Page 1

User Manual

Page 2

Page 3

CONTENTS

INTRODUCTION 7

I. FIRST STEPS WITH PRO-E 9

1. Descriptive diagrams 11

2. Using the edger 13

a. Turning on the edger 13

b. Switching off the edger 13

c. Using the touch screen and keypads 14

d. Edging screen 15

II. EDGING A LENS 17

1. Edger working environment 19

a. Menu screen 20

b. Calling up a shape 22

c. Lens set-up and feeling 22

2. Perform a Beveling 24

a. Automatic beveling 25

b. Legend screen for customized bevels 26

c. Customized beveling 27

d. Modifying the bevel curve 29

e. Modifying the bevel curve at a particular point 30

f. Displacing the bevel curve 31

3. Perform a high-base bevel 32

a. Captioned screens 33

b. High-base beveling 34

4. Perform a Step bevel 40

a. Captioned screens 41

b. Perform a Step bevel 42

5. Grooving 49

a. Automatic grooving 50

b. Customized groove legend screen 51

c. Customised grooving 52

d. Modifying the groove curve 54

e. Modifying a point in the groove curve 55

f. Displacement of the groove curve 56

6. Produce a Flat-edge finish 56

7. Do a mixed job 57

a. Legend screens 58

b. Configuring the mixed finish 60

8. Perform a Drilled job 62

a. Automatic drilling 63

b. Legend screen for customized drilling 64

c. Customized drilling 65

9. Perform a Polishing 67

10. Chamfering 67

11. Perform a Retouching 68

USER MANUAL> CONTENTS

Page 4

12. Perform a “Super Chamfer” (Pro-E 700) 70

13. Perform a Chemistrie TM job (Pro-E 700) 72

a. Prerequisites 72

b. Preparing a Chemistrie TM job 73

c. Prepare the Chemistrie TM lenses 77

d. Cut a Chemistrie lens 78

14. Carry out a Half Jacket job (Pro-E 700) 81

a. Outline the step bevel trajectory on a Half Jacket shape 81

b. Finalize the step bevel settings in “front surface follow-up” mode 94

c. Modify the shape on Essibox 96

15. M’EYE Sign feature (Pro-E 700) 100

a. To prepare the engraving 100

b. Performing engraving 112

c. Setting up the favorites 116

16. M’EYE Touch feature (Pro-E 700) 117

a. On Essibox 118

b. On the edger 125

III. PREPARING A DRILLED JOB 127

1. Menu screen 129

2. Configuring a drilling point 130

a. Creating a drilling point 131

b. Dimensioning a drilling point 131

c. Adjusting the position of a drilling point 132

IV. CONFIGURING THE EDGER 137

1. Configure the edger 139

a. Time, date and language 139

b. Connections 140

c. Screensaver 141

2. Adjusting the precision of the edger 141

a. Adjusting the diameter of the finished lenses 141

b. Adjusting the position of the bevel and groove 142

c. Adjusting the diameter of drill-holes 143

d. Adjusting the chamfer 144

e. Adjusting the groove 145

f. To adjust the engraving 146

g. Adjust the position of high-base bevel 147

h. Adjust the position of the step bevel 149

3. Restore the factory settings 150

V. MAINTENANCE & SERVICING 151

1. Carrying out the autotests 153

2. Calibrating the touch screen 154

3. Consulting the preventive maintenance screen of the “small tools” module 155

4. Changing or cleaning the edger tools 158

a. Changing or cleaning the drill bit 159

b. Changing or cleaning the mill bit 162

c. Changing the chamfering wheel 165

d. Install and change the step bevel ++ tool 168

e. Installing and changing the engraving tip 171

USER MANUAL> CONTENTS

Page 5

5. Statistics and technical log 174

a. Edger cycles 174

b. Technical log and errors 175

6. Maintaining and cleaning the edger 176

a. Precautions required 176

b. Clean the door, the “small tools” module and the wheels 176

c. Dress the wheels 178

TECHNICAL DATA 181

1. Edger 183

2. Environment 185

GENERAL INFORMATION 187

1. Symbols 189

2. Modifications 189

3. Declaration of conformity 190

4. Copyright 190

5. Materials and products 190

6. Safety instructions: 190

7. Electromagnetic waves 191

8. License agreement for M’EYE Sign™ (Engraving) software 191

a. General information 191

b. Accepted use of the Software and restrictions 192

c. Liability 192

d. Disclaimer of warranties 192

e. Limited liability 192

f. Termination 192

g. Applicable law 193

h. Entirety of the agreement; authentic language 193

GLOSSARY 195

USER MANUAL> CONTENTS

Page 6

Page 7

INTRODUCTION

To take full advantage of the features on your Pro-E 600 edger, we encourage you to read through the entire

manual.

You need to have at least memory version:

• V 3 for Pro-E 600,

• V 3 for Pro-E 700.

USER MANUAL> INTRODUCTION

7

Pro-E 600_Pro-E 700 > v1 -10.18

Page 8

Page 9

I. FIRST STEPS WITH PRO-E

Page 10

Pro-E 600_Pro-E 700 > v1 -10.18

10

USER MANUAL> I. FIRST STEPS WITH PRO-E

Page 11

This chapter contains all the information relating to the first use of the edger:

• Description of the edger (F p.11)

• Using the device (F p.13)

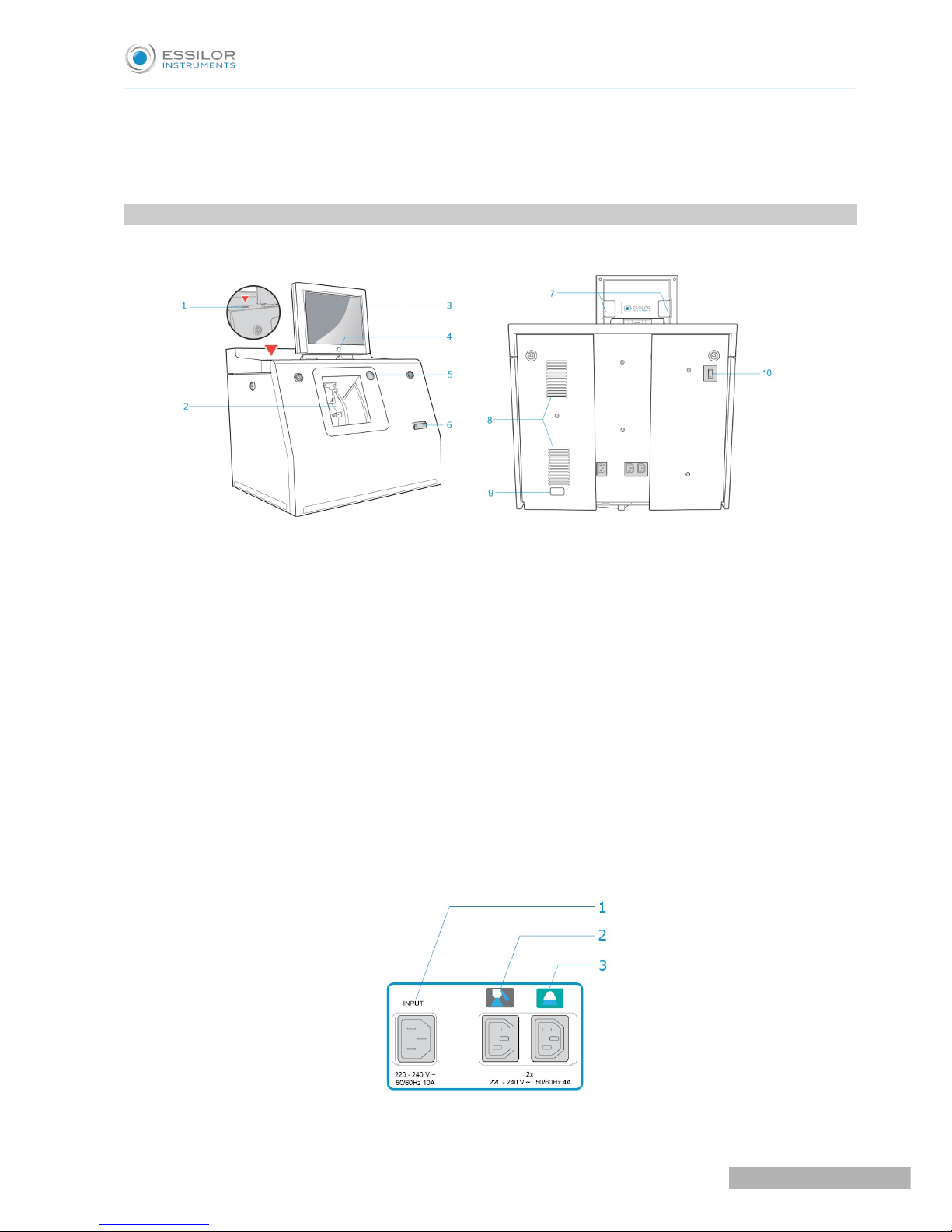

1. DESCRIPTIVE DIAGRAMS

This section consists of descriptions and lists of accessories.

1. USB plug

2. Trough

3. Screen

4. ON/OFF button

5. Cycle start/stop button

6. Barcode reader

7. Screen tilt buttons

8. Fans

9. Manufacturer plate

10. Main switch

Connectors

USER MANUAL> I. FIRST STEPS WITH PRO-E

11

Pro-E 600_Pro-E 700 > v1 -10.18

Page 12

1. Power socket

2. Solenoid valve socket

3. Pump socket (tank + pump) / Solenoid valve socket (town)

Accessories

Stylus

Posiblock removal pliers

Triangular key

White dressing stone for finishing wheel

Square dressing stone for polishing wheel

Transport wedges to be kept

Accessory box

Use :

• 22 mm posiblock holder

• 18 x 14 mm posiblock holder

• 22 mm stop

• 18 x 14 mm stop

• Mill/drill bit replacement tool (blocking key)

• Ø 1.0 mm drill bit (quantity 2, including one mounted on the module)

• Ø 0.8 mm drill bit (quantity 2)

• Ø 1.5 mm edging mill bit (quantity 2, including one mounted on the module)

• Ø 20 mm grooving wheel

• Chamfering wheel

• Step bevel wheel

• Torque wrench

• High-base edging wheel

• Metal ruler

• Modeling clay

• Description pamphlet of the accessories box

Maintenance

• Blocking key for tool changes (drill bit/mill bit)

• Adjustable wrench for tool changes (drill bit/mill bit)

• Accessory for Step bevel wheel assembly/dismantling

• Adjustable wrench for tool changes (drill bit, mill bit, chamfering wheel)

Options

• Open or closed circuit spraying kit

• Milling chip recovery tray

• Posiblock holder and “Weco” posiblock stop accessory kit

• M’Eye Sign Box

• Essibox

Connection accessories

• 220 V power cable

• RJ45 cable for the tracer-edger connection

• Essibox connection cable

Pro-E 600_Pro-E 700 > v1 -10.18

12

USER MANUAL> I. FIRST STEPS WITH PRO-E

Page 13

• Wastewater evacuation pipe with attachment ring

• 2 connectors to clip onto two internal water pipes and connect to the rinsing kit

2. USING THE EDGER

In this section, you will find all the information concerning the following:

• Turning on (F p.13) andoff (F p.13) the edger,

• the use of the touch screen and the keyboards (F p.14),

• the description of the work screens of the edger (F p.15).

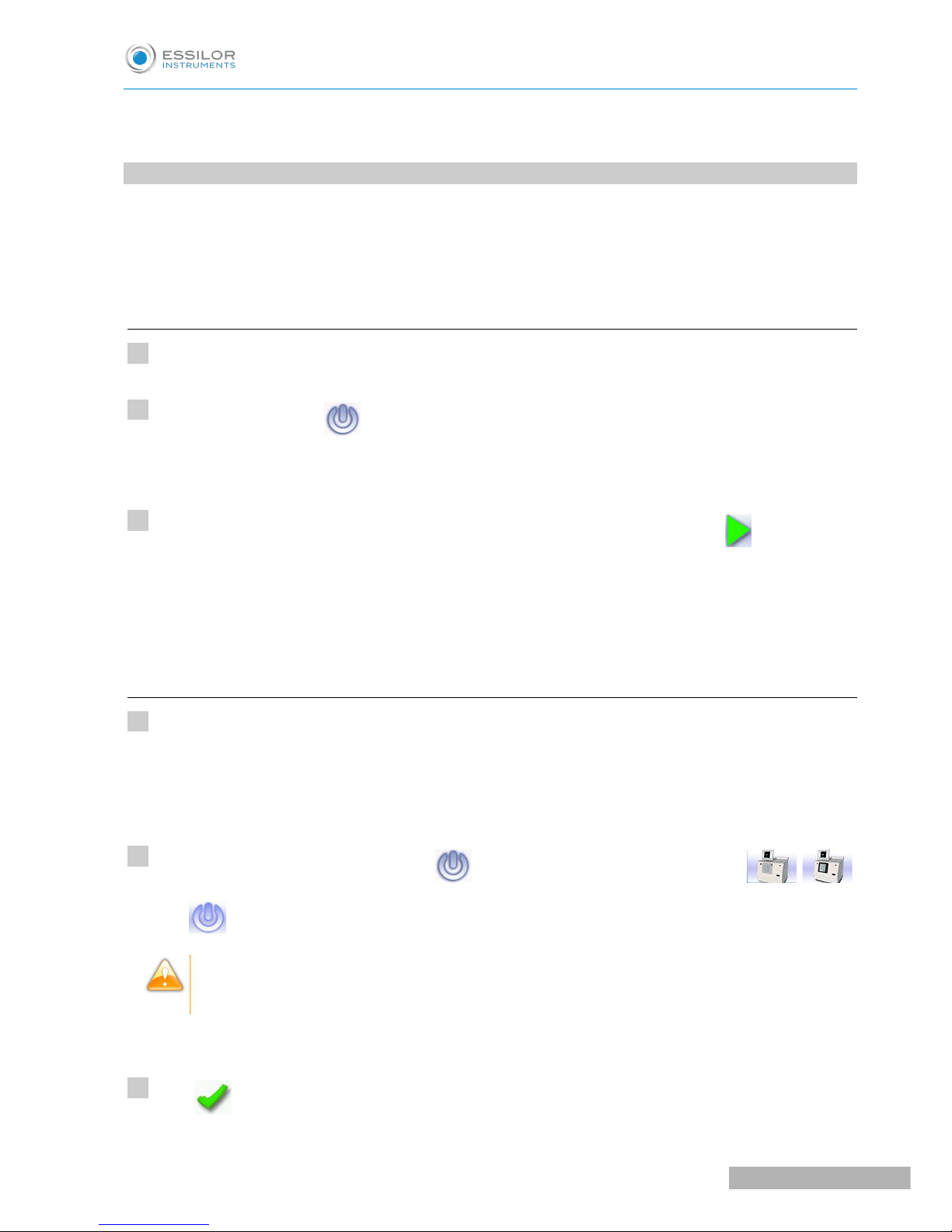

a. Turning on the edger

Press the main switch, located behind the edger on the left, to power it up.

