Estate AGP200VDW0, CG11000VDV0, TGP200VDQ0 Installation Guide

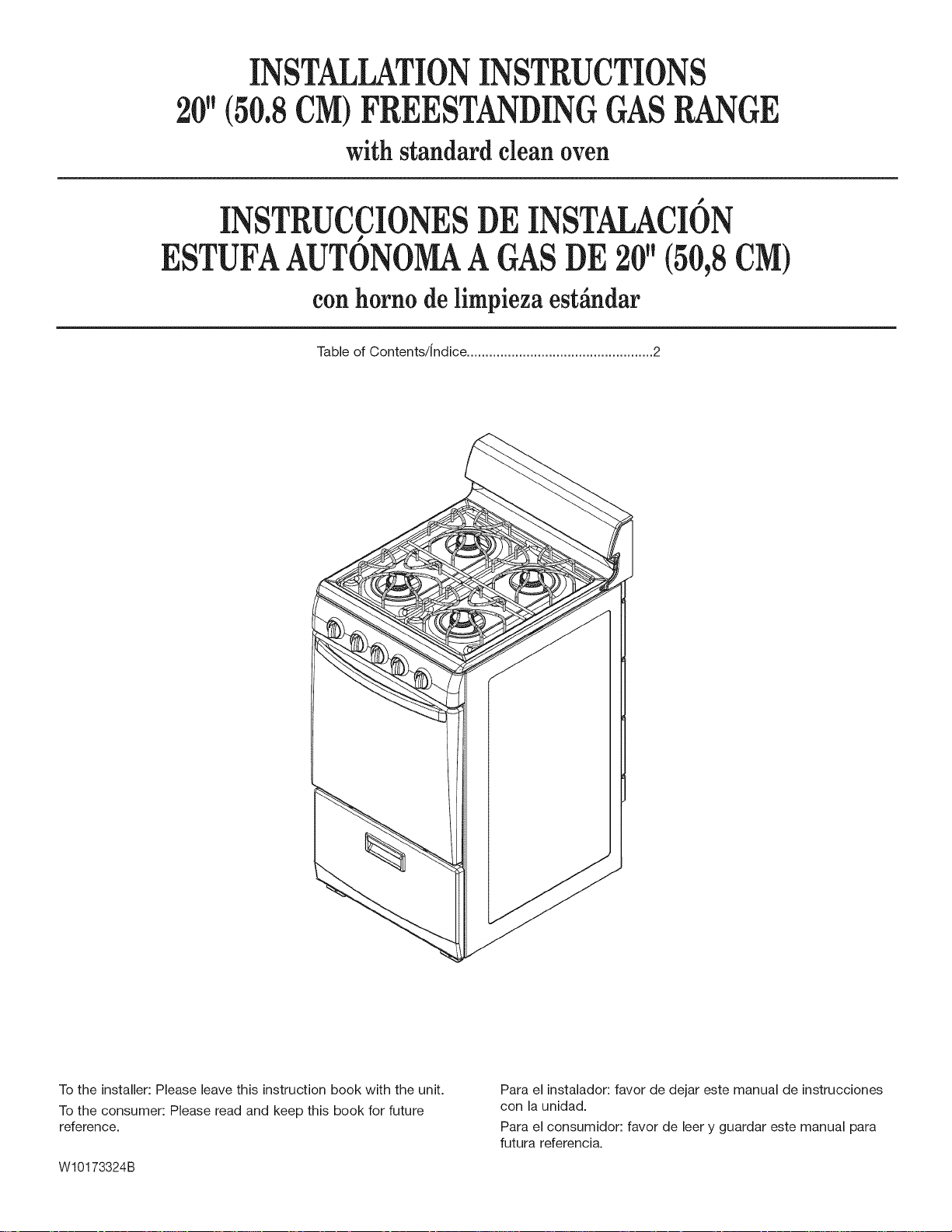

INSTALLATIONINSTRUCTIONS

(50.8CM)FREESTANDINGGASRANGE

with standard clean oven

P

INSTRUCCIONESDEINSTALACION

P

STUFAAUTONOMAA GASDE 20"(50,8CM)

con horno de limpieza est_indar

Table of Contents/fndice .................................................. 2

To the installer: Please leave this instruction book with the unit.

To the consumer: Please read and keep this book for future

reference.

W10173324B

Para el instalador: favor de dejar este manual de instrucciones

con la unidad.

Para el consumidor: favor de leer y guardar este manual para

futura referencia.

TABLEOFCONTENTS

P

INDICE

RANGE SAFETY .......................................................................... 2

iNSTALLATiON REQUIREMENTS .............................................. 4

Tools and Parts .......................................................................... 4

Location Requirements .............................................................. 4

Gas Supply Requirements ........................................................ 6

iNSTALLATiON iNSTRUCTiONS ................................................ 7

Unpack Range ............................................................................ 7

Install Anti-Tip Bracket .............................................................. 7

Verify Anti-Tip Bracket Location ................................................ 8

Level Range ................................................................................ 8

Make Gas Connection ................................................................ 9

Check Operation ...................................................................... 10

Check Operation of Oven/Broil Burner .................................... 11

Complete Installation .............................................................. 11

GAS CONVERSIONS ............................................................... 12

LP Gas Conversion .................................................................. 12

Pilot and By-pass Screws Conversion .................................. 13

Complete Conversion ............................................................ 14

Natural Gas Conversion .......................................................... 15

Pilot and By-pass Screws Conversion .................................. 17

Complete Conversion .............................................................. 17

SEGURIDAD DE LA ESTUFA .................................................... 18

REQUISITOS DE INSTALACION ................................................ 20

Herramientas y piezas ............................................................ 20

Requisitos de ubicaci6n .......................................................... 20

Requisitos del suministro de gas .......................................... 22

INSTRUCCIONES DE INSTALACION ........................................ 23

Desempaque la estufa .............................................................. 23

Instalaci6n del soporte anti-vuelco .......................................... 23

Verificaci6n de la ubicaci6n del soporte anti-vuelco .............. 24

Nivelaci6n de la estufa ............................................................ 25

Conexi6n del suministro de gas .............................................. 25

Verifique el funcionamiento ...................................................... 26

Verifique el funcionamiento del quemador

del horno/para asar .................................................................. 27

Complete la instalaci6n ............................................................ 27

CONVERSIONES DE GAS ....................................................... 28

Conversi6n de gas LP ............................................................ 28

Conversi6n de tornillos de desvio y piloto ............................ 29

Complete la conversi6n .......................................................... 30

Conversi6n de gas natural ...................................................... 30

Conversi6n de tornillos de desvio y piloto .............................. 32

Complete la conversi6n .......................................................... 32

RANGESAFETY

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual and on your appliance. Always read and obey all safety

messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word "DANGER" or "WARNING."

These words mean:

You can be killed or seriously injured if you don't immediately

follow instructions.

You can be killed or seriously injured if you don't follow

instructions.

