Estate E-SC 1600 User Manual

Instruction Manual for the

E-SC 1602 Series

Carriage Door Instructions

Manufactured by

CE DECLARATION OF CONFORMITY OF MACHINES

(Directive 89/392/EEC, Annex II, Part B)

Manufacturer: FAAC S.p.A.

Address: Via Benini, 1 – 40069 Zola Predosa Bologna – Italy

Declares that: Eurotrigon 0224 - Trigon K 24 A.K.A. Estate Swing (USA) mod operator

• Is built to be integrated into a machine or to be assembled with other machinery to create a machine under the provisions

of Directive 89/392/EEC, and subsequent amendments 91/368/EEC, 93/44/EEC.

• Conforms to the essential safety requirements of the following EEC directives:

Bologna, January 1, 2002

Managing Director

A. Bassi

o 73/23/EEC and subsequent amendment 93/68/EEC, 89/336/EEC and subsequent amendment 92/31/EEC and

93/68/EEC.

o And also declares the it is prohibited to put into service the machinery until the machine in which it will be

integrated or of which it will become a component has been identified and declared as conforming to the

conditions of Directive 89/392/EEC and subsequent amendments assimilated under national laws under DPR

#459 of July 24, 1996.

A

bassi

Warnings for the installer

General safety obligations

1. Attention! To ensure the safety of people, it is important that you read all the following instructions. Incorrect installation or incorrect

use of the product could cause serious harm to people.

2. Carefully read the instructions before beginning to install the product.

3. Store these instructions for future reference.

4. This product was designed and built strictly for the use indicated in the documentation. Any other use, not expressly indicated here,

could compromise the good condition/operation of the product and/or be a source of danger.

5. FAAC declines all liability caused by improper use or use other than that for which automated system was intended.

6. Do not install the equipment in an explosive atmosphere; the presence of inflammable gas or fumes is a serious danger to safety.

7. The mechanical parts must conform to the provisions of Standards EN 12604 and EN 12605.

For non-EU countries, to obtain an adequate level of safety, the standards mentioned above must be observed, in addition to national

legal regulations.

8. FAAC is not responsible for failure to observe Good Technique in the construction of the closing elements to be motorized, of for any

deformation that may occur during use.

9. The installation must conform to Standards EN 12453 and EN 12445.

The safety level of the automated system must be C+D.

10. Before attempting any job on the system, cut out electrical power and disconnect the batteries.

11. The main power supply of the automated system must be fitted with an all-pole switch with contact opening distance of 3 mm or

greater. Use of a 6A thermal breaker will all-pole circuit break is recommended.

12. Make sure that a differential switch with threshold of 0.03 A is fitted upstream of the system.

13. Make sure that the earthing system is perfectly constructed, and connect metal parts of the means of the closure to it.

14. The automated system is supplied with an intrinsic anti-crushing safety device consisting of a torque control. Nevertheless, its tripping

threshold must be checked as specified in the Standards indicated at point 10.

15. The safety devices (EN 12978 standard) protect any danger areas against mechanical movement risks, such as crushing, dragging, and

shearing.

16. Use of at least one indicator-light (e.g. FAACLIGHT 12VDC) is recommended for every system, as well as a warning sign adequately

secured to the frame structure, in addition to the devices mentioned at point “15”.

17. FAAC declines all liability as concerns safety and efficient operation of the automated system, is system components not produced by

FAAC are used.

18. For maintenance, strictly use original parts by FAAC.

19. Do not in any way modify the components of the automated system.

20. The installer shall supply all information concerning manual operation of the system in case of an emergency, and shall hand over to

the user the warnings handbook supplied with the product.

21. Do not allow children or adults to stay near the product while it is operating.

22. Keep remote controls or other pulse generators away from children, to prevent the automated system from being activated involuntarily.

23. Transit through the leaves is allowed only when the door is fully open.

24. The user must not attempt any kind of repair or direct action whatever and contact qualified personnel only.

25. Do not short-circuit the poles of the batteries and do not try to recharge the batteries with power supply units other than Master or Slave

cards.

26. Do not throw exhausted batteries into containers for other waste but dispose them in the appropriate containers to enable them to be

recycled.

27. Anything not expressly specified in these instructions is not permitted.

Estate Swing Summery of Functions

The Estate Swing is only to be used for vehicular swing doors in a Class I

setting.

