Page 1

www.espressif.com

ESP8266

Hardware Design Guidelines

Version 2.4

Espressif Systems

Copyright © 2018

Page 2

About This Guide

This document provides product information of ESP8266EX series, including ESP8266EX

chip, ESP-LAUNCHER development board and ESP8266EX modules.

Release Notes

Documentation Change Notification

Espressif provides email notifications to keep customers updated on changes to

technical documentation. Please subscribe at https://www.espressif.com/en/subscribe.

Certification

Download certificates for Espressif products from https://www.espressif.com/en/

certificates.!

Date

Version

Release Notes

2015.12

V1.3

Initial release.

2016.01

V1.4

Update Section 1.5.2, Section 1.5.3 and Section 1.6.

2016.06

V1.5

Update Section 3.1.

2016.07

V1.6

Update Section 2.1.

2017.01

V2.0

Updated the minimum voltage of ESP8266EX to 2.5V;

Updated Table 1-1.

2017.04

V2.1

Updated the chip’s output impedance from 50Ω to 39+j6 Ω;

Added a note that the size of ESP-LAUNCHER’s Flash1 and Flash2 is 32

Mbit;

Updated Section 1.4.5.

2017.06

V2.2

Updated Section 1.4.2.

2018.04

V2.3

Updated the name of the document from “ESP8266 System Description”

to “ESP8266 Hardware Design Guidelines”;

Updated all the figures in the document;

Updated Section 1.4 Schematic Checklist;

Updated Chapter 3 ESP8266EX Module.

2018.12

V2.4

Updated description in Section 1.4.2 about reset;

Updated formatting.

Page 3

Table of Contents

1. ESP8266EX 1 ............................................................................................................................

1.1. Overview! 1"....................................................................................................................................

1.2. Specifications! 2".............................................................................................................................

1.3. Pin Definitions! 3"............................................................................................................................

1.4. Schematic Checklist! 5"..................................................................................................................

1.4.1. Power Supply! 6"...............................................................................................................

1.4.2. Power-on Sequence and Power Reset! 8".........................................................................

1.4.3. Flash! 8".............................................................................................................................

1.4.4. Crystal Oscillator! 9"..........................................................................................................

1.4.5. RF! 10"...............................................................................................................................

1.4.6. External Resistor 12K! 10".................................................................................................

1.4.7. UART! 10"...........................................................................................................................

1.5. Slave SDIO/SPI! 11"........................................................................................................................

1.6. PCB Layout Design! 12"..................................................................................................................

1.6.1. General Principles of PCB Layout Design! 12"..................................................................

1.6.2. Positioning a ESP32 Module on a Base Board! 13"..........................................................

1.6.3. Standalone ESP8266EX Module! 14"................................................................................

1.6.4. ESP8266EX as a Slave Device! 17"...................................................................................

1.6.5. Typical Layout Problems and Solutions! 18"......................................................................

1.7. PCB Layout Design! 19"..................................................................................................................

1.7.1. UART to Wi-Fi Smart Device! 19"......................................................................................

1.7.2. Sensor! 19".........................................................................................................................

1.7.3. Smart Light! 20".................................................................................................................

1.7.4. Smart Plug! 20"..................................................................................................................

2. ESP-LAUNCHER 21 ..................................................................................................................

2.1. Overview! 21"..................................................................................................................................

2.2. Modules and Interfaces! 21"............................................................................................................

2.3. Schematics! 24"..............................................................................................................................

2.3.1. Interfaces! 24"....................................................................................................................

2.3.2. 5V Power Supply! 25"........................................................................................................

2.3.3. Test Module! 25"................................................................................................................

Page 4

2.4. Test Board! 26"................................................................................................................................

3. ESP8266EX Module 27 .............................................................................................................

3.1. ESP-WROOM-S2! 27".....................................................................................................................

3.2. ESP-WROOM-02! 27".....................................................................................................................

3.3. ESP-WROOM-02D/ESP-WROOM-02U! 28...................................................................................

Page 5

"

1. ESP8266EX

1. ESP8266EX

1.1. Overview

Espressif’s ESP8266EX delivers a highly integrated Wi-Fi SoC solution to meet the

continuous demand for efficient power usage, compact design and reliable performance in

the industry.

With its complete and self-contained Wi-Fi networking capabilities, ESP8266EX can

perform either as a standalone application, or as a slave to a host MCU. When ESP8266EX

hosts an application, it promptly boots up from the external flash. The integrated highspeed cache optimizes the system's performance and memory.

Also, ESP8266EX can be applied to any micro-controller design as a Wi-Fi adaptor through

SPI/SDIO or I2C/UART interfaces.

Besides the Wi-Fi functionalities, ESP8266EX also integrates an enhanced version of

Tensilica’s L106 Diamond series 32-bit processor and on-chip SRAM. It can be interfaced

with external sensors and other devices through the GPIOs, resulting in low development

cost at early stage and minimum footprint. Software Development Kit (SDK) provides

sample codes for various applications.

ESP8266EX integrates antenna switches, RF balun, power amplifier, low-noise receive

amplifier, filters and power management modules. The compact design minimizes the PCB

size and the external circuitry.

ESP8266EX enables sophisticated features, such as:

• Fast switching between sleep and wake-up modes for efficient energy use;

• Adaptive radio biasing for low-power operation;

•

Advanced signal processing;

• Spur cancellation;

• Radio co-existence mechanisms for common cellular, Bluetooth, DDR, LVDS, LCD

interference mitigation.

Figure 1-1 shows the functional blocks of ESP8266EX.

Espressif

" /301

2018.12

Page 6

"

1. ESP8266EX

"

Figure 1-1. ESP8266EX Block Diagram

1.2. Specifications

RF balun

Switch

RF

receive

RF

transmit

Analog

receive

Analog

transmit

PLL VCO 1/2 PLL

Digital baseband

MAC Interface

PMU Crystal Bias circuits SRAM PMU

SDIO

I2C

PWM

ADC

SPI

UART

GPIO

I2S

Flash

Registers

CPU

Sequencers

Accelerator

Table 1-1. ESP8266EX Specifications

Categories

Items

Parameters

Wi-Fi

Standard

FCC/CE/TELEC/SRRC

Protocols

802.11 b/g/n/e/i

Frequency Range

2.4G ~ 2.5G (2400M ~ 2483.5M)

Tx power

802.11 b: +20 dBm

802.11 g: +17 dBm

802.11 n: +14 dBm

Rx Sensitivity

802.11 b: -91 dBm (11 Mbps)

802.11 g: -75 dBm (54 Mbps)

802.11 n: -72 dBm (MCS7)

Antenna

on-board, external, IPEX connector, ceramic chip

Hardware

Peripheral interface

UART/SDIO/SPI/I2C/I2S/IR Remote Control

GPIO/PWM

Operating voltage

2.5V ~ 3.6V

Operating current

Average: 80 mA

Operating temperature range

-40℃ ~ 125℃

Storage temperature range

-40℃ ~ 125℃

Espressif

" /302

2018.12

Page 7

"

1. ESP8266EX

1.3. Pin Definitions

The pin layout for the 32-pin QFN package is illustrated in Figure 1-2.

"

Figure 1-2. ESP8266EX Pin Layout

Table 1-2 lists the definitions and functions of each pin.!

Package size

QFN32-pin (5 mm x 5 mm)

External interface

N/A

Software

Wi-Fi mode

Station/SoftAP/SoftAP+Station

Security

WPA/WPA2

Encryption

WEP/TKIP/AES

Firmware upgrade

UART Download/OTA (via network)

Software development

SDK for customized development/cloud server

development

Network Protocols

IPv4, TCP/UDP/HTTP/FTP

User configuration

AT Instruction Set, Cloud Server, Android/ iOS app

Categories

Items

Parameters

Espressif

" /303

2018.12

Page 8

"

1. ESP8266EX

Table 1-2. ESP8266EX Pin Definitions

Pin

Name

Type

Function

1

VDDA

P

Analog Power 2.5V ~ 3.6V

2

LNA

I/O

RF antenna interface

Chip output impedance=39+j6 Ω. It is suggested that users retain

the π-type matching network which matches the antenna.

3

VDD3P3

P

Amplifier Power 2.5V ~ 3.6V

4

VDD3P3

P

Amplifier Power 2.5V ~ 3.6V

5

VDD_RTC

P

NC (1.1V)

6

TOUT

I

ADC pin. It can be used to test the power-supply voltage of

VDD3P3 (Pin3 and Pin4) and the input power voltage of TOUT (Pin

6). However, these two functions cannot be used simultaneously.

