Espar Hydronic 4, Hydronic D4 SC, Hydronic 5, Hydronic B5 SC, Hydronic D5 SC Installation, Troubleshooting, Parts Manual

...

Hydronic 4/5 (Coolant Heaters)

Installation • Troubleshooting • Parts Manual

Heater Model 12 V

Hydronic D4 SC 25 1917 01

25 2096 05

Hydronic B4 SC 20 1789 05

Hydronic D5 SC 25 1920 05

25 2098 05

Hydronic D5 S 25 2031 05

25 2100 05

Hydronic B5 SC 20 1791 05

Hydronic B5 S 20 1793 05

Heater Model 24 V

Hydronic D5 SC 25 2147 05

Hydronic D5 S 25 2009 05

Espar

P/N 610-121-0201

January 2001

Table of Contents Page

Introduction Heater Warnings ........................................................ 3

Introduction ........................................................ 4

Specifications ........................................................ 4

Heater Components

Hydronic 4/5 SC, 12 volt, Diesel ........................................................ 5

Hydronic 5 SC, 24 volt, Diesel ........................................................ 6

Hydronic 4/5 SC, 12 volt, Gasoline ........................................................ 6

Hydronic 5 S, 12 + 24 volt, Diesel + Gas ........................................................ 7

Principal Dimensions ........................................................ 8

Installation Heater Location ........................................................ 8

Procedures Heater Mounting ........................................................ 9

Heater Plumbing ........................................................ 10

Fuel System ........................................................ 11

Electrical Connections ........................................................ 13

Exhaust/Intake Connections ........................................................ 14

Operating Switches ........................................................ 15

Heater Operation Pre-Start Procedures ........................................................ 16

Start-Up ........................................................ 16

Running ........................................................ 16

Switching Off ........................................................ 17

Safety Equipment ........................................................ 17

Operational Flow Chart ........................................................ 18

Schematics

Hydronic D4 SC 12 volt, diesel - 25 1917 01 ........................................................ 19

Hydronic D4 SC 12 volt, diesel - 25 2096 05 ........................................................ 20

Hydronic D5 SC 12 volt, diesel - 25 1920 05 ........................................................ 21

Hydronic D5 SC 12 volt, diesel - 25 2098 05 ........................................................ 22

Hydronic D5 SC 24 volt, diesel - 22 2147 05 ........................................................ 23

Hydronic B4 SC 12 volt, gas - 20 1789 05 ........................................................ 23

Hydronic B5 SC 12 volt, gas - 20 1791 05 ........................................................ 23

Hydronic D5 S 12 volt, diesel - 25 2031 05 ........................................................ 24

Hydronic D5 S 12 volt, diesel - 25 2100 05 ........................................................ 24

Hydronic B5 S 12 volt, diesel - 20 1793 05 ........................................................ 24

Hydronic D5 S 24 volt, diesel - 25 2009 05 ........................................................ 24

Maintenance, Periodic Maintenance ........................................................ 25

Troubleshooting & Basic Troubleshooting ........................................................ 25

Repairs Self Diagnostic Troubleshooting ....................................................... 25

Troubleshooting Chart ....................................................... 26

Fuel Quantity Test ........................................................ 29

Heater Disassembly / Repair Steps ........................................................ 30

Heater Components Parts Diagram / Scope ........................................................ 32

Description & Part #’s ........................................................ 33

Parts & Accessories Diagram / Scope ....................................................... 35

Description & Part #’s ....................................................... 36

Special Notes

Note: Highlight areas requiring special attention or clarification.

Caution: Indicates that personal injury or damage to equipment may occur unless specific guidelines are followed.

Warning: Indicates that serious or fatal injury may result if specific guidelines are not followed.

Heater Warnings

Warning To Installer

3

• Correct installation of this heater is necessary to ensure

safe and proper operation.

Read and understand this manual before attempting to

install the heater. Failure to follow all these instructions

could cause serious or fatal injury

Warning - Explosion Hazard

• Heater must be turned off while re-fueling.

• Do not install heater in enclosed areas where combustible fumes may be present.

• Do not install heaters in engine compartments of gasoline powered boats.

Warning - Fire Hazard

• Install the exhaust system so it will maintain a minimum

distance of 50mm (2”) from any flammable or heat sensitive material.

• Ensure that the fuel system is intact and there are no leaks.

Warning - Asphyxiation Hazard

Caution: During electrical welding work on the vehicle

disconnect the power to the heater in order

to protect the control unit.

Note: All measurements contained in this manual

contain metric and approximate SAE equivalents in brackets eg 25mm (1”)

Direct questions to Espar Heater Systems

USA 1-800-387-4800

CANADA 1-800-668-5676

• Route the heater exhaust so that exhaust fumes cannot

enter any passenger compartments.

• If running exhaust components through an enclosed

compartment, ensure that it is vented to the outside.

Warning - Safety Hazard on Coolant Heaters

Used With Improper Antifreeze Mixtures

• The use of Espar coolant heaters requires that the

coolant in the system to be heated contain a proper mixture of water and antifreeze to prevent coolant from

freezing or slushing.

• If the coolant becomes slushy or frozen, the heater’s

coolant pump cannot move the coolant causing a blockage of the circulating system. Once this occurs, pressure

will build up rapidly in the heater and the coolant hose

will either burst or blow off at the connection point to the

heater.

• This situation could cause engine damage and/or personal injury. Extreme care should be taken to ensure a

proper mixture of water and antifreeze is used in the

coolant system.

• Refer to the engine manufacturer’s or coolant manufacturer’s recommendations for your specific requirements.

