Estate YAED4370TQ0, AED4370TQ0, AED4470TQ0, AED4475TQ0, EED4300TQ0 Installation Guide

...

29" (73.7 CM) ELECTRICDRYER

INSTALLATIONINSTRUCTIONS

INSTRUCCIONES DE INSTALACION PAPA LA

SECADORA ELIT:CTRICADE 29" (73,7 CM)

INSTRUCTIONS POUR L'INSTALLATIONDE LA SECHEUSE

IT:LECTRIQUEDE 29" (73,7 CM)

Table of Contents / [ndice / Table des mati@res

DRYER SAFETY ............................................... 1

INSTALLATION INSTRUCTIONS ................... 2

Tools and Parts ............................................. 2

Location Requirements ................................ 2

Electrical Requirements - U.S.A ................... 3

Electrical Requirements - Canada ................ 4

Electrical Connection - U.S.A. Only .............. 5

Venting Requirements ................................. 10

Plan Vent System ........................................ 11

Install Vent System ...................................... 12

Install Leveling Legs .................................... 12

Level Dryer .................................................. 12

Connect Vent .............................................. 12

Reverse Door Swing (Optional) ................... 12

Complete Installation .................................. 13

SEGURIDAD DE LA SECADORA ................. 14

INSTRUCCIONES DE INSTALACION .......... 14

Herramientas y piezas ................................. 14

Requisitos de Iocalizacion ......................... 14

Requisitos el_ctricos - U.S.A...................... 15

Conexi6n el_ctrica - U.S.A. Only ................ 17

Requisitos de ventilaci6n ............................ 22

Planificaci6n del sistema de ventilaci6n ..... 23

Instalacion del sistema de ventilacion ........ 24

Instalacion de las patas niveladoras ........... 24

Nivelaci6n de la secadora ........................... 24

Conexi6n del ducto de escape ................... 25

Como invertir el cierre de la puerta

(opcional) ..................................................... 25

Complete la instalaci6n ............................... 26

SECURITE DE LA SECHEUSE ..................... 27

INSTRUCTIONS D'INSTALLATION .............. 28

Outillage et pi_ces ....................................... 28

Exigences d'emplacement ......................... 28

Specifications _lectriques - Canada ........... 30

Exigences concernant 1'6vacuation ............ 30

Planification du systeme d'_vacuation ....... 32

Installation du systeme d'_vacuation ......... 33

Installation des pieds de nivellement .......... 33

Mise & niveau de la s_cheuse ..................... 33

Raccordement du conduit d'6vacuation .... 34

Inversion de I'ouverture de la porte

(facultatif) ..................................................... 34

Achever I'installation ................................... 35

DRYERSAFETY

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual and on your appliance. Always read and obey all safety

messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word "DANGER" or "WARNING."

These words mean:

You can be killed or seriously injured if you don't immediately

follow instructions.

You can be killed or seriously injured if you don't follow

instructions.

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury, and tell you what can

happen if the instructions are not followed.

W10088970

INSTALLATIONINSTRUCTIONS

Gather the required tools and parts before starting installation.

Read and follow the instructions provided with any tools listed

here.

Flat-blade screwdriver

#2 Phillips screwdriver

Adjustable wrench that

opens to 1" (2.54 cm) or

hex-head socket wrench

(for adjusting dryer feet)

Wire stripper (for U.S.

only, direct wire

installations)

Parts supplied:

Remove parts package from dryer drum. Check that all parts were

included.

• Tin snips(new vent

installations)

• Level

• Vent clamps

• Caulking gun and

compound (for installing

new exhaust vent)

• Tape measure

• If you are using a power supply cord, a grounded electrical

outlet located within 2ft (61 cm) of either side of the dryer. See

"Electrical Requirements."

• A sturdy floor to support the total weight (dryer and load) of

200 Ibs (90.7 kg). The combined weight of a companion

appliance should also be considered.

• A level floor with a maximum slope of 1" (2.5 cm) under entire

dryer. (If slope is greater than 1" [2.5 cm], install Extended

Dryer Feet Kit, Part Number 279810.) Clothes may not tumble

properly and models with automatic sensor cycles may not

operate correctly if dryer is not level.

Do not operate your dryer at temperatures below 45°F (7°C). At

lower temperatures, the dryer might not shut off at the end of an

automatic cycle. Drying times can be extended.

The dryer must not be installed or stored in an area where it will be

exposed to water and/or weather.

Check code requirements. Some codes limit, or do not permit,

installation of the dryer in garages, closets, mobile homes or

sleeping quarters. Contact your local building inspector.

Installation Clearances

The location must be large enough to allow the dryer door to open

fully.

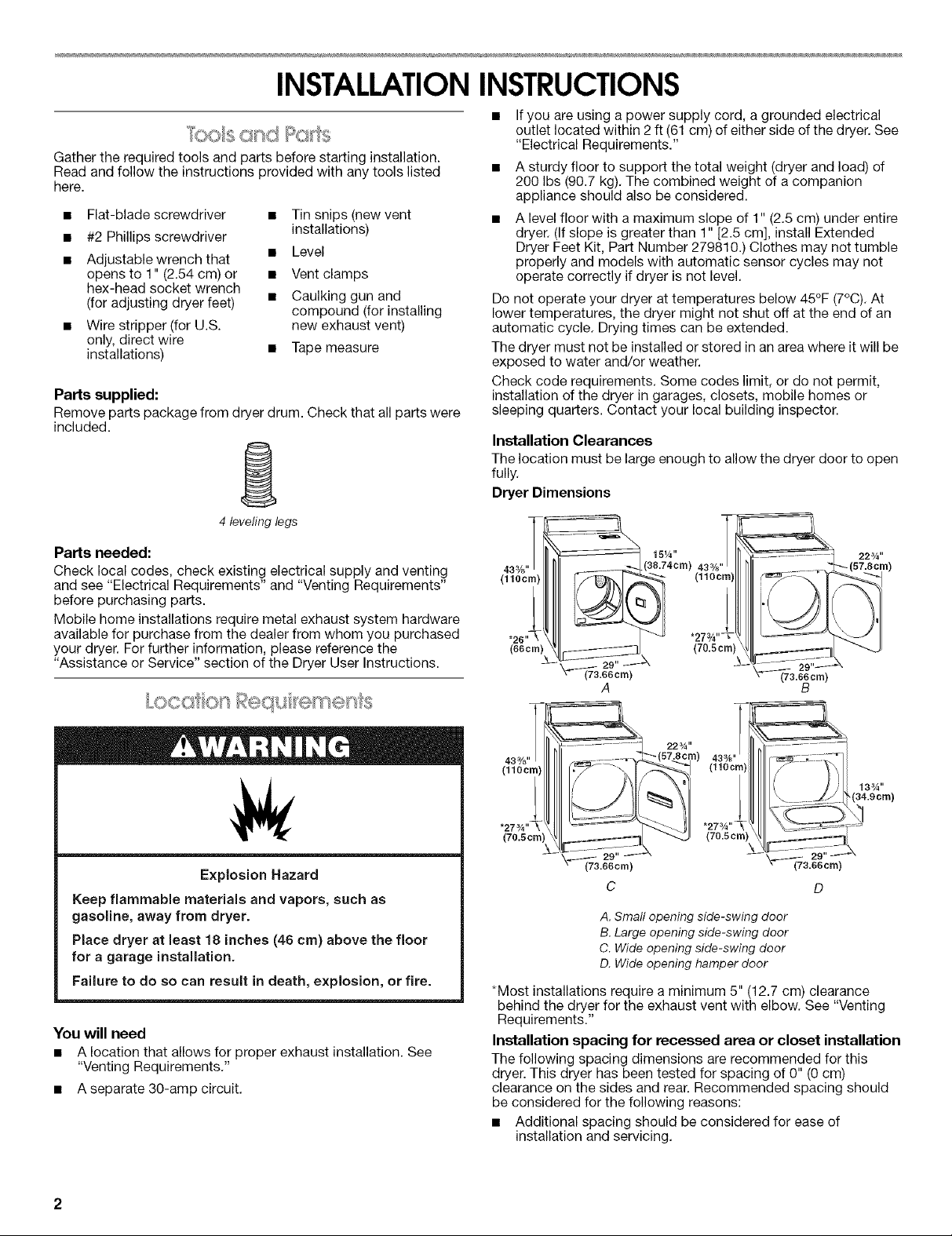

Dryer Dimensions

4 levelinglegs

Parts needed:

Check local codes, check existing electrical supply and venting

and see "Electrical Requirements" and "Venting Requirements"

before purchasing parts.

