Espar Hydronic M8 Biodiesel, Hydronic M-II, Hydronic M10, Hydronic M12, D12W Installation & Operating Instructions Manual

...Page 1

Hydronic M-II (Water Heater)

*

Technical Description

Installation Instructions

Operating Instructions

Maintenance Instructions

Troubleshooting and Repair Instructions

Parts List

HYDRONIC M8Biodiesel

25 2470 05 - 12 Volt

25 2471 05 - 24 Volt

HYDRONIC

25 2434 05 - 12 Volt

25 2435 05 - 24 Volt

M10

Espar Products, Inc.

(800) 387-4800

(905) 670-0960

www.espar.com

HYDRONIC

25 2472 05 - 12 Volt

25 2473 05 - 24 Volt

M12

Espar Heater Systems

P/N 20 2900 81 0102 0A 04.2009 Subject to Change Printed in Canada

Page 2

TTaabbllee ooff CCoonntteenntts

Introduction Heater Warnings .............................................. 3

Installation Procedures Heater Location / Mounting/ Fastening .............................................. 9

Heater Operation Pre-Start Procedures / Star t-Up .............................................. 20

s

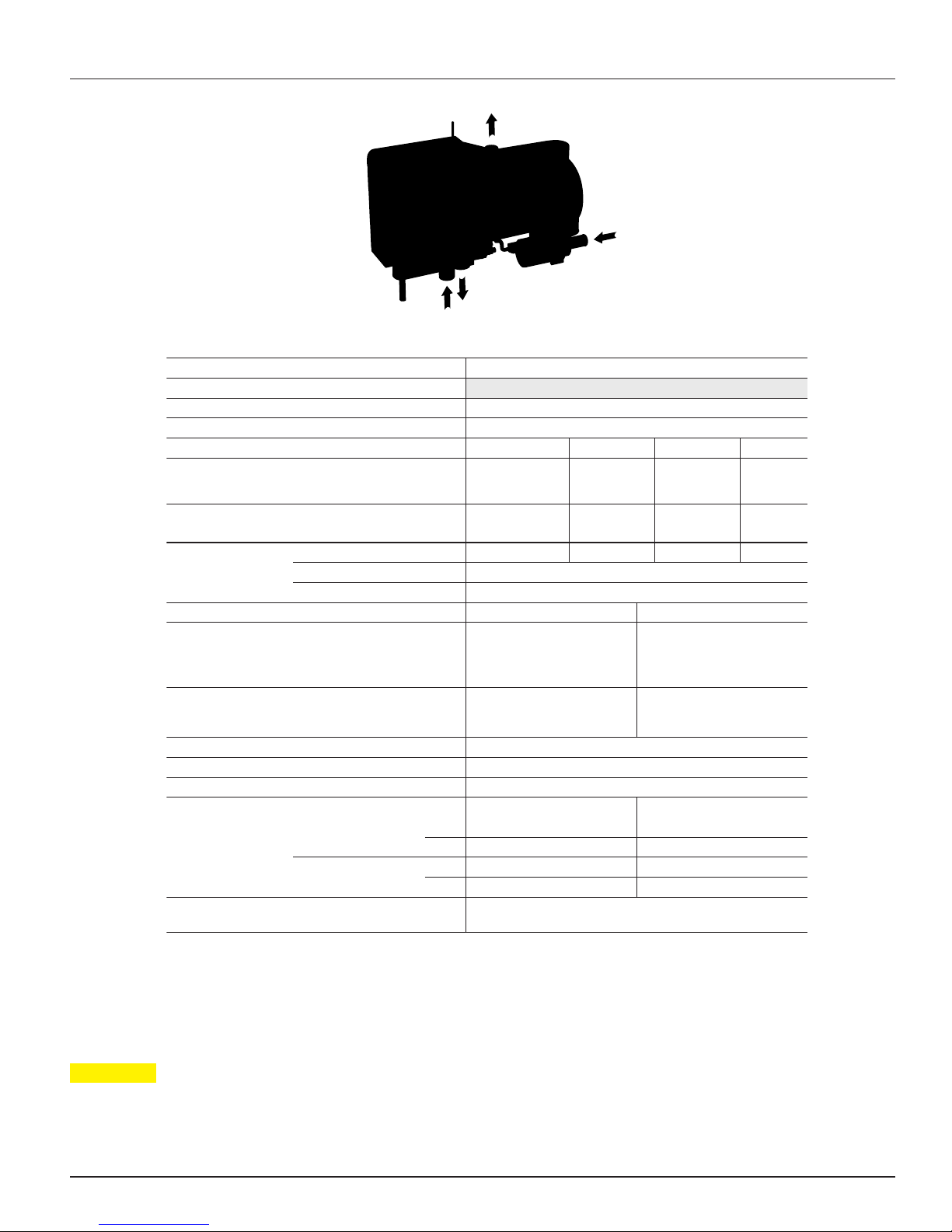

Technical Data Hydronic M8 Biodiesel .............................................. 4

Technical Data Hydronic M10 ............................................. 5

Technical Data Hydronic M12 .............................................. 6

Heater Components .............................................. 7

Principal Dimensions .............................................. 8

Heater & Engine Plumbing

Fuel Quality .............................................. 11

Fuel System .............................................. 12

Electrical Connections .............................................. 14

Exhaust / Intake Connections .............................................. 15

Operating Switches: 7 Day Timer .............................................. 16

Push/Pull Switch, Programmable Timer .............................................. 18

Heating Mode /

Switching Off /Safety Equipment .............................................. 20

Heater Wiring .............................................. 21

Parts List for Wiring Diagram .............................................. 22

Heater Wiring Diagram .............................................. 23

Controler wireing diagrams .............................................. 24

Termperature Drop .............................................. 20

.............................................. 10

PPaagge

e

Maintenance, Periodic Maintenance .............................................. 25

Troubleshooting & Basic Troubleshooting / Self Diagnostics .............................................. 25

Repairs Fault codes / Description / Repair

Repair Instructions .............................................. 30

Repair Steps .............................................. 31

Fuel Quantity .............................................. 47

Heater Components Parts Diagram .............................................. 48

iption & Part #’s .............................................. 49

Descr

Parts Diagram - Boxed units .............................................. 50

Description & Part #’s .............................................. 51

Special Notes

Note: Highlight areas requiring special attention or clarification.

Caution:Indicates that personal injury or damage to equipment may occur unless specific guidelines are followed.

.............................................. 26

Warning: Indicates that serious or fatal injury may result if specific guidelines are not followed.

This publication was correct at the time of going to print. However, Espar Inc.has a policy of continuous improvement

and reserves the right to amend any specifications without prior notice.

Page 3

IInnttrroodduuccttiioon

n

Heater Warnings

Warning T o Installer

• Correct installation of this heater is necessary to ensure

safe and proper operation.

Read and understand this manual before attempting to

install the heater. Failure to follow all these instructions

could cause serious or fatal injury.

Warning - Explosion Hazard

• Heater must be turned off while re-fueling.

• Do not install heater in enclosed areas where combustible

fumes may be present.

• Do not install heaters in engine compartments of marine

vessals.

Warning - Fire Hazard

• Install the exhaust system so it will maintain a minimum

distance of 50mm (2”) from an

tive material.

• Ensure that the fuel system is intact and there are no leaks.

y flammable or heat sensi-

Please note!

Installation of the heater is permitted in vehicles used

for the transport of dangerous goods as per ADR.

Caution

Note: All measurements contained in this manual contain

:

During electrical welding work on the vehicle disconnect the power to the heater in order to protect the

control unit.

metric and approximate SAE equivalents in brackets eg 25mm (1”).

Safety instructions for application and

proper purpose

The heater must only be used and operated for the range of

application stated by the manufacturer in compliance with the

“Operating instructions” included with ever y heater.

Direct questions to Espar Heater Systems:

Warning - Asphyxiation Hazard

• Route the heater exhaust so that exhaust fumes cannot

enter any passenger compartments.

• If running exhaust components through an enclosed compartment, ensure that it is vented to the outside.

Warning - Safety Hazard on Coolant Heaters

Used With Improper Antifreeze Mixtures

• The use of Espar coolant heaters requires that the coolant

in the system to be heated contains a proper mixture of

water and antifreeze to prevent coolant from freezing or

slushing.

• If the coolant becomes slushy or frozen, the heater’s

coolant pump cannot move the coolant causing a blockage of the circulating system. Once this occurs, pressure

will build up rapidly in the heater and the coolant hose will

either burst or blow off at the connection point to the

heater.

• This situation could cause engine damage and/or personal injury. Extreme care should be taken to ensure a proper mixture of water and antifreeze is used in the coolant

system.

• Refer to the engine manufacturer’s or coolant manufacturer’s recommendations for your specific requirements.

Canada & U.S.A. 1-800-387-4800

This publication was correct at the time of print. However,

Espar has a policy of contin

reserves the right to amend any specifications without

prior notice.

uous improvement and

3

Page 4

IInnttrroodduuccttiioon

Te chnical data

Heater type

HYDRONIC M-II

Heater HYDRONIC M8 Biodiesel

Version D 8 W

diulf gnilooC ,retaWmuidem gnitaeH

LowMediumHighPowerwolf taeh eht fo lortnoC

Heat flow (BTU) (Watt)

Figures for operation with diesel fuel. If operated with Biodiesel

the heat flow can reduce by up to 15 %.

27297 17061 11943 5118

8000

BTU

Watt50003500 1500

0.050.110.170.24

0.180.400.650.90

g/h

l/h

) (l/h)h/g( noitpmusnoc leuF

Electrical power (Watt) in operation 55 46 39 35

002Sec. 52 retfa – trats ta

23”FFO“ esahp lortnoc eht ni

tloV 42tloV 21egatlov detaR

Operating range

• Lower voltage limit: An undervoltage protection in

the controller switches the heater off on reaching the

voltage limit.

tloV 02tloV 01

• Upper voltage limit: An overvoltage protection in the

controller switches the heater off on reaching the

voltage limit.

tloV 03tloV 51

up to 200 kPa - 30 psierusserp gnitarepo elbareloT

1400 l/h

500 l/h

370 g/h

132 g/h

2 psi ta pmup retaw eht fo etar wolF

retaeh eht fo etar wolf retaw muminiM

gninnur toNnoitarepOerutarepmet gnitarepo elbareloT

Heater / Control box

Diesel

Biodiesel

Biodiesel

Dosing pump

Diesel

Weight with controller and water pump,

without dosing pump

approx. 6.2 kg - 13.7 lb

– 40 °F to +176 °F / –40 °C to +80 °C –40 °F to +185 °F / –40 °C to +85 °C

+17.6 °F to +176 °F / –8 °C to +80 °C –40 °F to +185 °F / –40 °C to +85 °C

– 40 °F to +122 °F / –40 °C to +50 °C –40 °F to +185 °F / –40 °C to +85 °C

+17.6 °F to +122 °F / –8 °C to +50 °C –40 °F to +185 °F / –40 °C to +85 °C

n

Caution:

Failure to comply with the technical data can

result in malfunctions.

4

Page 5

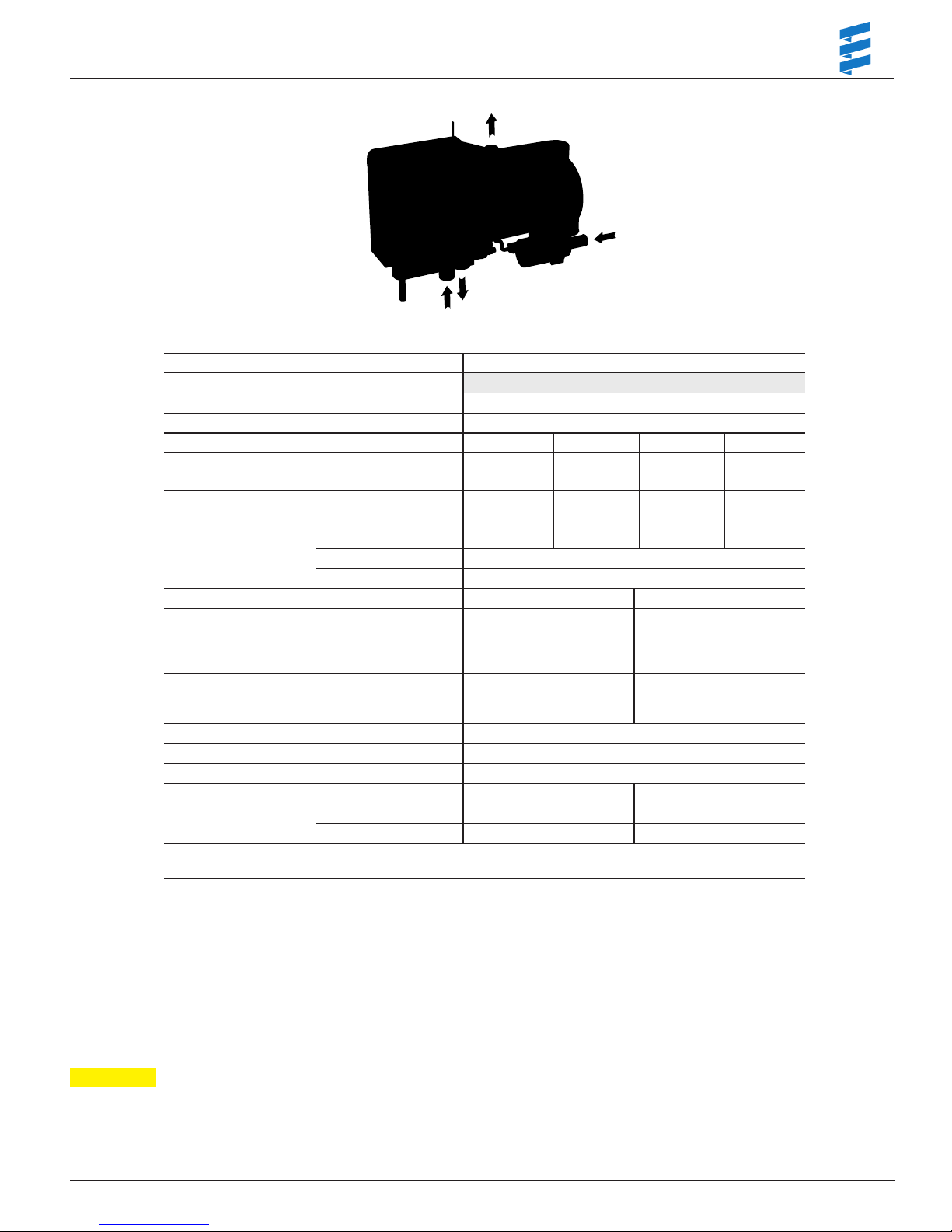

Introduction

Te chnical data

Heater type

H

YDRONIC M-II

H

eater HYDRONIC M10

Version D 10 W

diulf gnilooC ,retaWmuidem gnitaeH

wolf taeh eht fo lortnoC

5118119432729732415BTU wolf taeH

0.050.110.240.32

0.180.40.91.2

(g/h) noitpmusnoc leuF

Electrical power (Watt)

