Page 1

Operation and Installation Instruction

Fire Alarm Computer

8000C / M

Page 2

Safety

Intended purpose

This product must only be used for the applications outlined in the catalogue and the technical

description and in combination with external components and systems which have been

approved or recommended by ESSER.

Warning

In order to ensure correct and safe operation of the product, all guidelines concerning its

transport, storage, installation, and mounting must be observed. This includes the necessary

care in operating the product.

Safety-relevant user information

This manual includes all information required for the proper use of the products described here.

The term 'qualified personnel' in the context of the safety information included in this manual or

on the product itself designates:

• project engineers who are familiar with the safety guidelines concerning fire alarm and

extinguishing systems

• trained service engineers who are familiar with the components of fire alarm and

extinguishing systems and the information on their operation as included in this manual.

• trained installation or service personnel with the necessary qualification for carrying out

repairs on fire alarm and extinguishing systems or who are authorised to operate, ground

and label electrical circuits and/or safety equipment/systems.

Safety warnings

The following information is given in the interest of your personal safety and to prevent damage

to the product described in this manual and all equipment connected to it.

Safety information and warnings for the prevention of dangers putting at risk the life and health

of user and maintenance personnel as well as causing damage to the equipment itself are

marked by the following pictograms. Within the context of this manual, these pictograms have

the following meanings:

Danger of death, severe injury or considerable material damage if the relevant safety

!

precautions are not observed.

☞

Important information on the product or a particular section of this manual, which

should be read with particular attention.

Page 2

Fire Alarm Computer 8000C / M

Page 3

Table of Contents

1 General ....................................................................................................................................................4

2 General view............................................................................................................................................5

2.1 Key switch / enabling operation ............................................................................................................6

2.2 Function of the display and operating elements ..................................................................................7

3 Operating status of the fire alarm control panel...................................................................................16

3.1 Normal condition..................................................................................................................................16

3.2 Fire .......................................................................................................................................................16

3.3 Trouble .................................................................................................................................................17

3.4 CPU failure...........................................................................................................................................17

3.5 Disconnection ......................................................................................................................................18

3.6 Testmode .............................................................................................................................................18

4 Operation ...............................................................................................................................................19

4.1 Function keys / selection menu ..........................................................................................................19

4.1.1 Display / display control................................................................................................. 21

4.1.2 Display priority of the messages in the display ............................................................. 23

4.1.3 Info text / additional text and parameter display ............................................................ 24

4.2 Entering time/date ...............................................................................................................................25

4.3 Detector zones.....................................................................................................................................26

4.3.1 Switching on / resetting a detector zone ....................................................................... 26

4.3.2 Disconnect a detector zone........................................................................................... 27

4.3.3 Status of a detector zone .............................................................................................. 28

4.4 Detectors..............................................................................................................................................29

4.4.1 Switching on / resetting a detector ................................................................................ 29

4.4.2 Disconnect a detector.................................................................................................... 30

4.4.3 Status of a detector .......................................................................................................31

4.5 Controls................................................................................................................................................32

4.5.1 Switching on a control output ........................................................................................ 32

4.5.2 Disconnect a control output .......................................................................................... 33

4.5.3 Status of a control output .............................................................................................. 34

4.6 Common display of the status messages ..........................................................................................35

4.7 Delay and Verify ..................................................................................................................................36

4.7.1 Delay ............................................................................................................................. 37

4.7.2 Verify ............................................................................................................................. 37

4.8 Alarm counter ......................................................................................................................................38

4.9 Lamp test .............................................................................................................................................39

5 Service Level .........................................................................................................................................40

5.1.1 Primary loop functions ................................................................................................... 41

5.1.2 Sensor functions (loop) ................................................................................................. 43

5.1.3 Sensor functions (zone/detector) .................................................................................. 45

6 Installation Instruction............................................................................................................................47

12 Micromodule....................................................................................................................................... 107

24 Commissioning / Servicing ................................................................................................................ 145

Fire Alarm Computer 8000C / M

Page 3

Page 4

General

1 General

To equip buildings, facilities, commonly-frequented areas and working spaces with a fire warning

system can only be carried out economically and with reasonable propriety when correspondingly

well-founded safety concepts are developed and accordingly applied.

Wherever the highest requirements are made on a fire warning system, whether in small

commercial facilities or in industrial plants, the

Fire Alarm Computer 8000C / M

techniques and economy into practical reality. The modular design with different micro modules

and individual extension concepts allow the Fire Alarm Computer 8000C / M to be easily adapted

to special requirements. The Fire Alarm Computer 8000C / M represents the most modern

standard of fire warning technology. A reliable fire warning facility is guaranteed by the application

of "intelligent" fire detectors connected in an analog loop which is tolerant to short and open

circuits.

transforms safety

In this analog loop -

the esserbus

being configured into 127 individual detector zones can be connected with an overall cable length

of up to two kilometres. The esserbus

®

/

esserbus

®

is a two-wire line supplied and monitored at both ends in

®

-PLus

- up to 127 loop devices each capable of

ring topology. The Fire Alarm Computer 8000C / M automatically registers the wiring of the analog

loop and determines the logical addresses of the individual loop devices. A separate adjustment of

the addresses of the individual loop devices is unnecessary. Bei Systemen mit der

Ringleitung ist zusätzlich der direkte Anschluss von adressierbaren, busfähigen

PLus

Signalgebern möglich. Für diese, direkt über den

esserbus

®

-PLus

angesteuerten Signalgeber, ist

esserbus

®

keine weitere Spannungsversorgung erforderlich.

Subscribers in the esserbus

alarm modules (TAL) and the specially developed esserbus

These esserbus

®

transponders are loop devices with freely programmable inputs and outputs, for

®

are automatic and non-automatic intelligent fire detectors, technical

®

transponder input/output devices.

example for the activation and monitoring of external devices such as display panels, alarm

devices, door closers and other connected equipment.

Using the

essernet

®

safety network, 31 Fire Alarm Computer 8000C / M or other network

subscribers such as display and operating panels or alarm devices can be connected in a

homogenous network. Operation of the fire warning system, e.g. switching off a detector zone, is

possible from any fire alarm control panel or operating panel in the essernet

alarm, trouble, disconnection or other events are transferred to all subscribers in the essernet

can be accessed from any desired position. Data exchange can, according to the transfer rate, be

carried out either with a twisted pair or a LAN cable. The essernet

®

communications protocol

®

. Signals such as

®

and

guarantees reliable data exchange even if a short or open circuit occurs in the network.

-

These Operating Instructions are intended to aid you in the operation of the Fire Alarm Computer

8000C / M in addition to the description provided by the specialised installer and should be kept

together with the technical documentation of the fire alarm system. If you have any questions,

please consult your specialised installer.

The operation of an installed and operative fire alarm control panel may only be carried out by

authorised and trained persons under observance of the safety precautions and, if necessary, in

collaboration with other organisations (e.g. fire department).

