Page 1

Owner’s Manual

Model #’s

WC35, RWC35

N35W, RN35W

WC44, RWC44

WC46, RWC46

N46W, RN46W

WC50, RWC50

N50W, RN50W

Window Evaporative

Air Cooler

Evaporative Cooling

Evaporative cooling uses the principle of evaporation to lower the air

temperature. Hot, dry air is passed through wetted filters and is converted to

refreshingly cooled air. Champion/Essick coolers make the best use of the

evaporative process by controlling the flow of water, spreading the water evenly

over the filters, and keeping a steady stream of cooled air entering your home.

It is exhausted out open windows or doors, carrying heat, smoke and odors

along with it. Champion/Essick evaporative coolers are 80% less costly to

Read & Save This

Instruction Manual!

operate than refrigerated air conditioners.

P/N 71088

REV 1/06

1

Page 2

SAFETY GUIDE LINES & CAUTIONS

When Installing When Operating When Servicing

Make sure that unit is installed on a sound

structure that will support the full operating

weight of the cooler. See page 4.

Before attempting to hang the cooler in the

window, remove the louvers to reduce weight.

Do NOT connect power to cooler before

installation is complete.

Make sure that circuit cooler is plugged into is

equipped with a (slow blow) breaker large

enough to support the full amperage of the

cooler.

To reduce the risk of fire or electrical shock, DO

NOT use this fan with any Solid-state speed

control device.

This cooler is equipped with an

thermally protected motor. If it shuts off on its

own for any reason,

warningUUUU.

UUUUit can restart without

UUUUautomaticUUUU

MOUNTING

To install this cooler, the following tools are required:

• Adjustable wrenches

• Screwdrivers

• Electric drill

• 3/16” drill bit

• Level

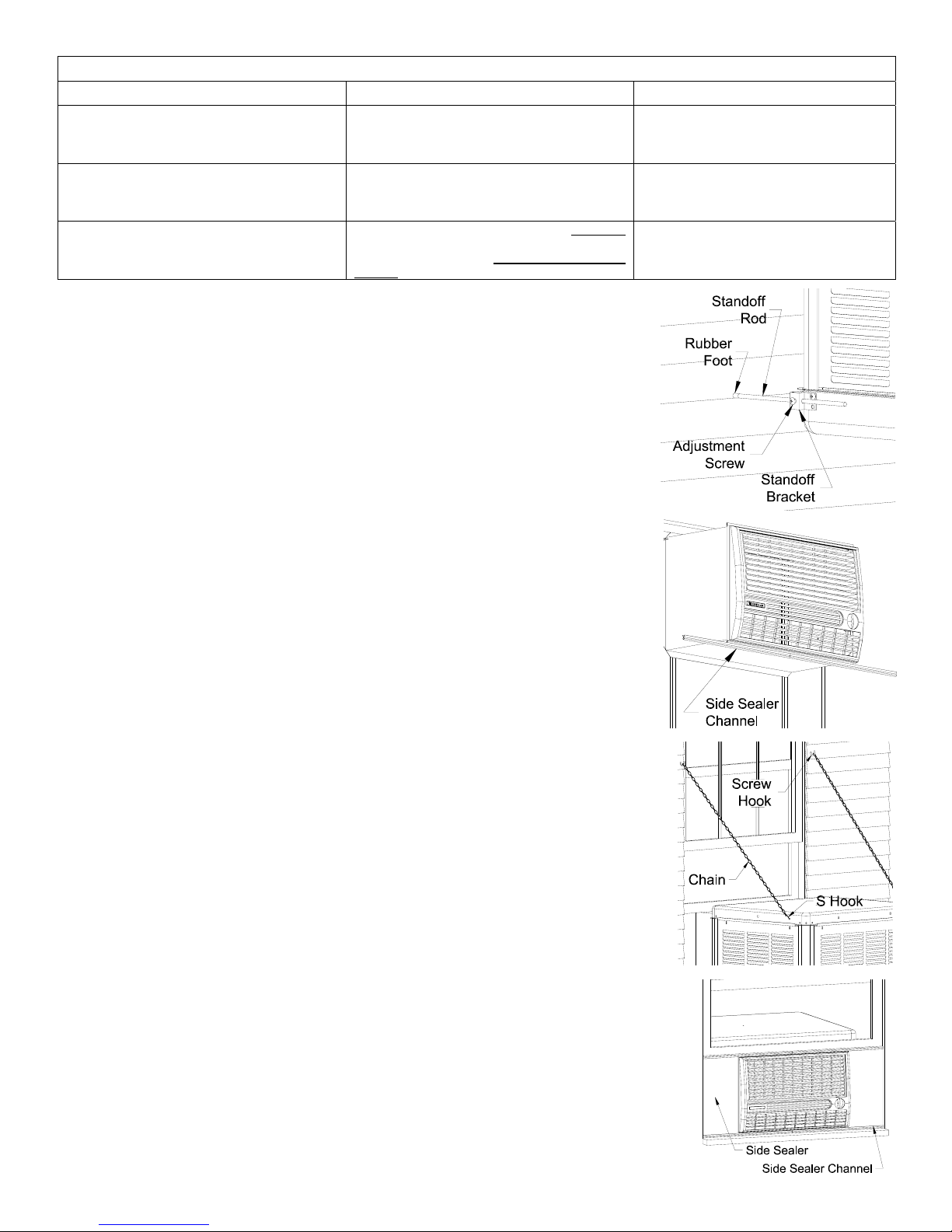

1. Loosen the Adjustment Screw in the Stand-Off Bracket. Remove the Spacer-Rod

from the installation package and insert them into the Stand-Off brackets as shown.

2. Cut the Side Sealer Channels so that two of them will span the window when

butted together. Place two of the channels on the bottom duct flange as shown.

3. Place the Cooler in the center of the window with the bottom duct flange resting

against the sill.

4. Pull out the Spacer-Rods so as to allow the Rubber Feet to rest against the side of

the house. Tighten the Adjustment Screws.

5. Lower the window to rest on top of the duct behind the top duct flange.

6. Fasten a stop above the inside window sash to prevent the window from being

raised. Raising the window may cause the cooler to fall.

7. Adjust the Spacer-Rods to level the cooler. This will ensure proper water flow to the

pads.

8. Install the Chain Supports.

a. Drill pilot holes in the window frame, 3 feet above the top of the duct and the width

of the cooler apart. Install the Screw-Hooks in these pilot holes to the full depth of the

thread.

b. Hook one end of each Chain over each Screw-Hook.

c. Place S-Hooks in the in the holes at the top-rear of the cooler.

d. Place the opposite end of the S-Hooks in the free end of each Chain. Make sure

the chains are taut, but not so tight they pull the bottom of the cooler away from the

wall.

9. Install the Side Sealer Panels. These panels are the correct height, but need to be

trimmed to fit the width of your window. Trim the panels so that they reach from the

window frame to the side of the duct. Slide the panels in the channels you placed on

the bottom duct flange. Install the remaining Side-Sealer Channels over the top duct

flange and the Side-Sealer Panels.

Always Unplug the cooler before attempting

service of any kind.