021 52 retfa – trats ta

23”FFO“ esahp lortnoc eht ni

tloV 42tloV 21egatlov detaR

Operating range

• Lower voltage limit: An undervoltage protection in

the controller switches the heater off on reaching the

voltage limit.

tloV 02tloV 01

• Upper voltage limit: An overvoltage protection in the

controller switches the heater off on reaching the

voltage limit.

tloV 03tloV 51

up to 200 kPa - 30 psierusserp gnitarepo elbareloT

1400 l/h - 370 g/h2 psi ta pmup retaw eht fo etar wolF

500 l/h - 132 g/hretaeh eht fo etar wolf retaw muminiM

gninnur toNnoitarepOerutarepmet gnitarepo elbareloT

Heater / Control box

Dosing pump

Weight with controller and water pump,

without dosing pump

approx. 6.2 g/h - 13.7 lb

–40 °F to +176 °F / –40 °C to +80 °C –40 °F to +185 °F / –40 °C to +85 °C

–40 °F to +122 °F / –40 °C to +50 °C –40 °F to +185 °F / –40 °C to +85 °C

in operation 86 60 39 35

LowMediumHighPower

9500Watt80003500 1500

(l/h)

Sec.

Caution:

Failure to comply with the technical data can

result in malfunctions.

5

Page 6

Introduction

Te chnical data

Heater type

H

YDRONIC M-II

H

eater HYDRONIC M12

Version D 12 W

diulf gnilooC ,retaWmuidem gnitaeH

Low3 muideM2 muideM1 muideMHighrewoPwolf taeh eht fo lortnoC

wolf taeH

noitpmusnoc leuF

in operation 132 86 46 39 35 34

02152 retfa – trats ta

23”FFO“ esahp lortnoc eht ni

tloV 42tloV 21egatlov detaR

Operating range

• Lower voltage limit: An undervoltage protection in

the controller switches the heater off on reaching the

voltage limit.

tloV 02tloV 01

• Upper voltage limit: An overvoltage protection in the

controller switches the heater off on reaching the

voltage limit.

tloV 03tloV 51

erusserp gnitarepo elbareloT

ta pmup retaw eht fo etar wolF

retaeh eht fo etar wolf retaw muminiM

gninnur toNnoitarepOerutarepmet gnitarepo elbareloT

Heater / Control box

Dosing pump

Weight with controller and water pump,

without dosing pump

409511943 5118170613241542000

.04.11.05.17.32.40

0.150.40 0.180.651.21.5

(g/h)

(l/h)

Electrical power (Watt)

2 psi

approx. 6.2 g/h - 13.7 lb.

Sec.

BTU

up to 200 kPa - 30 psi

1400 l/h - 370 g/h

500 l/h - 132 g/h

–40 °F to +176 °F / –40 °C to +80 °C –40 °F to +185 °F / –40 °C to +85 °C

–40 °F to +122 °F / –40 °C to +50 °C –40 °F to +185 °F / –40 °C to +85 °C

Caution:

6

Failure to comply with the technical data can

result in malfunctions

.

Page 7

1

3

F

2 WO

WI

E

CA

987

54

6

IInnttrroodduuccttiioon

n

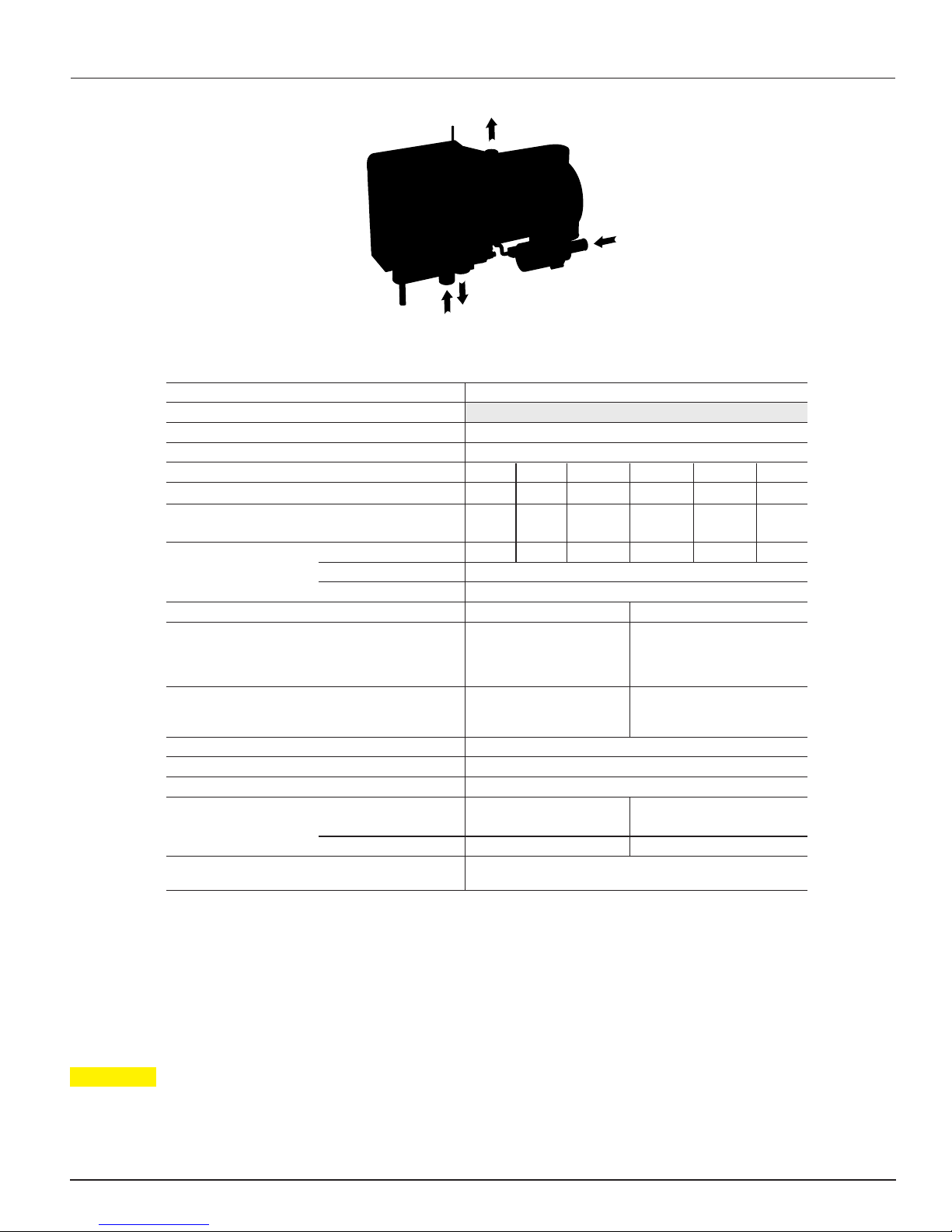

Heater Components

1 Control box

2 Burner motor

3 Glow plug

4 Flame pipe

5 Overheating sensor

6 Heat exchanger

7 Water pump

8 Combustion chamber

9 Flame sensor

WI = Water inlet

WO = Water outlet

= Combustion air

CA

F = Fuel

E = Exhaust

7

Page 8

IInnttrroodduuccttiioon

FWO

WI

CA E

M8 (x4)

n

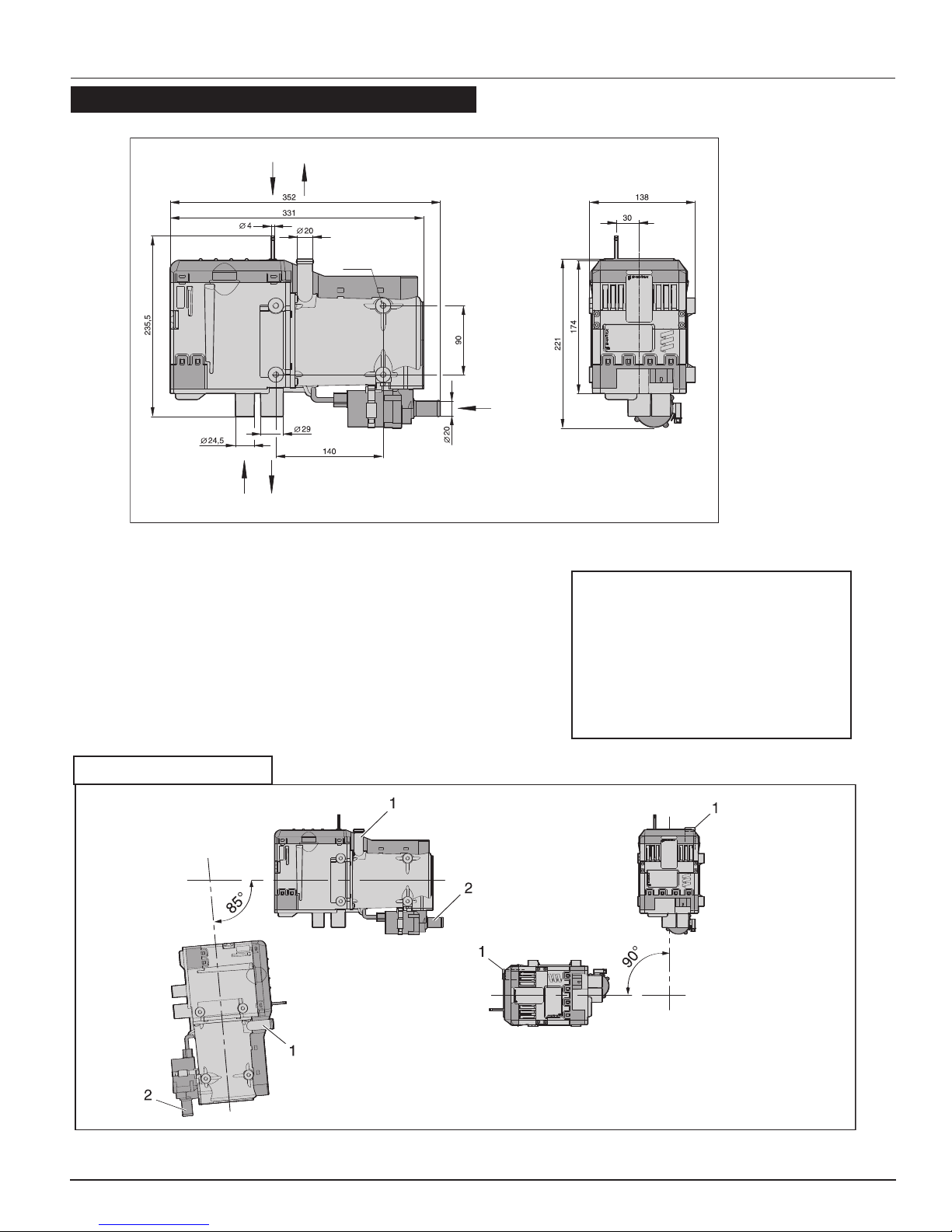

Principal Dimensions

E Exhaust

F Fuel

CA Combustion air

WO Water outlet

WI Water inlet

Permissible installation positions

* All measurements in millimeters 25.4 mm = 1”

Boxed Heaters Insure:

Minimum installation distance (clearance) to

open the lid and to dismount the glow pin and

the control unit.

Insure:

Minimum installation distance (clearance) to

take in combustion air.