Page 4

Fire Alarm Computer 8000C / M

Page 5

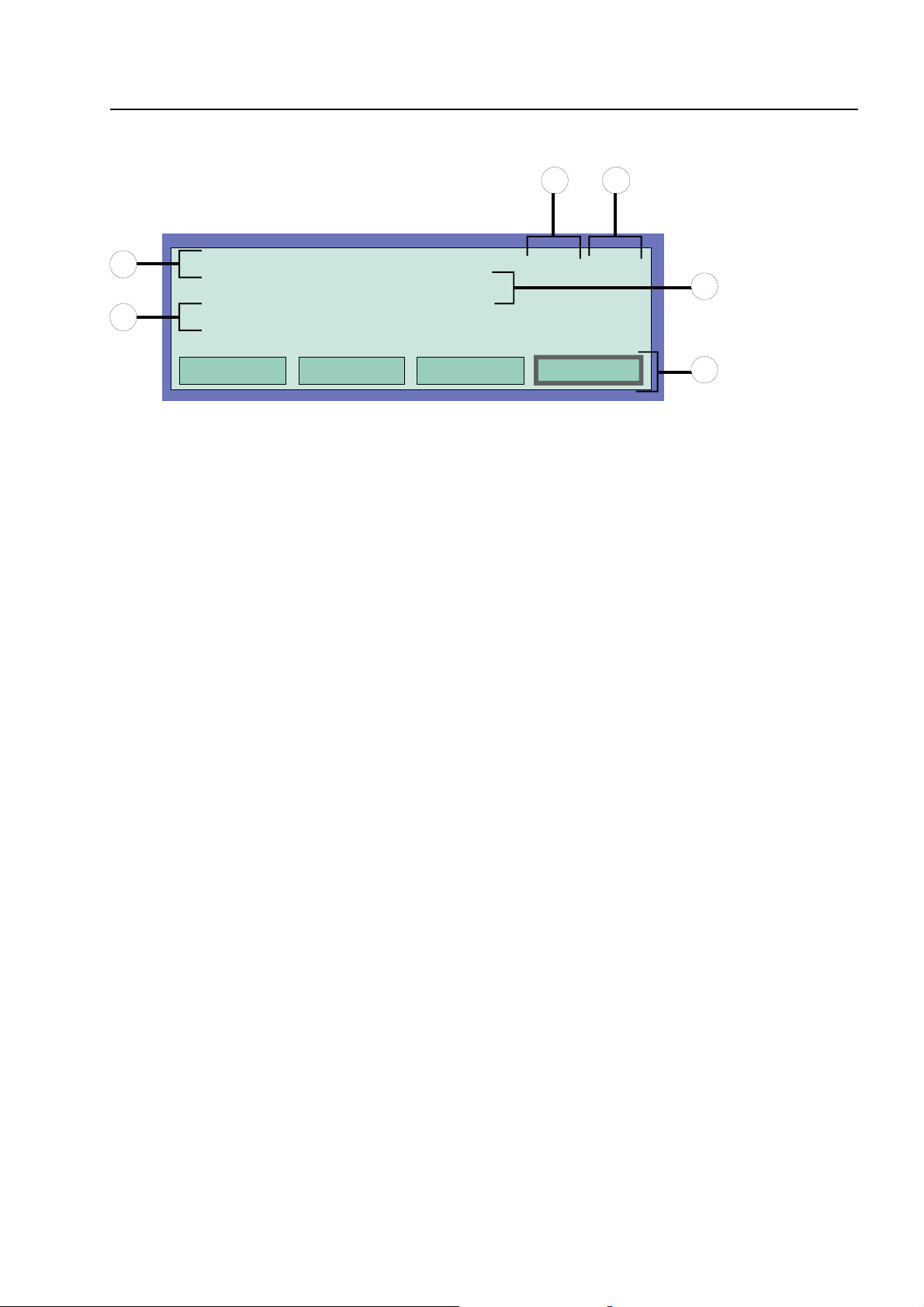

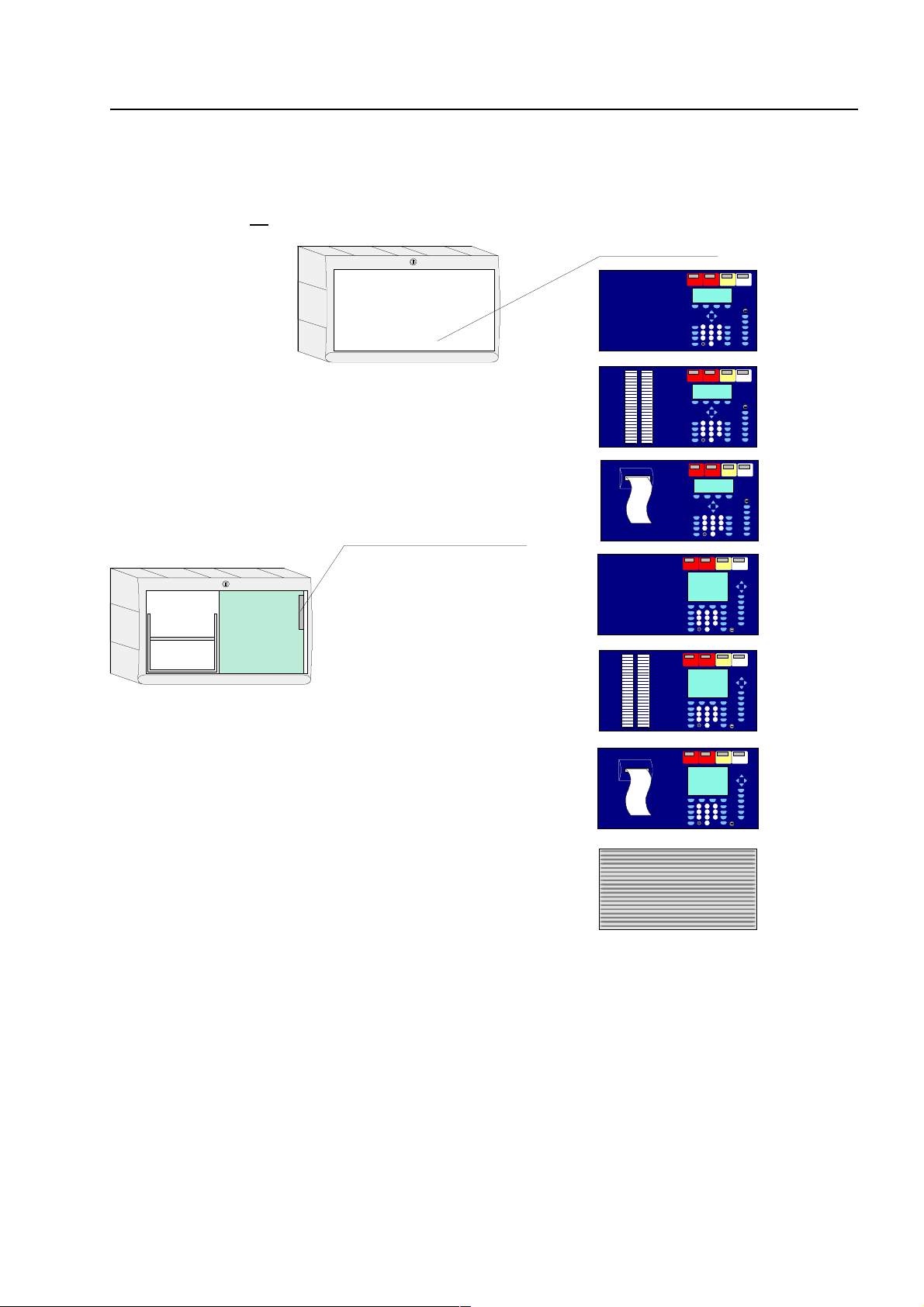

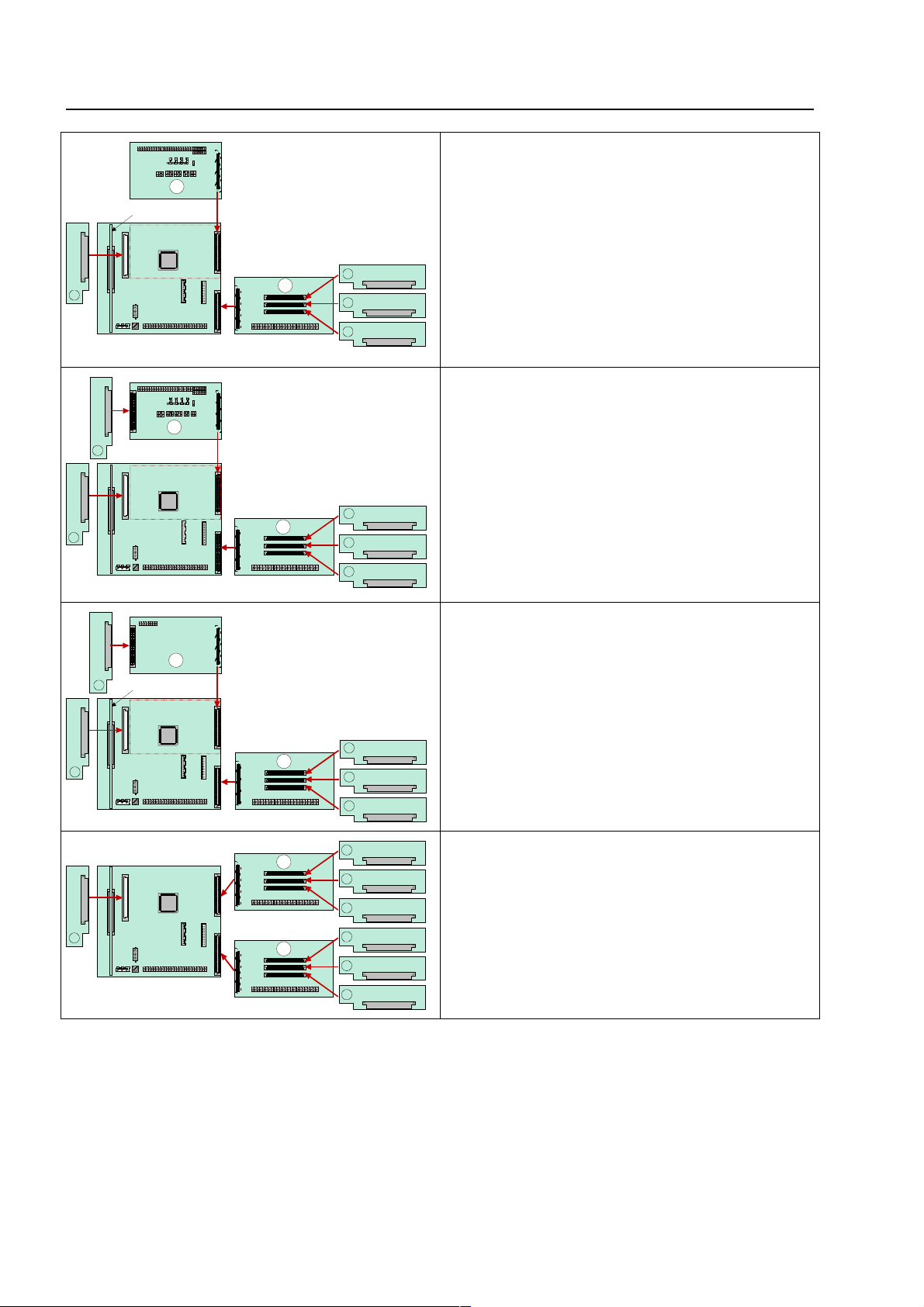

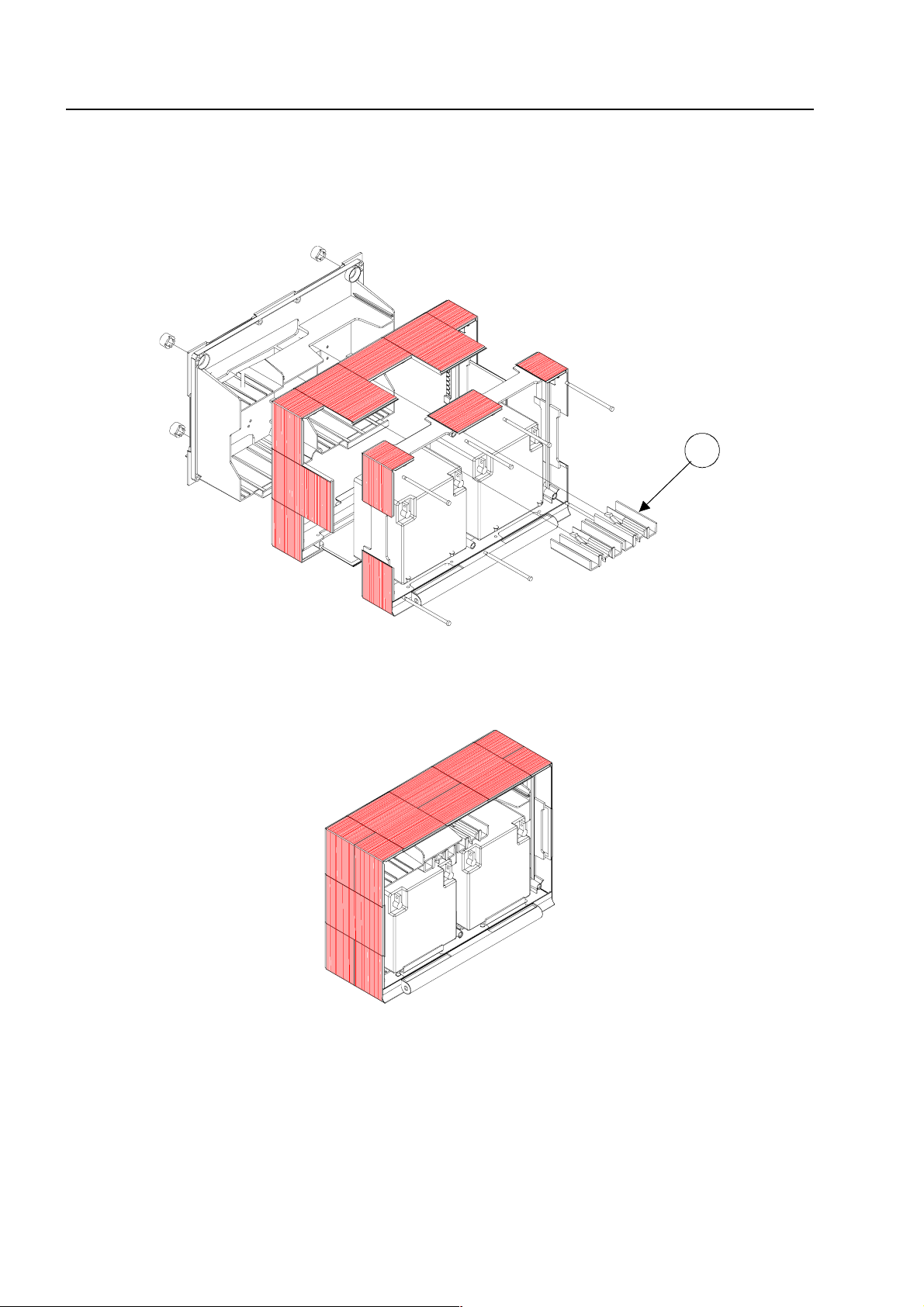

2 General view

1 5432

General view

Fire al arm

Disconn. / Trouble

Fire al arm

Disconn. / Trouble

Fire Pre-Alarm Trouble Disconnection

Releasi ng System

Master Box (MB)

Notify Fire Dept.

Detector

Fig. 1: General view of the display and operating elements

Delay

Verify

123

Zone

456

789

Relay

in Operation

CPU Failure

Power Supply

Relay Outputs

Master Box

Testmode

6

locked

7

8

On

Off

Test

Status

Panel

reset

Disconnect

Relay

Disconnect

Master Box

Additional

Messages

Delay

Verify

Buzzer off

unlocked

0

9

Single zone indicator units (GEA)

1

Common display FIRE

2

Common display PRE-ALARM

3

Common display TROUBLE

4

Common display disconnection

5

Alphanumeric display

6

Key switch

7

Operating elements

8

Function keys and keyboard

9

Fire Alarm Computer 8000C / M

Page 5

Page 6

Key switch / enabling operation

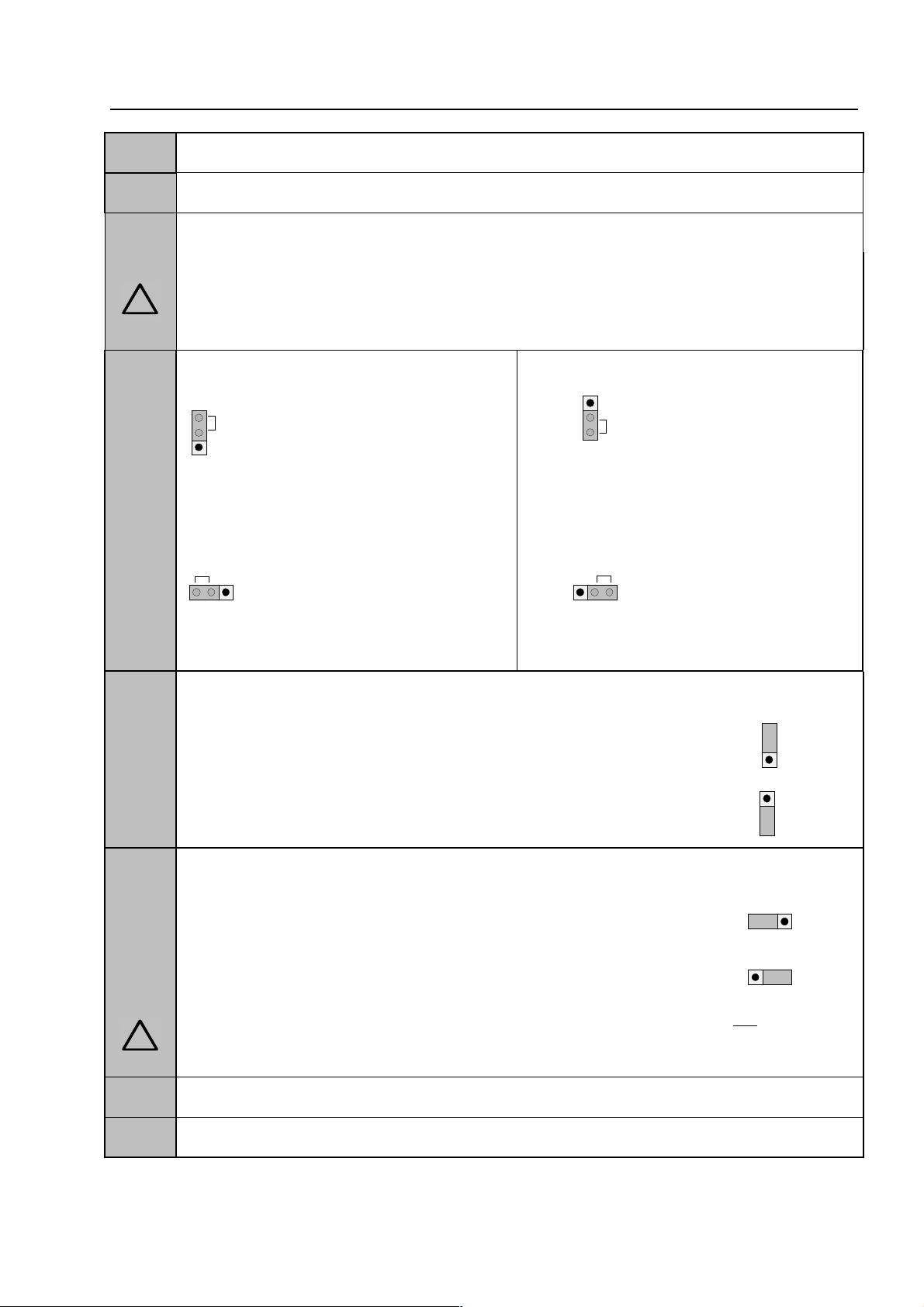

2.1 Key switch / enabling operation

Key switch in horizontal position

locked

unlocked

Fig. 2: Keyboard unlocked

♦ The keyboard is unlocked for the operation of the single Fire Alarm Computer 8000C / M and

other processors interconnected through the essernet

®

.

♦ The display menu is activated.

♦ If a fire alarm is activated, the activation of the master box (MB) is inhibited. (Works

adjustment - can be changed by client programming.)

In case of a fire alarm, activation of the master box (MB) will be disabled by the FACP.

!

The fire brigade will not be alarmed, automatically. In case of an event, the red LED Notify

fire department will be lit.

Key switch in vertical position

locked

unlocked

Fig. 3: Keyboard blocked

♦ The keyboard is blocked. The key can be removed.

♦ The keys Additional Messages and Verify / Buzzer off can still be operated when the keyboard

is blocked.

