Espar D7W, 25 1667, 25 1807, 20 1673, 25 1666 Installation, Troubleshooting, And Use

Table of contents

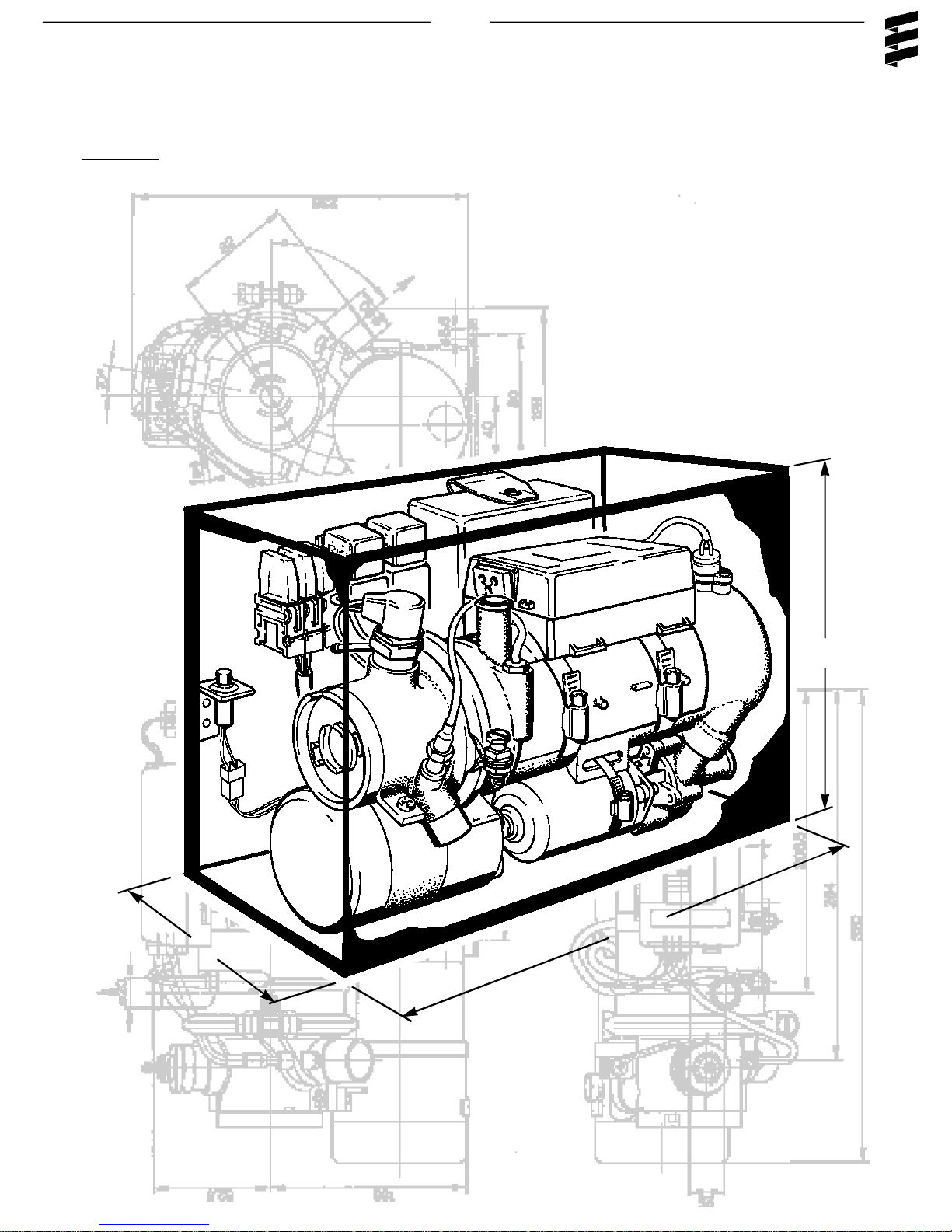

D7W Boxed

I. Introduction 1) General Specifications Page 1-5

2) Heater Warnings

3) Introduction

4) Principal Dimensions

5) Heater Components

II. Installation Procedures 1) Heater Location Page 6-15

2) Heater Mounting

3) Heater Plumbing

4) Fuel System

5) Electrical Connections

6) Exhaust Connection

7) Operating Switches

8) Optional Thermostat For Bunk Heat Exchanger

III. Heater Operation 1) Pre- Start Procedures Page 16-20

2) Start-Up

3) Running

4) Switching Off

5) Safety Equipment

6) Operational Flow Chart

7) Wiring Diagram

IV. Maintenance, 1) Recommended Periodic Maintenance Page 21-37

Troubleshooting & 2) Troubleshooting

Repairs 3) Fuel Quantity Test

4) Repair Steps

Appendix:

V. Heater Models 1) Principal Dimensions (25 1807) Page 38-48

Universal 25 1807 2) General Specifications (25 1666/25 1667)

25 1666 3) Location, Mounting, Plumbing, Fuel, Electrical, Exhaust

25 1667 4) Freightliner

Freightliner 5) Wiring Diagrams

VI. Heater Parts Section 1) Parts Diagram - Main Heater Components Page 49-59

2) D7WBoxed - Parts Diagram

3) Universal - Parts Diagram

4) Parts & Accessories Diagram

5) Description & Part #’s

Special Notes

Note: Highlight areas requiring special attention or clarification.

Caution: Indicates that personal injury or damage to equipment may occur unless specific

guidelines are followed.

Warning: Indicates that serious or fatal injury may result if specific guidelines are not followed.

2

1. General Specifications

Model 25 1807 05

Heat Output (±10%) 24,000 BTU (7 Kw) -High

6,000 BTU (1.75 Kw) -Low

Current at 12v (±10%) 24.6 amps/hr - Start (1-2 minutes)

5.8 amps/hr - Running High

4.2 amps/hr - Running Low

Fuel Consumption (±5%) High Low

Heat Heat

US Gal/hr 0.24 0.06

Litre/hr 0.90 0.22

Coolant Pump Flow (±10%) 420 US Gal/hr

1600 Litre/hr

Coolant Temperature 176° F to 201° F (80° C to 95° C)

Range (±5%)

Overheat Temperature 275°F (135°C)

Shutdown (±10%)

Low Voltage Shutdown 10.5 Volts

High Voltage Shutdown 15 Volts

2. Heater Warnings

Warning To Installer: Correct installation of this heater is necessary to ensure safe and

proper operation. Read and understand this manual before

attempting to install a heater.

Warning - Explosion Hazard

- Heater must be turned off while re-fueling.

- Do not install heater in enclosed areas where combustible fumes may be present.

- Do not install heaters in engine compartments of gasoline powered boats.

Warning - Fire Hazard

- Install the exhaust system so it will maintain a minimum distance of 2” from any flammable or heat

sensitive material.

- Ensure that the fuel system is intact and there are no leaks.

Warning - Asphyxiation Hazard

- Route the heater exhaust so that exhaust fumes cannot enter any passenger

compartments.

- If running exhaust components through an enclosed compartment, ensure that it is vented to

the outside.

Warning - Safety Hazard on Coolant Heaters Used With Improper Antifreeze Mixtures

- The use of ESPAR coolant heaters requires that the coolant in the system to be heated contain a

proper mixture of water and antifreeze to prevent coolant from freezing or slushing.

- If the coolant becomes slushy or frozen, the heater’s coolant pump cannot move the coolant

causing a blockage of the circulating system. Once this occurs,

pressure will build up rapidly in the heater and the coolant hose will either burst or blow off at the

connection point to the heater.

- This situation could cause engine damage and/or personal injury. Extreme care should be taken

to ensure a proper mixture of water and antifreeze is used in the coolant system.

- Refer to the engine manufacturer’s or coolant manufacturer’s recommendations for

your specific requirements.

Note: During electrical welding work on the vehicle disconnect the power to the heater in order to

protect the control unit.

Failure to follow all these instructions could cause serious or fatal injury.

