Espar Hydronic D4 SC, Hydronic B4 SC, Hydronic D5 S, Hydronic B5 SC, Hydronic B5 S User Manual

...Page 1

Hydronic 4/5 (Coolant Heaters)

Technical Description

Installation Instructions

Operating Instructions

Maintenance Instructions

Troubleshooting and Repair Instructions

Parts Diagrams and List

Heater Model 12 V

Hydronic D4 SC 25 2096 05

25 2257 05

Hydronic B4 SC 20 1824 05

Hydronic D5 SC 25 1920 05

25 2098 05

25 2219 05

FMP OUT 25 2325 05

Espar Heater Systems

Espar Products, Inc.

(800) 387-4800

(905) 670-0960

www.espar.com

Heater Model 24 V

Hydronic D5 SC 25 2147 05

Hydronic D5 S 25 2146 05

25 2218 05

Hydronic D5 S 25 2031 05

25 2217 05

Hydronic B5 SC 20 1820 05

Hydronic B5 S 20 1793 05

20 1819 05

08.2013 Subject to Change Web Edition

Page 2

Table of Contents Page

Introduction Heater Warnings ........................................................ 3

Introduction ........................................................ 4

Specifications ........................................................ 4

Heater Components

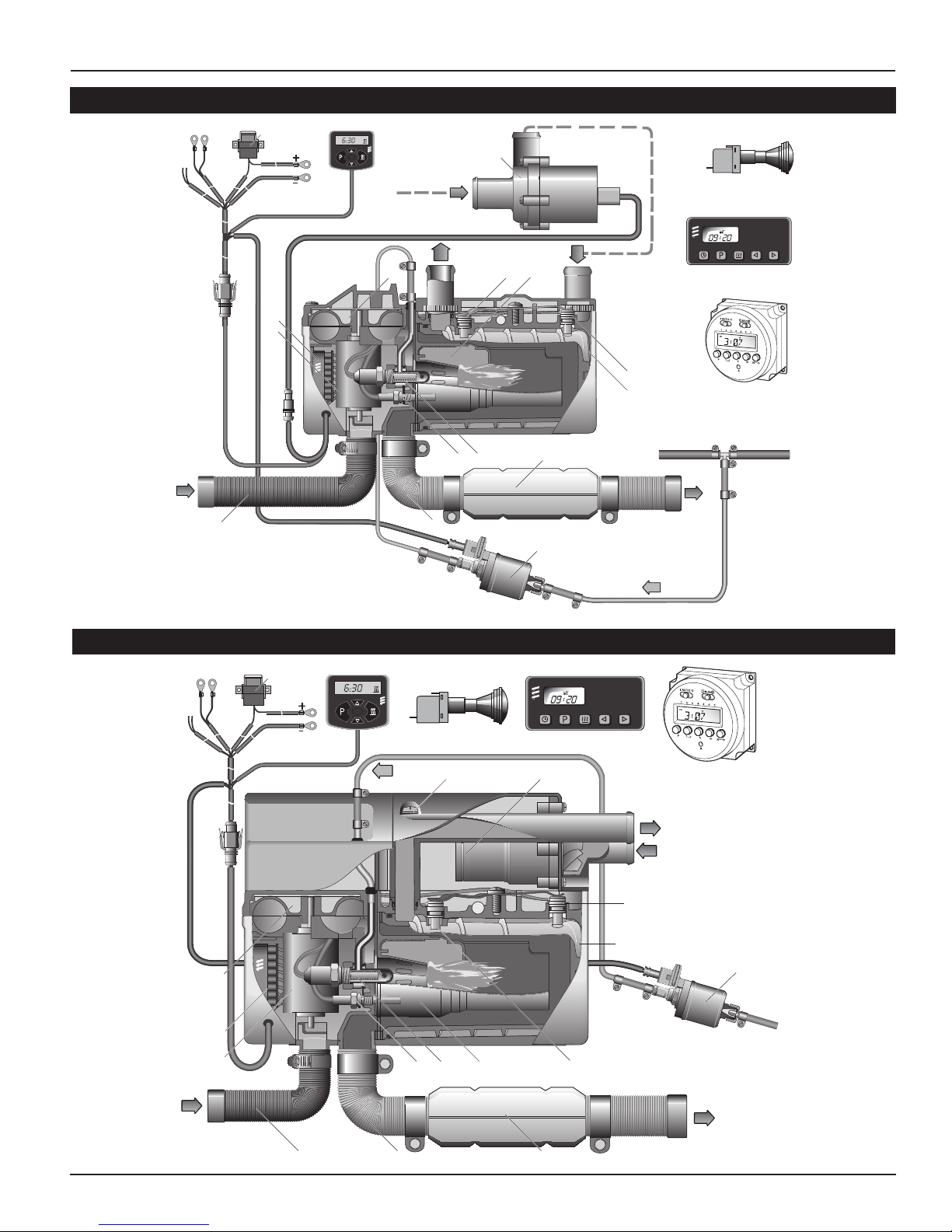

Hydronic 4/5 SC, 12 + 24 volt, Diesel ........................................................ 5

Hydronic 5 S, 12 + 24 volt, Diesel + Gas ........................................................ 6

Hydronic 4/5 SC, 12 volt, Gasoline ........................................................ 6

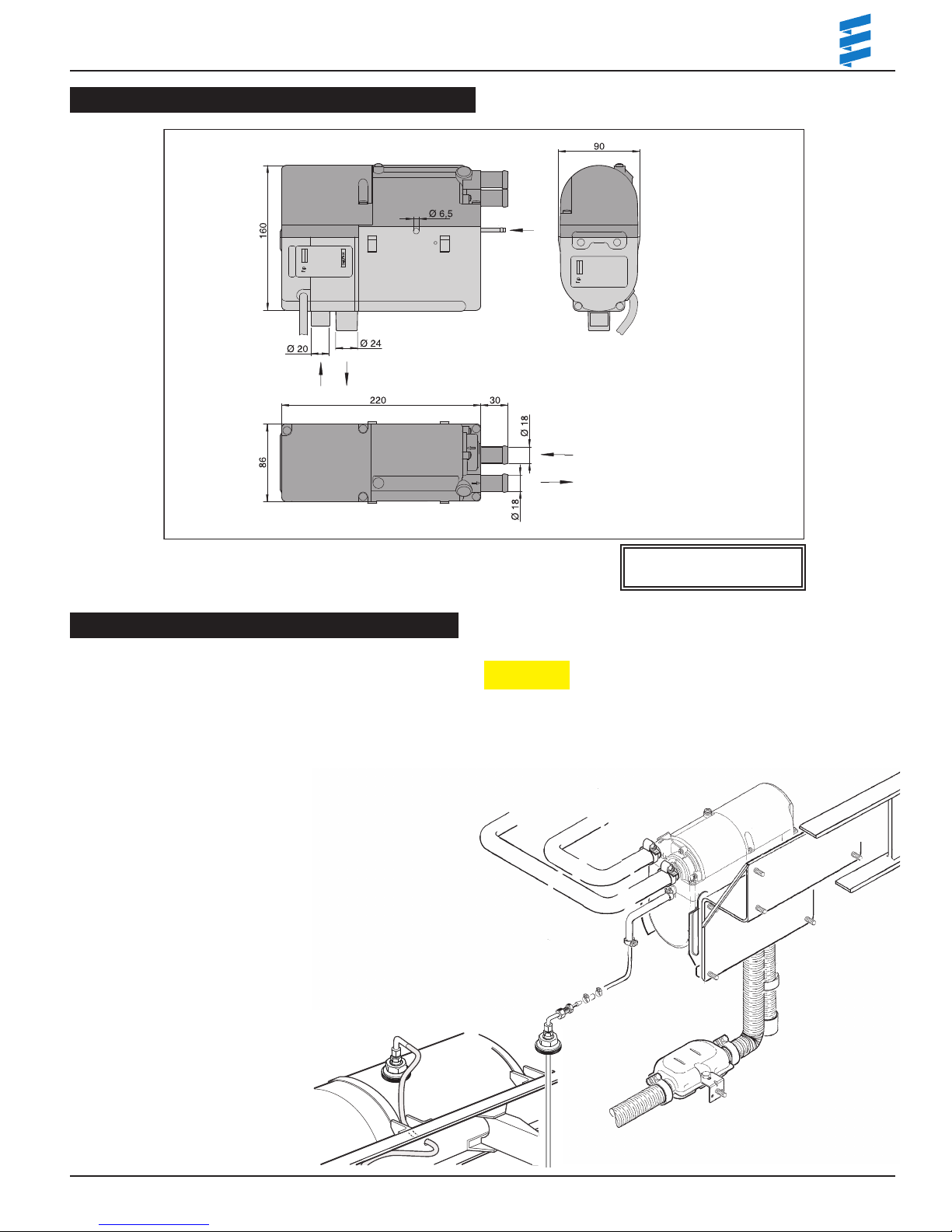

Principal Dimensions ........................................................ 7

Installation Heater Location ........................................................ 7

Procedures Heater Mounting ........................................................ 8

Heater Plumbing ........................................................ 9

Fuel System ........................................................ 10

Electrical Connections ........................................................ 12

Exhaust / Intake Connections ........................................................ 13

Control Options ........................................................ 14

Heater Operation Pre-Start Procedures ........................................................ 15

Start-Up ........................................................ 15

Running ........................................................ 15

Switching Off ........................................................ 16

Safety Equipment ........................................................ 16

Operational Flow Chart ........................................................ 17

Heater Diagnostics Schematics ........................................................ 18

Maintenance / Periodic Maintenance ........................................................ 24

Troubleshooting / Basic Troubleshooting ........................................................ 24

Repairs Self Diagnostic Troubleshooting ....................................................... 24

Troubleshooting Chart ....................................................... 26

Fuel Quantity Test ........................................................ 28

Heater Disassembly / Repair Steps ........................................................ 29

Heater Components Parts Diagram / Scope, Face Lift “SC” Heaters ........................................................ 32

Description & Part #’s, Face Lift “SC” Heaters ........................................................ 33

Parts Diagram / Scope, Face Lift “S” Heaters ........................................................ 40

Description & Part #’s, Face Lift “S” Heaters ........................................................ 41

Parts Diagram / Scope, Early “SC” Heaters ........................................................ 46

Description & Part #’s, Early “SC” Heaters ........................................................ 47

Parts Diagram / Scope, Early “S” Heaters ........................................................ 58

Description & Part #’s, Early “S” Heaters ........................................................ 59

Parts Diagram / Scope, North American Heaters ....................................................... 64

Parts Diagram / Scope, North American Heaters (F/L) ....................................................... 65

Description & Part #’s, North American Heaters ....................................................... 66

Special Notes

Note: Highlight areas requiring special attention or clarification.

Caution: Indicates that personal injury or damage to equipment may occur unless specific guidelines are followed.

Warning: Indicates that serious or fatal injury may result if specific guidelines are not followed.

2

Page 3

Introduction

Heater Warnings

Warning To Installer

• Correct installation of this heater is necessary to ensure

safe and proper operation.

Read and understand this manual before attempting to

install the heater. Failure to follow all these instructions

could cause serious or fatal injury.

Warning - Explosion Hazard

• Heater must be turned off while re-fueling.

• Do not install heater in enclosed areas where combustible

fumes may be present.

• Do not install heaters in engine compartments of gasoline

powered boats.

Warning - Fire Hazard

• Install the exhaust system so it will maintain a minimum

distance of 50mm (2”) from any flammable or heat sensitive

material.

• Ensure that the fuel system is intact and there are no leaks.

Warning - Asphyxiation Hazard

• Route the heater exhaust so that exhaust fumes cannot

enter any passenger compartments.

• If running exhaust components through an enclosed

compartment, ensure that it is vented to the outside.

ATTENTION

Operation with bio-diesel

HYDRONIC D4 / D5

HYDRONIC D4 / D5 is not certified for use with bio-diesel.

Admixtures of bio-diesel up to a magnitude of approx. 10%.

ATTENTION

Heating at high altitudes

Up to 1500 meters (4920’) - unrestricted heating operation is

possible.

Above 1500 meters (4920’) - heating operation is in principle

possible for short periods, e.g. when crossing a mountain

pass or during a brief stop. In cases of extended stays, the

fuel supply at the fuel metering pump has to be adapted to

high altitude conditions.

The following high altitude kits are available:

Note: P/N: 24 0221 00 00 00 (Contains high altitude fuel

pump)

or

P/N: 20 2900 70 00 07 (Contains high altitude

compensator, no extra fuel pump needed)

Only works with heaters that do not have “M-kit”

on the factory label.

or

P/N: 22 1000 33 22 00 (Only works with Hydronic Heaters

that have “H-Kit” on the factory label)

Warning - Safety Hazard on Coolant Heaters

Used With Improper Antifreeze Mixtures

• The use of Espar coolant heaters requires that the coolant

in the system to be heated contain a proper mixture of water

and antifreeze to prevent coolant from freezing or slushing.

• If the coolant becomes slushy or frozen, the heater’s

coolant pump cannot move the coolant causing a blockage

of the circulating system. Once this occurs, pressure will

build up rapidly in the heater and the coolant hose will either

burst or blow off at the connection point to the heater.

• This situation could cause engine damage and/or personal

injury. Extreme care should be taken to ensure a proper

mixture of water and antifreeze is used in the coolant

system.

• Refer to the engine manufacturer’s or coolant manufacturer’s recommendations for your specific requirements.

Note: Only one kit from the listed above is needed.

This publication was correct at the time of print.

However, Espar has a policy of continuous improvement and reserves the right to amend any specifications without prior notice.

3

Page 4

Introduction

Espar’s Hydronic D4/D5 Heater

Quality engineered to provide a dependable means of heating.

The Espar Hydronic 4/5 is a diesel fired coolant heater capable of between:

Hydronic 4 - 2.4 kW to 4.3 kW/hr (8,200 to 14,781 BTU/hr).

Hydronic 5 - 2.4 kW to 5 kW/hr (8,200 to 17,100 BTU/hr).

This compact coolant heater offers an affordable heating solution to many applications. The Hydronic 4/5 is ideal for preheating the engines of trucks, cars, off-road equipment, small

trucks and boats. It features automatic heat regulation while

being fuel and power efficient. Since the heater runs on fuel

and 12 or 24 volt power, it is able to perform this completely

independently of the vehicle engine. The unit regulates the

coolant temperature between a low of 65°C (149°F) and a high

of 80°C (176°F) by automatically cycling the heater between

heat levels.

The Hydronic 4/5 can be operated from the vehicle cab by an

on/off switch, a pre-select timer or a combination of both.

A flame sensor, temperature regulating sensor and overheat

sensor are among the safety features which makes the

Hydronic D4/D5 a safe and dependable heating system.

Specifications Hydronic 4 Hydronic 5

Heat output (±10%) 4.3 kW (14,781 BTU/hr) - High 5 kW (17,000 BTU/hr) - High

2.4 kW (8,188 BTU/hr - Low 2.4 kW (8,200 BTU/hr) - Low

12 volt 24 volt

Current draw (±10%)

4.0 amps High 4.16 amps High 2.08 amps High

1.91 amps Low 1.91 amps Low 0.95 amps Low

Fuel consumption (±10%)

0.53 l/hr (0.13 US gal/hr) High 0.62 l/hr (0.16 US gal/hr) High

0.27 l/hr (0.07 US gal/hr) Low 0.27 l/hr (0.08 US gal/hr) Low

Operating Voltage Range

Minimum Voltage 10.2 V 10.2 V 20.4 V

Maximum Voltage 16 V 16 V 32.0 V

Working pressure 2.5 bar (36 psi) 2.5 bar (36 psi)

Ambient operating temperature -40°C to +80°C (-40°F to 176°F) -40°C to +80°C (-40°F to 176°F)

Weight 2.7 kg. (5.94 lbs.) 2.9kg. (6.4lbs)

Controls available On/Off switch or 7-day timer On/Off switch or 7-day timer

(Multi-Function Timer) (Multi-Function Timer)

Note: The heater is equipped with a high-voltage

cutout as well as a low-voltage cutout.

4

Note: For specifications of gasoline heaters, please

see original manual in heater packaging.