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury, and tell you what can

happen if the instructions are not followed.

WARNING: if the information in this manual is not followed exactly, a fire or explosion

may result causing property damage, personal injury or death.

- Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this

or any other appliance.

-WHAT TO DO iF YOU SMELL GAS:

®Do not try to light any appliance.

• Do not touch any electrical switch.

• Do not use any phone in your building.

= immediately call your gas supplier from a neighbor's phone. Follow the gas supplier's

instructions.

®if you cannot reach your gas supplier, call the fire department.

- installation and service must be performed by a qualified installer, service agency, or

the gas supplier.

WARNING: Gas leaks cannot always be detected by smell.

Gas suppliers recommend that you use a gas detector approved by UL or CSA.

For more information, contact your gas supplier.

If a gas leak is detected, follow the "What to do if you smell gas" instructions.

In the State of Massachusetts, the following installation instructions apply:

[] Installations and repairs must be performed by a qualified or licensed contractor, plumber, or gasfitter qualified or licensed by

the State of Massachusetts.

[] If using a ball valve, it shall be aT-handle type.

[] A flexible gas connector, when used, must not exceed 3 feet.

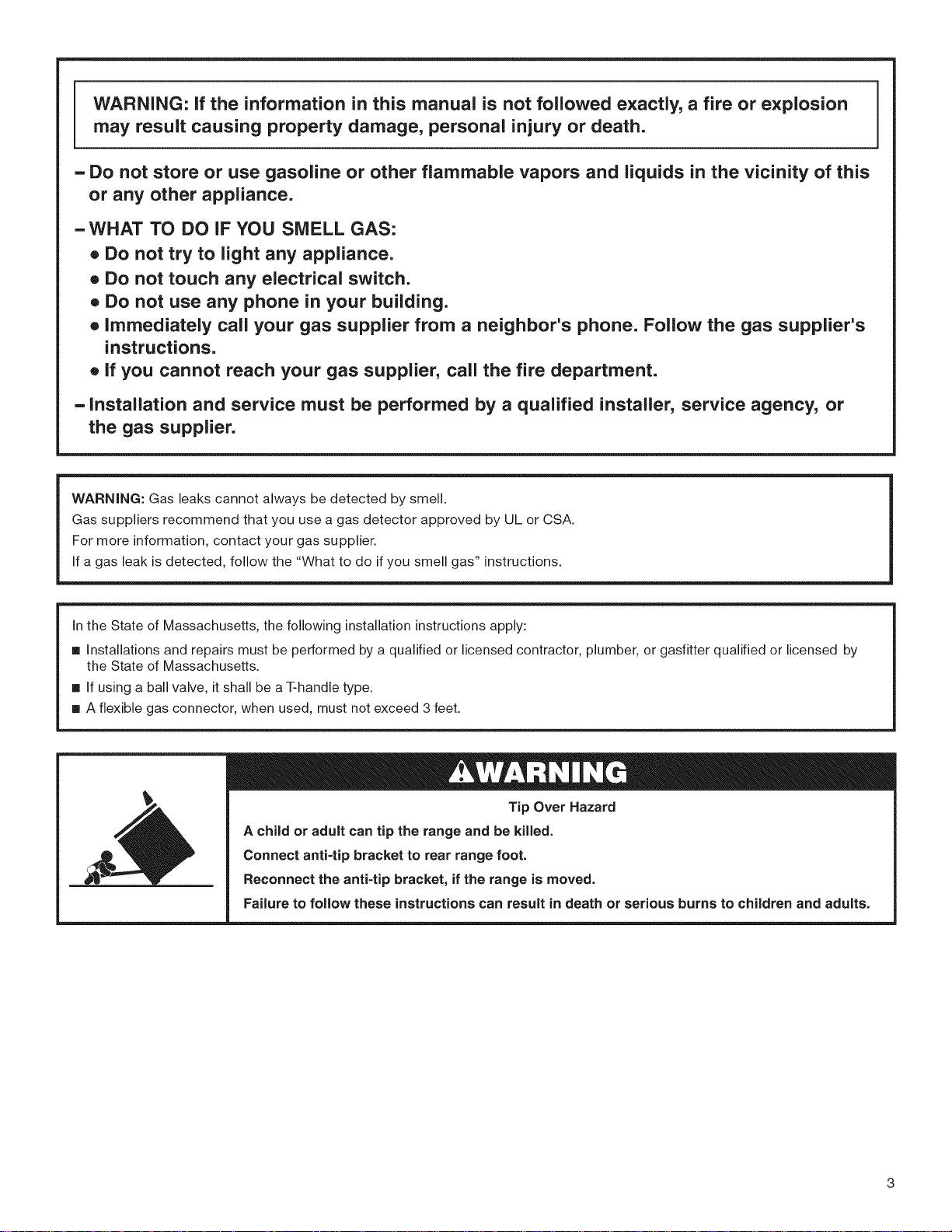

Tip Over Hazard

A child or adult can tip the range and be killed.

Connect anti-tip bracket to rear range foot.

Reconnect the anti-tip bracket, if the range is moved.

Failure to follow these instructions can result in death or serious burns to children and adults.

INSTALLATIONREQUIREMENTS

Gather the required tools and parts before starting installation.

Read and follow the instructions provided with any tools listed

here.

Tools needed

I Level

m 3/8" drive ratchet

=1 Tape measure

m Flat-blade screwdriver

m Phillips screwdriver

m Hand or electric drill

m Slip-joint pliers

m 7 mm combination wrench

m Pipe wrench

m 1/8" (3.2 mm) drill bit (for wood floors)

m 3/16" (4.8 mm) carbide-tipped masonry drill bit

(for concrete/ceramic floors)

