Page 1

Industrial / Commercial

Evaporative Cooler Manual

Models

75/85 DD 75/85 SD

95 DD 95 SD

10/12 DD 10/12 SD

14/21 DD 14/21 SD

Read Carefully All Of This Manual Before

Installing The Unit.

Lea Con Cuidado Todo Este Manual Antes De

Instalar La Unidad.

Read And Save These Instructions

Table Of Contents

Safety Instructions ...........................................................................2

Operation ..........................................................................................2

Installation Instructions ................................................................2-3

Maintenance Section ........................................................................3

Electrical Wiring Diagrams ..............................................................4

Troubleshooting ...............................................................................5

Warranty ...........................................................................................5

Parts Drawing (Dibujo de Piezas) - 10/12SD, 14/21SD ..................6

Parts Drawing (Dibujo de Piezas) - 10/12DD, 14/21DD ................7

Circle the model of your cooler and record the

serial number below.

Encierre con un circulo el modelo de su enfriador y

escribe el número de serie abajo.

Serial #

Número De Serie

Vea el Español en el interior.

Parts List (Lista de Piezas) - 10/12, 14/21 .......................................8

Parts List (Lista de Piezas) - 75/85, 95 ............................................9

Parts Drawing (Dibujo de Piezas) - 75/85DD, 95DD ....................10

Parts Drawing (Dibujo de Piezas) - 75/85SD, 95SD .....................11

Motor Specifi cations (Especifi caciones del Motor) - 75/85DD, 95DD

Motor Specifi cations (Especifi caciones del Motor) - 75/85SD, 95SD

Motor Specifi cations (Especifi caciones del Motor) - 10/12, 14/21

General Specifi cations (Especifi caciones Generales) ...................12

Spanish (Instrucciones en Español) .........................................13-16

.10

..11

....12

110525 9-09

Page 2

Safety Rules

1. Read instructions carefully.

2. Disconnect all electrical service that will be used for the unit before

you begin the installation.

3. Electrical hook up should be done by a qualifi ed electrician, so

that all electrical wiring will conform to your local standards.

4. For a maximum safety precaution, make sure cooler cabinet is

properly grounded to a suitable ground connection.

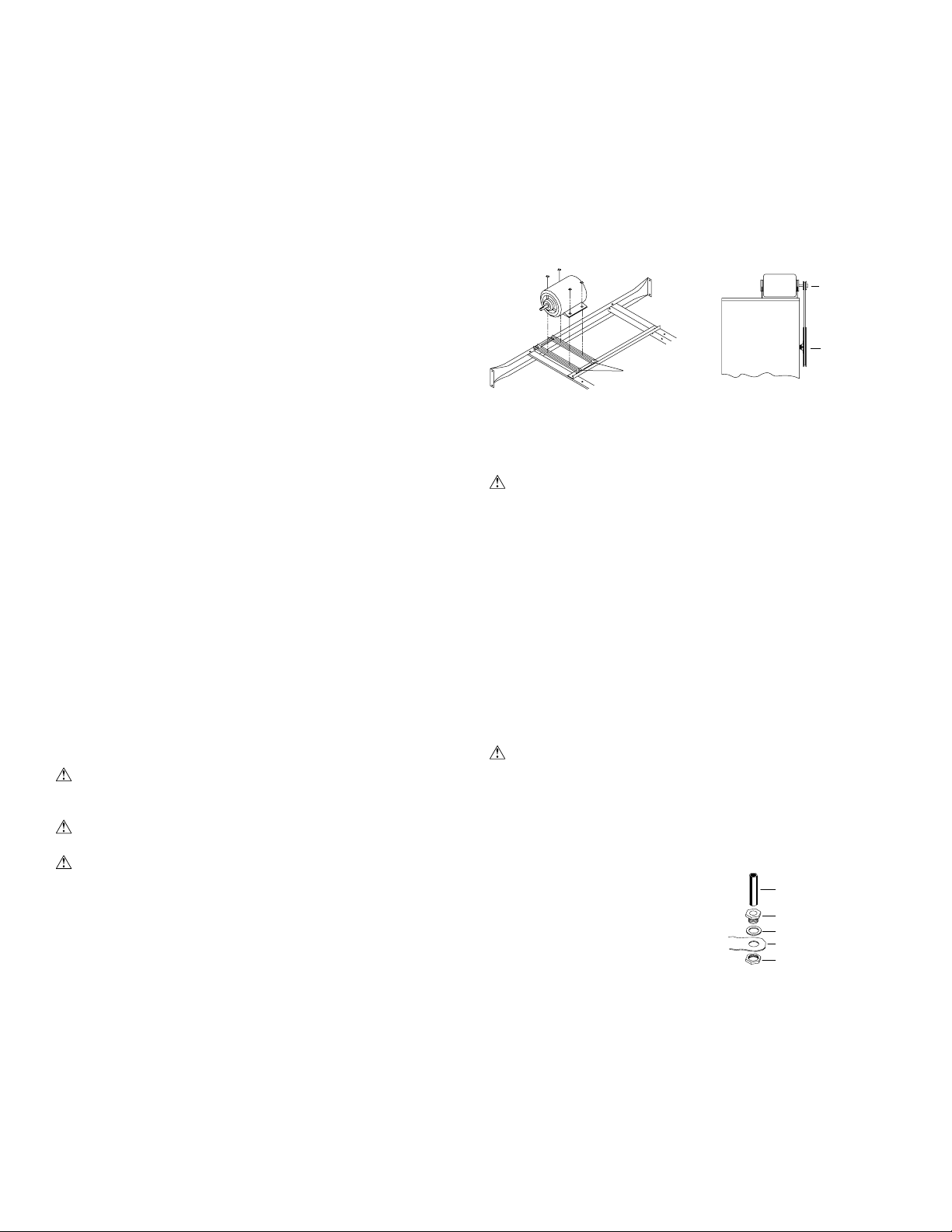

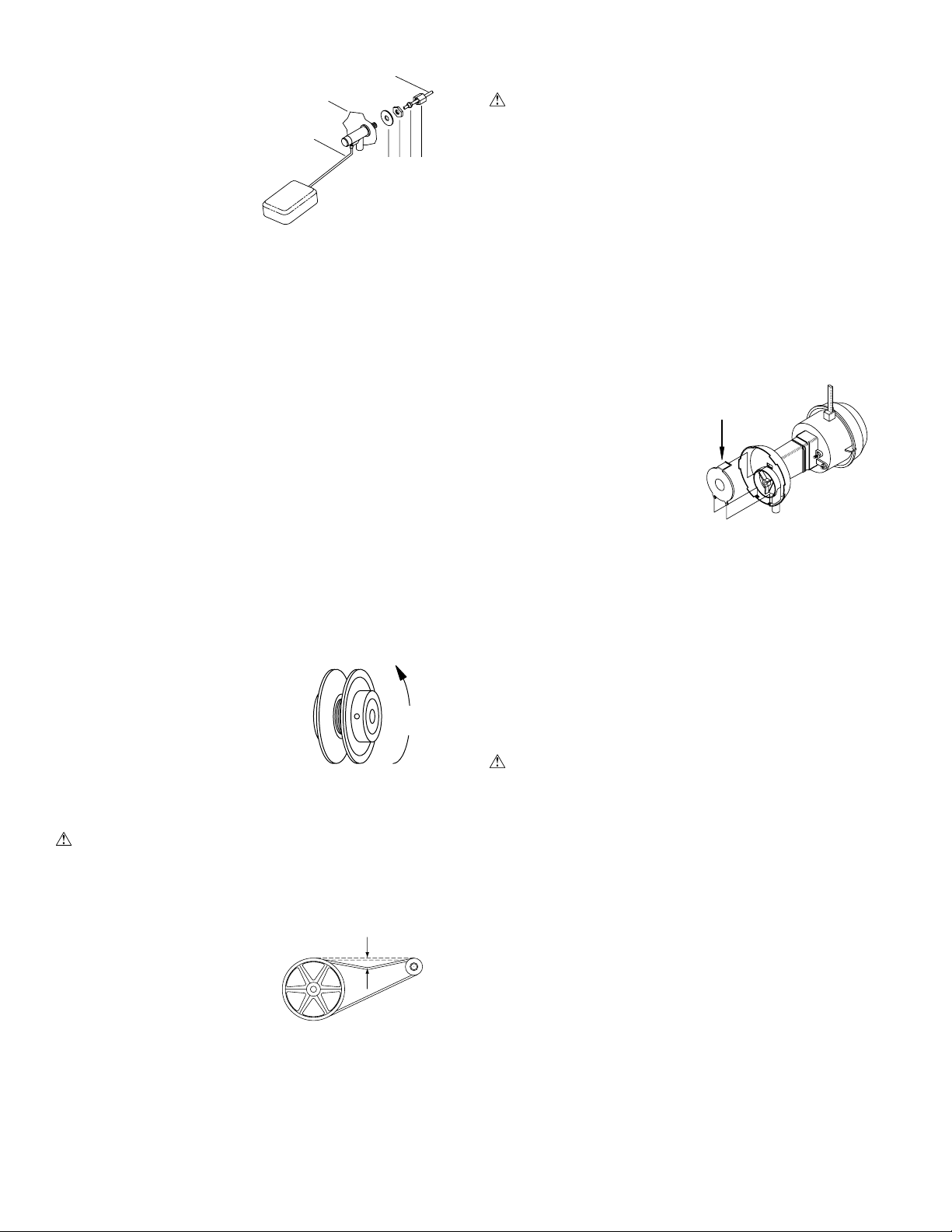

Motor Installation

• Mount motor. Slide the heads of the provided carriage bolts into

the slots of the adjustable channels. Slide these channels sideways

in the slotted holes to align with the holes in the motor base and to

align the motor shaft with the blower pulley. Mount the motor to

the motor mount using these carriage bolts and the washers and nuts

provided (see Fig. 1). Make sure all bolts are securely tightened.