This publication was correct at the time of print.

However, Espar has a policy of continuous improvement and reserves the right to amend any specifications without prior notice.

4

Introduction

Espar’s Hydronic D4/D5 Heater

Quality engineered to provide a dependable means of heating, the Espar Hydronic 4/5 is a diesel fired coolant heater

capable of between

Hydronic 4 - 1.6 kW to 4 kW/hr (5,500 to 13,700 BTU/hr).

Hydronic 5 - 2.4 kW to 5 kW/hr (8,200 to 17,100 BTU/hr).

This compact coolant heater offers an affordable heating

solution to many applications. The Hydronic 4/5 is ideal for

pre-heating the engines of trucks, cars, off-road equipment,

small trucks and boats. It features automatic heat regulation

while being fuel and power efficient. Since the heater runs on

fuel and 12 or 24 volt power, it is able to perform this completely independently of the vehicle engine. The unit regulates the coolant temperature between a low of 65°C (149°F)

and a high of 80°C (176°F) by automatically cycling the

heater.

The Hydronic 4/5 can be operated from the vehicle cab by an

on/off switch, a preselect timer or a combination of both.

A Flame sensor, temperature regulating sensor and overheat

sensor are among the safety features which makes the

Hydronic D4/D5 a safe and dependable heating system.

Specifications Hydronic 4 Hydronic 5

Heat output (±10%) 4 kW (13,700 BTU/hr) - Boost

3.3 kW (11,300 BTU/hr - High 5 kW (17,000 BTU/hr) - High

1.6 kW (5,500 BTU/hr - Low 2.4 kW (8,200 BTU/hr) - Low

12 volt 24 volt

Current draw (±10%) 4.3 amps Boost

3.0 amps High 4.16 amps High 2.08 amps High

2.0 amps Low 1.91 amps Low 0.95 amps Low

Fuel consumption (±10%) 0.51 l/hr (0.13 US gal/hr) Boost

0.40 l/hr (0.11 US gal/hr) High 0.62 l/hr (0.16 US gal/hr) High

0.20 l/hr (0.05 US gal/hr) Low 0.27 l/hr (0.08 US gal/hr) Low

Operating Voltage Range

Minimum Voltage 10 V 10 V 20.4 V

Maximum Voltage 16 V 16 V 32.0 V

Working pressure 2.5 bar (36 psi) 2.5 bar (36 psi)

Ambient operating temperature -40°C to +80°C (-40°F to 176°F) -40°C to +80°C (-40°F to 176°F)

Overheat temperature shutdown (±5%) 105°C (221°F) 105°C (221°F)

Weight 2.5 kg. (5.5 lbs.) 2.9kg. (6.4lbs)

Controls available On/Off switch or 7-day timer On/Off switch or 7-day timer

Note: The heater is equipped with a high-voltage

cutout as well a low-voltage cutout.