Press the ON/OFF button located under the touch screen.

The edger will initialise.

On the edger screen, press on the “cycle start” button on the front surface or on the icon to end the

initialization phase.

A beep indicates that initialization was successful.

The edger is ready for use when the initial screen is displayed.

b. Switching off the edger

Before switching off the edger:

• Check that there is no glass in the trough

• Check that the lens clamp shafts are loosened and that the trough door is open

• Go to the edging screen.

Press the ON/OFF button for a short time located under the touch screen or press / ,

then .

Do not press the ON/OFF button for several seconds. This would result in shut-down of the

machine and an error message would be displayed at the next switch-on.

A confirmation message is displayed on the screen.

Press to confirm.

>

>

>

1

2

3

1

2

3

USER MANUAL> I. FIRST STEPS WITH PRO-E

13

Pro-E 600_Pro-E 700 > v1 -10.18

Page 14

The edger will switch off.

Extended period of non-use

For a prolonged period of non-use (a few days), it is preferable to turn off the edger using the main

switch.

It must be turned off at least once a week.

c. Using the touch screen and keypads

Using the touch screen

Use the stylus supplied with the machine to use with the touch screen.

You can also touch the screen with your finger.

• If the screen is not sensitive enough to finger pressure, press lightly with a fingernail.

• If the response area does not correspond to the position of the key, you need to calibrate the touch

screen. For further information, refer to the section Maintenance and servicing > Check and calibrate

> Calibrate the touch screen (F p.154).

• Never press hard on the screen as this could break it.

• Never press on the screen with sharp objects such as pens, scissors, clamps, etc.

• Screen breakage is not covered by the guarantee.

On the screen, press the icon buttons to access the desired menus and job functions .

Using the keypads

When you need to enter or modify data, two types of keypads are automatically displayed, according to the

information to be entered.

• The numeric keypad is displayed for entering values.

• Reset the fields

• Go back

• Cancel and go back to the work screen

• Confirm

>

Pro-E 600_Pro-E 700 > v1 -10.18

14

USER MANUAL> I. FIRST STEPS WITH PRO-E

Page 15

• The alphanumeric keypad is displayed to save or search for jobs.

• Job ID

• Job reference (alphanumeric characters)

• Collection list (when the edger is connected to a Essilor range tracer)

• Job list

&

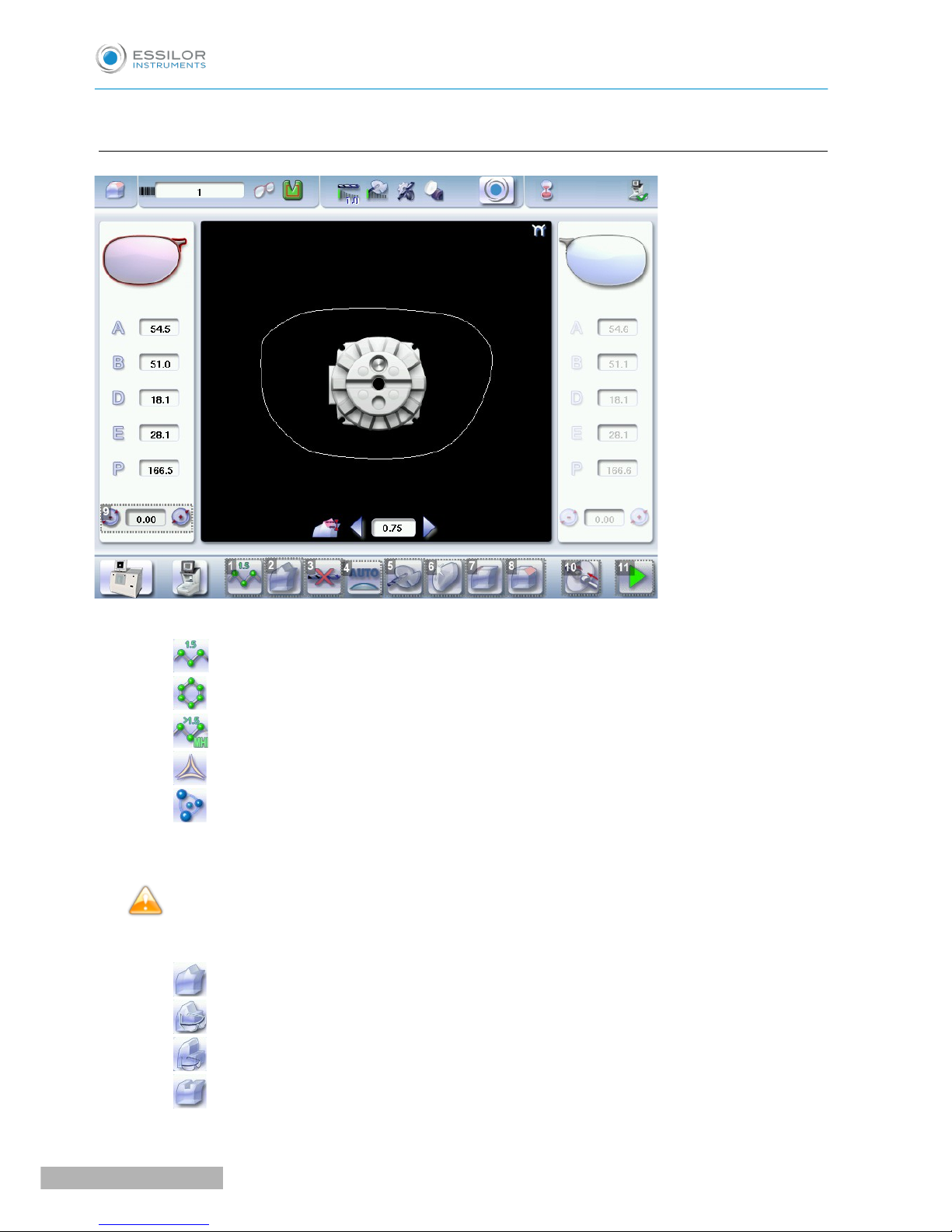

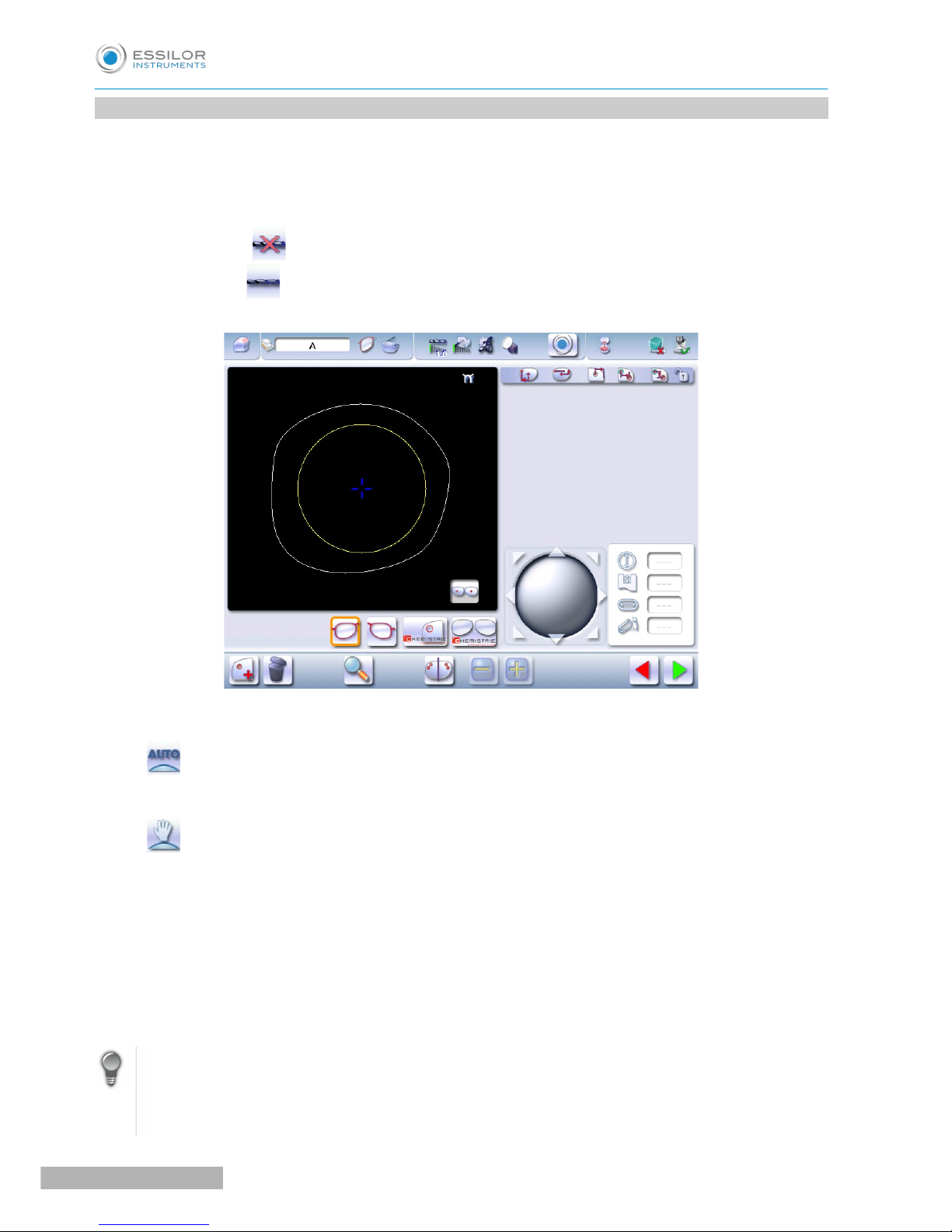

d. Edging screen

1. Work screen indicator

2. Tool wear indicator

3. Settings

4. Devices connected

5. Active eye

USER MANUAL> I. FIRST STEPS WITH PRO-E

15

Pro-E 600_Pro-E 700 > v1 -10.18

Page 16

6. Information on the shape

7. Size increase/reduction

8. Work area

9. Turning off the product/edging screen

or

10. Job call: Tracer menu

11. Actions available for the current screen

12. Start the edging cycle

Detailed functions

For more information, consult the section Edging a lens > Work environment of the edger > Captioned

screen. (F p.20)

Pro-E 600_Pro-E 700 > v1 -10.18

16

USER MANUAL> I. FIRST STEPS WITH PRO-E

Page 17

II. EDGING A LENS

Page 18

Pro-E 600_Pro-E 700 > v1 -10.18

18

USER MANUAL> II. EDGING A LENS

Page 19

This chapter describes the work environment of the edger and the procedures for edging any type of lens:

• Edger working environment (F p.19)

• Perform a Beveling (F p.24)

• Beveling for a high-base frame (F p.32)

• Perform a Step bevel, (F p.40)

• Grooving (F p.49)

• Produce a Flat-edge finish (F p.57)

• Do a mixed job (F p.57)

• Perform a Drilled job (F p.62)

• Perform a Polishing (F p.67)

• Perform a Chamfering (F p.67)

• Perform a Retouching (F p.68)

• Perform a “Super Chamfer” (F p.70) (Pro-E 700)

• Perform a Chemistrie job (F p.72) TM (Pro-E 700)

• Perform a Half-Jacket job (F p.81) (Pro-E 700)

• Create an engraving or a creative shape (F p.100) (Pro-E 700)

1. EDGER WORKING ENVIRONMENT

This section describes the edger working environment and the initial stages of the edging of a lens.

• Description of the edging screen (F p.20)

• Shape call-up procedure (F p.22)

• Putting the lens in place (F p.22)

USER MANUAL> II. EDGING A LENS

19

Pro-E 600_Pro-E 700 > v1 -10.18

Page 20

•

a. Menu screen

1. Lens material

◦ Plastic lens -index 1.5

&

◦ Polycarbonate lens

◦ Medium or high index plastic lens - index > 1.5

◦ Trivex lens

TM

◦ Tribrid lens

TM

The configuration of the edging cycles depends on the type of material. An incorrect choice may result in

material damage.

The Pro-E 600 edger does not edge glass lenses.

2. Type of finish

◦ Bevel

◦ High-base bevel

◦ “Step”/“Half-Jacket” bevel

◦ Groove

Pro-E 600_Pro-E 700 > v1 -10.18

20

USER MANUAL> II. EDGING A LENS

Page 21

◦ Flat-edge finish

◦ Mixed job

3. Drilling

◦ Drilling enabled

◦ Drilling disabled

4. Edging mode

◦ Automatic mode

The finish parameters are automatically calculated according to the information acquired when

tracing the frame and feeling the lens.

◦ Customized mode

The finish parameters can be fully customized.

5. Type of cycle

◦ Milling cycle

This cycle is recommended for lenses with a hydrophobic coating. It works with all types of

materials. Milling involves a specific feeling cycle: the edger will feel the contour of the shape to

be edged twice, then four feeling operations will be required every 90° to define the segments to

be cut.

◦ 2 stars Cycle

For all types of material. This cycle offers a more sophisticated edging mode than the standard

cycle, dedicated to thin lenses or to hydrophobic lenses when milling is not possible (lens too

quick for example).

