Page 1

SIGA-UM Universal Class A/B Module

Installation Sheet

Personality codes

Use the personality codes described below to configure the

SIGA-UM module. See Table 1 on page 2 for listing

information. See Table 2 on page 8 for personality code

electrical characteristics.

Personality code 1: Alarm - NO latching (Class B). Factory

default. Configures input 1 or 2 for Class B, normally open dry

contact initiating devices (e.g., pull stations, heat detectors,

etc.). When the NO input contact of an initiating device is

closed, an alarm signal is sent to the loop controller and the

alarm condition is latched at the module.

Description

The SIGA-UM Universal Class A/B Module is an addressable

module that you can configure to provide one of the following:

• Two Class B dry contact initiating device circuits

• One Class A dry contact initiating device circuit

• One Class A or Class B notification appliance circuit

• One Class A or Class B verified two-wire (conventional)

smoke detector circuit without dry contact initiating devices

on the same circuit

• One Class A or Class B unverified two-wire (conventional)

smoke detector circuit with or without dry contact initiating

devices on the same circuit

• One Form C dry contact relay output

The SIGA-UM requires two device addresses on the signaling

line circuit (SLC). Addresses are assigned electronically. There

are no addressing switches.

Diagnostic LEDs provide visible indication of the status of the

module:

• Normal: Green LED flashes

• Alarm/active: Red LED flashes

Personality code 2: Alarm - NO delayed latching (Class B).

Same as code 1 except that contact closure must be

maintained for approximately 16 seconds before an alarm

signal is sent. This code is only for use with nonretarded

waterflow alarm switches.

Personality code 3: Active - NO nonlatching (Class B).

Contact closure causes an active instead of an alarm status

and does not latch at the module. Code 3 is typically used for

monitoring fans, dampers, and doors.

Personality code 4: Active - NO latching (Class B). Contact

closure causes an active instead of an alarm status, which is

latched at the module. Code 4 is typically used for monitoring

supervisory and tamper switches.

Personality code 8: Signal - dry contact output. Configures

the module as a Form C dry relay contact to control external

appliances (door closers, fans, dampers) or equipment

shutdown. Note: Jumper JP1 must be moved to pins 2 and 3

for dry contact operation.

Personality code 9: Alarm - NO latching (Class A). Configures

the module for connection of Class A, normally open dry

contact initiating devices (e.g., pull stations, heat detectors,

etc.). When the NO input contact of an initiating device is

closed, an alarm signal is sent to the loop controller and the

alarm condition is latched at the module.

Personality Code 10: Alarm - NO delayed latching (Class A).

Same as code 9 except that contact closure must be

maintained for approximately 16 seconds before an alarm

signal is sent. Code 10 is typically used with waterflow alarm

switches.

Personality code 11: Active - NO nonlatching (Class A).

Same as code 9 except that contact closure causes an active

instead of an alarm status, and does not latch at the module.

Personality code 11 is typically used for monitoring fans,

dampers, and doors.

© 2016 Walter Kidde Portable Equipment, Inc. 1 / 8 P/N P-047550-1726-EN • REV 08 • ISS 05AUG16

Page 2

Personality code 12: Active - NO latching (Class A). Same as

code 9 except that contact closure causes an active instead of

an alarm status, which is latched at the module. Code 12 is

typically used for monitoring supervisory and tamper switches.

Personality code 13: Alarm - two-wire smoke unverified

(Class B). Configures the module for monitoring two-wire

conventional smoke detectors (that do not require alarm

verification) and normally open contact initiating devices (e.g.,

pull stations, heat detectors, etc.) on the same circuit.

Personality code 14: Alarm - two-wire smoke verified

(Class B). Configures the module for monitoring two-wire

conventional smoke detectors (that require alarm verification).

Normally open contact initiating devices may not be mixed with

two-wire conventional smoke detectors.

Personality code 15: Signal - supervised output (Class A).