5

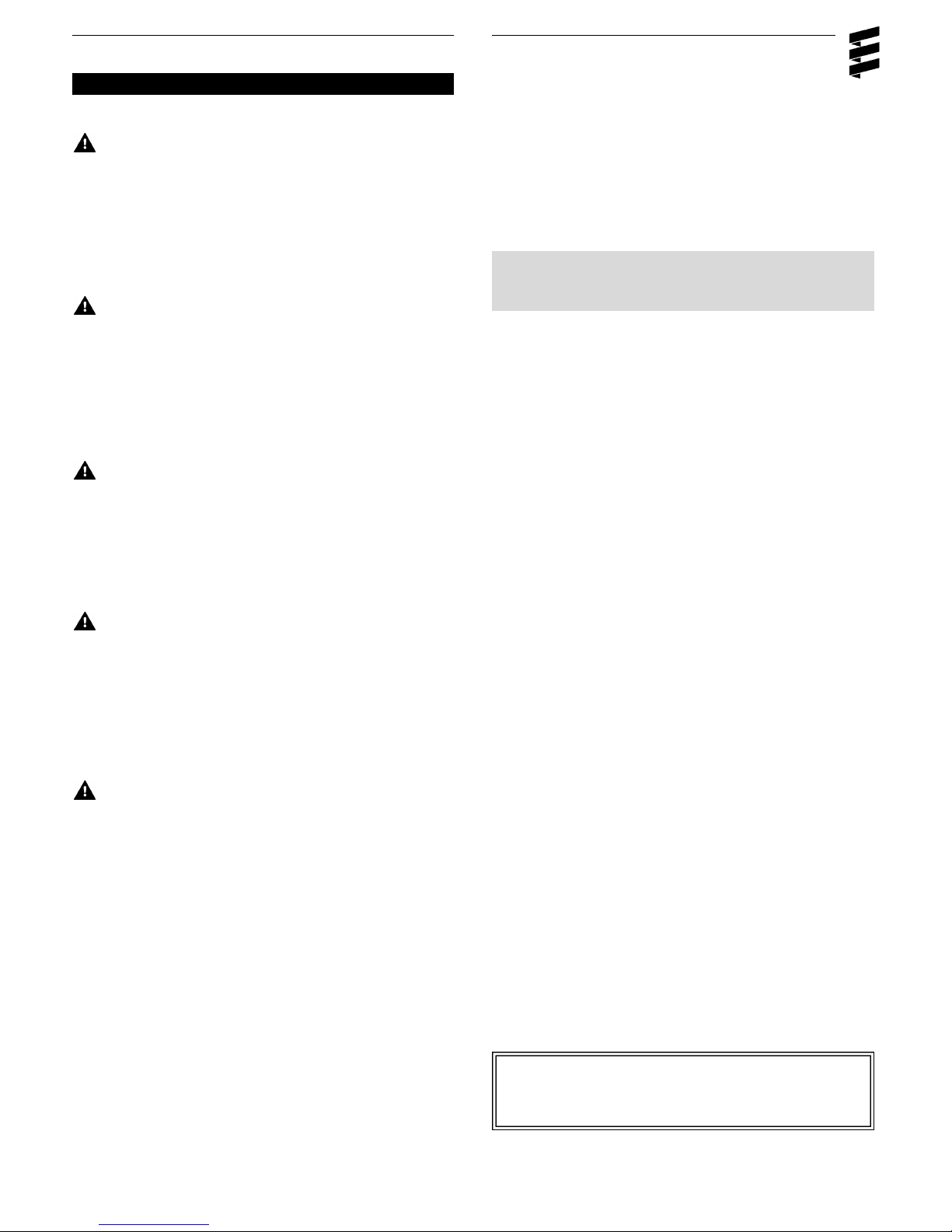

Heater Components - Hydronic 4 & 5 SC versions - 12 Volt - Diesel

25 1917 01

25 2096 05

25 1920 05

25 2098 05

17

1 Combustion air blower wheel

2 Electric motor

3 Heat exchanger

4 Combustion chamber

5 Glow pin

6 Flame sensor

7 Temperature sensor

8 Overheat temperature sensor

9 Control unit

18

A = Combustion air

E = Exhaust

F = Fuel supply line

WO = Water Outlet

WI = Water Inlet

10 Combustion air tube

11 Exhaust tube

12 Fuel-metering pump

13 Coolant pump

14 Main fuse

15 Interface/8-pin connector

16 Bleed screw

17 Push/Pull switch

18 7-day timer

6

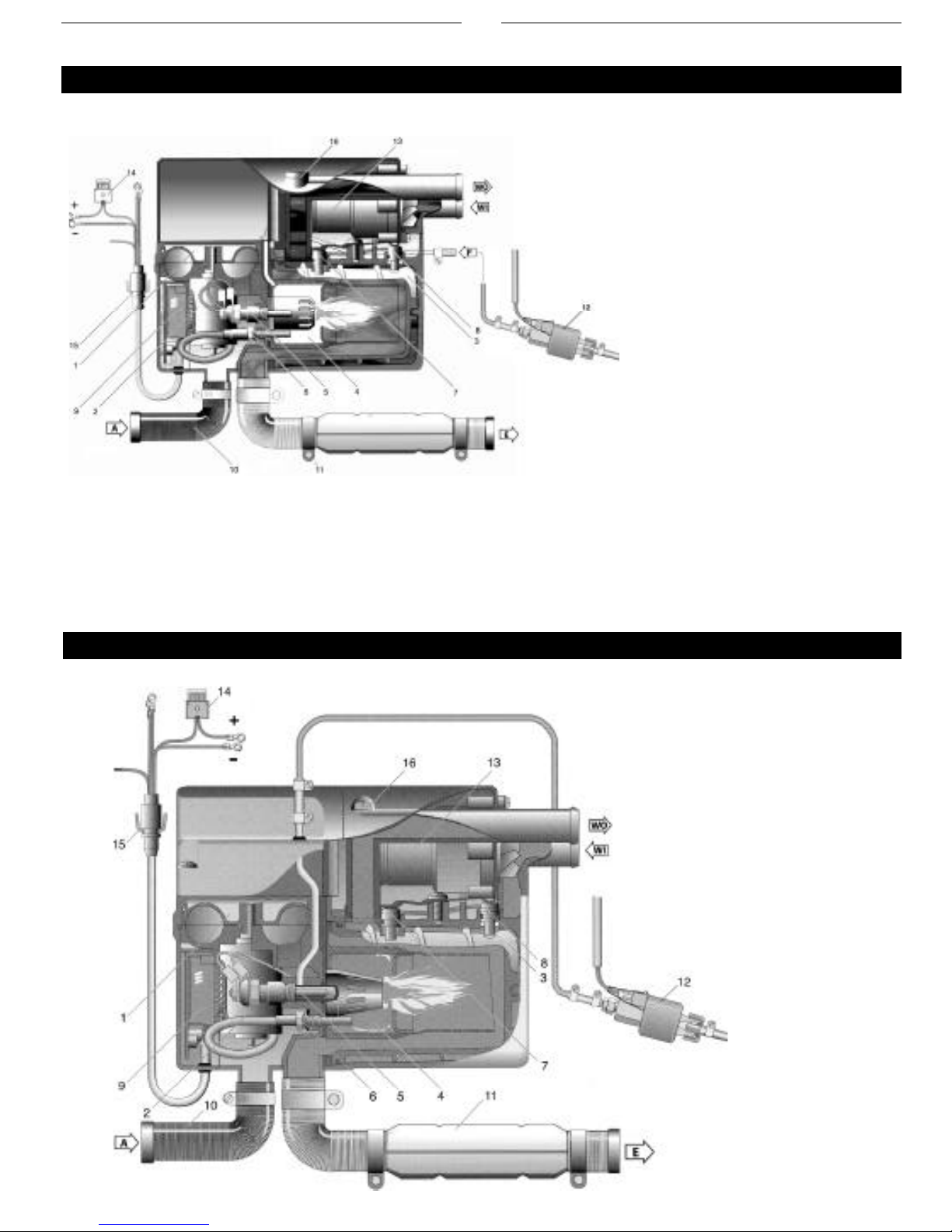

Heater Components - Hydronic 5 SC - 24 volt version - Diesel

Heater Components - Hydronic 4 & 5 SC - 12 volt version - Gasoline

25 2147 05

20 1789 05

20 1791 05

7

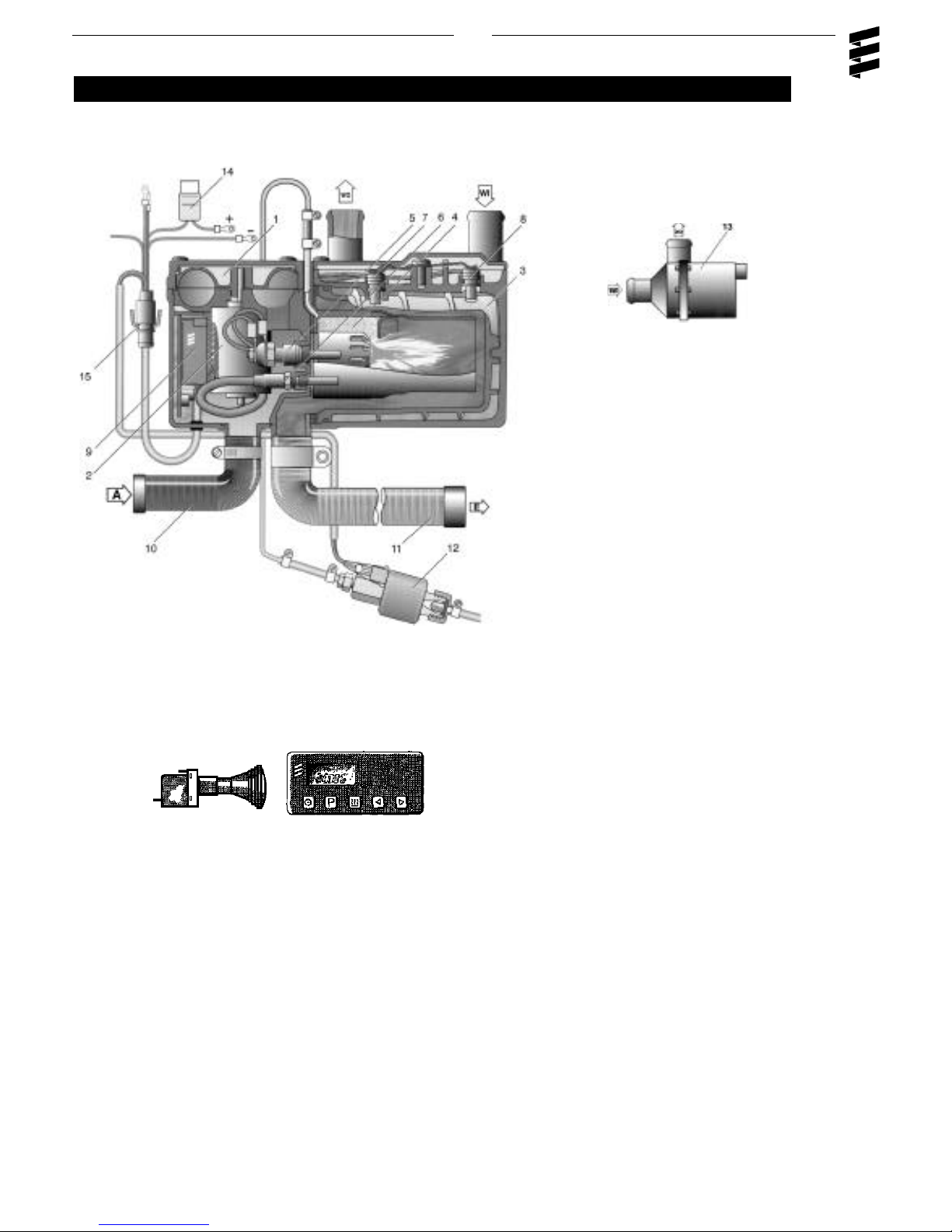

Heater Components - Hydronic 5 S - 12 & 24 volt versions - Diesel & Gasoline versions

25 2031 05

25 2100 05

20 1793 05

25 2009 05

17

18

1 Combustion air blower wheel

2 Electric motor

3 Heat exchanger

4 Combustion chamber

5 Glow pin

6 Flame sensor

7 Temperature sensor

8 Overheat temperature sensor

9 Control unit

A = Combustion air

E = Exhaust

F = Fuel supply line

WO = Water Outlet

WI = Water Inlet

10 Combustion air tube

11 Exhaust tube

12 Fuel-metering pump

13 Coolant pump

14 Main fuse

15 Interface/8-pin connector

16 Bleed screw

17 Push/Pull switch

18 7-day timer

8

Heater Location

Mount the heater in a protected area if you’re in extreme

conditions where heavy salting is experienced.

Eg: storage compartment, engine compartments, step box or

battery box.

Espar recommends you use the boxed unit. Boxed heaters

can be mounted by utilizing one of the existing brackets. See

following page.

If mounting on frame rail use an optional Espar Inside frame

bracket to mount to inside of frame rails. Heaters can also be

mounted on a cross tray behind the cab and on top of

the frame rails.

When mounting the heater adhere to the

following conditions.

• Situate the heater below the normal coolant level of the engine.

• Guard against excessive road spray.