Mobile home installations require metal exhaust system hardware

available for purchase from the dealer from whom you purchased

your dryer. For further information, please reference the

"Assistance or Service" section of the Dryer User Instructions.

Explosion Hazard

Keep flammable materials and vapors, such as

gasoline, away from dryer.

Place dryer at least 18 inches (46 era) above the floor

for a garage installation.

Failure to do so can result in death, explosion, or fire.

You will need

• A location that allows for proper exhaust installation. See

"Venting Requirements."

• Aseparate 30-amp circuit.

...... _ L

43% _.(38.74cm) 43s/8 _ .'_(57.8cm)

(73.66cm) _ (73.66crn)

A

15_/4'' h.................... 223/4"

B

c D

A. Small opening side-swing door

B. Large opening side-swing door

C. Wide opening side-swing door

D. Wide opening hamper door

*Most installations require a minimum 5" (12.7 cm) clearance

behind the dryer for the exhaust vent with elbow. See "Venting

Requirements."

Installation spacing for recessed area or closet installation

The following spacing dimensions are recommended for this

dryer. This dryer has been tested for spacing of 0" (0 cm)

clearance on the sides and rear. Recommended spacing should

be considered for the following reasons:

• Additional spacing should be considered for ease of

installation and servicing.

• Additionalclearancesmightberequiredforwall,doorand

floormoldings.

• Additionalspacingshouldbeconsideredonallsidesofthe

dryertoreducenoisetransfer.

• Forclosetinstallation,withadoor,minimumventilation

openingsinthetopandbottomofthedoorarerequired.

Louvereddoorswithequivalentventilationopeningsare

acceptable.

• Companionappliancespacingshouldalsobeconsidered.

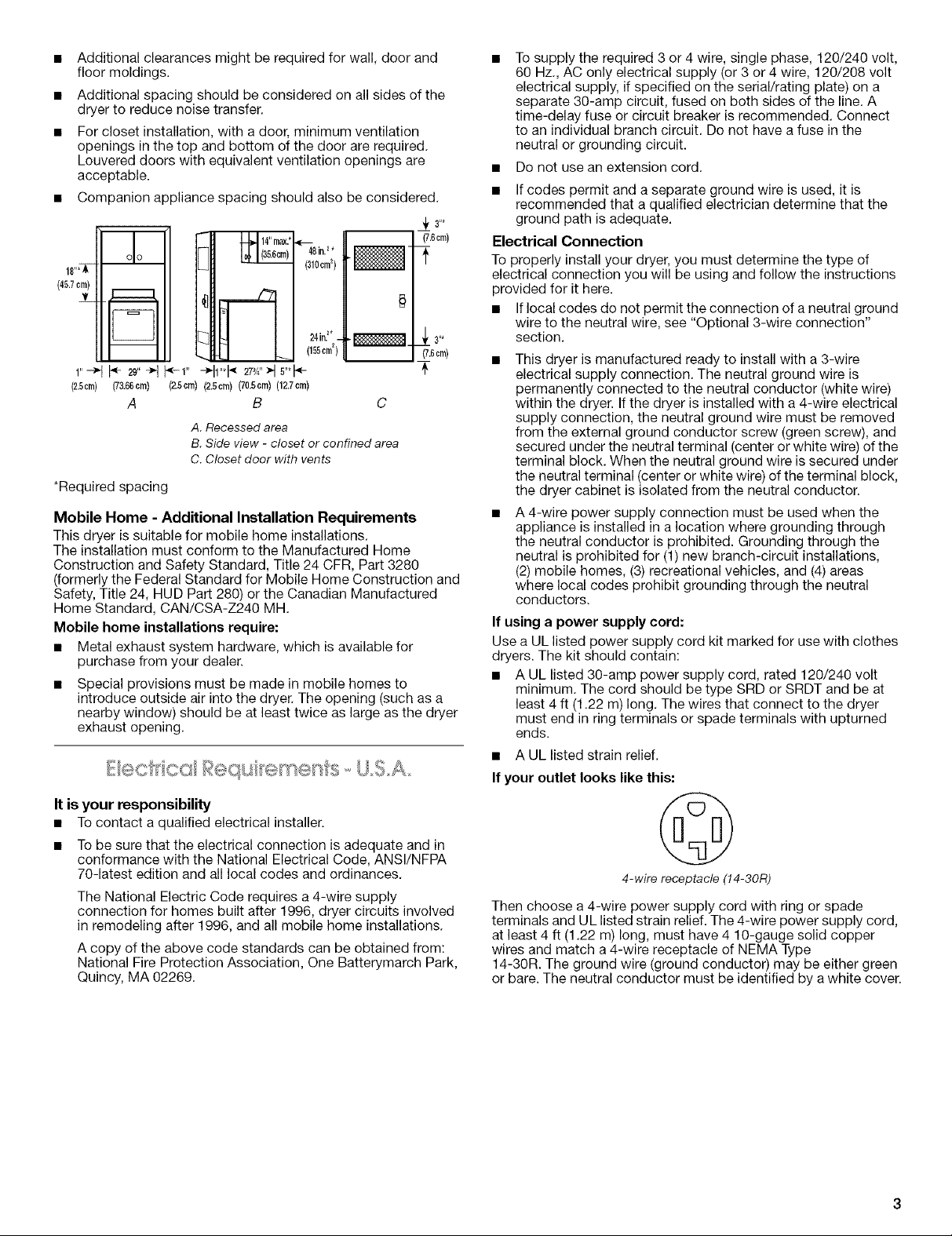

__ 3"*

(7.6cm)

I I_, I (3b.t_cm)

(4_.87''

-- __ ._ (155cm2',

1"-_ _ 2e"_ _1" ÷b"*_ 2#/,"_15"*F-

(2.5cm) (73.66cm) (2.5cm)(2.5cm) (70.5cm)(12.7crn)

A B

A. Recessed area

B. Side view - closet or confined area

C. Closet door with vents

*Required spacing

Mobile Home - Additional Installation Requirements

This dryer is suitable for mobile home installations.

The installation must conform to the Manufactured Home

Construction and Safety Standard, Title 24 CFR, Part 3280

(formerly the Federal Standard for Mobile Home Construction and

Safety, Title 24, HUD Part 280) or the Canadian Manufactured

Home Standard, CAN/CSA-Z240 MH.

Mobile home installations require:

• Metal exhaust system hardware, which is available for

purchase from your dealer.

• Special provisions must be made in mobile homes to

introduce outside air into the dryer. The opening (such as a

nearby window) should be at least twice as large as the dryer

exhaust opening.

E®CI CO I{;®q ®m®n's-. ,c

It is your responsibility

• To contact a qualified electrical installer.

• To be sure that the electrical connection is adequate and in

conformance with the National Electrical Code, ANSI/NFPA

70-latest edition and all local codes and ordinances.

The National Electric Code requires a 4-wire supply

connection for homes built after 1996, dryer circuits involved

in remodeling after 1996, and all mobile home installations.

A copy of the above code standards can be obtained from:

National Fire Protection Association, One Batterymarch Park,

Quincy, MA 02269.

(310cm2)

24in.2.

3,J*

(7.6 cm)

To supply the required 3 or 4 wire, single phase, 120/240 volt,

60 Hz., AC only electrical supply (or 3 or 4 wire, 120/208 volt

electrical supply, if specified on the serial/rating plate) on a

separate 30-amp circuit, fused on both sides of the line. A

time-delay fuse or circuit breaker is recommended. Connect

to an individual branch circuit. Do not have a fuse in the

neutral or grounding circuit.

Do not use an extension cord.

If codes permit and a separate ground wire is used, it is

recommended that a qualified electrician determine that the

ground path is adequate.

Electrical Connection

To properly install your dryer, you must determine the type of

electrical connection you will be using and follow the instructions

provided for it here.

• If local codes do not permit the connection of a neutral ground

wire to the neutral wire, see "Optional 3-wire connection"

section.

• This dryer is manufactured ready to install with a 3-wire

electrical supply connection. The neutral ground wire is

permanently connected to the neutral conductor (white wire)

within the dryer. If the dryer is installed with a 4-wire electrical

supply connection, the neutral ground wire must be removed

from the external ground conductor screw (green screw), and

secured under the neutral terminal (center or white wire) of the

terminal block. When the neutral ground wire is secured under

the neutral terminal (center or white wire) of the terminal block,

the dryer cabinet is isolated from the neutral conductor.