7

CHIP_EN

I

Chip Enable

High: On, chip works properly

Low: Off, small current consumed

8

XPD_DCDC

I/O

Deep-sleep wakeup (need to be connected to EXT_RSTB);

GPIO16

9

MTMS

I/O

GPIO 14; HSPI_CLK

10

MTDI

I/O

GPIO 12; HSPI_MISO

11

VDDPST

P

Digital/IO Power Supply (1.8V ~ 3.3V)

12

MTCK

I/O

GPIO 13; HSPI_MOSI; UART0_CTS

13

MTDO

I/O

GPIO 15; HSPI_CS; UART0_RTS

14

GPIO2

I/O

UART Tx during flash programming; GPIO2

15

GPIO0

I/O

GPIO0; SPI_CS2

16

GPIO4

I/O

GPIO 4

17

VDDPST

P

Digital/IO Power Supply (1.8V ~ 3.3V)

18

SDIO_DATA_2

I/O

Connects to SD_D2 (Series R: 200Ω); SPIHD; HSPIHD; GPIO 9

19

SDIO_DATA_3

I/O

Connects to SD_D3 (Series R: 200Ω); SPIWP; HSPIWP; GPIO 10

20

SDIO_CMD

I/O

Connects to SD_CMD (Series R: 200Ω); SPI_CS0; GPIO 11

21

SDIO_CLK

I/O

Connects to SD_CLK (Series R: 200Ω); SPI_CLK; GPIO 6

22

SDIO_DATA_0

I/O

Connects to SD_D0 (Series R: 200Ω); SPI_MSIO; GPIO 7

23

SDIO_DATA_1

I/O

Connects to SD_D1 (Series R: 200Ω); SPI_MOSI; GPIO 8

Espressif

" /304

2018.12

Page 9

"

1. ESP8266EX

1.4. Schematic Checklist

The highly-integrated design of ESP8266EX reduces the number of components required.

Besides ESP8266EX, less than 10 resistors and capacitors, one crystal oscillator and one

SPI flash are needed to make a complete module with wireless communication capability.

The following is a detailed description of ESP8266EX schematics, and the layout design

which ensures optimum functionality.

The complete circuit diagram of ESP8266EX is illustrated in Figure 1-3.!

24

GPIO5

I/O

GPIO 5

25

U0RXD

I/O

UART Rx during flash programming; GPIO 3

26

U0TXD

I/O

UART Tx during flash progamming; GPIO 1; SPI_CS1

27

XTAL_OUT

I/O

Connects to crystal oscillator output, can be used to provide BT

clock input

28

XTAL_IN

I/O

Connects to crystal oscillator input

29

VDDD

P

Analog Power 2.5V ~ 3.6V

30

VDDA

P

Analog Power 2.5V ~ 3.6V

31

RES12K

I

Serial connection with a 12 kΩ resistor and connect to the ground

32

EXT_RSTB

I

External reset signal (Low voltage level: Active)

Pin

Name

Type

Function

📖 Note:

GPIO2, GPIO0, and MTDO are configurable on PCB as the 3-bit strapping register that determines the

booting mode and the SDIO timing mode.

Espressif

" /305

2018.12

Page 10

"

1. ESP8266EX

"

Figure 1-3. ESP8266EX Schematics

The ESP8266EX schematics include seven aspects:

• Power supply

• Power-on sequence and reset

•

Flash

• Crystal oscillator

• RF

• External resistor

•

UART

1.4.1. Power Supply

1.4.1.1. Digital Power Supply

ESP8266EX has two digital pins for power supply, Pin11 and Pin17. For digital power

supply, there is no need to add additional filter capacitors. The operating voltage range of

digital power supply pins is 1.8V ~ 3.3V.!

GPIO15

RST

SDI/SD1

SDO/SD0

SCK/CLK

SCS/CMD

SWP/SD3

SCK/CLK

SCS/CMD

SHD/SD2

UTXDA

WIFI_ANT

GPIO14

GPIO12

URXD

GPIO13

GPIO16

GPIO0

CH_PU

GPIO2

GPIO4

GPIO5

TOUT

SWP/SD3

SDO/SD0

SDI/SD1

UTXD

SHD/SD2

GND

GND

VDD33

GND

GNDGND

GND

VDD33

GND

VDD33

GND

GND

GND

GND

VDD33

GND

GND

GND

ANT1

1

2

R1

12K±1%

C7

TBD(NC)

C1

6.8pF

C3

0.1uF

L3 4.3nH

C8

1uF(NC)

U3FLASH

/CS

1

DO

2

/WP

3

GND

4

DI

5

CLK

6

/HOLD

7

VCC

8

L1

2.4pF

R3 200R

C4

2.2nH

L2

3.0pF

C6

1uF

U1

26MHz±10ppm

XIN1GND

2

XOUT

3

GND

4

U2ESP8266EX

VDDA

1

LNA

2

VDD3P3

3

VDD3P3

4

VDD_RTC

5

TOUT

6

CHIP_EN

7

XPD_DCDC

8

MTMS9MTDI10VDDPST11MTCK12MTDO13GPIO214GPIO015GPIO4

16

VDDPST

17

SD_DATA_2

18

SD_DATA_3

19

SD_CMD

20

SD_CLK

21

SD_DATA_0

22

SD_DATA_1

23

GPIO5

24

U0RXD

25

U0TXD

26

XTAL_OUT

27

XTAL_IN

28

VDDD

29

VDDA

30

RES12K

31

EXT_RSTB

32

GND

33

C5

10uF

R2 499R

C2

6.8pF

Espressif

" /306

2018.12

Page 11

"

1. ESP8266EX

"

Figure 1-4. ESP8266EX Digital Power Supply Pins

1.4.1.2. Analog Power Supply

ESP8266EX has five analog pins for power supply, including Pin1, Pin3, Pin4 that are the

power supply for internal PA and LNA; and Pin29, Pin30 for the internal PLL. The operating

voltage for analog power supply pins is 2.5V ~ 3.6V.

Note that the power supply channel might be damaged due to the sudden increase of

current when ESP8266EX is transmitting analog signals. Therefore, an additional 10 μF

capacitor with a 0603 or 0805 package is needed to match the 0.1 μF capacitor.

"

Figure 1-5. ESP8266EX AVDD

VDD33

U2ESP8266EX

CHIP_EN

XPD_DCDC

MTMS9MTDI10VDDPST11MTCK12MTDO13GPIO214GPIO015GPIO4

16

VDDPST

17

SD_DATA_2

WIFI_ANT

GND

VDD33

GND

GND

GND

VDD33

GND

GND

GND

ANT1

1

2

R1

12K±1%

C7

TBD(NC)

L3 4.3nH

C3

0.1uF

10pF

C8

1uF(NC)

C4

2.2nH

C6

1uF

C5

10uF

VDDA

1

LNA

2

VDD3P3

3

VDD3P3

4

XTAL_IN

28

VDDD

29

VDDA

30

RES12K

31

EXT_RSTB

32

GND

33

📖 Note:

•

ESP8266EX’s EMC is in conformity with FCC and CE requirements. There is no need to add ferrite

beads in the analog power-supply circuit.

•

When using a single power supply, the recommended output current is 500 mA.

• It is suggested that users add an ESD tube at the power entrance.

Espressif

" /307

2018.12

Page 12

"

1. ESP8266EX

1.4.2. Power-on Sequence and Power Reset

1.4.2.1. Power-on Sequence

ESP8266EX uses a 3.3V system power supply. The chip should be activated after the

power rails have stabilized. This is achieved by delaying the activation of CH_EN (Pin7) by

time T after the 3.3V rails have been brought up. The recommended delay time (T) is given

by the parameter of the RC circuit. For reference design, please refer to Figure ESPWROOM-02 Peripheral Schematics in the ESP-WROOM-02 Datasheet.

1.4.2.2. Reset

Pin32 EXT_RSTB serves as the reset pin of ESP8266EX. This pin contains an internal pullup resistor and is active low. To avoid resets caused by external interference, we

recommend that you keep the PCB trace of EXT_RSTB as short as possible, and add an

RC circuit at the EXT_RSTB pin.