• Keep coolant hoses, fuel lines and electrical wiring as

short as possible

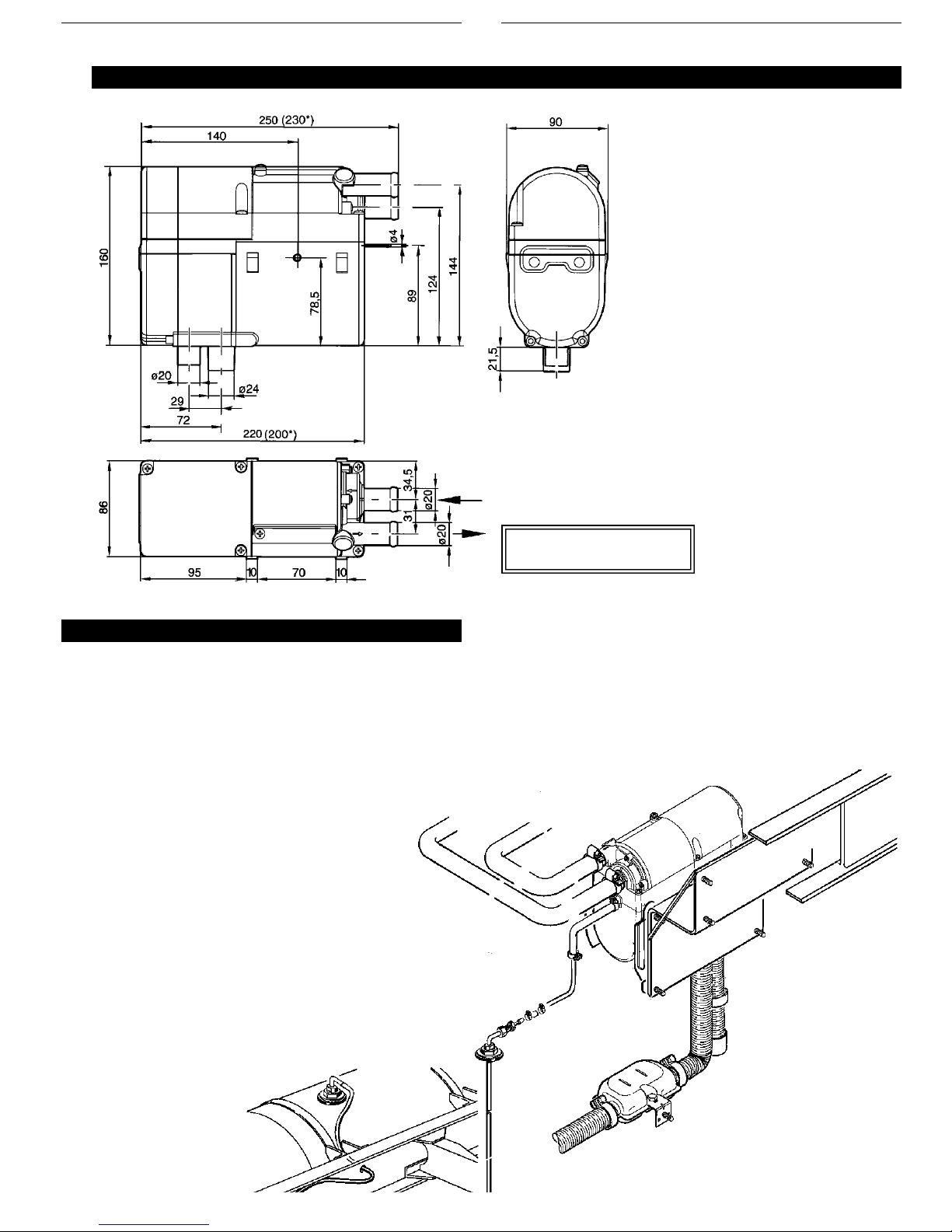

Principal Dimensions - Hydronic D4/D5 SC (values in brackets* = D4SC)

* All measurements in millimeters

25.4mm = 1”