Direct questions to Espar Heater Systems USA 1-800-387-4800

CDA 1-800-668-5676

3

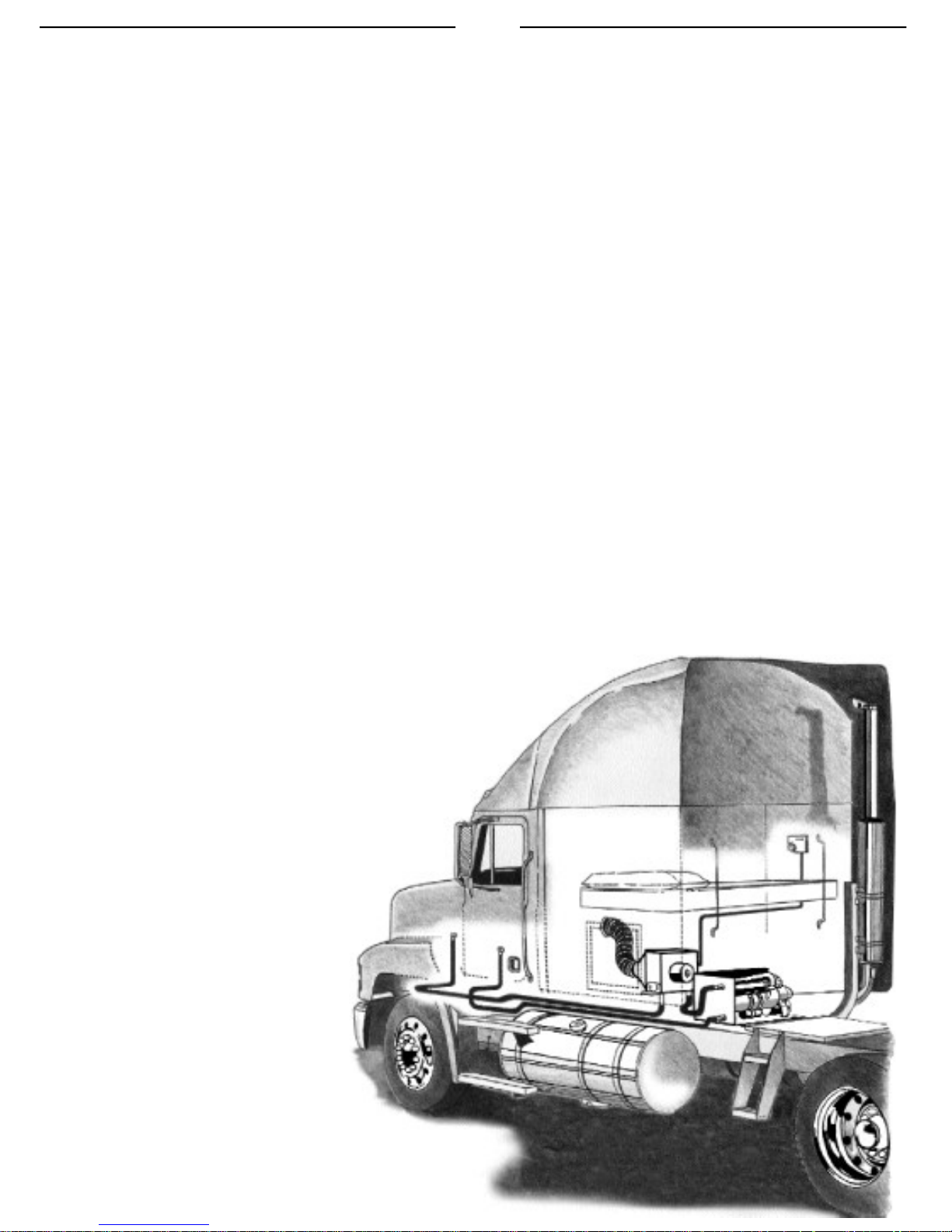

3. Introduction

The Espar D7W is a diesel fired 24,000 BTU/hr

coolant heater, quality engineered to provide a

dependable means of engine and sleeper heating. The heater can be purchased either in a

weather-resistant steel box to protect it and provide for ease of installation or in a universal form.

The heater simply pumps coolant from the

engine, heats it and returns it to the engine.

When used to provide sleeper heat, the coolant

is pumped through the sleeper heat exchanger

prior to returning to the engine. Since the heater

runs on diesel fuel and 12 volt power, it is able to

perform this completely independent of the vehicle engine. A temperature regulating switch in

the unit senses the coolant temperature and regulates the heater between a low of 176°F (80°C)

and a high of 201°F (94°C).

4

The heater may be operated from the vehicle cab

by a push/pull switch, a pre-select timer or a

combination of both.

The temperature sensor and overheat switch

form only a part of the safety features which

make this heater a safe and dependable unit.

4. Principal Dimensions

D7W Boxed Model 25 1807

Figure 1A

5

8.25”

10.75”

15.25”

