Estun E21 Instruction Book

E21 Instruction Book

Document Version: V1.03

Software Version: V1.11

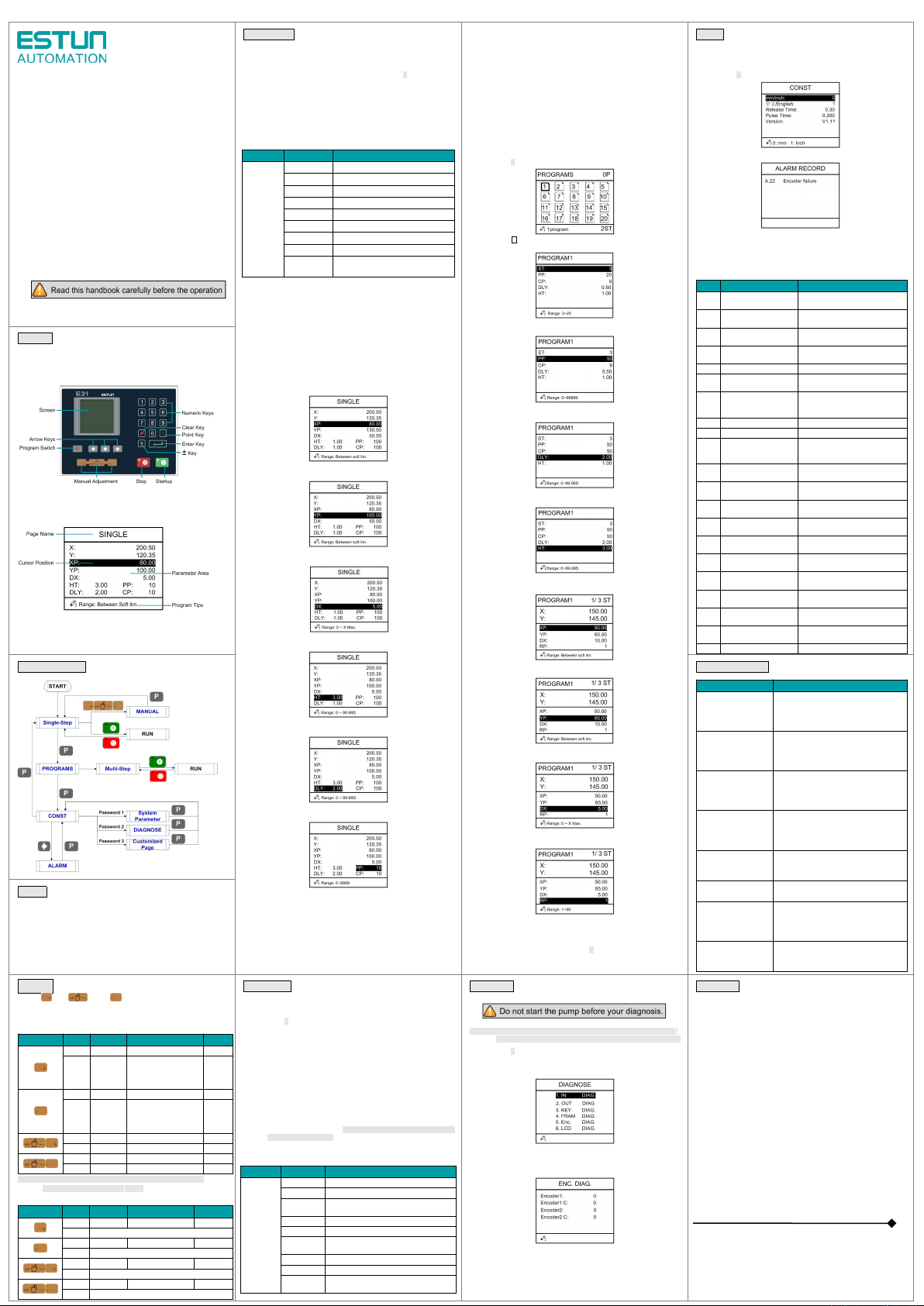

Single-Step

Description

1. The default page is SINGLE; also, you can press P key several

times, switching to the SIN GLE page.

2. Press Arrow Keys to select the parameter you want to program.

3. Press Numeric Keys to program a desired value.

4. Press Enter Key to complete the setting.

5. Follow the above meth ods to program the others parameters.

6. After finishing the program , press Startup Key to run the device.

Parameter

Page

Parameter

Description

Single-Step

X

Actual position of the back gauge

Y

Actual position of the slider

XP

Programmed position of the back gauge

YP

Programmed position of the slider

DX

Retract distanc e of the back gauge

HT

Hold time of punch at the bending point

DLY

Delay time in seconds f or X-axis retracting

PP

Preset work pieces

CP

■PP>0, indicat es the residual workpieces

■PP=0, indicat es the finished workpieces

Example

<INFO> There is one batch of mater ials, the requirement of bend ing are as

following: 10 pieces, bend depth is 100.00mm, back gauge position

is 80.00mm, the retract distance is 5.00mm, the delay time for

retracting is 2 seconds, and the hold ing time is 3 sec onds.