Caution: Guard the heater against excessive road

spray to avoid internal corrosion

For Illustration purposes only

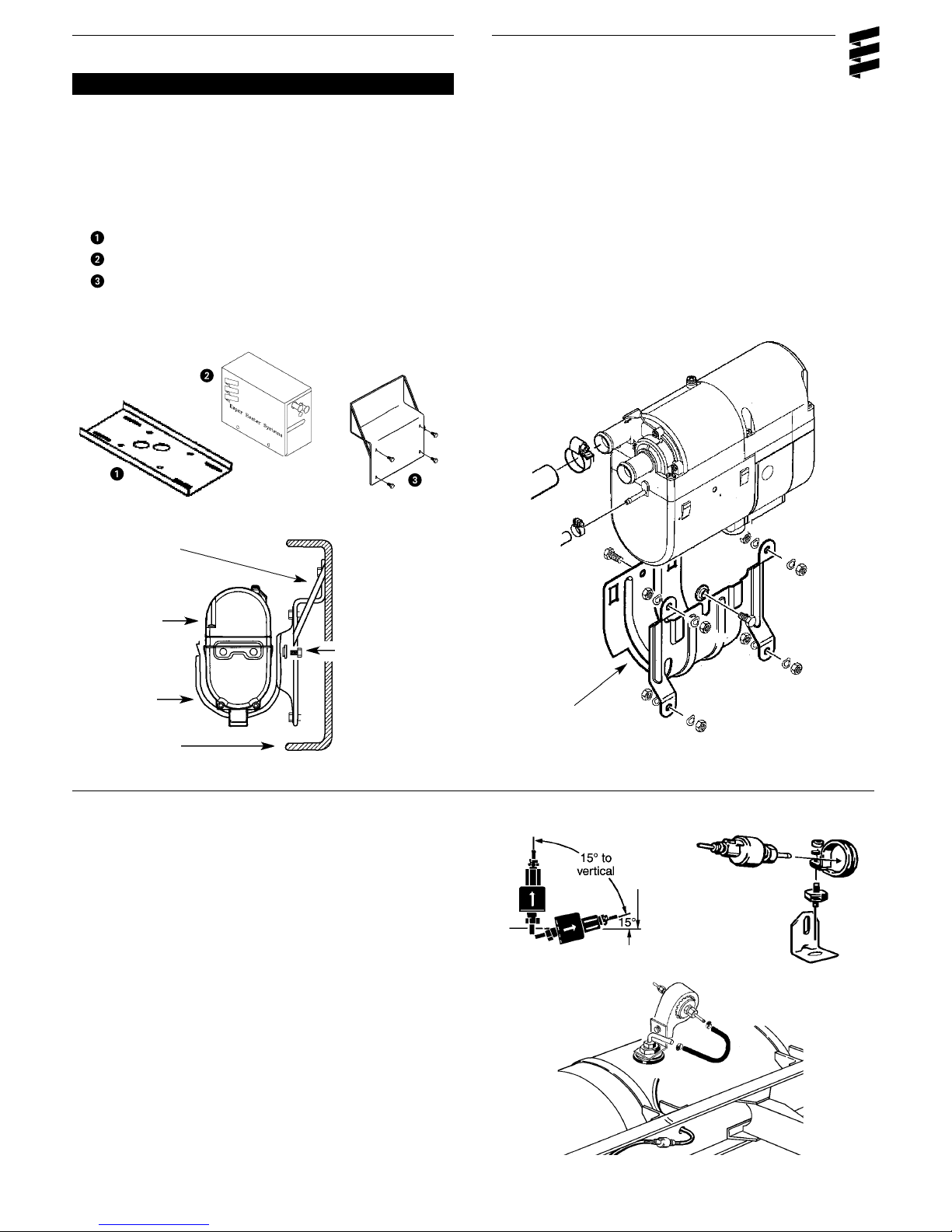

Heater Mounting

9

Mount heater in saddle bracket and secure with hardware

provided. If heater is not a boxed unit, mount bracket onto

inside frame rail bracket. Boxed unit can also be secured to

the inside frame bracket or mounted to the Cross frame

Mounting Tray

Cross Frame Mounting Tray

Hydronic 4/5 box

Inside frame mounting bracket

Inside frame

mounting bracket

Hydronic D4 SC boxed unit P/N CA 2096 55

Hydronic D5 SC boxed unit P/N CA 2098 55

Hydronic

Water Heater

Spacer and screw

Saddle bracket

Inside frame rail

For “S” and gasoline version heaters which have external

fuel metering pumps

• Choose a protected mounting location close to the fuel

pick-up pipe and heater.

• Using the bracket and rubber mount provided, install fuel

pump as shown

Note: Proper mounting angle of the fuel pump is nec-

essary to allow any air or vapor in the fuel lines

to pass through the pump rather than cause a

blockage.

