Page 1

ESSICKAIR

The Cool One

Owner’s Manual

Model #’s

SI-500S , SI-500D

SI-700D , SI-700S

SI-500S12 , SI-500D12

SI-700S12 , SI-700D12

SINGLE INLET

Horizontal And Down Discharge

Evaporative

Air Cooler

Read & Save This

Instruction Manual!

Our Mission:

We Will Respond to Our Customers With High Quality Products

and Service, While Eliminating Waste From Our Processes.

P/N 70093

REV 4/02

Page 2

Evaporative Cooling

Evaporative cooling uses the principle of evaporation to lower the air temperature. Hot, dry air is passed through wetted

filters and is converted to refreshingly cooled air. Essick Coolers make the best use of the evaporative process by

controlling the flow of water, spreading the water evenly over the filters, and keeping a steady stream of cooled air

entering your home. It is exhausted out open windows or doors, carrying heat, smoke and odors along with it. Essick

evaporative coolers are 80% less costly to operate than refrigerated air conditioners.

Cautions: To prevent harm to yourself and others, and to avoid damage to your cooler, PLEASE follow these guidelines.

SAFETY GUIDE LINES & CAUTIONS

When Installing When Operating When Servicing

Make sure that unit is installed on a sound

structure that will support the full operating

weight of the cooler. See page 5.

Before attempting to transport cooler to the roof.

Separate fan section from wet section to reduce

weight. Always plan a safe method of

transporting cooler to installation site without

damage to the cooler or injury to yourself.

Do Not connect power to cooler before

installation is complete.

Wear gloves and protective eyewear when

installing or servicing.

Make sure that cooler circuit is equipped with a

(slow blow) breaker large enough to support the

full amperage of the cooler.

To reduce the risk of fire or electrical shock, DO

NOT use this fan with any Solid-state speed

control device.

This cooler is equipped with an automatic

thermally protected motor. If it shuts off on its

own for any reason, it can restart without

warning.

Be sure to disconnect unit from power

source before servicing. If not, it can be

turned on from inside the house and start

unexpectedly.

Never drain water onto your roof. Water

residue could cause you to slip or may stain

your roof.

If the motor shuts off because of thermal

overload, check into the problem

immediately. If allowed to continue,

permanent damage will occur.

Tools and supplies needed for installation

Pliers

Screwdrivers

Adjustable wrenches

Tubing cutter

5/32 hex key wrench

Level

Electric drill

Drill bits

Hammer

Duct tape

Caulk

Sheet metal screws

ECR-6 wall switch

Safety glasses

Wiring supplies – It is recommended that a licensed

electrician do all electrical work.

Ductwork – A local sheet metal shop can supply ductwork.

¼” water line

Saddle valve or faucet adapter

Roof stand (if cooler is roof mounted)

Roof flashing and pitch

Mounting

1. Prepare duct to fit model used (500 series coolers 17 ¾” square; 700 series 19 ¾” square).

2. Cut opening in wall or roof to fit duct. If wall studs or roof joists are cut, reinforce them.

3. Mount the duct in the opening. The duct will fit inside the cooler opening. The duct length from roof to bottom of cooler

should be a minimum of 4” at the closest point, so there is access to the water drain.

4. Install flashing around roof opening to prevent water entry. Use pitch to seal the seams.

5. Measure cooler and layout mounting location.

6. Mount cooler to stand or pad. Cooler must be level front to back and left to right. Note: It is best that the fan section

end of the cooler face up the roof to achieve a lower profile and allow better access to the drain.

7. Be sure to securely fasten all four corners of cooler to stand or pad.

8. Caulk duct to the cooler to prevent air leakage.

Motor mounting

Warning: Do Not energize the cooler until the installation is complete.

1. Place the motor into the cradles. Be sure that the cradles fit into the groove in the

motor grommets.

2. Secure with the saddle clamps provided in the installation package. DO NOT

OVERTIGHTEN.