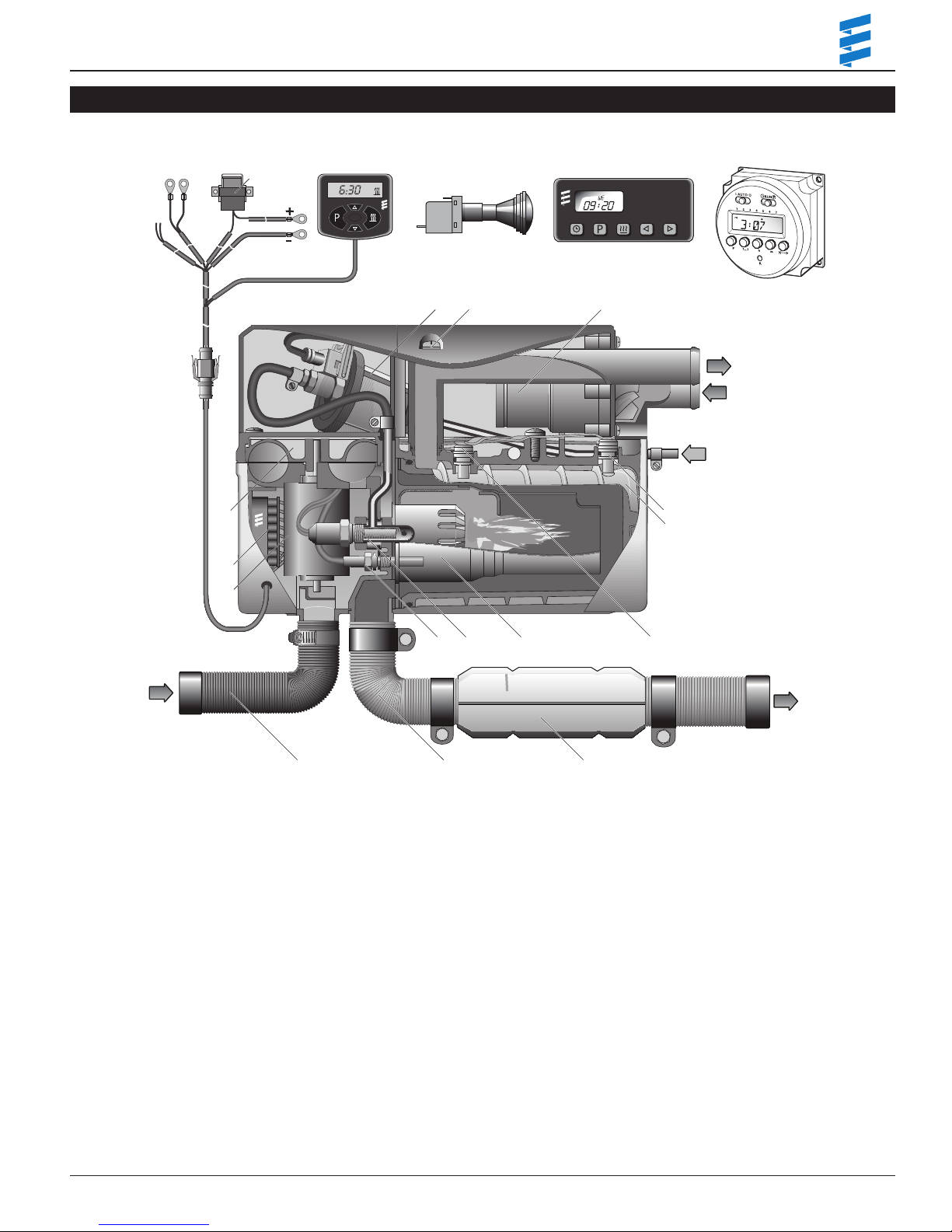

Page 5

Introduction

18

17

15

12 16 13

4

11 2110

56

9

1

2

7

8

3

19

20

A

A

E

E

WO

WO

WI

WI

F

F

14

Heater Components - Hydronic 4 & 5 SC versions - 12 + 24 Volt - Diesel

25 2219 05

25 2147 05

25 2257 05

A=Combustion air

E=Exhaust

F=Fuel supply line

WO = Water Outlet

WI = Water Inlet

1 Combustion air blower wheel

2 Electric motor

3 Heat exchanger

4 Combustion chamber

5 Glow pin

6 Flame sensor

7 Temperature sensor

8 Overheat temperature sensor

9 Control unit

10 Combustion air tube

11 Exhaust tube

12 Fuel-metering pump

13 Coolant pump

14 Main fuse

15 Interface/8-pin connector

16 Bleed screw

17 Mini Timer

18 Push/Pull switch

19 7-day timer

20 Programmable Timer

21 Exhaust silencer

5

Page 6

Introduction

18

17

11 2110

19

20

8

1316

3

4567

1

15

2

9

A

A

E

E

WO

WO

WI

WI

14

12

F

F

14

13

15

9

2

1

18

17

19

20

74

8

3

5216

12

10

11

A

A

E

E

WO

WO

WI

WI

WI

WI

F

F

Heater Components - Hydronic 5 S - 12 & 24 volt versions - Diesel & Gasoline versions

25 2217 05

25 2218 05

Heater Components - Hydronic 4 & 5 SC - 12 volt version - Gasoline

20 1820 05

20 1824 05

6

Page 7

Introduction and Installation Procedures

Ma in di me nsion s diese l heater

WI = Water inle t

WO = Water outl et

E = E xhaus t

F = F uel

A = C ombus tion air

F

A E

WO

WI

Principal Dimensions - Hydronic D4/D5 SC

Heater Location

Always mount the heater in a protected area. Eg: storage

compartment, engine compartments or step box. Espar

recommends you use the boxed unit. Boxed heaters can be

mounted by utilizing one of the existing brackets. See following page.

If mounting on frame rail use an optional Espar Inside frame

bracket to mount to inside of frame rails. Heaters can also be

mounted on a cross tray behind the cab and on top of the

frame rails.

When mounting the heater adhere to the following conditions:

• Situate the heater below the normal coolant level of the engine.

• Guard against excessive road spray.

• Keep coolant hoses, fuel lines and electrical wiring as short

as possible.

* All measurements in millimeters

25.4mm = 1”

Caution: Guard the heater against excessive road spray to

avoid internal corrosion.

For Illustration purposes only

7

Page 8

15° to

vertical

15°

Installation Procedures

Espar Heater Systems

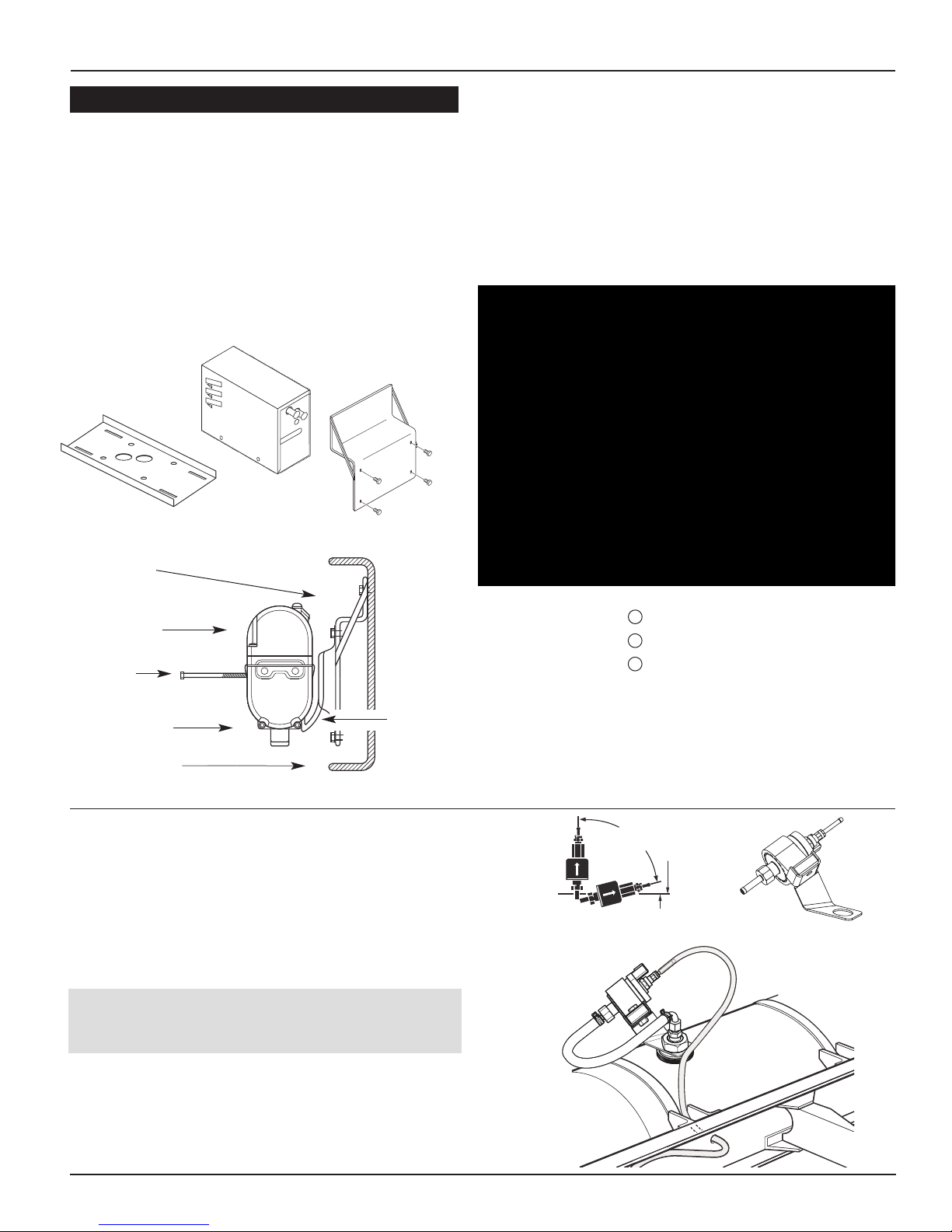

Heater Mounting

Mount the heater in the heater bracket and secure with

hardware provided. If heater is not a boxed unit, mount

bracket onto inside frame rail bracket. Boxed unit can also be

secured to the inside frame bracket or mounted to the Cross

Frame Mounting Tray.

Cross Frame Mounting Tray

Hydronic 4/5 box

Inside frame mounting bracket

Inside frame

mounting bracket

Hydronic

Water Heater

Mounting

thru bolt

Hydronic D4 SC boxed unit P/N 25 2822 57 04 55

Hydronic D5 SC boxed unit P/N 25 2822 19 05 55

(Please refer to product catalogue for more kits)

1 Heater bracket

2 HYDRONIC

3 Fastening screw

Heater bracket

Inside frame rail

For “S” and gasoline version heaters which have external

fuel metering pumps:

• Choose a protected mounting location close to the fuel

pick-up pipe and heater.

• Using the bracket and rubber mount provided, install fuel

pump as shown.

Note: Proper mounting angle of the fuel pump is necessary

to allow any air or vapor in the fuel lines to pass

through the pump rather than cause a blockage.

8

Heater bracket

FMP and bracket assembly

Page 9

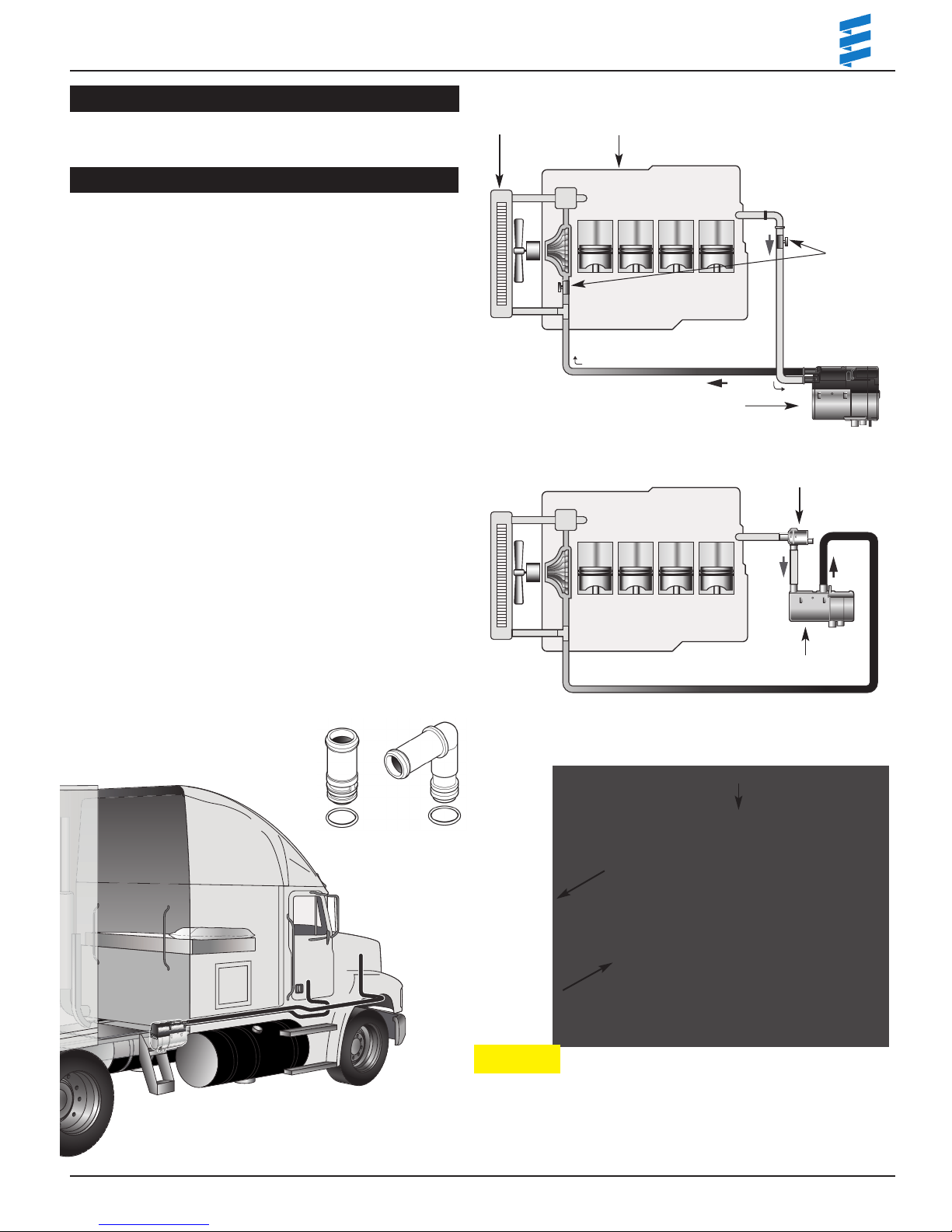

Installation Procedures

Heater Plumbing

The heater is incorporated into the engine’s cooling system

for engine preheating.

Engine Plumbing

Follow these guidelines and refer to engine plumbing diagram

shown.

• Use existing holes in the engine block (ie. remove

blanking plugs when possible). Install fittings into the block

for pick-up and returns.

• If possible, use 5/8 ball shut off valves minimum to ensure

the system can be isolated from the engine when not in

use.

• Provide (3/4”) hose barbs for hose connections.

• Use (3/4”) hoses to ensure adequate coolant flow.

• Keep the pick up and return points as far apart as

possible to ensure good heat distribution.

• Take the coolant from a low point on the engine to reduce

aeration in the system.

• Ensure proper direction of coolant flow by taking coolant

from a high pressure point in the engine and returning it to

a low pressure point. (ie. pickup from back of block and

return to the suction side of the engine's water pump).

• Ensure adequate flow rate through the heater by comparing

the incoming and outgoing coolant temperatures while

the heater is running. If the rise in temperature exceeds

10°C (18°F), coolant flow must be increased by modifying

the plumbing.

• Ensure the heater and water pump are installed as low as

possible to allow the purging of air. Bleed system via

radiator or bleed screw located on heater.

(If using silicone coolant line use appropriate clamps)

Radiator

Engine

Shut-off

valves

(Optional)

Hydronic SC Heater

External Water Pump

Hydronic “S” version

Optional Outlets available

in 18mm and 20mm

See Product Catalogue

Bleed Screw

Water out

Water in

Caution: The coolant must contain a minimum of 10%

antifreeze at all times as a protection against

corrosion. Fresh water will corrode internal

heater parts.

