Page 1

Models

AD1C51 AD2C51

AS1C51 AS2C51

AD1C5112 AD2C5112

AS1C5112 AS2C5112

AD1C71 AD2C71

AS1C71 AS2C71

AD1C7112 AD2C7112

AS1C7112 AS2C7112

AU1C7112 AU2C7112

Circle the model of your cooler and

record the serial number below.

Read Carefully All Of This Manual

Before Installing The Unit

Lea Con Cuidado Todo Este Manual Antes De

Instalar La Unidad

Table Of Contents

Safety Instructions .......................................................................1

Installation Instructions ............................................................2-3

Electrical Wiring Diagram ...........................................................3

Operation ..................................................................................3-4

Maintenance Section ....................................................................4

Troubleshooting ...........................................................................5

Vea el Español en el interior.

Read And Save These Instructions

Safety Rules

1. Read instructions carefully.

2. Electrical hook up should be done by a qualifi ed electrician, so

that all electrical wiring will conform to your local standards.

3. Always DISCONNECT POWER and UNPLUG motor and

pump inside the cooler before installing or performing any

maintenance.

4. Motor and pump have a grounded, molded plug and an automatic

thermal overload switch which will shut motor off when it

overheats. The motor will restart automatically when it cools

down.

WARNING: T o reduce the risk of fi re or electric shock, do not

use this fan with any “solid-state fan speed control device.”

Encierrre con un circulo el modelo de su

enfriador y escribe el número de série abajo.

Serial #

Número De Série

Warranty .......................................................................................5

Parts List (Down Discharge Units) .......................................... 6-7

Parts List (Side Discharge Units) .............................................8-9

Parts List (Up Discharge Units) ........................................... 10-11

Specifi cation Tables (Tablas de Especifi caciones) .....................12

Instrucciones en Español .....................................................12-16

Evaporative Cooling

Evaporative cooling is nature’s way of cooling. When air is moved

over a wet surface, water is evaporated and heat is absorbed. When

stepping out of swimming pool with the wind blowing, evaporative

cooling makes you feel cool, even though the air may be warm.

This unit works on the same principle. Air is drawn across wet

fi lter pads where the air is cooled by evaporation and then circulated

throughout the building. It is this combination of cooled air and the

movement of air over the skin which makes it feel cool.

Unlike refrigeration systems which recirculate the air, an evaporative

cooler continually brings in fresh air while exhausting old air. You

are completely replacing the air every 2 to 4 minutes by opening

windows or doors or a combination of both. The air is always fresh,

not stale, laden with smoke and odors as happens with refrigerated

air conditioning.

110498-3 9-09

www.championcooler.com

Page 2

Cooler Installation

CAUTION: Make sure that the mounting surface is strong

enough to support the operating weight of the cooler when in use.

(For operating weight, see Specifi cation Table.)

CAUTION: Never start cooler until installation is complete

and unit has been tested for rigidity.

CAUTION: Do not screw or drill within 5 inches of the bottom

of the wet module. You could puncture the reservoir.

CAUTION: If the unit is supported with legs at each corner ,

the middle of the unit where the two sections join must be supported as well.

NOTE: For ease of installation you can

separate the wet module from the blower

module by removing the 4 bolts from the wet

module side (Fig. 1). Remember to unplug

the pump and drain pump before separating

the modules.

Water Connection

• Install overfl ow assembly. Remove

nut and place nipple through the hole

in the pan, with the rubber washer between the pan and the head of the drain

nipple (Fig. 2). Screw on nut and draw

up tight against bottom of pan. Insert

overfl ow into nipple to retain water.

The overfl ow pipe comes from the fac-

tory connected to the dump pump hose.

The overfl ow pipe may be removed to

drain pan when necessary. A garden

hose may be screwed on the drain nipple

to drain water away from your unit.

• Connect water supply line. Install

a sillcock and water valve on faucet

as shown by fi gure 3. Place the nut

and ferrule on the tubing and tighten

the nut until water tight. NOTE:

Do not connect the water supply to

any soft water applications.

Sillcock

• Install fl oat valve and fi ll pan.

Refer to Fig. 4. Remove items 1,

2, 3, and 4. Insert fl oat body (5)

through hole in back post panel as

shown. Install washer (1) and nut

(2). Tighten to keep fl oat from turn-

ing. Place nut (4) and ferrule (3) on

water supply line. Connect to fl oat

fi tting and tighten until water tight.

Bend rod (6) to adjust fl oat until

6

water level is about 1 inch below

the top of the overfl ow pipe. Slide

fl oat shield (7) over fl oat body (5)

until it snaps into place.

Electrical Installation

WARNING: Disconnect all electrical service that will be used

for this unit before you begin the installation and leave it disconnected until the installation is complete.

5

Fig. 4

Wet

Module

Mounting

Bolts

Fig. 1

Fig. 2

Faucet

Fig. 3

7

Drain Pump

Hose

Overfl ow Pipe

Nipple

Rubber Washer

Bottom Pan

Nut

Water Supply

Valve

Ferrule

3

2

1

Nut

4

should be adequately protected against overloads and short circuits.

Note: Electrical installation should be performed by a qualifi ed

electrician. Be sure to follow all National and Local Electrical

Codes when installing this cooler.

• Install weatherproof switch box. Located inside the unit in a

plastic bag is a switch box and cover, a chase nipple, a seal ring

and a toggle switch. Remove the electrical junction box (Fig. 5)

which is mounted on the inside of the center panel. From inside

the unit, insert the chase nipple

through the electrical access

hole. Slide the seal ring over

the chase nipple. Mount the

Junction

Box

Seal Ring

Chase

Nipple

Electrical

Box

switch box to the outside of the

unit by threading the chase nipple into the switch box. Run

the three switch leads through

the nipple and into the switch

box and reinstall the junction

box. Connect the green ground

Fig. 5

lead to the ground screw in the

switch box.

• Supply power to unit. Run power to the external switch box and

connect to the two poles of the toggle switch. Connect the gray and

white leads from the cooler electrical box to the two poles of the

toggle switch. Refer to the appropriate wiring diagram to complete

the electrical installation of your cooler. Secure the switch into the

switch box and install the gasket and switch cover.

CAUTION: All openings in the external switch box must be

sealed to prevent water from entering the switch box.

CAUTION: Pump receptacles are for grounded evaporative

cooler pumps only. Do not plug anything else into receptacle.

WARNING: Make sure that cooler cabinet is properly

grounded to a suitable ground connection for maximum safety.

Thermostat Installation

1) Find a suitable location for the wall thermostat (away from sources

of heat, sunlight, or ventilation, and between 4 and 6 feet from the

fl oor). The thermostat may be mounted to a standard electrical

box.

2) Route an insulated four-conductor thermostat cable (or similar)

from the Control Box inside the cooler to the thermostat electrical

box. This cable is not supplied.

W ARNING: The thermostat

cable should not be routed next to or enter the cabinet through

the same inlet as the power supply wire.

3) Connect the thermostat wires to the terminals on the back of the

wall control and to the terminals located on the left side of the

control box in the unit. Make sure to follow the color code found

next to each terminal.

Amperage Draw And Belt Tension

This unit is equipped with an adjustable motor drive sheave for

adjusting the blower wheel speed to the proper loading on different

duct systems. It is important that the motor drive pulley is adjusted

to correct size to assure maximum air delivery without damage to the

motor. Be sure to follow these instructions carefully.

• Adjust drive pulley. After the unit is completely installed, adjust

the drive pulley to the least diameter and adjust belt tension. See

the maintenance section for adjusting belt tension.

The control box is factory wired and installed for either 120V or 230V

operation depending on the model you purchased. The supply power

2

110498-3

Page 3

• Start cooler. Install both inspection panels, start pump, and allow

to operate until pads are wet.

• Check amperage. With pads wet and unit started, check amperage

draw with an amperage meter.

During automatic operation, the control performs a 90 second water

dump cycle every 8 or 12 hours of pump operation. This interval can

be toggled between 8 or 12 hours by simultaneously holding the ‘Cool’

and ‘Fan’ buttons for 5 seconds. The selected interval is displayed for

a short time. This action also starts a manual dump cycle.

• Adjust pulley if necessary. If amperage draw is less than mo-

tor rating, turn off electrical power and

remove inspection panels. Unplug motor inside cooler, this will protect you

from someone turning on unit while

you are working inside. This should be

Decrease

Amperage

done for your safety. Adjust pulley to a

larger diameter and readjust belt tension,

plug motor in, install inspection panels,

Fig. 6

and retest amperage draw. Repeat this

process until correct amperage draw is attained. Increasing motor

pulley diameter increases amperage draw. Decreasing motor pulley

diameter decreases amperage draw (see Fig. 6).