• Install pulley. Install the adjustable motor pulley so that it aligns

with the blower drive pulley (see Fig. 2) and tighten set screw. See

page 3 for instructions on adjusting pulley.

5. Cooler must be connected to proper line current, voltage and cycle,

as stamped on cooler motor and pump motor specifi cation plate.

6. Do no allow pump to tip over and become submerged.

7. Always DISCONNECT POWER before installing unit or

performing any maintenance.

Operation

For the best cooling performance, if the pads are dry, pre-wet the pads

by running the pump for a few minutes before starting the blower.

These coolers may also be used without water for ventilation purposes.

When outside air is cool (for example, at night) or when humidity is

high the water pump can be turned off.

IMPORTANT: T o cool effi ciently, you must exhaust the stale or used

air from the building. Open windows or doors or use exhaust fans

located away from the cooler and in the direction you wish to cool

the air. The air will fl ow in the direction of the exhaust openings. A

common guide for the amount of exhaust opening needed is to have

at least 2 square feet of opening per 1000 CFM.

Installation

CAUTION: Make sure that the mounting surface is strong

enough to support the operating weight of the cooler when in use.

(For operating weight, see Specifi cation Table.)

CAUTION: Never plug in cooler until installation is complete

and unit has been tested for rigidity.

CAUTION: Make sure all bolts are securely tightened before

starting the cooler.

• Ductwork. See the General Specifi cation table for the duct open-

ing dimension for your specifi c cooler. For down discharge units

models 10/12DD and 14/21DD, the duct must go inside the opening.

Size these ducts slightly smaller than the duct opening in the cooler.

On 75/85DD and 95DD models the duct may go to the inside or

outside of the duct fl ange. The side discharge units have a 1 inch

fl ange. Size these ducts larger than the duct opening to fi t over the

fl ange of these units.

Note: Curbs are not provided. The installer is responsible for

providing curbs or other means to support the cooler.

Motor

Pulley

Fig. 1

Blower

Housing

Adjustable

Channels

Fig. 2

Blower

Pulley

Electrical Installation

NOTE: Local building code regulations must be observed.

WARNING: Disconnect all electrical service that will be used

for this unit before you begin the installation.

• Electrical Supply. Cooler must be supplied with the proper line

current, voltage and frequency, as stamped on cooler motor and

pump motor specifi cation plate. See the wiring diagrams on page

4 for typical electrical connections. NOTE: Connecting improper

voltage to motor will void motor warranty.

• Wire sizing. The conductor sizes are to be determined by motor

loads and length of run per national and local electrical codes.

• Switches or contactors. Motors require switches or contactors

of proper current capacity and should be sized and installed by a

competent electrician.

WARNING: Make sure that cooler cabinet is properly

grounded to a suitable ground connection for maximum safety.

Water Connection

• Overfl ow assembly. Remove nut and place nipple through the hole

in the pan, with the rubber washer between the pan and the head

of the drain nipple (Fig. 3). Screw on

nut and draw up tight against bottom

of pan. Insert overfl ow pipe in nipple

to retain water. Overfl ow pipe may be

removed to drain pan when necessary.

A garden hose may be screwed on the

drain nipple to drain water away from

your unit.

• Pump. The pump must be secured to prevent it from tipping over.

Secure the pump to the pump mounting bracket. For the 10/12 and

14/21 models, remove the mounting screw on the top of the pump

and using this same screw, secure the pump to the pump mount. T o

secure the pump for the 75/85 and 95 models, slide the pump into

the slot of the pump mount and secure with the plastic retainer.

Overfl ow Pipe

Nipple

Rubber Washer

Bottom Pan

Nut

Fig. 3

2

110525

Page 3

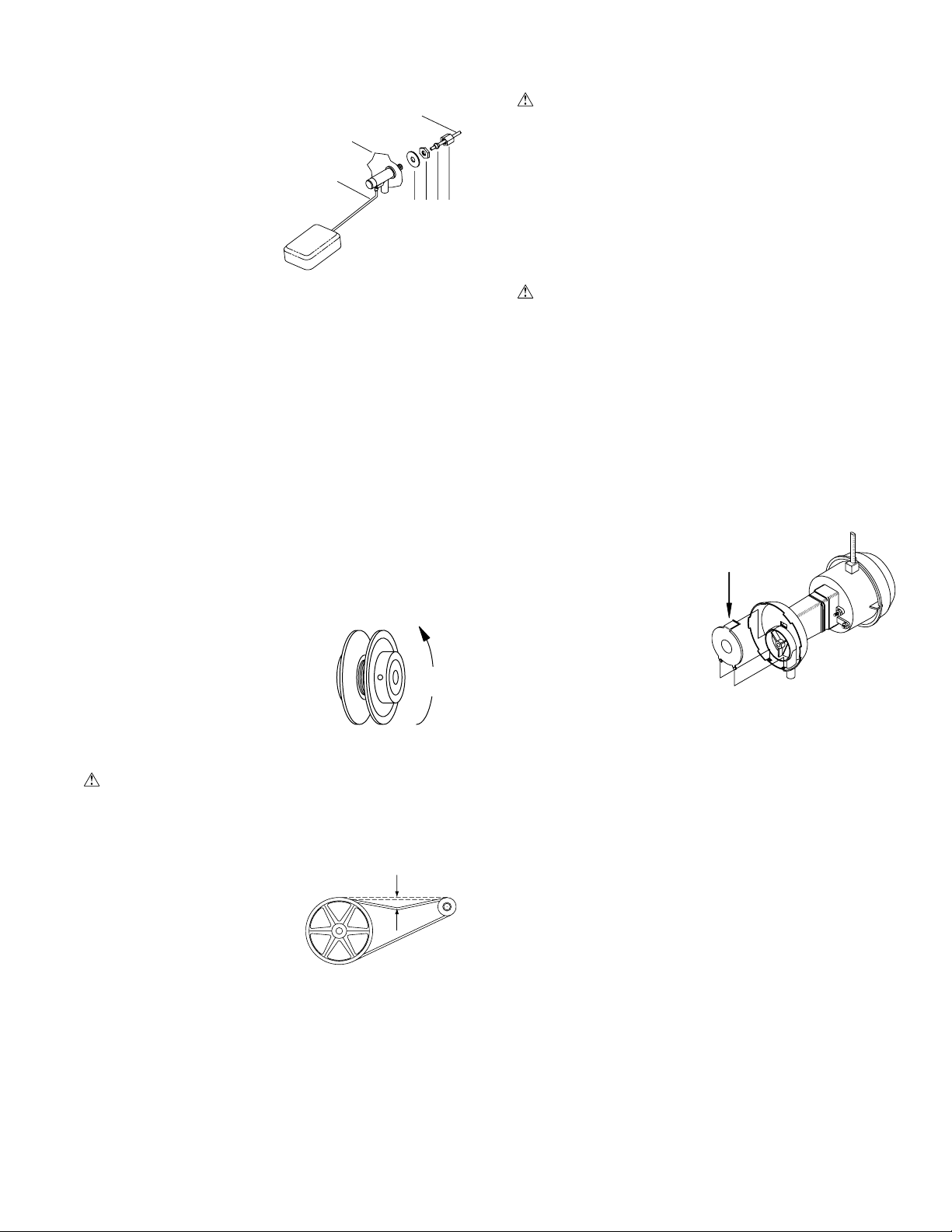

• Water Supply. Run a water supply line to the unit. The fl oat

valve requires a 3/8 inch tube connection. NOTE: Do not use

water supplied from a water

softener.

• Float valve. Install the fl oat

Mount Bracket

Water Supply

Line

valve to the mount bracket in

the cooler (Fig. 4) and attach

Float Rod

water supply line. Note: 75/85

and 95 units come with the fl oat

valve installed. For the other

models, the fl oat is purchased

separately.

Fig. 4

Washer

Nut

Nut

Ferrule

• Filling pan. Turn on water supply and check for leaks. Allow

water to fi ll to within 1” of top of pan. Loosen the screw on the

fl oat rod to adjust the fl oat and retighten the screw.

• Water troughs. Operate pump until pads are saturated. Check

each trough to see if water is evenly dispersed in the trough. If

they are not, loosen adjustment bolts and level trough. Retighten

bolts. Check to see that all pads are saturated with water and that

there are no dry spots or openings in the pads.