Configures the module for connection of a Class A output

notification appliance circuit (NAC). Code 15 is typically used

to control bells, speakers, etc.

Personality code 16: Signal - supervised output (Class B).

Configures the module for connection of a Class B output

notification appliance circuit (NAC). Code 16 is typically used

to control bells, speakers, etc.

Personality code 18: Alarm - soft short latching, European

Style C (Class B). A contact closure causes an alarm status

and a short condition causes a trouble status. Personality code

18 is typically used when a short condition must be

distinguished from an alarm condition.

Personality code 20: Alarm - two-wire smoke unverified

(Class A). Same as personality code 13, except that wiring is

Class A.

Personality code 21: Alarm - two-wire smoke verified

(Class A). Same as personality code 14, except that wiring is

Class A.

For personality codes 13, 14, 20 and 21

First SIGA-UM on a loop to go into alarm will maintain the 2

wire detector circuit voltage and current so that the 2 wire

detector can maintain its LED. Second SIGA-UM on the same

loop to get an alarm from a 2 wire detector will indicate the

alarm at the control panel but will reduce voltage and current

on its 2 wire circuit causing the detector LED to turn on and off.

Installation

Install this device in accordance with applicable national and

local codes, ordinances, and regulations.

WARNINGS

• Connecting a device that exceeds this module’s pilot duty

contact ratings may cause activation failure. This module

does not support capacitive loads. See “Specifications” on

page 7.

• The personality code for this device is factory set to 0.

This module will not operate until it is assigned a

personality code of 1, 2, 3, 4, 8, 9, 10, 11, 12, 13, 14, 15,

16, 18, 20, or 21.

• Electrocution hazard. Dangerous voltages may be present

at the module terminals even when power is shut off.

Table 1: Personality code listing information

Code Description UL 864 CAN/ULC-S527 EN 54-18

1 Alarm - NO latching (Class B) (default)

2 Alarm - NO delayed latching (Class B)

3 Active - NO nonlatching (Class B)

4 Active - NO latching (Class B)

8 Signal - dry contact output

9 Alarm - NO latching (Class A)

10 Alarm - NO delayed latching (Class A)

11 Active - NO nonlatching (Class A)

12 Active - NO latching (Class A)

13 Alarm - two-wire smoke unverified (Class B)

14 Alarm - two-wire smoke verified (Class B)

15 Signal - supervised output (Class A)

16 Signal - supervised output (Class B)

18 Alarm - soft short latching, European Style C (Class B)

20 Alarm - two-wire smoke unverified (Class A)

21 Alarm - two-wire smoke verified (Class A)

2 / 8 P/N P-047550-1726-EN • REV 08 • ISS 05AUG16

Page 3

)

(1)

(2)

Notes

• The module is shipped from the factory as an assembled

unit; it contains no user-serviceable parts and should not

be disassembled.

• This module does not operate without electrical power. As

fires frequently cause power interruption, discuss further

safeguards with the local fire protection specialist.

• This module does not support conventional four-wire

smoke detectors.