9

Page 10

Installation Procedures

Fuel System

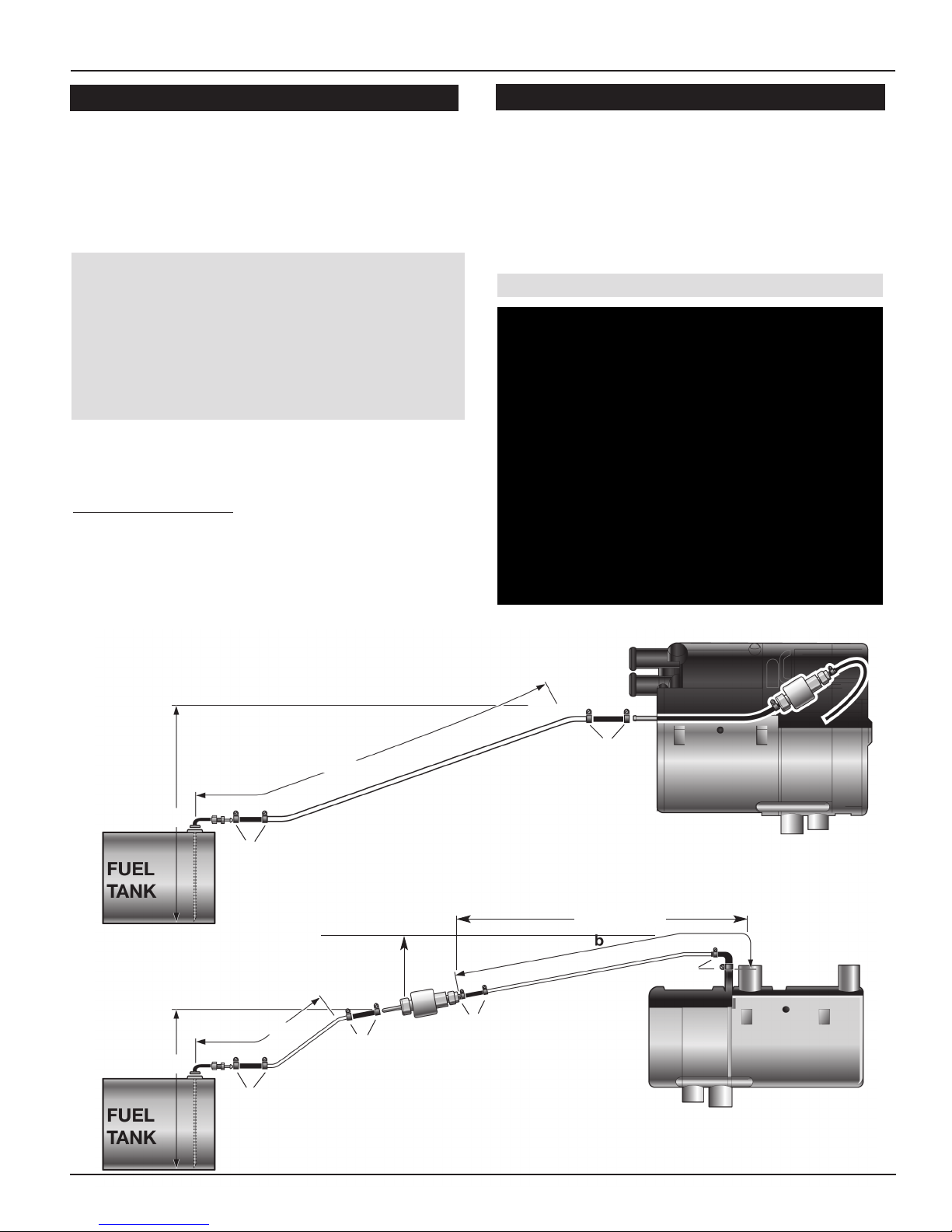

Some Hydronic water heaters (2219) typically have the fuel

metering pump mounted inside the unit. This is to reduce

installation time and to protect the pump from corrosion. Some

versions have an external fuel metering pump. Refer to

graphics for connections and specifications.

All parts necessary to do the installation are included in the kit

as shown.

Note: For 25 2219 and similar “SC” Heaters:

Fuel line limits must not be exceeded.

Ensure that the following conditions are met.

Hydronic heater must be within a height of 76cm (2’6”)

from the bottom of the fuel pick-up pipe.

Fuel-metering pump must be within a total distance of

200 cm (6’6”) from the fuel pick-up pipe.

If the above conditions cannot be met, a heater with

external fuel metering pump must be used.

Fuel System Tolerances

1. Fuel Pick-Up Pipe

2. Fuel Pipe Reducer

3. 9mm Clamp

4. 3.5mm Rubber Connector

5. 2.0mm White Plastic Fuel Line

6. Fuel Metering Pump

7. 1.5m White Plastic Fuel Line

Fuel Line

• Route fuel lines from the fuel pick-up pipe to the heater.

• Use only fuel lines provided.

• Other sizes or types of fuel lines may inhibit proper fuel flow.

• Make proper butt joints using clamps and connector pieces

as shown.

• Use a sharp utility knife to cut plastic fuel lines to avoid fuel

line pinching.

Note: Butt joints and clamps on all connections.

Hydronic Heater

Max. 76cm (2’6”)

Max. 76cm (2’6”)

2

4

3

1

Max. 2 M (6’6”)

2

4

3

1

Max. 2 M (6’6”)

Max. 2 M (6.5’)

4

3

5

4

6

3

5

“SC” Models

25 2219 05

and similar

Max. 6 M (19.8’)

4

4

3

6

7

3

“S” Models

25 2217 05

and similar

10

Page 11

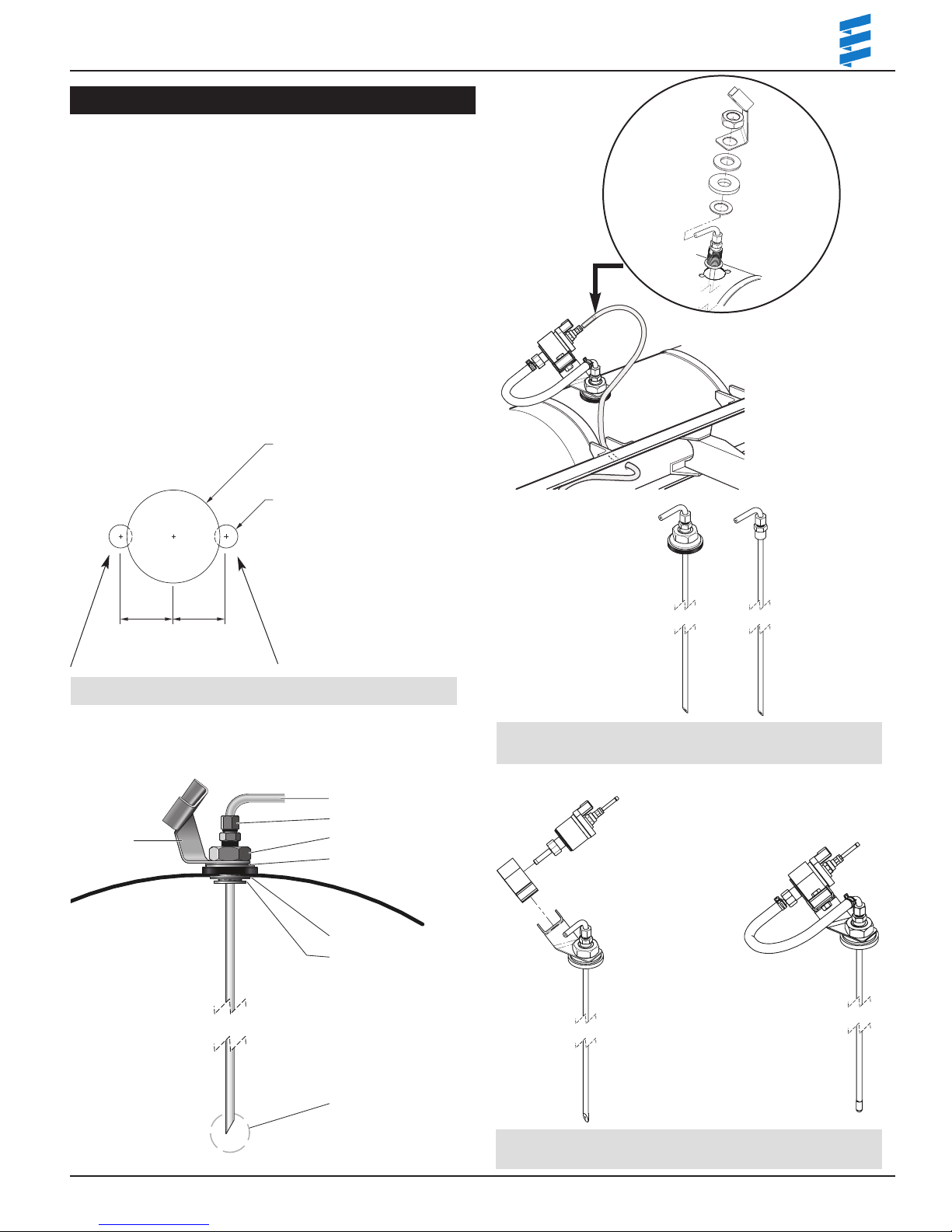

Installation Procedures

Ø 1.0”

9 / 16” 9 / 16”

Ø 1 / 4” (2 HOLES)

Fuel Pick-up Pipe

Ferrul Nut (Tighten before installing)

Nut

Sheet Metal Washer

(raised center to top)

Reinforc ing Washer

Holdin g Tabs

Allow 4" from Fuel

Pick-up to tank bottom.

Allow only 1" for flat

bottom tanks.

Fuel Tank

FMP bracket

Fuel Pick-Up Pipe Installation (Drill Option)

• Choose a protected mounting location close to the pump and

heater. A spare fuel sender gauge plate provides an ideal

mounting location. If one is not available...

• Drill mounting holes in tank to accommodate pick-up pipe as

shown.

• Tighten Ferrule nut to pick-up pipe at desired height.

• Cut the fuel pick-up pipe to length. Allow 2-2.5” from bottom of

tank.

• Mount the fuel pick-up pipe as shown.

• Lower the fuel pick-up pipe (with reinforcing washer) into the tank

using the slot created by the two 0.6cm (1/4”) holes.

• Lift the assembly into position through the 2.5cm (1”) hole.

• Assemble the rubber washer, metal cup washer and nut.

ø 2.5cm (ø1.0”)

ø 0.625 cm (2 Holes)

(ø 1/4”)

1.5 cm

(9/16”)

1.5 cm

(9/16”)

Note: Drill the two (1/4”) holes first.

Note: Some pick-up pipes can be installed by either

drill or NPT.

Typical standard assembly, if

not using this format please

adhere to specifications on

pg. 10

Note: NPT fittings are available in various sizes

(Refer to ESPAR Product Catalogue).

11

Page 12

-

+

B

C

D

A

E

Vehicle

Chassis

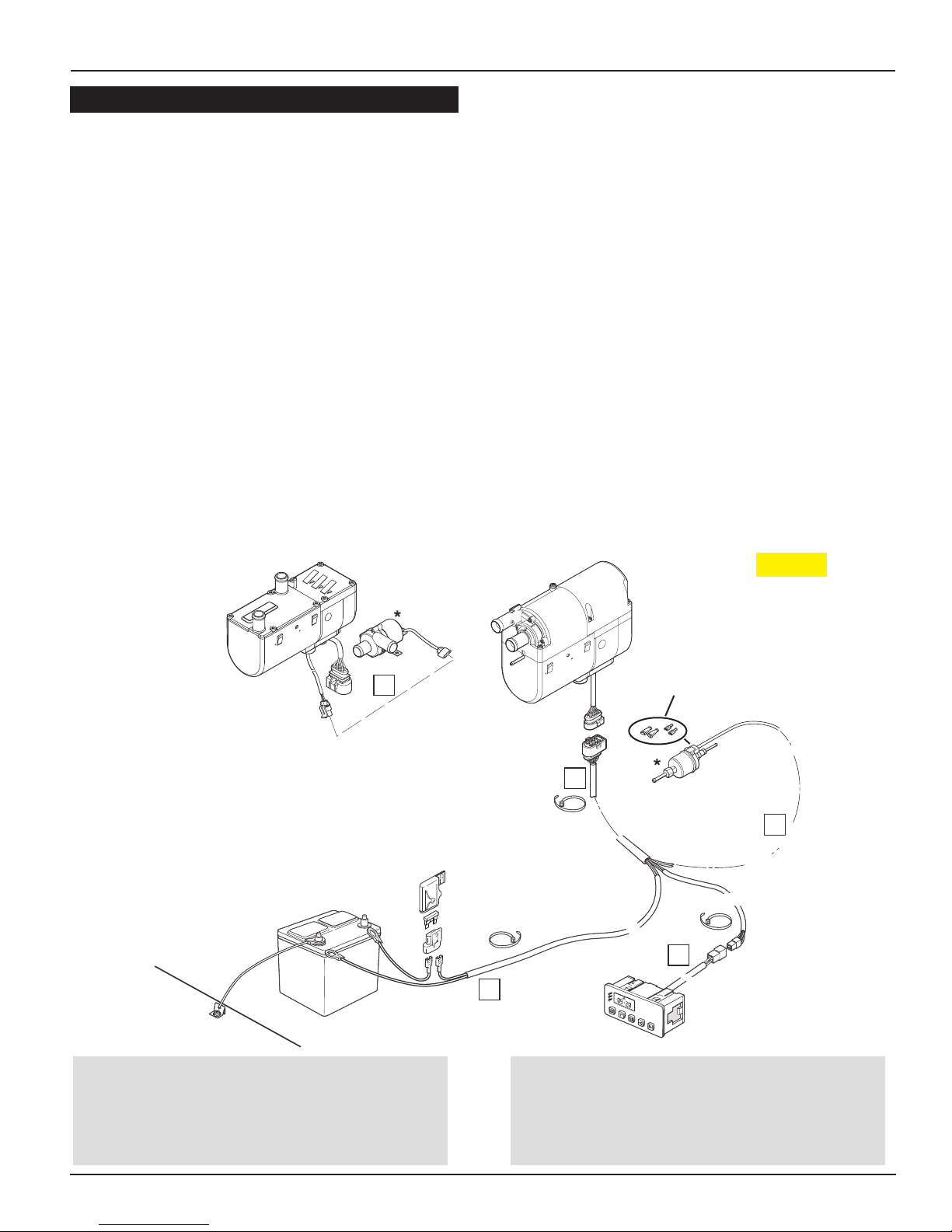

Installation Procedures

Electrical Connections

All parts needed are included with the kit. ( * ) indicates external mounted fuel and or water pump versions of Hydronics.

A. Main Heater Harness...................................................

B. Power Harness............................................................

C. Switch Harness............................................................

D.* Fuel Metering Pump Harness........................................

E.*Water Pump Harness......................................................

Hydronic Heaters

• Connects switch and power harness to the heater harness.

( * in some cases power to fuel metering pump).

• 2 core harness (red, brown).

• Connect red wire to fuse link and terminal.

• Attach ring terminal to vehicle battery (+).

• Connect brown wire to vehicle battery (-) using ring terminal

provided.

• 20 amp fuse - 12V.

15 amp fuse - 24V.

• 4 core harness (red/yellow, brown, yellow, blue/white).

• Run to location of control option. Make terminal connections

at control option. Espar has 2 available switches, see control

option instructions on following pages.

• 2 core harness (green, green) or (green, brown).

• Connect to fuel metering pump using terminals and protective

seals + connector block (no polarity required).

• 2 core harness (black, brown).

• Connect to main harness at heater.

Caution:

To avoid potential short circuit

damage during installation, insert

20 amp fuse on power harness

after all electrical connections are

complete.

Important: Negative battery terminal must always be

grounded.

If a vehicle is equipped with switch on negative battery wire, install additional 20 A fuse in negative wire of

heater’s harness.

Connector

Block

(Multi Functional)

Note: All harnesses should be cut to length.

All exposed electrical connections should be coated with

protective grease.

Installation Note: Wire must be inserted into fuse

holder prior to terminating.

7 Day Timer

12

Page 13

Installation Procedures

Exhaust Connection

A 24mm flexible tube exhaust pipe is required for the exhaust.

An exhaust clamp is used to secure the exhaust to the heater.

Connect the exhaust as follows:

• Connect the exhaust pipe to the exhaust port on the heater

and attach with clamp provided.

• Run exhaust to an open area to the rear or side of the vehicle

so that fumes can not build up and enter the passenger compartment or the heater combustion air intake.

• Install exhaust pipe with a slight slope or drill a small hole in

the lowest point to allow water to run out. Any restriction in

exhaust will cause operational problems.