Class I: A vehicular door opener (or system) intended for use in a home of

one-to-four single family dwelling, or a garage or parking area associated

therewith.

The FAAC Estate Swing automated system was designed and built for controlling

vehicle access. Do not use for any other purpose.

The external automation with articulated arms automates residential swing-leaf

doors with leaves of up to 16’ in length, and is ideal for applications on large pilasters without the need to provide niches (sometimes required to observe the installation dimensions of piston driven devices). It consists of an irreversible electromechanical operator with guard and an articulated-arm activation system to be fitted to the door with the appropriate accessories. The irreversible system ensures

the door is mechanical locked when the motor is not operating. A lock still needs

be installed if security of high winds are a concern. A manual release makes it possible to move the door in the event of a power-cut or fault.

Keep this manual safely stored after

installation.

Serial Number__________________________

Date of Purchase_______________________

Place of Purchase______________________

Have this information on hand while handling all

service and warranty issues.

This manual and its contents are produced by Web Direct Brands, Inc. and is based on the instructions

written by FAAC,

The table of contents are listed to assist you locating a desired section. We do however strongly suggest studying every page of the instruction manual before attempting installation.

SECTION:

• Review of specifications, warnings, and tools 1

Table of Contents

⇒Specifications of the Estate Swing and Components 1.1

⇒System Overview & Preliminary Checks 1.2

⇒Tools Needed for Installation 1.3

• Operator Basics 2

⇒Manual Operation, Restoring Automation 2.1

• Installation 3

⇒IMPORTANT: Determining Setback—Pull to Open 3.1

⇒Installation of operator 3.2-.3

• Pre-Programming 4

⇒Mounting the Control Board and Box 4.1

⇒Removing Terminal Strips for Wiring 4.2

⇒Installation of Limit Switches and Positive Stops 4.3-.4

⇒Temporary Safety Jumpers 4.5

⇒Wiring the Operator Arm(s) 4.6

⇒Installing and Setting Transmitters and Receivers 4.7

⇒Power 4.8

• Programming the Operator 5

⇒Programming Operating Parameters 5.1

⇒Operating Parameters Chart 5.2-.3

⇒Programming Door Movements 5.4-.5

The table of contents are listed to assist you locating a desired section. We do however strongly suggest studying every page of the instruction manual before attempting installation.

SECTION:

• Diagnostics and Troubleshooting 6

Table of Contents

• Accessories 7

⇒LED Lights and Operational Displays 6.1

⇒Troubleshooting 6.2-.3

⇒Control Board Overview 7.1-.2

⇒Photocell and Safety Device Guide 7.3

⇒Accessories 7.4

Marks pages with opener or usage warnings. Although we have marked these as very

important warnings, please read the entire manual. Every step is important to the

correct installation of your door opener.

