ProNet Plus Series AC Servo User's Manual

(Version: V1.05)

Copyright © 2011 ESTUN AUTOMATION TECHNOLOGY CO., LTD

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any form, or

by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior written permission of ESTUN.

No patent liability is assumed with respect to the use of the information contained herein.

ProNet Plus Series AC Servo User's Manual

- 1 -

About this manual

This manual describes the following information required for designing and maintaining ProNet Plus Series ACservo

drives.

•Specification of the servo drives and servomotors.

•Procedures for installing the servo drives and servomotors.

•Procedures for wiring the servo drives and servomotors.

•Procedures for operating of the servo drives.

•Procedures for using the panel operator.

•Communication protocols.

•Ratings and characteristics.

Intended Audience:

•Those designing ProNet series servo drive systems.

•Those installing or wiring ProNet series servo drives.

•Those performing trial operation or adjustments of ProNet series servo drives.

•Those maintaining or inspecting ProNet series servo drives.

ProNet Plus Series AC Servo User's Manual

- 2 -

Safety Precautions

■ Do not connect the servomotor directly to the local electrical network.

Failure to observe this may result in damage to servomotor.

■ Do not plug or unplug connectors from servo drivewhen power is on.

Failure to observe this may result in damage to servo drive and servomotor.

■Please note that even after power is removed, residual voltage still remains in the capacitor inside the servo drive. If

inspection is to be performed after power is removed, please wait 5 minutes to avoid risk of electrical shock.

■Keep servo drives and other devices separated by at least 10mm.

The servo drive generates heat. Install the servo drive so that it can radiate heat freely. When installing servo drives

with other devices in a control panel, provide at least 10mm space between them and 50mm space above and below

them.Please install servo drives in an environment free from condensation, vibration and shock.

■Perform noise reduction and grounding properly.

Please comply with the following instructions to avoid noise generated by signal lines.

1. Separate high-voltage cables from low-voltage cables.

2. Use cables as short as possible.

3. Single point grounding is required for the servomotor and servo drive (grounding resistance 100mΩ or below).

4. Never use a line filter for the motor's power supply in the circuit.

■Conduct a voltage resistance test for the servo drive under the following conditions:

1. Input voltage:AC 1500Vrms, 1 minute

2. Braking current:100mA

3. Frequency:50/60Hz

4. Voltage applied point:Between L1, L2,L3 terminals and frame ground.

■Use a fast-response type ground-fault interrupter.

For a ground-fault interrupter, always use a fast-response type or one designed for PWM inverters. Do not use a

time-delay type.

■ Do not make any extreme adjustments or setting changes of parameters.

Failure to observe this caution may result in injury or damage to the product due to unstable operation.

■The servomotor cannot be operated by turning the power on and off.

Frequently turning the power ON and OFF causes the internal circuit elements to deteriorate, resulting in unexpected

problems.Always start or stop the servomotor by using reference pulses.

■Follow the instructions for PCB use:

1.Before touch the PCB,the body of the user must be discharged.

2.The PCB cannot be contact with highly insulating materials.

3.The PCB is only allowed to put on the conductive pad.

4.The PCB is only allowed to store and transport packaging in conductive wrapper or conductive foam rubber or

aluminum foil.

■ Precautions on turning ON and turning OFF the servo drive:

1.When turning on the servo drive, make sure that the control power supply has be turned on before turningon the main

circuit power supply.

2.When turning off the servo drive, make sure that the main circuit power supply has be turned off before turningoff the

control power supply.

ProNet Plus Series AC Servo User's Manual

- 3 -

—Contents—

About this manual ........................................................................................................................................................... - 1 -

Safety Precautions .......................................................................................................................................................... - 2 -

Chapter 1 ........................................................................................................................................................................ - 7 -

Checking Products and Parts Names ............................................................................................................................. - 7 -

1.1 Checking Products on Delivery ......................................................................................................................... - 7 -

1.1.1 Servomotor ............................................................................................................................................ - 7 -

1.1.2 Servo drive .......................................................................................................................................... - 10 -

1.2 Part Names ................................................................................................................................ ..................... - 13 -

1.2.1 Servomotor .......................................................................................................................................... - 13 -

1.2.2 Servo drive .......................................................................................................................................... - 14 -

Chapter 2 ...................................................................................................................................................................... - 18 -

Installation ..................................................................................................................................................................... - 18 -

2.1 Servomotor ..................................................................................................................................................... - 18 -

2.1.1 Storage ................................................................................................................................................ - 18 -

2.1.2 Installation Sites .................................................................................................................................. - 18 -

2.1.3 Installation Alignment ........................................................................................................................... - 19 -

2.1.4 Installation Orientation ................................................................................................ ......................... - 19 -

2.1.5 Handling Oil and Water ........................................................................................................................ - 19 -

2.1.6 Cable Tension ...................................................................................................................................... - 20 -

2.1.7 Install to the Client ............................................................................................................................... - 20 -

2.2 Servo Drive ..................................................................................................................................................... - 20 -

2.2.1 Storage ................................................................................................................................................ - 20 -

2.2.2 Installation Sites .................................................................................................................................. - 20 -

2.2.3 Installation Orientation ................................................................................................ ......................... - 21 -

2.2.4 Installation Method .............................................................................................................................. - 21 -

Chapter 3 ...................................................................................................................................................................... - 23 -

Wiring ............................................................................................................................................................................ - 23 -

3.1 Main Circuit Wiring .......................................................................................................................................... - 23 -

3.1.1 Names and Functions of Main Circuit Terminals .................................................................................. - 23 -

3.1.2 Typical Main Circuit Wiring Examples .................................................................................................. - 24 -

3.2 I/O Signals ...................................................................................................................................................... - 26 -

3.2.1 Examples of I/O Signal Connections ................................................................................................... - 26 -

3.2.2 I/O Signal Names and Functions ......................................................................................................... - 27 -

3.2.3 I/O Signal Connector (CN1) Terminal Layout ...................................................................................... - 30 -

3.2.4 Interface Circuit ................................................................................................................................... - 31 -

3.3 Wiring Encoders .............................................................................................................................................. - 32 -

3.3.1 Connecting an Encoder(CN2) .............................................................................................................. - 32 -

3.3.2 Encoder Connector(CN2) Terminal Layout ......................................................................................... - 35 -

3.4 Communication Connection ............................................................................................................................ - 35 -

3.4.1 Communication Connector(CN3) Terminal Layout .............................................................................. - 35 -

3.4.2 Communication Connector(CN4) Terminal Layout .............................................................................. - 36 -

3.5 Standard Wiring Examples ............................................................................................................................. - 37 -

ProNet Plus Series AC Servo User's Manual

- 4 -

3.5.1 Single-phase 200V ProNet-A5A~04A ................................................................................................ - 37 -

3.5.2 Three-phase 200V ProNet-08A~50A ................................................................................................. - 39 -

3.5.3 Three-phase 400V ProNet-10D~50D ................................................................................................. - 41 -

3.5.4 Position Control Mode ......................................................................................................................... - 43 -

3.5.5 Speed Control Mode ............................................................................................................................ - 44 -

3.5.6 Torque Control Mode ........................................................................................................................... - 45 -

3.6 Wiring for Noise Control .................................................................................................................................. - 46 -

3.6.1 Noise Control ....................................................................................................................................... - 46 -

3.6.2 Precautions on Connecting Noise Filter .............................................................................................. - 47 -

3.7 Installation Conditions of EMC Directives ....................................................................................................... - 49 -

3.8 Using More than One Servo Drive .................................................................................................................. - 51 -

Chapter 4 ...................................................................................................................................................................... - 53 -

Operation ...................................................................................................................................................................... - 53 -

4.1 Trial Operation ................................................................................................................................................ - 53 -

4.1.1 Trial Operation for Servomotor Without Load ...................................................................................... - 55 -

4.1.2 Trial Operation for Servomotor without Load from Host Reference ..................................................... - 57 -

4.1.3 Trial Operation with the Servomotor Connected to the Machine .......................................................... - 61 -

4.1.4 Trial Operation for Servomotor with Brakes ......................................................................................... - 62 -

4.1.5 Position Control by Host Controller ...................................................................................................... - 62 -

4.2 Control Mode Selection ................................................................................................................................... - 63 -

4.3 Setting Common Basic Functions ................................................................................................................... - 64 -

4.3.1 Setting the Servo ON Signal ................................................................................................................ - 64 -

4.3.2 Switching the Servomotor Rotation Direction ...................................................................................... - 65 -

4.3.3 Setting the Overtravel Limit Function ................................................................................................... - 66 -

4.3.4 Setting for Holding Brakes ................................................................................................................... - 68 -

4.3.5 Instantaneous Power Loss Settings .................................................................................................... - 72 -

4.4 Absolute Encoders .......................................................................................................................................... - 72 -

4.4.1 Selecting an Absolute Encoder ............................................................................................................ - 72 -

4.4.2 Handling Battery .................................................................................................................................. - 72 -

4.4.3 Replacing Battery ................................................................................................................................ - 73 -

4.4.4 Absolute Encoder Setup(Fn010, Fn011) .............................................................................................. - 74 -

4.5 Operating Using Speed Control with Analog Reference ................................................................................. - 74 -

4.5.1 Setting Parameters .............................................................................................................................. - 74 -

4.5.2 Setting Input Signals ............................................................................................................................ - 75 -

4.5.3 Adjusting Reference Offset .................................................................................................................. - 75 -

4.5.4 Soft Start.............................................................................................................................................. - 77 -

4.5.5 Speed Reference Filter Time Constant ................................................................................................ - 78 -

4.5.6 S-curve Risetime ................................................................................................................................. - 78 -

4.5.7 Using the Zero Clamp Function ........................................................................................................... - 79 -

4.5.8 Encoder Signal Output ........................................................................................................................ - 81 -

4.5.9 Speed coincidence output ................................................................................................................... - 82 -

4.6 Operating Using Position Control .................................................................................................................... - 83 -

4.6.1 Basic Setting in Position Control .......................................................................................................... - 83 -

4.6.2 Setting the Clear Signal ....................................................................................................................... - 86 -

4.6.3 Setting the Electronic Gear .................................................................................................................. - 87 -

4.6.4 Smoothing ........................................................................................................................................... - 90 -

ProNet Plus Series AC Servo User's Manual

- 5 -

4.6.5 Low Frequency Vibration Suppression ................................................................................................ - 91 -

4.6.6 Positioning Completion Output Signal ................................................................................................. - 92 -

4.6.7 Reference Pulse Inhibit Function (INHIBIT) ......................................................................................... - 93 -

4.6.8Position Control (contact reference) ..................................................................................................... - 94 -

4.6.9 Position Homing Control (Homing Function)........................................................................................ - 97 -

4.7 Operating Using Torque Control .................................................................................................................... - 100 -

4.7.1 Setting Parameters ............................................................................................................................ - 100 -

4.7.2 Torque Reference Input ..................................................................................................................... - 101 -

4.7.3 Adjusting the Reference Offset .......................................................................................................... - 102 -

4.7.4 Limiting Servomotor Speed During Torque Control ........................................................................... - 103 -

4.8 Operating Using Speed Control with an Internally Set Speed ....................................................................... - 104 -

4.8.1 Setting Parameters ............................................................................................................................ - 104 -

4.8.2 Input Signal Settings .......................................................................................................................... - 105 -

4.8.3 Operating Using an Internally Set Speed .......................................................................................... - 105 -

4.9 Limiting Torque .............................................................................................................................................. - 106 -

4.9.1 Internal Torque Limit .......................................................................................................................... - 106 -

4.9.2 External Torque Limit ......................................................................................................................... - 107 -

4.9.3 Torque Limiting Using an Analog Voltage Reference ........................................................................ - 108 -

4.10 Control Mode Selection ............................................................................................................................... - 109 -

4.10.1 Setting Parameters .......................................................................................................................... - 109 -

4.10.2 Switching the Control Mode ............................................................................................................. - 109 -

4.11 Other Output Signals ................................................................................................................................... - 110 -

4.11.1 Servo alarm output........................................................................................................................... - 110 -

4.11.2 Rotation Detection Output Signal (/TGON) ...................................................................................... - 111 -

4.11.3 Servo Ready (/S-RDY) Output ......................................................................................................... - 111 -

4.11.4 Encoder C Pluse Output (/PGC) ...................................................................................................... - 111 -

4.11.5 Over travel signal output (OT) .......................................................................................................... - 112 -

4.11.6 Servo Enabled Motor Excitation Output(/RD) .................................................................................. - 112 -

4.11.7 Torque Limit Detection Output (/CLT) ............................................................................................... - 112 -

4.11.8 Torque Detection Output (/TCR) ...................................................................................................... - 113 -

4.12 Online Autotuning ........................................................................................................................................ - 114 -

4.12.1 Online Autotuning ............................................................................................................................ - 114 -

4.12.2Online Autotuning Procedure ............................................................................................................ - 114 -

4.12.3 Setting Online Autotuning ................................................................................................................ - 115 -

4.12.4 Load Rigidity Setting for Online Autotuning ..................................................................................... - 116 -

4.13 Inertia .......................................................................................................................................................... - 117 -

4.14 Updating Operation ..................................................................................................................................... - 117 -

Chapter 5 .................................................................................................................................................................... - 118 -

Panel Operator ............................................................................................................................................................ - 118 -

5.1 Basic Operation ............................................................................................................................................ - 118 -

5.1.1 Functions on Panel Operator ............................................................................................................. - 118 -

5.1.2 Resetting Servo Alarms ..................................................................................................................... - 118 -

5.1.3 Basic Mode Selection ........................................................................................................................ - 119 -

5.1.4 Status Display Mode .......................................................................................................................... - 119 -

5.1.5 Operation in Parameter Setting Mode ............................................................................................... - 121 -

5.1.6 Operation in Monitor Mode ................................................................................................................ - 121 -

ProNet Plus Series AC Servo User's Manual

- 6 -

5.2 Operation in Utility Function Mode ................................................................................................................ - 123 -

5.2.1 Alarm Traceback Data Display ........................................................................................................... - 125 -

5.2.2 Parameter Settings Initialization ........................................................................................................ - 125 -

5.2.3 Operation in JOG Mode ..................................................................................................................... - 126 -

5.2.4 Automatic Adjustment of the Speed Reference Offset ....................................................................... - 126 -

5.2.5 Manual Adjustment of the Speed Reference Offset ........................................................................... - 128 -

5.2.6 Offset-adjustment of Servomotor Current Detection Signal ............................................................... - 129 -

5.2.7 Software Version Display ................................................................................................................... - 130 -

5.2.8 Position Teaching Function ................................................................................................................ - 130 -

5.2.9 Static Inertia Detection ...................................................................................................................... - 131 -

5.2.10 Absolute Encoder Multiturn Data and Alarm Reset .......................................................................... - 131 -

5.2.11 Absolute Encoder Related Alarms Reset ......................................................................................... - 131 -

Chapter 6 .................................................................................................................................................................... - 133 -

MODBUS Communication ........................................................................................................................................... - 133 -

6.1 RS-485 Communication Wiring ..................................................................................................................... - 133 -

6.2 MODBUS Communication Related Parameters ........................................................................................... - 134 -

6.3 MODBUS Communication Protocol ................................ ................................................................ .............. - 135 -

6.3.1 Code Meaning ................................................................................................................................... - 135 -

6.3.2 Communication Error Disposal .......................................................................................................... - 141 -

6.3.3 Data Communication Address of Servo State .................................................................................... - 142 -

Chapter 7 .................................................................................................................................................................... - 145 -

Specifications and Characters ..................................................................................................................................... - 145 -

7.1 Servo drive Specifications and Models ......................................................................................................... - 145 -

7.2 Servo drive Dimensional Drawings ................................................................................................ ............... - 148 -

7.3 Servo motor Specifications and Models ........................................................................................................ - 150 -

7.4 Servo Motor Dimensional Drawings .............................................................................................................. - 153 -

Appendix A .................................................................................................................................................................. - 158 -

Parameter ................................................................................................................................................................... - 158 -

A.1 Parameter List (ProNet-□□□MG) .............................................................................................................. - 158 -