◦ Standard cycle

For all types of material.

6. Polishing

◦ Polished lens

◦ Non-polished lens

7. Front surface chamfering

◦ Small chamfer

◦ Large chamfer

◦ No chamfering

8. Rear surface chamfering

◦ Small chamfer

◦ Large chamfer

USER MANUAL> II. EDGING A LENS

21

Pro-E 600_Pro-E 700 > v1 -10.18

Page 22

◦ No chamfering

9. Size reduction/increase (mm)

10. Manual lens clamping

Press and hold to close the lens clamp shafts manually.

11. Start the edging cycle

The door closing and lens clamping are automatic.

Function also available via the “cycle start” button on the front surface.

Always browse from left to right: depending on your selection, certain menus will be available while

others will not.

Your habits taken into account

The edger memorizes your working habits: as time goes by, the buttons of the functions you use most

often will be displayed by default.

b. Calling up a shape

There are 3 ways of calling up the shape you want to edge:

• Calling up the current job:

> Press to display the shape being processed on the tracer.

• Calling up the number of a shape saved on the tracer:

> Press for a few seconds to open the numeric keypad.

> You can then call up a shape via the ID allocated to it.

• Job call via a barcode:

> Scan the barcode using the barcode reader (optional).

Always lock down your 2 lenses before proceeding with the edging. If a job in the course of modification on

the tracer (display of the symbol beside the reference) is called up on the edger, a warning message is

displayed.

> Press to continue and display the job on the edger. The modifications underway are then ignored.

> Press to prevent the display of the job and finish the modifications underway on the tracer.

A reminder of the type of posiblock required is displayed on the shape. It is crucial to use the proper

accessory to edge the lens. Otherwise, an error message is displayed at the start of the cycle.

c. Lens set-up and feeling

Prerequisite: the lens must be centered and blocked before placing it in the edger.

Pro-E 600_Pro-E 700 > v1 -10.18

22

USER MANUAL> II. EDGING A LENS

Page 23

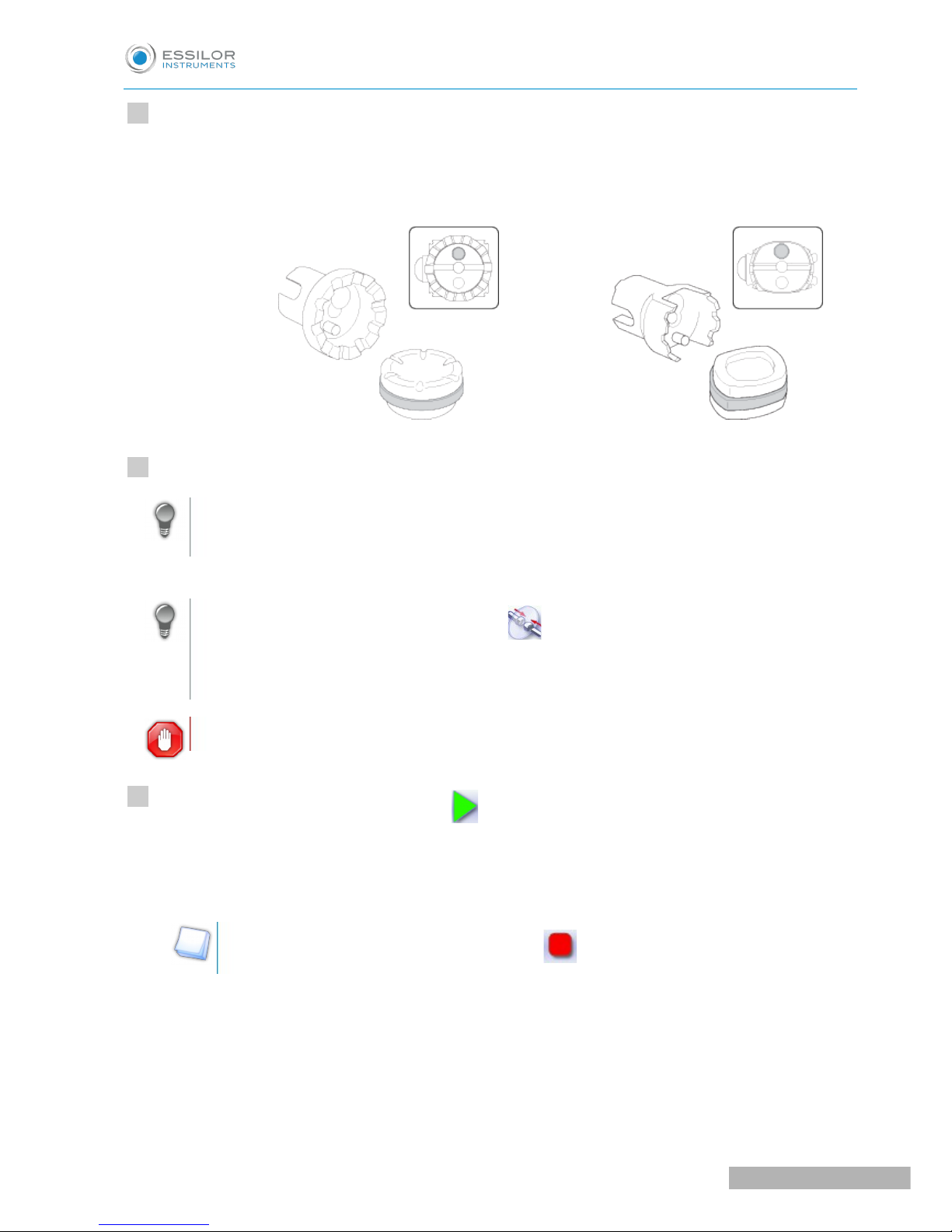

Check that the posiblock holder and the stop correspond to the posiblock used. Otherwise, you will need

to remove them from the lens clamp shafts and replace them with the tools matching the diameter of the

posiblock.

• For a 22 mm posiblock • For an 18 × 14 mm posiblock

Place the lens in the posiblock holder.

Place the metal peg of the posiblock upwards and the positioner downwards: a magnet is used to

hold the lens in position on the axis.

You can clamp the lens manually by pressing . Manual lens clamping is particularly suited to

hydrophobic lenses, thick lenses and high-camber lenses, as it ensures that the lens won't come

off the pad before clamping.

Make sure you move your hand well away before you start the edging cycle.

Press the “cycle start” button (front face) or

The door closes then the lens clamping operation starts.

The size of the posiblock holder is checked then the feeling cycle starts.

To interrupt the feeling cycle at any time, press .

>

>

1

2

3

USER MANUAL> II. EDGING A LENS

23

Pro-E 600_Pro-E 700 > v1 -10.18

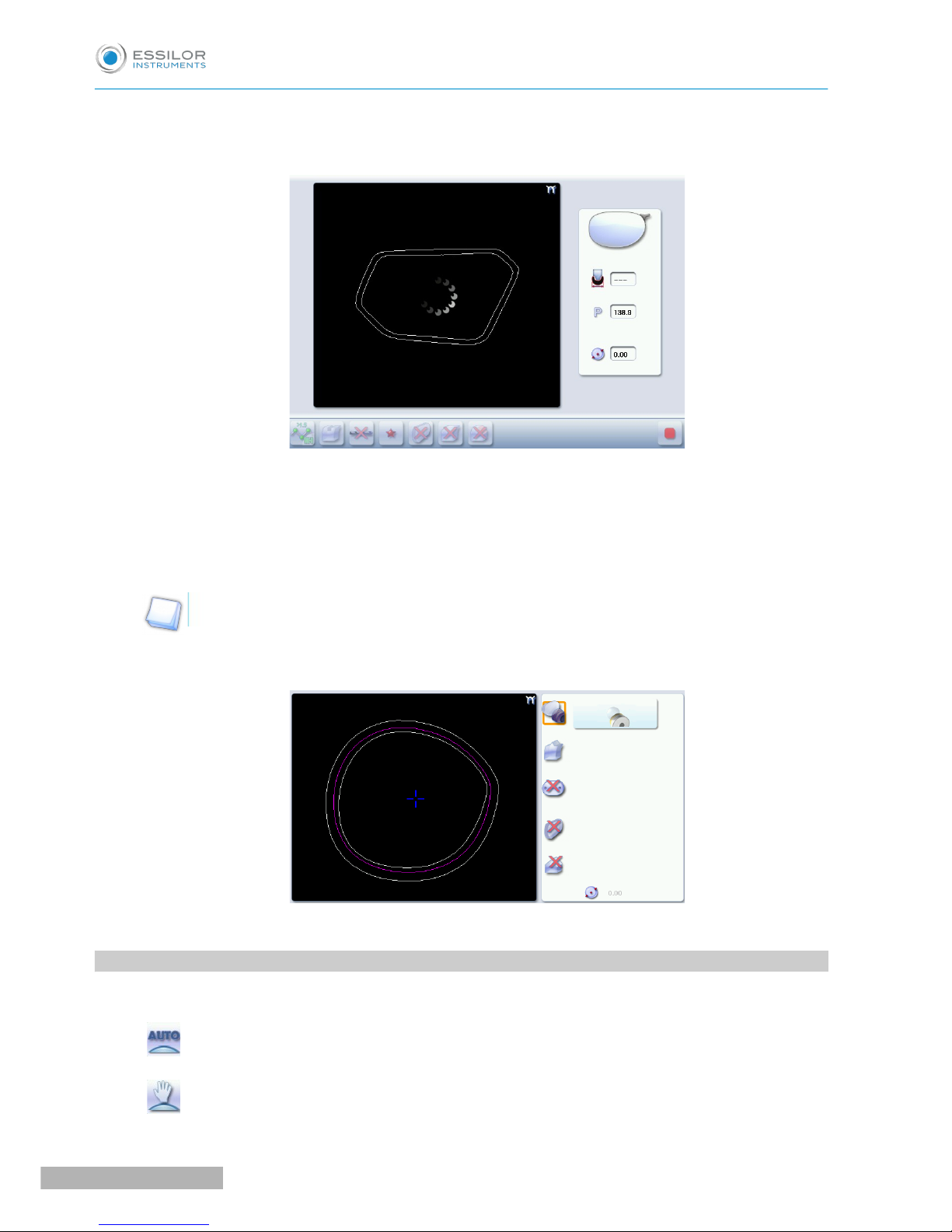

Page 24

As the lens is felt, its shape appears on screen. The double tracing represents the profile of the front

surface of the shape (inner shape) and its rear surface (outer shape).

In the case of edging mode selection:

• automatic, you do not have to configure anything, all the data is automatically recovered from

the tracer. The lens edging starts automatically after the feeling cycle.

• customized, the finish parameters can be fully customized.

For further information, refer to the section concerning your type of finish.

The different lens edging stages appear on the screen.

2. PERFORM A BEVELING

This section describes the procedures for the creation of a bevel:

• In automatic mode (F p.25), you do not have to configure anything. All the data is automatically

retrieved from the tracer. The lens edging starts automatically after the feeling cycle.

• In customized mode (F p.27), you can opt for front/rear surface tracking, a distributed bevel,

lens curve tracking or frame rim tracking. You can also do the following:

>

>

>

Pro-E 600_Pro-E 700 > v1 -10.18

24

USER MANUAL> II. EDGING A LENS

Page 25

◦ a general modification of the bevel curve (F p.29)

◦ a modification at a point of the bevel curve (F p.30)

◦ a displacement of the bevel curve (F p.31)

• You can consult the description of the customized bevel screen (F p.26).

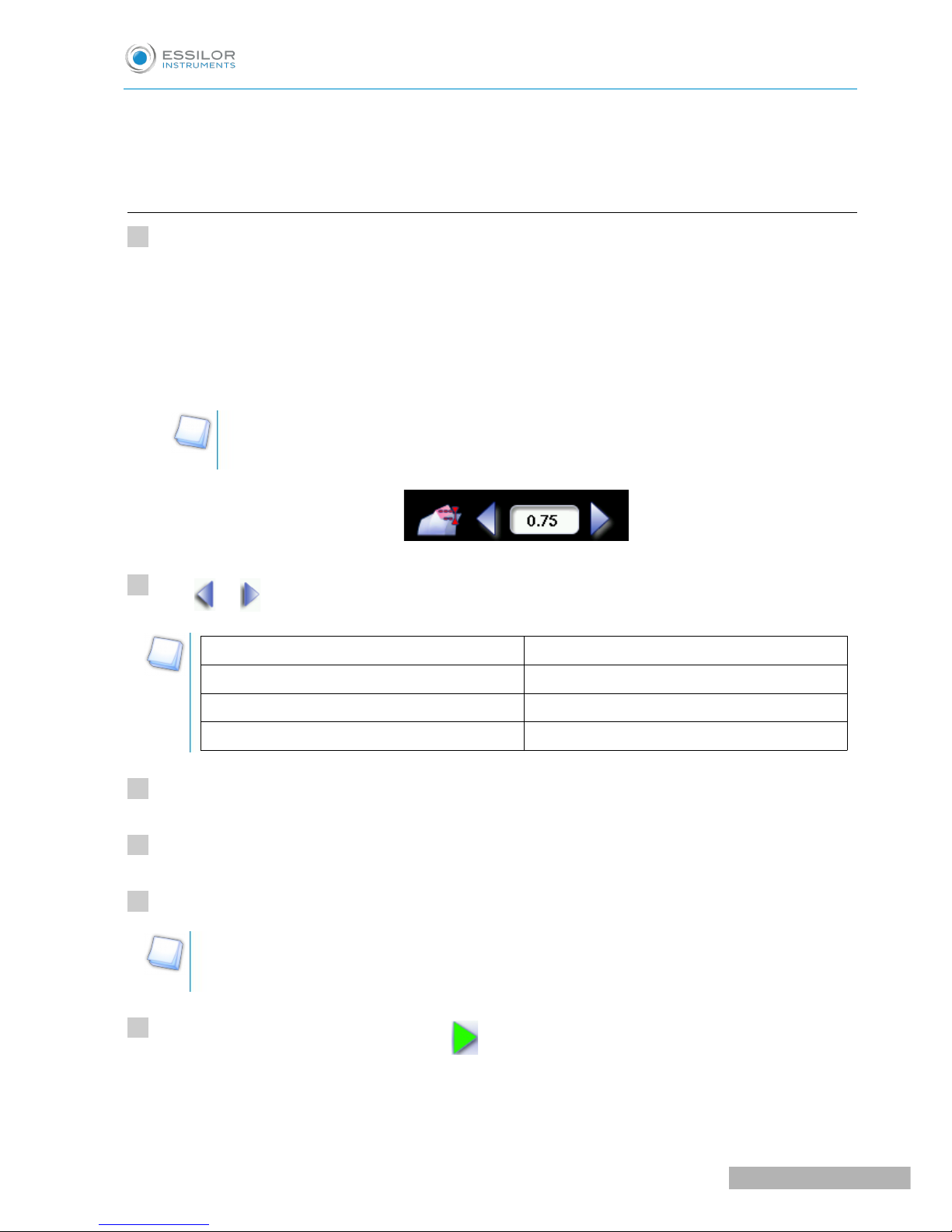

a. Automatic beveling

Call up the desired shape located on the tracer or on the job management program.

