Page 1

User Guide

Auto Lensmeter ALM 700

Version 2

April 2015

UMALM700

Page 2

Page 3

Introduction

This device is aims to measure S, C, A, prism refractive power, UV transmission and PD of the

framed lens and contact lens.

About This Manual

Please read this manual thoroughly so that safe and effective operation is ensured.

(1) The information contained in this manual is subject to change without notice.

(2) While reasonable efforts have been made in the preparation of this document to ensure its

accuracy, you should contact your local distributor immediately if any queries arise due to

editorial errors or omissions etc.

(3) If finding any imperfect collating or missing pages, contact your local distributor for

replacement.

This manual contains important contents to prevent users or others from harms and to use this

device safely.

Read this manual after understanding the symbols below and follow the instructions in use.

This symbol indicates that mishandling as a result of failure to

Warning

NOTE

comply with the indications can result in “personal death” or

“serious injury”.

Denote general ban or prohibition.

General mandatory action.

Additional information which is important to the text or useful/

convenient to know.

The number on the left is the lower limit and the one on the right is

the upper limit of the temperature.

The number on the left is the lower limit and the one on the right is

the upper limit of the humidity.

Avoid direct sunlight.

1

Page 4

this product complies with applicable CE directives.

This manual contains the information about basic operation, inspection and

maintenance etc. of ALM700.

Manufacturer

Electrical and Electronical Waste – please contact your

distributor to recycle this product

2

Page 5

Safety Consideration

General Cautions

It affects its measurement accuracy if fingerprints or dust etc. are on the optical components such

as glass parts under the lens stand.

Do not touch them with hands, and avoid dust.

If fingerprints or dust are adhered on the optical parts such as a lens etc., wipe it gently with

a soft cloth.

Observe the following environmental conditions for use, storage and transportation.

Avoid installation near TV or radio. The reception can be disturbed by electrical noise.

If liquid is spilled on this device or a foreign substance is entered in it, unplug the power cord and

contact your local distributor.

Turn off the power immediately and contact your local distributor if malfunction (noise, smoke

etc.) occurs. It can result in fire or injury if you keep using it.

Do not attempt to disassemble it. It can result in malfunction or fire.

If malfunction occurs, do not touch the inside of this device. Unplug the power cord and contact

Use

Storage

Transportation

No Dew Condensation

your local distributor.

In case of disposal, comply with the regulations and recycle plan of the local government.

Inappropriate disposal causes a negative effect on environment.

3

Page 6

Contents

Introduction.......................................................................................................................................1

About This Manual ...........................................................................................................................1

Safety Consideration.........................................................................................................................3

1. Accessories.....................................................................................................................................6

2. Device.............................................................................................................................................7

2.1 General Descritpion of Device.................................................................................................7

2.2 Parts Identification..................................................................................................................7

3. Instructions for Use.......................................................................................................................9

3.1 Installation...............................................................................................................................9

3.2 Connection/ Wiring................................................................................................................10

3.3 Maintenance/ Inspection .......................................................................................................10

3.4 Disposal..................................................................................................................................11

4. Measurement Screen...................................................................................................................12

4.1 Description of Measurement Screen.....................................................................................12

4.2 Preparation for Measurement...............................................................................................13

4.2.1 Device Setting .................................................................................................................13

4.2.2 Setup (Device Setting) Screen ........................................................................................13

4.2.3 ID Screen .........................................................................................................................15

4.2.4 Data Output Screen ........................................................................................................16

4.2.5 Data/Time Screen............................................................................................................17

4.2.6 Default Setting Screen....................................................................................................17

5. Operating Instructions of Device...............................................................................................

5.1 Lens Holder............................................................................................................................18

5.2 Lens Plate ..............................................................................................................................18

5.3 Marking Lever .......................................................................................................................19

5.3.1 Operating Instructions....................................................................................................19

5.3.2 Replacement of Marking Pen .........................................................................................20

5.4 Printer....................................................................................................................................21

5.4.1 Operating Instructions....................................................................................................21

5.4.2 Installation and Replacement of Printer Paper.............................................................22

5.5 Replacement of Fuse..............................................................................................................23

6. Measurement...............................................................................................................................24

6.1 Checkup before Measurement ..............................................................................................24

6.2 Measurement of Single Lens.................................................................................................25

6.3 Measurement of Framed Lens ..............................................................................................26

6.4 Pupillary Distance (PD) Measurement.................................................................................27

6.4.1 Device Setting .................................................................................................................27

6.4.2 Measurement Procedure.................................................................................................27

6.5 Measurement of Multifocal Lens ..........................................................................................28

6.6 Measurement of Progressive Lens........................................................................................29

6.7 Measurement of Ultraviolet (UV) Transmission..................................................................32

6.7.1 Device Setting .................................................................................................................32

6.7.2 Measurement of UV Transmission after Measuring Degree……………… .... ……… 32

6.8 Measurement of Contact Lens ..............................................................................................33

6.8.1 Preparation......................................................................................................................33

.18

4

Page 7

6.8.2 Measurement Procedure.................................................................................................33

7. Marking .......................................................................................................................................34

7.1 Lens without Astigmatism....................................................................................................34

7.2 Lens with Astigmatism .........................................................................................................34

7.3 Marking of Prism Lens..........................................................................................................35

8. Other Functions ..........................................................................................................................36

8.1 Auto Memory Function..........................................................................................................36

8.1.1 Operation Procedure.......................................................................................................36

8.2 Power Saving Function .........................................................................................................37

9. Error Display...............................................................................................................................38

9.1 Type........................................................................................................................................38

9.2 Error Handling Procedure.....................................................................................................39

10. Storage of Device.......................................................................................................................40

11. Specification...............................................................................................................................41

12. EMC (Electromagnetic compatibility) 42

5

Page 8

1. Accessories

Power cord: 1

(2.5m)

Dust cover: 1 Contact lens stand: 1

Use the accessories specified by us.

The printer paper is the thermal paper roll.

Avoid direct sunlight, high humidity and high temperature at the time of storage.

Printer paper: 1

(Width: 58mm)

Operation manual: 1

6

Page 9

2. Device

2.1 General Descritpion of Device

This device aims to take the measurements of SPH, CYL, AXIS, prism refractive power and

optical axis coordinate of unprocessed lens, processed framed lens and contact lens, and to

put dots on them to find its axis.

As an external feature, the angle of the LCD can be changed.

Refer to “3. Instructions for Use” about the operating precautions of this device.

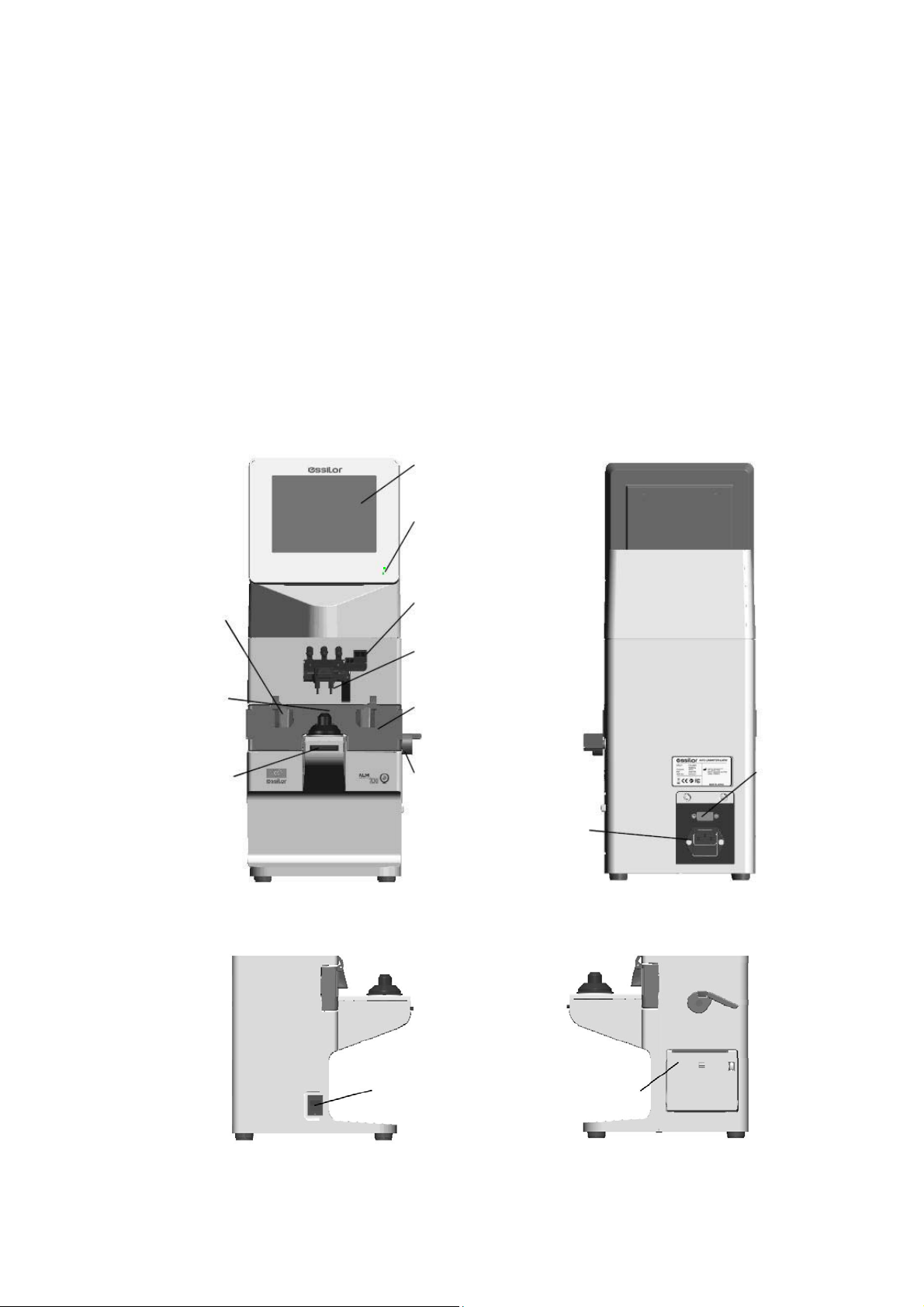

2.2 Parts Identification

Nose pad

Lens stand

Memory/Add

switch

LCD (with

touch panel)

Pilot lamp

Marking lever

Lens holder

Lens plate

Lens plate lever

Power inlet

(with fuse holder)

Communication

connector

Power switch

7

Printer

Page 10

LCD

Color LCD with 640 X 480 dots

User-friendly LCD which is adjustable vertically within operating range (60°)

Touch panel is adopted.