Be sure to disconnect unit from power

source before servicing. If not, it can be

turned on from inside the house and start

unexpectedly.

If the motor shuts off because of thermal

overload, check into the problem

immediately. If allowed to continue,

permanent damage will occur.

2

Page 3

INSTALL OVERFLOW AND DRAIN

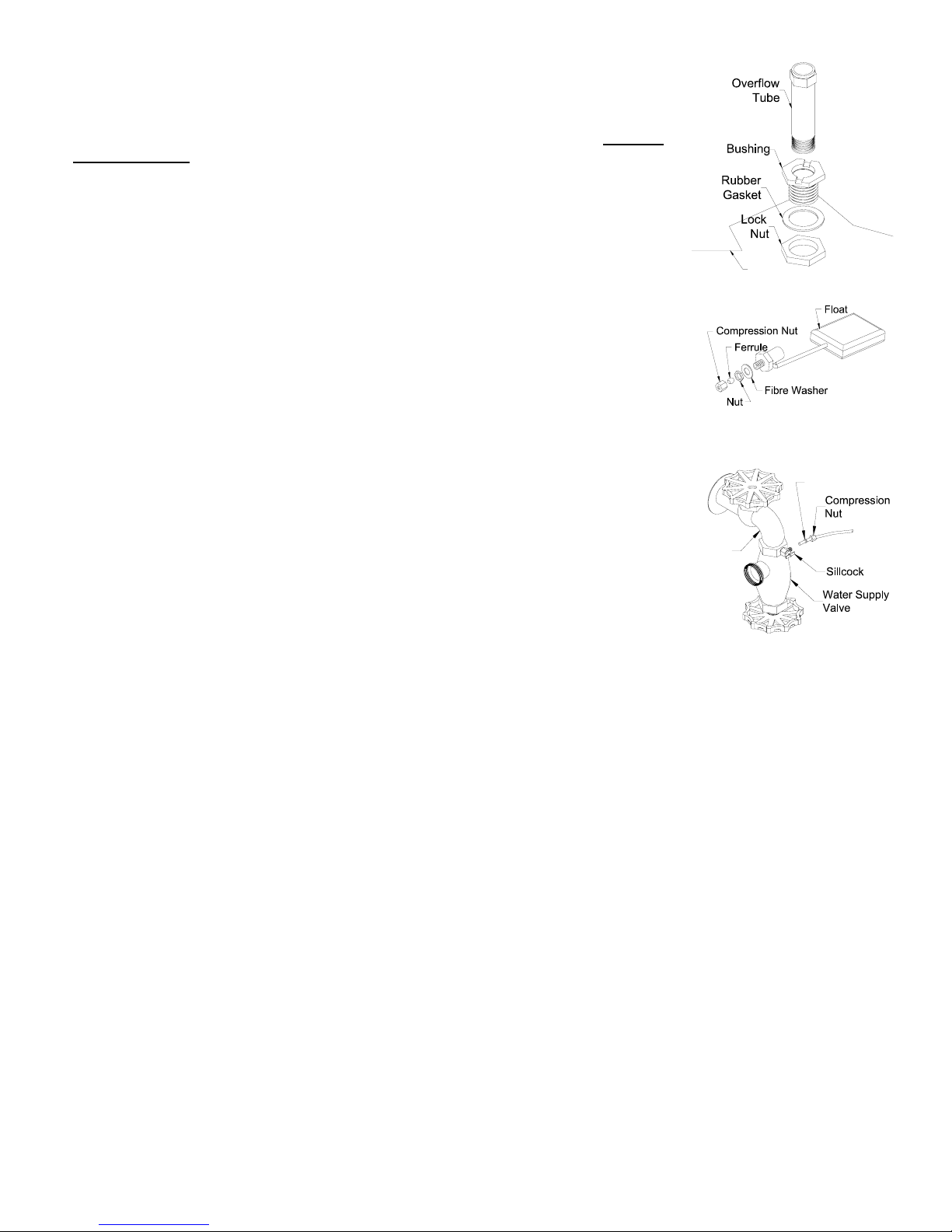

1. Slide the Rubber Washer over the Drain Bushing and push through the hole in the

bottom of the cooler from the top side.

2. Secure the Drain Bushing from beneath the pan with the Lock Nut. Make sure the

Rubber Washer does not twist while tightening, which could cause it to leak.

UUUUDO NOT

OVERTIGHTEN.UUUU

3. Thread the Overflow Tube into the Drain Bushing and HAND TIGHTEN.

4. If leakage occurs after Reservoir is full, retighten the Overflow Pipe until leaking stops.

A small amount of silicone caulk may be used if necessary.

FLOAT VALVE INSTALLATION

1. Place the threaded portion of the Float Valve through the hole provided in the Corner

Reservoir

Post from the inside.

2. Slip the Fiber Washer over the threaded portion outside the corner post and secure with

the Nut. Be sure the Float does not turn while you are tightening the Nut.

WATER LINE CONNECTION

Find the closest outside water faucet, and install a Water Connection Kit (not included with

cooler) as shown. If an exterior faucet is not available, locate the closest cold water pipe

and install a saddle valve assembly.

Route tubing to cooler. Place Compression Nut and Ferrule over end of tubing. Insert the

Ferrule

tubing into float valve and tighten Compression Nut to secure. NOTE: Over tightening the

compression fitting will cause that fitting to leak. It is best to secure the connections, turn

on the water, and then snug the fitting until leaking stops.

ADJUSTING WATER LEVEL AND FLOAT VALVE

Faucet

• To adjust water level, bend the float valve rod.

• Check all water connections for leaks.

• Make sure the Float Valve cuts off completely when the desired water level has been

reached (½” to ¾” below top of Overflow Tube). If the float does not stop the water

completely, the water level will rise and run out the Overflow Tube.

• Double check the Overflow Tube for leaks.

START UP

1. Plug in the electrical cord to a standard grounded receptacl e. Be sure the Circuit Breaker protecting the receptacle is of

sufficient size.

2. Open windows in rooms where you wan t cooling to be directed.

3. Turn the cooler to the High Fan position. Observe the amount of air being delivered. Note: on cool nights (or days) or

when the humidity level is high, the fan positions may be used for ventilation purposes.

4. Turn the cooler to the Low Fan position. This should significantly reduce the amount of air bei ng delivered.

5. Turn the cooler to the Pump Only position. The pump should run and not the fan. Check to see that water is flowing

from all three Water Trays.

6. Turn the cooler to the High Cool position. Check to see that all three Pads are wetting evenly with no dry patches. The

Pads may take up to 20 minutes to wet fully. If the Pads have dry patches, you can adjust the level of each Water Tray

by screws on each end.

