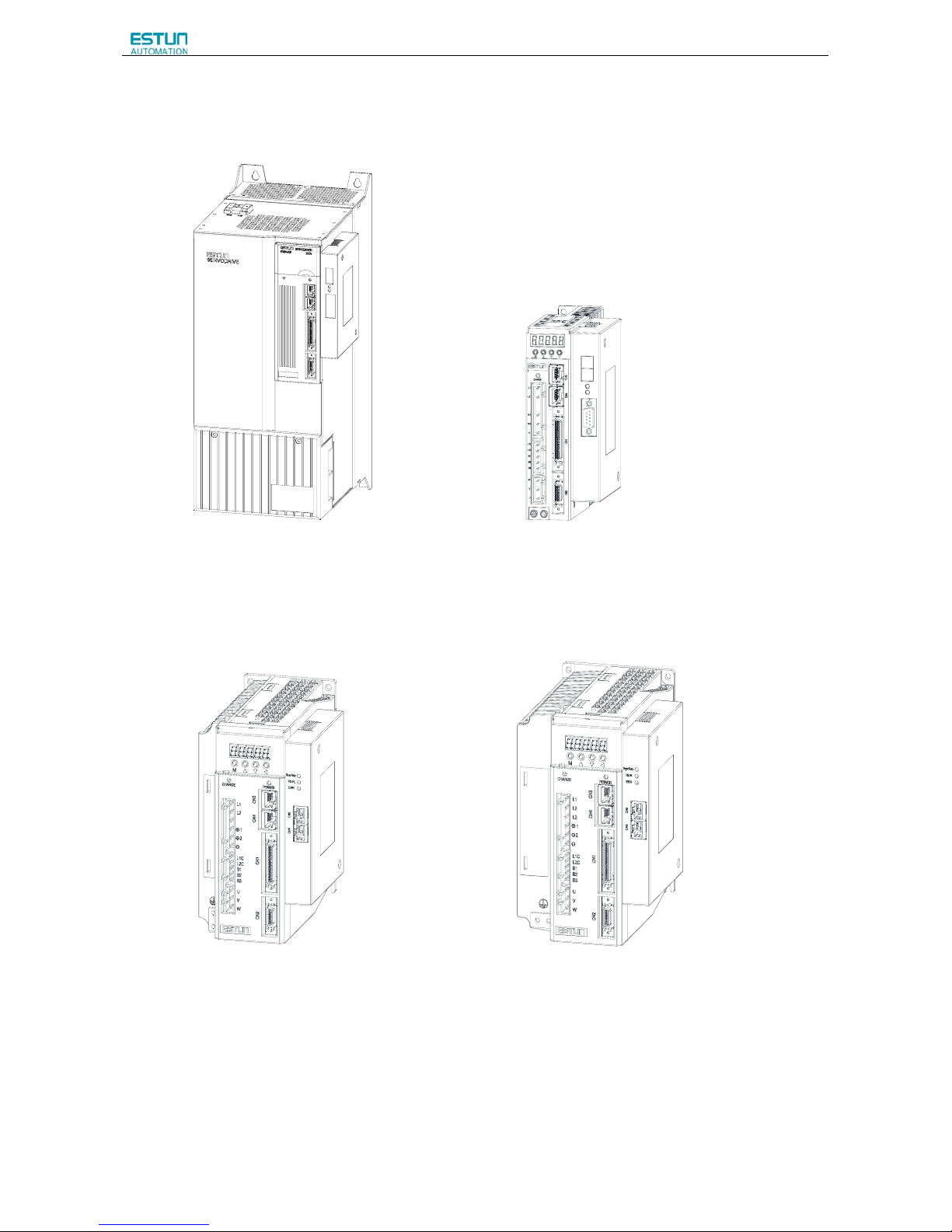

ProNet-1AD/1ED/2BD ProNet-02B

ProNet-04B ProNet-08B

ProNet Series AC Servo User's Manual

- 12 -

ProNet-E Servo Drive Appearance

ProNet-E-02A/04A ProNet-E-08A/10A

CN3CN4

CN1

CN2

L1

L2

FG

L1C

L2C

-

1

2

+

+

B1

B2

B3

W

V

U

CHARGE

L

1

L

2

L

3

C

N

3

C

N

4

C

N

1

C

N

2

L

1

C

L

2

C

B

1

B

2

B

3

U

V

W

+

-

1

+

2

C

H

A

R

G

E

P

O

W

E

R

ProNet-E-15A/20A ProNet-E-10D/15D/20D

L1

L2

L3

CN3

CN4

CN1

CN2

L1C

L2C

B1

B2

B3

U

V

W

+

-

1

+

2

CHARGE

POWER

L1

L2

L3

CN3

CN4

CN1

CN2

24V

GND

B1

B2

B3

U

V

W

+

-

1

+

2

CHARGE POWER

ProNet Series AC Servo User's Manual