m Pipe joint compound resistant to LP gas

m Non-corrosive leak-detection solution

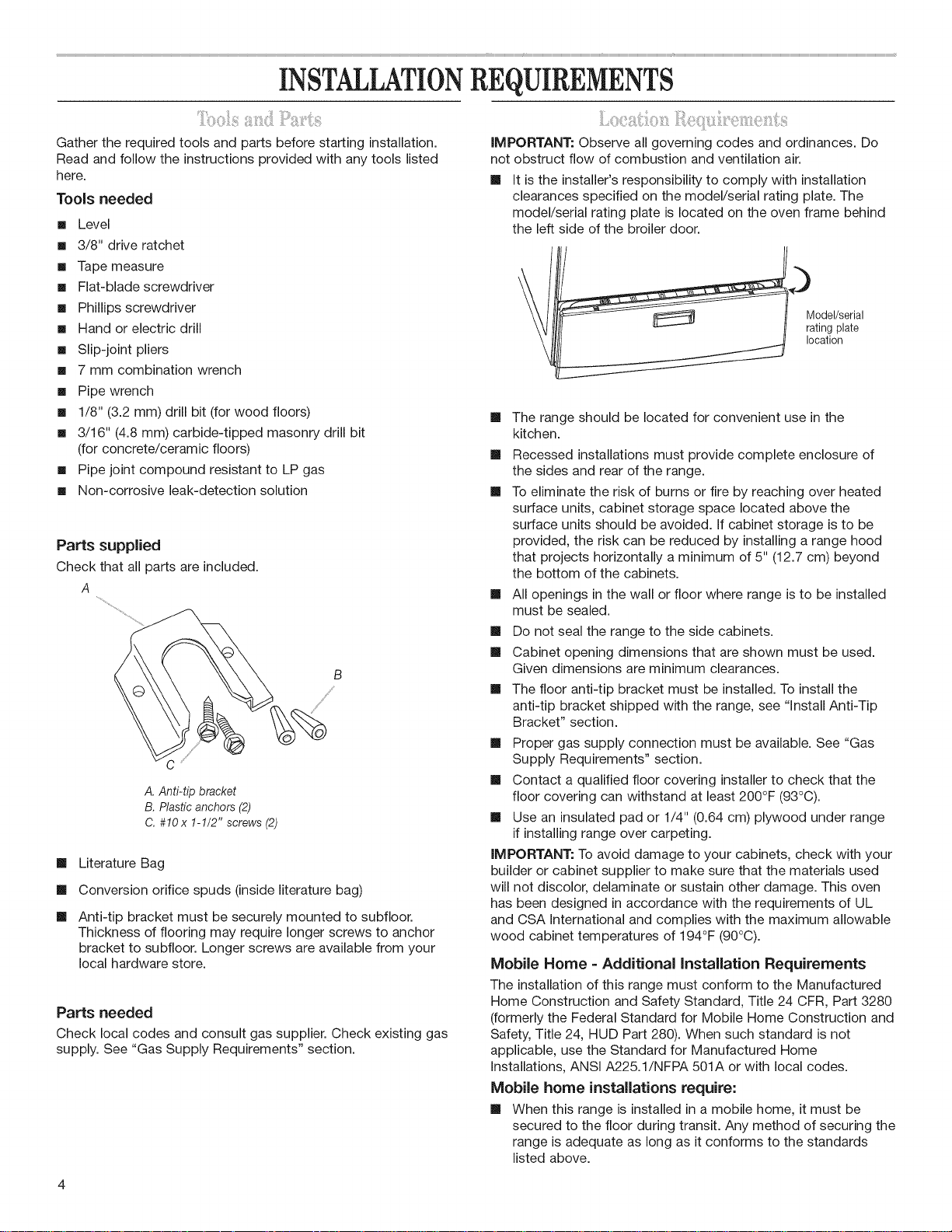

Parts supplied

Check that all parts are included.

A

A. Anti-tip bracket

B. Plastic anchors (2)

C. #10 x 1-1/2" screws (2)

[]

Literature Bag

[]

Conversion orifice spuds (inside literature bag)

[]

Anti-tip bracket must be securely mounted to subfloor.

Thickness of flooring may require longer screws to anchor

bracket to subfloor. Longer screws are available from your

local hardware store.

Parts needed

Check local codes and consult gas supplier. Check existing gas

supply. See "Gas Supply Requirements" section.

IMPORTANT: Observe all governing codes and ordinances. Do

not obstruct flow of combustion and ventilation air.

[] It is the installer's responsibility to comply with installation

clearances specified on the model/serial rating plate. The

model/serial rating plate is located on the oven frame behind

the left side of the broiler door.

[] The range should be located for convenient use in the

kitchen.

[] Recessed installations must provide complete enclosure of

the sides and rear of the range.

[] To eliminate the risk of burns or fire by reaching over heated

surface units, cabinet storage space located above the

surface units should be avoided, if cabinet storage is to be

provided, the risk can be reduced by installing a range hood

that projects horizontally a minimum of 5" (12.7 cm) beyond

the bottom of the cabinets.

[] All openings in the wall or floor where range is to be installed

must be sealed.

[] Do not seal the range to the side cabinets.

[] Cabinet opening dimensions that are shown must be used.

Given dimensions are minimum clearances.

[] The floor anti-tip bracket must be installed. To install the

anti-tip bracket shipped with the range, see "Install Anti-Tip

Bracket" section.

[] Proper gas supply connection must be available. See "Gas

Supply Requirements" section.

[] Contact a qualified floor covering installer to check that the

floor covering can withstand at least 200°F (93°C).

[] Use an insulated pad or 1/4" (0.64 cm) plywood under range

if installing range over carpeting.

IMPORTANT: To avoid damage to your cabinets, check with your

builder or cabinet supplier to make sure that the materials used

will not discolor, delaminate or sustain other damage. This oven

has been designed in accordance with the requirements of UL

and CSA International and complies with the maximum allowable

wood cabinet temperatures of 194°F (90°C).

Mobile Home - Additional Installation Requirements

The installation of this range must conform to the Manufactured

Home Construction and Safety Standard, Title 24 CFR, Part 3280

(formerly the Federal Standard for Mobile Home Construction and

Safety, Title 24, HUD Part 280). When such standard is not

applicable, use the Standard for Manufactured Home

Installations, ANSI A225.1/NFPA 501A or with local codes.

Mobile home installations require:

[] When this range is installed in a mobile home, it must be

secured to the floor during transit. Any method of securing the

range is adequate as long as it conforms to the standards

listed above.