1 Water outlet socket, heater

2 Water inlet socket, water pump

8

Page 9

IInnssttaallllaattiioonn PPrroocceedduurrees

s

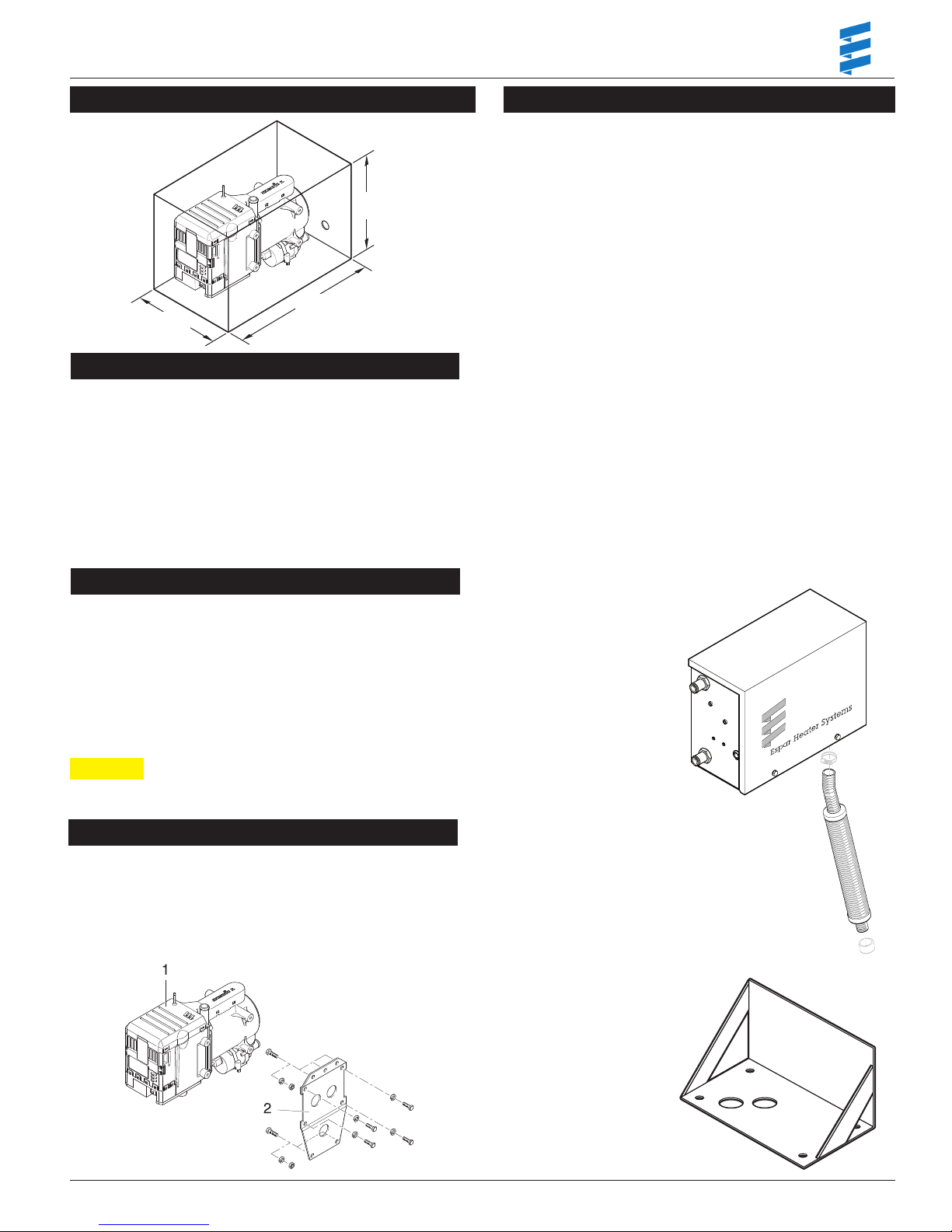

Principal Dimensions - Boxed Version

317 mm

(12.4”)

197 mm

(7.76”)

430 mm (16.9”)

Heater Location

Always mount the heater in a protected area.Eg: storage compartment, engine compar tments, step box or battery box.

Espar recommends you use the boxed unit. Refer to fig. 1

When mounting the heater adhere to the following conditions:

• Situate the heater below the normal coolant level of the engine.

• Guard against excessive road spray.

• Keep coolant hoses, fuel lines and electrical wiring as short

as possible.

Arrangement of the heater

Parts of the structure and other components near the heater

must be protected from excess heat exposure and possible

contamination from fuel or oil.

The heater must not pose a fire hazard even when it

overheats.

– This requirement is deemed to be fulfilled when

adequate clearance to all parts is observed during

installation, sufficient ventilation is provided and fireproof

materials or heat plates are used.

The heater must not be located in the passenger compartment.

A unit may however be used in a hermetically sealed housing

which also corresponds to the conditions stated above.

The factory nameplate or duplicate must be affixed so that it

can still be easily read when the heater is installed in the

vehicle.

All appropriate precautions must be taken when

arranging the heater to minimise the risk of injuries

to persons or damage to other property.

Heater Mounting

Mount the heater using the four (4) shock mounts provided

with kit and one of the following mounting methods:

• Use the Side Mount Bracket to mount the heater on the

side of the fr

• Use a spare step box or battery box.

• Use the saddle bracket and hardware provided

Caution: Guard the heater against excessive road spray to

ame rail.

avoid internal corrosion.

Mounting and Fastening

Fix the unit holder from the installation kit to the heater

using 4 hexagon screws M8 and 4 spring washers.

Fix the heater and the mounted unit holder in a suitable

place in the vehicle using 5 hexagon screws M8, 5 spring

washers and 5 hexagon nuts M8

Fig. 1

Box Base

P/N 25 2800 40 10 02

Box Lid

P/N 25 2800 40 10 03

Intake Silencer

always needed

P/N 25 1786 80 02 00

1 Heater

2 Heater bracket

Side Mount Bracket

P/N 20 2900 40 00 75

9

Page 10

IInnssttaallllaattiioonn PPrroocceedduurrees

42

3

1

s

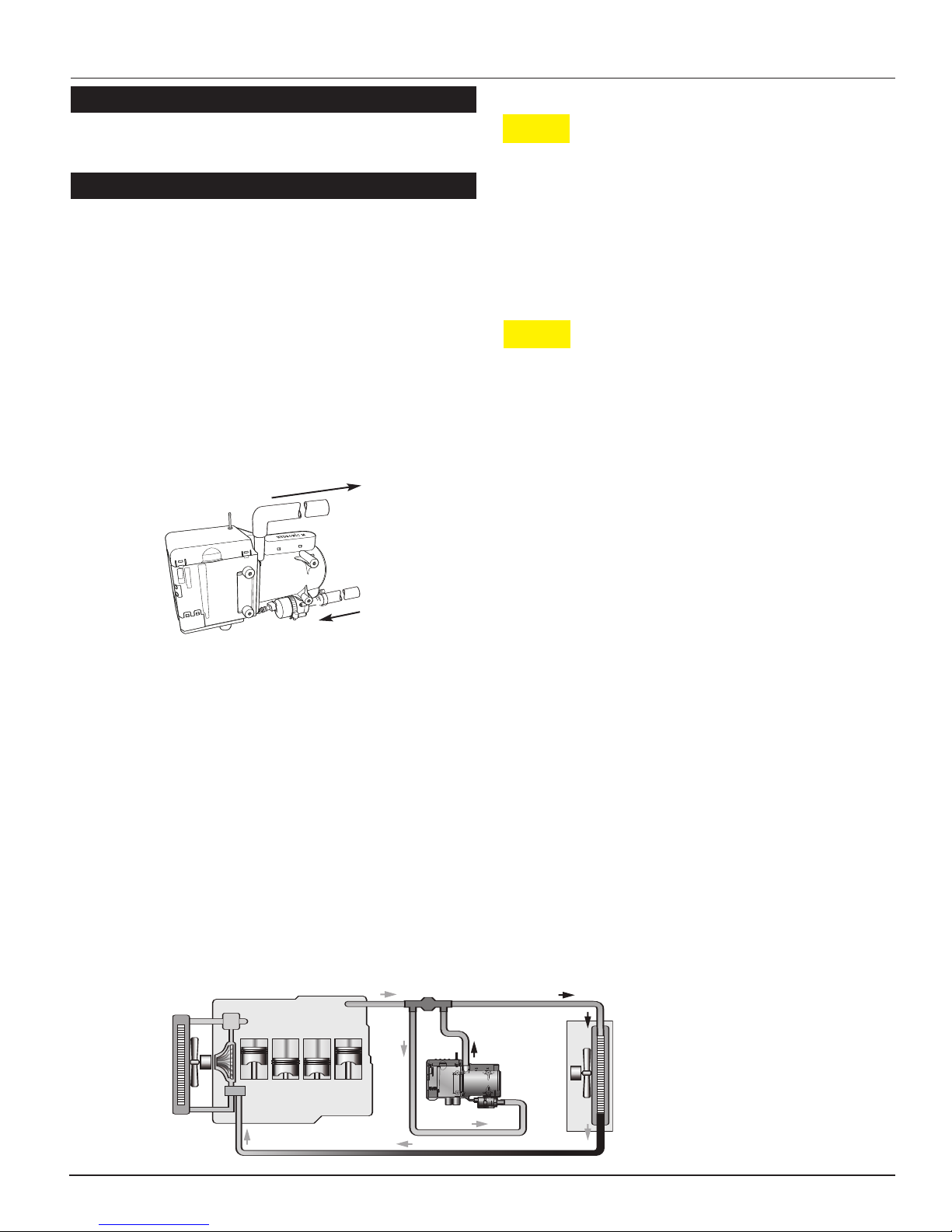

Heater Plumbing

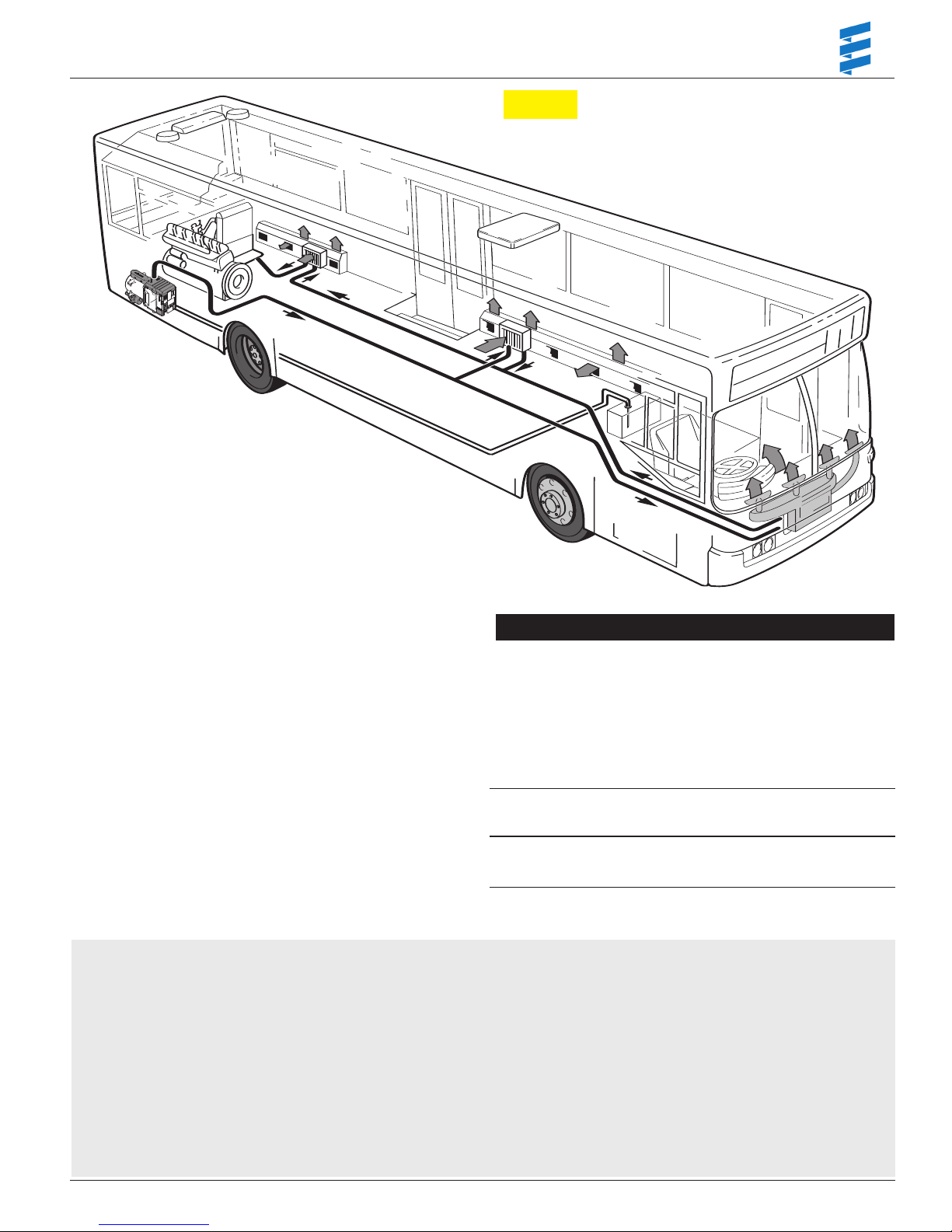

The heater is incorporated into the engine’s cooling system for

engine preheating.

Caution: It is possible for the coolant and components of the

coolant circuit to get very hot.

Engine Plumbing

Follow these guidelines and refer to the engine plumbing diag r am

shown below.

• Install hose fittings into the engine block for pick-up and return

lines.

• Use existing holes in the engine block (ie. remove

blanking plugs when possible).

• Use shut off valves to ensure the system can be isolated from

the engine when not in use. Alternatively “T” piece connectors

in existing coolant hoses can be used if no blanking plugs are

available.

• Provide 20mm (3/4” ) hose barbs for hose connections.

• Use 20mm (3/4” ) hoses to ensure adequate coolant flow.

• Keep the pick up and return points as far apart as possible to

ensure good heat distribution.

Water out

Water in

• Take the coolant from a low point on the engine to reduce

aeration in the system.

• Ensure proper direction of coolant flow by taking coolant from a

high pressure point in the engine and returning it to a low pressure point. (ie. pickup from back of block and retur n to the

suction side of the engine's water pump).

• Ensure adequate flow rate through the heater b y comparing the

incoming and outgoing coolant temperatures while the heater is

running. If the rise in temperature exceeds 10°C (18°F), coolant

flow must be increased by modifying the plumbing.

• Ensure the heater and water pump are installed as low as pos

sible to allow the purging of air.

• If a bunk heat exchanger is incor porated into the system,

proper plumbing layouts must be followed.

• Parts conveying water must be routed and fastened in such

a way that they pose no temperature risk to man, animals or

material sensitive to temperature from radiation / direct

contact.