A.2 Parameters in detail (ProNet-□□□MG) ..................................................................................................... - 165 -

A.3 Parameter List (ProNet-□□□EG-EC) ........................................................................................................ - 185 -

A.4 Parameters in detail (ProNet-□□□EG-EC) ................................................................ ................................ - 192 -

Appendix B .................................................................................................................................................................. - 211 -

Alarm Display .............................................................................................................................................................. - 211 -

ProNet Plus Series AC Servo User's Manual

- 7 -

Chapter 1

ESTUN Servomotor

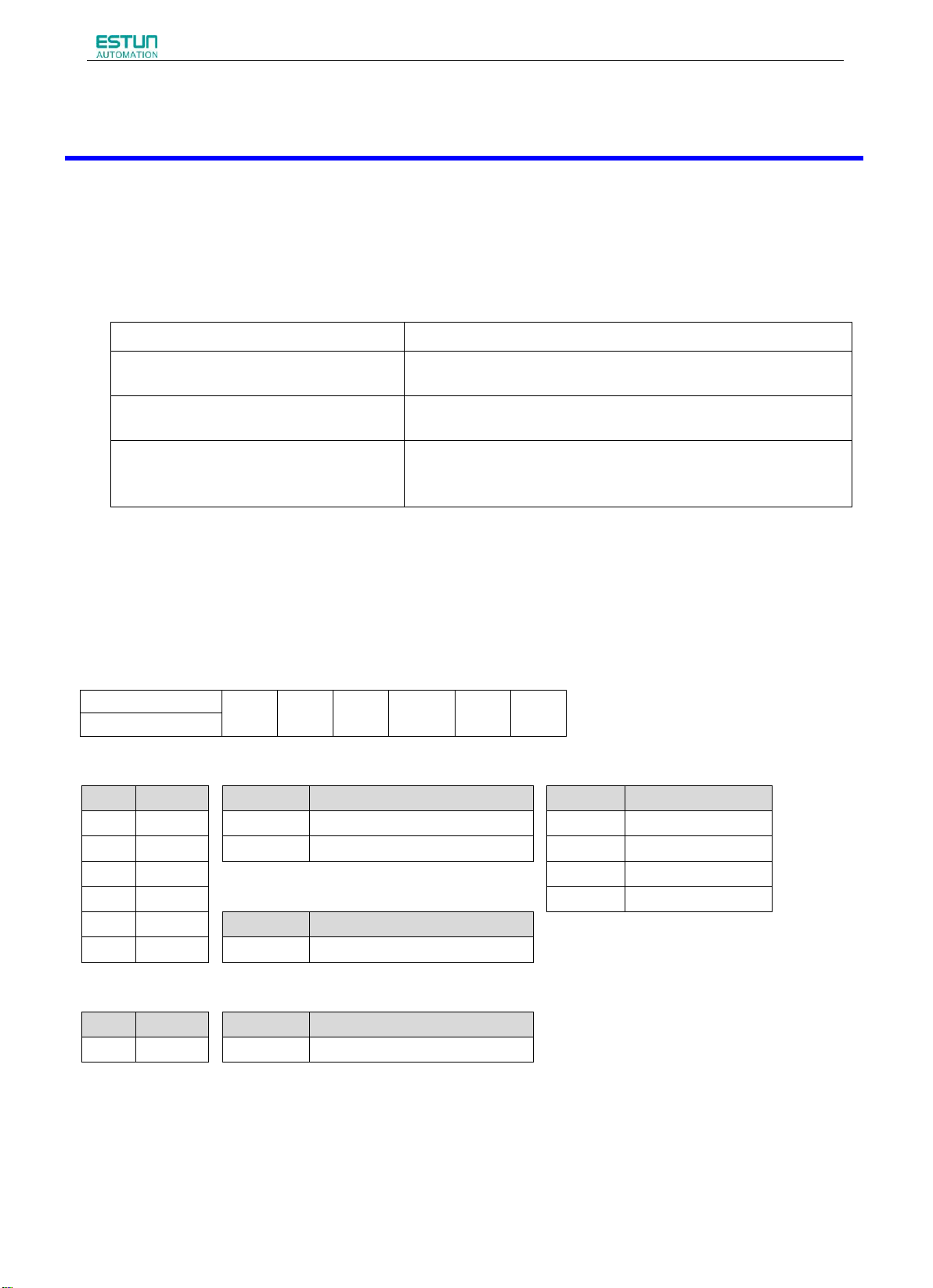

【1+2】

【3】

【4】

【5】

【6】

【7】

EMJ Model

【1+2】Rated Output

【4】Encoder

【7】Option

Code

Spec.

Code

Spec.

Code

Spec.

A5

0.05 kW

F 20 bit incremental encoder: 1048576P/R

1

Without oil seal and brake

01

0.1 kW

S 17 bit absolute encoder: 131072P/R

2

With oil seal, Without brake

02

0.2kW

3

Without oil seal, With brake

04

0.4kW

【5】Designing Sequence

4

With oil seal and brake

08

0.75kW

Code

Spec.

10

1.0kW

A,B,D,H,M

Designing sequence

【3】Voltage

【6】Shaft End

Code

Spec.

Code

Spec.

A 200VAC

2

Straight with key and tap

Check Items

Comments

Are the delivered products theones that

were ordered?

Check the model numbers marked on the nameplate on the

servomotor and servo drive.

Is there any damage?

Check the overall appearance, and check for damage or scratches

that may have occurred during shipping.

Does the servomotor shaft rotatesmoothly?

If the servomotor shaft can be easily rotated by hand, then the motor

is working normally. However, if a brake is installed on the

servomotor, then it cannot be turned by hand.

Checking Products and Parts Names

1.1 Checking Products on Delivery

If any of the above items are faulty or incorrect, contact your ESTUN representative or the dealer from whom you

purchased the products.

1.1.1 Servomotor

Servomotor Model Designation

EMJ– 08 A F B 2 4

ProNet Plus Series AC Servo User's Manual

- 8 -

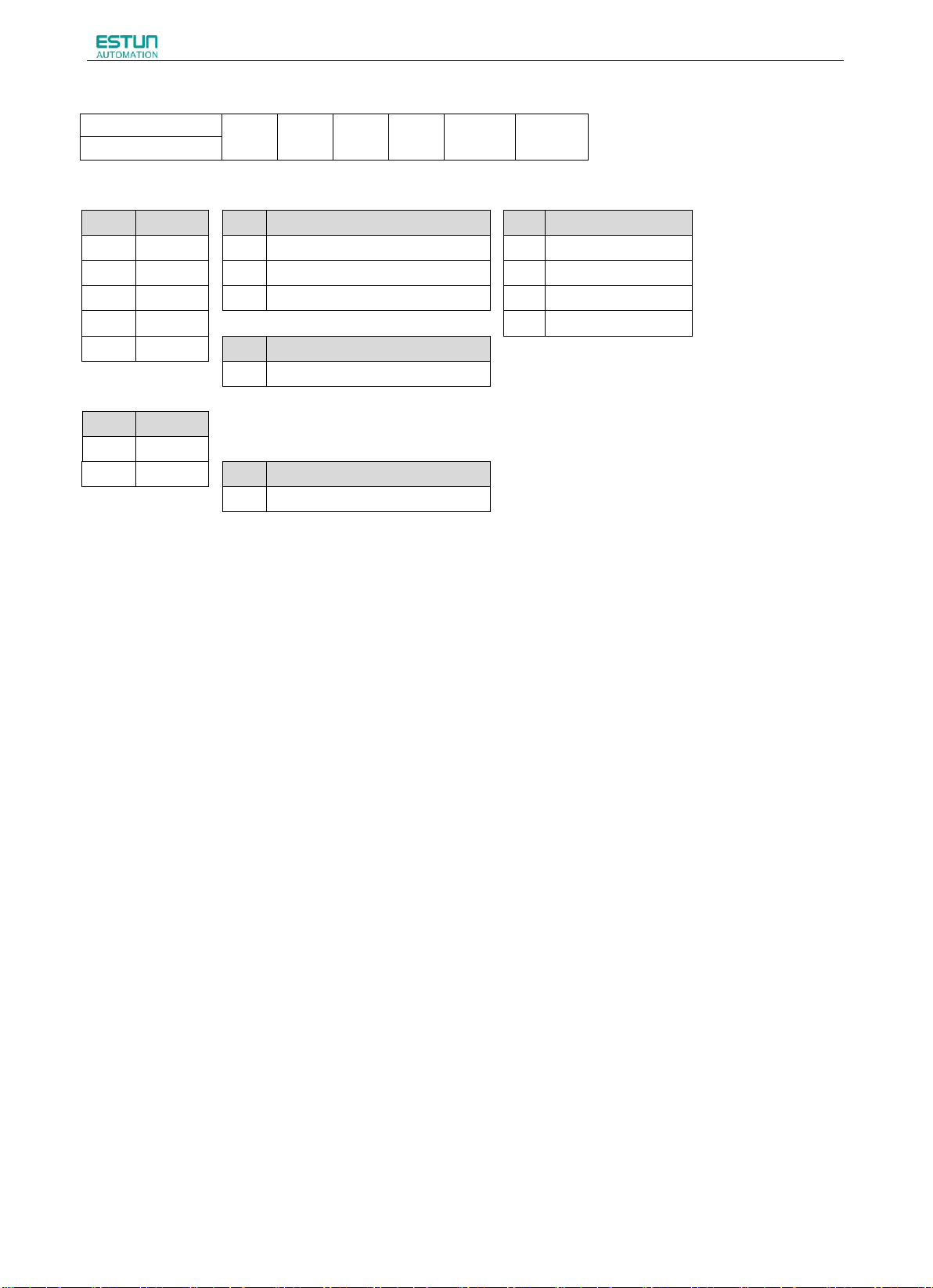

EMG– 10 A F D 2 4

ESTUN Servomotor

【1+2】

【3】

【4】

【5】

【6】

【7】

EMG Model

【1+2】Rated Output

【4】Encoder

【7】Option

Code

Spec.

Code

Spec.

Code

Spec.

10

1.0kW

F 20 bit incremental encoder: 1048576P/R

1

Without oil seal and brake

15

1.5kW

S 17 bit absolute encoder: 131072P/R

2

With oil seal, Without brake

20

2.0kW

L 23 bit absolute encoder: 8388608 P/R

3

Without oil seal, With brake

30

3.0kW

【5】Designing Sequence

4

With oil seal and brake

50

5.0kW

Code

Code

A,B,D

Designing sequence

【3】Voltage

Code

Spec.

A

200VAC

【6】Shaft End

D

400VAC

Code

Spec.

2

Straight with key and tap

ProNet Plus Series AC Servo User's Manual

- 9 -

ESTUN Servomotor

【1+2】

【3】

【4】

【5】

【6】

【7】

EML Model

【1+2】Rated Output

【4】Encoder

【7】Option

Code

Spec.

Code

Spec.

Code

Spec.

10

1.0kW

F 20 bit incremental encoder: 1048576P/R

1

Without oil seal and brake

20

2.0kW

S 17 bit absolute encoder: 131072P/R

2

With oil seal, Without brake

30

3.0kW

L 23 bit absolute encoder: 8388608 P/R

3

Without oil seal, With brake

40

4.0kW

【5】Designing Sequence

4

With oil seal and brake

Code

Spec.

【3】Voltage

A,B,D

Designing sequence

Code

Spec.

A

200VAC

D

400VAC

【6】Shaft End

Code

Spec.

2

Straight with key and tap

ESTUN Servomotor

【1】

【2+3】

【4】

【5】

【6】

【7】

【8】

【9】

【10】

EM3 Model

【1】Servomotor Type

【2+3】Rated Output

【7】Shaft End

Code

Spec.

Code

Spec.

Code

Spec.

A

Low inertia,3000rpm

A5

0.05 kW

1 Without Key

01

0.1 kW

2 With Key

02

0.2 kW

【4】Voltage

04

0.4 kW

【8】Option Parts

Code

Spec.

08

0.75 kW

Code

Spec.

A

200VAC

10

1 kW 1

Without oil seal and brake

2

With oil seal, Without brake

【5】Encoder

3

Without oil seal, With brake

【6】Shaft End

Code

Spec.

4

With oil seal and brake

Code

Spec.

F

20 bit incremental encoder: 1048576P/R

A Designing Sequence A

L 23 bit absolute encoder: 8388608 P/R

【9】Plug

Code

Spec.

【10】Customized

1 Leadwire

Code

Spec.

