Estun PRONET-10AMA, EMG-20ADA22 User Manual

ProNet series AC servo system user’s manual V.1.08

ProNet

ProNet

ProNet

ProNet series

series

series

series AC

AC

AC

AC servo

servo

servo

servo system

system

system

system

User’s Manual

V.

1.08

Estun Limited Warranty

This manual does not entitle you to any rights. Estun reserves the right to change this

manual without prior notice. All rights reserved. The copyright is held by Estun. No part

of this publication may be copied or reproduced without written permission fr om Estun.

Contents

- 1 -

About this manual

This manual describes the following information required for designing and maintaining ProNet

series servodrives.

• Specification of the servodrives and servomotors.

• Procedures for installing the servodrives and servomotors.

• Procedures for wiring the servodrives and servomotors.

• Procedures for operation of the servodrives.

• Procedures for using the panel operator.

• Communication protocols.

• Ratings and characteristics.

Intended Audience:

• Those designing ProNet series servodrive systems.

• Those installing or wiring ProNet series servodrives.

• Those performing trial operation or adjustments of ProNet series servodrives.

• Those maintaining or inspecting ProNet series servodrives.

ProNet series AC servo system User’s manual V.1.08

- 2 -

Safety Precaution s

■

Do not connect the servomotor directly to the local electrical network.

Failure to observe this may result in damage to servomotor.

■

Do not plug or unplug connectors from servodrive after power is on.

Failure to observe this may result in damage to servodrive and servomotor.

■

Note that residual voltage

still

remains in the servodrive even after the power is turned off.

Please be noted that even after the power is turned off, residual voltage

still

remains in the capacitor

inside the servodrive. I f inspection is to be performed after the power is turned off, always wait at least

5 minutes to avoid the risk of an electrical shock.

■

Keep servodrives and other devices separated by at least 10mm.

The servodrive generates heat. Install the servodrive so that it can radiate heat freely. When installing

servodrives with other devices in a control panel, provide at least 10mm space between them and

50mm space above and below them.Please install servodrives in an environment free from

condensation, vibration and shock.

■

Perform noise reduction and grounding properly.

Please comply w ith the following instructions strictly to avoid the noisy generated by signal lines.

1. Separate high-voltage cables from low-voltage cables.

2. Use cables as short as possible.

3. Sigle point grounding is required for the servomotor and servodrive (grounding resistance 100 Ω or

below).

4. Never use a line filter for the power supply in the circuit.

■

Conduct a voltage resistance test for the servodrive under the following conditions:

1. Input voltage: AC 1500Vrms, 1 minute

2. Braking current: 100mA

3. Frequency:50/60Hz

4. Voltage applied point: Between L1, L2,L3 terminals and frame ground.

■

Use a fast-response type ground-fault interrupter.

For a ground-fault interrupter, always use a fast-response type or one designed for PWM inverters. Do

not use a time-delay type.

■

Do not make any extreme adjustments or setting changes of parameters.

Failure to observe this caution may result in injury or damage to the product due to unstable operation .

■

The servomotor cannot be operated by turning the power on and off.

Frequently turning the power ON and OFF causes the internal circuit elements to deteriorate, resulting

in unexpected problems.Alw ays start or stop the servomotor by using reference pulses.

Contents

- 3 -

Contents

ProNet series AC servo system

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

-

1

-

About this manual

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

-

1

-

Safety Precautions

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

-

2

-

Contents

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

-3-

Chapter 1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

-

7

-

Checking Products and Parts Names

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

-

7

-

1.1 Checking Products on Delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . - 7 -

1.1.1 Servomotor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . - 7 -

1.1.2 Servodrive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . - 9 -

1.2 Product Part N ames . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . - 11 -

1.2.1 Servomotor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . - 11 -

1.2.2 Servodrive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . - 12 -

Chapter 2

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

-

15

-

Installation

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

-

15

-

2.1 Servomotor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . - 15 -

2.1.1 Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . - 15 -

2.1.2 I nstallation Sites . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . - 15 -

2.1.3 I nstallation Alignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . - 16 -

2.1.4 I nstallation Orientation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . - 16 -

2.1.5 H andling

Oil

and Water . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . - 16 -

2.1.6 Cable Tension . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . - 17 -

2.2 Servodrive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . - 17 -

2.2.1 Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . - 17 -

2.2.2 I nstallation Sites . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . - 17 -

2.2.3 I nstallation Orientation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . - 18 -

2.2.4 I nstallation Method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . - 18 -

Chapter 3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

-

20

-

Wiring

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

-

20

-

3.1 Main Circuit Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . - 20 -

3.1.1 N ames and Functions of Main Circuit Terminals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . - 20 -

3.1.2 Typical Main Circuit Wiring Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . - 21 -

3.2 I/O Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . - 23 -

3.2.1 Examples of I/O Signal Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . - 23 -

3.2.2 I /O Signal Names and Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . - 24 -

3.2.3 I /O Signal Connector (CN1) Terminal Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . - 26 -

3.2.4 I nterface Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . - 27 -

3.3 Wiring Encoders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . - 28 -

3.3.1 Connecting an Encoder(CN2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . - 28 -

3.3.2 Encoder Connector(CN2) Terminal Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . - 29 -

ProNet series AC servo system User’s manual V.1.08

- 4 -

3.4 Communication Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . - 30 -

3.4.1 Communication Connector(CN3) Terminal Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . - 30 -

3.4.2 Communication Connector(CN4) Terminal Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . - 30 -

3.5 Standard Wiring Ex amples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . - 31 -

3.5.1 Three-phase 200V(ProNet-02A ~ 04A) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . - 31 -

3.5.2 Three-phase 200V(ProNet-08A ~ 50A) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . - 32 -

3.5.3 Three-phase 400V(ProNet-75D ~ 1ED) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . - 33 -

3.5.4 Position Control Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . - 34 -

3.5.5 Speed Control Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . - 35 -

3.5.6 Torque Control Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . - 36 -

Chapter 4

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

-

37

-

Operation

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

-

37

-

4.1 Trial Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . - 37 -

4.1.1 Trial Operation for Servomotor Without Load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . - 39 -

4.1.2 Trial Operation for Servomotor w ithout Load from Host Reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . - 42 -

4.1.3 Trial Operation with the Servomotor Connected to the Machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . - 46 -

4.1.4 Trial Operation for Servomotor w ith Brakes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . - 47 -

4.1.5 Position Control by H ost Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . - 47 -

4.2 Control Mode Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . - 48 -

4.3 Setting Common Basic Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . - 49 -

4.3.1 Setting the Servo ON Signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . - 49 -

4.3.2 Switching the Servomotor Rotation Direction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . - 50 -

4.3.3 Setting the Overtravel Limit Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . - 51 -

4.3.4 Setting for Holding Brakes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . - 54 -

4.3.5 I nstantaneous Power Loss Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . - 56 -

4.4 Absolute Encoders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . - 57 -

4.4.1 Selecting an Absolute Encoder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . - 57 -

4.4.2 H andling Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . - 58 -

4.4.3 Replacing Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . - 59 -

4.4.4 Absolute Encoder Setup(Fn010 、 Fn011) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . - 59 -

4.5 Operating Using Speed Control with Analog Reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . - 60 -

4.5.1 Setting Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . - 60 -

4.5.2 Setting I nput Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . - 61 -

4.5.3 Adjusting Reference Offset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . - 61 -

4.5.4 Soft Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . - 64 -

4.5.5 Speed Reference Filter Time Constant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . - 64 -

4.5.6 S-curve Risetime . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . - 64 -

4.5.7 U sing the Z ero Clamp Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . - 65 -

4.5.8 Encoder Signal Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . - 66 -

4.5.9 Speed coincidence output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . - 68 -

4.6 Operating Using Position Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . - 69 -

4.6.1 Setting Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . - 69 -

4.6.2 Setting the Electronic Gear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . - 70 -

4.6.3 Position Reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . - 72 -

4.6.4 Smoothing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . - 76 -

4.6.5 Low Frequency Vibration Suppression . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . - 77 -

Contents

- 5 -

4.6.6 Positioning Completion Output Signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . - 79 -

4.6.7 Reference Pulse Inhibit Function(IN HIBIT) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . - 80 -

4.7 Operating Using Torque Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . - 81 -

4.7.1 Setting Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . - 81 -

4.7.2 Torque Reference I nput . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . - 82 -

4.7.3 Adjusting the Reference Offset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . - 83 -

4.7.4 Limiting Servomotor Speed During Torque Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . - 84 -

4.8 Operating Using Speed Control with an Internally Set Speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . - 85 -

4.8.1 Setting Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . - 85 -

4.8.2 I nput Signal Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . - 86 -

4.8.3 Operating Using an Internally Set Speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . - 86 -

4.9 Limiting Torque . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . - 88 -

4.9.1 I nternal Torque Limit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . - 88 -

4.9.2 External Torque Limit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . - 89 -

4.10 Control Mode Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . - 91 -

4.10.1 Setting Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . - 91 -

4.10.2 Switching the Control Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . - 91 -

4.11 Other Output Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . - 92 -

4.11.1 Rotation Detection Output Signal(/TGON) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . - 92 -

4.11.2 Servo Ready(/S-RDY) Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . - 92 -

Chapter 5

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

-

93

-

Panel Operator

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

-

93

-

5.1 Basic Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . - 93 -

5.1.1 Functions on Panel Operator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . - 93 -

5.1.2 Resetting Servo Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . - 93 -

5.1.3 Basic Mode Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . - 94 -

5.1.4 Status Display Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . - 94 -

5.1.5 Operation in Parameter Setting Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . - 96 -

5.1.6 Operation in Monitor Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . - 97 -

5.2 Operation in Utility Function Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . - 99 -

5.2.1 Alarm Traceback Data Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . - 99 -

5.2.2 Parameter Settings I nitialization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . - 100 -

5.2.3 Operation in J OG Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . - 101 -

5.2.4 Automatic Adjustment of the Speed Reference Offset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . - 102 -

5.2.5 Manual Adjustment of the Speed Reference Offset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . - 103 -

5.2.6 Offset-adjustment of Servomotor Current Detection Signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . - 105 -

5.2.7 Software Version Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . - 107 -

5.2.8 Position Teaching Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . - 107 -

5.2.9 Static I nertia Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . - 107 -

5.2.10 Absolute Encoder Multiturn Data and Alarm Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . - 108 -

5.2.11 Absolute Encoder Related Alarms Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . - 108 -

Chapter 6

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

-

109

-

MODBUS Communication

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

-

109

-

6.1 RS-485 Communication Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . - 109 -

6.2 MODBUS Communication Related Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -

110

-

ProNet series AC servo system User’s manual V.1.08

- 6 -

6.3 MODBUS Communication Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -

111

-

6.3.1 Code Meaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -

111

-

6.3.2 Communication Error Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -

118

-

6.3.3 Data Communication Address of Servo State . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -

119

-

Chapter 7

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

-

121

-

Specifications and Characters

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

-

121

-

7.1 Servodrive Specifications and Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . - 121 -

7.2 Servodrive Dimensional Drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . - 123 -

Appendix A

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

-

126

-

Parameter

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

-

126

-

A.1 Parameter List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . - 126 -

A.2 Description of Parameter Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . - 132 -

A.3 Parameters in detail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . - 133 -

Appendix B

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

-

148

-

Alarm Display

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

-

148

-

- 7 -

Chapter 1

Checking Products and Parts Names

1.1 Checking Products on Delivery

If any of the above items are faulty or incorrect, contact your ESTUN representative or the dealer

from whom you purchased the products.

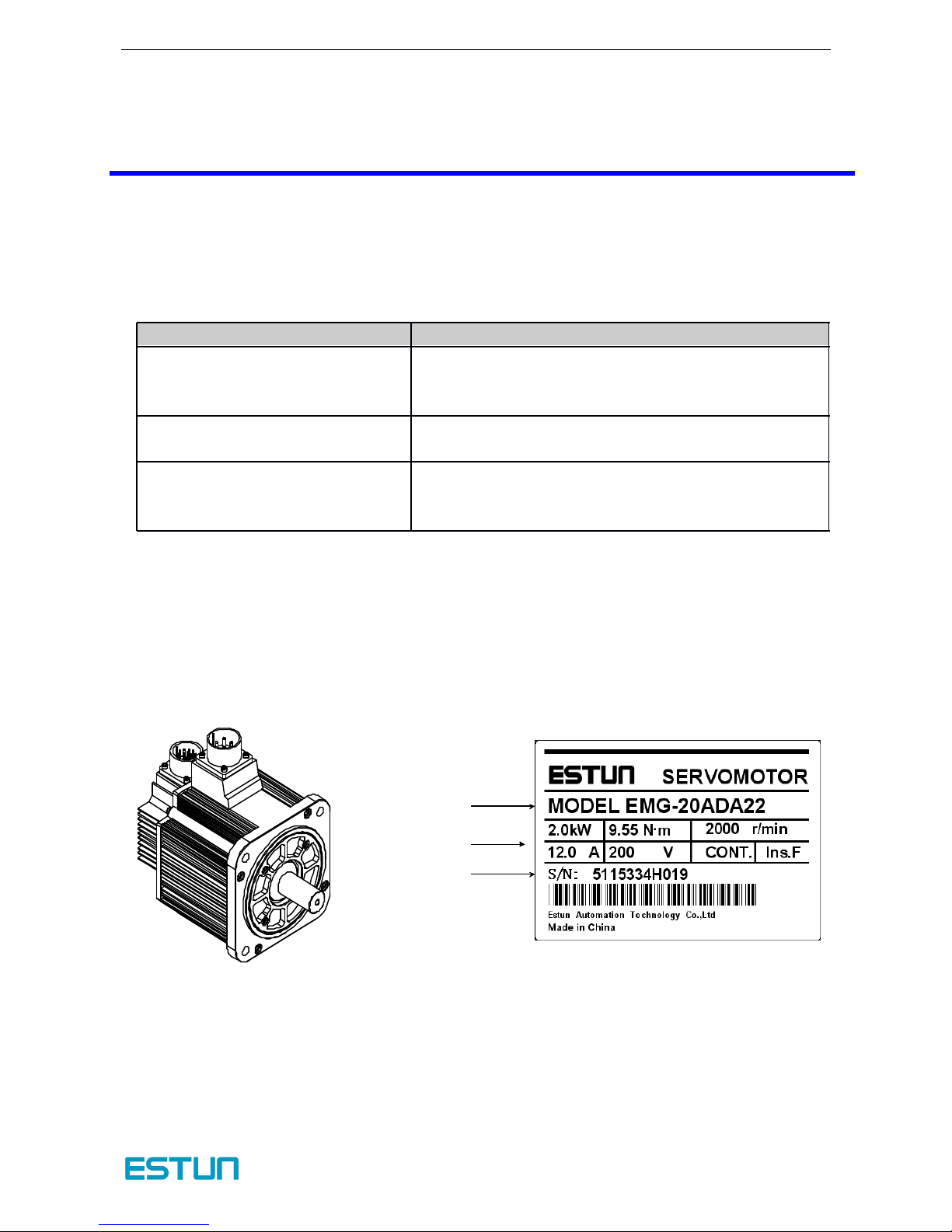

1.1.1 Servomotor

�

�

�

� Appearance

Appearance

Appearance

Appearance and

and

and

and Nameplate

Nameplate

Nameplate

Nameplate

Check

Check

Check

Check Items

Items

Items

Items

Comments

Comments

Comments

Comments

Are the delivered products the

ones that were ordered?