• Before working on the coolant circuit, switch the heater off

and wait until all components have cooled down completely,

if necessary where safety gloves.

Caution:

• When installing the heater, please take note of the direction

w of the coolant circuit.

of flo

• Fill the heater and water hoses with coolant before con-

necting to the coolant circuit.

• Route the water hoses without any kinks, and in a rising

position if possible.

• When routing the water pipes, observe a sufficient clea-

rance to hot vehicle parts.

• Protect all water hoses / water pipes from chafing and from

extreme temperatures.

• Secure all hose connections with hose clips.

• After the vehicle has been operating for 2 hours or travelled

100 km, tighten the hose clips again.

• The minimum water flow rate is only guaranteed if the tem

perature difference of the heating medium does not exceed

15°C

(60°C)

between water inlet and water outlet during

heating.

• Only overpressure valves with an opening pressure of min.

6 psi – max. 30 psi bar may be used in the coolant circuit.

• The coolant liquid must contain at least 10 % antifreeze all

year round as corrosion protection.

• The cooling liquid must contain sufficient antifreeze for low

temperatures.

• Before commissioning the heater or after changing the

cooling liquid, the whole coolant circuit including heater must

be vented free of bubb les according to the instructions issued

by the vehicle manufacturer.

• Only top up with coolant approved by the vehicle manufac-

turer.

10

1 Heater

2 Non-retur n valve (Optional)

3 Heat exchanger

4 Vehicle engine

Page 11

IInnssttaallllaattiioonn PPrroocceedduurrees

s

Caution: The coolant must contain a minimum of 10%

antifreeze at all times as protection against

corrosion.

Fresh water will corrode internal heater parts.

• The exhaust outlet must end in the open air.

• The exhaust pipe must not protrude beyond the lateral limits of

the vehicle.

• Install the exhaust pipe sloping slightly downwards.

If necessary, make a drain hole approx. Ø 5 mm at the lowest

point to drain off condensation.

• Important functional parts of the vehicle must not be impaired

(keep sufficient clearance).

• Mount the exhaust pipe with sufficient clearance to heat-sensitive parts. Pay particular attention to fuel pipes (plastic or

metal), electrical cables and brake hoses etc.!

• Exhaust pipes must be fastened safely (recommended clearance of 50 cm) to avoid damage from vibrations.

• Route the exhaust system so that the emitted fumes are not

sucked in with the combustion air.

• The mouth of the exhaust pipe must not get clogged by dirt

and snow.

• The mouth of the exhaust pipe must not point in the direction

of travel.

• Always fasten silencer to the vehicle.

• The e xhaust end pipe should be much shorter than the flexib le

exhaust pipe from the heater to the exhaust silencer.

Note:

The heater is approved for operation with biodiesel up to a temperature of – 8°C (17.5°F) (the flowability reduces at temperatures below 0 °C (35°F)).

• When using 100 % biodiesel, the heater should be run on diesel fuel twice a year (in the middle and at the end of a heating

period) to burn off possibly accumulated biodiesel deposits.To do so, let the vehicle tank run almost empty and fill with diesel fuel

without adding any biodiesel. While running on this tank filling, switch the heater on 2 to 3 times for 30 minutes at a time at the

highest temperature setting.

• If constantly operated with diesel / biodiesel mixtures of up to 50 % biodiesel, intermediate operation with pure diesel fuel is not

necessary.

Both heaters are not approved for operation with biodiesel. Up to 10 % biodiesel may be added.

HYDRONIC

HYDRONIC

M8 Biodiesel

M10 /

HYDRONIC

M12

Fuel Quality

This means that difficulties are only to be expected for extreme

drops in temperature, as also apply to the vehicle engine.Please

also refer to the vehicle manual.

If no special diesel fuel is available for low temperatures, then

kerosene or gasoline should be mixed with the fuel according to

the following table:

Temperature Winterdiesel Addition

0 °C to –25 °C 100 % –

(32 °F to –13 °F) 100 % –

–25 °C to –40 °C 50 %* 50 % paraffin or petrol

(32 °F to –13 °F) 50 %* –

* or 100 % special cold diesel fuel (Arctic diesel).

11

Page 12

IInnssttaallllaattiioonn PPrroocceedduurrees

FUEL

TANK

Right Wrong

Bubble

Correct

Wrong

s

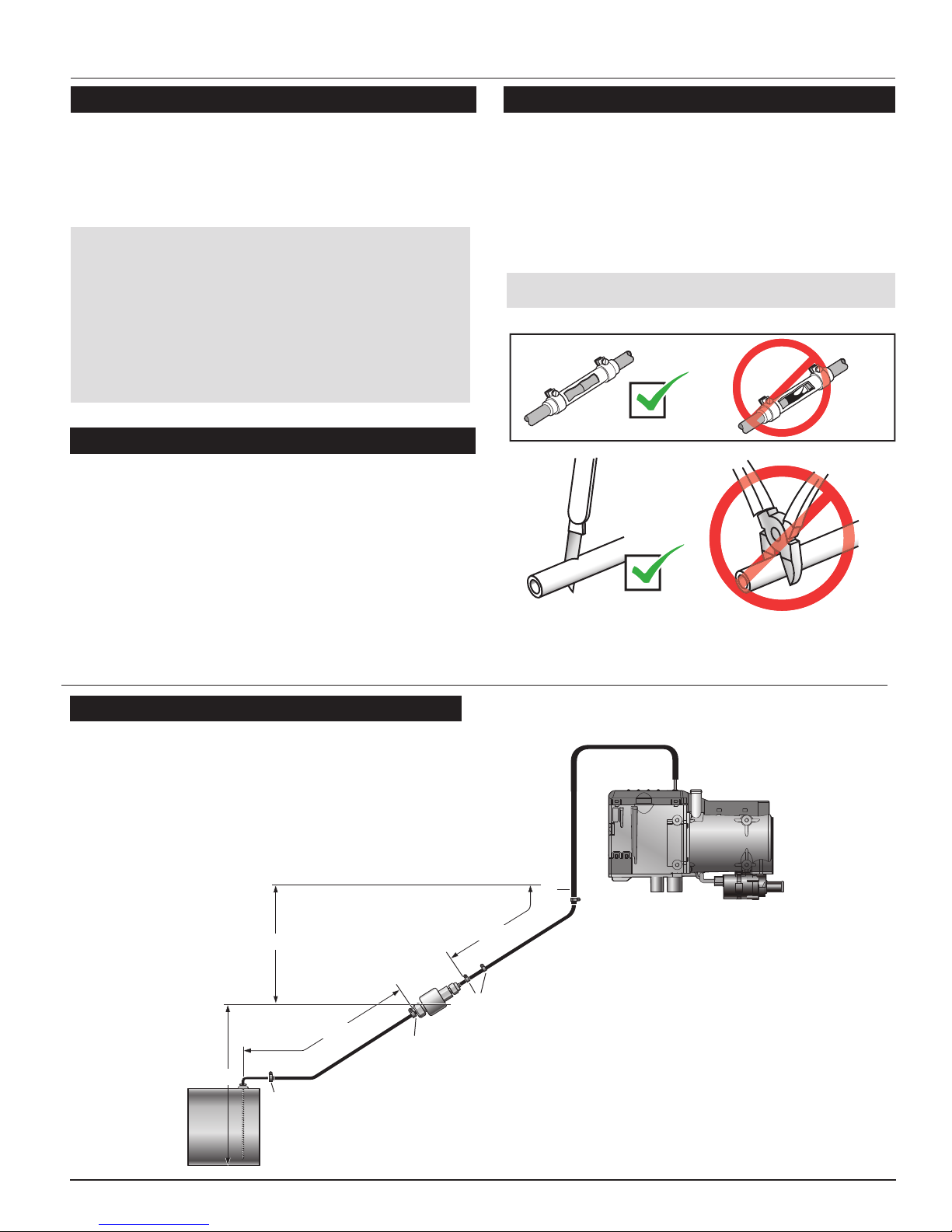

Fuel System

The Hydronic MII boxed unit is most commonly provided with the

fuel metering pump mounted inside the box. This is to reduce

installation time and to protect the pump from corrosion. If specifications cannot be met the pump must be mounted externally.

See illustration for connections and specifications. All par ts

necessary to do the installation are included in the kit as shown.

Note: Fuel line limits must not be exceeded.

Ensure that the following conditions are met.

Bottom of the fuel metering pump must be within a height

of 2’6” of the bottom of the fuel pick-up pipe.

Fuel metering pump must be within a total distance of

6’6” from the fuel pick-up pipe.

Pressure runs of less than 1.3 mtrs (50”) use only 3.5mm

rubber (360 75 300)

Control and Safety Devices

Emergency shutdown – EMERGENCY OFF

If an emergency shutdown – EMERGENCY OFF – is necessary

during operation, proceed as follows:

• Switch the heater off with the control

• pull the fuse out

• disconnect the heater from the battery.

Fuel Line

• Route fuel lines from the fuel pick-up pipe to the heater.

• Use Espar approved fuel lines.

• Other sizes or types of fuel lines may inhibit proper fuel flow.

• Make proper butt joints using clamps and connector pieces

as shown

• Use a sharp utility knife to cut plastic fuel lines to avoid burrs.

Note: Butt joints and clamps on all connections.

Fuel System Tolerances

Max. 6’6”

Max. 6’6”

Max. 2’6”

2

12

3

1

6

5

Max. 20”

6

7

1. Fuel Pick-Up Pipe

5

4

2

2. 11mm Clamp

3. 5.0mm Fuel Line

4. Fuel Metering Pump

5. 9mm Clamp

6. 3.5mm Rubber Connector

7. 2.0mm White Plastic Fuel Line

See notes if length is less than

1.3 mtr (50”)

Page 13

IInnssttaallllaattiioonn PPrroocceedduurrees

Ø

2.5 cm (Ø 1.0”)

1.5 cm 1.5 cm

9 / 16” 9 / 16”

Ø

0.625 cm

(2 HOLES)

(

Ø

1 / 4”)

15° to

vertical

s

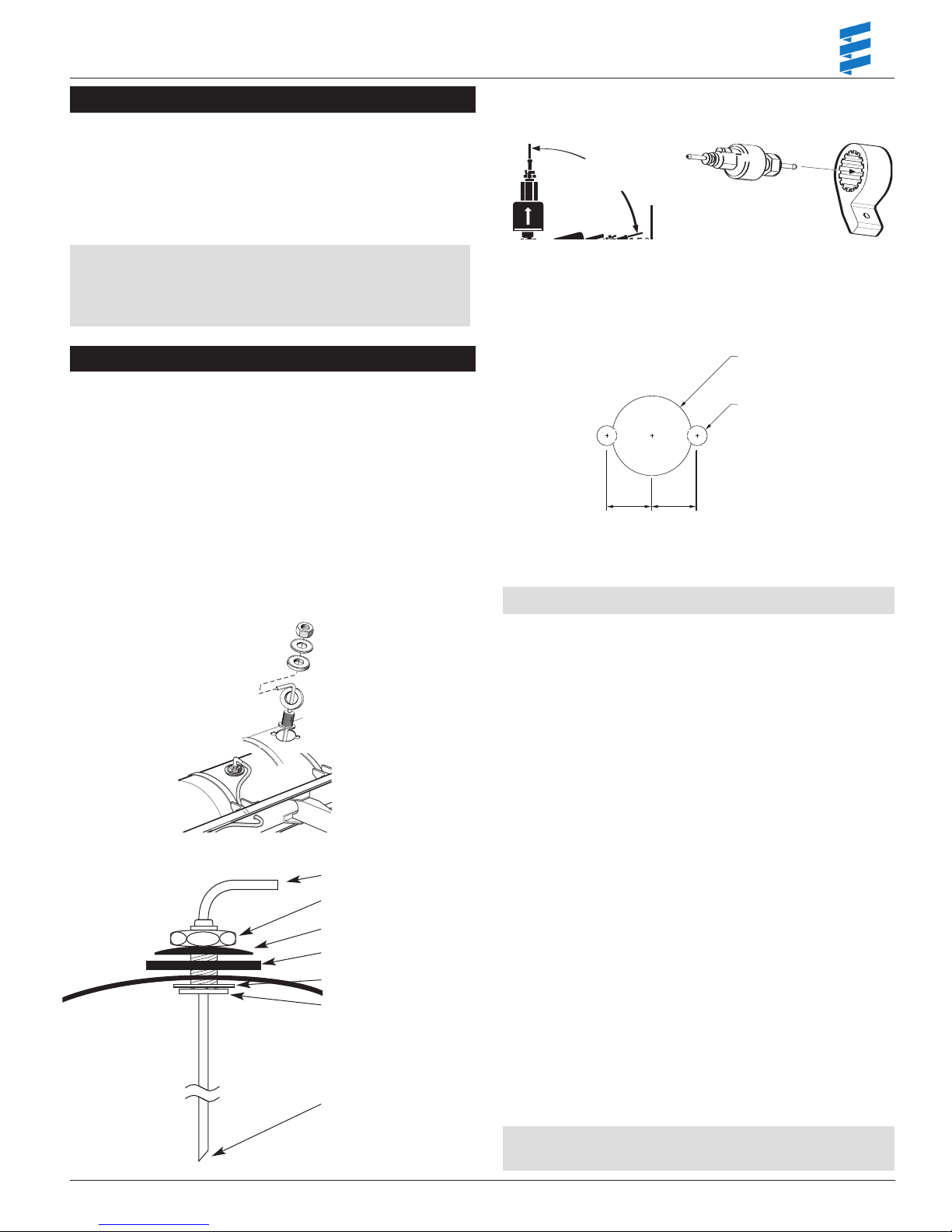

Fuel Metering Pump Installation

If the pump needs to be mounted externally follow these guidelines:

• Choose a protected mounting location close to the fuel pickup pipe and heater.

• Using the bracket and rubber mount provided, install pump as

shown.