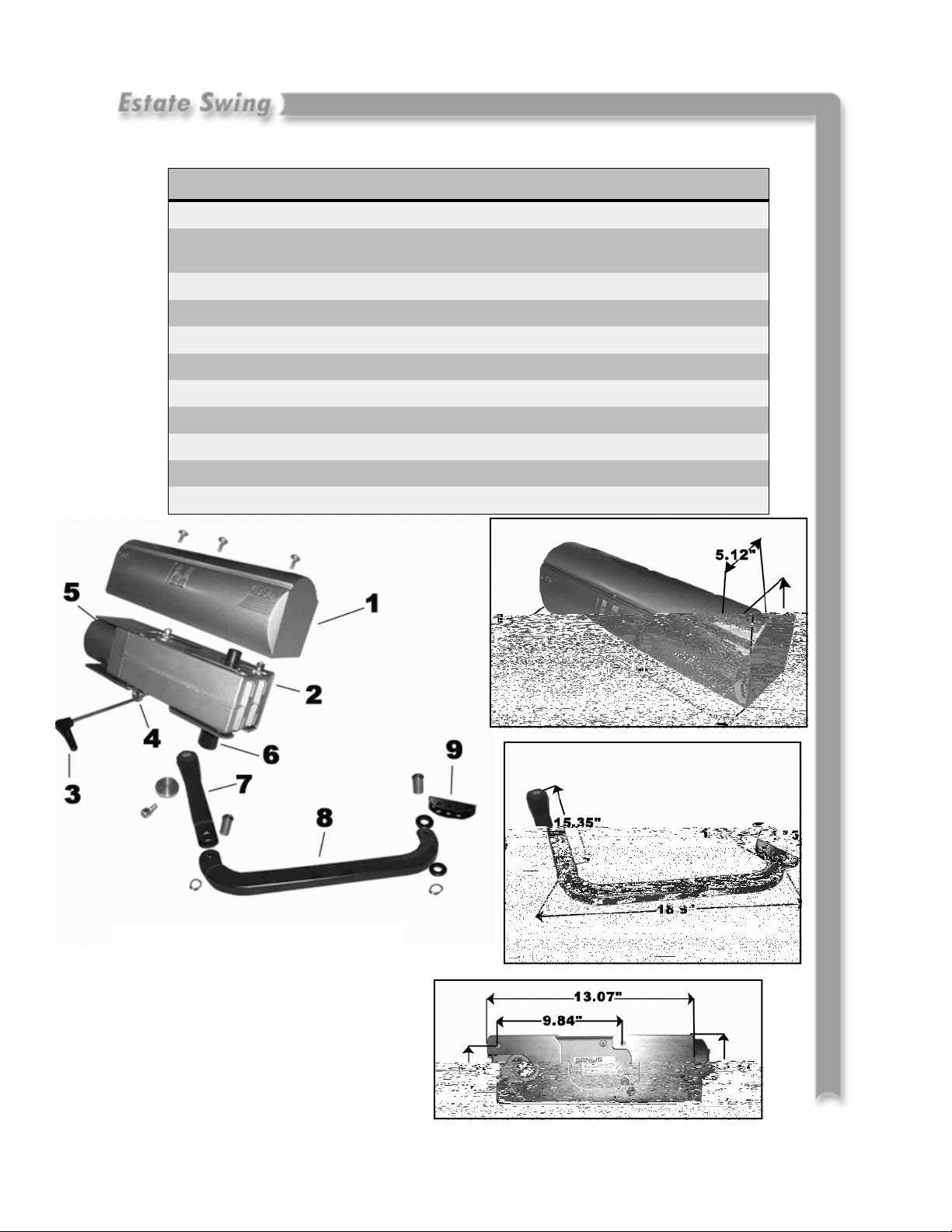

MODEL Estate Swing E-SC 1600

Power Supply

Specifications

Rated Absorbed Power (Amperage pull on

a 120V AC outlet)

Max Torque (Nm)

Use frequency (cycles/hour)

Operating ambient temperature

Gearmotor weight (lbs)

Protection class

Door leaf max length (ft.)

Door leaf max weight (lbs.)

Operator overall dimensions LxHxD(in.)

