Encon Evolution User Manual

Original Operating Instructions

(Rev. 4.5)

Notices

No part of this manual may be reproduced in any form or by any means (including electronic

storage and retrieval or translation into a foreign language) without prior agreement and written

consent for EST Analytical.

Edition

Version

Rev. 4.5

EST Analytical

503 Commercial Dr.

Fairfield OH, 45014 USA

Acknowledgements

Encon Evolution® is a registered trademark of EST Analytical. Carbopack®, Carbosieve®,

Carboxen®, SP®, and Vocarb® are trademarks of Sigma-Aldrich Co. Tenax® is a trademark of

Enka Research Institute Arhem. HP® is a registered trademark of Hewlett-Packard Company.

Perkin Elmer® is a registered trademark of Perkin Elmer Inc. Varian® is a trademark of Varian

Inc. Swaglock® is a registered trademark of the Crawford Fitting Co. Teflon® and Vespel® are

trademarks of E.I. DuPont de Nemours and Company Inc. Windows®XP is a registered

trademark of the Microsoft Corp. Chemrex® is a trademark of Chemrex Inc. Siltek® is a

trademark of Restek Corp.

Registered names and trademark information are accurate to the best of our knowledge at the

time of printing.

The

CAN/CSAC22.2 No.61010.1, 2nd edition, including Amendment 1.

symbol marked on the product indicates compliance with the requirements of

Warranty

The material contained in this document is provided “as is”, and is subject to change without

notice, in future editions. EST Analytical warrants the products it manufactures and distributes,

except those specially exempted, to be free from defects for (1) full year from the date of

shipment. This warranty is limited to the original purchaser of the product and is not

transferable. This limited warranty does not extend to any products that have been damaged as a

result of accident, misuse, abuse, unauthorized service or modification by anyone.

Except as expressly set forth above, no other warranties are expressed or implied including, but

not limited to, any implied warranties merchantability and fitness for a particular purpose, and

EST expressly disclaims all warranties not stated herein. In the event the product is not free

from defect as warranted above, the purchaser’s sole remedy shall be provided above. Under no

circumstances will EST Analytical be liable to the purchaser or any user for any damages,

including the incidental or consequential damages, expenses, lost profits, lost savings or other

damages arising out of the use or inability to use the product. This warranty shall not be

applicable to the extent that any provision of this warranty is prohibited by any federal, state, or

municipal law that cannot be preempted.

Federal Communications Commission advisory:

This equipment has not been tested or found to comply with the limits of Class A computing

device, pursuant to part 15 of the FCC Rules. These limits are designed to provide reasonable

protection against harmful interference when the equipment is operated in a commercial

environment. This equipment generates, uses, and can radiate radio frequency energy and, if not

installed and used in accordance with the instruction manual, may cause harmful interference to

radio communications. Operation of this equipment in a residential area is likely to cause

harmful interference in which case the user will be required to correct the interference at his

expense.

Safety Notices

CAUTION

A CAUTION notice denotes a hazard. It calls attention to an operating procedure, practice, or

the like that, if not properly performed or adhered to, could result in damage. Do not proceed

beyond a CAUTION notice until the indicated conditions are completely understood and met.

ATTENTION

La mention ATTENTION signale un danger. Il attire l'attention sur une procédure

d'exploitation, la pratique ou la comme ça, s'il n'est pas correctement effectuée ou respectée, peut

entraîner des dommages. Ne pas aller au-delà d'une mention ATTENTION jusqu'à ce que les

conditions indiquées sont complètement comprises et respectées.

WARNING

A WARNING notice denotes a hazard. It calls attention to an operating procedure or practice,

or the like that, if not properly performed or adhered to, could result in personal injury of death.

Do not proceed beyond a WARNING notice until the indicated conditions are completely

understood and met.

AVERTISSEMENT

La mention AVERTISSEMENT signale un danger. Il attire l'attention sur une procédure ou une

pratique exploitation, ou le comme ça, s'il n'est pas correctement effectuée ou respectée, peut

entraîner des blessures de la mort. Ne pas aller au-delà d'une mention AVERTISSEMENT

jusqu'à ce que les conditions indiquées sont complètement comprises et respectées.

Table of Contents

Chapter 1: Introduction

1.1 Product Description

1.2 Product Specifications

1.3 Warnings and Symbols

1.4 Disposal and Recycling Information

Chapter 2: Encon Evolution Installation and Set-up

2.1 General Information

2.2 Work Space Requirements

2.3 Power Requirements

2.4 Unpacking the Encon Evolution

2.5 System Setup

2.5.1 Interface Connection

2.5.2 Monitor Connection

2.5.3 Mouse Connection

2.5.4 Gas Connection

2.5.5 Power Connection

2.5.6 System Power Up

Chapter 3: Encon Evolution Operation

3.1 Powering on the Encon Evolution

3.2 Opening the Encon Evolution Application

3.3 Powering off the Encon Evolution

3.4 Main Screen

3.5 Diagnostics Screen

3.6 Home/Login Screen

3.7 Exit Icon

3.8 Options Screen

3.9 Sequence Screen

3.10 Method Screen

3.10.1 Method Setup Tab

3.10.2 Purge and Trap Tab

3.10.3 Sample Heater Tab (OPTION)

3.11 Run Status Screen

3.12 Active Run Log Screen

3.13 Report Screen

3.14 Integrity

3.15 Help Screen

3.16 Recommended Encon Evolution Purge and Trap Parameters USEPA

Method 8260b

Chapter 4: User Maintenance

4.1 Technical Support Contact Information

4.2 Cleaning the Encon Evolution

4.3 Trap and MoRT Replacement

4.4 Diagnostics Screen

4.4.1 Icons

4.4.2 Manual Heater Control

4.4.3 Manual Valve Control

4.4.4 Flow Pathway Drop Down Menu

4.4.5 Flow

4.4.6 Flow Calibration

4.4.7 Trap Bake

4.4.8 Calibration

4.4.9 Drain

4.4.10 Manual Injection

4.5 Fuse Replacement

4.6 Spare Parts Website

Chapter 5: Flow Diagrams

User Manual

Introduction

Chapter 1

1.1 Product Description

Over the past several years, the Encon has proven itself to be an extremely reliable instrument

providing 24/7 hours of operation. EST Analytical is now introducing the Encon Evolution with

features such as: the Foam Sensor, Modular Pressure/Flow Control for programmable flow rates

and an automated leak/pressure check. The modular design of the flow controller allows the user

to replace individual components in case of failure instead of the expense of replacing the entire

Mass Flow controller. Moisture control is performed during the purge cycle to reduce the

sample desorb pathway. Optional touch screen interface along with easy trap access from the

front of the instrument make daily use and operation very simple. With superior

chromatographic resolution, the Encon has evolved with features that will make the laboratory

more productive and ensure data integrity.

As limits are pushed lower in many states, carryover within the purge and trap system is

becoming a greater concern. In the past, efforts have been to reduce carryover with new sample

pathway materials and programmable flow rates during the bake cycle, but little has been done to

deal with the primary cause of the carryover, the sparge vessel itself. If an analyst runs a high

level sample, followed by a blank, a certain level of carryover can be seen on all purge and trap

systems. If an analyst runs a high level sample, replaces the glassware, then runs a blank a 7090% reduction in carryover can be seen. The new Encon Evolution employs a mode where

during the bake cycle of the concentrator, the sparge vessel is heated (Patent Pending). The result

is the lowest level of carryover of any concentrator today.

Other features like; DPC – Desorb Pressure Control (Patent Pending) can help provide superior

chromatographic resolution. There are many different parameters that can affect peak shape,

especially with the early eluting compounds. The peak shape of these compounds can be greatly

affected by flow rates and pressure changes within the trap. One of the problems is that the trap

pressure is often different than the GC column head pressure. When the concentrator goes into

desorb, the multiport valve turns to allow GC carrier flow to travel through the trap. If the trap is

at a pressure lower than the column head pressure, the trap will experience a surge in gas flow to

adjust to the new pressure causing poor peak shape and/or recovery of the light compounds. The

Encon Evolution allows the user, after purge, to establish a set pressure within the trap. Users

can adjust this setting depending upon the column head pressure they are using to optimize peak

shape.

EST Analytical was the first to introduce a foam sensor to purge and trap. Fritted sparge vessels

improve purging efficiency but they also increase the frequency of samples foaming. With the

Encon Evolution, if a foamed sample is detected the sample will be drained; the GC will be sent

a start signal to perform a blank run, ensuring the GCs sequence table is accurate. The sample

pathway is then baked out and a notification is written to the instrument’s sample log.

Windows XPe Graphical Display is the new EST Analytical user interface. This is an easy to use

programming environment that provides total system information. Basic status screens display

real time pressure and flow paths. Modes and times of operation give the user an easy way to

review overall system parameters and current status. System maintenance screens give users

complete control of the entire system. Click on each valve to manually actuate solenoids or the

multi-port valve, perform automated leak and flow checks or condition a new trap with the press

of a button. Users can be locked out of this area by an administrator if desired. The complete log

can be viewed at any time showing any errors, trap changes, leak and flow check status etc. This

information is stored until printed or deleted from the system.