Saddle bracket

10

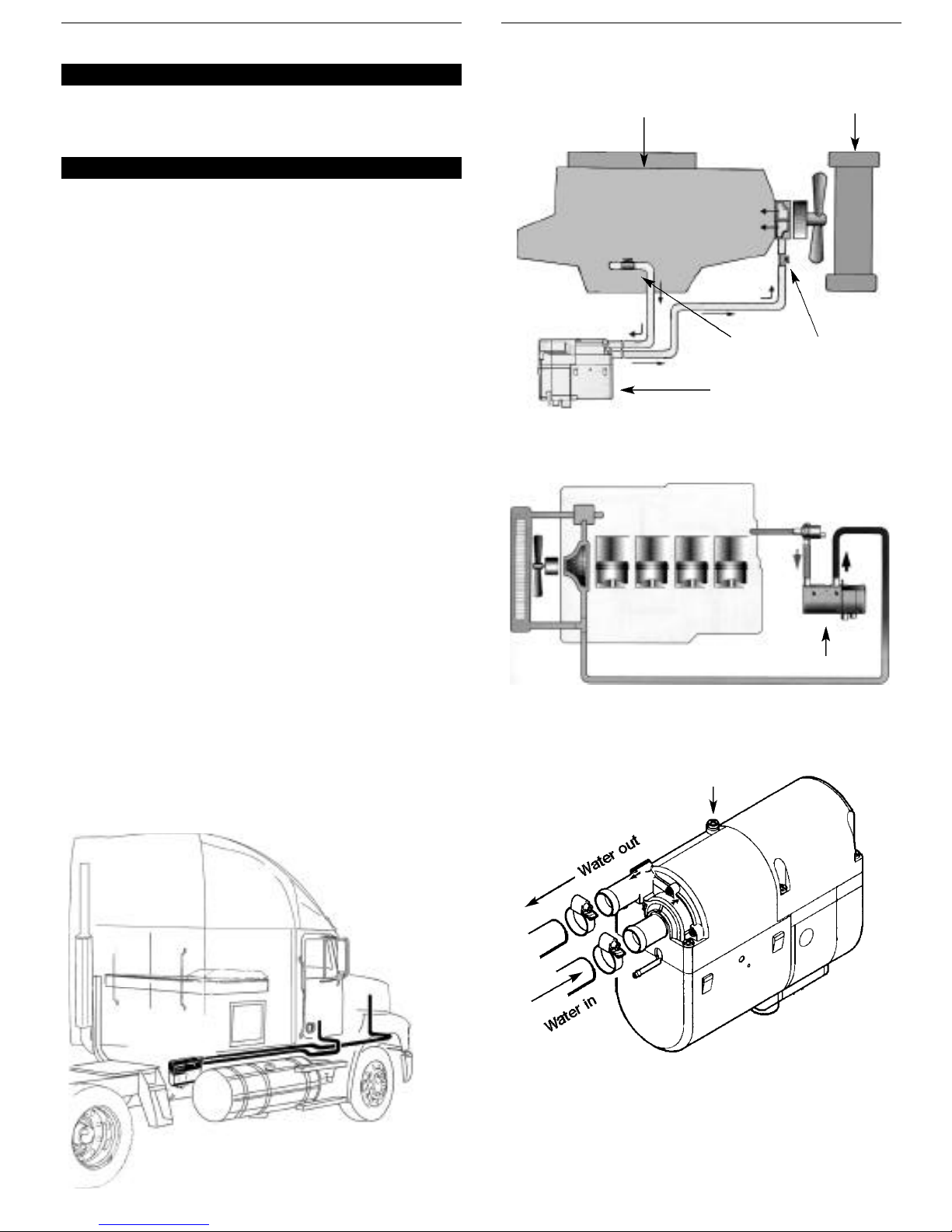

Heater Plumbing

The heater is incorporated into the engine’s cooling system

for engine preheating

Engine Plumbing

Follow these guidelines and refer to engine plumbing diagram shown below.

• Use existing holes in the engine block (ie. remove

blanking plugs when possible). Install fittings into the block

for pick-up and returns.

• If possible, use shut off valves to ensure the system can

be isolated from the engine when not in use.

• Provide 20mm (3/4”) hose barbs for hose connections.

• Use 20mm (3/4”) hoses to ensure adequate coolant flow.

• Keep the pick up and return points as far apart as

possible to ensure good heat distribution.

• Take the coolant from a low point on the engine to

reduce aeration in the system.

• Ensure proper direction of coolant flow by taking coolant

from a high pressure point in the engine and returning it to

a low pressure point. (ie. pickup from back of block and

return to the suction side of the engine's water pump).

• Ensure adequate flow rate through the heater by comparing the incoming and outgoing coolant temperatures while

the heater is running. If the rise in temperature exceeds

10°C (18°F), coolant flow must be increased by modifying

the plumbing.

• Ensure the heater and water pump are installed as low as

possible to allow the purging of air. Bleed system via radiator or bleed screw located on heater.

Caution: The coolant must contain a minimum of 10%

antifreeze at all times as a protection against

corrosion. Fresh water will corrode internal

heater parts.