7. Adjust window openings to achieve desire d cooling level.

3

Page 4

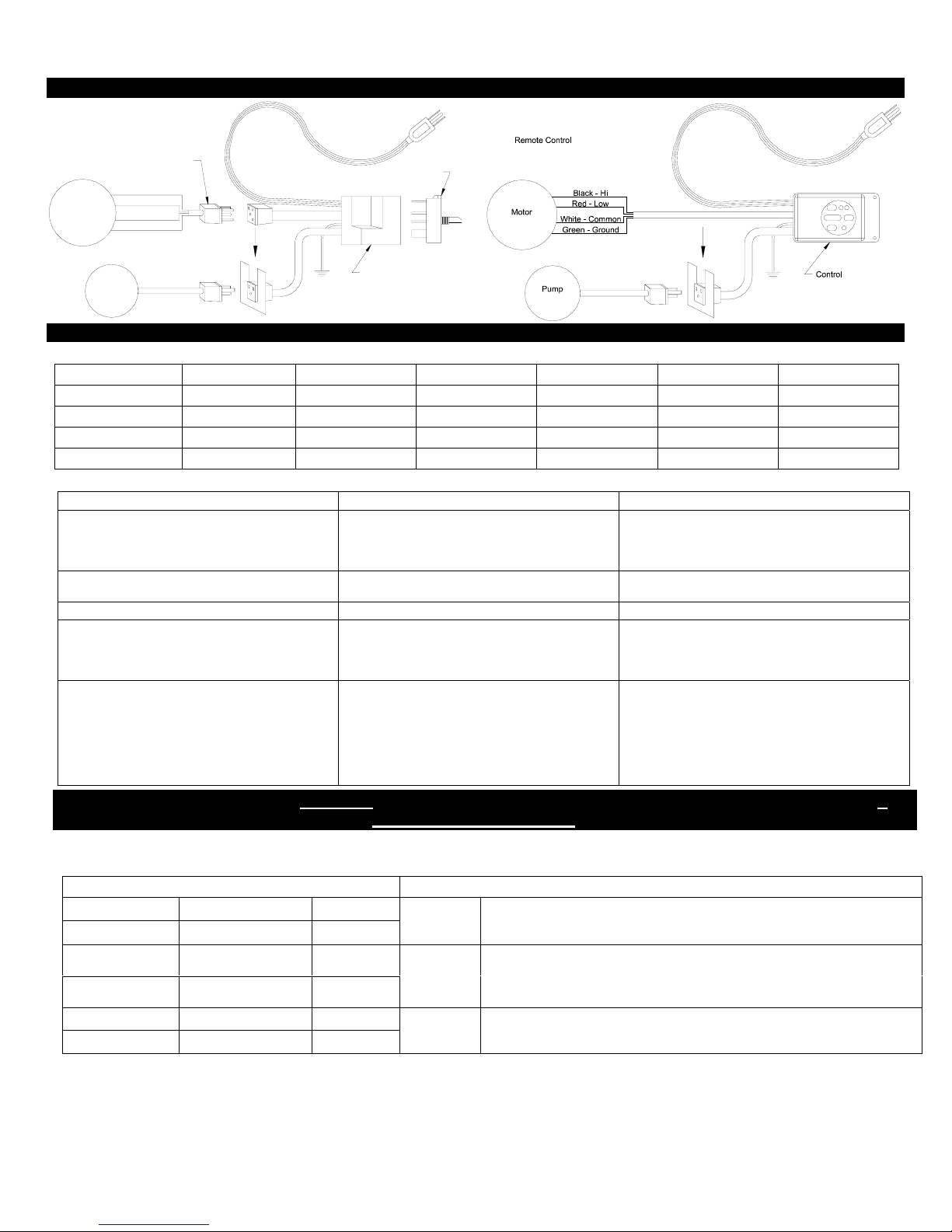

WIRING DIAGRAM

CAUTION: Always unplug cooler before opening or attempting service of any kind.

Manual Control

Motor Cord

Black - Hi

Motor

Red - Low

White - Common

Green - Ground

Switch

Pump

WARNING: To reduce the risk of fire or electric shock, do not use this fan with any solid-state speed control device.

Wiring Harness

COOLER SPECIFICATIONS

Model Height Width Depth Amps Shipping Weight Operating Weight

(R)WC50/(R)N50W 35” 34” 34” 8.4 165 249

(R)WC46/(R)N46W 35” 34” 34” 7.4 165 249

(R)WC44 35” 34” 28” 7.4 147 217

(R)WC35/(R)N35W 31” 32” 21” 7.4 135 184

TROUBLE SHOOTING

Problem Cause Remedy

• Adjust belt tension

• Lubricate or replace bearings

• Choose a shorter or heavier gauge cord

• Consult a licensed electrician

• Check all electrical connections and cords

• Reset circuit breaker or replace fuse

• Adjust belt or tighten pulley

• Replace the blower wheel

• Clear debris

• Check incoming water line, float and water

distributor for blockages and clear.

• Adjust window openings

• Level water trays, check for blocked water

slots in water trays

• Clean or replace pump

• Replace pads

Motor cycles on and off

Fails to start

Water draining from overflow

Blower vibrates excessively

Not cooling

• Excessive belt tension

• Blower shaft not spinning freely

• Extension cord (if one used) too long

• Circuit breaker not large enough

• No electrical power

• Circuit breaker tripped or fuse blown

• Float improperly adjusted • Adjust float

• Belt or pulley loose

• Blower wheel out of balance or out of

alignment

• Debris in blower housing

• Blocked water lines

• Windows opened too little or too much.

• Uneven pad wetting

• Pump clogged or failed

• Pads plugged with dirt and water deposits

This cooler is equipped with an UUUUautomaticUUUU thermally protected motor. If it shuts off on its own for any reason, UUUUit

can restart without warningUUUU.

Your cooler may be controlled by a rotary switch (MANUAL CONTROLS) or by a touch pad/remote control. See below for

functions.

Switch Operation Remote Control Operation

OFF Fan off Pump off

PUMP ONLY Fan off Pump on

HIGH COOL Fan high speed Pump on

LOW COOL Fan low speed Pump on

HIGH VENT Fan high speed Pump off

LOW VENT Fan low speed Pump off

Note: pressing the ON/OFF button while the unit is running will turn off power to the entire unit. Pressing the button again

will turn the unit back on at the same setting, which the unit was at when it was turned off.

ON/OFF

FAN

PUMP

Controls power to unit. Does not change fan speed or turn

Pump on or off.

Controls Fan speed. Press once for high speed (HI light on).

Press again for low speed (LO light on). Press again to turn

fan off (HI and LO lights off).

Controls Pump. Press once for pump on (PUMP light on).

Press again for pump off (PUMP light off).

4

Page 5

MAINTENANCE

NOTE: The fan motor is thermally protected with an automatic reset and will

automatically stop if overloaded. After the motor cools, it will restart automatically.

If this occurs, check into the problem before permanent damage occurs.

3/4"

Once a month during cooling season, inspect your cooler for leaks, proper belt

tension and alignment, blocked water lines and excessive residue build-up on the

pads.