The shape is displayed on the edger work screen.

After the tracing of a rimmed frame:

• The bevel finish is selected by default.

• The automatic mode is selected by default.

If you want to produce a bevel less than 0.75mm high, configure the bevel directly on the

screen.

Press and to adjust the height of the bevel.

Height (mm)

By default 0.75

Minimum 0.30

Maximum 0.75

Select lens material.

Select the type of cycle.

Choose whether or not to polish and/or chamfer your lens.

For more information, consult the section Edging a lens > Perform a polishing (F p.67) and Edging a

lens > Perform a chamfering (F p.67).

Press the “cycle start” button (front face) or .

The door closes, the lens is clamped, then the feeling operation starts.

The edging cycle starts.

>

>

>

>

1

2

3

4

5

6

USER MANUAL> II. EDGING A LENS

25

Pro-E 600_Pro-E 700 > v1 -10.18

Page 26

When the edging cycle is finished, the retouch screen is displayed.

Press to release the lens.

If necessary, retouch the lens.

Otherwise, start edging the second lens. Select the lens directly on the screen, on the left or right of the

work area.

The edging screen for the second lens is displayed. All finishes chosen and the modifications made

are kept.

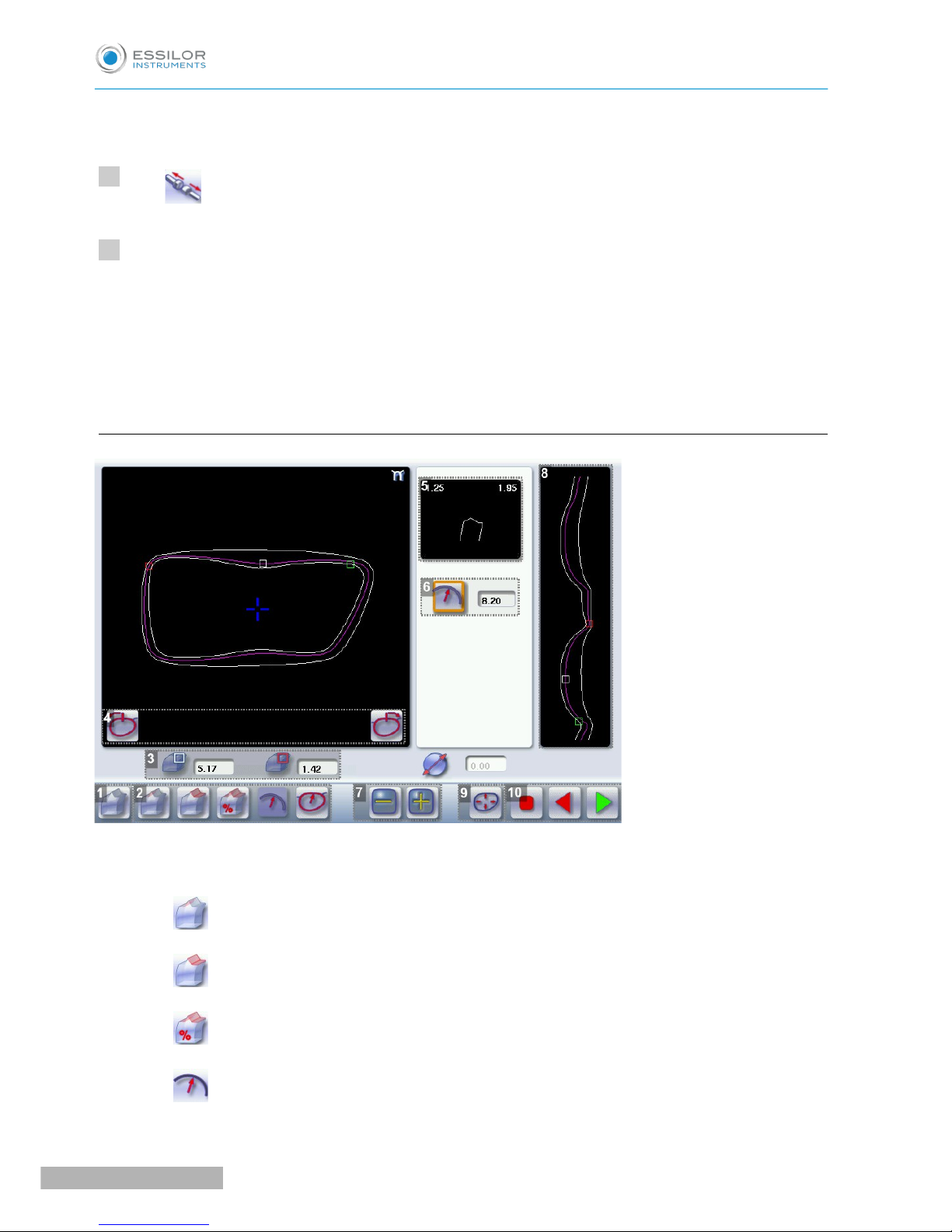

b. Legend screen for customized bevels

1. Automatic bevel

2. Customized bevel

◦ Front surface tracking: the crest of the bevel is positioned at a constant distance from the

front surface.

◦ Rear surface tracking: the crest of the bevel is positioned at a constant distance from the

rear surface.

◦ Distributed bevel: the position of the crest of the bevel is proportional to the thickness of

the lens, with respect to the front surface.

◦ Lens curve tracking: the camber of the bevel is adjustable.

>

>

7

8

Pro-E 600_Pro-E 700 > v1 -10.18

26

USER MANUAL> II. EDGING A LENS

Page 27

◦ Frame rim tracking: the bevel tracks the groove precisely, according to the data obtained

on frame tracing.

3. Lens thickness

◦ Maximum lens thickness - represented by the white square along the shape.

◦ Minimum lens thickness - represented by the red square along the shape.

4. Cursor movement

The cursor is represented by the green square along the shape. To move it, select it directly or use the

and buttons.

5. Zoom window

Represents the bevel profile and indicates the distance between the bevel crest and the front and rear

surfaces of the lens at the cursor position.

6. Bevel distribution value

Distribution value modifiable for:

◦ front/rear surface tracking

◦ a distributed bevel

◦ lens curve tracking

7. Modify the selected value

Reduce or increase the distribution value.

8. Bevel trajectory

Flat representation of the lens making it possible to assess the distances between the bevel crest and the

front & rear surfaces of the lens.

9. Trajectory modification

◦ General modification of the bevel curve

◦ Modification of the bevel curve at a particular point

◦ Displacement of the bevel curve

10. Navigation

◦ Stop the cycle

◦ Return to the main edging screen without saving your changes.

◦ Start the edging cycle

c. Customized beveling

The use of the customized bevel depends on 2 parameters: the frame and the lens. Before starting your job,

identify the major constraint.

USER MANUAL> II. EDGING A LENS

27

Pro-E 600_Pro-E 700 > v1 -10.18

Page 28

BEVEL FRAME LENS ADVANTAGES

Classic Lens for which the front surface

base is approximately equal to the

frame base.

Makes it possible to do an aesthetically pleasing

job. The lens material does not protrude beyond

the front of the frame.

Classic Lenticular lens&, Executive lens&Makes it possible to do a job with specific lenses.

Classic Thin lens Makes it possible to balance out the bevel when

thin lenses are used.

Flat base

High base

Thin lens for which the front

surface base is approximately

equal to the frame base.

Makes it possible to retrieve the frame base in a

pattern tracing (base = 0).

Particular

groove

(groove with

meniscus&)

Thin lens for which the base is

approximately equal to the

meniscus of the groove.

Compliance with original shape.

Job using a specific frame.

Call up the desired shape located on the tracer or on the job management program.

The shape is displayed on the edger work screen.

After the tracing of a rimmed frame:

• The bevel finish is selected by default.

• The automatic mode is selected by default.

Select lens material.

Change the edging mode. Press to select customized mode .

Select the type of cycle.

Choose whether or not to polish and/or chamfer your lens.

For more information, consult the section Edging a lens > Perform a polishing (F p.67) and Edging a

lens > Perform a chamfering (F p.67).

Press the “cycle start” button (front face) or .

The door closes, the lens is clamped and then felt.

The customized bevel finish screen is displayed.

>

>

>

>

1

2

3

4

5

6

Pro-E 600_Pro-E 700 > v1 -10.18

28

USER MANUAL> II. EDGING A LENS

Page 29

Select the type of customized bevel you want to do.

To avoid reproducing defects when tracking a frame rim, check that the frame groove is in perfect

condition and that the hinges are properly closed. All groove imperfections will be reproduced.

Press and to adjust the distribution value if required.

Press .

The edging cycle starts.

When the edging cycle is finished, the retouch screen is displayed.

Press to release the lens.

If necessary, retouch the lens.

Otherwise, start edging the second lens. Select the lens directly on the screen, on the left or right of the

work area.

The edging screen for the second lens is displayed. All finishes chosen and the modifications made

are kept.

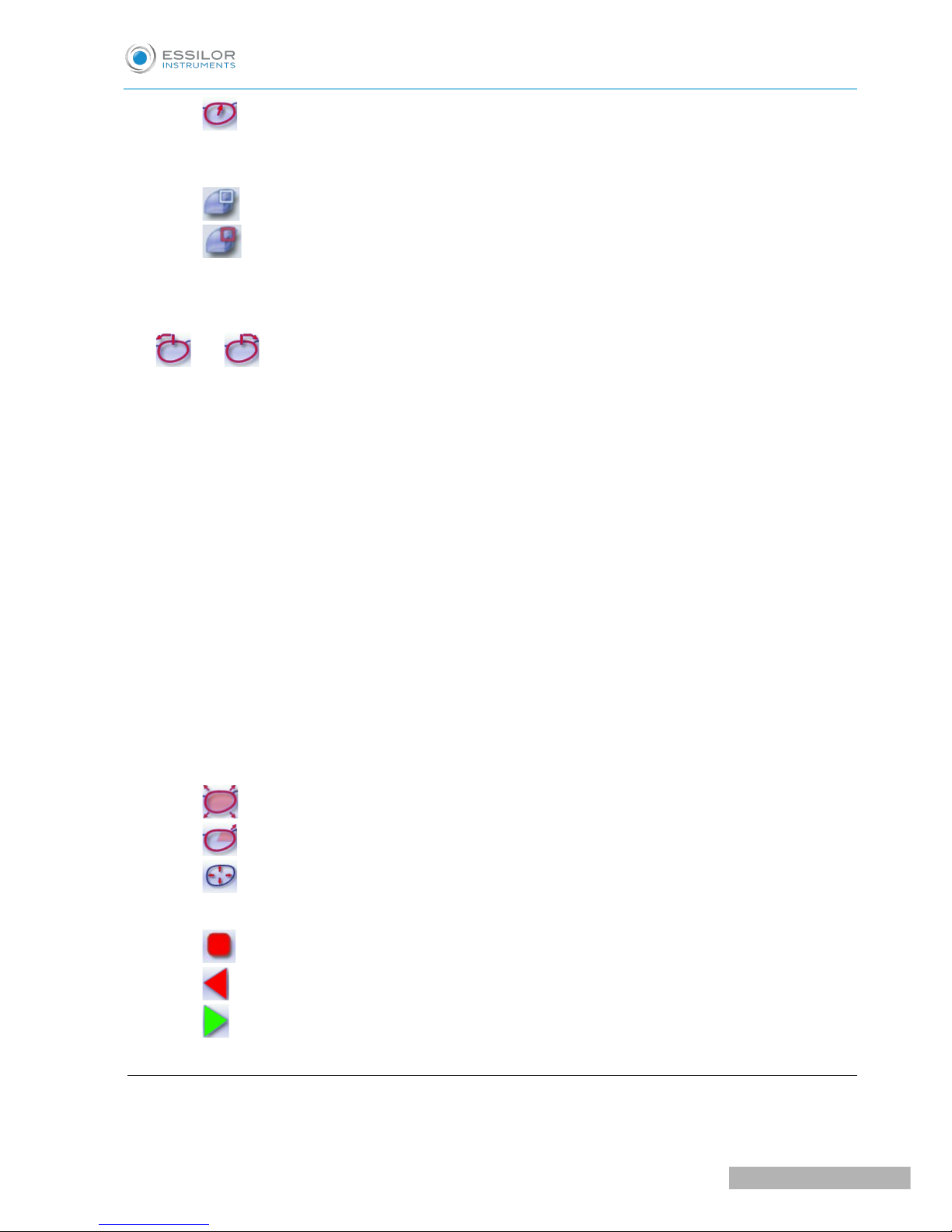

d. Modifying the bevel curve

Once you have configured the desired type of customized bevel, you can complete your customization by

moving the bevel curve towards the front or rear surface of the lens so it takes on its shape.

Press from the customized bevel finish screen.

You will access the trajectory modification screen.

Press to select the general modification of the bevel curve.

Use the buttons and to move the bevel curve:

• Press to move the curve towards the front surface of the lens.