Engine

Radiator

External Water Pump

Shut-off valves

Hydronic SC Heater

Bleed Screw

Hydronic “S” version

11

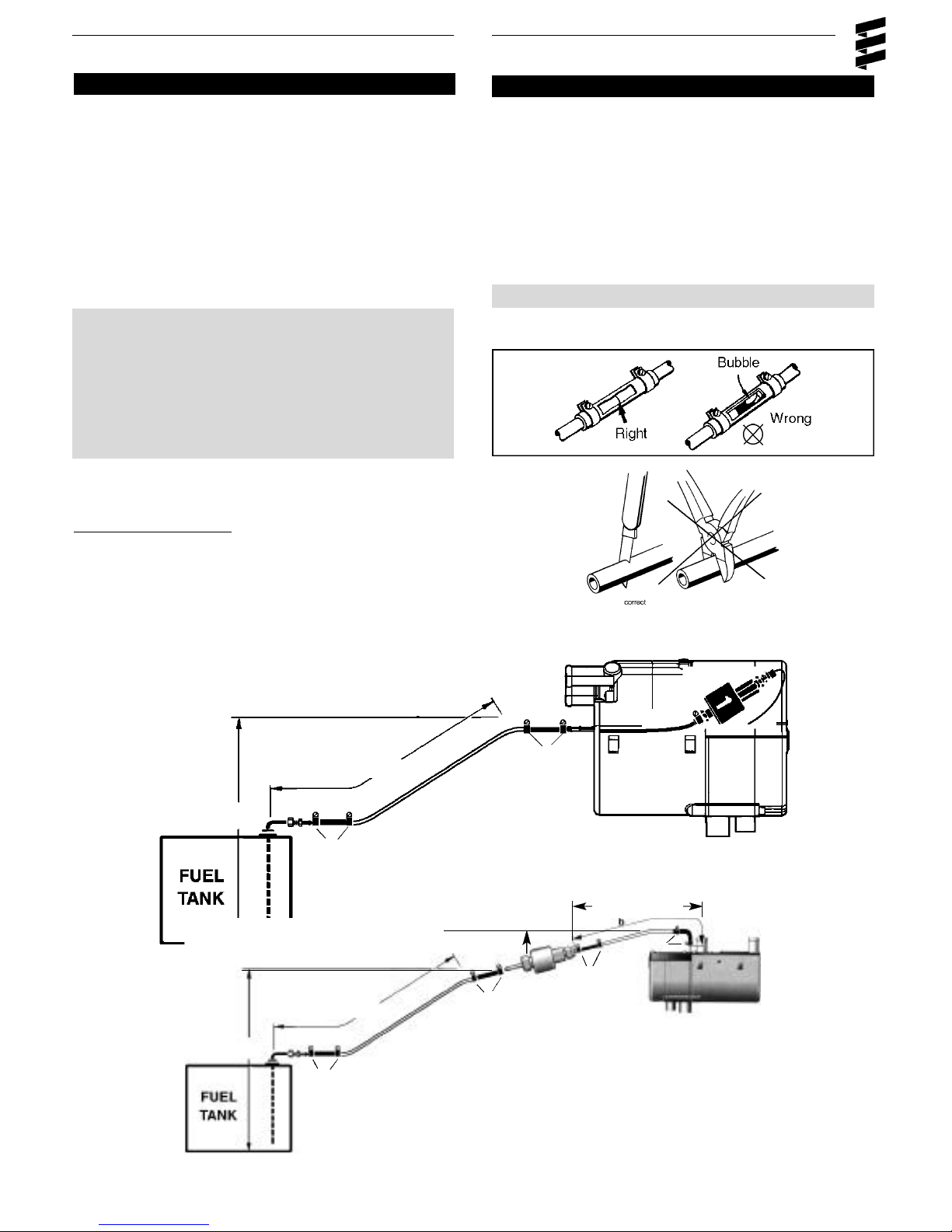

Fuel System

The Hydronic water heaters typically have the fuel metering

pump mounted inside the unit. This is to reduce installation

time and to protect the pump from corrosion. Some versions

have an external fuel metering pump. Refer to graphics for

connections and specifications.

All parts necessary to do the installation are included in the

kit as shown.

Note: Fuel line limits must not be exceeded.

Ensure that the following conditions are met.

Hydronic heater must be within a height of 76cm

(2’6”) from the bottom of the fuel pick-up pipe.

Fuel-metering pump must be within a total

distance of 200 cm (6’6”) from the fuel pick-up pipe.

If the above conditions cannot be met, a heater

with external fuel metering pump must be used.

Fuel System Tolerances

Fuel Line

• Route fuel lines from the fuel pick-up pipe to the heater.

• Use fuel lines provided.

• Other sizes or types of fuel lines may inhibit proper fuel

flow.

• Make proper butt joints using clamps and connector

pieces as shown

• Use a sharp utility knife to cut plastic fuel lines to avoid

burrs.

Note: Butt joints and clamps on all connections.

1. Fuel Pick-Up Pipe

2. Fuel Pipe Reducer

3. 9mm Clamp

4. 3.5mm Rubber Connector

5. 2.0mm White Plastic Fuel Line

6. Fuel Metering Pump

7. 1.5m White Plastic Fuel Line

Max. 76cm (2’6”)

1

Max. 76cm (2’6”)

Max. 2 M (6’6”)

4

2

3

Max. 2 M (6’6”)

2

4

3

5

5

Max. 2 M (6.5’)

4

3

Hydronic Heater

6

4

3

Max. 6 M (19.8’)

4

7

3

6

4

3

1

12

Note: Drill the two (1/4”) holes first.

( Optional Pick-Up Pipe with NPT fitting )

• Remove an existing plug from the top of

the fuel tank.

• Cut the fuel pick-up pipe to length.

• Secure the fuel pick-up pipe into position

using the combined NPT compression

fitting as shown

Double pick ups (used with combo kits)

• Double NPT pipe.

P/N: CA0 12 107

Note: NPT fittings are available in various sizes

(Refer to parts section).

Fuel Pick-Up Pipe

Nut

Sheet Metal Washer

Rubber Gasket

Steel Safety Washer

Holding Tabs

Allow 2.5” from fuel pick-

up to tank bottom. Allow

only 1” for flat bottom

tanks.

End tip of the fuel pick-up

pipe should have angle to

avoid picking up dirt and

subsequent blockage

Fuel Pick-Up Pipe Installation (Standard Pick-Up)

• Choose a protected mounting location close to the pump

and heater. A spare fuel sender gauge plate provides an

ideal mounting location. If one is not available.....

• Drill mounting holes in tank to accommodate pick-up pipe

as shown.

• Cut the fuel pick-up pipe to length. Allow 2-2.5” from bottom of tank.

• Mount the fuel pick-up pipe as shown

• Lower the fuel pick-up pipe (with reinforcing washer) into the

tank using the slot created by the two 0.6cm (1/4”) holes.

• Lift the assembly into position through the 2.5cm (1”) hole.

• Assemble the rubber washer, metal cup washer and nut.

ø 2.5cm (ø1.0”)

ø 0.625 cm (2 Holes)

(ø 1/4”)

1.5 cm

(9/16”)

1.5 cm

(9/16”)

Fuel Pick-Up Pipe reducer

13

Electrical Connections

All parts needed are included with the kit. ( * ) indicates external mounted fuel and or water pump versions of Hydronics.

A. Main Heater Harness...................................................

B. Power Harness............................................................

C. Switch Harness............................................................

D.*Fuel Metering Pump Harness........................................

E.*Water Pump Harness......................................................

Hydronic Heaters

• Connects switch and power harness to the heater harness.

( * in some cases power to fuel metering pump )

• 2 core harness (red, brown).

• Connect red wire to fuse link and terminal.

• Attach ring terminal to vehicle battery (+).

• Connect brown wire to vehicle battery (-) using ring

terminal provided.

• Insert 25 amp fuse

• 4 core harness (red/yellow, brown, yellow, blue/white)

• Run to location of switch. Make terminal connections at

switch. Espar has 2 available switches see switch

instructions on following pages.

• 2 core harness (green, green)

• Connect to fuel metering pump using single terminals

and rubber protective boots (no polarity required).

• 2 core harness (black, brown)

• Connect to main harness at heater.

Caution:

To avoid potential short

circuit damage during

installation, insert 25

amp fuse on power

harness after all

electrical connections

are complete.

E

Note: All harnesses should be cut to length.

All exposed electrical connections should be

coated with protective grease.

Note: Wire must be inserted into fuse holder prior

to terminating

A

D

B

C

7 Day Timer

switch harness

7 Day Timer

Loading...

Loading...