Check the model numbers marked on the nameplate on

the

servomotor and servodrive.

Is there any damage?

Check the overall appearance, and check for damage or

scratches that may have occurred during shipping.

Dose the servomotor shaft rotate

smoothly?

If the servomotor shaft is smoothly turned by hand, it is

normal. H owever, if the servomotor has brakes, it cannot

be turned manually.

{

Serial number

Ratings

Servomotor model

ProNet series AC servo system User’s manual V.1.08

- 8 -

�

�

�

� Servomotor

Servomotor

Servomotor

Servomotor Model

Model

Model

Model Designation

Designation

Designation

Designation

EMG

EMG

EMG

EMG –

–

–

– 10

10

10

10

A

A

A

A

D

D

D

D

A

A

A

A

1

1

1

1 1

1

1

1

Notes :

1. The EMG-30A□A □□,EMG-50A□A □□ servomotors are not mounted the incremental encoder.

2. There is no brake in EMG- □□ ADA □□ servomotor.

ESTUN Servomotor

【 1+2】【 3 】

【 4 】

【 5 】

【 6 】

【 7 】

EMG M odel

【 1+2 】 Rated Output

【 4 】 Encoder

【 7 】 Option

Code

Rated Output

Code

Encoder

Code

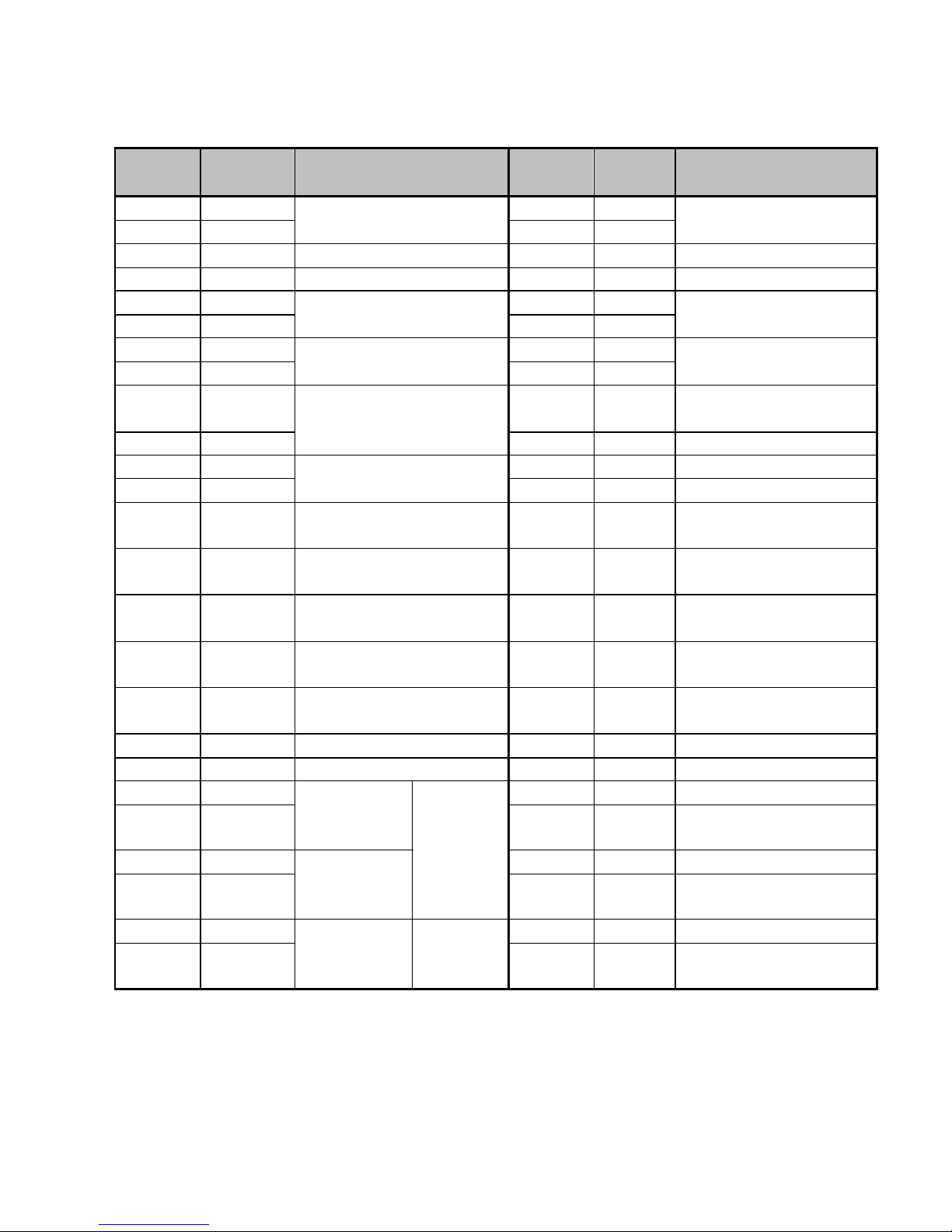

Option101.0kWDIncremental encoder : 131072P/R

1

None

15

1.5kWSAbsolute encoder : 131072P/R

2

With oil sea l

20

2.0kWRResolver

3

With brake(DC 24V)

30

3.0kW4With oil sea l and brake(DC 24V )

50

5.0kW

【 5 】 Designing Sequence

Code

Designing Sequence

A

Designing sequence

【 3 】 V oltage

【 6 】 Shaft End

Code

Voltage

Code

Shaft End

A

200V AC

1

Straight without key(Standard)