Pilot lamp

Lamp to indicate ON (light on)/ OFF (light off) and power saving mode (blink)

Marking lever/ lens holder

The marking lever and lens holder are integrated.

・Marking lever: puts the dots by pressing the lever down.

・Lens holder: fixes the framed glass on the lens stand by moving the lever up and down.

Lens stand

Take a measurement by placing the framed lens on the lens stand.

Lens plate

The plate to be reference of the cylindrical axis and specified direction of the prism.

For the framed lens, take a measurement so as that the lens frame contacts with the lens plate.

Lens plate lever

Moves the lens plate back and forth

Nose pad

Used for measuring PD of the framed lens.

Set the framed lens so as that the nose pad is placed on it. The judgment of right and left and PD

measurement are performed based on the position of the nose pad.

Memory/Add switch

The switch to store the measurement values on the measurement screen of single focus lens,

multifocal lens and contact lens.

Freezes the display of the measurement values and store them.

The switch to execute the near and far points in case of manual measurement on the progressive

lens measurement screen

Communication connector

The communication connector to transfer the measurement data to the other devices and

computers.

Power inlet

The inlet to connect the power cord supplied to supply power.

Power supply switch

The switch to turn on/ off the power of the device

Printer

Prints out the measurement values

8

Page 11

3. Instructions for Use

3.1 Installation

(1) Do not expose the device to sunlight or bright light from lighting

equipments.

NOTE

Do not install the device in places where either dust or rubbish may

Take extra caution to avoid strong light because

it may cause the failure of measurement.

accumulate.

Also, the environments with extremes in heat and

humidity should be avoided.

In case of using the device, ensure to comply with the

environmental conditions of unpacking and usage before

starting a measurement.

・Temperature range for use: 5 to 40

・Humidity range for use: 30%HR to 95%HR

・Temperature range for storage: -10 to 55 (No dew condensation)

・Humidity range for storage: 10%HR to 95%HR (No dew condensation)

(2) Keep away from inflammable or explosive gases as

well as storage area of the medical supplies and

chemicals.

(3) Keep away from the sites that experience strong

vibrations or sudden shocks.

Dust

Gas

(4) The device might be broken if it falls down. Also,

it might cause injury if dropping it. Therefore, do

not store it at an unstable place or in high, ‘out of

reach’ place.

(5) Keep this device away from water (liquid).

・Degree of protection: IP20

9

Page 12

3.2 Connection/ Wiring

(1) The earth cable of the power code should be connected to the earth terminal.

(2) Avoid damaging the power cord (such as bending it in an extremely small size, pulling,

placing a heavy object on it etc.). Also, do not fabricate the cord.

(3) When the power cord is damaged, (breaks, damage of cover etc.), replace it to the new one.

Fire or electric shock may occur if you keep using it.

(4) Insert the power cord firmly into the outlet and device. If not, fire or electric shock may occur.

(5) Keep the power cord clean without any dust or oil etc. on it. The dirty terminal may cause

malfunction or fire.

(6) When the power cord gets hot after use, check for the dirt of the terminal unit. If you find no

dirt, replace the power cord to the new one. Fire or electric shock may occur if you keep

using it.

(7) Use it with the correct power-supply voltage. Fire or electric shock may occur if using it with

more than the rated supply voltage.

(8) Always hold the plug when plugging or unplugging the power cord.

(9) Do not touch the plug with wet hands. You may get an electric shock.

(10) If the device is not used for a long time, unplug the power cord from the outlet.

3.3 Maintenance/ Inspection

(1) This is the precision optical device. Make sure not to mishandle

or drop it.

(2) Do not touch or allow dust to adhere on the optical parts

(i.e. lenses), as the measurement accuracy could be adversely

affected by fingerprints and dust etc.

When fingerprints or dust are adhered onto the optical parts,

gently wipe them with the accompanying dust cloth or a soft

cloth. In this instance, make sure not to scratch them.

10

Page 13

(3) If the main unit cover or operation panel is dirty, gently wipe it

with a dry cloth. For hard to remove stains, a damp cloth or

neutral cleanser is recommended.

(4) If the device is not used for any length of time, unplug

the power cord.

When the device is not in use, protect it with the

accompanying dustproof cover. The measurement

accuracy could be affected by dust.

(5) Never attempt to fix or remodel the device. When the

device fails to function properly, do not touch the inside.

Contact us or your local distributor.

Avoid using organic solvent such as thinner

which may damage the water based paint

finish or device.

3.4 Disposal

In case of disposal, comply with the regulations and recycle plan of the local government.

Inappropriate disposal causes a negative effect on environment.

11

Page 14

4. Measurement Screen

A

4.1 Description of Measurement Screen

Measurement setting

Type of lens: left/

right/ single

XIS mark

-3

Display of alignment

condition or error

message

Cross cursor

Measurement screen of single focus lens, multifocal lens and contact lens

※ The display of the measurement screen reflects the setting and condition of the device.

The touch panel is adopted. They are corresponding to the icons on the monitor.

【Explanation about switches】

Name of icon Icon Description of function

Bottom of monitor: 5

Device setting

Switch of

measurement

Switch to the Setup (device setting)

screen.

Switches to multifocal lens

measurement from single focus lens.

Unprocessed lens/

framed lens

selection switch

Clear

Measurement

value output

Lens stand unit: 1

Memory/Add

switch

No icon

Selects unprocessed, left or right lens.

Deletes measurement values stored in

memory.

Prints out measurement result, outputs

data from RS232C or both.

Stores measurement values in memory

and take a measurement of ADD.

12

Page 15

4.2 Preparation for Measurement

4.2.1 Device Setting

This device is ready for use with the standard mode but the setting can be changed easily

as needed.

Switch to the Setup (setup of device) screen by touching

of screen.

Change of switch function

The functions of each switch are changed on the menu screen.

The icons are displayed on the screen. Touch the icon in accordance with the display.

NOTE

:Moves the cursor downward at each setting item

:Moves the cursor upward at each setting item

:Goes to a further page of Setup. ( → → → )

:Selects the item of each setting item. The selection cursor moves vertically.

:Switches back to the measurement screen.

4.2.2 Setup (Device Setting) Screen

【1/4 screen】

at the bottom

Item Description of Function

Cyl Selects sign for Cyl:- / + / ±

Step

Prog.

Lens

Memory

ADD

Measure

PD

Measure

Selects step to display measurement value

0.25 / 0.12 / 0.01

Sets auto detection of progressive lens Auto

On / Off

Selects lens to be measured

Normal: Framed lens

H CL: Hard contact lens

S CL: Soft contact lens

Sets auto memory at the time of “Marking OK” Auto

On / Off

Selects auto/ manual memory of far and near

points

F/N.AT: Stores both near and far points

automatically

N.AT: Stores only near point automatically

Manual: Stores data manually

Selects if performing PD measurement or not

On: Perform / Off: Not perform

13

Page 16

【2/4 screen】

Item Description of Function

UV

Measure

UV

Graph

Prog.

Graph

Graph

Print

Prism

Prism

(mm)

Abbe

Selects if performing UV transmission

measurement or not

On:Perform / Off: Not perform

Selects if displaying UV transmission

graph or not

(displayed only on the progressive lens

measurement screen)

On:Perform / Off: Not perform

Selects if displaying the assessment graph

or not

On:Display / Not display

Selects if printing out the assessment

graph after measuring progressive lens

On: Print out / Off: Not print out

Selects if displaying prism or not, and

selects the unit to be displayed

Off: Not display X-Y:X-Y display

P-B: Prism value – base direction

Select if displaying prism value of X-Y

direction in mm

On: Display / Off: Not display

Selects Abbe number : 20 / 30 / 40 / 50 / 60

【3/4 screen】

Item Description of Function

Ray

Standby

Language

Brightness

Sound Mute

ID

Data Output

Selects measurement wavelength

e-line / d-line

Selects time to activate standby mode

Off / 3 min. / 5min. / 10min.