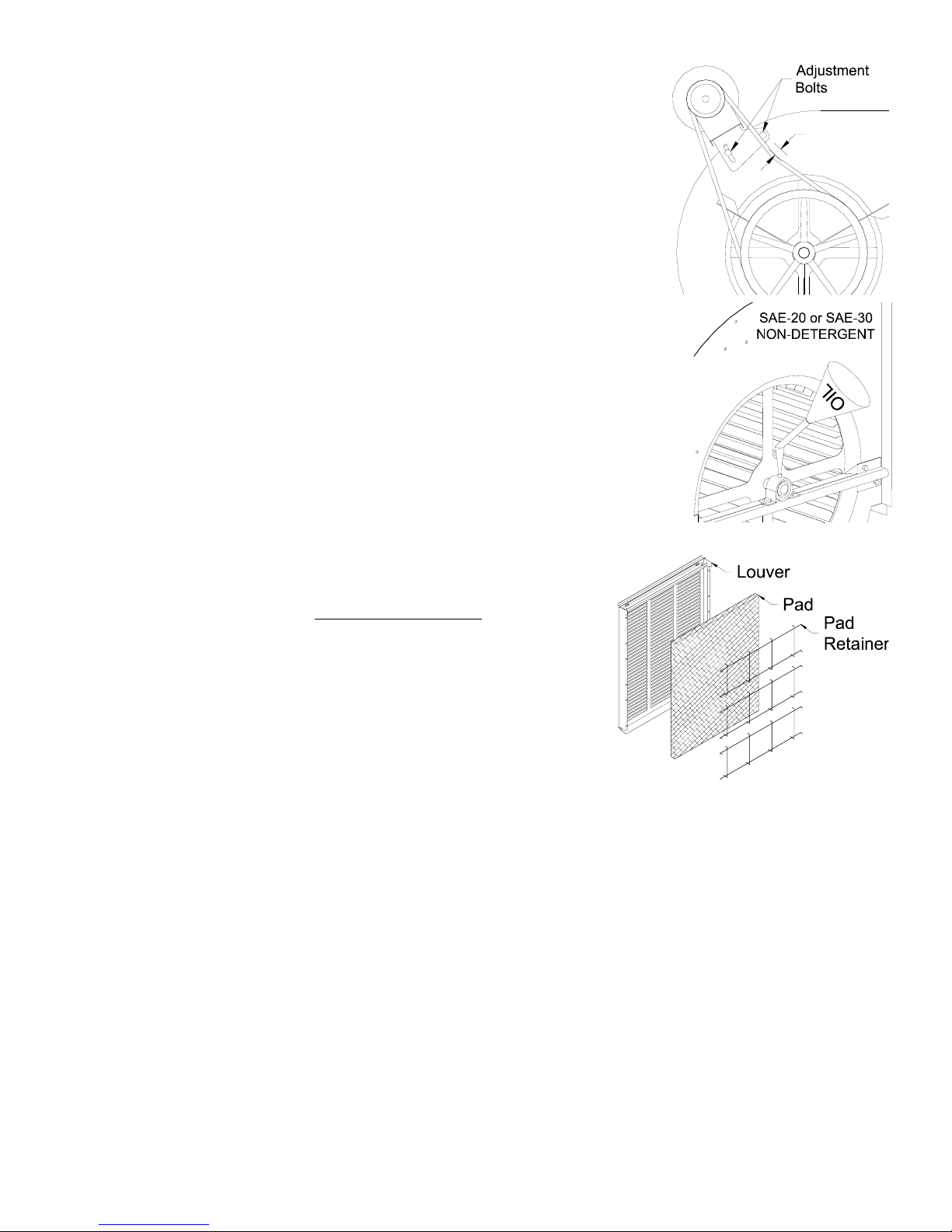

• To adjust belt tension, loosen the 4 Adjustment Bolts (2 each side) on the Motor

Mount. Adjust belt tension so that 3 pounds of pressure (lightly push with one

finger) will cause the belt to deflect ¾”, as shown. Retighten the Adjustment

Bolts.

• Use SAE 20W or SAE 30W non-detergent oil to lube the bearings. Place 2 to 3

drops in the bearing oil cups at the beginning of the season and no more than once a

season during cooling season. If the motor has oil holes (usually plugged with yellow

caps that read “OIL” at either end of the motor) oil the motor also, following the same

procedure as for bearings.

NOTE: Excessive oil in the bearings may leak out and be drawn into the air stream.

Excessive oil in the motor may leak onto the motor windings and damage the motor.

Do NOT oil bearings prior to initial start-up.

• To replace pads

1. Remove louver from cooler.

2. Unhook pad holders and remove.

3. Remove and discard old pad.

4. Clean water deposits from the louver. If the paint is chipped or rust spots o c cur, sand

the spots and paint louver with a rust resistant exterior paint.

5. Place new filter in louver and tuck in to prevent hot air from bypassing.

6. Replace pad holders and hook into place.

7. Replace louver in cooler.

NOTE: It is best to replace filter pads

UUUUat the end of the seasonUUUU. Old filter pads

soak up lime and salts that can rust louvers and the cabinet during the wet,

rainy winter months.

• At the end of the season

1. Remove the Overflow Tube and let the water drain from the reservoir.

(The bushing is threaded to accept a standard garden hose. If desired, a

garden hose may be used to route water away from your house.)

2. Rinse dirt and debris from the pan and clean any water deposits that may

have collected in the reservoir or on any interior surface of the cooler.

3. If the paint is chipped or rust spots occur sand the spots and p aint with a

rust resistant exterior paint.

4. Replace the Overflow Tube when you start the cooler for the next season.

NOTE: Do not get water on the Fan Motor or Pump Motor. This will cause damage.

• If freezing weather occurs in your area, it is best to shut off the water supply at the source and drain the supply line to

the cooler.

• A canvas cooler cover is recommended to prevent rain and weather from damaging your cooler.

• To prevent the Shaft from rusting, coat with a wax based lubricant. Allow Lubricant to dry completely and all fumes to

disperse before turning on the cooler.

5

Page 6

Repair Parts

WC35, N35W

RWC35, RN35W

Item

1 70735 70738 71090 71090 Top

2 70737 70740 70740 70740 Front

3 70736 70739 70759 70759 Bottom

4 504242 504245 504245 504245 Corner Post – Plain

4* 504243 504246 504246 504246 Corner Post – W/Float Valve Hole

5 70808 70808 70808 70808 Duct

6 70806 70744 70744 70744 Blower Housing

7 30318 30322 30322 30322 Blower Wheel

8 30241 30238-02 30238-02 30238-02 Blower Shaft

9 501244 501241 501241 501241 Fiber Washer

10 524330 524331 524331 524331 Set Collar

11 583000 60PB 60PB 60PB Bearing

12 583009 583091 583091 583091 Blower Pulley

13 582093 582030 582030 582030 Belt

14 504302 504289 504296 504296 Blower Brace

15 515160 512574 512574 512574 Motor Mount

16 595121 595121 595121 595121 Motor Cord

17 524162 524162 524162 524162 Motor Saddle Clamps

18 581188 581188 581188 50310 Motor

19 31085 31085 31085 16579 Motor Pulley

20 *** *** *** *** Water Tube Holder

21 598474 598474 598472 598472 Water Hose

22 512551 512550 512548 512548 Water Distributor

23 71098 70488 70488 70488 Pump Bracket

24 506669 506669 506669 506669 Pump

25 70613 70613 70613 70613 Overflow Kit

26 504253 504254 504256 504256 Pad Retainer (Side)