2

Straight with key and tap

Contents

- 9 -

1.1.2 Servodrive

�

�

�

� Appearance

Appearance

Appearance

Appearance

ProNet-200W ~ 400W ProNet-750W-1.0KW

ProNet-1.5KW ProNet-2.0/3.0/5.0KW

CN3

CN3

CN3

CN3CN4

CN4

CN4

CN4

CN1

CN1

CN1

CN1

CN2

CN2

CN2

CN2

L1

L1

L1

L1

L2

L2

L2

L2

L3

L3

L3

L3

L 1C

L 1C

L 1C

L 1C

L 2C

L 2C

L 2C

L 2C

-

1

1

1

1

2

2

2

2

+

+

B1

B1

B1

B1

B2

B2

B2

B2

B3

B3

B3

B3

U

V

W

CHARGE

CHARGE

CHARGE

CHARGE

L1

L2

L3

CN3

CN3

CN3

CN3CN4

CN4

CN4

CN4

CN1

CN1

CN1

CN1CN2

CN2

CN2

CN2

L1C

L1C

L1C

L1C

L2C

L2C

L2C

L2C

B1

B2

B3

B3

B3

B3

U

V

W

+

-

1

+

2

CHAR GE

POWER

L1

L2

L3

CN3

CN3

CN3

CN3CN4

CN4

CN4

CN4

CN1

CN1

CN1

CN1CN2

CN2

CN2

CN2

L1C

L1C

L1C

L1C

L2C

L2C

L2C

L2C

B1

B2

B3

U

V

W

+

-

1

+

2

CHARGE POWER

ProNet series AC servo system User’s manual V.1.08

- 10 -

ProNet-7.5/11/15KW

�

�

�

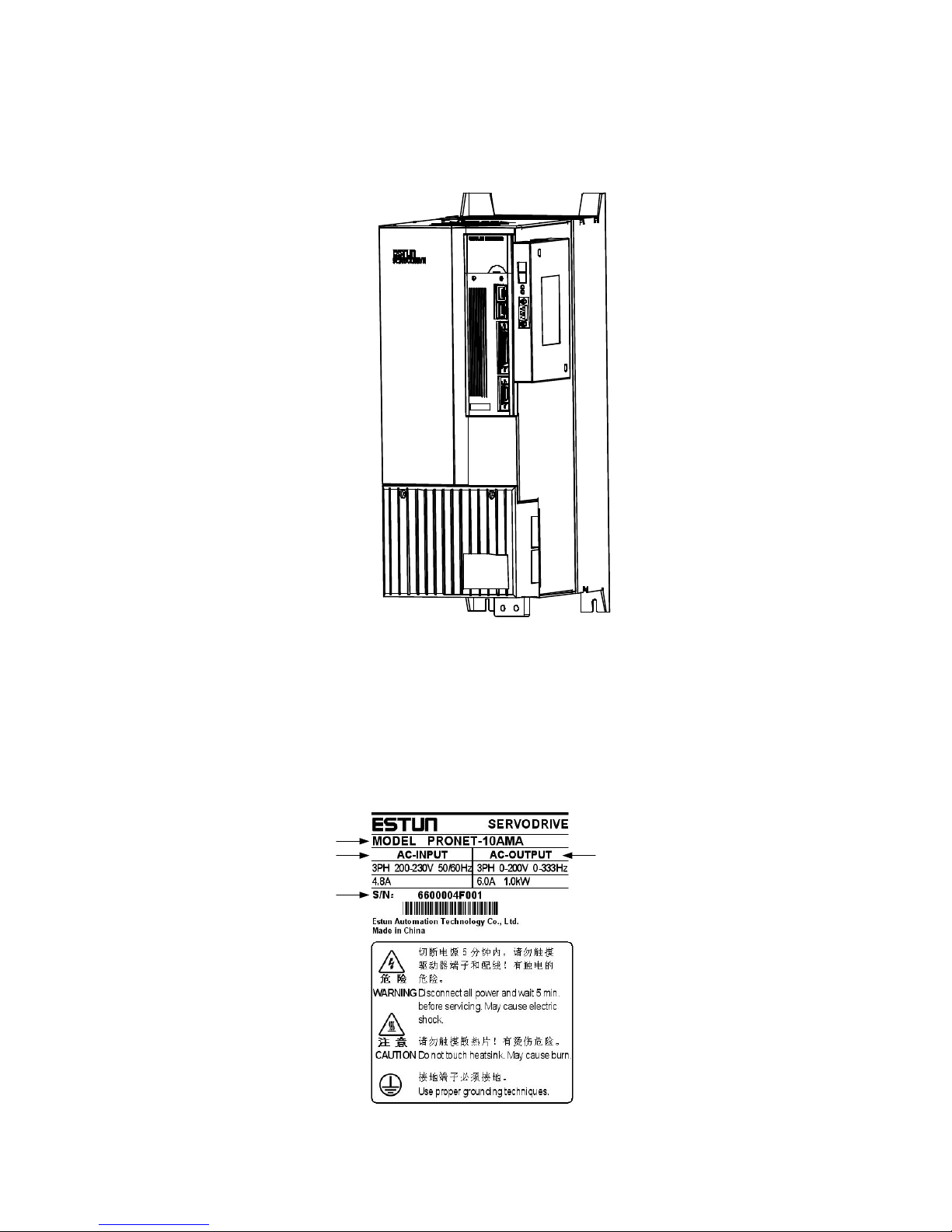

� Nameplate

Nameplate

Nameplate

Nameplate

CN3

CN3

CN3

CN3CN4

CN4

CN4

CN4

CN1

CN1

CN1

CN1CN2

CN2

CN2

CN2

Serv odrive m odel

Applic able

power

supply

Appl icable ser vomotor

capacity

Seri al number

Contents

-11-

�

�

�

� Servodrive

Servodrive

Servodrive

Servodrive Model

Model

Model

Model Designation

Designation

Designation

Designation

PRONET

PRONET

PRONET

PRONET –

–

–

– 10

10

10

10 A

A

A

A M

M

M

M A

A

A

A

1.2

1.2

1.2

1.2 Product

Product

Product

Product Part

Part

Part

Part Names

Names

Names

Names

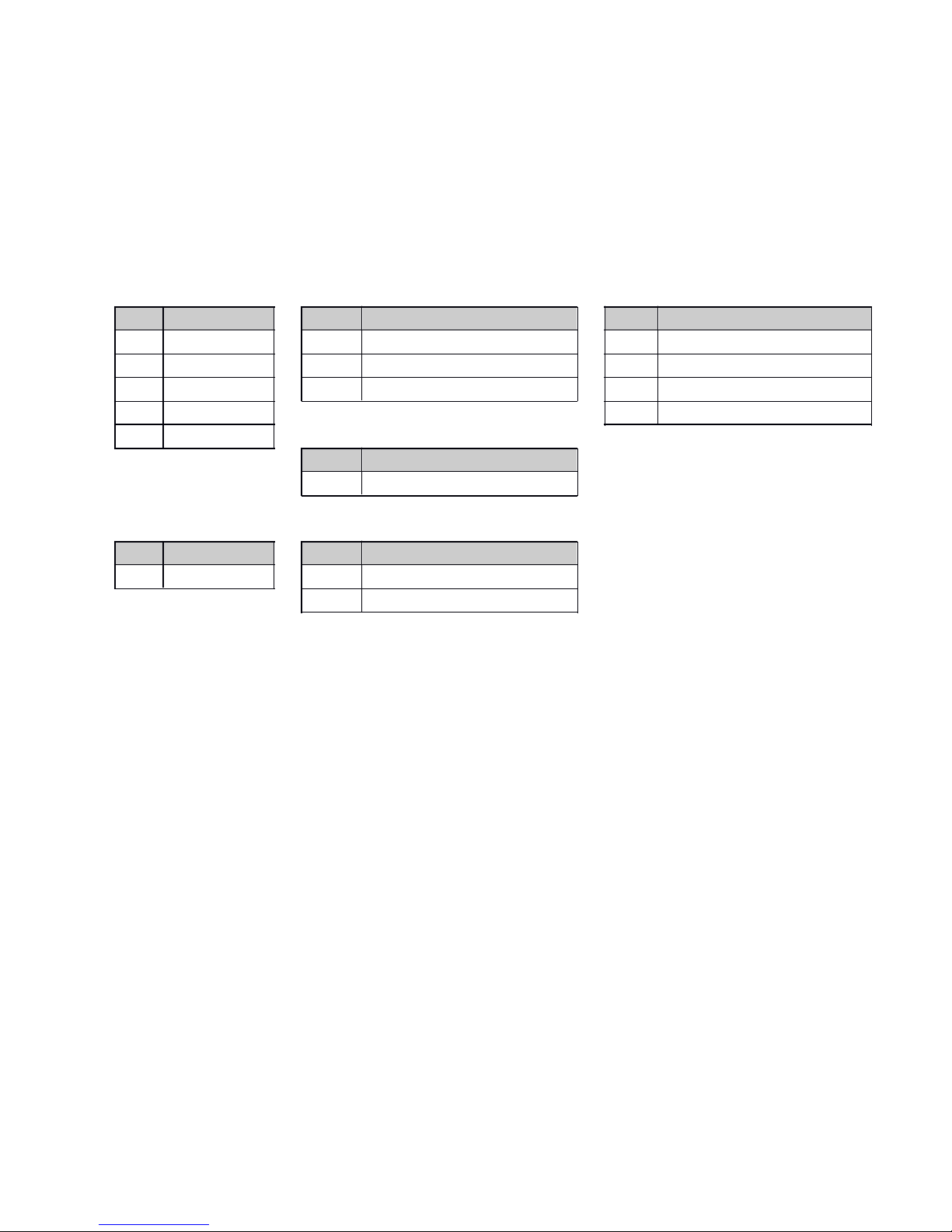

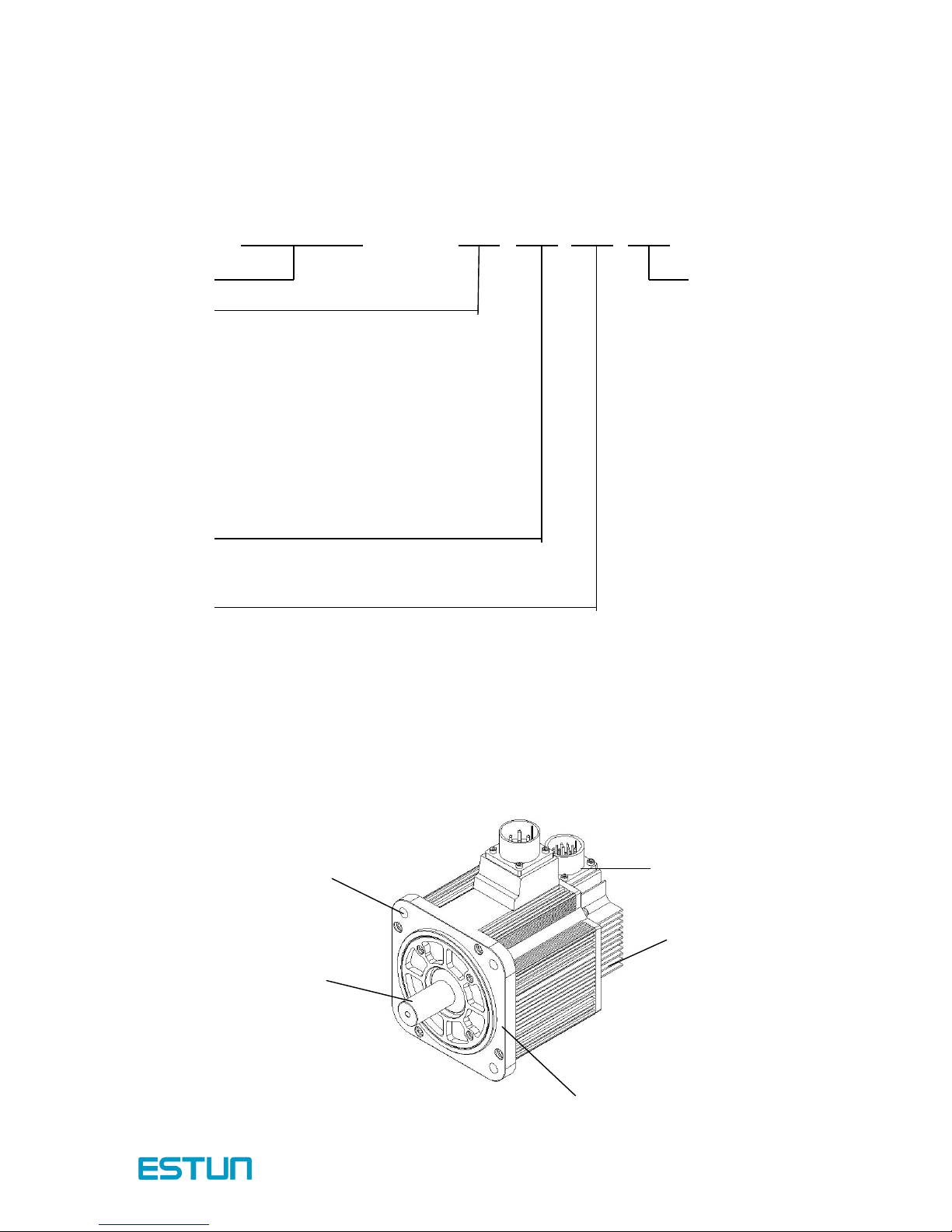

1.2.1 Servomotor

Servomotor w ithout gear and brake.

Rated

Rated

Rated

Rated Output

Output

Output

Output

02 0.2 kW

04 0.4 kW

08 0.75 kW

10 1.0 kW

15 1.5 kW

20 2.0 kW

30 3.0 kW

50 5.0 kW

75 7.5 kW1A11

kW

1E 15 kW

Voltage

Voltage

Voltage

VoltageA200VAC

D 400VA C

Control

Control

Control

Control M

M

M

M ode

ode

ode

ode

M Speed control, torque control, position control

E Speed control, torque contro l, position control (Support ex tended module)

Encoder

Encoder

Encoder

EncoderA17-bit serial encoder

B Resolver

ProNet

ProNet

ProNet

ProNet Model

Model

Model

Model

Encoder

Encoder

Encoder

Encoder

Shell

Shell

Shell

Shell

Flange

Flange

Flange

Flange

Output

Output

Output

Output

shaft

shaft

shaft

shaft

Mounting

Mounting

Mounting

Mounting

hole

hole

hole

hole

ProNet series AC servo system User’s manual V.1.08

- 12 -

1.2.2 Servodrive

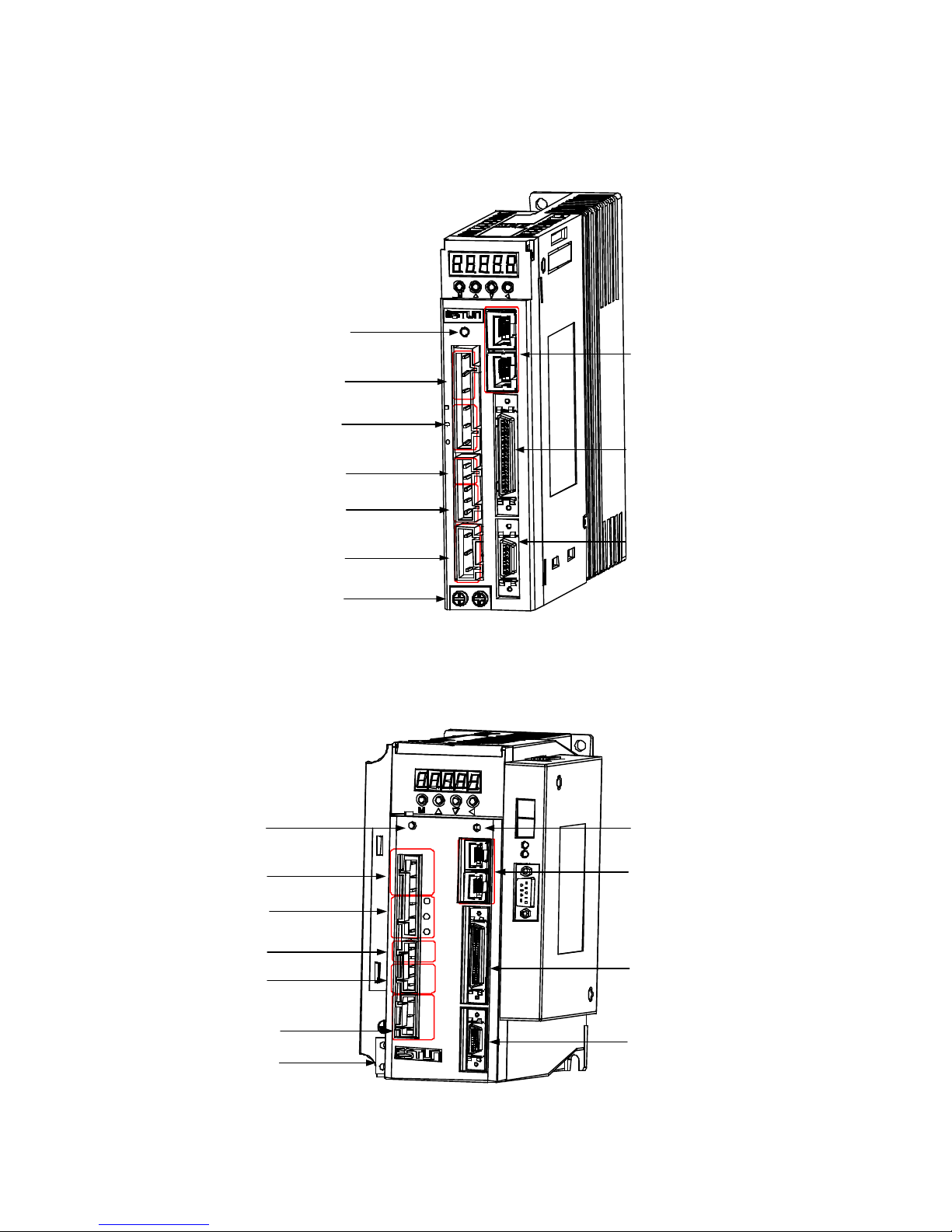

ProNet-200W ~ 400W

ProNet-750W ~ 1.0kW

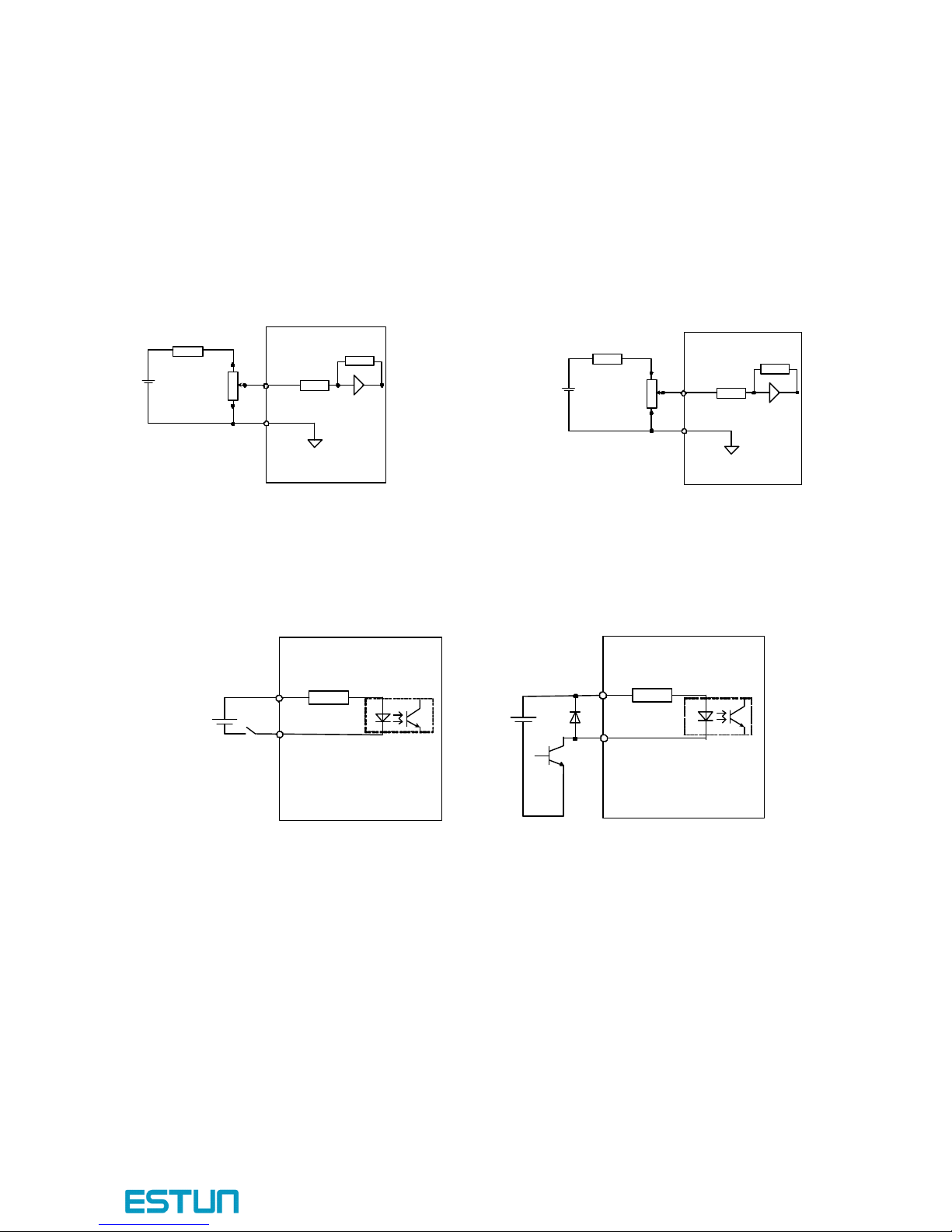

Connector for communic ation

Connector for communic ation

Connector for communic ation

Connector for communic ation

Use d t o co mmunicate with o the r device s

.

