Estia HWS-2101CSHM3-E, HWS-1501CSHM3-E, HWS-3001CSHM3-E Installation Manual

AIR TO WATER HEAT PUMP SYSTEM

Installation manual

HOT WATER CYLINDER

INDIRECT HEATING METHOD

CLOSED OUTLET (UNVENTED)

150 litre HWS-1501CSHM3-E

210 litre HWS-2101CSHM3-E

300 litre HWS-3001CSHM3-E

AIR TO WATER HEAT PUMP SYSTEM

INSTALLATIONAND SERVICE MANUAL 3

EN

SYSTÈMEDE POMPE À CHALEUR AIR-EAU

MANUELD'INSTALLATION ET DE RÉPARATION 14

FR

LUFT-WASSER-WARMERPUMPENSYSTEM

INSTALLATIONS - UND WARTUNGSANLEITUNG 26

DE

SYSTÉM TEPELNÉHO ČERPADLA(VZDUCH - VODA)

SERVISNÍA MONTÁŽNÍ MANUÁL 38

CZ

CR

LEVEGŐ-VÍZ HŐSZIVATTYÚ RENDSZER

FELSZERELÉSI ÉS SZERVIZELÉSI KÉZIKÖN 60

HU

ΣΥΣΤΗΜΑΑΝΤΛΙΑΣ ΘΕΡΜΑΝΣΗΣ ΑΕΡΑ - ΝΕΡΟΥ

ΕΓΧΕΙΡΙ∆ΙΟ ΕΓΚΑΤΑΣΤΑΣΗΣ ΚΑΙ ΣΥΝΤΗΡΗΣΗΣ 72

GR

LUFT/VATTEN-VÄRMEPUMPSSYSTEM

INSTALLATIONS- OCH SERVICEMANUAL 84

SV

LUFT-TIL-VANN VARMEPUMPESYSTEM

INSTALLASJONS- OG VEDLIKEHOLDSHÅNDBOK 95

NO

SYSTÉMTEPELNÉHO ČERPADLA VZDUCH-VODA

NÁVOD NA INŠTALÁCIU A OBSLUHU 106

SK

SISTEM TOPLOTNE ČRPALKE ZRAK–VODA

PRIROČNIK ZA MONTAŽO IN VZDRŽEVANJE 118

SL

SUSTAV S TOPLINSKOM CRPKOM ZRAK-VODA

PRIRUČNIK ZA UGRADNJUI SERVISIRANJE 49

AIR TO WATER HEAT PUMP SYSTEM INSTALLATION AND SERVICE MANUAL

3

EN

AIR TO WATER HEAT PUMP SYSTEM

HOT WATER CYLINDER

INDIRECT HEATING METHOD

CLOSED OUTLET (UNVENTED)

INSTALLATION AND SERVICE MANUAL

IMPORTANT

PLEASE READ AND UNDERSTAND THESE INSTRUCTIONS BEFORE

INSTALLING THE WATER CYLINDER. INCORRECT INSTALLATION MAY

INVALIDATE GUARANTEE. THE WATER CYLINDER MUST BE INSTALLED

BY A QUALIFIED INSTALLER IN ACCORDANCE WITH LOCAL PLUMBING,

BUILDING AND ELECTRICAL REGULATIONS. PLEASE LEAVE THIS MANUAL

WITH THE UNIT FOR FUTURE REFERENCE.

TECHNICAL SPECIFICATIONS

Rated pressure 1.0 MPa (10 bar)

Test pressure (hydraulic) 1.5 MPa (15 bar)

Minimum recommended supply pressure 0.1 MPa (1 bar)

Max. primary circuit working pressure 0.35 MPa (3.5 bar)

Electrical rating (cylinder heater) 2.75kW @ 230V~

Weight (full) 150 litre indirect 181 kg

210 litre indirect 251 kg

300 litre indirect 360 kg

COMPONENTS SUPPLIED

• Water cylinder incorporating electric cylinder heater and thermal controls.

• Safety Group incorporating a Pressure Relief Valve, Check (Non-return) Valve

and Isolating Valve.

• Compression nuts and olives.

• Cylinder heater key spanner.