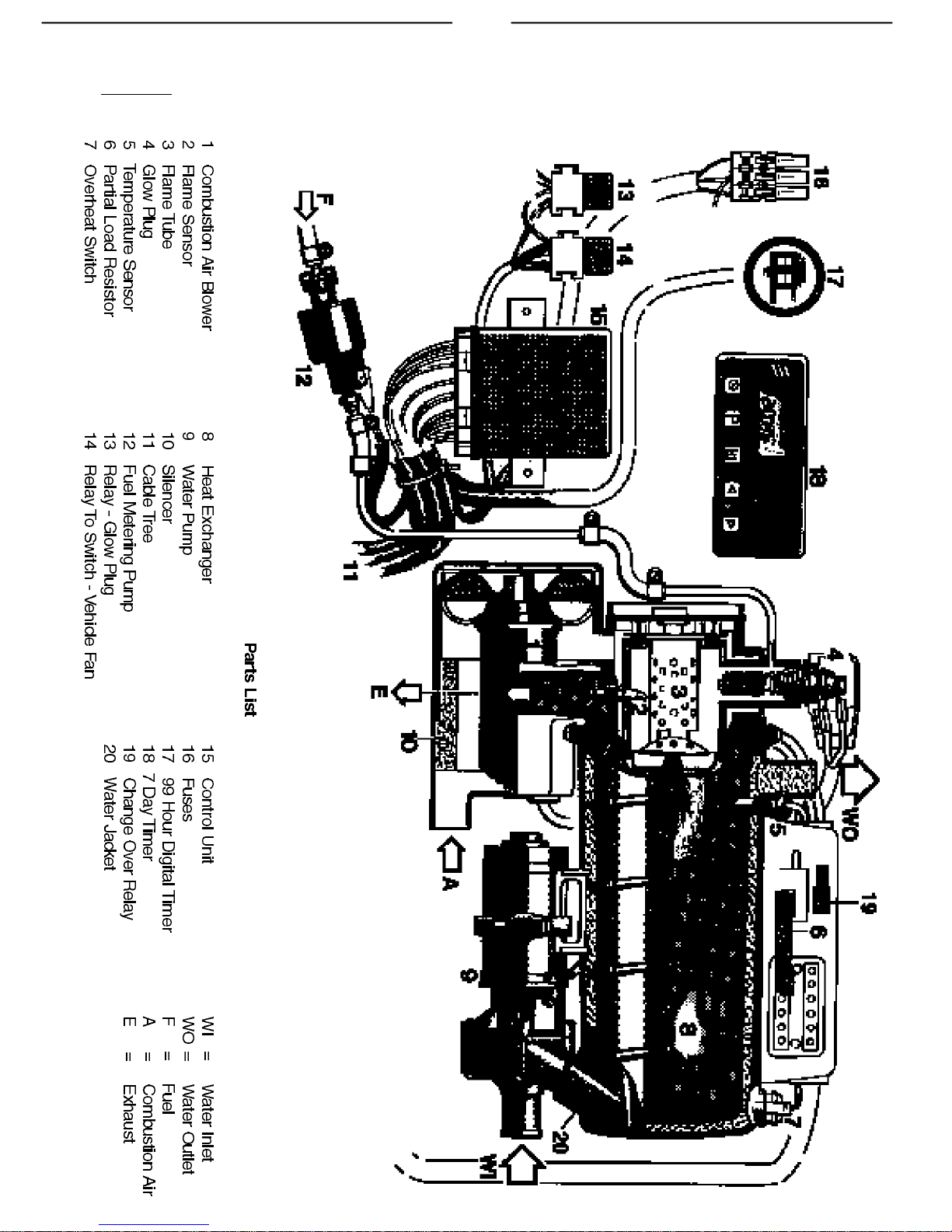

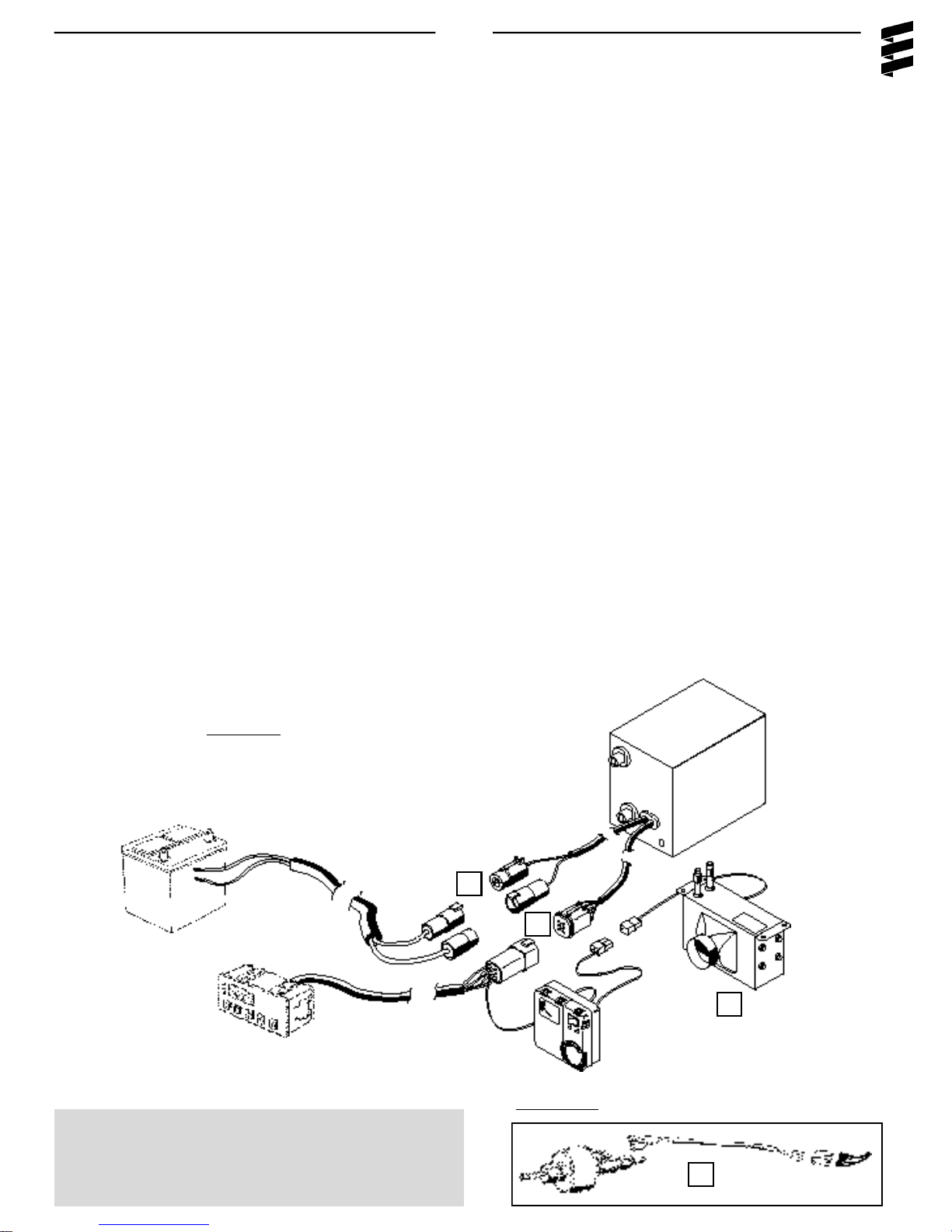

5. Heater Components

Figure IB

6

II. Installation Procedures

1. Heater Locations

Select the best mounting location while adhering to

the following conditions:

- Situate the heater below the normal coolant

level of the engine.

- Guard against excessive road spray.

- Keep coolant hoses, fuel lines and electrical

wiring as short as possible.

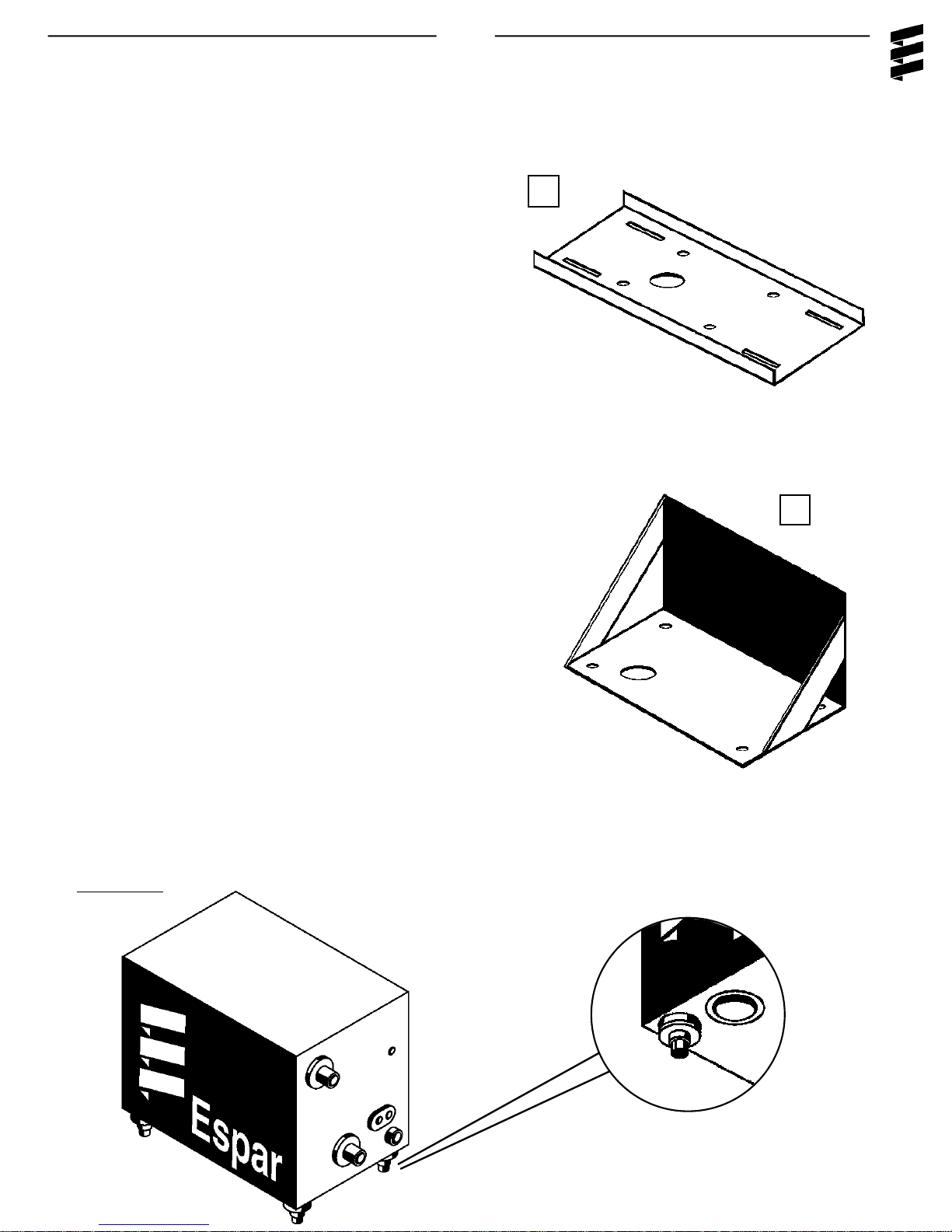

2. Heater Mounting

Mount the heater using the four (4) shock mounts

provided and one of the following mounting

methods: Figures IIA.

- Use the Cross Frame Mounting Tray (A) to

mount the heater behind the cab and on top

of the frame rails.

- Use the Side Mount Bracket (B) to mount the

heater on the side of the frame rail.

7

A

B

- Use a spare step box or battery box.

Figures IIA

3. Heater Plumbing

8

Connect the heater to the the engine coolant system while considering these following points

- Install hose fitting in existing holes in the engine

block (these will have blanking plugs in them).

- Full flow shut off valves should be installed on

the pickup and return hoses at the engine.