1.2 Product Specifications

Major Features

Modular Flow Control

Optional Sample Foam Sensor

Optional Sample Heater for reduced carryover during Bake

Optional Touch Screen Interface

High Temperature capability

Precise Temperature control

Siltek sample pathway

Dimensions

17”H x 11”W x 16”D (43.2cm x 27.94cm x 40.6cm)

Weight

45lbs. (20.4kg)

Indoor Use

Up to 2000 m altitude

10°C to 25°C operating temperature

5°C to 85°C storage temperature

10 to 90% relative humidity

Programmable Time Ranges

999.99 min for all timed events

Programmable Temp. Ranges

Trap: ambient to 270°C

Transfer Line: ambient to 250°C

Valve Oven: ambient to 250°C

Trap

Standard EPA Specified Traps

Conductive heating/replaceable insert

Various sorbent materials available for US EPA methods and other applications

Valve

Electrically actuated

8-port, 45 degree rotation

Replaceable valve rotor

Transfer Line

Siltek tubing, 0.020 ID

60“ (152.4cm) standard

Optional Glassware

5 ml Needle sparge kit

25 ml Needle sparge kit

25 ml frit sparge kit

20 ml Disposable Test tubes

Electronic Control

1GB RAM, volatile

Compact Flash = 2GB nonvolatile memory

20 local method storage with battery backup

Display Std mouse, optional keyboard, optional touch screen

USB communication

Trap

1000°C/min heating rate

Cool down rate less than 90 sec.

Optional Sparge Glass Heater

Up to 150°C glassware bake

Temperature

Accuracy/Stability +/- 1°C for all heated zones

PID monitored

Water Elimination Trap

Operates at ambient to 210°C

Conductive heating/replaceable

Pass-through tube

Sample Pathway

Inert Siltek pathway

Gas Requirements

Helium or Nitrogen 60-80 PSI (414-552kPa) 99.999% GC/MS grade purity; BTU/hr. = NA

(compressed gas used for pressurization only)

Voltage

115/230 VAC (+/-10%) 50/60 Hz

Current

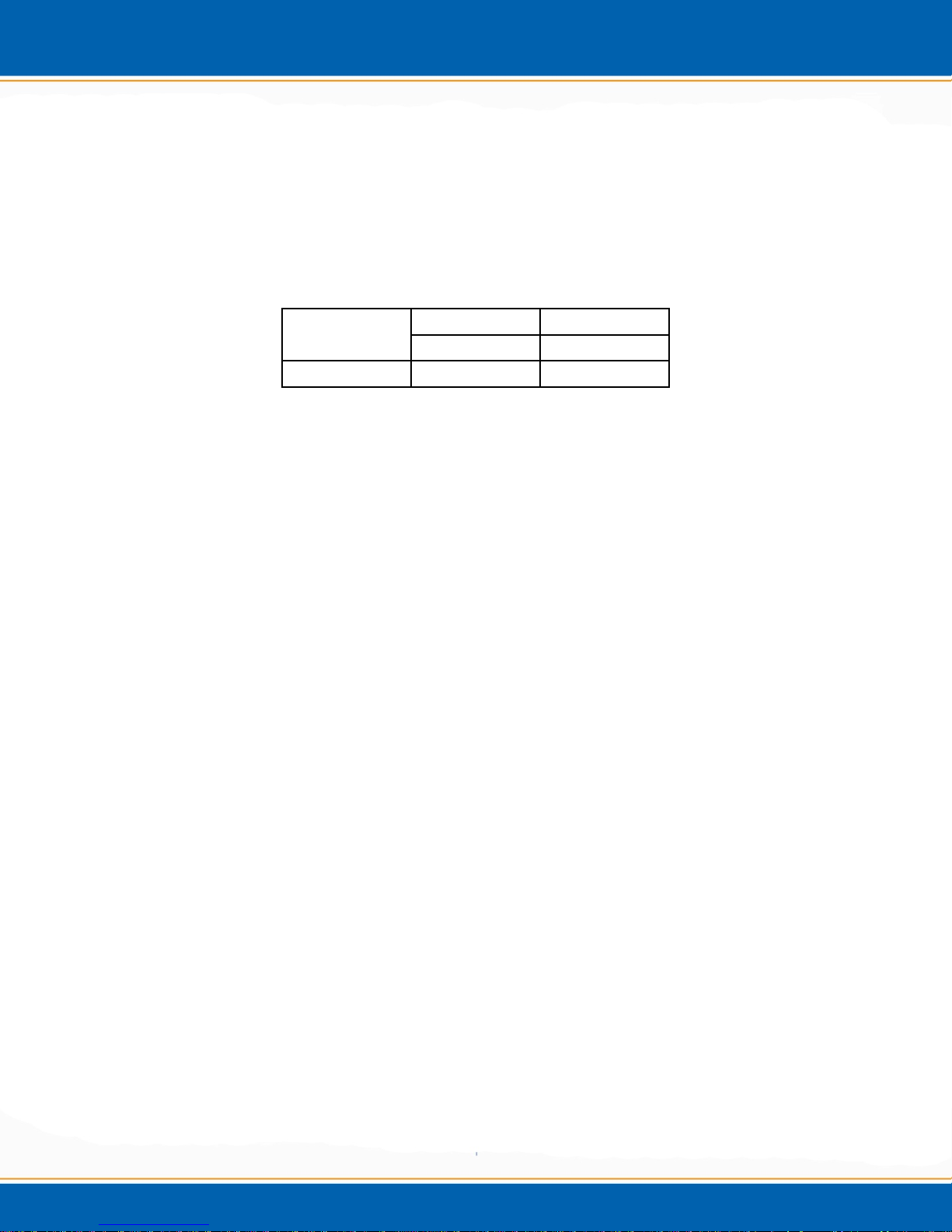

Model

EnconEvolution 10 6.3

115VAC 230VAC

Current(A) Current(A)

Battery:

CR2032 battery contained on SBC (CPU) board

Installation Category

II

Pollution Degree

2

Major Options

Sample Foam Sensor

Heated Glassware Kit

Touch Screen Monitor

1.3 Warnings and Symbols:

English

Warnings in the manual or on the Encon Evolution to be observed during installation,

operation, service and/or repair of the instrument. EST Analytical will assume no

responsibility for customers failing to comply with the safety precautions stated.

Use of the Encon Evolution for something other than the intended use of the instrument is

prohibited.

The use of the Encon Evolution is for trained personnel only.

Personnel operating the Encon Evolution should wear safety glasses, safety shoes and

gloves where appropriate.

The Encon Evolution is not intended for use in a hazardous environment.

Installation of the Encon Evolution requires that there is nothing blocking the vents of the

system.

Installation of the Encon Evolution requires that the instrument be placed on a non-

flammable surface capable of handling the weight of the instrument.

Heaters and heated transfer line(s) require surrounding space to be non-combustible

material.

Sound pressure level of the Encon Evolution is 58db (A).

When cleaning the Encon Evolution please refer to section 4.2 of the User Manual. No

other cleaning agents may be used other than what is specified in this section.

Français

Les avertissements dans le manuel ou sur l'évolution Encon à observer lors de

l'installation , le fonctionnement , le service et / ou la réparation de l'instrument . EST

analytique n'assume aucune responsabilité pour les clients qui ne respectent pas les

consignes de sécurité indiquées .

Utilisation de l'évolution Encon pour autre chose que l'utilisation prévue de l'instrument

est interdite.

L'utilisation de l'Evolution Encon est de personnel qualifié seulement .

Le personnel d'exploitation l'évolution Encon doivent porter des lunettes de protection,

chaussures de sécurité et gants le cas échéant .

Le Encon Evolution n'est pas destiné à être utilisé dans un environnement dangereux .

Installation de l'évolution Encon exige que rien ne bloque les orifices de ventilation du

système .

l'installation de l' Evolution Encon exige que l' instrument est placé sur une surface no n

inflammable capable de supporter le poids de l'instrument.

Chauffe et ligne de transfert chauffée (s) nécessitent de l'espace environnant à un

matériau incombustible .

le niveau de l'évolution Encon de pression acoustique est de 58 dB ( A) .

Lors du nettoyage de l'évolution Encon s'il vous plaît se référer à la section 4.2 du

Manuel de l'utilisateur . Pas d'autres agents de nettoyage peuvent être utilisées autrement

que ce qui est spécifié dans cette section.

See Accompanying Instructions for more Information

Voir les instructions d'accompagnement pour plus d'informations

Indicates an Electrical Hazard

Indique un danger électrique

Indicates Hot Surface

Indique surface chaude

Indicates Bulky/Heavy Item, Use Two Person Lift

Indique objet volumineux / lourds, utilisez deux personnes ascenseur

1.4 Disposal and Recycling Information

United States:

This symbol indicates that your product must be disposed of properly according

to local laws and regulations. When your product reaches its end of life, contact

your local authorities to learn about recycling options.

European Union:

This symbol above means that according to local laws and regulations your product should be

disposed of separately from household waste. When this product reaches its end of life, take it to

a collection point designated by local authorities. Some collection points accept products for

free. The separate collection and recycling of your product at the time of disposal will help

conserve natural resources and ensure that it is recycled in a manner that protects human health

and the environment.