Angular velocity

115V AC/ 24V AC

3 Amp/single

5 Amp/dual

200

> 100

-4 to 131 Deg F

25

IP44

Up to 8

Up to 800

See below

8 Degrees / Second

1) Guard

2) Operator securing base-plate

3) Release wrench

4) Release

5) Gearmotor

6) Transmission shaft

7) Straight lever of articulating arm

8) Curved lever of articulating arm

9) Front coupling

1.1

Estate Swing Part s List

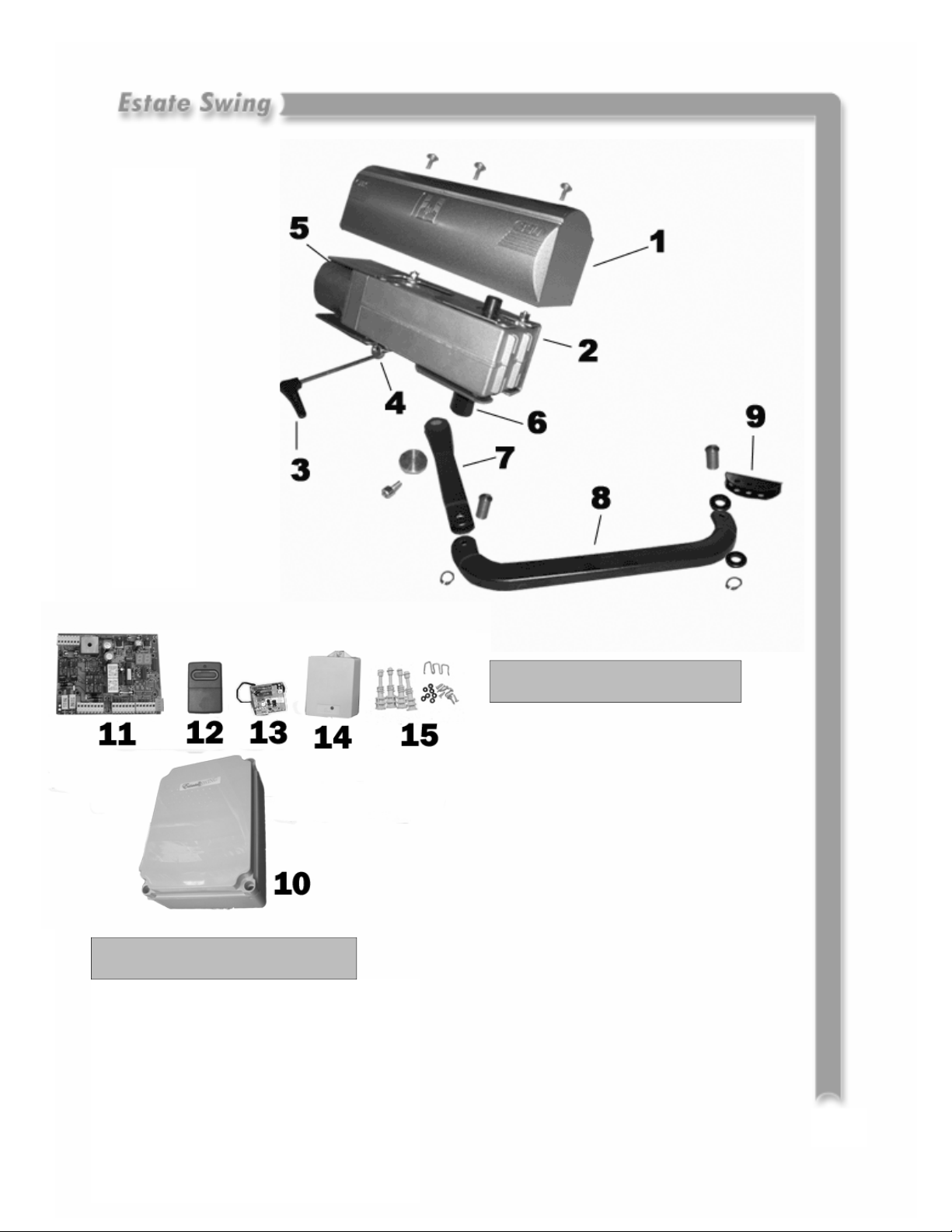

Slave Operator (If Applicable)