• Route the exhaust pipe from the heater using “p” clamps

provided.

Caution: Run exhaust so that it cannot be plugged by

dirt, water or snow. Ensure the outlet does not

face into the vehicle slip stream.

Intake Connection

Combustion air must be drawn in from the outside. The combustion air opening must be kept free at all times.

• Connect the air intake pipe to the intake port on the heater and

secure with clamp provided.

Caution: Do not install the intake opening facing the

vehicle slipstream. Ensure that the opening

cannot become clogged with dirt or snow and that

any water entering the intake can drain away.

Exhaust

Clamp

(27mm - 30mm)

24mm Flexible Exhaust

Min 8” (0.4 mtr)

Max 78” (2 mtr)

Air Intake Hose

Min 8” (0.04 mtr)

Max 39” (1 mtr)

(When not mounted in

a Protective Box)

End Sleeve

Warning - Fire Hazard

The exhaust is hot, keep a minimum of 5cm (2”)

clearance from any heat sensitive material.

Route exhaust so that the exhaust fumes cannot enter

the passenger compartment.

Warning - Asphyxiation Hazard

Route exhaust beyond the skirt of the cab and

outside of the frame area.

Failure to comply with this warning could result in

Carbon Monoxide Poisoning.

13

Page 14

Installation Procedures

Yellow

Red

Brown

Blue

DIAG

TRS

Yellow

Red

Blue

Brown

12 11 10 9 8 7 6 5 4 3 2 1

MO

1

2

3

18:00

P

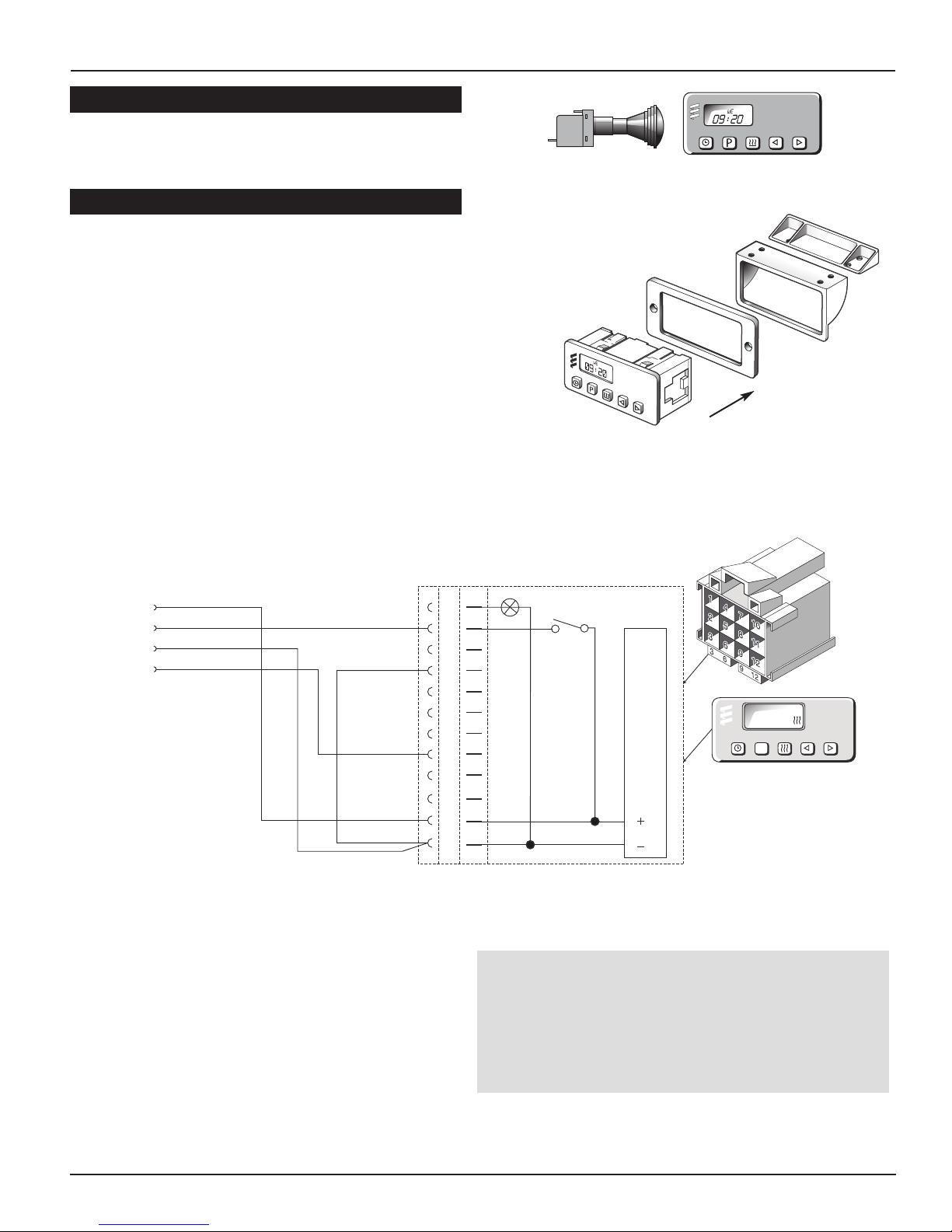

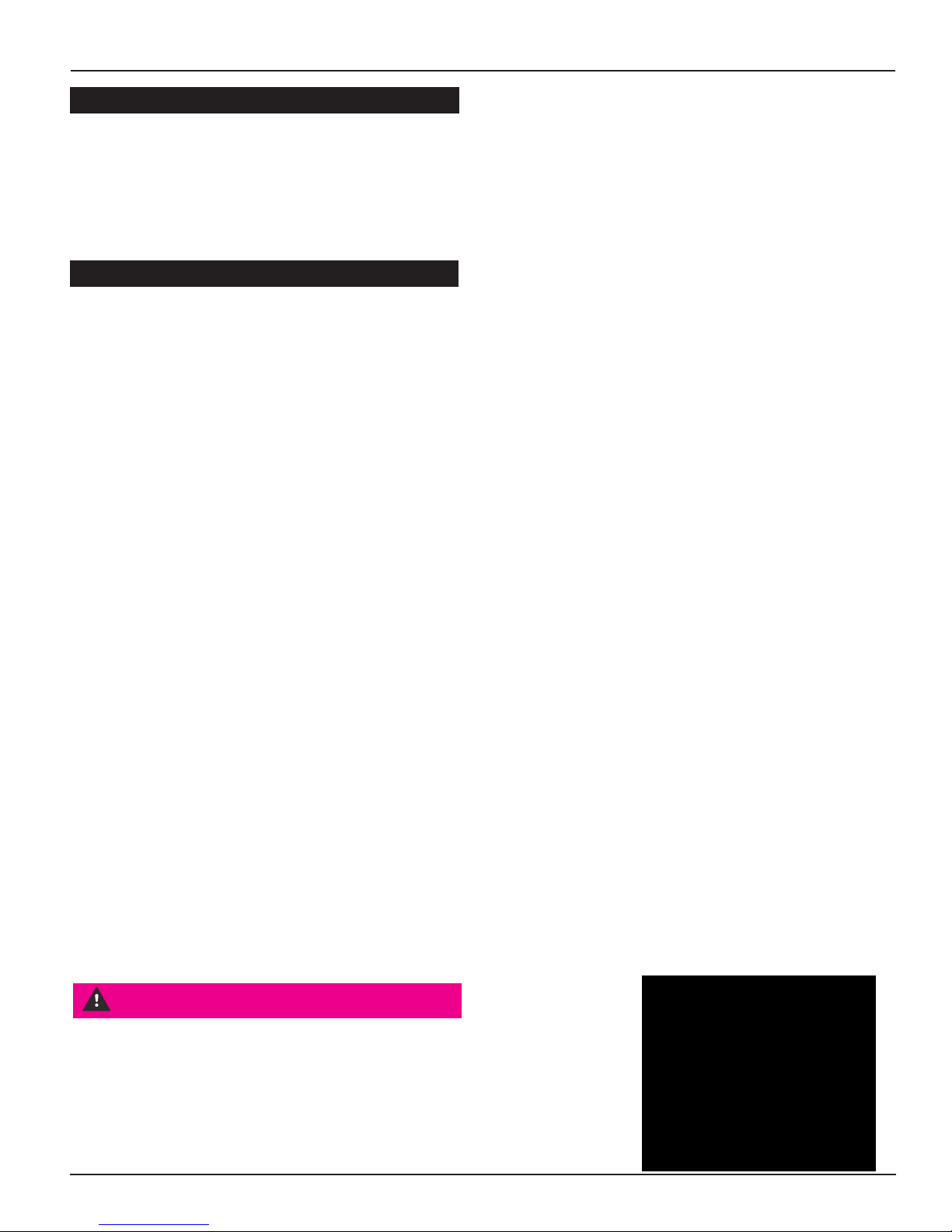

Control Options

A Push/Pull switch or a Multifunction (7 Day Timer) are available.

7 Day Timer

Multifunction

The multifunction is capable of multiple start functions within a

7 day period. Other functions include current time display and

automatic heater numeric fault code. Display refer to instructions provided with timer for setting options.

• Mount timer and bracket in a suitable location.

• Connect the switch harness to the connector at the heater

and run the harness to the control location.

• Cut harness to length at the control and install terminals.

• Connect switch harness to timer as shown below.

• Refer to timer instructions for other wiring options.

a)

b)

c)

d)

a) Power from battery “+”.

b) Switch control to the heater.

c) Power from battery “-”.

d) Diagnostic from heater.

Option #1: Dash lights to timer - connect wire between

dash lights circuit and timer at ter minal #1.

Option #2: Operate heater continuously - connect

wire from ignition circuit to terminal #10.

See also multifunction (7 day) timer in

instructions.

14

Page 15

Heater Operation

Push/Pull Switch

• Mount switch in a location where it is easily accessible.

• Mount using hardware supplied.

• Connect the switch harness to the connector at the heater

and run the harness to the switch location.

• Cut harness to length at the switch and install terminals.

• Connect wiring as shown.

Control Wiring

Push/Pull Switch

Brown- 31 Power from battery “-”

Red- K(15) Power from battery “+”

Yellow-15(K) Switch control to the heater

Blue/White Diagnostic from heater (disregard - tape end

and tie off to the side)

Note: Wired as above the switch light glows when pulled

out and is off when pushed in.

Ø

Ø

Heater Operation

Pre-Start Procedures

Upon completion of installation prepare the heater as follows:

• Check all fuel, electrical and plumbing connections.

• Refill the engine coolant.

• Bleed air from the coolant system by loosening the bleed

screw on top of the heater to allow air to escape.

• Loosen rad cap and run engine to allow air to be purged.

• Top up engine coolant.

Start Up

Once switched on the following sequence occurs:

• Control unit does a systems check (flame sensor, glow pin,

motors, temperature sensor and various other control unit

checks).

• Water pump starts circulating coolant.

• Combustion air blower comes on.

• Glow pin begins to preheat 20-50 secs.

• Metering pump starts and combustion air blower speeds up

gradually.

• Once ignition takes place the flame sensor alerts the control

unit and the control unit shuts off the glow pin (ignition time:

1.5 - 2 minutes).

Running

Running

Once ignition is successful the following operations take place:

• Heater runs in high heat mode and the temperature is monitored at the heat exchanger.

• Once coolant reaches 80°C (176°F) the heater automatically

switches to low heat mode and continues to run.

• If coolant temperature drops to 75°C (167°F) the heater will

automatically switch back to high heat mode.

• If the coolant temperature continues to rise, the heater will

automatically switch off once temperature reaches 86°C

(187°F).

• The water pump will continue to circulate coolant to allow the

heater to monitor engine temperature.

• The heater will automatically re-start once coolant temperature reaches 75°C (167°F).

• The heater continues to run as described above until it is

switched off, either manually, automatically by a timer or

heater malfunction shutdown.

Note: If the heater should shut down due to flame out

while in running mode, it will automatically

attempt one restart. If successful, it will continue

to run. If not, it will shut down completely with a

cool-down cycle.

Note: If the heater fails to start the first time it will

automatically attempt a second start.

If unsuccessful, the heater will shut down completely.

Note: On initial start up the heater may require several

start attempts to self prime the fuel system.

Note: During operation the heater continually senses

the input voltage from the batteries. If the input

voltage drops to approximately 10.5 volts or

rises above 16 volts the heater will automatically shut down with a cool-down cycle, and display

a fault code when using a multifunction timer.

15

Page 16

Heater Operation

Switching Off

• When the heater is switched off, manually or automatically,

it starts a controlled cool down cycle.

• The fuel metering pump stops delivering fuel and the flame

goes out.

• The combustion air blower and water pump continue to run

for 3 minutes to cool down.

• The heater shuts off.

Safety Equipment

The control unit, temperature sensor, overheat sensor and

flame sensor continually monitor heater functions and will shut

down the heater in case of a malfunction.

• The control unit ensures electrical circuits (fuel pump, combustion air blower etc.) are complete prior to starting the

heater.

• If the heater fails to ignite within 90 seconds of the fuel

pump being started, the starting procedure will be repeated.

If the heater again fails to ignite after 90 seconds of fuel

being pumped, a “no start safety shutdown” follows. (Fault

#52)

• If the heater flames out during operation, the heater automatically attempts to restart. If the heater fails to i g n i t e

within 90 seconds of fuel delivery, the heater will turn off the

fuel pump and complete a cool down and display a F052

code. After troubleshooting the problem the heater can be

started again by switching the heater off and then back on

again.

• Overheating due to lack of water, a restriction or a poorly

bled coolant system results in the overheat shutdown

(F012). Fuel delivery will cease and an “overheat shut

down” follows. If heater overheats 3 consecutive times, a

lockout on the control unit will occur. To unlock the control

unit you will need to use the Fault Code Retrieval Device.

See following pages for self diagnostics.

• If at any time the voltage drops below 10.5V for 20 seconds,

or rises above 16.0V for 20 seconds the heater will shut

down and display the associated Fault Code.

Warning

The heater must be switched off while any fuel tank on

the vehicle is being filled.

The heater must not be operated in garages or enclosed

areas.

16

Page 17

Heater Operation

STARTING PHASE

RUNNING PHASE SHUT DOWN PHASE

Operating

Mode

Time

Fuel

Pump

Glow

Pin

Blower

Water Pump

System

Check

Pre-heat Pre-heat

2nd. attempt

Ignition

Attempt

Ignition

Attempt

2nd. attempt

Controlled

Heating

Off

Off

Off

OffOn

Off

Off

On:

if in stand by

OnOnOnOnOn On

OnOnOnOn

Momentarily

OnOnOnOn

On

On

On

On

Off

Off

Off

Off Off Off Off Off

On

On On

After

Glow

Cool

Down

Off

or

Stand by

1- 3 sec.

40 sec.

20 sec.

40 sec

.

Up to

80 sec.

Up to 80 sec.

If Required

High/Low

Operation

until switched off

manually or automatically

2.5 min.

Note: During the controlled heating cycle, if the coolant temperature exceeds 86°C (187°F) the heater will cycle off.