Selects language displayed on screen

English, French, Spanish, Italian,

Portuguese, German, Chinese

Sets brightness of screen

(50% to 100%)

Sets On/ Off of buzzer at the time of

operating switches

Switches to ID screen

Switches to Data Output screen

14

Page 17

【4/4 screen】

4.2.3 ID Screen

This screen is to create the data for printing out the distributor’s name or message on

the printout.

(1)

Item Description of Function

Date/Time

Switches to Date/Time screen

Displays the Setup items

Default

Setting

changed from default and

changes the setting back to the

default by pressing

The screen shown on the left appears by

selecting “ID Screen”.

(1) is the screen for writing the information.

(2) is the screen for changing or erasing the

information.

How to input

.

The cursor in moves by pressing

the arrows.

(2) While Memory/Add switch is held

The cursor in moves while the

Memory/ADD switch is held

In the Screen (1), select the characters with

and enter them with

. Any changes made will overwrite the

original characters.

The maximum number of characters is

44 (22 characters X 2 lines).

In case of changing the characters, move the

cursor to the one changed by pressing

with holding the

Memory/Add switch. Return to Screen (1) and

select the character to be input with

and press .

How to delete

In case of deleting the characters, move the

cursor to the one deleted with

15

and press .

Page 18

4.2.4 Data Output Screen

This screen is to set the communication parameter for outputting the measurement values to the

externally-connected PC etc.

The measurement values and data created on the “ID Screen” are output by selecting “RS232C” or

“Both” of “Data Output” on the Setup screen.

NOTE

The output content is same with the one of the printout.

However, the graph at the time of progressive lens measurement is not output.

Communication setting to PC etc.

The communication from RS232C port is set on “Data Output”.

【Setting screen in case of outputting from RS232C】

Item Description

Setting of output destination

Output Device

Display on

measurement screen

Print RS232C Both

Device

printer

RS232C

terminal

Setting

“Off” “On”

Auto Comm

Band Rate

(communication

speed)

Output by touching

the measurement

screen output icon

Measurement values

are output

continuously

Select from 115200, 38400 or 9600.

In case of output from RS232C, the data is output only in English regardless of language

NOTE

setting.

【Example of connection】

D-Sub: 9Pin

(male)

D-Sub 9pin

Lensmete

(male)

Connection

D-Sub 9pin

(female)

PC

D-Sub: 9Pin (female)

Use the straight cable (D-sub 9 pin: male/ D-sub 9: female) as the connection cable at the

time of outputting the measurement values by using the RS232C.

※ Contact your local distributor if you have anything unclear or any questions regarding

operation and connection.

Use a shield wire for a connecting cable to protect the output data from noise.

NOTE

Both

16

Page 19

4.2.5 Data/Time Screen

The screen to set the date and time for printout and communication output

(1)

Select the item to be changed with

and set the detail with .

“Date Form”:YMD → Year, Month, Day

“Date Form”:DMY → Day, Month, Year

“Date Form”:MDY → Month, Day, Year

The setting can be also changed by touching the

screen.

(2) While Memory/Add is pressed

4.2.6 Default Setting Screen

Date: change of date

Select “Date” with

Move the cursor to the item to be changed with

.

While the Memory/Add switch is held, the Screen

(2) is displayed. Make changes with

.

Time: change of time

Select “Time” with

Move the cursor to the item to be changed with

.

While Memory/Add switch is pressed, the Screen

(2) is displayed. Make changes with

.

.

.

The screen to change the setting of the device back to the default

Touc h P res s

setting back to the default.

Press

setting back to the default. It goes back to the

measurement screen by selecting it.

17

if you do not wish to change the

if you wish to change the

Page 20

5. Operating Instructions of Device

5.1 Lens Holder

(1)

(1) Raise the lever to the operational

direction until it is unlocked.

(2) Lower the lens holder slowly and fix

the lens.

Do not give strong impact to a lens when lowering the lens holder.

When rising the lens holder, make sure to move to the top.

Operational

direction

(2)

5.2 Lens Plate

The lens plate is the reference of the cylindrical axis.

Place the framed lens and rotate the lens plate lever to the direction of the arrow so that the

bottom of the lens touches the lens plate. After that, lower the lens holder and fix the lens.

Lens plate

Lens plate lever

18

Page 21

5.3 Marking Lever

5.3.1 Operating Instructions

(1) Turn and lower the marking lever.

(2) Place the tips of the marking pens on the lens

surface softly.

Do not mark several times at the same point.

The marking pen may be worn out quickly.

(3) Release the finger after marking.

(4) The marking lever returns to the initial position.

Marking lever

Avoid the followings since they may damage the tips of the marking pens.

・ Perform marking roughly

・ Operate the marking lever without a lens set.

・ Touch a tip of the marking pen during cleaning.

19

Page 22

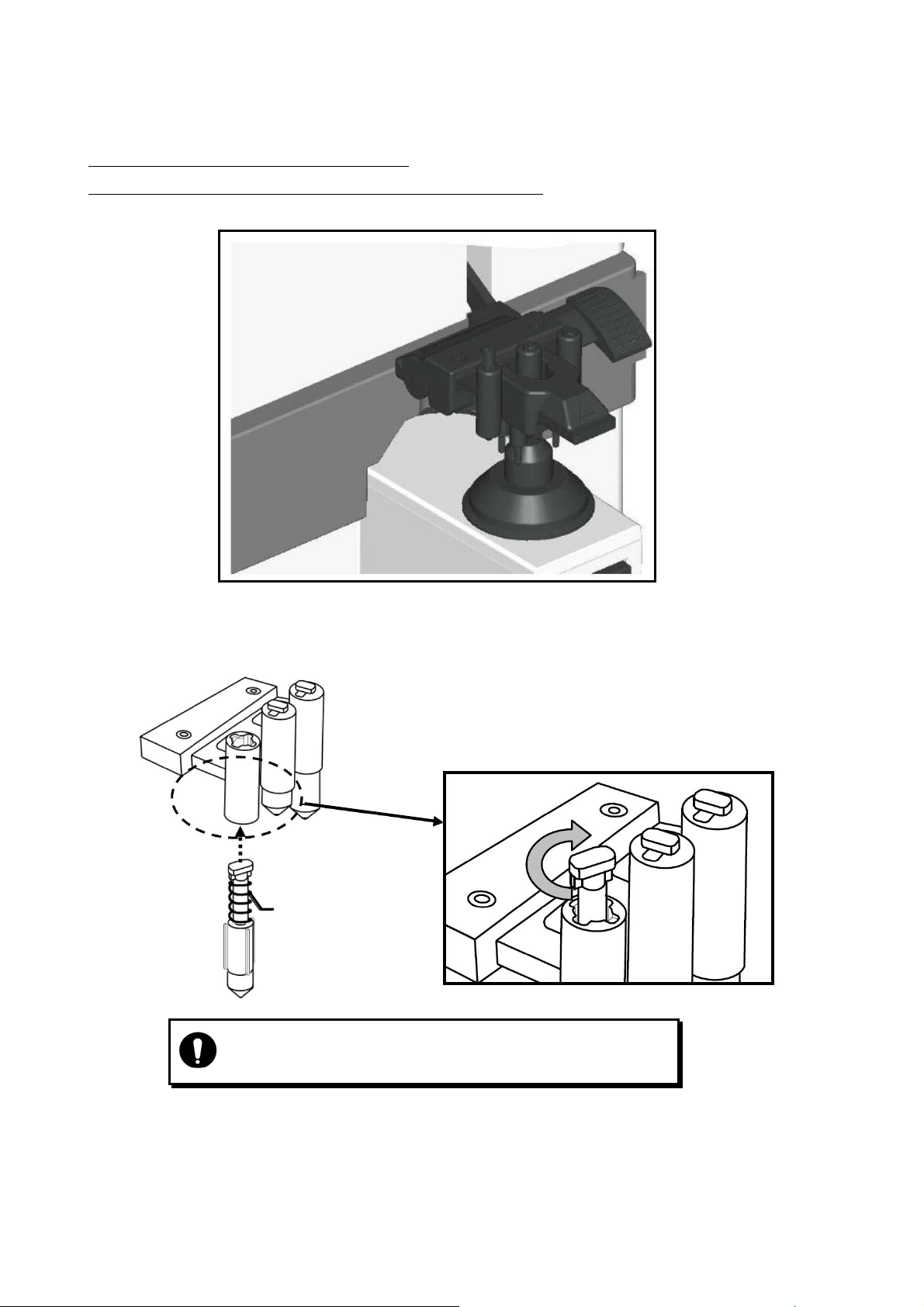

5.3.2 Replacement of Marking Pen

The marking pen is the consumable item.

Replace it if the imprint becomes thin or the pen tip is worn.

(1) Remove the marking pen by pressing and rotating it 90 degrees as shown below.

(2) Insert the new pen back to the initial position as shown below.

Insert the marking pen, and fix it by rotating

90 degrees.

Marking pen

・Ensure to use the marking pen specified for “ALM700”.

・Do not touch the pen tip at the time of replacement.