User Manual

Installation and Setup

Chapter 2

2.1 General Information

The system setup and installation is intended to be as thorough as possible. If in doubt at

any point during the installation, please contact EST Analytical toll free at (800) 283-

3510, or outside the United States at (513) 642-0100. If installation is not directed or

performed by EST Analytical personnel, the operator must be thoroughly familiar with

setup and installation sections of this manual.

NOTE: Failure to follow the installation instructions as set forth could result in

damage to the product and nullify the warranty.

2.2 Work Space Requirements

Dimensions: 17”H x 11”W x 16”D (43.2cm x 27.94cm x 40.6cm).

NOTE: Allow for added space on all sides of the instrument for proper ventilation.

The Encon Evolution weighs approximately 45 lbs. (20.4 kg).

2.3 Power Requirements

Voltage:

115/230 VAC (±10%)

50/60 Hz

10/6.3 Amps

15/20A circuit breaker

2.4 Unpacking the Encon Evolution

1. The Encon Evolution is packaged in one carton as shown in Figure 2a containing all

components necessary for instrument installation and operation.

Figure 2a: Shipping Container

2. Before unpacking the Encon Evolution visually inspect the shipping carton for any

damage. If visual damage is present; call EST Analytical at (800) 283-3510 or (513)

642-0100 immediately.

3. Cut the strapping and lift the top box cover off the box and put aside. Lift the outer

box shell off the Encon Evolution and put aside. Remove the excess foam packing

material from the box and put aside.

4. Remove the box inside the main Encon Evolution body. This box contains the

installation kit, monitor, mouse, I/O cable and power cable.

5.

With the help of another person tilt the Encon Evolution gently on one side

and remove the foam inserts. The Encon Evolution is now ready to be placed on the

bench. With one person on each side of the Encon Evolution transfer the Encon

Evolution to the bench.

NOTE: The Encon Evolution needs to be lifted from the base of the instrument.

WARNING: The Encon Evolution needs enough space on all sides of the

instrument to ensure proper cooling of instrument components AND to ensure

that the power cord can be easily disconnected.

AVERTISSEMENT: Le Encon Evolution a besoin de suffisamment d'espace sur

tous les côtés de l'appareil pour assurer le bon refroidissement des composants

de l'instrument et de veiller à ce que le cordon d'alimentation peut être

facilement déconnecté .

NOTE: Please retain all shipping material.

2.5 System Setup

Please refer to Figure 2b for a view of the back panel of the Encon Evolution.

Figure 2b: View of the Encon Evolution’s back panel

2.5.1 Interface Connection

Install the supplied interface cable between the Encon Evolution and Gas

Chromatograph. Call EST at (800) 283-3510 or (513) 642-0100 if you have any questions

about your interface connection.

2.5.2 Monitor Connection

Mount the monitor to the post and tighten the mounting bracket to the hold down post

screw. Plug the VGA cable to the VGA port on the bottom of the monitor. Plug power

cable to the 24 VDC port on the back of the monitor. Note: If optional touch screen

monitor is purchased an additional a 9 pin cable will be included to connect to the

monitor.

2.5.3 Mouse Connection

Place the mouse on the bench and run the cable under the Encon Evolution and out the

back of the instrument. Plug the mouse into the USB connector labeled “Mouse”.

2.5.4 Gas Connections

Pressurization Gas

Connect the 1/8” helium line to the bulkhead of the

Encon Evolution and set the tank pressure between 60-80 psi (414-552kPa).

Carrier Gas

Connect the carrier gas line of the Encon Evolution to the union at the cut in carrier gas

pathway of the gas chromatograph. The heated transfer line will connect to the other end

of the cut in the carrier gas line pathway that is closest to the inlet.

WARNING: The transfer line is heated and needs to be installed so as to keep a

minimum of 10 inches between the transfer line and any adjacent cables or objects.

AVERTISSEMENT: La ligne de transfert est chauffé et doit être installé de manière

à maintenir un minimum de 25.4 cm entre la ligne de transfert et les câbles ou les

objets adjacents.

2.5.5 Power Connection

Plug power cord into the power entry module located on the back of the Encon

Evolution.

WARNING: Ensure proper grounding of the Encon Evolution system before

powering the system up.

AVERTISSEMENT: S'assurer de la bonne mise à la terre du système Encon

Evolution avant de mettre le système en place.

2.5.6 System Power Up

The Encon Evolution is ready for power cycle. Turn on the Encon Evolution and follow

the Encon Evolution Installation checklist below. The power switch is located in the rear

right side of the unit.

NOTE: EST strongly recommends you familiarize yourself with the rest of the

manual before proceeding to the installation checklist. If you have any questions

regarding installation please do not hesitate to call EST Analytical at (800) 283-3510

or (513) 642-0100, or your local authorized dealer.

User Manual

Operation

Chapter 3

3.1 Power On

1. Please read the user manual and become familiar with the operation of the Encon EV

prior to installation of the concentrator. NOTE: Only a trained operator may run

the Centurion.

1. Be sure that all electrical connections are in place and the plumbing connections are

free of gas leaks before powering on the concentrator.

2. Be sure that the pressure of the gas tank or gas line connected to the EV is between 60

and 80psi (414-552kPa), with (80psi 552kPa) being the maximum.

3. Press ON at the power switch located on the right side of the rear panel.

4. The embedded Windows XPe™ operating system will load and then the MCR relay

will load. The MCR relay is a self-loading communication device between the Encon

EV and the Windows XPeTM operating system.

3.2 Open the Encon EV Application

1. The user will control the operation of the Encon EV using the mouse provided or the

touch screen.

2. <click> Encon EV on the desktop.

3. The EST Analytical screen will appear while the application is loading.

4. When the application has loaded, the user will need to input the password in order to

log on. The default password is ESTAnalytical (case sensitive).

5. Finally, the Main screen will be displayed and the Encon EV is ready for operation.

3.3 Power Off

1. From the Main screen <click> Exit, this will close the Encon EV

application.

2. <click> Start from the taskbar.

3. Select shut down.

TM

4. After Windows XPe

off your computer.

5. Press OFF at the power switch located on the right side of the rear panel. NOTE:

Using other means to power off the Encon EV may result in damage to the

operating system.

has shut down it will prompt the user: It is now safe to turn

3.4 The Main Screen

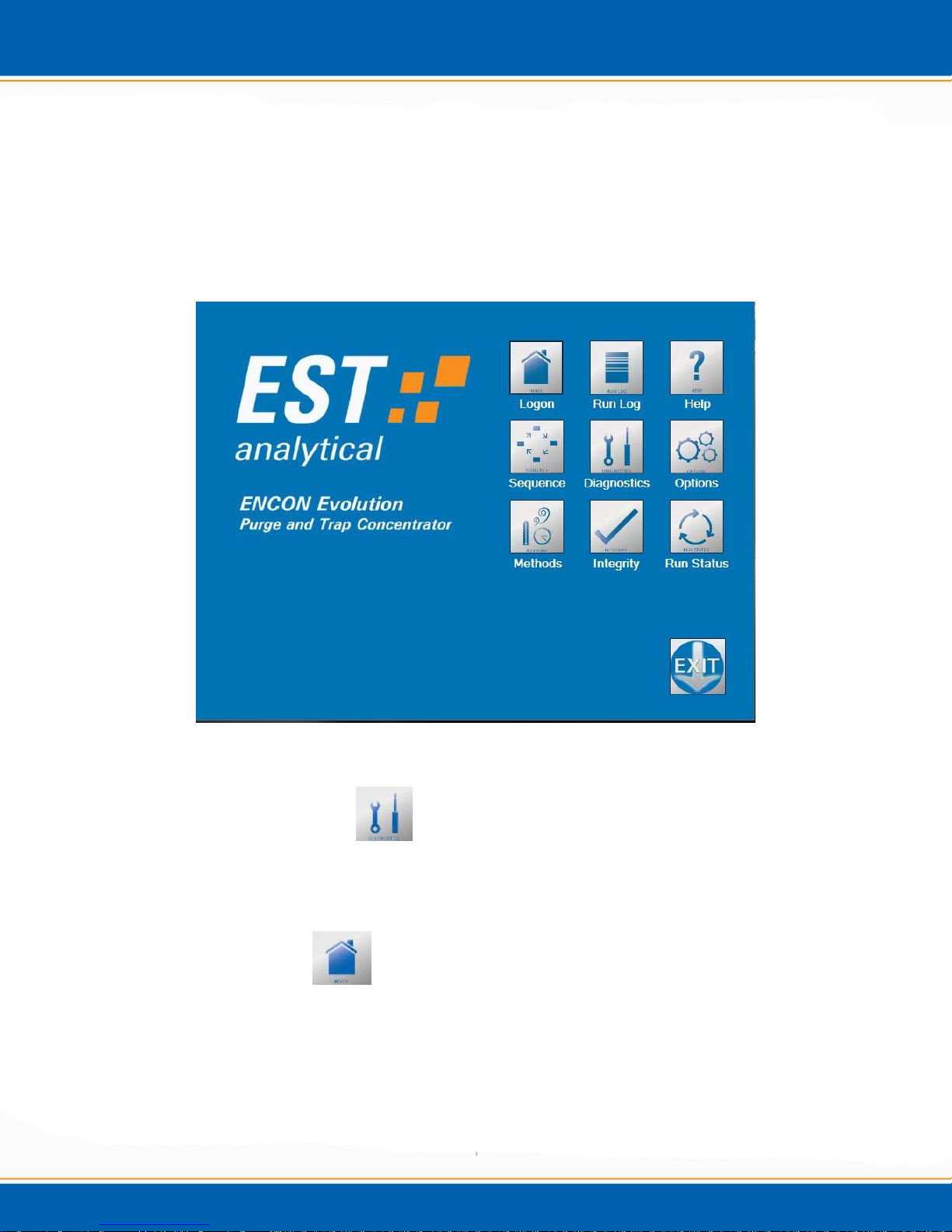

The Encon EV Main screen (shown in Figure 3a) displays a series of icons which allow

the user to navigate through the application, build methods, monitor the status of the

concentrator, trouble shoot and view the status logs. After a screen has been accessed the

icons will be displayed along the left side of the screen to allow the user to simply click

on the icon to load another screen of the program.