2

Page 3

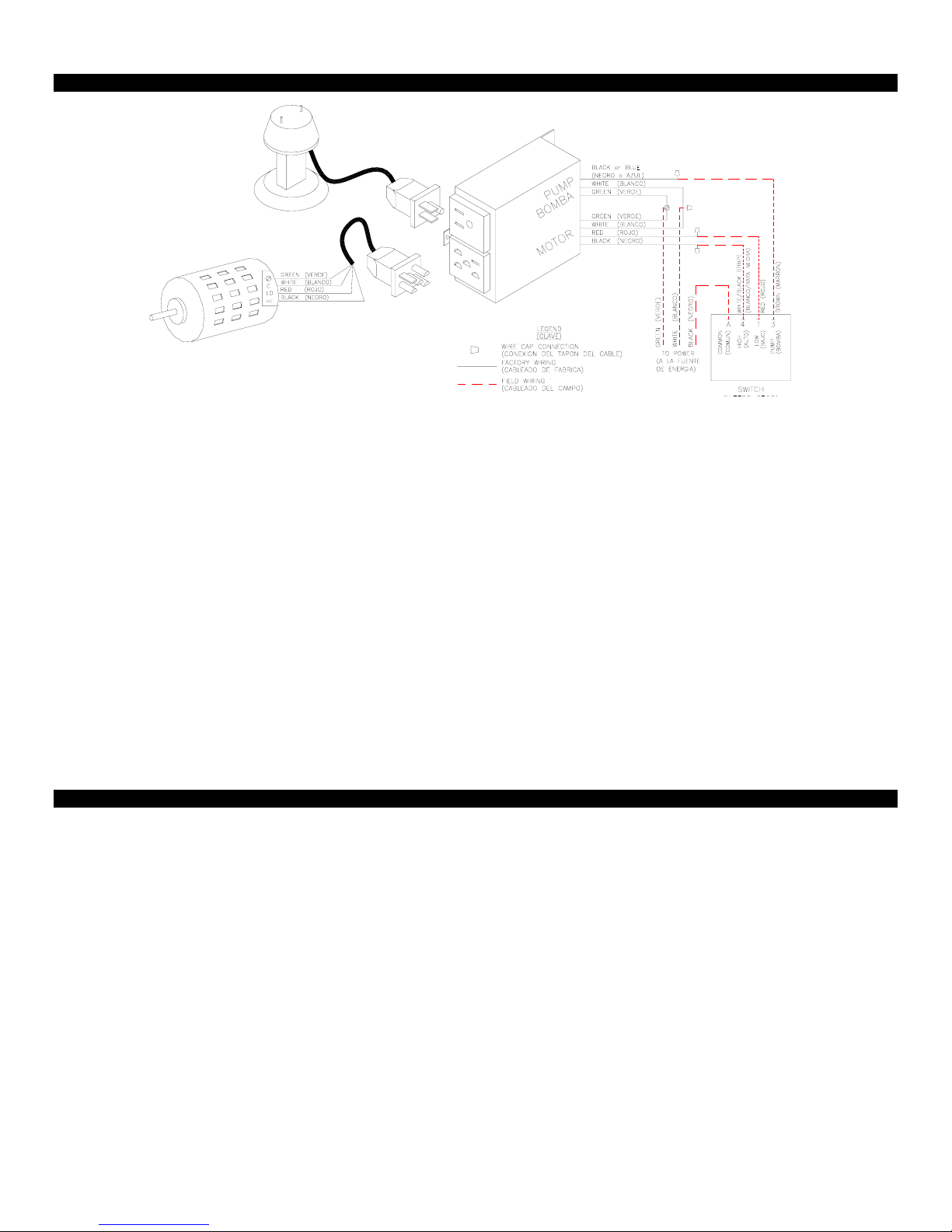

Electrical connections

CAUTION: Disconnect all electrical power at the breaker or fuse box before you begin to install or service any cooler.

Wiring for this cooler must comply with any and all applicable codes. It is recommended that a licensed electrician

install any required wiring.