Page 6

Fire Alarm Computer 8000C / M

Page 7

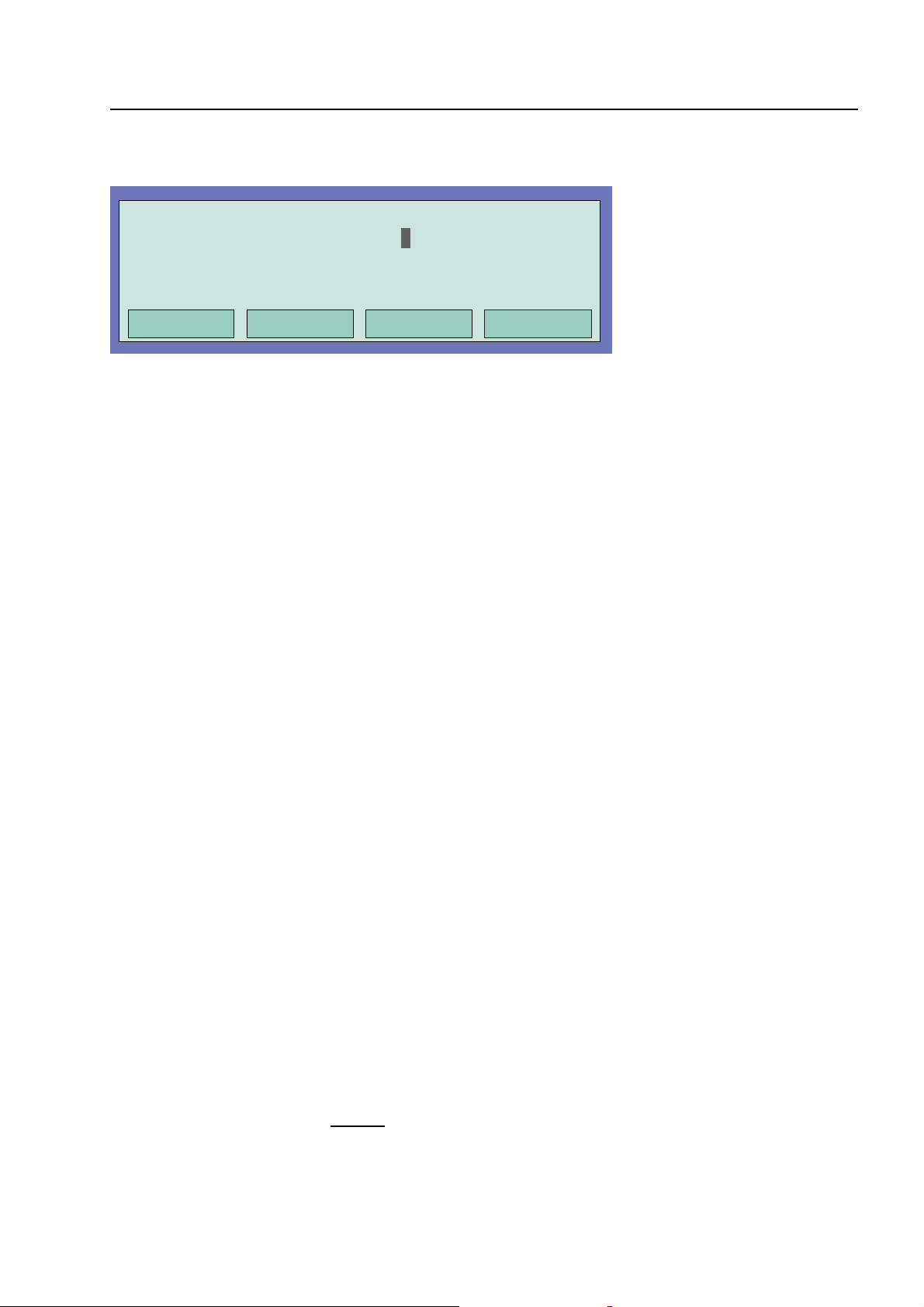

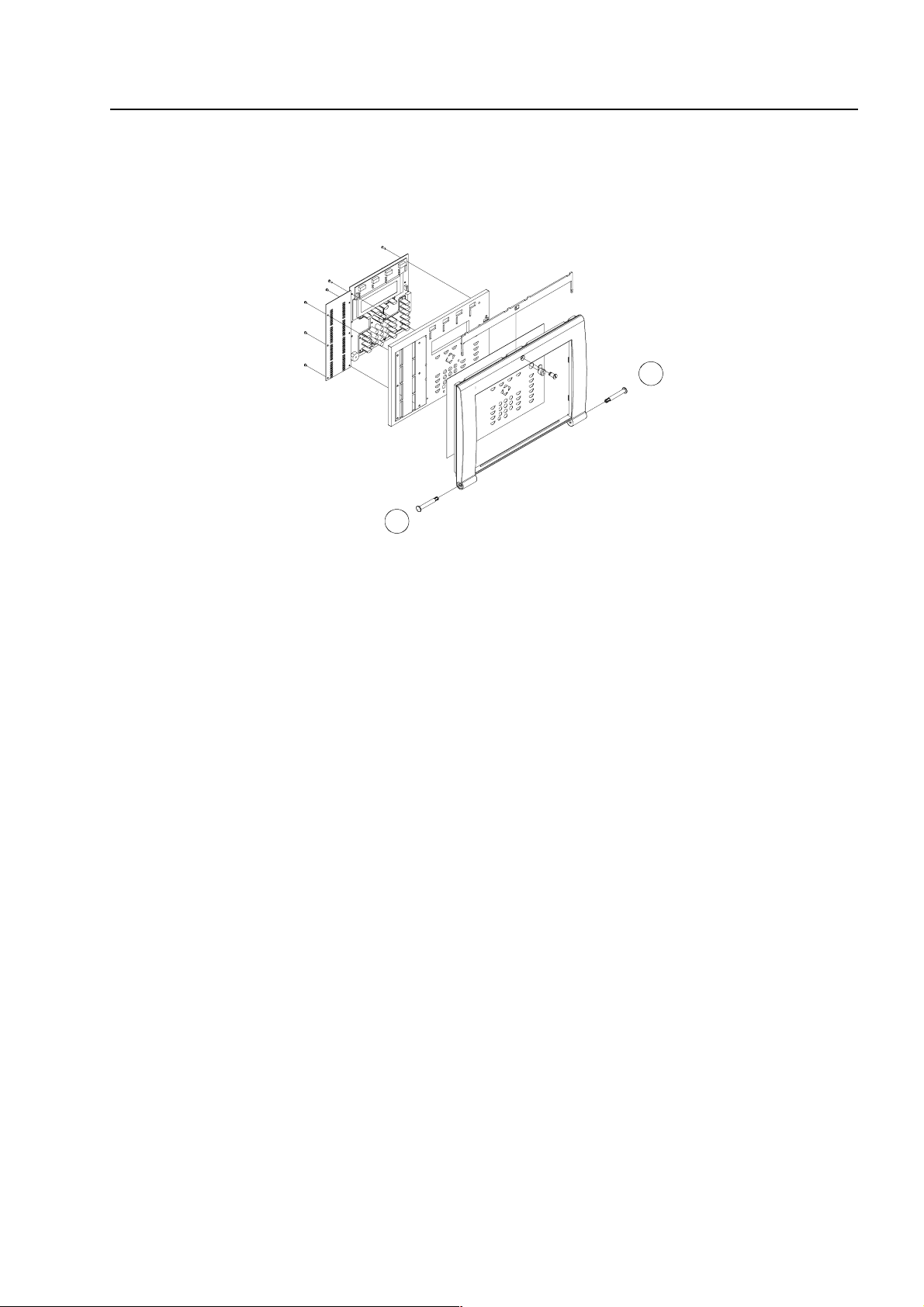

Function of the display and operating elements

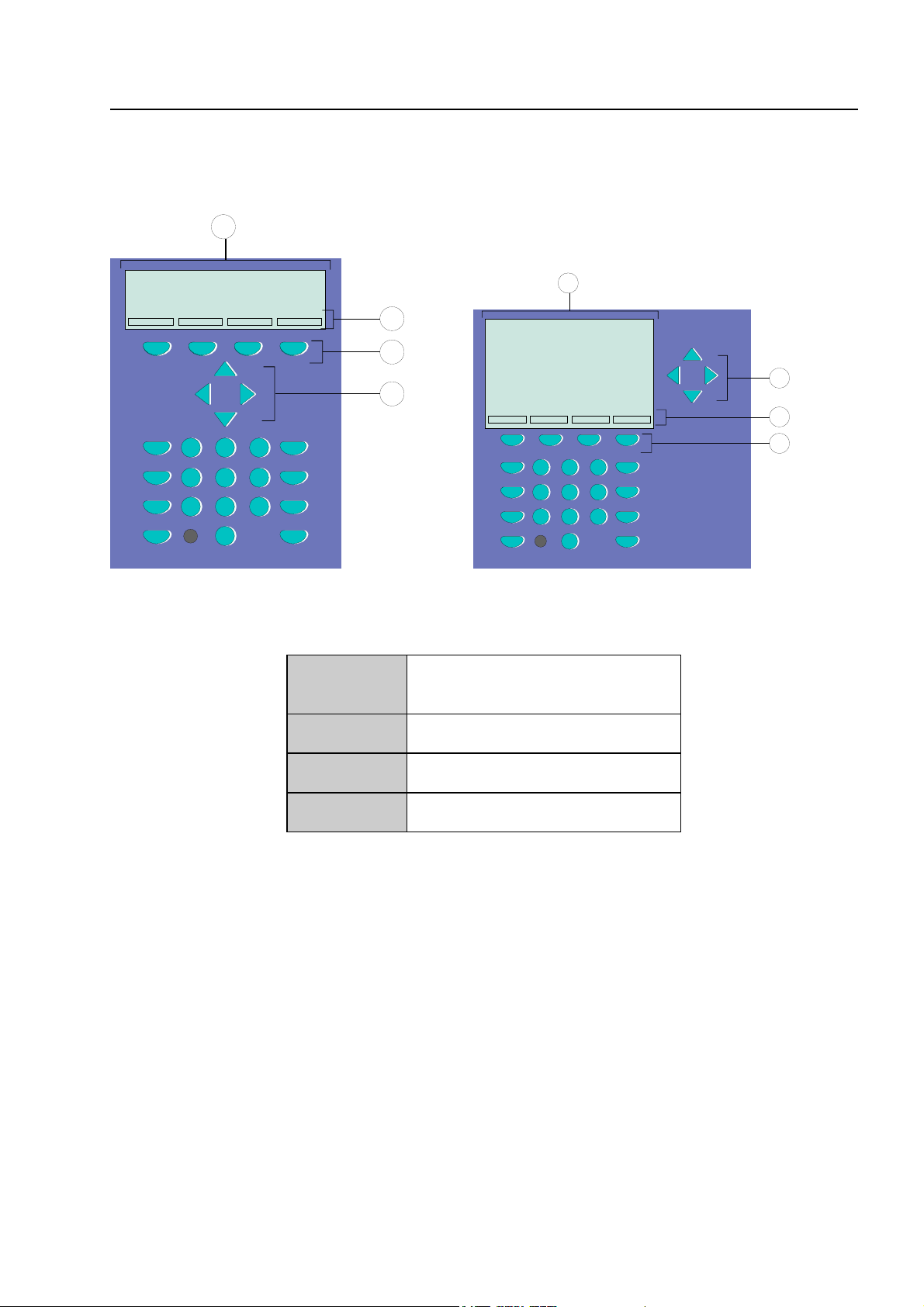

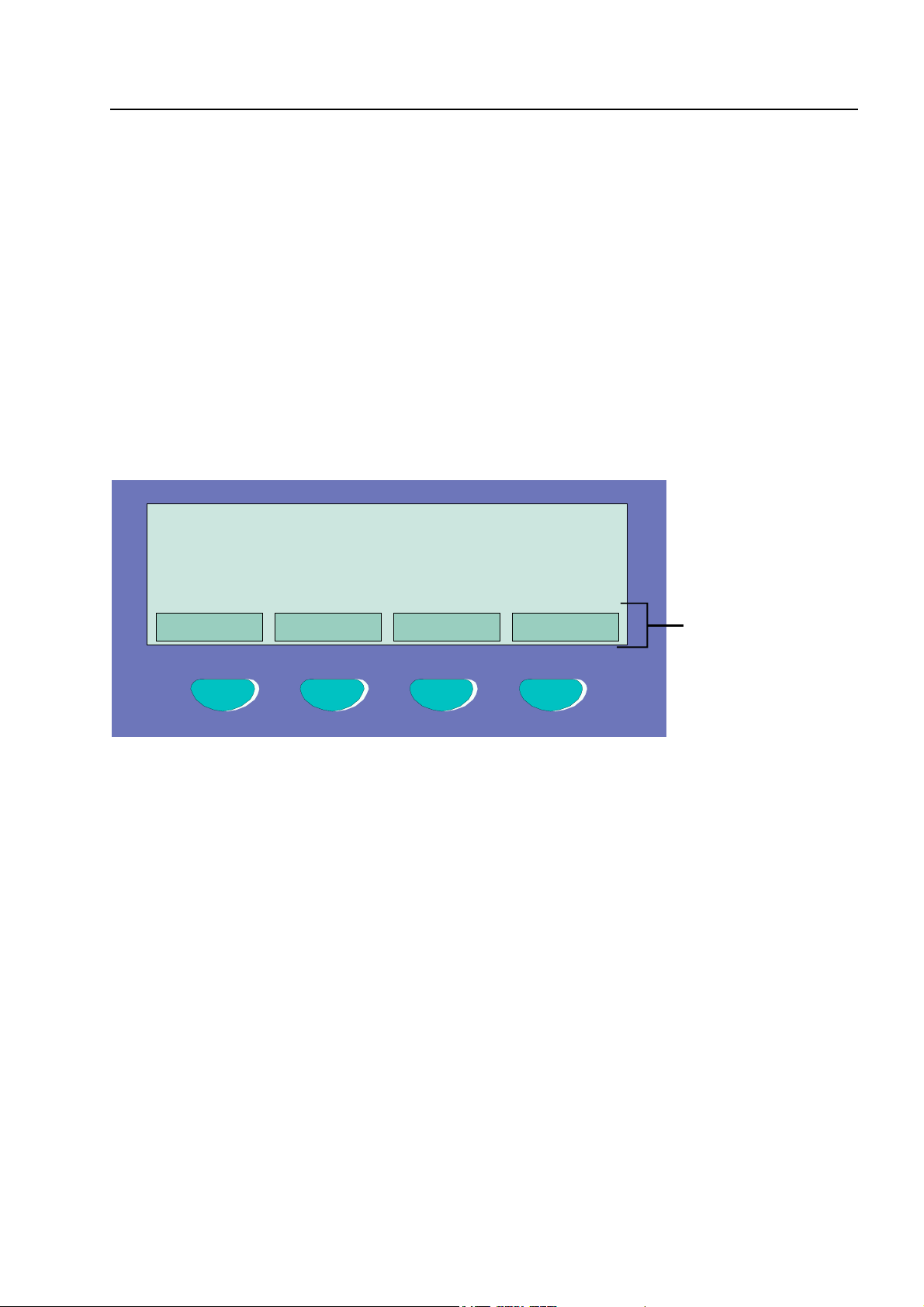

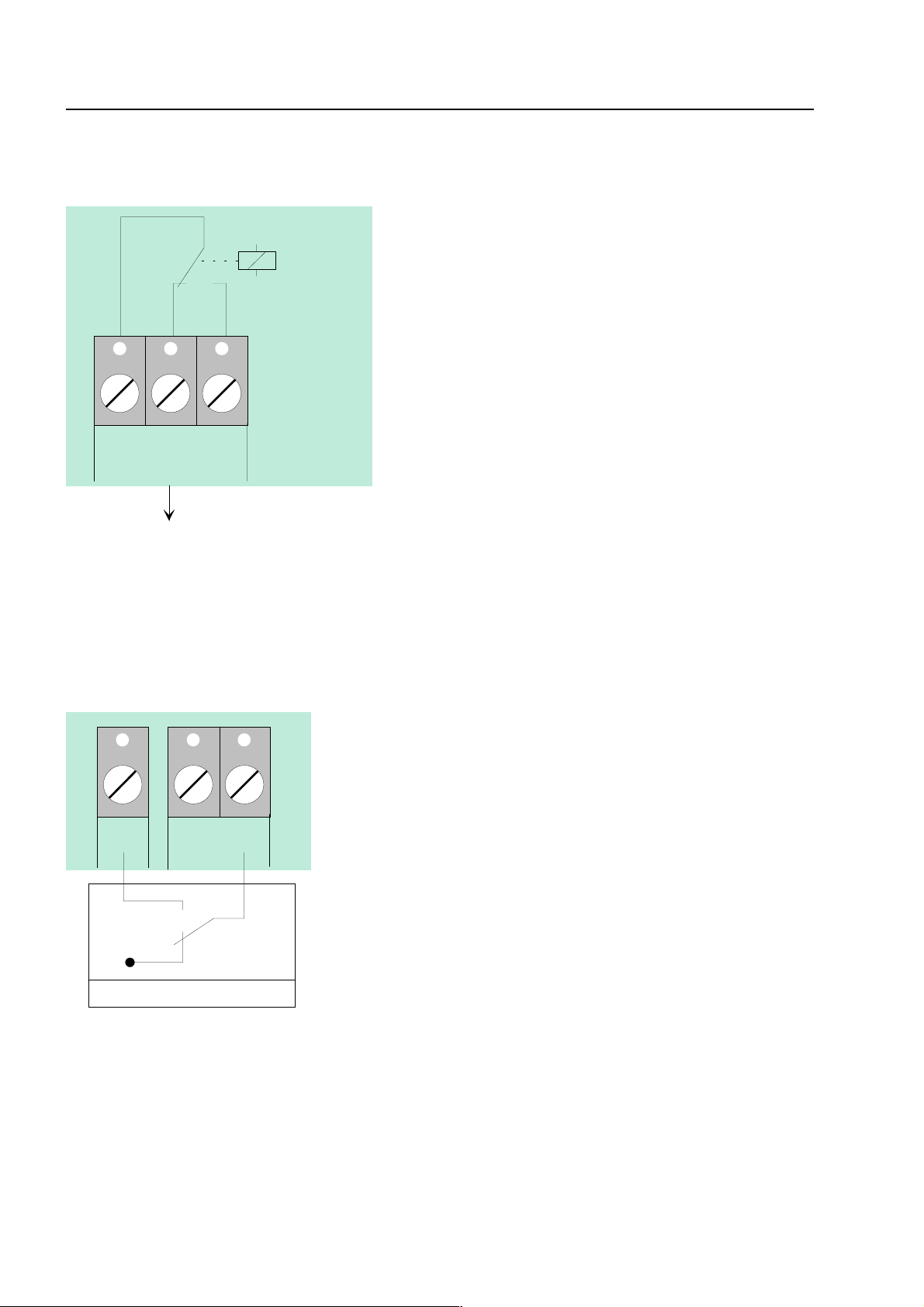

2.2 Function of the display and operating elements

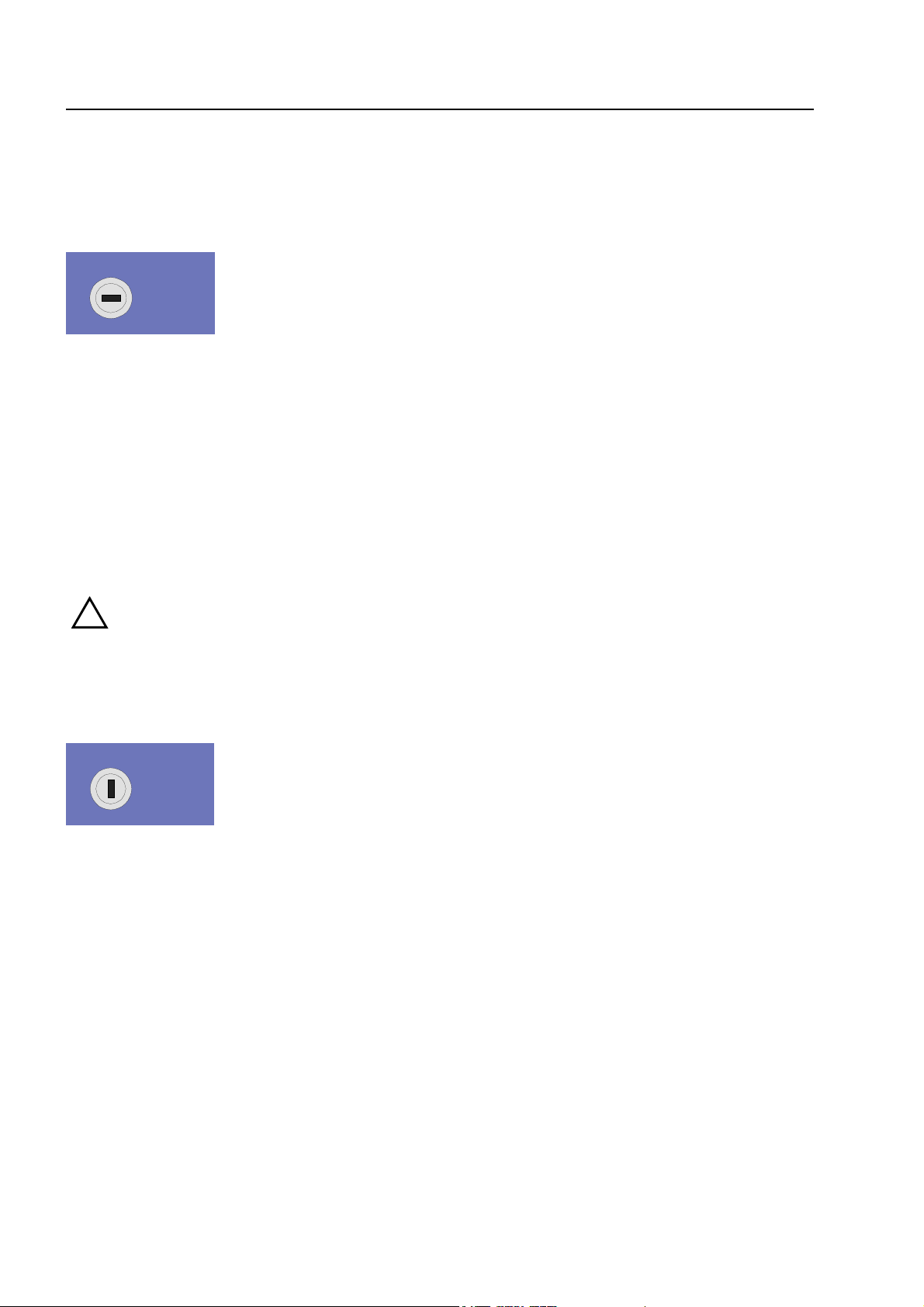

The Display System 8000 is available with standard and ¼-VGA-Display.

1

1

2

3

4

123

Zone

456

Detector

789

Relay

0

On

Off

Test

Status

123

456

789

0

4

2

3

Fig. 4: Operating elements - keypad - display Operating elements - keypad - 1/4 VGA display

1

Alphanumeric display

standard or ¼ VGA display

2

3

4

Menu

Function key

Cursor key

All received signals such as fire, trouble or switch-off are shown in the alphanumeric display in

alphanumeric form (8 lines, 40 characters per line).

Keyboard

By means of the key switch, the keyboard is unlocked for operation. With these keys, it is possible

to control panel functions such as switching detector zones and detectors on and off.