Figure 3a: Main screen

3.5 Diagnostics Screen

Refer to Maintenance and Troubleshooting chapter #4 for the Diagnostic Screen

functions.

3.6 Home/Log On

This icon serves a dual purpose. 1) On the Main screen it serves as the user logon icon.

The logon allows for multiple users with various levels of access to the Encon EV

application. 2) To return to the Main screen from any other accessed screen, <click> on

the Home icon and the Main screen will be displayed.

3.7 Exit

The Exit icon is only displayed on the Main screen. The user cannot exit the application

without first returning to the Main screen with the Home icon. To exit the Encon EV

application, <click> Exit icon. This will drop the Encon EV application and return to the

Windows XPe

TM

desktop.

3.8 Options

The Options screen enables all instrument options. To open the Options screen, <click>

the Options icon. The Options screen will be displayed. This screen contains three tabs:

Instrument, System Setup and User Accounts.

Figure 3b: Options screen – Instrument tab

Instrument tab - <click> the Instrument tab, the screen will appear as shown in Figure

3b. This provides information specific to the Encon EV instrument.

Encon Evolution – Listed in the Encon Evolution box is the instrument name, serial

number and software version. This information is used in troubleshooting and generating

key codes for the optional hardware additions to the standard Encon EV platform.

Instrument Options – Listed in the instrument options box are the manufacturer

supplied key codes to activate hardware options.

Figure 3c: Options screen – System Setup tab

System Setup tab - <click> the System Setup tab, the screen will appear as shown in

Figure 3c. From this screen select instrument configurations and settings such as type of

trap, GC ready signal, pressure units, maximum temperatures and to set the trap

maintenance reminder.

Signal setup – The Encon EV can be interfaced to most gas chromatograph (GC)

models. The GC Ready pull down provides the various selections for ready output

signals.

TTL Low - TTL Low must be selected when interfacing with a GC which gives

a high voltage output signal when ready and a low voltage output signal when not

ready.

TTL High – TTL High must be selected when interfacing with a GC which gives

a low voltage output signal when ready and a high voltage output signal when not

ready.

CC Open – CC Open, (Contact Closure), must be selected when interfacing with

a GC which gives a contact open output signal when ready and a contact closure

output signal when not ready.

CC Closure – CC Closure must be selected when interfacing with a GC which

gives a contact closure output signal when ready and a contact open output signal

when not ready.

NOTE: Changing the signal set up settings may require a hardware jumper

change. Please contact Technical Support at 1-800-283-3510.

Gas Type – There are two gas options available from the pull down menu: Helium and

Nitrogen.

I/O Handshaking - There are two I/O Handshaking options available from the pull down

menu: Remote and Local modes.

Remote – When remote mode is selected the Encon EV will only desorb the

sample when a ready signal is received from the GC. If the Encon EV is ready to

desorb and the GC is not ready a Waiting for GC Ready message will be

displayed on the Run Status screen.

Local – When the local mode is selected the Encon EV will not wait for a ready

output signal from the GC before going into desorb.

Pressure Units – All programmable pressure settings can be expressed in units of psi or

kPa. The pressure unit selections are available from the pull down menu.

Trap Name – Using the pull down menu select the type of trap installed in the Encon

EV. The trap type will be displayed on the Run Status and Diagnostics screens.

Trap Ready Max (°C) – This is the maximum temperature value that will be accepted in

an Encon EV method to generate a purge ready signal for the analytical trap chosen. The

temperature is programmable in increments of 1°C using the up/down selection arrows.

Trap Dry Sweep Max (°C) – This is the maximum temperature value that will be

accepted in an Encon EV method for the analytical trap chosen. The temperature is

programmable in increments of 1ºC using the up/down selection arrows.

Trap Desorb Max (°C) - This is the maximum temperature value that will be accepted in

an Encon EV method for the analytical trap chosen. The temperature is programmable in

increments of 1ºC using the up/down selection arrows.

Trap Bake Max (°C) - This is the maximum temperature value that will be accepted in

an Encon EV method for the analytical trap chosen. The temperature is programmable in

increments of 1ºC using the up/down selection arrows.

Set Reminder – A reminder can be programmed to prompt the user to replace the trap on

a selected date, <click> on the check box. From the pull down, a calendar will be

displayed to allow the user to select the future date. After the date has passed a pop up

reminder box will appear when initializing the Encon EV application and every 24 hours

after the date has passed. When the pop up box appears, the user can choose to ignore

this reminder, <click> OK and proceed as usual. The pop up will keep appearing as long

as the enable reminder is set.

Install Trap – After a new trap has been installed, <click> the Install Trap button to

display the install date.

Save – To save the trap setup parameters, <click> the Save button.

Trap Back Pressure – This system pressure is determined from calibrating the purge

flow. When the desired purge flow is established from the Diagnostics screen the

pressure will be displayed in the pressure display pop-up box. This figure must be

manually added to the Trap Back Pressure field.

Figure 3d: Options screen – User Accounts tab

User Accounts - <click> the User Accounts tab, the screen will appear as

shown in Figure 3d. This tab provides the current user logon information

including date, time and duration.

Add – This selection allows for the addition of Encon EV users.

Remove – This selection allows for the removal of Encon EV users.

Properties – This selection allows for the level of access to a specific user. The user(s)

will be identified and set up by the authorized Field Service Engineer during the Encon

EV installation.

3.9 Sequence Screen

The Sequence screen provides the ability to analyze batches of samples using different

Encon EV methods. <click> the Sequence icon, the screen will appear as shown in

Figure 3e.

Line – Ten sequence lines are available for sample analysis by different Encon EV

methods. Ten different methods can be linked together to create a sequence.

Description – User supplied description names.

Method – The drop down lets the user select from the available methods.

Number of samples – The number of samples analyzed per method.

Printing a Sequence -

NOTE: To print, a printer must be interfaced with the Encon EV.

Figure 3e: Sequence screen

<click> on the Printer icon.

Saving a Sequence - <click> on the Save icon and the sequence will be saved.

Open a Saved Sequence - <click> on the Open icon and all previously saved

sequences are available to be loaded.

3.10 Method Screen

The Method screen contains the settings and conditions necessary to create an Encon EV

purge and trap method. <click> the Method screen icon, the Method screen will be

displayed as shown in Figure 3f. Every Encon EV Method screen will consist of two

tabs: Method Setup and Purge & Trap. Each additional option to the Encon EV will

have its own specific tab.

Figure 3f: Method screen – Method Setup tab

3.10.1 Method Setup tab - <click> the Method Setup tab, the screen will appear as

shown in figure 3f. This tab contains the parameters for the operation of the

concentrator.

Overfill – (OPTION, Included with Foam Detector) – In purge ready status, if the sample

failed to drain from the prior run, the Overfill will protect against flooding the Encon EV

with sample. If Overfill is detected, a note will be made in the Run Log.

Foam Sensor – (OPTION) – If selected, during purge a fiber optic beam monitors for

foam in the glassware. If a foamed sample is detected the sample will be drained; the GC

will be sent a start signal to perform a blank run, ensuring the GCs sequence table is

accurate. The sample pathway is then baked out and a notification is written to the

instrument’s sample log.

Automatic Leak Check – This feature provides the ability to leak check the concentrator

prior to beginning a method run. This is a separate function from the manual leak check

(Refer to the Troubleshooting section for manual leak check).

Off – Select Off and the leak check is disabled.

On – Select On and the Encon EV will perform a leak check each time the

concentrator steps from standby status and prior to Ready status.

First Pass – Select this option and the Encon EV will perform a leak check each time a

new sequence line is loaded

GC Cycle Time (min) – This is the time in minutes between the start of a sample desorb

and the time the GC is ready for the next desorb cycle from the Encon EV. This value is

equal to or greater than the sum of the total GC analytical run plus the GC cool down

time and equilibration time. The GC Cycle Time can be set to a value of 0.0 - 999.9

minutes using the up/down selection arrows. Note: The GC cycle time is used when the

GC run time is longer than the purge and trap cycle time or when utilizing the dual

concentrator option of the Encon Evolution system.

Start Delay (min) – This is the time in minutes that the Encon EV will wait until sending

out a ready signal. The start delay time can be set to a value of 0.0 - 999.9 minutes using

the up/down selection arrows.