CAUTION: Do not operate cooler with larger amperage draw

than specifi ed on motor plate.

Thermostat Operation

Automatic Operation (Cool Mode)

The fan and water pump are contr olled automatically to achieve the

desired comfort level.

This mode is activated by pressing the ‘Cool’ button. A blue LED

is illuminated, and for a few seconds the LCD will display the

‘Set’ temperature. Pressing the ‘Cool’ button again deactivates this

mode.

The Set temperature (the target temperature for control) may be altered

by repeatedly pressing or holding the ‘Up’ and ‘Down’ buttons. The

LCD will display ‘Set’ rather than ‘Room’ temperature for a short

time after pressing the ‘Up’ or ‘Down’ button.

On starting, if the pads in the cooler are too dry, the fan may be delayed

from starting until the pads have absorbed some water. This is called

Pre-wet and lasts for 2 minutes, indicated by a fl ashing blue LED.

Selecting ‘Fan’ and then ‘Cool’ will bypass the pre-wet and cause the

fan and pump to start immediately. (If cooling is required).

Ventilation Operation (Fan Mode)

The fan speed is set by the user, the water pump is turned off.

This mode is activated by pressing the ‘Fan’ button. A green LED

is illuminated, and the LCD indicates fan speed. Pressing the ‘Fan’

button again deselects this mode.

Pressing the ‘Up’ button selects maximum Fan speed, and ‘Hi’ is

displayed in the LCD; pressing the ‘Down’ button selects minimum

Fan speed, and ‘Lo’ is displayed in the LCD.

Time Delay Operation (Timer Mode)

Delayed start or fi nish in ‘Cool’ or ‘Fan’ mode.

The ‘Timer’ button is used to set a delay period of 2, 4 or 8 hours,

depending on how many times the button is pressed.

If the cooler is operating in ‘Cool’ or ‘Fan’ modes when the ‘Timer’

button is pressed, the delay period determines when the cooler will

switch off. If the cooler is Off when the ‘Timer’ button is pressed,

the delay period determines when the cooler switches on.

The starting mode is indicated by a fl ashing LED. You can change

this mode by pressing the appropriate button (‘Cool’ or ‘Fan’).

Y ou can cancel the T imer function at any time by pressing the ‘Timer’

button until all the timer LED’s go out.

In The Event Of A Power Outage

If the cooler is operating in ‘Cool’ or ‘Fan’ mode when power is

interrupted, the cooler will resume in the same mode of operation

when the power is restored.

If the cooler was in any ‘Timer’ mode at the time of a power

interruption, the cooler will remain off when power is restored.

FAN MOTOR

RECEPTACLE

CIRCULATING PUMP

RECEPTACLE

DRAIN PUMP

RECEPTACLE

110498-3

COOLER TERMINAL BOX

BLACK

RED

WHITE

GREEN

ORANGE

GREEN

WHITE

BLUE

ORANGE

BROWN

GREEN

WHITE

BLUE

ORANGE

BROWN

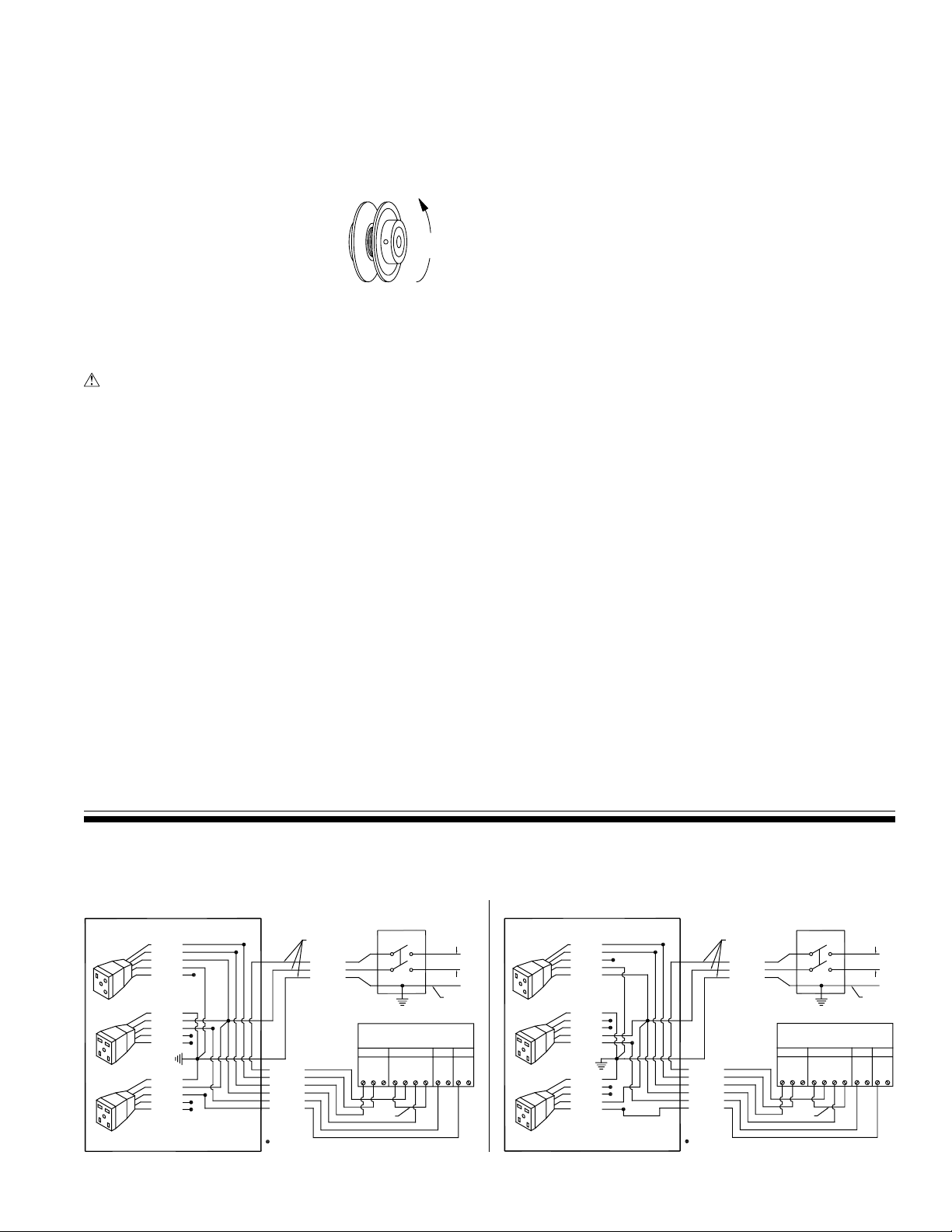

Wiring Diagrams

120 Volt 240 Volt

GRAY

BLACK

RED

YELLOW

BLUE

VIOLET

=WIRE NUT

(11)

SWITCH LEADS

GRAY

WHITE

GREEN

TOGGLE SWITCH

THERMOSTAT

FCom

LINK

FLo

FHi

WHITE

120 VAC

GROUND

DUMPPUMPFAN PWR. SUPPLY

DCom

PCom

NLink

DP

PP

L1

N

COOLER TERMINAL BOX

FAN MOTOR

RECEPTACLE

CIRCULATING PUMP

RECEPTACLE

DRAIN PUMP

RECEPTACLE

BLACK

RED

WHITE

GREEN

ORANGE

GREEN

WHITE

BLUE

ORANGE

BROWN

GREEN

WHITE

BLUE

ORANGE

BROWN

GRAY

BLACK

RED

YELLOW

BLUE

VIOLET

=WIRE NUT

(11)

SWITCH LEADS

GRAY

WHITE

GREEN

TOGGLE SWITCH

THERMOSTAT

PWR. SUPPLYFAN

FCom

LINK

FLo

FHi

WHITE

240 VAC

GROUND

PUMP DUMP

DCom

PCom

NLink

DP

PP

L1

N

3

Page 4

Required Exhaust Openings

An often misunderstood concept of evaporative cooling is the amount

of air that should be exhausted. How much should you open your

windows? The fact is that most people do not open their windows

enough. The following two methods will help you determine the

amount to open your windows.

First Method

You should allow an opening of at least 2 square feet (288 square

inches) for each 1000 CFM rating of your unit. Example: At 3790

CFM, model AD1C51 (3/4 hp) requires 7.6 square feet (1094 square

inches) of opening (3790/1000 * 2 = 7.6). Multiply the number of

windows by window width in inches and divide this into the number

of square inches required for your size unit. This will give you the

height to open windows. In this example, four 36 inch wide windows

should be opened 7.6 inches each.

Champion Air Balancing Method

1. Take a piece of tissue paper and cut it lengthwise into 3 equal

strips.