• A 4-wire power supply connection must be used when the

appliance is installed in a location where grounding through

the neutral conductor is prohibited. Grounding through the

neutral is prohibited for (1) new branch-circuit installations,

(2) mobile homes, (3) recreational vehicles, and (4) areas

where local codes prohibit grounding through the neutral

conductors.

If using a power supply cord:

Use a UL listed power supply cord kit marked for use with clothes

dryers. The kit should contain:

• A UL listed 30-amp power supply cord, rated 120/240 volt

minimum. The cord should be type SRD or SRDT and be at

least 4 ft (1.22 m) long. The wires that connect to the dryer

must end in ring terminals or spade terminals with upturned

ends.

• A UL listed strain relief.

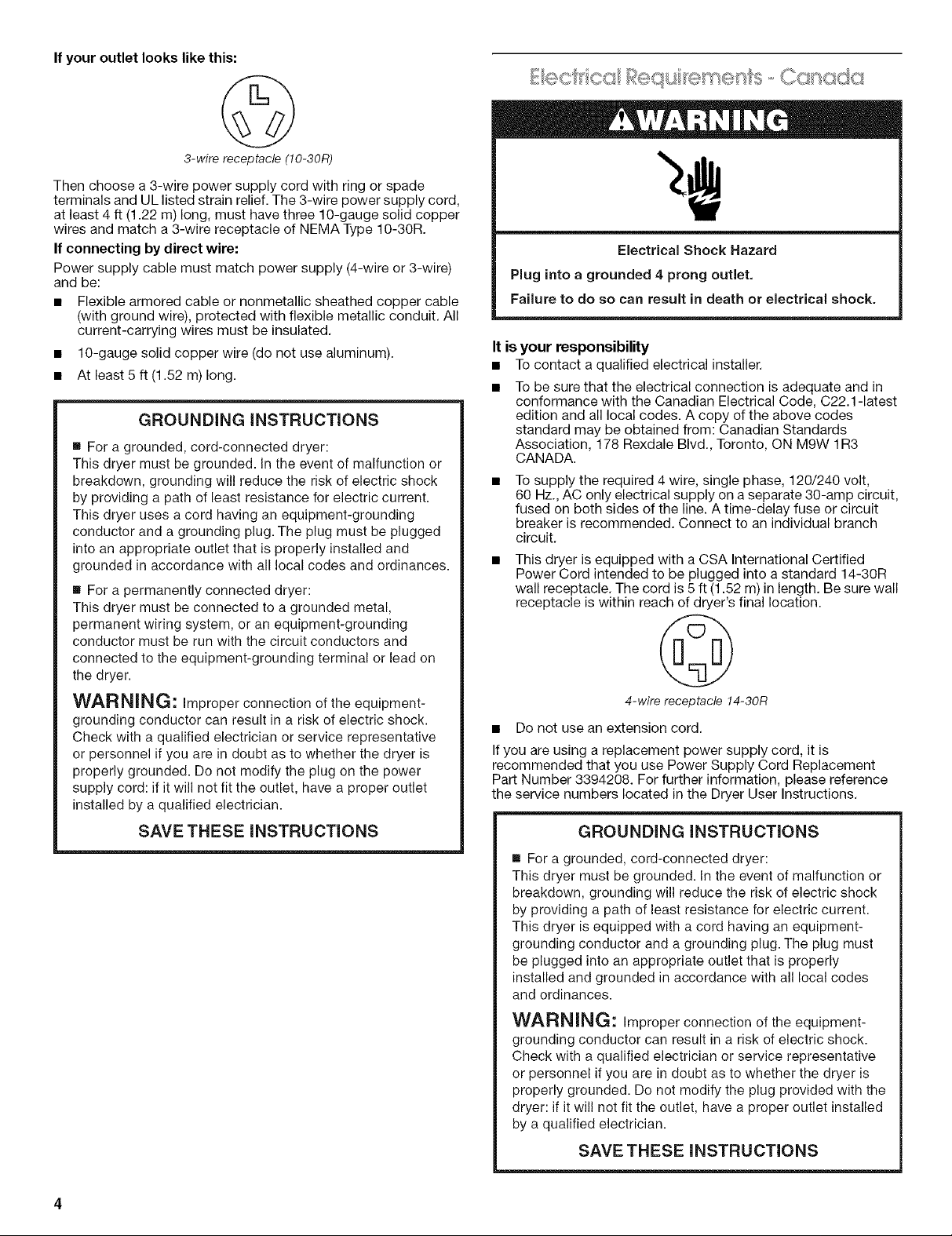

If your outlet looks like this:

4-wire receptacle (!4-30R)

Then choose a 4-wire power supply cord with ring or spade

terminals and UL listed strain relief. The 4-wire power supply cord,

at least 4 ft (1.22 m) long, must have 4 10-gauge solid copper

wires and match a 4-wire receptacle of NEMA Type

14-30R. The ground wire (ground conductor) may be either green

or bare. The neutral conductor must be identified by a white cover.

If your outlet looks like this:

3-wire receptacle (10-30R)

Then choose a 3-wire power supply cord with ring or spade

terminals and UL listed strain relief. The 3-wire power supply cord,

at least 4 ft (1.22 m) long, must have three 10-gauge solid copper

wires and match a 3-wire receptacle of NEMA Type 10-30R.

If connecting by direct wire:

Power supply cable must match power supply (4-wire or 3-wire)

and be:

[] Flexible armored cable or nonmetallic sheathed copper cable

(with ground wire), protected with flexible metallic conduit. All

current-carrying wires must be insulated.

[] 10-gauge solid copper wire (do not use aluminum).

[] At least 5 ft (1.52 m) long.

GROUNDING iNSTRUCTiONS

[] For a grounded, cord-connected dryer:

This dryer must be grounded. In the event of malfunction or

breakdown, grounding will reduce the risk of electric shock

by providing a path of least resistance for electric current.

This dryer uses a cord having an equipment-grounding

conductor and a grounding plug. The plug must be plugged

into an appropriate outlet that is properly installed and

grounded in accordance with all local codes and ordinances.

[] For a permanently connected dryer:

This dryer must be connected to a grounded metal,

permanent wiring system, or an equipment-grounding

conductor must be run with the circuit conductors and

connected to the equipment-grounding terminal or lead on

the dryer.

WARNING: Improper connection of the equipment-

grounding conductor can result in a risk of electric shock.

Check with a qualified electrician or service representative

or personnel if you are in doubt as to whether the dryer is

properly grounded. Do not modify the plug on the power

supply cord: ifit will not fit the outlet, have a proper outlet

installed by a qualified electrician.

SAVE THESE INSTRUCTIONS

Electrical Shock Hazard

Plug into a grounded 4 prong outlet,

Failure to do so can result in death or electrical shock.

It is your responsibility

[] To contact a qualified electrical installer.

[] To be sure that the electrical connection is adequate and in

conformance with the Canadian Electrical Code, C22.1-latest

edition and all local codes. A copy of the above codes

standard may be obtained from: Canadian Standards

Association, 178 Rexdale Blvd., Toronto, ON M9W 1R3

CANADA.

To supply the required 4 wire, single phase, 120/240 volt,

60 Hz., AC only electrical supply on a separate 30-amp circuit,

fused on both sides of the line. A time-delay fuse or circuit

breaker is recommended. Connect to an individual branch

circuit.

This dryer is equipped with a CSA International Certified

Power Cord intended to be plugged into a standard 14-30R

wall receptacle. The cord is 5 ft (1.52 m) in length. Be sure wall

receptacle is within reach of dryer's final location.

@

4-wire receptacle 14-30R

[] Do not use an extension cord.

If you are using a replacement power supply cord, it is

recommended that you use Power Supply Cord Replacement

Part Number 3394208. For further information, please reference

the service numbers located in the Dryer User Instructions.

GROUNDING INSTRUCTIONS

[] For a grounded, cord-connected dryer:

This dryer must be grounded. In the event of malfunction or

breakdown, grounding will reduce the risk of electric shock

by providing a path of least resistance for electric current.

This dryer is equipped with a cord having an equipment-

grounding conductor and a grounding plug. The plug must

be plugged into an appropriate outlet that is properly

installed and grounded in accordance with all local codes

and ordinances.

WARNING: Improper connection of the equipment-

grounding conductor can result in a risk of electric shock.