• Press to move the curve towards the rear surface of the lens.

>

>

>

>

7

8

9

10

11

1

2

3

USER MANUAL> II. EDGING A LENS

29

Pro-E 600_Pro-E 700 > v1 -10.18

Page 30

The curve cannot be moved more than the minimum distance between the front and rear surfaces

observed on the bevel before the modification.

The position of the bevel as well as the distances between the crest of the bevel and the front and

rear surfaces of the lens are displayed in the zoom window at the position of the cursor.

Press the “cycle start” button (front face) or .

The edging cycle starts.

When the edging cycle is finished, the retouch screen is displayed.

Press to release the lens.

If necessary, retouch the lens.

Otherwise, start edging the second lens. Select the lens directly on the screen, on the left or right of the

work area.

The edging screen for the second lens is displayed. All finishes chosen and the modifications made

are kept.

e. Modifying the bevel curve at a particular point

Once you have configured the desired type of customized bevel, you can complete your customization by

partially moving the bevel curve towards the front or rear surface of the lens so it takes on its shape.

Press from the customized bevel finish screen.

You will access the trajectory modification screen.

Press to select modification of the bevel curve at a particular point.

Using the cursor, select the point on the curve that you want to move or click directly on the position of

the shape you want to modify.

Use the buttons and to move the point on the selected curve.

• Press to move it towards the front surface of the lens.

>

>

>

>

>

4

5

6

1

2

3

4

Pro-E 600_Pro-E 700 > v1 -10.18

30

USER MANUAL> II. EDGING A LENS

Page 31

• Press to move it towards the rear surface of the lens.

The curve cannot be moved more than the minimum distance between the front and rear surfaces

observed on the bevel before the modification.

The position of the bevel as well as the distances between the crest of the bevel and the front and

rear surfaces of the lens are displayed in the zoom window at the position of the cursor.

Press the “cycle start” button (front face) or .

Press to go back to the customized bevel finish screen.

For the second lens, the customized bevel icon is pre-selected and the trajectory modification icon is

displayed.

f. Displacing the bevel curve

The displacement of the bevel curve makes it possible to move the bevel without modifying its curve.

Press from the customized bevel finish screen.

You will access the trajectory modification screen.

Press to select the displacement of the bevel curve.

Use the and buttons to displace the bevel curve:

• Press to displace it towards the front surface of the lens.

• Press to displace it towards the rear surface of the lens.

The position of the bevel as well as the distances between the crest of the bevel and the front and

rear surfaces of the lens are displayed in the zoom window at the position of the cursor.

Press the “cycle start” button (front face) or .

The edging cycle starts.

When the edging cycle is finished, the retouch screen is displayed.

>

>

>

>

>

>

5

1

2

3

4

USER MANUAL> II. EDGING A LENS

31

Pro-E 600_Pro-E 700 > v1 -10.18

Page 32

Press to release the lens.

If necessary, retouch the lens.

Otherwise, start edging the second lens. Select the lens directly on the screen, on the left or right of the

work area.

The edging screen for the second lens is displayed. All finishes chosen and the modifications made

are kept.

3. PERFORM A HIGH-BASE BEVEL

This section describes the procedures for the creation of a high-base bevel:

• Description of the high-base bevel screens, (F p.33)

• Perform a high-base bevel in “automatic trajectory” mode or “front surface tracking” mode. (F p.34)

The use of the high-base bevel is determined by two parameters: frame and lens.

• Concerning the lens, the main constraint is the thickness of the nasal and temporal edges.

• Concerning the frame, the crucial elements are the bridge and shape of the groove. The hinge is an

additional factor in the case of a metal frame, the arms for a plastic frame.

For this job, the lens base must always match the frame base perfectly. Too great a difference

between the two could be detrimental to the quality of your job.

Cross-section of a high-base bevel

1: Shelf bevel value

2: Width of the flat side of the bevel

3. Front surface tracking value

>

5

6

Pro-E 600_Pro-E 700 > v1 -10.18

32

USER MANUAL> II. EDGING A LENS

Page 33

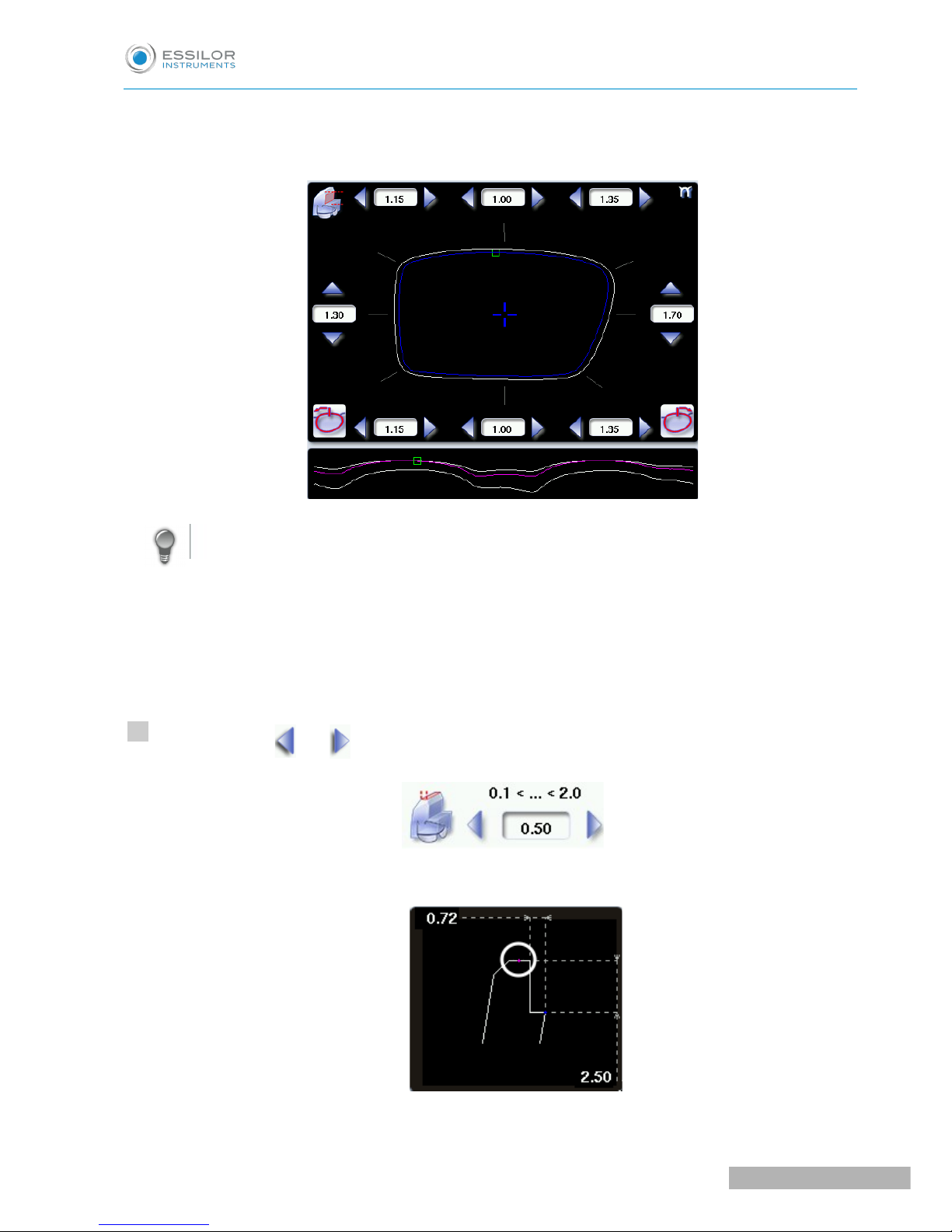

a. Captioned screens

1. High-base bevel screen “front surface monitoring”

2. Work area

Image of the shape to be edged:

Frame shape at bottom of groove

Bevel trajectory on rear surface

Bevel trajectory on rear surface if the lens used is too thin to achieve the desired finish.

3. Cursor movement

The cursor is represented by the square located along the shape. To move it, select it directly or use the

and buttons.

4. Zoom window

Represents the bevel profile at the position of the cursor.

5. Shelf bevel value (8 or 4 values)

◦ Nasal (the value must be between 0.25 and 3 mm)

◦ Mid-nasal (the value must be between 0.25 and 3 mm)

◦ Upper (the value must be between 0.25 and 3 mm)

◦ Mid-upper (the value must be between 0.25 with 3 mm)

◦ Temporal (the value must be between 0.25 and 3 mm)

◦ Mid-temporal (the value must be between 0.25 and 3 mm)

◦ Lower (the value must be between 0.25 and 3 mm)

◦ Mid-lower (the value must be between 0.25 and 3 mm)

6. Width of the flat side of the bevel

The value of the flat side of the bevel must be between 0.1 mm and 1 mm.

7. Front surface tracking value

The value of front surface tracking must be between 0 mm and 1.3 mm. This value is definable only in

the “front surface tracking” screen.

USER MANUAL> II. EDGING A LENS

33

Pro-E 600_Pro-E 700 > v1 -10.18

Page 34

8. Frame base

9. Lens base

10. Bevel Base_Range of values of the lens base necessary for the frame

If the lens base used is out of range: the range values are shown in red.

11. Reminder of size reduction/increase applied to lens diameter

12. Window showing the bevel trajectory on the lens section

Centre of the flat side of the bevel

Front surface/rear surface of lens

13. Number of shelf bevel values

Transition from 4 to 8 shelf bevel values.

Transition from 8 to 4 shelf bevel values.

14. Navigation

◦ Stop the cycle

◦ Return to the main edging screen without saving your changes

◦ Start the edging cycle

15. High base bevel screen “automatic trajectory”

In this screen, the trajectory on the lens section cannot be configured: it is calculated automatically. This

calculation harmonises as best as possible, the lens base, the base of the frame and the shape.

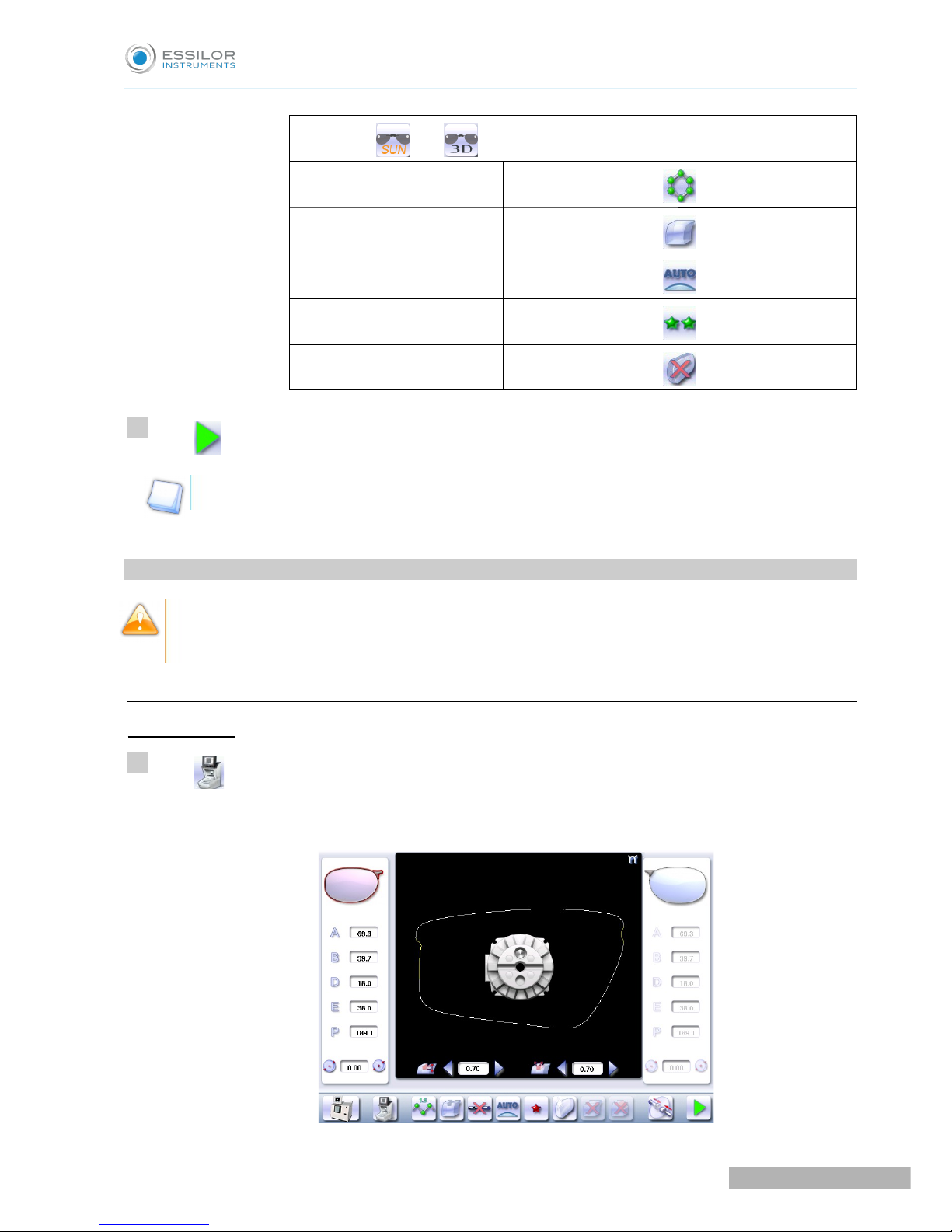

b. High-base beveling

Call up the desired shape located on the tracer or on the job management program.

The shape is displayed on the edger work screen.

After the tracing of a high-base frame:

• The high-base finish is selected by default.

• The customized mode is selected by default.

In the high-base finish, you cannot polish your bevel. Nevertheless, the high-base wheel was

designed to create an equivalent finish for polycarbonate lenses.

It is possible to perform the polishing of the flat side of the bevel.

Select lens material.

Select the type of cycle.

>

>

1

2

3

Pro-E 600_Pro-E 700 > v1 -10.18

34

USER MANUAL> II. EDGING A LENS

Page 35

Choose to create or not create a small or large chamfer on the rear surface of the lens.