I

I

I

I /

/

/

/

O signal c onnector

O signal c onnector

O signal c onnector

O signal c onnector

Use d f or ref eren ce inp ut

signa ls an d se qu ence I/O

signals

.

Encoder connec tor

Encoder connec tor

Encoder connec tor

Encoder connec tor

Co nn ects to t he en cod er

in th e se rvomoto r

.

Ground termina l

Ground termina l

Ground termina l

Ground termina l

Be sure t o co nn ect t o p rote ct

electric shock

.

Serv omotor terminals

Serv omotor terminals

Serv omotor terminals

Serv omotor terminals

Co nn ects to t he servomotor

power line

.

Re gener ative re sis tor

Re gener ative re sis tor

Re gener ative re sis tor

Re gener ative re sis tor

connec ting terminal s

connec ting terminal s

connec ting terminal s

connec ting terminal s

Use d t o co nn ect exte rnal

rege nera tive resisto rs

.

Control power supply

Control power supply

Control power supply

Control power supply

terminal s

terminal s

terminal s

terminal s

Used f or con trol po we r

supp ly inpu t

.

Connecting termina l

Connecting termina l

Connecting termina l

Connecting termina l

of DC reac tor

of DC reac tor

of DC reac tor

of DC reac tor

Ma in ci rcuit powe r

Ma in ci rcuit powe r

Ma in ci rcuit powe r

Ma in ci rcuit powe r

supply terminal s

supply terminal s

supply terminal s

supply terminal s

Used f or main circuit

power supp ly inpu t

.

Cha rge i ndicator

Cha rge i ndicator

Cha rge i ndicator

Cha rge i ndicator

Ligh ts whe n t he ma in circu it

power supp ly is ON an d

stays lit a s long a s th e main

circuit po wer sup ply

capa cit or remains cha rged

.

CN3

CN3

CN3

CN3CN4

CN4

CN4

CN4

CN1

CN1

CN1

CN1

CN2

CN2

CN2

CN2

L1

L1

L1

L1

L2

L2

L2

L2

L3

L3

L3

L3

L1C

L1C

L1C

L1C

L2C

L2C

L2C

L2C

-

1

1

1

1

2

2

2

2

+

+

B1

B1

B1

B1

B2

B2

B2

B2

B3

B3

B3

B3

U

V

W

CHA RGE

CHA RGE

CHA RGE

CHA RGE

Power on indicator

Power on indicator

Power on indicator

Power on indicator

Lights when the control power supply is

on

.

Connector for communication

Connector for communication

Connector for communication

Connector for communication

Used to communicate with other devices .

I

I

I

I /

/

/

/

O signal connector

O signal connector

O signal connector

O signal connector

Used for reference input

signals and sequence I /

O

signals

.

Encoder connector

Encoder connector

Encoder connector

Encoder connector

Connects to the encoder

in the servomotor .

Charge indicator

Charge indicator

Charge indicator

Charge indicator

Lights when the main circuit

power supply is ON and

stays lit as long as the main

circuit power supply

capacitor remains charged

.

Main circuit power

Main circuit power

Main circuit power

Main circuit power

supply terminals

supply terminals

supply terminals

supply terminals

Used for main circuit

power supply input .

Connecting terminal

Connecting terminal

Connecting terminal

Connecting terminal

of DC reactor

of DC reactor

of DC reactor

of DC reactor

Control power supply

Control power supply

Control power supply

Control power supply

terminals

terminals

terminals

terminals

Used for control power

supply input

.

Regenerative resistor

Regenerative resistor

Regenerative resistor

Regenerative resistor

connecting terminals

connecting terminals

connecting terminals

connecting terminals

Used to connect external

regenerative resistors

.

Ground terminal

Ground terminal

Ground terminal

Ground terminal

Be sure to connect to protect

electric shock

.

Servomotor terminals

Servomotor terminals

Servomotor terminals

Servomotor terminals

Connects to the servomotor

power line

.

L1

L2

L3

CN3

CN3

CN3

CN3CN4

CN4

CN4

CN4

CN1

CN1

CN1

CN1CN2

CN2

CN2

CN2

L1C

L1C

L1C

L1C

L2C

L2C

L2C

L2C

B1

B2

B3

U

V

W

+

-

1

+ 2

CHAR GE

POW ER

Contents

- 13 -

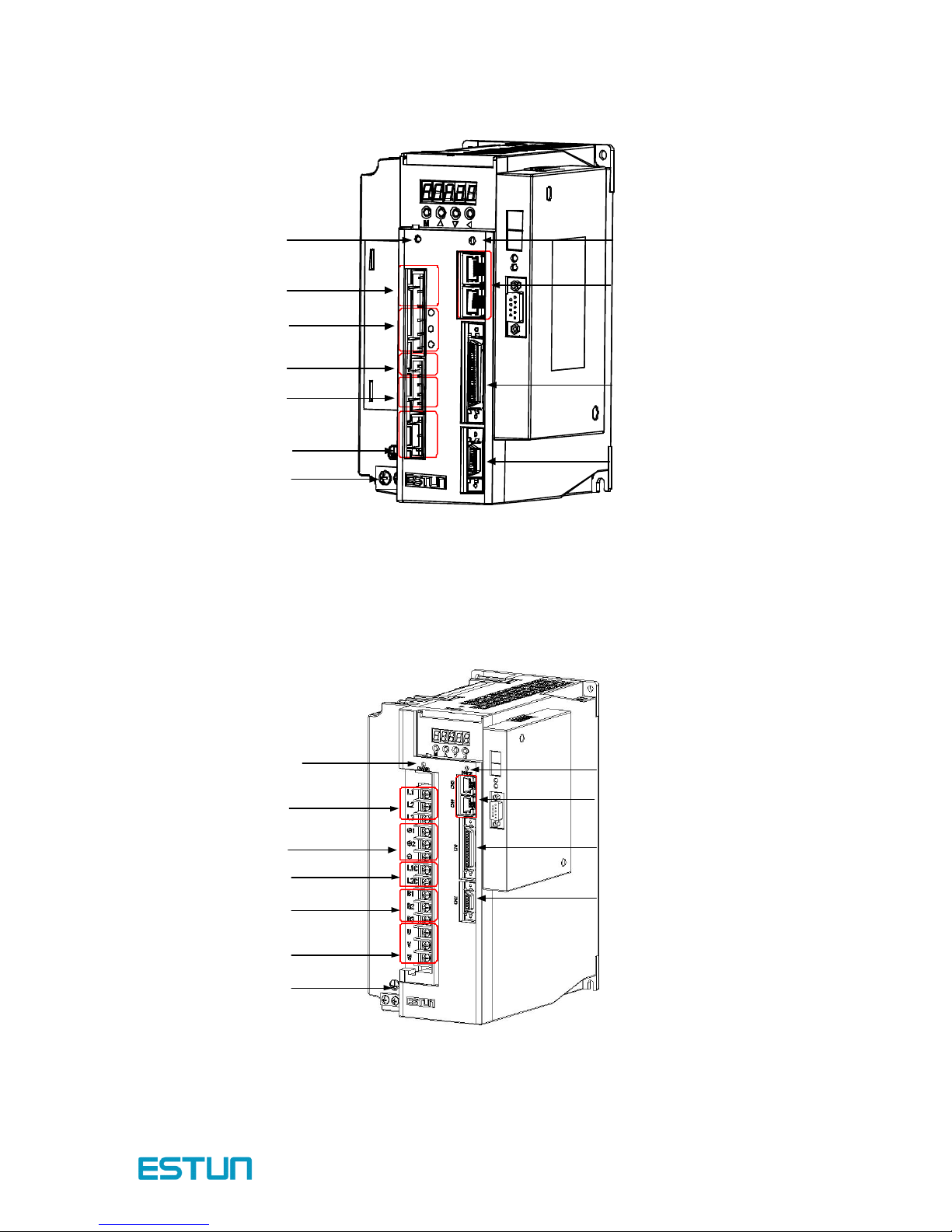

ProNet-1.5kW

ProNet-2.0kW ~ 5.0kW

Power on indicator

Power on indicator

Power on indicator

Power on indicator

Lights when the control power supply is

on

.

Connector for communication

Connector for communication

Connector for communication

Connector for communication

Used to communicate with other devices

.

I

I

I

I /

/

/

/

O signal connector

O signal connector

O signal connector

O signal connector

Used for reference input

signals and sequence I/O

signals

.

Encoder connector

Encoder connector

Encoder connector

Encoder connector

Connects to the encoder

in the servomotor

.

Charge indicator

Charge indicator

Charge indicator

Charge indicator

Lights when the main circuit

power supply is ON and

stays lit as long as the main

circuit power supply

capacitor remains charged

.

Main circuit power

Main circuit power

Main circuit power

Main circuit power

supply terminals

supply terminals

supply terminals

supply terminals

Used for main circuit

power supply input

.

Connecting terminal

Connecting terminal

Connecting terminal

Connecting terminal

of DC reactor

of DC reactor

of DC reactor

of DC reactor

Control power supply

Control power supply

Control power supply

Control power supply

terminals

terminals

terminals

terminals

Used for control power

supply input

.

Regenerative resistor

Regenerative resistor

Regenerative resistor

Regenerative resistor

connecting terminals

connecting terminals

connecting terminals

connecting terminals

Used to connect external

regenerative resistors

.

Ground terminal

Ground terminal

Ground terminal

Ground terminal

Be sure to connect to protect

electric shock

.

Servomotor terminals

Servomotor terminals

Servomotor terminals

Servomotor terminals

Connects to the servomotor

power line

.

L1

L2

L3

CN3

CN3

CN3

CN3CN4

CN4

CN4

CN4

CN1

CN1

CN1

CN1CN2

CN2

CN2

CN2

L1C

L1C

L1C

L1C

L2C

L2C

L2C

L2C

B1

B2

B3

U

V

W

+

-

1

+

2

CHARGE

POWER

Cha rge i ndicator

Cha rge i ndicator

Cha rge i ndicator

Cha rge i ndicator

Ligh ts when t he main circuit

power supp ly is ON an d

stays lit a s long a s th e main

circuit po wer sup ply

capa cit or remains cha rged

.

Main ci rcuit power

Main ci rcuit power

Main ci rcuit power

Main ci rcuit power

supply terminal s

supply terminal s

supply terminal s

supply terminal s

Used f or m ain circuit

power supp ly inpu t

.

Connecting termina l

Connecting termina l

Connecting termina l

Connecting termina l

of DC reac tor

of DC reac tor

of DC reac tor

of DC reac tor

Control power supply

Control power supply

Control power supply

Control power supply

terminal s

terminal s

terminal s

terminal s

Used f or con trol po we r

supp ly inpu t

.

Re gener ative re sis tor

Re gener ative re sis tor

Re gener ative re sis tor

Re gener ative re sis tor

connec ting terminal s

connec ting terminal s

connec ting terminal s

connec ting terminal s

Use d t o co nn ect exte rnal

rege nera tive resisto rs

.

Ground termina l

Ground termina l

Ground termina l

Ground termina l

Be sure t o co nn ect t o p rote ct

electric shock

.

Serv omotor terminals

Serv omotor terminals

Serv omotor terminals

Serv omotor terminals

Co nn ects to t he servomot or

power line

.

Power on indica tor

Power on indica tor

Power on indica tor

Power on indica tor

Ligh ts whe n t he con trol po we r supp ly is

on

.

Connector for communic ation

Connector for communic ation

Connector for communic ation

Connector for communic ation

Use d t o co mmunicate with o the r device s

.

I

I

I

I /

/

/

/

O signal c onnector

O signal c onnector

O signal c onnector

O signal c onnector

Use d f or ref eren ce inp ut

signa ls an d se qu ence I/O

signals

.

Encoder connec tor

Encoder connec tor

Encoder connec tor

Encoder connec tor

Co nn ects to t he en cod er

in the servomotor

.

ProNet series AC servo system User’s manual V.1.08

- 14 -

ProNet-7.5kW ~ 15kW

Power on indicator

Power on indicator

Power on indicator

Power on indicator

Lights when the control power supply is

on

.

Connector for communication

Connector for communication

Connector for communication

Connector for communication

Used to communicate with other devices

.

I

I

I

I /

/

/

/

O signal connector

O signal connector

O signal connector

O signal connector

Used for reference input

signals and sequence I/O

signals

.

Encoder connector

Encoder connector

Encoder connector

Encoder connector

Connects to the encoder

in the servomotor

.