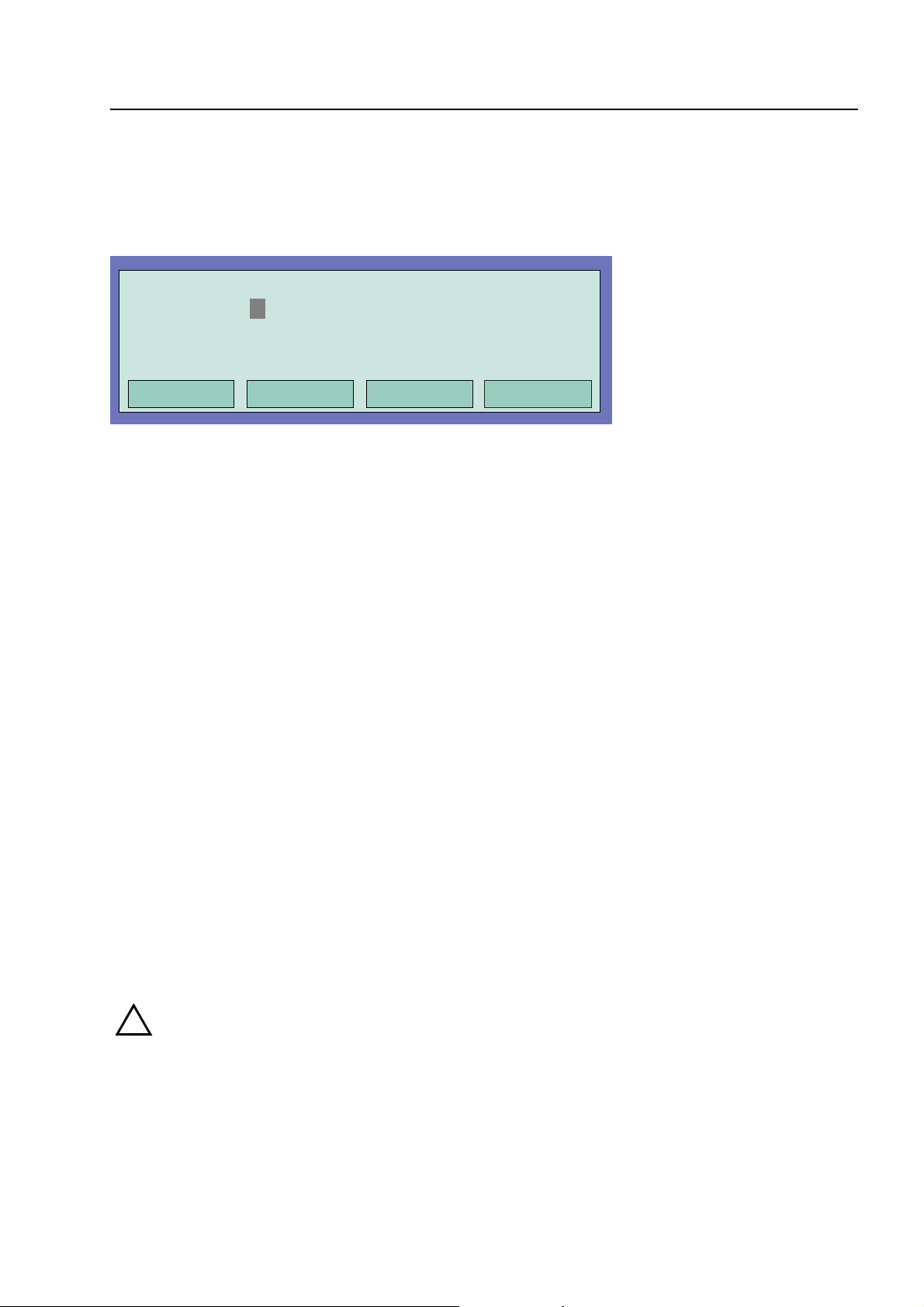

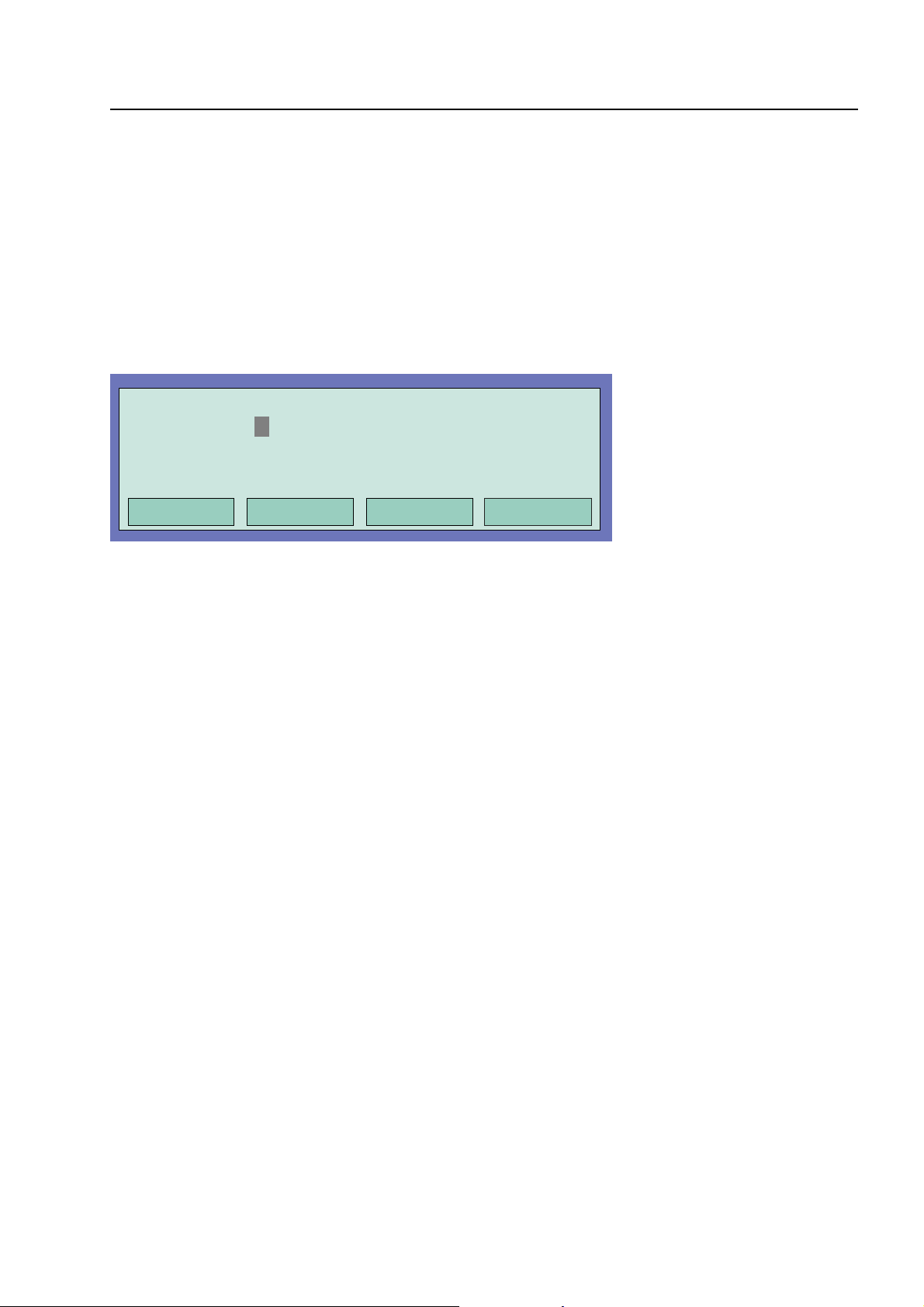

Function keys

With the four function keys, the menu options positioned above them in the alphanumeric display

are selected. Depending on the current state of the fire alarm control panel or the operation level,

differing menu options are shown in the display.

Fire Alarm Computer 8000C / M

Page 7

Page 8

Function of the display and operating elements

Fire

Releasing System

Master Box (MB)

Notify Fire Dept.

Fig. 5: Common display fire

The common display Fire is activated if at least one fire alarm has been detected. The originating

detector or detector zone will be shown on the alphanumeric display.

☞

Fire

Red LED is permanently on

Fire Releasing System

Red LED is permanently on

Master box (MB)

Red LED is permanently on

If evacuation plans or guidelines exist for cases of fire alarm, these plans have to be

followed and the premises have to be evacuated, if necessary. Make sure to inform yourself

well in advance about existing escape routes and required measures in case of a fire.

Fire alarm !

⇒

At least one detector and / or one manual call point and / or a

loop is signalling a fire condition.

The fire releasing control equipment is been activated.

⇒

The master box (MB) is activated and the intervention staff

⇒

(e.g. fire department) has been alarmed.

Notify fire department

Red LED is permanently on

Page 8

Fire Alarm Computer 8000C / M

The master box (MB) has malfunctioned or is switched off and

⇒

cannot be activated. Call the fire department immediately !

Page 9

Function of the display and operating elements

Pre-Alarm

Delay

Verify

Fig. 6:Common display pre-alarm

In the Pre-alarm status, the master box (MB) is not activated to route the alarm to the assisting

bodies. A Pre-alarm is signalled when an intelligent fire detector reaches the pre-alarm level or

when in a programmed twin-loop/twin detector connection a loop or a detector have detected a fire

alarm. The controls programmed in the customer data for this situation such as relay outputs to

actuate alarm devices are activated.

The Pre-alarm is automatically reset if no further signals are transmitted. The common display Prealarm is extinguished and any activated alarm devices are switched off. If further alarm signals

occur, a fire alarm is automatically initiated and the master box (MB) is activated.

PRE-ALARM

Red LED is permanently on

Control actions assigned to this event by means of customer data programming, e.g. relay outputs

for activating internal signalling devices or evacuation signals will be executed.

☞

On pre-alarm, the master box for alarming the emergency services will not be activated.

At least one detector or detector zone is signalling the pre-alarm

⇒

condition.

The activated detector or the activated detector zone is

indicated on the alphanumeric display.

Fire Alarm Computer 8000C / M

Page 9

Page 10

Function of the display and operating elements

Delay

Yellow LED lights

Yellow LED blinks

Verify

Yellow LED lights

An on/off switching interval has been programmed for the delay

⇒

function.

During this time, the activating of the master box (MB) due to a

fire alarm is automatically delayed by the delay time

programmed in the customer data base.

An alarm signal has been detected during the active delay time

⇒

and the programmed delay time (max. 600 seconds, according

to programming) has been initiated.

The master box is activated after expiry of this time.

The function Verify has been activated by the Verify/Buzzer off

⇒

key. The programmed Verify time (max. 600 seconds) for the

Verify of the cause of the alarm is running.

The master box is only activated after the expiry of the Verify

time.

☞

The function delay/Verify is described in Section 4.7.

Page 10

Fire Alarm Computer 8000C / M

Page 11

Function of the display and operating elements

Trouble

in Operation

CPU Failure

Power Supply

Fig. 7: Common display TROUBLE

The common display Trouble is activated if at least one malfunction has been detected. The

reason will be shown on the alphanumeric display.

Yellow LED lights

Operation

Green LED is permanently on

CPU failure

Yellow LED is permanently on

A component of the fire alarm control panel or a monitored relay

⇒

output such as an external alarm device or a master box has

malfunctioned.

The power supply (battery or mains voltage) is connected. The

⇒

fire alarm control panel is in an operative condition.

The fire alarm control panel is only partially operative due to a

⇒

malfunction of the control panel functions. Display or operation

of the control panel is no longer possible (Exception: Key

Buzzer off).

The activating of the master box (MB) and the LED Master box

(MB) and Notify fire department is still operative in the CPU failure

mode of the control panel in the case of a fire alarm.

Power supply

Yellow LED is permanently on

☞

In cases of malfunction or emergency operation, correct functioning of the FACP is no

longer ensured. Inform customer/maintenance service!

The power supply (battery or mains voltage) is out of order.

⇒

Fire Alarm Computer 8000C / M

Page 11

Page 12

Function of the display and operating elements

Disconnection

Relay Outputs

Master Box

Testmode

Fig. 8: Common display Disconnection

The common display Disconnection indicates that at least one output, input, or other component of

the FACP has been disconnected. The disconnection will also be shown on the alphanumeric

display.

Disconnection (common display)

Yellow LED is permanently on

Outputs

Yellow LED is permanently on

Master box (MB)

Yellow LED is permanently

on

!

A switched off master box will not transmit an alarm signal in the case of an event !

Testmode

Yellow LED lights

At least one input/output - e.g. a detector zone or relay has

⇒

been switched off.

At least one relay output (AE) such as an internal control panel

⇒

relay or the control of an esserbus

switched off.

The master box (MB) is switched off, e.g. for servicing, by

⇒

enablement of the keyboard with the key switch.

A component of the control panel (e.g. detector zone) has been

⇒

set to Testmode for servicing and maintenance work.

®

transponder has been

!

Page 12

A detector zone in Testmode will not transmit an alarm in the case of an event.

Fire Alarm Computer 8000C / M

Page 13

Function of the display and operating elements

Fire al arm

Discon n. / Troub le

Fire al arm

Discon n. / Troub le

Fig. 9: Single zone indicator units (GEA)

Optical displays (LED) for a total of 64 detector zones may be integrated into the control panel of

the fire alarm computer 8000C / M. Fire is signalled by a red LED. Malfunctions and disconnections

are signalled by a yellow LED. There is a labelling field for each detector zone which can be

marked with the name of the zone or of the area monitored by this group of detectors.

Fire alarm

Red LED is permanently on

At least one detector and / or one manual call point in the

⇒

detector zone is signalling an fire alarm.

Red LED blinks

For the zone, which first signalled the fire alarm (initial alarm

⇒

detection).

Disconnection / Trouble

Yellow LED is permanently on

The detector zone is switched off. Switching detector zones

⇒

on/off see Section 4.2.

Yellow LED blinks

At least one detector of the detector zone has malfunctioned.

⇒

Inform customer/maintenance service !

Switched off or malfunctioning detector zones will not transmit an alarm in the case of an

!

event.

Fire Alarm Computer 8000C / M

Page 13

Page 14

Function of the display and operating elements

Panel reset

All detected fire alarms, detector zones, displays and technical

Panel

reset

alarm signals (TAL alarm) are cancelled and returned to normal

condition.

Audible Alarm off

The connected alarm facilities are switched on or off (toggle

Disconnect

Relay

function).

Disconnect Master Box

The activating of the master box (MB) is switched on or off (toggle

Disconnect

Master Box

Switched off alarm devices and master boxes will not transmit an alarm in the case of an

!

event.

function). Switch-offs are displayed visually in the Common display

disconnection field.

Page 14

Fire Alarm Computer 8000C / M

Page 15

Additional messages

Additional

Messages

Delay

Delay

Verify / Buzzer off

Function of the display and operating elements

Additional messages can be shown in the display.

The first and last message with the highest priority are shown in the

display approximately 20 seconds after the key was last pressed.

By pressing this key the next message of the same or next level will

be displayed. The key Additional Messages remains functional

when the keyboard is locked (key-operated switch)!

When this key is pressed, the delay time is enabled/disabled

(toggle function)

See Section 4.7 Delay/Verify.

Verify

Buzzer off

Verify

Start of the programmed Verify time up to the delay activating of

the master box.

The Delay/Verify function is explained in section 4.7.

Buzzer off

Acknowledgement of the control panel buzzer. This key remains

active when the keyboard is locked. The buzzer is reactivated in

the case of a further event.

Fire Alarm Computer 8000C / M

Page 15

Page 16

Operating status of the fire alarm control panel

3 Operating status of the fire alarm control panel

The current operating status of the fire alarm control panel 8000C / M is shown on the operating

panel. Six different operating conditions are possible:

3.1 Normal condition

The normal condition refers to an operative monitoring state of the control panel unchanged by

external influences.

♦ The green LED in Operation lights.

♦ No further displays or messages.

♦ The operating panel keyboard is locked by the key switch.

3.2 Fire

♦ The control panel is in alarm mode, i.e. it is signalling a fire alarm.

♦ The common display FIRE (red LED) lights.

♦ The master box (MB) has been activated.

♦ The internal control panel buzzer sounds.

♦ External alarm devices, e.g. acoustic alarm devices or control panel buzzers are activated.

♦ The zone which has detected the fire is shown in the display with the programmed additional

text.

♦ The red LED of the corresponding zone(s) lights in the single zone indicator units (optional). If

several zones signal a fire alarm, the red LED of the zone which first detected the fire blinks

(initial alarm detection).

♦ The red LED Master box (MB) lights when a master box for automatic transmission of the alarm

is connected and the fire department has been informed.

♦ Possibly, the red LED Notify fire department may light. The fire department has not been

informed via the master box.

Call the fire department immediately!

Page 16

Fire Alarm Computer 8000C / M

Page 17

Operating status of the fire alarm control panel

3.3 Trouble

The common display TROUBLE (yellow LED) lights and the control panel buzzer sounds

intermittently.

♦ At least one control panel function has failed!

♦ A message is shown in the display describing the failure/cause.

♦ The yellow LED of the zone in which the malfunction has possibly occurred blinks on the single

zone indicator units (optional).

Detector zones/relay loops or inputs/outputs will not signal an alarm in the case of an

!

event. Inform customer/maintenance service!

3.4 CPU failure

The fire alarm control panel is only partially operative!

♦ No messages on the alphanumeric display.

♦ No evaluation of information.

♦ No activation of external equipment such as alarm sounders.

♦ The master box and the Master box (MB) LED and Notify fire department will be activated

even in the control panel CPU failure mode.

A comprehensive operation of the fire alarm control panel is no longer provided. Call

!

customer/maintenance service immediately!

Fire Alarm Computer 8000C / M

Page 17

Page 18

Operating status of the fire alarm control panel

3.5 Disconnection

The normal condition of the control panel has been changed by an external influence.

Displays:

♦ The common display disconnection (yellow LED) lights

♦ Possibly, a further display in the Common display disconnection field may be signalled,

showing which components have been switched off, e.g. Relay, Master box (MB)

♦ The disconnection is reported in the display as a plaintext message.

♦ A switched off detector zone is indicated on the single zone indicator units (optional) by a

permanently lighting yellow LED.

Switched off detector zones, detectors and controls (AE) and other parts of the equipment

!

will not signal an alarm in the case of an event!

3.6 Testmode

The yellow LED Testmode lights. The Testmode mode of the control panel has been activated for

service and maintenance purposes:

♦ The function of detectors/detector zones is under inspection.

!

A detector zone in Testmode will not signal an alarm in the case of an event.

Page 18

Fire Alarm Computer 8000C / M

Page 19

4 Operation

Operation

The following section describes the most important operating actions for a single fire alarm control

panel 8000C / M. If several processors are connected in a network through the essernet

deviations from this description are possible. In this case, please ask your specialised installer.

☞

The operation of an installed and operative fire alarm control panel may only be carried out

by authorised and trained personnel under observance of the safety precautions and, if

necessary, in co-operation with the relevant emergency services (e.g. fire department).

®

4.1 Function keys / selection menu

or param. / add. text

Overview Service Time func. Info

,

F1 F2 F3 F4

Fig. 10: Function keys / selection menu

Summary of the various menu options

The selection menu allows direct access to logically grouped menu options. When the keyboard is

unlocked, up to four menu options are constantly shown in the display, each of which can be

selected using the function key located below it.

Status

Summary

Service

⇒

⇒

⇒

Status display of current messages in order of significance.

Group display and number of the various types of message, such as fire,

trouble, disconnection etc.

Transfer to the service level to operate the primary loop functions such as

switching primary loops, sensors etc. on/off.

Fire Alarm Computer 8000C / M

Page 19

Page 20

Operation

Installer

Time funct.

Escape

Acknowledge

Function

Rem. text

Information and additional text

Info

Operating actions for the specialised installer for service and maintenance

purposes. (Individual password code required, if a code has been

programmed.)

Entry of time/date and the switching times of the Delay/Verify function.

Termination of the current input prompt without storing or executing the

function.

Acknowledge the selected menu point/operation.

Confirmation of the execution of the previously selected function.

Query of the additional text display (Remote text) of other fire alarm control

panels in the essernet

control panel in the essernet

control panel can be displayed by the remote text function on another fire alarm

control panel.

Display of any programmed information text relating to the message in the

alphanumeric display. If information text exists, i.e. has been programmed for

this message, the menu point Info is displayed. If info text has not been

programmed, the menu point Info is not displayed.

®

network. If an event has been detected by a fire alarm

®

, the additional text from the activated fire alarm

Param/AT

☞

If information or additional text has been programmed for a message, the additional text

(Param/AT) is always displayed first. Pushing the function key during the display of the

additional text shows the information text.

Display of the additional text programmed for the current message or a

parameter. For a parameter, a works-programmed information text for the

current message in the alphanumeric display is shown. It is possible to switch

from additional text/parameter display using the function key. If additional text

has not been programmed, the menu point Add. text is not displayed.

Page 20

Fire Alarm Computer 8000C / M

Page 21

4.1.1 Display / display control

Display / display control

32

1

1

Fig. 11: Example display for a fire alarm (additional display)

1. FIRE Zone : 002 Det : 02 15:10 28:07

Office 1 Room 17 1st floor

3. FIRE Zone : 002 Det : 02

EDP room Room 21 1st floor

Overview Service Time func. Info

In all, three fire signals were detected. The display shows the first (1.) and the last signal

(in this case 3.) respectively. The display is scrolled by pressing the cursor key, and the

next signal (2.) is displayed.