Heater will automatically restart in high mode once coolant temperature reaches 75°C (167°F)

17

Page 18

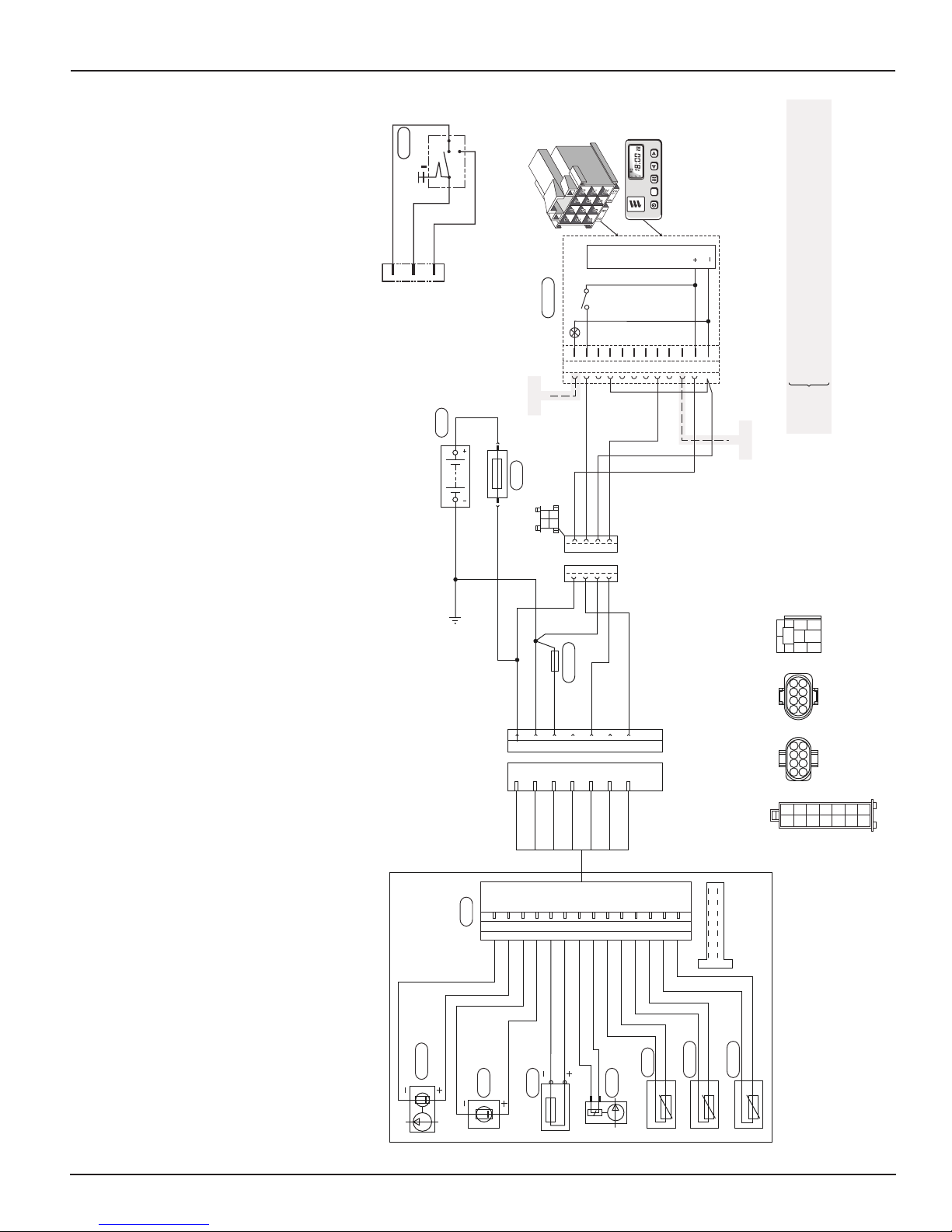

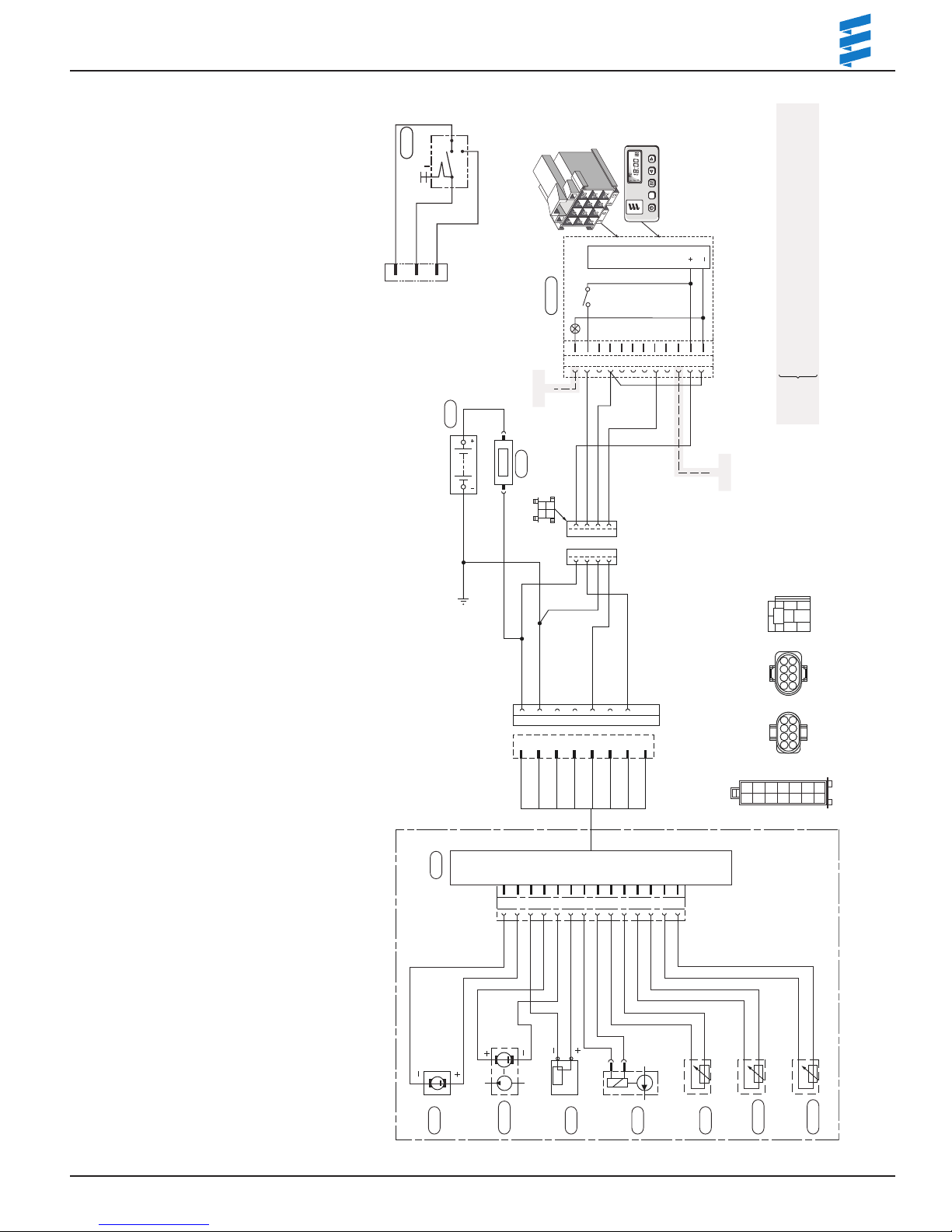

Heater Diagnostics

Red

K(15)

15(K)

Yellow

Brown

31

0

3.1.1

Optional

Brown

e)

Optional

Optional

f)

M

M

Yel low

Yel low

Red

Brown

Brown

Brown

Blue

Blue/White

Blue/White

DIAG

TRS

a) Power from battery “+”.

b) Switch control to heater.

c) Power from battery “-”.

d) Diagnostics from heater.

e) To vehicle dimmer switch for light display.

f) To vehicle ignition accessories for continuous

operation of heater.

121110 9 8 7 6 5 4 3 2 1

4 3 2 1

1

2

3

4

5

6

7

8

1

2

3

4

5

6

7

8

1 2

3 4

b)a)d)

c)

4 3 2 1

2 4 6 8

1 3 5 7

8 6 4 2

7 5 3 1

P

3.2.9

2.5.8

5.1

2.7

RedRed

Red

Brown

Red

Brown

Green

Light Green

Blue/White

Black

Blue

S1 B1

S1 B1

B2

B2

B3

2.1

2.12

1.1

1.2

2.2

1.5

1.13

1.12

Violet

Brown

Light Brown

Black

White

Brown

Green

Green

Red

Red

Blue

Blue

Brown

Blue

14 13 12 11 10 9 8 7 6 5 4 3 2 1

1 3 5 7 9 11 13

2 4 6 8 10 12 14

2 4 6 8 10 12 14

1 3 5 7 9 11 13

87

87a

85

30

86

Red/Yellow

Hydronic D4 SC 12 Volt

Model 25 1917 01

Wiring Harness P/N:

20 2900 70 04 01

(CA0 60 401)

Push/Pull switch

7 day timer

3.12

2.2 Fuel metering pump

2.5.8 Blower lock out resistor

2.7 20 amp main fuse

3.12 Push/Pull switch

3.2.9 7 day timer

5.1 Battery

1.1 Blower motor

18

1.2 Glow pin

1.5 Overheat sensor

1.12 Flame sensor

1.13 Temperature sensor

2.1 Control unit

2.12 Water Pump

Page 19

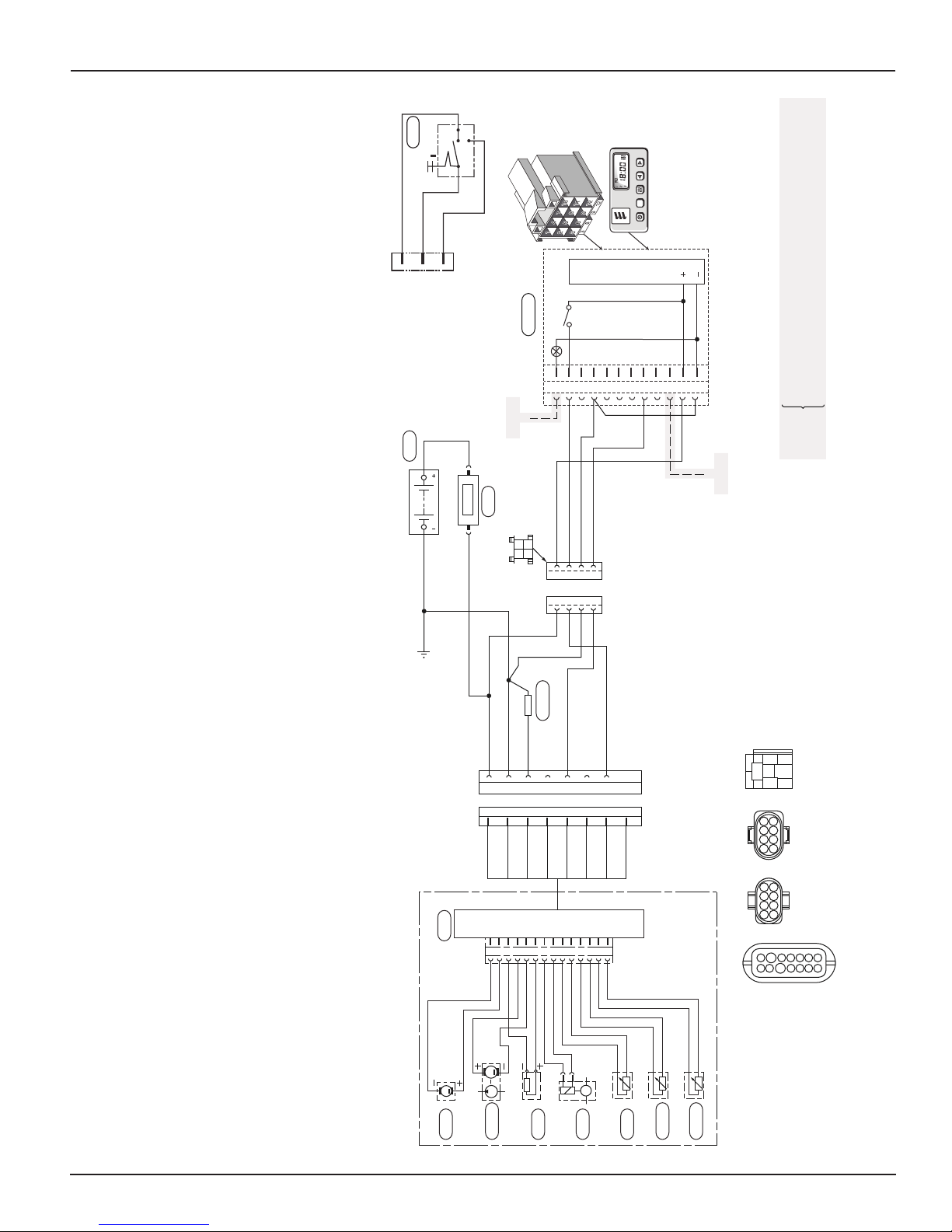

Heater Diagnostics

Brown

Violet

Brown

Light Brown

Black

White

Brown

Green

Green

Red

Red

Blue

Blue

Brown

Blue

1 2 3 4 5 6 7 8 9 10 1 12 13 14

Yel low

Brown

Red

Brown

Brown

Blue

Blue/White

DIAG

TRS

Yel low

a) Power from battery “+”.

b) Switch control to heater.

c) Power from battery “-”.

d) Diagnostics from heater.

e) To vehicle dimmer switch for light display.

f) To vehicle ignition accessories for continuous

operation of heater.

12 11 10 9 8 7 6 5 4 3 2 1

4 3 2 1

123

4

567

8

123

4

567

8

b)a)d)

c)

4 3 2 1

2 4 6 8

1 3 5 7

8 6 4 2

7 5 3 1

3.2.9

5.1

2.7

RedRed

Red/Yellow

Red

Brown

Red

Brown

Black/Red

Light Green

Blue/White

Blue

Yel low

Black/White

S1 B1

S1 B1

B3

2.1

2.12

1.1

1.2

2.2

1.5

1.13

1.12

1 3 5 7 9 11 13

2 4 6 8 10 12 14

87

87a

85

30

86

M

1 2

3 4

B2

B2

M

P

h)

Optional

e)

Optional

f)

Optional

Red

K(15)

15(K)

Yellow

Brown

31

0

3.1.1

Hydronic D4 SC 12 Volt

Model 25 2096 05

Wiring Harness P/N:

20 2900 70 05 03

Push/Pull switch

7 day timer

3.12

3.2.9 7 day timer

5.1 Battery

1.1 Blower motor

1.2 Glow pin

1.5 Overheat sensor

1.12 Flame sensor

1.13 Temperature sensor

2.1 Control unit

2.12 Water Pump

2.2 Fuel metering pump

2.7 20 amp main fuse

3.12 Push/Pull switch

19

Page 20

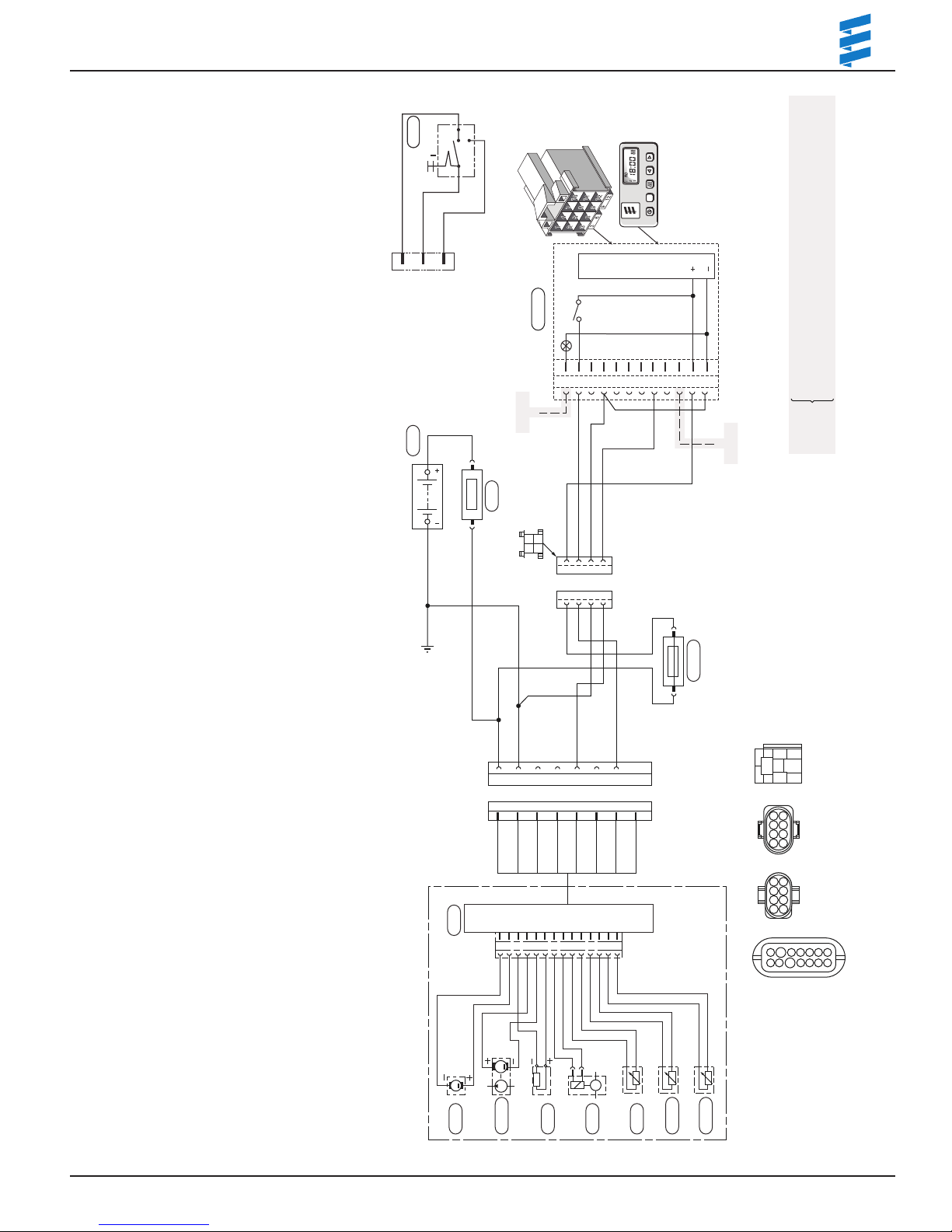

Heater Diagnostics

M

Optional

Brown

Black

Brown

Violet

Brown

White

Green

Green

Red

Red

Blue

Blue

Brown

Blue

1 2 3 4 5 6 7 8 9 10 11 12 13 14

Yel low

Yel low

Red

Brown

Brown

Brown

Blue

Blue/White

Black/Red

DIAG

TRS

Blue

a) Power from battery “+”.

b) Switch control to heater.

c) Power from battery “-”.

d) Diagnostics from heater.

e) To vehicle dimmer switch for light display.

f) To vehicle ignition accessories for continuous

operation of heater.