- 13 -

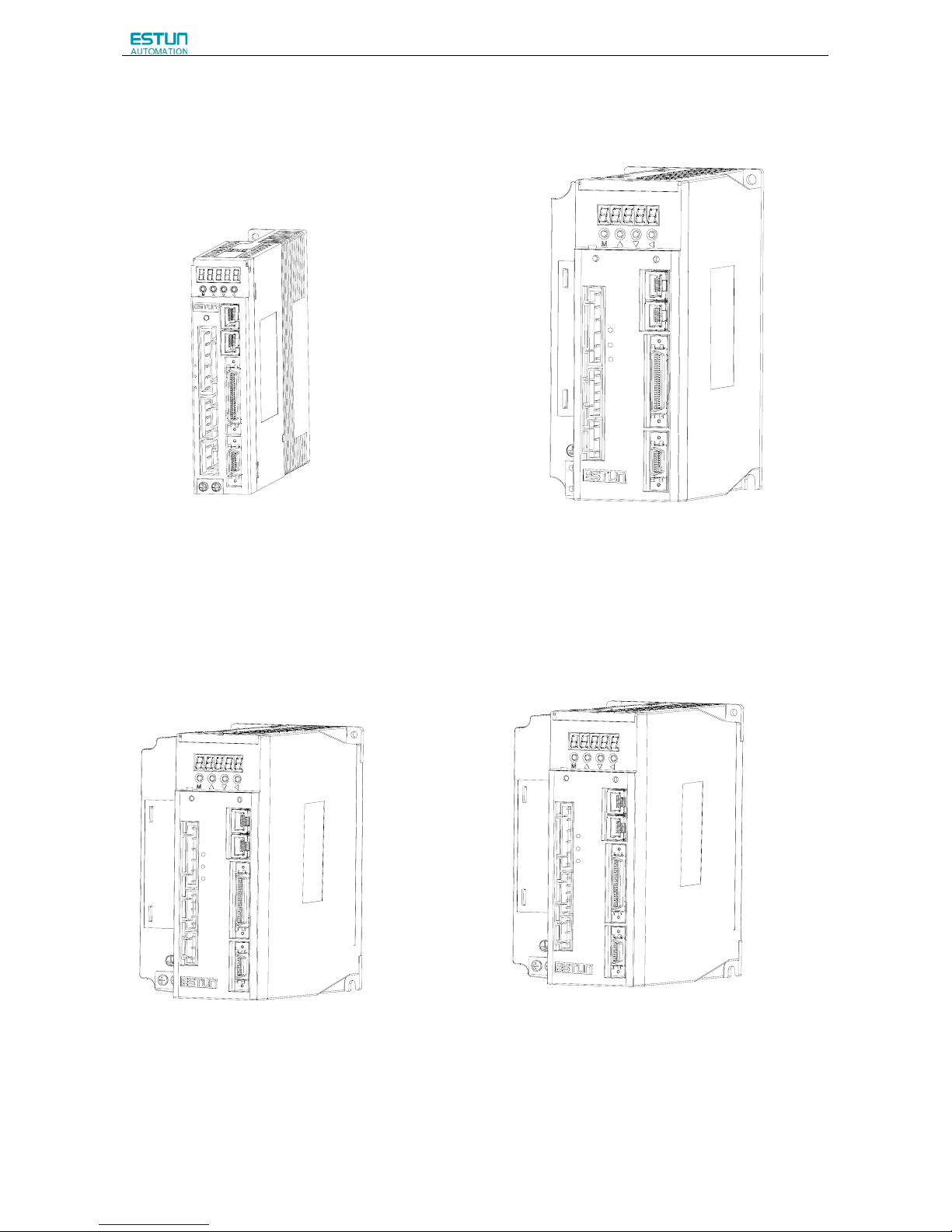

ProNet-E-30A/50A ProNet-E-30D/50D

CN3

CN4

CN1

CN2

CHARGE

POWER

L1

L2

L3

L1C

L2C

B1

B2

B3

U

V

W

+-1

+

2

CN3

CN4

CN1

CN2

CHARGE

POWER

L1

L2

L3

24V

GND

B1

B2

B3

U

V

W

+

-

1

+

2

ProNet-E-02B ProNet-E-04B

ProNet Series AC Servo User's Manual

- 14 -

ProNet-E-08B

ProNet Servo Drive Nameplate

Servodrive model

Applicable power

supply

Applicable servomotor

capacity

Serial number

ProNet Series AC Servo User's Manual

- 15 -

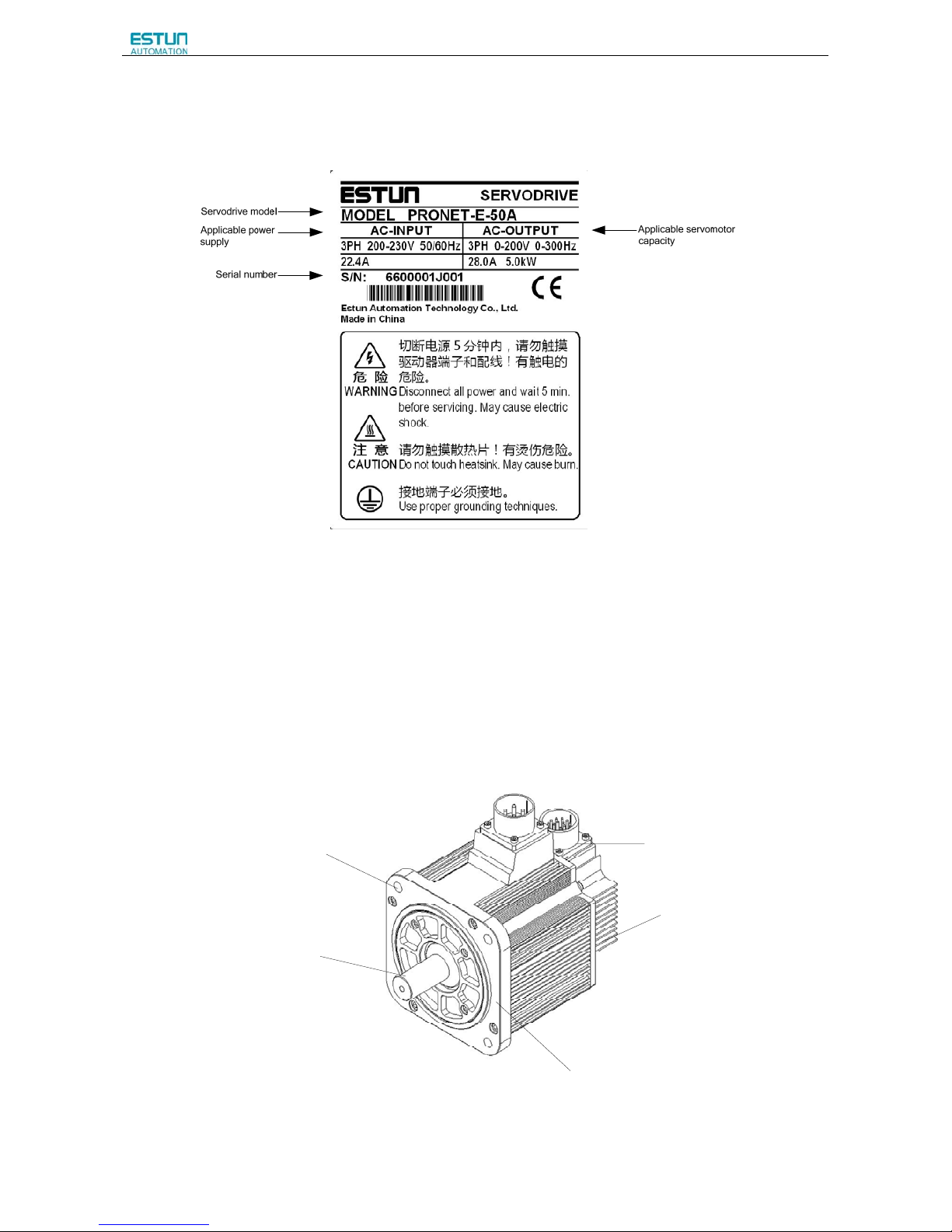

ProNet-E Servo Drive Nameplate

1.2 Part Names

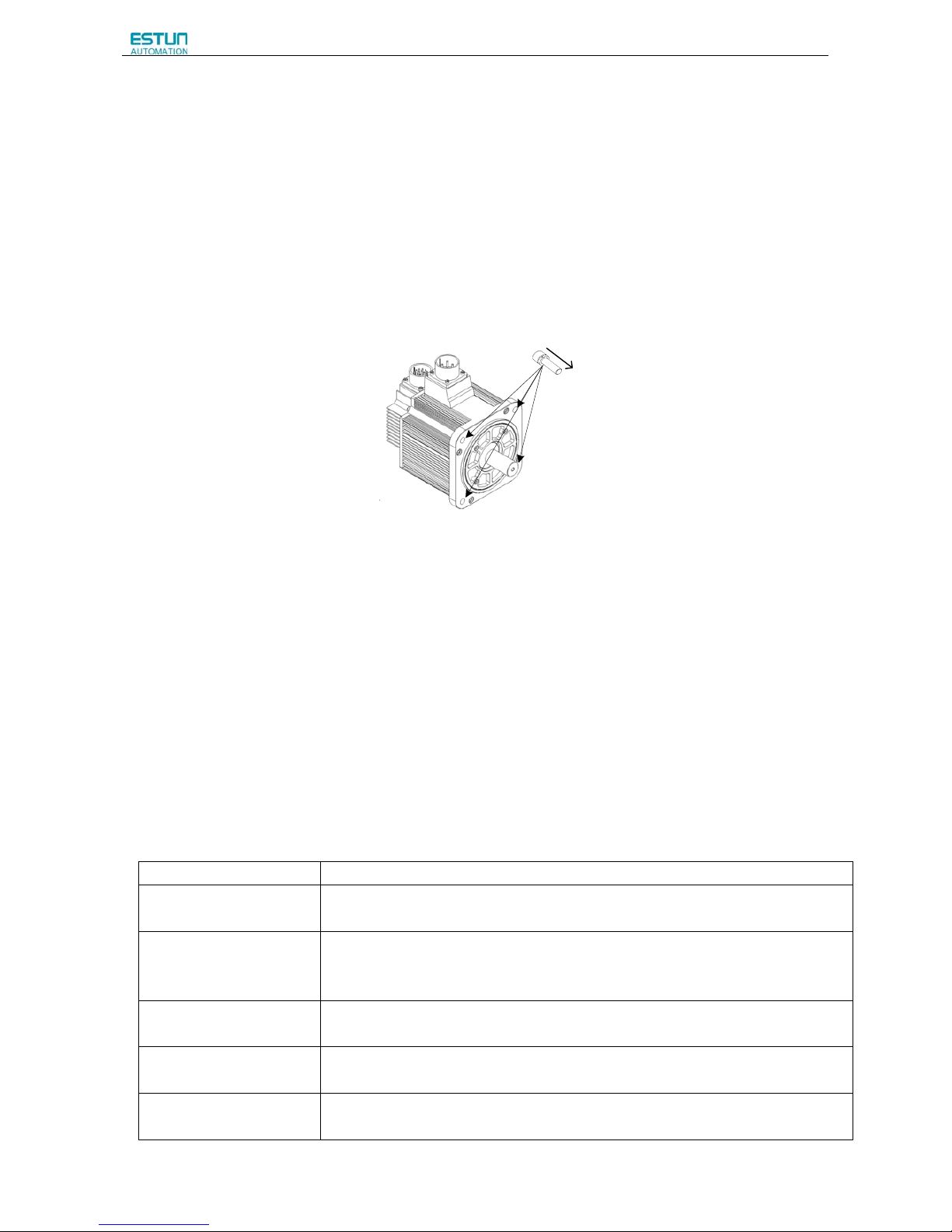

1.2.1 Servomotor

Servomotor without gear and brake.