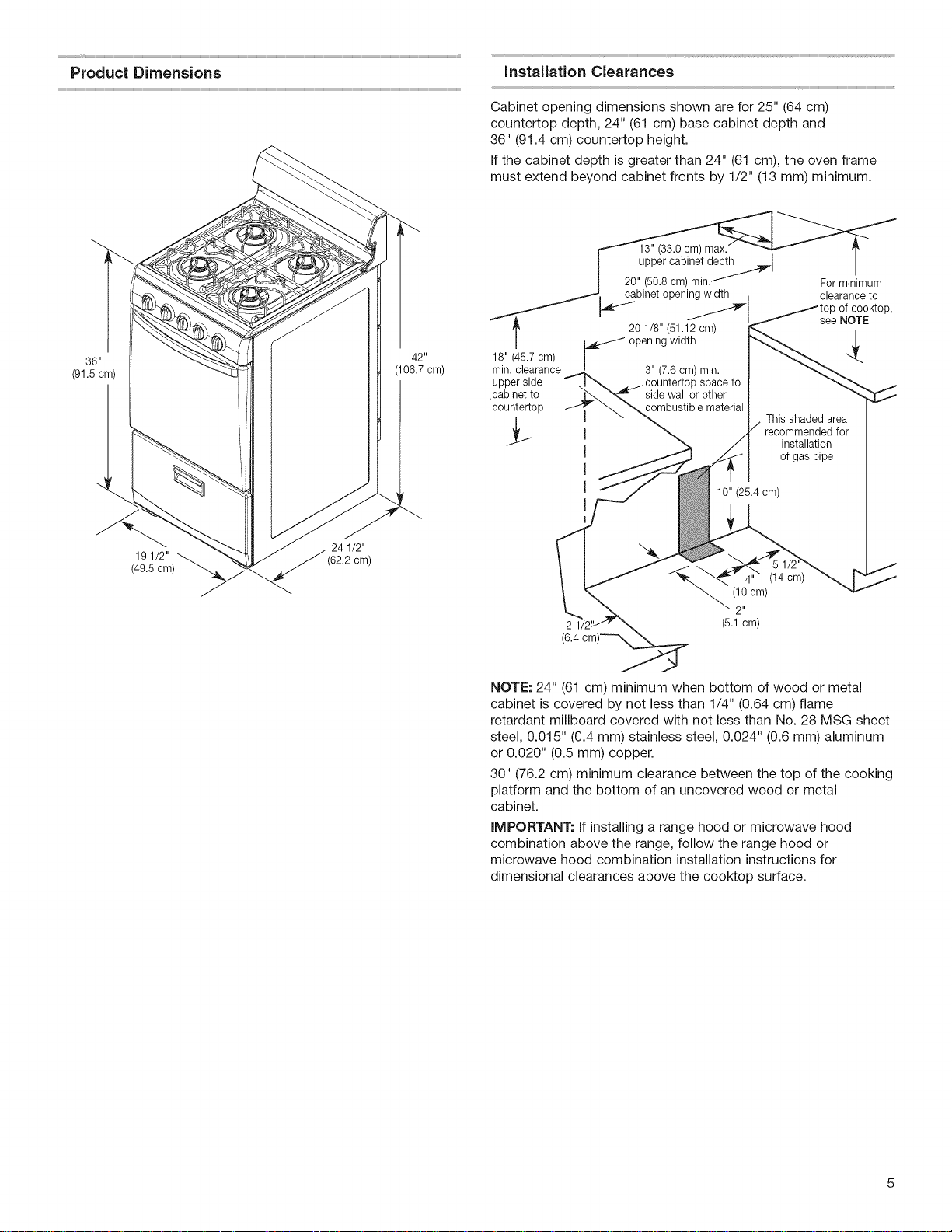

Product Dimensions

{nsta{{ationClearances

Cabinet opening dimensions shown are for 25" (64 cm)

countertop depth, 24" (61 cm) base cabinet depth and

36" (91.4 cm) countertop height.

If the cabinet depth is greater than 24" (61 cm), the oven frame

must extend beyond cabinet fronts by 1/2" (13 mm) minimum.

20 1/8" (51.12 cm)

36" 42"

(91.5 cm) (106.7 cm)

19 1/2"

(49.5 cm)

24 1/2"

18"(45.7cm)

min.clearance

upperside

.cabinet to

countertop

,,_" opening width ,_

{

{

3" (7.6 cm) min.

side wall or other

combustible material

space to

installation

of gas pipe

{

{

10" (25.4 cm)

{

{

(14 cm)

(10cm)

2"

(5.1cm}

(6.4 cm)'--__

NOTE: 24" (61 cm) minimum when bottom of wood or metal

cabinet is covered by not less than 1/4" (0.64 cm) flame

retardant millboard covered with not less than No. 28 MSG sheet

steel, 0.015" (0.4 mm) stainless steel, 0.024" (0.6 mm) aluminum

or 0.020" (0.5 mm) copper.

30" (76.2 cm) minimum clearance between the top of the cooking

platform and the bottom of an uncovered wood or metal

cabinet.

IMPORTANT: If installing a range hood or microwave hood

combination above the range, follow the range hood or

microwave hood combination installation instructions for

dimensional clearances above the cooktop surface.

J

J

J

Explosion Hazard

Use a new CSA International approved gas supply line.

install a shut-off valve.

Securely tighten all gas connections.

if connected to LP, have a qualified person make sure

gas pressure does not exceed 14" (36 cm) water

column.

Examples of a qualified person include:

licensed heating personnel,

authorized gas company personnel, and

authorized service personnel.

Failure to do so can result in death, explosion, or fire.

Observe all governing codes and ordinances.

iMPORTANT: This installation must conform with all local codes

and ordinances. In the absence of local codes, installation must

conform with American National Standard, National Fuel Gas

Code ANSI Z223.1 - latest edition.