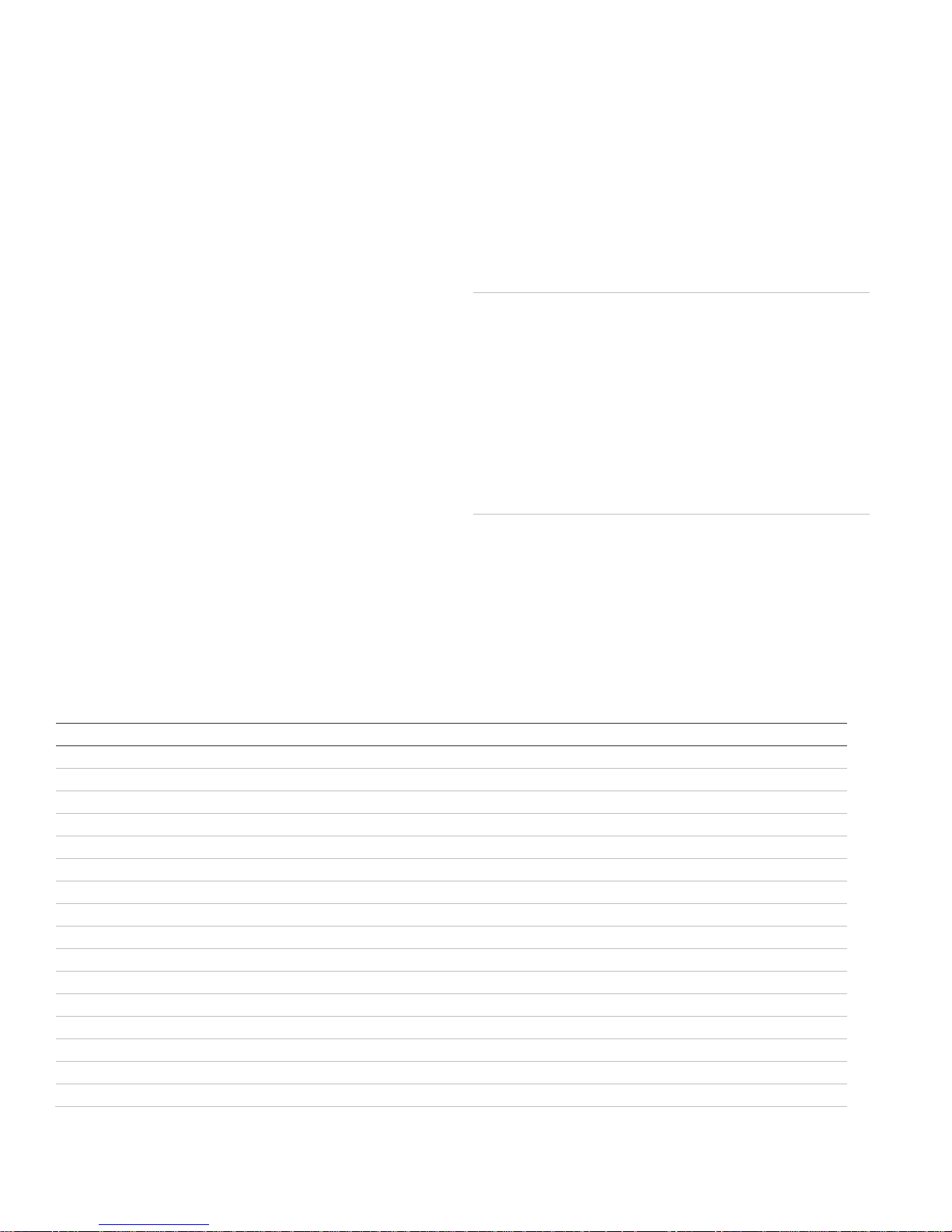

To install the module:

1. Write the address assigned to the module on the label

provided and apply the label to the module. Remove the

serial number label from the module and attach it to the

project documentation.

2. Wire in accordance with “Wiring” below.

3. Using the self-tapping screw provided, attach the wall

plate to the module. See Figure 1.

4. Using the four machine screws provided, attach the wall

plate and module to the electrical box.

Figure 1: Installing the SIGA-UM module

(1)