- Alternatively “T” piece connectors in existing

coolant hoses can be used if no blanking plugs

are available

- Ensure proper coolant flow by using a minimum

of 3/4” hoses.

- Keep the coolant pick up point as low as

possible on the engine to reduce air in the

system.

- Take coolant from a high pressure point and

return it to a lower pressure point. (eg. back of

block to suction side of water pump).Ensure

that engine and heater are pumping fluids in the

same direction.

Caution: If your bunk heater exchanger has a flow

control valve integrated into it, provisions

must be made to ensure that flow through

the Espar heater cannot be blocked.

- Ensure proper heat distribution by keeping pick

up point and return point as far apart as

possible.

- Check flow rate through heater by measuring

the incoming coolant temperature and the out

going temperature. The rise in temperature

should not exceed 18°F (10°C). If the

temperature rise exceeds 18°F (10°C),

modifications should be made to increase the

flow rate. Check for restrictions in heat

exchanger and fittings.

- If a bunk heat exchanger is incorporated into the

system, proper plumbing layouts must be

followed. (Refer to Figure II B and Figures IIB 1

on following page for specific guidelines.).

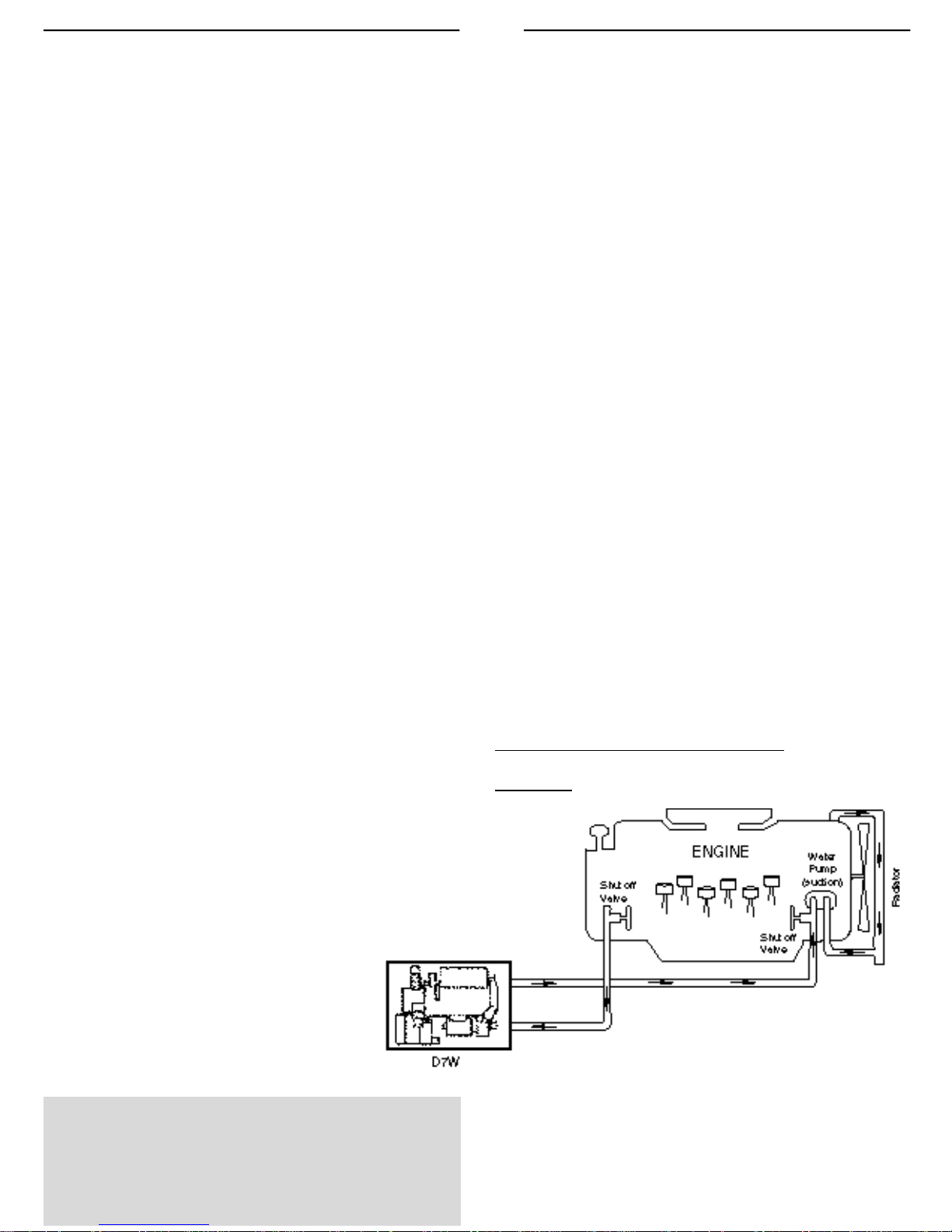

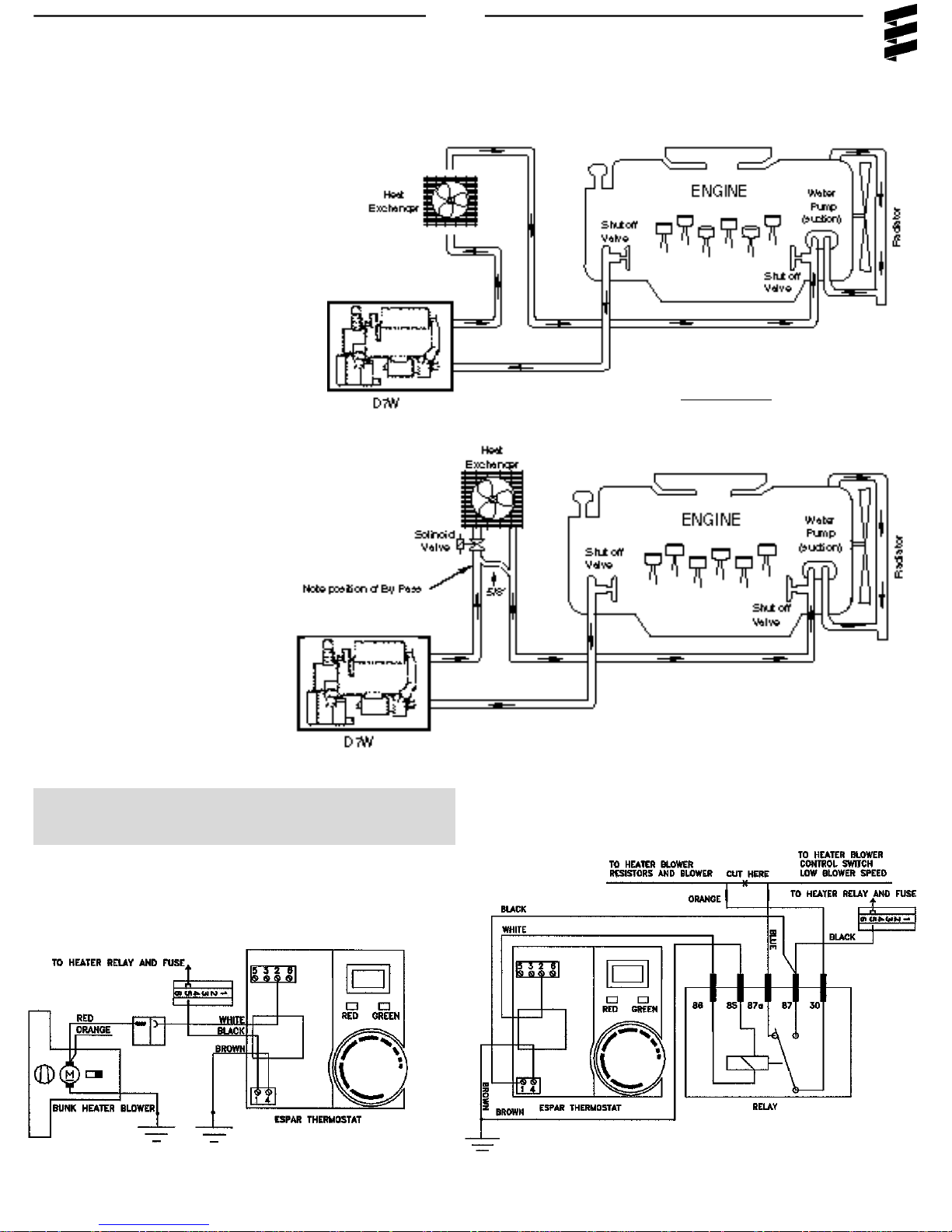

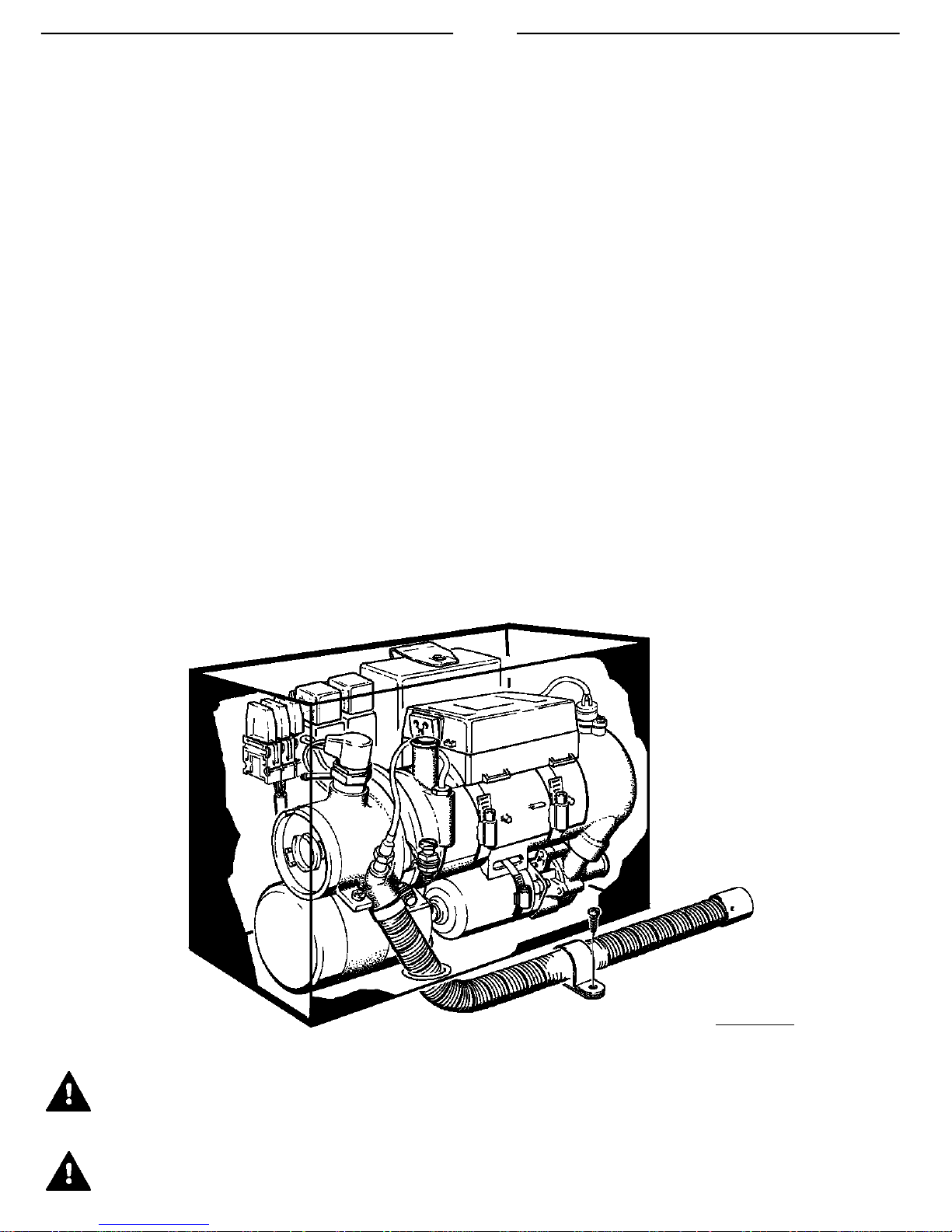

D7WB plumbed for engine pre-heat

Figure IIB

Note: The coolant must contain a minimum of

10% antifreeze at all times as a protection

against corrosion. Fresh water will corrode

internal heater parts.

When being used to provide bunk heat with a heat

exchanger the D7WB should be plumbed and wired to

one of the following methods.

1. D7WB plumbed with an

Espar heat exchanger.

9

Figures IIB1

2. D7WB plumbed with an

OEM heat exchanger.

Note: By pass must be used to ensure that

coolant flow can’t be completely stopped.

D7W Thermostat Options

1. D7WB wiring schematics for

the Espar heat exchanger.

2. D7WB wiring schematics for

OEM heat exchanger.

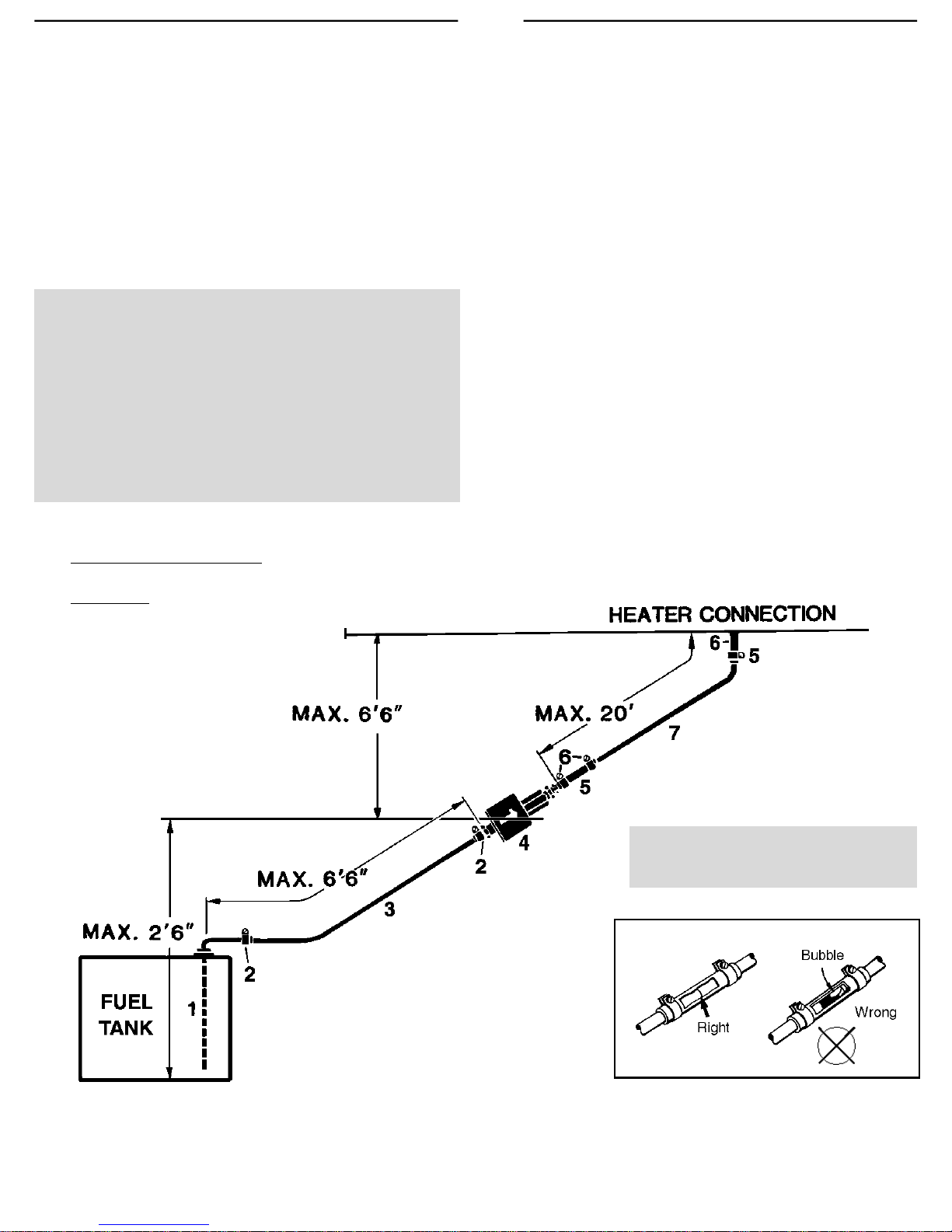

4. Fuel System

The D7WB is most commonly provided with the

fuel metering pump mounted inside the box.This

is to reduce installation time and to protect the

pump from corrosion. If specifications cannot be

met the pump must be mounted externally. Refer

to Figure IIC for connections and specifications.