“Super Chamfer” is not available for the high-base bevel finish.

For more information, consult the section Edging a lens > Perform a polishing (F p.67) and Edging a

lens > Perform a chamfering (F p.67).

Press the “cycle start” button (front face) or .

The door closes, the lens is clamped and then felt.

The high-base bevel finish “automatic trajectory” screen is displayed by default.

By default, the edger shows the values corresponding to the frame material (metal or plastic).

Check and modify these values according to the thickness of your lens and your frame.

You can:

• produce a high-base bevel in mode “automatic trajectory”, (F p.36)

• high-base bevel in “front surface tracking” mode. (F p.37)

>

>

4

5

USER MANUAL> II. EDGING A LENS

35

Pro-E 600_Pro-E 700 > v1 -10.18

Page 36

High-base bevel in “automatic trajectory” mode

Press to select the bevel in “automatic trajectory ” mode.

The following screen will appear:

Press the buttons and on the right of your screen to modify the width of the flat side of the bevel.

The result can be viewed in the zoom window.

Press the and buttons to modify the shelf bevel value at each point of the shape in

each area:

• Temporal

• Mid-temporal

• Nasal

• Mid-nasal

• Upper

• Mid-upper

• Lower

• Mid-lower

>

>

1

2

3

Pro-E 600_Pro-E 700 > v1 -10.18

36

USER MANUAL> II. EDGING A LENS

Page 37

Move the cursor along the shape to see the bevel profile in the zoom window.

The edger calculates the shelf bevel value to be applied between each of the four points in each area.

The bevel trajectory on the rear surface is modified in the work screen. The result can be viewed in

the zoom window.

Press the “cycle start” button (front face) or .

The edging cycle starts.

When the edging cycle is finished, the retouch screen is displayed.

Press to release the lens.

If necessary, retouch the lens.

Otherwise, start edging the second lens. Select the lens directly on the screen, on the left or right of the

work area.

The edging screen for the second lens is displayed. All finishes chosen and the modifications made

are kept.

High-base bevel in “front surface tracking” mode

Press to select the bevel in “front surface tracking” mode.

>

>

>

>

>

4

5

6

1

USER MANUAL> II. EDGING A LENS

37

Pro-E 600_Pro-E 700 > v1 -10.18

Page 38

The following screen will appear:

Press the buttons and on the right of your screen to modify the width of the flat side of the bevel.

The result can be viewed in the zoom window.

Press the and buttons to modify the shelf bevel value at each point of the shape in

each area:

• Temporal

• Mid-temporal

• Upper

• Mid-upper

• Nasal

• Mid-nasal

• Lower

• Mid-lower

>

>

2

3

Pro-E 600_Pro-E 700 > v1 -10.18

38

USER MANUAL> II. EDGING A LENS

Page 39

Move the cursor along the shape to see the bevel profile in the zoom window.

The edger calculates the shelf bevel value to be applied between each of the four points in each area.

The bevel trajectory on the rear surface is modified in the work screen. The result can be viewed in

the zoom window.

Press the buttons and on the right of your screen to modify the value of front surface tracking.

The result can be viewed in the zoom window and the display window of the bevel trajectory on the

lens section.

Press the “cycle start” button (front face) or .

The edging cycle starts.

When the edging cycle is finished, the retouch screen is displayed.

Press to release the lens.

If necessary, retouch the lens.

Otherwise, start edging the second lens. Select the lens directly on the screen, on the left or right of the

work area.

The edging screen for the second lens is displayed. All finishes chosen and the modifications made

are kept.

>

>

>

>

>

>

4

5

6

7

USER MANUAL> II. EDGING A LENS

39

Pro-E 600_Pro-E 700 > v1 -10.18

Page 40

4. PERFORM A STEP BEVEL

A step bevel is strongly recommended for a high-base sports frame or a safety frame.

The step bevel finishing is active and available only if the tool is installed on the “small tools” module

(F p.168).

For more information, refer to the section Maintenance servicing> Changing edger tools > Installing

the Step ++ wheel (F p.168).

This section describes the procedures for the creation of a step bevel:

◦ description of the Step bevel screens (F p.41)

◦ perform a Step bevel in “automatic trajectory” mode (F p.44) or “front surface tracking” mode.

(F p.46)

The use of the step bevel is determined by two parameters: frame and lens.

• Concerning the lens, the main constraint is the thickness of the nasal and temporal edges.

• Concerning the frame, the crucial elements are the bridge and shape of the groove. The hinge is an

additional factor in the case of a metal frame, the arms for a plastic frame.

For this job, the lens base must always match the frame base perfectly. Too great a difference

between the two could be detrimental to the quality of your job.

Cross-section of a step bevel

1: Value of shelf bevel of rear surface

2: Width of the flat side of the bevel

3. Front surface tracking value

Pro-E 600_Pro-E 700 > v1 -10.18

40

USER MANUAL> II. EDGING A LENS

Page 41

a. Captioned screens

1. Automatic trajectory step bevel screen.

In this screen, the trajectory on the lens section cannot be configured: it is calculated automatically. This

calculation harmonises as best as possible, the lens base, the base of the frame and the shape.

2. Work area

Image of the shape to be edged:

Frame shape at bottom of groove

Bevel trajectory on rear surface

Bevel trajectory on rear surface if the lens used is too thin to achieve the desired finish.

3. Cursor movement

The cursor is represented by the square located along the shape. To move it, select it directly or use the

and buttons.

4. Zoom window

Represents the bevel profile at the position of the cursor.

5. Shelf bevel value (8 or 4 values)

◦ Nasal (the value must be between 0.40 and 5.3 5mm)

◦ Nasal (the value must be between 0.40 and 5.35 mm)

◦ Upper (the value must be between 0.40 and 5.35 mm)

◦ Intermediary upper (the value must be between 0.40 and 5.35 mm)

◦ Temporal (the value must be between 0.40 and 5.35 mm)

◦ Intermediary temporal (the value must be between 0.40 and 5.35 mm)

◦ Lower (the value must be between 0.40 and 5.30 mm)

◦ Intermediary lower (the value must be between 0.40 and 5.35 mm)

6. Width of the flat side of the bevel

The value of the flat side of the bevel must be between 0.1 mm and 2 mm.

7. Back chamfer of assembly aid

USER MANUAL> II. EDGING A LENS

41

Pro-E 600_Pro-E 700 > v1 -10.18

Page 42

8. Bevel tilt

9. Front surface tracking step bevel screen

10. Front surface tracking value

The value of front surface tracking must be between 0 mm and 1.3 mm. This value is definable only in

the “front surface tracking” screen.

11. Frame base

12. Lens base

13. Bevel Base_Range of values of the lens base necessary for the frame

If the lens base used is out of range: the range values are shown in red.

14. Reminder of size reduction/increase applied to lens diameter

15. Window showing the bevel trajectory on the lens section

Centre of the flat side of the bevel

Front surface/rear surface of lens

16. Number of shelf bevel values

Transition from 4 to 8 shelf bevel values.

Transition from 8 to 4 shelf bevel values.

Transition into free shelf-bevel creation mode (Half Jacket specific_option)

17. Navigation

◦ Stop the cycle

◦ Return to the main edging screen without saving your changes.

◦ Start the edging cycle

b. Perform a Step bevel

Call up the desired shape located on the tracer or on the job management program.

The shape is displayed on the edger work screen.

After the tracing of a high-base frame:

• The step finish is selected by default.

• The customized mode is selected by default.

In the step finish, you cannot polish your bevel. Nevertheless, the step wheel was designed to

create a finish that is equivalent to polycarbonate lenses.

You have the option of polishing the flat side of the bevel.

>

>

1

Pro-E 600_Pro-E 700 > v1 -10.18

42

USER MANUAL> II. EDGING A LENS

Page 43

Press to select the Step bevel.

The button appears grayed if the step bevel wheel was not mounted beforehand: .

Select lens material.

Select the type of cycle.

Choose or not to chamfer your lens.

If you have a pro-E 700, it is to recommend to carry out a “Super Chamfer” .

For more information, consult the section Edging a lens > Perform a polishing (F p.67) and Edging a

lens > Perform a chamfering (F p.67).

Press the “cycle start” button (front face) or .

The door closes, the lens is clamped and then felt.

The “automatic trajectory” step finish screen is displayed by default.

By default, the edger shows the values corresponding to the frame material (metal or plastic).

Check and modify these values according to the thickness of your lens and your frame.

You can:

• perform a step bevel in “automatic trajectory” mode (F p.44),

In this mode, the bevel trajectory follows the base of the frame as closely as possible.

• perform a step bevel in “front surface tracking” mode (F p.46).

In this mode, the trajectory of bevel follows the front surface lens base as closely as possible.

>

>

2

3

4

5

6

USER MANUAL> II. EDGING A LENS

43

Pro-E 600_Pro-E 700 > v1 -10.18

Page 44

Step bevel in “automatic trajectory” mode

Press to select the bevel in “automatic trajectory ” mode.

The following screen will appear:

Press the buttons and on the right of your screen to modify the width of the flat side of the bevel.

The result can be viewed in the zoom window.

Press on the buttons and to modify the shelf bevel value in each point of the shape in

each of the areas, 4 or 8 areas:

• Temporal

• Mid-temporal

• Upper

• Mid-upper

• Nasal

• Mid-nasal

>

>

1

2

3

Pro-E 600_Pro-E 700 > v1 -10.18

44

USER MANUAL> II. EDGING A LENS

Page 45

• Lower

• Mid-lower

Move the cursor along the shape to see the bevel profile in the zoom window.

The edger calculates the shelf bevel value to be applied between each of the four or eight points of

each area.

The bevel trajectory on the rear surface is modified in the work screen. The result can be viewed in

the zoom window.

Press to perform a back chamfer of the assembly aid.

The chamfer is selected .

The result can be viewed in the zoom window.

Press systematically to tilt of the bevel (mounting aid).

The bevel tilt is selected .

The result can be viewed in the zoom window.

>

>

>

>

>

>

4

5

USER MANUAL> II. EDGING A LENS

45

Pro-E 600_Pro-E 700 > v1 -10.18

Page 46

Press the “cycle start” button (front face) or .

The edging cycle starts.

When the edging cycle is finished, the retouch screen is displayed.

Press to release the lens.

If necessary, retouch the lens.

Otherwise, start edging the second lens. Select the lens directly on the screen, on the left or right of the

work area.

The edging screen for the second lens is displayed. All finishes chosen and the modifications made

are kept.

Step bevel in “front surface follow-up” mode

Press to select the bevel in “front surface tracking” mode.

The following screen will appear:

Press the and buttons to modify the shelf bevel value at each point of the shape in

each area:

• Temporal

• Mid-temporal

• Upper

• Mid-upper

• Nasal

>

>

>

>

6

7

8

1

2

Pro-E 600_Pro-E 700 > v1 -10.18

46

USER MANUAL> II. EDGING A LENS

Page 47

• Mid-nasal

• Lower

• Mid-lower

Move the cursor along the shape to see the bevel profile in the zoom window.

The edger calculates the shelf bevel value to be applied between each of the four or eight points of

each area.

The bevel trajectory on the rear surface is modified in the work screen. The result can be viewed in

the zoom window.

Press the buttons and on the right of your screen to modify the width of the flat side of the bevel.

The result can be viewed in the zoom window.

>

>

>

3

USER MANUAL> II. EDGING A LENS

47

Pro-E 600_Pro-E 700 > v1 -10.18

Page 48

Press the buttons and on the right of your screen to modify the value of front surface tracking.

The result can be viewed in the zoom window and the display window of the bevel trajectory on the

lens section.

Press to perform a back chamfer of the assembly aid.

The chamfer is selected .

The result can be viewed in the zoom window.

Press systematically to tilt of the bevel (mounting aid).

The bevel tilt is selected .

The result can be viewed in the zoom window.

>

>

>

>

>

4

5

6

Pro-E 600_Pro-E 700 > v1 -10.18

48

USER MANUAL> II. EDGING A LENS

Page 49

Press the “cycle start” button (front face) or .

The edging cycle starts.

When the edging cycle is finished, the retouch screen is displayed.

Press to release the lens.

If necessary, retouch the lens.

Otherwise, start edging the second lens. Select the lens directly on the screen, on the left or right of the

work area.

The edging screen for the second lens is displayed. All finishes chosen and the modifications made

are kept.

5. GROOVING

This section describes the procedures for the creation of a groove:

• In automatic mode (F p.50), you do not have to configure anything. All the data is automatically

retrieved from the tracer. The lens edging starts automatically after the feeling cycle.

• In customized mode (F p.52), you can perform a front/rear surface tracking, a distributed groove

or a lens curve tracking. You can also do the following:

◦ a general modification of the groove curve (F p.54)

◦ a modification at a point of the groove curve (F p.55)

◦ a displacement of the groove curve (F p.56)

• You can consult the description of the customized groove screen.

In certain cases, the lens base or thickness makes grooving impossible.

> An error message is displayed.

> The white central line becomes red on the entire contour of the lens.

>

>

>

7

8

9

USER MANUAL> II. EDGING A LENS

49

Pro-E 600_Pro-E 700 > v1 -10.18

Page 50

a. Automatic grooving

Call up the desired shape located on the tracer or on the job management program.

The shape is displayed on the edger work screen.

After tracing a pattern, demo lens or re-cut lens, without any drilling settings:

• the groove finish is selected by default.

• the automatic mode is selected by default.

If you wish to produce a groove the depth and the width of which are less than 0.60 mm:

Directly define the groove in the screen.

Press and to regulate the depth and the width of the groove

Depth (mm) Width (mm)

By default 0.60 0.60

Minimum 0.20 0.60

Maximum 1.20 1.20

Select lens material.

Select the type of cycle.

Choose whether or not to polish and/or chamfer your lens.

For more information, consult the section Edging a lens > Perform a polishing (F p.67) and Edging a

lens > Perform a chamfering (F p.67).

Press the “cycle start” button (front face) or .

The door closes, the lens is clamped and then felt.

The edging cycle starts.