Pin7 CHIP_EN serves as the enable pin of ESP8266EX. In this case, ESP8266EX powers

off when this pin is held low. Pin7 CHIP_EN also serves as the reset pin of ESP8266EX. In

this case, ESP8266EX reboots when the input level of this pin is below 0.6 V and lasts for

at least 200 μs.

We recommend that you use CHIP_EN, instead of EXT_RSTB, to reset the chip.

1.4.3. Flash

The demo flash used on ESP8266EX is an SPI Flash with 2-MB ROM in an SOP8 (208 mil)

package. Pin21 SD_CLK is connected to the flash CLK pin together with a 0402 resistor in

serial connection, which reduces the drive current and eliminates external interruption. The

initial resistance of the resistor is 200Ω.!

⚠ Notice:

If CHIP_EN is driven by a power management chip, then the power management chip controls the

ESP8266EX power state. When the power management chip turns on/off Wi-Fi through the high/low level on

GPIO, a pulse current may be generated. To avoid level instability on CHIP_EN, an RC delay (R=10 kΩ,

C=100 nF) circuit is required.

⚠ Notice:

CHIP_EN cannot be left floating.

Espressif

" /308

2018.12

Page 13

"

1. ESP8266EX

"

Figure 1-6. ESP8266EX Flash

1.4.4. Crystal Oscillator

ESP8266EX can support 40 MHz, 26 MHz and 24 MHz crystal oscillators. The accuracy of

crystal oscillators should be ± 10 PPM, and the operating temperature range should be

between -20°C and 85°C.

Please select the right type of crystal oscillator that is used in the ESP Flash Download Tool.

In circuit design, capacitors C1 and C2, which are connected to the ground are added to

the input and output terminals of the crystal oscillator respectively. The values of the two

capacitors can be flexible, ranging from 6 pF to 22 pF. However, the specific capacitive

values of C1 and C2 depend on further testing of and adjustment to the overall

performance of the whole circuit. The crystal precision should be ±10 PPM.

"

Figure 1-7. ESP8266EX Crystal Oscillator

SDI/SD1

SDO/SD0

SCK/CLK

SCS/CMD

SWP/SD3

SCK/CLK

SCS/CMD

SHD/SD2

GPIO5

SWP/SD3

SDO/SD0

SDI/SD1

SHD/SD2

GND

VDD33

U3FLASH

/CS

1

DO

2

/WP

3

GND

4

DI

5

CLK

6

/HOLD

7

VCC

8

R3 200R

U2

VDDPST

17

SD_DATA_2

18

SD_DATA_3

19

SD_CMD

20

SD_CLK

21

SD_DATA_0

22

SD_DATA_1

23

GPIO5

24

UTXDA

GNDGND

GND

C2

C1

U1

26MHz±10ppm

XIN

1

GND2XOUT

3

GND

4

U0RXD

25

U0TXD

26

XTAL_OUT

27

XTAL_IN

28

VDDD

29

⚠ Notice:

Defects in the craftsmanship of the crystal oscillators (for example, high frequency deviation and unstable

working temperature) may lead to the malfunction of ESP8266EX, resulting in the decrease of overall

performance.

Espressif

" /309

2018.12

Page 14

"

1. ESP8266EX

1.4.5. RF

The impedance of the ESP8266 PA output end is (39+j6)Ω, so the matched impedance is

(39-j6)Ω (from antenna to the chip).

"

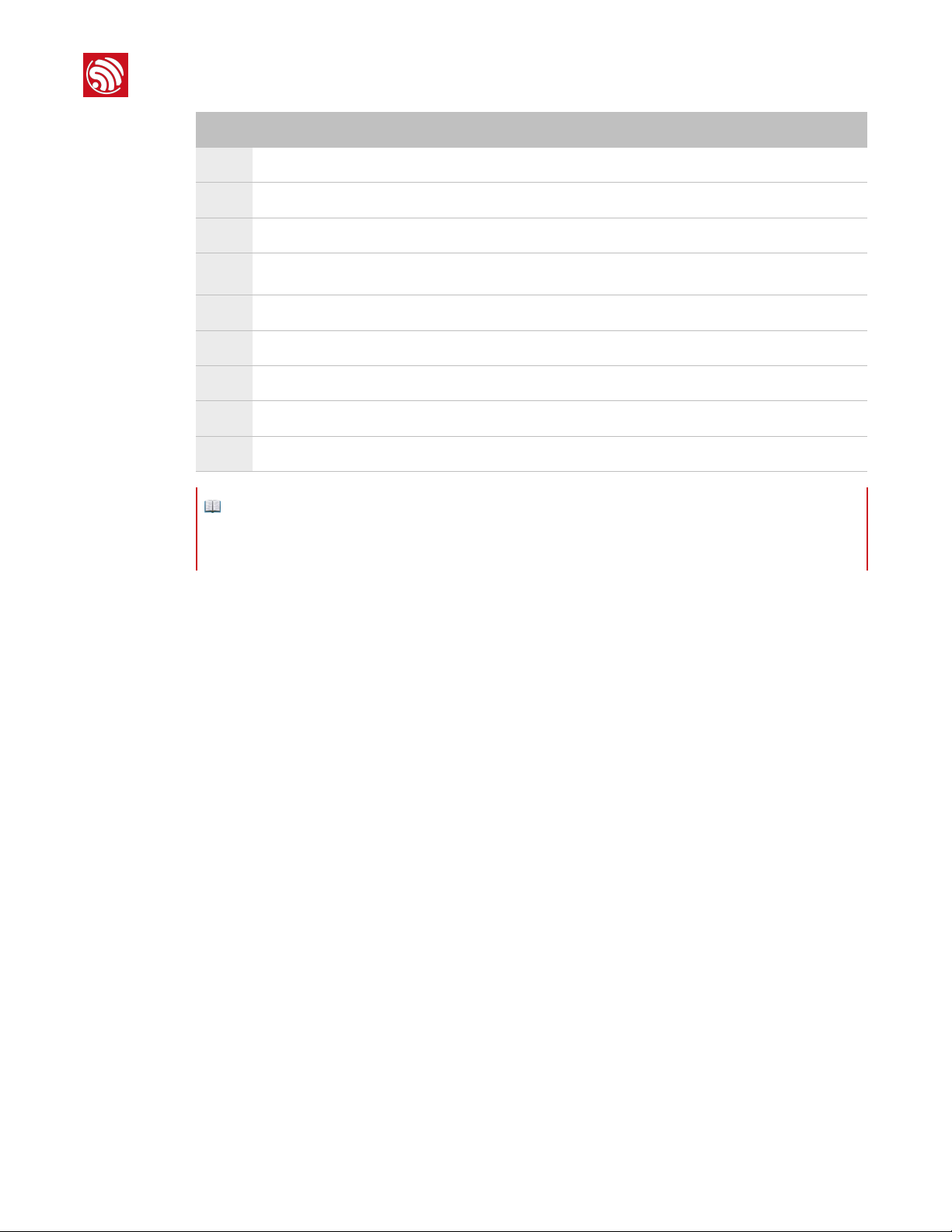

Figure 1-8. ESP8266EX RF

1.4.6. External Resistor 12K

An external ground resistor should be connected o the ERS12K pin (Pin31). The ground

resistor requires high accuracy when controlling the bias current. An accuracy of 12K ± 1%

is recommended.

"

Figure 1-9. ESP8266EX External Resistor

1.4.7. UART

Users need to connect a 499Ω resistor to the U0TXD line in order to suppress the 80 MHz

harmonics.

"

Figure 1-10. ESP8266EX UART

WIFI_ANT

GNDGND

GND

ANT1

1

2

L1

2.4pF

C4

2.2nH

L2

3.0pF

VDDA

1

LNA

2

VDD3P3

3

VDD3P3

4

VDD_RTC

5

TOUT

6

CHIP_EN

7

XPD_DCDC

8

GND

R1

12K±1%

30

RES12K

31

EXT_RSTB

32

UTXDA

URXD

UTXD

U0RXD

25

U0TXD

26

R2 499R

Espressif

" /3010

2018.12

Page 15

"

1. ESP8266EX

1.5. Slave SDIO/SPI

!

Figure 1-11. Schematics of ESP8266EX as a Slave SDIO!