12 11 10 9 8 7 6 5 4 3 2 1

4 3 2 1

1

2

3

4

5

6

7

8

b)a)d)

c)

4 3 2 1

2 4 6 8

1 3 5 7

8 6 4 2

7 5 3 1

3.2.9

5.1

2.7

2.5.8

RedRed

Red/Yellow

Red

Brown

Red

Brown

Black/Red

Green

Blue/White

Blue

Yel low

Black/White

S1 B1

S1 B1

B3

2.1

1.1

2.12

1.2

2.2

1.5

1.13

1.12

1 3 5 7 9 11 13

8 7 6 5 4 3 2 1

87

87a

85

30

86

1 2

3 4

B2

B2

P

2 4 6 8 10 12 14

M

h)

Optional

e)

Optional

f)

Brown

Red

K(15)

15(K)

Yellow

Brown

31

0

3.1.1

Hydronic D5 SC 12 Volt

Model 25 1920 05

Wiring Harness P/N:

20 2900 70 04 01

Push/Pull switch

7 day timer

3.12

2.1 Control unit

2.12 Water Pump

2.2 Fuel metering pump

2.5.8 Blower lock out resistor

2.7 20 amp main fuse

3.12 Push/Pull switch

3.2.9 7 day timer

5.1 Battery

1.5 Overheat sensor

1.12 Flame sensor

1.13 Temperature sensor

1.1 Blower motor

1.2 Glow pin

20

Page 21

Heater Diagnostics

M

1 2 3 4 5 6 7 8 9 10 11 12 13 14

B2

P

M

Optional

e)

Optional

Optional

f)

Red

2.7.1

Yel low

Brown

Brown

Blue

Blue/White

Yel low

Red

Red/Yellow

Red

Brown

4 3 2 1

b)a)d)

c)

4 3 2 1

Brown

RedRed

DIAG

TRS

Brown

a) Power from battery “+”.

b) Switch control to heater.

c) Power from battery “-”.

d) Diagnostics from heater.

e) To vehicle dimmer switch for light display.

f) To vehicle ignition accessories for continuous

operation of heater.

121110 9 8 7 6 5 4 3 2 1

3.2.9

5.1

2.7

Red

Brown

Black/Red

Green

Blue/White

Blue

Yel low

Black/White

S1 B1

1

2

3

4

5

6

7

8

8 7 6 5 4 3 2 1

1 2

3 4

Brown

Black

Brown

Violet

Brown

White

Green

Green

Red

Red

Blue

Blue

Brown

Blue

1.1

2.12

1.2

2.2

1.5

1.13

1.12

h)

S1 B1

B3

2.1

B2

2 4 6 8

1 3 5 7

8 6 4 2

7 5 3 1

1 3 5 7 9 11 13

87

87a

85

30

86

2 4 6 8 10 12 14

Red

K(15)

15(K)

Yellow

Brown

31

0

3.1.1

Hydronic D5 SC 12 Volt

Model 25 2098 05

25 2219 05

25 2257 05

Wiring Harness P/N:

20 2900 70 05 03

No Blower Relay

Internal FMP

Push/Pull switch

7 day timer

3.12

2.12 Water Pump

2.2 Fuel metering pump

2.7 20 amp/12V main fuse

15 amp/24V main fuse

2.7.1 5 amp fuse

3.12 Push/Pull switch

3.2.9 7 day timer

5.1 Battery

1.12 Flame sensor

1.13 Temperature sensor

2.1 Control unit

1.1 Blower motor

1.2 Glow pin

1.5 Overheat sensor

21

Page 22

Heater Diagnostics

Optional

e)

Optional

Optional

f)

Red

2.7.1

M

Brown

Black

Brown

Violet

Brown

White

Green

Green

Red

Red

Blue

Blue

Brown

Blue

1 2 3 4 5 6 7 8 9 10 11 12 13 14

Yel low

Brown

Brown

Brown

Brown

Green

Brown

Blue

Blue/White

DIAG

TRS

Yel low

Red

a) Power from battery “+”.

b) Switch control to heater.

c) Power from battery “-”.

d) Diagnostics from heater.

e) To vehicle dimmer switch for light display.

f) To vehicle ignition accessories for continuous

operation of heater.

12 11 10 9 8 7 6 5 4 3 2 1

4 3 2 1

1

2

3

4

5

6

7

8

b)a)d)

c)

4 3 2 1

2 4 6 8

1 3 5 7

8 6 4 2

7 5 3 1

3.2.9

5.1

2.7

2.2

RedRed

Red/Yellow

Red

Brown

Red

Brown

Black/Red

Green

Blue/White

Blue

Yel low

Black/White

S1 B1

S1 B1

B3

2.1

1.1

2.12

1.2

1.5

1.13

1.12

1 3 5 7 9 11 13

8 7 6 5 4 3 2 1

87

87a

85

30

86

1 2

3 4

B2

B2

P

2 4 6 8 10 12 14

M

2.2

h)

Red

K(15)

15(K)

Yellow

Brown

31

0

3.1.1

Hydronic D5 SC 24 Volt

Model 25 2147 05

Wiring Harness P/N:

20 2900 70 20 13

External FMP

No Blower Relay

Push/Pull switch

7 day timer

Also applicable to:

Hydronic 4 & 5 SC 12 volt

Gasoline versions

Model 20 1820 05

20 1824 05

25 2325 05

3.12

2.12 Water Pump

2.2 Fuel metering pump

2.7 20 amp/12V main fuse

15 amp/24V main fuse

2.7.1 5 amp fuse

3.12 Push/Pull switch

3.2.9 7 day timer

5.1 Battery

1.12 Flame sensor

1.13 Temperature sensor

2.1 Control unit

1.1 Blower motor

1.2 Glow pin

1.5 Overheat sensor

22

Page 23

Heater Diagnostics

Optional

Brown

Black

Brown

Violet

Brown

White

Red

Red

Blue

Blue

Brown

Blue

1 2 3 4 5 6 7 8 9 10 11 12 13 14

Yel low

Brown

Brown

Brown

Brown

Green

Brown

Blue

Red

Blue/White

DIAG

TRS

Yel low

a) Power from battery “+”.

b) Switch control to heater.

c) Power from battery “-”.

d) Diagnostics from heater.

e) To vehicle dimmer switch for light display.

f) To vehicle ignition accessories for continuous

operation of heater.

12 11 10 9 8 7 6 5 4 3 2 1

4 3 2 1

1

2

3

4

5

6

7

8

b)

a)

e)

d)

c)

4 3 2 1

2 4 6 8

1 3 5 7

8 6 4 2

7 5 3 1

3.2.9

5.1

2.7

2.2

RedRed

Red

Red/Yellow

Red

Brown

Red

Brown

Brown

Violet

Brown

Black

Black/Red

Green

Blue/White

Blue

Yel low

Black/White

S1 B1

S1 B1

B3

2.1

1.1

1.2

1.5

1.13

1.12

1 3 5 7 9 11 13

8 7 6 5 4 3 2 1

87

87a

85

30

86

1 2

3 4

B2

B2

P

2 4 6 8 10 12 14

M

2.12

M

2.7.1

Optional

Optional

f)

Red

K(15)

15(K)

Yellow

Brown

31

0

3.1.1

Hydronic 5 S - 12 & 24 volt versions

Diesel & Gasoline versions

Model 20 1793 05 12 volt

Model 20 1819 05 12 volt

Model 25 2146 05 24 volt

Model 25 2217 05 12 volt

Model 25 2218 05 24 volt

Model 25 2100 05 12 volt

Wiring Harness P/N:

12V 2 0 2 9 0 0 7 0 0 5 07

24V 2 0 2 9 0 0 7 0 0 5 08

Push/Pull switch

7 day timer

3.12

2.12 Water Pump

2.2 Fuel metering pump

2.7 20 amp/12V main fuse

15 amp/24V main fuse

2.7.1 5 amp fuse

3.12 Push/Pull switch

3.2.9 7 day timer

5.1 Battery

1.12 Flame sensor

1.13 Temperature sensor

2.1 Control unit

1.1 Blower motor

1.2 Glow pin

1.5 Overheat sensor

23

Page 24

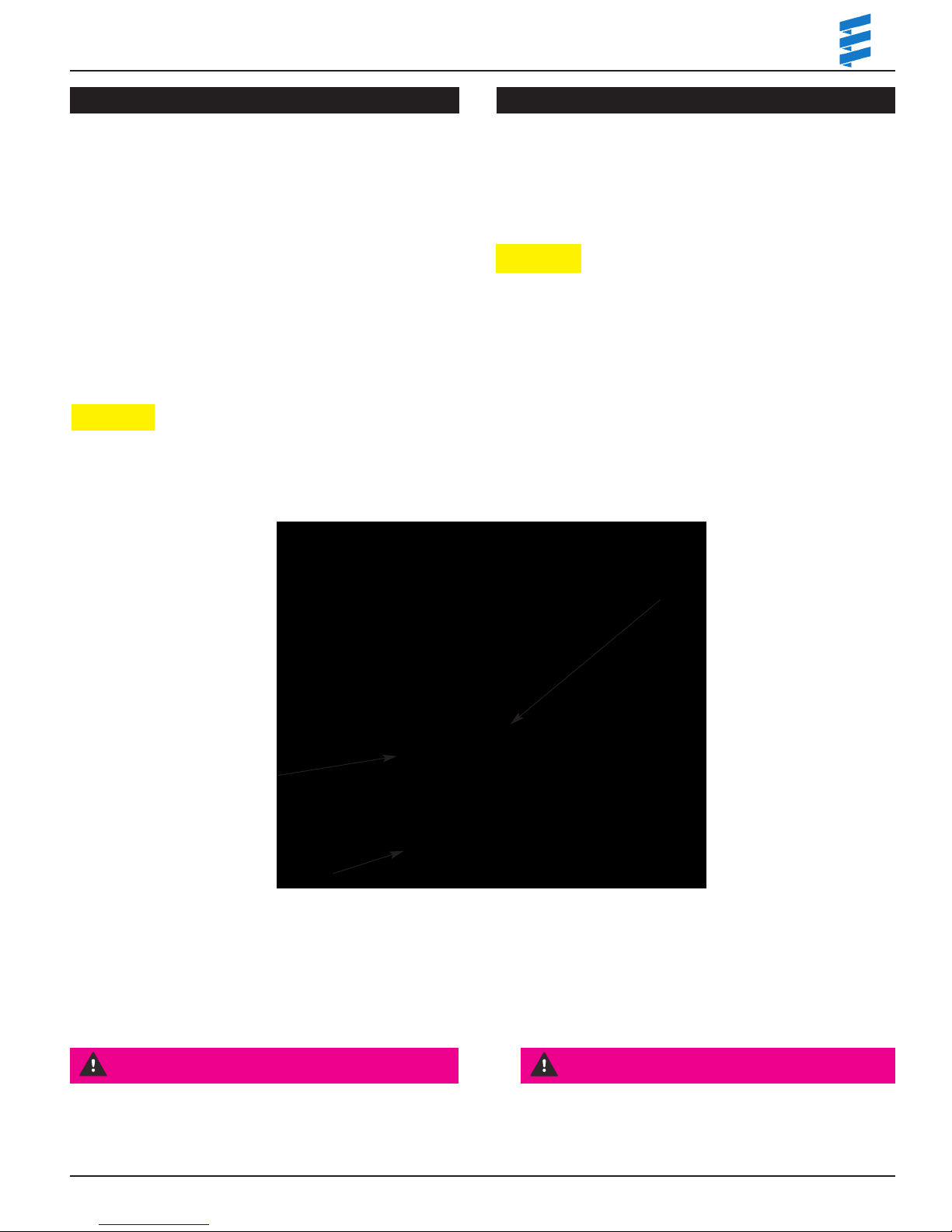

Maintenance / Troubleshooting / Repair

Periodic Maintenance Self Diagnostics

• Check coolant hoses, clamps, and make sure all valves are

open. Maintain the engine manufacturers recommended

coolant level and ensure that the heater is properly bled after

service on or involving the coolant system.

• Visual check of all fuel lines for leaks.

• Check and if necessary replace fuel filter inserts.

• Visual check of electrical lines and connections for corrosion.

• Run your heater at least once a month during the year (for a

minimum of 15 minutes).

• Maintain your batteries and all electrical connections in good

condition. With insufficient power the heater will not start.

• Low and high voltage cutouts will shut the heater down auto-

matically.

• Use fuel suitable for the climate (see engine manufacturers

recommendations). Blending used engine oil with diesel fuel

is NOT permitted.

• Check the glow pin and replace if necessary.

Troubleshooting

Basic Troubleshooting

In the event of failure there are several items which should be

checked first before any major troubleshooting is done.

Check:

• Circuit breakers and fuses.

• Electrical lines and connections.

• For interference in combustion air and exhaust pipes.

• That there is fuel in the tank.

• Battery voltage.

The heater is equipped with self diagnostic capability. You can

retrieve information on the heaters last 5 faults using the Espar

multifunction timer or Espar’s Fault Code Retrieval Device.

Multifunction

Espar’s multifunction timer has a fault code retrieval device

built into the unit. This function automatically activates if the

heater is experiencing problems.

• Fault codes appear on the LCD display screen.

• Codes can then be translated from the charts on the following pages.

Fault Code Retrieval Device

Equipment Face and Controls

Symbols seen on the display

face are as follows:

AF Actual fault.

F1-F5 Up to five stored faults can be accessed.

The AF and F1 are the same number.

This sign is displayed when the heater is in operation.

24

DIAG The word (Diagnostic) will come on when the diag-

nostic number is requested.

000 Three digit diagnostic fault code number.

Instructions:

• Connect as shown on following page.

• Switch the fault code retrieval device on and wait 10

seconds.

• Press the "D" button.

• Wait 3-5 seconds for the current fault code to appear (AF).

• To review the previous faults use the arrow buttons

(F1= Most Recent, F5= Oldest).

• To erase the faults that are in memory press both "L" keys

at the same time.

• See the fault code chart on following pages for code number descriptions.

Page 25

Maintenance / Troubleshooting / Repair

35

30

25

20

15

10

5

0

020406080100120

3000

2750

2500

2000

2250

1000

1250

1750

1500

750

0

-50 0 50 100 150 200 250 300 350 400 450 500

550

Hook Up

• Disconnect the main harness from heater and insert adapter

cable harness between them.

• Connect adapter cable to the cable loom of the Fault code

retrieval device.