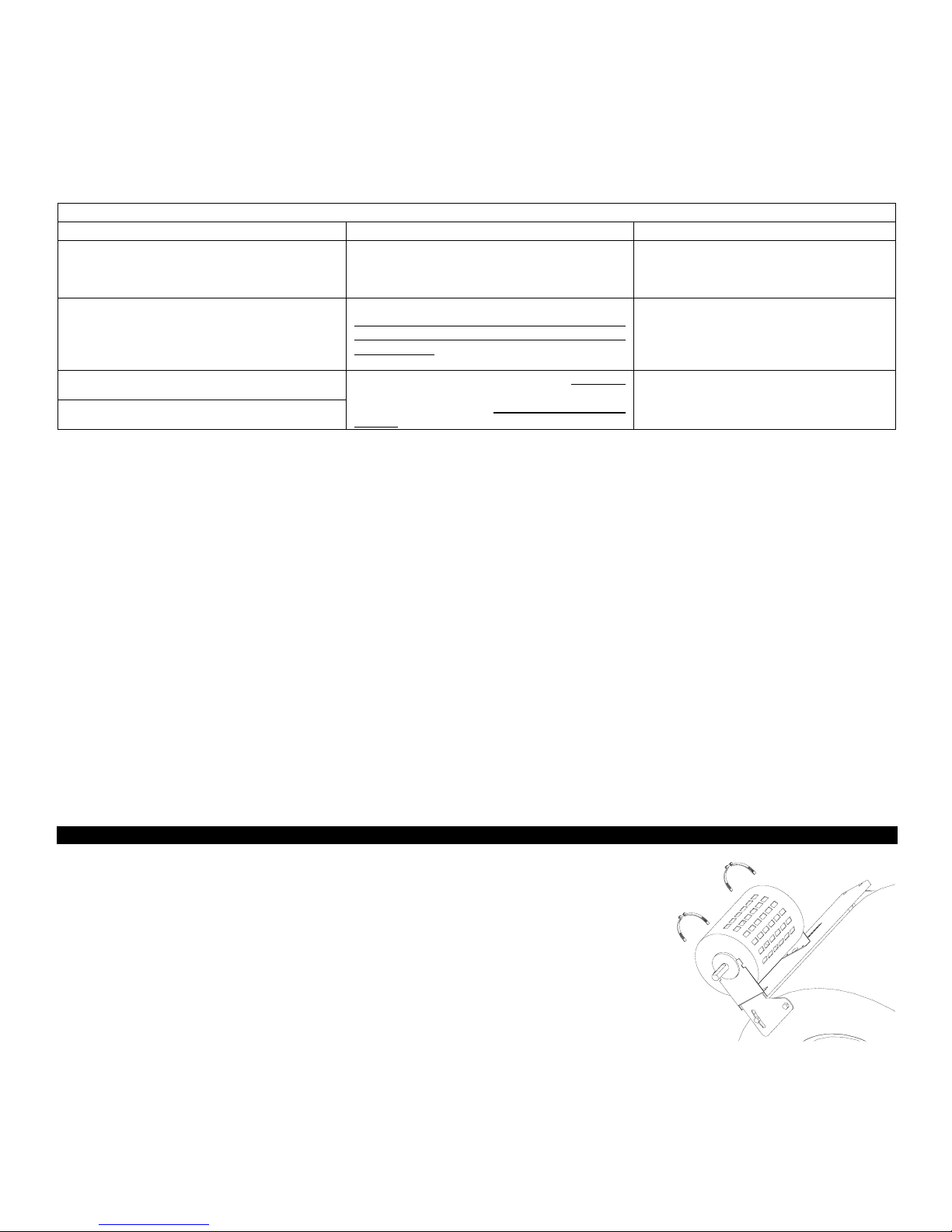

To remotely operate this unit, use an ECR-6 switch. It is equipped with 2 cooling positions, 2 vent positions and a pump

only position to wash or pre-wet the pads.

The junction box mounts in the corner post of the fan section. Receptacles are provided for the motor and pump.

All wiring connections must be made inside the junction box. See wiring diagram below.