Encoder

Shell

Flange

Output shaft

Mounting hole

ProNet Series AC Servo User's Manual

- 16 -

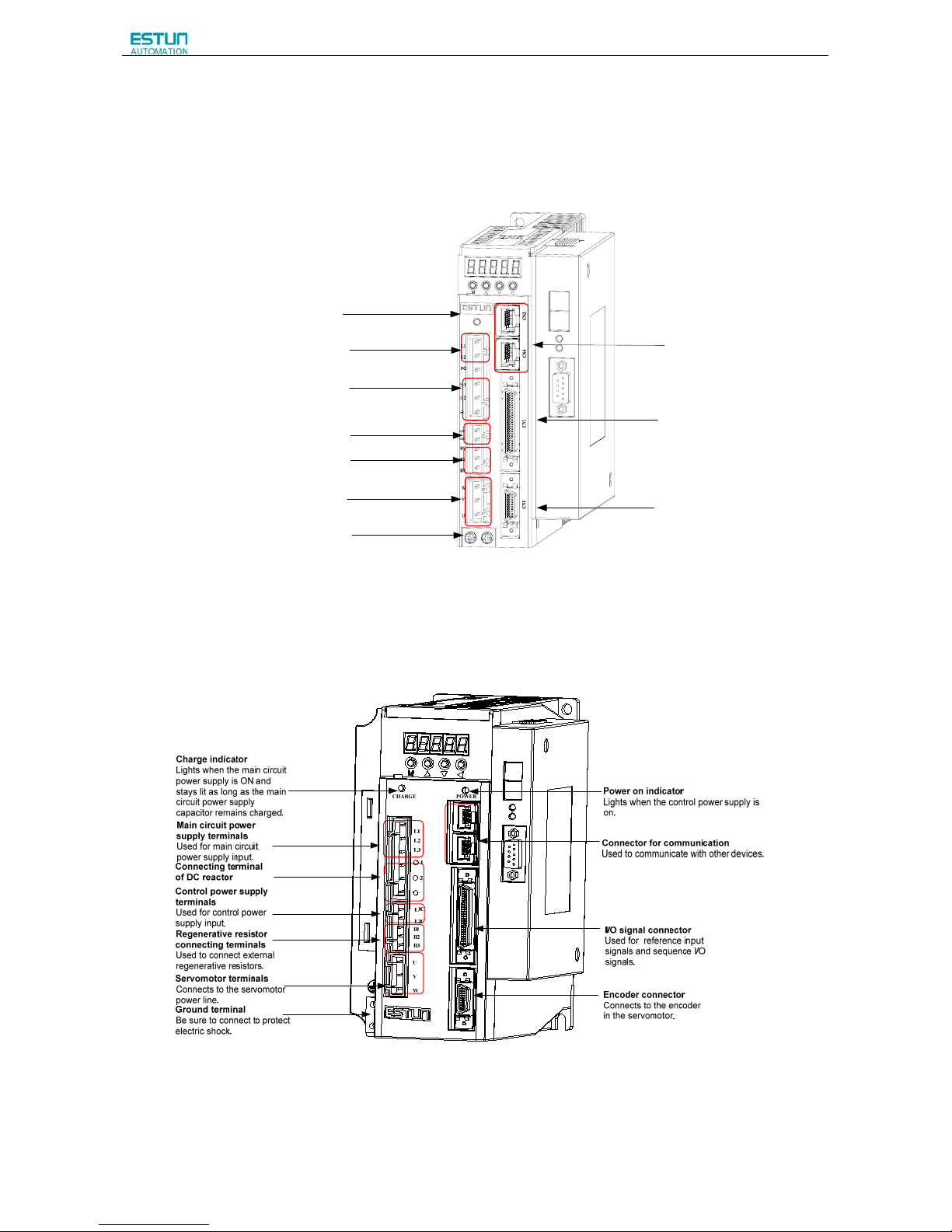

1.2.2 Servo drive

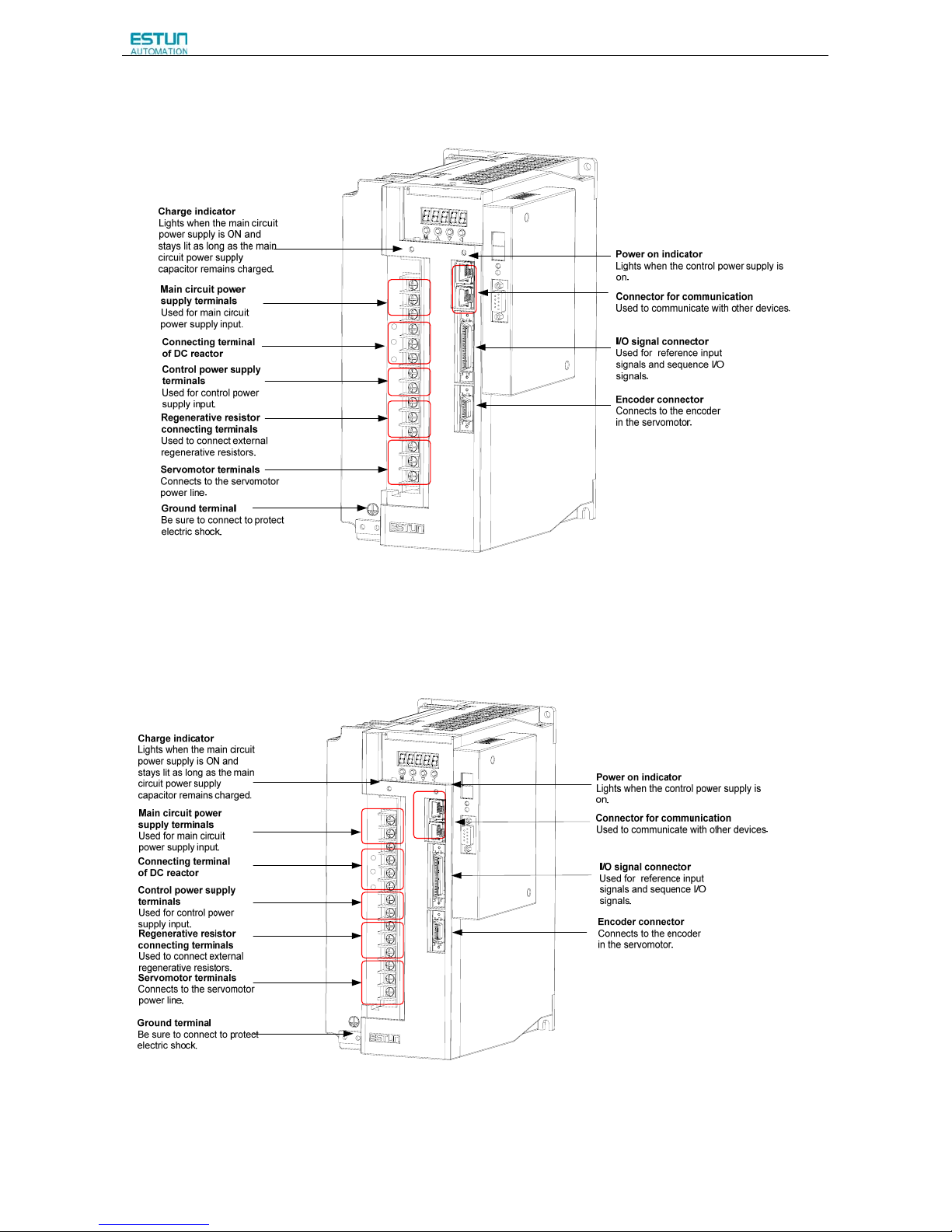

ProNet-02A/04A/ProNet-E-02A/04A

Charge indicator

Lights when the main circuit power supply is

ON and stays lit as long as the main circuit

power supply capacitor remains charged.

Ground terminal

Be sure to connect to protect electric shock.

Servomotor terminals

Connects to the servomotor power line.

Regenerative resistor connecting terminals

Used to connect external regenerative resistors.

Control power supply terminals

Used for control power supply input.

Connecting terminal of DC reactor

Main circuit power supply terminals

Used for main circuit power supply input.

Connector for communication

Used to communicate with other devices.

I/O signal connector

Used for reference input signals

and sequence I/O signals.

Encoder connector

Connects to the encoder in the

servomotor.