MTDO

SD3/CS

SD2

RXD0

MTCK

GPIO16

GPIO0

CHIP_PU

GPIO2

GPIO4

GPIO5

MTDO

MTMS

MTMS

MTDI

MTCK

MTDI

CMD/MOSI

CLK

SD0/MISO

SD1/INT

TXD0

SD1/INT

SD0/MISO

CMD/MOSI

SD3/CS

SD2

GND

GND

VDD33

GND

GND

GND

GND

GND

GND

GND

GND

VDD33

GND

VDD33

GND

GND

VDD33

GND

GND GND

GND

GND

VDD33

VDD33

Optional

C4

1uF(NC)

J1

Jumper

1

2

C2

6.8pF

ANT1

1

2

R1

12K±1%

R13 100R

C1

6.8pF

C6

0.1uF

C8 10pF

R12 100R

R6

10K

C9

2.4pF

R3 10K

R7

10K

R14 50R

C7

TBD(NC)

R5 499R

C5

10uF

R10 100R

R11

10K

U1

26MHz±10ppm

XIN

1

GND2XOUT

3

GND

4

R16

10K

R15

10K

R8 100R

U3FLASH

/CS

1

DO

2

/WP

3

GND

4

DI

5

CLK

6

/HOLD

7

VCC

8

U2ESP8266EX

VDDA1LNA2VDD3P33VDD3P34VDD_RTC5TOUT6CHIP_EN7XPD_DCDC

8

MTMS

9

MTDI

10

VDDPST

11

MTCK

12

MTDO

13

GPIO2

14

GPIO0

15

GPIO4

16

VDDPST

17

SD_DATA_218SD_DATA_3

19

SD_CMD

20

SD_CLK

21

SD_DATA_022SD_DATA_1

23

GPIO5

24

U0RXD

25

U0TXD

26

XTAL_OUT

27

XTAL_IN

28

VDDD

29

VDDA

30

RES12K

31

EXT_RSTB

32

GND

33

C3

1uF

L2

1.6nH

C10

0.1uF

R4 10K

R2 10K

R9

10K

L1 4.3nH

Espressif

" /3011

2018.12

Page 16

"

1. ESP8266EX

1.6. PCB Layout Design

The chapter introduces the ESP8266EX PCB layout design by using the ESP8266EX as an

example. The PCB layout design guidelines are applicable to cases when

• the ESP8266EX module functions as a standalone device, and when

• the ESP8266EX functions as a salve device.

"

Figure 1-12. ESP8266EX PCB Layout

1.6.1. General Principles of PCB Layout Design

The PCB has four layers:

• The first layer is the TOP layer for signal lines and components.

•

The second layer is the GND layer, where no signal lines are laid to ensure a complete

GND plane.

📖 Note:

•

Please refer to the design of ESP-WROOM-S2 for further details.

•

UART Download Mode: Jumper J1 short circuit.

•

SDIO Boot Mode: Jumper J1 open circuit.

• If the external host CPU's SDIO or SPI interface has been pulled up, the optional pull-up resistor can

be omitted.

Espressif

" /3012

2018.12

Page 17

"

1. ESP8266EX

• The third layer is the POWER layer where only power lines can be placed. It is

acceptable to place some signal lines under unavoidable circumstances.

• The forth layer is the BOTTOM layer. Only signal lines can be laid. Placing

components on this layer is not recommended.

Below are the suggestions for a two-layer PCB design.

•

The first layer is the TOP layer for signal traces and components.

• The second layer is the BOTTOM layer, where power traces are routed. Placing any

components on this layer is not recommended. Do not route any power or signal

traces under or around the RF and crystal oscillator, and so that there is a complete

GND plane, which is connected to the Ground Pad at the bottom of the chip.

1.6.2. Positioning a ESP32 Module on a Base Board

If users adopt on-board design, they should pay attention to the layout of the module on

the base board. The interference of the base board on the module's antenna performance

should be reduced as much as possible.

It is recommended that the PCB antenna area of the module be placed outside the base

board while the module be put as close as possible to the edge of the base board so that

the feed point of the antenna is closest to the board.

"

Figure 1-13. ESP32 Module Antenna Position on Base Board!

Base Board

1 2 3

4

5

Espressif

" /3013

2018.12

Page 18

"

1. ESP8266EX

If the positions recommended are not suitable, please make sure that the module is not

covered by any metal shell. The antenna area of the module and the area 15 mm outside

the antenna should be kept clean, (namely no copper, routing, components on it) as shown

in Figure 1-14:

"

Figure 1-14. Keepout Zone for ESP8266 Module's Antenna on the Base Board

1.6.3. Standalone ESP8266EX Module

1.6.3.1. Power Supply Design

The 3.3V power lines are highlighted in yellow in Figure 1-15. The width of the power lines

should be greater than 15 mil.

Before power traces reach the analog power-supply pins (Pin1、3、4、28、29), a 10 μF

capacitor is required, which can work in conjunction with the 0.1 μF capacitor. A C circuit

and an L circuit should be added to the power supplies of Pin3 and Pin4. As Figure 1-15

shows, C5 (10 μF capacitor) is placed by the 3.3V stamp hole; C7, L3 and C7 are placed

as close as possible to the analog power-supply pin. Note that all decoupling capacitors

should be placed close to the power pin, and ground vias should be added adjacent to the

ground pin for the decoupling capacitors to ensure a short return path.

Power lines should be placed on the third layer. When the power lines reach the pins of the

chipset, vias are needed so that the power lines can go through the layers and connect to

the pins of the chipset on the TOP layer. The diameter of the via holes should exceed the

📖 Note:

As is shown in Figure 1-13, the recommended position of ESP32 module on the base board should be:

•

Position 3: Highly recommended;

•

Position 4: Recommended;

• Position 1, 2, 5: Not recommended.

15 mm

Base Board

15 mm

Clearance

15 mm

Espressif

" /3014

2018.12

Page 19

"

1. ESP8266EX

width of the power lines and the diameter of the drill should be 1.5 times that of the radius

of the vias.

The center ground pad at the bottom of the chip should be connected to ground plane

through at least 9 ground vias.

"

Figure 1-15. ESP8266EX PCB Layout

1.6.3.2. Crystal Oscillator Design

The crystal oscillator should be placed as close to the XTAL pins as possible (without the

traces being too long). However, the crystal cannot be placed too close to the chip to

prevent the crystal from interfering with the chip, as Figure 1-15 shows. The recommended

distance is 0.8 mm (see Figure 1-16). However, the crystal cannot be too close to the chip

to prevent the crystal from interfering with the chip. The recommended distance is 0.8mm

(see Figure 1-16). It is good practice to use via stitching around the clock trace for low

ground-plane impedance.

There should be no vias on the input and output traces, which means the traces cannot

cross layers. In addition, the input and output traces should not be routed over one

another, not even on different layers.

Place the input and output bypass capacitors on the near left or right side of the chip. Do

not place them on the traces.

Do not route high-frequency digital signal lines under the crystal oscillator. It is best not to

route any signal line under the crystal oscillator. The larger the copper area on the top layer

is, the better. As the crystal oscillator is a sensitive component, do not place any magnetic

components nearby that may cause interference, for example, power-switching converter

components or unshielded inductors.

Espressif

" /3015

2018.12

Page 20

"

1. ESP8266EX

"

Figure 1-16. ESP8266EX Crystal Oscillators

1.6.3.3. RF Design

The characteristic RF impedance is 50Ω. The ground plane should be complete. The RF

trace should be as short as possible with dense ground via stitching around it for isolation.

The width of RF lines should be as short as possible and there should be dense vias

stitched around.

π-type matching circuitry should be reserved on the RF trace and placed close to the RF

Pin2. The components of the π-matching network should be placed in the same direction

(see Figure 1-17).

There should be no vias for the RF trace. The RF trace should be routed at a 135° angle, or

with circular arcs if trace bends are required.

There should be no RF routing around the high-frequency signal lines.

The RF antenna should be set away from high-frequency transmitting devices, such as

crystal oscillators, DDR, and certain high frequency clocks (SDIO_CLK, etc.). Besides, the

USB ports, USB-to-UART signal chips, UART signal lines (including traces, vias, test points,

headers, etc.) must be placed as far away from the antenna as possible. The UART signal

line is packaged and ground shielding is added.

For PCB onboard antenna design please refer to Type-A version by Espressif. If there are

power traces near the antenna, the power traces and antenna must be isolated with GND

copper.