26 504255 504256 504256 504256 Pad Retainer (Back)

27* 141N 120N 71099 71099 Filter Set

27 516153 516157 503314 503314 Filter (Side)

27* 516155 503314 503314 503314 Filter (Back)

28 504258 504262 504263 504263 Louver (Side)

28* 514260 504263 504263 504263 Louver (Back)

29 504266 504267 504269 504269 Water Tray (Side)

29* 504268 504269 504269 504269 Water Tray (Back)

** 70940 70944 70945 70945 Louver Assembly (Side)

** 70941 70945 70945 70945 Louver Assembly (Back)

30 70655 70655 70655 70655 Wiring Harness (manual units only)

31 524299 524299 524299 524299 Switch (manual units only)

32 70664 70664 70664 70664 Knob (manual units only)

33 70798 70798 70798 70798 Switch Bracket (manual units only)

34

35 70741 70741 70741 70741 Sub-Vent Assembly

36 70925 70924 70924 70924 Bearing Support

37 70667 70667 70667 70667 Grill Cover (Sold separately)

38 70656 70656 70656 70656 Side Sealer Channel

39 70618 70618 70618 70618 Side Sealer

40 524344 524344 524344 524344 Rubber Foot

41 504341 504341 504341 504341 Spacer Rod

42 504337 504337 504337 504337 Stand-Off Bracket

43 502389 502389 502389 502389 Float

44 70801 70801 70801 70801 Pump Basket

* 70804 70804 70804 70804 Duct Mount Strip

45 71113 71113 71113 71113 Dress Ring (remote units only)

46 71114 71114 71114 71114 Electronic Control Assembly (remote units only)

47 71115 71115 71115 71115 Lock Plate (remote units only)

48 71116 71116 71116 71116 Remote Control (remote units only)

Part No.

70658 70658 70658 70658 Grill Frame, manual control units

71145 71145 71145 71145 Grill Frame, remote control units

WC44

RWC44

Part No.

WC46, N46W

RWC46, RN46W

Part No.

WC50, N50W

RWC50, RN50W

Part No.

Description

* Item not shown

** Contains louver, water tray, pad and pad retainers

*** Not used

6

Page 7

Models/Modelos:

WC35/N35W,

WC46/N46W,

WC50/N50W

23

Models/Modelos:

RWC35/RN35W,

RWC46/RN46W,

RWC50/RN50W

7

Page 8

Instructions to Convert Unit to Vertical Duct Configuration

1. Remove the 13 screws holding the Duct in place.

2. Replace the 4 screws removed from the Top Pan.

3. Turn the Duct 90 degrees counter-clockwise. Be careful not to unplug the switch from the wiring harness.

4. Align the Duct with the 3 holes at the top of the Front Panel (just below the Top Pan).

5. Insert 3 screws at the top and bottom of the duct.

6. Place the Duct Mount Strips (found in bottom of cooler) over the side Du ct Flanges and insert screws 3 each side into

the holes provided (3 screws will be in installation kit).

Proceed with the installation as normal. The Side Sealer Channels will go on the same flanges as for a horizontal duct.

You may use the Side Sealers provided to close off the window above your cooler’s duct.

LIMITED WARRANTY

This warranty is extended to the original purchaser only. It does not cover damages incurred during shipping or

through accident, neglect, or abuse by the owner. Champion Cooler/Essick Air Products does not authorize any person

or representative to assume any other or different liability in connection with this cooler.

TERMS AND CONDITIONS OF WARRANTY

The BOTTOM PAN is guaranteed against leakage due to rusting out

by Champion Cooler/Essick Air Products are warranted against defects in material or factory workm an ship for One Year.

EXCLUSIONS FROM THE WARRANTY

Champion Cooler/Essick Air Products is not responsible for incidental or consequential damage resulting from any

malfunction.

Champion Cooler/Essick Air Products is not responsible for any damage occurring from the use of water softeners,

chemicals, descale material, or if a higher horsepower motor than what Champion Cooler/Essick Air Products

recommends is used in the unit.

Champion Cooler/Essick Air Products is not responsible for the cost of service calls to diagnose cause of trouble, or labor

charge to repair and/or replace parts.

HOW TO OBTAIN SERVICE UNDER THIS WARRANTY

Contact the Dealer where you purchased the evaporative cooler. If for any reason you are not satisfied with the response

from the Dealer, contact Customer Service Department: Essick Air Products Inc. 5800 Murray Street, Little Rock,

Arkansas 72209. 1-800-643-8341.

for Eight Years. All other original parts provided

8

Page 9

Manual del

Propietario

Modelos #

WC35, RWC35

N35W, RN35W

WC44, RWC44

WC46, RWC46

N46W, RN46W

WC50, RWC50

N50W, RN50W

Lea Y Gaurde Este

Enfriador Evaporativo

De Ventana

Enfriamiento por evaporación

El enfriamiento por evaporación usa el principio de la evaporación para bajar la

temperatura del aire. El aire seco y caliente pasa por filtros mojados y es

transformado en aire frío y fresco. Los enfriadores Champion/Essick utilizan en

forma óptima el proceso evaporativo controlando el flujo de agua, esparciendo el

agua en forma pareja sobre los filtros y manteniendo un flujo constante de aire

frío en la casa. El enfriador se agota a través de ventanas o de puertas abiertas,

extrayendo el calor, el humo y los olores. Los enfriadores evaporativos de

Champion/ Essick son 80% más económicos de operar que los acondicionadores

de aire por refrigeración.

Manual de Instrucción!

P/N 71088

REV 01/06

1

Page 10

Indicaciones y precauciones de seguridad

Instalación Operación Servicio

Asegure que la unidad está instalada sobre una

estructura firme que soporte el peso total

operativo del enfriador.

Vea página 4.

Antes de intentar instalar el enfriador en la

ventana, retire las parrillas para eliminar el peso

innecesario.

No enchufe el enfriador en una fuente de

electricidad antes de haber terminado la

instalación .

Asegure que el circuito al que el enfriador está

enchufado (soplador lento) tenga instalado un

disyuntor de suficiente capacidad para soportar

el amperaje total del enfriador.

Para reducir el riesgo de incendio o de choque

eléctrico, NO USE este soplador junto con

ningún artefacto de control de velocidad de

estado sólido

Esta unidad está equipada con un motor de

protección termal automático

sólo y por cualquier motivo, también puede

volver a encenderse sin previo aviso.

. Si se apaga por si

Siempre desenchufe el enfriador antes de

iniciar cualquier clase de servicio de

mantenimiento.

Asegure de desconectar la unidad de la

fuente de electricidad, antes de iniciar el

servicio. De no hacerlo, la unidad puede ser

encendida desde otro lugar y comenzar a

funcionar sin previo aviso.

Si el motor se apaga por recalentamiento,

revise el problema de inmediato. Si se deja

funcionando, puede ocurrir un daño

permanente.

MONTAJE

Para instalar el enfriador se necesitan las siguientes herramientas:

• Llave de tuerca regulable

• Desatornillador

• Taladro eléctrico

• Nivel

1. Afloje el tornillo de ajuste en la ménsula distanciadora. Retire las varillas di stanciadoras

del paquete de instalación e insértelos en las ménsulas distanciadoras tal como se

muestra.