1. Housing Cover

2. Wall Mounting Plate

3. Manual Release Key

4. Manual Release

5. 24VDC Motor

6. Transmission Shaft

7. Straight lever of articulating arm

8. Curved lever of articulating arm

9. Door Mounting Bracket

Master or Single Operator

1. Housing Cover

2. Wall Mounting Plate

3. Manual Release Key

4. Manual Release

5. 24VDC Motor

6. Transmission Shaft

7. Straight lever of articulating arm

8. Curved lever of articulating arm

9. Door Mounting Bracket

10. Control Box

11. Control Board

12. Transmitter

13. Receiver

14. Transformer

15. Control Box Screws, Control Board

Screws and Washers, Jumper Wire

1.2

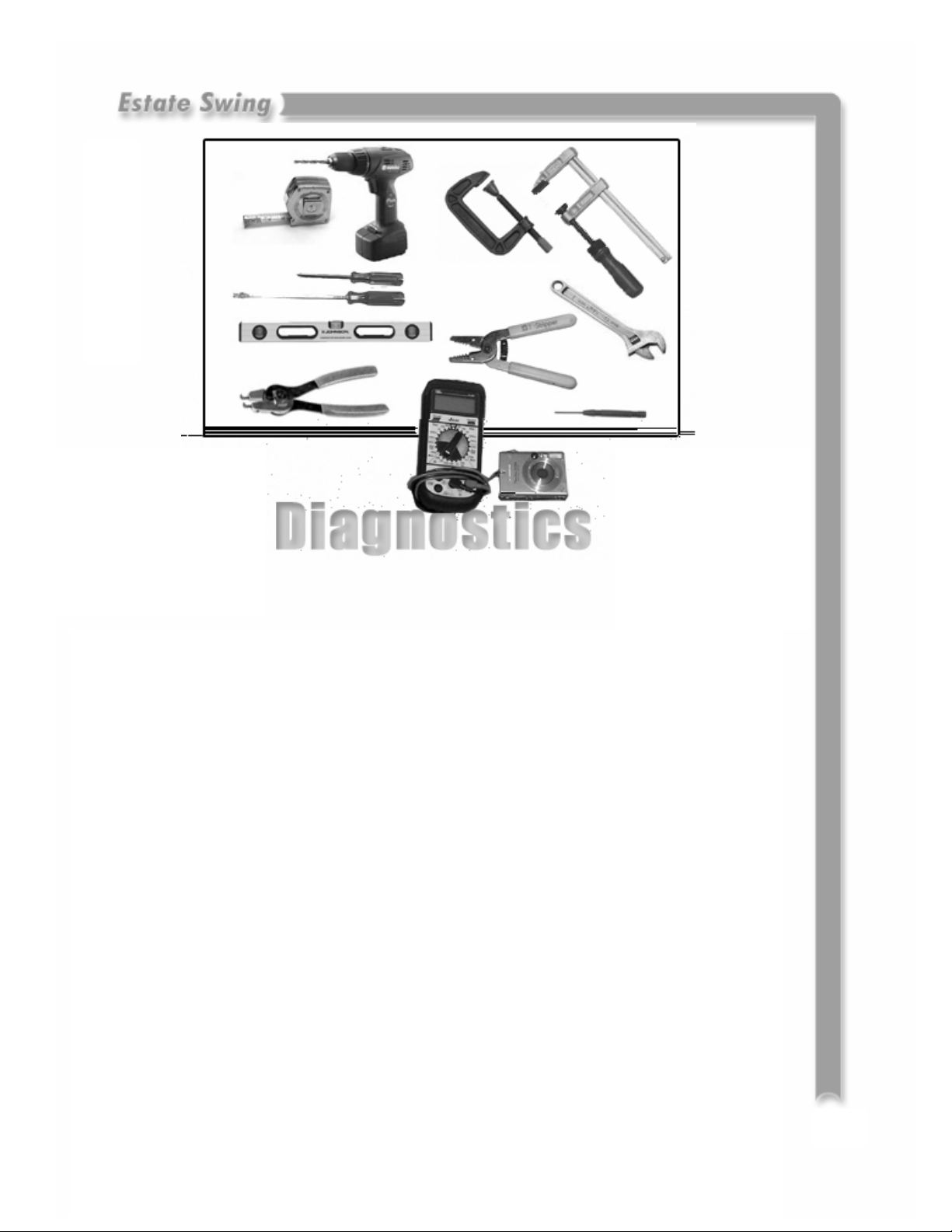

Tools Needed

• Power Drill and appro-

priately sized bits.

• Crescent Wrench

• Flat Head Screwdriver

• Nuts, Bolts, Anchors

and Washers (see below)

• C-Ring Pliers

• Phillips Head Screw-

driver

• Tape Measure

• Level

• Wire Strippers

• C-clamps

• Carpenters Clamps

Other items that may be needed prior to commencing installation.

• Start and stop post, bracket or door stop. Although the Estate Swing E-SC 1602 features

soft start/stop and can be used with limit switches (not included), it is possible to use the

E-SC 1602 without limit switches, relying on the positive stops to determine end positions.

• 16, 14 or 12 gauge, 2 conductor stranded direct burial low voltage wire will be re-

quired to run power to your operator. Length is determined by distance between transformer power supply and the control box.

• A voltage meter and digital camera may be necessary to run diagnostic checks.

• 4 - 3/8” Red Heads, Lag Screws and Shields, or another brand wall mounting 3/8”

bolt and anchor will be needed to connect the Base Plate to the wall.

• 2 - 5/16” Hex Bolts will be needed to connect the Door Mounting Bracket to the door.

Length will be determined by what is needed for a secure anchor.

• If your transformer is going to be plugged into an outdoor outlet you will need to weather-

proof that outlet and transformer. Electrical boxes or plug covers can be obtained from a

local hardware store to accommodate both the plug and transformer.

• Hardware to attach the control box to a wall.

• Watertight connectors for running wires into the control box.

1.4

Manual Operation Mode

Manual operation mode will be necessary to learn from installation and programming. It is also

useful for emergency situations where as using the motor is not an option from operation the

doors.