Charge indicator

Charge indicator

Charge indicator

Charge indicator

Lights when the main circuit

power supply i s O N and

stays lit as long as the main

circuit power supply

capacitor remains charged

.

CN3

CN3

CN3

CN3

CN4

CN4

CN4

CN4

CN1

CN1

CN1

CN1CN2

CN2

CN2

CN2

CHARGE

POWER

- 15 -

Chapter 2

Installation

2.1 Servomotor

Servomotor can be installed either horiz ontally or vertically. H owever, if the servomotor is installed

incorrectly , the service life of the servomotor will be shortened or unexpected problems will occur.

Please observe the installation instructions described below to install the servomotor correctly.

2.1.1 Storage

When the servomotor is not used, store it in the temperature between -20 ℃ and 60 ℃ w ith the

power cable disconnected.

2.1.2 Installation Sites

The servomotor is designed for indoor use.Install the servomotor in an environment which meets

the following conditions.

Free from corrosive and explosive gases.

Well-ventilated and free from dust and moisture.

Ambient temperature from 0 to 40 ℃ .

Relative humidity from 26% to 80%( non-condensing).

Facilitates inspection and cleaning.

Before

Before

Before

Before installation:

installation:

installation:

installation:

Anticorrosive paint is coated on the edge of the servomotor shaft. Clean off the anticorrosive paint

thoroughly using a cloth moistened w ith thinner.

Avoid getting thinner on other parts of the servomotor when cleaning the shaft.

Anticorrosive paint

Anticorrosive paint

Anticorrosive paint

Anticorrosive paint

ProNet series AC servo system User’s manual V.1.08

- 16 -

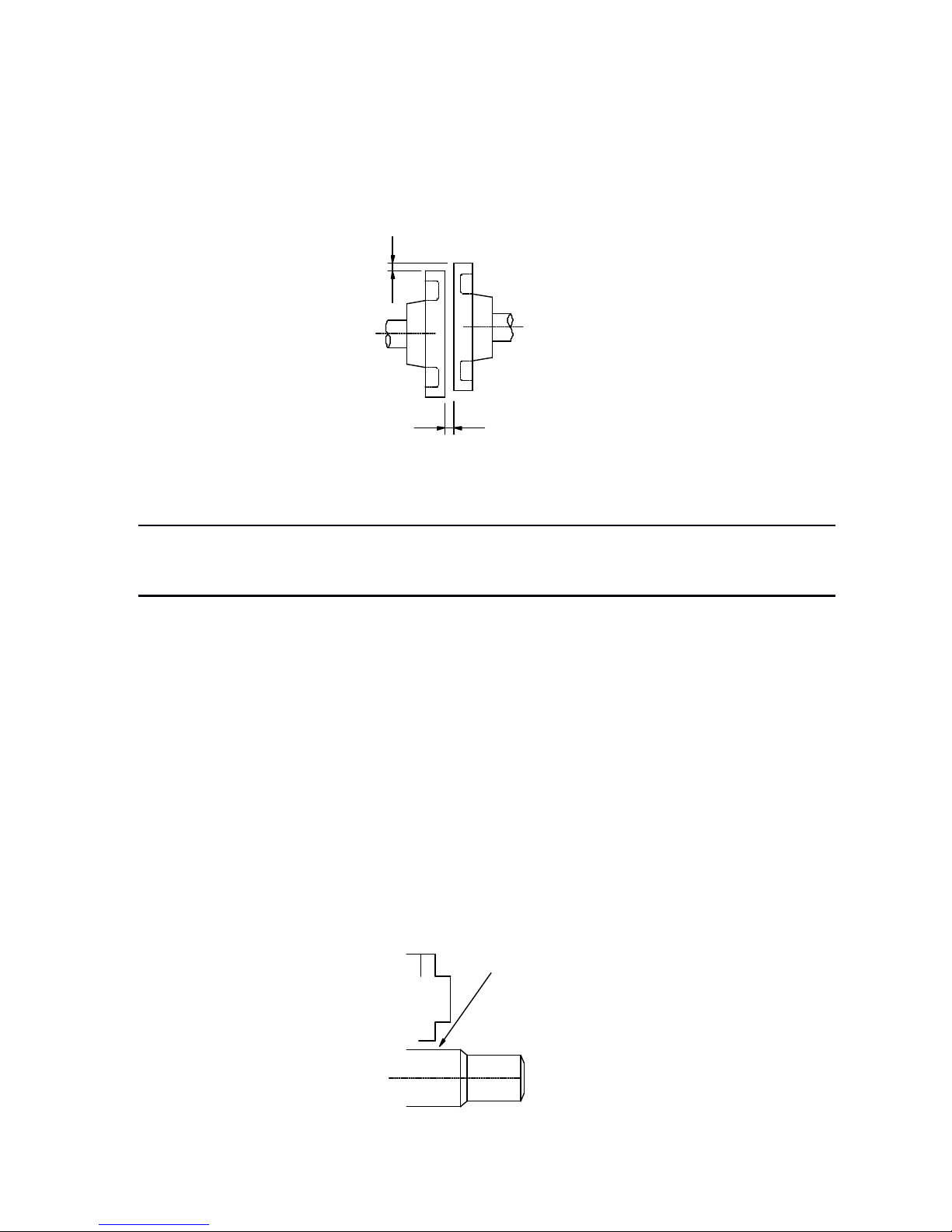

2.1.3 Installation Alignment

Align the shaft of the servomotor with that of the machinery to be controlled, and then connect the

shafts with elastic couplings. Install the servomotor so that alignment accurancy falls within the

range shown below.

Measure this distance

at

four different positions in the circumference. The difference between the

maximum and minimum measurements must be 0.03mm or less.(Turn together with couplings.)

2.1.4 Installation Orientation

Servomotor can be installed ethier horiz ontally or vertically.

2.1.5 Handling

Oil

and Water

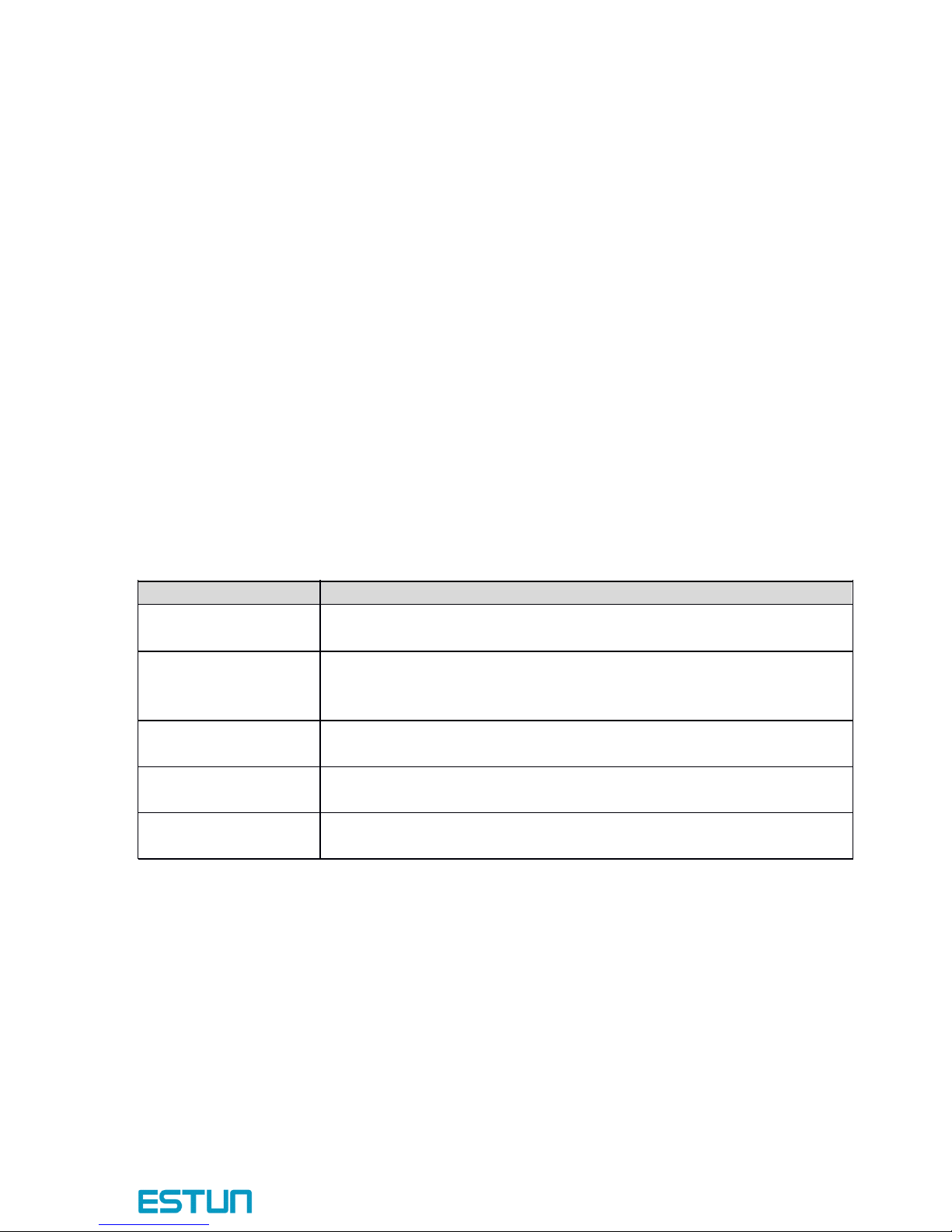

If the servomotor is used in a location that is subject to water or oil drops, make sure of the

servomotor protective specification. If the servomotor is required to meet the protective

specification to the through shaft section by default, use a servomotor with an oil seal.

Through

Through

Through

Through shaft

shaft

shaft

shaft section:

section:

section:

section:

It refers to the gap where the shaft protrudes from the end of the servomotor.

Note:

Note:

Note:

Note:

·

If the alignment accurancy is incorrect,vibration will occur, resulting in damage to the bearings.

·

Mechanical shock to the shaft end is forbidden, otherwise it may result in damage to the encoder of the servomotor.

Through Shaft Section

Chapter 2 Installation

- 17 -

2.1.6 Cable

Tension

When connecting the cables, the bending radius should not be too small, do not bend or apply

tension to cables.

Since the conductor of a signal cable is very thin (0.2 to 0.3 mm), handle it with adequate care.

2.2 Servodrive

ProNet series servodrive is a base-mounted type. Incorrect installation w ill cause problems. Always

observe the installation instructions described below.

2.2.1 Storage

When the servodrive is not used, store it in the temperature between -20 ℃ and 85 ℃ w ith the

power cable disconnected.

2.2.2 Installation Sites

Notes on installation are shown below.

Situation

Situation

Situation

Situation

Notes

Notes

Notes

Notes on

on

on

on installation

installation

installation

installation

When installed in a control

panel

Design the control panel siz e, unit layout, and cooling method so that the temperature

around the periphery of the serv odrive does not exceed 55 ℃

.

When installed near a

heating unit

Suppress radiation heat from the heating unit and a temperature rise caused by

convection so that the temperature around the periphery of the servodrive does not

exceed 55 ℃

.

When installed near a

source of vibration

Install a vibration iso lator underneath the serv odrive to prevent it from recev ing vibration.

When installed in a location

subject to corrosive gases

Take appropriate action to prevent corrosive gases. Corrosive gases do not immediately

affect the servodrive, but will eventually cause contactor-related devices to malfunction.

Others

Avoid installation in a hot

and

humid site or where excessive dust or iro n powder is

present in the air.

ProNet series AC servo system User’s manual V.1.08

- 18 -

2.2.3 Installation Orientation

Install the servodrive perpendicular to the w all as shown in the figure. The servodrive must be

oriented this way because it is designed to be cooled by natural convection or a cooling fan if

required. Firmly secure the servodrive through two mounting holes.

2.2.4 Installation Method

When installing multiple servodrives side by side in a control panel, observe the following

installation method.

Cooling Fan

Cooling Fan

Colling Fan

Colling Fan

Wall

Ventilation

Chapter 2 Installation

- 19 -

■

■

■

■

Installation

Installation

Installation

Installation Orientation

Orientation

Orientation

Orientation

Install servodrive perpendicular to the w all so that the front panel (containing connectors) faces

outward.

■

■

■

■

Cooling

Cooling

Cooling

Cooling

Provide sufficient space around each servodrive to allow cooling by natural convection or fans.

■

■

■

■

Installing

Installing

Installing

Installing side

side

side

side by

by

by

by side

side

side

side

When installing servodrives side by side, provide at least 10 mm space between them and at least

50 mm space above and below them as shown in the figure above. Make sure that the temperature

inside the control panel is evenly, and prevent the temperature around each servodrive from

increasing excessively. Install cooling fans above the servodrives if required.

■

■

■

■

Working

Working

Working

Working conditions

conditions

conditions

conditions

1.Temperature : 0~ 55 ℃

2.Humidity : 90%RH or less

3.Vibration : 4.9m/s2or less

4.Ambient temperature to ensure long-term reliability: 45 ℃ or less

- 20 -

Chapter 3

Wiring

3.1 Main Circuit Wiring

Please observe the following instructions while wiring the main circuit.