Note: Proper mounting angle of the pump is necessary to

allow any air or vapor in the fuel lines to pass through

the pump rather than cause a blockage.

Fuel Pick-Up Pipe Installation (Standard Pick-Up)

• Choose a protected mounting location close to the pump and

heater.A spare fuel sender gauge plate provides an

ideal mounting location.

• Drill the mounting holes as shown.

• Cut the fuel pick-up pipe to length.

• Mount the fuel pick-up pipe as shown

• Lower the fuel pick-up pipe (with reinforcing washer) into

the tank using the slot created by the two 0.6cm (1/4”) holes.

• Lift the assembly into position through the 2.5cm (1”) hole.

• Assemble the rubber washer, metal cup washer and nut.

Note: Drill the two (1/4”) holes first.

Fuel Pick-Up Pipe

Nut

Sheet Metal Washer

Rubber Gasket

Steel Safety Washer

Holding Tabs

Allow 4” from fuel pick-up

to tank bottom. Allow

only 1” for flat bottom

tanks.

End tip of the fuel pick-up

pipe should have angle

so as to avoid picking up

dirt and

subsequent blockage

( Optional Pick-Up Pipe with NPT fitting )

• Remove an existing plug from the top of

the fuel tank.

•

Cut the fuel pick-up pipe to length.

• Secure the fuel pick-up pipe into position

using the combined NPT compression

fitting as shown

Note: NPT fittings are available in var ious sizes

(Refer to parts catalogue).

13

Page 14

IInnssttaallllaattiioonn PPrroocceedduurrees

++

--

A

B

C

A

UT

O

M

A

N

U

A

L

R

E

S

E

T

C

L

O

C

K

T

I

M

E

R

D

A

Y

H

O

U

R

M

I

N

M

A

N

U

AL

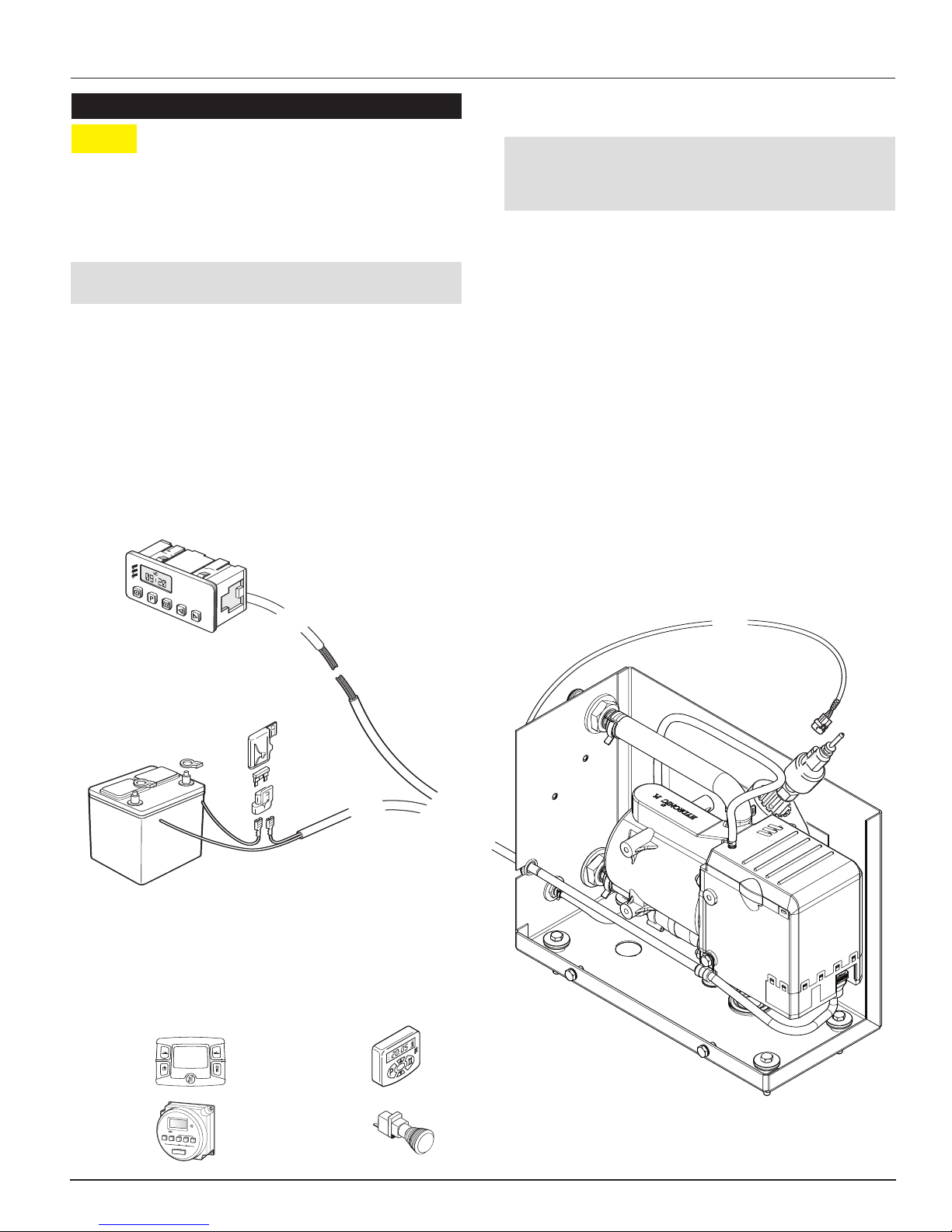

Electrical Connections

s

Caution: To avoid potential short circuit damage during instal

lation, insert main fuse into the power harness after

all electrical connections are complete.

A) Power Harness...................................................................

Note: Wire must be inserted into fuse holder pr ior to

terminating.

B) Switch Harness..................................................................

C) Fuel Metering Pump Harness...........................................

7 Day Timer

Note: All harnesses should be cut to length.

All exposed electrical connections should be coated

with protective grease.

• 2 core harness (red, brown).

• Connect red wire to fuse link and terminal.

• Attach ring terminal to vehicle battery (+).

• Connect brown wire to vehicle battery (-) using ring

terminal provided.

• Insert fuse. (15A-24V, 20A-12V)

• 4 core harness (red, brown, yellow, blue/white)

Run to location of switch.Make terminal connections at

•

switch. Espar has different available switches.

See switch instructions for more information.

• 2 core harness (green, green).

•

Fuel Metering Pump Harness is pre-connected when

box is provided with pump pre-mounted.

• If mounted externally, connect wires to fuel meter ing

pump using connector and terminals supplied, with the

heater - (no polarity required).

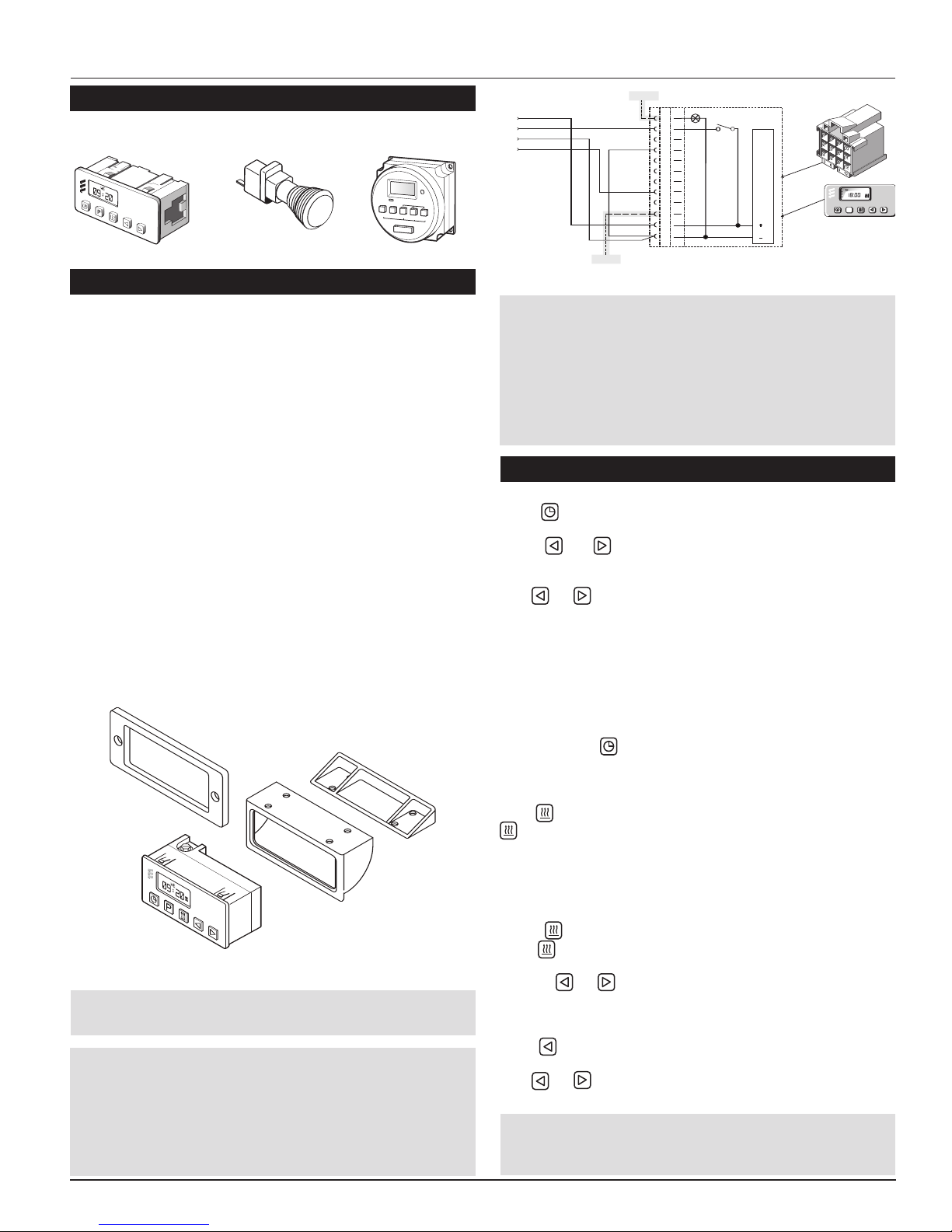

Shown is a

Standard - Power, Switch, Fuel Metering Pump harnesses

and optional 7 day timer.

Other timers or switch options are available.

Easy Start Mini Timer

Hydronic

MII boxed version, 12 volt with

7 Day Timer

switch harness

Programable Push and

Timer Pull Switch

14

Page 15

IInnssttaallllaattiioonn PPrroocceedduurrees

s

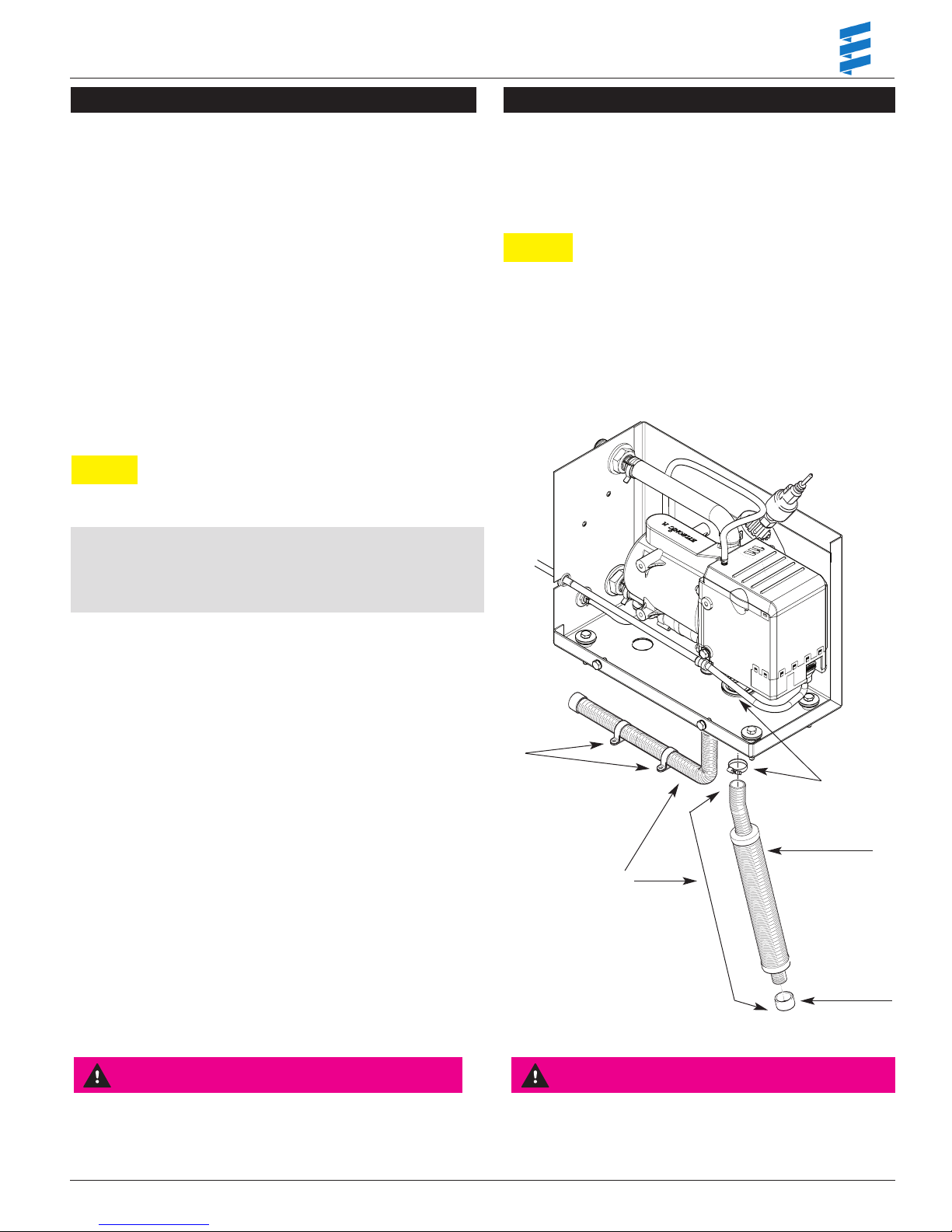

Exhaust Connection

A 30 mm flexible tube e xhaust pipe with a length of 1M long is supplied with the kit for the exhaust. An exhaust clamp is needed to

secure the exhaust to the the heater.The exhaust hose cannot be

any longer than 2 m. Connect the exhaust as follows:

• Connect the exhaust pipe to the exhaust port on the heater and

attach with clamp provided. Feed the exhaust pipe through the

silicone (white) grommet on the bottom of the box.