When the edging cycle is finished, the retouch screen is displayed.

>

>

>

>

>

1

2

3

4

5

6

Pro-E 600_Pro-E 700 > v1 -10.18

50

USER MANUAL> II. EDGING A LENS

Page 51

Press to release the lens.

If necessary, retouch the lens.

Otherwise, start edging the second lens. Select the lens directly on the screen, on the left or right of the

work area.

The edging screen for the second lens is displayed. All finishes chosen and the modifications made

are kept.

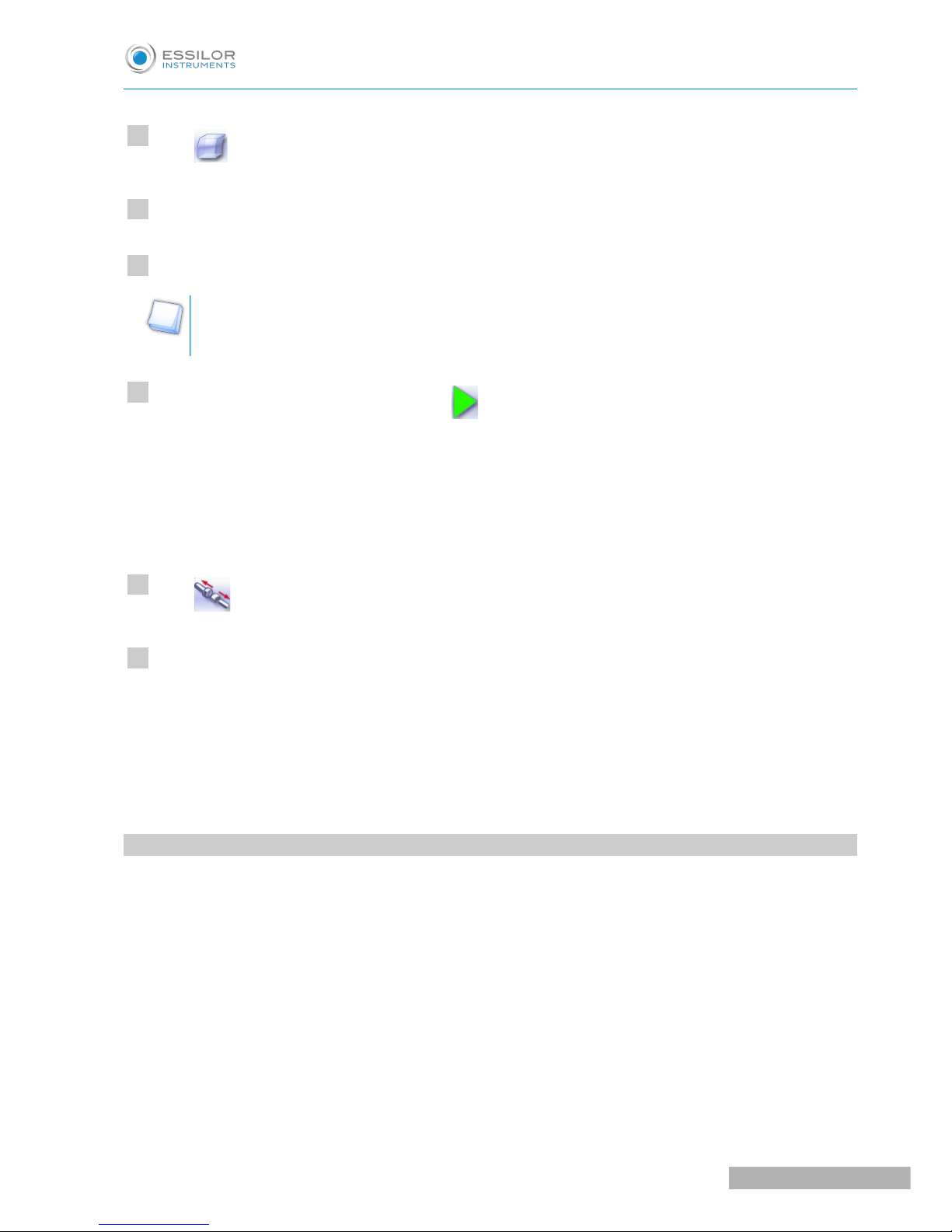

b. Customized groove legend screen

1. Automatic groove

2. Customised grooving

◦ Front surface tracking: the middle of the groove is positioned at a constant distance from

the front surface.

◦ Rear surface tracking: the middle of the groove is positioned at a constant distance from

the rear surface.

◦ Distributed groove: the middle of the groove is positioned in proportion to the thickness of

the lens, with respect to the front surface.

◦ Lens curve tracking: the camber of the groove is adjustable.

3. Lens thickness

◦ Maximum lens thickness - represented by the white square along the shape

>

7

8

USER MANUAL> II. EDGING A LENS

51

Pro-E 600_Pro-E 700 > v1 -10.18

Page 52

◦ Minimum lens thickness - represented by the red square along the shape

4. Cursor movement

The cursor is represented by the green square along the shape. To move it, select it directly or use the

and buttons.

5. Zoom window

Distance between the edges of the groove and the front & rear surfaces of the lens at the position of the

cursor.

6. Groove settings

◦ Distribution value - according to the type of customized groove selected

◦ Groove depth (in mm)

◦ Groove width (in mm)

7. Modify the selected setting

8. Groove trajectory

Flat representation of the lens making it possible to measure the distances between the groove and the

front & rear surfaces of the lens.

9. Modify the trajectory

◦ General modification of the groove curve

◦ Modification of a point in the groove curve

◦ Displacement of the groove curve

10. Navigation

◦ Stop the cycle

◦ Return to the main edging screen without saving your changes

◦ Start the edging cycle

c. Customised grooving

The use of the customized groove depends on 2 parameters: the frame and the lens. Before starting your

job, identify the major constraint.

GROOVE FRAME LENS ADVANTAGES

Standard

groove

Lens for which the front surface

base is approximately equal to the

frame base.

Makes it possible to do an aesthetically pleasing job.

The lens material does not protrude beyond the front

of the frame.

Pro-E 600_Pro-E 700 > v1 -10.18

52

USER MANUAL> II. EDGING A LENS

Page 53

GROOVE FRAME LENS ADVANTAGES

Standard

groove

Lens for which the rear surface

base is not as high as the front

surface base.

Minimises the risks of the nylon thread coming out.

Standard

groove

Thin lens Makes it possible to balance out the groove when thin

lenses are used.

Flat base

High base

Thin lens for which the front

surface base is approximately

equal to the frame base.

In the event of pattern tracing (base = 0), makes it

possible to retrieve the frame base.

Call up the desired shape located on the tracer or on the job management program.

The shape is displayed on the edger work screen.

After tracing a pattern, demo lens or re-cut lens, without any drilling settings:

• the groove finish is selected by default.

• the automatic mode is selected by default.

Select lens material.

Change the edging mode. Press to select customized mode .

Select the type of cycle.

Choose whether or not to polish and/or chamfer your lens.

For more information, consult the section Edging a lens > Perform a polishing (F p.67) and Edging a

lens > Perform a chamfering (F p.67).

Press the “cycle start” button (front face) or .

The door closes, the lens is clamped and then felt.

The customized groove finish screen is displayed.

Select the type of customized groove you want to do.

Select the values you want to modify and press and to adjust them if necessary

>

>

>

>

1

2

3

4

5

6

7

8

USER MANUAL> II. EDGING A LENS

53

Pro-E 600_Pro-E 700 > v1 -10.18

Page 54

Press .

The edging cycle starts.

When the edging cycle is finished, the retouch screen is displayed.

Press to release the lens.

If necessary, retouch the lens.

Otherwise, start edging the second lens. Select the lens directly on the screen, on the left or right of the

work area.

The edging screen for the second lens is displayed. All finishes chosen and the modifications made

are kept.

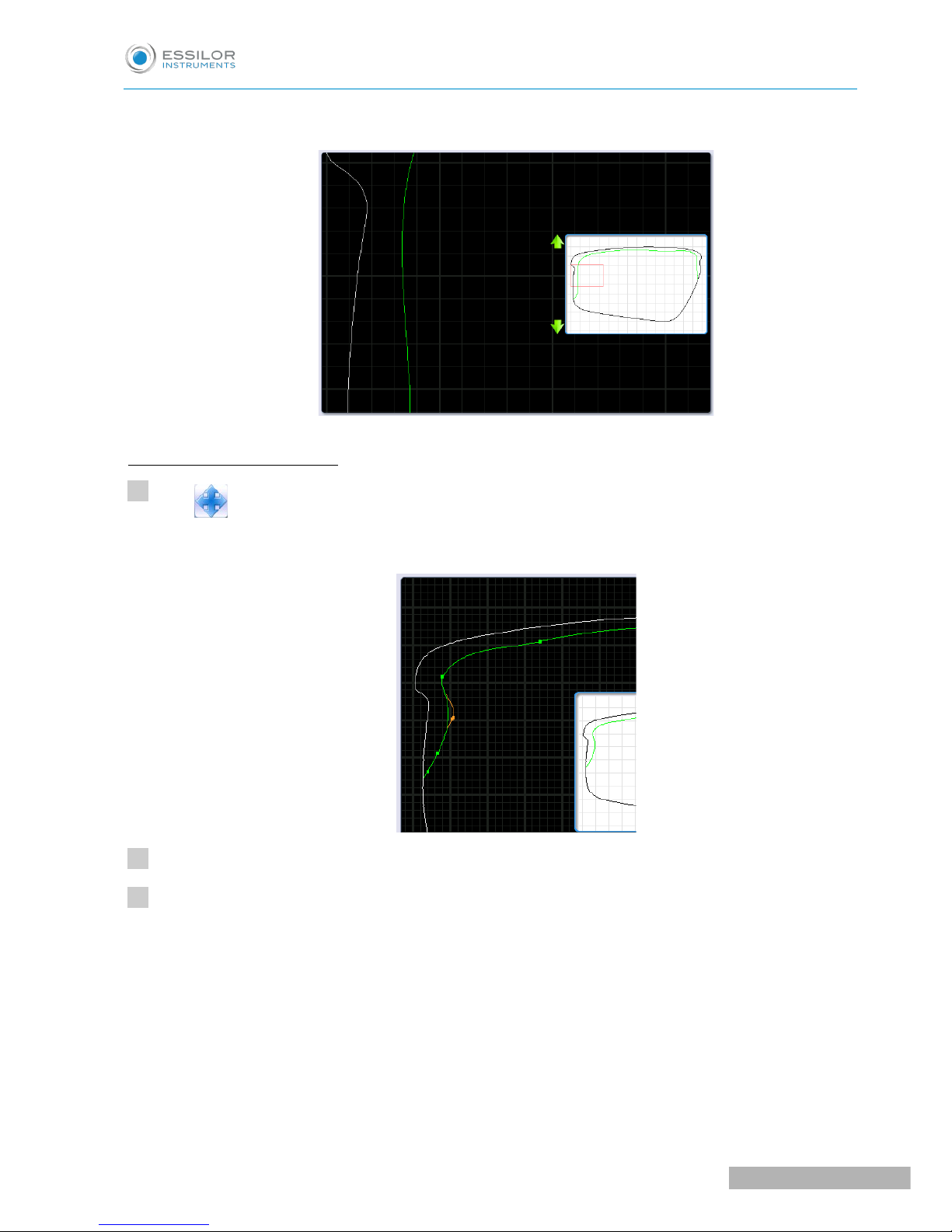

d. Modifying the groove curve

Once you have configured the desired type of customized groove, you can complete your customization by

moving the groove curve towards the front or rear surface of the lens so it takes on its shape.

Press from the customized groove finish screen.

You will access the trajectory modification screen.

Press to select the general modification of the groove curve.

Use the buttons and to move the groove curve.

• Press to move the curve towards the front surface of the lens.

• Press to move the curve towards the rear surface of the lens.

The curve cannot be moved more than the minimum distance between the front and rear surfaces

observed on the groove before the modification.

The position of the groove as well as the distances between the center of the groove and the front &

rear surfaces of the lens are displayed in the zoom window.

Press the “cycle start” button (front face) or .

The edging cycle starts.

>

>

>

>

>

>

9

10

11

1

2

3

4

Pro-E 600_Pro-E 700 > v1 -10.18

54

USER MANUAL> II. EDGING A LENS

Page 55

When the edging cycle is finished, the retouch screen is displayed.

Press to release the lens.

If necessary, retouch the lens.

Otherwise, start edging the second lens. Select the lens directly on the screen, on the left or right of the

work area.

The edging screen for the second lens is displayed. All finishes chosen and the modifications made

are kept.

e. Modifying a point in the groove curve

Once you have configured the desired type of customized groove, you can complete your customization by

moving the groove curve towards the front or rear surface of the lens so it takes on its shape.

Press from the customized groove finish screen.

You will access the trajectory modification screen.

Press to select modification of a point in the groove curve.

Using the cursor, select the point on the curve that you want to move or click directly on the screen.

Use the buttons and to move the point on the selected curve.

• Press to move it towards the front surface of the lens.

• Press to move it towards the rear surface of the lens.

The curve cannot be moved more than the minimum distance between the front and rear surfaces

observed on the groove before the modification.

The position of the groove as well as the distances between the center of the groove and the front &

rear surfaces of the lens are displayed in the zoom window.

Press .

Press to go back to the customized bevel finish screen.

For the second lens, the customized groove icon is pre-selected and the trajectory modification icon

is displayed.

>

>

>

>

>

5

6

1

2

3

4

5

USER MANUAL> II. EDGING A LENS

55

Pro-E 600_Pro-E 700 > v1 -10.18

Page 56

f. Displacement of the groove curve

The displacement of the groove curve enables you to move the groove without modifying its curve or

perimeter.

Press from the customized groove finish screen.

You will access the trajectory modification screen.

Press to select the displacement of the curve.

Use the and buttons to displace the curve.

• Press to displace it towards the front surface of the lens.

• Press to displace it towards the rear surface of the lens.

The position of the groove as well as the distances between the center of the groove and the front &

rear surfaces of the lens are displayed in the zoom window.