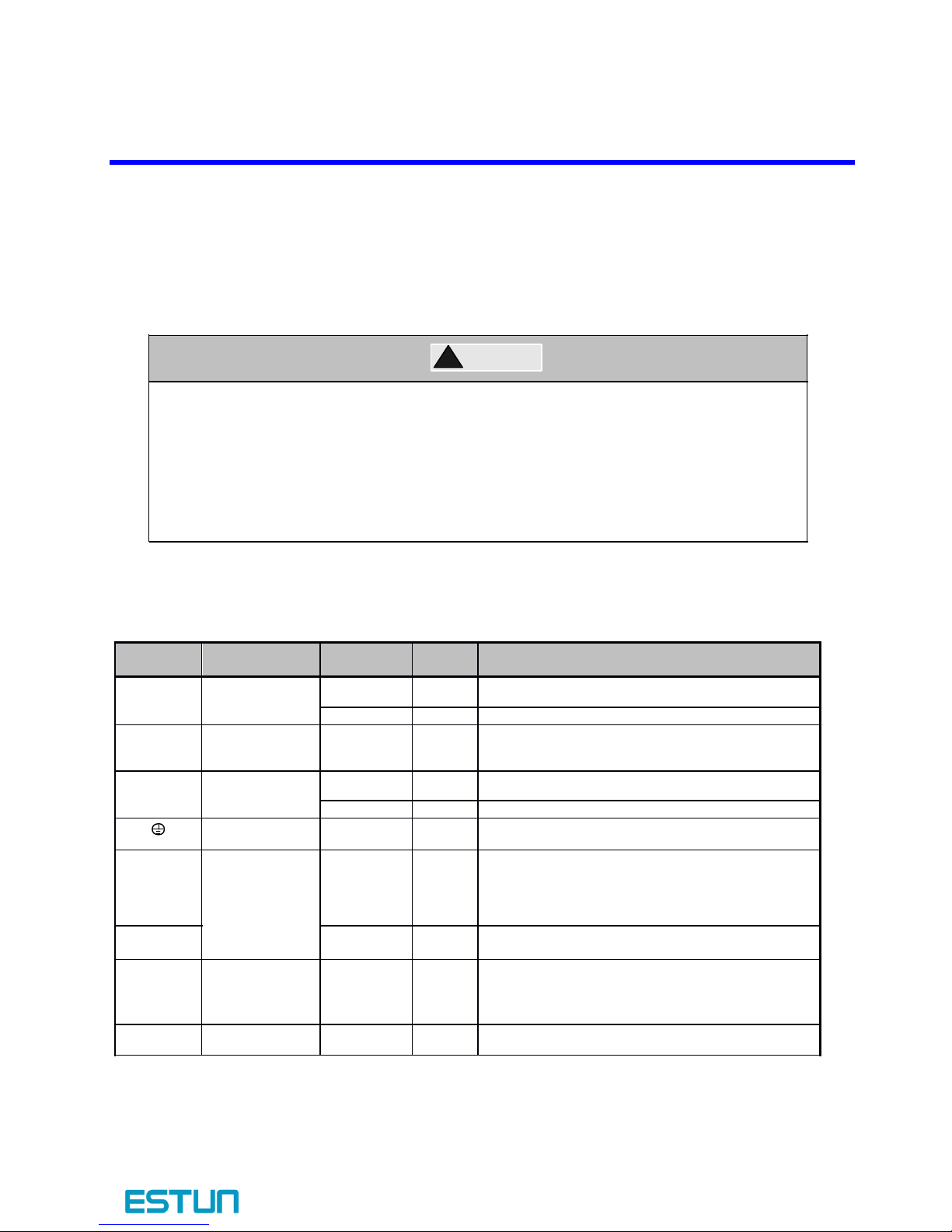

3.1.1 Names and Functions of Main Circuit T erminals

· Do not bundle or run power and signal lines together in the same duct. Keep power and

signal lines separated by at least 300 mm.

· U se twisted-pair shielded wires or multi-core twisted-pair shielded wires for signal and

encoder feedback lines.

· The maximum length is 3 m for reference input lines and is 20 m for encoder feedback lines.

· Do not touch the power terminals for 5 minutes after turning power OFF because high

voltage may still remain in the servodrive.

Terminal

Terminal

Terminal

Terminal

Symbol

Symbol

Symbol

Symbol

Name

Name

Name

Name

Main

Main

Main

Main C ircuit

Circuit

Circuit

Circuit

Voltage(V)

Voltage(V)

Voltage(V)

Voltage(V)

ProNet-

ProNet-

ProNet-

ProNet-

Functions

Functions

Functions

Functions

L1 , L2 , L3

Main circuit

power supply

input terminal

200

□□ A

Three-phase 200 ~ 230VAC+10% -15% (50/60Hz)

400

□□ D

Three-phase 380 ~ 440VAC+10% -15% (50/60Hz)

U , V , W

Servomotor

connection

terminals

--Connects to the serv omotor.

L1C , L2C

Control circuit

power supply

input terminal

200

□□ A

Single-phase 200 ~ 230VAC+10% -15% (50/60Hz)

400

□□ D

Single-phase 380 ~ 440VAC+10% -15% (50/60Hz)

Ground terminals

-

-

Connects to the power supply ground terminals and

servomotor gro und terminal.

B1 , B2 ,

B3

External

regenerative

resistor

connection

terminal

200

□□ A

If use an internal regenerative resistor, please short B2

and B3. Remove the wire between B2 and B3 and

connect an external regenerative resistor(provided by

customer) between B1 and B2, if the capacity of the

internal regenerative resistor is incufficien t.

B1 , B2

400

□□ D

Connect an external regenerative resistor between B1

and B2.

+

○ 1,+○ 2

DC reactor for

harmonic

suppression

terminal

200

□□ A

Normally short

+

○

1and

+

○

2.

If a countermeasure against power supply harmonic

waves is needed, connect a DC reactor between

+

○ 1and+○ 2.

-

○

Main circuit

minus terminal

200

□□ A

Normally not connected.

!

CAUTION

Chapter 3 Wiring

- 21 -

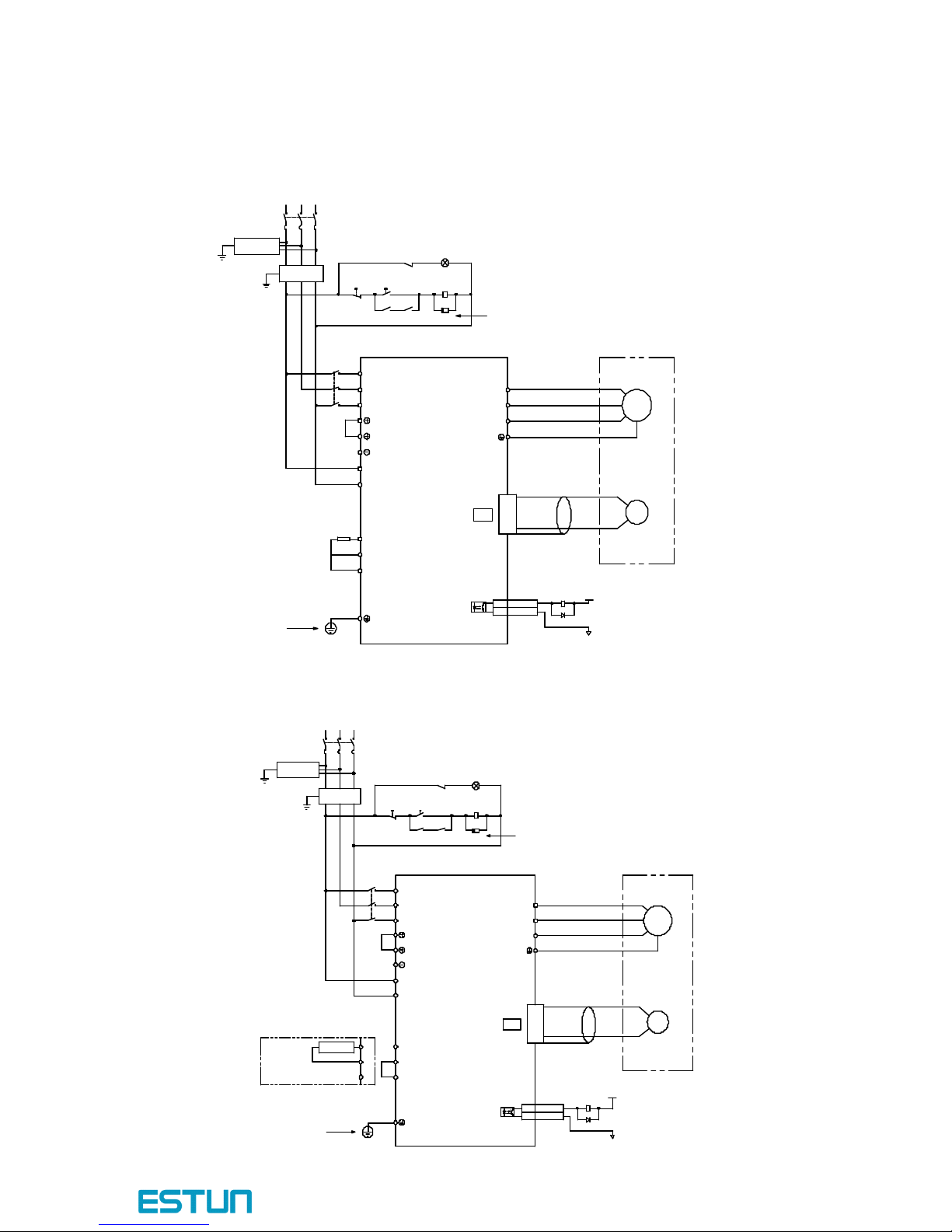

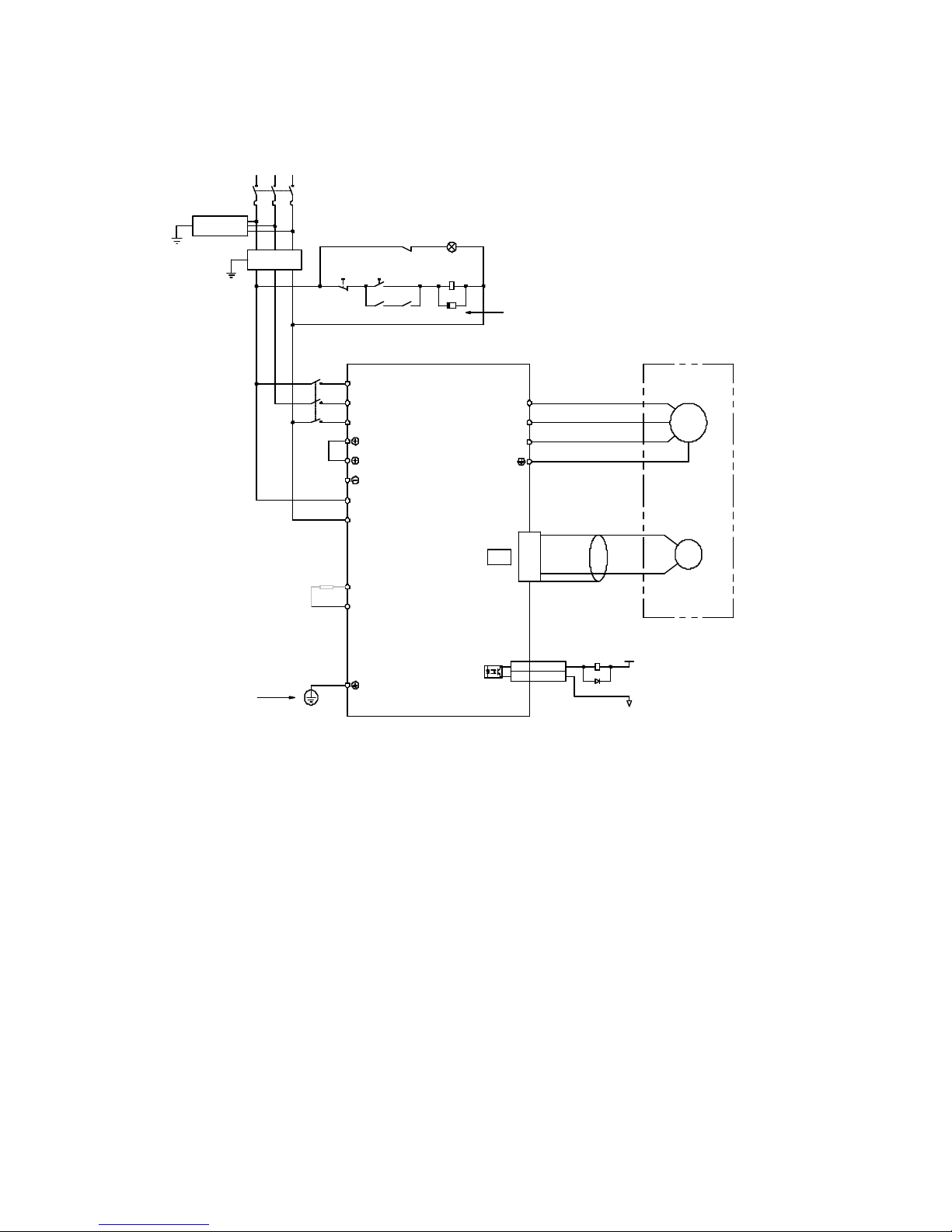

3.1.2

Typical

Main Circuit Wiring Examples

Three-phase 200V ProNet-02A ~ 04A

Three-phase 200V ProNet-08A ~ 50A

L1 L2 L3

Th ree-pha se 200~2 30V (50/60H z)

+

10%

-

15%

Powe r OF F

Powe r ON

1 KM 1SU P

1 KM

1 Ry

L

1

L2

L3

W

V

U

M

PG

A(1)

B(2)

C(3)

D(4)

L2C

L1C

CN2

1 Ry1D+24 V

0 V

1 Ry

1PL ( Servo Alarm Di splay )

ALM+

7

ALM-

8

ProNe t

ProNe t

ProNe t

ProNe t

Serie s Servo drive

1

2

B1

B2

B3

External Reg enerative Resi stor

Ground Terminal

Encod er

Servod rive

Magn etic Contactor

Mold ed-case Ci rcuit Breaker

Surge Protector

Surge Protector

Surge Protector

Surge Protector

Noi se Filter

Be sure to conn ect a surge supp ressor to the

excitatio n coil of the magne tic contactor an d relay.