• Bleed-Off. Use of a bleed-off kit is recommended to prevent scale

build up by bleeding off small amounts of circulating water during

operation. Do not add any type of water treatment chemicals to the

water.

Pulley And Belt Adjustments

• Pulley adjustment. With an ammeter, check the motor amper-

age. Adjust the pulley until the amperage draw on the motor is

just below that specifi ed on the motor

nameplate. T o adjust the pulley , loosen

the adjustment set screw and rotate the

sheave. Tighten the set screw so that

it is over a fl at area, otherwise thread

damage will occur. To increase amperage draw, increase pulley diameter.

To decrease amperage draw, decrease

pulley diameter (Fig. 5). Recheck belt

alignment.

CAUTION: When it is necessary to adjust pulley, amperage

of motor must be checked to make certain it does not exceed the

maximum allowed as stamped on motor specifi cation plate. Im-

proper pulley adjustment will overload and burn out motor.

Decrease

Amperage

Fig. 5

Maintenance

WARNING: Before doing any maintenance be sure to discon-

nect from power source. This is for your safety.

Spring Start-Up

• Belt tension. Check belt tension and readjust if needed.

• Oil bearings. The blower bearings and cooler motor in this unit

should be oiled with a few drops of non-detergent 20/30 weight oil

once each year. The motor does not need oil if it has no oil lines

for oiling. Motors that have no oil lines are lifetime oiled at the

factory and require no further oiling for the life of the unit.

CAUTION: Do not over oil. Over oiling can cause motor burn

out, due to excessive oil getting into motor winding.

• Change Pads. The pads should be replaced once or twice a season,

depending upon the length of the season. At the beginning and at

mid season a clean pad is more absorbent and effi cient and will

deliver substantially more cool air.

• Clean pump. Cleaning the pump is necessary once a year at start-

up. For your safety, disconnect from power source and unplug

pump. Remove the pump from the mount bracket. Remove the base

of the pump (Fig. 7). Clean the pump and turn the impeller to ensure

free operation. Remove the pump spout and check for any blockage.

After cleaning, reinstall the

base onto the pump. Reattach the pump to the mount

in the cooler to ensure that

the pump will not overturn.

Do not forget to replace the

spout and water delivery tube

onto the pump outlet. The

pump has automatic reset

thermal protection. Pump

will operate normal again

after obstruction is cleared.

• Bleed off. Check bleed-off valve to be sure it is not clogged.

Winter Shut Down

• Drain water. Always drain all of the water out of the cooler and

water supply line when not in use for prolonged periods, and particularly at the end of the season. Keep the water line disconnected

from both the unit and water supply so that it does not freeze.

Remove

Fig. 7

• Belt tension. Loosen the motor

mount bolts and slide the motor

back until the belt is properly

tensioned. A 3 lb. force should

defl ect the belt 3/4 inches (see Fig.

6). Retighten motor mount bolts.

Do not adjust pulley to tighten

belt.

110525

3 lb.

3/4 Inches

Fig. 6

• Disconnect from power supply when not in use for extended

periods of time.

• Cover unit. To protect the life of the fi nish, a cover for the unit is

suggested in extended periods of non use.

By following the operating, installation, and maintenance suggestions as outlined, you can get many years of effi cient and satisfac-

tory service from your cooler. In the event additional information

is desired, your dealer will be more than glad to assist you in every

possible way.

3

Page 4

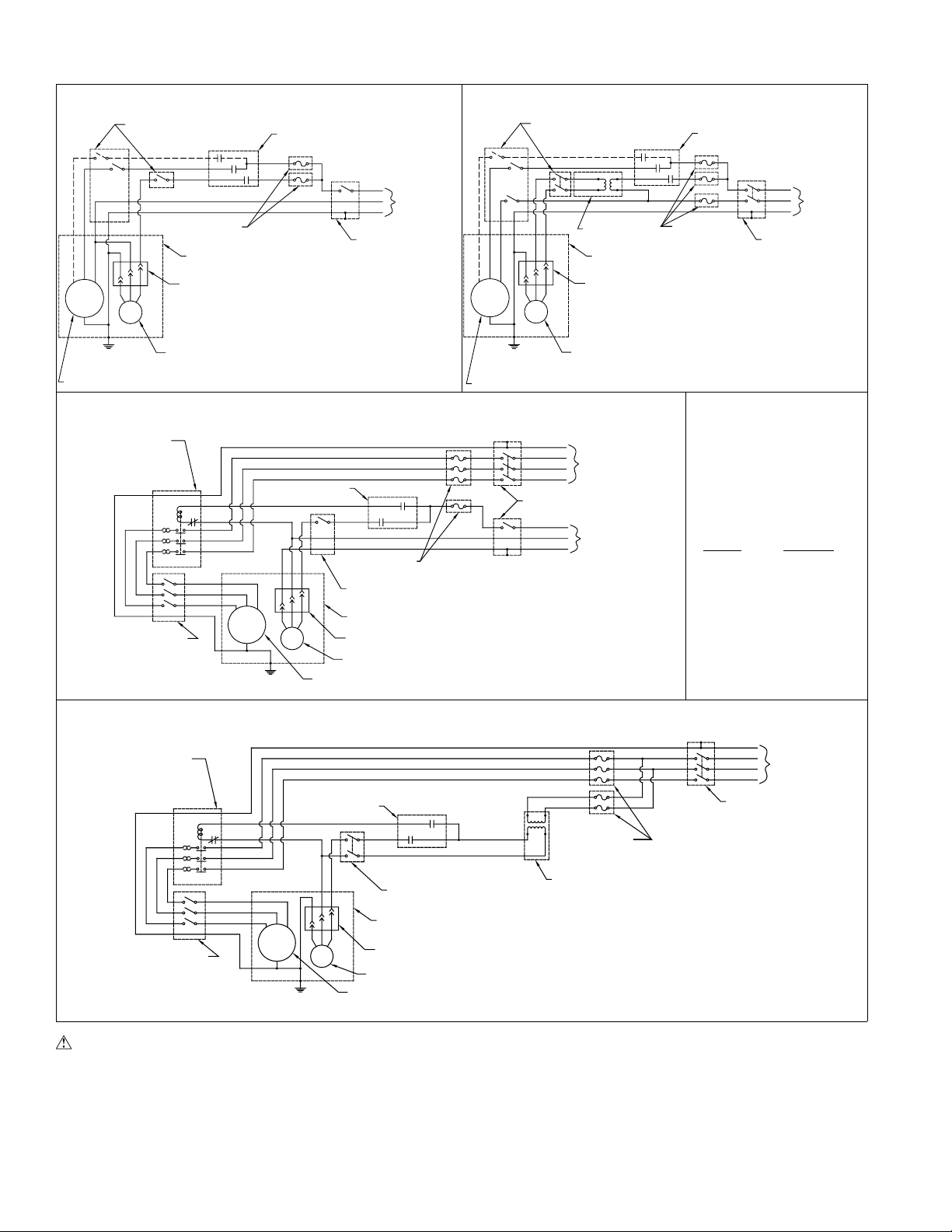

Typical Electrical Wiring Diagrams

Disconnect Switch At Cooler

See Notes 1 & 2

Equipment

Ground

Blower Motor

208, 240, or 480 Volt, 3 Phase Blower & 120 Volt 1 Phase Pump & Control Electric Supply

Motor Starter With

Overload Protection Sized

To Match Motor Full Load

Current

See Note 1

Disconnect Switch At

Cooler

See Notes 1 & 2

120 Volt, 1 Phase Electric Supply

Control Contacts

L

H

P

N

Fuses

See Note 1

Cooler Cabinet

See Note 3

See Note 4

• 115 Volt single phase blower motor.

• 120 Volt pump motor.

• Diagram shown for two speed motor.

Low speed circuit drawn with dashed

Pump Motor

T3

T2

T1

Gnd

Equipment

Ground

lines is not required for single speed.

Control Contacts

See Note 4

Blower Motor

L1

120 Volts

N

Power Supply

N

Gnd

Fuses

See Note 1

1 Phase

• Three phase single speed blower motor

• Three pole motor starter with overload

• 120V single phase control and pump shown.

GndGnd

Main Disconnect

See Note 1

H

P

Disconnect Switch At Cooler

See Note 1&2

Cooler Cabinet

See Note 3

Pump Motor

240 Volt, 1 Phase Electric Supply

Disconnect Switch At Cooler

See Notes 1 & 2

L

H

120V

P

Gnd

Transformer

Cooler Cabinet

See Note 3

L2

• 230 Volt single phase blower motor.

• 120V pump motor shown. Trans-

Equipment

Ground

Blower Motor

Pump Motor

Gnd

L1

L2

L3

Main Disconnects

See Note 1

L1

Gnd

208, 240, or 480V

N

3 Phase

Power Supply

120V

1 Phase

Power Supply

• Diagram shown for two speed motor.

protection

If 240V control and pump are to be used, then

both legs of power supply must be fused.

Control Contacts

See Note 1

L1

208 or 240V

Fuses

See Note 1

L2

Gnd

Main Disconnect

See Note 1

1 Phase

Power Supply

former may be omitted when a 240V

pump is used with a 240V supply

Low speed circuit drawn with dashed

lines is not required for single speed.