2. Turn your cooler on high cool.

3. Open one window at least six inches wide in each room that you

want to cool.

4. Take the piece of tissue paper and put it up against the screen of

the open window furthest from the cooler discharge opening. Let

go of it. It will do one of three things.

IMPORTANT: In order to get the best performance from your

cooling pads, they must be installed properly. If you have purchased a pad with two equal angles, the following instructions can

be disregarded. Pads must always be installed with the steeper

fl ute angle sloping down

towards the air entering

side (Fig. 7). The reason

is simple. The steeper

angle puts more water on

the hot, dry, dirty side of

the pad where it is needed

most. It also counteracts

the tendency of the air to

push the water toward the

back of the pad.

• Check belt tension. A 3 lb. force

should defl ect the belt 3/4 inches

(see Fig. 8). Readjust belt if needed.

• Oil bearings. The blower bearings

and cooler motor in this unit should be oiled with a few drops of

non-detergent 20/30 weight oil once each year. The motor does

not need oil if it has no oil lines for oiling. Motors that have no oil

lines are lifetime oiled at the factory and require no further oiling

for the life of the unit.

Entering

Air

Fig. 7

45°

Leaving Air

15°

3 Lb.

3/4 Inches

Fig. 8

CAUTION: Do not over oil. Over oiling can cause motor burn

out, due to excessive oil getting into motor winding.

IF It falls down.

THEN CLOSE all of the windows one inch and try step 4 again.

IF It plasters itself to the screen.

THEN OPEN all of the windows one inch and try step 4 again.

IF It stays on the screen lightly.

THEN PERFECT. You are done. Enjoy your cooler.

NOTES:

• When switching to low cool, you must rebalance your home. Repeat

step 4.

• Once you balance your home you can cool some areas more than

others by opening those windows more and closing the others by

the same amount. Repeat step 4 to make sure your home is still air

balanced.

Maintenance

WARNING: Before doing any maintenance be sure power

is off. At the time you remove either inspection panel be sure to

unplug motor and pumps. This is for your safety.

Spring Start-Up

• Clean pads. A clean pad is more absorbent, effi cient and will give

more cool air. Annually, or when required, using a garden hose

with nozzle, back wash to clean out the openings, then clean off

the inlet face any scale or other obstruction to the passages. Slight

scraping may be required to remove hardened scale.

• Change pads if necessary. The pads should be replaced after 5

years or if necessary. To change pads, remove top access panel,

remove grill, and disconnect water delivery tube. Remove water

distributor holder and lift out media sections. Replace with the

same type media. You can purchase them from your dealer.

• Clean water pump and dump pump. Cleaning both pumps is

necessary once a year at start-up. For your safety, turn unit off

and unplug motor and pumps. Remove the pump from the mount

slot. Remove the base of the pump as shown in Fig. 9. Clean the

pump and turn the impeller to ensure free operation. Remove the

pump spout and check for any blockage. After cleaning, reinstall

the base onto the pump. Press

fi rmly to make sure it is secure.

Reattach the pump to the mount

in the cooler using the plastic

retainer to ensure that the pump

will not overturn. Do not forget

to replace the spout and water

delivery tube onto the pump

outlet.

Remove

Base

Impeller

Fig. 9

Winter Shut-Down

• Drain water. Always drain all of the water out of the cooler and

water supply line when not in use for prolonged periods, and particularly at the end of the season. Keep the water line disconnected

from both the unit and water supply so that it does not freeze.

• Unplug motor and pumps. When cooler is not used for extended

periods unplug the motor and pumps from inside cooler.

• Cover unit. To protect the life of the fi nish, a cover for the unit is

suggested in extended periods of non use.

By following the operating, installation, and maintenance suggestions

as outlined, you ca n get many years of e fficient and satisfactory service

from your cooler . In the e vent additional inf ormation is desired, your

dealer will be more than glad to assist you in every possible way.

4

110498-3

Page 5

Troubleshooting Guide

Problem Possible Cause Remedy

Failure to

start or no air

delivery/ No

LCD display

Inadequate

air delivery

with cooler

running

1. No electrical power

to unit

• Fuse blown

• Circuit breaker tripped

2. Motor overheated

• Belt too tight

• Blower bearings dry

• Motor pulley diameter

too large

3. Motor locked

4. Fuse blown in unit

control box

5. Incorrect wiring between wall thermostat

and cooler

6. Poor connection to

Fan motor terminals

7. Unit control board or

wall thermostat faulty

1. Insuffi cient air exhaust

2. Belt too loose

3. Pads plugged

4. Motor underloaded

1. Check power

• Replace fuse

• Re-set breaker

2. Determine cause

• Adjust belt tension

• Oil blower bearings

• Adjust pulley to correct

diameter

3. Replace motor

4. Replace Fuse

5. Check that wiring is correct

and secured to terminals

6. Check connections to terminal

7. Supply power to control box

and check DC voltage at

wall thermostat

• If voltage between Black

& Red terminals is close to

3.5VDC and LCD is blank

- wall thermostat is faulty

• If voltage is much less than

3.5VDC, remove red wire

from terminal. If voltage

rises to 3.5VDC - thermostat

is faulty. If voltage remains

low - unit control board is

faulty.

1. Open windows or doors to

increase air fl ow

2. Adjust belt tension or

replace if needed

3. Clean pads

4. Adjust pulley

Problem Possible Cause Remedy

Water draining onto roof

Musty or

unpleasant

odor

Motor cycles

on and off

Noisy

Inadequate

cooling

Excessive

humidity in

house

1. Float arm not adjusted

properly

2. Overfl ow assembly

leaking

1. Stale or stagnate water

in cooler

1. Low voltage

2. Excessive belt tension

3. Blower shaft tight or

locked

4. Bearings dry

5. Motor pulley diameter

too large causing motor

overload

1. Bearings dry

2. Wheel rubbing blower

housing

3. Loose parts

1. Inadequate exhaust in

house

2. Pads not wet

• Pads plugged

• Dist. tube holes clogged

• Pump not working properly

3. Poor connection to Pump

terminals on Control

Board

1. Insuffi cient air exhaust

1. Adjust fl oat

2. Tighten nut and overfl ow

pipe

1. Drain pan and clean pads

1. Check voltage

2. Adjust belt tension

3. Oil or replace bearings

(Unplug unit)

4. Oil bearings

5. Adjust pulley so full load

ampere rating of motor is

not exceeded

1. Oil bearings

2. Inspect and realign (Unplug unit)

3. Tighten loose parts

1. Open windows or doors to

increase air fl ow

2. Check water distribution

system

• Clean pads

• Clean

• Replace or clean pump

(Unplug unit)

3. Check connections

1. Open doors or windows

Register your product online at www.championcooler.com/eac/onlineregistration-eac.htm

Limited W arranty

This warranty is extended to the original purchaser of an evaporative cooler installed and used under normal conditions. It does not cover damages incurred through accident, neglect, or abuse by the owner. We do not authorize any person or representative to assume for us any other or different liability

in connection with this product.

Terms And Conditions Of Warranty

Lifetime Limited Coverage on water reservoir against any leakage due to defects in material. From date of purchase, if any original component part

provided by Champion Cooler fails due to defect in material or factory workmanship only, we will provide the replacement part as follows:

One year on the cabinet components.

Five years on the evaporative media.

Two years on the original blower motor if furnished by Champion Cooler.

Exclusions From The Warranty

We are not responsible for any incidental or consequential damage resulting from any malfunction.

We are not responsible for any damage received from the use of water softeners, chemicals, descale material, plastic wrap, or if a motor of a higher

horsepower than what is shown on the serial plate is used in the unit.

We are not responsible for the cost of service calls to diagnose cause of trouble, or labor charge to repair and/or replace parts.

How To Obtain Service Under This Warranty

Contact the Dealer where you purchased the evaporative cooler. If for any reason you are not satisfi ed with the response from the dealer, contact the Customer

Service Department: Champion Cooler, 5800 Murray Street, Little Rock, Arkansas 72209. 1-800-643-8341. E-mail: info@championcooler.com.

This limited warranty applies to original purchaser only.

110498-3

5

Page 6

Replacement Parts List / Lista De Piezas De Repuesto

When ordering parts, please be sure to furnish the following information on all orders. Failure to do so may delay your order. /

Al pedir piezas, incluya toda la información siquiente con su pedido. El no proporcionar toda esta información resultará en una demora.