Noi se Filt er

L1 L2 L3

Th ree-pha se 20 0~230 V (50/ 60Hz)

+ 10%

- 15%

Power OF F

Powe r ON

1

KM

1SUP

1

KM

1 Ry

L

1

L2

L3

W

V

U

M

PG

Servom ot or

Encod er

A(1)

B(2)

C(3)

D(4)

L2C

L1C

CN2

1 Ry

1D

+24 V

0 V

Surge Protect or

Magnetic Contactor

M olded -case C ircuit Breake r

1 Ry

1PL (

Servo Alarm Di splay

)

ALM+

7

ALM -

8

Be sure t o co nnect a surge suppresso r to th e

excitat ion coil of the magn etic con tact or an d rel ay.

.

ProNet

ProNet

ProNet

ProNet

Series Servodrives

1

2

B1

B2

B3

B2

B1

External Regenerator Resistor

B3

Ground Terminal

ProNet series AC servo system User’s manual V.1.08

- 22 -

Three-phase 400V ProNet-75D ~ 1ED

L1 L2 L3 Three-phase 380~440V (50/60Hz)

+

10%

-

15%

Power OFF Power ON

1 KM 1SUP

1 KM

1

Ry

L 1

L2

L3

W

V

U

M

PG

A(1)

B(2)

C(3)

D(4)

L2C

L 1 C

CN2

1

Ry

1D

+24 V

0 V

1

Ry

1PL ( Ser vo Alarm Display )

ALM+7

ALM-

8

ProNet

ProNet

ProNet

ProNet

Series Servodrive

1

2

B1

B2

External Regenerativ e Resistor

Ground Terminal

Encoder

Servodrive

Magnetic Contactor

Surge Protector

Surge Protector

Surge Protector

Surge Protector

Noise Filter

Be sure to connect a surge s uppress or to the

excitation coil of the magnetic contactor and relay.

- 23 -

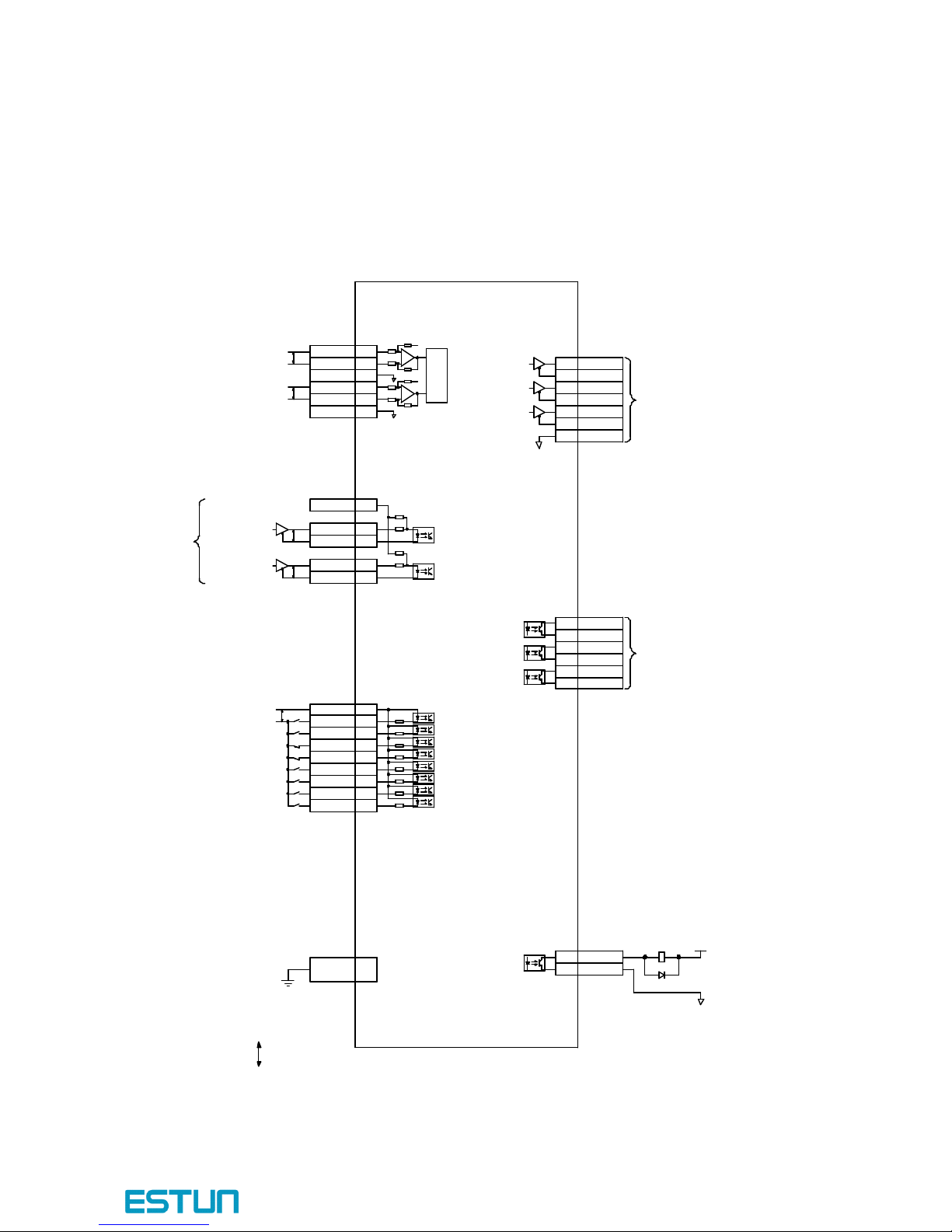

3.2 I/O Signals

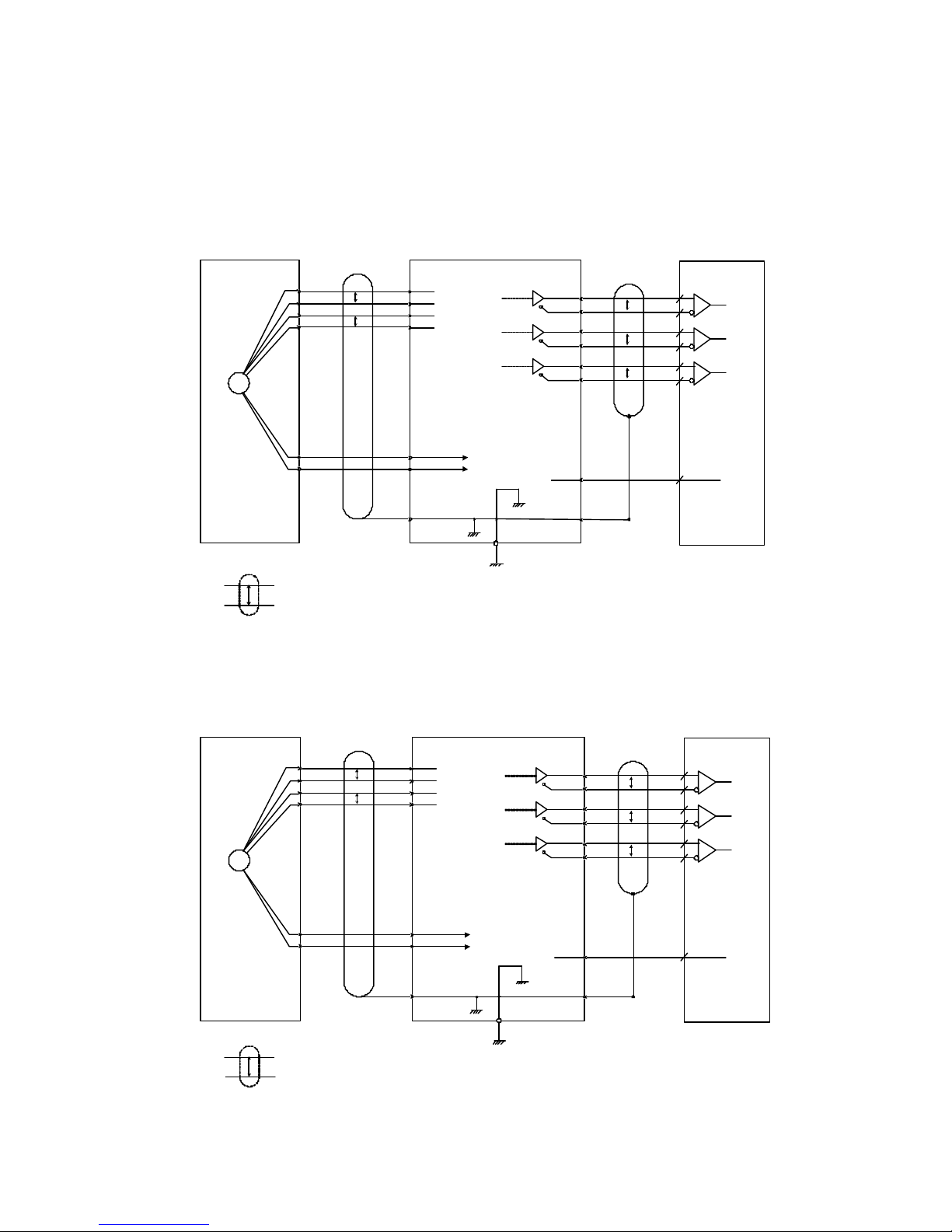

3.2.1 Examples of I/O Signal Connections

+

A/D

2KΩ

150Ω

150Ω

3.3KΩ

2KΩ

PULS

/ CW /

A

SIGN

/

CCW

/

B

Co nn ect Shie ld to C on nect or Sh ell

Open-Col lector Reference Use

Speed Refe re nce(± 1V~1 0V/Rated Sp ee d)

Torque Reference(±1V~10V/Rated Torque)

Position Reference

Signal Allocations can be Modified:

S-ON: Servo ON

P-CON: Proportion Control

P-OT:Forward Run Prohibited

N-OT:Reverse Run Prohibited

ALM-RST: Alarm Reset

CLR: Clear Error Pulse

P-CL:Forward Torque Limit

N-CL:Reverse Torque Limit

+2 4 V

P P P P

PG Divide d R atio Outpu t

App licable Line Ou tpu t

AM26L S32 A Man ufa ctured by TI or the Equ ivalen t.

Sign al Alloca tion s can be Modifie d:

V- CMP: Sp eed Coincid ence

COIN : Po sitionin g C ompletion

TGON:R ota tion D ete ction

S-RDY: Servo Read y

CLT :T or que L imit Detectio n

BK:B ra ke Inte rlo ck

PGC: E nco der C- Pulse Outpu t

P

Repr esents T wisted-p air Wires

ALM: Ser vo Alar m Output

Pho toco upler Output :

Maximum Opera ting Vo ltage :DC3 0V

Maximum Output Cur re nt: DC50mA

-

-

+

ref

ref

40K

10K

40K

10K

1

Ry

1D

+24

V

0

V

PAO+20

PAO-21

PBO+22

PBO-23

PCO+24

PCO-25

DGND

50

TGON+

5

TGON- 6

S-RDY+ 9

S-RDY- 10

V-CMP+ 11

V-CMP- 12

ALM+ 7

ALM-8

VREF+ 1

VREF- 2

AGND 3

TREF+

26

TREF-

27

AGND 28

PPI 34

PULS+ 30

PULS- 31

SIGN+ 32

SIGN- 33

DICOM

13

S-ON 14

P-CON 15

P-OT 16

N-OT 17

ALM-RST 39

CLR

40

P-CL 41

N-CL 42

Shield

ProNet

ProNet

ProNet

ProNet

Series Servodrive

ProNet series AC servo system User’s manual V.1.08

- 24 -

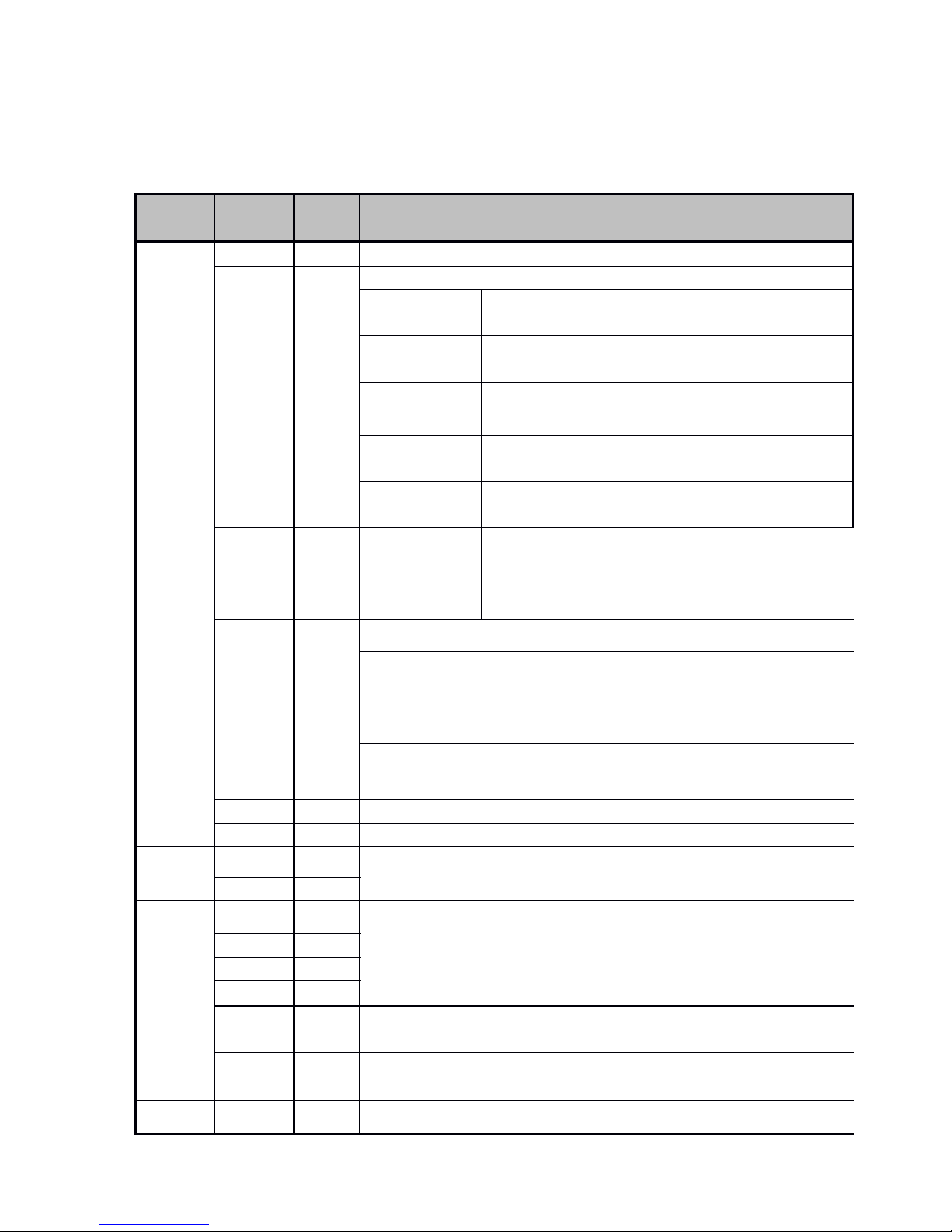

3.2.2 I/O Signal Names and Functions

�

�

�

� Input

Input

Input

Input Signals

Signals

Signals

Signals

Control

Control

Control

Control

Mode

Mode

Mode

Mode

Signal

Signal

Signal

Signal

Name

Name

Name

Name

Pin

Pin

Pin

Pin No

No

No

No .