Press the “cycle start” button (front face) or .

The edging cycle starts.

When the edging cycle is finished, the retouch screen is displayed.

Press to release the lens.

If necessary, retouch the lens.

Otherwise, start edging the second lens. Select the lens directly on the screen, on the left or right of the

work area.

The edging screen for the second lens is displayed. All finishes chosen and the modifications made

are kept.

6. PRODUCE A FLAT-EDGE FINISH

For a flat-edge finish, only automatic mode is accessible.

Call up the desired shape located on the tracer or on the job management program.

The shape is displayed on the edger work screen.

Select lens material.

>

>

>

>

>

>

1

2

3

4

5

6

1

2

Pro-E 600_Pro-E 700 > v1 -10.18

56

USER MANUAL> II. EDGING A LENS

Page 57

Press to select the flat-edge finish.

Select the type of cycle.

Choose whether or not to polish and/or chamfer your lens.

For more information, consult the section Edging a lens > Perform a polishing (F p.67) and Edging a

lens > Perform a chamfering (F p.67).

Press the “cycle start” button (front face) or .

The door closes, the lens is clamped and then felt.

The edging cycle starts.

When the edging cycle is finished, the retouch screen is displayed.

Press to release the lens.

If necessary, retouch the lens.

Otherwise, start edging the second lens. Select the lens directly on the screen, on the left or right of the

work area.

The edging screen for the second lens is displayed. All finishes chosen and the modifications made

are kept.

7. DO A MIXED JOB

In this section, you will find the required procedure to do a mixed job:

• Description of menu screens (F p.58)

• Configuring the mixed finish (F p.60)

This finish enables you to do mixed jobs such as the following:

• Groove - Groove

• Bevel - Groove

• Flat-edge - Groove

• Flat-edge - Bevel

>

>

>

>

3

4

5

6

7

8

USER MANUAL> II. EDGING A LENS

57

Pro-E 600_Pro-E 700 > v1 -10.18

Page 58

To do a mixed finish, you need to define the points between which the two types of finish will be done. Only

the customized mode is thus accessible.

a. Legend screens

Main screen for mixed jobs

1. Modes available for a mixed finish

◦ Automatic mode: the position of the bevel or groove is automatically calculated according to

the information acquired when tracing the frame and feeling the lens.

◦ Front surface tracking: the crest of the bevel or the middle of the groove is positioned at a

constant distance from the front surface.

◦ Distributed mixed finish: the crest of the bevel or the middle of the groove is positioned in

proportion to the thickness of the lens, with respect to the front surface.

2. Access to the area defining screen

Access on a 1:1 scale.

3. Cursor movement

The cursor is represented by the green square along the shape. To move it, select it directly or use the

and buttons.

4. Settings for area 1

◦ Bevel finish

Pro-E 600_Pro-E 700 > v1 -10.18

58

USER MANUAL> II. EDGING A LENS

Page 59

◦ Groove finish

◦ Flat-edge finish

5. Zoom window

Display of the distance from the edges of the lens to the position of the cursor.

6. Position of the center of the groove or bevel

Value expressed in mm ('Front surface tracking' mode) or in % ('Distributed mixed finish' mode).

7. Settings for area 2

◦ Bevel finish

◦ Groove finish

◦ Flat-edge finish

8. Navigation

◦ Stop the cycle

◦ Return to the main edging screen without saving your changes

◦ Start the edging cycle

Area definition screen

1. Lock / unlock the area delimitation points

2. Move the area delimitation points

3. Back to the main screen

USER MANUAL> II. EDGING A LENS

59

Pro-E 600_Pro-E 700 > v1 -10.18

Page 60

4. Enable area delimitation on the touch screen

5. Modify the selected value

Legend of colours delimiting the shape areas:

(pink) Bevel finish

(yellow) / (orange) Groove finish (in the case of a Groove - Groove mixed job, the colours make it

possible to differentiate grooves with different parameters)

(black) Flat-edge finish

b. Configuring the mixed finish

Initiating a mixed finish

Call up the desired shape located on the tracer or on the job management program.

The shape is displayed on the edger work screen.

Select lens material.

Press to select mixed job mode.

Select your type of cycle.

Choose whether or not to polish the lens.

You cannot do a chamfer on a mixed job.

For more information on polishing, refer to the section Edging a lens > Polishing (F p.67).

Press .

The door closes, the lens is clamped and then felt.

The mixed finish screen is displayed:

The default setting is the bevel - groove finish in automatic mode.

Customizing the mixed finish

Select the desired type of mixed finish.

Press to access the area definition screen.

>

>

>

>

1

2

3

4

5

6

1

2

Pro-E 600_Pro-E 700 > v1 -10.18

60

USER MANUAL> II. EDGING A LENS

Page 61

The area definition screen is displayed on a 1:1 scale. You can thus refer to a sample lens placed on

the screen.

Select the finish you want in area 1, then area 2.

Press the button to unlock an area delimitation point.

Press the and buttons to move the unlocked point.

Press to move the delimitation points directly on the touch screen. The two points are then

unlocked. Drag them with the stylus.

If necessary, press to modify the position of the center of the groove or bevel using the buttons

and .

This value cannot be modified in automatic mode.

If necessary, press and to modify the groove depth and width using the and

buttons.

Press .

The edging cycle starts.

When the edging cycle is finished, the retouch screen is displayed.

Press to release the lens.

If necessary, retouch the lens.

Otherwise, start edging the second lens. Select the lens directly on the screen, on the left or right of the

work area.

The edging screen for the second lens is displayed. All finishes chosen and the modifications made

are kept.

>

>

>

>

3

4

5

6

7

8

9

10

USER MANUAL> II. EDGING A LENS

61

Pro-E 600_Pro-E 700 > v1 -10.18

Page 62

8. PERFORM A DRILLED JOB

You have the option of adding or modifying drillings on a job.

The function can be accessed on the edging screen:

Carry out:

• a short click on (when the job does not show drilling),

• a long click on (when the job already shows drilling).

The following screen will appear:

You can do the drilling in automatic mode or in customized mode:

• In automatic mode (F p.63), you do not have anything to configure. The drilling angle consists of

the average value calculated at right angles with the front surface of the lens for each drilling point.

The lens edging starts automatically after the feeling cycle.

• In customized mode (F p.65), you can do the following:

◦ Drilling at right angles with the front or rear surface: you can modify the diameter but not the

drilling angle which is automatically calculated by the edger based on the lens curve.

◦ Customized drilling: you can modify the diameter and angle for each drilling point.

• You can consult the description of the customized drilling screen (F p.64).

Two different diameter drill bits are available: a 1 mm bit and a 0.8 mm bit. If the diameter of the drilling

point is smaller than that of the installed drill bit, an error message is displayed. Change the drill bit or

modify the diameter of the drilling points.

You can also create various combinations:

• Drilled bevel

• Drilled high-base bevel

Pro-E 600_Pro-E 700 > v1 -10.18

62

USER MANUAL> II. EDGING A LENS

Page 63

• Drilled groove

• Drilled mixed finish

You have the option of adding or modifying drillings on a job.

The function can be accessed on the edging screen:

Carry out:

• a short click on (when the job does not show drilling),

• a long click on (when the job already shows drilling).

The following screen will appear:

For more information, consult the section Preparing a drilled job. (F p.128).

a. Automatic drilling

Call up the desired shape located on the tracer or on the job management program.

The shape is displayed on the edger work screen.

After the tracing of a shape with drilling settings:

• The drilling function is selected by default.

• The automatic mode is selected by default.

Select lens material.

Select the type of finish.

Select the type of cycle.

Choose whether or not to polish and/or chamfer your lens.

>

>

1

2

3

4

5

USER MANUAL> II. EDGING A LENS

63

Pro-E 600_Pro-E 700 > v1 -10.18

Page 64

For more information, consult the section Edging a lens > Perform a polishing (F p.67) and Edging a

lens > Perform a chamfering (F p.67).

Press the “cycle start” button (front face) or .

The door closes, the lens is clamped and then felt.

The edging cycle starts.

When the edging cycle is finished, the retouch screen is displayed.

Press to release the lens.

If necessary, retouch the lens.

Otherwise, start edging the second lens. Select the lens directly on the screen, on the left or right of the

work area.

The edging screen for the second lens is displayed. All finishes chosen and the modifications made

are kept.

b. Legend screen for customized drilling

1. Type of drilling

◦ Perpendicular to the front surface

◦ Perpendicular to the rear surface

◦ Customized

>

>

>

>

6

7

8

Pro-E 600_Pro-E 700 > v1 -10.18

64

USER MANUAL> II. EDGING A LENS

Page 65

2. Select the drilling points

◦ Nasal side

◦ Temporal side

◦ All drilling points

3. Modify the selected value

4. Modify the diameter

◦ Diameter value (mm)

◦ Difference between the initial value and the modified value

5. Modify the drilling angle

◦ Drilling angle value (degrees)

◦ Difference between the initial value and the modified value

6. Cross-sectional view

Cross-sectional view of the lens after the feeling cycle, showing the angle of the drill bit at the selected

drilling point.

7. Reminder of size reduction/increase applied to lens diameter

8. Navigation

◦ Stop the cycle

◦ Return to the main edging screen without saving your changes

◦ Starting the cycle

c. Customized drilling

Call up the desired shape located on the tracer or on the job management program.

The shape is displayed on the edger work screen.

After the tracing of a shape with drilling settings:

• The drilling function is selected by default.

• The automatic mode is selected by default.

Select lens material.

Change the edging mode. Press to select customized mode .

Select the type of cycle.

Choose whether or not to polish and/or chamfer your lens.

>

>

1

2

3

4

5

USER MANUAL> II. EDGING A LENS

65

Pro-E 600_Pro-E 700 > v1 -10.18

Page 66

For more information, consult the section Edging a lens > Perform a polishing and Edging a lens >

Perform a chamfering (F p.67).

Press the “cycle start” button (front face) or .

The feeling cycle starts.

The customized drilling screen is displayed.

Select the type of drilling you want to do.

If necessary, select the drilling point(s) you want to modify.

If necessary, modify the diameter and/or angle of the selected drilling point.

The difference between the initial value and the modified one is displayed in the delta column.

Press .

The edging cycle starts.

When the edging cycle is finished, the retouch screen is displayed.

Press to release the lens.

If necessary, retouch the lens.

Otherwise, start edging the second lens. Select the lens directly on the screen, on the left or right of the

work area.

The edging screen for the second lens is displayed. All finishes chosen and the modifications made

are kept.

>

>

>

>

>

>

6

7

8

9

10

11

12

Pro-E 600_Pro-E 700 > v1 -10.18

66

USER MANUAL> II. EDGING A LENS

Page 67

9. PERFORM A POLISHING

Press the button to activate/deactivate polishing.

LENS MATERIAL AVAILABLE OPTIONS

The polishing option is pre-selected and is strongly recommended by the manufacturer to

prevent small cracks.

Make sure you select the correct type of material for MHI (> 1.5) or Tribrid lenses and never

polish a lens of this type without water. Otherwise, the polishing wheel could suffer irreversible

damage.

The polishing option is pre-selected.

The polishing option is not available for a high-base job. Nevertheless, the wheel was designed to

create an equivalent finish for polycarbonate lenses.

10. CHAMFERING

The chamfer, also called counter-bevel, removes the sharp edge of the lens.

• Standard value of a small chamfer: 0.20 mm

• Standard value of a large chamfer: 0.40 mm

Before you select a type of chamfer, make sure it is compatible with the lens characteristics:

• Lens material

LENS MATERIAL AVAILABLE OPTIONS

The quality of the chamfer depends on the spraying. Make sure there is a constant

flow of water until the end of the chamfering operation.

USER MANUAL> II. EDGING A LENS

67

Pro-E 600_Pro-E 700 > v1 -10.18

Page 68

• Thickness at the edge of the lens

LENS THICKNESS AVAILABLE OPTIONS

> 1.2 mm

between 1 and 1. 2 mm

< 1 mm

• Distance between the edge of the groove and the edge of the lens

DISTANCE AVAILABLE OPTIONS

> 0.8 mm

between 0.5 and 0.8 mm

< 0.5 mm

The chamfers available also depend on the lens shape and the posiblock used when blocking.

Press on the buttons and to configure a small chamfer, a large chamfer or no chamfer on the

front and rear surfaces of the lens.

11. PERFORM A RETOUCHING

Pro-E 600_Pro-E 700 > v1 -10.18

68

USER MANUAL> II. EDGING A LENS

Page 69

1. Diameter modification

2. Manual lens clamping

3. Retouch launch

Differences with the edging screen

The edging screen is different to the retouch

screen through:

• the presence of the posiblock

• no frame thickness

• the “departure cycle” button.

When the first-lens edging cycle is finished:

Press to release the lens.

Proceed to lens assembly and check that edging was correctly configured.

Depending on your job:

• If your job is perfect, proceed with the machining of your second lens.

> All of the selected finishing options and modifications made are kept.

• If the lens requires adjustment, do a retouch on the edged lens to obtain optimal results.

Indicate the size reduction to be applied to the lens you want to retouch.

The chosen finish and the modifications made during the edging cycle are automatically selected.

Insert the lens in the posiblock holder.

To close the clamp shafts manually, do a long press on .

Press .

For a customized finish, the customized finish screen is displayed.

In all other cases, the door closes, the lens is clamped automatically, then the retouching starts.

Select the second lens to be edged directly on screen, on the left or right of the work area.

>

>

>

>

1

2

3

4

5

6

USER MANUAL> II. EDGING A LENS

69

Pro-E 600_Pro-E 700 > v1 -10.18

Page 70

The edging screen for the second lens is displayed.

All finishes chosen and the modifications made are kept. The retouch done on the first lens is

automatically saved for the edging of the second lens.

12. PERFORM A “SUPER CHAMFER” (PRO-E 700)

The “Super Chamfer” is strongly recommended on:

=>a fairly flat frame with weak or negative index lenses, for which the thickness of the lens would prevent

the closing of the arms.

Without the “Super Chamfer” With the “Super Chamfer”