20

Page 23

A

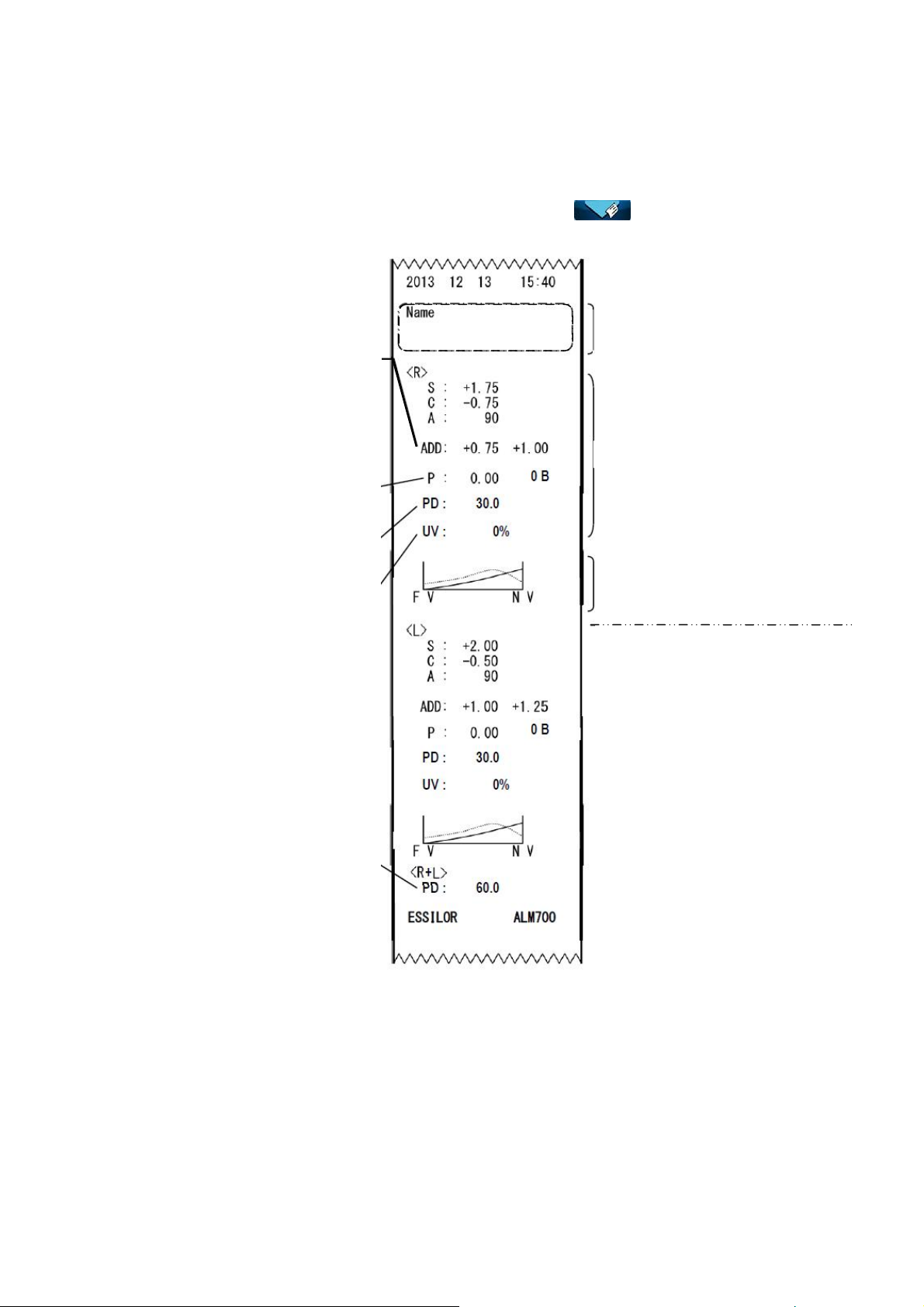

5.4 Printer

5.4.1 Operating Instructions

The measurement values can be printed out by touching after taking

a measurements.

dd measurement values are

displayed only at the time of

measurements of multifocal

lens and progressive lens

(Left: ADD1, Right: ADD2)

The unit of the prism value

is different according to the

setting.

PD of right eye

UV transmission

of right eye

PD (PD of right eye

and left eye)

Distributor’s name, comment etc.

(printed out only when ID is set)

Number of characters input:

44 characters (22 characters X 2 lines)

Measurement value of right lens

When the assessment graph is

printed (when “Graph Print” is set

as “On” at the time of progressive

lens measurement)

Shown below is the measurement

value of the left lens

(Same as that for a right lens)

21

Page 24

【Printout sample when

unprocessed lens is measured】

ESSILOR ALM700

Other error displays

・SPH Over

・CYL Over

・Prism Over

・Center Error

Error display

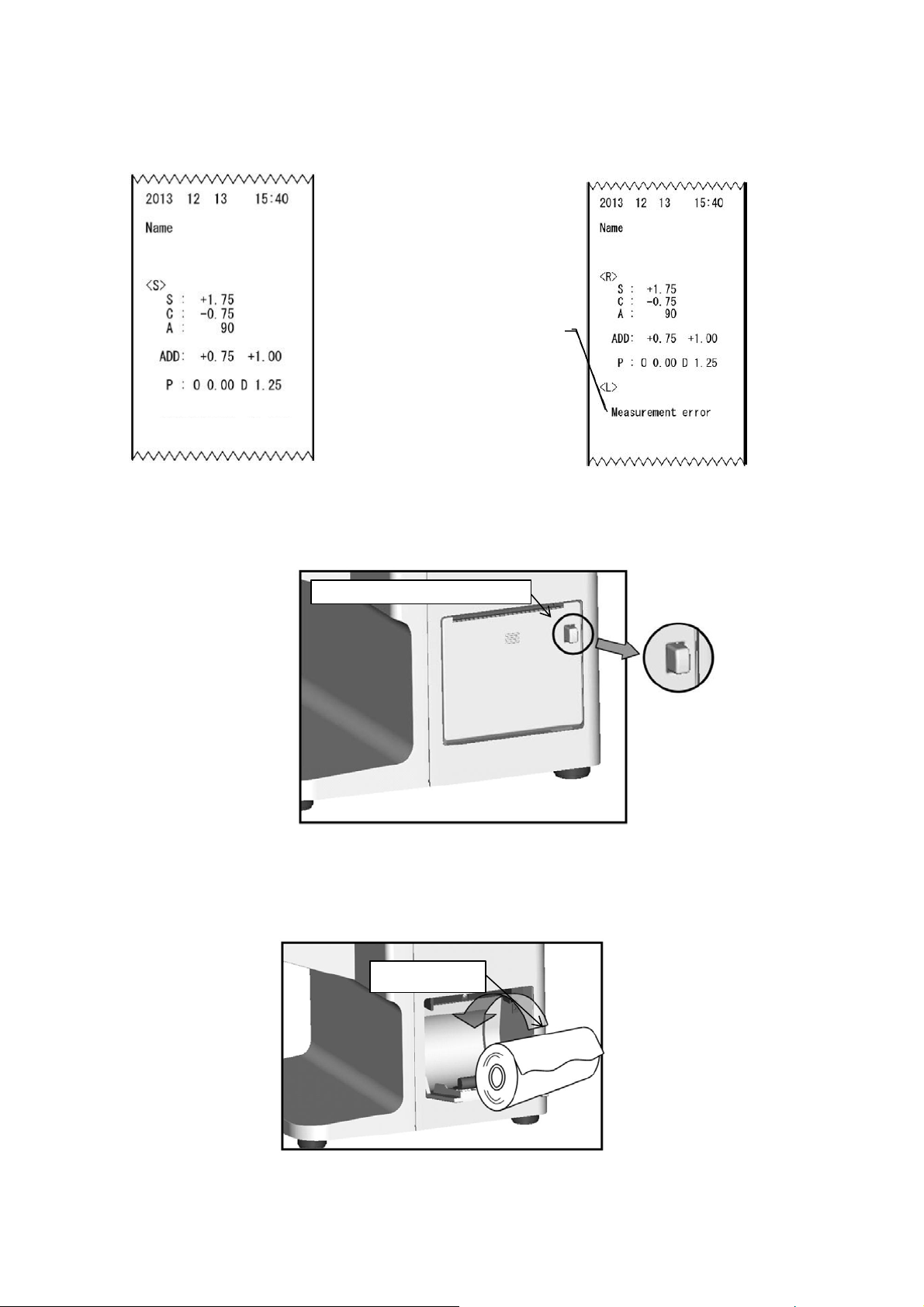

5.4.2 Installation and Replacement of Printer Paper

(1) Open the printer cover by pressing the printer cover button.

【Printout sample in case of

measurement error】

ESSILOR ALM700

(2) Insert the printer paper with attention to the winding direction.

Note) Insert the printer paper so as that the printer paper comes out from the upside.

Printer cover button

Printer paper

22

Page 25

(3) Close the printer cover with the end of the paper taken out a little.

At this time, close it completely until hearing the clicking noise. The error is displayed and

the data is not printed out if the cover is opened.

Printer paper

Use the printer paper specified for “ALM700”.