Check with a qualified electrician or service representative

or personnel if you are in doubt as to whether the dryer is

properly grounded. Do not modify the plug provided with the

dryer: if it will not fit the outlet, have a proper outlet installed

by a qualified electrician.

SAVE THESE INSTRUCTIONS

Power Supply Cord

Direct Wire

Fire Hazard

Use a new UL listed 30 amp power supply cord.

Use a UL listed strain relief.

Disconnect power before making electrical connections.

Connect neutral wire (white or center wire) to center

terminal (silver).

Ground wire (green or bare wire) must be connected to

green ground connector.

Connect remaining 2 supply wires to remaining

2 terminals (gold).

Securely tighten all electrical connections.

Failure to do so can result in death, fire, or

electrical shock.

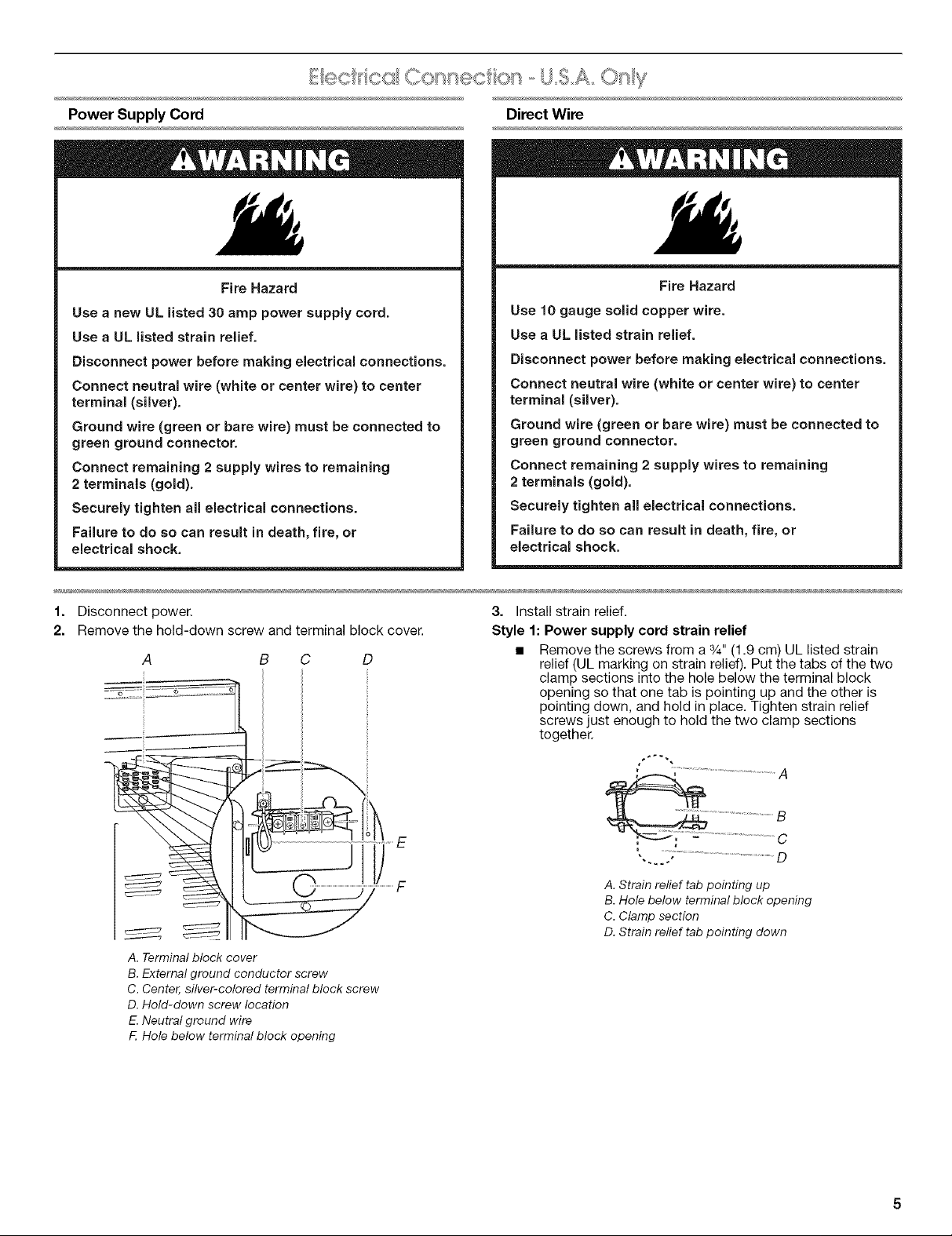

1. Disconnect power.

2. Remove the hold-down screw and terminal block cover.

B C D

Fire Hazard

Use 10 gauge solid copper wire.

Use a UL listed strain relief.

Disconnect power before making electrical connections.

Connect neutral wire (white or center wire) to center

terminal (silver).

Ground wire (green or bare wire) must be connected to

green ground connector.

Connect remaining 2 supply wires to remaining

2 terminals (gold).

Securely tighten all electrical connections.

Failure to do so can result in death, fire, or

electrical shock.

3. Install strain relief.

Style 1: Power supply cord strain relief

• Remove the screws from a %" (1.9 cm) UL listed strain

relief (UL marking on strain relief). Put the tabs of the two

clamp sections into the hole below the terminal block

opening so that one tab is pointing up and the other is

pointing down, and hold in place. Tighten strain relief

screws just enough to hold the two clamp sections

together.

A.Terminalblock cover

B.Externalground conductor screw

C.Center,silver-colored terminal block screw

D.Hold-down screw location

E.Neutral ground wire

E Hole below terminalblock opening

A. Strain relief tab pointing up

B. Hole below terminal block opening

C. Clamp section

D. Strain relief tab pointing down

Put power supply cord through the strain relief. Be sure

that the wire insulation on the power supply cord is inside

the strain relief. The strain relief should have a tight fit with

the dryer cabinet and be in a horizontal position. Do not

further tighten strain relief screws at this point.