All parts necessary to do the installation are

included in the kit as shown in Figure IIC.

N o t e : Fuel line limits must not be ex c e e d e d .

Ensure that the fo l l owing conditions are

m e t .

Bottom of the fuel metering pump must be

within a height of 2’6” of the bottom of the

fuel pick-up pipe.

Fuel metering pump must be within a total

distance of 6’6” from the fuel pick-up pipe.

10

Fuel System Tolerances

Figure IIC

Note: Butt joints and clamps on

all connections.

1. Fuel Pick-Up Pipe 5. 9mm Clamp

2. 11mm Clamp 6. 3.5mm Rubber Connector

3. 5.0mm Fuel Line 7. 2.0mm White Plastic Fuel Line

4. Fuel Metering Pump

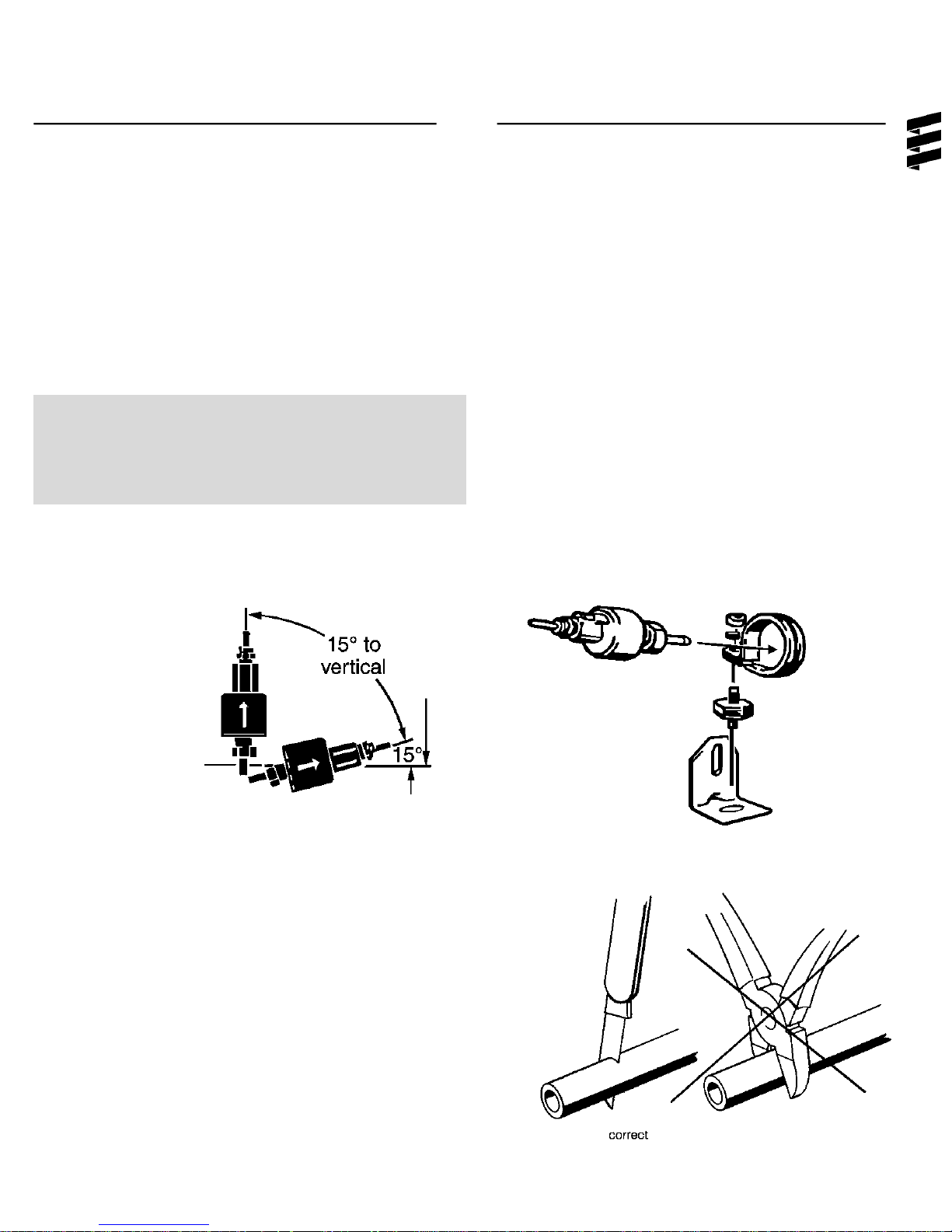

B) Fuel Metering Pump

If the pump needs to be mounted externally follow

these guidelines:

Choose a protected mounting location close to

the fuel pick-up pipe and heater.

Using the bracketand rubber mount provided,

install pump as shown in Figure II D.

Note: Proper mounting angle of the pump is

necessary to allow any air or vapor in the

fuel lines to pass through the pump rather

than cause a blockage.

Fuel Metering Pump Installation

Figure II D:

C) Fuel Line

- Route fuel lines from the fuel pick-up pipe to the

fuel metering pump then to the heater.

- Use fuel lines provided.

- Other sizes or types of fuel lines may inhibi

proper fuel flow.

- Make proper butt joints using clamps and

connector pieces as shown in Figure II E.

- Use a sharp utility knife to cut plastic fuel lines

to avoid burrs.

11

Figure II E

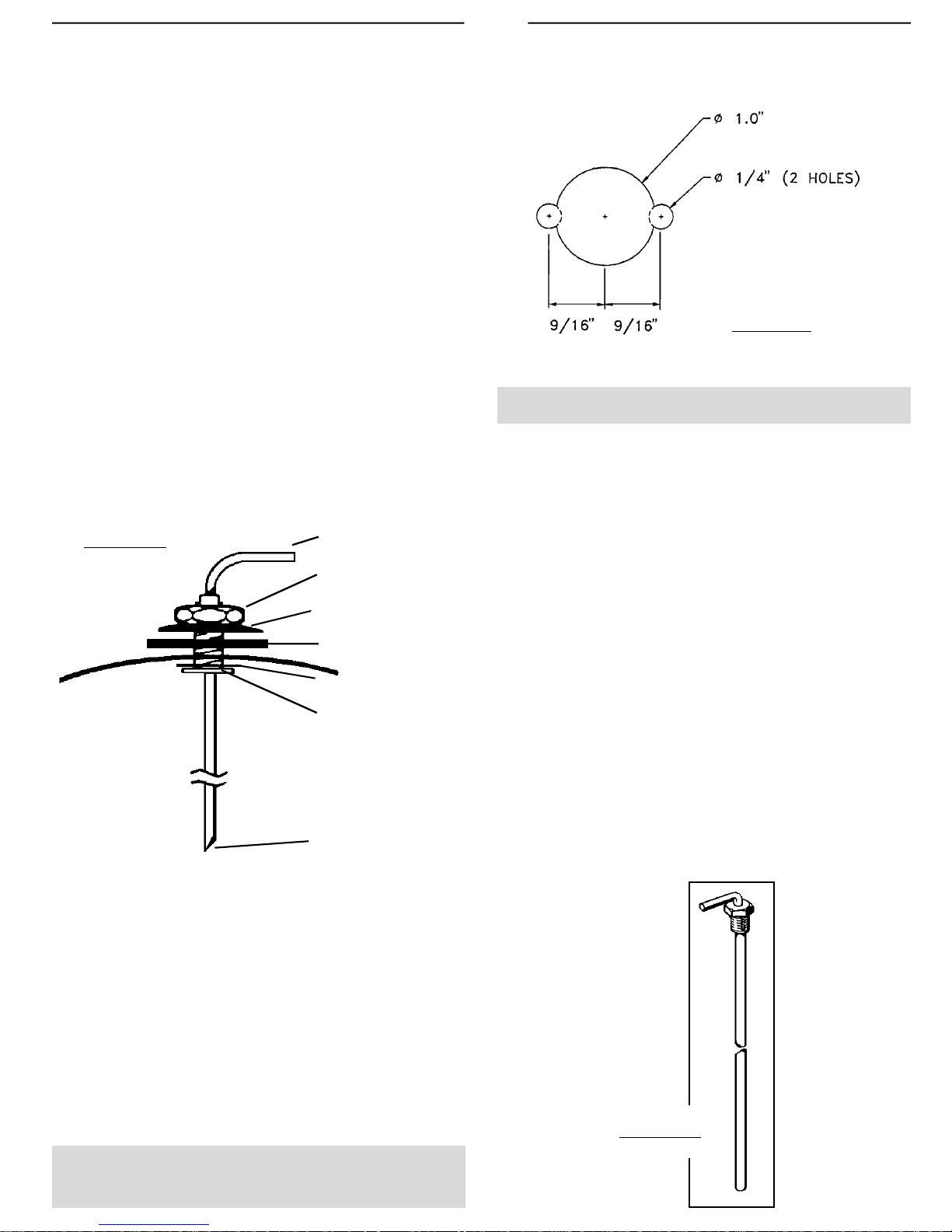

D) Fuel Pick-Up Pipe Installation

(Standard Pick-Up)