Espressif

" /3016

2018.12

Page 21

"

1. ESP8266EX

"

Figure 1-17. ESP8266EX RF Design

1.6.4. ESP8266EX as a Slave Device

When ESP8266EX works as a slave device in a system, users need to pay more attention

to signal integrity in the PCB design. It is important to keep ESP38266EX away from the

interferences caused by the complexity of the system and an increased number of highfrequency signals. We use the mainboard of a PAD or TV Box as an example here to

provide guidelines for the PCB layout and design.

"

Figure 1-14. PCB/TV Box Layout

The digital signal between the CPU and the DDR is the major producer of high-frequency

noise and interferes with Wi-Fi radio from the air. Below are the key points when designing

the PCB layout:

•

As shown in Figure 1-14, ESP8266EX should be placed near the edge of the PCB

and away from the CPU and DDR, the main high-frequency noise sources. The

Espressif

" /3017

2018.12

Page 22

"

1. ESP8266EX

distance between the chip and the noise sources decreases the interference and

reduces the coupled noise.

• It is suggested that a 100Ω~200Ω series resistor is added to the six signal traces

when ESP8266EX communicates with the CPU via SDIO to decrease the drive

current and any interferences, and also to eliminate the sequencing problem caused

by the inconsistent length of the SDIO traces.

• On-board PCB antenna is not recommended, as it receives much interference and

coupling noise, both of which impact the RF performance. We suggest that you use

an external antenna which should be directed away from the PCB board via a cable,

in order to weaken the high frequency interference with Wi-Fi.

• The high-frequency signal traces between the CPU and associated memory should

be routed strictly ac- cording to the routing guidelines (please refer to the DDR trace

routing guidelines). CLK and data/addr lines should be laid underground.

• The GND of the Wi-Fi circuit and that of other high-power devices should be

separated and connected through wires if there are high-power components, such as

motors, in the design.

•

The antenna should be kept away from high-frequency noise sources, such as LCD,

HDMI, Camera Sensor, USB, etc.

1.6.5. Typical Layout Problems and Solutions

•

Q: The current ripple is not large, but the Tx performance of RF is rather poor.

Analysis:

Ripple has a strong impact on the performance of RF Tx. It should be noted that ripple

must be tested when ESP8266EX is in the normal working mode. The ripple increases

when the power gets high. Generally, the ripple should be <80 mV when sending 11n

MCS7 packets, and <120 mV when sending 11b packets.

Solution:

Add a 10-μF filter capacitor to the branch of source circuit (ESP8266EX AVDD pin). The 10-

μF capacitor should be adjacent to the VDDA pin.

• Q: The power ripple is small, but the Tx performance is poor.

Analysis:

The RF Tx performance can be affected not only by power ripples, but also by the crystal

oscillator itself. Poor quality and big frequency offsets (more than ±40 ppm) of the crystal

oscillator decrease the RF Tx performance. The crystal oscillator clock may be corrupted

by other interfering signals, such as high-speed output or input signals. Besides, sensitive

components or radiation components, such as inductors and antennas, may also decrease

the RF performance.

Solution:

Espressif

" /3018

2018.12

Page 23

"

1. ESP8266EX

This problem is caused by improper layout and can be solved by re-layout. See Section 1.5

for details.

• Q: When ESP8266EX sends data packages, the power value is much higher or

lower than the target power value, and the EVM is relatively poor.

Analysis:

The disparity between the tested value and the target value may be due to signal reflection

caused by the impedance mismatch on the transmission line connecting the RF pin and the

antenna.

Solution:

Match the antenna’s impedance with the reserved π-type circuit on the RF trace, so that

the resistance from the RF pin to the antenna approaches (39-j6)Ω.

• Q: TX performance is not bad, but the Rx sensitivity is low.

Analysis:

Good Tx performance indicates proper RF impedance matching. External coupling to the

antenna can affect the Rx performance. For instance, the crystal oscillator signal harmonics

could couple to the antenna. If ESP8266EX serves as slave device, there will be other high-

frequency interference sources on the board, which may affect the Rx performance.

Solution:

Keep the antenna away from crystal oscillators. Do not route high-frequency signal traces

close to the RF trace.

1.7. PCB Layout Design

1.7.1. UART to Wi-Fi Smart Device

The two UART interfaces are defined in Table 1-3.

AT instruction and examples are provided here: http://www.espressif.com/en/support/

download/documents?keys=&field_type_tid%5B%5D=14

Application example: ESP8266EX development board (please see Chapter 2).

1.7.2. Sensor

ESP8266EX can be used for developing sensor products by using the I2C interface. The

Table 1-3. Pin definitions of UART Interfaces

Category

Pin definition

Function

UART0

(Pin 25) U0RXD+ (Pin 26) U0TXD

Receive and transmit user’s data packages.

UART1

(Pin 14) GPIO2 (U1TXD)

Print information.

Espressif

" /3019

2018.12

Page 24

"

1. ESP8266EX

I2C works in the master mode and can connect to multiple sensors. The slave devices are

identified through the addressing mode, as each slave device has a unique address.

The sensor products send real-time data to ESP8266EX via the I2C interface, and

ESP8266EX uploads the data to the server wirelessly. Users can acquire information from

the server through the mobile app when their mobile phones connect to the internet.

1.7.3. Smart Light

ESP8266EX can be used for developing such smart home products as smart light by using

the PWM and infrared interfaces. The three PWM interfaces control red, blue, and green

LEDs respectively. The minimal PWM duty ratio is 1/214. In addition, the infrared interface

allows specific control on LEDs, such as reset, power on/off, color switch, etc.

1.7.4. Smart Plug

ESP8266EX can be used for developing smart plug products. The GPIOs control the power

switch through the high/low-level switch and connection/disconnection of relay. A smart

plug requires three modules: 220V to 3.3V power conversion module, ESP8266EX Wi-Fi

module and relay control module.!

Espressif

" /3020

2018.12

Page 25

"

2. ESP-LAUNCHER

2. ESP-LAUNCHER

2.1. Overview

Espressif provides ESP8266EX development board—ESP-LAUNCHER for quick

configuration and further development. The size of the board is 46 mm x 78.5 mm (see

Figure 2-1).

"

Figure 2-1. ESP-LAUNCHER

2.2. Modules and Interfaces

ESP-LAUNCHER can be configured through USB serial or Wi-Fi connection. The modules/

interfaces integrated on the development board are described in Table 2-1 and 2-2.

7

2

17

11

4

4

1

1 1

1

MISO

MOSI

CS

IO 14

IO 12

IO 13

IO 15

Pin 9

Pin 10

Pin 12

Pin 13

HSPI

Reset key

IO 13

Pin 12

Micro USB

USB UART

Micro USB5 V power

CTS0

TX1

RX0

TX0

IO 13

IO 2

IO 3

IO 1

Pin 12

Pin 14

Pin 25

Pin 26

RTS0IO 15Pin 13

GND

UART

Mode selectIO 0Pin 15

Chip_EnPin 7

R IO 12 Pin 10

G IO 15 Pin 13

B IO 14 Pin 9

W IO 4 Pin 16

PWM

5 V

GND

Relay control IO 15 Pin 13

Transmittor IO 14 Pin 9

Detector IO 5 Pin 24

IR remote control

SD_D2

IO 9

SD_D3

IO 10

SD_CMD

IO 11

Pin 20

SD_CLK IO 6 Pin 21

SD_D0

IO 8

Pin 22

SD_D1

IO 7

Pin 23

GND

Deep sleep

wake up

XPD-DCDC

EXT_RSTB

IO 16 Pin 8

Pin 32

TOUTADC_IN Pin 6

I2C

SCLIO 14Pin 9

Pin 14 IO 2 SDA

GND

3V3

3

5

6

8

109

12

13

14

16

18

19

20

21

22

23

24

24

15

25

26

CLK

SDIO / SPI

Pin 19

Pin 18

1

Chip positioning hole

8

5V power switch

15

Relay control

22

Undefined LED and buttons

2

Reset Button

9

IO0 control

16

SMA ANT

23

1.27 mm pin header

3

Wi-Fi LED, Link LED

10

CH_EN switch

17

Test board

24

2.0 mm pin header

4

Micro USB: USB-UART, 5V

power

11

Flash2: HSPI

18

Flash1: SPI

25

ADC_IN

5

UART12CS of Flash2

19

SDIO/SPI

26

Deep-sleep wakeup

6

UART SWAP

13

HSPI20IR_T, IR_R

7

USB-UART chip

14

3.3 V power

21

I2C

Espressif

" /3021

2018.12

Page 26

"

2. ESP-LAUNCHER

Table 2-1. ESP-LAUNCHER Module Description

Module

Functional description

Micro USB

interface

There are two USB interfaces. Both can be used as a 5V power supply or for serial

communication (2-1-4).