France

Carrier S.A. Route de Thil

BP 49 01122 Montiuel

Cedex France

Germany / Deutchsland

Carrier GmbH & Co. KG

Edisonstrasse 2 85716

Unterschleissheim

Czech Republic / Česko

AIRCOND, Klimaanlagen

Handelsgesellshcaft m.b.H

Petersgasse 45, A-8010

Graz Austria

Croatia / Hrvatska

AIRCOND, Klimaanlagen

Handelsgesellshcaft m.b.H

Petersgasse 45, A-8010

Graz Austria

Austria / Österreich

AIRCOND, Klimaanlagen

Handelsgesellshcaft m.b.H

Petersgasse 45, A-8010

Graz Austria

Hungary / Magyar

AIRCOND, Klimaanlagen

Handelsgesellshcaft m.b.H

Petersgasse 45, A-8010

Graz Austria

Greece / Ελλάδα

Carrier Hellas

Aircondilioning S.A.- 4g

Andersen street-11525

Athens Greece

Sweden / Sverige

Carrier AB - P.O.BOX 8946Arods Industrivag 32. S-402

73 Gothenburg Sweden

Norway / Norge

Carrier AB - P.O.BOX 8946Arods Industrivag 32. S-402

73 Gothenburg Sweden

Slovakia / Slovensko

AIRCOND, Klimaanlagen

Handelsgesellshcaft m.b.H

Petersgasse 45, A-8010

Graz Austria

Slovenia / Slovenija

AIRCOND, Klimaanlagen

Handelsgesellshcaft m.b.H

Petersgasse 45, A-8010

Graz Austria

AIR TO WATER HEAT PUMP SYSTEM INSTALLATION AND SERVICE MANUAL

4

EN

1.0 IMPORTANT INSTALLATION POINTS

1.1 The unit, for use with the ESTIA air to water heat pump system, is a purpose

designed unvented water cylinder.

1.2 The water cylinder MUST be fitted with a Pressure Relief Valve that complies

with your local Plumbing and Building Regulations. FAILURE TO PROVIDE

ADEQUATE PRESSURE RELIEF WILL INVALIDATE ANY GUARANTEE

AND LEAD TO A DANGEROUS INSTALLATION.

1.3 Where the inlet pressure exceeds 0.6 MPa (6 bar) a Pressure Reducing Valve

(set at max. 0.5 MPa (5 bar)) should be fitted to the inlet supply to the water

cylinder. This MUST NOT be fitted between the Pressure Relief Valve and the water

cylinder.

1.4 A Check (non-return) Valve should be fitted to the inlet supply to the water cylinder.

This MUST NOT be fitted between the Pressure Relief Valve and the water cylinder.

1.5 This appliance is not intended for use by persons (including children) with

reduced physical, sensory or mental capabilities, or lack of experience or

knowledge, unless they have been given supervision or instruction concerning

use of the appliance by a person responsible for their safety. Children should be

supervised to ensure that they do not play with the appliance.

2.0 INSTALLATION – GENERAL REQUIREMENTS

2.1 National Wiring Regulations may contain restrictions concerning the installation

of these units in certain areas, eg. Bathrooms.

2.2 The unit MUST be installed vertically.

2.3 The unit must be positioned on a level surface.

2.4 Enough space should be left around the unit for pipe connections and for access

to controls and any safety valves fitted. Refer to Diagram 1 and the Dimensions

Table to determine a suitable position for the water cylinder.

2.5 NOTE: Ensure the floor can support the full weight of the unit (see TECHNICAL

SPECIFICATIONS).

2.6 DO NOT install where the unit may freeze.

2.7 The mains water supply to the property will be supplying both the hot and cold

water requirements simultaneously. It is recommended that the maximum water

demand is assessed and the water supply checked to ensure this demand can

be satisfactorily met.

NOTE: a high mains water pressure will not always guarantee high flow rates.

We suggest the minimum supply requirements should be 0.1 MPa (1.0 bar)

pressure and 20 litres per minute flowrate. However, at these values outlet flow

rates may be poor if several outlets are used simultaneously. The higher the

available pressure and flow rate the better the system performance.

2.8 LIMITATIONS:

The water cylinder should not be used in association with any of the following:

• Situations where maintenance is likely to be neglected or safety devices

tampered with.

AIR TO WATER HEAT PUMP SYSTEM INSTALLATION AND SERVICE MANUAL

5

EN

• Water supplies that have either inadequate pressure or where the supply

may be intermittent.

• Situations where it is not possible to safely pipe away any discharge from the

safety valves.

• Areas where the water supply consistently contains a high proportion of

solids or suspended matter unless adequate filtration can be ensured on the

inlet water supply.

3.0 INSTALLATION – PLUMBING

3.1 Refer to section IMPORTANT INSTALLATION POINTS. Plumb in valves in the

sequence shown in Diagram 2. Ensure the valves are installed in the correct

orientation by reference to the direction of flow arrows marked on them.

The water cylinder MUST be fitted with a Pressure Relief Valve that complies

with your local Plumbing and Building Regulations. (Safety Group supplied).

FAILURE TO PROVIDE ADEQUATE PRESSURE RELIEF WILL INVALIDATE

ANY GUARANTEE AND LEAD TO A DANGEROUS INSTALLATION. Any

discharge pipe connected to the Pressure Relief device must be installed in a

continuously downward direction in a frost free environment.

3.2 The water connections on the unit accept direct connection of 22mm outside

diameter pipe; nuts and olives are supplied for this purpose. The thread on the

connections is G3/4 to enable the use of G3/4 female connections to be used if

required. DO NOT use zinc plated water pipes. When steel pipes are used the

pipe should be insulated from the stainless steel vessel by using di-electric

couplings.