- Choose a protected mounting location close to

the pump and heater. A spare fuel sender

gauge plate provides an ideal mounting

location.

- Drill the mounting holes as shown in Figure II F.

- Cut the fuel pick-up pipe to length.

- Mount the fuel pick-up pipe as shown in

FigureIIG.

12

- Lower the fuel pick-up pipe (with reinforcing

washer) into the tank using the slot created by

the two 1/4” holes.

- Lift the assembly into position through the 1”

hole.

- Assemble the rubber washer, metal cup washer

and nut.

Figure II G

Fuel Pick-Up Pipe

Nut

Sheet Metal Washer

Rubber Gasket

Steel Safety Washer

Holding Tabs

Allow 4” from fuel pick-up

to tank bottom. Allow

only 1” for flat bottom

tanks.

Figure II F

Note: Drill the two 1/4” holes first.

( Optional Pick-Up Pipe with NPT fitting )

- Remove an existing plug from the top of the

fuel tank.

- Cut the fuel pick-up pipe to length.

- Secure the fuel pick-up pipe into position using

the combined NPT compression fitting as

shown in Figure II H.

Note: NPT fittings are available in various

sizes (Refer to parts section).

End tip of the fuel pick-up

pipe should have angle

so as to avoid picking up

dirt and subsequent

blockage

Figure II H

5. Electrical Connections

13

Caution: To avoid potential short circuit

damage during installation, Make

connection to the positive terminal at

battery after all electrical connections

are complete.

A) Power Harness....................................................

B) Switch Harness.....................................................

C) Fuel Metering Pump Harness...............................

All harnesses should connect to mating plugs atthe

heater box.

- 2 core harness (red and brown).

- Connect red wire to vehicle battery (+), use ring

terminal provided.

- Connect brown wire to vehicle battery (-), use ring

terminal provided.

- 5 core harness [(red, brown, yellow, blue)

black-optional, for bunk fan power supply]

- Fuel Metering Pump Harness is pre-connected

when box is provided with pump pre-mounted.

- If mounted externally, connect wires to fuel

metering pump using single terminals and rubber

protective boots provided with the heater- no

polarity required ).

- 2 core harness (green, green).

- Connect fuel metering pump harness using two

single connectors. Figure IIa.

D) Bunk Heat Exchanger (optional).......................

Figure II I

- single black wire from switch connector.

- connect as described in Heat Exchanger

plumbing section. (pg.8)

A

B

D

Note: All harnesses should be cut to length.

All exposed electrical connections should

be coated with protective grease.

Figure II Ia

C

6 Exhaust Connection

A 30mm flexible stainless steel exhaust pipe (1

meter long), exhaust clamps and holders are

provided with the heater kit. Connect the

exhaust as follows:

Caution: Run exhaust so that it cannot be

plugged by dirt, water or snow.

Ensure the outlet does not face into

the vehicle slip stream.

Install exhaust pipe with a slight

slope or drill 5mm holes in lowest

point to allow water to run off.

Any restriction in exhaust will cause

operational problems.

Feed the exhaust pipe through the silicone

(white) gasket on the bottom of the box. Run to

an open area to the rear or side of the vehicle so

that fumes can not build up and enter the cab or

the heater box.

Secure the exhaust pipe internally at the heater

and externally using clamps and holders provided. Figure II J.

14

Warning: The exhaust is hot, keep a

minimum of 2” clearance from any heat

sensitive material

Warning: Route exhaust so that the

exhaust fumes cannot enter the passenger compartment.

Figure II J

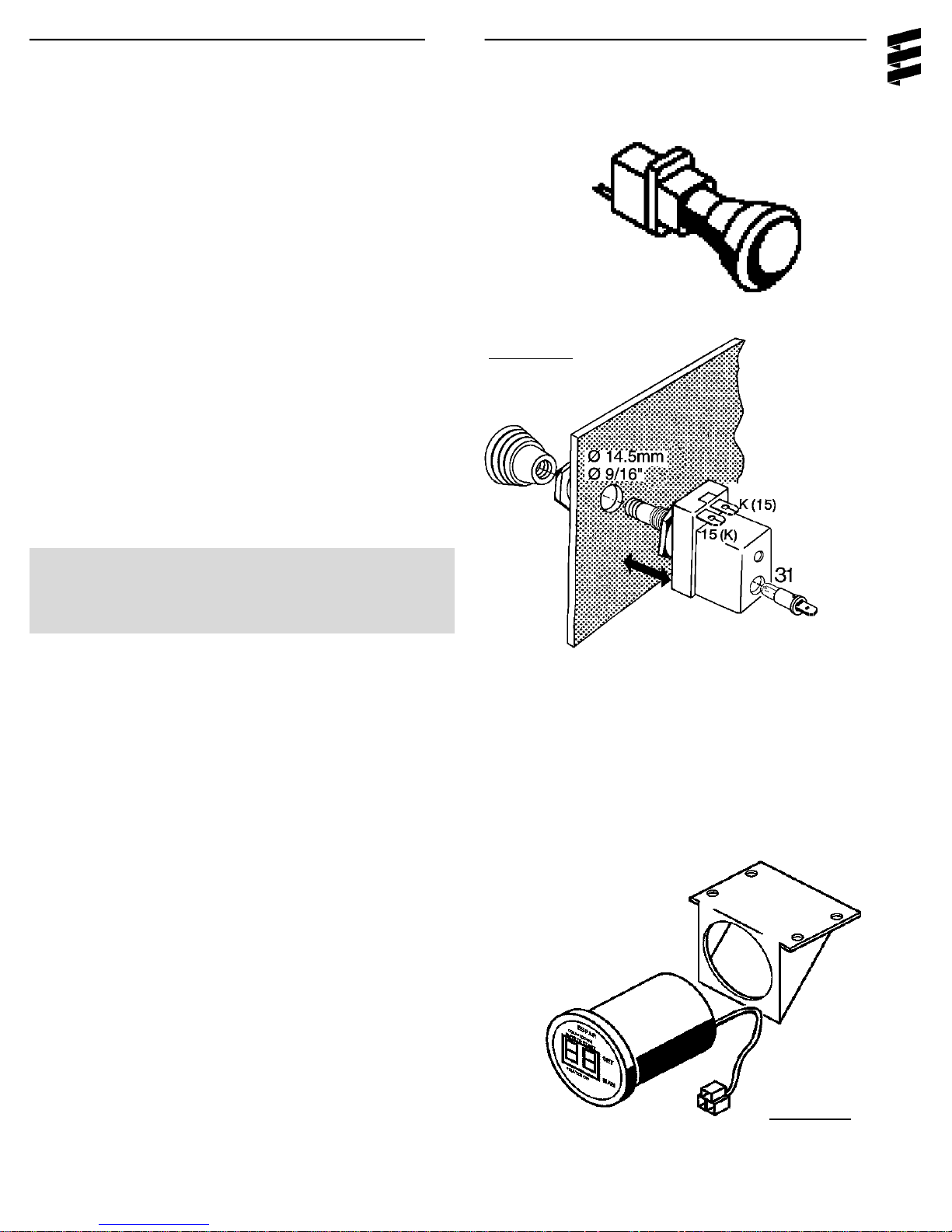

7. Operating Switches

A Push/Pull Switch is supplied with the heater, an

optional 99 Hour Digital Timer or a 7 Day Timer are

also available. Connect the operating switch as follows.