Typical Control Contacts

Function and Connection

L - Low Fan

P - Pump

H - Hi Fan

L1 - Supply Power

Function Connection

Off None

Pump Only L1-P

Hi-Cool L1-H

* Low-Cool L1-L & L1-P

Hi-Fan L1-H

* Low-Fan L1-L

* Omit for single speed blower motor

208, 240, or 480 Volt, 3 Phase Blower Electric Supply With Transformer For Pump & Control

Motor Starter With

Overload Protection

Sized To Match Motor

Full Load Current

See Note 1

Disconnect Switch At Cooler

See Notes 1 & 2

T3

T2

T1

Gnd

Equipment

Ground

Control Contacts

See Note 4

Blower Motor

H

P

Disconnect Switch At Cooler

See Notes 1 & 2

Cooler Cabinet

See Note 3

Pump Motor

120

V

Fuses

See Note 1

Transformer

See Note 1

• Three phase single speed blower motor.

• Three pole motor starter with overload protection.

• 120V single phase pump powered by a transformer.

Transformer may be omitted when 240V control &

pump are used with a 240V supply.

Gnd

L1

L2

L3

Main Disconnect

See Note 1

208, 240 or 480V

3 Phase

Power Supply

WARNING: Electrical hookup should be performed by a qualifi ed electrician. All electrical wiring must conform to national and

local standards.

NOTE 1. All switches, motor starters, transformers, fuses, junction boxes, receptacles, receptacle boxes, cover plates, and conductors shall be supplied by the

NOTE 2. The national electric code requires a disconnect switch located at equipment if the main disconnect at equipment controller is not visible from the equip-

NOTE 3. A receptacle for a NEMA 5-15P plug is required for 120V recirculating pump and a receptacle for a NEMA 6-15P plug for 230V pump.

NOTE 4. The control contacts may be part of a switch, thermostat or other control device.

installer and must comply with local and national electrical codes.

ment. If more than one disconnect is used they must be mounted adjacent to one another.

4

110525

Page 5

Troubleshooting Guide

Problem Possible Cause Remedy

Failure to

start or no

air delivery

Inadequate

air delivery

with cooler

running

Musty or

unpleasant

odor

1. No electrical power to unit

• Fuse blown

• Circuit breaker tripped

2. Belt too loose or tight

3. Motor overheated

• Belt too tight

• Blower bearings dry

• Motor bearings dry

• Motor pulley diameter too

large

4. Motor locked

1. Insuffi cient air exhaust

2. Belt too loose

3. Pads plugged

4. Insufficient water flow

over pads

1. Stale or stagnate water in

cooler

2. Pads not wetting properly

• Trough holes clogged

• Pump not working properly

• Insufficient water flow

over pads

1. Check power

• Replace fuse

• Reset breaker

2. Adjust belt tension

3. Determine cause of overheating

• Adjust belt tension

• Oil blower bearings

• Oil motor bearings

• Adjust pulley to correct

diameter

4. Replace motor

1. Open windows or doors

to increase air fl ow

2. Adjust belt tension or

replace if needed

3. Clean pads

4. Clean water distribution system and trough

openings

1. Drain pan and clean

pads

2. Check water distribution

system

• Clean

• Replace or clean pump

(Unplug)

• Clean distribution sys-

tem and trough openings

Problem Possible Cause Remedy

Motor

cycles on

and off

Noisy

Inadequate

cooling

Excessive

humidity in

house

1. Low voltage

2. Excessive belt tension

3. Blower shaft tight or

locked

4. Bearings dry

5. Motor pulley diameter

too large causing motor

overload

6. Faulty motor

1. Bearings dry

2. Wheel rubbing blower

housing

3. Loose parts

1. Inadequate exhaust in

house

2. Pads not wet

• Pads plugged

• Open spots in pads

• Trough holes clogged

• Pump not working prop-

erly

1. Inadequate exhaust

1. Check voltage

2. Adjust belt tension

3. Oil or replace bearings

(Disconnect unit)

4. Oil bearings

5. Adjust pulley so full load

ampere rating of motor

is not exceeded

6. Replace motor

1. Oil bearings

2. Inspect and realign (Disconnect unit)

3. Tighten loose parts

1. Open windows or doors

to increase air fl ow

2. Check water distribution

system

• Clean pads

• Repack pads

• Clean

• Replace or clean pump

(Unplug)

1. Open doors or windows

Register your product online at: www.championcooler.com/eac/onlineregistration-eac.htm

Limited W arranty

This warranty is extended to the original purchaser of an evaporative cooler installed and used under normal conditions. It does not cover damages incurred

through accident, neglect, or abuse by the owner. We do not authorize any person or representative to assume for us any other or different liability in connection with this product.

Terms And Conditions Of Warranty

For Five Years from date of purchase, we will replace the base assembly if water leakage should occur due to rust out.

For One Year from date of purchase, we will replace any original cabinet component which fails due to defect in material or factory workmanship only.

Exclusions From The Warranty

We are not responsible for replacement of cooler pads. These are disposable components and should be replaced periodically. We are not responsible for

any incidental or consequential damage resulting from any malfunction.

We are not responsible for any damage received from the use of water softeners, chemicals, descale material, plastic wrap or if a motor of a higher horsepower

than what is shown on the serial plate is used in the unit.

We are not responsible for the cost of service calls to diagnose cause of trouble, or labor charge to repair and/or replace parts.

How To Obtain Service Under This Warranty

Contact the Dealer where you purchased the evaporative cooler. If for any reason you are not satisfi ed with the response from the dealer, contact the

Customer Service Department: 5800 Murray Street, Little Rock, Arkansas 72209. 1-800-643-8341. E-mail: info@championcooler.com, Web: www.

championcooler.com.

This limited warranty applies to original purchaser only.

110525

5

Page 6

Replacement Parts / Piezas De Repuesto

10/12 SD, 14/21 SD

6

110525

Page 7

Replacement Parts / Piezas De Repuesto

10/12 DD, 14/21 DD

110525

7

Page 8

Replacement Parts List / Lista De Piezas De Repuesto

All parts may be ordered from your dealer, but not directly from the factory. Be sure that you furnish the following information on all orders. /

Todas las partes pueden ser pedidas con su concesionario, pero no directamente a la fábrica. Incluya toda la información siguiente con su pedido:

1. Cooler serial number / Número de serie de la unidad

2. Description and part number / Descripción y número de parte

3. Cooler size / Tamaño de la unidad

4. Date of purchase / Fecha de compra

Failure to supply all of this information will delay your order. / El no proporcionar toda esta información resultará en una demora.

No.

N° Description / Descripción 10/12 SD 10/12 DD 14/21 SD 14/21 DD

1. Top Pan / Bandeja Superior ----------------------------------------------------------218116-037 218116-001 216117-005 216117-001

2. Bottom Pan / Bandeja Inferior --------------------------------------------------------218116-038 318116-025 216117-006 316117-002

3. Front Panel / Panel Del Frente--------------------------------------------------------318116-002 - 318117-002 -

4. Louvered Side / Reja Lateral ---------------------------------------------------------222116-003 222116-003 222117-003 222117-003

5. Corner Post, Right / Poste De Esquina, Derecho-----------------------------------218003-001 218003-001 218003-002 218003-002

6. Corner Post, Left / Poste De Esquina, Izquierdo -----------------------------------218003-003 218003-003 218003-004 218003-004

7. Center Post / Poste Central ------------------------------------------------------------218002-001 218002-001 218002-002 218002-002

8. Water Trough / Canal De Agua -------------------------------------------------------226003-001 226003-001 226003-002 226003-002

9. Aspen Pads / Filtros De Paja ---------------------------------------------------------110097 110097 110098 110098

10. Pad Retainers / Soporte Para El Filtro ----------------------------------------------3PW-8 3PW-8 3PW-9 3PW-9

11. Water Distributor Assembly / Sistema Del Distribuidor De Agua ---------------3D-11 3D-12 3D-13 3D-14

12. Nozzle, Water Distributor / Boquilla Del Distribuidor De Agua -----------------110569 110569 110569 110569

13. Pump Screen / Malla Para La Bomba -----------------------------------------------281001-001 281001-001 281001-001 281001-001

14. Blower Wheel / Rueda -----------------------------------------------------------------110750 110750 110751 110751

15. Shaft, Blower Wheel / Eje De La Rueda --------------------------------------------110158 110158 110159 110159

16. Bearings, Blower Wheel Shaft / Cojinetes Del Eje De La Rueda ----------------110358 110358 110358 110358

17. Channel Retainer Support / Retendedor De Canal --------------------------------214007-007 214007-002 214007-008 214007-004

18. Motor Mount Support / Soporte Para El Montura Del Motor --------------------214116-003 214116-003 214117-003 214117-003

19. Motor Mount Crossbrace / Travesaño De La Montura Del Motor --------------214001-009 214001-006 214001-007 214001-007

20. Motor Mount Adjustable Channel / Montura Ajustable Del Motor -------------214112-002 214112-002 214112-003 214112-003

21. Bearing Mount Support / Soporte Para Los Cojinetes ----------------------------214116-001 214116-005 212103-001 212102-001