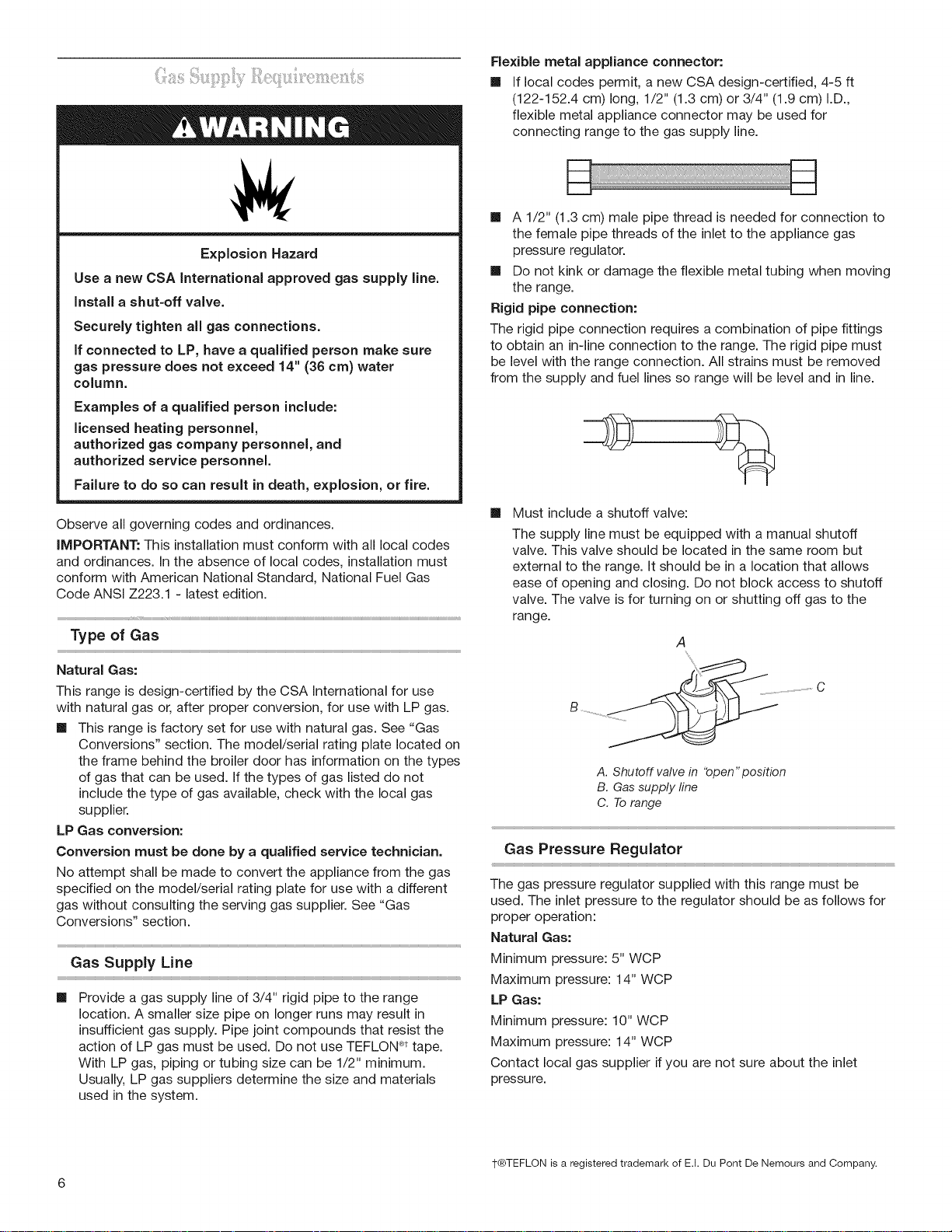

Type of Gas

Flexible metal appliance connector:

[] if local codes permit, a new CSA design-certified, 4-5 ft

(122-152.4 cm) long, 1/2" (1.3 cm) or 3/4" (1.9 cm)i.D.,

flexible metal appliance connector may be used for

connecting range to the gas supply line.

[] A 1/2" (1.3 cm) male pipe thread is needed for connection to

the female pipe threads of the inlet to the appliance gas

pressure regulator.

[] Do not kink or damage the flexible metal tubing when moving

the range.

Rigid pipe connection:

The rigid pipe connection requires a combination of pipe fittings

to obtain an in-line connection to the range. The rigid pipe must

be level with the range connection. All strains must be removed

from the supply and fuel lines so range will be level and in line.

[] Must include a shutoff valve:

The supply line must be equipped with a manual shutoff

valve. This valve should be located in the same room but

external to the range, it should be in a location that allows

ease of opening and closing. Do not block access to shutoff

valve. The valve is for turning on or shutting off gas to the

range.

A

Natural Gas:

This range is design-certified by the CSA International for use

with natural gas or, after proper conversion, for use with LP gas.

[] This range is factory set for use with natural gas. See "Gas

Conversions" section. The model/serial rating plate located on

the frame behind the broiler door has information on the types

of gas that can be used. If the types of gas listed do not

include the type of gas available, check with the local gas

supplier.

LP Gas conversion:

Conversion must be done by a qualified service technician.

No attempt shall be made to convert the appliance from the gas

specified on the model/serial rating plate for use with a different

gas without consulting the serving gas supplier. See "Gas

Conversions" section.

Gas Supply Line

[] Provide a gas supply line of 3/4" rigid pipe to the range

location. A smaller size pipe on longer runs may result in

insufficient gas supply. Pipe joint compounds that resist the

action of LP gas must be used. Do not use TEFLON ®¢tape.

With LP gas, piping or tubing size can be 1/2" minimum.

Usually, LP gas suppliers determine the size and materials

used in the system.

A. Shutoff valve in 'bpen" position

B. Gas supply line

C. To range

Gas Pressure Regulator

The gas pressure regulator supplied with this range must be

used. The inlet pressure to the regulator should be as follows for

proper operation:

Natural Gas:

Minimum pressure: 5" WCP

Maximum pressure: 14" WCP

LP Gas:

Minimum pressure: 10" WCP

Maximum pressure: 14" WCP

Contact local gas supplier if you are not sure about the inlet

pressure.

1-®TEFLON is a registered trademark of E.I. Du Pont De Nemours and Company,

Burner input Requirements

Gas Supply Pressure Testing

input ratings shown on the model/serial rating plate are for

elevations up to 2,000 ft (609.6 m).

For elevations above 2,000 ft (609.6 m), ratings are reduced at a

rate of 4% for each 1,000 ft (304.8 m) above sea level.

INSTALLATIONINSTRUCTIONS

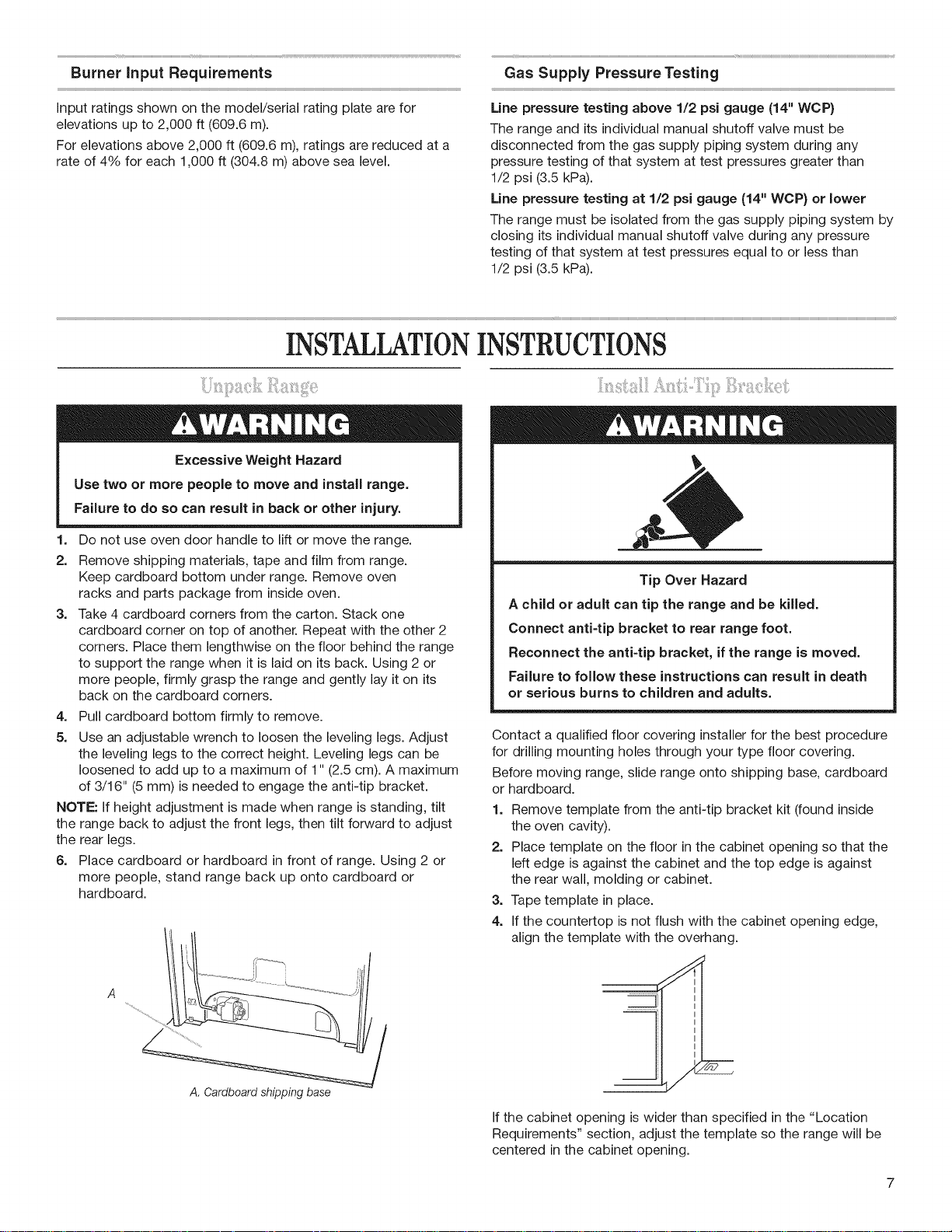

Excessive Weight Hazard

Use two or more people to move and install range.