ProNet-08A/10A /ProNet-E-08A/10A

CN3

CN4

CN1

CN2

ProNet Series AC Servo User's Manual

- 17 -

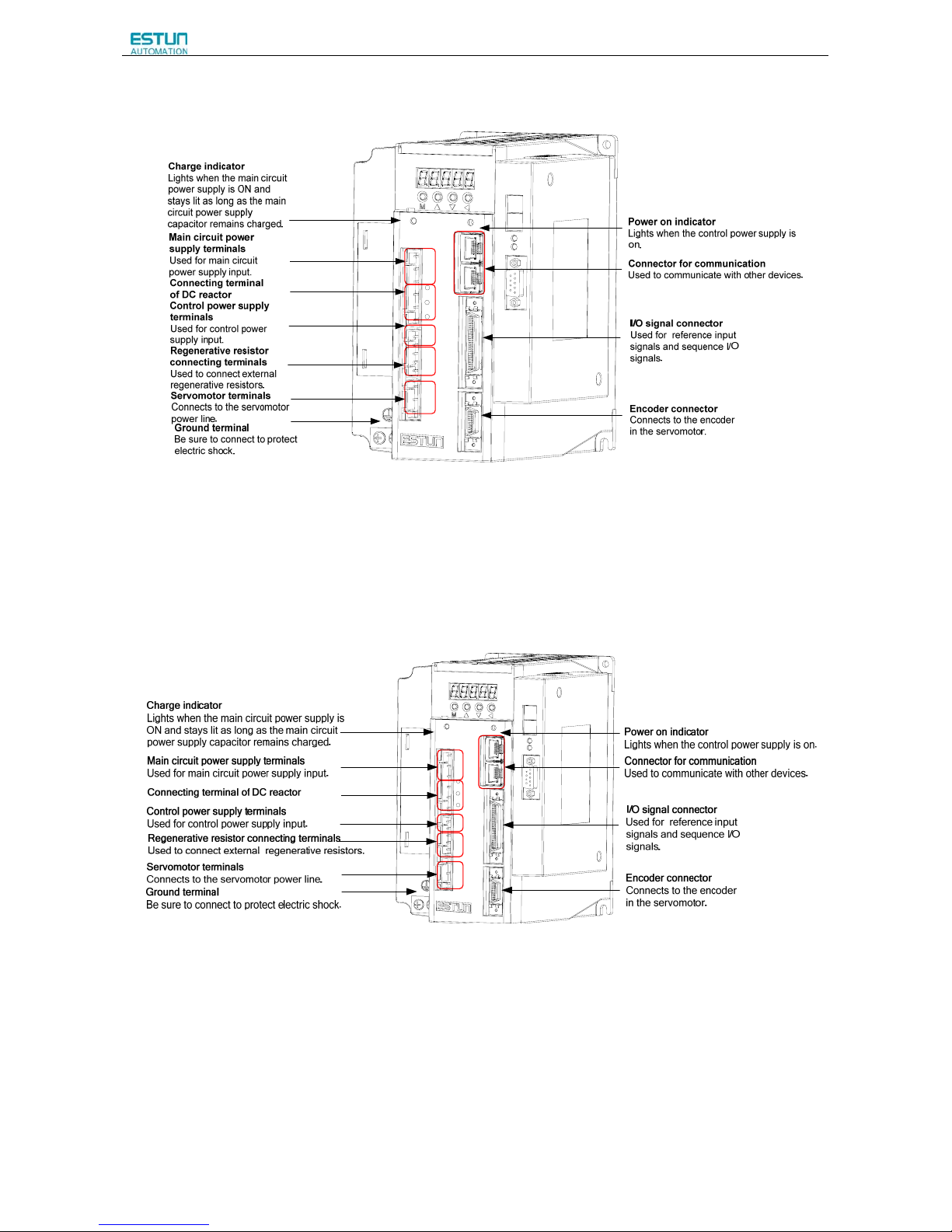

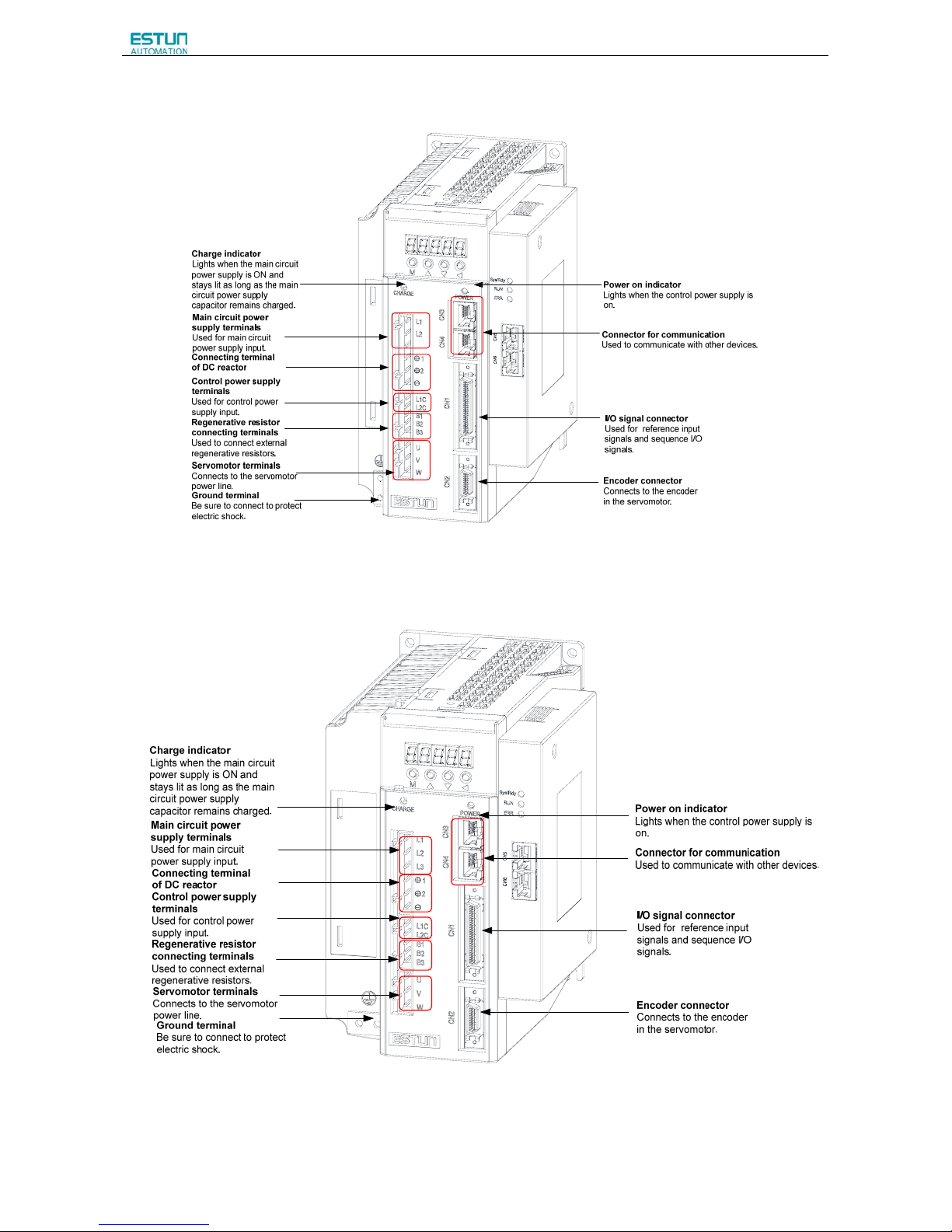

ProNet-15A/20A

/ ProNet-E-15A/20A

L1

L2

L3

CN3

CN4

CN1

CN2

L1C

L2C

B1

B2

B3

U

V

W

+

-

1

+

2

CHARGE

POWER

ProNet-10D/15D/20D/ProNet-E-10D/15D/20D

L1

L2

L3

CN3

CN4

CN1

CN2

24V

B1

B2

B3

U

V

W

+

-

1

+

2

CHARGE POWER

GND

ProNet Series AC Servo User's Manual

- 18 -

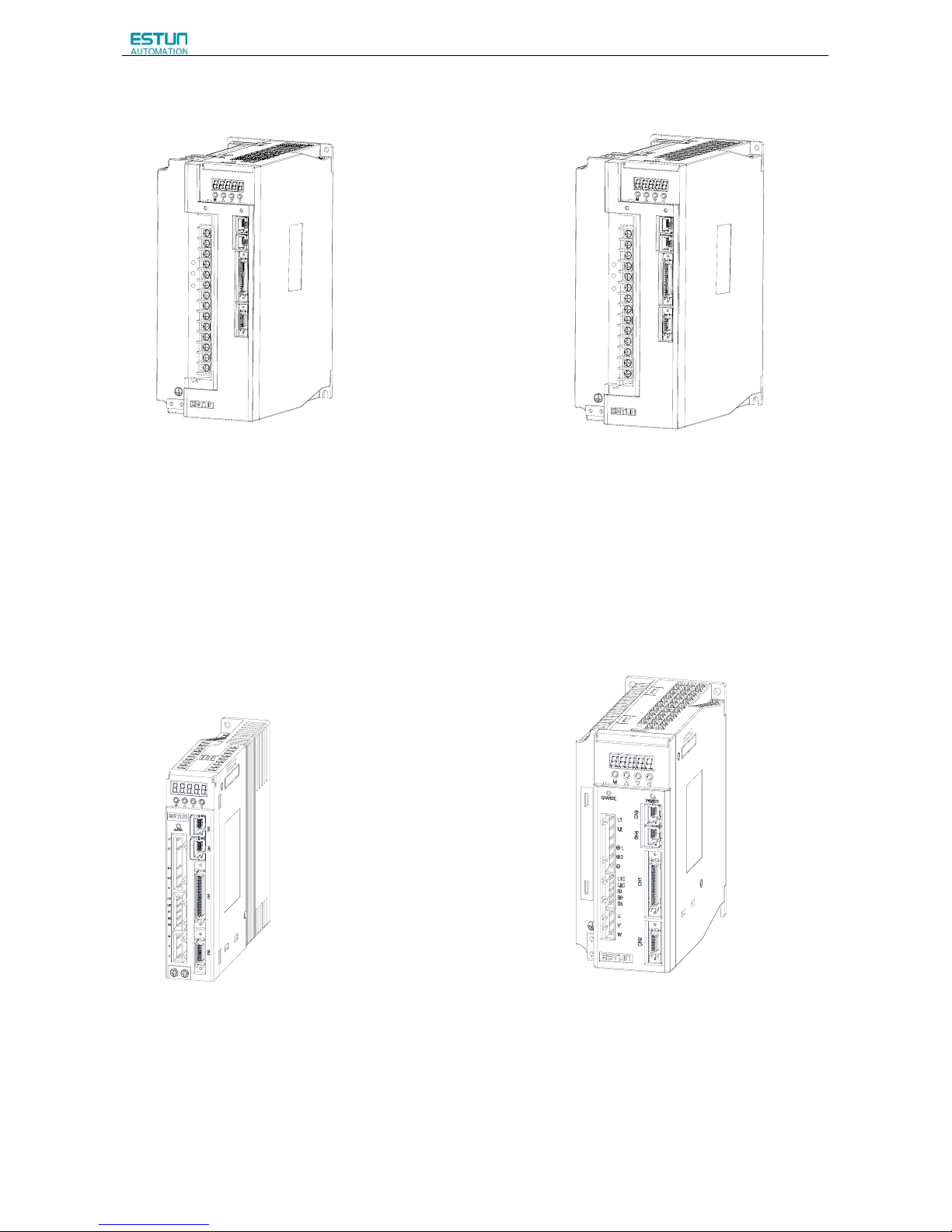

ProNet-30A/50A/ ProNet-E-30A/50A

CN3

CN4

CN1

CN2

CHARGE

POWER

L1

L2

L3

L1C

L2C

B1

B2

B3

U

V

W

+

-

1

+

2

ProNet-30D/50D/70D/75D/ ProNet-E-30D/50D

CN3

CN4

CN1

CN2

CHARGE

POWER

L1

L2

L3

24V

GND

B1

B2

B3

U

V

W

+

-

1

+

2

ProNet Series AC Servo User's Manual

- 19 -

ProNet-1AD/1ED/2BD

ProNet-02B/ProNet-E-02B

ProNet Series AC Servo User's Manual

- 20 -

ProNet-04B

/ProNet-E-04B

ProNet-08B /ProNet-E-08B

ProNet Series AC Servo User's Manual

- 21 -

Chapter 2

Installation

2.1 Servomotor