2 Connector

None

Non-customized

EML– 10 A F A 2 4

EM3 A –02 A F A 2 4 1

ProNet Plus Series AC Servo User's Manual

- 10 -

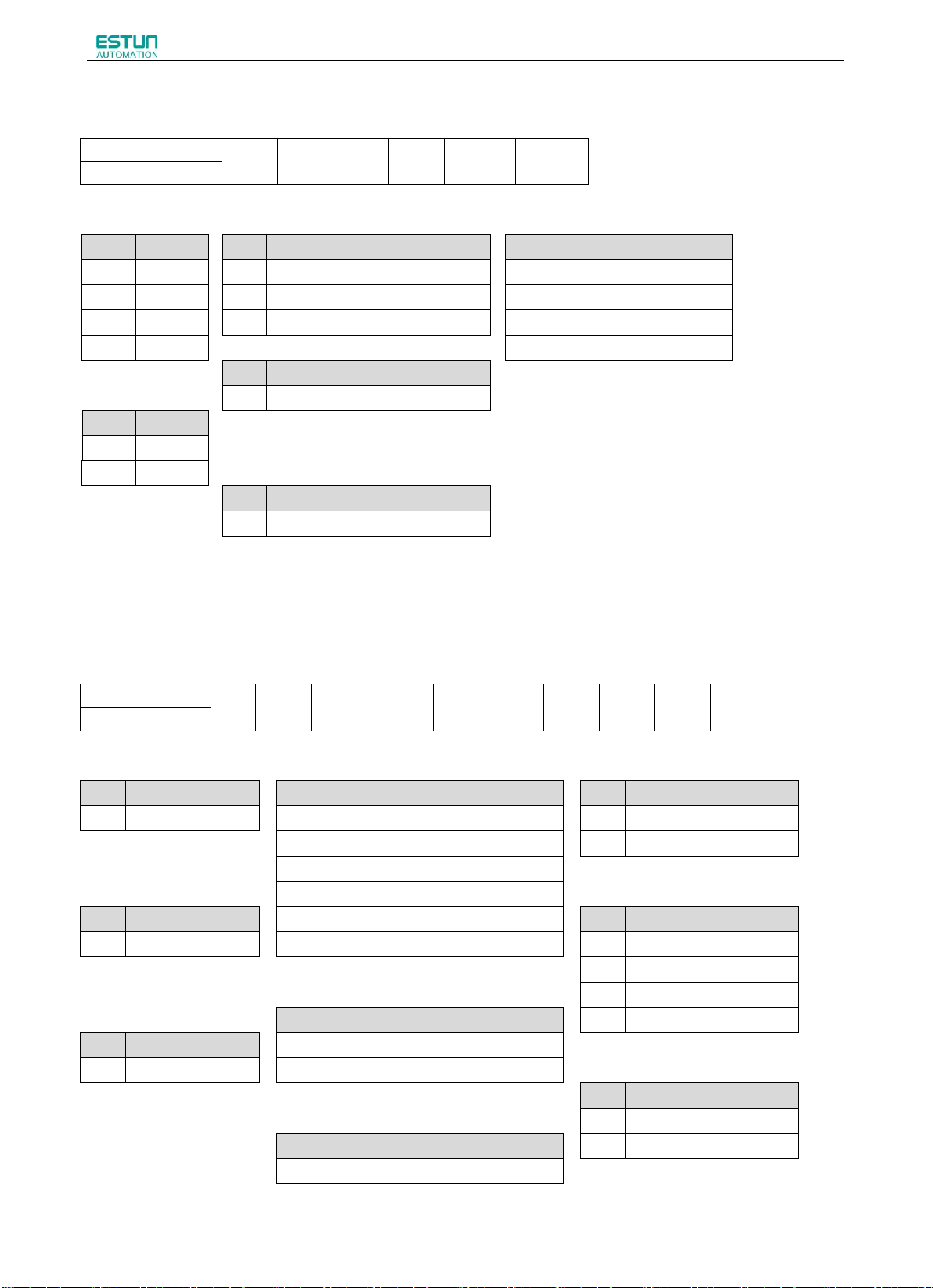

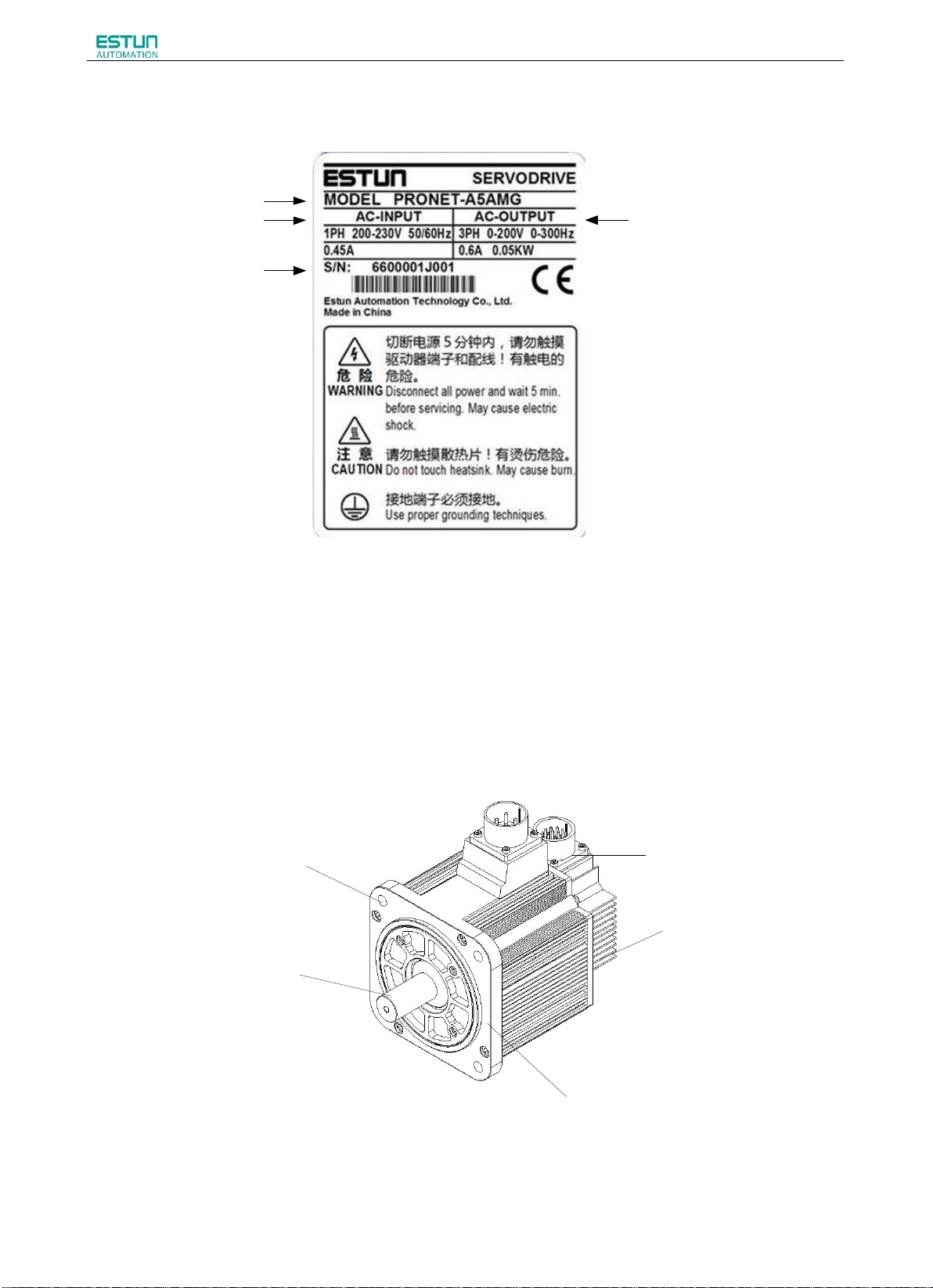

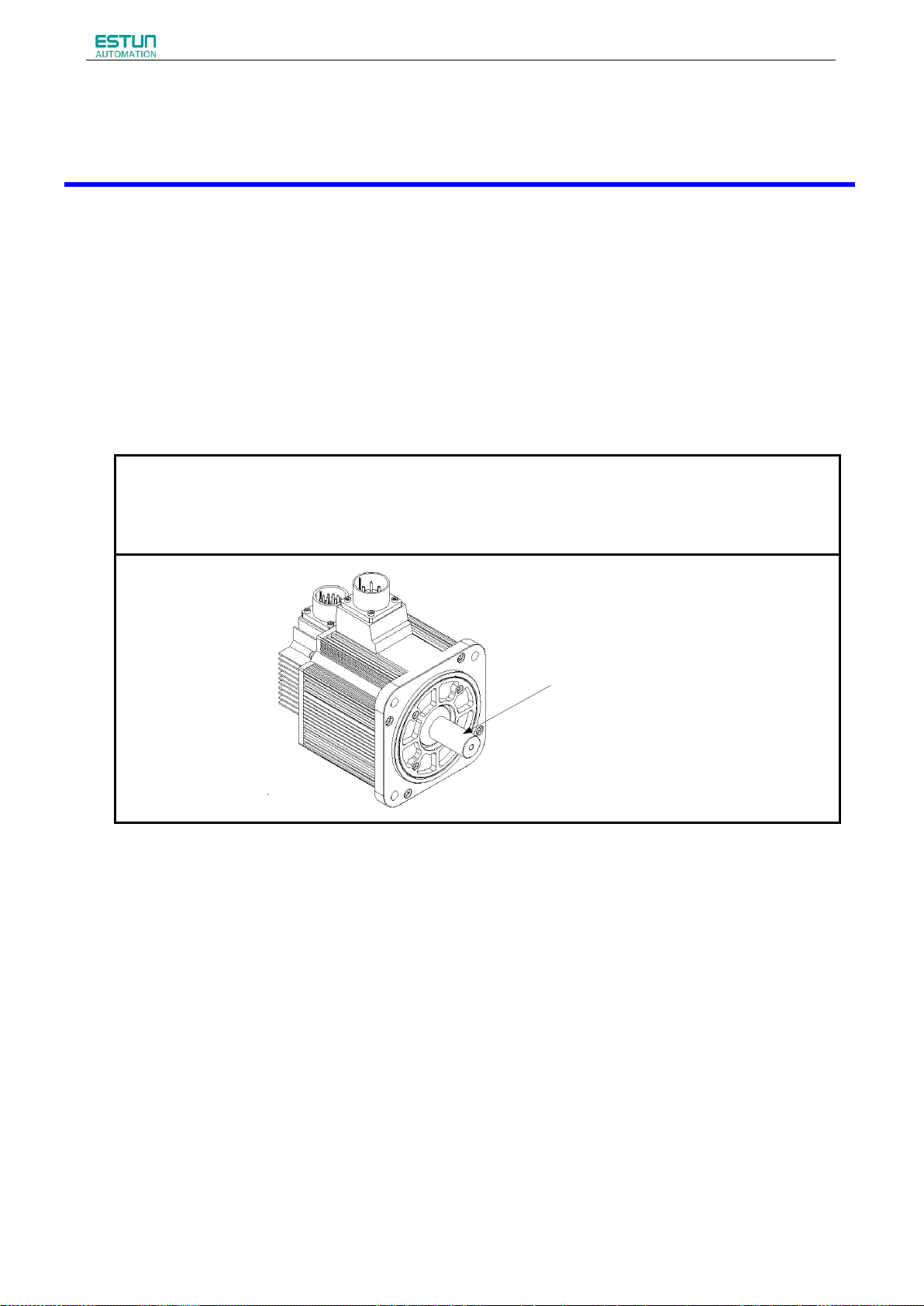

Appearance and Nameplate

{

Serial number

Ratings

Servomotor model

Rated Output

Voltage

Control Mode

E Support extended bus function

Encoder Interface

ProNet Model

Extended module type

1.1.2 Servo drive

ProNet Servo drive Model Designation

A5 0.05kW

01 0.1kW

02 0.2kW

04 0.4 kW

08 0.75 kW

10 1.0 kW

15 1.5 kW

20 2.0 kW

30 3.0 kW

50 5.0 kW

A200VAC

D400VAC

M Pulse analog,CANopen control

ProNet – 10 A E G -EC

-EC EtherCAT bus

None M control style

G 17/20/23 bit serial encoder

(Automatic identification)