.

.

.

Function

Function

Function

Function

Speed

Position

Torque

/S-ON14Servo ON: Turns the servomotor on.

/P-CON

15

Function selected by parameter.

Proportional

control reference

Switches the speed control loop from PI to P control when

ON.

Direction

reference

With the internally set speed selection: Switch the rotation

direction.

Control mode

switching

Enables control mode switching.

Z ero-clamp

reference

Speed control with z ero-clamp function: Reference speed is

z ero when ON.

Reference pulse

block

Position control with reference pulse: Stops reference pulse

input when ON.

P-OT

N-OT1617

Forward run

prohibited

Reverse run

prohibited

Overtravel prohibited: Stops serv omotor when ON.

/PCL

/NCL4142

Function selected by parameter.

Forward external

torque limit ON

Reverse external

torque limit ON

Current limit function enabled when ON.

Internal speed

switching

With the internally set speed selection: Switches the internal

speed settings.

/ALM-RST

39

Alarm reset: Releases the servo alarm state.

DICOM

13

Control power supply input for I/O signals: Provide the +24V DC power supply

Speed

VREF+

1

Speed reference input: ± 10V.

VREF-

2

Position

PULS+

30

Pulse reference input mode :

Sign + pulse string

CCW + CW pulse

Two-phase pulse (90ºphase differential)

PULS-31SIGN+

32

SIGN-

33

PPI

34

Power supply input for open collector reference (2K Ω /0.5W resistor is built into

the servodrive).

/CLR

40

Positional error pulse clear input: Clears the positional error pulse during position

control.

Torque

T-REF+

26

Torque reference input: ± 10V.

- 25 -

�

�

�

� Output

Output

Output

Output signals

signals

signals

signals

Control

Control

Control

Control

Mode

Mode

Mode

Mode

Signal

Signal

Signal

Signal

Name

Name

Name

Name

Pin

Pin

Pin

Pin No.

No.

No.

No.

Function

Function

Function

Function

Speed

Speed

Speed

Speed

Position

Position

Position

Position

Torque

Torque

Torque

Torque

/TGON+

5

Detects when the servomotor is rotating at a speed higher

than the motor speed seeting.

/TGON-

6

ALM+

7

Servo alarm:

Turns off when an error is detected.

ALM-

8

/S-RDY+

9

Servo ready:

ON if there is no servo alarm when the control/main circuit

power supply is turned ON.

/S-RDY-

10

PAO+

20

Phase-A signal

Converted two-phase pulse(phases A and

B) encoder output.

PAO-

21

PBO+

22

Phase-B signal

PBO-23PCO+

24

Phase-C signal

Z ero-point pulse(Phase-C) signal

PCO-

25

FG

Shell

Connected to frame ground if the shield wire of the

I/O signal cable is connected to the connector shell.

Speed

Speed

Speed

Speed

/V-CMP+

11

Speed coincidence:

Detects whether the motor speed is w ithin the setting range

and if it matches the reference speed value.

/V-CMP-

12

Position

Position

Position

Position

/COIN +

11

Positioning completion:

Turns ON when the number of positional error pulses reaches

the value set. The setting is the number of positional error

pulses set in the reference units.

/COIN -

12

Reserved

Reserved

Reserved

Reserved

/CLT

—

Reserved terminals:

The functions allocated to /TGON, /S-RDY, and /V-CMP

(/COIN) can be changed by using the parameters.

/CLT: Torque limit output

Turns on when it reaches the value set.

/BK: Brake interlock output

Releases the brake when ON,

/BK

—

4,18,19,29,35

36,37,38,43

44,45,47,49

Not used.

ProNet series AC servo system User’s manual V.1.08

- 26 -

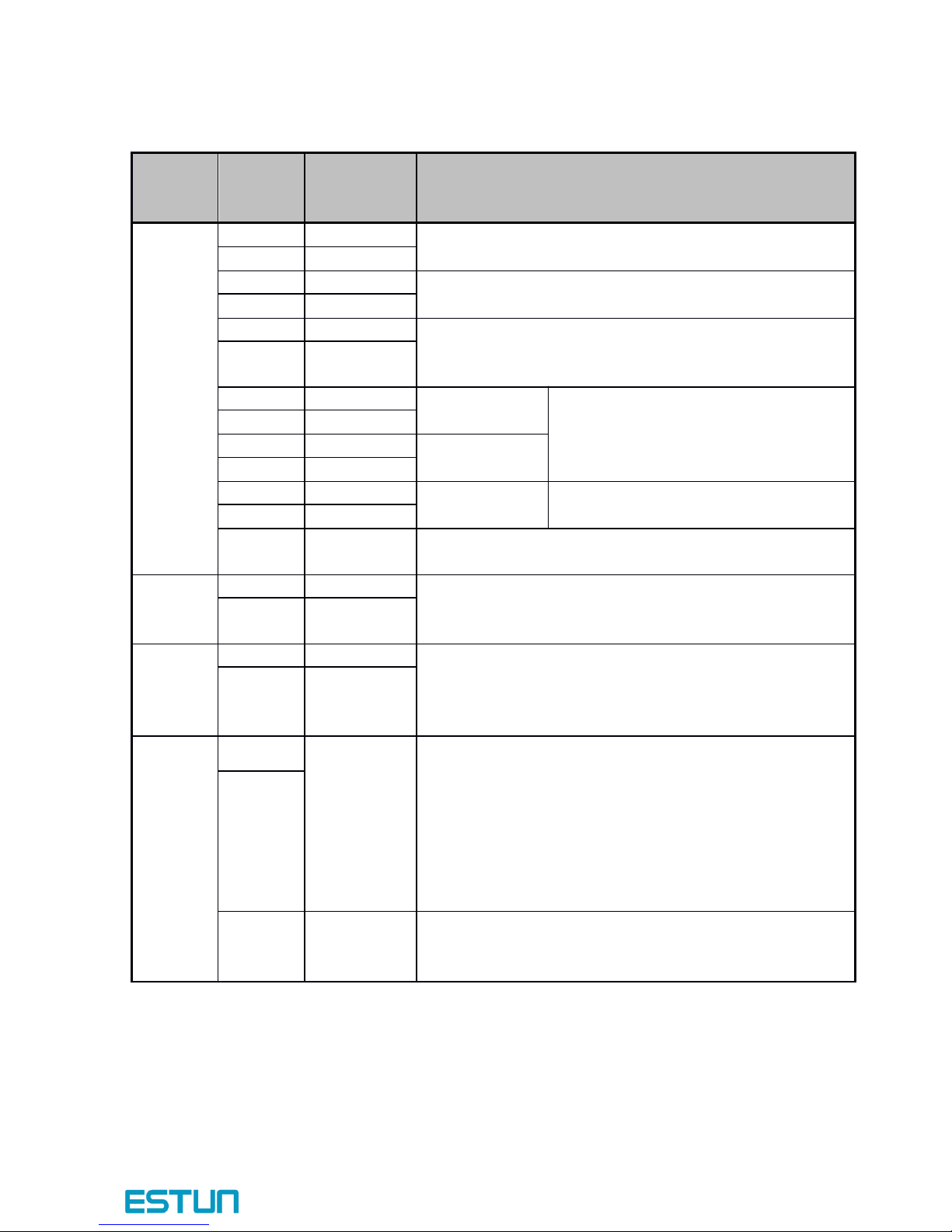

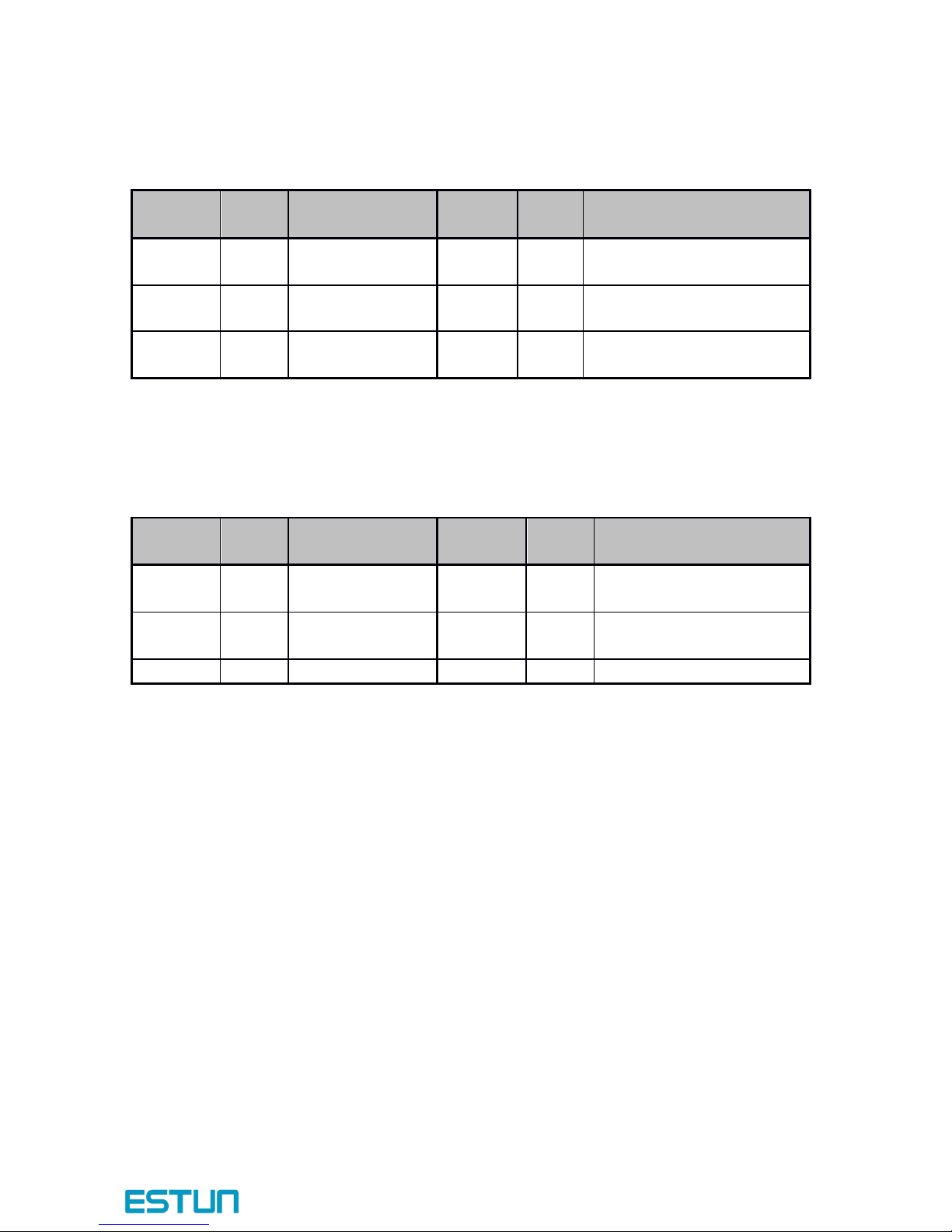

3.2.3 I/O Signal Connector (CN1) Terminal Layout

Note:

Note:

Note:

Note: The functions allocated to the following input and output signals can be changed by using the

parameters.

· Input signals: /S-ON , /P-CON , P-OT , N-OT , /ALM-RST , /CLR , /PCL , /NCL

· Output signals: /TGON , /S-RDY , /COIN

Please refer to A.3

A.3

A.3

A.3 Parameters

Parameters

Parameters

Parameters in

in

in

in details

details

details

details for detailed information.

Term inal

Term inal

Term inal

Term inal

No.

No.

No.

No.

Name

Name

Name

Name

Function

Function

Function

Function

Term inal

Term inal

Term inal

Term inal

No.

No.

No.

No.

Name

Name

Name

Name

Function

Function

Function

Function

1

VREF+

Speed reference input: ± 10V

26

T-REF+

Torque reference

input: ± 10V

2

VREF-

27

T-REF-3AGND

AGND28AGND

AGND4—

Reserved29—

Reserved

5

/TGON+

Running signal output

30

PULS+

Reference pulse input

6

/TGON-

31

PULS-

7

ALM+

Servo alarm

32

SIGN+

Reference sign input

8

ALM-

33

SIGN-

9

/S-RDY+

Servo ready

34

PPI

Open collector