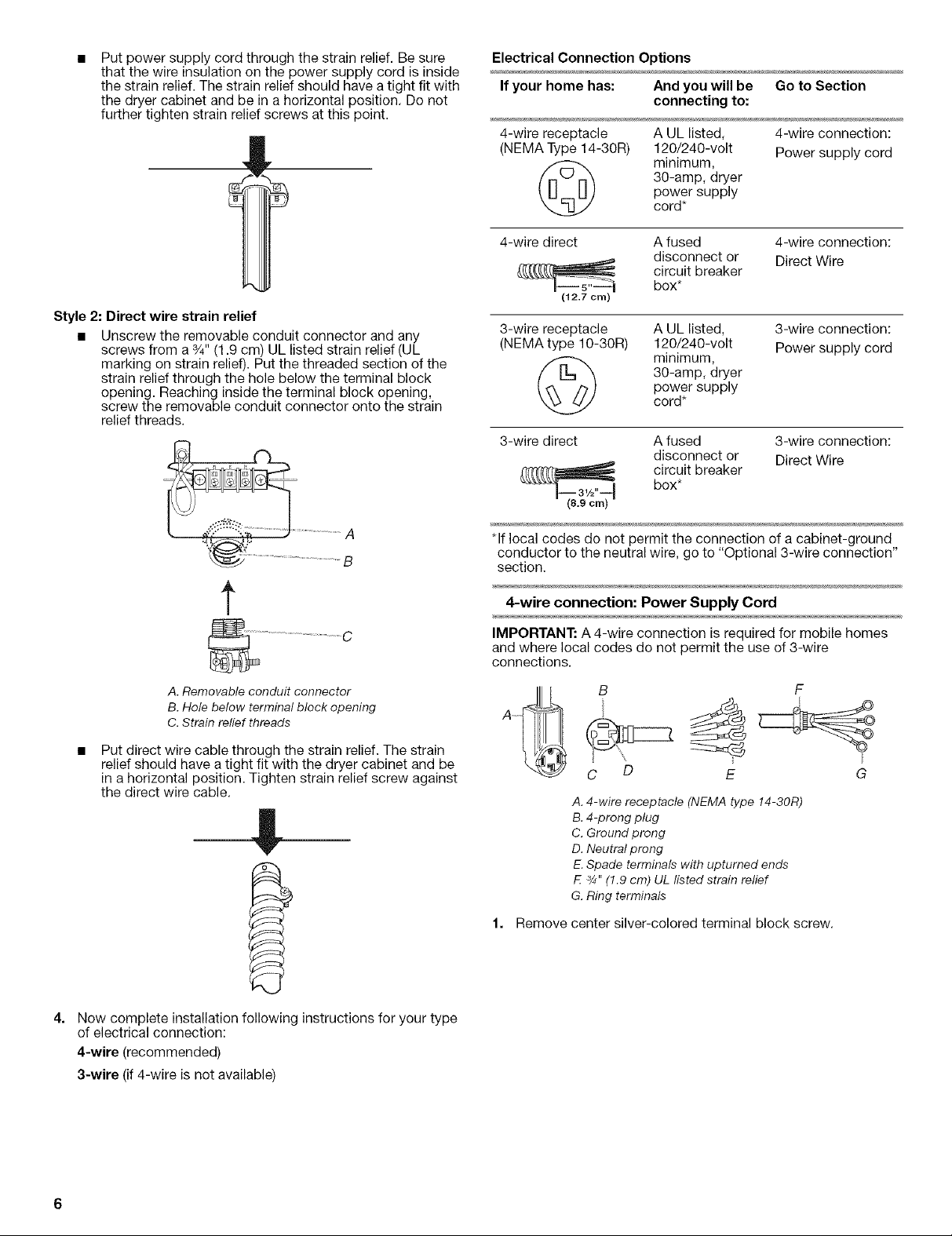

Style 2: Direct wire strain relief

• Unscrew the removable conduit connector and any

screws from a 3/4"(1.9 cm) UL listed strain relief (UL

marking on strain relief). Put the threaded section of the

strain relief through the hole below the terminal block

opening. Reaching inside the terminal block opening,

screw the removable conduit connector onto the strain

relief threads.

Electrical Connection Options

If your home has: And you will be Go to Section

connecting to:

4-wire receptacle A UL listed, 4-wire connection:

(NEMA Type 14-30R) 120/240-volt Power supply cord

30-amp, dryer

_.._ minimum,

4-wire direct A fused 4-wire connection:

(12.7 ore)

3-wire receptacle A UL listed,

(NEMA type 10-30R) 120/240-volt

3-wire direct A fused 3-wire connection:

power supply

cord*

disconnect or Direct Wire

circuit breaker

box*

3-wire connection:

Power supply cord

30-amp, dryer

power supply

minimum,

cord*

disconnect or Direct Wire

box*

circuit breaker

.......................................................g

t

A. Removable conduit connector

B. Hole below terminal block opening

C. Strain relief threads

Put direct wire cable through the strain relief. The strain

relief should have a tight fit with the dryer cabinet and be

in a horizontal position. Tighten strain relief screw against

the direct wire cable.

*If local codes do not permit the connection of a cabinet-ground

conductor to the neutral wire, go to "Optional 3-wire connection"

section.

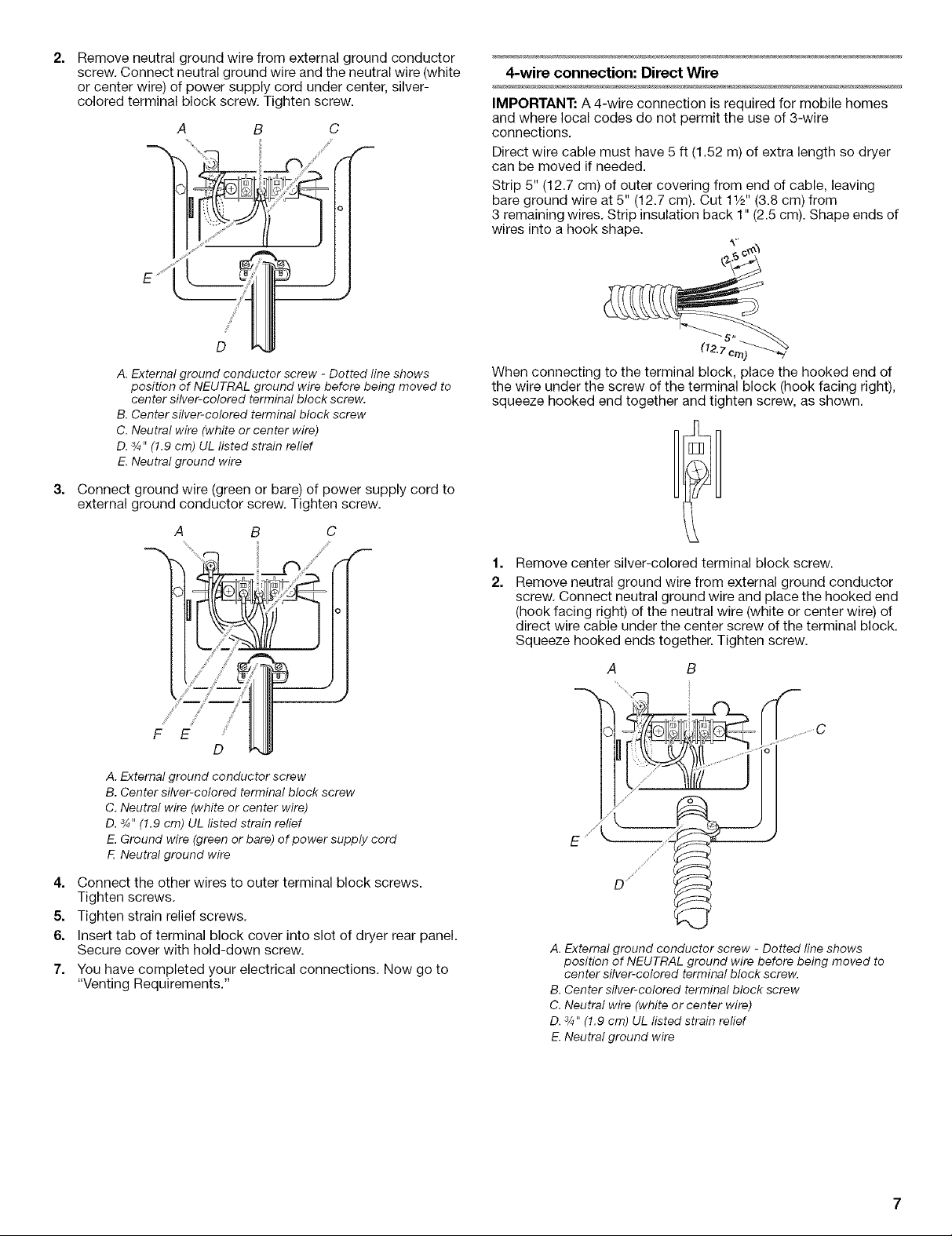

4-wire connection: Power Supply Cord

IMPORTANT: A 4-wire connection is required for mobile homes

and where local codes do not permit the use of 3-wire

connections.

B F

C D E G

A. 4-wire receptacle (NEMA type 14-30R)

B. 4-prong plug

C. Ground prong

D. Neutral prong

E.Spade terminals with upturned ends

F. 3_,,(!.9 cm) UL listed strain relief

G. Ring terminals

1. Remove center silver-colored terminal block screw.

4=

Now complete installation following instructions for your type

of electrical connection:

4-wire (recommended)

3-wire (if 4-wire is not available)

2=

Remove neutral ground wire from external ground conductor

screw. Connect neutral ground wire and the neutral wire (white

or center wire) of power supply cord under center, silver-

colored terminal block screw. Tighten screw.

A C

A. External ground conductor screw - Dotted line shows

position of NEUTRAL ground wire before being moved to

center silver-colored terminal block screw.

B. Center silver-colored terminal block screw

C. Neutral wire (white or center wire)

D. 3/4,,(1.9 cm) UL listed strain relief

E.Neutral ground wire

3=

Connect ground wire (green or bare) of power supply cord to

external ground conductor screw. Tighten screw.

4-wire connection: Direct Wire

IMPORTANT: A 4-wire connection is required for mobile homes

and where local codes do not permit the use of 3-wire

connections.

Direct wire cable must have 5 ft (1.52 m) of extra length so dryer

can be moved if needed.

Strip 5" (12.7 cm) of outer covering from end of cable, leaving

bare ground wire at 5" (12.7 cm). Cut 11/2''(3.8 cm) from

3 remaining wires. Strip insulation back 1" (2.5 cm). Shape ends of

wires into a hook shape.

(12, 7 err

When connecting to the terminal block, place the hooked end of

the wire under the screw of the terminal block (hook facing right),

squeeze hooked end together and tighten screw, as shown.