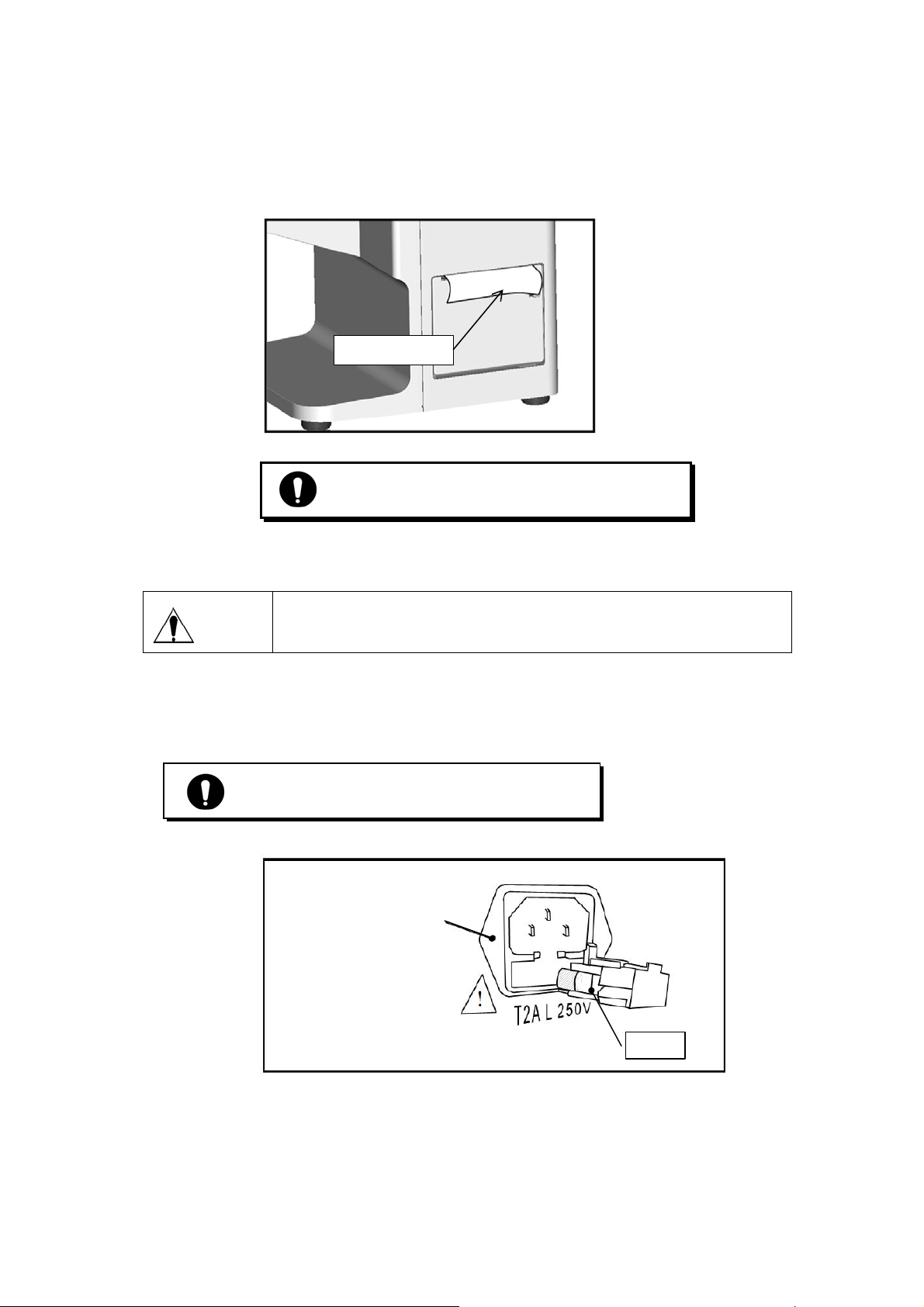

5.5 Replacement of Fuse

Unplug the power cord before removing the fuse holder at the time of

Warning

When the fuse is brown out, replace it after removing the fuse holder of the power inlet. The

fuse holder is removed from the main unit by pulling it out.

replacing the fuse.

Electric shock may occur if removing the fuse holder without

Always use the specified fuse (T2A L 250V).

Power inlet

(with fuse holder)

Fuse

23

Page 26

6. Measurement

6.1 Checkup before Measurement

The lens holder is set properly.

The lens under the lens stand is clean.

(In case that the lens is dirty, clean it with

a soft cloth.)

Plug the power cord to the outlet.

Set the printer paper in the printer.

(Refer to “5.4.2. Installation and Replacement of Printer Paper”.)

Always connect the earth terminal to a ground.

Lens stand is removed

Lens under

lens stand

Confirm that the lens is not placed on the lens stand.

Turn on the power switch. The screen is displayed in seconds.

Single lens measurement screen

Spherical degree

Cylindrical degree

Cylindrical axis

Prism value

Basal angle

Cross cursor

Measurement value

display area

24

Page 27

6.2 Measurement of Single Lens

(1) Place the lens on the lens stand.

Lower the lens holder softly on the lens.

The screen as shown on the right appears.

(2) Bring the cross cursor to the alignment mark by

moving the lens. The message “Alignment OK”

appears on the screen when alignment completes.

If the lens is the cylindrical one, rotate the lens

to fit the axis direction.

(3) Move the lens until the alignment mark and

cross cursor overlap. When they overlap, the

message “Marking OK” appears to indicate that

the marking is ready to be carried out.

S, C, A and prism value are stored by pressing

the Memory/Add switch.

The color of the measurement value area is

reversed, and the values are fixed.

※ In case of setting “Auto Memory” on the

Memory/Add

Do not give strong impact to a lens when lowering the lens holder.

When rising the lens holder, make sure that it is moved to the top and locked.

The alignment mark represents the optical center of the lensmeter and the

NOTE

cross cursor represents the optical center of the lens.

Setup screen as “On”, the measurement

values are stored in memory automatically

after the message “Marking OK” appears.

In case of deleting the data stored in

memory, touch

In case of printing it out, touch

switch

Alignment mark

Cross cursor

.

25

Page 28

6.3 Measurement of Framed Lens

Lens holder

(1) Place the framed lens on the lens stand and lower the

lens holder softly on the lens. Move the lens plate to the

near side with the lens plate lever so that the bottom of

the lens touches the lens plate.

(2) Specify the right or left of the framed lens by touching

. The icon in the upper right corner of the screen

switches to

.

(3)

Perform alignment so as that the bottom of the framed

lens always touches the lens plate in a manner similar to

the single lens.

(4) Save the measurement values in memory by pressing the

Memory/Add switch after measurement.

The color of the measurement value area is changed, and

the measurement values are fixed.

In case of setting “Auto Memory” on the Setup screen as “On”, the measurement values

NOTE

are automatically stored in memory after the message “Marking OK” appears.

(5)

Switch the lens from right to left and place the lens in

a manner similar to (1).

Switch the measurement to the left lens by touching

Lens plate

. At this time, the measurement values of the

right lens remain on the screen.

In case of measuring PD with the setting of PD Measure

On, the right eye and left eye are switched automatically.

The measurement of the lens can be started from either right or left.

In case that the measurement values of both right and left are stored, the

NOTE

values on the selected side are deleted by touching

26

.

Page 29

6.4 Pupillary Distance (PD) Measurement

6.4.1 Device Setting

On the setup screen, confirm that “PD Measure” is set as “On”, and the lens measurement is set

for both of right and left lens.

※ In case that “PD Measure” is “Off”, the PD measurement value and measurement area are

not displayed.

6.4.2 Measurement Procedure (Right lens ⇒ Left lens)

(1) Pull the lens plate toward the examiner.

(2) Place the framed lens so as that the bottom of the frame

contacts with the lens plate with the frame contacting with

the left nose pad

and hold it with the lens holder softly.

(3) Achieve an alignment by moving the right lens back and

forth, and right and left with the frame always

contacting with the lens plate. Store the measurement

values and PD measurement values of the right lens

by pressing the Memory/ Add switch after

completing alignment.

(4) After the measurement of right lens, place the left lens

on the lens stand with the frame contacting with the

right nose pad

softly. At this time, it is switched from right lens to left

lens automatically based on the position of the nose pad.

(5) In a manner similar to (3), achieve an alignment of the left lens. After

completing alignment, store the measurement value of the right lens and PD

measurement values by pressing the Memory/ Add switch.

NOTE

In case that “Auto Memory” on the setup screen is set as “On”, the measurement

values are stored automatically after the message “Marking OK” is displayed.

. Place the right lens on the lens stand

, and hold the lens with the lens holder

Measurement screen

Measurement of right lens

Measurement of left lens

Left PD

measurement value

+3 +3

Right and left PD measurement values

27

Right PD

measurement value

Page 30

6.5 Measurement of Multifocal Lens

(1) Place the lens on the lens stand and hold it with the

lens holder softly.

(2) Take a measurement of far point, and press the

Memory/ Add switch. SPH, CYL, AX and prism values

are stored. The measurement result stored is fixed,

and color of the measurement value display area

changes. “Ad1” is added by pressing the Memory/ Add

switch one more time.

(3) Perform the measurement of near point after

confirming that “Ad1” is displayed. Move the lens

so as that the near point (near-sight segment)

comes to the center of the lens stand.

NOTE

A measurement can be taken even if

the messages of “Alignment OK” and

“Marking OK” are not displayed.

Near point

(Near-sight segment)

(4) Store the ADD value of the near point (near-sight

segment) in memory by pressing the Memory/Add

switch. The color of the Ad value is reversed after

storing it.