Time of this alarm message

Date of this alarm message

Additional text line

(the additional text programmed for the triggered zone or detector will be displayed)

Additional information text or parameter / additional text (Param/AT)

4

15:10 28:07

5

Significance of the display to "1. Fire" :

♦ First fire signal on 28.07 at 15:10 hours.

♦ The detector No. 02 in the detector zone No. 02 signals FIRE.

♦ The additional text programmed for this detector zone "Office 1 Room 17 1st floor" provides

information on the location of the fire.

♦ The display field Info shows that an information text has been programmed for this detector

zone, which can be accessed by pressing the corresponding function key.

Fire Alarm Computer 8000C / M

Page 21

Page 22

Display / display control

1) First / last message with the next higher priority

2) A next message with equal priority

3) First / last message with the next lower priority

4) Prior message with equal priority

Fig. 12: Cursor keys

Further Displays / Messages

For your information, the following additional messages (if existing) are shown in the alphanumeric

display:

MB disconnected

MB trouble

Acoustic trouble

Acoustic disconnected

Revision active

when the activation of at least one master box (MB) for the warning of the

fire department has been switched off, e.g. by enablement of the

keyboard.

when at least one master box (MB) has malfunctioned.

when at least one acoustic alarm device has malfunctioned.

when at least one acoustic alarm device has been disconnected.

when the fire alarm control panel has been switched to revision on the fire

department operating panel.

Page 22

Fire Alarm Computer 8000C / M

Page 23

Operation

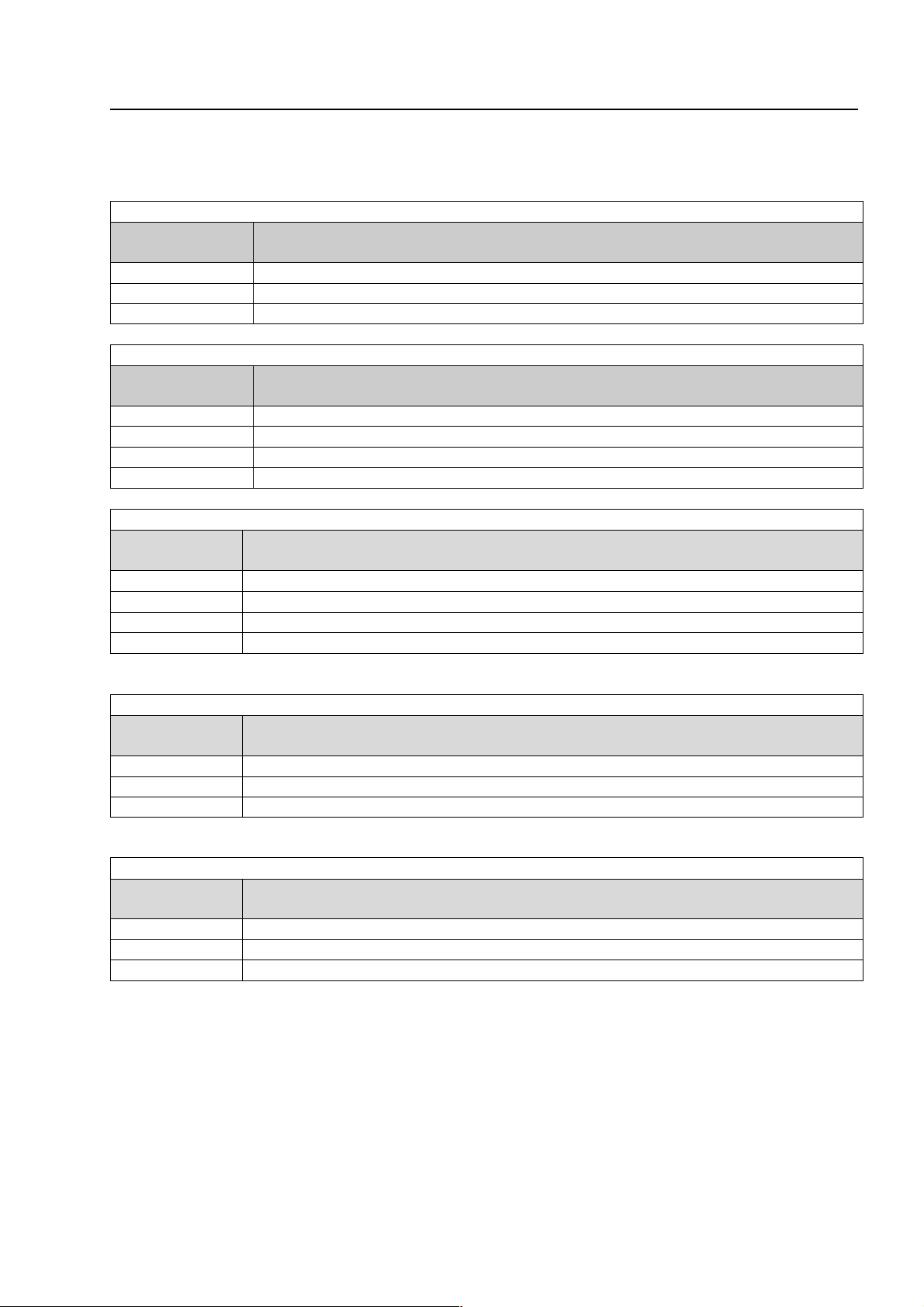

4.1.2 Display priority of the messages in the display

Additional

Messages

Fig. 13: Additional Message Key

Display priority

The first and last message with the highest current priority are shown in the alphanumeric display

of the Fire alarm control panel 8000C / M respectively. If several messages with equal priority are

imminent, these can be queried by pressing the key Additional Messages.

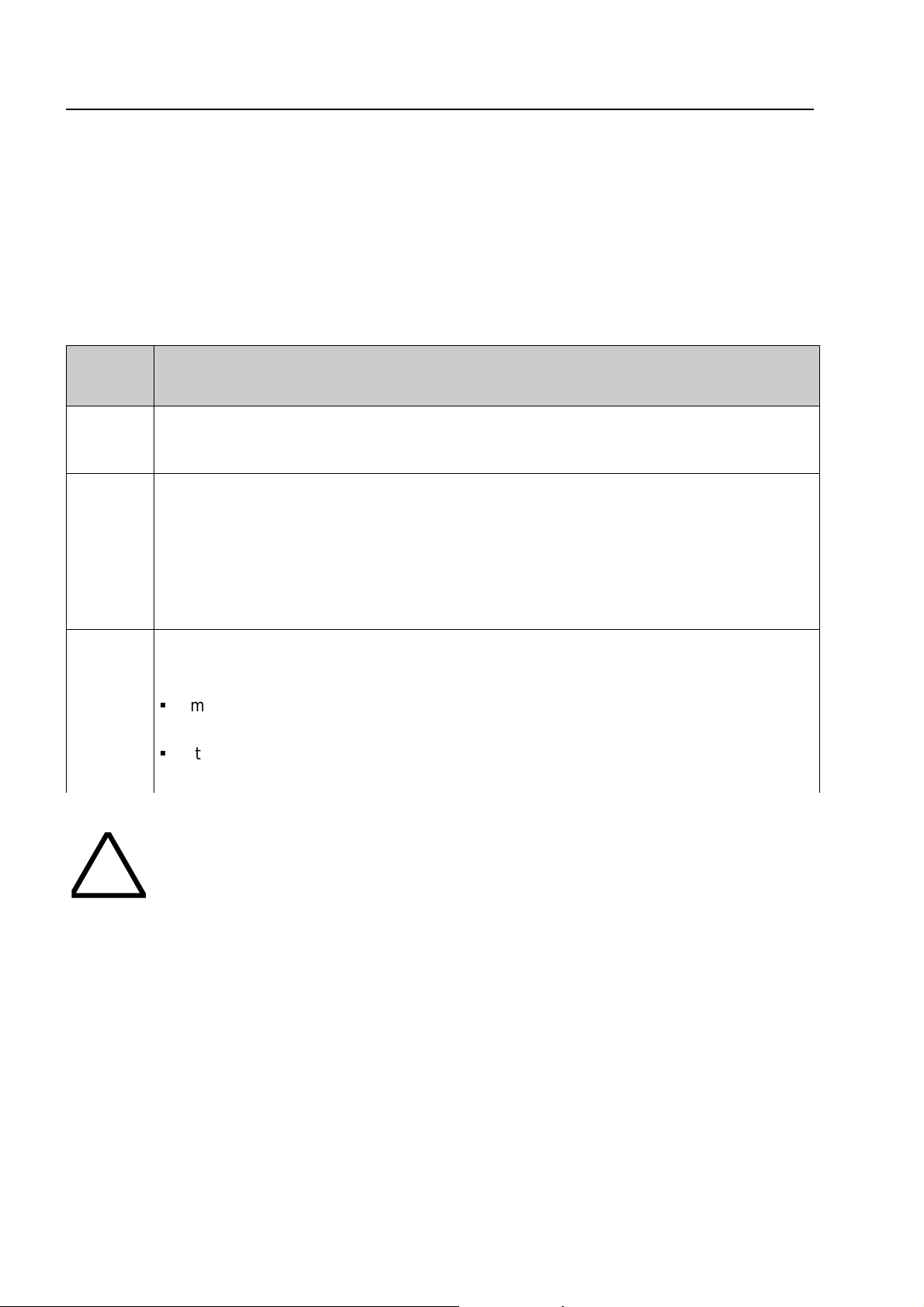

Priority stage Condition Display

1

2

3

4

5

6

7

8

9

10

11

12

Fire alarm

Fire alarm primary loop

Technical alarm

Pre-alarm

Trouble

Trouble primary loop

Transfer route switched on (Primary loop)

System trouble

Disconnection

Disconnection primary loop

Trouble relay output AE

Switch-off relay output AE

FIRE

FIRE

T-ALARM

PRE-ALARM

TROUBLE

LINE TROUBLE

LINE ON

SYS TROUBLE

DISCONNECTION

LINE OFF

TROUBLE

O/P OFF

☞

13

14

If the control panel is operated during the display, the corresponding function is carried out.

The message with the highest priority reappears in the display automatically approx. 20

seconds after the last key has been pressed.

Activate AE

Testmode

ACTIVATE

TEST

Fire Alarm Computer 8000C / M

Page 23

Page 24

Info text / additional text and parameter display

4.1.3 Info text / additional text and parameter display

1. FIRE Zone : 002 Det : 02 15:10 28:07

Office 1 Room 17 1st floor

2

1

Fig. 14: Info text display

Access via stairway right

Inform Mr. J. Smith (Tel. 02137 / 99152)

Status Param/*T

Info

Param/AT

Display of any programmed information text relating to the message in the

alphanumeric display. If information text exists, i.e. has been programmed for

this message, the menu point Info is displayed. If info text has not been

programmed, the menu point Info is not displayed.

Display of the additional text programmed for the current message or a

parameter. For a parameter, a works-programmed information text for the

current message in the alphanumeric display is shown. It is possible to switch

between additional text/parameter display using the function key. If additional

text has not been programmed, the menu point Add. text is not displayed.

If information or additional text and a parameter have been programmed for a message, the

information and additional text is always displayed first. Pushing the Param./AT function key during

the display of the additional text shows the parameter.

Example of an info text display (Fig. 14)

Access to programmed information text for this message programmed in the customer data and

related to the zones (max. 4 lines / 40 characters per line) can be attained by pressing the function

key Info.

In this example, the following two-line info text was programmed for detector zone 02 in a fire

condition:

Access via stairway right !

Inform Mr. J. Smith (Tel. 02137/ 99152)

Info text / additional text and parameter display

☞

Pressing the Condition function key returns the panel to the condition display. The display

switches automatically to the preceding menu point approx. 20 sec. after the last operation.

Page 24

Fire Alarm Computer 8000C / M

Page 25

4.2 Entering time/date

Time fct. Time/Date

Time

Date

Delay on

: 10:4

: Tu. 02.06.99

: --:-- off: --:--

Entering time/date

Escape

Fig. 15: Entering time/date

Year 2000 compliance

All functions of the Fire alarm control panel 8000 C/M work correctly in accordance with the

LPS2000 requirement. There is no action recommended on reaching the end date.

The end date of the implemented real time clock is the year 2080. After year 2080, leap

years will not be compensated and events will be displayed or printed with an incorrect date,

however time will remain accurate. Also any elements operated on specific dates or certain

days of the week will be actioned on the wrong day. The System 8000 C/M panel does not

incorporate any user codes that employ the calendar function to access or operate other

features.

Entering the time or the date is carried out under the menu point Time functions which is accessed

by pressing the corresponding function key.

The corresponding input field (hour, minute, day, etc.) is marked using the cursor keys and the

desired value is entered on the numeric keypad. When a date is entered DD.MM.YY, the day of the

week (Mo, Tu, We...) is automatically calculated.

Function

Escape

Function

Entering times for the function Delay/Verify; see Section 4.6 !

☞

Approx. 20 seconds after the last operating action, the display switches back automatically

to the last menu point without storing the changes/inputs !

⇒

⇒

Exits the menu point without storing the changes/inputs.

The numeric values shown in the display are stored.

Fire Alarm Computer 8000C / M

Page 25

Page 26

Detector zones

4.3 Detector zones

4.3.1 Switching on / resetting a detector zone

With switch-on/reset, a detector zone which has been switched off -incl. all fire alarms- is switched

into the operative status or an operative detector zone is reset and any imminent messages such

as Fire or Trouble are deleted.

Zone

Press Key

Fig. 16: Switching on / resetting a detector zone 4 (example)

Operation

Zone:

Detector: 0

Fig. 17: Display switching on zone 4

4

4

Off

in progress

On

Page 26

Fire Alarm Computer 8000C / M

Page 27

Detector zones

4.3.2 Disconnect a detector zone

With the disconnection, the corresponding detector zone -incl. all fire alarms- is disconnected.

The detector zone is selected by means of the corresponding zone number.

Zone

Press Key

Fig. 18: Switching off / resetting a detector zone 4 (example)

Operation

Zone:

Detector: 0

Fig. 19: Display switching off zone 4

In addition to the message on the display, the Disconnect is indicated optically by the common

display Disconnect on the control panel and the corresponding continuous lighting of the yellow

LED on the single zone indicator unit (if present).

4

4

Off

in progress

Off

1. Disconnect Zone: 0004 Det: 15

Additional text (client text)

Overview Service Time funct. Info

Fig. 20: Disconnect to status display

!

A disconnected detector zone will not signal an alarm in the case of an event!

11:10 22:11

Fire Alarm Computer 8000C / M

Page 27

Page 28

Detector zones

4.3.3 Status of a detector zone

With this function, the current status, e.g. Normal, Alarm and Trouble, of the corresponding detector

zone can be interrogated directly.

Zone

Press Key

Fig. 21: Status detector zone 2 (example)

Operation Zone : 0002

Status: normal

End

Fig. 22: Display Status zone 2

Status query

2

Page 28

Fire Alarm Computer 8000C / M

Page 29

Detectors

4.4 Detectors

Functions relating to detectors are only possible for addressable fire detectors of the ESSER

detector series 9100 and 9200. These fire detectors can be selected and controlled by a detector

address.

4.4.1 Switching on / resetting a detector

With switch-on, an individual disconnected detector of the selected detector zone is switched into

the operative status or an active detector is reset and any imminent messages such as Fire or

Trouble for this detector are deleted.

Please note that the zone number has to be entered before the detector number.

Zone

Press Key

Fig. 23: Switching on detector zone 2 /detector 12 (example)

Operation

Zone: 2

Detector: 12

Fig. 24:Display switching on detector zone 2 / detector 12

2 1

on

in progress

Detector

On

2

Fire Alarm Computer 8000C / M

Page 29

Page 30

Detectors

4.4.2 Disconnect a detector

With the disconnection, an individual detector of the selected detector zone is disconnect. In

addition to the message on the display, the disconnection of the detector is indicated optically in

the Common display Disconnect field.

Individual detectors within a detector zone can only be disconnected if addressable ESSER series

9100 and 9200 detectors are used. Series 9000 standard fire detectors can not be disconnected

individually.

Please note that the zone number has to be entered ahead of the detector number.

Zone

Press Key

Fig. 25: Disconnect detector zone 2 /detector 12 (example)

Operation

Zone: 2

Detector: 12

Fig. 26: Display disconnect detector zone 2 / detector 12

2 1

off

in progress

Detector

Off

2

!

Page 30

A disconnected detector will not signal an alarm in the case of an event!

Fire Alarm Computer 8000C / M

Page 31

Detectors

4.4.3 Status of a detector

With this function, the current status, e.g. Normal, Alarm and Trouble, of the corresponding

detector can be queried directly.

Individual status query within a detector zone is only possible if addressable ESSER series 9100

and 9200 detectors are used. Series 9000 standard fire detectors can not be queried individually.

Please note that the zone number has to be entered ahead of the detector number.

Zone

Press Key

Fig. 27: Status detector zone 2 /detector 12 (example)

Operation Zone : 0002 Det : 0012

Status: normal

End

Fig. 28: Display Status detector zone 2 / detector 12

2 1

Detector

Status query

2

Fire Alarm Computer 8000C / M

Page 31

Page 32

Controls

4.5 Controls

4.5.1 Switching on a control

With the switch-on, a previously switched off control (relay, open collector output) is switched back

on.

In case of an event, the switched-on output will be controlled in accordance with the programmed

control conditions.

Relay

Press Key

Fig. 29: Switching on Relay 2 (example)

Operation

Relay : 2

Fig. 30: Display switching on Relay 2

On

2

On

in progress

Page 32

Fire Alarm Computer 8000C / M

Page 33

Controls

4.5.2 Disconnect a control

With the disconnection, a control (relay, open collector) is disconnected. In addition to the plaintext

message in the display, the Disconnection of the control is indicated optically in the Common

display disconnect field.

Relay

Press Key

Fig. 31: Disconnect Relay 2 (example)

Operation

Relay : 2

Fig. 32: Display disconnect Relay 2

Relays may be set to inverse by means of customer data programming of the 8000C / M FACP. In

this case, the relays will be activated in the normal state of the FACP and deactivated in case of

the associated event.