A. Push/Pull Switch

- Mount switch in a location where it is easily

accessible.

- Mount using hardware supplied.

- Connect the 25’ switch harness to the

connector at the heater and run the harness to

the switch location.

- Cut harness to length at the switch and install

terminals.

- Connect wiring as shown in Figure II K.

15

Figure II K

Control Wiring

Push/Pull Switch

Brown - 31

Red - K (15)

Yellow - 15 (K)

Note Wired as above the switch light glows

when pulled out and is off when

pushed in.

B. 99 Hour Digital Timer

This timer is pre-set by Espar to operate the heater

for one (1) hour only. If an alternative run time setting is desired refer to the instructions provided with

the timer.

- Mount the timer using a 2” hole in the dash or

the optional mounting bracket.

- Mount timer using hardware supplied.

- Connect the 25’ switch harness to the

connector at the heater and run the harness to

the switch location.

- Cut harness to length and terminate wires.

- Attach using connector provided.

Red-Red

Yellow-Yellow

Brown-Brown

Figure II L

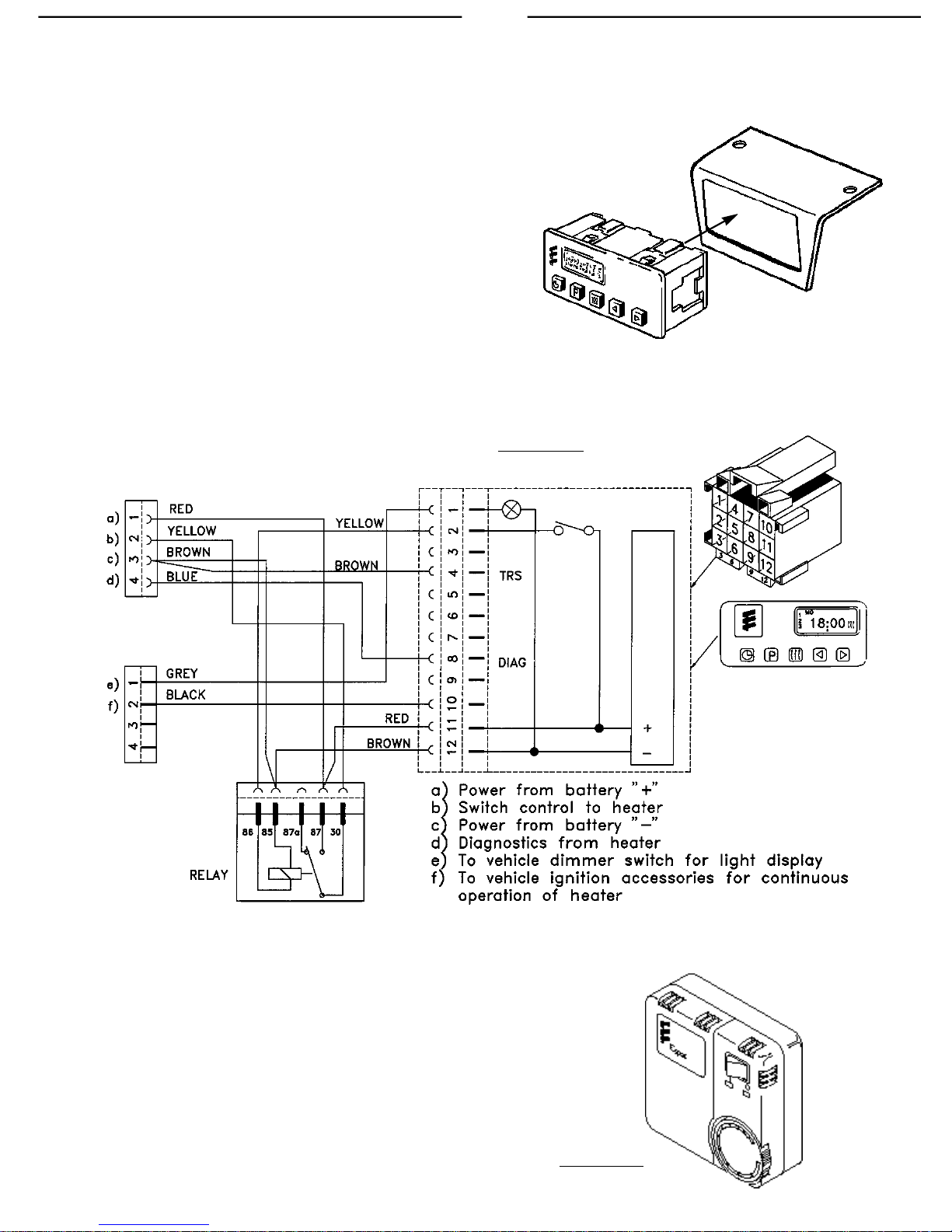

C. 7 DayTimer

The 7 day timer is capable of setting up to 3 preset

start times within 24 hrs. or 1 start time with in 7

days. It also has other functions such as a current

time display and a heater numeric fault code. Refer

to instructions provided with timer for setting

options.

- Mount timer and bracket in a suitable location.

- Connect the 25’ switch harness to the

connector at the heater and run the harness to

the switch location.

- Cut harness to length at the switch and install

terminals.

- Connect switch harness to timer..Figure II M

- Refer to timer instructions for other wiring

options.

16

Figure II M

8. Optional Thermostat for Bunk Heat Exchanger

This thermostat is used to control the fan motor of

the heat exchanger (OEM or optional Espar Heat

Exchanger) inside the truck’s sleeper, thereby

allowing for interior cab heating.

- Mount the thermostat in a location where it is

easily accessible and it’s temperature sensor is

representative of the area being heated.

- Mount using the mounting slots in it’s base.

- Connect wiring as shown on page 8

Figure II N

17

III Heater Operation

1. Pre-Start Procedures

Upon completion of installation prepare the heater

as follows:

- Check all fuel, electrical and plumbing

connections.

- Refill the engine coolant

- Bleed air from the coolant system by loosening

the top heater hose to allow air to escape.

Resecure the heater hose.

- Run engine to further bleed the system.

- Top up engine coolant.

2. Start Up

Once switched on the following sequence occurs:

3. Running

Once ignition is successful the following

operations take place:

- Heater runs in full heat mode.

- Once coolant reaches 194°F (90°C) the

heater automatically switches to low heat mode

and continues to run.

- If coolant temperature drops to 176°F (80°C) the

heater will automatically switch back to full

heat mode.

- If coolant temperature continues to rise, the

heater will automatically switch off once coolant

temperature reaches 201°F (94°C).

- The water pump will continue to circulate

coolant to allow the heater to monitor engine

temperature.

- The heater will automatically re-start once

coolant temperature reaches 176°F (80°C).

- Combustion air blower starts.

- Water pump starts.

- Control unit checks all functions.

- Glow plug begins to preheat combustion

chamber.

- Control unit checks input voltage (under or over

voltage will cause heater to shut down).

- After the 20-50 second combustion chamber

preheat the fuel pump will start.

- Once ignition takes place the flame sensor will

automatically switch the glow plug off

(ignition time: 1-3 minutes maximum).

Note: If the heater fails to start the first time it will

automatically attempt a second start. If

unsuccessful the heater will shut down

completely.

Note: On initial start up the heater may require

several start attempts to self prime the fuel

system

- The heater will continue to run as described

above until it is switched OFF, either manually,

automatically by a timer or heater malfunction

shutdown.

Note: While in running mode if the heater should

shut down due to flame out, it wil

automatically attempt one restart, if

successful it will continue to run, if not it

shuts down completely.

Note: During operation the heater continually

senses the input voltage from the batteries,

if the input voltage drops to approximately

10.0 volts (20.0 V for a 24 V system) the

heater will automatically shut down.

4. Switching Off

When the heater is switched off, manually or automatically, it starts a controlled cool down cycle.

- The fuel metering pump stops delivering fuel

and the flame is extinguished.

- The glow plug is re-energized for a 15 second

after glow.

- The combustion air blower and water pump

continue to run for a three (3) minute cool down

cycle, then switch OFF.

Loading...

Loading...