22. Blower Housing / Caja De La Rueda ------------------------------------------------320116-001 320116-001 320117-001 320117-001

23. Pulley, Blower Wheel / Polea De La Rueda ----------------------------------------110281 110281 110298 110298

24. Cut-Off Plate / Placa Externa ---------------------------------------------------------318112-004 318112-004 318112-003 318112-003

25. Air Baffl e / Bafl e Del Aire -------------------------------------------------------------220116-002 220116-002 220116-005 222119-001

26. Pump Mount / Soporte De La Bomba ------------------------------------------------214003-023 214003-023 214003-023 214003-023

27. Drive Belt / Correa ---------------------------------------------------------------------110232 110231 *110219 *110219

28. Over Flow Assembly / Montaje De Desagüe ---------------------------------------3OA-1 3OA-1 3OA-1 3OA-1

29. Tube, Water Delivery / Tubo De Agua -----------------------------------------------310717 310717 310717 310717

30. Defl ecter Strip / Tira De Desviación -------------------------------------------------222116-002 222116-002 222117-002 222117-002

31. Float Mount / Soporte Del Flotador -------------------------------------------------- 214003-010 - 214003-010

32. Water Distributer Support Bracket / Soporte Del Distribuidor De Agua--------218002-003 - 218002-003 -

* 14/21SD & 14/21DD Coolers require 2 belts / Los modelos 14/21SD y 14/21DD requiren dos correas.

NOTE: Standard hardware items may be purchased from your local hardware store.

NOTA: Artículos de uso corriente pueden comprarse en la ferretería de su localidad.

8

110525

Page 9

Replacement Parts List / Lista De Piezas De Repuesto

All parts may be ordered from your dealer, but not directly from the factory. Be sure that you furnish the following information on all orders. /

Todas las partes pueden ser pedidas con su concesionario, pero no directamente a la fábrica. Incluya toda la información siguiente con su pedido:

1. Cooler serial number / Número de serie de la unidad

2. Description and part number / Descripción y número de parte

3. Cooler size / Tamaño de la unidad

4. Date of purchase / Fecha de compra

Failure to supply all of this information will delay your order. / El no proporcionar toda esta información resultará en una demora.

No. 75/85DD 75/85SD

N° Description / Descripción 95DD 95SD

1. Top Pan / Bandeja Superior ----------------------------------------------------------------------------------220905-005 220905-004

2. Bottom Pan / Bandeja Inferior --------------------------------------------------------------------------------320908-004 220906-004

3. Louvered Side / Reja Lateral ---------------------------------------------------------------------------------222115-004 222115-004

4. Water Trough / Canal De Agua -------------------------------------------------------------------------------226003-004 226003-004

5. Aspen Pads / Filtros De Paja ---------------------------------------------------------------------------------110096 110096

5A. *Glass Fiber Pads / Filtros De Vidrio ------------------------------------------------------------------------*110129-004 *110129-004

6. Pad Retainers / Soporte Para El Filtro ----------------------------------------------------------------------3PW-7 3PW-7

7. Corner Post, With Float Hole / Poste De Esquina, Con Agujero Para Flotador -----------------------224003-011 224003-018

8. Corner Post, No Float Hole / Poste De Esquina, Sin Agujero Para Flotador --------------------------224003-019 -

8A. Corner Post, For Pump Mount / Poste De Esquina, Para Montar Bomba ------------------------------224003-044 224003-045

9. Cut-Off Plate / Placa Externa ---------------------------------------------------------------------------------320102-002 320102-002

10. Blower Housing / Caja De La Rueda ------------------------------------------------------------------------322115-002 322115-002

11. Blower Wheel / Rueda -----------------------------------------------------------------------------------------110749 110749

12. Shaft, Blower Wheel / Eje De La Rueda --------------------------------------------------------------------110157 110157

13. Bearings, Blower Wheel Shaft / Cojinetes Del Eje De La Rueda ----------------------------------------110357 110357

14. Pulley, Blower Wheel / Polea De La Rueda ----------------------------------------------------------------110280 110280

15. Drive Belt / Correa ---------------------------------------------------------------------------------------------** **

16. Float Valve / Válvula Del Flotador ---------------------------------------------------------------------------FL 3/8 FL 3/8

17. Pump Mount / Soporte De La Bomba ------------------------------------------------------------------------218001-031 218001-031

18. Pump Screen / Malla Para La Bomba -----------------------------------------------------------------------281001-001 281001-001

20. Tube, Water Delivery / Tubo De Agua -----------------------------------------------------------------------310716 310716

22. Water Distributor Assembly / Sistema Del Distribuidor De Agua ---------------------------------------3D-7 3D-8

23. Holder, Water Distributor / Soporte Para El Distribuidor De Agua -------------------------------------110574 110574

24. Over Flow Assembly / Montaje De Desagüe ---------------------------------------------------------------3OA-1 3OA-1

25. Air Baffl e / Bafl e Del Aire -------------------------------------------------------------------------------------220116-002 220116-006

27. Bearing Mount Support / Soporte Para Los Cojinetes ----------------------------------------------------214118-001 214115-006

28. Motor Mount Crossbrace / Travesaño De La Montura Del Motor --------------------------------------214001-005 214001-005

29. Motor Mount Support, Right / Soporte Para El Montura Del Motor, Direcho ------------------------214118-004 214115-002

30. Motor Mount Support, Left / Soporte Para El Montura Del Motor, Izquierdo ------------------------214118-004 214115-002

31. Channel Retainer Support / Retendedor De Canal --------------------------------------------------------218115-023 218115-001

32. Motor Mount Adjustable Channel

34. Bleed-Off Kit / Equipo De La Válvula De Desahogo -----------------------------------------------------310586 310586

35. Defl ecter Strip / Tira De Desviación -------------------------------------------------------------------------222115-003 2221 15-003

36. Front Panel / Panel Del Frente--------------------------------------------------------------------------------- 320115-001

37. Pump Retainer / Retenedor De La Bomba ------------------------------------------------------------------110714 110714

/ Montura Ajustable Del Motor -------------------------------------214112-004 214112-004

* Used for 95DD and 95SD units only. / Utilizado por los modelos 95DD y 95SD solamente.

** See Motor Specifi cation table. / Véase la table de especifi caciones del motor.

NOTE: Standard hardware items may be purchased from your local hardware store.

NOTA: Artículos de uso corriente pueden comprarse en la ferretería de su localidad.

110525

9

Page 10

Replacement Parts / Piezas De Repuesto

75/85 DD, 95 DD

Motor Specifi cations / Especifi caciones Del Motor

Model

ModeloHPC.V.

3/4

75/85 DD

1

1-1/2

95 DD

2

3 +110465-9 3 1 208-230/460 1-1/8

* Re silient mo unte d moto r s / M o to r es c o n b a s es r e sist entes .

+ EPAC T Motors / Motores de buen rendimiento.

† For motors with 1/2 in. shaft / Para motores con el eje de 1/2 pulgadas de diámetro.

~ For motors with 5/8 in. shaft / Para motores con el eje de 5/8 pulgadas de diámetro.

10

Motor

Mot o r

*110455

*110480

110461

*110457

*110458

+110462-9

*110459-1

+110463-9

*110460-1

+110464-9

Phas e

Fase

1

1

3

1

1

3

1

3

1

3

Speed

Velocidad

1

2

1

1

2

1

1

1

1

1

Vo lt s

Voltios

115/208-230

230

208-230/460

115/208-230

230

208-230/460

115/208-230

208-230/460

115/208-230

208-230/460

Shaft (in.)

Eje (pulgadas)

5/8

1/2

5/8

5/8

5/8

7/8

5/8

7/8

7/8

7/8

Drive Belt

Correa

110217

(4L-830)

110217

(4L-830)

110217

(4L-830)

110217

(4L-830)

110218

(4L-850)

Motor Sheave

Polea Del Motor

†110279-002 (0 - 0.7" Static)

†110279-004 (0.3 - 0.8" Static)

~110308 (0 - 0.7" Static)

~110279-003 (0.3 - 0.8" Static)

~110279-003 (0 - 0.8" Static)

~110306-1 (0.6 - 1.0" Static)

110302 (0 - 0.8" Static)

110299 (0.6 - 1.0" Static)

~110279-003 (0 - 0.7" Static)

~110306-1 (0.4 - 1.0" Static)

110302 (0 - 0.7" Static)

110299 (0.4 - 1.0" Static)

110299 (0 - 1.0" Static)

110304 (0 - 0.6" Static)

110300 (0.2 - 1.0" Static)

110525

Page 11

Replacement Parts / Piezas De Repuesto

75/85 SD, 95 SD

Motor Specifi cations / Especifi caciones Del Motor

Model

ModeloHPC.V.

3/4

75/85 SD

1

1-1/2

95 SD

2

* Re silient mo unte d moto r s / Motores con bases resistent es.

+ EPAC T Motors / Motores de buen rendimiento.

† For motors with 1/2 in. shaft / Para motores con el eje de 1/2 pulgadas de diámetro

~ For motors with 5/8 in. shaft / Para motores con el eje de 5/8 pulgadas de diámetro.