Failure to do so can result in back or other injury.

1. Do not use oven door handle to lift or move the range.

2. Remove shipping materials, tape and film from range.

Keep cardboard bottom under range. Remove oven

racks and parts package from inside oven.

3. Take 4 cardboard corners from the carton. Stack one

cardboard corner on top of another. Repeat with the other 2

corners. Place them lengthwise on the floor behind the range

to support the range when it is laid on its back. Using 2 or

more people, firmly grasp the range and gently lay it on its

back on the cardboard corners.

4. Pull cardboard bottom firmly to remove.

5. Use an adjustable wrench to loosen the leveling legs. Adjust

the leveling legs to the correct height. Leveling legs can be

loosened to add up to a maximum of 1" (2.5 cm). A maximum

of 3/16" (5 mm) is needed to engage the anti-tip bracket.

NOTE: If height adjustment is made when range is standing, tilt

the range back to adjust the front legs, then tilt forward to adjust

the rear legs.

6. Place cardboard or hardboard in front of range. Using 2 or

more people, stand range back up onto cardboard or

hardboard.

Line pressure testing above 1/2 psi gauge (14" WCP)

The range and its individual manual shutoff valve must be

disconnected from the gas supply piping system during any

pressure testing of that system at test pressures greater than

1/2 psi (3.5 kPa).

Line pressure testing at 1/2 psi gauge (14" WCP} or lower

The range must be isolated from the gas supply piping system by

closing its individual manual shutoff valve during any pressure

testing of that system at test pressures equal to or less than

1/2 psi (3.5 kPa).

Tip Over Hazard

A child or adult can tip the range and be killed.

Connect anti-tip bracket to rear range foot.

Reconnect the anti=tip bracket, if the range is moved.

Failure to follow these instructions can result in death

or serious burns to children and adults.

Contact a qualified floor covering installer for the best procedure

for drilling mounting holes through your type floor covering.

Before moving range, slide range onto shipping base, cardboard

or hardboard.

1. Remove template from the anti-tip bracket kit (found inside

the oven cavity).

2. Place template on the floor in the cabinet opening so that the

left edge is against the cabinet and the top edge is against

the rear wall, molding or cabinet.

3. Tape template in place.

4. If the countertop is not flush with the cabinet opening edge,

align the template with the overhang.

A. Cardboard shipping base

If the cabinet opening is wider than specified in the "Location

Requirements" section, adjust the template so the range will be

centered inthe cabinet opening.

5. Tomounttheanti-tipbrackettoawoodfloor,drilltwo1/8"

(3.2mm)holesatthepositionsmarkedonthebracket

template.Removethetemplatefromthefloor.

/

To mount the anti-tip bracket to a concrete or ceramic floor, use

a 3/16" (4.8 mm) masonry drill bit to drill 2 holes at the positions

marked on the bracket template. Remove the template from the

floor.

6. Tap plastic anchors into holes with a hammer.

7. Align the anti-tip bracket holes with the holes in the floor.

Fasten the anti-tip bracket with the screws provided.

Depending on the thickness of your flooring, longer screws may

be necessary to anchor the bracket to the subfloor. Longer

screws are available from your local hardware store.

8. Move the range close to the opening. Remove the shipping

base, cardboard or hardboard from under the range.

9. Open the broiler door. Use a 3/8" drive ratchet to lower the

rear leveling legs one-half turn. Use slip-joint pliers to lower

the front leveling legs one-half turn.