2

Off

in progress

Off

If a relay for which inverse activation has been programmed is disconnected, it will be deactivated.

Control of external equipment depends on the way in which it is connected to the NO/NC contacts

of the relay.

The equipment connected to a disconnection control (e.g. alarm devices) are not activated

!

in the case of an event.

Fire Alarm Computer 8000C / M

Page 33

Page 34

Controls

4.5.3 Status of a control

With this function, the current status, e.g. Normal, Activated, Disconnection or Trouble of the

corresponding control can be queried directly.

Relay

Press Key

Fig. 33: Status Relay 2 (example)

Operation Relay : 0002

Status query: 0001 message

End

Fig. 34: Display status Relay 2

Status query

2

Relays may be set to inverse by means of customer data programming of the 8000C / M FACP. In

this case, the relays will be activated in the normal state of the FACP and deactivated in case of

the associated event.

In normal operation of the 8000C / M FACP, relays programmed for inverse activation are indicated

as 'active'.

Page 34

Fire Alarm Computer 8000C / M

Page 35

Common display of the status messages

4.6 Common display of the status messages

In the common display Overview, all current messages such as Fire, disconnection, Trouble and

other conditions of the fire alarm control panel are displayed, sorted by priority.

If more messages are imminent than can be shown in the display, it is possible to "scroll" in the

display with the cursor keys.

Overview 13:51 28:04

Fire

Switch-off

Switch-off AE

Status Service Time func.

Fig. 35: Display overview

For a detailed status display of a particular message, mark the corresponding message line with

the cursor and press the function key Status.

: 1 message

: 1 message

: 2 messages

Alarm counter

1. FIRE Zone : 002 Det : 02 14:10 28:04

EDP room, paper store

1

Overview

Fig. 36: Display for a detailed status message fire alarm (example)

Additional text line associated with the triggered zone/detector (example)

c

Additional information or parameters may be displayed by pressing function key Info.

d

Service Time func.

Info

Fire Alarm Computer 8000C / M

2

Page 35

Page 36

Delay and Verify

4.7 Delay and Verify

A switching time can be entered under this menu point Time functions by the operator of the fire

alarm system in addition to the switching times programmed under the Delay/Verify function in the

customer data (if programmed by the installer).

If a fire alarm occurs during the active delay function, the master box (MB) is only activated after

the expiry of the programmed delay time (max. 600 seconds). If the key Verify is pressed during

the delay time, the delay of the activating of the master box is extended by the verification time

programmed in the customer data (max. 600 seconds). The cause of the alarm can be verified in

this period.

After the expiry of the delay and the verification times, the master box (MB) is activated

automatically if the alarm state has not been cancelled and the activation of the master box

inhibited by pressing the panel reset key.

Time func. Time/Date

Time

Date

Delay on

: 10:42

: Tu. 02.06.99

:

:-- off: --:--

Escape Function

Fig. 37: Entering a switching point for the delay time

If a switching time for the function Delay/Verify has been programmed in the customer data by the

installer of the fire alarm system, the

accepted as the valid switching time when an additional switching time is entered under this menu

point Time functions. Exceptional days can be specified in the customer data programming on which

the automatic, i.e. delay/Verify times programmed by the installer will not take effect.

Example:

Customer data programming: Switch on

Operator's entry under this menu point: Switch on 10.00, switch off

Valid switching time: Switch on 06.30, switch off 15.00

first switch-on time and the first switch-off time

, switch off 21.30

06.30

15.00

is

☞

Page 36

Please consult your installer to find out whether the function Delay/Verify has been

programmed in the customer data of your fire alarm control panel. If this function is not

activated, e.g. for technical reasons or requirements, the functions described in this section

can not be used.

Fire Alarm Computer 8000C / M

Page 37

Delay and Verify

4.7.1 Delay

By pressing the Delay key, the function Delay is started or ended manually (toggle function). The

activated delay function is indicated on the operating panel by the continuously illuminated yellow

LED delay.

Delay

Fig. 38: Delay key

If a fire alarm occurs when the delay function is activated, the activation of the master box (MB) is

delayed by the delay time programmed in the customer data (max. 600 seconds). The initiated

delay time is indicated in the operating panel by the blinking yellow LED.

4.7.2 Verify

If the delay time has been started due to a fire alarm, the activation of the master box can be

delayed additionally to the delay time (max. 600 seconds) by the verification time (max. 600

seconds) for the Verify of the cause of the alarm by pressing this key.

Verify

Buzzer off

Fig. 39: Verify key

VdS

The guidelines of the Association of German Property Insurance Companys (Verband der

Schadenversicherer VdS, Cologne) must be observed for the function Delay and Verify.

Fire Alarm Computer 8000C / M

Page 37

Page 38

Alarm counter

4.8 Alarm counter

Differentiated display of the detected alarm signals from fire and technical alarm zones for this

individual fire alarm control panel and the aggregate value of all other fire alarm control panels

interconnected in the essernet

®

.

Alarm counter

Fire alarm : 6

Tech. alarm : 2

Sum : 50

Sum : 2

10:24 10:05

Overview

Fig. 40: Display alarm counter

Example display

6 Fire alarms and 2 technical alarms have been detected by this fire alarm control panel up to now.

The sum of all alarm signals detected in the essernet

technical alarms (TAL alarms).

☞

The alarm counter cannot be reset to -0000-.

®

network amounts to 50 fire alarms and 7

Page 38

Fire Alarm Computer 8000C / M

Page 39

Lamp test

4.9 Lamp test

The Lamp test function is activated for approx. 10 seconds to check the optical displays.

Test

Press Key

Fig. 41: Lamp test start

♦ All optical displays (LED) of the operating panel and the single zone indicator unit (if installed)

illuminate.

♦ The display area of the alphanumeric display is completely darkened.

♦ The control panel buzzer sounds.

♦ The versions No. of the panel software is then shown on the display.

This function ends automatically after approx. 10 seconds!

Pressing the Test key again stops the lamp test before the expiry of 10 seconds!

Fire Alarm Computer 8000C / M

Page 39

Page 40

Service Level

5 Service Level

The service level allows the operator to carry out operations or to switch off individual fire detectors

and primary loops in a functional fire alarm system. These functions can also be performed on

interconnected control panels integrated in the essernet

panel.

®

network, i.e. independently of the control

Overview

Fig. 42: Function key "Service“ in the status level

Service time func.

Service

1 Primary loop function

2 Sensor function (loop)

3 Sensor function (zone / det.)

Escape Installer Select

Fig. 43: Display in the service level

The following operations and switch-offs can be carried out in the service level on the fire alarm

control panel without entering an authorisation code:

♦ Primary loop functions (see Section 5.1.1)

♦ Sensor function (loop) (see Section 5.1.2)

♦ Sensor function (zone/detector) (see Section 5.1.3)

Enter the number of the desired function or select the menu point directly with the cursor keys and

press the Select function key.

The service level is protected from unauthorised access by means of an access code. Any

operation of the FACP may only be carried out by authorised and trained persons under

observance of the safety precautions and, if necessary, in cooperation with the emergency

services (e.g. fire department).

Page 40

Fire Alarm Computer 8000C / M

Page 41

Service Level

5.1.1 Primary loop functions

Using this function, primary loops including all connected zones and loop devices can be switched

on or off at the keypad.

The switching state is indicated on the control panel and the alphanumeric display.

Primary loop / Transfer route

Primary loop :

1 on / off

2 reset

Func. menu Repeat Select

Fig. 44: Entering the primary loop number

all analog loop modules included in this FACP

♦

(including the analog loop with all associated devices connected to this module)

all 4-zone-modules included in this FACP

♦

(including all detector zones and detectors connected to this module)

certain modules such as relays or the interface on the basic/peripheral module

♦

Switch on / disconnect Primary loops:

♦ Enter the number of the primary loop which is to be switched on and press the Select function

key

♦ Enter the number of the desired function (1 = switch on/reset, 2 = switch off) or select the menu

point with the cursor keys and press the Function key

In the case of an input error, the display can be erased by pressing the Zone key and the primary

loop number can be re-entered.

When a primary loop, for example a 4-zone module or an analog loop module is

!

disconnected, all zones and loop devices connected to this module are disconnected.

Disconnected fire detectors and call points will not activate an alarm in the case of an

event.