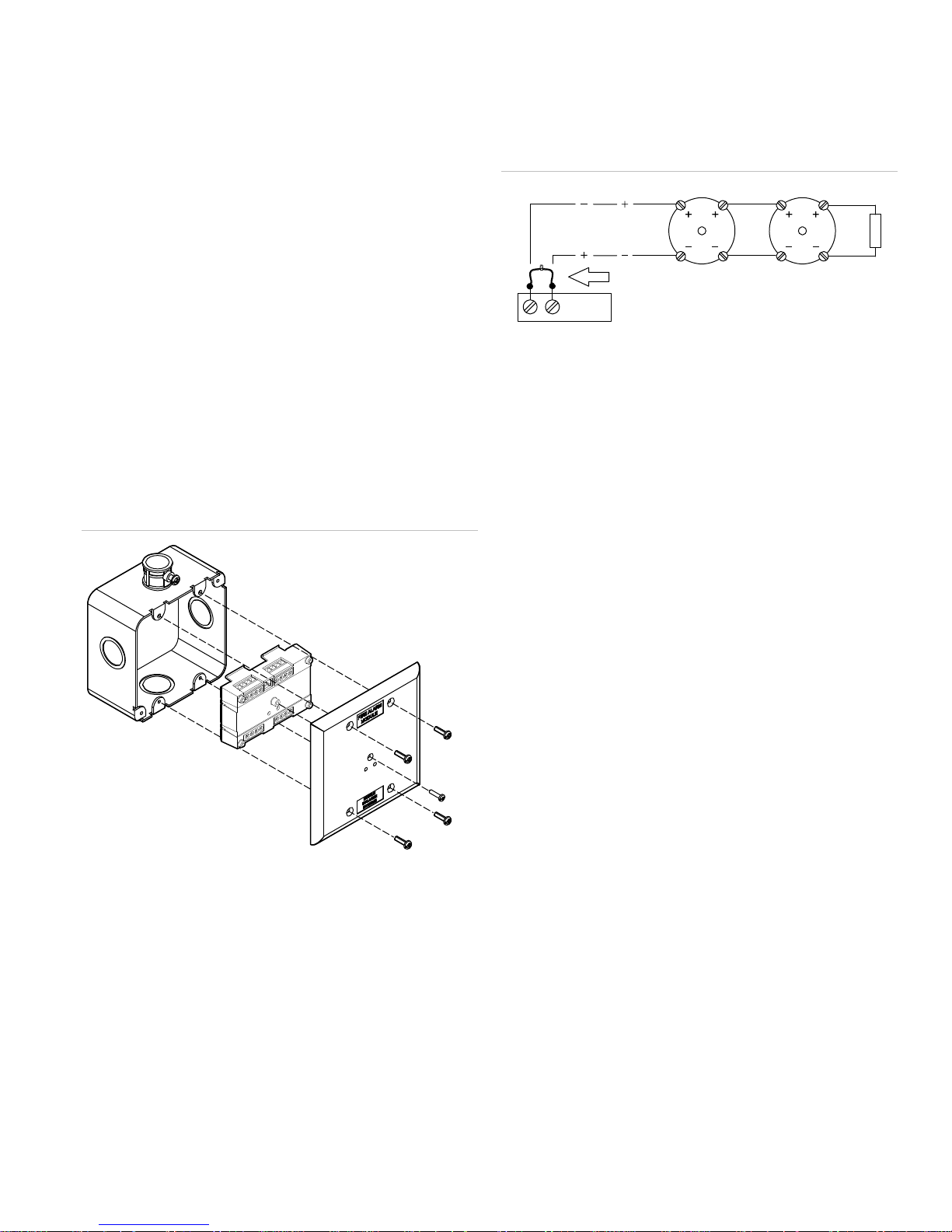

To install a transient protector:

1. Install the transient protector across the output circuit

inside the electrical box with the module. See Figure 2.

Figure 2: Bell circuit showing bipolar transient protector

placement

12 11

(1) Normal state (2) Active state

Wiring

Wire this device in accordance with applicable national and

local codes, ordinances, and regulations.

General wiring notes

• Refer to the Signature loop controller installation sheet for

SLC wiring specifications.

• Each terminal on the module is limited to a single

conductor.

(2)

(3)

(5)

(1) Compatible electrical box

(2) SIGA-UM module

(3) Wall plate

(4) #6-32 × 5/8 machine screw

(4X)

(5) #4 × 1/2 self-tapping screw

Protection from transient spikes

For installations in which the output circuit connects to

electromechanical bells or horns, install a bipolar transient

protector (P/N 235196P) to protect the module from transient

spikes caused by switching inductive loads. Locate bells and

horns at least 6 ft. (1.8 m) from the module.

