Estun E21S Operation Manual

E21S Operation Manual

(Version: V1.05)

E21S Operation Manual

Contents

Preface ...................................................................................................................... 1

Chapter 1 Product Overview ................................................................................... 2

1.1 Product i ntroduction ....................................................................................... 2

1.2 Operation p anel ............................................................................................. 2

1.3 Displayer ........................................................................................................ 4

Chapter 2 Operati on Instruction ............................................................................. 5

2.1 Basic operation procedure ............................................................................. 5

2.2 Programming ................................................................................................. 6

2.2.1 Single-step programming ................................................................................... 6

2.2.2 Multi-step programming ...................................................................................... 8

2.3 Parameter setting ......................................................................................... 11

2.4 Manual movement ....................................................................................... 14

Chapter 3 Alarm ..................................................................................................... 15

Appendix Common fault and troubleshooting .................................................. 17

E21S Operation Manual

1

Preface

This manual describes operation of E21S numerical control device and is meant for

operators who are instructed for operation of the device. Operator shall read this manual and

know operation requirements before using this device.

Copy right is preserved by ESTUN. It is not allowed to add or delete part or all of the

manual content without ESTUN’s consent. Do not use part or all of manual content for the third

party’s design.

E21S device provides complete software control and has no mechanical protection device

for operator or the tool machine. Therefore, in case of malfunction , ma chi ne tool mu s t pro vide

protection device for operator and external part of the machine tool. ESTUN is not responsible

for any direct or indirect losses caused by normal or abnorm al oper ati on of the de vice.

ESTUN preserves the right to modifying this manual in th e event of function adding or print

error.

E21S Operation Manual

2

Chapter 1 Product Overview

1.1 Product introduction

This product is equipped with the shear machine dedicated numerical con trol device which

is applicable to various users. Based on ensuring work precision, the cost of numerical control

shearing machine is reduced significantly.

Features and functions of this product are as following:

Back gauge can be controlled.

Cut-angle can be controlled.

Cut-gap can be controlled.

Stroke time can be controlled.

Intelligent positioning control.

Unilateral and bidirectional positioning which eliminates spindle clearance effectiv ely.

Retract functions.

Automatic reference searching.

One-key parameter backup and restore.

Fast po sition indexing.

40 progr am s s torage space, each program has 25 steps.

Power-off protection.

1.2 Operation pane l

Operation panel is shown in Figure 1-1.