Fire Alarm Computer 8000C / M

Page 41

Page 42

Service Level

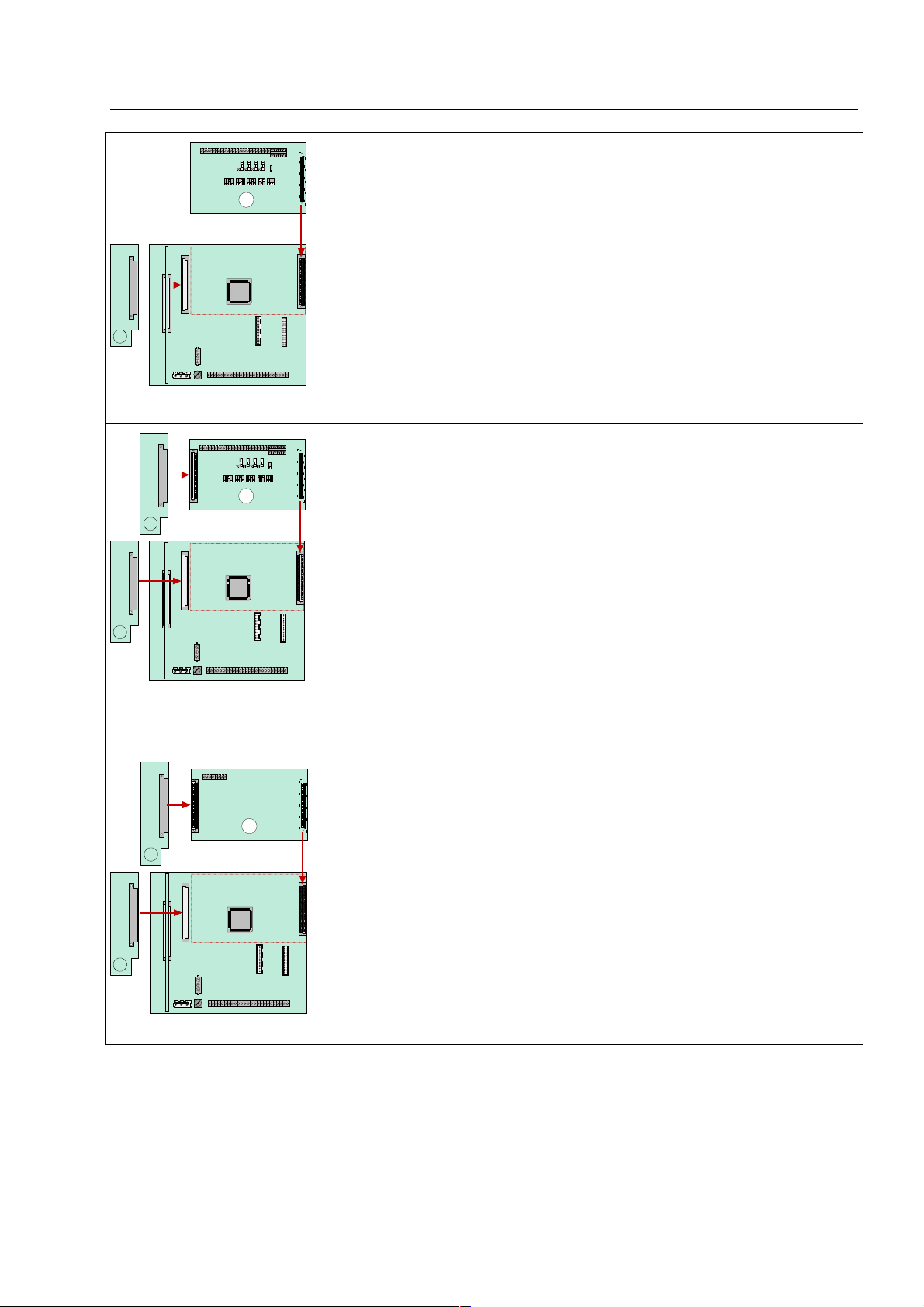

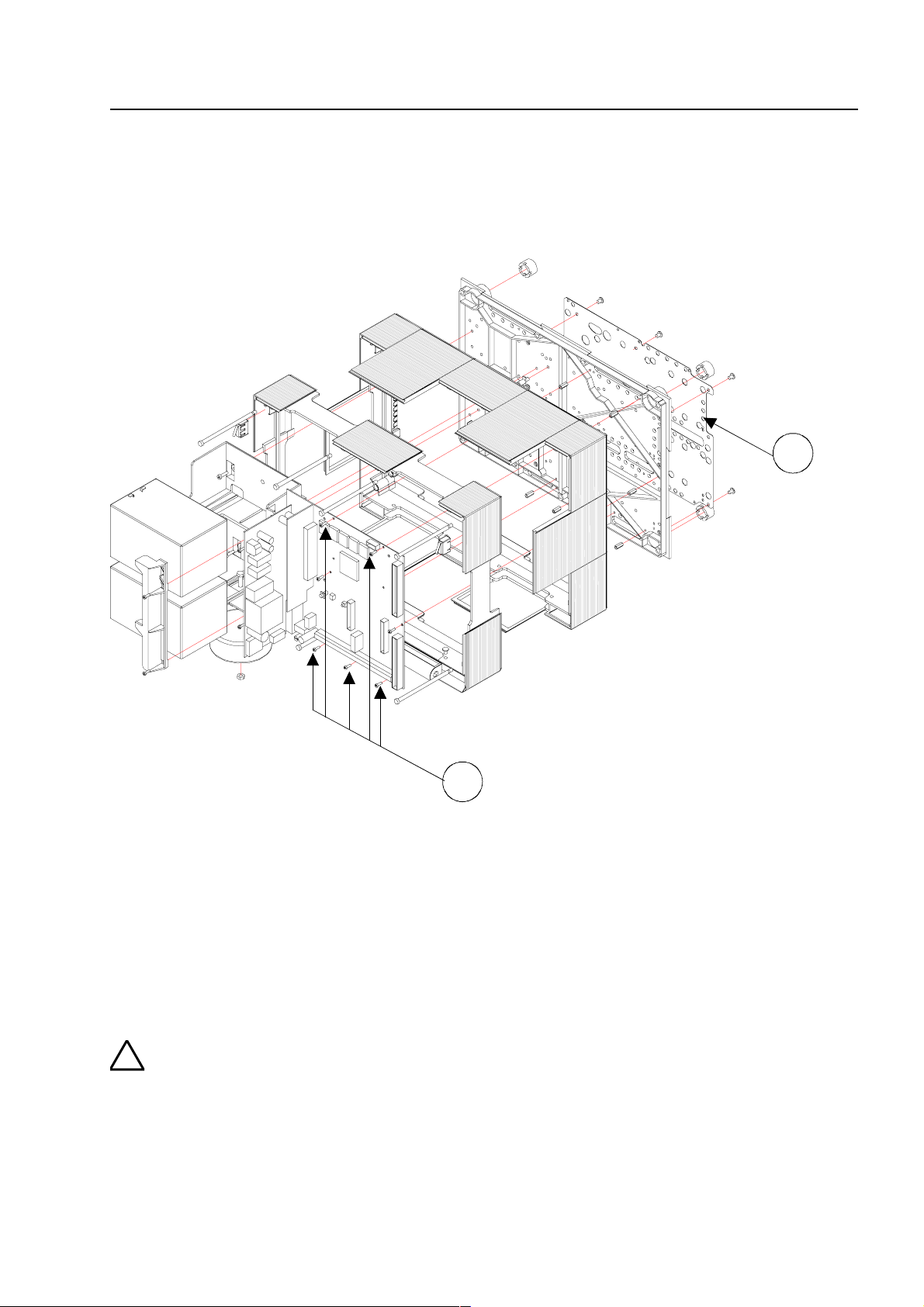

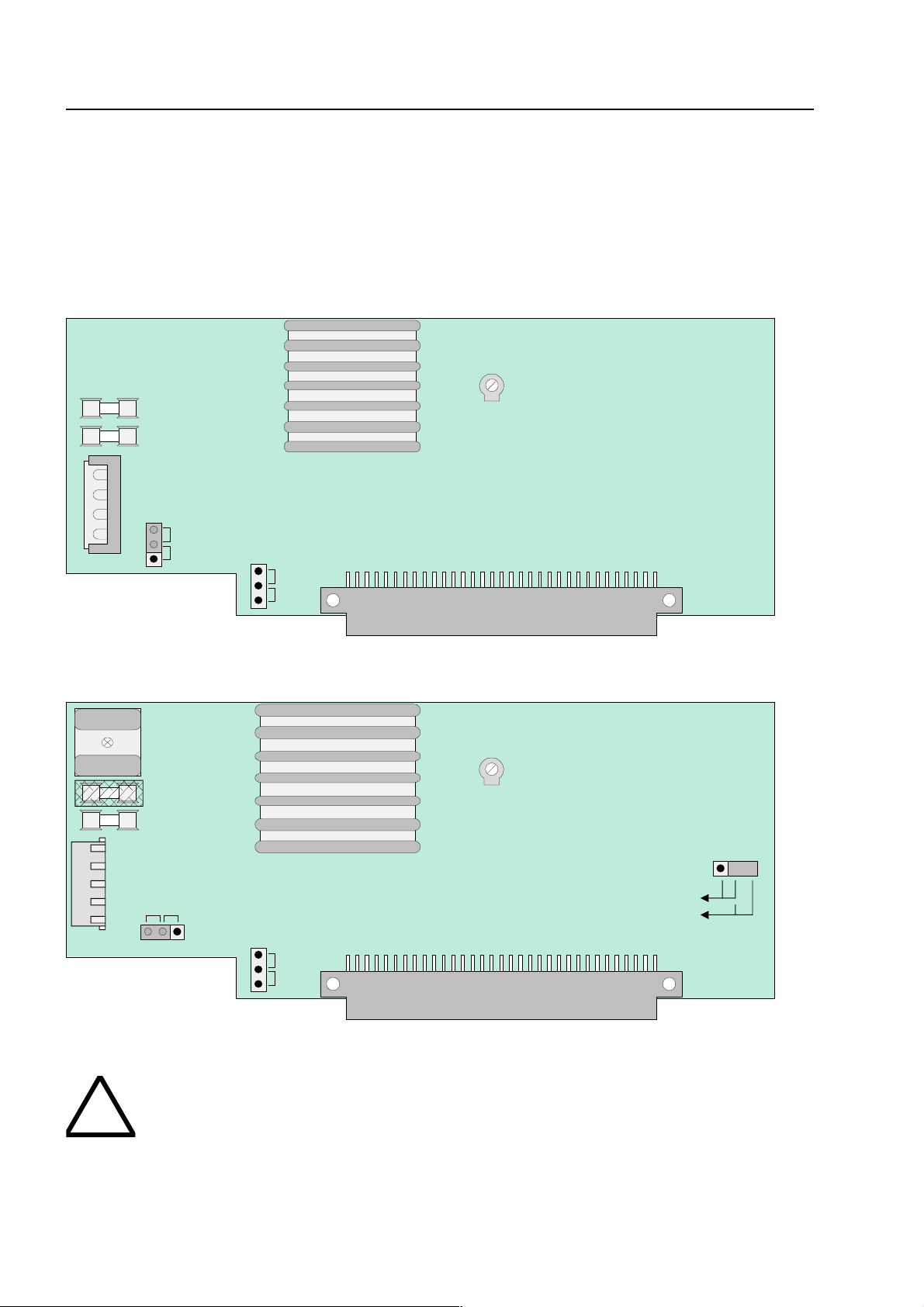

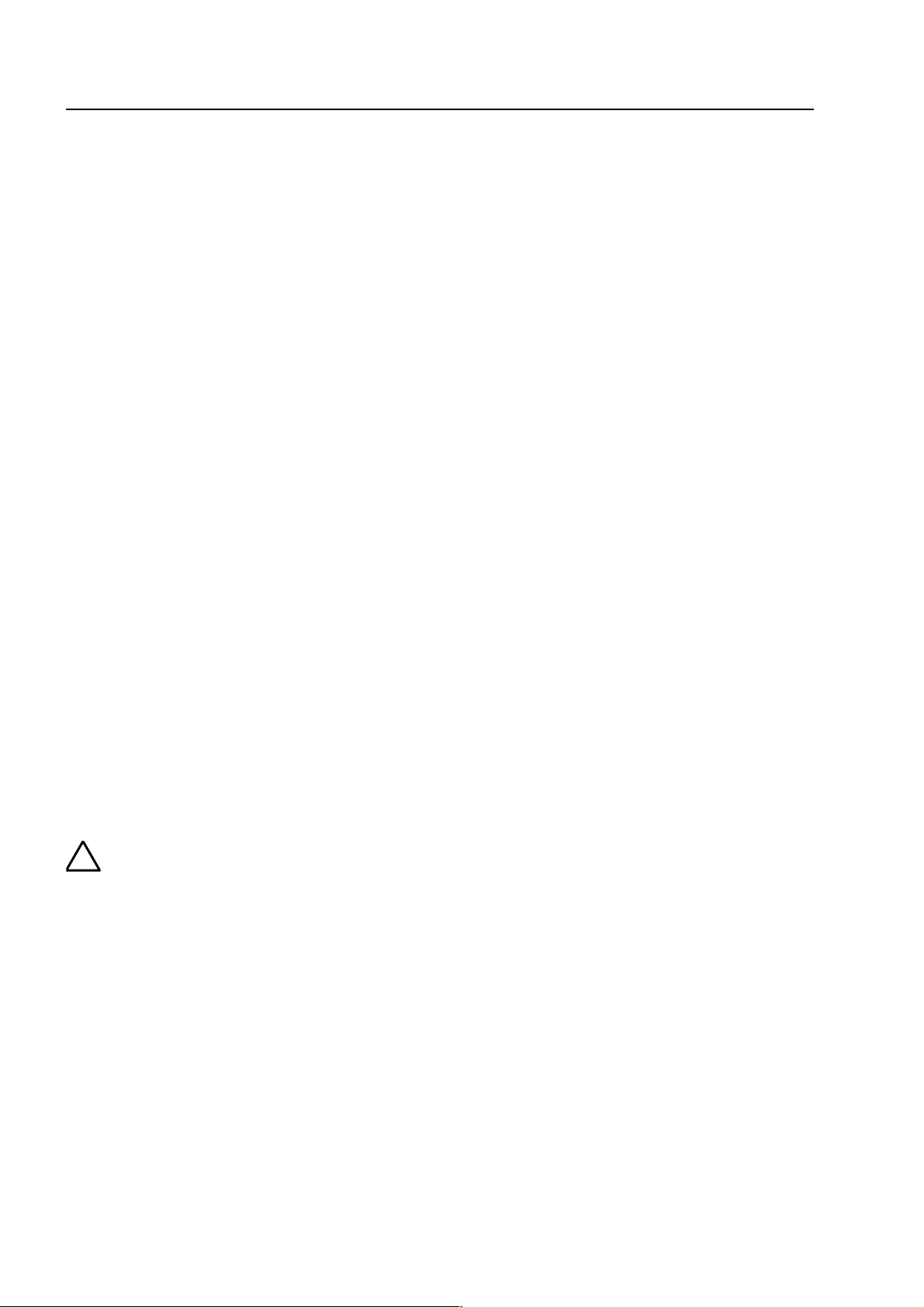

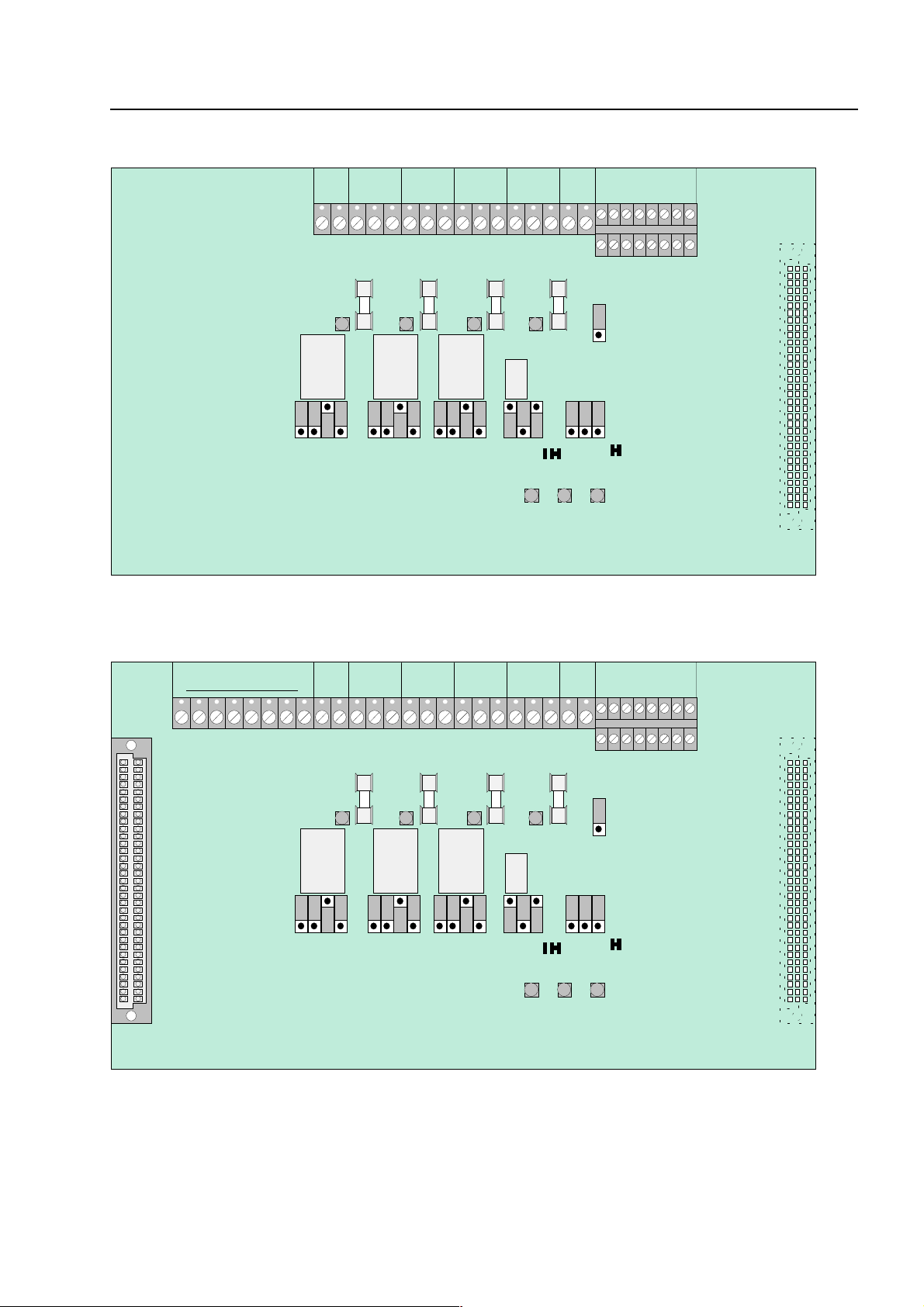

Example: FACP 8000C/M (Panel number 01)

Primary loop number 0113

Primary loop number 0123

Primary loop number 0131

B

2

1

2

1

B

3

D

4

5

Fig. 45 Example FACP 8000C Example FACP 8000M

Definition of primary loop numbers

Individual assemblies of the FACP 8000C/M can be switched on/off with the internal primary loop

number through the control panel keyboard or programmed with the customer data editor. This

internal primary loop number is composed of the control panel number, the slot and the assembly

number.

0 1 2 3

Subassembly number of the Basic-, Field deviceor extension module

Page 42

Slot number: Basic module = No. 1

Basic module Slot 1 = No. 2

Basic module Slot 2 = No. 3 (only 8000M)

Number of the Fire Alarm Panel (01 to max. 31)

Fire Alarm Computer 8000C / M

Page 43

Service Level

5.1.2 Sensor functions (loop)

Using this function, detector sensors of the multisensor fire detector such as all O sensors (Optical

= photoelectric sensor) or all I sensors (I = ionisation smoke sensors) or in OHI multisensor

detectors the OI sensor combination in an analog loop can be switched off.

Disconnecting sensors is only possible for OH and OHI multisensor fire detectors. These fire

detectors are fitted with two or three different sensors.

If, for example, OHI multisensor detectors are disconnected with the function OI sensors off, only the

third sensor - the H sensor (heat detector) - remains active. Disconnecting the heat sensors (H

sensors) is not possible.

Sensors (loop)

Primary loop :

1 O -Sensor off

2 OI-Sensor off

3 I -Sensor off

4 Sensors on

Escape Function

Fig. 46: Sensor functions reladed to primary loops

O detector

T detector

I detector

OT detector

OTI detector

⇒

⇒

⇒

⇒

⇒

Optical fire detector with a single sensor (photoelectric sensor)

Heat detector with a single sensor (Thermosensor)

Ionisation smoke detector with a single sensor (Ionisation sensors)

Multisensor fire detectors with two various sensors

(OT= Photoelectric and Thermosensor)

Multisensor fire detectors with three various sensors

(OTI= Photoelectric-, Thermo- and Ionisation sensors)

☞

Switching off sensors is only possible for OH and OHI multisensor fire detectors. If

multisensor fire detectors and standard detectors (detectors with a single sensor) are

installed together in an analog loop, only the sensor in multisensor detectors are switched

off.

Fire Alarm Computer 8000C / M

Page 43

Page 44

Service Level

Example of switching off sensors in an analog loop:

♦ Press key "2" to select the Service function (loop) or select the menu point with the cursor keys

and acknowledge by pressing the Select function key.

♦ Enter the primary loop number of the analog loop in which the sensors are to be switched off

and press the Select function key.

♦ Enter the number of the desired function (1 = O sensor off, 2 = OI sensor off, 3 = I sensor off,

4 = all sensors on) or select the function with the cursor keys and press the Function key.

☞

Switching on/off not permissible

The switching on/Disconnection of the detector sensors is indicated in the display.

If sensors have already been disconnected in an analog loop, for example I sensor off for all fire

detectors or if there are no sensors of the selected type in this analog loop or a zone disconnect

has been detected, the message "Switch on/Disconnect not permissible" is displayed.

In an analog loop, it is generally only possible to execute a disconnection function, e.g.

disconnected sensors or detectors, when no further, lower-order disconnected functions have been

carried out; i.e. when individual detector sensors within a detector zone have been disconnected,

this detector zone cannot be additionally disconnected, as disconnect functions for this detector

zone have been carried out. However, it is possible to switch off other zones of this analog loop in

which sensors/detectors have not been disconnected.

In order to change the existing sensor switching status, all disconnected detector sensors must first

be switched on, for example with the command All sensors on. After all detector sensors have been

switched on, a further switching off/sensor disconnect can be performed.

Switching off sensors is only possible for OH and OHI multisensor fire detectors. If

multisensor fire detectors with unifunctional detectors (detectors with only one sensor) are

installed together in an analog loop, only the sensors in multisensor detectors are switched

off.

Page 44

Fire Alarm Computer 8000C / M

Page 45

Service Level

5.1.3 Sensor functions (zone/detector)

Using this function, it is possible to switch off sensors in detector zones or in individual fire

detectors in an analog loop.

By entering the zone and detector number, individual sensors can be switched off in each single

multisensor detector.

If only the zone number is entered (detector number = 0), the desired sensor switch-off is

performed for all multisensor detectors in this detector zone. If sensors have already been

switched off in individual multisensor detectors in this zone, the message "Switch on/off not

permissible" appears. All sensors must first be switched on in this zone before the desired sensors

can be switched off.

(See also above Sensor function loop)

Sensors (loop)

Primary loop

Detector

:

:

1 O -Sensor off

2 OI-Sensor off

3 I -Sensor off

4 Sensors on

Func. menu Repeater Select

Fig. 47: Sensor function related to zones/detectors

☞

☞

Switching off sensors is only possible for OH and OHI multisensor fire detectors. If

multisensor fire detectors with unifunctional detectors (detectors with only one sensor) are

installed together in an analog loop, only the sensors in multisensor detectors are switched

off.

If a switch-off has already been performed, e.g. the sensors of a zone have been switched

off, this detector zone or the entire analog loop cannot be additionally switched off. It is

possible to switch off other detector zones of this analog loop in which detectors or sensors

have not been switched off.

Fire Alarm Computer 8000C / M

Page 45

Page 46

Notes

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

Page 46

Fire Alarm Computer 8000C / M

Page 47

Installation Instructions

Fire Alarm Computer 8000C / 8000M

from Version V2.41

Page 48

T

able of Contents

6 Installation Instructions......................................................................................................................... 49

6.1 Standards, guidelines and instructions for installation.......................................................................49

6.2 Standards and guidelines................................................................................................................... 50

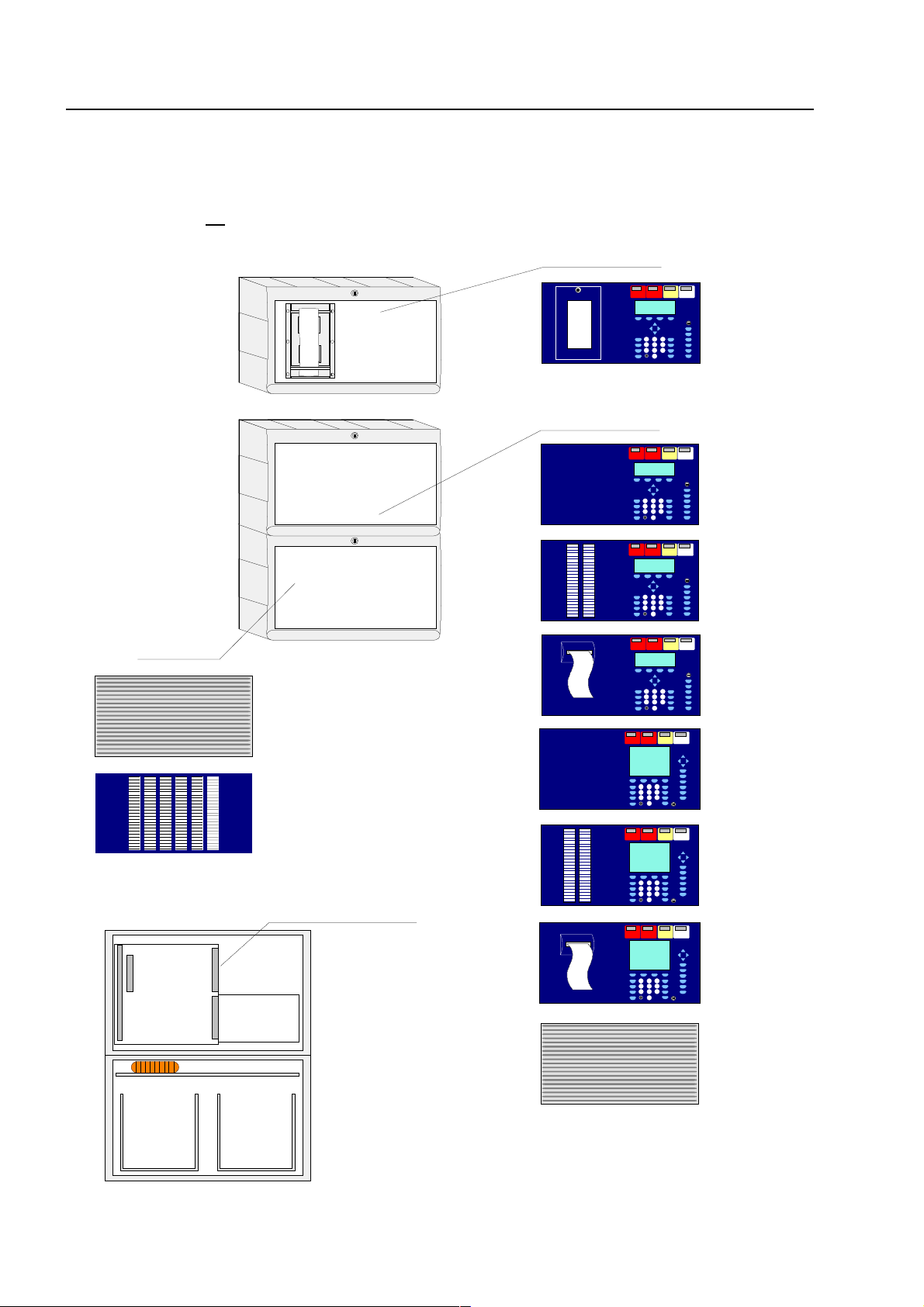

7 Overview...............................................................................................................................................51