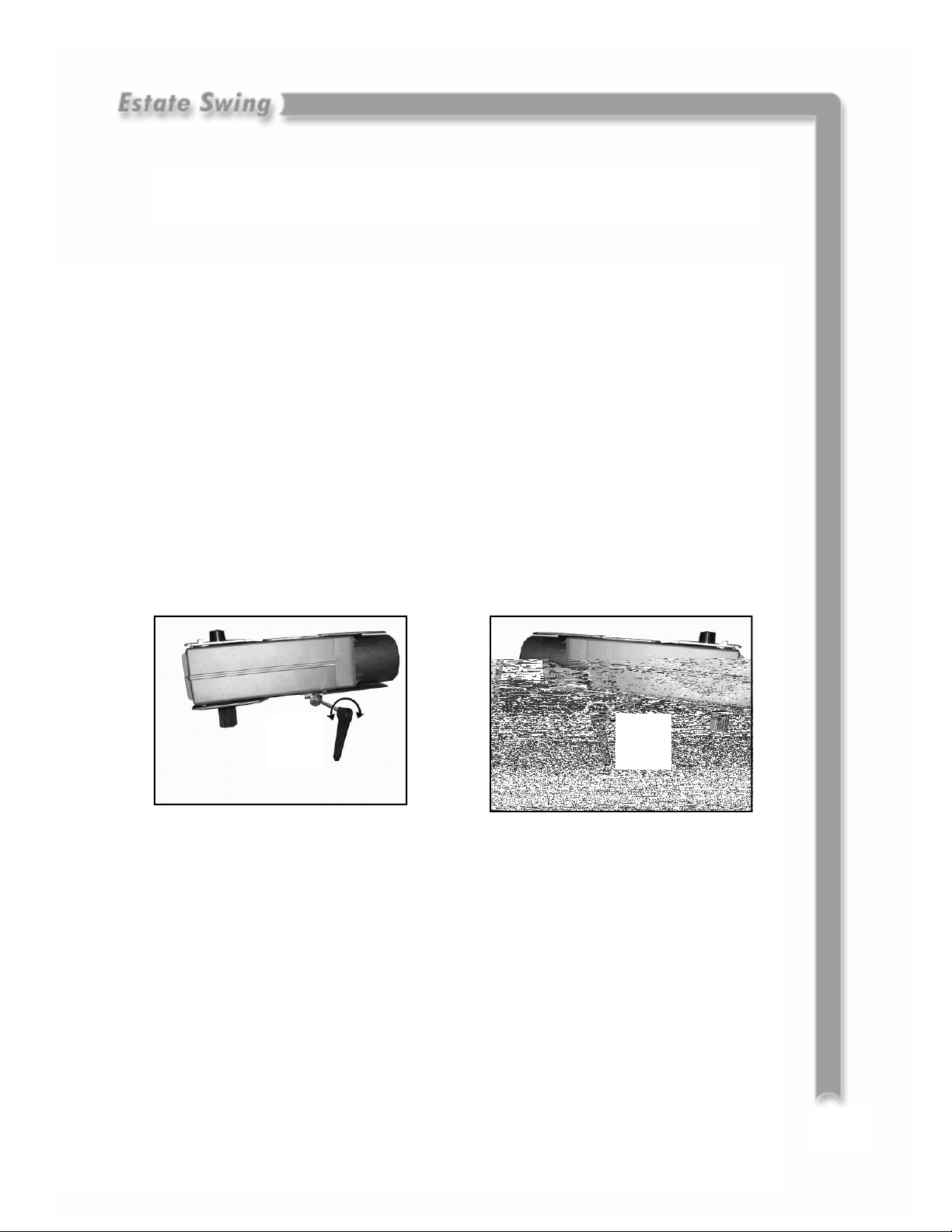

Fit the supplied Allen wrench and turn it by approximately a half a turn until it stops. Turn it in

the direction that is dictated below.

For left-hand side:

Turn counterclockwise to lock, clockwise to unlock.

For right-hand side:

Turn counterclockwise to unlock, clockwise to lock.

To avoid an involuntary pulse activating the doors during the maneuver, before relocking the operator, switch off all power.

Fit the supplied Allen wrench and turn it by approximately a half a turn until it stops. Turn it in

the direction that is dictated above.