Motor pulley installation

1. Loosen both set screws on the pulley. Use 5/32” hex key Allen wrench.

2. Slide the pulley onto the motor shaft with the threaded side out.

3. Install the belt and align the motor pulley and blower pulley.

4. Align the set screw on the motor side of the pulley with the flat portion of the motor shaft and tighten.

Motor pulley adjustment

1. Turn the outside jaw of the motor pulley clockwise until the pulley is fully closed.

2. Align the outside set screw with the nearest flat spot on the threaded portion of the pulley. This is the zero position.

3. Turn the outside jaw of the pulley counterclockwise 3 full turns. Align set screw with a flat on the threaded portion of the

pulley and tighten. This step will ensure that your cooler will run without overloading the motor. Further adjustment

may be required.

Warning: if set screw is tightened onto threads, damage will occur and pulley will no longer be able to be adjusted.

When the installation is complete and all panels are in place, check the motor amperage using clamp-on type ammeter.

Since all the cooler access panels must be in place to get a true reading, check amperage at a disconnect box, breaker or

fuse box.

4. Find out the amperage from the motor nameplate.

5. Clamp ammeter around the incoming white lead.

6. Start the cooler on HI VENT.

7. If amperage is less than motor nameplate rating, loosen the outer set screw of motor pulley, then turn the outer jaw of

the pulley clockwise ½ turn and tighten the outer set screw. Recheck the amperage and repeat step if necessary.

8. If amperage is more than motor nameplate rating, loosen the outer set screw of motor pulley, then turn the outer jaw of

the pulley counterclockwise ½ turn and tighten the outer set screw. Recheck the amperage and repeat step if

necessary.

9. Proper belt tension is crucial to efficient operation and motor and belt life. See the maintenance section for instructions

on achieving proper belt tension.

3

Page 4

Install overflow and drain

1. Slide rubber washer onto drain bushing and place through hole in reservoir from the top side.

2. Secure it from below with the lock nut. Make sure rubber washer does not twist while tightening,

which could cause it to leak. Hand tighten first and then tighten ¾ turn further with proper tool. Do

not over tighten.

3. Thread the plastic overflow tube into the drain bushing and hand tighten until snug.

Note: If leakage occurs after reservoir is filled, further snug the fitting until leakage stops. Plumber’s

tape or thread putty may be used if necessary.

Float valve installation

1. Place the threaded portion of the Float Valve through the hole provided in the Corner Post from the

Reservoir

inside.

2. Slip the Fiber Washer over the threaded portion outside the corner post and secure

with the Nut. Be sure the Float does not turn while you are tightening the Nut.

3. Slip the Float Tube onto the float so that the key hole is just behind the water inlet

and the float rod is able to move up and down freely. The object is to contain any

spray.

Water line connection

1. Find the closest outside water faucet, and install a Water Connection Kit (not

included with cooler) as shown. If an exterior faucet is not available, locate the

closest cold water pipe and install a saddle valve assembly.

2. Route tubing to cooler. Place Compression Nut and Ferrule over end of tubing. Insert the tubing into float valve and

tighten Compression Nut to secure.

Note: Tightening a compression fitting will cause that fitting to leak. It is best to secure

the connections, turn on the water, and then snug the fitting until leaking stops.

Ferrule

Adjusting water level and float

In order for the float to shutoff the flow of water at the desired level, you must adjust the

float.

Faucet

1. Fill reservoir to ½” below top of overflow tube.

2. Bend float rod down, slightly, until adequate pressure is achieved and float shuts off

completely.

Note: Never use “soft water” from water softening equipment. This water is very corrosive and will cause damage to your

cooler. Using a water softener in conjunction with this cooler will void the warranty. Use of caustic cleaners or other

harsh chemicals will also void the warranty.

Start-up inspection

Before starting the cooler, make sure all installations are correct. Be sure that:

1. Cooler is grounded and electrical connections are safe

ECR-6 switch operation

and secure.

2. Cooler is level and duct is sealed

3. Blower wheel does not rub the housing.

4. Water supply is turned on.

5. Drain fitting and water connections are secure and do

Switch setting Blower motor Pump

Off Off Off

Pump Only Off On

not leak.