<PROCEDURE>

1. Program the parameter XP to 80.

2. Press Enter Key, movin g the cursor to the next parameter; and

program the parameter YP to 100.00

3. Press Enter Key, movin g the cursor to the next parameter, and

program the parameter DX to 5.00

4. Press Enter Key, movin g the cursor to the next parameter, and

program the parameter HT to 3.00

5. Press Enter Key, movin g the cursor to the next parameter, and

program the parameter DLY to 2.00

6. Press Enter Key, movin g the cursor to the next parameter, and

program the parameter PP to 10

7. Press Enter Key to finish the program.

8. Press Startup Key to run the device.

Example

<INFO> T here are 50 pieces of material, which are bent as following:

The first bending: bend dep th is 85.00mm, back gauge position is

50.00mm, retrac t distance is 5.00mm

The second bending: bend depth is 85.00mm, back gauge position

is 100.00mm, retract distance is 5.00mm

The third bending: bend dep th is 85.00mm, back gau ge position is

300.00mm, retract distance is 5.00mm

Put the aboveprogram into Program-No 1.

<PROCEDURE>

1. Press P key several times, switching to the PROGRAMS page

2. Select 1 and press Enter Key to enter the General Parameters

page; and program the parameter ST to 3

3. Press Enter Key, moving the cursor to the next parameter; and

program the parameter PP to 50

4. Press Enter Key, moving the cursor to the next parameter; and

program parameter DLY to 2.00

5. Press Enter Key, moving the cursor to the next parameter; and

program the parameter HT to 3.00

6. Press Enter Key and <Arrow Right> Key to enter the Step 1

Setting page; and program the parameter XPto 50.00

7. Press Enter Key, moving the cursor to the next parameter; and

program the parameter YP to 85.00

8. Press Enter Key, moving the cursor to the next parameter; and

program the parameter DX to 5.00

9. Press Enter Key, moving the cursor to the next parameter; and

program the parameter RP to 1

10. Press Enter Key and <Arrow Right> Key to enter the next step

parameters setting page; follow the above methods toprogram the

parameters of Step 2 and Step 3

11. After finishing the program, press P key to back the Total

Parameters page or the Step 1 page

12. Press Startup Key to run the device.

Alarm

Procedure

1. Press P key several times, switching to the CONST page.

2. Press <arrow right> key to enter the ALARM RECORD page.

Alarm List

The page can show the latest 6alarm info.And, thefollowin g table lists

all the alarm info.

No.

Name

Resolver

A.02

XPos < minimum

Move X-axis forwards in Manual

Movement.

A.03

XPos > maximum

Move X-axis backwards in Manual

Movement.

A.04

YPos < minimum

Move Y-axis forwards in Manual

Movement.

A.05

YPos > maximum

Move Y-axis backwards in Manual

Movement.

A.06

X out oflmt.

Re-teach the position of X-axis.

A.11

Count reached

shut-down

Rerun, the alarm is c leared

automatically.

A.12

Beam is not on upper

dead point

Step on the Foot Up Switch, moving

the slider tothe TDC, and the alarm

will be cleared automatically.

A.13

X Un-teachI n

Re-teach the position of X-axis.

A.14

Y Un-teachI n

Re-teach the position of Y-axis.

A.21

Oil pump not started

Check whether the pump signal is

connected, an d check whether the

pump switch is on.

A.22

Encoder failure

Check whether the encoder wiring is

normal.

A.25

Drive mode err

Reprogram the Drive Mode for

X-axis and Y-axis.

A.26

X Stop Err

Check whether the back gauge

motor is run normally.

A.27

Y Stop Err

Check whether the slider motor is

run normally.

A.28

X V2 Err

Check whether the back gauge

motor is run normally.

A.29

X V3 Err

Check whether the back gauge

motor is run normally.

A.30

Y V2 Err

Check whether the slider motor is

run normally.

A.31

Y V3 Err

Check whether the slider motor is

run normally.

A.32

XPos < 0

Move X-axis forwards to the setting

range in Manual Movement.

A.33

YPos < 0

Move Y-axis forwards to the setting

range in Manual Movement.

A.41

Parameter storage error

Back to factory for repairing

Display

PanelPage

Operation Flow

Troubleshooting

Fault

Trouble shooting

The screen don’t display

when power on.

■The terminal ofpower supply wiring is error.

Follow the nameplate to rewire.

■The source voltage is too low.

■The connec tor is not connected well.

The back gauge motor

doesn’t run when X-axis

is operated, butthe

slider motor runs.