110525

Motor

Mot o r

*110455

*110480

110461

*110457

*110458

+110462-9

*110459-1

+110463-9

*110460-1

+110464-9

Phas e

Fase

1

1

3

1

1

3

1

3

1

3

Speed

Velocidad

1

2

1

1

2

1

1

1

1

1

Vo lt s

Voltios

115/208-230

230

208-230/460

115/208-230

230

230/460

115/208-230

230/460

115/208-230

230/460

Shaft (in.)

Eje (pulgadas)

5/8

1/2

5/8

5/8

5/8

7/8

5/8

7/8

7/8

7/8

Drive Belt

Correa

110217

(4L-830)

110217

(4L-830)

110217

(4L-830)

110217

(4L-830)

Motor Sheave

Polea Del Motor

†110279-002 (Static < 0.6")

†110279-004 (Static > 0.3")

~110308 (Static < 0.6")

~110279-003 (Static > 0.3")

~110279-003 (Static < 0.8")

~110306-1 (Static > 0.6")

110302 (Static < 0.8")

110299 (Static > 0.6")

~110279-003 (Static < 0.6")

~110306-1 (Static > 0.2")

110302 (Static < 0.6")

110299 (Static > 0.2")

110299

11

Page 12

Motor Specifi cations / Especifi caciones Del Motor

Model

Mod el o

10/12 DD

10/12 SD

14/21 DD

HP

C.V.

1

1 1/2

2

1

1 1/2

2

1 1/2

2

3 +110465-9 3 1 208-230/460 1-1/8

5 +110466-9 3 1 208-230/460 1-1/8

1 1/2

Motor

Mot o r

*110457

*110458

+110462-9

*110459-1

+110463-9

*110460-1

+110464-9

*110457

*110458

+110462-9

*110459-1

+110463-9

*110460-1

+110464-9

*110459-1

+110463-9

*110460-1

+110464-9

*110459-1

+110463-9

Phas e

Fase

1

1

3

1

3

1

3

1

1

3

1

3

1

3

1

3

1

3

1

3

Speed

Velocidad

1

2

1

1

1

1

1

1

2

1

1

1

1

1

1

1

1

1

1

1

Vo lt s

Voltios

115/208-230

230

208-230/460

115/208-230

208-230/460

115/208-230

208-230/460

115/208-230

230

208-230/460

115/208-230

208-230/460

115/208-230

208-230/460

115/208-230

208-230/460

115/208-230

208-230/460

115/208-230

208-230/460

Shaft (in.)

Eje (pulgadas)

5/8

5/8

7/8

5/8

7/8

7/8

7/8

5/8

5/8

7/8

5/8

7/8

7/8

7/8

5/8

7/8

7/8

7/8

5/8

7/8

Drive Belt

Correa

110231

(4L970)

110231

(4L970)

110231

(4L970)

110232

(4L-980)

110232

(4L-980)

110232

(4L-980)

110219

(B-108)

110219

(B-108)

110219

(B-108)

110219

(B-108)

110219

(B-108)

Motor Sheave

Polea Del Motor

~110308

110309

110302 (Static < 0.6)

110299 (Static > 0.4)

~110279-003 (Static < 0.6)

~110306-1 (Static > 0.4)

110302 (Static < 0.5)

110299 (Static > 0.2)

~110308

110309

110302 (Static < 0.5)

110299 (Static > 0.3)

~110279-003 (Static < 0.5)

~110306-1 (Static > 0.3)

110299 (Static < 0.8)

110307-1 (Static > 0.6)

110290

~110286

110290 (Static < 0.6)

110289 (Static > 0.4)

110291

110291 (Static < 0.6)

110304-1 (Static > 0.4)

110290

~110286

14/21 SD

* Re silient mo unte d mo to r s / Motores con bases resistent es.

+ EPAC T Motors / Motores de buen rendimiento.

~ For motors with 5/8 in. shaft / Para motores con el eje de 5/8 pulgadas de diámetro.

2

3 +110465-9 3 1 208-230/460 1-1/8

5 +110466-9 3 1 208-230/460 1-1/8

*110460-1

+110464-9

1

3

1

1

115/208-230

208-230/460

7/8

7/8

110219

(B-108)

110219

(B-108)

110219

(B-108)

110290 (Static < 0.6)

110289 (Static > 0.3)

110291

110291 (Static < 0.5)

110304-1 (Static > 0.3)

General Specifi cations / Especifi caciones Generales

*Weight (lbs.)

Mode l No.

Modelo

75/85 DD

95 DD

75/85 SD

95 SD

10/12 DD 447 622 53 5/8 50 50 26 7/8 26 7/8

10/12 SD 439 689 53 5/8 50 50 26 7/8 26 7/8

14/21 DD 621 896 61 1/4 62 62 31 3/4 31 3/4

14/21 SD 617 1000 61 1/4 62 62 31 3/4 31 3/4

*Doe s not i ncl ude motor we ight. / No incluye el peso del motor.

Peso (libras)

Dry

Seco

281 373 53 5/8 41 1/4 41 1/4 21 3/4 21 3/4

259 426 53 5/8 41 1/4 41 1/4 21 3/4 21 3/4

Operating

Lleno

Height

Altura

Cabine t Dime nsions ( in.)

Dimensiones De La Caja (pulgadas)

Width

Anchura

Profundidad

Depth

Duct Opening (in.)

Abertura De Ducto (pulgadas)

Width

Anchura

Height

Altura

12

110525

Page 13

Lea y Conserve Estas Instrucciones

Reglas De Seguridad

1. Lea las instrucciones con cuidado.

2. Desconecte todos los servicios eléctricos que serán usados en esta

unidad antes de instalar el enfriador.

3. Las conexiones eléctricas deben ser hechas por un electricista

competente, para que todo el cableado eléctrico cumpla con los

requisitos establecidos en su localidad.

4. Para una máxima y segura precaución, debe estar muy seguro que

la caja del aparato está conectada con la tierra.

5. El enfriador debe ser conectado con el propio voltaje, corriente

alterna y ciclos, lo que se encuentran en la placa de especifi caciones

de la bomba y del motor.

6. Asegure la bomba para no se vuelca en el agua.

7. Siempre CORTE LA CORRIENTE antes de realizar cualquier

labor de mantenimiento.

Puede deslizar las monturas ajustables hacia un lado u otro lado para

alinear los pernos con los agujeros en el base del motor y para alinear

la polea del motor con la polea de la rueda. Instale el motor usando

los pernos y las tuercas provistos (véase fi g. 1). Asegúrese que los

pernos estén apretados seguramente.

• Instalar la polea del motor. Instale la polea ajustable del motor

para que quede alineada con la polea del ventilador (véase fi g. 2) y

apriete el tornillo de presión. Vea la página 14 para instrucciones de

ajustar la polea.

Polea Del

Motor

Caja De

La Rueda

Montura

Ajustable

Fig. 1

Polea Del

Ventilador

Fig. 2

Operación

Para el mejor funcionamiento, si los fi ltros son secos, prenda sólo la

bomba durante unos cuantos minutos antes de prender el motor del

ventilador.

Su enfriador puede ser utilizado sin agua para proporcionar ventilación

solamente. Cuando esté fresco (por ejemplo, de noche) o cuando la

humedad es alta, la bomba de agua puede ser apagada.

IMPORTANTE: El proceso de enfriamiento por evaporación requiere

que agota el aire viejo del edifi cio. Abre las ventanas o puertas o utilice

los extractores de aire situados lejos del enfriador y en la dirección

que desea enfriar. El aire fl uirá en la dirección de las aberturas de

escape. Debe tener a lo menos 2 pies cuadrados de abertura por cada

1000 CFM.

Instalación

PRECAUCIÓN: La superfi cie en que ha de colocarse el

enfriador deberá aguantar el peso completo de la unidad cuando

ésta está en funcionamiento. (Para saber este peso, vea la tabla

de especifi caciones.)

PRECAUCIÓN: No conecte el enfriador hasta que la ins-

talación esté completa y se haya comprobado la estabilidad del

mismo.

PRECAUCIÓN: Asegúrese que todos los tornillos estén

apretados seguramente antes de prender el enfriador.

• El sistema del ducto. Vea la tabla de especifi caciones generales

para el tamaño del abertura del ducto. Para los modelos 10/12DD y

14/21DD con salida de abajo, el ducto debe entrar por el interior del

abertura. El tamaño de estos ductos debe ser menos de la abertura

del enfriador. El ducto puede entrar por el interior o el exterior del

reborde de salida de los modelos 75/85DD y 95DD. Las unidades

con salida del lado tienen un reborde de 1 pulgada. El tamaño de

estos ductos debe ser más grande de la abertura del enfriador para

caber sobre el reborde.

Nota: Los soportes para montar el enfriador no están provistos.

El instalador es responsable para soportar el enfriador.

Instalación Del Motor

• Montar el motor. Deslice la cabeza de los pernos provistos con

cuellos cuadrados por la ranura en la montura ajustable del motor.

Instalación Eléctrica

NOTA: Los códigos locales de construcción deben ser observadas.