Figure 1-1 Operation panel

E21S Operation Manual

3

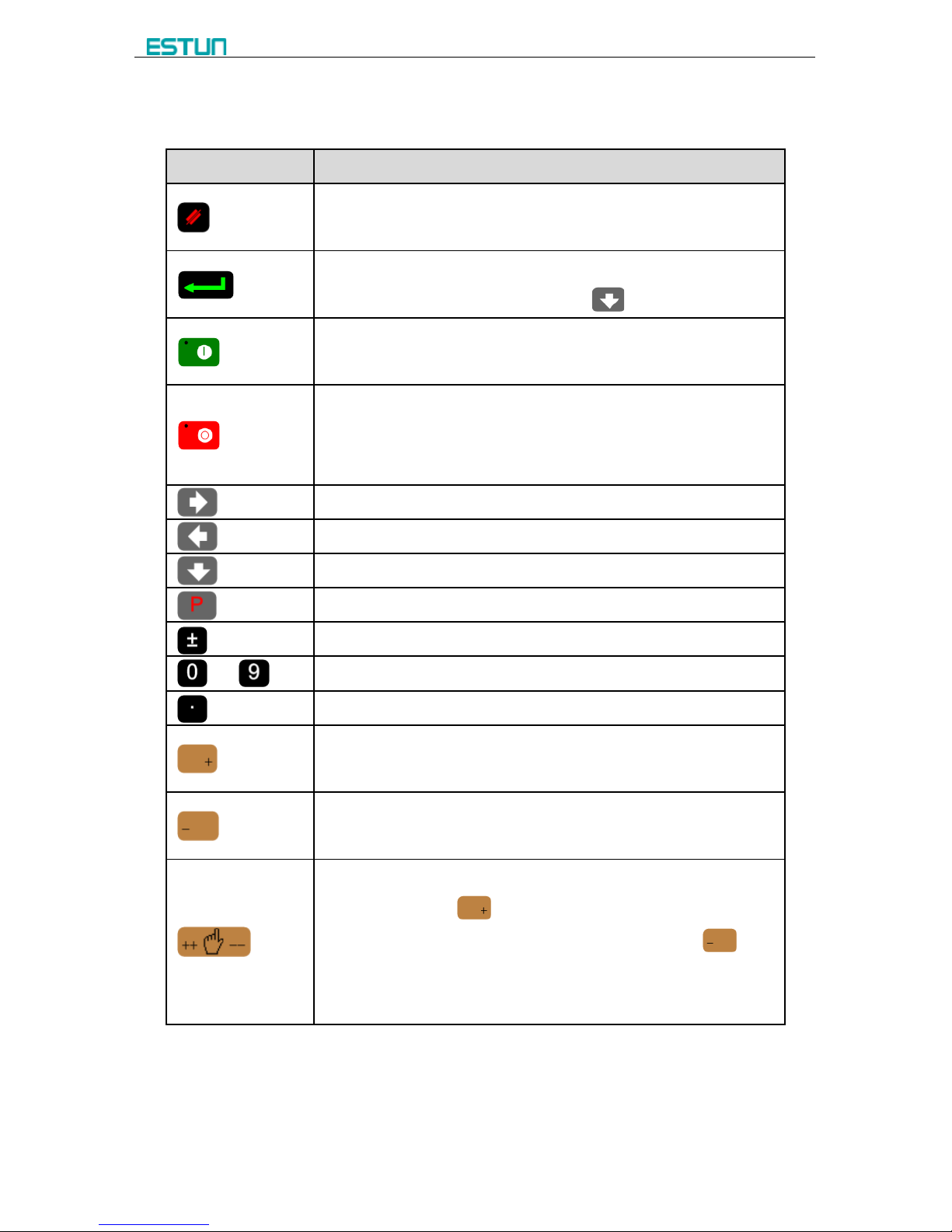

Functions of panel keys are described in Table 1-1.

Table 1-1 Desc ription of key functions

Key Function description

Delete key: delete all data in input area on left bottom of

displayer.

Enter key: confirm the input content . If no content is inp ut, the key

has the similar funct ion to direction key .

Start key : auto mati c sta rt-up, top left corner of the key is operation

indicator LED. When operat ion is started, this indicator LED is on.

Stop key: stop operation, top left corner of the key is Stop

indicator LED. When initialize normal start-up and no operation,

this indicat or LED is on.

Left direction key: page forward, cursor remove

Right direction key: page backward, cursor remove

Down direction key: select parameter downward

Function switch: switch over different function pages

Symboli c key: user input symbol, or start diagnosis.

~

Numeric key: when setting parameter, input value.

Decimal point key: when set up parameter, input decimal point.

Manual movement key: in case of manual adjustment, make

adjus t ment obj ect move in f or ward direction at low speed.

Manual movement key: in case of manual adjustment, make

adjus t ment obj ect move in backward direction at low speed.

High speed selection key: in case of manual adjustment, press

this key and press

simultaneously, make adjustment object

move in increasing dir ec tion at high speed , t hen press

,

make adjustment object move in decreasing direction at high

speed.

E21S Operation Manual

4

1.3 Displayer

E21S numerical control device adopt s 160*160 dot matrix LC D display er. The displ ay area

is shown in Figure 1-2.

X: 200.00

Range: 0~9999.999mm

Single

XP: 20.00

A: 50.00 G: 9.98

DX: 2 F: 0

CUT: 3.00 PP: 0

DLY: 1.00 CP: 14

Title bar

Parameter

display area

Status bar

Figure 1-2 Display area

Title bar: dis play rel evant information of cur rent page, such as it s name, etc .

Parameter display area: display parameter name, parameter value and system

information.

Status bar: display area of input information and promp t messa ge, et c.

The paraphrases of shortening on this page are as shown in Table 1-2.

Table 1-2 The paraphrases of shortening

Shortening Description

X The current backgauge position

A The current cutting angle

G The current gap dis tanc e

XP The desired backgauge position

DX Backgauge retract distance

CUT Cutting delay

DLY Retracting delay

F Function output value

PP Preset workpiece

CP Current workpiece

Loading...

Loading...