Economy Mode - During idle instrument time the Encon EV can remain powered on and

programmed to conserve energy and gas. To display the Economy Mode, <click> the

Program button. A screen will be displayed as shown in Figure 3g. Enable the desired

Saver mode(s). Enter the Initiate Time (time after the system becomes ready in which

you wish to enter this mode) in minutes. Enter the reduced Gas Flow if the Gas Saver is

enabled. Once the elapsed initiate time is reached the Economy Mode will go into effect

and the flow will be reduced to the set point and/or the heaters will be disabled. A

caution box will be displayed indicating the Economy Mode is active. To deactivate the

Economy Mode and return to the Standby mode, <click> OK. The Encon EV will

remain in standby until the heated zones reach the set points.

Figure 3g: Economy Mode screen

Standby Flow (ml/min) – The rate at which the gas flows through the sample pathway

while the instrument is in standby and purge ready. This parameter is off (no standby

flow) or on with a programmed value of 0 – 500ml/min using the up/down selection

arrows.

Automatic Drain Sparge Vessel – Select On and the Encon EV will drain the sample

from the sparge tube at desorb. Select Off and the Encon EV will not drain the sample

from the sparge tube.

NOTE: If the drain function is off and the Encon EV has the Sample Heater

option installed and turned on, the sample must be manually drained at desorb.

Bake Gas Bypass – Select Off and during bake the gas flow pathway will be through the

sparge tube. Select On and during bake the gas flow pathway will be diverted and not

flow through the sparge tube.

Transfer Line Temperature (°C) – This is the temperature of the transfer line which

connects the Encon EV to the GC Inlet. This parameter can be set to a temperature

between 35°C and 350°C in 1°C increments using the up/down selection arrows

Valve Oven Temperature (°C) – This is the temperature of the oven which contains the

8 port rotary valve and sample pathway tubing. This parameter can be set to a

temperature between 35°C and 350°C in 1°C increments using the up/down arrows.

Auto Sample Prep Time (min) – When connected to an autosampler, the Encon EV can

be programmed to send out a decoy ready signal to the autosampler to begin the sampling

process before the concentrator reaches the purge ready status and sends out the true

ready signal to the autosampler. This is useful with syringe style auto samplers where it

may take several minutes to complete the transfer of sample from the autosampler to the

Encon EV. This can reduce overall cycle by the time it takes the autosampler to process a

sample.

Mount Temperature (°C) – (OPTION) – This is the temperature of the sample mount.

This parameter can be set to a temperature between 35°C and 100°C in 1°C increments

using the up/down arrows.

Auxiliary Temperature (°C) – (OPTION) – This is the temperature of the auxiliary

heater. This parameter can be set to a temperature between 35°C and 350°C in 1°C

increments using the up/down arrows.

Figure 3h: Method screen – Purge & Trap tab

3.10.2 Purge & Trap tab - <click> the Purge & Trap tab. The screen will appear as shown in

Figure 3h. This tab contains the parameters for the operation of the concentrator in its

various modes: ready, purge, dry purge, desorb and bake.

Trap Ready Temperature (°C) – This is the temperature the adsorbent trap must reach

before going to purge ready status. The adsorbent trap will continue to cool (free fall)

after reaching the set point. The adsorbent trap ready temperature can be programmed to

a value of 25°C to the maximum set point, in 1°C increments.

MoRT Ready Temperature (°C) – This is the temperature the MoRT (Moisture

Reduction Trap) trap must reach before going to purge ready status. When the MoRT

tube temperature is set to 40°C or above the Encon EV will maintain that temperature. If

the temperature is set below 40°C the MoRT tube will continue to cool (free fall) after

reaching the set point. The MoRT tube ready temperature can be programmed to a value

of 25°C to the maximum set point, in 1°C increments.

Purge Flow Rate (ml/min) – This setting is the rate at which the purge gas is

programmed to flow through the sample pathway during purge. The purge flow rate can

be programmed from 1 to 500mL/min in 1mL/min increments.

Programmable Purge Flow Control - <click> the Program button to enable this

feature. This feature can be used to change purge flow rates during the purge cycle. The

screen will appear as shown in Figure 3i. Check the Enable Ramp Control box to

program the desired settings.

Initial Flow (ml/min) – This is the beginning purge flow rate programmed in

ml/min. The initial flow can be programmed from 0 to 500ml/min in 1ml/min

increments.

Initial Hold Time (min) – This is the time in minutes the initial flow is

maintained. The initial hold time can be programmed from 0 to 99.9 minutes in

0.1 minute increments.

Ramp Rate ((ml/min)/min) – This is the rate programmed in ml/min, the purge

flow will increase after the initial hold time has expired to the desired final flow

set point. The ramp rate can be programmed from 1ml/min to 500ml/min in

1ml/min increments.

Final Flow (ml/min) – This is the ending purge flow rate programmed in ml/min.

The final flow can be programmed from 0 to 500ml/min in 1ml/min increments.

Once the desired options are selected, <click> the Exit button to return to the

method parameters page.

Figure 3i: Programmable Purge Flow Control

Final Hold Time (min) – This is not a programmable setting but a function of the

set conditions. The final hold time will be the difference of the final purge time

from the sum of the initial time and the time needed to achieve the final flow rate.

For Example: Total Purge Time = 4 minutes

Initial Flow = 40ml/min

Initial Hold Time = 0.5 minutes

Ramp Rate = 40ml/min per minute

Final Flow = 200ml/min

The Final Hold time at 200ml/min would be 0.5 minutes.

Explanation: It takes 4 minutes to ramp from 40ml/min to 200ml/min at a

rate of 40ml/min per minute. The final hold time is calculated to be 0.5

minutes.

4 minutes – (0.5 minutes + 3 minutes) = 0.5 minutes

Purge Time (min) – This is the length of time for the sample purge. The purge time can

programmed from 0.0 to 999.9 minutes.

Trap Dry Purge Temperature (°C) – This is the temperature of the adsorbent trap

during dry purge. The temperature can be programmed from 25°C to the set point in 1°C

increments.

NOTE: This temperature should be set to below ambient to eliminate the possibility

of analyte migration within the trap prior to desorb.

Dry Purge Flow Rate (ml/min) – This is the rate the pressurization gas flows through

the adsorbent trap during the dry purge process. The Dry Purge Flow Rate can be

programmed from 1 to 500ml/min in 1ml/min increments.

Programmable Dry Purge Flow Control - <click> the Program button to enable this

feature. This feature can be used to change dry purge flow rates during the dry purge

cycle. The screen as shown in Figure 3j will appear. Check the Enable Ramp Control

box to program the desired settings.

Initial Flow (ml/min) – This is the beginning dry purge flow rate programmed in

ml/min. The initial flow can be programmed from 0 to 500ml/min in 1ml/min

increments.

Initial Hold Time (min) – This is the time in minutes the initial flow is

maintained. The initial hold time can be programmed from 0.0 to 999.9 minutes.

Ramp Rate ((ml/min)/min) – This is the rate programmed in ml/min per minute

the dry purge flow will increase after the initial hold time has expired to the

desired final flow set point. The ramp rate can be programmed from 1ml/min to

500ml/min in 1ml/min per minute increments.

Final Flow (ml/min) – This is the ending dry purge flow rate programmed in

ml/min. The final flow can be programmed from 0 to 500ml/min in 1ml/min

increments.

Once the desired options are selected, <click> the Exit button to return to the

Method Screen.

Figure 3j: Programmable Dry Purge Parameters

Final Hold Time (min) – The final hold time will be the difference of the final

dry purge time from the sum of the initial time and the time needed to achieve the

final flow rate.

For Example: Total Dry Purge Time = 5 minutes

Initial Flow = 40ml/min

Initial Hold Time = 0.5 minutes

Ramp Rate = 40ml/min per minute

Final Flow = 200ml/min

The Final Hold time at 200ml/min would be 0.5 minutes.

Explanation: It takes 4 minutes to ramp from 40ml/min to 200ml/min at a

rate of 40ml/min per minute. The final hold time is calculated to be 0.5

minutes.

5 minutes – (0.5 minutes + 4 minutes) = 0.5 minutes

Dry Purge Time (min) – This is the total length of time for dry purge. The dry purge

time can be programmed from 0.0 to 999.9 minutes.

Desorb Pressure Control (psi/kPa) – This pressure setting enables the Encon EV to

equilibrate the concentrator system pressure to that of the GC head pressure prior to

desorb preheat.

Desorb Flow Control (psi/kPa) – DFC is an enhanced feature of EST Analytical’s water

management system. It provides for lower flow through the trap during desorb while

maintaining higher split ratios at the GC inlet. Setpoint is tied to EV pressure and must

be above the initial column head pressure to increase split flow.

Desorb Preheat Temperature (°C) – This is the temperature the adsorbent trap is heated

to before the GC carrier gas is directed to the adsorbent trap to back flush and transfer the

analytes to the GC inlet. This temperature can be programmed from 25°C to the set point

in 1°C increments

Desorb Temperature (°C) – This is the temperature the adsorbent trap maintains during

the desorb process. The temperature can be programmed from 25°C to the set point in

1°C increments.