1. Cooler model number / El modelo de su enfriador

2. Cooler serial number / Número de serie de la unidad

3. Description and part number / Descripción y número de pieza

4. Date of purchase / Fecha de compra

No. AD1C51 AD1C5112 AD1C71 AD1C7112

N° Description / Descripción AD2C51 AD2C5112 AD2C71 AD2C7112

1. Top, Cabinet / Tapa De La Caja ................................................................................222130-070 222130-070 222140-053 222140-053

2. Top Access Panel / Panel Superior De Acceso ...........................................................222130-074 222130-075 222130-074 222130-075

3. Bottom, Blower Section / Base De La Sección De La Rueda ....................................322130-068 322130-068 322140-051 322140-051

4. Bottom, Wet Module / Base De La Sección De Agua ................................................222130-072 222130-073 222130-072 222130-073

5. Front Panel / Panel Del Frente ...................................................................................222130-076 222130-076 222140-055 222140-055

6. Inspection Panel / Panel De Inspección .....................................................................224130-002 224130-002 224140-002 224140-002

7. Center Post, Right / Poste Central, Derecho ..............................................................222130-062 222130-062 222140-045 222140-045

8. Center Post, Left / Poste Central, Izquierdo ...............................................................222130-063 222130-063 222140-046 222140-046

9. Back Post, Right / Poste Trasero, Derecho ................................................................222130-064 222130-066 222140-047 222140-049

10. Back Post, Left / Poste Trasero, Izquierdo .................................................................222130-065 222130-067 222140-048 222140-050

11. Blower Housing / Caja De La Rueda .........................................................................324130-202 324130-202 324140-202 324140-202

12. Cut-Off Plate / Placa Externa .....................................................................................224003-015 224003-015 224004-003 224004-003

13. Blower Housing Supports / Soporte Para La Caja De La Rueda ..............................218001-034 218001-034 218001-037 218001-037

14. Grill / Parrilla .............................................................................................................222130-078 222130-078 222140-057 222140-057

15. Electrical Junction Box / Caja De Empalme ..............................................................322009-001 322009-001 322009-001 322009-001

16. Motor Mount / Montura Del Motor ............................................................................314003-011 314003-011 314003-012 314003-012

17. Motor Mount Clips / Seguros Para Montar Motor ....................................................314005-001 314005-001 314005-001 314005-001

18. Motor / Motor .............................................................................................................* * * *

19. Pulley, Motor / Polea Del Motor ................................................................................110279-004 110279-004 110279-003 110279-003

20. Electrical Cord, Motor (115V) / Cable Eléctrico Del Motor (115V) ..........................110372 110372 110372 110372

20. Electrical Cord, Motor (230V) / Cable Eléctrico Del Motor (230V) .........................110372-2 110372-2 110372-2 110372-2

21. Shaft, Blower Wheel / Eje De La Rueda ....................................................................110183 110183 110183 110183

22. Blower Wheel / Rueda ................................................................................................16BW 16BW 20BW 20BW

23. Pulley, Blower Wheel / Polea De La Rueda ...............................................................110275 110275 110276 110276

24. Drive Belt / Correa .....................................................................................................110229 110229 110230 110230

25. Bearings, Blower Wheel Shaft / Cojinetes Del Eje De La Rueda ..............................110351 110351 110351 110351

26. Receptacle, Motor / Toma De Corriente Del Motor ...................................................110393 110393 110393 110393

27. Receptacle, Pump / Toma De Corriente De La Bomba ..............................................110361 110361 110361 110361

28. Media Shield Right / Protector Para El Medio Evaporativo, Direcho ......................281043-002 281045-002 281044-002 281046-002

29. Media Shield Left / Protector Para El Medio Evaporativo, Izquierdo ......................281043-001 281045-001 281044-001 281046-001

30. Water Distributor Housing / Caja Del Distribuidor De Agua

31. Water Distributor Tube / Tubo Del Distribuidor De Agua .........................................3D-23 3D-23 3D-23 3D-23

32. Evaporative Media / Medio Evaporativo ....................................................................310117-001 310118-001 310117-002 310118-002

33. Distributor Filter Pad / Filtro Del Distribuidor ..........................................................110120 110120 110120 110120

34. Water Reservoir / Bandeja Acumuladora De Agua ....................................................281041 281042 281041 281042

35. Tube, Water Delivery / Tubo De Agua ........................................................................310716 310716 310716 310716

36. Over Flow Assembly / Montaje De Desagüe .............................................................310571-2 310571-2 310571-2 310571-2

37. Float Valve / Flotador .................................................................................................FL-C FL-C FL-C FL-C

38. Float Shield / Salpicadero Del Flotador .....................................................................281006 281006 281006 281006

39. Pump / Bomba.............................................................................................................** ** ** **

40. Pump Screen / Malla Para La Bomba ........................................................................281001-001 281001-001 281001-001 281001-001

41. Pump Mount / Montura De La Bomba .......................................................................218002-012 218002-012 218002-012 218002-012

42. Pump Retainer / Sujetador De La Bomba...................................................................110714 110714 110714 110714

43. Anti-Flattening Coil / Espiral Protectora ...................................................................110847 110847 110847 110847

44. Dump Pump Bracket / Bomba ....................................................................................220101-011 220101-011 220101-011 220101-011

45. Thermostat Mounting Bracket / Soporte Del Termostato ...........................................220101-010 220101-010 220101-010 220101-010

46. T’Stat Thermostat Controls / Controles De Termostato .............................................110423 110423 110423 110423

47. Switch Box / Caja De Interuptor................................................................................110821 110821 110821 110821

48. Toggle Switch / Interuptor De Palanca ......................................................................110419 110419 110419 110419

49. Switchbox Cover & Gasket / Cubierta y Junta De La Caja Del Interruptor .............110821-1 110821-1 110821-1 110821-1

50. Liquidtight Conduit / Conduit Flexible ......................................................................110816 110816 110816 110816

51. Liquidtight Connectors / Conectores Para Conduit Flexible .....................................110817 110817 110817 110817

52. Chase Nipple / Niple Roscado ....................................................................................110812 110812 110812 110812

....................................281038-001 281033-001 281038-001 281033-001

* See the motor specifi cation table on page 12. / Vea la tabla de especifi caciones del motor en la página 12.

** Pump for 115V units - #110436, Pump for 230V units - #C60P-240 / Bomba de 115V - #110436, Bomba de 230V - #C60P-240

NOTE: Standard hardware items may be purchased from your local hardware store.

NOTA: Artículos de uso corriente pueden comprarse en la ferretería de su localidad.

6

110498-3

Page 7

Replacement Parts / Piezas De Repuesto

AD1C51, AD2C51, AD1C5112, AD2C5112,

AD1C71, AD2C71, AD1C7112, AD2C7112

110498-3

7

Page 8

Replacement Parts List / Lista De Piezas De Repuesto

When ordering parts, please be sure to furnish the following information on all orders. Failure to do so may delay your order. /

Al pedir piezas, incluya toda la información siquiente con su pedido. El no proporcionar toda esta información resultará en una demora.

1. Cooler model number / El modelo de su enfriador

2. Cooler serial number / Número de serie de la unidad

3. Description and part number / Descripción y número de pieza

4. Date of purchase / Fecha de compra

No. AS1C51 AS1C5112 AS1C71 AS1C7112

N° Description / Descripción AS2C51 AS2C5112 AS2C71 AS2C7112

1. Top, Cabinet / Tapa De La Caja ................................................................................222130-070 222130-070 222140-053 222140-053

2. Top Access Panel / Panel Superior De Acceso ...........................................................222130-074 222130-075 222130-074 222130-075

3. Bottom, Blower Section / Base De La Sección De La Rueda ....................................222130-069 222130-069 222140-052 222140-052

4. Bottom, Wet Module / Base De La Sección De Agua ................................................222130-072 222130-073 222130-072 222130-073

5. Front Panel / Panel Del Frente ...................................................................................322130-077 322130-077 322140-056 322140-056

6. Inspection Panel / Panel De Inspección .....................................................................224130-002 224130-002 224140-002 224140-002

7. Center Post, Right / Poste Central, Derecho ..............................................................222130-062 222130-062 222140-045 222140-045

8. Center Post, Left / Poste Central, Izquierdo ...............................................................222130-063 222130-063 222140-046 222140-046

9. Back Post, Right / Poste Trasero, Derecho ................................................................222130-064 222130-066 222140-047 222140-049

10. Back Post, Left / Poste Trasero, Izquierdo .................................................................222130-065 222130-067 222140-048 222140-050

11. Blower Housing / Caja De La Rueda .........................................................................324130-203 324130-203 324140-203 324140-203

12. Cut-Off Plate / Placa Externa .....................................................................................224003-015 224003-015 224004-003 224004-003

13a. Blower Housing Support, Right / Soporte Para La Caja De La Rueda, Derecho .....218001-035 218001-035 218001-038 218002-038

13b. Blower Housing Support, Left / Soporte Para La Caja De La Rueda, Izquierdo ......218001-036 218001-036 218001-038 218002-038