ProNet Plus Series AC Servo User's Manual

- 11 -

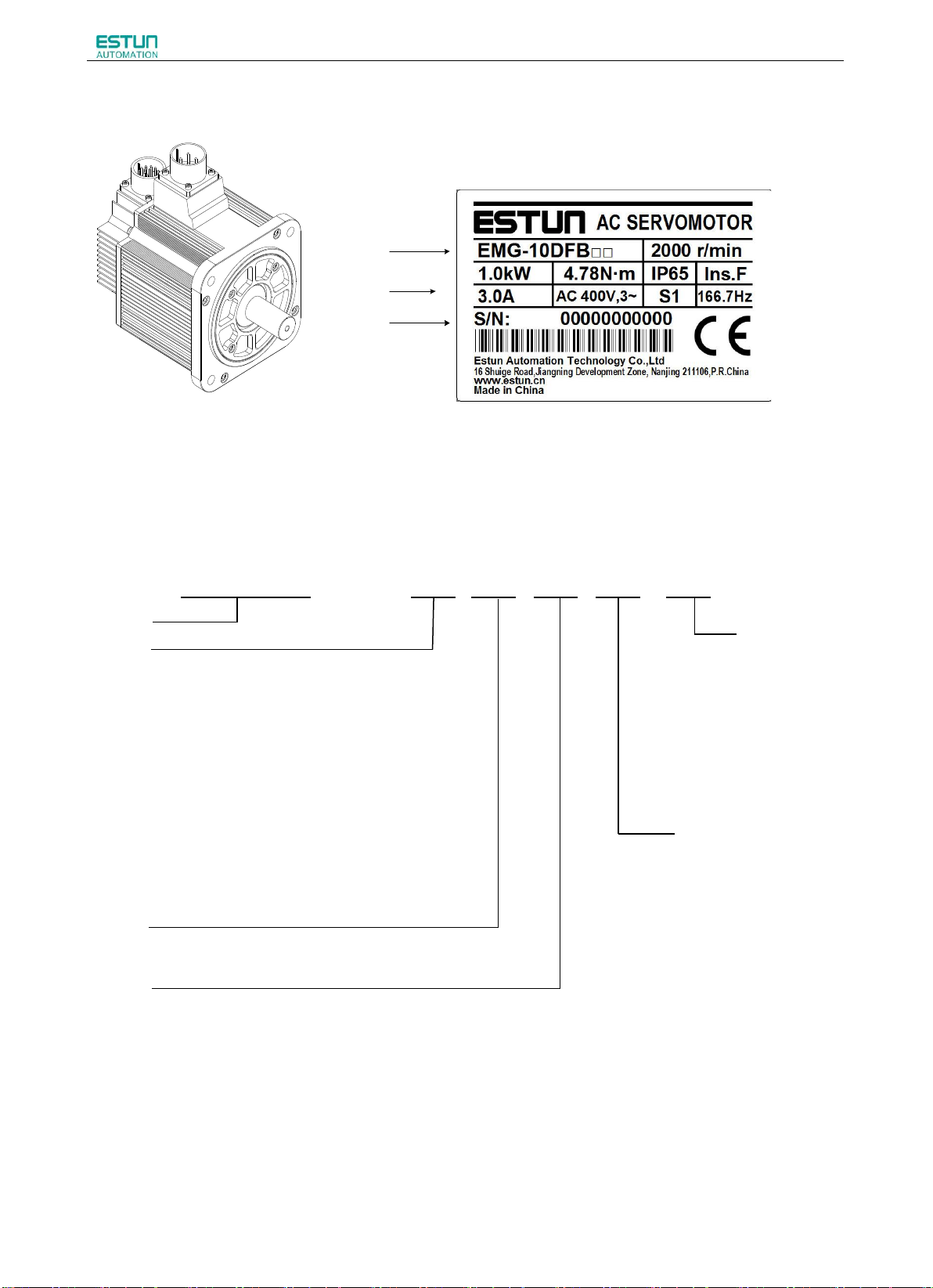

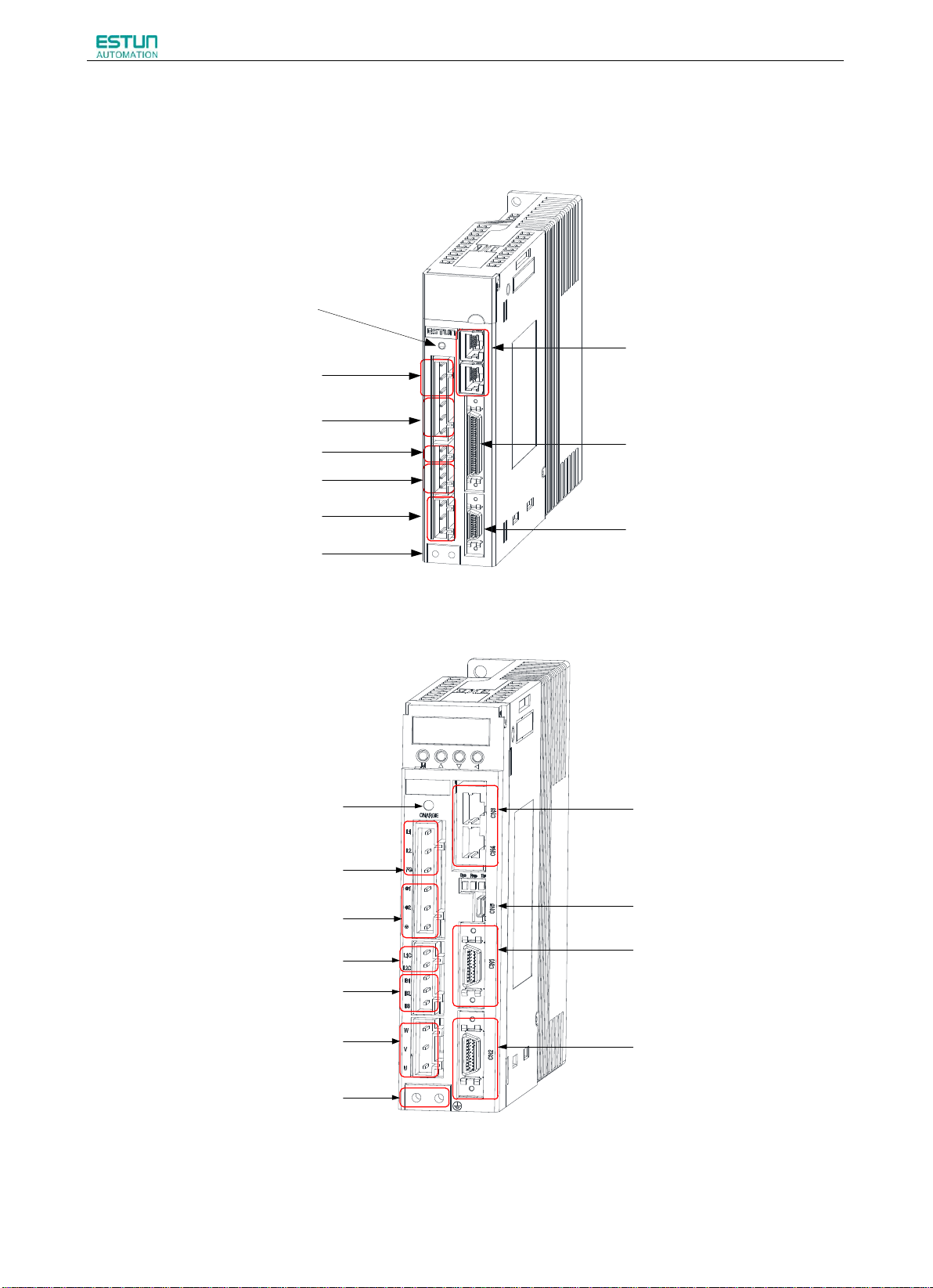

ProNet Servo Drive Appearance

ProNet-A5A/01A/02A/04A ProNet-A5A/01A/02A/04A-EC

ProNet-08A/10A ProNet-08A/10A-EC

ProNet Plus Series AC Servo User's Manual

- 12 -

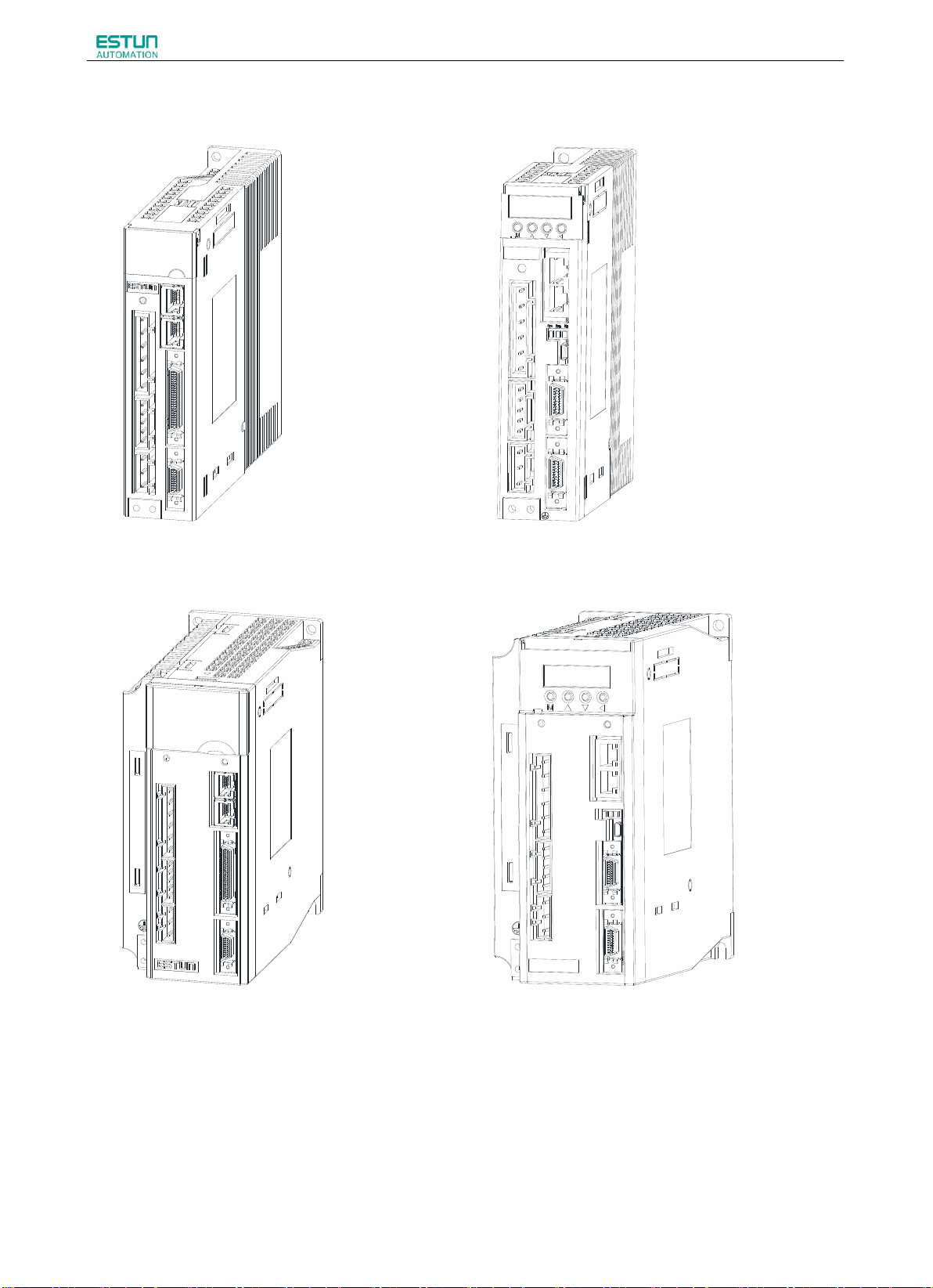

ProNet-15A/20A/10D/15D/20D ProNet-15A/20A/10D/15D/20D-EC

ProNet-30A/50A/30D/50D ProNet-30A/50A/30D/50D-EC

ProNet Plus Series AC Servo User's Manual

- 13 -

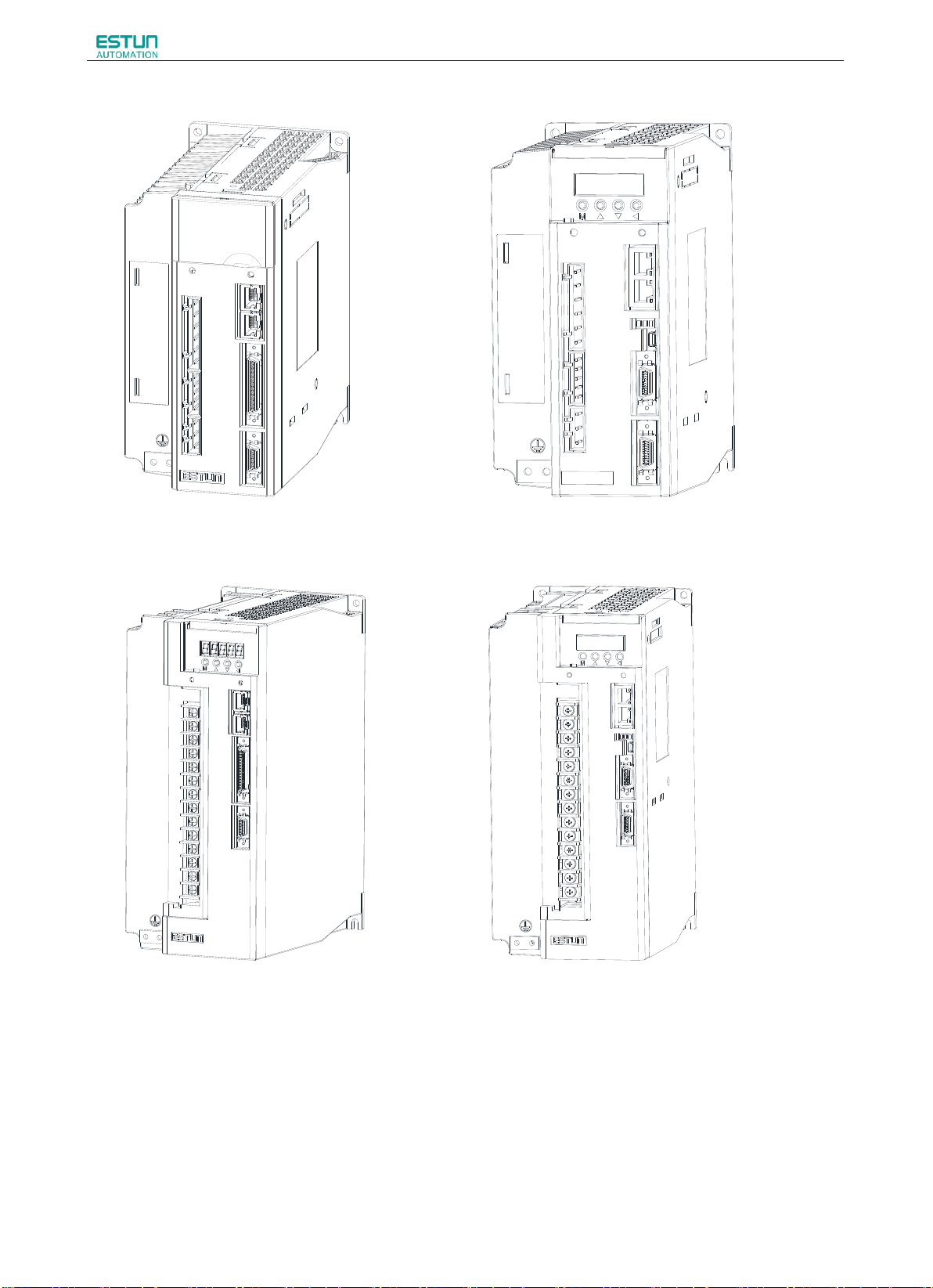

ProNet Servo Drive Nameplate

Servodrive model

Applicable power supply

Applicable servomotor capacity

Serial number

Encoder

Shell

Flange

Output shaft

Mounting hole

1.2 Part Names

1.2.1 Servomotor

Servomotor without gear and brake

ProNet Plus Series AC Servo User's Manual

- 14 -

1.2.2 Servo drive

Charge indicator

Lights when the main circuit power

supply is ON and stays lit as long

as the main circuit power supply

capacitor remains charged.

Main circuit power supply terminals

Connecting terminal of DC reactor

Control power supply terminals

Regenerative resistor

connecting terminals

Ground terminal

Servomotor terminals

Connector for communication

I/O signal connector

Used for reference input signals

and sequence I/O signals.

Encoder connector

Connects to the encoder

in the servomotor.

Charge indicator

Lights when the main circuit power supply is

ON and stays lit as long as the main circuit

power supply capacitor remains charged.

Main circuit power supply terminals

Connecting terminal of DC reactor

Connector for communication

I/O signal connector

Used for reference input

signals and sequence I/O

signals.

Encoder connector

Connects to the encoder

in the servomotor.

Control power supply terminals

Regenerative resistor

connecting terminals

Servomotor terminals

Ground terminal

Connector for debugging

ProNet-A5A/01A/02A/04A

ProNet-A5A/01A/02A/04A-EC

ProNet Plus Series AC Servo User's Manual

- 15 -

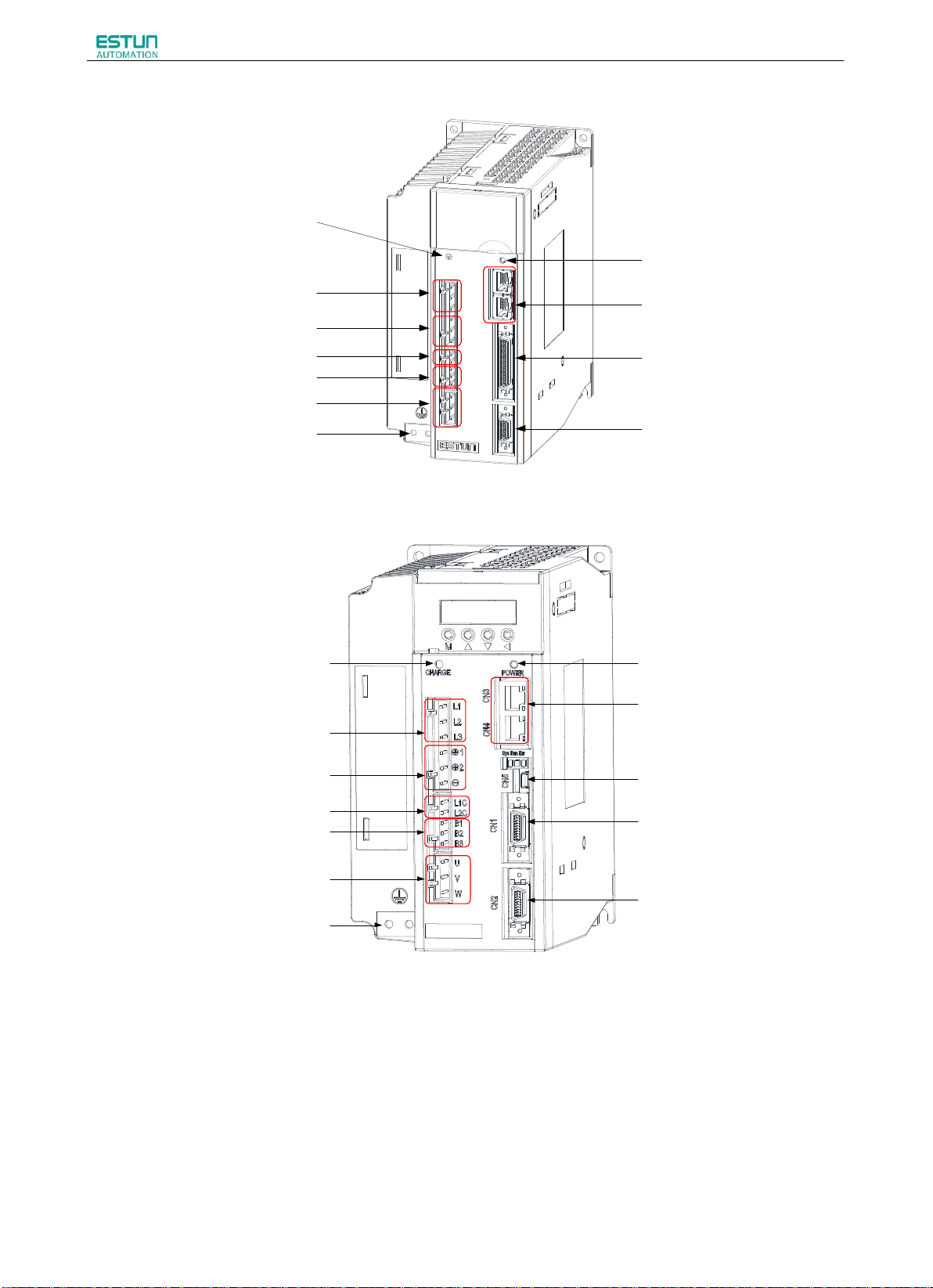

ProNet-08A/10A

Charge indicator

Lights when the main circuit power supply is

ON and stays lit as long as the main circuit

power supply capacitor remains charged.

Main circuit power supply terminals

Connecting terminal of DC reactor

Control power supply terminals

Regenerative resistor

connecting terminals

Ground terminal

Servomotor terminals

Power on indicator

Lights when the control

power supply is on.

Connector for communication

I/O signal connector

Used for reference input signals

and sequence I/O signals.

Encoder connector

Connects to the encoder

in the servomotor.

Charge indicator

Lights when the main circuit power supply is

ON and stays lit as long as the main circuit

power supply capacitor remains charged.

Connecting terminal of DC reactor

Ground terminal

Power on indicator

Lights when the control

power supply is on.

Connector for communication

I/O signal connector

Used for reference input signals

and sequence I/O signals.

Encoder connector

Connects to the encoder

in the servomotor.

Servomotor terminals

Regenerative resistor

connecting terminals

Control power supply terminals

Main circuit power supply terminals

Connector for debugging

ProNet-08A/10A-EC

ProNet Plus Series AC Servo User's Manual

- 16 -

ProNet-15A/20A/10D/15D/20D

Charge indicator

Lights when the main circuit power supply is

ON and stays lit as long as the main circuit

power supply capacitor remains charged.

Main circuit power supply terminals

Connecting terminal of DC reactor

Control power supply terminals

Regenerative resistor

connecting terminals

Ground terminal

Servomotor terminals

Power on indicator

Lights when the control

power supply is on.

Connector for communication

I/O signal connector

Used for reference input signals

and sequence I/O signals.

Encoder connector

Connects to the encoder

in the servomotor.

Charge indicator

Lights when the main circuit power supply is

ON and stays lit as long as the main circuit

power supply capacitor remains charged.

Main circuit power supply terminals

Connecting terminal of DC reactor

Control power supply terminals

Regenerative resistor

connecting terminals

Connector for communication

I/O signal connector

Used for reference input signals

and sequence I/O signals.

Encoder connector

Connects to the encoder

in the servomotor.

Power on indicator

Lights when the control

power supply is on.