In case of trifocal lens, display “Ad2” by pressing

the Memory/Add switch one more time. After that,

repeat (3) and (4) after bringing the second near

point (near-sight segment) to the center of the lens

stand.

Refer to “6.3. Measurement of Framed Lens ”

Display of ADD value

28

Page 31

6.6 Measurement of Progressive Lens

(1) Take a measurement of progressive lens.

Set “Auto Prog.” and “ADD Measure”.

(2) Switching to progressive lens measurement screen

NOTE

Auto Prog.

Off :No auto judgment for a progressive lens

On :Auto judgment for a progressive lens

ADD Measure

F/N.AT :Auto memory of far and near points

N.AT :Auto memory of near point

Manual :Manual memory of far and near points

The icon is changed to

, and the progressive

lens measurement screen is displayed by pressing

(single/ progressive lens selection switch).

In case that Auto Prog is set as “On”, the lens is automatically judged whether the lens

is a progressive lens or not.

Set the lens in the center region of the progressive zone. It starts the auto judgment of

the progressive lens. When the lens is identified as a progressive lens, the screen is

switched to the progressive lens measurement screen. If not, the measurement screen

remains as the single focus lens measurement screen.

When the ADD value is small (less than 1D), the auto detection may not be performed.

Also, if the progressive zone cannot be found at where the lens is set, the auto detection

may not be performed.

In these cases, move the lens back and forth, and right and left slowly.

When the ADD value is small (less than 1D), the framed lens is small, or the lens is dirty

or has some flaws, the far point and near point may not be detected automatically. In

such case, take a measurement manually.

29

Page 32

(3) Measuring procedure of progressive lens (when N.AT is selected for ADD Measure)

1) Detection of progressive zone

First, find the progressive zone by moving the lens back and forth, and right and left slowly.

The cross cursor (screen shown below) appears when the progressive zone is found.

NOTE

Press the Memory/Add switch in case that the progressive zone cannot be detected

because ADD value is small etc. It switches to the measurement screen of the far point.

2) Measurement of far point

Take a measurement of far point. Move the lens toward the

device so as that the center of the alignment mark overlaps

with the cross cursor.

The color of the cross cursor is changed to blue by pressing

the Memory/Add switch after they overlaps.

At this time, the measurement values of the far point

are stored.

NOTE

3) Measurement of near point

When “ADD Measure” on the Setup screen is set as “F/N.AT”, it is detected

automatically and the measurement values are stored in memory.

Progressive area

Take a measurement of near point. As shown on the right,

move the lens slowly

to move the cross cursor (red)

according to

. If it goes out of the progressive zone, the

cross cursor moves right or left. If it goes out of the

progressive zone, bring it back to the zone and move the lens

toward near point.

NOTE

The cross cursor on the screen indicates the actual

measurement position on the lens. For example, if it

goes to the right side of the lens which is out of the

progressive zone at the time of moving from far point

to near point, the cross cursor is displayed on the

right deviated from the progressive zone.

Perform the alignment carefully when it comes closer to the

near point and

starts blinking. Once the near point is

detected, it blips. The cross cursor is fixed at the near point

and its color changes to blue. When the near point is attained,

the ADD value is stored in memory automatically.

※Another ADD value (Ad2) can be stored in memory anywhere

by pressing the Memory/Add switch after measurement.

The progressive judgment screen appears again by setting

+2

25

the lens for the left eye and touch

after completing

the measurement. Take a measurement of the left lens in the

same manner as right lent.

※Measurement can be started from either right or left lens.

30

Page 33

A

A

(4) Display of ADD value and assessment graph, and manual operation

(when “Manual” of “ADD Measure” is selected)

When setting “Prog. Graph” as “On” on the Setup screen, the graph is displayed on the

progress lens measurement screen.

Depending on the type of lens, it may be difficult to detect each point automatically even

though normally the near and far points are detected automatically. In such case, take a

measurement manually by reference to the ADD value and assessment graph.

To take a measurement of far point manually, carry out the alignment in the same manner

as the auto measurement.

For the measurement of near point, press the Memory/Add switch where the ADD value is

the highest while the alignment cursor stays in the progressive area.

The near point is where the assessment line moves closer to the Y coordinate. Therefore,

carry out alignment by reference to the shape of the graph and blinking of

ssessment lineADD value line

High Low

【Framed lens: reference】

Near the center of lens

pprox. 5 to 10mm

Far point

.

Graph

31

Page 34

6.7 Measurement of Ultraviolet (UV) Transmission

Checks the UV protection function by taking a measurement of the UV transmission of lens.

The light wavelength for UV transmittance measurement is 375 nm. This does not measure the transmittance

of a whole area of UV light.

6.7.1 Device Setting

Confirm that “UV Measure” is set as “On” before the measurement of UV transmission.

※ In case of setting “UV Measure” as “Off”, neither UV transmission nor UV transmission

display area is displayed.

If displaying UV transmission graph, set “UV Graph” as “On”.

※ The graph is displayed only in the progressive lens measurement mode.

(Refer to 4.2.1. Device Setting.)

6.7.2 Measurement of UV Transmission after Measuring Degree

The UV transmission measurement is performed after achieving an alignment of the lens and

pressing the “Memory/Add switch” to store the measurement values.

NOTE

At the time of progressive lens measurement, the UV transmission measurement is

performed after taking a measurement of far point

.

In case of taking a measurement again, clear the measurement values first by touching

※The values are cleared in order of degree of lens and UV transmission.

UV transmission graph

UV transmission

.

32

Page 35

6.8 Measurement of Contact Lens

6.8.1 Preparation

(1) In case of taking a measurement of hard contact

lens, select “H CL” on Setup screen. In case of

taking a measurement of soft contact lens, select

“S CL” on Setup screen.

(2) Change the lens stand to the accompanying

contact lens stand.

6.8.2 Measurement Procedure

(1) Set the contact lens on the contact lens stand as shown below.

Contact lens

Contact lens stand

(2) Replace the standard lens stand with the contact lens stand.

(3) Lower the lens holder, and hold the contact lens stand which the contact lens is already

placed.

NOTE

Contact lens stand

Remove the water or moisture from the lens, and set it

on the stand with paying attention not to distort it.

Then, take a measurement quickly.

A bifocal contact lens cannot be measured.

Contact lens stand

33

Page 36

7. Marking

Refer to “5.3. Marking Lever.”

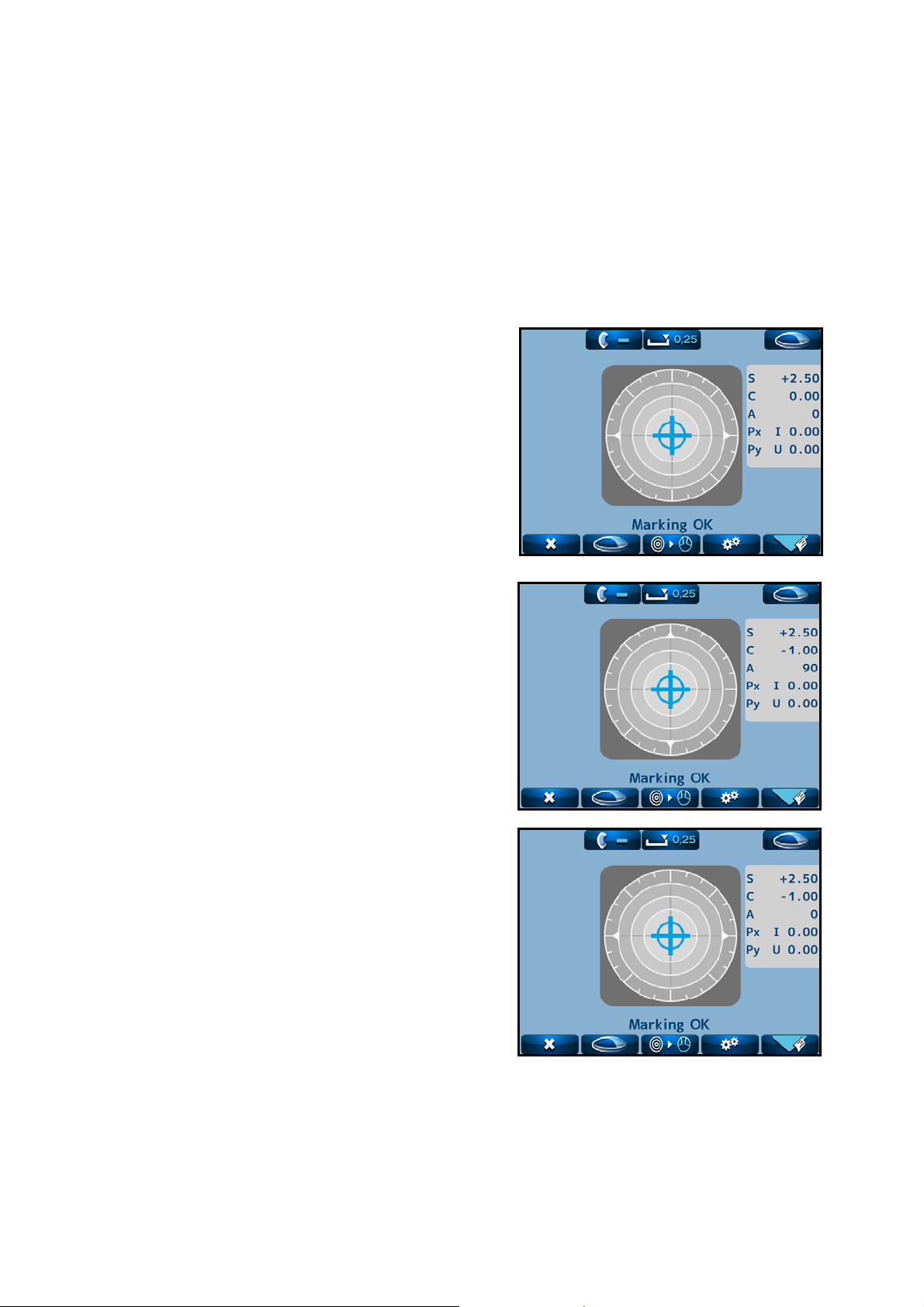

7.1 Lens without Astigmatism

(1) Overlap the cross cursor with the alignment mark

on the screen by moving the lens.