2. Corte las canaletas selladoras laterales para que ambas cubran todo el ancho de la

ventana cuando se instalan una junto a la otra. Coloque dos canaletas en el canal

embridado inferior como se muestra.

3. Coloque el enfriador en el centro de la ventana con el canal embridado inferior

apoyado en la solera de la ventana.

4. Estire las varillas espaciadoras para permitir que las patas de goma se apoyen

contra el costado de la casa. Apriete los tornillos de ajuste.

5. Baje la ventana hasta que se apoye dentro del ducto que está detrás del canal

embridado superior.

6. Asegure un tope en la parte interior del bastidor de la ventana para evitar que la

ventana sea abierta. Si se abre la ventana, el enfriador puede caerse.

7. Ajuste las varillas espaciadoras para nivelar el enfriador. Esto permite un flujo de agua

adecuado hacia las almohadillas.

8. Instale las cadenas de soporte.

a. Perfore orificios pilotos en el marco de la ventana, a 3 pies por en cima de la parte

superior del ducto y separados por el ancho del enfriador. Atornille los ganchos de

tornillo en estos orificios pilotos hasta que la rosca esté introducida completamente.

b. Enganche un eslabón del extremo de cada cadena en cada gancho de tornillo.

c. Coloque los gancho en S en los orificios en la parte superior trasera del enfriador

d. Enganche la punta opuesta al extremo de los ganchos en S en el eslabón del

extremo libre de cada cadena. Asegure que las cadenas están tensas pero no

excesivamente tirantes como para que separen el enfiador de la pared.

9. Instale los paneles selladores lateral es. Estos paneles tienen la altura correcta pero

necesitan ser recortados para que se ajusten al ancho de la ventana. Recorte los

paneles para que estos puedan llenar el espacio entre el enfriador y el marco de la

ventana. Deslice los paneles por las canaletas selladoras que instal ó, dentro del canal

embridado inferior. Instale las demás canaletas selladoras po r encima del canal

embridado superior y los paneles selladores laterales.

2

Page 11

INSTALACIÓN DE REBOSADURA Y DESAGÜE

1. Deslice la arandela de goma sobre el buje del dea sgüe y empuje a través del orificio desde

la parte superior del enfriador, hacia la parte inferior.

2. Asegure el buje de desagüe por debajo de la bandeja con la contra-tuerca. Asegure que la

arandela no se tuerza mientras se la está apretando, pues esto puede causar filtración.

NO LA APRIETE DEMASIADO.

3. Enrosque el tubo de rebosamiento en la boquilla y APRIETE A MANO.

4. Si ocurre una filtración después de llenar el tanque , vuelva a apretar el tubo de

rebosamiento hasta detener la filtración. Puede usarse una pequeña cantidad de calafate

con silicona de ser necesario.

INSTALACIÓN DE LA VÁLVULA DE FLOTACIÓN

1. Introduzca la parte enroscada de la válvula flotadora a través del orificio inte rior que se

encuentra en el poste esquinero.

Tanque

2. Deslice la arandela de fibra por sobre la parte enroscada que sobresale el

poste esquinero y asegúrela con la tuerca. Asegure que la válvula no gire

mientras está ajustando la tuerca.

CONEXIÓN DEL TUBO PARA AGUA

Encuentre el grifo de agua exterior más cercano e instale el Juego para la

Conexión de Agua (no incluída) tal como se muestra. Si no encuentra un grifo de

agua exterior, ubique la cañeria de agua fria más cercana e instale un juego de

válvula de asiento.

Dirija el tubo hacia el enfriador. Coloque la tuerca de compresión y el casquillo sobre

el extremo del tubo. Introduzca el tubo en la válvula flotadora y apriete la tuerca de

Casquillo

compresión para asegurarla. NOTA: el apretar demasiado un conector de compresión

puede causar una filtración. Es mejor primero asegurar las conexiones y abrir el agua

para sólo después ajustar la conexion hasta detener la filtración.

AJUSTE DE DEL NIVEL DE AGUA Y DE LA VÁLVULA FLOTADORA

Grifo

• Para ajustar el nivel de agua, doble la varilla de la válvula flotadora.

• Busque por si hay filtraciones en alguna de las conexiones.

• Asegure que la válvula flotadora corte completamente el flujo de agua cuando se

llega al nivel deseado (½” a ¾” por debajo del tope del tubo de rebosamiento). Si el

flotador no corta el flujo de agua totalmente, el nivel de agua subirá y desaguará por

el tubo de rebosamiento.

• Verifique nuevamente que no haya filtraciones por el tubo de rebosamiento

ARRANQUE

1. Enchufe el cordón eléctrico a un enchufe estándar con conexión a tierra. Asegure que el disyuntor que proteje el

receptáculo tenga suficiente capacidad.

2. Abra las ventanas en los cuartos adonde usted q uiera que se dirija el aire frío.

3. Coloque el enfriador en la posición de Soplad or Alto (Fan High). Observe la cantidad de aire producida. NOTA: en

noches (o días) frescos o cuando el nivel de humedad es alto, el enfriador puede ser u sad o sólo como ventilador.

4. Coloque el enfriador en la posición de Soplad or Bajo (Fan Low). Esto reduce significativamente la cantidad de aire

producido.

5. Coloque el enfriador en la posición de Sólo Bomba (Pump Only). Sólamente debe funcionar la bomba y no el soplador.

Verifique que el agua está circulando desde las tres bandejas de agua.

6. Coloque el enfriador en la posición Frío Alto (High Cool). Verifique que las tres almohadillas se están impregnando

uniformemente sin dejar áreas secas. Puede tomar hasta 20 min utos para que las almohadillas se impregnen

totalmente. Si las almohadillas tienen áreas secas, usted puede ajustar el nivel de ca da bandeja de agua girando los

tornillos ubicados en los extremos.

7. Ajuste la abertura de las ventanas para obtener el enfriamiento de seado.

3

Page 12

DIAGRAMA DEL CABLEADO

ATENCIÓN: siempre desenchufe el enfriador antes de abrirlo o de tratar de darle servicio o mantenimiento de

cualquier tipo.

Mando Manual

Motor

Blanco - Comun

Bomba

Cordon del Motor

Negro - Alta

Rojo - Baja

Verde - Tierra

Montaje de Mando

Cambia

PRECAUCIÓN: para reducir el riesgo de incendio o de choque eléctrico, no use este soplador con ningún tipo de

artefacto de control de velocidad de estado-sólido.

ESPECIFICACIONES DEL ENFRIADOR

Modelo Alto Ancho Profundidad Amperes Peso de embalaje Peso operativo

(R)WC50/(R)N50W 35” 34” 34” 8.4 165 249

(R)WC46/(R)N46W 35” 34” 34” 7.4 165 249

(R)WC44 35” 34” 28” 7.4 147 217

(R)WC35/(R)N35W 31” 32” 21” 7.4 135 184

SOLUCIÓN POR MAL FUNCIONAMIENTO

Problema Causa Solución

Motor en ciclos de enciende y apaga

No arranca

Agua desagota por rebalsamiento

Enfriador vibra demasiado

No enfría

• Correa demasiado tensa.