Power supply

The USB interface provides 5V power supply which can be converted to 3.3V through a

DC-to-DC converter. An LED light indicates the power, and a header pin is used for testing

the power current.

Slide switch

Three slide switches are used for the 5V power supply (2-1-8), GPIO0 voltage level switch

(2-1-9) and chip enable pin CH_EN (2-1-10), respectively. When the switches are toggled to

the outer side, the voltage level is high, while when the switches are toggled to the inner

side, the voltage level is low.

• For the 5V power switch:

- Toggled to the inner side, the board is powered on;

- Toggled to the outer side, the board is powered off.

• For the GPIO0 Control:

- Toggle to the inner side, the UART download mode is enabled and users can

download firmware with ESP Flash Download Tool;

- Toggle to the outer side, the Flash boot mode is enabled and the UART debug tool

can be used for debugging.

Reset Key

SW1 is connected to MTCK (GPIO13) for application reset and clearing the Wi-Fi

configuration (2-1-2). SW2 is not defined (2-1-22).

Indicator light

• Red light (D2) indicates Wi-Fi work status (2-1-3).

• Blue (D3) indicates communication with server (2-1-3)

• Green light (D1) indicates relay switch control (2-1-15)

• Blue light (D11) and red light (D10) indicate Rx and Tx work status, respectively (2-1-7)

• Red light (D12) indicates a 5V power supply (2-1-8)

• D4/13/14/16 are not defined (2-1-22).

Jumper

• J82: It needs to be shorted by a jumper, so that the 3.3V power supply can be

channeled into other circuits. It can also be used to test the power current (2-1-14).

• J3: CS of HSPI flash. HSPI flash is disabled when the two upper pins are shorted by a

jumper. HSPI flash is enabled when the two lower pins are shorted by a jumper (2-1-12).

• J14 and J67: Short-circuit J14 to connect GPIO13 to U0CTS. Short-circuit J67 to

connect GPIO15 to U0RTS (2-1-6).

• J77: Short-circuit J77 to connect GPIO16 to EXT_RSTB for Deep-sleep wake up

(2-1-26).

Interfaces

UART, HSPI, SDIO/SPI, I2C, ADC_IN, GPIO16, relay control, PWM and IR TX/RX

Flash

• 32-Mbit Flash1 (mounted on the test board): Flash1 is connected to the chip via the SPI

interface. Currently, Flash1 is used when the chip is working in the Wi-Fi standalone

mode. R9 and R85 can be used for the CS of Flash1. By default, Flash1 is enabled

(2-1-18).

• 32-Mbit Flash2 (mounted on the baseboard): Flash2 is connected to the chip via the

HSPI interface. HSPI is used in SIP mode. For the ESP-LAUNCHER, when ESP8266EX

works as a slave device, it connects to the host MCU via the SPI interface that is defined

in SDIO specifications. HSPI is connected to Flash2. J3 can be used for the CS of

Flash2 (2-1-11).

Espressif

" /3022

2018.12

Page 27

"

2. ESP-LAUNCHER

Table 2-2 lists the function description of ESP-LAUNCHER.

To use the SDIO/SPI interfaces on ESP-LAUNCHER, please follow the steps below:

1. Move the 0R at R85 to R9, and then disable the flash on the ESP_Test Board;

2. Short-circuit the two lower pins on J3 with a jumper to enable HSPI flash;

3. Remove C8 (next to the Reset key on the left of the PCB);

Test modules

There are multiple modules that can be connected to the ESP-LAUNCHER for testing and

development, through the 1.27mm double-row pin headers (2-1-23) and 2.00 mm doublerow pin headers (2-1-24).

Please note that module pins should be connected to their corresponding pins on the

board. Besides, only one module at a time can be used.

Module

Functional description

Table 2-2: ESP-LAUNCHER interfaces

Interfaces

Function description

HSPI

It can interface SPI flash (Flash2), display screen, MCU, etc (2-1-13).

SDIO/SPI

It can interface flash, host MCU, display screen, etc (2-1-19).

PWM

Currently the PWM interface has four channels, and users can extend the channels as

needed. The PWM interface can be used to control LED lights, buzzers, relays, motors, etc

(2-1-20).

IR

The functionality of the infrared remote control interface can be implemented via software

programming. NEC coding, modulation and demodulation are used by this interface. The

frequency of the modulated carrier signal is 38 KHz (2-1-24).

ADC

The interface is used to test the power supply voltage of VDD3P3 (pin3 and pin4), as well

as the input voltage of TOUT (pin6). It can also be used in sensors (2-1-25).

I2C

It can interface sensors and display screens with 2.54 mm or 1.27 mm pin headers

(2-1-21).

UART

UART0: U0TXD, U0RXD, MTDO (U0RTS), MTCK (U0CTS)

UART1: GPIO2 (U1TXD)

It can interface other UARTdevices (2-1-5).

• For firmware downloading: U0TXD+U0RXD or GPIO2+U0RXD

• For communication: UART0: U0TXD, U0RXD, MTDO(U0RTS), MTCK(U0CTS)

• For debugging: UART1_TXD (GPIO2) can be used to print debugging information.

By default, UART0 will output some printed information when the device is powered on. For

the applications that are sensitive to this feature, users can exchange the pins of UART

during system initialization, that is, exchange U0TXD, U0RXD with U0RTS, U0CTS.

R1/3/5/7 should not be mounted with other components, while R2/4/6/8 can be mounted

with other components. J14 and J67 should be shorted.

Relay control

terminal

It is used to control, with an indicator light, the on-and-off switch of the relay in a smart plug

application ( 2-1-15).

Espressif

" /3023

2018.12

Page 28

"

2. ESP-LAUNCHER

4. Remove R58 on the PCB and disconnect GPIO14 with the infrared transmitting tube;

5. Remove the pull-down resistor R29 of MTDO/IO15 (next to J11);

6. When downloading firmware, pull the IO15/CS at J11 to low level and toggle the

switch of GPIO0 inwards to enable UART Download mode;

7. When downloading is completed, release IO15/CS to enable SDIO Boot mode;

8. Connect SDIO/SPI at J5 to host for communication.

2.3. Schematics

2.3.1. Interfaces

!

Figure 2-2. ESP-LAUNCHER Interface!

DM

DP

TX_LED

RX_LED

U0CTS

U0RTS

U0RXD

GPIO15

GPIO13

U0RTS

U0CTS

U0TXD

U0RXD

GPIO2

U0CTS

U0RTS

U0TXD

VBUS

GND

GNDGND

GND

VDD33

GND

GND

GND

EXT_5V

TXD

RXD

RTS

CTS

TXD

RXD

CTS

RTS

U0TXD

U0RXD

UART

1.Normal:use R1 R3 R5 R7

2. Swap: use R2 R4 R6 R8

(for cancelling log print when power on )

3.Flow control: short J14 and J67

Micro USB

5V&USB-UART

R54

0R

R5 0R

R55 2K

J6

CON8

VBUS

1

D-

2

D+

3

GND

5

NC

4

GND

6

GND

7

GND

8

GND

9

C11

47pF

R7 0R

R51 0R

R3 0R

J69

CON6

1

2

3

4

5

6

R2 NC C22

0.1uF

U5

FT232RL

3V3OUT

17

GND

18

VCCIO

4

CUSB2

13

USBDM

16

AGND

25

CUSB3

14

CUSB4

12

DTR#

2

DCD#

10

OSCO

28

NC

8

VCC

20

RI#

14

CUSB1

22

GND

21

USBDP

15

RESET#

19

NC

24

OSCI

27

GND7TEST

26

CUSB0

23

DSR#

9

CTS#

11

RXD

5

TXD

1

RTS#

3

R49 0R

D11

BLUE LED

R4 NC

J7

CON8

VBUS

1

D-

2

D+

3

GND

5

NC

4

GND

6

GND

7

GND

8

GND

9

R1 0R

D10

RED LED

J14

CON2

1

2

J67

CON2

1

2

C10

47pF

C9

10nF

R56 2K

R46 0R

R8 NC

R47 10K

R6 NC

Espressif

" /3024

2018.12

Page 29

"