LLLL RRRR

Restoring Standard Operation

2.1

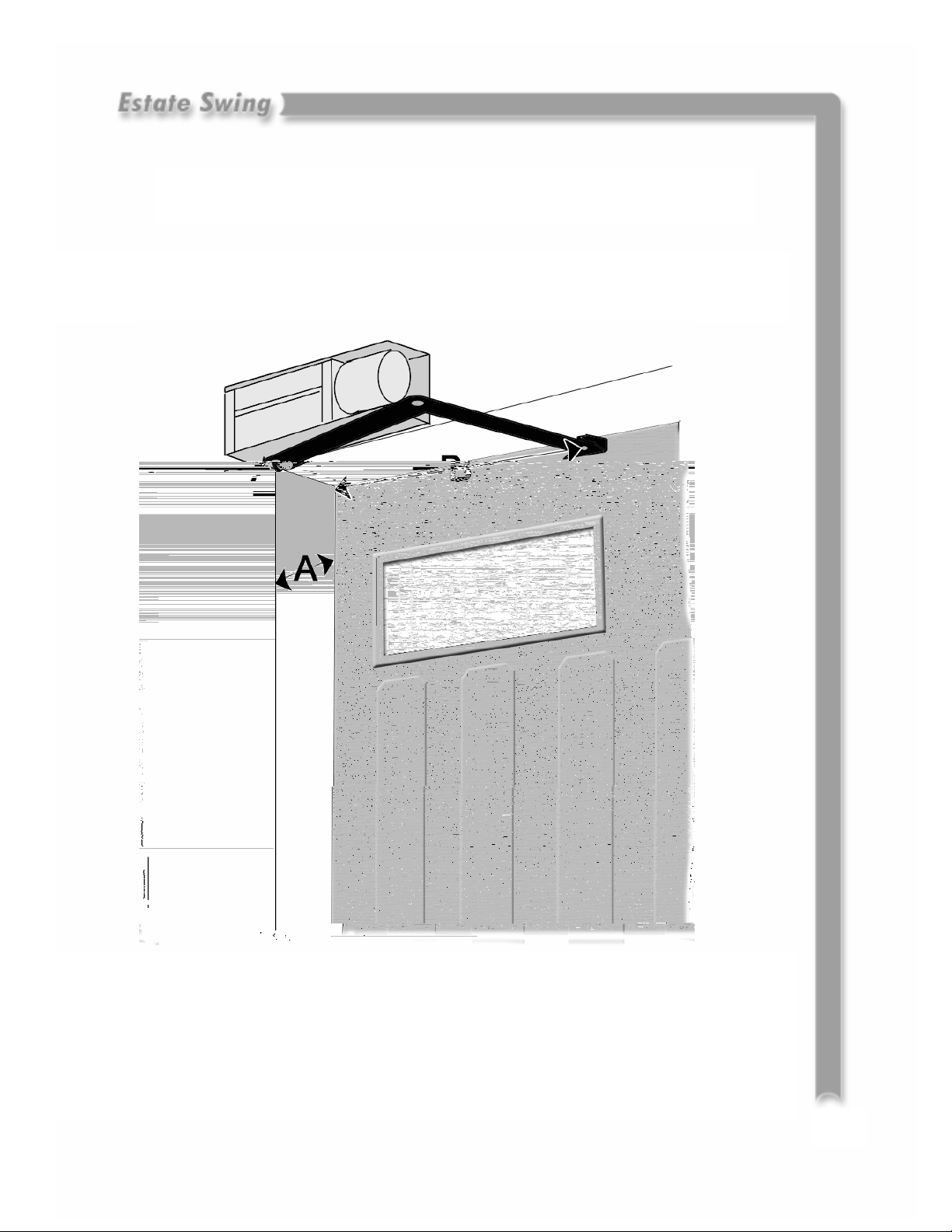

IMPORTANT: Determining Correct Position

This operator is intended to be on the inside of the garage and push

the carriage doors out towards the driveway.

Position the mounting plate above the door frame with the inside end in line with the edge of the

door frame. The drive shaft (piece that comes down from the motor that makes the arm pivot)

should be positioned on the side of the bracket closest to the door frame.

A = No minimum, but do not exceed 12”

B = 29” - A from hinges of door. Example: if A is 8” then B (29-8) is 21”

3.1

Loading...

Loading...