Desorb Time (min) – This is the total amount of time the GC carrier gas is in line with

the adsorbent trap to sweep the analytes to the GC inlet. The trap desorb time can be

programmed from 0.0 to 999.9 minutes. The Encon EV will send out a start signal to the

GC as soon as desorb starts.

Trap Bake Temperature (°C) – This is the set point temperature of the adsorbent trap

during bake. The trap bake temperature can be programmed from 35°C to the set point in

1°C degree increments.

Programmable Trap Bake Temperature - <click> the Program button to enable this

feature. The screen as shown in Figure 3k will appear. <Check > the Enable Ramp

Control box to program the desired settings.

Initial Temperature (°C) – This is the beginning temperature programmed in °C.

The temperature can be programmed from 25°C to the set point in 1°C

increments.

Initial Hold Time (min) – This is the time in minutes the initial temperature is

maintained. The initial hold time can be programmed from 0.0 to 999.9 minutes.

Ramp Rate ((°C/min)/min) – This is the rate programmed in °C/min per minute

the bake temperature will increase after the initial hold time has expired to the

desired final temperature set point. The temperature can be programmed in

1°C/min to the final temperature set point 1°C/min increments.

Final Temperature (°C) – This is the ending temperature programmed in °C.

The temperature can be programmed from 35°C to the recommended bake

temperature in 1°C increments.

Final Hold Time (min) – The final hold time is not a value to be entered by the

User. The final hold time is the calculated difference of the final bake time taken

from the sum of the initial time and the ramping time needed to achieve the final

temperature.

For Example: Total Bake Time = 10 minutes

Initial Temperature = 200°C

Initial Hold Time = 2 minutes

Ramp Rate = 10°C/min per minute

Final Temperature = 260°C

Final Hold time = 2 minutes.

Explanation: Since it takes 6 minutes to ramp from 200°C to 260°C at a

rate of 10°C/min per minute. The final hold time is calculated to be 2

minutes.

10 minutes – (2 minutes + 6 minutes) = 2 minutes

Once the desired options are selected, <click> the Exit button to return to the Method

Screen.

MoRT Bake Temperature (°C) - This is the set point temperature of the MoRT tube

during bake. The MoRT bake temperature can be programmed from 35°C to the set

point in 1°C increments.

Programmable MoRT Bake Temperature - <click> the Program button to enable this

feature. The screen as shown in Figure 3l will appear. <Check > the Enable Ramp

Control box to program the desired settings.

Figure 3k: Programmable Trap Bake Temperature Control

Initial Temperature (°C) – This is the beginning temperature programmed in

°C. The temperature can be programmed from 25°C to the set point in 1°C

increments.

Initial Hold Time (min) – This is the time in minutes the initial temperature is

maintained. The initial hold time can be programmed from 0.0 to 999.9 minutes.

Ramp Rate ((°C/min)/min) – This is the rate programmed in °C/min per minute

the bake temperature will increase after the initial hold time has expired to the

desired final temperature set point. The temperature can be programmed in

1°C/min to the final temperature set point 1°C/min increments.

Final Temperature (°C) – This is the ending temperature programmed in °C.

The temperature can be programmed from 35°C to the recommended bake

temperature in 1°C increments.

Final Hold Time (min) – The final hold time is not a value to be entered by the

User. The final hold time is the calculated difference of the final bake time taken

from the sum of the initial time and the ramping time needed to achieve the final

temperature.

For Example: Total Bake Time = 10 minutes

Initial Temperature = 200°C

Initial Hold Time = 2 minutes

Ramp Rate = 10°C/min per minute

Final Temperature = 260°C

Final Hold time = 2 minutes.

Explanation: Since it takes 6 minutes to ramp from 200°C to 260°C at a

rate of 10°C/min per minute. The final hold time is calculated to be 2

minutes.

10 minutes – (2 minutes + 6 minutes) = 2 minutes

Once the desired options are selected, <click> the Exit button to return to the

Method Screen.

Figure 3l: Programmable MoRT Trap Bake Temperature Control

Bake Flow Rate (ml/min) – This is the flow rate of the pressurization gas during the

bake cycle. The bake flow rate can be programmed from 0 to 500ml/min in 1ml/min

increments.

NOTE: It is suggested to have a minimum a flow rate of at least 10ml/min

passing through the trap when the trap temperature is above ambient. This will

prevent damage to the trap material.

Programmable Bake Flow Control - <click> the Program button to enable this feature.

The screen as shown in Figure 3m will appear. <Check > the Enable Ramp Control

box to program the desired settings.

Initial Flow (ml/min) – This the beginning bake flow rate programmed in

ml/min. The initial flow can be programmed from 0 to 500ml/min in 1ml/min

increments.

Initial Hold Time (min) – This is the time in minutes the initial flow is

maintained. The initial hold time can be programmed from 0.0 to 999.9 minutes.

Ramp Rate ((ml/min)/min) – This is the rate programmed in ml/min the bake

flow will increase after the initial hold time has expired to the desired final flow

set point. The ramp rate can be programmed from 1 ml/min per minute to 500

ml/min 1 ml/min increments.

Final Flow (ml/min) – This is the ending bake flow rate programmed in ml/min.

The final flow can be programmed from 0 to 500ml/min in 1ml/min increments.

Final Hold Time (min) – The final hold time is not a value to be entered by the

User. The final hold time is the calculated difference of the final bake time taken

from the sum of the initial time and the ramping time needed to achieve the final

flow rate.

For Example: Total Bake Time = 10 minutes

Initial Flow = 40ml/min

Initial Hold Time = 2 minutes

Ramp Rate = 40ml/min per minute

Final Flow = 240ml/min

Final Hold time = 3 minutes.

Explanation: Since it takes 5 minutes to ramp from 40ml/min to

240ml/min at a rate of 40ml/min per minute. The final hold time is

calculated to be 3 minutes.

10 minutes – (2 minutes + 5 minutes) = 3 minutes

Figure 3m: Programmable Bake Flow Control

Once the desired options are selected, <click> the Exit button to return to the

method parameters screen.

Bake Time (min) – This is the total length of time for one bake cycle. The bake time can

programmed from 0.0 to 999.9 minutes.

Bake Cycles – The number of bake cycles for one sample analysis. This can be

programmed from 1 to 10 cycles. After the first bake cycle is completed the trap and

MoRT will cool to approximately 60°C before beginning to heat for the next bake cycle.

Printing the Method - <click> on the Printer icon. The method can be printed if

the Encon EV is interfaced to a printer

Saving the Method -

<click> on the Save icon and the method will be saved.

NOTE: After saving a method, it must be opened to activate.

Open a Saved Method - <click> on the Open icon and all previously saved

Methods are available to be loaded.

Figure 3n: Method screen – Sample Heater tab

3.10.3 Sample Heater tab (Option) – If this Option is installed <click> on the Sam ple

Heater tab. The screen will appear as shown in Figure 3n. This tab contains the

parameters for the operation of the sample sparge tube heater. The sample heater

comes on at desorb and through the bake cycle to reduce carryover from run to

run.

Sample Heater Type – Select On and the heater will be active during the bake

cycle. Select Off and the heater will be inactive during the bake cycle.

Pre Purge Time (min) – The amount of time that the sample is purged with

pressurization gas before the pre heat function begins.

Preheat Temperature (°C) – The temperature applied to the sample in the sparge

tube prior to purge.

Preheat Time (min) – The duration of time, in minutes, that heat will be applied

to the sample in the sparge tube prior to purge.

Purge Temperature (°C) – The temperature applied to the sample in the sparge

tube during purge.

Bake Temperature (°C) – The temperature applied to the sparge tube during

bake.

3.11 Run Status Screen

The Run Status screen contains all the information needed to monitor the Encon EV

during the purge and trap process. <click> on the Run Status screen icon. The Run

Status screen will be displayed as shown in Figure 3o.

Figure 3o: Run Status screen

The Run Status screen displays the current Encon EV instrument settings for real time

monitoring of the concentrator and contains the buttons necessary to apply the Step To,

Start / Stop and Hold functions.

Step To – The Step To button will display the following functions:

Standby

Purge Ready

Purge

Dry Purge

Desorb Ready

Desorb Preheat

Desorb

Bake

Step to Standby With Drain

Step to Bake With Drain

These function keys allows the user to navigate through the entire purge and trap process.

By selecting a step to the desired task the Encon EV will override the current function

that the concentrator is engaged in and proceed to that choice.

Start / Stop –This is a dual function button. <click> the Start button and the Encon EV

will begin the selected P&T method. <click> the Stop button and the P&T method will

be stopped.

Hold – <click> the Hold button and the Encon EV will remain in the mode that it is

currently engaged. A timer will show on the Run Status screen displaying the elapsed

hold time. Also displayed will be the remaining time of the process that is in hold. The

concentrator will remain in hold until the Hold button is clicked again.

Current Run Status and Time Counter – This displays the current status of the Encon

EV and the remaining time of the current function.

Position of 8 Port Valve – The position of the 8 port valve is displayed and the

corresponding flow pathway is shown.

GC Ready / Not Ready – In the upper left corner of the Status screen is an icon of a GC.

When the GC is outlined in green it is ready. When the GC is outlined in red it is not

ready.