• Run exhaust to an open area to the rear or side of the vehicle so

that fumes can not build up and enter the passenger compartment or the heater combustion air intake.

• Install exhaust pipe with a slight slope or drill a small hole in the

lowest point to allow water to run off.Any restriction in exhaust

will cause operational problems.

• Route the exhaust pipe from the heater using holders provided.

Caution: Run exhaust so that it cannot be plugged by dirt, water

or snow. Ensure the outlet does not face into the vehicle slip stream.

Intake Connection

Combustion air must be drawn in from the outside of vehicle.

The combustion air opening must be kept free at all times.

• Connect the air intake pipe to the intake port on the heater

and secure with clamp provided.

Caution: Do not install the intake opening facing the vehi-

cle slipstream. Ensure that the opening cannot

become clogged with dirt or snow and that any

water entering the intake can drain away.

Note: 1. Exhaust hose cannot be any longer than 2m (80”)

2. Minimum length 0.2 m (8”)

3. Air intake silencer always needed.

Holding clamps

Flexible Exhaust

& Air intake hose

cannot be any

longer than

Max 2M (80”)

Exhaust & Intake

Clamps

P/N 25 1786 80 02 00

Air Intake silencer

Always needed

End Sleeve

Warning: Asphyxiation Hazard Warning: Fire Hazard

Route exhaust beyond the skirt of the cab and outside of the

frame area. Route exhaust so that the exhaust fumes cannot

enter the passenger compartment. Failure to comply with this

warning could result in Asphyxiation.

The exhaust is hot, keep a minimum of 5cm (2”) clearance

from any heat sensitive material. Failure to comply with this

warning could result in fire and serious injury.

15

Page 16

IInnssttaallllaattiioonn PPrroocceedduurrees

A

U

T

O

M

A

N

U

A

L

R

E

S

E

T

C

L

O

C

K

T

I

M

E

R

D

A

Y

H

O

U

R

M

I

N

M

A

N

U

A

L

Option #1

Option #2

Yellow

Red

Brown

Blue

DIAG

TRS

Yellow

R

ed

Blue

Brown

12 11 10 9 8 7 6 5 4 3 2 1

P

a4)

a

3

)

a

5

)

a

2

)

s

Operating Switches

A 7 Day Timer , a Push/Pull switch or an easy start timer are

available for the heater.

7 Day Timer Instructions

The 7 Day Timer has been designed to provide a simple means

to control the operation of the heater system and to include the

capability for diagnostics. This timer connects to the diagnostic

circuit of the heater. The timer then displays any heater fault

codes in three digit number form automatically. The timer allows

for pre-selection of turn on time, up to 7 days in advance, as well

as an option for run times up to 2 hours before automatically turning off.In addition, there is an on/off switch for manual operation.

By default the timer is pre-set by Espar to operate for two hours.

Refer to instructions provided with timer for setting options.

• Mount bezel into dash and insert timer or use Espar’s optional

mounting bracket and secure to dash.

• Use hardware supplied for connections.

• Connect the switch harness to the connector at the heater and

run harness to switch location. (Har ness should be neatly

routed and secured under dashboard).

• Cut harness to length and terminate wires. Attach using connectors provided.

• Refer to timer instructions for other wiring options.

Mounting Bracket & Bezel

P/N 25 1482 70 01 00

Option #2: Operate heater continuously - connect wire from

ignition circuit to terminal #10.

Note: An alternative to connecting pin 10 to the vehicle

ignition accessor

ies “On” circuit may also be considered for some applications where extended run

times are desired. Connecting pin 10 with the red

wire will enable the heater to run continuously on

manual mode.

Operating Instructions

Setting Time and Weekday

Push button once 12:00 will begin to flash (this will occur

upon initial hook up to po

Using or set the present time of day (24 hour clock).

When the time stops flashing the time has been stored.

The weekday will now begin to flash.

Use or to set the present weekday.

When the weekday stops flashing the weekda y has been stored.

When the vehicle ignition is turned “on” the time display will

appear, if optional connection on pin 10 is insatlled.

When the vehicle ignition is turned “off” the timer display will go

off after 15 seconds.

Changing the Time or Day

Push and hold button until the time displa

Continue to set the time as listed in setting time and weekday.

wer).

y begins to flash.

Bezel

Mounting Bracket

Note: If installing a remote star ter, refer to remote starter

instructions before terminating wires.

Option #1: Dash lights to timer - connect wire between dash

Note: The timer display is automatically illuminated while the

16

lights circuit and timer at terminal #1.

heater is operating.

mer switch will allow the timer display to illuminate with

the vehicles dash lights.

Connecting pin 1 to the vehicle dim-

Using the Timer with the Vehicle Ignition “Off”

Push button.

will appear on the display as well as the operation countdown

timer.

The running time is factory set to maximum of 120 minutes.

This running time can be reset once or permanently as desired.

Adjusting Preheat Time Once

Press button.

The will appear in the display and the preselected run

time will appear in the display (maximum time of 120 min

utes).

Use the or to adjust the desired run time.

Adjusting the Heater Preheat Time Permanently

(Maximum Preheat Time of 120 min

utes)

Push and hold (about 3 seconds) until the display lights up

and flashes. Release button.

Use or to set the new fixed preheat time.

When the display goes off the new preheat time is set.

Note: At the end of a preheat cycle the timer will tur n the

heater off.The heater will complete a cool down cycle

and turn itself off.

Page 17

IInnssttaallllaattiioonn PPrroocceedduurrees

s

Using the Heater Manually with the Vehicle Accesory “On”

(Optional wire on pin 10 is connected to the ignition lock)

Push buton.

The symbol will appear in the display next to the time of day.

The time of day will remain display ed during ignition on operation.

The heater will function continually as long as the vehicle ignition

is “On”.

When the vehicle ignition is turned “Off” the heater will continue

to operate for an additional 15 minutes.

The run time can be altered by pressing the or buttons.

The heater can be turned off by pressing button.

Set Preheat Times into Memory

Press b

utton until the desired memory location is shown in

the display (Three memory locations are available).

Using the or buttons set the desired preheat start time

of day.

When the time stops flashing the time of day is set.

Using the or buttons set the desired day of the week.

When the day of the week stops flashing the day is set.

To Use Preset Star t Times

Press the button until the desired memory location appears

in the displa

y.

The heater will start at the day and time displayed.

The display will go off in 15 seconds. The memory location

number will stay displayed (1, 2 or 3).

Note: When preset is chosen this symbol will flash red.

Control Unit Locking

The control unit may becomed locked due to one of the following conditions:

Overheat – If the heater overheats three times in succes-

1.

sion, fault message F15 is displayed and the

control unit is locked.

2.Too many failed start attempts - If the heater performs

many start attempts in succession (i.e. Fault 52), fault

messsage F50 is displayed and the control unit is locked.

king Control Units and Erasing Fault Memory

Unloc

Note: The electrical connection for the ignition / accessory

wire to the timer terminal #10 must be in place.

1. Tur n on the vehicle ignition to activate timer display.

Press the key.The current fault code (i.e.F15 or F50) is

2.

now displayed.

3. Press the key and hold it down and press the key

within two seconds.The timer is now in the retrieval mode.

4. Tur n off the ignition.

5. Press the key and hold it down and press the key

within two seconds and hold it down.

6. While holding down keys, turn ignition on and wait

until the following display appears:

To Turn Heater “Off” - All Modes

Press the button once.

The heat signal to the heater will be tur

ned “Off”.

The heater will do a normal cooldown and turn itself “Off”.

Note: · This timer is equipped to display fault code numbers if

the heater should shut down due to an operating fault.

The fault code will show in the timer display next to the

flashing heat wave symbol. This applies to all current

model heaters when the blue diagnostic wire is connected.

· If the timer is purchased without the harness kit, the

f

ollowing heaters will need a load relay intalled (D8Lc,

D7W, D12W, D24W and D30W), These heaters carry a

load on the switch wire.(i.e. fuel metering pump or noid

sole valve).

· An outside temperature sensor is available as an option.

Wiring Connections at Connector

Terminal 1 Power from vehicle dash lights.

Ter minal 2 Heater switch wire - Yellow wire.

Ter minal 4 Connect to vehicle ground.

Terminal 6 Temperature setting “+” (air only).

Ter minal 8 Heater diagnostic lead - blue wire.

Ter minal 9 Temperature setting “-” (air only).

Terminal 10 To vehicle “ACC” accessory for

Terminal 11 Positive power from heater - red “+”.

Ter minal 12 Ground lead from heater - brown “-”.

Ter minal 3,5,7 Left blank, not required.

continuous overnight use, and for

unlocking ECU.

7. Press the key to turn the heater off.

8. Press the key to turn the heater on.

9. Repeat step three. The following display appears:

10. The control unit lock is cancelled after three seconds

and the heater starts.

Retreaving the Stored Fault Codes

1. Press the key. The heater is switched on.

Press the key and hold it down and press the key

2.

within two seconds.The current fault code is now displayed

(Example: AF:64).

3. The stored fault codes (maximum of 5) can now be retrieved

using the arrow keys and (Example:F1:64).

Note: Consult the Troubleshooting and Repair manuals for

code definition and corrective action. If the heater is

not being operated using the 7-day timer, fault code

retrieval can be obtained using the “Fault Code

Retrieval Device”, part number: 20 2900 70 50 20.

17

Page 18

IInnssttaallllaattiioonn PPrroocceedduurrees

14.5mm

9/16”

K (15)

15 (K)

31

Ø

Ø

A

UT

O

M

A

N

U

A

L

R

E

S

E

T

C

L

O

C

K

T

I

M

E

R

D

A

Y

H

O

U

R

M

I

N

M

A

N

U

A

L

Yellow (Signal to Heater)

a

3

)

a

5

)

a

4

)

5

4

5670100 - 12 Volt

5670099 - 24 Volt

Programmable

Timer

3

2

1

Brown (-)

Red (+)

A

U

T

O

M

A

N

U

A

L

R

E

S

E

T

C

L

O

C

K

T

I

M

E

R

D

A

Y

H

O

U

R

M

I

N

M

A

N

U

A

L

Programmable Timer

Push/Pull Switch

s

• Mount switch in a location where it is easily accessible

• Mount using hardware supplied

• Connect the switch harness to the connector at the heater

and run the harness to the switch location

• Cut har ness to length at the switch and install terminals

• Connect wiring as descr ibed below

Note: Switch light glows when pulled out and is off when

pushed in.

Brown- 31 Power from battery “-”

Red- K(15) Power from battery “+”

Yellow-15(K) Switch control to the heater

Blue/White Diagnostic from heater (disregard - tape end

and tie off to the side)

P/N 5670007 (12v)

P/N 5670008 (24v)

Setting the time

Press and hold the CLOCK button.

Press D

AY button to select the correct day.

Press HOUR button to select the correct hour.

Press MIN button to select the correct minutes.

When the MIN button is released the time will be set.

Holding down or repeatedly pressing the appropriate button will

advance the days, hours and minutes.

Programming of Switching Times

The Auto Time Switch has the capacity for 8 ON/OFF switches.

By using the b

locks of days available, you can save program

capacity. The block days are:

MO, TU, WE, TH, FR, SA, SU – Individual days of the week

MO, TU , WE, TH, FR

SA, SU

MO, TU , WE, TH, FR, SA

MO, WE, FR

TU, TH, SA

MO, TU , WE

Programmable Timer

P/N 5670100 (12v)

P/N 5670099 (24v)

IMPORTANT: This electronic timer has a maximum loading

printed on the rating label and under no circumstances should this be exceeded.

Features:

• Up to 8 ON and OFF switches a day/56 ON and OFF

switches per week

• Option to program individual days or 8 different weekday

groups

• Minimum switching period of one minute

• Summer/Winter time changeover

• Manual Override button

• Easy to read LCD display

• Battery Back-up

Note: As soon as you have connected 12 volts you will

18

have to push down the RESET button to activate

the timer.

Programmable Timer Instructions

Each ON time and each OFF time, the da

ys, hours and minutes

must be set.

Press the TIMER button once to set the first ON time – you will

see “on” and the number “1” appears.

Enter the first ON time.

Press the DAY button to choose the required day or block of

days.

Set the hour and minutes using the HOUR and MIN buttons.

Press TIMER button to save first on time and are ready to set

first off time you will see “OFF” and the number “1” appear.

Use the DAY, HOUR and MIN buttons as above.

Press the TIMER button to save off time.

Repeat the same steps for the remaining 7 ON and OFF set-

tings as desired.

When you have set the required ON/OFF settings, press the

CLOCK button to return the display to the clock.

The timer is now ready to operate.

Note: You can check the settings you have programmed

by pressing the TIMER button repeatedly. Each set

ting will appear on the screen.

Page 19

Notes:

19

Page 20

HHeeaatteerr OOppeerraattiioon

n

Pre-Start Procedures

Upon completion of installation prepare the heater as follows:

• Check all fuel, electrical and plumbing connections.