• Eje del soplador no gira libremente.

• Cordón de extensión demasiado largo (si se

usa).

• Disyuntor de capacidad insuficiente.

• No hay electricidad.

• Disyuntor disparado o fusible quemado.

• Flotador mal ajustado. • Ajustar flotador.

• Correa o polea sueltas.

• Rueda del soplador desbalanceada o fuera

de alineamiento.

• Desechos dentro de la caja del soplador.

• Cañería de agua taponada.

• Ventanas abiertas demasiado o muy poco.

• Almohadillas no impregnadas de forma

uniforme.

• Bomba tapada o con fallas.

• Almohadillas obturadas por suciedad o

depositos calcáreos del agua.

• Ajustar la tensión de la correa

• Lubricar o reemplazar cojinetes.

• Escoger un cordón más corto o de mayor

calibre.

• Consultar con un electricista licenciado

• Revisar todas las conexiones eléctricas y

cordones.

• Reposicionar disyuntor o reemplazar fusible.

• Ajustar correa o apretar polea.

• Reemplazar la rueda del soplador.

• Limpiar los desechos.

• Revisar la cañería de entrada de agua,

flotador y distribuidor de agua por posible

bloqueos.

• Ajustar abertura de ventanas.

• Nivelar bandejas de agua, buscar posible

agua taponada en las ranuras de las

bandejas de agua.

• Limpiar o cambiar bomba.

• Cambiar almohadillas.

Este enfriador está equipado con un motor de protección termal automático. Si se apaga por si sólo por

cualquier motivo, también puede volver a encenderse sin previo aviso.

Su más fresco puede ser controlado por un interruptor (CONTROLES MANUALES) o por una almohadilla del toque/el

mando a distancia. Vea abajo para funciones.

Switch Operation Remote Control Operation

OFF Ventilador apagar Pompa apagar

PUMP ONLY Ventilador apagar Pompa prender

HIGH COOL Alto Ventilador Pompa prender

LOW COOL Bajo Ventilador Pompa prender

HIGH VENT Alto Ventilador Pompa apagar

LOW VENT Bajo Ventilador Pompa apagar

Nota: apretando el EN/LEJOS botón mientras la unidad corre girará lejos poder a la unidad entera. Apretar el botón otra

vez girará la espalda de la unidad en en la misma colocación, que la unidad estaba en cuando se giró lejos.

ON/OFF

FAN

PUMP

Controla corriente se unidad. No cambia velocidad del

ventilador cuando bomba es apagada o prendida.

Controla velocidad del ventilador. Presione una vez mas

para alta velocidad (luz HI se prende). Presione otra vez

mas para baja velocidad (luz LOW se prende). Presione otra

vez mas para apagar ventilador (luz HI y LOW se apaga).

Control de bomba. Presionar una vez para prender bomba

(luz PUMP prende). Presionar otra vez para apagar bomba

(luz PUMP se apaga).

4

Page 13

MANTENIMIENTO

NOTA: el motor de este soplador está térmicamente protegido con un reposicionador

automático y se detendra automáticamente en caso de una sobrecarga. Después de que

el motor se enfrie, arrancará nuevamente de forma automática. Si sucede esto, corrija el

problema antes de que ocurra un daño permanente.

3/4"

En forma mensual durante la estación fría, inspeccione su enfriador para buscar

filtraciones, verifivar tensión y alineamiento correcto de la correa, cañerías de agua

taponadas y acumulación excesiva de residuos en las almohadillas.

• Para ajustar la tensión de la correa, suelte los 4 pernos de ajuste ( dos a cada lado)

ubicados en el montaje del motor. Ajuste la tensión del motor para que 3 libras de

presión (empuje levemente con un dedo) causen que la correa se desvíe ¾” como se

muestra. Vuelva a apretar los pernos de ajuste.

• Use aceite SAE-20 o SAE-30 sin detergente para lubricar los cojinetes. Coloque 2 a 3

gotas en cada taza lubricadora del cojinete al comenzar la temporada y no más

de una vez durante la temporada fría. Si el motor tiene orificios para lubricación

(generalmente tapados con tapones amarillos que tienen escritos la palabra

ACEITE (OIL) en cualquier costado del motor, también lubrique el motor,

siguiendo el mismo procedimiento que en el caso de los cojinetes.

NOTA: una lubricación excesiva en los cojinetes puede rebasar y ser aspirada por la

corriente de aire. Una lubricación excesiva en el motor puede reba sar hacia el

bobinado del motor y dañar el motor.

• Para reemplazar las almohadillas.

1. Retire las parrillas del enfriador

2. Desenganche los retenes de las almohadillas y retírelos

3. Retire y bote las almohadillas viejas

4. Limpie los depósitos de agua de las parrillas. Si la pintura está picada u oxidada,

lije las oxidaciones y vuelva a pintar con una pintura para exterior resistente a la

corrosión.

5. Coloque el filtro nuevo en la parrilla y ajústelo bien para evitar que deje

pasar aire caliente

6. Vuelva a instalar correctamente la parrillas de las almohadillas y sus

retenes

7. Vuelva a colocar las parrillas en el enfriador.

NOTA: es recomendable reemplazar las almohadillas filtrantes al final de la

temporada. Las almohadillas viejas chupan caliza y sales minerales que

pueden corroer las parrillas y la caja del enfriador durante los meses

húmedos y lluviosos del invierno.

• Al final de la temporada

1. Retire el tubo de rebosamiento y deje desa gotar el agua del tanque (el buje tiene una rosca para permitir la conexión

de una manguera de riego común, si se desea usar una manguera para desagotar directamente lejos de la casa).

2. Enjuague la suciedad y los desechos de la bandeja y limpie cualquier depósito de agua que pueda haberse juntado en

el tanque o en cualquier superficie interior del enfriador.

3. Si la pintura está picada u oxidada, lije las oxidaciones y vuelva a pintar con una pintura para exterior resi stente a la

corrosión.

4. Vuelva a instalar el tubo de rebosamiento al inicio de la próxima temporada y antes de arrancar el enfriador.

NOTA: No moje el motor del soplador ni el motor de la bomba. Esto puede causar dañ os.

• Si sucede una helada en su área, es recomendable cortar el agua en el grifo de suministro de agua y desagotar el

tubo de alimentación que va hacia el enfriador.

• Se recomienda colocar una cubierta lona protectora sobre el enfriador para prevenir daños causados por la lluvia y el

mal tiempo.

• Para prevenir la corrosión del eje, cúbralo con un lubricante a base de cera. Deje que el lubricante se seque

completamente y que todos los vapores se hayan dispersado antes de arrancar el enfriador nuevamente.