Servomotor can be installed either horizontally or vertically. However, if the servomotor is installed incorrectly, the

service life of the servomotor will be shortened or unexpected problems may occur.

Please observe the installation instructions described below to install the servomotor correctly.

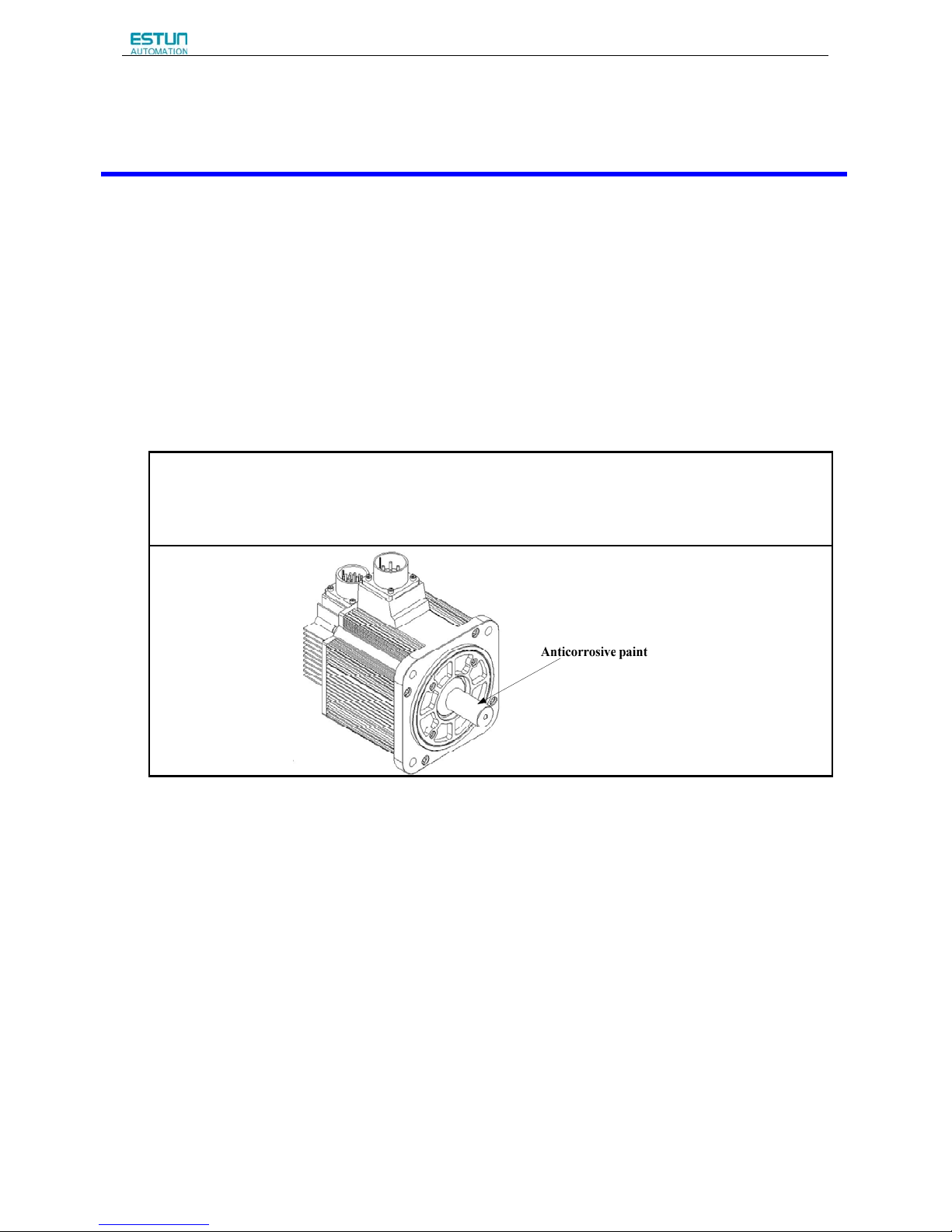

Before installation:

Anticorrosive paint is coated on the edge of the servomotor shaft. Clean off the anticorrosive paint thoroughly using

a cloth moistened with thinner.

Avoid getting thinner on other parts of the servomotor when cleaning the shaft.

2.1.1 Storage

When the servomotor is not being used, store it in an area with a temperature between -25℃ and 60℃ with the power

cable disconnected.

2.1.2 Installation Sites

The servomotor is designed for indoor use. Install the servomotor in an environment which meets the following

conditions.

z Free from corrosive and explosive gases.

z Well-ventilated and free from dust and moisture.

z Ambient temperature from 0 to 40℃.

z Relative humidity from 26% to 80%( non-condensing).

z Facilitates inspection and cleaning.