• Only personality codes 13, 14, 20, and 21 support twowire smoke detectors.

• Test resistors are supplied with the SIGA-UM to prevent

trouble signals on unused circuits during installation.

When connecting field wires, remove the test resistors and

install a UL/ULC Listed 47 kΩ EOLR at the end of the

circuit.

(4

Riser wiring notes

• For maximum line impedance, refer to the installation

manual for the fire alarm panel. Maximum circuit

capacitance is 0.1 µF.

• If the riser is used for more than one notification zone,

install in accordance with the survivability from attack by

fire requirements in NFPA 72 National Fire Alarm and

Signaling Code.

Two-wire smoke detector notes

• A maximum of 15 SIGA-UM modules per circuit can be

configured to support two-wire smoke detectors

(personality codes 13, 14, 20, and 21). However, if a

Signature Series IM module or Signature Series detector

with an isolator base is installed on the SLC, only 7

SIGA-UM modules may be configured to support two-wire

smoke detectors.

• Use compatible smoke detectors. See the control panel

compatibility list for type and quantity.

P/N P-047550-1726-EN • REV 08 • ISS 05AUG16 3 / 8

Page 4

)(1)

(2)

• Polarity at terminals is shown in the supervisory condition.

Connect as shown in the diagram. (Polarity reverses on

alarm.)

• IDC wiring is Style B (Class B) or Style D (Class A).

To wire the module:

1. Verify that all field wiring is free of opens, shorts, and

ground faults.

2. Strip 1/4 in. (about 6 mm) from the ends of all wires that

connect to the terminal block of the module.

When stripping wire ends, exposing more wire may cause

a ground fault; exposing less wire may result in a faulty

connection.

3. Make all wiring connections using the appropriate figure

below for the desired function (personality code). See

Figure 3 to Figure 7.

Figure 3: Class B initiating device circuit (personality codes 1, 2, 3, 4, 18)

(2)

(1)

(1) 47 kΩ EOL resistor (PN EOL-47) used for Class B only

(2) For personality code 18, use a 22 kΩ resistor

(3) Input 2: Typical NO initiating device

(4) Input 1: Typical NO initiating device

(5) 10 VDC at 350 µA max.

(6) Signaling line circuit (SLC) to next device

(7) Signaling line circuit (SLC) from previous device, power-limited

and supervised

(1)

(7)

(4)

+

(3)

(1

(5)

321

JP1

+

(6)

4 / 8 P/N P-047550-1726-EN • REV 08 • ISS 05AUG16

Page 5

1

–

–

Figure 4: Form C dry contact relay (personality code 8)

(1)(2)(3)

NO

NC

C

++

(4)

(5)

(6)

321

(7)(8)

JP

(1) SIGA-UM must be installed in the same room as the device it

controls

(2) Power-limited unless connected to a nonpower-limited source. If

the source is nonpower-limited, eliminate the power-limited mark

and maintain a minimum of 0.25 in. (6.4 mm) space from powerlimited wiring. For other mounting methods, see enclosure and

bracket installation sheets to maintain separation of powerlimited and nonpower-limited wiring. The wire size must be

capable of handling fault current from nonpower-limited source.

— or —

Use type FPL, FPLR, FPLP, or permitted substitute cables,

provided these power-limited cable conductors extending

beyond the jacket are separated by a minimum of 0.25 in.

(6.4 mm) space or by a nonconductive sleeve or nonconductive

barrier from all other conductors. Refer to the NFPA 70 National

Electrical Code for more details.

(3) The relay function is programmable

(4) Normally open

(5) Normally closed

(6) Common

(7) Signaling line circuit (SLC) to next device

(8) Signaling line circuit (SLC) from previous device, power-limited

and supervised

Figure 5: Class A initiating device circuit (personality codes 9, 10, 11, 12)

21

3

JP1

(6)

+

+

(5)

(1) Input 1: Typical NO initiating device

(2) 10 VDC at 350 µA max.