D

A. External ground conductor screw

B. Center silver-colored terminal block screw

C. Neutral wire (white or center wire)

D. 3/4"(1.9 cm) UL listed strain relief

E. Ground wire (green or bare) of power supply cord

F Neutral ground wire

4. Connect the other wires to outer terminal block screws.

Tighten screws.

5. Tighten strain relief screws.

6. Insert tab of terminal block cover into slot of dryer rear panel.

Secure cover with hold-down screw.

7. You have completed your electrical connections. Now go to

"Venting Requirements."

1=

Remove center silver-colored terminal block screw.

2.

Remove neutral ground wire from external ground conductor

screw. Connect neutral ground wire and place the hooked end

(hook facing right) of the neutral wire (white or center wire) of

direct wire cable under the center screw of the terminal block.

Squeeze hooked ends together. Tighten screw.

A B

.......C

//

/'!

/,

b /

A. External ground conductor screw - Dotted line shows

position of NEUTRAL ground wire before being moved to

center silver-colored terminal block screw.

B. Center silver-colored terminal block screw

C. Neutral wire (white or center wire)

D. 3/4. (1.9 cm) UL listed strain relief

E.Neutral ground wire

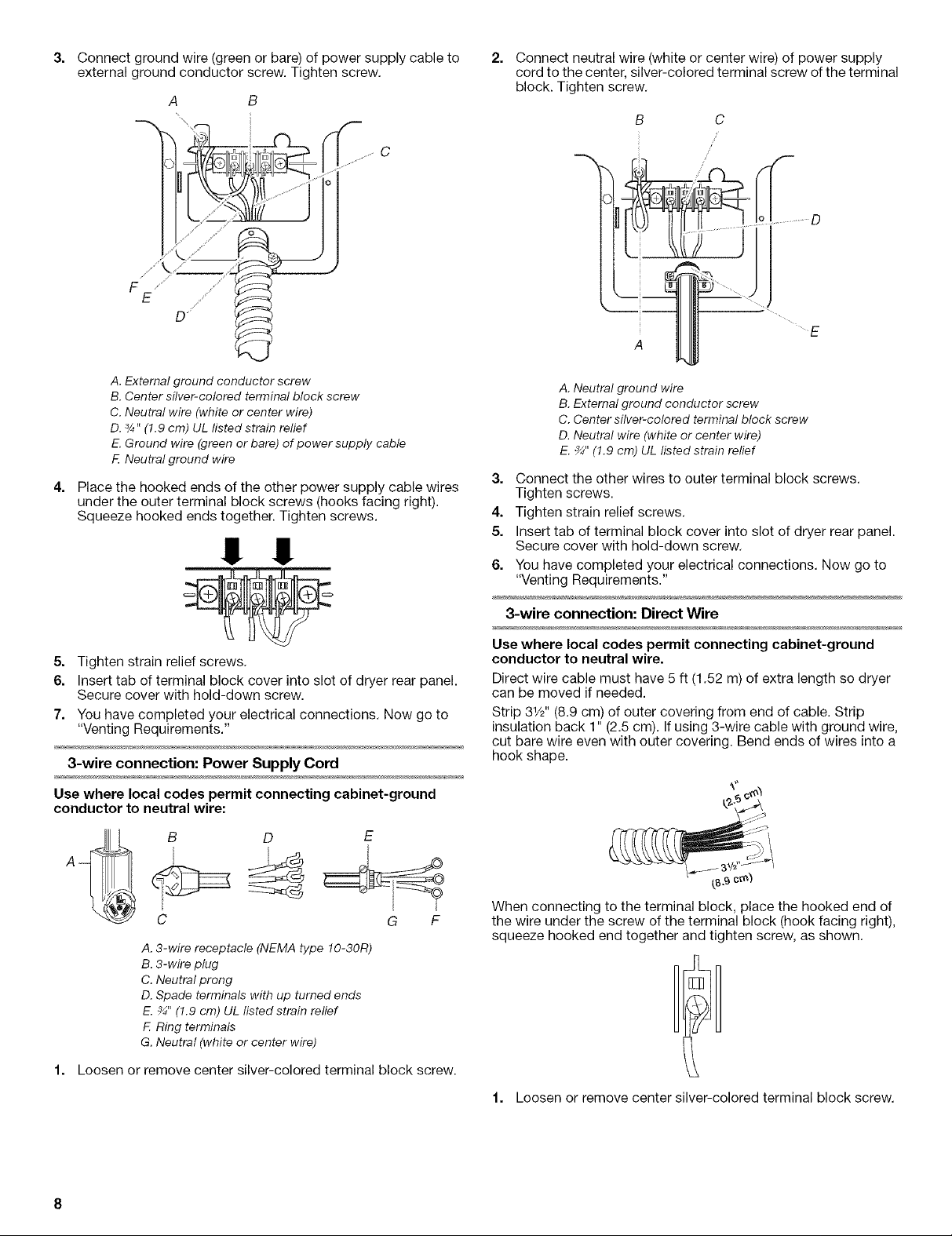

3. Connect ground wire (green or bare) of power supply cable to

external ground conductor screw. Tighten screw.

A B

io Ei[] •

F............J.........................

D .....

Connect neutral wire (white or center wire) of power supply

cord to the center, silver-colored terminal screw of the terminal

block. Tighten screw.

B C

E

A. External ground conductor screw

B. Center silver-colored terminal block screw

C. Neutral wire (white or center wire)

D. s_,, (1.9 cm) UL listed strain relief

E.Ground wire (green or bare) of power supply cable

R Neutral ground wire

4. Place the hooked ends of the other power supply cable wires

under the outer terminal block screws (hooks facing right).

Squeeze hooked ends together. Tighten screws.

!! !!

5. Tighten strain relief screws.

6. Insert tab of terminal block cover into slot of dryer rear panel.

Secure cover with hold-down screw.

7. You have completed your electrical connections. Now go to

"Venting Requirements."

3-wire connection: Power Supply Cord

Use where local codes permit connecting cabinet-ground

conductor to neutral wire:

B D E

, i

A. Neutralground wire

B. Externalground conductor screw

C. Center silver-colored terminal block screw

D. Neutral wire (white or center wire)

E. _" (1.9 cm)UL Iisted strain relief

3. Connect the other wires to outer terminal block screws.

Tighten screws.

4. Tighten strain relief screws.

5. Insert tab of terminal block cover into slot of dryer rear panel.

Secure cover with hold-down screw.

6. You have completed your electrical connections. Now go to

"Venting Requirements."

3-wire connection: Direct Wire

Use where local codes permit connecting cabinet-ground

conductor to neutral wire.

Direct wire cable must have 5 ft (1.52 m) of extra length so dryer

can be moved if needed.

Strip 31/2'' (8.9 cm) of outer covering from end of cable. Strip

insulation back 1" (2.5 cm). If using 3-wire cable with ground wire,

cut bare wire even with outer covering. Bend ends of wires into a

hook shape.

t"

C G F

A. 3-wire receptacle (NEMA type 10-30R)

B. 3-wire plug

C. Neutral prong

D. Spade terminals with up turned ends

E. _" (1.9 cm) UL listed strain relief

F. Ring terminals

G. Neutral (white or center wire)

1. Loosen or remove center silver-colored terminal block screw.

When connecting to the terminal block, place the hooked end of

the wire under the screw of the terminal block (hook facing right),

squeeze hooked end together and tighten screw, as shown.