ProNet Series AC Servo User's Manual

- 22 -

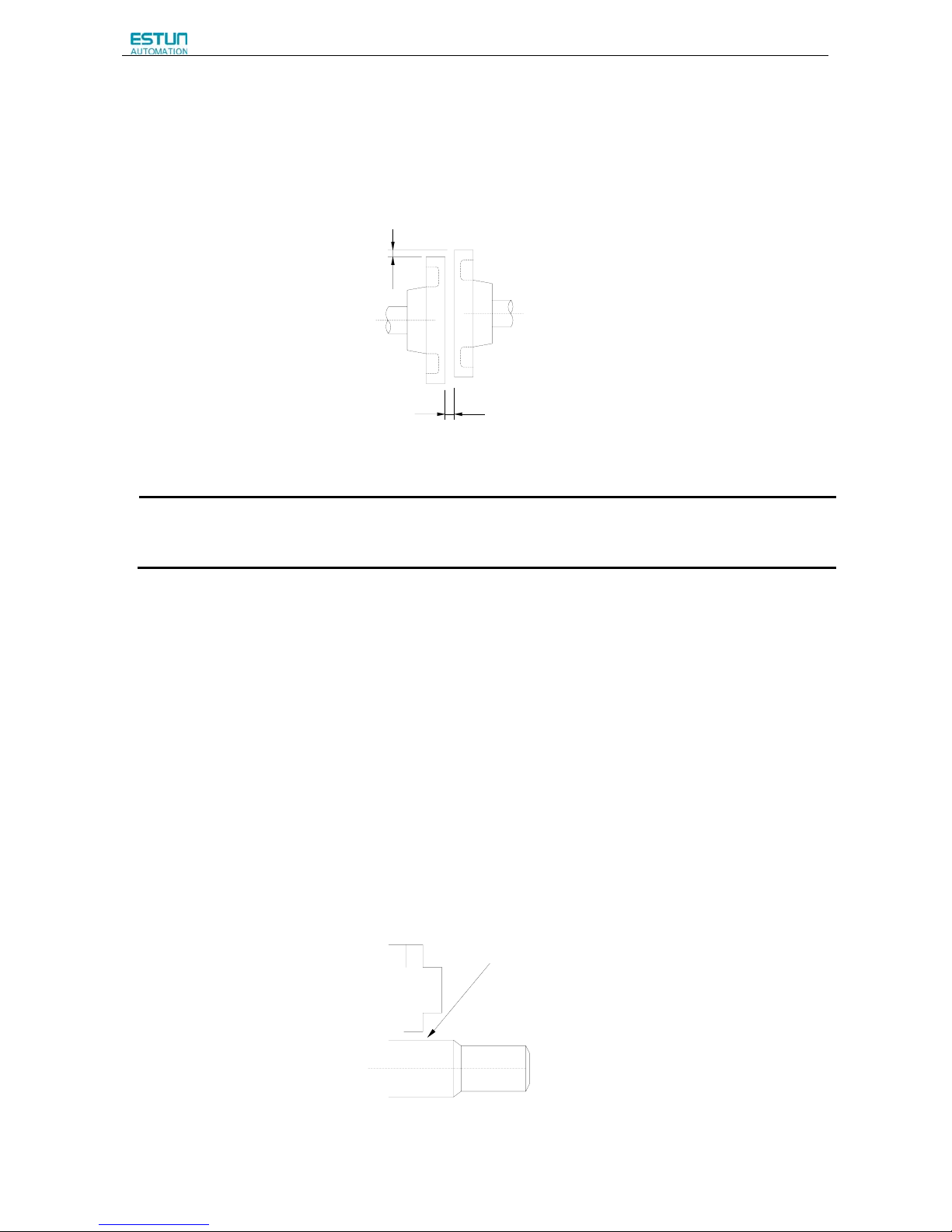

2.1.3 Installation Alignment

Align the shaft of the servomotor with that of the machinery shaft to be controlled. Then connect the two shafts with an

elastic coupling.

Install the servomotor so that alignment accurancy falls within the range shown below.

Measure this distance at four different positions in the circumference. The difference between the maximum and

minimum measurements must be 0.03mm or less.(Turn together with couplings.)

Note:

·If the alignment accurancy is incorrect , vibration will occur, resulting in damage to the bearings.

·Mechanical shock to the shaft end is forbidden, otherwise it may result in damage to the encoder of the servomotor.

2.1.4 Installation Orientation

Servomotor can be installed ethier horizontally or vertically.

2.1.5 Handling Oil and Water

If the servomotor is used in a location that is subject to water or oil drops, make sure of the servomotor protective

specification. If the servomotor is required to meet the protective specification to the through shaft section by default,

use a servomotor with an oil seal.

Through shaft section:

It refers to the gap where the shaft protrudes from the end of the servomotor.

Through Shaft Section

ProNet Series AC Servo User's Manual

- 23 -

2.1.6 Cable Tension

When connecting the cables, the bending radius should not be too small, do not bend or apply tension to cables.

Since the conductor of a signal cable is very thin (0.2 mm or 0.3 mm), handle it with adequate care.

2.1.7 Install to the Client

When the servo motor is mounted to the client, please firmly secure the servo motor by the screws with backing ring

as shown in the figure.

I

n

s

t

a

l

l

a

t

i

o

n

o

r

i

e

n

t

a

t

i

o

n

2.2 Servo Drive

ProNet series servo drive is a base-mounted type. Incorrect installation will cause problems. Always observe the

installation instructions described below.

2.2.1 Storage

When the servomotor is not being used, store it in an area with a temperature between -25℃ and 55℃ with the

power cable disconnected.

2.2.2 Installation Sites

Notes on installation are shown below.

Situation Notes on installation

When installed in a control

panel

Design the control panel size, unit layout, and cooling method so that the temperature

around the periphery of the servo drive does not exceed 55℃.

When installed near a

heating unit

Suppress radiation heat from the heating unit and a temperature rise caused by

convection so that the temperature around the periphery of the servo drive does not

exceed 55℃.

When installed near a

source of vibration

Install a vibration isolator underneath the servo drive to prevent it from receiving vibration.

When installed in a location

subject to corrosive gases

Take appropriate action to prevent corrosive gases. Corrosive gases do not immediately

affect the servo drive, but will eventually cause contactor-related devices to malfunction.

Others

Avoid installation in a hot and humid site or where excessive dust or iron powder is

present in the air.