ADVERTENCIA: Desconecte todos los servicios eléctricos

que serán usados en esta unidad antes de instalar el enfriador.

• Conexión eléctrica. El enfriador debe ser conectado con el propio

voltaje, corriente de línea y frecuencia, que se encuentran en la

placa de información de la bomba y del motor. Vea las esquemas de

cableado en la página 15 para las conexiones típicas.

NOTA: El conectar el motor a voltaje impropio anulará la garantía

del motor.

• Calibre de cable. La carga del motor y el longitud del cable requerido

por los códigos eléctricos nacionales y locales determinará el calibre

de cable que debe usar.

• Interruptores y contactores. Los motores requieren interruptores

o contactores de propia capacidad de corriente. Un electricista cualifi cado debe determinar su tamaño e instalarlos.

ADVERTENCIA: Compruebe que la caja del enfriador tenga

la debida conexión a tierra para proveer máxima seguridad.

Conectar El Agua

• La instalación del montaje de desagüe. Quite la tuerca y pase la

boquilla por el agujero de la bandeja, colocando la arandela de hule

entre la bandeja y la cabeza de la boquilla (véase fi g. 3). Coloque la

tuerca en la boquilla y atorníllela hasta que quede apretada contra la

parte inferior de la bandeja. Inserte

el tubo de desagüe en la boquilla para

retener el agua. El tubo de desagüe

se puede quitar para desaguar el agua

de la bandeja cuando sea necesario.

Se puede conectar una manguera de

jardín a la boquilla para desaguar el

agua hacia otra parte.

• La Bomba. Debe asegurar la bomba al soporte de la bomba para

evitar que incline encima. Para los modelos 10/12 y 14/21, quite la

tuerca de la tapa de la bomba y asegure la bomba al soporte usando

este tuerca. Para asegurar la bomba a los modelos 75/85 y 95, deslice

la bomba por la horquilla del soporte y asegúrela con el retenedor de

plástico.

• El suministro de agua. Conecte un tubo de suministro de agua de

3/8 pulgadas en diámetro a la válvula de fl otador. NOTA: Nunca

utilice el agua suministrado de un suavizador de agua.

Tubo De Desagüe

Boquilla Roscada

Arandela De Hule

Bandeja

Tuerca

Fig. 3

110525

13

Page 14

• La válvula de fl otador. Instale

la válvula de flotador en el

soporte del fl otador dentro del

enfriador y conecte el tubo de

agua (véase fi g. 4). Nota: La

válvula de fl otador está instala-

Soporte Del

Varilla Del

Flotador

Tubo De Abas-

tecimiento De

Agua

Flotador

da en los modelos 75/85 y 95.

Necesitará comprar la válvula

de fl otador por separado para

los otros modelos.

Fig. 4

Ferula

Tuerca

Arandela

Tuerca

• Llenar la bandeja con agua.

Permita que se llene la bandeja con agua hasta una altura de una

pulgada por debajo del borde superior de la bandeja. Ajuste el

fl otador para que mantenga este nivel. Al ajustar el fl otador, afl oje

el tornillo de la válvula, ajuste la varilla y apriete el tornillo. Compruebe que no escape el agua.

• Los canales de agua. Ponga a funcionar la bomba hasta saturar de

agua los fi ltros. Luego revise cada canal para ver si la distribución

del agua es pareja. Si no es así, afl oje los tornillos de ajuste y nivele

cada canal. Vuelva a apretar los tornillos. Compruebe que todos

los fi ltros hayan quedado saturados de agua y que no contengan

áreas secas o roturas.

• La válvula de desahogo. Recomendamos usar la válvula de des-

ahogo para prevenir la formación de escama, por la segregación

de pequeñas cantidades de agua durante la operación. No agregue

ningún tipo de productos químicos del tratamiento de aguas al

agua.

Ajustar La Polea y La Correa

• Ajustar la polea. Con un amperímetro, mide el amperio del motor.

Ajuste la polea del motor hasta que el amperio sea menos por poco

de lo que se especifi ca la placa de identifi cación del motor. Al ajustar

la polea, afl oje el tornillo de ajuste con

punta plana y gire la polea. Apriete el

tornillo de modo que la punta del tornillo

queda sobre el área plana, si no, dañaría

las roscas. El incrementar el diámetro de

la polea, incrementa también el amperio;

el disminuir el diámetro de la polea, disminuye también el amperio (véase fi g.

5). V uelva a inspeccionar la alineación

de la correa.

Disminuir

Amperio

Fig. 5

Mantenimiento

ADVERTENCIA: Antes de hacer cualquier mantenimiento,

compruebe que la corriente esté desconectada. Esto es por su

seguridad.

Puesta En Marcha En La Primavera

• Cambiar los fi ltros. Debe cambiar los fi ltros de paja una o dos ve-

ces durante cada temporada, según la duración de ésta. Al principio

y a mediados de la temporada, un fi ltro limpio es más absorbente y

efi ciente y producirá un mayor volumen de aire fresco.

• Limpiar la bomba. Es necesario limpiar la bomba una vez al

principio de cada año. Por su propia seguridad, apague la unidad

y desconecte el motor y la bomba. Quite la bomba de su montura.

Quite la base de la bomba (véase fi g. 7). Limpie la bomba. Dé le

vuelta a la hélice para verifi car que se mueve libremente. Quite

el pico de la bomba y vea si está obstruido. Vuelva a colocar la

base de la bomba. Coloque la

bomba en la unidad y fíjela en

su montura. Esto impedirá que

se caiga la bomba al agua, lo que

dañaría el motor. No se olvide de

volver a conectar el tubo de agua

a la bomba. La bomba contiene

un depósito protector en caso de

sobrecalentamiento (se apagará

automáticamente).

• La válvula de desahogo. Inspeccione la válvula de desahogo para

verifi car que no esté obstruida.

• La tensión de la correa. Inspeccione la tensión de la correa y

reajústela si sea necesario.

• Lubrique los cojinetes. Los cojinetes de la rueda y el motor del

ventilador deben ser lubricados usando unas gotas de un aceite

no detergente de densidad 20/30 una vez al año. No obstante, los

motores sin tuberías para aceite no necesita ser lubricados. Estos

motores son lubricados en la fábrica de por vida y no requieren

nunca ninguna lubricación.

PRECAUCIÓN: No lubrique demás. El agregar demasiado

aceite puede ocasionar que se queme el motor, a causa del aceite

entrando al interior del motor.

Remueve

Fig. 7

PRECAUCIÓN: Cuando sea necesario ajustar la polea, mida

el amperio del motor para verifi car que no exceda el máximo

encontrado en la placa del motor. Un inadecuado ajuste quemará el motor.

• Tensar la correa. Afl oje los pernos

del motor y deslice el motor detrás

3 Libras

3/4 Pulgadas

hasta que la correa está tensada correctamente. Una fuerza de 3 libras

debe desviar la correa 3/4 pulgadas

(véase fi g. 6). Reafl oje los pernos

del motor. Nunca ajuste la polea

Fig. 6

para tensar la correa.

14

Preparar La Unidad Para El Invierno

• Drene el agua. Drene siempre toda el agua del enfriador y del

tubo de abastecimiento de agua cuando no use el enfriador durante

períodos prolongados, especialmente al fi n de la temporada. El tubo

debe quedarse desconectado del abastecimiento de agua para que

no lo congele.

• Desconecte de la electricidad cuando no se utiliza el enfriador

por períodos extendidos.

• Cubra la unidad. Para proteger y alargar la vida útil del acabado,

se sugiere cubrir el enfriador durante períodos largos cuando no

sea utilizado.

Si usted sigue estas sugerencias en cuanto a instalación, operación y

mantenimiento, podrá disfrutar de muchos años de servicio efi ciente

y satisfactorio de este enfriador. Si desea más información, su concesionario tendrá mucho gusto en ayudarle con respecto a cualquier

duda o pregunta.

110525

Page 15

Esquemas Típicas Del Cableado Eléctrico

Alimentación Eléctrica De 120 Voltios y 1 Fase

Desconectador Al Enfriador

Vea Las Notas 1 & 2

L

H

P

N

Fusibles

Vea Nota 1

Caja Del Enfriador

Vea Nota 3

Contactos Del Mando

Vea Nota 4

TierraTierra

Desconectador

Principal

Vea Nota 1

• Motor del ventilador de 115V y una fase.

L1

N

Alimentación

Eléctrica

120 Voltios

1 Fase

Alimentación Eléctrica De 240 Voltios y 1 Fase

Desconectador Al Enfriador

Vea Las Notas 1 & 2

L

H

120V

P

L2

Tierra

Transformador

Caja Del Enfriador

Vea Nota 3

• Motor de la bomba de 120V.

• Esta diagrama se muestra un motor de

Tierra Del

Equipo

Motor Del Ventilador

Motor De La

Bomba

dos velocidades. El circuito de velocidad

baja dibujado con líneas discontinuas no

se requiere para un motor de una sola

velocidad.

Tierra Del

Equipo

Motor Del Ventilador

Motor De La

Bomba

Alimentación Eléctrica Del Ventilador Trifásica De 208, 240, o 480V y De La Bomba y El Mando De 120V y 1 Fase

Arrancador De Motor Con

Protección De Sobrecarga y

El Tamaño Correspondiendo Con La Corriente De

Carga Completa Del Motor.