Servomotor terminals

Ground terminal

Connector for debugging

ProNet-15A/20A/10D/15D/20D-EC

ProNet Plus Series AC Servo User's Manual

- 17 -

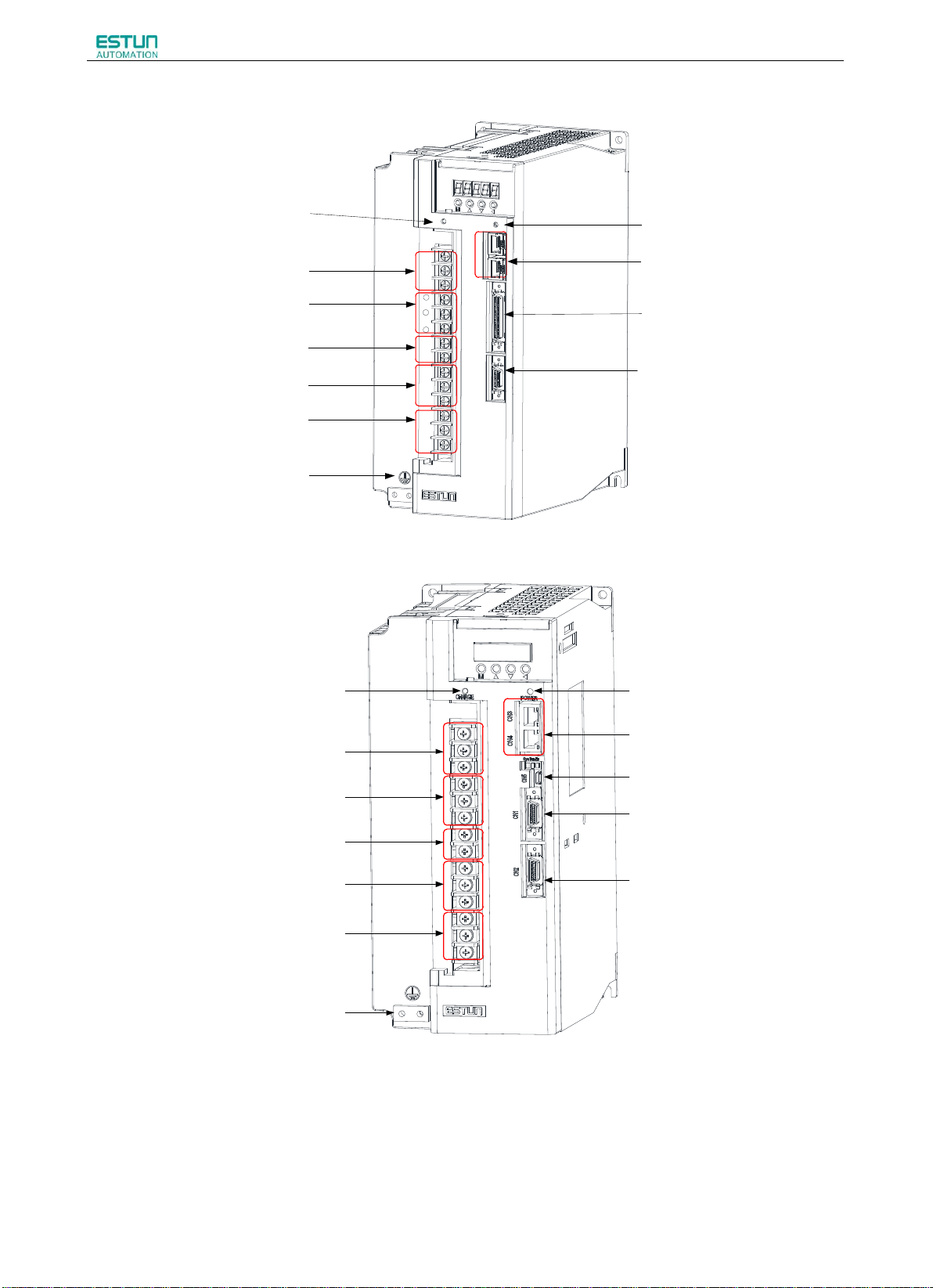

ProNet-30A/50A/30D/50D

Charge indicator

Lights when the main circuit power supply is

ON and stays lit as long as the main circuit

power supply capacitor remains charged.

Main circuit power supply terminals

Connecting terminal of DC reactor

Control power supply terminals

Regenerative resistor

connecting terminals

Ground terminal

Servomotor terminals

Power on indicator

Lights when the control

power supply is on.

Connector for communication

I/O signal connector

Used for reference input signals

and sequence I/O signals.

Encoder connector

Connects to the encoder in

the servomotor.

CN3

CN4

CN1

CN2

CHARGE

POWER

L1

L2

L3

L1C

L2C

B1

B2

B3

U

V

W

+

-

1

+

2

Power on indicator

Lights when the control

power supply is on.

Connector for communication

I/O signal connector

Used for reference input signals

and sequence I/O signals.

Encoder connector

Connects to the encoder

in the servomotor.

Charge indicator

Lights when the main circuit power supply is

ON and stays lit as long as the main circuit

power supply capacitor remains charged.

Main circuit power supply terminals

Connecting terminal of DC reactor

Control power supply terminals

Regenerative resistor

connecting terminals

Servomotor terminals

Ground terminal

Connector for debugging

ProNet-30A/50A/30D/50D-EC

ProNet Plus Series AC Servo User's Manual

- 18 -

Chapter 2

Before installation

Anticorrosive paint is coated on the edge of the servomotor shaft. Clean off the anticorrosive paint thoroughly using

a cloth moistened with thinner.

Avoid getting thinner on other parts of the servomotor when cleaning the shaft.

Anticorrosive paint

Installation

2.1 Servomotor

Servomotor can be installed either horizontally or vertically. However, if the servomotor is installed incorrectly, the

service life of the servomotor will be shortened or unexpected problems may occur.

Please observe the installation instructions described below to install the servomotor correctly.

2.1.1 Storage

When the servomotor is not being used, store it in an area with a temperature between -25℃ and 60℃ with thepower

cable disconnected.

2.1.2 Installation Sites

The servomotor is designed for indoor use.Install the servomotor in an environment which meets the following

conditions.

Free from corrosive and explosive gases.

Well-ventilated and free from dust and moisture.

Ambient temperature from 0 to 40℃.

Relative humidity from 26% to 80%( non-condensing).

Facilitates inspection and cleaning.

ProNet Plus Series AC Servo User's Manual

- 19 -

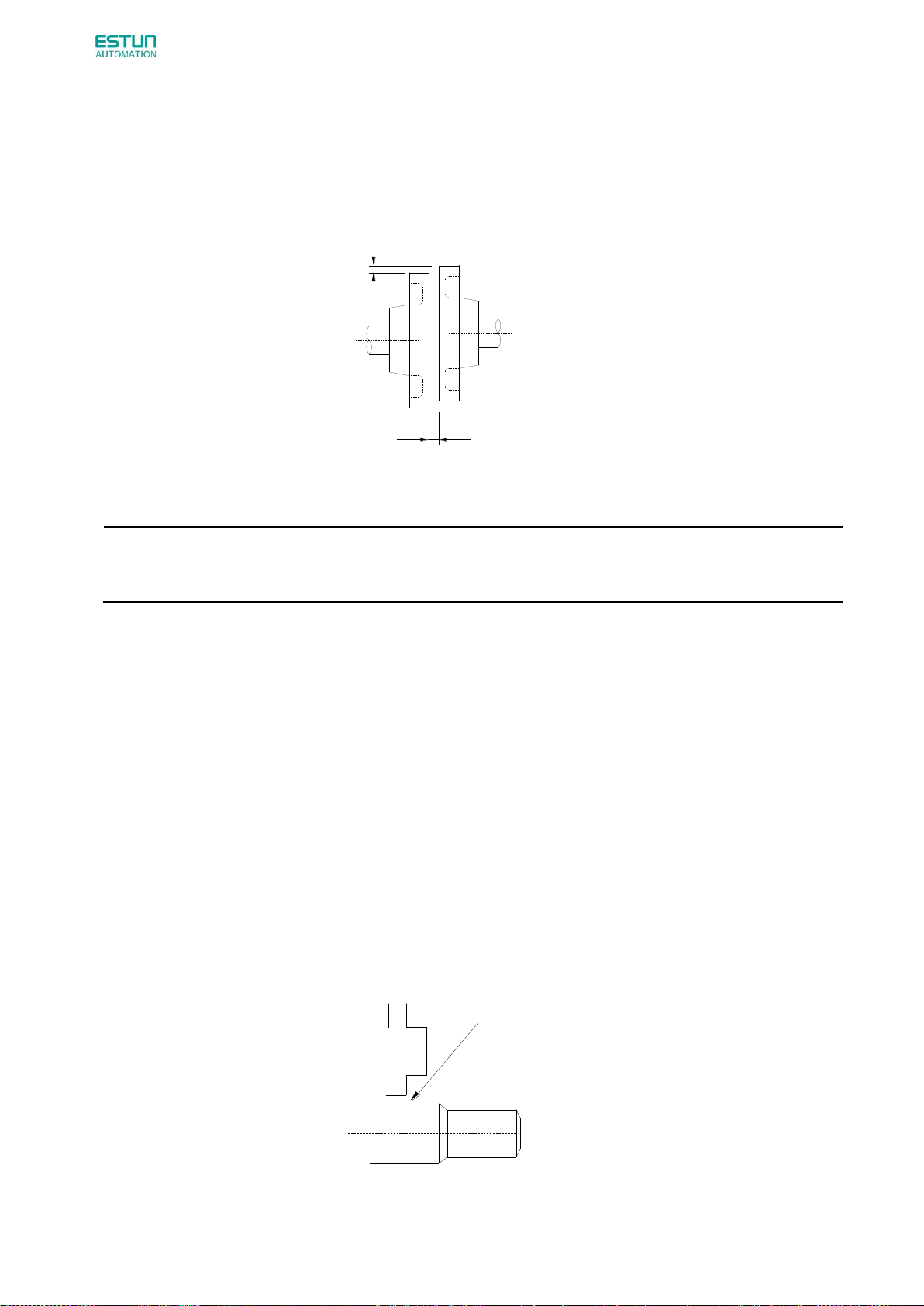

2.1.3 Installation Alignment

Note:

·If the alignment accurancy is incorrect , vibration will occur, resulting in damage to the bearings.

·Mechanical shock to the shaft end is forbidden, otherwise it may result in damage to the encoder of the servomotor.

Through Shaft Section

Align the shaft of the servomotor with that of the machinery shaft to be controlled. Then connect the two shafts withan

elastic coupling.

Install the servomotor so that alignment accurancy falls within the range shown below.

Measure this distance at four different positions in the circumference. The difference between the maximum and

minimum measurements must be 0.03mm or less.(Turn together with couplings.)

2.1.4 Installation Orientation

Servomotor can be installed ethier horizontally or vertically.

2.1.5 Handling Oil and Water

If the servomotor is used in a location that is subject to water or oil drops, make sure of the servomotor protective

specification. If the servomotor is required to meet the protective specification to the through shaft section by default,

use a servomotor with an oil seal.

Through shaft section

It refers to the gap where the shaft protrudes from the end of the servomotor.

ProNet Plus Series AC Servo User's Manual

- 20 -

2.1.6 Cable Tension

I

n

s

t

a

l

l

a

t

i

o

n

o

r

i

e

n

t

a

t

i

o

n

Situation

Notes on installation

When installed in a control

panel

Design the control panel size, unit layout, and cooling method so that the temperature

around the periphery of the servo drive does not exceed 55℃.

When installed near a

heating unit

Suppress radiation heat from the heating unit and a temperature rise caused by

convection so that the temperature around the periphery of the servo drive does not

exceed 55℃.

When installed near a

source of vibration

Install a vibration isolator underneath the servo drive to prevent it from receiving vibration.

When installed in a location

subject to corrosive gases

Take appropriate action to prevent corrosive gases. Corrosive gases do not immediately

affect the servo drive, but will eventually cause contactor-related devices to malfunction.

Others

Avoid installation in a hot and humid site or where excessive dust or iron powder is

present in the air.

When connecting the cables, the bending radius should not be too small, do not bend or apply tension to cables.

Since the conductor of a signal cable is very thin (0.2 mm or 0.3 mm), handle it with adequate care.

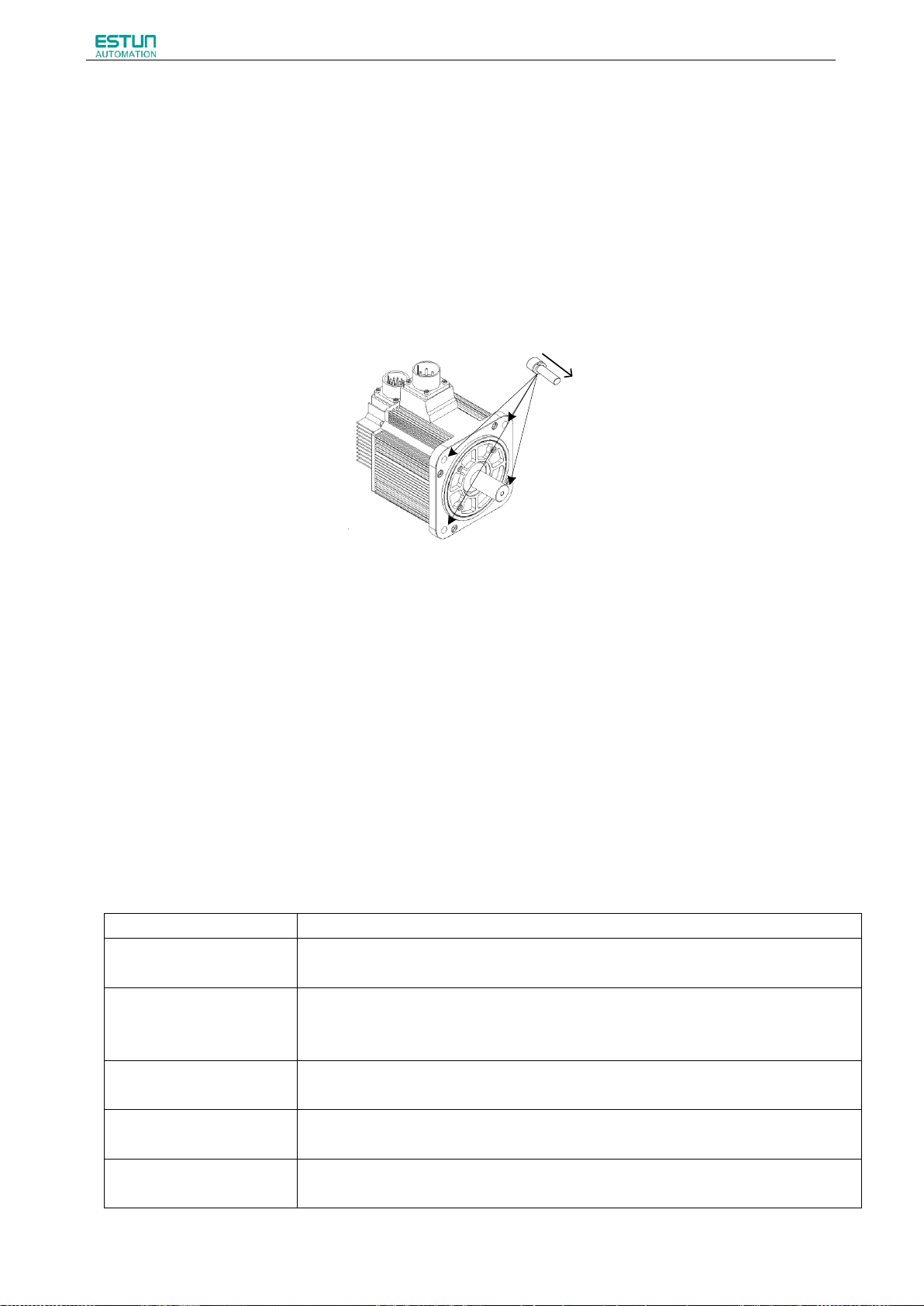

2.1.7 Install to the Client

When the servo motor is mounted to the client, please firmly secure the servo motor by the screws with backing ring

as shown in the figure.