14. Grill / Parrilla .............................................................................................................222130-078 222130-078 222140-057 222140-057

15. Electrical Junction Box / Caja De Empalme ..............................................................322009-001 322009-001 322009-001 322009-001

16. Motor Mount / Montura Del Motor ............................................................................314003-011 314003-011 314003-012 314003-012

17. Motor Mount Clips / Seguros Para Montar Motor ....................................................314005-001 314005-001 314005-001 314005-001

18. Motor / Motor .............................................................................................................* * * *

19. Pulley, Motor / Polea Del Motor ................................................................................110279-004 110279-004 110279-003 110279-003

20. Electrical Cord, Motor (115V) / Cable Eléctrico Del Motor (115V) ..........................110372 110372 110372 110372

20. Electrical Cord, Motor (230V) / Cable Eléctrico Del Motor (230V) .........................110372-2 110372-2 110372-2 110372-2

21. Shaft, Blower Wheel / Eje De La Rueda ....................................................................110183 110183 110183 110183

22. Blower Wheel / Rueda ................................................................................................16BW 16BW 20BW 20BW

23. Pulley, Blower Wheel / Polea De La Rueda ...............................................................110275 110275 110276 110276

24. Drive Belt / Correa .....................................................................................................110212 110212 110213 110213

25. Bearings, Blower Wheel Shaft / Cojinetes Del Eje De La Rueda ..............................110351 110351 110351 110351

26. Receptacle, Motor / Toma De Corriente Del Motor ...................................................110393 110393 110393 110393

27. Receptacle, Pump / Toma De Corriente De La Bomba ..............................................110361 110361 110361 110361

28. Media Shield, Right / Protector Para El Medio Evaporativo, Direcho .....................281043-002 281045-002 281044-002 281046-002

29. Media Shield, Left / Protector Para El Medio Evaporativo, Izquierdo .....................281043-001 281045-001 281044-001 281046-001

30. Water Distributor Housing / Caja Del Distribuidor De Agua ....................................281038-001 281033-001 281038-001 281033-001

31. Water Distributor Tube / Tubo Del Distribuidor De Agua .........................................3D-23 3D-23 3D-23 3D-23

32. Evaporative Media / Medio Evaporativo ....................................................................310117-001 310118-001 310117-002 310118-002

33. Distributor Filter Pad / Filtro Del Distribuidor ..........................................................110120 110120 110120 110120

34. Water Reservoir / Bandeja Acumuladora De Agua ....................................................281041 281042 281041 281042

35. Tube, Water Delivery / Tubo De Agua ........................................................................310716 310716 310716 310716

36. Over Flow Assembly / Montaje De Desagüe .............................................................310571-2 310571-2 310571-2 310571-2

37. Float Valve / Flotador .................................................................................................FL-C FL-C FL-C FL-C

38. Float Shield / Salpicadero Del Flotador .....................................................................281006 281006 281006 281006

39. Pump Assembly / Bomba ............................................................................................** ** ** **

40. Pump Screen / Malla Para La Bomba ........................................................................281001-001 281001-001 281001-001 281001-001

41. Pump Mount / Montura De La Bomba .......................................................................218002-012 218002-012 218002-012 218002-012

42. Pump Retainer / Sujetador De La Bomba...................................................................110714 110714 110714 110714

43. Anti-Flattening Coil / Espiral Protectora ...................................................................110847 110847 110847 110847

44. Dump Pump Bracket / Bomba ....................................................................................220101-011 220101-011 220101-011 220101-011

45. Thermostat Mounting Bracket / Soporte Del Termostato ...........................................220101-010 220101-010 220101-010 220101-010

46. T’Stat Thermostat Controls / Controles De Termostato .............................................110423 110423 110423 110423

47. Switch Box / Caja De Interuptor................................................................................110821 110821 110821 110821

48. Toggle Switch / Interuptor De Palanca ......................................................................110419 110419 110419 110419

49. Switchbox Cover & Gasket / Cuberta y Junta De La Caja Del Interruptor ..............110821-1 110821-1 110821-1 110821-1

50. Liquidtight Conduit / Conduit Flexible ......................................................................110816 110816 110816 110816

51. Liquidtight Connectors / Conectores Del Conduit Flexible .......................................110817 110817 110817 110817

52. Chase Nipple / Niple Roscado ....................................................................................110812 110812 110812 110812

* See the motor specifi cation table on page 12. / Vea la tabla de especifi caciones del motor en la página 12.

** Pump for 115V units - #110436, Pump for 230V units - #C60P-240 / Bomba de 115V - #110436, Bomba de 230V - #C60P-240

NOTE: Standard hardware items may be purchased from your local hardware store.

NOTA: Artículos de uso corriente pueden comprarse en la ferretería de su localidad.

8

110498-3

Page 9

Replacement Parts / Piezas De Repuesto

AS1C51, AS2C51, AS1C5112, AS2C5112

AS1C71, AS2C71, AS1C7112, AS2C7112

110498-3

9

Page 10

Replacement Parts List / Lista De Piezas De Repuesto

When ordering parts, please be sure to furnish the following information on all orders. Failure to do so may delay your order. /

Al pedir piezas, incluya toda la información siquiente con su pedido. El no proporcionar toda esta información resultará en una demora.

1. Cooler model number / El modelo de su enfriador

2. Cooler serial number / Número de serie de la unidad

3. Description and part number / Descripción y número de pieza

4. Date of purchase / Fecha de compra

No. AU1C7112

N° Description / Descripción AU2C7112

1. Top, Cabinet / Tapa De La Caja ...........................................................................................................................322140-053

2. Top Access Panel / Panel Superior De Acceso ......................................................................................................222130-075

3. Bottom, Blower Section / Base De La Sección De La Rueda ...............................................................................222140-052

4. Bottom, Wet Module / Base De La Sección De Agua ...........................................................................................222130-073

5. Front Panel / Panel Del Frente ..............................................................................................................................222140-058

6. Inspection Panel / Panel De Inspección ................................................................................................................224140-002

7. Center Post, Right / Poste Central, Derecho .........................................................................................................222140-045

8. Center Post, Left / Poste Central, Izquierdo ..........................................................................................................222140-046

9. Back Post, Right / Poste Trasero, Derecho ...........................................................................................................222140-049

10. Back Post, Left / Poste Trasero, Izquierdo ............................................................................................................222140-050

11. Blower Housing / Caja De La Rueda ....................................................................................................................324140-204

12. Cut-Off Plate / Placa Externa ................................................................................................................................224004-003

13. Blower Support Bracket / Soporte Para La Caja De La Rueda ............................................................................218001-038

14. Grill / Parrilla ........................................................................................................................................................222140-057

15. Electrical Junction Box / Caja De Empalme .........................................................................................................322009-001

16. Motor Mount / Montura Del Motor .......................................................................................................................314003-012

17. Motor Mount Clips / Seguros Para Montar Motor ...............................................................................................314005-001

18. Motor / Motor ........................................................................................................................................................*

19. Pulley, Motor / Polea Del Motor ...........................................................................................................................110279-003

20. Electrical Cord, Motor (115V) / Cable Eléctrico Del Motor (115V) .....................................................................110372-1

20. Electrical Cord, Motor (230V) / Cable Eléctrico Del Motor (230V) ....................................................................110372-2

21. Shaft, Blower Wheel / Eje De La Rueda ...............................................................................................................1 10183

22. Blower Wheel / Rueda ...........................................................................................................................................20BW

23. Pulley, Blower Wheel / Polea De La Rueda ..........................................................................................................110276

24. Drive Belt / Correa ................................................................................................................................................110213

25. Bearings, Blower Wheel Shaft / Cojinetes Del Eje De La Rueda .........................................................................1 10351

26. Receptacle, Motor / Toma De Corriente Del Motor ..............................................................................................110393

27. Receptacle, Pump / Toma De Corriente De La Bomba .........................................................................................110361

28. Media Shield, Right / Protector Para El Medio Evaporativo, Derecho................................................................281046-002

29. Media Shield, Left / Protector Para El Medio Evaporativo, Izquierdo ................................................................281046-001

30. Water Distributor Housing / Caja Del Distribuidor De Agua ...............................................................................281033-001

31. Water Distributor Tube / Tubo Del Distribuidor De Agua ....................................................................................3D-23

32. Evaporative Media / Medio Evaporativo ...............................................................................................................310118-002

33. Distributor Filter Pad / Filtro Del Distribuidor .....................................................................................................1 10120

34. Water Reservoir / Bandeja Acumuladora De Agua ...............................................................................................281042

35. Tube, Water Delivery / Tubo De Agua ...................................................................................................................310716

36. Over Flow Assembly / Montaje De Desagüe ........................................................................................................310571-2

37. Float Valve / Flotador ............................................................................................................................................FL-C