• Refill the engine coolant.

• Bleed air from the coolant system by running the engine and

refilling the antifreeze as needed. Resecure heater hose.

• Run engine to further bleed the system

• Top up engine coolant.

Start Up

Once switched on, the following sequence occurs:

• Control unit does a systems check (flame sensor, tempera

ture, and various other control unit checks).

• Water pump starts circulating coolant fluid.

• Combustion air blower starts.

• Glow pin begins to preheat 20-30 secs.

• After about 20-30 seconds the Fuel Metering Pump starts delivering fuel and the combustion air blower ramps up gradually.

• Once ignition takes place the flame sensor alerts the control

unit and the control unit shuts off the glow pin (ignition time:

1.5 - 2 minutes).

Note: If the heater fails to star t the first time it will automa-

tically attempt a second start. If unsuccessful the heater

will shut down completely.

Note: On initial star t up the heater may require several

star

t attempts to self prime the fuel system.

Heating Mode

At the initial start the heater is operated with the “POWER” stage

until the water temperature exceeds the “POWER” / “HIGH”

changeover threshold.

HYDRONIC M8 / M10

Then, depending on the heat requirement, the heater switches to

“HIGH – MEDIUM – LOW – STAND BY” stages.

the

If the heating requirement in the “LOW”stage is so small that the

cooling water temperature reaches 85 °C, the heater switches

from “LOW” to “STAND BY”.

HYDRONC M12

Then, depending on the heat requirement, the heater switches to

the

“HIGH – MEDIUM 1 / MEDIUM 2 / MEDIUM 3 – LOW –

STAND BY” stages.

If the heating requirement in the “LOW”stage is so small that the

cooling water temperature reaches 85 °C, the heater switches

from “LOW” to “STAND BY”.

This is followed by the after-run with additional after glowing of the

glow plugs (like when heater is switched off).

After the cooling water has cooled to approx. 70 °C the

HYDRONIC M8 / M10 heater starts in the “MEDIUM” stage, the

HYDRONC M12 heater in the “MEDIUM 1” stage.

If the cooling water temperature reaches approx. 55 °C the

temperature sensor switches the vehicle fan on.

The temperature can be lowered by connecting the positive

cable (+) to connector S2, terminal C3 of the heater (see circuit

diagrams).

Switching Off

With the switching off the heater starts the after-run of

180 sec. During the after-run the first glow plug is switched

on after 90 seconds for a period of 45 seconds,

then the second glow plug is switched on until the end

of the after-run.

Safety Equipment

The heater is equipped with the following control and safety

devices.

• If the heater does not ignite within 74 seconds after the fuel

starts to pump, the start is repeated.

If the heater still does not ignite after another 65 seconds of

fuel being pumped, the heater is automatically shut down.

After an unacceptable number of failed start attempts, the

control box is locked.*

• If the flame goes off by itself during operation, the heater is

restarted.

If the heater does not ignite within 74 seconds after the fuel

starts to pump again, the heater is automatically shut down.

The shutdown on faults can be cancelled by briefly switching

off and on again.

• In the case of overheating (e.g.water shortage, poorly ventilated cooling water circuit), the overheating sensor triggers,

the fuel feed is interrupted and the heater is automatically

shut down.

Once the cause of the overheating has been eliminated, the

heater can be re-started by switching it off and on again

(provided that the heater has cooled down sufficiently, cooling

water temperature < 70 °C).

After the heater has been shut down due to overheating an

unacceptable number of times, the control box is locked.*

* The ECU can be unlocked and the fault can be displayed

with:

• EasyStart.

• Diagnostics Unit.

• EDiTH diagnostics software.

For operation and fault list, please refer to the enclosed

operating instructions or these troubleshooting and repair

instructions.

• If the lower or upper voltage limit is reached, the heater

will shut down.

• The heater does not start up if the electric cable to the

metering pump is not connected.

• If one of the two glow plugs is defective, the start sequence

takes place with one glow plug only .

• The speed of the blower motor is continuously monitored.

If the blower motor does not start up, if it is blocked or if the

speed differs by > 12.5 % of the desired speed, the heater

will automatically shut down after 60 sec.

• The function of the water pump is continuously monitored.

Temperature Drop

Temperature drop only becomes active while the vehicle is runing

and if the heater is switched on.The control stages are reached

earlier and the heater‘s control action is adjusted to the lower heat

requirement.

20

Warning:

The heater must be switched off while any

fuel tank on the vehicle is being filled.

The heater must not be operated in

garages or enclosed areas.

Page 21

HHeeaatteerr OOppeerraattiioon

Cable harness

H

YDRONIC M

Rewiring

1

2-pin connector

Connection

C

able colour HYDRONIC

M

PIN

H

YDRONIC M-II

PIN

M

etering pump

g

reen

4C A1

T

erminal (-)

brown

3C A2

Terminal ( +)

r

ed

2C A3

P

lus signal

m

ain battery switch

white / red

1C A4

Plus signal

Solenoid valve relay

–

4B B1

D

iagnosis

b

lue

3B B4

Plus signal

ADR auxiliary drive

violet

2B B3

Third party control

Water pump

– 1B

B2

remains

unused

Blower relay

red / yellow

4A C1

D+

for ADR operation

violet / green

3A C2

Te mperature drop –

2A C3

Heater ON

yellow

1A C4

Connector is shown

f

rom the lead entry

s

ide.

n

Heater Wiring

The heater is to be connected up electrically according to the

EMC directives.

Caution:

EMC can be affected if the heater is not connected up correctly.

For this reason, comply with the following instructions:

• Ensure that the insulation of electrical cables is not damaged.

Avoid:

chafing, kinking, jamming or exposure to heat.

• In water proof connectors, seal any connector chambers not

in use with filler plugs to ensure they are dirt-proof and waterproof.

• Electrical connections and ground connections must be free

of corrosion and firmly connected.

• Lubricate connections and ground connections outside the

heater interior with contact grease.

Note: Comply with the following when wiring the heater and the

control unit: fuses and controlers.

• Electrical leads, must be positioned in the vehicle so that they

can function perfectly under normal operating conditions without impairment (e.g. due to heat exposure, moisture, etc.).

12-pin Connection Pin Assignment

• The following wire gauge are to be used between the battery

and heater.

This ensures that the max. allowable voltage drop in the

cables does not exceed 0.5 V for 12 V or 1 V for 24 V rated

voltage.

Cable cross-sections for a cable length (plus cable + minus

cable) of:

– up to 5 m (plus cable + minus cable) = 10 AWG

– from 5 m up to 8 m (plus cable + minus cable) = 8 AWG

• If the ( + ) cable is to be connected to the fuse box, the

vehicle's cable from the battery to the fuse box must also be

included in the calculation for the total cable length and

re-dimensioned if necessary.

• Insulate unused cable ends.

If replacing the HYDRONIC 10 / M with the HYDRONIC M-II, the

cable harness installed in the vehicle is retained and continues to

be used, it is necessary to remove the 12-pin connector using the

terminal removal tool and to rewire it according to the following

table.

21

Page 22

HHeeaatteerr OOppeerraattiioon

PIN-No. Connection

pmup gnisoD1A

B1 Solenoid valve, optional

rewolb ,yaleR1C

B2 Diagnosis cable (OEM)

B3 TRS signal (ADR)

C3 Temperature drop

B4 Diagnosis

NO retaeH4C

Battery ( - )

Battery ( + )3A

2A

n

Parts list for wiring diagram,

1.1 Blower motor

1.2 Glow pin I

1.2.1 Glow pin II (optional 12 kW)

1.5 Overheating sensor

1.12 Flame sensor

1.13 Temperature sensor

2.1 Control unit

2.2 Fuel metering pump

2.5.7 Relay, vehicle blower (fan)

2.5.18 Relay, changeover water circuit

(To be fitted by customer if required)

2.7 Main fuse 12 volt = 20A

24 volt = 15A

2.7.1 Fuse, control option 5A

2.7.5 Fuse, vehicle blower (fan) 25A

2.12 Water pump

5.1 Battery

5.10 Vehicle blower (fan)

a) Connection to 7 day timer, programmable timer, easy star t or

push pull switch

b) Water circuit change-over: Relay makes contact at 68°C and

breaks contact at 63 °C water temperature (with temperature

drop 58 °C / 45 °C)

c) Temperature drop

x) Disconnect cable

Hydronic

M-II - 12 Volt / 24 Volt

Diagnosis

a

2

a

Switch on signal

3

a

Power supply plus

4

a

Power supply minus

5

Connectors and bush holdings are shown from the cable

inlet side.

Connector pin assignment: 12-pin connector (external).

22

Page 23

HHeeaatteerr OOppeerraattiioon

2.5.7

2.7.1

1.2.1 2.12 1.13 1.12

2.5.18

2.2

2.7

1.2

2.1

1.5 1.1

5.1

5.10

2.7.5

1

1 14 10 7 4 12 13 1 2 8 5 6 3 9

B1

x

)

a)

B2

S2

B1 B2 B3 S2 S3

B3

B3

S3

Circuit diagram HYDRONIC M-II – 12 Volt / 24 Volt

Brown / Green

Brown

Green

Brown

Red

White / Red

Blue / White

Red / Yellow

Yel low

Brown / Black

Brown

Brown

Brown

Pink

Green

Orange

Red

White

White

White / Red

Blue / White

Blue

Yel low

Black/Violet

Black

Red

Brown

Red / Yellow

Optional

b

)

Brown

Brown

Blue/White

White/Red

Brown

Red

Y

ellow

b

)

Red

Brown

Red

Red

Red

a1)

a

2

)

a

3

)

a

4

)

a

5

)

A1A2A3A4B1B4B3B2C1C2C3

C4

c)

n

Hydronic

M-II,Wiring Diagram - 12 Volt / 24 Volt

23

Page 24

HHeeaatteerr OOppeerraattiioon

R

ED

a

4)

a

3)

a

5)

YELLOW

BROWN

15 (K)

0

0

K (15)

31

Push/Pull switch

Yellow (Signal to Heater)

a

3

)

a

5

)

a

4

)

5

4

5670100 - 12 Volt

5670099 - 24 Volt

Programmable

Timer

3

2

1

Brown (-)

Red (+)

A

U

T

O

M

A

N

U

A

L

R

E

S

E

T

C

L

O

C

K

T

I

M

E

R

D

A

Y

H

O

U

R

M

I

N

M

A

N

U

A

L

Programmable Timer

Easy Start T

LCD

White / Red

Blue / White

Brown

Grey

B1B1B1S1S1S1

a

1

)

Red

Brown / White

Grey

Grey / Black

Blue / White

Violet

Brown

Yellow

Red

a

2

)

a

5

)

a

4

)

1 2 3 4 5 6 7 8 9

O

ption #1

O

ption #2

Yellow

Red

Brown

Blue

D

IAG

TRS

Yellow

Red

Blue

Brown

12 11 10 9 8 7 6 5 4 3 2 1

P

a4)

a

3

)

a

5

)

a

2

)

n

Hydronic

M-II, Controler Options

Push / Pull Switch

7 Day Timer

24

Programmable Timer

Easy Start T

Optional On/Off Switch

Page 25

MMaaiinntteennaannccee,, TTrroouubblleesshhoooottiinngg && RReeppaaiirrs

LDL

Periodic Maintenance

Subtitle Right Page

Fault Code Retrieval Device

s

• Check coolant hoses, clamps, and make sure all valves

are open. Maintain the engine manufacturers recommended

coolant level and ensure that the heater is properly bled after

service on or involving the coolant system.

• Visual check of all fuel lines for leaks. Check and if necessary

replace fuel filter inserts.

• Visual check of electrical lines and connections for corrosion.

• Run your heater at least once a month during the year (for a

minimum of 15 minutes).

• Maintain your batteries and all electrical connections in good

condition.With insufficient power the heater will not start.

Low and high voltage cutouts will shut the heater down automatically.

• Use fuel suitable for the climate. Blending used engine oil

with diesel fuel is not permitted.

Troubleshooting

Basic Troubleshooting

In the event of failure there are several items which should be

checked first before any major troubleshooting is done.

Check:

Equipment Face and Controls

Symbols seen on the display

face are as follows:

AF Actual f

F1-F5 Up to five stored faults can be accessed.

The AF and F1 are the same.

This sign is displayed when the heater is in operation.

DIAG The word (Diagnostic) will come on when the

diagnostic n

000 Three digit diagnostic fault code number.

ault.

umber is requested.

Hook Up

•

Disconnect the main harness from heater and insert adapter

cable harness between them.

• Connect adapter cable to the cable loom of the Fault code

retrieval device.

• Star t diagnostic unit - switch heater on from switch.

Instructions:

• Fuses.

• Electrical lines and connections

• Interference in Combustion air and Exhaust pipes.

• Fuel in the tank.

• Batter y voltage on heater side of harness

• Coolant flow

Self Diagnostics

The heater is equipped with self diagnostic capability. You can

retrieve information on the heaters last 5 faults using the Espar 7

day timer , Espar’ s Fault Code Retrieval Device or ISO adapter and

computer.

Multifunction

Espar’s 7 day timer has a fault code

retrieval device built into the unit. This

function automatically activates if the

heater is experiencing problems.

• Fault codes appear on the LCD display screen.

• Codes can then be translated from the charts on the following

pages.

• Pg 10 - 17 for more detailed instructions.

• Switch the fault code retrieval device on and wait 10 seconds.

• Press the "D" button.

• Wait 3-5 seconds for the current fault code to appear (AF).

• To review the previous faults use the arrow buttons

(F1= Most Recent, F5= Oldest).

• To erase the faults that are in memory press both "L" keys at

the same time.

• See the fault code chart on following pages for code number

descriptions.