2. ESP-LAUNCHER

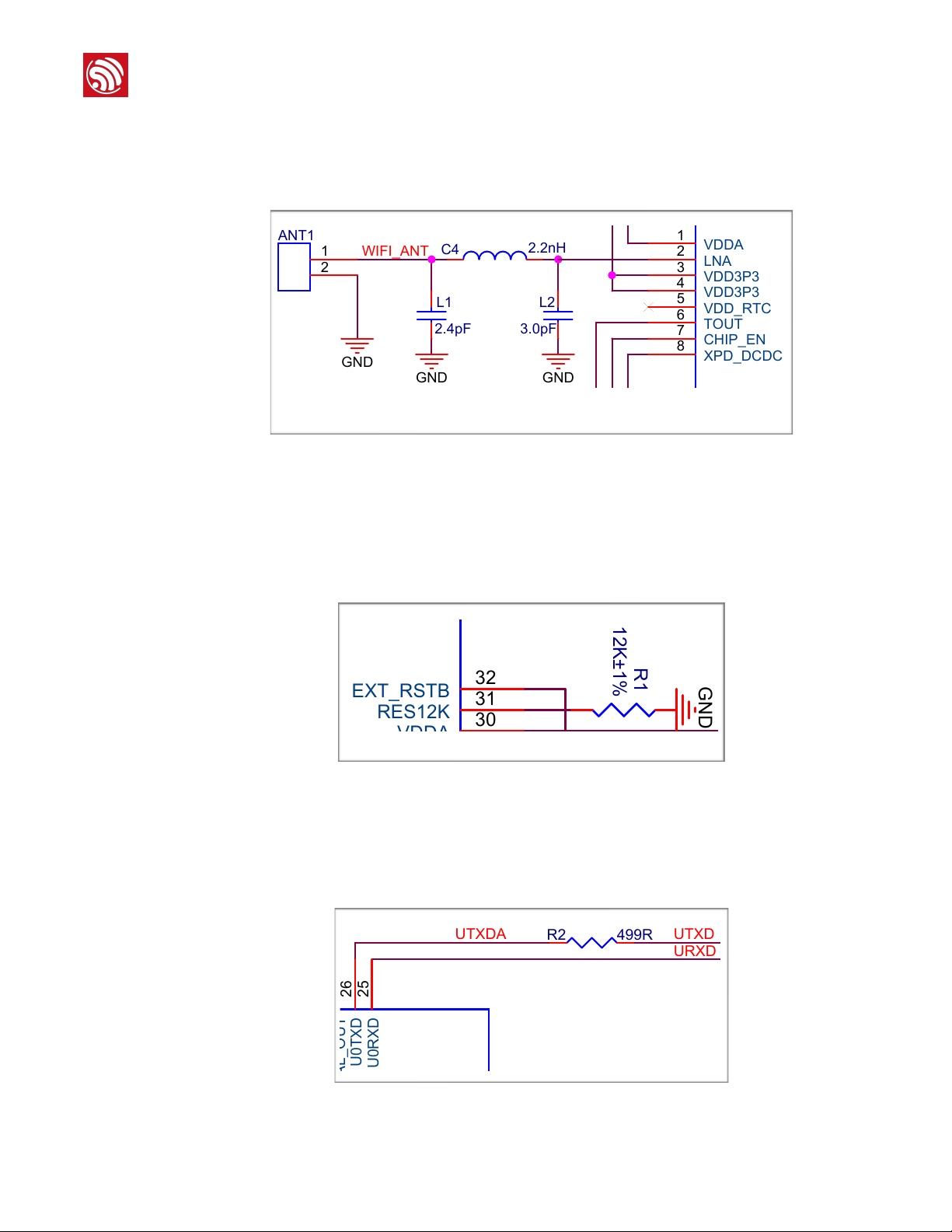

2.3.2. 5V Power Supply

"

Figure 2-3. ESP-LAUNCHER 5V Power Supply Schematics

2.3.3. Test Module

!

Figure 2-4. ESP-LAUNCHER Test Module Schematics!

GND

GND

GND

VDD33

GND

EXT_5V

GND

EXT_5V

GND

Toggle Switch

5V Power LED

R57

2K

J64

CON3

123

J82

CON2

1

2

D12

RED LED

C13

6.8pF

IN

GND

EN FB

LX

U6

AN_SY8088

4

2

1 5

3

R59

680K

R60

150K

C14

22uF

C12

4.7uF

C24

4.7uF

C23

0.1uF

L3 2.2uH

RST

U0RXD

U0TXD

GPIO5

GPIO14

GPIO12 GPIO13

GPIO15 GPIO2

GPIO0 GPIO4

GPIO16

CH_EN

TOUT

RST

U0RXD

U0TXD

GPIO5

GPIO14

GPIO12 GPIO13

GPIO15 GPIO2

GPIO0 GPIO4

GPIO16

CH_EN

TOUT

TOUT

GPIO14

GPIO12

GPIO13

GPIO15

GPIO2

GPIO0

GPIO4

SD_D2

SD_D3

SD_CMD

SD_CLK

SD_D0

SD_D1

U0RXD

U0TXD

GPIO5

GPIO16

RST

CH_EN

GND

GND

GND

VDD33

GND

GND

GND

VDD33

GND

GND

VDD33

GND

GND GND

VDD33

GND

VDD33

VDD33

GND

VDD33

GPIO14

GPIO12

GPIO13

GPIO15

GPIO2

GPIO0

GPIO4

SD_D2

SD_D3

SD_CMD

SD_CLK

SD_D0

SD_D1

U0RXD

U0TXD

GPIO5

GPIO16

TOUT

RST

CH_EN

ESP_WROOM-01/02 2 . 0

ESP8266EX Module 1 . 27

ESP_Test board

C18

10uF

C21

0.1uF

C19

10uF

C20

0.1uF

J9

CON9

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

9

9

J4

CON12

1

2

3

4

5

6

7

8

9

10

11

12

J16

CON9

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

9

9

J8

CON9

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

9

9

J2

CON12

1

2

3

4

5

6

7

8

9

10

11

12

J15

CON9

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

9

9

Espressif

" /3025

2018.12

Page 30

"