6. Float is adjusted to the proper level.

7. Important: motor pulley is set at the correct diameter. If

not, motor can overheat and fail.

8. Belt tension is OK.

Low Vent Low Off

High Vent High Off

Low Cool Low On

9. Pulley alignment is OK.

10. Check switch for proper operation.

High Cool high On

4

Page 5

Trouble shooting

Problem Cause Solution

Motor cycles on and off

Water draining from overflow

Motor pulley set too large

Excessive belt tension

Blower shat frozen

Float improperly adjusted

Lime build up in float valve

Adjust motor pulley

Adjust belt tension

Lubricate or replace bearings

Adjust float

Clean or replace float

Blower shakes Belt or pulley loose Adjust or tighten

Fails to start

Not cooling

No electrical power

Blown fuse or popped circuit breaker

Water supply turned off

Blocked water distributor

Check power

Replace or reset

Check water supply

Clean distributor

Maintenance

Caution: turn off all electrical power to the cooler before opening or attempting service of any kind

The motor is equipped with automatic thermal protection. If it shuts off for any reason, it can start back up without warning!

Occasionally inspect your cooler for leaks, loose belt, blocked water lines, correct belt

alignment or excessive residue build up on the pads.

Belt tension

1/2" to 3/4"

Deflection

At the proper tension, the belt will deflect ½” to ¾” when 3 to 5 pounds of pressure is

applied to the belt approximately half way between the blower and motor pulleys.

Adjust the belt tension using the motor bracket do not change the diameter of the pulley

in order to adjust the belt tension.

Lubrication

Lube the oil cups on the blower bearing. Use SAE20 or SAE30 Non-Detergent

oil. Oil the

blower motor only if oil holes exist.

End of season

1. Drain and clean the reservoir. Do not get water on the blower motor or pump motor.

2. Remove the belt and hang it from the motor pulley.

3. Remove the pads and clean carefully.

4. Remove water distributor and hose out with garden hose. Use a small nail to clean any

deposits from the water holes.

Pad Replacement

Lime build up can occur in the water reservoir and on the pads. Clean this off at least

once per season. If any rust or bare metal spots occur on the cabinet, the metal should be

sanded, primed and painted with good quality paint.

1. Remove wet section top.

2. Remove water distributor assembly.

3. Remove and discard old pads.

4. Install new pad set. Refer to diagram below or pad installation instructions

for correct orientation.

5. Ensure that water distributor pad is centered over cooler pads.

Tapa de la Seccion de Agua

Water Distributor

Distribuidora de Agua

Water Distributor Pad

Filtro que Distribuidora

Wet Section Top

de Agua

6. Carefully replace water distributor; ensure pads are not damaged while

replacing assembly.