1. Loosen or remove center silver-colored terminal block screw.

2=

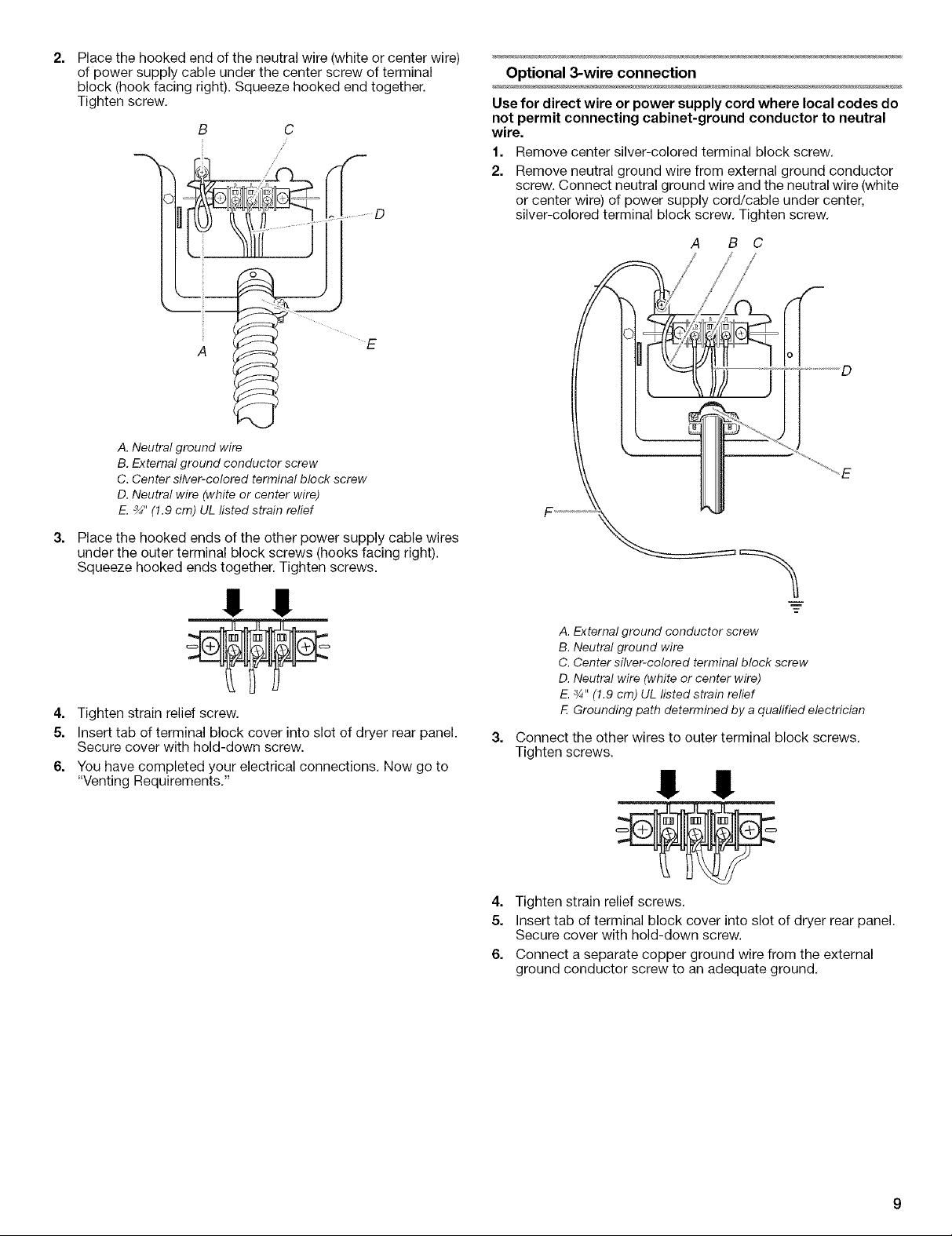

Place the hooked end of the neutral wire (white or center wire)

of power supply cable under the center screw of terminal

block (hook facing right). Squeeze hooked end together.

Tighten screw.

B C

/

A. Neutral ground wire

B. External ground conductor screw

C. Center silver-colored terminal block screw

D. Neutral wire (white or center wire)

E. _" (1.9 cm) UL listed strain relief

3=

Place the hooked ends of the other power supply cable wires

under the outer terminal block screws (hooks facing right).

Squeeze hooked ends together. Tighten screws.

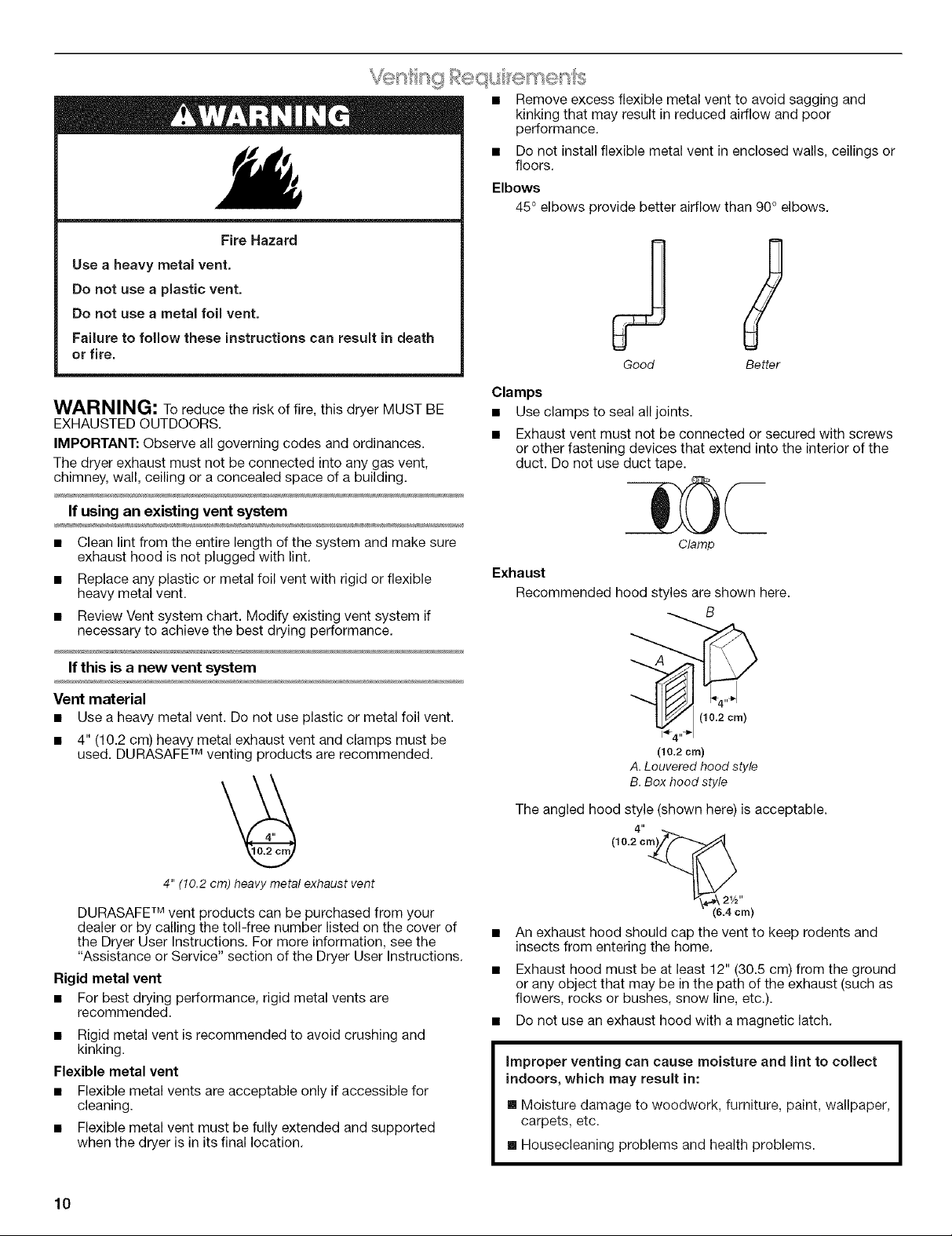

Optional 3-wire connection

Use for direct wire or power supply cord where local codes do

not permit connecting cabinet-ground conductor to neutral

wire.

1. Remove center silver-colored terminal block screw.

2. Remove neutral ground wire from external ground conductor

screw. Connect neutral ground wire and the neutral wire (white

or center wire) of power supply cord/cable under center,

silver-colored terminal block screw. Tighten screw.

A B C

D

!! !!

4. Tighten strain relief screw.

5. Insert tab of terminal block cover into slot of dryer rear panel.

Secure cover with hold-down screw.

6. You have completed your electrical connections. Now go to

"Venting Requirements."

A. External ground conductor screw

B. Neutral ground wire

C. Center silver-colored terminal block screw

D. Neutral wire (white or center wire)

E. %" (1.9 cm) UL listed strain relief

E Grounding path determined by a qualified electrician

Connect the other wires to outer terminal block screws.

Tighten screws.

!! !!

4. Tighten strain relief screws.

5. Insert tab of terminal block cover into slot of dryer rear panel.

Secure cover with hold-down screw.

6. Connect a separate copper ground wire from the external

ground conductor screw to an adequate ground.

Fire Hazard

Use a heavy metal vent.

Do not use a plastic vent.

Do not use a metal foil vent.

Failure to follow these instructions can result in death

or fire.