ProNet Series AC Servo User's Manual

- 24 -

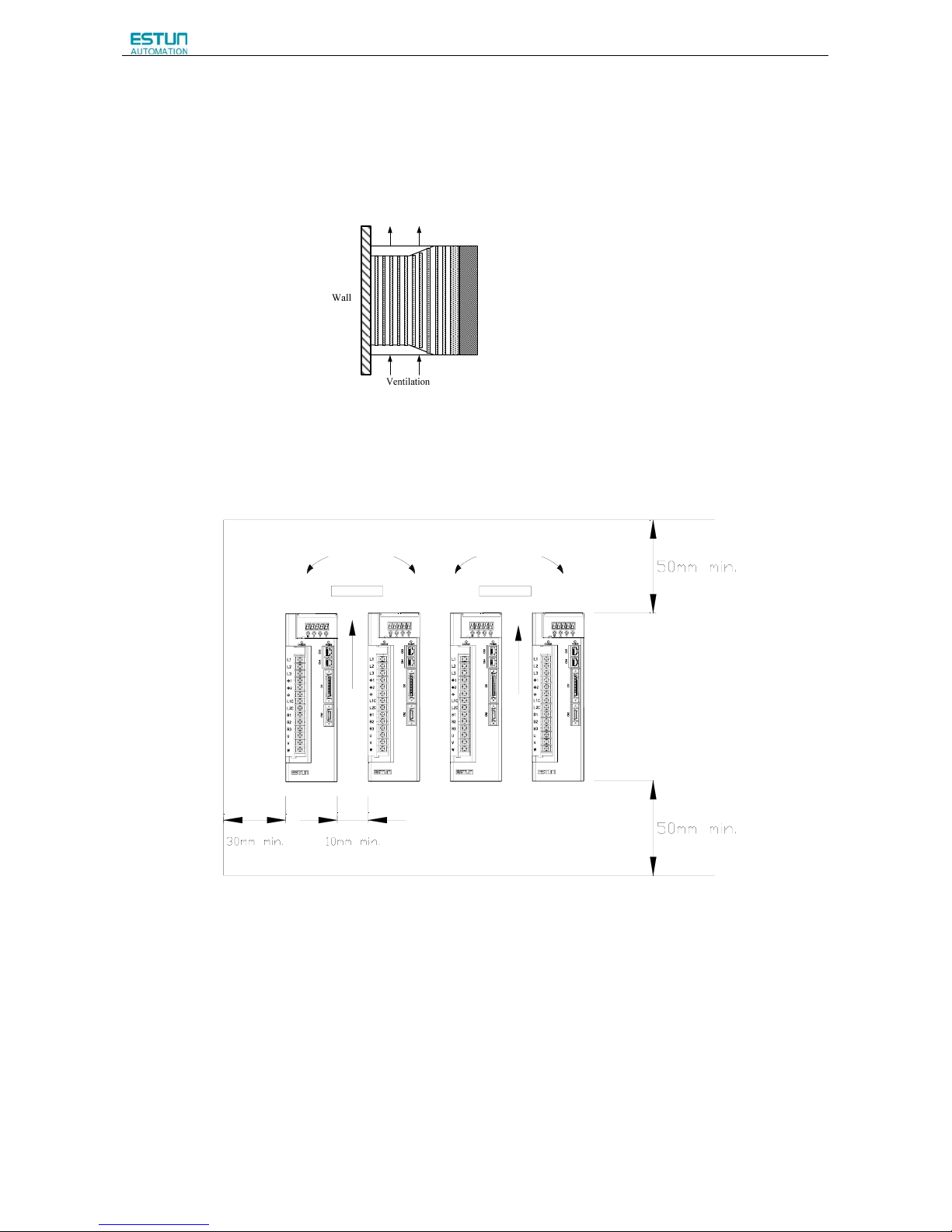

2.2.3 Installation Orientation

Install the servo drive perpendicular to the wall as shown in the figure. The servo drive must be oriented this way

because it is designed to be cooled by natural convection or a cooling fan if required. Firmly secure the servo drive

through two mounting holes.

2.2.4 Installation Method

When installing multiple servo drives side by side in a control panel, observe the following installation method.

Colling Fan

Colling Fan

■Installation Orientation

Install servo drive perpendicular to the wall so that the front panel (containing connectors) faces outward.

■Cooling

Provide sufficient space around each servo drive to allow cooling by natural convection or fans.

■Installing side by side

When installing servo drives side by side, provide at least 10mm space between each individual servo drive and at

least 50mm space above and below each one as well as shown in the figure above. Ensure the temperature inside the

control panel is evenly distributed, and prevent the temperature around each servo drive from increasing excessively.

Cooling Fan Cooling Fan

ProNet Series AC Servo User's Manual

- 25 -

Install cooling fans above the servo drives if necessary.

■Working conditions

1.Temperature:-20~ 55℃

2.Humidity:5%~95%RH

3.Vibration:4.9m/s

2

or less

4.Ambient temperature to ensure long-term reliability: 45 or less℃

5.Condensation and Freezing: None

ProNet Series AC Servo User's Manual

- 26 -

Chapter 3

Wiring

3.1 Main Circuit Wiring

Please observe the following instructions while wiring the main circuit.

· Do not bundle or run power and signal lines together in the same duct. Keep power and signal lines

separated by at least 300 mm.

· Use twisted-pair shielded wires or multi-core twisted-pair shielded wires for signal and encoder feedback

lines.

· The maximum length is 3 m for reference input lines and 20 m for encoder feedback lines.

· Do not touch the power terminals for 5 minutes after turning power OFF because high voltage may still

remain in the servo drive.

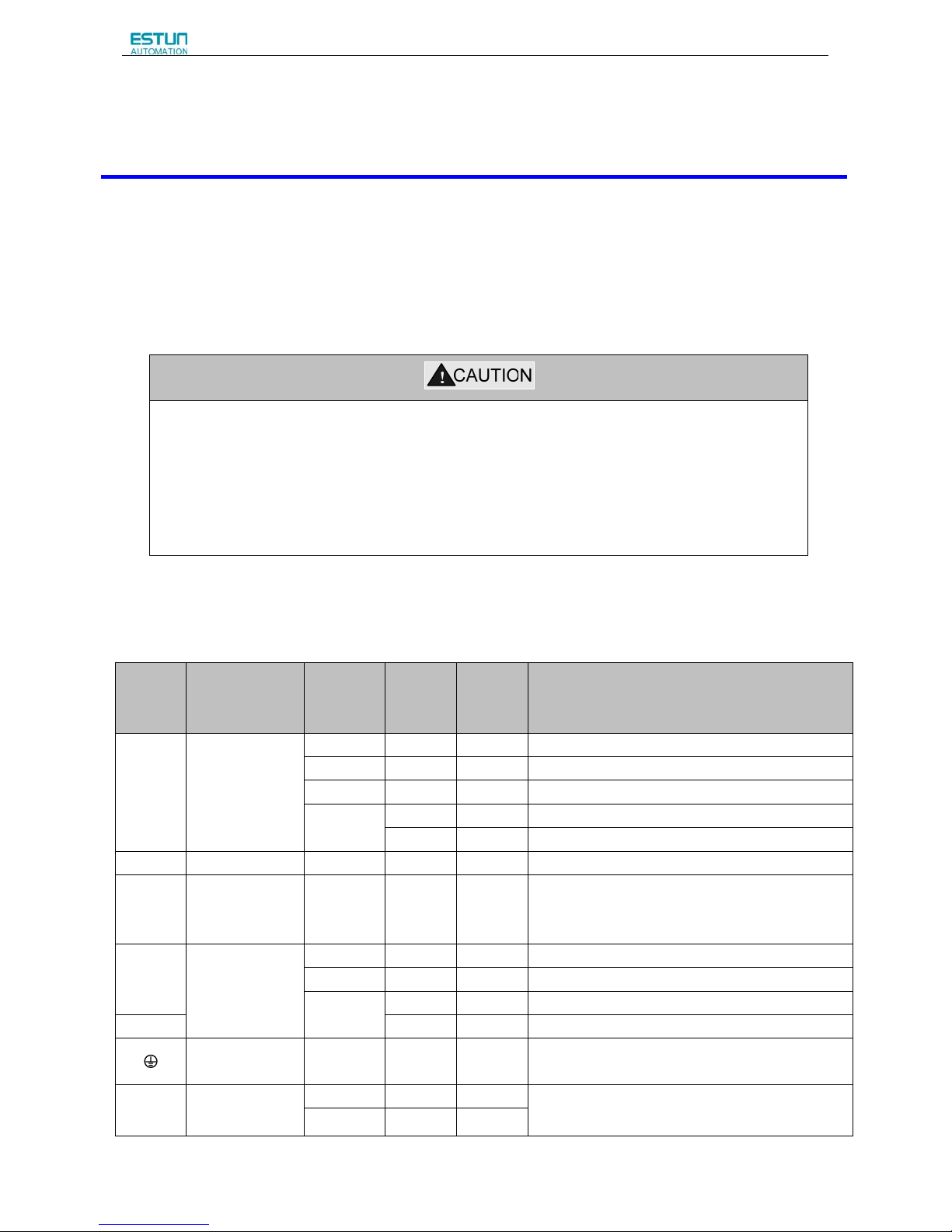

3.1.1 Names and Functions of Main Circuit Terminals

Terminal

Symbol

Name

Main

Circuit

Voltage(V)

Servo

Drive

Model

ProNet-

Servo

Drive

Model

Pronet-E-

Functions

L1,L2

Main circuit

power supply

input terminal

100

02B-08B 02B-08B

Single-phase 100~120VAC +10%~-15% (50/60Hz)

200 02A-04A 02A-04A

Single-phase 200~230VAC +10%~-15% (50/60Hz)

200 08A-50A 08A-50A

Three-phase 200~230VAC +10%~-15% (50/60Hz)

400

10D-75D 10D-50D Three-phase 380~480VAC +10%~-15% (50/60Hz)

1AD-2BD

-

Three-phase 380~440VAC +10%~-15% (50/60Hz)

FG FG 200 02A-04A 02A-04A Norma lly not connect ed.

U,V,W

Servomotor

connection

terminals

- - -

Connect to the servomotor.

L1C,L2C

Control circuit

power supply

input terminal

100

02B-08B 02B-08B

Single-phase 100~120VAC +10%~-15% (50/60Hz)

200 02A-50A 02A-50A

Single-phase 200~230VAC +10%~-15% (50/60Hz)

400

1AD-2BD

- Single-phase 380~440VAC +10%~-15% (50/60Hz)

24V,GND 10D-75D 10D-50D

24VDC +10%~-10%

Ground terminals

- - -

Connects to the power supply ground terminals and

servomotor ground terminal.