(3) Maximum 12.5 Ω resistance per wire for Class A configurations.

(4) Supervised and power-limited unless connected to a nonpower-

limited source. If the source is nonpower-limited, eliminate the

power-limited mark and maintain a minimum of 0.25 in.

(6.4 mm) space from power-limited wiring. For other mounting

methods, see enclosure and bracket installation sheets to

maintain separation of power-limited and nonpower-limited

wiring. The wire size must be capable of handling fault current

from nonpower-limited source.

— or —

Use type FPL, FPLR, FPLP, or permitted substitute cables,

provided these power-limited cable conductors extending

beyond the jacket are separated by a minimum of 0.25 in.

(6.4 mm) space or by a nonconductive sleeve or nonconductive

barrier from all other conductors. Refer to the NFPA 70 National

Electrical Code for more details.

(5) Signaling line circuit (SLC) to next device

(6) Signaling line circuit (SLC) from previous device, power-limited

and supervised

P/N P-047550-1726-EN • REV 08 • ISS 05AUG16 5 / 8

Page 6

l

1

(

)

(

Figure 6: Two-wire smoke detectors and initiating devices (personality codes 13, 14, 20, 21)

(1) Class A two-wire smoke circuit

(2) Maximum 12.5 Ω resistance per wire for Class A configurations

(3) Class B two-wire smoke circuit

(4) Not allowed with personality codes 14 and 21

(5) UL/ULC Listed 15 kΩ EOLR (PN EOL-15) for Class B only

(6) Smoke detector power (24 VDC) from Signature controller,

SMK, or 2-SMK

(7) Signaling line circuit (SLC) to next device

(8) Signaling line circuit (SLC) from previous device, power-limited

(1)(2)

(3)

+

(5)

-

(4)

+

-

(4)

and supervised

(9) UL/ULC Listed 22 kΩ EOLR (PN EOL-22) for Class A only

(9)

(6)

321

JP

(8)

+

+

(7)

Figure 7: Class A or B notification appliance circuit (personality codes 15, 16)

(1) Class A notification appliance circuit

(2) Class B notification appliance circuit

(3) Signal polarity shown when the circuit is normal. Polarity

(2)(3)(4)(5)

-

+

(4) Use twisted pair wires for speaker circuits. All other circuit types

(7)

(9)

+

+

(1)(3)(4)(5)

-

+

-+

321

JP1

+

+

(5) Supervised and power-limited unless connected to a nonpower-

(8)

(6) 47 kΩ EOLR (P/N EOL-47) used for Class B only

(7) Signaling line circuit (SLC) from previous device, power-limited

(10

(8) Signaling line circuit (SLC) to next device

3

)

1

(

2

)

1

(

1

)

1

)

2

1

(9) Audio riser (from previous device)

(10) Audio riser (to next device)

(11) Power-limited regulated, power supply listed for fire protective

(12) Use twisted pair wires for audio riser. All other riser types use

(13) If using horns while connected to a compatible fire alarm control

reverses when the circuit is active

use untwisted pair

limited source. If the source is nonpower-limited, eliminate the

power-limited mark and maintain a minimum of 0.25 in.

(6.4 mm) space from power-limited wiring. For other mounting

methods, see enclosure and bracket installation sheets to

maintain separation of power-limited and nonpower-limited

wiring. The wire size must be capable of handling fault current

from nonpower-limited source.

— or —

Use type FPL, FPLR, FPLP, or permitted substitute cables,

provided these power-limited cable conductors extending

beyond the jacket are separated by a minimum of 0.25 in.

(6.4 mm) space or by a nonconductive sleeve or nonconductive

barrier from all other conductors. Refer to the NFPA 70 Nationa

Electrical Code for more details.

and supervised

signaling use

untwisted pair.

panel that does not produce a temporal pattern, a CDR-3 bell

coder must be used to comply with ANSI S3.41.This module

does not provide signal synchronization.