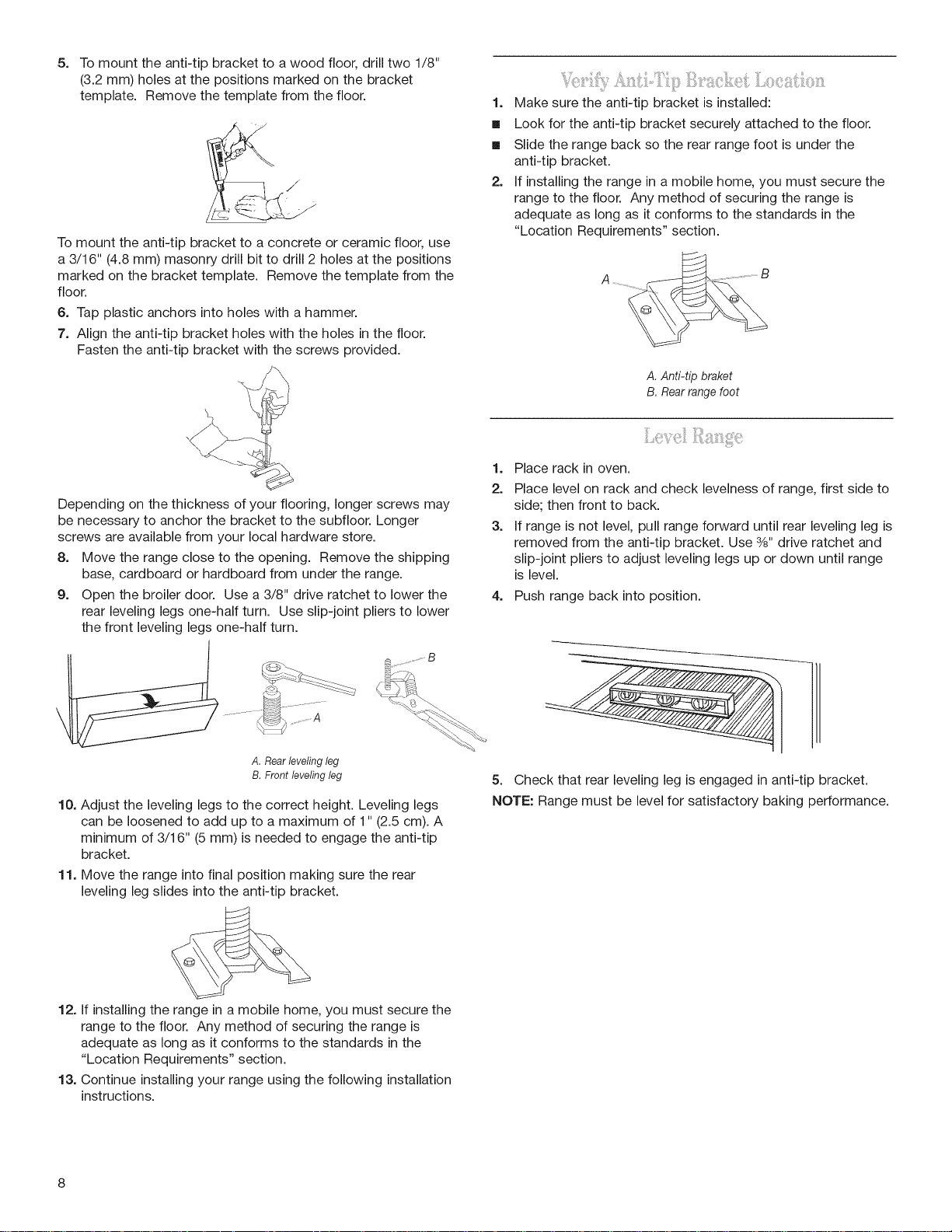

1. Make sure the anti-tip bracket is installed:

[] Look for the anti-tip bracket securely attached to the floor.

[] Slide the range back so the rear range foot is under the

anti-tip bracket.

2. If installing the range in a mobile home, you must secure the

range to the floor. Any method of securing the range is

adequate as long as it conforms to the standards in the

"Location Requirements" section.

A. Anti-tip braket

B. Rear range foot

1. Place rack in oven.

2. Place level on rack and check levelness of range, first side to

side; then front to back.

3. If range is not level, pull range forward until rear leveling leg is

removed from the anti-tip bracket. Use 3A" drive ratchet and

slip-joint pliers to adjust leveling legs up or down until range

is level.

4. Push range back into position.

A. Rear leveling leg

B. Front leveling leg

10. Adjust the leveling legs to the correct height. Leveling legs

can be loosened to add up to a maximum of 1" (2.5 cm). A

minimum of 3/16" (5 mm) is needed to engage the anti-tip

bracket.

11. Move the range into final position making sure the rear

leveling leg slides into the anti-tip bracket.

12. If installing the range in a mobile home, you must secure the

range to the floor. Any method of securing the range is

adequate as long as it conforms to the standards in the

"Location Requirements" section.

13. Continue installing your range using the following installation

instructions.

1

5. Check that rear leveling leg is engaged in anti-tip bracket.

NOTE: Range must be level for satisfactory baking performance.

¸ ii!i i (ii ¸ Co J:ii !io J:ii

Explosion Hazard

Use a new CSA international approved gas supply line.

Instal a shut-off vane.

Securely tighten all gas connections.

if connected to LP, have a qualified person make sure

gas pressure does not exceed 14" (36 cm) water

column.

Examples of a qualified person include:

licensed heating personnel,

authorized gas company personnel, and

authorized service personnel.

Failure to do so can result in death, explosion, or fire.

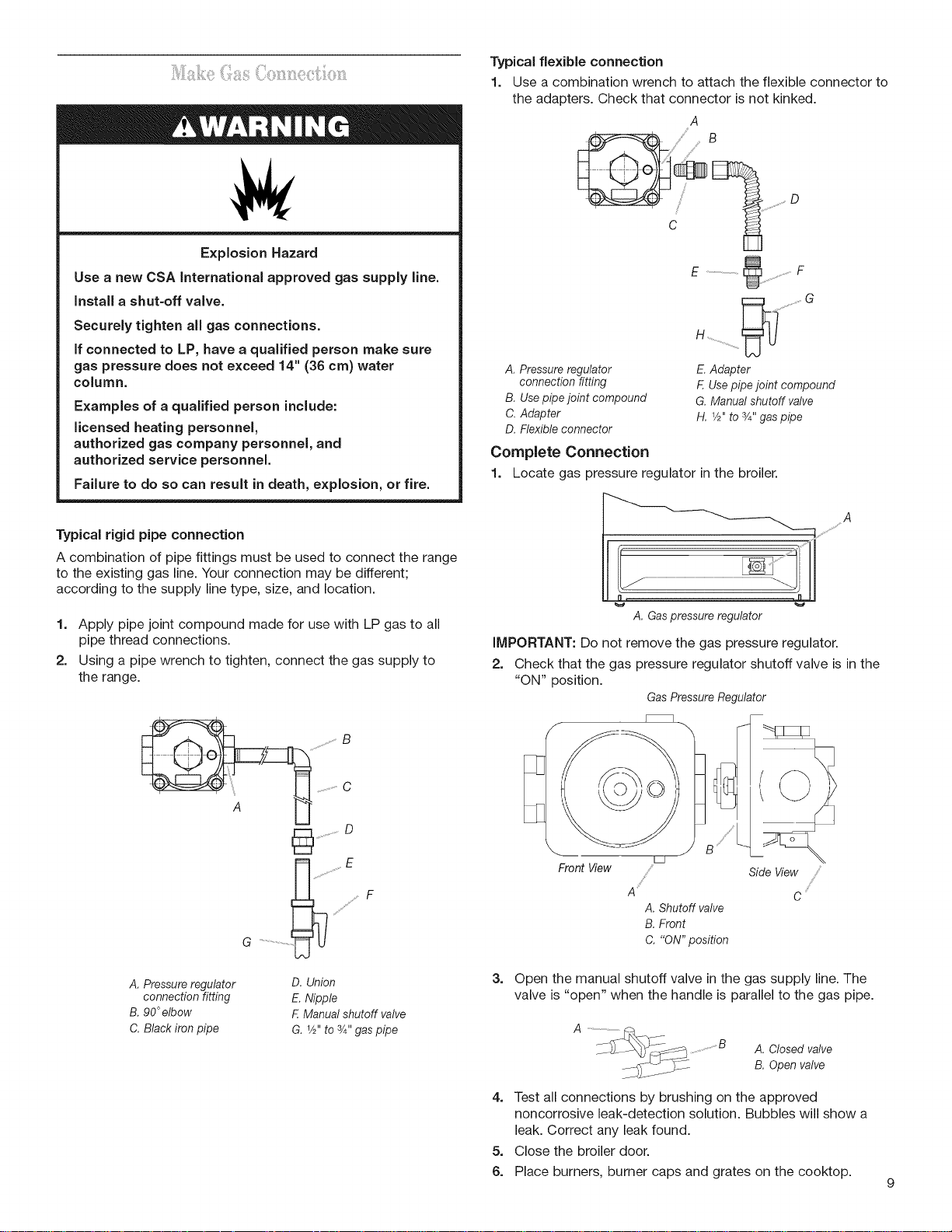

Typical flexible connection

1. Use a combination wrench to attach the flexible connector to

the adapters. Check that connector is not kinked.

A

B

A. Pressure regulator

connection fitting

B. Usepipe joint compound

C. Adapter

D. Flexible connector

Complete Connection

1.