7. Replace wet section top.

Red Stripe

Rojo Raya

Model

SI500-S 153 224

SI500-D 153 224

SI700-S 184 255

SI700-D 184 255

Weight

Dry Operating

5

Page 6

Replacement Parts

6

Page 7

No. Description

Fan section

1

Access Panel

2

Blower Housing

3

Blower Brace

4

Blower bearing

5

Motor

6

Motor pulley

7

Motor mount

8

Blower Pulley

9

10

11

12

13

14

15

16*

17*

18

19

20

21

22*

23*

24*

25*

26

27*

28

29

30

31

32

33

Blower wheel

Blower belt

Set collar

Blower shaft

Float valve

Float tube

Wet section top

Wet section housing

Water hose

Pump bracket

Pump

Water distributor tube

Water distributor

Pad media set

Water shield set

Pad support tray

Overflow kit

Reservoir

Inlet Screen

Electrical junction box

Motor plug

Pump plug

Blower cutoff

Water distributor pad

Descripci∧n

Seccion del abanico 1 70018 70001 70023 70038

Panel de acceso 2 70005 70005 70027 70027

Caja del ventilador 1 70021 70014 70034 70040

Conjinette del ventilador 2 70151 70045 70151 70045

Abrazedera del ventilador 2 30289 30289 30288 30288

Motor 1 *** *** *** ***

Polea del motor 1 70170 70170 583041 583041

Montaje del motor 1 70154 70154 70125 70125

Polea del ventilador 1 583013 583013 30314 30314

Rueda del ventilador 1 30322 30322 70120 70120

Banda del ventilador 1 582090 582009 4L690 582001

Collar fijo 1 524331 524331 524331 524331

Eje del ventilador 1

Valvula flotadora 1 524198 524198 524198 524198

Tubo flotador 1 70132 70132 70132 70132

Tapa de seccion del agua 1 70009 70009 70009 70009

Estructura de la seccion de agua 1 70006 70006 70028 70028

Manguera del agua 1 70196 70196 70197 70197

Abrazadera de la bomba 1 70067 70067 70067 70067

Bomba 1 506674 506674 506674 506674

Tubo del distribuidor del agua 1 70116 70116 70116 70116

Distribuidor del agua 1 70043 70043 70043 70043

Juego de filtros 1 70054 70054 70055 70055

Juego de protectores del agua 1 70095 70095 70098 70098

Bandeja para sostenerlos filtros 1 70010 70010 70010 70010

Equipo de desbordimiento 1 70613 70613 70613 70613

Deposito 1 70053 70053 70053 70053

Alambrera 1 70012 70012 70031 70031

Caja de union electrica 1 70130 70130 70130 70130

Enchufe del motor 1 595098 595098 595098 595098

Enchufe de la bomba 1 595121 595121 595121 595121

Tapon de la caja del ventilador 1 504280 504280 70124 70124

Filtros del distribuidor del agua 1 70155 70155 70155 70155

Qty SI500S SI500D SI700S SI700D

30238-02 30238-02 30238-01 30238-01

*** Speak with Essick Air Products representative for specific motor requirements.

*For units with 12” media, refer to table below for Wet Section parts.

No. Description

Wet section top

16*

Wet section housing

17*

Water distributor

22*

Pad media set

23*

Water shield

24*

Pad support tray

25*

Reservoir

27*

Descripci∧n

Qty

Tapa de seccion del agua 1 70877 70877 70877 70877

Estructura de la seccion de agua 1 70907 70907 70879 70879

Distribuidor del agua 1 70872 70872 70872 70872

Juego de filtros 1 70912 70912 70875 70875

Juego de protectores del agua 2 70909 70909 70874 70874

Bandeja para sostenerlos filtros 1 70887 70887 70887 70887

Deposito 1 70871 70871 70871 70871

SI500S-12 SI500D-12 SI700S-12 SI700D-12

7

Page 8

Limited Warranty

This warranty is extended to the original purchaser only

of an evaporative cooler installed and used under normal

conditions. It does not cover damages incurred during shipping or through accident, neglect, or abuse by the owner.

Essick Air Products does not

authorize any person or representative to assu

me any other or dierent liability in connection

with this product.

Terms and conditions of warranty

This warranty includes lifetime limited coverage on water reservoir against any leakage due to defects in material. From

date of installation, if any original comp onent part provided by Essick Air Products fails due to defect in material or factory

workmanship only, Essick Air Products will provide the replacemen t parts as follows:

Cabinet components for one year from date of installation

Evaporative media for ve years from date of installation

Exclusions from this warranty

Essick Air Products is not responsible for incidental or consequential damage resulting from any malfunction.

Essick Air Products is not responsible fo r any damage occurring from the use of

water softeners, chemicals, descale

material, or if a higher horsepower motor than what Essick Air Products recommends is used in the unit.

Essick Air Products is not responsible for th e cost of service calls to diagnose caus e of trouble, or labor charge to repair

and/or replace parts.

How to obtain service under this warranty

Contact the Dealer where you purchased t

he evaporative cooler. If for any reason you are not satised with the response

for the Dealer, contact Customer Service Department: Essick Air Products Inc. 5800 Murray Street, Little Rock, Arkansas

72209. 1-800-643-8341.

8

Loading...

Loading...