2. ESP-LAUNCHER

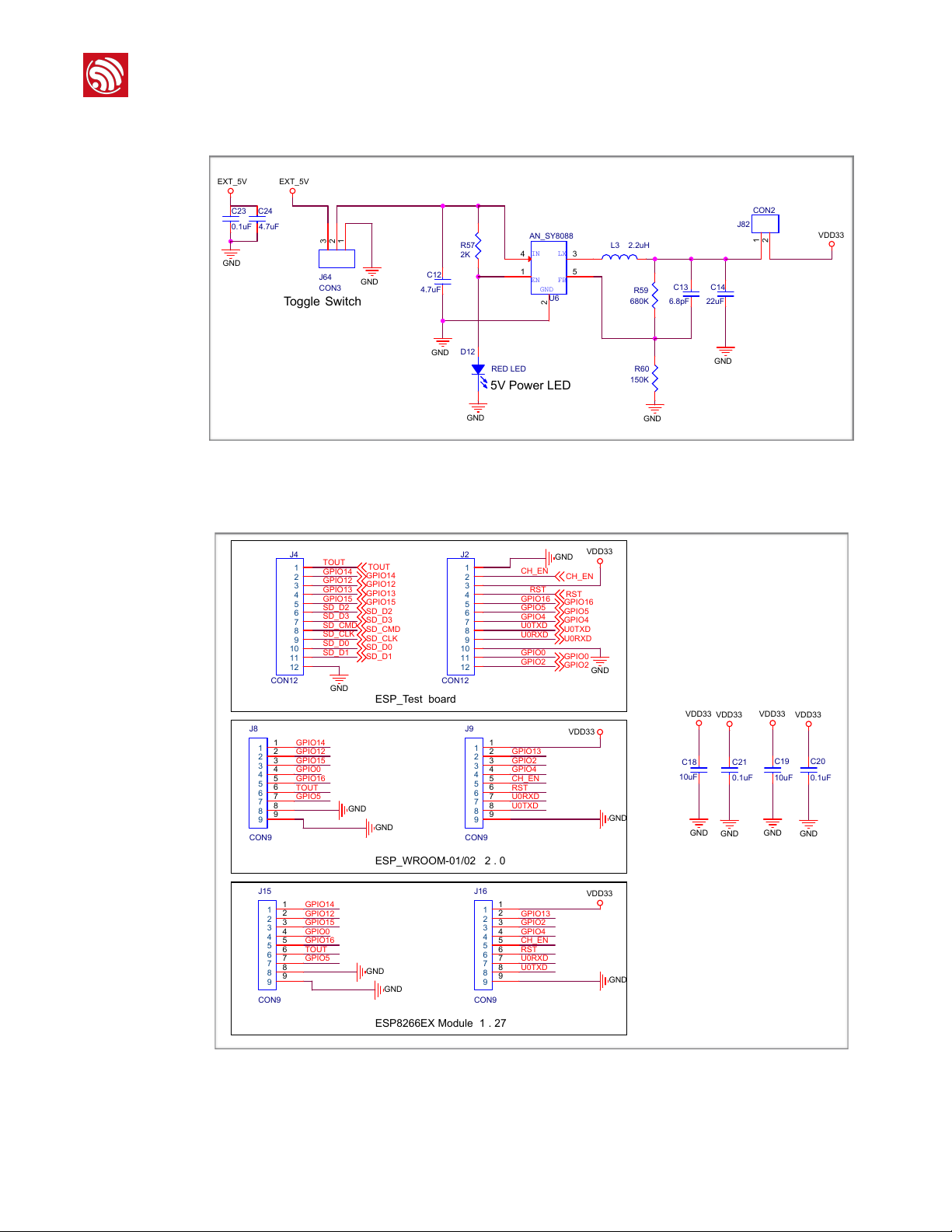

2.4. Test Board

A test board is embedded in ESP-LAUNCHER, as shown in Figure 2-5. The external size of

the test board is 20 mm x 31 mm. A 2-dBi SMA antenna or other testing equipment can be

connected to the test board via the SMA antenna connector. The 2.54 mm pin headers

makes test and development easy and convenient when using a breadboard.

Figure 2-5. ESP-LAUNCHER Test Board

"

Figure 2-6. ESP-LAUNCHER Test Board Schematics

MTDO

EXT_RSTB

SD_CLK

MTMS

MTDI

U0RXD

MTCK

U0TXD

GPIO0

GPIO4

GPIO5

GPIO2

SD_D0

SD_D1

SD_CMD

SD_CLK

SD_D2

SD_D1

SD_D0

SD_D3

SD_CMD

WIFI_ANT

SD_D3

SD_D2

CH_EN

TOUT

CH_EN

GPIO16

MTMS

MTDI

MTCK

MTDO

GPIO2

GPIO0

GPIO4

SD_D2

SD_D3

SD_CMD

SD_CLK

SD_D0

SD_D1

GPIO5

U0RXD

U0TXD

EXT_RSTB

GPIO16

TOUT

GND

GND

GND GND

GND

VDD33

GND

GNDGND

GND

GND

VDD33

GND

GND

VDD33VDD33

VDD33

GND

GND

GND

VDD33

GND

U1

26MHz±10ppm

XIN1GND

2

XOUT

3

GND

4

J2

CON1

1

C4

0.1uF

J12

CON1

1

J5

CON1

1

R9

NC

J19

CON1

1

R76 100R

J24

CON1

1

J10

CON1

1

J18

CON1

1

J15

CON1

1

J3

CON1

1

R12 100R

C6 5.6pF

J9

CON1

1

J8

CON1

1

J20

CON1

1

R13 100R

U2

ESP8266EX

VDDA

1

LNA

2

VDD3P3

3

VDD3P3

4

VDD_RTC

5

TOUT

6

CHIP_EN

7

XPD_DCDC

8

MTMS9MTDI10VDDPST11MTCK12MTDO13GPIO214GPIO015GPIO4

16

VDDPST

17

SD_DATA_2

18

SD_DATA_3

19

SD_CMD

20

SD_CLK

21

SD_DATA_0

22

SD_DATA_1

23

GPIO5

24

U0RXD

25

U0TXD

26

XTAL_OUT

27

XTAL_IN

28

VDDD

29

VDDA

30

RES12K

31

EXT_RSTB

32

GND

33

J21

CON1

1

R11 100R

J1

CON1

1

J16

CON1

1

J7

CON1

1

C3

10uF

C1

6.8pF

R10 100R

J17

CON1

1

J14

CON1

1

R140R

J4

CON1

1

C19

10uF

J6

CON1

1

R75 100R

J23

CON1

1

R150R

L1

NC

R4

12K±1%

J11

CON1

1

J13

CON1

1

R85

0RL2

NC

U3

FLASH

/CS

1

DO

2

/WP

3

GND

4

DIO

5

CLK

6

/HOLD

7

VCC

8

J22

CON1

1

C2

6.8pF

U4

SMA

1

2

3

4

5

Espressif

" /3026

2018.12

Page 31

"

3. ESP8266EX Module

3. ESP8266EX Module

Espressif provides two types of modules, the SMD module (ESP-WROOM-02) and the DIP

module (ESP-WROOM-01). The modules have been improved to achieve the optimum RF

functionality. It is recommended that users use these modules for testing or further

development.

3.1. ESP-WROOM-S2

The module size is 16±0.2 mm x 23±0.2 mm x 3±0.15 mm (see Figure 1-1). The flash used

on this module is a 2-MB SPI flash connected to HSPI, with a package size of SOP 8-150

mil. The gain of the on-board PCB antenna is 2 dBi.

The ESP-WROOM-S2 works as the SDIO/SPI slave with the SPI speed of up to 8 Mbps.

" "

Figure 3-1. ESP-WROOM-S2 Module

For details of ESP-WROOM-S2, please refer to ESP-WROOM-S2 Datasheet.

3.2. ESP-WROOM-02

The module size is (18±0.2) mm x (20±0.2) mm x (3±0.15) mm. The type of flash used on

this module is an SPI flash with a package size of SOP 8-150 mil. The gain of the on-board

PCB antenna is 2 dBi.

Espressif

" /3027

2018.12

Page 32

"

3. ESP8266EX Module

!

Figure 3-2. ESP-WROOM-02 Module

For details of ESP-WROOM-S2, please refer to ESP-WROOM-02 Datasheet.

3.3. ESP-WROOM-02D/ESP-WROOM-02U

The module size of ESP-WROOM-02D is (18±0.2) mm x (20±0.2) mm x (3±0.15) mm. The

type of flash used on this module is an SPI flash with a package size of SOP 8-150 mil. The

gain of the on-board PCB antenna is 3 dBi.

"

Figure 3-3. ESP-WROOM-02D Module

The module size of ESP-WROOM-02U is (18±0.1) x (14.3±0.1) x (3.2±0.1) mm. The type of

flash used on this module is an SPI flash with a package size of SOP 8-150 mil. ESP-

WROOM-02U integrates a U.FL connector and has no onboard antenna.

Espressif

" /3028

2018.12

Page 33

"

3. ESP8266EX Module

"

Figure 3-4. ESP-WROOM-02U Module

For detailed information on ESP-WROOM-02D/ESP-WOOM-02U, please refer to ESP-

WROOM-02D/ESP-WROOM-02U Datasheet.

Espressif

" /3029

2018.12

Page 34

Disclaimer and Copyright Notice

Information in this document, including URL references, is subject to change without

notice.

THIS DOCUMENT IS PROVIDED AS IS WITH NO WARRANTIES WHATSOEVER,

INCLUDING ANY WARRANTY OF MERCHANTABILITY, NON-INFRINGEMENT, FITNESS

FOR ANY PARTICULAR PURPOSE, OR ANY WARRANTY OTHERWISE ARISING OUT

OF ANY PROPOSAL, SPECIFICATION OR SAMPLE.

All liability, including liability for infringement of any proprietary rights, relating to use of

information in this document is disclaimed. No licenses express or implied, by estoppel or

otherwise, to any intellectual property rights are granted herein.

The Wi-Fi Alliance Member logo is a trademark of the Wi-Fi Alliance. The Bluetooth logo is

a registered trademark of Bluetooth SIG.

All trade names, trademarks and registered trademarks mentioned in this document are

property of their respective owners, and are hereby acknowledged.

Copyright © 2018 Espressif Inc. All rights reserved.

Espressif IoT Team"

www.espressif.com

Loading...

Loading...