Locate gas pressure regulator in the broiler.

Typical rigid pipe connection

A combination of pipe fittings must be used to connect the range

to the existing gas line. Your connection may be different;

according to the supply line type, size, and location.

1. Apply pipe joint compound made for use with LP gas to all

pipe thread connections.

2. Using a pipe wrench to tighten, connect the gas supply to

the range.

C

B

.......................D

G ..........................................

A. Pressure regulator D. Union

connection fitting E. Nipple

B. 90°elbow F.Manual shutoff valve

C. Black iron pipe G. 1/2"to 3/4"gas pipe

A. Gaspressure regulator

IMPORTANT: Do not remove the gas pressure regulator.

2. Check that the gas pressure regulator shutoff valve is in the

"ON" position.

GasPressureRegulator

l

Front View

3=

Open the manual shutoff valve in the gas supply line. The

valve is "open" when the handle is parallel to the gas pipe.

/

/

A.Shutoffvalve

B.Front

C. "ON" position

SideView

A. Closed valve

B. Open valve

/

c

4. Test all connections by brushing on the approved

noncorrosive leak-detection solution. Bubbles will show a

leak. Correct any leak found.

5. Close the broiler door.

6. Place burners, burner caps and grates on the cooktop.

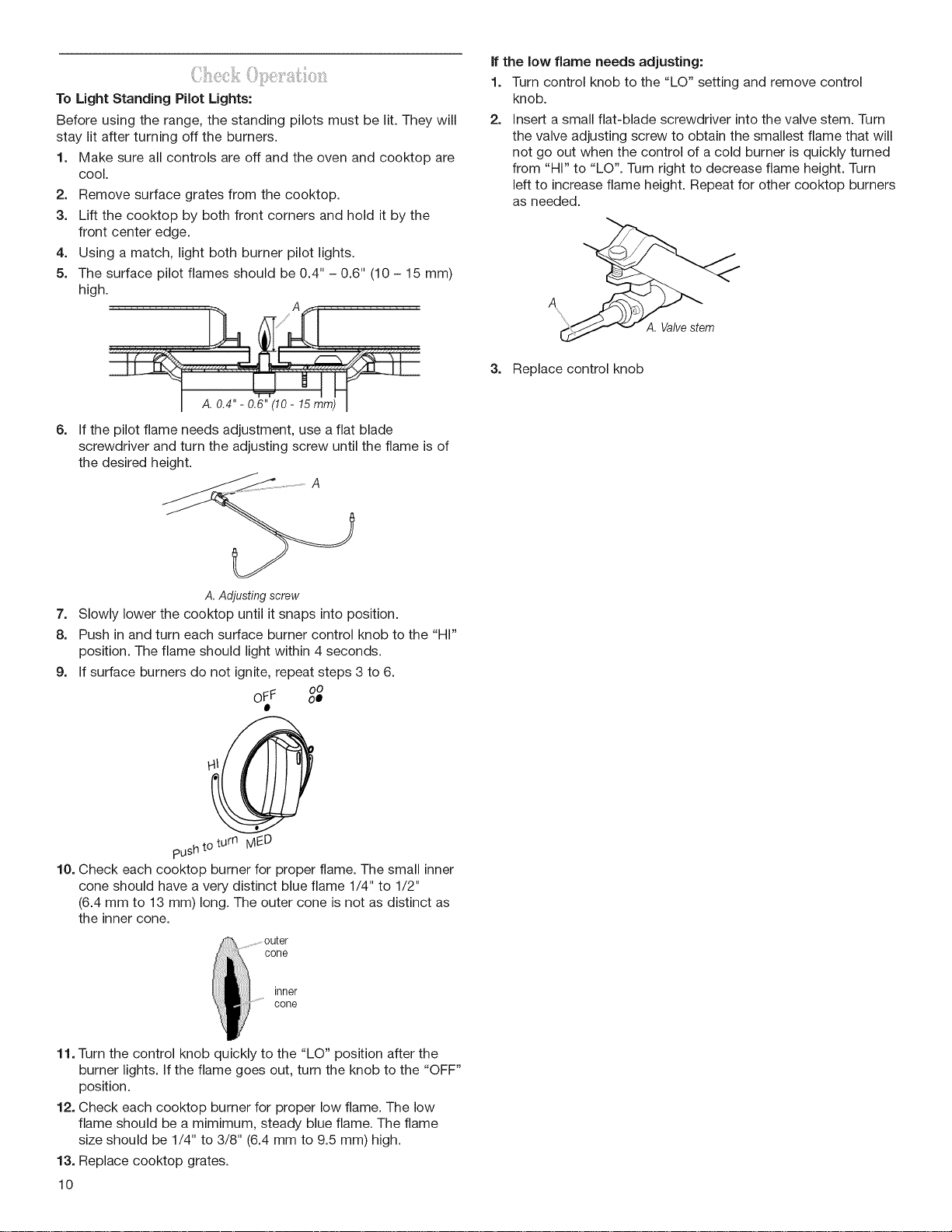

ToLight Standing Pilot Lights:

Before using the range, the standing pilots must be lit. They will

stay lit after turning off the burners.

1. Make sure all controls are off and the oven and cooktop are

cool.

2. Remove surface grates from the cooktop.

3. Lift the cooktop by both front corners and hold it by the

front center edge.

4. Using a match, light both burner pilot lights.

5. The surface pilot flames should be 0.4" - 0.6" (10 - 15 mm)

high.

6.

If the pilot flame needs adjustment, use a flat blade

screwdriver and turn the adjusting screw until the flame is of

the desired height.

If the low flame needs adjusting:

1. Turn control knob to the "LO" setting and remove control

knob.

2. Insert a small flat-blade screwdriver into the valve stem. Turn

the valve adjusting screw to obtain the smallest flame that will

not go out when the control of a cold burner is quickly turned

from "HI" to "LO". Turn right to decrease flame height. Turn

left to increase flame height. Repeat for other cooktop burners

as needed.

A

A, Valvestem

3. Replace control knob

A.Adjustingscrew

7. Slowly lower the cooktop until it snaps into position.

8. Push in and turn each surface burner control knob to the "HF

position. The flame should light within 4 seconds.

9. If surface burners do not ignite, repeat steps 3 to 6.

OFF oo

04t

pushto turn MI_D

10. Check each cooktop burner for proper flame. The small inner

cone should have a very distinct blue flame 1/4" to 1/2"

(6.4 mm to 13 mm) long. The outer cone is not as distinct as

the inner cone.

cone

inner

cone

11. Turn the control knob quickly to the "LO" position after the

burner lights. If the flame goes out, turn the knob to the "OFF"

position.

12. Check each cooktop burner for proper low flame. The low

flame should be a mimimum, steady blue flame. The flame

size should be 1/4" to 3/8" (6.4 mm to 9.5 mm) high.

13. Replace cooktop grates.

10

Loading...

Loading...