HYDRONIC 5 adapter for

Fault code retrieval device

P/N 12V 2 0 2 9 0 0 70 5 0 28

Fault code retrieval device

P/N 12V 2 0 2 9 0 0 70 5 0 20

Test Values

Resistance

Metering pump approx. 10

Ω for 12 volt heater; approximately 36 Ω for 24 volt heater

Glow Pin approx. 0.9 Ω

Checking the sensors

To check the sensors, measure the resistance at current temperature, see following diagrams:

Temperature sensor

Overheating sensor

Resistance (Kohms)

Temperature (°C)

R> 2 Ω = open circuit

R< 50 Ω = short circuit

Flame sensor

Resistance (ohms)

Temperature (°C)

R> 3400 Ω = open circuit

R< 50 Ω = short circuit

25

Page 26

Maintenance / Troubleshooting / Repair

Fault Code Fault Description Causes / Repair

000 Normal Operation

010 Overvoltage Check voltage between terminals 1(red) and 2(brown) at connector (B1).

If voltage is > 15 volts then check battery, electrical leads and vehicle charging

system.

011 Under voltage shut down Check voltage between terminals 1(red) and 2(brown) at connector (B1).

If voltage is < 10 volts then check battery, electrical leads and vehicle charging

system.

012 Overheating Check for possible causes of overheat (water circuit), Sensor.

Check overheat switch resistance values. Temperature at temperature sensor or

overheat sensor is greater than 125°C.

014 Possible overheating detected Difference of measured values at temperature sensor >25°C (min. 80°C (difference

evaluation) water temperature and metering pump in operation);

Check temperature sensor and overheating sensor, replace if necessary.

Check for air in coolant system. Check values from previous page.

015 Too many overheats Remove cause of over heat. Reset control unit using an Espar diagnostic option.

Permanent overheating counter reading exceeded. Heating enable only possible by

means of diagnostics system (press both “LL” keys simultaneously).

017 Overheating detected Temperature at temperature or overheating sensor > 130 °C, emergency OFF if

Fault Code 012 or 014 not applicable; check water circuit, check temperature sen-

sor and overheating sensor; replace if necessary.

See graph on previous page.

020 Open circuit - glow pin Check glow pin and electrical leads for continuity, replace if necessary.

021 Short circuit - glow pin Check glow pin and electrical leads for continuity, replace if necessary.

030 Combustion air blower motor Blower impeller or electric motor may be jammed (frozen solid, dirty, etc.)

Fix jam, replace electric motor if necessary.

031 Combustion air blower motor Check lead to combustion air motor for continuity, replace motor if necessary.

032 Combustion air blower motor short-circuit Check combustion air blower motor (electric motor); replace if necessary.

Check power supply (chafed, corroded etc.)

038 Vehicle fan relay control break Check electric lead to relay, fix break, replace relay if necessary.

For wiring harness (20 2900 70 0401) without relay, replace harness.

039 Vehicle fan relay control short circuit Check electric lead to relay, fix break, replace relay if necessary.

For wiring harness (20 2900 70 0401) without relay, replace harness.

041 Water pump break Check supply lead to water pump for continuity, remedy break, replace water pump

if necessary.

042 Water pump short-circuit Check supply lead to water pump for short circuit, check water pump, re-place

047 Short circuit - fuel metering pump Check for wires for short to fuel metering pump. Test fuel metering pump.

048 Open circuit - fuel metering pump Check supply lead to metering pump for continuity, remedy break, replace if neces-

26

water pump if necessary.

Replace if necessary.

sary.

Page 27

Maintenance / Troubleshooting / Repair

Fault Code Fault Description Causes / Repair

050 Too many no start attempts Safety time counter reading exceeded. Reset control unit using 7 day timer or fault

code retrieval device to unlock control unit.

051 Faulty flame recognition At start, if flame sensor is a above 70°C > 240 seconds; check exhaust gas and

combustion air supply, check flame sensor, replace if necessary. For flame sensor

values see graph on previous page.

052 No start safety time exceeded No flame detected on start attempt. Check fuel delivery and fuel supply,

Check exhaust gas and combustion air ducts.

053 Flame cutout in high modew Heater has started successfully the flame has extinguished.

Check fuel supply. Check combustion air and exhaust flow.

Check flame sensor resistance value. Replace flame sensor if necessary.

054 Flame cutout in bust mode Heater has started successfully the flame has extinguished.

Check fuel supply. Check combustion air and exhaust flow.

056 Flame cutout in low mode Check flame sensor resistance value.

060 Open circuit - temperature sensor Temperature sensor detects a value beyond it's range.

Check connections. Check sensor resistance values between 11 and 12 at

connector B2 > 2 M (if open circuit).

061 Short circuit - external temperature sensor Check connections. Check sensor resistance values between 11 and 12 at

connector B2 < 50 Ω (if short circuit).

Temperature sensor values on previous pages.

064 Open circuit - flame sensor Sensor is sensing value outside of range. Check connection leads.

Resistance values between 1 and 2 at connector B2 > 3040 Ω (if open circuit).

065 Short circuit - flame sensor Check connection leads. Resistance values between 1 and 2 at connec tor

B2 > 780 Ω (if short circuit). Flame sensor values on page 17.

071 Open circuit - overheat sensor Check connection leads. Resistance values between 9 and 10 at connector

B2 > 2 M Ω (if open circuit).

072 Short circuit - overheat sensor Check connection leads. Resistance values between 9 and 10 at connector

B2 < 50 M Ω (if short circuit).

091 External interference voltage Error in controller from interference voltage from vehicle network possible causes:

poor batteries, poor battery charges, other interference sources; eliminate interfe-

rence voltages.

090 Controller defect Control unit malfunction due to interference voltage from vehicle electrical 092 -103

system; possible causes low batteries, charges, other sources of interference,

eliminate interference voltages.

Internal faults detected in microprocessor/memory. Replace control unit.

Internal failure. Replace control unit.

Faults not shown by the diagnosis system After switching HYDRONIC on, the water pump and vehicle fan start immediately.

HYDRONIC won’t start · Remove and check temperature sensor.

Note: For codes starting with 9x (e.g.91,93), try to put a good known working battery. Be sure to have the engine off and any

equipment as well. Try to restart heater and check for any codes. This has to be done before/prior replacing the ECU.

After switching HYDRONIC on, the vehicle fan starts, functioning “preventing” is

activated.

· Changeover venting to heating at “heating/venting changeover switch.

27

Page 28

Maintenance / Troubleshooting / Repair

Fuel Quantity Test

The fuel Quantity should be tested if the heater has difficulty

starting or maintaining a flame, using graduated cylinder part

# 5 5 2 0 0 04 10ml.

Note: Measure the fuel quantity when the battery is

sufficiently charged. At least 11V and at most

13V should be applied at the control unit during measurement.

Preparation

• Remove metering pump cover in the cases of SC versions.

• Pull the fuel line off the combustion chamber and insert into

a graduated measuring glass.

• Switch the heater on, when fuel delivery is uniform (approximately 40 seconds after switching on), the fuel line is full

and bled.

• Switch heater off.

• Empty measuring glass and replace.

Measurement

• Switch heater on.

• Fuel delivery starts automatically approximately 40

seconds after switching on.

• Hold the graduated measuring glass at the glow pin height

during measurement.

• After 90 seconds of fuel delivery, it will shut off automatically.

• Switch heater off.

• Read off quantity of fuel delivery in the graduated measuring glass.

Evaluation

Hydronic D4W SC Hydronic D5W SC Hydronic D5W S Hydronic B4W SC Hydronic B5W SC

3

8.4 cm

7.3 cm

If measured quantity of fuel is over or under the nominal value,

the metering pump must be replaced or fuel restriction eliminated.

28

/ 90 seconds 9.5 cm3/ 90 seconds 8.6 cm3/ 90 seconds 11.3 cm3/ 90 seconds 11.9 cm3/ 90 seconds Max

3

/ 90 seconds 8.5 cm3/ 90 seconds 7.6 cm3/ 90 seconds 10.1 cm3/ 90 seconds 10.7 cm3/ 90 seconds Min

Diesel Gasoline

Hydronic B5W S

Page 29

Maintenance / Troubleshooting / Repair

Repair Steps covered are for the Hydronic 4 & 5 SC versions - other models are similar

Disassembly / Assembly

1 Cover, metering pump

2 Water pump, assembly

3 Metering pump and bracket

4 Cover, blower

5 Control unit and cover

6 Glow pin

1 Cover, metering pump

7 Flame sensor

8 Cable harness

9 Electric motor, complete

10 Combustion chamber with flame tube

11 Heat exchanger and jacket

4 Cover, blower

2 Water pump assembly. When mounting, place O-rings

on connection on water pump housing

3 Metering pump and bracket

5 Control unit and cover

6 Glow pin

29

Page 30

Maintenance / Troubleshooting / Repair

7 Flame sensor, For removal of tab receptacles, use

AMP extractor tool

10 Combustion chamber with flame tube

8 Cable Harness

9 Electric motor, complete

11 Heat exchanger and jacket, Align slot on heat

exchanger (arrow) with lug in jacket

30

Page 31

Maintenance / Troubleshooting / Repair

Magnetic Drive Coolant Pump Cleaning

It is advised to make this procedure part of an annual

pre-season check up for this heater.

Remove the four screws holding the colant

pumps two halves together.

“O” Ring 45mm x 1 1/2 m, Part #: 556 00 06

Motor / Impeller Assembly

Pump Motor

Motor Assembly

Impeller with Magnet

31

Page 32

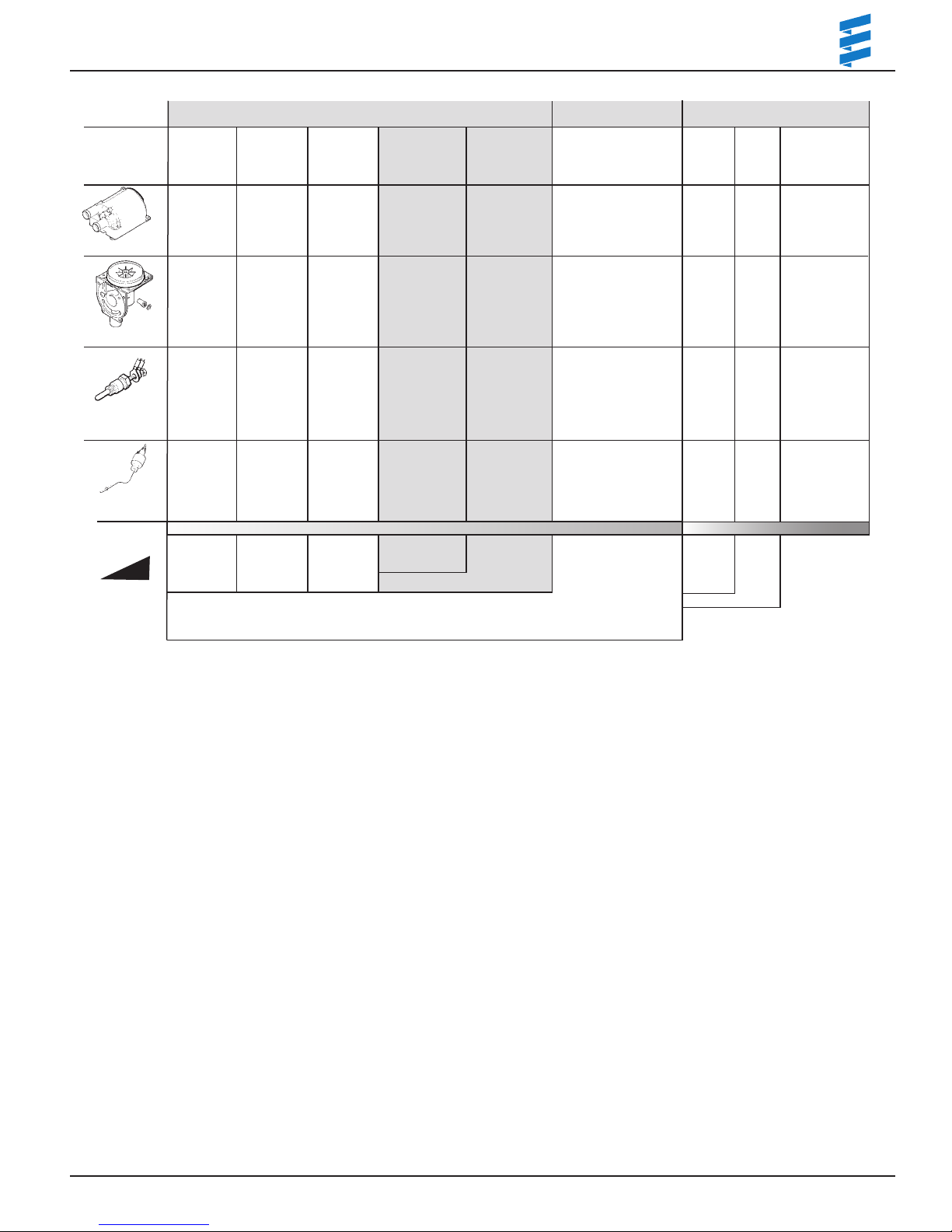

Heater Components Face Lift “SC” Heaters

Parts Diagram - Hydronic 4 / 5 W SC - Face Lift - 12 volt - Diesel & Gasoline versions

Model 20 1824 05

Model 25 2257 05

Model 20 1820 05

Model 25 2219 05

Model 25 2325 05

with external FMP

32

Page 33

Heater Components Face Lift “SC” Heaters

HYDRONIC 4 / 5 W SC - Face Lift - 12 volt - Diesel & Gasoline versions

Description & Part #’s

Ref. No. Description Part Number

1 Outer casing 25 2149 01 01 01 • • • • •

2 Combustion air blower 20 1819 99 16 00 • • • • •

3 Cover 25 1917 01 00 02 • • • • •

4 Burner 20 1818 11 00 00 • •

25 2216 10 00 00 • • •

5 Heat exchanger 25 2149 06 00 01 • • • • •

6 Control unit 22 5201 04 00 07 •

22 5201 04 00 06 •

22 5201 04 00 01 •

22 5201 04 00 11 • •

7 Cover 20 1752 99 01 03 • • • • •

8 Coolant Pump 25 2219 25 00 00 • • • • •

9 Fuel metering pump 22 4504 03 00 00 • •

Internal fuel pipe 25 2118 01 00 01 •

Intermediate piece 25 2137 01 00 01 •

10 Integrated fuel filter 20 1312 00 00 06 • ••••

11 Holder fuel metering pump 25 1917 01 00 07 • •

12 Seal 20 1820 99 00 01 • • • • •

20 1824 05 12v

Model #

25 2257 05 12v

20 1820 05 12v

25 2219 05 12v

25 2325 05 12v

13 O-Ring 74 x 3 mm 22 1000 70 00 18 • • • • •

14 Glow pin with cable section 25 2106 01 10 00 •••• •

15 Plug connection 20 1752 01 10 00 • •

25 2147 01 14 00 • • •

16 Atomizing Screen with O rings 20 1752 99 01 02 • •

25 2121 99 01 13 •••

17 Holder 20 1752 01 00 04 • •••

18 Groomet 20 1752 01 00 02 • •

19 Flame sensor 25 1920 36 00 00 Old P/N • • • • •

25 1920 37 00 00 New P/N • • • • •

20 Overheat sensor/temperature with cable section 25 2147 01 20 00 • •

25 2219 01 20 00 • • •

21 Plug kit 14 pin 22 1000 30 10 10 • ••••

22 Cable section Waterpump 20 1753 01 18 00 • • • • •

23 Leaf spring 25 1922 01 00 05 • • • • •

24 Fuel metering pump cover 20 1752 01 00 03 • •

25 1917 01 00 03 • • •

25 O-Ring 14 x 2.6 22 1000 70 00 06 • • • ••

26 O-Ring 7 x 2 22 1000 70 00 09 • • • ••

27 Hose 25 1917 01 00 11 • ••

28 Cable band 209 31 071 • ••

33

Page 34

Heater Components Face Lift “SC” Heaters

HYDRONIC 4 / 5 W SC - Face Lift - 12 volt - Diesel & Gasoline versions

Description & Part #’s

Ref. No. Description Part Number

29 Screw 25 1917 25 00 12 ••• ••

30 O-Ring 5 x 1.5 mm

31 Screw M5 x 12 109 10 153 • • • • •

32 Sleeve 25 1917 01 00 05 • • •

34 Tapite screw M5 x 35 Torx 109 10 154 • ••••

35 Tapite screw M5 x 25 Torx 109 10 152 • • •••

36 Cheese-head screw M5 x 65 Torx 100 10 350 ••• ••

37 Tapite screw M5 x 16 Torx 109 10 151 • • • ••

38 Tapite screw M4 x 10 Torx 109 10 150 • • • ••

39 Counter sunk screw M5 x 12 Torx 102 10 302 • • • • •

* H

Model #

20 1824 05 12v

20 1820 05 12v

25 2257 05 12v

25 2219 05 12v

25 2325 05 12v

34

* H = Available at local harware store

Page 35

Notes:

35

Page 36

Heater Components Face Lift “SC” Heaters

Parts Diagram - Hydronic 4 / 5 W SC - Face Lift - 12 volt - Diesel & Gasoline versions

Model 20 1824 05

Model 20 1820 05

Model 25 2219 05

Model 25 2257 05

Model 25 2325 05

36

Page 37

Heater Components Face Lift “SC” Heaters

Hydronic 4 / 5 W SC - Face Lift - 12 volt - Diesel & Gasoline versions

Description & Part #’s

Ref. No. Description Part Number

01 T-piece 8 x 6 x8 mm 262 31 151 •••••

02 T-piece 8 x 4 x8 mm 262 31 155 •••••

03 Hose 5 x 3 360 75 350 •••••

04 Hose 3.5mm x 3mm 360 75 300 •••••

05 Pipe 2mm 890 31 055 •••••

06 Pipe 1.5mm 890 31 118 •••••

07 Pipe 2mm 890 31 125 •••••

08 Hose 7.5mm Not available

09 Supporting sleeve with collar Not available

10 Hose clip 11mm 10 2068 01 10 98 • •

11 Hose clip 9mm 10 2068 00 90 98 • • • •

12 Hose clip 14mm 10 2068 01 40 98 • •

13 Hose clip 12mm 10 2068 01 20 98 • • • •

14 Holder 25 2220 80 00 01 • • • •

15 Central screw 100 10 258 • • • •

16 Rubber shockmount 6 mm 20 1185 00 00 01 • • • •

17 Fuel metering pump 22 4517 04 00 00 •••

18 Integrated fuel filter 20 1312 00 00 06 ••

19 Holder metering pump 22 1000 50 03 00 •••

20 Main harness - J.E - Universal w/relay 25 1917 80 10 00 • • •

25 1917 80 11 00 • •

20a Main harness ESPAR 20 2900 70 05 03 ••

21 Connection Kit 22 1000 30 10 21 ••••

22 Relay 203 00 095 ••••

23 Cable 22 1000 31 28 00 ••••

Model #

20 1824 05 12v

20 1820 05 12v

25 2257 05 12v

25 2219 05 12v

25 2325 05 12v

* H = Available at local harware store

37

Page 38

Heater Components Face Lift “SC” Heaters

3

5

4

1

2

7

8

10

11

8

8

9

12

13

14

14

14

14

14

14

9

6

Parts Diagram - Hydronic 4 / 5 W SC - Face Lift - 12 volt - Diesel & Gasoline versions

Model 20 1824 05

Model 25 2257 05

Model 20 1820 05

Model 25 2219 05

Model 25 2325 05

38

Page 39

Heater Components Face Lift “SC” Heaters

Hydronic 4 / 5 W SC - Face Lift - 12 volt - Diesel & Gasoline versions

Description & Part #’s

Ref. No. Description Part Number

1 Flexible air intake hose - 20mm x 1mtr 360 00 099 •••••

2 End cap with bar 25 1688 80 12 01 ••• ••

3 Hose clamp 16 - 32mm 10 2067 01 60 25 ••• ••

4 Exhaust hose - 24mm x 1mtr / with cap 25 1774 80 02 00 •••••

5 Exhaust hose 24 mm 360 61 299 •••••

6 Exhaust end cap w/bar 20 2900 30 24 00 ••• ••

7 Exhaust silencer 25 1864 81 01 00 ••

22 1000 40 09 00 • • •

8 Exhaust clamp 22 1000 50 05 00 ••• ••

9 “P” clamp 28mm 152 09 010 •••••

10 Double angle bracket 20 1533 88 00 07 ••• ••

11 Water Hose - Moulded - 18mm 20 1690 81 00 01 •••••

12 Water hose union - 18mm 20 1528 88 00 03 ••• ••

13 Water hose union - 18mm - 15mm 20 1645 80 02 01 ••• ••

14 Hose clamp 20 - 32mm 10 2066 02 00 32 ••• ••

Model #

20 1824 05 12v

20 1820 05 12v

25 2257 05 12v

25 2219 05 12v

25 2325 05 12v

* H = Available at local harware store

39

Page 40

Heater Components Face Lift “S” Heaters

1

2

3

28

15

26

18

19

32

6

31

29

30

28

8

24

25

27

13

14

5

4

7

17

31

32

32

16

22

20

9*

9

10* 10

11

11

12

21

23

25

01

Parts Diagram - Hydronic B5 / D5 - 12 & 24 volt - Diesel & Gasoline versions

Model 20 1819 05

Model 25 2217 05

Model 25 2218 05

40

Page 41

Heater Components Face Lift “S” Heaters

Hydronic B5 / D5 - 12 & 24 volt - Diesel & Gasoline versions

Description & Part #’s

Ref. No. Description Part Number

1 Casing 25 2149 01 01 01 •••

2 Combustion air blower with cover 20 1819 99 16 00 ••

25 2146 99 17 00 •

3 Cover 25 2217 01 00 01 •• •

4 Burner 20 1818 11 00 00 •

25 2216 10 00 00 •

25 2146 10 00 00 •

5 Heat exchanger 25 2149 06 00 01 •• •

6 Control unit 22 5201 04 00 01 •

22 5201 04 00 11 •

22 5202 01 10 01 •

7 Cover - heater base 20 1756 99 01 03 •• •

8 Cover 25 2216 01 00 02 •• •

9 Hose barb assly 18mm 25 2216 99 01 06 •• •

10 Hose barb assly - 90° - 18 mm 25 2216 99 01 05 •••

11 O-Ring 16x2 22 1000 70 00 19 •• •

12 Hose barb locks 25 2216 01 00 10 •• •

13 Gasket / seal set 20 1820 99 00 01 •• •

Model #

20 1819 05 12V

25 2217 05 12V

25 2218 05 24V

14 O-Ring - 74x3 22 1000 70 00 18 •• •

15 Glow pin 25 2106 01 10 00 ••

16 Glow plug housing 20 1756 01 10 00 •

17 Glow pin screen and 2 O-rings 20 1752 99 01 02 •

18

Flame sensor 25 1920 36 00 00 Old P/N • • •

25 2107 01 10 00 •

25 2121 01 14 00 ••

25 2121 99 01 13 ••

25 1920 37 00 00 New P/N • • •

19 Holder 20 1752 01 00 04 •••

20 Over heat / temperature sensor with cable 25 2150 01 20 00 •• •

21 Grommet for cable 25 2216 01 17 01 •• •

22 Control unit plug kit 22 1000 30 10 10 •• •

23 Water pump harness 25 2009 01 15 00 •• •

24 Leaf spring 25 1922 01 00 05 •• •

25 O-ring 7 x 2 22 1000 70 00 09 •••

26 Grommet 20 1756 01 00 04 •••

27 Screw M5 x 12 torx 109 10 153 •• •

28 Taptite screw M5 x 25 torx 109 10 152 •••

29 Cheese-head screw M5 x 65 torx 100 10 350 •• •

30 Taptite screw M5 x 16 torx 109 10 151 •••

31 Taptite Screw M4 x 10 torx 109 10 150 •• •

32 Countersunk screw M5 x 12 torx 102 10 302 •• •

41

Page 42

Heater Components Face Lift “S” Heaters

Parts Diagram - Hydronic B5 / D5 - 12 & 24 volt - Diesel & Gasoline versions

Model 20 1819 05

Model 25 2217 05

Model 25 2218 05

42

Page 43

Heater Components Face Lift “S” Heaters

Hydronic B5 / D5 - 12 & 24 volt - Diesel & Gasoline versions

Description & Part #’s

Ref. No. Description Part Number

1 T-piece 8 x 6 x 8 mm 262 31 151 •••

2 Fuel pick up pipe 2.0mm - Universal

3 Fuel filter 25 1226 89 00 37 •• •

4 Fuel hose 3.5 x 3mm 360 75 300 •

5 Hose 5 x 3mm 360 75 350 •• •

6 Plastic fuel line 1.5 mm 890 31 118 •••

7 Plastic fuel line 2 mm 890 31 125 •• •

8 Hose 7.5mm Not available

9 Supporting sleeve with collar Not available

10 Fuel line clamp 11mm 10 2068 01 10 98 •• •

11 Fuel line clamp 9mm 10 2068 00 90 98 •• •

12 Fuel line clamp 14mm 10 2068 01 40 98 •• •

13 Fuel line clamp 12mm 10 2068 01 20 98 •• •

14 Fuel metering pump 12 V 22 4517 04 00 00 ••

24 V 25 1942 45 00 00 •

15 Integrated fuel filter 20 1312 00 00 06 •• •

16 Holder metering pump 22 1000 50 03 00 •• •

17 Main harness - J.E Universal w/relay 25 1917 80 10 00 ••

17a Main harness ESPAR

18 Connector kit 22 1000 30 10 21 •••

19 Relay 12 V 203 00 095 ••

24 V 203 00 066 •

31 Angle bracket 20 2900 40 01 04 •• •

20 2900 20 20 10 •• •

25 2009 80 10 00 •

20 2900 70 05 03 •• •

Model #

20 1819 05 12v

25 2217 05 12v

25 2218 05 24v

* H = Available at local harware store

43

Page 44

Heater Components Face Lift “S” Heaters

4

1

2

5

6

7

8

9

9

9

9

11

12

13

14

14

15

10

15

15

15

15

3

Parts Diagram - Hydronic B5 / D5 - 12 & 24 volt - Diesel & Gasoline versions

Model 20 1819 05

Model 25 2217 05

Model 25 2218 05

44

Page 45

Heater Components Face Lift “S” Heaters

Hydronic B5 / D5 - 12 & 24 volt - Diesel & Gasoline versions

Description & Part #’s

Ref. No. Description Part Number

1 Bracket 25 2220 80 00 01 • • •

2 Rubber mount 6mm 20 1185 00 00 01 •••

3 Central screw, M6 x 97 Hex bolt 100 10 258 •••

4 Flexible air intake hose 360 00 099 •••

5 End cap with bar 25 1688 80 12 01 •••

6 Hose clamp 16 - 25mm 10 2067 01 60 25 •••

7 Exhaust Hose - 24mm x 1mtr with cap 25 1774 80 02 00 •••

8 Exhaust silencer 24mm 22 1000 40 09 00 •••

9 Exhaust clamp 22 1000 50 05 00 • • •

10 P clamp 28mm 152 09 010 • • •

11 Double angle bracket 20 1533 88 00 07 • • •

12 Coolant pump 12 V 25 2217 27 00 00 • •

24 V 25 2218 25 00 00 •

13 Coolant hose - moulded - 18mm 20 1690 81 00 01 • • •

14 Coolant hose union - 18mm 20 1528 88 00 03 • • •

15 Hose clip 20 - 32mm 10 2066 02 00 32 • • •

Model #

20 1819 05 12v

25 2217 05 12v

25 2218 05 24v

45

Page 46

1

6

5

7

8

9

11

12

13

14

15

19

20

21

22

28

30

31

32

34

27

29

35

36

37

38

39

39

41

42

43

44

45

2

3

10

40

24

29

28

23

25

26

18

22

Heater Components Early “SC” Heaters

Parts Diagram - Hydronic B4 / B5 / D4 / D5 - 12 & 24 volt - Diesel & Gasoline versions

Model 25 2096 05

Model 25 1920 05

Model 25 2098 05

Model 25 2147 05 24 V

with external fuel pump

46

Page 47

Heater Components Early “SC” Heaters

Hydronic B4 / B5 / D4 / D5 - 12 & 24 volt - Diesel & Gasoline versions

Description & Part #’s

Ref. No. Description Part Number

1 Casing 25 1917 01 01 01 •

25 1920 01 01 01 • ••

25 1922 01 01 01 •

2 Combustion air blower 25 2219 99 16 00 • •

with cover - 26 1922 99 16 00 • •

25 2013 99 16 00 •

25 2146 99 17 00 •

3 Cover 25 1917 01 00 02 • • •

25 2137 01 00 02 •

5 Burner 25 1917 19 00 00 •

25 1920 10 00 00 • •

25 2146 10 00 00 •

6 Heat exchanger 25 1864 06 00 01 •

25 1922 06 00 01 • • •

7 Control unit 25 1917 55 00 01 •

22 5201 00 10 01 •

22 5201 00 30 01 •

22 5202 01 10 01 •

8 Cover 20 1752 99 01 03 • • • •

9 Coolant pump 25 1920 25 00 00 • • •

25 2118 25 00 00 •

Model #

25 2096 05 12V

25 1920 05 12V

25 2098 05 12V

25 2147 05 24V

10 Fuel metering pump 25 1917 45 00 00 •

25 1920 45 00 00 • •

25 1942 45 00 00 •

11 Integrated fuel filter 20 1312 00 00 06 • • •

12 Holder Fuel metering pump 25 1917 01 00 07 • • •

13 Seal 20 1820 99 00 01 • • • •

14 O-Ring 74 x 33mm 320 75 104 • • • •

15 Glow pin 25 1864 01 10 00 •

25 2107 01 10 00 •

25 2106 01 10 00 • •

16 Plug connection complete 25 2147 01 13 00

17 Holder 25 1752 01 00 04

18 Glow pin assembly 25 2147 01 13 00 •

19 Holder 20 1752 01 00 04 •

20 Sleeve 20 1752 01 00 02 •

21 Flame sensor 25 1920 36 00 00 Old P/N • • • •

25 1920 36 00 00 New P/N • • • •

22 Overheat sensor with cable 25 1920 01 17 00 • • •

25 2147 01 20 00 •

23 Plug kit 14 pin 22 1000 30 10 10 • • • •

24 Glow plug harness 25 1920 01 80 00 • • • •

25 Cable section complete assembly 25 2219 01 20 00 • • • •

47

Page 48

Heater Components Early “SC” Heaters

Hydronic B4 / B5 / D4 / D5 - 12 & 24 volt - Diesel & Gasoline versions

Description & Part #’s

Ref. No. Description Part Number

25a Cable section waterpump 20 1753 01 18 00 • • • •

26 Spring 25 1864 01 00 05 •

25 1922 01 00 05 • • •

27 Cover Fuel metering pump 25 1917 01 00 03 • • • •

28 O-Ring 14 x 2.6 22 1000 70 00 06 • • • •

29 O-Ring 7.5 x 2 22 1000 70 00 09 • • • •

30 Hose 25 1917 01 00 11 • • • •

31 Cable band 209 31 071 • • • •

32 Screw M4 x 10 25 1917 25 00 12 • • • •

34 Taptite screw M5 x 12 Torx 109 10 153 • • • •

35 Spring washer 4mm 5590087 • • • •

36 Hexagon nut 4mm Din 934-5 5590066 • • • •

37 Sleeve 25 1917 01 00 05 • • • •

39 Taptite screw M5 x 35 Torx 109 10 154 • • • •

40 Taptite screw M5 x 25 109 10 152 • • • •

41 Cheese-head screw M5 x 65 Torx 100 10 350 • • • •

Model #

25 2096 05 12V

25 1920 05 12V

25 2098 05 12V

25 2147 05 24V

42 Taptite screw M5 x 16 Torx 109 10 151 • • • •

43 Taptite screw M4 x 10 Torx 109 10 150 • • • •

44 Countersunk screw M5 x 12 Torx 102 10 302 • • •

45 Sleeve 320 31 120 • • • •

48

Page 49

Notes:

49

Page 50

Heater Components Early “SC” Heaters

6

1

2

3

4

5

8

9

10

12

13/14

15

16

17

18

19

20 20a

22

4

4

4

3

3

9

10

16

32

11

11

33

31

12

13/14

23

26

27/28

24

21

25

29

30

12

13/14

13/14

12

11

34

Parts Diagram - Hydronic B4 / B5 / D4 / D5 - 12 & 24 volt - Diesel & Gasoline versions

Model 25 2096 05

Model 25 1920 05

Model 25 2098 05

Model 25 2147 05

with external FMP

50

Page 51

Heater Components Early “SC” Heaters

Hydronic B4 / B5 / D4 / D5 - 12 & 24 volt - Diesel & Gasoline versions

Description & Part #’s

Ref. No. Description Part Number

1 T - piece -8-6-8 262 31 151 •

2 T - piece -8-4-8 262 31 155 • • •

3 Hose 5 x 3mm 360 75 350 • • • •