B1,B2,B3

External

regenerative

100

02B 02B

Connect an external regenerative resistor(provided

by customer) between B1 and B2.

200 02A-04A 02A-04A

ProNet Series AC Servo User's Manual

- 27 -

Terminal

Symbol

Name

Main

Circuit

Voltage(V)

Servo

Drive

Model

ProNet-

Servo

Drive

Model

Pronet-E-

Functions

resistor

connection

terminal

100

04B-08B 04B-08B

If using an internal regenerative resistor, please short

B2 and B3. Remove the wire between B2 and B3 and

connect an external regenerative resistor(provided

by customer) between B1 and B2, if the capacity of

the internal regenerative resistor is insufficient.

200 08A-50A 08A-50A

400

10D-75D 10D-50D

B1,B2 1AD-2BD

-

Connect an external regenerative resistor between

B1 and B2.

○

+ 1,○+ 2

DC reactor for

harmonic

suppression

terminal

200 02A-50A 02A-50A

Normally short ○+ 1and ○+2.

If a countermeasure against power supply harmonic

waves is needed, connect a DC reactor between ○+

1and ○+2.

400 10D-75D 10D-50D

○

-

Main circuit

minus terminal

200 02A-50A 02A-50A Norma lly not connect ed.

400 10D-75D 10D-50D

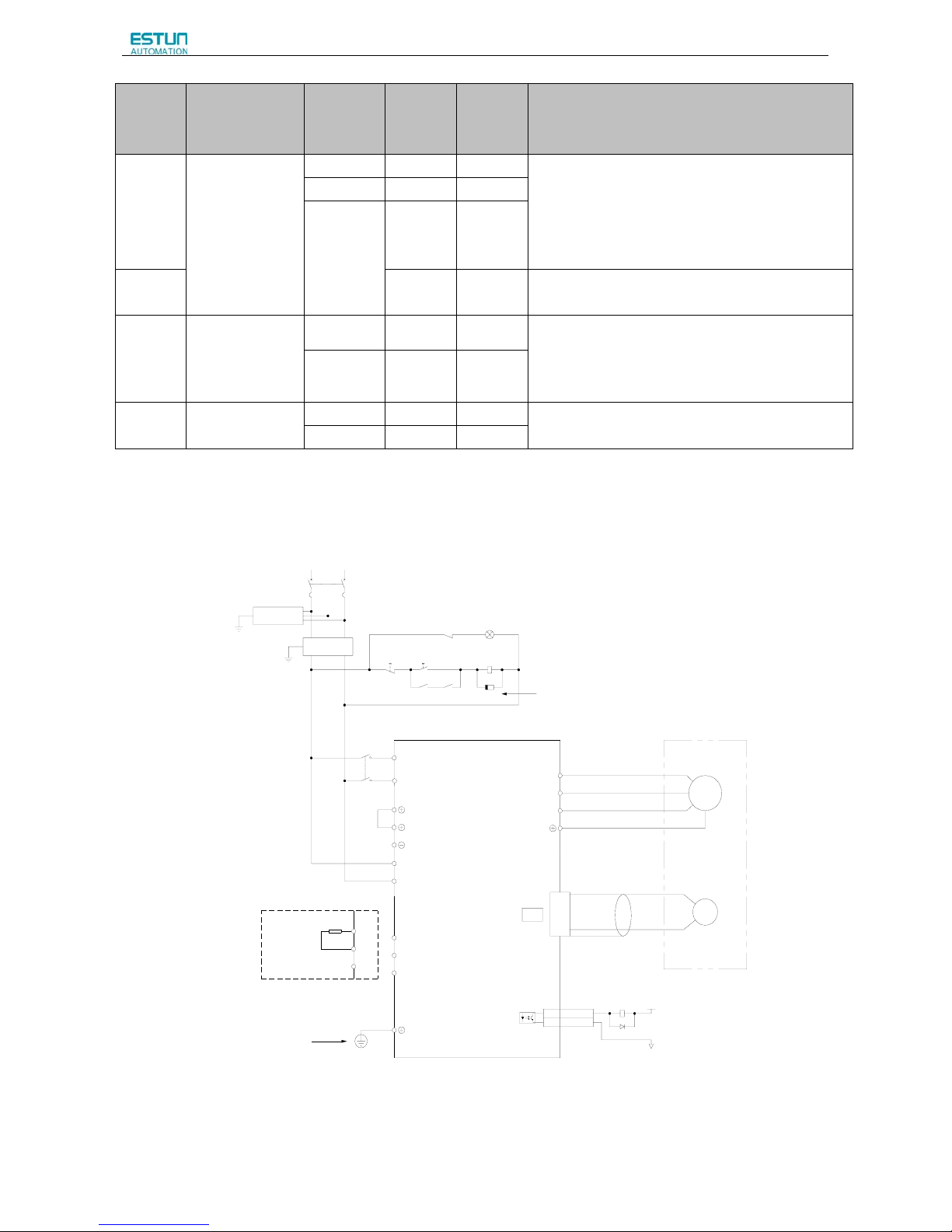

3.1.2 Typical Main Circuit Wiring Examples

Single-phase 200V ProNet-02A~04A/ Single-phase 200V ProNet-E-02A~04A

L1 L2

Single-phase 200~230V (50/60Hz)

+10%

-15%

Power OFF Pow er ON

1KM 1 SUP

1KM

1Ry

L1

L2

W

V

U

M

PG

A(1)

B(2)

C(3)

D(4)

L2C

L

1C

CN2

1Ry

1D

+24V

0V

1Ry

1PL (Servo Alarm Display)

ALM+7

ALM-

8

ProNet

Series Servodrive

1

2

Ground Terminal

Encoder

Servodrive

Magnetic Contactor

Molded-case Circuit Breaker

Surge Protector

Noise Filter

Be sure to connect a surge suppressor t o the

excitation coil of the magnetic contactor and relay.

B1

B2

B3

B1

B2

B3

External regenerator resistor

Note

1.The L1,L2,L3 and L1C,L2C terminals wiring method of ProNet-02A~04A/ProNet-E-02A~04A servo drives is different

from other ProNet series servo drives. Please note the specific terminal definition while wiring.

2.The main circuit power supply of ProNet-02A~04A/ProNet-E-02A~04A is Single-phase 200V

ProNet Series AC Servo User's Manual

- 28 -

3. External regenerative resistor for ProNet-02A~04A/ProNet-E-02A~04A is provided by customer, the model of 60W,

50Ωresistor is recommended.

4.Change Pn521.0 from “1” to “0” when using the external regenerative resistor in ProNet-02A~04A/ProNet-E-02A~04A

servo drives.

·Three-phase 200V ProNet-08A~50A/ Three-phase 200V ProNet-E-08A~50A

Noise Filter

L1 L2 L3

Three-phase 200~230V (50/60Hz)

+10%

-15%

Power OFF Power ON

1KM 1SUP

1KM

1Ry

L1

L2

L3

W

V

U

M

PG

Servomotor

Encoder

A(1)

B(2)

C(3)

D(4)

L2C

L

1C

CN2

1Ry

1D

+24V

0V

Surge Protector

Magnetic Contactor

Molded-case Circuit Breaker

1Ry

1PL (Servo Alarm Display)

ALM+7

ALM-

8

Be sure to connect a surge suppressor to the

excitation coil of the magnetic contactor and relay.

.

ProNet

Series Servodrives

1

2

B1

B2

B3

B2

B1

External Regenerator Resistor

B3

Ground Terminal

Three-phase 400V ProNet-10D~75D

/ Three-phase 400V ProNet-E-10D~50D

Noise Filter

L1 L2 L3

Three-phase 380~440V (50/60Hz)

+10%

-15%

Power OFF Power ON

1KM 1SUP

1KM

1Ry

L1

L2

L3

W

V

U

M

PG

Servomotor

Encoder

A(1)

B(2)

C(3)

D(4)

CN2

1Ry

1D

+24V

0V

Surge Protector

Magnetic Contactor

Molded-case Circuit Breaker

1Ry

1PL (Servo Alarm Display)

ALM+7

ALM-

8

Be sure to connect a surge su ppressor to the

excitation coil of the magnetic contactor and relay.

.

ProNet

Series Servodrives

1

2

B1

B2

B3

B2

B1

External Regenerator Resistor

B3

Ground Terminal

GND

24V

24VDC Power Supply

Loading...

Loading...