5

Page 14

Lista de Repuestos

WC35, N35W

RWC35, RN35W

Item

Parte #

1 70735 70738 71090 71090 Tapa

2 70737 70740 70740 70740 Frente

3 70736 70739 70759 70759 Base

4 504242 504245 504245 504245 Poste esquinero – simple

4* 504243 504246 504246 504246 Poste esquinero con orificio para válvula flotadora

5 70808 70808 70808 70808 Canal

6 70806 70744 70744 70744 Caja para el soplador

7 30318 30322 30322 30322 Rueda del soplador

8 30241 30238-02 30238-02 30238-02 Eje del soplador

9 501244 501241 501241 501241 Arandela de fibra

10 524330 524331 524331 524331 Juego de collar

11 583000 60PB 60PB 60PB Cojinete

12 583009 583091 583091 583091 Polea del soplador

13 582093 582030 582030 582030 Correa

14 504302 504289 504296 504296 Abrazadera para soplador

15 515160 512574 512574 512574 Montaje para motor

16 595121 595121 595121 595121 Cable para motor

17 524162 524162 524162 524162 Grapas para asiento de motor

18 581188 581188 581188 50310 Motor

19 31085 31085 31085 16579 Polea de motor

20 *** *** *** *** Sujetador de tubo de agua

21 598474 598474 598472 598472 Manguera para agua

22 512551 512550 512548 512548 Distribuidor de agua

23 71098 70488 70488 70488 Ménsula para bomba

24 506669 506669 506669 506669 Bomba

25 70613 70613 70613 70613 Juego para desagüe

26 504253 504254 504256 504256 Retén de filtro (lateral)

26 504255 504256 504256 504256 Retén de filtro (trasero)

27* 141N 120N 71099 71099 Juego de filtros

27 516153 516157 503314 503314 Filtro (lateral)

27* 516155 503314 503314 503314 Filtro (trasero)

28 504258 504262 504263 504263 Rejilla (lateral)

28* 514260 504263 504263 504263 Rejilla (trasera)

29 504266 504267 504269 504269 Bandeja de agua (lateral)

29* 504268 504269 504269 504269 Bandeja de agua (trasera)

** 70940 70944 70945 70945 Assemblea de rejilla (lateral)

** 70941 70945 70945 70945 Assemblea de rejilla (trasera)

30 70655 70655 70655 70655 Arnés de cableado (unidades manuales solo)

31 524299 524299 524299 524299 Interruptor (unidades manuales solo)

32 70664 70664 70664 70664 Perilla (unidades manuales solo)

33 70798 70798 70798 70798 Ménsula para interruptor (unidades manuales solo)

34

35 70741 70741 70741 70741 Conjunto de rejilla de ventilación

36 70925 70924 70924 70924 Retén para tapa de rejilla

37 70667 70667 70667 70667 Tapa de rejilla

38 70656 70656 70656 70656 Canaleta para panel sellador

39 70618 70618 70618 70618 Panel sellador lateral

40 524344 524344 524344 524344 Pata de goma

41 504341 504341 504341 504341 Varilla distanciadora

42 504337 504337 504337 504337 Ménsula distanciadora

43 502389 502389 502389 502389 Flotador

44 70801 70801 70801 70801 Malla parra la bomba

* 70804 70804 70804 70804 Strip para canal

45 71113 71113 71113 71113 Dress Ring (unidades remotas sólo)

46 71114 71114 71114 71114 Electronic Control Assembly (unidades remotas sólo)

47 71115 71115 71115 71115 Lock Plate (unidades remotas sólo)

48 71116 71116 71116 71116 Remote Control (unidades remotas sólo)

70658 70658 70658 70658 Marco de rejilla (unidades manuales solo)

71145 71145 71145 71145 Marco de rejilla (unidades remotas sólo)

WC44

RWC44

Parte #

WC46, N46W

RWC46, RN46W

Parte #

WC50, N50W

RWC50, RN50W

Parte #

Descripción

* Item no mostrado

** Contiene rejilla, bandeja de agua, filtro y Retén de filtro

*** No utilizado

6

Page 15

Models/Modelos:

WC35/N35W,

WC46/N46W,

WC50/N50W

23

Models/Modelos:

RWC35/RN35W,

RWC46/RN46W,

RWC50/RN50W

7

Page 16

Instrucciones para convertir la unidad para el montaje en una ventana batiente.

1. Retire los 13 tornillos que fijan el ducto en su lugar.

2. Vuelva a colocar los 4 tornillos que se retiraron de la cubeta superior.

3. Vire el ducto 90 grados en el sentido contrario al reloj. Tenga cuidado de no desenchufar el interruptor del arnés de

cableado.

4. Alinie el ducto con los 3 orificios en la parte superior del panel frontal (justo debajo de la cubeta superior).

5. Inserte 3 tornillos en la parte superior y en la parte inferior del ducto.

6. Coloque los flejes para montaje del ducto (que se encuentran en la parte inferior del enfriador), sobre las cantone ras

laterales del ducto e inserte los tornillos, 3 a cada lado, en los orificios provi stos (encontrará 3 tornillos en el juego para

instalación).

Continue normalmente con la instalación, tomando en cuenta que su ventana se

desplaza horizontalmente en lugar de verticalmente. Las canaleta s selladoras

laterales se montarán en los mismos flejes normales. Usted puede usar las

selladoras laterales que se suministran, para sellar su ventana por encim a del ducto

del enfriador. Si las selladoras laterales no son lo suficientemente grandes, puede

contactar a nuestra oficina para comprar selladoras adicionales. No trate de instalar

el enfriador con la base del ducto colocada más alta que la solera de la ventana.

Esto resultará en una instalación inestable y creará una situación de mucho peligro.

GARANTIA LIMITADA

Esta garantía se extiende sólamente al comprador original. No cubre daños ocurridos durante el transporte por causa

de accidentes, negligencia o abuso por el propietario. Champion Cooler/Essick Air Produ cts no autoriza a ninguna

persona o representante para asumir cualquier otra o diferente responsabilidad civil en relación a este enfriador.

TÉRMINOS Y CONDICIONES DE LA GARANTÍA

Garantía por Ocho Años sobre la cubeta de agua por filtraciones causadas por corrosión

originales suministradas por Champion Cooler/Essick Air Products están garantizadas contra defectos del material o de

mano de obra por un año.

EXCLUSIÓNES DE LA GARANTÍA

Champion Cooler/Essick Air Products no es responsa ble por daños incidentales o consecuentes como resultado de un

funciónamiento defectuoso.

Champion Cooler/Essick Air Products no es responsable por ningún daño causado por el uso de ablandadores de agu a,

productos químicos, material anticorrosivo, o si se utiliza un motor con más caballos de fuerza de los recomendados por

Essick Air Products para esta unidad.

Champion Cooler/Essick Air Products no es respo nsable por el costo de las visitas de servicio para diagnosticar la causa

del problema, o los costos por la mano de obra para reparar y/o reemplazar piezas.

COMO OBTENER SERVICIO BAJO ESTA GARANTÍA

Contactar al concesiónario donde compró el enfriador evaporativ o. Si por alguna razón no está satisfecho con la

respuesta del concesiónario, contactar el Servicio de Atención al Cliente; Essick Air Products Inc.; 5800 Murray Street,

Little Rock, Arkansas 72209. Teléfono 1-800-643-8341

. Todas las demás piezas

8

Loading...

Loading...