3.3 The sanitary water INLET is marked BLUE, the OUTLET is marked RED.

Several hot outlets can be served, however, individual site demands should be

considered when choosing capacity and the number of outlets to be served.

3.4 It is recommended that an isolating valve is fitted on the cold water supply to

the water cylinder.

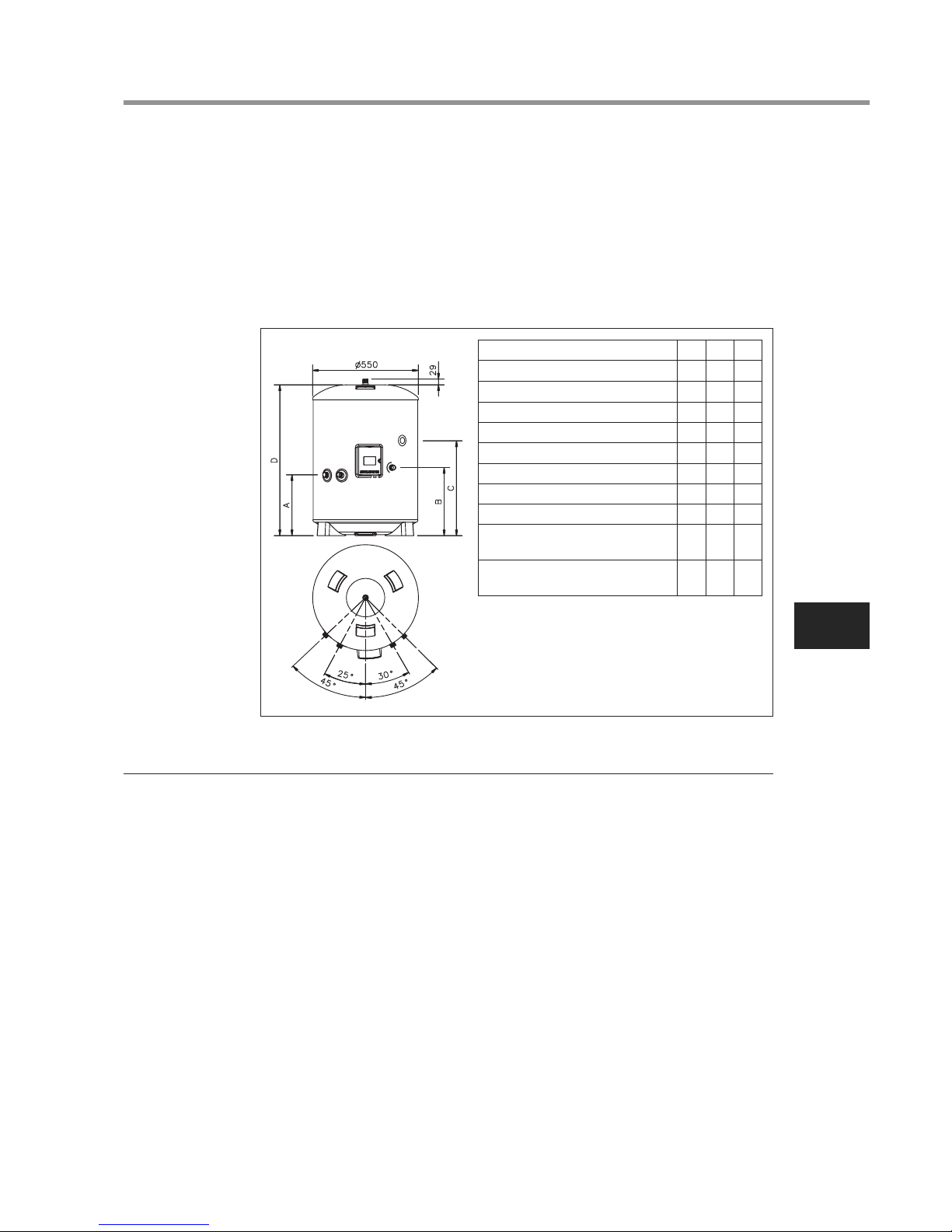

Diagram 1

NOMINAL CAPACITY(litres)

A (mm)

B (mm)

C (mm)

D (mm)

SURFACE AREA (sq.m)

HOT WATER OUTPUTAT60ºC (litres)

MIXEDHOTWATER OUTPUT AT 40ºC (litres)

HEAT LOSS(kWh/24h)

HEATING TIME 15ºC TO 60ºC- USING ELECTRIC

CYLINDER HEATER ONLY(mins)

CAPACITY HEATED USING ELECTRIC

CYLINDER HEATER ONLY(litres)

150 210 300

315 315 315

354 354 354

800 1184 1474

1090 1474 2040

0.65 0.79 0.79

102 163 254

243 329.5 476

1.45 1.91 2.52

123 188 262

102 163 254

Loading...

Loading...