38. Float Shield / Salpicadero Del Flotador ................................................................................................................281006

39. Pump / Bomba........................................................................................................................................................**

40. Pump Screen / Malla Para La Bomba ...................................................................................................................281001-001

41. Pump Mount / Montura De La Bomba ..................................................................................................................218002-012

42. Pump Retainer / Sujetador De La Bomba..............................................................................................................110714

43. Anti-Flattening Coil / Espiral Protectora ..............................................................................................................110847

44. Dump Pump Bracket / Bomba ...............................................................................................................................220101-011

45. Thermostat Mounting Bracket / Soporte Del Termostato ......................................................................................220101-010

46. T’Stat Thermostat Controls / Controles De Termostato ........................................................................................110423

47. Switch Box / Caja De Interuptor...........................................................................................................................110821

48. Toggle Switch / Interuptor De Palanca .................................................................................................................110419

49. Switchbox Cover & Gasket / Cubierta y Junta De La Caja Del Interruptor ........................................................110821-1

50. Liquidtight Conduit / Conduit Flexible .................................................................................................................110816

51. Liquidtight Connectors / Conectores Para Conduit Flexible ................................................................................1 10817

52. Chase Nipple / Niple Roscado ...............................................................................................................................110812

* See the motor specifi cation table on page 12. / Vea la tabla de especifi caciones del motor en la página 12.

** Pump for 115V units - #110436, Pump for 230V units - #C60P-240 / Bomba de 115V - #110436, Bomba de 230V - #C60P-240

NOTE: Standard hardware items may be purchased from your local hardware store.

NOTA: Artículos de uso corriente pueden comprarse en la ferretería de su localidad.

10

110498-3

Page 11

Replacement Parts / Piezas De Repuesto

AU1C7112, AU2C7112

110498-3

11

Page 12

General Specifi cations / Especifi caciones Generales

Models

Modelos

AD1C51, AD2C51, AS1C51,

AS2C51

AD1C5112, AD2C51 12,

AS1C5112, AS2C51 12

AD1C71, AD2C71, AS1C71,

AS2C71

AD1C7112, AD2C71 12,

AS1C7112, AS2C71 12,

AU1C7112, AU2C71 12

Weight (lbs.)

Peso (libras)

Dry

Seco

183 233 28 42 45 17 3/4 17 3/4

196 263 28 42 49 17 3/4 17 3/4

219 269 34 5/8 42 48 19 3/4 19 3/4

239 306 34 5/8 42 52 19 3/4 19 3/4

Operating

Lleno

Cabinet Dimensions (in.)

Dimensiones De La Caja (pulgadas)

Height

Altura

Width

Anchura

Depth

Profundidad

Duct Opening (in.)

Abertura De Ducto (pulgadas)

Width

Anchura

Height

Altura

Motor Specifi cations / Especifi caciones Del Motor

Models

Modelos

AD1C51,

AD1C5112,

AS1C51,

AS1C5112

AD2C51,

AD2C5112,

AS2C51,

AS2C5112

AD1C71,

AD1C7112,

AS1C71,

AS1C7112,

AU1C7112

AD2C71,

AD2C7112,

AS2C71,

AS2C7112,

AU2C7112

*Motor amperage based on National Electrical Code. Use motor nameplate amperage when sizing electrical components. / El amperaje listado

es del código eléctrico nacional. Utilize el amperaje indicado en la placa del motor para determinar los componentes elécticos.

HP

C.V.

3/4 110449 2 115 15.8 110279-004

3/4 110480 2 230 8.3 110279-004

Motor #

Motor - N°

1 110471 2 115 18 110279-003

1 110458 2 230 9.4 110279-003

Speed

Velocidad

Volts

Voltios

*Amps

Amperaje

Motor Pully #

Polea Del Motor-N°

Model

Modelo

AD1C51,

AD1C5112

AS1C51,

AS1C5112

AD2C51,

AD2C5112

AS2C51,

AS2C5112

AD1C71,

AD1C7112

AS1C71,

AS1C7112

AU1C7112

AD2C71,

AD2C7112

AS2C71,

AS2C7112

AU2C7112

Drive Belt Part #

Correa - N°

110229 (4L-530)

110212 (4L-570)

110229 (4L-530)

110212 (4L-570)

110230 (4L-640)

110213 (4L-670)

110214 (4L-690)

110230 (4L-640)

110213 (4L-670)

110214 (4L-690)

Lea Y Conserve Estas Instrucciones

Reglas De Seguridad

1. Lea las instrucciones con cuidado.

2. Las conexiones eléctricas deben ser hechas por un electricista competente, para que todo el cableado eléctrico cumpla con los requisitos

establecidos en su localidad.

3. Siempre CORTE LA CORRIENTE y DESCONECTE el motor y la

bomba en el interior del aparato antes de instalar o realizar cualquier

labor de mantenimiento.

4. El motor y la bomba están provistos de clavijas moldeadas, con toma de

tierra, y se apagarán automáticamente en caso de sobrecalentamiento.

Los motores volverán a funcionar cuando se enfrían.

ADVERTENCIA: Para reducir el riesgo de incendio o toques

eléctricos, no use este ventilador con ningún “dispositivo de estado

sólido para controlar la velocidad del ventilador.”

12

Enfriamiento Por Evaporación

El enfriamiento por medio de evaporación es la manera de la naturaleza

de refrescarse. Cuando el aire se mueve sobre una superfi cie mojada,

se evapora el agua y se absorbe el calor. Al salir de una piscina con el

viento que sopla usted se siente fresco, aunque el aire puede ser caliente.

El cuerpo humano sí mismo es refrescado principalmente por la evaporación del sudor.

Este enfriador funciona usando el mismo principio. El aire se traza a

través de los fi ltros mojados donde el aire se enfría por medio de evapo-

ración y después circula a través del edifi cio. Se hace frío de la sensación

cuando tiene esta combinación del aire enfriado y del movimiento del

aire sobre la piel.

A diferencia de los acondicionadores de aire que recirculan el aire, un

enfriador evaporativo trae continuamente por dentro el aire fresco mientras

agota el aire viejo. Se reemplaza completamente el aire cada 2 a 4 minutos,

abriendo las ventanas o las puertas o una combinación de ambas. El aire

es siempre fresco, no es viciado, cargado de humo y olores como ocurre

con los sistemas de aire acondicionado a base de refrigeración.

110498-3

Page 13

Instalación Del Enfriador

PRECAUCIÓN: La superfi cie en que ha de colocarse el en-

friador deberá aguantar el peso completo de la unidad cuando

ésta está en funcionamiento. (Para saber este peso, vea la tabla

de especifi caciones.)

PRECAUCIÓN: No conecte el enfriador hasta que la instalación esté completa y se haya comprobado la estabilidad del

mismo.

PRECAUCIÓN: No atornille ni taladre a 5 pulgadas del

fondo de la sección de agua. Usted podría pinchar la bandeja

acumuladora de agua.

PRECAUCIÓN: Si instale la unidad

con piernas a cada esquina, también debe

soportar la unidad en el centro donde se

ensamblan las dos secciones.

NOTA: Para una instalación más fácil, puede

separar la sección de agua de la sección de la

rueda quitando los cuatro pestillos del lado de

la sección de agua (fi g. 1). Desenchufe las dos

bombas antes de separar las secciones.

Sección

De Agua

Pestillos

Fig. 1

La caja de control es instalado y atado con alambre en la fábrica para el

alimentación de 120V o de 230V, dependiendo del modelo comprado. La

alimentación eléctrica se debe proteger adecuadamente contra sobrecargas

y circuitos cortos. Nota: La instalación eléctrica se debe realizar por un

electricista cualifi cado. Siga todos los códigos eléctricos nacionales y

locales al instalar este enfriador.

• Instale la caja de interruptor. Dentro de la unidad está un bolso plástico

que contiene la caja y cubierta del interruptor, una niple roscada, un anillo

de estanquidad y un interruptor de palanca. Quite la caja de empalme

eléctrica que se encuentra en el interior del panel central (véase Fig 5).

Por dentro de la unidad, inserte la

niple roscada a través del agujero

de acceso eléctrico. Resbale el

anillo de estanquidad sobre la

niple roscada. Instale la caja del

interruptor al exterior de la unidad

atornillando la niple roscada en la

caja del interruptor. Inserte los tres

conductores del interruptor a través de la niple roscada y en la caja

del interruptor y reinstale la caja de

empalme. Conecte el conductor a

tierra verde al tornillo de puesta a

tierra en la caja del interruptor.