You are ready for marking when the message

“Marking OK” is displayed.

(2) Lower the marking lever to mark on the lens.

7.2 Lens with Astigmatism

Marking according to the axis in the prescription

(1) Move the lens so as that the axis mark aligned with

the angle in the prescription approximately.

(2) To be more precise, align it according to the axis

value indicated.

Marking on the cylindrical axis

(1) Move the lens so as that the axis mark aligned with

0° approximately.

(2) To be more precise, align it so as that the axis value

indicated becomes 0°.

34

Page 37

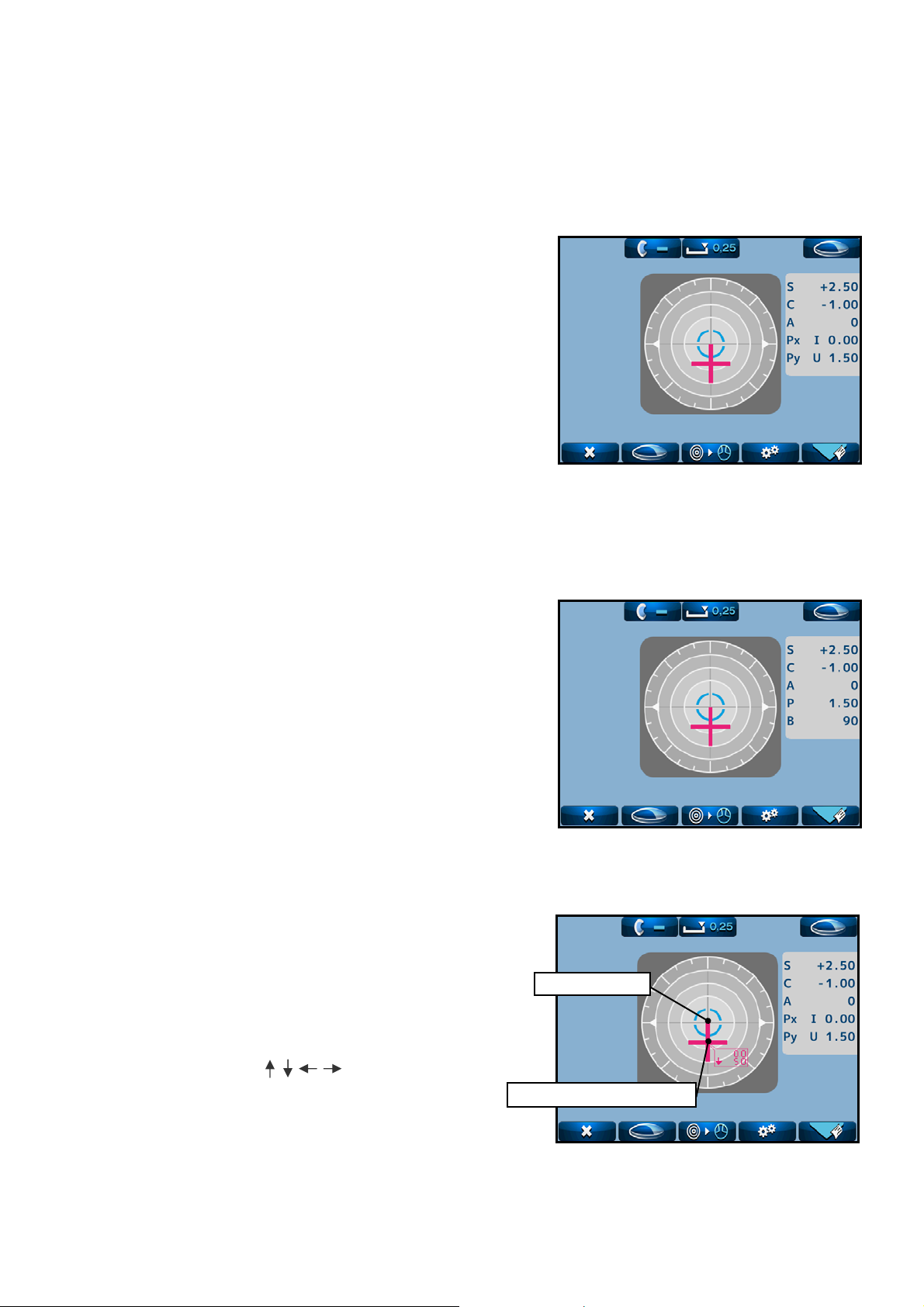

7.3 Marking of Prism Lens

In case that prescription is expressed in X-Y

(1) Select “X-Y” from “Prism” on the “Setup” screen.

(2) Move the lens so that the prism values displayed on

the screen match with the ones on the prescription.

The meanings of the prism values displayed are as

shown below.

Px I Base In (base inward)

Px O Base Out (base outward)

Py U Base Up (base upward)

Py D Base Down (base downward)

In case that prescription is expressed in P-B

(1) Select “P-B” from “Prism” on the “Setup” screen.

(2) Move the lens so that the prism values displayed

on the screen match with the ones in the

prescription.

P: Prism value

B: Base direction

In case that prescription is expressed in mm

(1) Set “Prism (mm)” as “On” on the “Setup” screen.

(2) Move the lens so that the prism values displayed

on the screen match with the ones in the

Optical center

prescription.

The arrows ( ) indicate the direction of

the measuring position on the lens from its

optical center.

Measurement position

35

Page 38

A

8. Other Functions

8.1 Auto Memory Function

This device has the function to store the measurement values in memory automatically when

the alignment is achieved, and the message “Marking OK” is displayed at the time of the

measurements of single focal lens, multifocal lens and contact lens.

8.1.1 Operation Procedure

Move the cursor to “Auto Memory” with or

and select “On” with .

Return to the measurement switch with

after the settings or changes are completed.

he measurement values are stored in memory

automatically when the message “Marking OK”

appears after the alignment mark and cross cursor

overlap as shown on the right.

mark

Cross cursor

lignment

+2.50

36

Page 39

8.2 Power Saving Function

The power saving function is activated if no switches are operated or no measurement values

are updated with the power on. The switching time to the power saving mode can be set on

“Standby” of the Setup screen.

Power indicator (PW) Light on

Power indicator (PW) Blinking

Power indicator (PW) Light on

Measurement mode

No operation for a set time

Power saving

Return to measurement mode

Press any switch

While this function is activated, the power to

the measurement light and LCD monitor is

turned off.

It returns to the measurement mode by

pressing any switch.

37

Page 40

9. Error Display

An error message appears when the measurement condition or measurement result is judged

as unreasonable. Also, an error message appears when the performance of the device is

abnormal.

9.1 Type

※ Display with a three-digit code (number)

Message Status Error Detail

Any of the measurement values is more than “±0.25”.

Initial Error

Paper Empty No printer papers.

Printer Cover Opened Printer is opened.

Printer Overheated Printer head is overheated.

EEPROM Failure Abnormality of memory

Sensor Error Abnormality of CMOS sensor

※Error * * * (100 -163)

SPH Over

CYL Over

Prism Over

ADD Over

Measurement Error

Center Error

Abnormality

of device

Measurement

abnormality

Abnormality

of image

processing

Lens is set on the lens stand.

Abnormal measurement because of dust or

unnecessary light.

Abnormality of electronic parts

SPH measurement value is more than the upper

limit of the measurement range.

CYL measurement value is more than the upper

limit of the measurement range.

The prism measurement value is more than the

upper limit of the measurement range.

ADD measurement value is more than the upper

limit of the measurement range

Abnormal light receiving image because of dust,

scratch on lens or unnecessary light etc.

(The measurement light does not enter into the light

receiving sensor normally.)

Measurement light LED does not light on.

Unexpected light receiving image because of

unnecessary light.

38

Page 41

9.2 Error Handling Procedure

Warning

Do not disassemble, remodel or repair.

It may cause electric shock.

・Initial Error

This message appears if the lens is placed on the lens stand when the power is turned on or

the lens under the lens stand is dirty.

Remove the lens. When the lens under the lens stand is dirty, gently wipe it with a soft

cloth. After that, turn the power back on.

(Refer to “6.1 Checkup before Measurement”.)※

・Paper Empty

This message appears if no papers are set or papers are not set appropriately.

Set the paper appropriately. (Refer to “5.4.2 Installation and Replacement of Printer

Paper”.)