2.2 Servo Drive

ProNet series servo drive is a base-mounted type. Incorrect installation will cause problems. Always observe the

installation instructions described below.

2.2.1 Storage

When the servomotor is not being used, store it in an area with a temperature between -25℃ and 85℃ with the

power cable disconnected.

2.2.2 Installation Sites

Notes on installation are shown below.

ProNet Plus Series AC Servo User's Manual

- 21 -

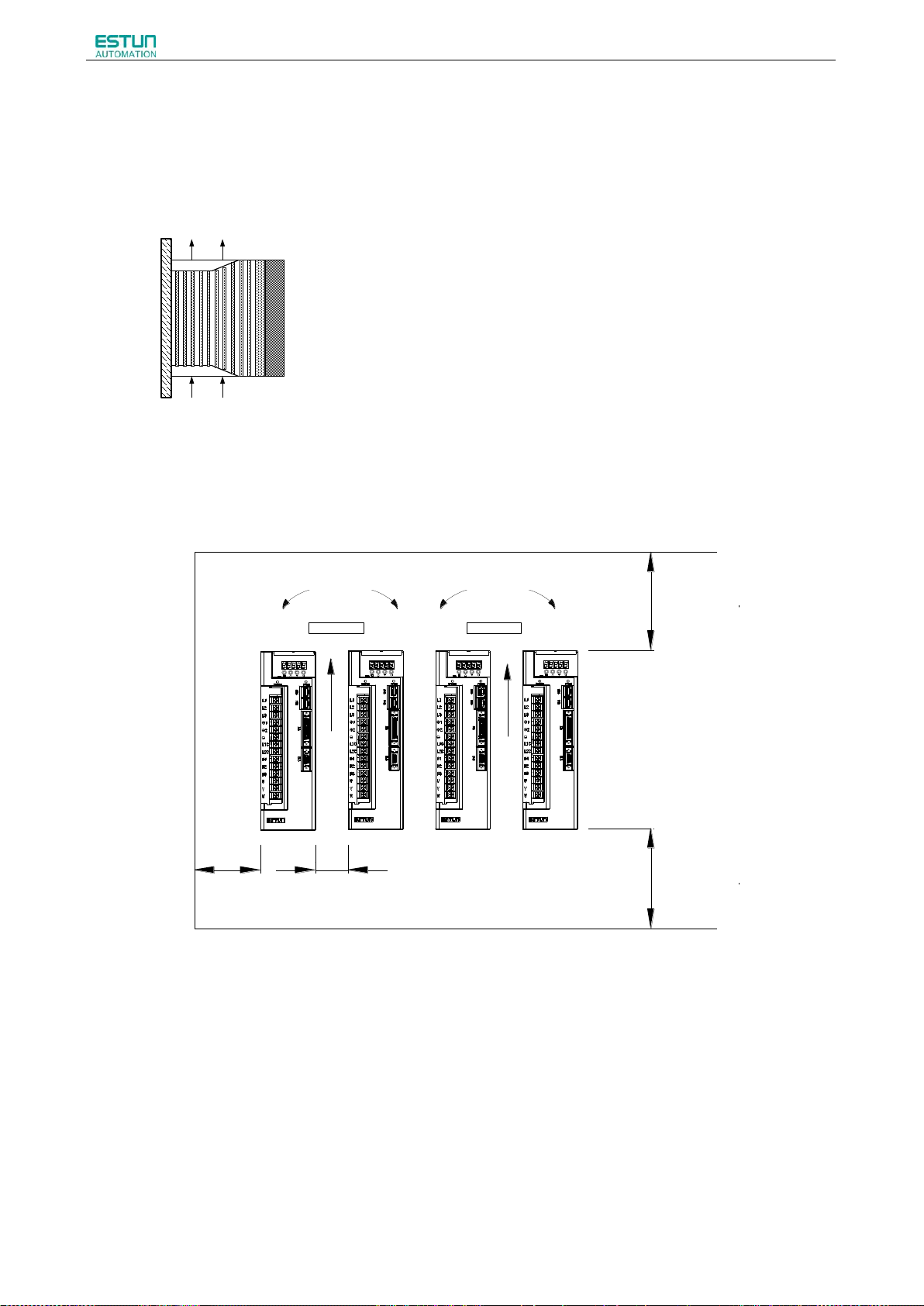

2.2.3 Installation Orientation

Wall

Ventilation

Colling Fan

Colling Fan

Cooling Fan

Cooling Fan

30mm min

10mm min

50mm min

50mm min

Install the servo drive perpendicular to the wall as shown in the figure. The servo drive must be oriented this way

because it is designed to be cooled by natural convection or a cooling fan if required. Firmly secure the servo drive

through two mounting holes.

2.2.4 Installation Method

When installing multiple servo drives side by side in a control panel, observe the following installation method.

■Installation Orientation

Install servo drive perpendicular to the wall so that the front panel (containing connectors) faces outward.

■Cooling

Provide sufficient space around each servo drive to allow cooling by natural convection or fans.

■Installing side by side

When installing servo drives side by side, provide at least 10mm space between each individual servo drive and at

least 50mm space above and below each one as well as shown in the figure above. Ensure the temperature inside the

control panel is evenly distributed, and prevent the temperature around each servo drive from increasing excessively.

ProNet Plus Series AC Servo User's Manual

- 22 -

Install cooling fans above the servo drives if necessary.

■Working conditions

1.Temperature: 0~ 55℃

2.Humidity: 5%~95%RH

3.Vibration: 4.9m/s2 or less

4.Ambient temperature to ensure long-term reliability:45℃ or less

5.Condensation and Freezing: None

ProNet Plus Series AC Servo User's Manual

- 23 -

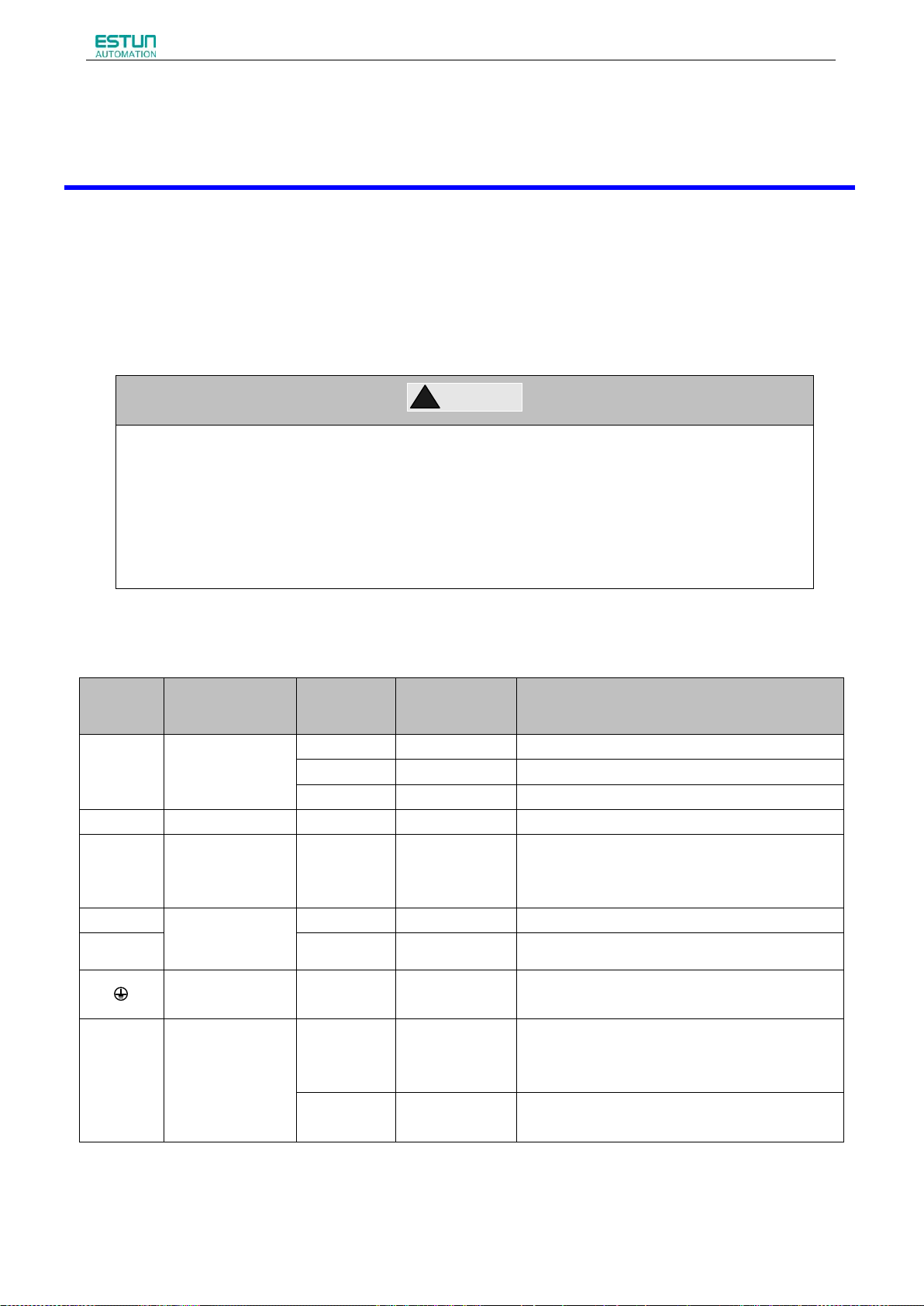

3.1 Main Circuit Wiring

!

CAUTION

·Do not bundle or run power and signal lines together in the same duct. Keep power andsignallines

separated by at least 300 mm.

·Use twisted-pair shielded wires or multi-core twisted-pair shielded wires for signal and encoder feedback

lines.

·The maximum length is 3 m for reference input lines and 20 m for encoder feedback lines.

·Do not touch the power terminals for 5 minutes after turning power OFF because high voltage may still

remain in the servo drive.

Terminal

Symbol

Name

Main Circuit

Voltage(V)

Servo Drive

Model

ProNet-

Functions

L1,L2,L3

Main circuit

power supply

input terminal

200

A5A-04A

Single-phase 200~230VAC +10%~-15% (50/60Hz)

200

08A-50A

Three-phase 200~230VAC +10%~-15% (50/60Hz)

400

10D-50D

Three-phase 380~440VAC +10%~-15% (50/60Hz)

FG

FG

200

A5A-04A

Normally not connected.

U,V,W

Servomotor

connection

terminals

-

-

Connect to the servomotor.

L1C,L2C

Control circuit

power supply

input terminal

200

A5A -50A

Single-phase 200~230VAC +10%~-15% (50/60Hz)

24V,GND

400

10D-50D

24VDC +10%~-10%

Ground terminals

-

-

Connects to the power supply ground terminals

and servomotor ground terminal.

B1,B2,B3

External

regenerative

resistor

connection

terminal

200

A5A -04A

Connect an external regenerative

resistor(provided by customer) between B1 and

B2.

200

08A-50A

If using an internal regenerative resistor, please

short B2 and B3. Remove the wire between B2

Please observe the following instructions while wiring the main circuit.

Chapter 3

Wiring

3.1.1 Names and Functions of Main Circuit Terminals

ProNet Plus Series AC Servo User's Manual

- 24 -

Terminal

Symbol

Name

Main Circuit

Voltage(V)

Servo Drive

Model

ProNet-

Functions

400

10D-50D

and B3 and connect an external regenerative

resistor(provided by customer) between B1 and

B2, if the capacity of the internal regenerative

resistor is insufficient.

○

+ 1,○+ 2

DC reactor for

harmonic

suppression

terminal

200

A5A-50A

Normally short○+ 1and○+ 2.

If a countermeasure against power supply

harmonic waves is needed, connect a DC reactor

between○+ 1and ○+ 2.

400

10D-50D

○

-

Main circuit

minus terminal

200

A5A-50A

Normally not connected.

400

10D-50D

L1 L2

Single-phase 200~230V (50/60Hz)

+10%

-15%

Power OFF Power ON

1KM 1SUP

1KM

1Ry

L1

L2

W

V

U

M

PG

A(1)

B(2)

C(3)

D(4)

L2C

L1C

CN2

1Ry

1D

+24V

0V

1Ry

1PL (Servo Alarm Display)

ALM+

ALM-

ProNet

Series Servodrive

1

2

Ground Terminal

Encoder

Servodrive

Magnetic Contactor

Molded-case Circuit Breaker

Surge Protector

Noise Filter

Be sure to connect a surge suppressor to the

excitation coil of the magnetic contactor and relay.

B1

B2

B3

B1

B2

B3

External regenerator resistor

3.1.2 Typical Main Circuit Wiring Examples

Single-phase 200V ProNet-A5A~04A

Note

1.The L1,L2,L3 and L1C,L2C terminals wiring method of ProNet-A5A~04Aservo drives is different from other ProNet

series servo drives. Please note the specific terminal definition while wiring.

2.The main circuit power supply of ProNet-A5A~04A is Single-phase 200V.

3.External regenerative resistor for ProNet-A5A~04A is provided by customer, the model of 60W,50Ωresistor is

recommended.

4.Change Pn521.0 from “1” to “0” when using the external regenerative resistor in ProNet-A5A~04A servo drives.

ProNet Plus Series AC Servo User's Manual

- 25 -

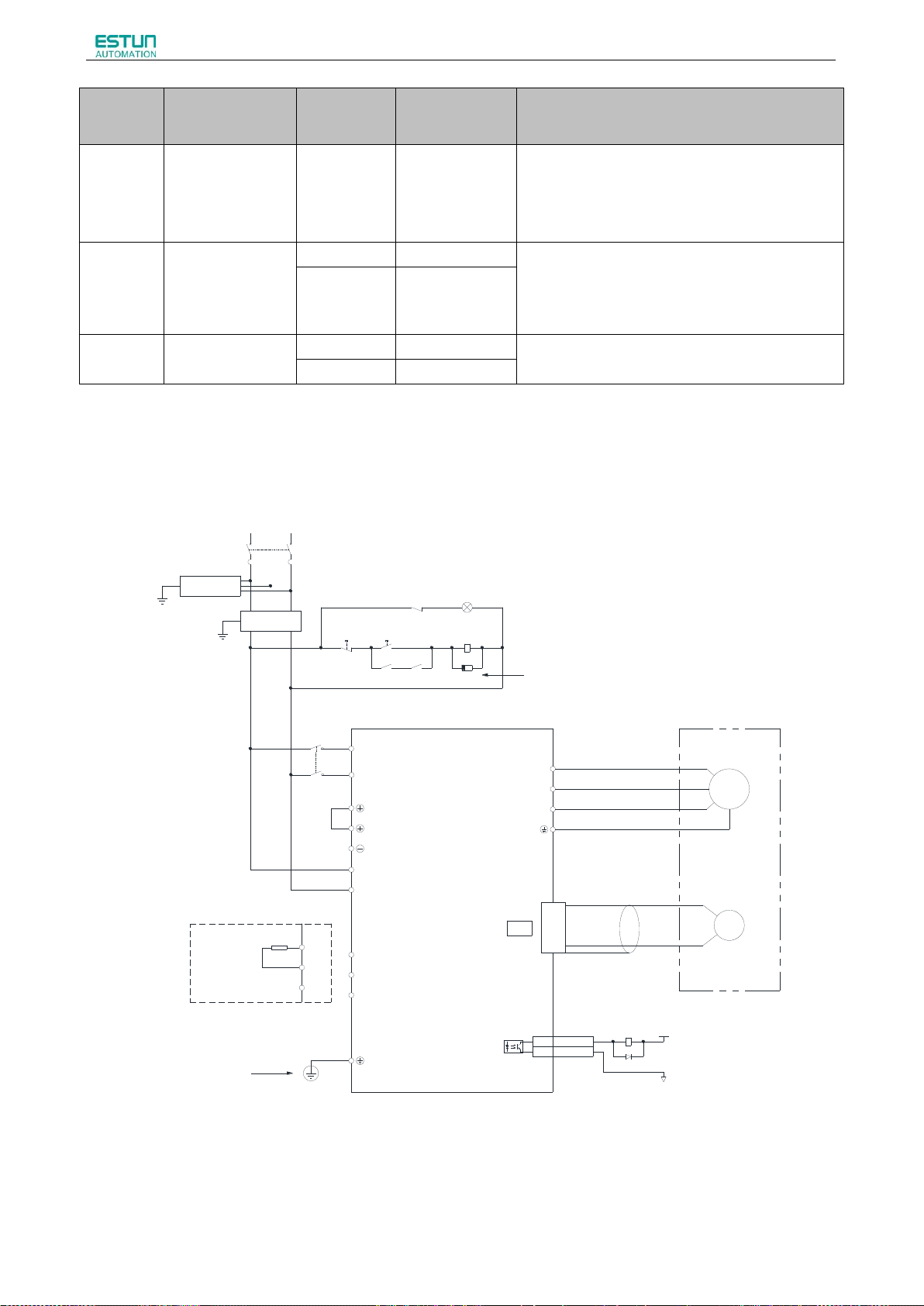

Three-phase200V ProNet-08A~50A

Noise Filter

L1 L2 L3

Three-phase 200~230V (50/60Hz)

+10%

-15%

Power OFF Power ON

1KM 1SUP

1KM

1Ry

L1

L2

L3

W

V

U

M

PG

Servomotor

Encoder

A(1)

B(2)

C(3)

D(4)

L2C

L1C

CN2

1Ry

1D

+24V

0V

Surge Protector

Magnetic Contactor

Molded-case Circuit Breaker

1Ry

1PL (Servo Alarm Display)

ALM+

ALM-

Be sure to connect a surge suppressor to the

excitation coil of the magnetic contactor and relay..