6 / 8 P/N P-047550-1726-EN • REV 08 • ISS 05AUG16

Page 7

Specifications

Operating voltage range 15.20 to 19.95 VDC

Current See Table 2 on page 8

Output ratings (special

applications)

24 VDC

25 VRMS audio

70 VRMS audio

End-of-Line Resistor

Circuit capacitance

Initiating device circuit (IDC)

Circuit resistance

Circuit capacitance

Alarm current

Operating voltage

Maximum line impedance Refer to the fire alarm panel

Ground fault impedance 10 kΩ

Compatible smoke detectors Refer to the fire alarm panel

Two-wire smoke ripple voltage 2 VAC

EOLR part numbers

15 kΩ

22 kΩ

47 kΩ

Circuit designation

Signaling line circuit

Notification line circuit

Initiating device circuit

Telephone riser circuit

Contact ratings (pilot duty) 24 VDC at 2 A

Contact type Form C, programmable

Compatible electrical boxes 2-1/2 in. (64 mm) deep double-gang

LPCB/CPR electrical box

Requirements

Minimum size W × H × D

Wire size 12 to 18 AWG wire (1.0 to 4.0 mm)

Operating environment

Temperature

Relative humidity

Storage temperature range −4 to 140°F (−20 to 60°C)

2 A

50 W

35 W

47 kΩ, UL/ULC listed

0.1 µF max.

50 Ω max. (25 Ω per wire)

0.1 µF max.

17 mA max.

16.0 to 24.0 VDC

installation manual

compatibility list.

EOL-15

EOL-22

EOL-47

Class A, Style 6 or Class B, Style 4

Class A, Style Z or Class B, Style Y

Class A, Style D

Class B, Style 4

120 VAC at 0.5 A

box;

4 in. square box, 1-1/2 in. (38 mm)

deep, with a double-gang cover

Plastic box with cover plate, no gaps

or unused holes

3.5 × 3.5 × 1.5 in. (85 × 85 × 38 mm)

32 to 120°F (0 to 49°C)

0 to 93%, noncondensing

Regulatory information

FCC compliance This device complies with part 15 of the FCC

North American

standards

EN 54 EN 54-18: 2005 Input/output devices

EU compliance

CPR certificates 0832-CPR-F0335

Rules. Operation is subject to the following two

conditions: (1) This device may not cause

harmful interference, and (2) this device must

accept any interference received, including

interference that may cause undesired operation.

UL864, CAN/ULC-S527

2002/96/EC (WEEE directive): Products marked

with this symbol cannot be disposed of as

unsorted municipal waste in the European Union.

For proper recycling, return this product to your

local supplier upon the purchase of equivalent

new equipment, or dispose of it at designated

collection points. For more information, see:

www.recyclethis.info.

Contact information

For contact information, see www.est-fire.com.

P/N P-047550-1726-EN • REV 08 • ISS 05AUG16 7 / 8

Page 8

Table 2: Personality code characteristics

Personality code Mode of operation Standby current Activated current EOL resistor

1, 2, 3, 4, 18 Class B initiating device circuit 458 µA 700 µA 47 kΩ

8 Form C dry contact relay 127 µA 120 µA N/A

9, 10, 11, 12 Class A initiating device circuit 307 µA 450 µA N/A

13, 14, 20, 21 Two-wire smoke detectors and initiating devices 3.1 mA

(from 3rd wire)

N/A First UM module to go into alarm (Class A or B) N/A 12 mA smoke detector

N/A Each subsequent UM to go into alarm N/A 100 µA (from data line) N/A

15, 16 Class A or B notification appliance circuit 317 µA 140 µA Class A: N/A

N/A Class A: 22 kΩ

Class B: 15 kΩ

N/A

17 mA contact closure

Class B: 47 kΩ

8 / 8 P/N P-047550-1726-EN • REV 08 • ISS 05AUG16

Loading...

Loading...