・Printer Cover Opened

This message appears when the printer cover is opened. Check the cover and close it

properly.

・SPH/CYL/Prism/ADD Over

This message appears in case of measuring the lens which exceeds the upper limit of the

measurement range of the device.

Take a measurement of the lens within the measurement range

(Refer to “11. Specification”.)

・Measurement Error or Center Error

This message appears when the direct sunlight or strong glare is on the device, or the lens

under the lens stand is extremely dirty or has scratches.

If the lens under the lens stand is extremely dirty, gently wipe it with a soft cloth. Then,

turn the power back on.

If an error message other than shown above is displayed or an error message

is still displayed even after performing the procedure above, turn off the

power, disconnect the power cord and contact your local distributor.

39

Page 42

10. Storage of Device

(1) Points to be checked for long-term storage

Turn OFF the power.

Remove the power cord from the outlet.

Put the dust proof cover on the main unit.

(2) Notes on storage environment

(3) Avoid storage under the following conditions

Dusty place

Where water may get on the device

High-temperature and humidity

Where sunlight directly contacts

Unstable and high place

Observe the environment conditions below for storage.

Environmental condition for storage

Check the above in case that the device is not used or is stored for a long time.

When using the device after long-term storage, operate it in accordance with

“4.2 Preparation for Measurement”.

40

Page 43

11. Specification

Sphere -25D to +25D (0.01/0.12/0.25 step)

Cylinder 0 to ±10D (0.01/0.12/0.25 step)

Measurement range

Measurable lens

Measurement

wavelength

UV transmission

UV transmission

measurement

wavelength

PD measurement

Power Rating

Power Consumption 40VA

Printer Thermal printer (paper width 58mm)

Monitor Color LCD monitor (5.7 inches)

Size, weight

Environmental

condition of use

Axis 0 to 180° (1°)

Addition 0 to +10D (0.01/0.12/0.25 step)

Prism

Unprocessed lens

(diameter:100mm)

Framed processed lens

Hard contact lens

Soft contact lens

525nm

0 to 100% (-25D to +25D)

375nm (UV-A)

45 to 85mm (0.5mm step)

100 to 240V

50/60Hz

170mm(W)×205mm(D)×468mm(H)(400mm: when the monitor is stored)

Approx. 4.3kg

Temperature range: 5 to 40

Humidity range: 30 to 95%HR (No dew condensation allowed)

0 to 10△

Single lens, multifocal lens, progressive

lens

Accompanying lens stand is required

(0.01/0.12/0.25 step)

41

Page 44

12. EMC (Electromagnetic Compatibility)

This device conforms to the requirements of the EMC (electromagnetic compatibility) standard

as shown below.

Guidance and manufacturer’s declaration – electromagnetic emissions

This device is intended for use in the electromagnetic environment specified below.

The customer or user of this device should assure that it is used in such an environment.

Emission test Compliance Electromagnetic environment – guidance

RF emissions

CISPR11

RF emissions

CISPR11

Harmonic

emissions

IEC 61000-3-2

Vol ta ge

fluctuations/

flicker emissions

IEC 61000-3-3

Group 1

Class A

Class A

Complies

This device uses RF energy only for its internal function.

Therefore, its RF emissions are very low and are not likely to

cause any interference in nearby electronic equipment.

This device is suitable for use in all establishments other than

domestic and those directly connected to the public

low-voltage power supply network that supplies buildings

used for domestic purposes.

42

Page 45

Guidance and manufacture’s declaration – electromagnetic immunity

This device is intended for use in the electromagnetic environment specified below.

The customer or user of this device should assure that it is used in such an environment.

Immunity test

Electrostatic

discharge

(ESD)

IEC 61000-4-2

IEC 60601

test level

±6kV contact

±8kV air

Compliance level

±6kV contact

±8kV air

Electromagnetic environment

- guidance

Floors should be wood,

concrete of ceramic tile. If

floors are covered with

synthetic material, the

relative humidity should be

at least 30%.

Electrical fast

transient/ burst

IEC 61000-4-4

Surge

IEC 61000-4-5

±2kV for power

supply lines

±1kV for input/

output lines

±1kV differential

mode

±2kV common mode

±2kV for power

supply lines

±1kV for input/

output lines

±1kV differential

mode

±2kV common mode

Mains power quality should

be that of a typical

commercial or hospital

environment.

Mains power quality should

be that of a typical

commercial or hospital

environment.

Voltage dips,

short

interruptions

and voltage

variations on

power supply

input lines

IEC 61000-4-11

Power

frequency

(50/60Hz)

Magnetic field

IEC 61000-4-8

<5 %

U

T

(>95% dip in

for 0.5cycle

40 %

U

T

(60% dip in

for 5 cycles

70 %

U

T

(30% dip in

for 25 cycles

<5 %

U

T

(>95% dip in

for 5s

U

U

U

U

T)

T)

T

T)

)

<5 %

U

T

(>95% dip in

for 0.5 cycle

40 %

U

T

(60% dip in

for 5 cycles

70 %

U

T

(30% dip in

for 25 cycles

<5 %

U

T

(>95% dip in

for 5s

U

U

U

U

)

T

)

T

)

T

)

T

3A/m 0.3A/m If image distortion occurs, it

Mains power quality should

be that of a typical

commercial or hospital

environment. If the user of

this device requires continued

operation during power

mains interruptions, it is

recommended that this device

be power from an

uninterruptible power supply

or a battery.

may be necessary to position

the device further from

sources of power frequency

magnetic fields or to install

magnetic shielding. The

power frequency magnetic

field should be measured in

the intended installation

location to assure that it is

sufficiently low.

NOTE

U

is the a.c. mains voltage prior to application of the test level.

T

43

Page 46

Guidance and manufacturer’s declaration – electromagnetic immunity

This device is intended for use in the electromagnetic environment specified below. The

customer or the user of this device should assure that it is used in such an environment.

Immunity test

Conducted RF

IEC 61000-4-6

Radiated RF

IEC 61000-4-3

IEC60601

test level

3 Vrms

150 kHz to 80

MHz

3 V/m

80 MHz to 2.5

GHz

Compliance

level

3 Vrms

3 V/m

Electromagnetic environment - guidance

Portable and mobile RF communications

equipment should be used no closer to any

part of this device, including cables, than

the recommended separation distance

calculated from the equation applicable to

the frequency of the transmitter.

Recommended separation distance

√

d

=1.2

P

√

d

=1.2 80 MHz to 800 MHz

P

√

d

P

=2.3 800 MHz to 2.5 GHz

where P is the maximum output power

rating of the transmitter in watts (W)

according to the transmitter manufacturer

and

d

is the recommended separation

distance in metres (m).

Field strengths from fixed RF

transmitters, as determined by an

electromagnetic site survey,

a

should be less

than the compliance level in each

frequency range.

b

Interference may occur in the vicinity of

equipment marked with the following

symbol:

NOTE 1 At 80 MHz and 800MHz, the higher frequency range applies.

NOTE 2 These guidelines may not apply in all situations. Electromagnetic propagation is

affected by absorption and reflection from structures, objects and people.

a

Field strengths from fixe transmitters, such as base stations for radio (cellular/cordless)

telephones and land mobile radios, amateur radio, AM and FM radio broadcast and TV

broadcast cannot be predicted theoretically with accuracy. To assess the electromagnetic

environment due to fixed RF transmitters, an electromagnetic site survey should be considered.

If the measured field strength in the location in which this device is used exceeds the applicable

RF compliance level above, this device should be observed to verify normal operation. If

abnormal performance is observed, additional measures may be necessary, such as re-orienting

or relocating this device.

b

Over the frequency range 150kHz to 80MHz, field strengths should be less than 3 V/m.

Recommended separation distances between portable and mobile RF communications

equipment and this device

This device is intended for use in an electromagnetic environment in which radiated RF

44

Page 47

disturbances are controlled. The customer or the user of this device can help prevent

electromagnetic interference by maintaining a minimum distance between portable and mobile

RF communications equipment (transmitters) and this device are recommended below, according

to the maximum output power of the communications equipment.

Separation distance according to frequency of transmitter

m Rated maximum

output power of

transmitter

W

0.01 0.12 0.12 0.23

0.1 0.38 0.38 0.73

1 1.2 1.2 2.3

10 3.8 3.8 7.3

100 12 12 23

For transmitters rated at a maximum output power not listed above, the recommended

separation distance d in metres (m) can be estimated using the equation applicable to the

frequency of the transmitter, where

watts (W) according to the transmitter, where

transmitter in watts (W) according to the transmitter manufacturer.

NOTE 1 At 80 MHz and 800MHz, the separation distance for the higher frequency range

applies.

NOTE 2 These guidelines may not apply in all situations. Electromagnetic propagation is

affected by absorption and reflection from structures, objects and people.

150kHz to

80MHz

√

d

=1.2

P

P

80MHz to

800MHz

√

d

=1.2

P

is the maximum output power rating of the transmitter in

P

is the maximum output power rating of the

800MHz to 2.5GHz

√

d

=2.3

P

45

Page 48

46

Page 49

Page 50

Essilor Instruments USA

8600 W. Catalpa Avenue, Suite 703

Chicago, IL 60656

Phone: 855.393.4647

Email: info@essilorinstrumentsusa.com

www.essilorinstrumentsusa.com

Loading...

Loading...