Temperatures (°C) – Displayed on the Run Status screen are the actual temperatures of

the absorbent trap, MoRT tube, transfer line, 8 port valve, sample heater and mount.

Pressure (psi or kPa) – Displayed on the Run Status screen are the actual system

pressures in the form of a value and a bar graph.

Flow (ml/min) – Displayed on the Run Status screen are the actual system flows in the

form of a value and a bar graph.

Current Flow Pathway – Displayed on the Run Status screen is the general flow

pathway.

3.12 Active Run Log

The active run log is an automatically updated listing of Encon EV functions performed.

This log will be generated until the Encon EV application is closed. Opening the Encon

EV application will begin a new active run log. The active run can be saved if desired.

The Active Run Log screen will be displayed as shown in Figure 3p.

Printing the Run Log – <click> the Printer icon. The Error Log can be printed if

the Encon EV is interfaced to a printer.

Saving the Run Log – <click> the Save icon. The Error Log can be saved.

Opening a saved Run Log –

logs are available to be viewed.

3.13 Reports Page

Printing the Error Log– <click> the Printer icon. The Error Log can be printed if

the Encon EV is interfaced to a printer.

Figure 3p: Active Run Log screen

<click> the Open icon. All previously saved Error

Saving the Error Log –

Opening a saved Error Log – <click> the Open icon. All previously saved Error

Logs are available to open.

<click> the Save icon. The Error Log can be saved.

3.14 Integrity

This icon is reserved for a feature that may be issued in a future release.

3.15 Help Screen

By placing the cursor and clicking on the Help icon the Help screen will appear as shown

in Figure 3q. The Help screen provides the ability to view help files that are stored

locally on the Encon EV software.

Encon Evolution User Manual – By placing the cursor and clicking on ENCON EV

User Manual the user can view a PDF version of the operation manual.

Encon Evolution Software Update – By placing the cursor and clicking on HOW TO –

Encon Evolution Updates the user can view the instructions to update the Encon

Evolution software.

Encon Evolution Printer Installation – By placing the cursor and clicking on HOW TO

– Encon EV Printer Installation the user can view the printer installation instructions.

Figure 3q: Help Screen

HOW TO - Encon Evolution Update.

The Encon EV update file will either be a ZIP archive or a self-extracting EXE archive.

Encon EV updates may be accomplished through either of the two available USB ports

and a USB memory stick.

ZIP Archive

1. Transfer Encon EV update to USB memory stick from desktop or laptop

computer.

2. Extract zip file on USB memory stick. Extraction will create a folder named

Encon EV Update containing all update files which require transfer to the

instrument.

3. Remove memory stick from computer and insert into USB port on instrument.

4. Open file ReadMeFirst.txt inside Encon EV Update folder and follow instructions

for transfer of applicable update files to instrument.

5. When transfer of update files are complete, open My Computer, right click on

Removable Drive and select Eject.

6. Remove memory stick from USB port on instrument. Encon EV update is now

complete.

EXE Archive

1. Transfer Encon EV update to USB memory stick from desktop or laptop

computer.

2. Remove memory stick from computer and insert into USB port on instrument.

3. Double click on EXE file to start update process. Update process is complete

when a dialog box appears stating Encon EV Updates Complete.

4. Acknowledge dialog box by selecting OK.

5. When transfer of update files are complete, open My Computer, right click on

Removable Drive and select Eject.

6. Remove memory stick from USB port on instrument. Encon EV update is now

complete.

3.16 Recommended Encon Evolution Purge & Trap Parameters

USEPA Method 8260B

Valve Temperature 150oC

Transfer Line Temperature 150oC

Automatic Drain Sparge Vessel On

Bake Gas Bypass Off

Standby Flow Rate On @ 40ml/min

Trap Ready Temperature 35oC

MoRT Ready Temperature 39oC

Purge Flow Rate 40ml/min

Purge Flow Time 11 minutes

Dry purge Temperature Off

Dry purge flow rate 40ml/min

Dry Purge Flow Time 1 minute

Desorb Pressure Control On 5.0 (Note: Set to 1 to 2psi below the inlet head

pressure, no more than 10psi)

Desorb Flow Control Off

Desorb Preheat Temperature 245oC

Desorb Temperature 250oC

Desorb Time 0.5 minutes

Trap bake temperature 260oC

MoRT Bake Temperature 210oC

Trap Bake Flow 85ml/min = 5ml purge volume

30ml/min = 25ml purge volume

Trap Bake Time 6 minutes

Trap Bake Cycles 1

Purge Temperature (option) Off

Sparge Bake Temperature (option) On – Program: 40oC initial, hold for 3 minutes, ramp at

o

C/min to 110oC final temperature

100

Trap Back Pressure Equal to pressure at 40ml/min purge flow

TRAP DESORB, BAKE, AND CONDITION TEMPS (FROM SUPELCO).

User Manual

Maintenance and Troubleshooting

Chapter 4

This chapter contains information necessary to maintain and/or

troubleshoot the EST Analytical Encon Evolution.

The purpose of this Chapter is to familiarize the user with the various integrated maintenance

and troubleshooting functions of the Encon Evolution.

The Encon Evolution will require minimal maintenance of consumable items such as, tubing,

traps, septa, Teflon ferrules, power cord, etc. The interval at which maintenance is required

depends on use and sample types.

In order to maintain the safety integrity provided by the instrument for parts containing liquids,

during maintenance, ONLY use replacement parts provided by EST Analytical.

CAUTION: Before Maintaining and Servicing any component of the Encon

Evolution the instrument must be:

1. Turned off (Note: Windows should be turned off properly.)

2. Disconnected from the Power Supply

3. Hot Surfaces should be given time to cool

4. After servicing instrument, all covers need to be placed back on the instrument.

ATTENTION: Avant de maintenance et d'entretien tout composant de

l'évolution Encon l'instrument doit être:

1. Désactivé (Note: Windows doit être désactivé correctement)

2. Déconnecté de l'alimentation

3. Surfaces chaudes devraient avoir le temps de refroidir

4. Après instrument entretien, tous les couvercles doivent être placés sur

l'instrument.

4.1 Technical Support

To ask technical questions or to obtain technical services please contact EST Analytical:

Within the United States and Canada call toll free: (800) 283-3510.

Outside of the United States and Canada call: Regional Authorized Distributor.

Before calling for technical assistance or onsite service:

Note the serial number of the instrument. (The serial number can be located in the

Option Screen under the Instrument tab or on the back of the unit.)

Note the type of problem you are experiencing and the conditions under which the

problem occurred.

Note the exact wording of the error message (if applicable).

Please have the compact disc manual open and available.

4.2 Cleaning the Encon Evolution

1. Wipe the outside of the Encon Evolution with a clean, damp, lint-free cloth. Cloth

should be dampened with water only. Avoid any cleaning agents that could cause a

hazard as a result of a reaction with parts of the equipment of with the material

contained in it.

2. Use canned air to remove any dust or lint from the fans or inside the unit.

4.3 Trap/MoRT Replacement

1. CAUTION: Make certain the instrument is not running and the trap is cool.

ATTENTION: Assurez-vous que l'instrument n'est pas en cours d'exécution et

le piège est cool.

2. Remove trap MoRT cover(s) on the front of the Encon Evolution. When facing the

EV, the adsorbent trap in on the right and the MoRT is on the left.

Note: Instrument cover/wrap and front panel must be removed for units with a serial

number less than EV252051410.

3. Loosen the nut from the top of trap fitting and the nut from the bottom of trap.

4. Remove the trap insert from the trap heater sleeve coils.

5. Install the new trap by repeating the above steps in reverse order.

6. Verify the Encon Evolution is free of leaks by performing a Leak Check routine

discussed later in this Chapter.

7. Condition the new trap by performing the single button ‘Trap Bake’ routine discussed

later in this Chapter. Please use recommended conditions outlined by the trap

manufacturer. These conditions are included with the new trap.

8. Update the ‘Install Trap’ function in the ‘Options’ page of the Encon Evolution

program and set the reminder to the next scheduled replacement. Refer to the

Operations Chapter for further instructions.

NOTE: Be sure the analytical trap is installed properly with the markings and the

pre-swaged ferrule at the top.

4.4 Diagnostics Screen

<click> the Diagnostics screen icon. The Diagnostics screen will be displayed as shown

in Figure 4a. The Diagnostics screen contains the settings and controls necessary to

manually operate and trouble shoot the Encon EV. It enables the user to leak and flow

check the concentrator. It also displays the various flow pathways. Other functions

include manual activation of the solenoid valves and manual temperature control of the

heated zones.

Figure 4a: Diagnostics screen

4.4.1 Icons

8 Port Valve icon - The 8 port valve can be manually actuated. <click> the 8 Port

Valve icon. When actuated, the flow pathway will change indicating which ports are

connected at that given position. Position A is the sample pathway and Position B is the

desorb pathway.

GC icon - In the upper left corner of the Diagnostics screen is an image of a GC. When

the image is outlined in green the GC is sending out a ready signal. When the image is

outlined in red the GC is sending a not ready signal.

Trap icon - Displays the trap type installed. <click> the Trap icon and the Options

screen will open to the System Setup tab. To return to the Diagnostic screen, <click> the

Diagnostic screen icon.