Caja De

Empalme

Fig. 5

Anillo De

Estanquidad

Niple

Roscada

Caja

Eléctrica

Conectar El Agua

• Instale el montaje de desagüe. Quite la

tuerca y pase la boquilla por el agujero

de la bandeja, colocando la arandela de

goma entre la bandeja y la cabeza de la

boquilla (véase fi g. 2). Coloque la tuerca

en la boquilla y atorníllela hasta que

quede apretada contra la parte inferior de

la bandeja. Inserte el tubo de desagüe en

la boquilla para retener el agua. El tubo

de desagüe viene de la fábrica conectado

a la manguera de la bomba de desagüe.

El tubo de desagüe se puede quitar para

desaguar el agua de la bandeja cuando sea

necesario. Se puede conectar una manguera de jardín a la boquilla para desaguar el

agua hacia otra parte.

• Conecte el tubo de abastecimiento de

agua. Instale la llave de paso y la válvula

de agua en el grifo según indica la fi gura

3. Coloque la tuerca y la férula en el tubo

y apriete bien la tuerca para impedir que

gotee el agua. NOTA: No conecte el abastecimiento de agua con ninguna aplicación

de agua blanda.

• Instale la válvula del fl otador y llene la bandeja con agua. Véase la

fi gura 4. Remueve los partes 1, 2, 3 y 4. Inserte el cuerpo del fl otador (5)

por el agujero en el poste trasero segun lo indicado. Instale la arandela (1)

y la tuerca (2). Apriete la tuerca para que el fl otador no de vuelta. Ponga

la tuerca (4) y la férula (3) en la línea

de abastecimiento de agua. Conecte la

línea al fl otador y apriete la tuerca hasta

que no salga agua. Doble la varilla (6)

para ajustar el fl otador hasta que el nivel

del agua esté a una altura de 1 pulgada

por debajo de la tapa del tubo de desagüe. Ponga el salpicadero del fl otador

(7) sobre el cuerpo del fl otador hasta que

se agarre.

Llave De

6

Fig. 2

Paso

5

Fig. 4

Manguera De La

Bomba de Desagüe

Tubo De Desagüe

Boquilla Roscada

Arandela De Goma

Bandeja

Tuerca

Grifo

Valvula

Fig. 3

7

1

De Agua

Ferula

3

2

Tuerca

4

Instalación Eléctrica

ADVERTENCIA: Desconecte todos los servicios eléctricos que

serán usados en esta unidad antes de instalar el enfriador y queda

desconectada hasta que la instalación es completa.

• Suministre electricidad a la unidad. T ienda cables de alimentación hasta

la caja del interruptor externo y conéctelos con los dos polos del interruptor

de palanca. Conecte los conductores gris y blanco de la caja eléctrica de

enfriador con los dos polos del interruptor de palanca. Refi era al diagrama

eléctrico apropiado para terminar la instalación eléctrica de su enfriador.

Coloque el interruptor en la caja del interruptor e instale la junta y la cubierta

de la caja de interruptor.

PRECAUCIÓN: Todas las aberturas de la caja externa de

interruptor se deben sellar para evitar la entrada del agua.

PRECAUCIÓN: Los enchufes de la bomba están para las

bombas puestas a tierra del enfriador evaporativo solamente.

No enchufe cualquier otra cosa en los enchufes.

ADVERTENCIA: Compruebe que la caja del enfriador tenga

la debida conexión a tierra para proveer máxima seguridad.

Instalación Del Termostato

1) Localice una localización apropiada para el termostato de pared (lejos de

fuentes del calor, de la luz del sol, o de la ventilación, y entre 4 y 6 pies

del piso). El termostato se puede montar a una caja eléctrica estándar.

2) Tienda un cable aislado de termostato con cuatro conductores (o similar)

desde la caja de control dentro del enfriador hasta la caja eléctrica del

termostato. Este cable no está provisto. ADVERTENCIA: El

cable de termostato no debe ser encaminado al lado de o

entrar el enfriador a través de la misma entrada del cable de

alimentación.

3) Conecte los conductores del cable de termostato a los terminales por detrás

del control de pared y a los terminales localizados en el lado izquierdo de

la caja de control dentro de la unidad. Siga el código de color encontrado

al lado de cada terminal.

Amperio Y Tensión De La Correa

Esta unidad viene equipada de una polea ajustable que permite ajustar la

velocidad del ventilador según la capacidad del motor en sistemas diferentes

de conductos. Es importante que la polea del motor sea ajustada al tamaño

correcto, para asegurar el máximo rendimiento sin dañar el motor. Siga

cuidadosamente estas instrucciones.

• Ajuste la polea del motor. Después de instalar el enfriador completo,

ajuste la polea al diámetro mínimo y ajuste la tensión de la correa. Vea

la sección de mantenimiento para ajustar la correa.

110498-3

13

Page 14

• Poner en marcha la unidad. Instale los paneles de inspección, prenda

la bomba y permita que siga funcionando hasta que todos los fi ltros

estén mojados.

• Revise el amperio. Con los fi ltros mojados y la unidad en funciona-

miento, revise el amperio del motor con un medidor de amperio.

• Ajuste la polea si es necessario. Si la lectura de amperio es menos

del valor especifi cado del motor, apague la unidad y quite el panel de

inspección (la tapa para modelos ADA35 y ASA35). Desconecte el

motor dentro de la caja para protegerse en caso de que alguien intente

poner en marcha el aparato mientras usted está

trabajando. Esto hay que hacerlo por su propia seguridad. Ajuste la polea a un diámetro

mas grande y vuelva a ajustar la tensión de la

correa. Conecte el motor, coloque el panel y

compruebe de nuevo el amperio. Repita estos

Disminuir

Amperio

pasos hasta obtener la lectura de amperio correcta. El incrementar el diámetro de la polea,

incrementa también el amperio; el disminuir

Fig. 6

el diámetro de la polea, disminuye también el

amperio (véase fi g. 6).

PRECAUCIÓN: No permita que funcione esta unidad si toma

mas amperio del que se indica la placa del motor.

NOTA: No se debe intentar la instalación completa de esta unidad sin la

ayuda de un electricista o alguien que sepa medir el amperio. Si usted no

sigue esta instrucción, podrá ser anulada su garantía.

Funcionamiento Del Termostato

Funcionamiento Automático (Modo de

Enfriador)

El ventilador y la bomba de agua se controlan automáticamente para alcanzar

el nivel deseado de la comodidad.

Este modo es activado presionando el botón ‘Cool’. Un diodo LED de azul está

iluminado, y por algunos segundos el LCD exhibirá la temperatura ‘Objetiva’.

Presionar el botón “Cool” otra vez desactiva este modo.

La temperatura ‘Objetiva’ (la temperatura objetiva para el control) se puede

cambiar presionando o sosteniendo el botón ‘Arriba’ o ‘Abajo’. El LCD

indicará la temperatura ‘Objeto’ en vez de la temperatura del ‘Cuarto’ por un

tiempo corto después de presionar el botón ‘Arriba’ o ‘Abajo’.

Al funcionar, si los fi ltros en el enfriador son demasiado secos, el ventilador

se puede retrasar de comenzar hasta que los fi ltros han absorbido un poco de

agua. Esto se llama ‘Pre-Wet’ y dura por 2 minutos, indicado por un LED

azul que destella. Seleccionar ‘Fan’ y después ‘Cool’ evitará el ciclo ‘Pre-

Wet’ y comenzará el ventilador y la bomba inmediatamente. (Si se requiere

refrescarse).

Durante el funcionamiento automático, el control realiza un ciclo de la descarga

de agua que dura 90 segundos cada 8 o 12 horas del funcionamiento de la

bomba. Este intervalo se puede cambiar entre 8 o 12 horas simultáneamente

sosteniendo los botones ‘Fan’ y ‘Cool’ por 5 segundos. El intervalo seleccionado se indica por un tiempo corto. Esta acción también comienza un ciclo

manual de la descarga de agua.

Funcionamiento Del Ventilador (Modo de

Ventilador)

La velocidad del ventilador es determinado por el usuario, la bomba de agua

está apagada.

Este modo es activado presionando el botón ‘Fan’. Un diodo LED verde está

iluminado y el LCD indica la velocidad del ventilador. Al presionar el botón

‘Fan’ otra vez desactiva este modo.

Al presionar el botón ‘Arriba’ selecciona la velocidad máxima del ventilador

y el LCD indica ‘Hi’. Al presionar el botón ‘Abajo’ selecciona la velocidad

mínima del ventilador y el LCD indica ‘Lo’.

Funcionamiento Retardado (Modo de

Temporizador)

Retardo del empieza o fi n en el modo ‘Cool’ o ‘Fan’

El botón ‘Timer’ (temporizador) está utilizado para determinar un retardo de

2, 4 o 8 horas, dependiendo en las veces que presione el botón.