The wires of these two motor are in reverse,

please rewire.

The motor doesn’t run

when operating .

■Check whet her the machine is impede d, or

whether the slider is back to TDC

■Check whet her the motor wire is connected

well.

The motor can’t mutually

convert from high to low

■Check whet her the signal is in effect, or

whether f requency c onverter is normal.

■Check whet her parameter Mute Dis. is

programmed correctly.

The step can’t be

changed in Multi-Step

mode.

Check the START terminal is connected to

+24V when the slider is on TDC.

The counter doesn’t

work in Multi-Step mode.

Check the START terminal is connected to

+24V when the slider is on TDC.

Lose control ofthe

system

■Check whet her the encoder cable is

connected w ell.

■Check whet her the motor direction wiring

(X+, X-, Y+,Y-) is correct.

The actual position of

X-axis or Y-axis is

unchanged or unshown.

Check whether the encoder cable is

connected well or correctly.

Notice

W hen the REDindicat or light is on, you can program the parameters.

Only when the page is onS INGLE, Total Parameters page or the Step 1

page, you can press Startu p Key to run the device.

Press StopKey to stop themachine, and the device backsto theprevious

page.

When the page

displays

the alarm info,you should resolve the problem

with some effective measures (see Alarm List). The device will be reset

by the self-diagnosis function.

Manual

Press key, key or key to enterthe MANUAL page.

Press Arrow Keys to select the axis you w ant to adjust, and follow the

below table to operate.

The drive mode of the corresponding axis ismotor .

Press Key

Status

Direction

Duration

Speed

STOP

increasing

Press Time

Slow

RUN

increasing

■Press Time (PressTime <

Pulse Time)

■Pulse Time (PressTime >

Pulse Time)

Slow

STOP

decreasing

Press time

Slow

RUN

decreasing

■Press Time (PressTime <

Pulse Time)

■Pulse Time (PressTime >

Pulse Time)

Slow

STOP

increasing

Press time

Slow

RUN

increasing

Press time

Slow

STOP

decreasing

Press time

Slow

RUN

decreasing

Press time

Slow

<Note>: W hen the systemis on run s tatus, the operation of manu al

movement is just valid f or the X-axis.

The drive mode of the corresponding axis isfrequ ency converte r.

Press Key

Status

Direction

Duration

Speed

STOP

increasing

Press Time

Slow

RUN

Unable

STOP

decreasing

Press Time

Slow

RUN

Unable

STOP

increasing

Press Time

Fast

RUN

Unable

STOP

decreasing

Press Time

Fast

RUN

Unable

Multi-Step

Description

1. Press P key several times, switching to the PROGRAMS page.

2. Press Arrow Keys to select a desired No, or you can press

Numeric Keys to input a desired N o, and then press Enter Key to

enter the General Parameters page.

4. Press Arrow Keys to select the parameter you want to program.

5. Press Numeric Keys to program a desired value.

6. Press Enter Key to complete the setting.

7. Follow the above meth ods to program the others general

parameters.

8. After finishing the program , press <arrow right> key to enter the

Step Setting page.

9. Follow the above meth ods to program the others step parameters.

10. Press <arrow right> or <arrow left> key to enter the others Step

Setting page, and program the desired parameters.

11. After finishingthe program,you should back to the Total Parameters

page or theStep 1 page, and press Startup Key to run the device.

Parameter

Page

Parameter

Description

Multi-Step

ST

The number of steps

PP

Preset workpieces

CP

■PP>0, indicat es the residual workpieces

■PP=0, indicat es the finished workpieces

DLY

Delay time in seconds f or X-axis retracting

HT

Hold time of punch at the bending point

XP

Programmed position of the back gauge in

the step

YP

Programmed posi tion of the slider in thestep

DX

Retract distanc e of the back gauge

RP

The number of times a step is repeated

before the next step is executed

Diagnosis

<NOTE> The following is only described how todiagnos e the encoder, and

for the othersdiagn osis, just according to the page tips to operate.

1. Press P key several times, switching to the CONST page.

2. Press Numeric Keys to input the password 5656, and press Enter

Key to enter the DIAGNOS E page.

3. Select 5. Enc. DIAG. or press Numeric Key 5 directly, and then

press Enter Key to enter the ENC. DIAG. page.

4. Rotate the encoders of X-axis and Y-axis, the page displays the

pulse changing. The corresponding C-pulse will jumpbetw een 0

and 1, whichind icates the encoder port is normal.

Reference

< E21 Installation Manual >

< E21 Operation Manual >

ESTUN AUTOMATION CO., LTD

Add: 155 Jiangjun Road, Jiangning Development Zone,

Nanjing 211106, P.R.China

TEL: 025-52785866

FAX: 025-52785992

WEB: www.estun.com

Email: info@estun.com

4

6

1

2

3

579

8

Loading...

Loading...