7.1 esserbus

7.1.1 Signalgeber für den esserbus

®

-PLus function.................................................................................................................... 52

®

-PLus...........................................................................53

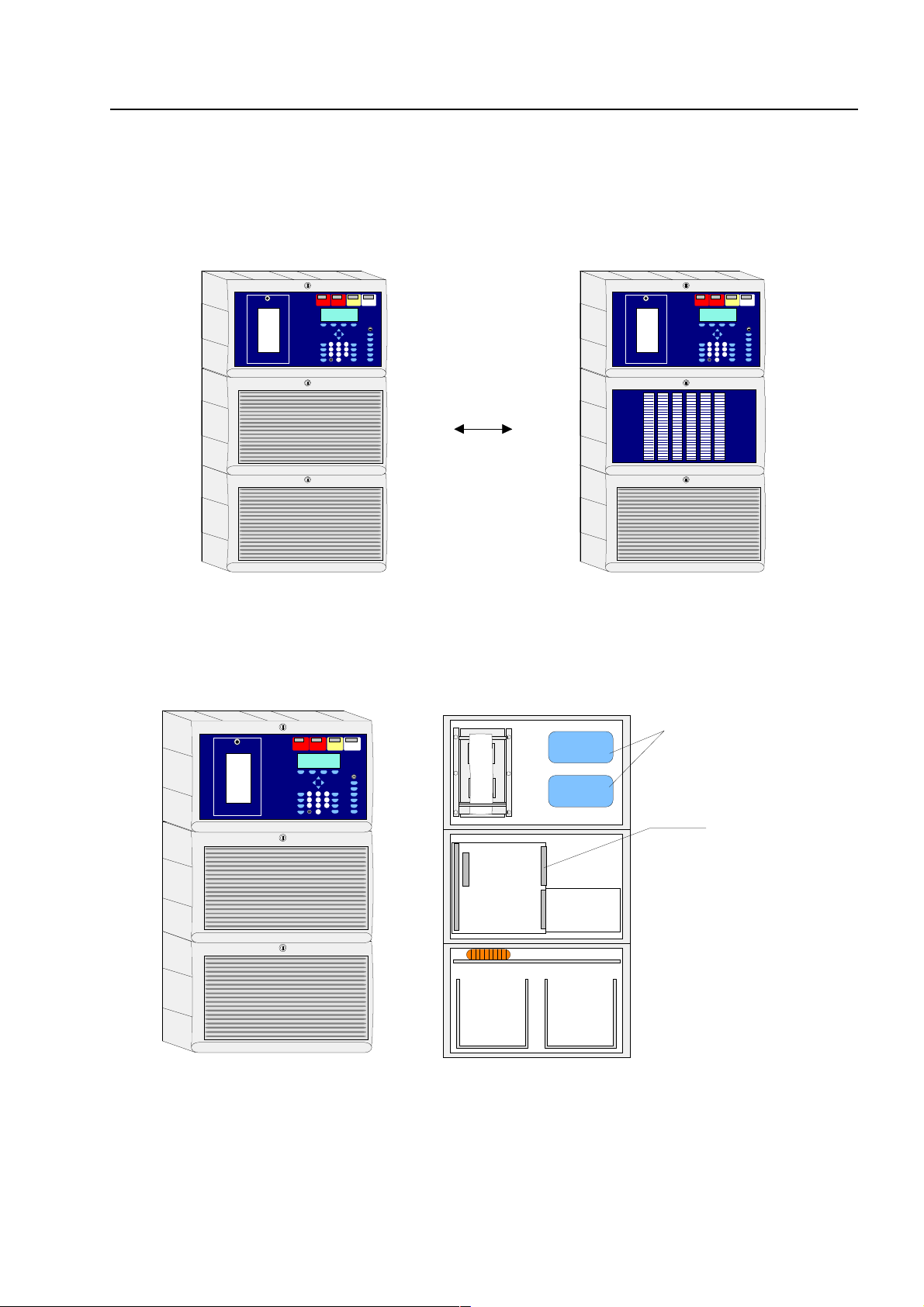

7.2 Configuration options FACP 8000C................................................................................................... 55

7.3 Configuration options FACP 8000 M..................................................................................................58

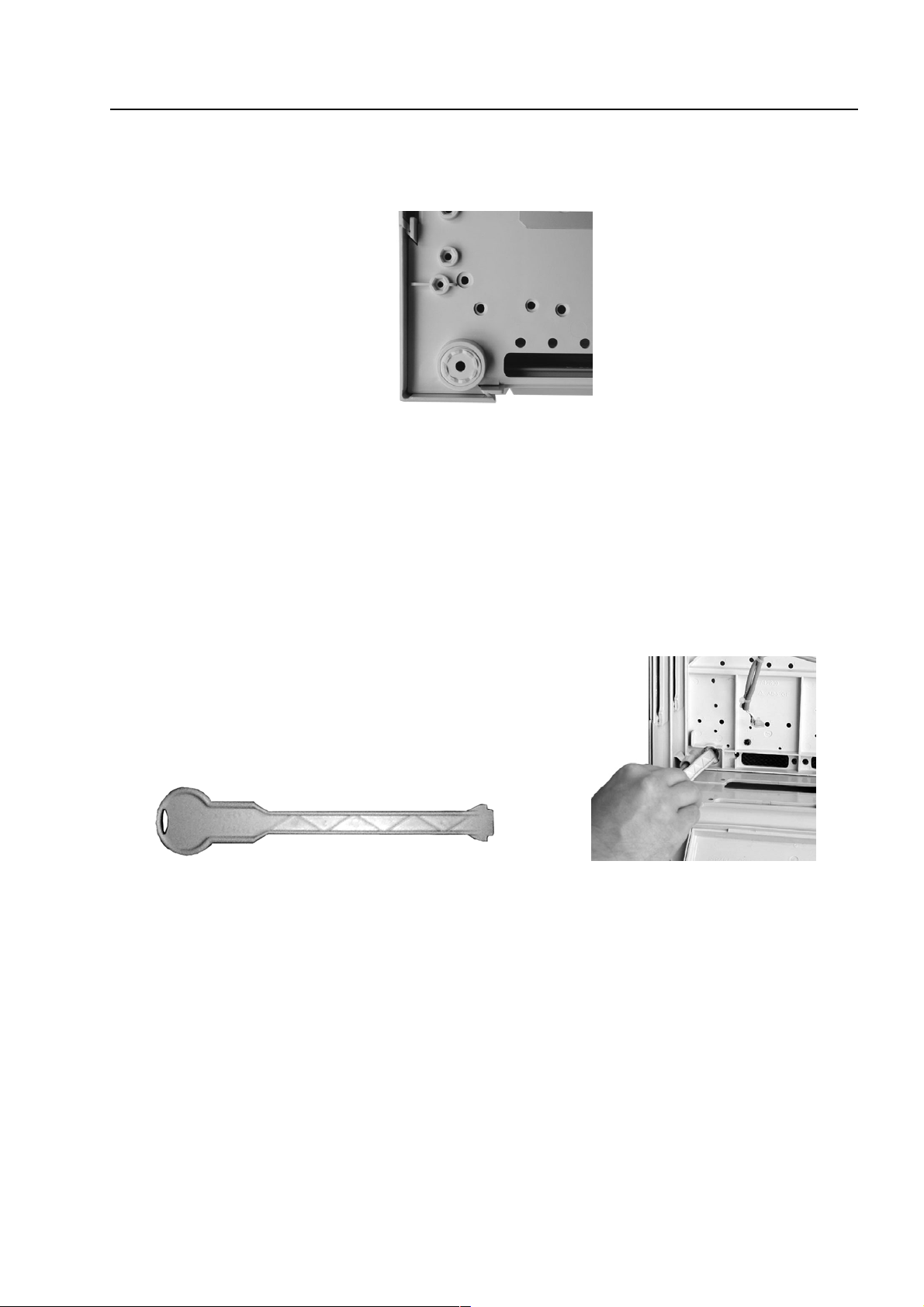

8 Assembly...............................................................................................................................................63

8.1 Wallmounting ......................................................................................................................................64

8.1.1 Connection between the central housing and the extension housing ..........................66

8.2 Central housing...................................................................................................................................67

8.3 Mounting the cabinet / Installation...................................................................................................... 69

8.4 Extension housing............................................................................................................................... 72

8.5 Extension housing for two rechargeable batteries (789300/01)........................................................74

8.6 Operating module / housing door.......................................................................................................75

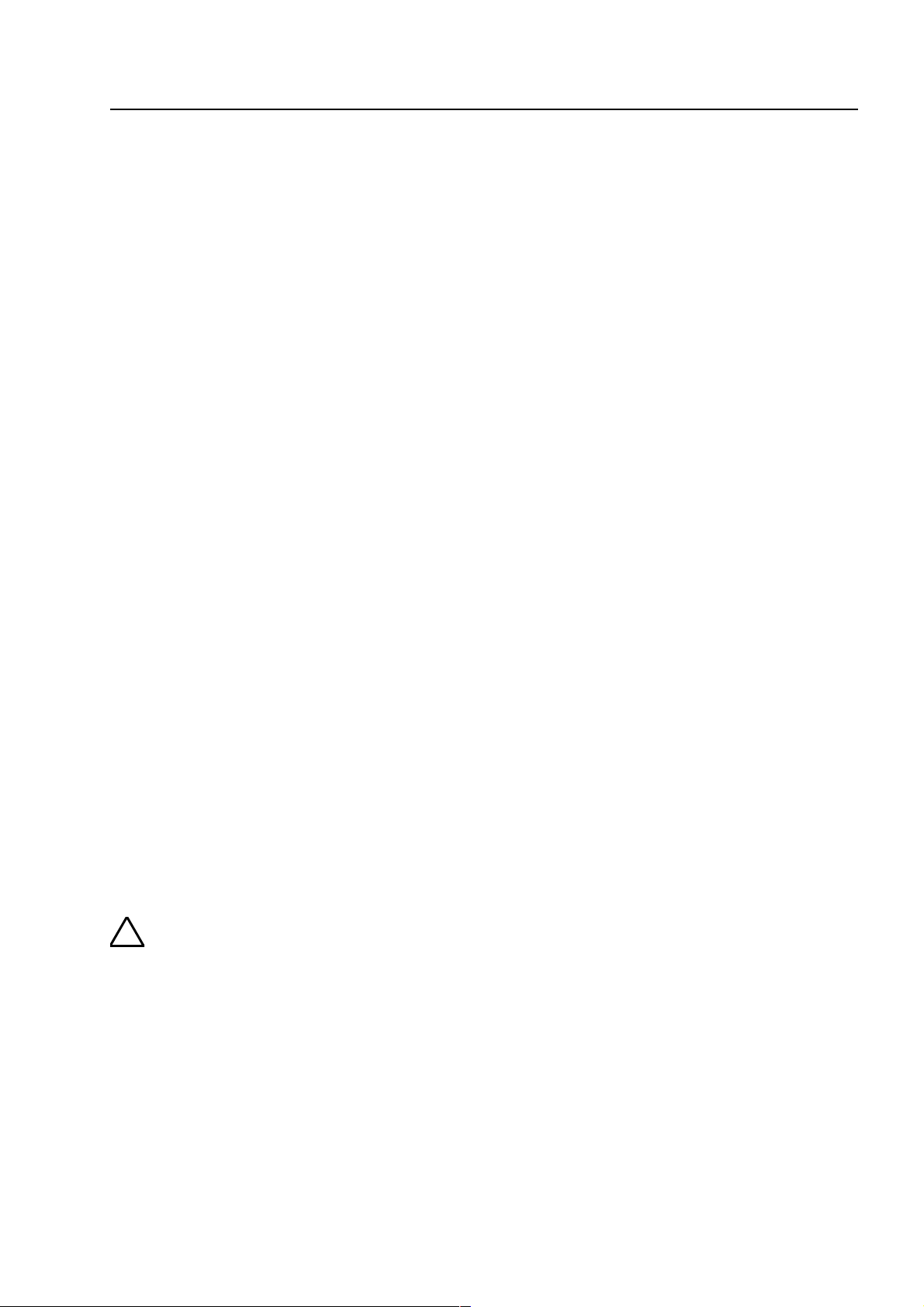

8.6.1 Opening and closing the housing door........................................................................ 75

8.7 Definition of the Primary loop number................................................................................................ 76

9 Power supply module (standard / esserbus

®

-Plus)............................................................................ 78

10 Basic module of the FACP 8000C / M................................................................................................. 82

10.1 Mains connection............................................................................................................................ 85

10.1.1Protective Earth - FACP 8000 C ................................................................................86

10.1.2Protective Earth - FACP 8000 M................................................................................ 87

10.2 Connecting the micro module......................................................................................................... 88

10.3 Serial interface.................................................................................................................................89

10.4 Common trouble relay ....................................................................................................................90

10.5 Inputs IN1 and IN2.......................................................................................................................... 90

10.6 Connection of the cover contacts...................................................................................................91

10.7 DIL switch S5 ..................................................................................................................................92

10.8 Reset-Function................................................................................................................................ 92

10.9 Connecting the built-in printer......................................................................................................... 93

11 Field device module..............................................................................................................................94

11.1 Connection of the micro module..................................................................................................... 97

11.2 Primary loop input Pri+/Pri-............................................................................................................. 97

11.3 Connecting a fire department operating panel............................................................................... 98

11.4 Connecting the master box (Relay K1).......................................................................................... 99

11.4.1Connecting the Relays K2, K3, K4........................................................................... 102

12 Extension module (Part no. 772419)................................................................................................. 104

13 Extension module (Part no. 772421)................................................................................................. 105

14 Configuration of the FACP 8000C / M with customer data editor.................................................106

15 Technical Data....................................................................................................................................107

Page 48

Fire Alarm Computer 8000C / M

Page 49

!

c

.

r

s

Installation Instruction

6 Installation Instructions

The terminal assignment and wiring illustrated in these installation instructions refer exclusively to the

facilities of the operating system software for the Federal Republic of Germany [D].

Operation of the f ire alarm control panel 8000C/M is governed by the national version of the operating

system software used and the country version programmed in the customer data.

6.1 Standards, guidelines and instructions for installation

S

The fire alarm panel may only be installed in a dry, clean room with controlled access and

appropriate lighting. T he environmental conditions must comply with IEC 721-3-3:1994, class

3k5.

S

The panel must be mounted on a flat surface using appropriate hardware (screws and dowels).

Avoid mechanical stressing. It may only be commissioned aft er correct mounting on a wall or

other mounting surface of sufficient streng t h t o support the weight of the unit.

S

Avoid strong electric or magnetic fields as well as mechanical influences. This applies

especially to the presence of fluorescent lighting or energy cabling in the close vicinity of the

panel, its components and the associated cabling. Do not mount on vibrating, unstable

surfaces such as light partitioning walls.

S

Do not install the system in places where adverse conditions prevail. Parts and components of

the system may only be installed in or led through locations which allow compliance with DIN

VDE 0800.

S

Connect the FE (functional earth) and PE (protective earth) terminals of the panel’s cabinet

with the PE rail of the power distributon panel from which the fire alarm system will be

powered.

S

Control panels and visual indicators mounted on a wall should be installed at a height of 800 to

1800 mm above the floor.

S

The fire alarm system is not suited for connection to IT power supply systems.

Danger – Electrical shock !

Remove all power from the panel before carrying out any installation work!

ESD protection

While handling electronic assemblies, the necessary precautions against electrostati

discharge must be taken.

Protective and functional earth

The PE conductor must be connected to the corr esponding terminal at the mains supply

Connect the FE terminal of the panel’s cabinet with the PE rail of the power distributo

panel from which the fire alarm system will be powered.

Fire Alarm Computer 8000C / M

Page 49

Page 50

I

nstallation Instructions

6.2 Standards and guidelines

The general technical rules must be observed when installing fire alarm systems. Any deviation

from those rules is only admissible if the same degree of safety can be ensured with different

means. Installations within the European Community are primarily subject to all EU regulations

defining the current standar ds for security systems.

In Germany, systems are considered to be in compliance with the general technical rules or the

standards of the EU f or security systems if they meet the technical guidelines of the VDE (Verband

Deutscher Elektrotechniker, Association of German Electrical Engineers). They may also be

considered to be in compliance with the standards of the EU f or security systems if they meet the

technical guidelines of another compar able institution within the European Community which have

been accepted in accordance with directive 73/23 EEC of the Council dd. 19 February 1973 –

directive on low-voltage systems- (ABL. EG No. L 77 page 29).

These are examples:

S

DIN VDE 0100 Installation of power systems with nominal voltages up to 1000 Volt

S

DIN VDE 0105 Operation of power installations

S

DIN VDE 0108 Installation and operation of power installat ions in com m unal facilities

S

DIN VDE 0185-103 Lightning protect ion systems

S

DIN VDE 0701 Repair, modificat ion and testing of electrical household appliances and similar

equipment

S

DIN VDE 0800 Telecommunications

S

DIN VDE 0815 Installation cables for communication and data processing systems

S

DIN VDE 0833 Hazard detection systems

S

DIN 14675 Fire alarm systems

S

DIN VDE 0845 Protection of telecommunication systems against lightning, electrostatic

discharges, and surge fr om electric power installations

These technical guidelines must be observed within the European Community. The VDE

guidelines must be observed within Germany. In other countries (e.g. U.S.A.: NFPA and UL

requirements), the r elevant national st andards, guidelines and legislation must be observed.

In addition to the above, the guidelines of the German VdS Schadenversicherer GmbH,

Association of German Property Insur er s ) m ay apply for system s inst alled in Germany.

These are e.g.:

S

VdS 2046 Safety rules for electrical power systems with voltages up to 1000 V

S