ProNet

Series Servodrives

1

2

B1

B2

B3

B2

B1

External Regenerator Resistor

B3

Ground Terminal

Noise Filter

L1 L2 L3

Three-phase 380~440V (50/60Hz)

+10%

-15%

Power OFF Power ON

1KM 1SUP

1KM

1Ry

L1

L2

L3

W

V

U

M

PG

Servomotor

Encoder

A(1)

B(2)

C(3)

D(4)

CN2

1Ry

1D

+24V

0V

Surge Protector

Magnetic Contactor

Molded-case Circuit Breaker

1Ry

1PL (Servo Alarm Display)

ALM+

ALM-

Be sure to connect a surge suppressor to the

excitation coil of the magnetic contactor and relay..

ProNet

Series Servodrives

1

2

B1

B2

B3

B2

B1

External Regenerator Resistor

B3

Ground Terminal

GND

24V

24VDC Power Supply

Three-phase 400V ProNet-10D~50D

ProNet Plus Series AC Servo User's Manual

- 26 -

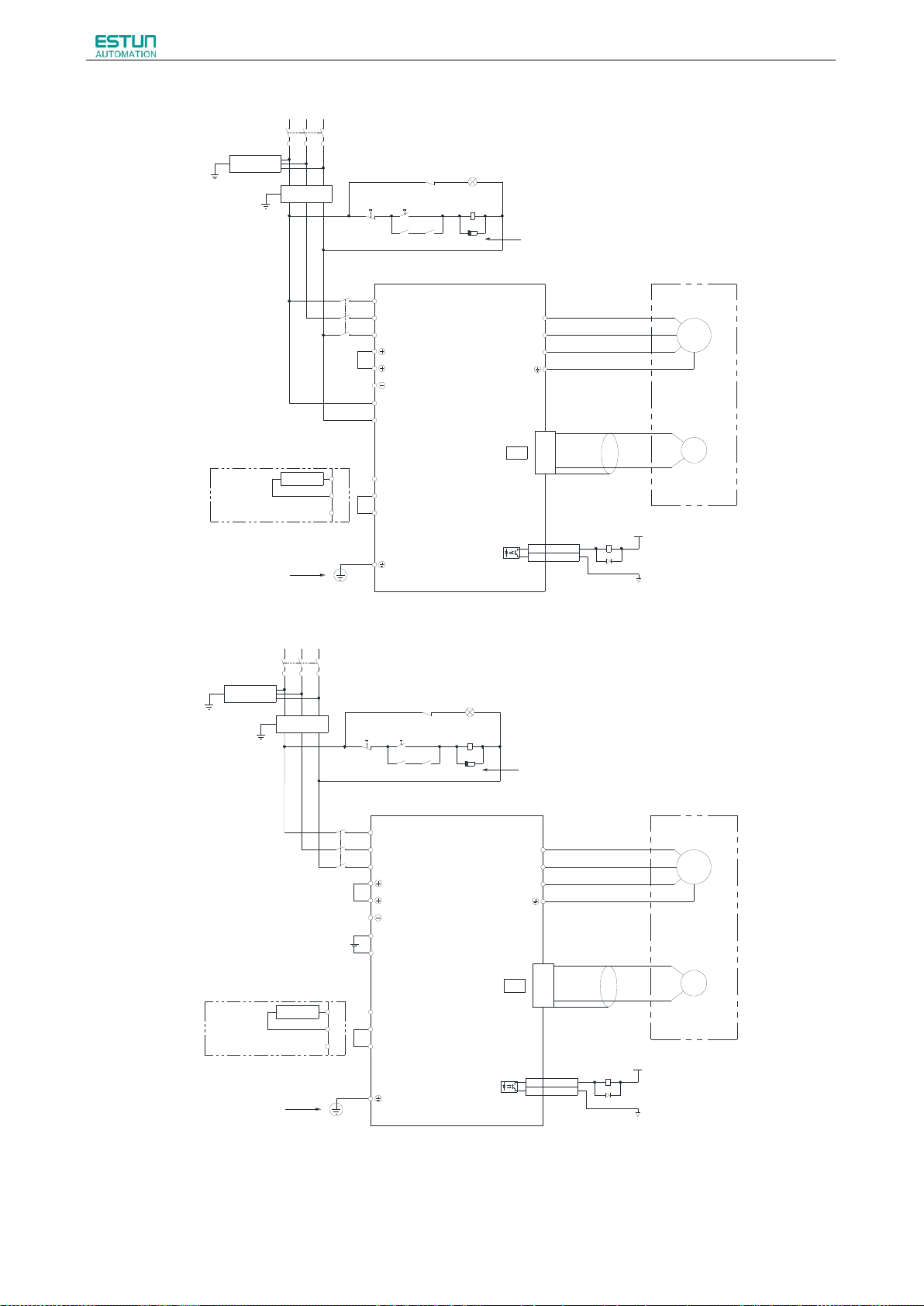

3.2 I/O Signals

+

A/D

2KΩ

150Ω

150Ω

2KΩ

PULS / CW / A

SIGN / CCW / B

Connect Shield to Connector Shell

Open-Collector Reference

Use

Speed Reference(±0~10V/Rated Speed)

Torque Reference(±0~10V/Rated Torque)

Position Reference

Signal Allocations can be Modified:

S-ON: Servo ON

P-CON: Proportion Control

P-OT:Forward Run Prohibited

N-OT:Reverse Run Prohibited

ALM-RST: Alarm Reset

CLR: Clear Error Pulse

P-CL:Forward Torque Limit

N-CL:Reverse Torque Limit

SHOM: Home

ORG: Zero Position

+24V

P P P P

PG Divided Ratio Output

Applicable Line Output

AM26LS32A Manufactured by TI or the Equivalent.

Signal Allocations can be Modified:

V-CMP: Speed Coincidence

COIN: Positioning Completion

TGON:Rotation Detection

S-RDY:Servo Ready

CLT:Torque Limit Detection

BK:Brake Interlock

PGC: Encoder C-Pulse Output

OT: Over Travel

RD: Servo Enabled Motor Excitation Output

HOME: Home Completion Output

P

Represents Twisted-pair Wires

ALM: Servo Alarm Output

Photocoupler Output:

Maximum Operating Voltage:DC30V

Maximum Output Current:DC50mA

-

-

+

ref

ref

40K

10K

40K

10K

1Ry

1D

+24V

0V

PAO+

20

PAO-21

PBO+

22

PBO-

23

PCO+24

PCO-

25

DGND

50

TGON+

5

TGON-

6

S-RDY+

9

S-RDY-

10

V-CMP+11

V-CMP-

12

ALM+7

ALM-

8

VREF+ 1

VREF-

2

TREF+

26

TREF- 27

PPI

34

PULS+

30

PULS-

31

SIGN+

32

SIGN-

33

DICOM

13

S-ON

14

P-CON

15

P-OT

16

N-OT 17

ALM-RST

39

CLR

40

P-CL 41

N-CL 42

Shield

3.3KΩ

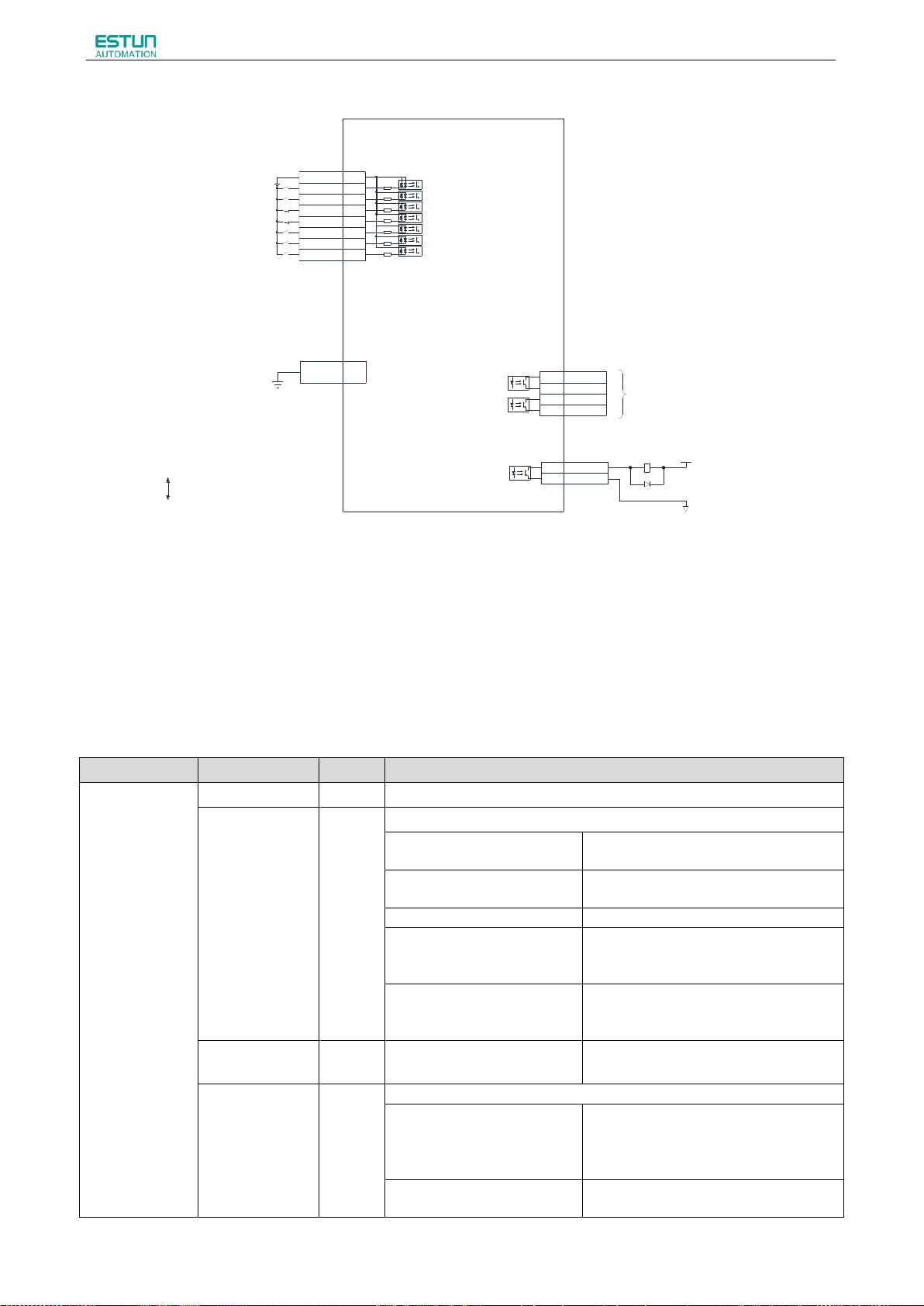

3.2.1 Examples of I/O Signal Connections

The I/O signal connections diagram of the ProNet-□□□MG servo drives is as shown in the following figure.

ProNet Plus Series AC Servo User's Manual

- 27 -

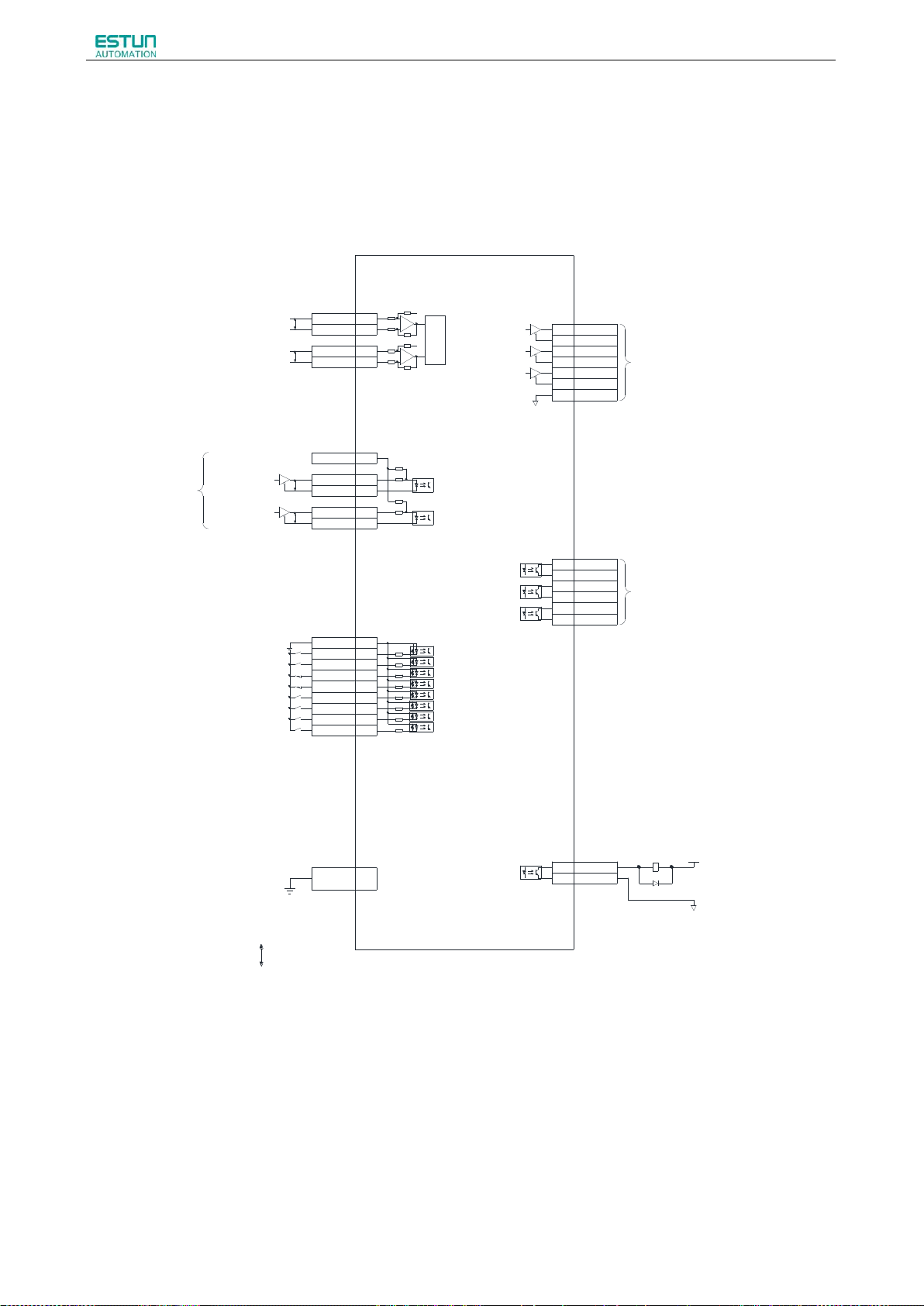

The I/O signal connections diagram of the ProNet-□□□EG-EC servo drives is as shown in the following figure.