Sparge Vessel icon - <click> the Sparge Vessel icon and the Pressurization Valve PID

calibration screen will open as shown if Figure 4b.

Figure 4b: Pressurization Valve PID Calibration Screen

Pressure Transducer – The current Encon EV system pressure is displayed in this box.

Current flow – The current Encon EV flow is displayed in this box.

4.4.2 Manual Heater Control

The heated zones, which consist of the Trap, MoRT, Sample (option), Mount (option),

Transfer Line and Valve Oven may be manually heated to a specific set point

temperature. <click> the temperature display box located next to the respective icon for

any given heated zone and the manual temperature control will appear as shown in Figure

4c.

NOTE: The system continuously monitors for over temperature conditions and will

provide a pop-up screen to alert of any over temperature problems.

Figure 4c: Setpoint Temperature screen (Sample Heater)

Current Temperature (°C) – Displays the current temperature.

Setpoint (°C) – Enter the desired set point (SP) temperature.

Heat to SP - <click> the Heat to SP button. The selected zone will heat to the entered

set point. The temperature will be maintained as selected until it is manually changed

again or a method is loaded.

CAUTION: Heating the trap or MoRT tube without flow may damage the trap

sorbent materials or the MoRT tube Silco treated surface.

ATTENTION: Le chauffage du piège ou MoRT tube sans écoulement peut

endommager les matériaux absorbants piège ou le tube MoRT Silco surface traitée.

CAUTION: Manual heating will not recognize maximum temperature set points

(see Operations chapter, Options screen, System Settings tab.)

ATTENTION: chauffage manuel ne reconnaît pas les points de consigne de

température maximale (voir chapitre des opérations, l'écran Options, onglet

Paramètres système.)

4.4.3 Manual Valve Control

NOTE: There are five solenoid valves on a single manifold and six solenoid valves

on a dual manifold system.

Five solenoid valves can be activated from the diagnostic screen. <click> the Flow

(Pressurization) (#1), the Dry Purge (#2), the Vent (#3), the Backflush (#4) and the

Bake (#6) valve(s) to energize or de-energize. If energized, the valve is outlined in red

and the gas flow will follow the appropriate pathway. A de-energized valve will not be

outlined in red and the gas will follow the appropriate pathway. <click> the valve again

to de-energize or energize. The valve(s) will stay in the selected position until manually

changed or a method or a new flow pathway is loaded. NOTE: When de-energized the

valves are normally closed, when energized they are open.

<click> the Flow (pressurization) valve icon and the pressurization valve screen will be

displayed as in shown in Figure 4d.

Figure 4d: Pressurization Valve manual setpoint screen.

Current Flow (ml/min) – Displays the current flow.

Setpoint (ml/min) – Enter the desired flow.

Flow to SP - <click> the Flow to SP button, this will activate the flow to the set point.

The flow will be maintained as selected until it is manually changed again or a method is

loaded.

Exit - <click> Exit to return to the Diagnostic screen.

4.4.4 Flow Pathway Drop Down Menu

Located at the upper right corner, the flow pathway drop down lists the flow pathway

diagrams for standby, purge, dry purge, desorb ready, desorb and bake, as shown in

Figure 4e. Select a pathway and <click>. The appropriate valve(s) will be energized

(outlined in red) and if required the 8 port valve will rotate to the correct position.

NOTE: If a run is in progress the solenoid valve(s) and the 8 port valve will not

change away from the current pathway.

Figure 4e: Diagnostics Screen with Drop Down Menu

4.4.5 Flow

<click> the Flow button. This will open the leak check and pressure check features.

NOTE: It is recommended performing a leak check before proceeding with a flow

check.

NOTE: Flow diagrams of the Leak Check procedure are displayed in Chapter 5,

Figures 5.9 and 5.10.

Leak Check

<click> Leak Check and the process will begin.

1. The concentrator will pressurize to 20psi and then hold for 30 seconds.

+

2. If the concentrator maintains the pressure (

3. If the concentrator fails to reach or maintain the set point the 8 port valve will actuate

and the concentrator will begin a secondary leak check.

/-0.5psi) the leak check passes.

4. Upon completion of the secondary leak check a pop up window will direct the user to

the Log screen to determine the results of the leak check.

If the Leak Check fails, refer to the Leak Check Flow Diagram within this manual

or contact EST- Technical Support at (800) 283-3510 or (513) 642-0111 or your local

authorized service representative.

Flow Check

This check uses the purge flow set in the method parameters. <click> Flow Check and

the process will begin.

1. Use a flow meter to determine the purge flow out of the vent bulkhead on the front of

the unit.

2. If the flow is within +/- 2.0ml/min of the purge flow, <click> Yes and the flow check

passes.

3. If the flow is +/- > 2.0ml/min of the purge flow, <click> No* and the next pop up will

ask if the flow is +/- 5.0 ml/min of the set point.

4. If the flow is within > 5.0ml/min of the purge flow, <click> No* and the flow check

fails. Check for leaks and/or restrictions.

5. If the flow is within <5.0ml/min of the purge flow,<click> Yes and the flow check

will automatically advance to the flow calibration process. See section 4.4.6.

* If the flow is outside of the +/- 2.0ml/min window, the default user does not have

access past step 4.

4.4.6 Flow Calibration

Before performing a flow calibration, the Evolution must pass leak check. After

verifying that the Evolution is leak free, a flow calibration can be done. <click>

Calibration Flow Calibration Instrument Flow. After accessing flow calibration,

see Figure 4f, follow the instructions given. Connect a flow meter to the vent bulkhead.

Choose the calibration flow to be calibrated. Adjust the up/down output arrows so that

the actual flow from the vent bulkhead is the same as the calibration flow point. Save the

calibration. Repeat this process for every calibration flow point to be adjusted. Exit

Flow Calibration and Step to Standby.

4.4.7 Trap bake

This function enables a manual bake of the trap and/or MoRT tube. The sparge vessel

heater (option) will not heat during this process. <click> on Trap Bake. The Manual

Trap Bake screen will appear as shown in Figure 4g.

Figure 4f: Flow Calibration Screen

Figure 4g: Manual trap bake screen.

Bake Time (min) – Set the bake time from 0.0 to 999.9 minutes.

Bake Cycles – Set the number of cycles from 1 to 10. After the bake time is

completed the trap will cool to approximately 65°C before beginning the

next bake cycle.

Trap Bake Temperature (°C) – Set the bake temperature from 35°C to

the method set point in 1°C degree increments.

MoRT Bake Temperature (°C) – Set the bake temperature from 35°C up

to the method set point in 1°C degree increments.

Bake Gas Bypass – Select Off and during bake the gas flow pathway will be through

the sparge tube. Select On and during bake the gas flow pathway will be diverted and

not flow through the sparge tube.

Enable Ramp Control - <click> the Enable Ramp Control button to

program the desired settings. NOTE: Enabling Ramp Control is an

optional function.

Initial Flow (ml/min) – This is the beginning bake flow rate. The initial flow can be

programmed from 0 to 250 in 1 ml/min increments.

Initial Hold Time (min) – This is the time in minutes the initial flow is maintained. The

initial hold time can be programmed from 0.0 to 999.9 minutes.

Ramp Rate ((ml/min)/min) – This is the programmed rate the flow will increase after

the initial hold time. The ramp rate can be programmed from 1 to 500 in 1 ml/min

increments.

Final Flow (ml/min) – This is the final flow rate. The final flow can be programmed

from 0 to 250 in 1 ml/min increments.

Final Hold Time (min) – The final hold time is not an entered value. Final hold time is

the calculated difference of the final bake time taken from the sum of the initial time and

the ramping time needed to achieve the final flow rate.

Example: Total Bake Time = 10 minutes

Initial Flow = 40ml/min

Initial Hold Time = 2 minutes

Ramp Rate = 40ml/min

Final Flow = 240ml/min

Final Hold time = 3 minutes

Explanation: Since it takes 5 minutes to ramp from 40ml/min to 240ml/min at a

rate of 40ml/min. The final hold time is calculated to be 3 minutes.

10 minutes – (2 minutes + 5 minutes) = 3 minutes

Start - <click> Start to begin the manual bake.

Exit - <click> Exit to return to the Diagnostics screen.

NOTE: The remaining bake time and bake cycles will be displayed on the Status

screen and not on the Diagnostics screen.

4.4.8 Calibration

<click> the Calibration button and the following functions will be displayed.

Flow calibration Service only access

Heater calibration Service only access

Pressure calibration Service only access

8 port valve calibration Service only access

Digital input/output calibration Common access

Digital Input / Output - <click> the digital input/output selection. The digital

input/output screen will be displayed as shown in Figure 4h. <click> on any of the

input/output functions. The selected function will be activated or de-activated. When

activated the button is highlighted green, when de-activated the button is highlighted

blue.

Figure 4h: Digital input/output screen (Trap fan, MoRT fan, LED 2 and Purge Ready

activated)

4.4.9 Drain

This option allows you to manually drain the sparge vessel. <click> the Drain button

and the following options will be displayed Drain and Drain w/Bake. Here you can

choose to manually drain the sparge vessel or to drain the sparge vessel and also bake the

traps.

4.4.10 Manual Injection

This function allows you to manually inject your sample directly onto the trap of the