Diagnostic Adapter

P/N 25 2800 70 1004

Fault code

retrieval device

P/N 20 2900 70 5020

25

Page 26

Maintenance, Troubleshooting & Repairs

Fault Code Fault Description Causes / Repair

— — — Diagnosis not possible • Adapter cable not connected properly.

• Diagnostic connection damaged.

• Internal control box fault, replace control box / blower unit.

000 No faults — —

005 Warning • Check connection and / or lead for continuity, shor t circuit and

Short circuit in "Burglar Alarm" output damage.

009 ADR / ADR99 shutdown • Switch the heater off and then on again –

The shutdown must be cancelled by D+ or HA / NA.

010 Overvoltage cutoff Overvoltage applied to control box for at least 6 seconds

–> heater not working.

• Disconnect heater / cable harness plug-in connector, start

the vehicle engine, measure the voltage. Connector B2, PIN

A2 and A3:

– If the voltage is >15 volt or >30 volt, check the generator

regulator and / or the battery.

011 Undervoltage cutoff Undervoltage applied to control box for at least 20 seconds

without interruption –> heater not working.

• Disconnect heater / cable harness plug-in connector, start the

vehicle engine, measure the voltage. Connector B2, PIN

A2 and A3:

– If the voltage is <10 volt or <20 volt, then check the fuses,

the supply cables, the negative connections and the positive

support point at the battery for voltage drop (corrosion).

012 Overheating Overheating sensor signals temperature greater than 120°C.

• Measure the resistive value of the overheating sensor,

connector B1, PIN 2 and 4, for measured values. See page 44.

– If overheating sensor ok, check connection leads for conti-

nuity, shor t circuit and damage.

014 Possible overheating dettected Difference between measured value in overheating sensor and

(Temperature difference evaluation) temperature sensor is too large.

• Measure the resistive value of the temperature sensor,

connector B1, PIN 2 and 4 and connector B1 PIN 1 and 2; for

measured values.See page 44.

– If temperature sensor ok, check connection leads for

continuity, shor t circuit and damage.

015 Too many overheats, Control box locked due to too frequent overheating (fault code

Control box is locked 012 or 014) in succession.

• Unlock the control box by deleting the fault memory, see

pages 16 and 25.

017 Overheating, Max. temperature exceeded at the overheating sensor (180°C).

Sensor threshold exceeded • Check overheating sensor —> fault code 012.

• Check control box.

019 Glow plug 1, Glow plug 1 energy input is too low (< 2000 Ws)

Ignition energy too low • Check glow plug for continuity, short circuit and damage

—> Fault code 020.

• Check control box.

26

Page 27

MMaaiinntteennaannccee,, TTrroouubblleesshhoooottiinngg && RReeppaaiirrs

s

Fault Code Fault Description Causes / Repair

020 Glow plug 1, interruption • Measure cold resistance of the glow plug at approx. 20°C

ambient temperature – connector B1, PIN 7 and 10.

021 Glow plug 1, over load / shor t circuit If the values are as follows the glow plug is ok, if the values

downstream of (–) differ – replace the glow plug.

022 Glow plug 1, short circuit downstream Measured value:

of (+) • 12 volt – glow plug = 0.42 – 0.6 ohm

• 24 volt – glow plug = 1.2 – 1.9 ohm

– If the glow plug is ok, check the lead harness of the glow plug

for continuity, short circuit and damage.

023 Glow plug 2, interruption • Measure cold resistance of the glow plug at approx. 20°C

ambient temperature – connector B1, PIN 11 and 14.

024 Glow plug 2, over load / shor t circuit If the values are as follows the glow plug is ok, if the values

downstream of ground differ – replace the glow plug.

Measured value:

• 12 volt – glow plug = 0.42 – 0.6 ohm

• 24 volt – glow plug = 1.2 – 1.9 ohm

– If the glow plug is ok, check the lead harness of the glow plug

for continuity, short circuit and damage.

025 Diagnostic line fault • Check diagnostics cable for continuity, short circuit and

Heater remains ready for operation damage – connector B2, PIN B4.

– if ok, check control box.

026 Glow plug 2, short circuit downstream see fault code 023 / 024

of (+)

029 Glow plug 2, Ignition energy too low Glow plug 2 energy input is too low (< 2000 W)

• Check glow plug for continuity, short circuit and damage.

—> Fault code 023.

• Check control box.

033 Burner motor, interr uption • Check the burner motor's connection leads for continuity, shor t

circuit and damage – connector B1, PIN 3, 6 and 9.

033 Burner motor, overload • Check burner motor for easy movement b y manually rotating the

impeller.

– if not smooth r unning, remove the blockage.

033 Burner motor, speed error / blocked – if ok, replace control box / blower unit.

034 Burner motor shor t circuit

downstream of (+) or (–)

037 Water pump not working • Check water pump.

Apply voltage to the water pump – connector B1, PIN 12 and 13

(power input = max. 4 A or 2 A)

– If water pump does not rotate, replace water pump.

– If water pump is ok –> replace control box / blower unit.

041 Water pump, interruption • Check the water pump's connection and lead harness for con-

tinuity, short circuit and damage – connector B1, PIN 12 and 13.

042 Water pump

Overload short circuit Water pump running dry.

043 Water pump • Vent heater (water shortage), open heater slide valve, check

Overload downstream of +Ub water flow rate

– If ok, check water pump —> fault code 037.

27

Page 28

Maintenance, Troubleshooting & Repairs

Fault Code Fault Description Causes / Repair

047 Metering pump • Check the metering pump's connection and lead harness for

Overload short circuit continuity, short circuit and damage – connector B2, PIN A1.

If ok, check the resistance of metering pump – setpoint value

–

approx. 20 ohm.

048 Metering pump interruption

049 Metering pump

Overload downstream of +Ub

050 Too many attempted starts Control box locked due to repeated switching on in succession

Control box is locked without flame detection (fault code 052).

• Check fuel supply, exhaust and combustion air system.

• Check glow plug –> see fault code 019 to 024 / 026 / 029.

• Check flame sensor –> fault code 064 / 065.

• Unlock the control box by deleting the fault memor y.

052 Exceeding of safety time No flame detected within the start phase. Flame sensor value <

80°C,

therefore automatic shutdown because safety time exceeded.

• Check fuel supply, exhaust and combustion air system.

• Check glow plug –> see fault code 019 to 024 / 026 / 029.

• Check flame sensor –> fault code 064 / 065.

053 Flame cutout in Heater ignited (flame detected) and signals flame cutout during a

"POWER" control stage power stage.

• Check fuel quantity, blower speed, fuel supply, exhaust and combustion air system.

054 Flame cutout in "HIGH" control stage • Check flame sensor –> fault code 064 / 065.

055 Flame cutout in "Medium" control stage

(D 8 W / D 10 W) "Medium1" control stage

(D 12 W)

056 Flame cutout in

"Medium 2" control stage (D 12 W)

057 Flame cutout in

"Medium 3" control stage (D 12 W)

058 Flame cutout in "LOW" control stage

059 Too rapid r ise in water temperature • Vent air from system, open heater slide valve, check water flow

rate.

• Check temperature sensor –> fault code 060 / 061

060 Temperature sensor interruption Temperature sensor signals temperature value outside the

measuring range.

061 Temperature sensor short circuit • Measure the resistive value of the temperature sensor,

064 Flame sensor interruption Flame sensor signals temperature value outside the measuring

065 Flame sensor shor t circuit • Measure the resistive value of the flame sensor – connector B1,

28

Connector B1, PIN 1 and 2; for measured values. See page 44.

– If temperature sensor ok, check connection leads for continuity,

short circuit and damage.

range.

PIN 5 and 8; for measured values. See page 45.

– If flame sensor ok, check connection leads for continuity, short

circuit and damage.

Page 29

MMaaiinntteennaannccee,, TTrroouubblleesshhoooottiinngg && RReeppaaiirrs

s

Fault Code Fault Description Causes / Repair

071 Overheating sensor interruption Overheating sensor signals temperature value outside the mea-

suring range.

• Check overheating sensor –> fault code 012.

072 Overheating sensor short circuit

074 Overheating detection hardware is • Control box is defective.

defective, operating lock-out Replace control box / blower unit.

090 External reset • Control box reset by external interference voltage.

Check voltage supply, e.g. battery, leads, generator, fuses.

091 Internal reset • Internal control box fault, replace control box / blower unit.

092 ROM error

093 RAM error, at least one RAM cell is

not working

094 EEPROM error, checksum error within

the area of the operating data, diagnostic

parameters or calibration values

095 Invalid data record, checksum error

096 Internal temperature sensor is defective

/ ECU too hot

097 Internal device error

098 Main relay is faulty

099 Too many resets, operating lock-out

29

Page 30

MMaaiinntteennaannccee,, TTrroouubblleesshhoooottiinngg && RReeppaaiirrs

Repair Instructions

s

The permitted repair work on the heater is described in the

"Repair Instructions" chapter. The heater must be removed

from the vehicle for the repair work to be carried out.

The heater is assembled in the reverse order, note and follow

any additional instructions.

Note: After completing all the work and installing the heater

in the vehicle, perform a functional check on the heater.

Always observe the following safety instructions before

orking on the heater

w

Warning - Risk of injury, burns and

poisoning

• Ensure power is disconnected from heater and that coolant is

cool bef

• The heater must not be operated in closed rooms such as

garages or workshops.

Exception:

Exhaust suction available directly at the entry to the exhaust

pipe on the heater.

ore dismantling the heater.

Terminal Removal Tools are used to release plug-in contacts

in a connector housing.

Terminal Removal Tool 1.6mm 206 00 205

Terminal Removal Tool 2.8mm 206 00 215

Caution: • The seals of dismantled components must be

renewed.

• During repair work, check all components for

damage and if necessary replace.

• Check connector contacts, plug-in connections

and cables for corrosion and damage and if

necessary repair.

• Only use Espar spare parts if replacements are

necessary.

• After working on the coolant circuit the level of the

coolant must be checked and if necessary topped

up according to the vehicle manufacturer's

instructions.

The coolant circuit must then be vented.

• Operation or the “after running” of the heater ma

only be stopped in an emergency (Turn off switch,

remove fuse or disconnect battery) by interrupting

the battery current (risk of heater over-heating).

Heater Components

1 Impeller cover

2 O-ring 117.07 x 3.53

3 Cover, side

4 Impeller

5 Glow plug 1

6 Glow plug 2

7 Spark plug socket lining

8 Combustion chamber

9 M5 x 16 TAPTITE / DIN 7500 TORX screw

10 Control box / blower unit

11 Flame sensor

12 Cable tie

13 Electric motor cover

14 M5 x 16 TAPTITE / DIN 7500 TORX screw

15 M4 x 12 TAPTITE / DIN 7985 TORX screw

16 Compression spring

17 Overheating sensor

18 Temperature sensor

19 Overheating / temperature sensor cable loom

20 Jacket with heat exchanger

21 M5 x 25 TAPTITE / DIN 7500 TORX screw

22 Grommet

23 Combustion chamber seal

24 Water pump cable loom connector

25 Hose clip

26 Water pump

27 O-ring 19.8 x 2.3

28 14-pin connector

30

Page 31

MMaaiinntteennaannccee,, TTrroouubblleesshhoooottiinngg && RReeppaaiirrs

Preparatory work for all repairs

Figure 1 and 2

Clamp the removed heater in a retaining device (vice).

•

• Using 2 screwdrivers, always undo 2 snap connections

of the impeller cover at a time, starting at the control

box/blower unit. Keep to the order shown in the figure

(1.– 8.)

• Remove cover.

• Remove O-ring (2).

Note: The O-ring (2) must always be renewed.

s

Remove overheating sensor and temperature sensor

Figure 3 – 5

• Remove the (15) M4 x 12 screws of the compressive springs

(16) and use pliers to pull off the overheating (17) and

temperature sensor (18).

Note: Do not pull out the overheating (17) and temperature

sensor (18) from the holder by pulling on the connection cable, always use pliers to remove them.

31

Page 32

MMaaiinntteennaannccee,, TTrroouubblleesshhoooottiinngg && RReeppaaiirrs

Repair step 1

Dismantle control box/blower unit and jacket

Remove water pump connector

Figure 6

• Disconnect the connector (24) at the water pump (26) and pull

the cable loom out of the holder.

Remove side cover and dismantle jacket

Figure 7

• Pull out side cover (3) from abo

• Undo the 4 screws (21) M5 x 25 in the jacket (20) and remove

the jacket from the control box / blower unit.

ve.

s

Note: The control box / blower unit may not be placed on the

exposed impeller.

Remove electric motor cover

Figure 8

• Undo the 2 screws (14) M5 x 16 of the electric motor co

and remove the cover.

Note: The control box / blower unit may not be placed on the

exposed impeller.

ver (13)

32

Page 33

MMaaiinntteennaannccee,, TTrroouubblleesshhoooottiinngg && RReeppaaiirrs

A Long wire (brown, white)

Figure 11

B Short wire (brown, white)

A AMP release tool

Figure 10

29 14-pin connector

1

1 Flame sensor

Figure 9

1

2 Cable tie

1

2 14-pin connector

Sketch 1

Temperature sensor, Yellow

Sensor ground, Blue / White

Overheating sensor, Red

Motor, Phase 1, Pink

Motor, Phase 2, Green

Motor, Pha se 3, Orange

Flame sensor +, Blue

Flame sensor, Brown

Glow pl ug 1, long c able , Brown

Glow pl ug 1 +, long cable , White

Glow plug 2 +, short cable , White

Glow plug 2, short c able , Brown

Water pump, Black / Red

Water pump, Brown / Black

Repair step 1

Dismantle control box/blower unit and jacket

Disconnect 14-pin connector at control box and release cables

Figure 9 – 11 / Sketch 1

Use side cutters to open the cable tie (12).

•

• Disconnect the 14-pin connector (29).