Si el enfriador está funcionando en el modo ‘Cool’ o ‘Fan’ cuando presiona el

botón ‘Timer’, el periodo de retraso se determina cuando el enfriador apagará.

Si el enfriador está apagada cuando presiona el botón ‘Timer’, el período de

retraso se determina cuando arranque el enfriador.

El modo de empezar se indica por un diodo LED que destella. Se puede

cambiar este modo presionando el botón apropiado (‘Cool’ o ‘Fan’).

Se puede cancelar la función del temporizador en cualquier momento presionando el botón ‘Timer’ hasta no ilumina ninguno de los diodos LED de

temporizador.

En Caso de una Interrupción de la Energía

Si el enfriador está funcionando en el modo ‘Cool’ o ‘Fan’ cuando se interrumpe la energía, el enfriador reasumirá en el mismo modo cuando restaura

la energía.

Si el enfriador estaba en cualquier modo del temporizador cuando interrumpe

la energía, el enfriador será apagada cuando restaura la energía.

CAJA DE EMPALME DEL ENFRIADOR

NEGRO

ROJO

BLANCO

VERDE

NARANJA

ENCHUFE DEL

MOTOR

ENCHUFE DE BOMBA

DE AGUA

ENCHUFE DE

BOMBA DE DESAGÜE

VERDE

BLANCO

AZUL

NARANJA

MARRÓN

VERDE

BLANCO

AZUL

NARANJA

MARRÓN

14

Esquemas Del Cableado

120 Voltios 240 Voltios

CONDUCTORES

DEL INTERRUPTOR

GRIS

BLANCO

VERDE

GRIS

NEGRO

ROJO

AMARILLO

AZUL

VIOLETA

=EMPALME PLÁSTICO

(11)

INTERRUPTOR DE PALANCA

TERMOSTATO

PWR. SUPPLY

FCom

NLink

LINK

FLo

FHi

BLANCO

PP

L1

N

120 VAC

TIERRA

DUMPPUMPFAN

PCom

DP

DCom

CAJA DE EMPALME DELENFRIADOR

NEGRO

ROJO

BLANCO

VERDE

NARANJA

ENCHUFE DEL

MOTOR

ENCHUFE DE LA

BOMBADEAGUA

ENCHUFE DE LA

BOMBA DE DESAGÜE

VERDE

BLANCO

AZUL

NARANJA

MARRÓN

VERDE

BLANCO

AZUL

NARANJA

MARRÓN

CONDUCTORES

DEL INTERRUPTOR

GRIS

BLANCO

VERDE

GRIS

NEGRO

ROJO

AMARILLO

AZUL

VIOLETA

=EMPALME PLÁSTICO

(11)

INTERRUPTOR DE PALANCA

THERMOSTATO

PWR. SUPPLYFAN PUMP DUMP

FCom

NLink

LINK

FLo

FHi

BLANCO

PP

L1

N

110498-3

240 VAC

TIERRA

PCom

DP

DCom

Page 15

¿Cuanto Debe Abrir Las Ventanas?

Un concepto a menudo entendido mal de enfriamiento por evaporación es la

cantidad de aire que debe ser agotada. Cuánto debe usted abrir sus ventanas?

El hecho es que la mayoría de la gente no abre sus ventanas bastante. Los dos

métodos siguientes le ayudarán.

El Método Primero

Usted debe dejar una abertura de dos pies cuadrados por cada 1000 P.C.M.

(pies cúbicos por minuto), según la capacidad de su modelo. Ejemplo: Un

Modelo AD1C51 (3/4 c.v .) de 3790 P.C.M. requiere 7,6 pies cuadrados (1094

pulgadas cuadradas) de abertura (3790/1000 * 2 = 7,6). Ahora, multiplique

el número de las ventanas por el ancho de las mismas; luego divida esta cantidad entre el número de pulgadas cuadradas requeridas para su unidad. El

resultado le dice hasta qué altura hay que abrir las ventanas. En este ejemplo,

cuatro ventanas que miden 36 pulgadas (0,9 m) de ancha se deben abrir 7,6

pulgadas por cada una.

El Método De Equilibrar El Aire

1. Tome un pedazo de papel de seda y córtelo a lo largo en 3 tiras iguales.

2. Ponga en marcha a su enfriador a “High-Cool”.

3. Abra una ventana por lo menos seis pulgadas de ancho en cada sitio

que usted desee refrescar.

4. Tome un pedazo de papel de seda y póngalo contra la pantalla de la

ventana abierta más lejos de la apertura del enfriador. Suéltalo al

papel de seda. Hará una de tres cosas:

SI: Se caiga.

ENTONCES: CIERRE todas las ventanas una pulgada e intente el

paso 4 otra vez.

SI: Se queda contra la pantalla con fuerza.

ENTONCES: ABRA todas las ventanas una pulgada e intente el paso

4 otra vez.

SI: Se queda ligeramente contra la pantalla.

ENTONCES: PERFECTO. Se ha acabado. Goce del aire refrescan-

te.

Notas:

• Al poner el enfriador a “low-cool”, usted debe reequilibrar el aire de

su hogar. Repita el paso 4.

• Al equilibrar el aire de su hogar usted puede refrescar algunas áreas

más que otras abriendo esas ventanas más y cerrando las otras por la

misma cantidad. Repita el paso 4. Asegurarse de que el aire de su hogar

sea equilibrado.

IMPORTANTE: Para que el enfriador funcione lo mejor, debe instalar

el medio evaporativo correctamente. Si usted ha comprado fi ltros con

dos ángulos iguales, las instrucciones siguientes no serán provechosas

para usted. Los fi ltros deben ser instalados con el ángulo más escar-

pado inclinándose por la entrada

del aire (véase fi g. 7). La razón

es que el ángulo más escarpado

le ayuda a poner más agua en

el lado seco y caliente donde lo

necesita más. T ambién le ayuda a

contrarrestar la tendencia del aire

a empujar el agua hasta atrás de

los fi ltros.

• Limpie la bomba. Es necesario limpiar la bomba una vez al principio

de cada año. Por su propia seguridad, apague la unidad y desconecte el

motor y la bomba. Quite el sujetador de plástico de la montura y quite

la bomba, deslizándola hacia usted. Quite la base de la bomba según

se muestra en la fi gura 8. Limpie la bomba. Dé le vuelta a la hélice

para verifi car que se mueve libremente. Quite el pico de la bomba y

vea si está obstruido. Después

de limpiar, reinstale la base en

la bomba. Presione fi rmemente

para asegurarse de que es segura.

Vuelva a colocar la bomba en la

unidad y fíjela en la montura con

el sujetador de plástico. Esto

impedirá que se caiga la bomba

al agua, lo que dañaría el motor.

No se olvide de volver a conectar

el tubo de agua a la bomba.

• Compruebe la tensión de la correa.

Una fuerza de 3 libras debe desviar la

correa 3/4 pulgadas (véase fi g. 9). Ajuste

la correa si es necesario.

• Lubrique los cojinetes. Los cojinetes de

la rueda y el motor del ventilador deben

ser lubricados usando unas gotas de un

aceite no detergente de densidad 20/30 una vez al año. No obstante,

los motores sin tuberías para aceite no necesitan ser lubricados. Estos

motores son lubricados en la fábrica de por vida y no requieren nunca

ninguna lubricación.

Entrada

Del Aire

Fig. 7

Quite

La Base

Fig. 8

3 Libras

45°

Salida Del

Aire

15°

hélice

3/4 Pulgadas

Fig. 9

PRECAUCIÓN: No lubrique demás. El agregar demasiado aceite

puede ocasionar que se queme el motor, a causa del aceite entrando al

interior del motor.

Mantenimiento

ADVERTENCIA: Antes de hacer cualquier mantenimiento,

compruebe que la corriente esté apagada. Al quitar un panel de

inspección, desconecte el motor y la bomba dentro de la caja. Esto

es por su seguridad.

Puesta En Marcha En La Primavera

• Limpie el medio evaporativo. Un fi ltro limpio es más absorbente

y efi ciente y producirá un mayor volumen de aire frío. Cada año o

cuando sea necesario, limpie con una manguera de jardín las aberturas.

Luego limpie el lado de adentro de cualquier escama u otra obstrucción

a las aberturas. Si requiere, raspe ligeramente para remover escama

endurecida.

• Cambie el medio evaporativo después de 5 años o cuando sea ne-

cessario. El cambiar el medio evaporativo, remueva el panel superior

de acceso, remueva la parrilla y desconecte el tubo del distribuidor de

agua. Quite la caja del distribuidor de agua y saque el medio evaporativo. Reemplace con los fi ltros de mismo tipo lo que puede encontrar

de su comerciante.

110498-3

• Compruebe la válvula de desahogo para verifi car que no esté obs-

truida.