WARNING: To reduce the risk of fire, this dryer MUST BE

EXHAUSTED OUTDOORS.

IMPORTANT: Observe all governing codes and ordinances.

The dryer exhaust must not be connected into any gas vent,

chimney, wall, ceiling or a concealed space of a building.

If using an existing vent system

• Removeexcessflexiblemetalventtoavoidsaggingand

kinkingthatmayresultinreducedairflowandpoor

performance,

• Donotinstallflexiblemetalventinenclosedwalls,ceilingsor

floors.

Elbows

45° elbows provide better airflow than 90° elbows.

/

Good Better

Clamps

• Use clamps to seal all joints.

• Exhaust vent must not be connected or secured with screws

or other fastening devices that extend into the interior of the

duct. Do not use duct tape.

• Clean lint from the entire length of the system and make sure

exhaust hood is not plugged with lint.

• Replace any plastic or metal foil vent with rigid or flexible

heavy metal vent.

• Review Vent system chart. Modify existing vent system if

necessary to achieve the best drying performance.

If this is a new vent system

Vent material

• Use a heavy metal vent. Do not use plastic or metal foil vent.

• 4" (10.2 cm) heavy metal exhaust vent and clamps must be

used. DURASAFF Mventing products are recommended.

4" (10.2cm) heavymetal exhaustvent

DURASAFE TM vent products can be purchased from your

dealer or by calling the toll-free number listed on the cover of

the Dryer User Instructions. For more information, see the

"Assistance or Service" section of the Dryer User Instructions.

Rigid metal vent

• For best drying performance, rigid metal vents are

recommended.

• Rigid metal vent is recommended to avoid crushing and

kinking.

Flexible metal vent

• Flexible metal vents are acceptable only if accessible for

cleaning.

• Flexible metal vent must be fully extended and supported

when the dryer is in its final location.

Clamp

Exhaust

Recommended hood styles are shown here.

B

(10.2 cm)

A. Louveredhood style

B.Box hood style

The angled hood style (shown here) is acceptable.

4-"

(10.2 cm)_C _

I_ 21/2.

(6.4cm)

An exhaust hood should cap the vent to keep rodents and

insects from entering the home.

Exhaust hood must be at least 12" (30.5 cm) from the ground

or any object that may be in the path of the exhaust (such as

flowers, rocks or bushes, snow line, etc.).

Do not use an exhaust hood with a magnetic latch.

improper venting can cause moisture and lint to collect

indoors, which may result in:

[] Moisture damage to woodwork, furniture, paint, wallpaper,

carpets, etc.

[] Housecleaning problems and health problems.

10

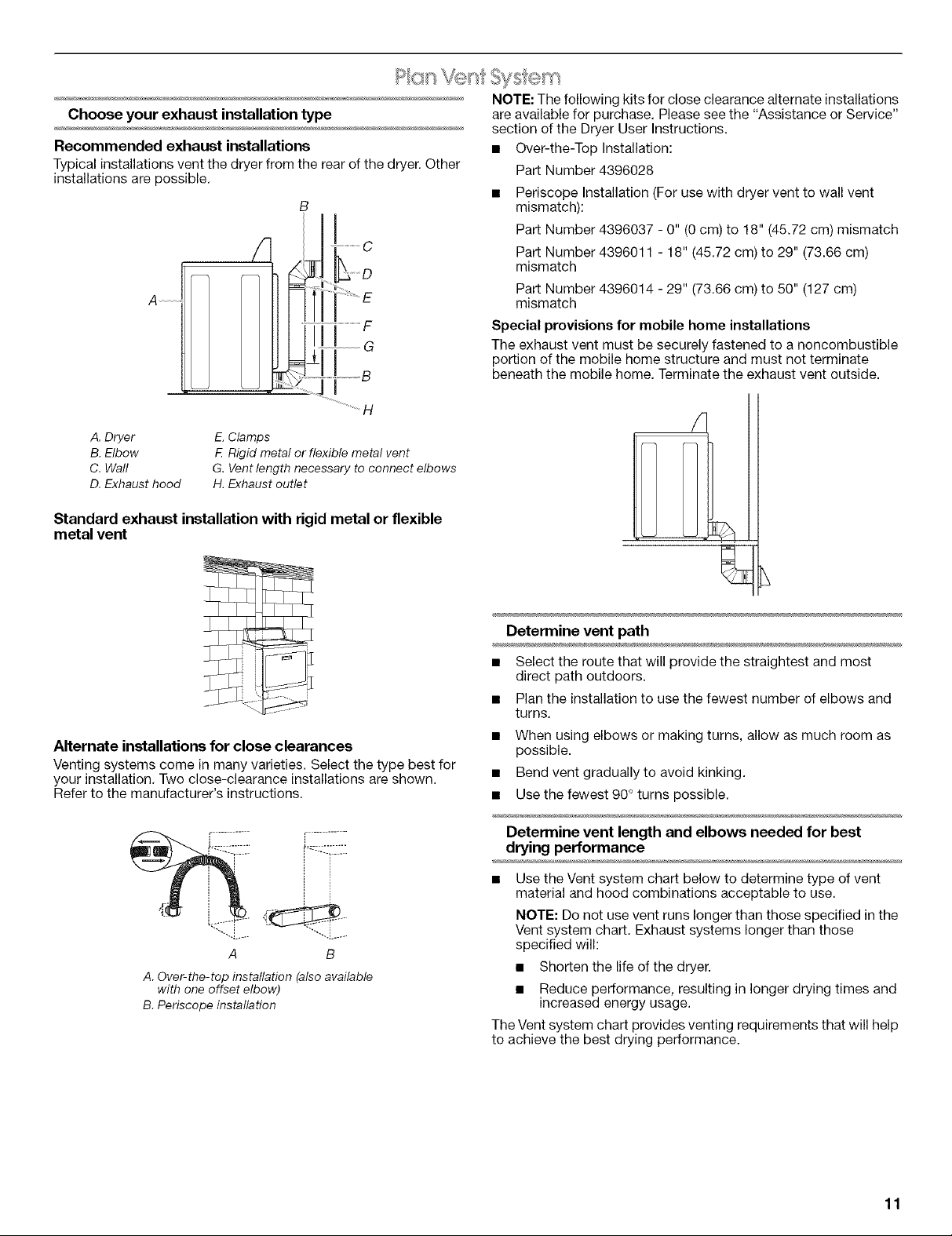

NOTE: The following kits for close clearance alternate installations

Choose your exhaust installation type are available for purchase. Please see the "Assistance or Service"

Recommended exhaust installations

Typical installations vent the dryer from the rear of the dryer, Other

installations are possible,

B

A

il

section of the Dryer User Instructions.

• Over-the-Top Installation:

Part Number 4396028

Periscope Installation (For use with dryer vent to wall vent

mismatch):

Part Number 4396037 - 0" (0 cm) to 18" (45.72 cm) mismatch

Part Number 4396011 - 18" (45.72 cm) to 29" (73.66 cm)

mismatch

Part Number 4396014 - 29" (73.66 cm) to 50" (127 cm)

mismatch

Special provisions for mobile home installations

The exhaust vent must be securely fastened to a noncombustible

portion of the mobile home structure and must not terminate

beneath the mobile home. Terminate the exhaust vent outside.

A. Dryer

B. Elbow

C. Wall

D. Exhaust hood

E. Clamps

F. Rigid metal or flexible metal vent

G. Vent length necessary to connect elbows

H. Exhaust outlet

Standard exhaust installation with rigid metal or flexible

metal vent

Alternate installations for close clearances

Venting systems come in many varieties. Select the type best for

your installation, Two close-clearance installations are shown.

Refer to the manufacturer's instructions.

A. Over-the-top installation (also available

with one offset elbow)

B. Periscope installation

/

Determine vent path

• Select the route that will provide the straightest and most

direct path outdoors.

• Plan the installation to use the fewest number of elbows and

turns,

• When using elbows or making turns, allow as much room as

possible.

• Bend vent gradually to avoid kinking.

• Use the fewest 90 °turns possible,

Determine vent length and elbows needed for best

drying performance

• Use the Vent system chart below to determine type of vent

material and hood combinations acceptable to use,

NOTE: Do not use vent runs longer than those specified in the

Vent system chart. Exhaust systems longer than those

specified will:

• Shorten the life of the dryer.

• Reduce performance, resulting in longer drying times and

increased energy usage.

The Vent system chart provides venting requirements that will help

to achieve the best drying performance.

11