Allocable signals are as following:

S-ON: Servo ON

P-CON: P Control

P-OT: Forward Run Prohibited

N-OT: Reverse Run Prohibited

ALM-RST: Alarm Reset

ALM: Servo Alarm Output

Photocoupler Output:

Maximum Operating Voltage: DC30V

Maximum Output Current: DC50mA

TGON+11

COM2

14

S-RDY+

13

COM214

Allocable signals are as following:

COIN: Positioning Completion

TGON:Rotation Detection

S-RDY:Servo Ready

CLT:Torque Limit Detection

BK:Brake Interlock

PGC: Encoder C-Pulse Output

OT:Over Travel

RD: Servo Enabled Motor Excitation Output

HOME: Home Completion Output

ALM+

12

COM2

14

1Ry

1D

+24V

0V

+24V

DICOM

20

S-ON

15

P-CON

16

P-OT 17

N-OT

18

ALM-RST

19

3.3KΩ

Connect Shield to Connector Shell.

Shield

Shell

P

Represents Twisted-pair Wires

EXT1

3

EXT2

4

Signals EXT1 and EXT2 are unable

to allocate, which shall be

connected to external signals.

Control Mode

Signal Name

Pin No.

Function

Speed

Position

Torque

/S-ON

14

Servo ON:Turns the servomotor on.

/P-CON

15

Function selected by parameter.

Proportional control

reference

Switches the speed control loop from PI

to P control when ON.

Direction reference

With the internally set speed

selection:Switch the rotation direction.

Control mode switching

Enables control mode switching.

Zero-clamp reference

Speed control with zero-clamp

function:Reference speed is zero when

ON.

Reference pulse block

Position control with reference

pulse:Stops reference pulse input when

ON.

P-OT

N-OT

16

17

Forward run prohibited

Reverse run prohibited

Overtravel prohibited: Stops

servomotor when OFF.

/PCL

/NCL

41

42

Function selected by parameter.

Forward external

torque limit ON

Reverse external

torque limit ON

Current limit function enabled when

ON.

Internal speed switching

With the internally set speed selection:

Switches the internal speed settings.

3.2.2 I/O Signal Names and Functions

Input Signals

The input signals description of ProNet-□□□MG servo drives is as shown in the following table.

ProNet Plus Series AC Servo User's Manual

- 28 -

Control Mode

Signal Name

Pin No.

Function

/ALM-RST

39

Alarm reset: Releases the servo alarm state.

DICOM

13

Control power supply input for I/O signals: Provide the +24V DC power

supply

Speed

VREF+

1

Speed reference input: ±10V.

VREF-

2

Position

PULS+

30

Pulse reference input mode:

Sign + pulse train

CCW + CW pulse

Two-phase pulse (90º phase differential)

PULS-

31

SIGN+

32

SIGN-

33

PPI

34

Power supply input for open collector reference (2KΩ/0.5W resistor is

built into the servo drive).

/CLR

40

Positional error pulse clear input: Clear the positional error pulse during

position control.

SHOM

-

Homing trigger signal(effective at the rising edge),allocated by Pn509 or

Pn510

ORG

-

Zero Position(effective at high level), allocated by Pn509 or Pn510

Torque

T-REF+

26

Torque reference input: ±10V.

T-REF-

27

Control Mode

Signal Name

Pin No.

Function

Speed

Position

Torque

/S-ON

15

Servo ON:Turns the servomotor on.

/P-CON

16

Function selected by parameter.

Proportional control

reference

Switches the speed control loop from PI

to P control when ON.

P-OT

N-OT

17

18

Forward run prohibited

Reverse run prohibited

Overtravel prohibited: Stops

servomotor when OFF.

/ALM-RST

19

Alarm reset: Releases the servo alarm state.

DICOM

20

Control power supply input for I/O signals: Provide the +24V DC power

supply

Position

EXT1

3

Touch Probe input signals

EXT2

4

Control Mode

Signal Name

Pin No.

Function

Speed

Position

Torque

/TGON+

5

Detects when the servomotor is rotating at a speed higher than

the motor speed seeting.

/TGON-

6

ALM+

7

Servo alarm:

Turns off when an error is detected.

ALM-

8

/S-RDY+

9

Servo ready:

ON if there is no servo alarm when the control/main circuit power

supply is turned ON.

/S-RDY-

10

PAO+

20

Phase-A signal

Converted two-phase pulse(phases A

and B) encoder output.

PAO-

21

PBO+

22

Phase-B signal

PBO-

23

PCO+

24

Phase-C signal

Zero-point pulse(Phase-C) signal

The input signals description ofProNet-□□□EG-EC servo drives is as shown in the following table.

Output signals

The output signals description ofProNet-□□□MG servo drives is as shown in the following table.

ProNet Plus Series AC Servo User's Manual

- 29 -

Control Mode

Signal Name

Pin No.

Function

PCO-

25

FG

Shell

Connect frame to ground if the shield wire of the

I/O signal cable is connected to the connector shell.

Speed

/V-CMP+

11

Speed coincidence:

Detects whether the motor speed is within the setting range and

if it matches the reference speed value.

/V-CMP-

12

Position

/COIN+

11

Positioning completion:

Turns ON when the number of positional error pulses reaches

the value set. The setting is the number of positional error pulses

set in the reference units.

/COIN-

12

Reserved

/CLT

—

Reserved terminals:

The functions allocated to /TGON, /S-RDY, and /V-CMP (/COIN)

can be changed by using the parameters.

/CLT:Torque limit output

Turns on when it reaches the value set.

/BK:Brake interlock output

Releases the brake when ON,

/PGC: C pulse output

OT: Over travel signal output

/RD: Servo enabled motor excitation output

/HOME: Home completion output

/BK

—

4,18,19,29,35

36,37,38,43

44,45,47,49

Not used.

Control Mode

Signal Name

Pin No.

Function

Speed

Position

Torque

/TGON+

11

Detects when the servomotor is rotating at a speed higher than

the motor speed seeting.

/TGON-

14

ALM+

12

Servo alarm:

Turns off when an error is detected.

ALM-

14

/S-RDY+

13

Servo ready:

ON if there is no servo alarm when the control/main circuit power

supply is turned ON.

/S-RDY-

14

FG

Shell

Connect frame to ground if the shield wire of the

I/O signal cable is connected to the connector shell.

Reserved

/CLT

—

Reserved terminals:

The functions allocated to /TGON and /S-RDY can be changed

by using the parameters.

/CLT:Torque limit output

Turns on when it reaches the value set.

/BK:Brake interlock output

Releases the brake when ON,

OT: Over travel signal output

/RD: Servo enabled motor excitation output

/BK

—

1,2,5,6,7

8,9,10

Not used.

The output signals description of ProNet-□□□EG-EC servo drives is as shown in the following table.

ProNet Plus Series AC Servo User's Manual

- 30 -

No.

Name

Function

No.

Name

Function

1

VREF+

Speed reference input:±10V

26

T-REF+

Torque referenceinput:±10V

2

VREF-

27

T-REF-

3

DGND

DGND

28

DGND

DGND 4 —

Reserved

29

—

Reserved

5

/TGON+

Running signal output

30

PULS+

Reference pulse input

6

/TGON-

31

PULS-

7

ALM+

Servo alarm

32

SIGN+

Reference sign input

8

ALM-

33

SIGN-

9

/S-RDY+

Servo ready

34

PPI

Open collector reference

power supply

10

/S-RDY-

35

—

Reserved

11

/COIN+

Positioning completion

36

—

Reserved

12

/COIN-

37

—

Reserved

13

DICOM

I/O signal power supply 24V

DC

38

—

Reserved

14

/S-ON

Servo ON

39

/ALM-RST

Alarm reset

15

/P-CON

P/PI control input

40

/CLR

Position error pulseclear input

16

P-OT

Forward run prohibited

41

/PCL

Forward torque limitinput

17

N-OT

Reverse run prohibited

42

/NCL

Reverse torque limitinput

18

—

Reserved

43

—

Reserved

19

—

Reserved

44

—

Reserved

20

PAO+

PG dividing

pulse output

phase A

PG

dividing

pulse

output

45

—

Reserved

21

PAO-

46

DGND

DGND

22

PBO+

PG dividing

pulse output

phase B

47

—

Reserved

23

PBO-

48

DGND

DGND

24

PCO+

PG dividing

pulse output

phase C

Zero-point

pulse

49

—

Reserved

25

PCO-

50

DGND

DGND

No.

Name

Function

No.

Name

Function

1

—

Reserved

11

/TGON+

Running signal output

2

—

Reserved

12

ALM+

Servo alarm

3

EXT1

Touch Probe input signals

13

/S-RDY+

Servo ready

4

EXT2

14

COM2

Common port of output signal

5

—

Reserved

15

/S-ON

Servo ON

6

—

Reserved

16

/P-CON

P/PI control input

3.2.3 I/O Signal Connector (CN1) Terminal Layout

The signals description in CN1 terminal of ProNet-□□□MG servo drives is as shown in the following table.

The signals description in CN1 terminal of ProNet-□□□EG-EC servo drives is as shown in the following table.

ProNet Plus Series AC Servo User's Manual

- 31 -

No.

Name

Function

No.

Name

Function

7

—

Reserved

17

P-OT

Forward run prohibited

8

—

Reserved

18

N-OT

Reverse run prohibited

9

—

Reserved

19

/ALM-RST

Alarm reset

10

—

Reserved

20

DICOM

I/O signal power supply 24V

DC

10V

470Ω(1/2W)min.

1

2

3

2KΩ

V-REF

GND

About 40KΩ

0V

Servodrive

10V

470Ω(1/2W)min.

1

2

3

2KΩ

T-REF

GND

About 40KΩ

0V

Servodrive

Servodrive

3.3KΩ

+24VIN

/S-ON,etc.

DC24V

50mA min.

Servodrive

3.3KΩ

+24VIN

/S-ON,etc.

DC24V

50mA min.

Note:The functions allocated to the following input and output signals can be changed by using the parameters.

·Input signals:/S-ON,/P-CON,P-OT,N-OT,/ALM-RST,/CLR,/PCL,/NCL,SHOM,ORG

·Output signals:/TGON,/S-RDY,/COIN,/HOME

Please refer to A.3 Parameters in details for detailed information.

3.2.4 Interface Circuit

This section shows examples of servo drive I/O signal connection to the host controller.

■Interface for Analog Reference Input Circuit

Analog signals are either speed or torque reference signals at about 40kΩimpedance, and the maximum allowable

voltages for input signals is ±10V.

Reference speed input Reference torque input

■Interface for Sequence Input Circuit

The sequence input circuit interface connects through a relay or open-collector transistor circuit.Select a low-current relay

otherwise a faulty contact will result.

ProNet Plus Series AC Servo User's Manual

- 32 -

■Interface for Line Driver Output Circuit

Servo dirve

DC5V~24V

0V

Relay

The amount of two-phase (phase A and phase B) pulse output signals (PAO,/PAO,PBO,/PBO) and zero-point pulse

signals(PCO,/PCO) are output via line-driver output circuits.Normally, the servo drive uses this output circuit in speed

control to comprise the position control system at the host controller. Connect the line-driver output circuit through a line

receiver circuit at the host controller.

■Interface for Sequence Output Circuit

Photocoupler output circuits are used for Servo Alarm (ALM), Servo Ready(S-RDY), and other sequence output signal

circuits.Connect a photocoupler output circuit through a relay circuit.

3.3 Wiring Encoders

3.3.1 Connecting an Encoder(CN2)

Absolute Encoders

ProNet Plus Series AC Servo User's Manual

- 33 -

Encoders

Servodrive

PG

K(1)

L(2)

T(3)

S(4)

PS

/PS

BAT+

BAT-

H(5)

G(6)

PAO

/PAO

20

21

P

P

P

*

*

PG5V

PG0V

Connector shell

Connector shell

shielded wires

P

Represents multi-core twisted pair shielded wires.

*

Phase-A

Output line driver

AM26LS31 manufactured

by TI or the equivalent.

CN1

CN2

7

8

17

18

9

19

FG

Applicable linereceiver SN75175

manufactured by TI

or the equivalent.

PBO

/PBO

22

23

P

Phase-B

PCO

/PCO

24

25

P

Phase-C

0V

DGND

0V

50

(Shell)

Note: The pin numbers for the connector wiring differ depending on the servomotors.

Host controller

J(7)

ProNet Plus Series AC Servo User's Manual

- 34 -

Incrementa Encoders

Encoders

Servodrive

PG

S+

S-

MA+

MA-

PAO

/PAO

20

21

P

P

P

*

*

PG5V

PG0V

Connector shell

Connector shell

shielded wires

P

Represents multi-core twisted pair shielded wires.

*

Phase-A

Output line driver

AM26LS31 manufactured

by TI or the equivalent.

CN1

CN2

7

8

5

6

9/10

19/20

FG

Applicable linereceiver SN75175

manufactured by TI

or the equivalent.

PBO

/PBO

22

23

P

Phase-B

PCO

/PCO

24

25

P

Phase-C

0V

DGND

0V

50

(Shell)

Note: The pin numbers for the connector wiring differ depending on the servomotors.

Host controller

K(1)(1)

L(2)(2)

N(5)(3)

P(6)(4)

H(8)(5)

G(7)(6)

J(10)(7)

ProNet Plus Series AC Servo User's Manual

- 35 -

3.3.2 Encoder Connector(CN2) Terminal Layout

Terminal No.

Name

Function

Terminal No.

Name

Function

7

PS

PG serial signal input

17

BAT+

Battery(+)

(For an absolute encoder)

8

/PS

PG serial signal input

18

BAT-

Battery(-)

(For an absolute encoder)

9

PG5V

PG power supply +5V

19

GND

PG power supply 0V

Terminal No.

Name

Function

Terminal No.

Name

Function

7

S+

PG serial signal input

5

MA+

PG serial clock output

8

S-

PG serial signal input

6

MA-

PG serial clock output

9/10

PG5V

PG power supply +5V

19/20

GND

PG power supply 0V

Terminal No.

Name

Function

1

—

Reserved

2 — 3

485+

RS-485 communication terminal

4

ISO_GND

Isolated ground

5

ISO_GND

6

485-

RS-485 communication terminal

7

CANH

CAN communication terminal

8

CANL

CAN communication terminal

Terminal No.

Name

Function

1

TD+

Communication terminal

2

TD-

Communication terminal

3

RD+

Communication terminal

4

NC

Reserved

5

NC

Reserved

6

RD-

Communication terminal

Absolute Encoder

Incremental Encoder

3.4 Communication Connection

3.4.1 Communication Connector(CN3) Terminal Layout

The signals description in CN3 terminal of ProNet-□□□MG servo drives is as shown in the following table.

Note:

1. Do not short terminal 1 and 2 of CN3.

2. If connecting more than 16 CAN nodes,please contact ESTUN customer service.

The signals description in CN3 terminal of ProNet-□□□EG-EC servo drives is as shown in the following table.

ProNet Plus Series AC Servo User's Manual

- 36 -

7

NC

Reserved

8

NC

Reserved

3.4.2 Communication Connector(CN4) Terminal Layout

Terminal No.

Name

Function

1

—

Reserved

2 — 3

485+

RS-485 communication terminal

4

ISO_GND

Isolated ground

5

ISO_GND

6

485-

RS-485 communication terminal

7

CANH

CAN communication terminal

8

CANL

CAN communication terminal

Terminal No.

Name

Function

1

TD+

Communication terminal

2

TD-

Communication terminal

3

RD+

Communication terminal

4

NC

Reserved

5

NC

Reserved

6

RD-

Communication terminal

7

NC

Reserved

8

NC

Reserved

The signals description in CN4 terminal of ProNet-□□□MG servo drives is as shown in the following table.