Vea Nota 1.

Desconectador Al

Enfriador

Vea Las Notas 1 & 2

T3

T2

T1

Tierra

Contactos Del Mando

Tierra Del

Equipo

Vea Nota 4

H

P

Desconectador Al Enfriador

Vea Las Notas 1&2

Caja Del Enfriador

Vea Nota 3

Motor De La Bomba

Motor Del Ventilador

N

Tierra

Fusibles

Vea Nota 1

Tierra

Desconectador Principal

Vea Nota 1

Tierra

L1

L2

L3

L1

N

Alimentación Eléctrica

208, 240, o 480V

Trifásica

Alimentación Eléctrica

120V

1 Fase

• Motor trifásico del ventilador de una velocidad.

• Arrancador de tres polos con protección de

sobrecarga.

• Se muestra un mando y bomba de 120V y

de una fase. Si utiliza un mando y bomba

de 240V , entonces debe fusar ambas líneas

de la alimentación eléctrica.

Contactos Del Mando

Vea Nota 4

Alimentación

L1

Eléctrica

L2

208 or 240V

Fusibles

Vea Nota 1

Tierra

Desconectador

Principal

Vea Nota 1

1 Fase

• Motor del ventilador de 230V y una fase.

• Motor de la bomba de 120V. Para utilizar

una bomba de 240V con una alimentación

de 240V, omite el transformador.

• Esta diagrama se muestra un motor de dos

velocidades. El circuito de velocidad baja

dibujado con líneas discontinuas no se requiere para un motor de una sola velocidad.

Contactos De Mandos Típicos

L - Bajo

P - Bomba

H - Alto

L1 - Alimentación Eléctrica

Función Conexión

Apagada Nada

Bomba L1-P

Alto-Fresco L1-H

* Bajo-Fresco L1-L & L1-P

Alto-Ventilador L1-H

* Bajo-V entilador L1-L

* Omite para el motor del ventilador

de una velocidad.

Alimentación Eléctrica Trifásico Del Ventilador De 208, 240, o 480V Con Transformador Para La Bomba y El Mando

Arrancador De Motor Con

Protección De Sobrecarga y

El Tamaño Correspondiendo

Con La Corriente De Carga

Completa Del Motor.

Vea Nota 1.

Desconectador Al Enfriador

Vea Las Notas 1 & 2

T3

T2

T1

Tierra

Tierra De

Equipo

Contactos Del

Mando

Vea Nota 4

Motor Del Ventilador

H

P

Desconectador Al Enfriador

Vea Las Notas 1&2

Caja Del Enfriador

Vea Nota 3

Motor De La Bomba

120

V

Fusibles

Vea Nota 1

Transformador

Vea Nota 1

• Motor trifásico del ventilador de una velocidad.

• Arrancador de tres polos con protección de sobrecarga.

• Motor de la bomba de 120V y una fase con alimentación

eléctrica suministrado de un transformador. Para utilizar

una bomba y mando de 240V con una alimentación de

240V, omite el transformador.

Tierra

L1

L2

L3

Alimentación Eléctrica

208, 240, o 480V

Desconectador Principal

Vea Nota 1

Trifásica

ADVERTENCIA: La conexión eléctrica debe efectuarse por un electricista califi cado. Todo el cableado eléctrico debe efectuarse con

las normas nacionales y locales.

NOTA 1. Todos los interruptores, marchas, transformadores, fusibles, cajas de empalmes, enchufes, cajas para enchufes, placas protectoras, y conductores deben

NOTA 2. El código eléctrico nacional requiere un desconector localizado en el equipo si el desconector principal en el equipo no está visible. Si usa mas de un

NOTA 3. Se requiere un receptáculo de NEMA 5-15 para una bomba de 120V y un receptáculo de NEMA 6-15 para una bomba de 230V.

NOTA 4. Los contactos del mando puede ser un parte de un interruptor, un termostato, u otro dispositivo.

ser abastecidos por el instalador y cumplir con los códigos nacionales y locales.

desconector, debe colocarse en el lado adyacente uno a otro.

110525

15

Page 16

La Localización De Averias

Problema Causa Posible Remedio

No arranca o

no sale aire

Sale poco

aire cuando

la unidad está

funcionando

Enfriamiento

inadecuado

1. No llega corriente

• Fusible fundido

• Cortacircuito desactivado

2. Correa muy fl oja o apre-

tada

3. Motor recalentado

• Correa muy apretada

• Cojinetes de la rueda están

secos

• Cojinetes del motor están

secos

• Diámetro de la polea del

motor demasiado grande

4. Motor parado

1. Insufi ciente abertura para

que salga el aire

2. Poca tensión en la correa

3. Filtros obstruidos

4. Agua insuficiente en los

fi ltros

1. Insufi ciente abertura para

que salga aire

2. Los fi ltros no están mo-

jados

• Filtros obstruidos

• Filtros agujereados

• Agujeros de los canales

obstruidos

• Bomba no funciona

1. Revise la corriente

• Cambie el fusible

• Restablecer el cortacircuito

2. Ajuste la tensión de la

correa

3. Determine la causa

• Ajuste la tensión de la

correa

• Lubrique los cojinetes

• Lubrique los cojinetes

• Ajústela al diámetro correcto

4. Cambie el motor

1. Abra ventanas o puertas

para aumentar flujo de

aire

2. Ajuste la tensión o cam-

bie la correa

3. Cambie los fi ltros

4. Limpie el sistema de dis-

tribución y los agujeros

del canal

1. Abra más las ventanas o

puertas

2. Revise la distribución

de agua

• Cambie los fi ltros

• Acomode la paja en el

fi ltro

• Límpielos

• Cámbiela o límpiela

(Desconecte la unidad)

Problema Causa Posible Remedio

Motor se apaga

y se enciende

Hace Ruido

Demasiada

humedad en la

casa

Olor a encerrado, olor

desagradable

1. Voltaje defi ciente

2. Demasiada tensión en la

correa

3. Eje del ventilador atorado

4. Cojinetes secos

5. Diámetro demasiado grande de la polea del motor

dando por resultado sobrecarga del motor

6. Motor defectuoso

1. Cojinetes secos

2. Rueda roza contra caja de

la rueda

3. Partes sueltas

1. Insufi ciente salida de aire

1. Agua estancado en la

unidad

2. Filtros secos

• Agujeros del canal tapa-

dos

• Bomba no trabaja ade-

cuada

• Insuficiente flujo de

agua

1. Compruebe el voltaje

2. Ajuste la tensión de la

correa

3. Lubrique o cambie los

cojinetes (Desconecte la

unidad)

4. Lubrique los cojinetes

5. Ajústela para no exceder

el grado a carga plena del

amperio del motor

6. Cámbielo

1. Lubrique los cojinetes

2. Inspeccione y alinee

(Desconecte la unidad)

3. Apriételas

1. Abra puertas o ventanas

1. Desagüe y limpie los

fi ltros

2. Revise la distribución

de agua

• Límpielos

• Reemplace o limpie la

bomba (Desconecte la

unidad)

• Limpie el sistema de dis-

tribución y los agujeros

de los canales

Registre su producto en línea a: www.championcooler.com/eac/onlineregistration-eac.htm

Garantía Limitada

La presente garantía se extiende al comprador original de un enfriador evaporativo instalado y utilizado bajo condiciones normales. No cubre daños ocurridos

por accidente, descuido o abuso por parte del propietario. No autorizamos que ninguna otra persona o representante asuma por nosotros cualquier otra o

diferente responsabilidad en relación con este producto.

Términos y Condiciones De La Garantía

Durante Cinco Años a partir de la fecha de compra, nosotros reemplazaremos la base original del enfriador en caso de gotera de agua debido a oxidación.

Durante Un Año a partir de la fecha de compra reemplazaremos estos componentes originales que fallen debido a cualquier defecto de materiales o mano

de obra en la fábrica.

Exclusiones De La Garantía

No somos responsables por reemplazar los fi ltros del enfriador. Estos son componentes desechables y deben cambiarse periódicamente. No somos respon-

sables por daños que resulten a consecuencia de alguna falla de funcionamiento.

No somos responsables por cualquier daño producido por el uso de suavizadores de agua, productos químicos, materiales desincrustantes, envolturas de

plástico, o si se usa en esta unidad un motor de mayor potencia de la que se indica en la placa de número de serie.

No somos responsables por el costo del servicio por diagnosticar la causa del problema ni por la mano de obra necesaria para reparar y/o reemplazar partes.

Como Obtener Servicio Bajo Esta Garantía

Póngase en contacto con el Concesionario que le vendió el enfriador. Si por alguna razón usted no queda satisfecho con la respuesta por parte del Concesionario, comuníquese con el departamento de servicio al cliente: 5800 Murray Street, Little Rock, Arkansas 72209. 1-800-643-8341. E-mail: info@

championcooler.com Web: www.championcooler.com

Esta garantía limitada se aplica al comprador original solamente.

16

110525

Loading...

Loading...