Page 1

mm

..

TECHNICAl DESCRIPTION AND INSTAllATION INSTRUCTIONS

-

U

BN4Heater with fuel metering pump

(a gasolinehot air heater for universal installation)

Part No. 20 1462 - 12 volt

20 1463 - 24 volt

.

TECHNlCAL DES(RIPTION

The BN4 is a gasoline operated hot air heater with ils own

heat source. It cao be operated independently of the

vehicle engine.

TECHNlCAL DATA

Heating capacity in BTU

Hours peTgallon) U.S.

of Fuel ) IMP.

4,000-16,000

6-16.5

7-18

50 Watt

Power çonsumption

Voltage 12/24 V

DESIGNAND OPERATION

~

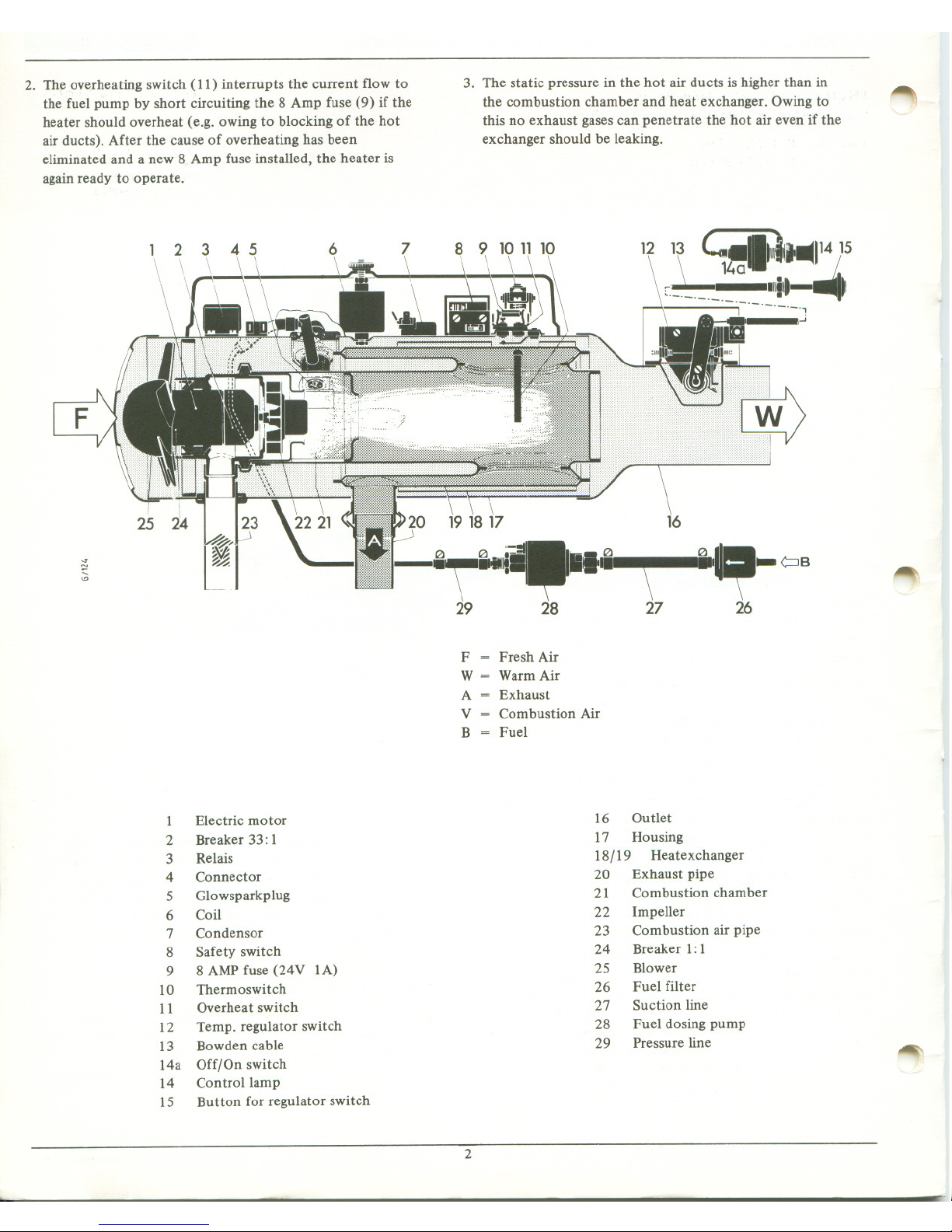

A complete heating system comprises a basic unit and the

additional parts for installation, air ducting, exhaust, fuel

supp1y and contro1s. After switching on the heater with the

puch-pull switch (14a) a pilot light (14) lights up and the

blower motor (1) receives current. The fresh air blower (25)

supplies heating air and the irnpeller (22) combustion air.

The fuel metering pump (28) supplies fuel in accurately

metered quantities to the combustion chamber (21). It is

solenoid powered and controlled by the impulses of a circuit

breaker in the blower motor. (reduction ratio 33: 1).

~

The fuel forms an ignitable mixture together with the

combustion air, is preheated by a glow-plug (5) and ignited by

a spark plug. The ignition coil (6) provides the high voltage. It

receives ils impulses from a second circuit breaker (24) in the

blower motor. (ratio 1: 1). The combusted gages flow

through the heat exchanger (19) and heat up the sensor

of the thermoswitch (10), which switches off the glow plug

and the resistor in the safety switch after about 45 sec.

operation. The combustion process DOWcontinues on ils own,

assisted by the high voltage ignition.

The air supplied by the fresh air°blower is heated at the heat

exchanger and then routed to the passenger compartment,

past the bi-metal coil of the regulating switch (12). Depending

on the temperature of the hot air and position of the regula-

ting knob (15) the bi-metal coil actuates the regulating switch

which switches off the heater, when the required temperature

is exceeded or switches it on again as soon as the hot air has

cooled off below the set temperature. After each regulating

HOT AIR HEATERS

.1

6480 VISCOUNT ROAD

MISSISSAUGA, ONTARIO

L4V 1H3

TEL.: (416) 678--1661/1663

TELEX: 06-968783

...

Il

6/125

cycle the flame is ignited by the high voltage ignition. After

switching off the push-pull switch the pilot light is extinguish-

ed. The blower motor however keeps on running until the heat

exchanger has cooled down to approx. 40°C and has been

blown clear of residual gages. It is then automatically switched

off by the thermoswitch.

Safety Deviees are as follows:

1. The safety switch (8). It interrupts the current supply to

the heater if no ignition occurs 2 - 3 minutes after

switching on. (e.g. owing to a faulty glow plug coil or

lack of fuel). It cao be reset by the lever projecting from

the sid~ after the bi-metal strip.has cooled down.

Subject to change.

201547908413 UN

December 1973

Printed in Canada.

A/B 4.1

Page 2

2. The overheating switch (11) interrupts the CUITentflow to

the fuel pump by short circuiting the 8 Amp fuse (9) if the

heater should overheat (e.g. owing to blocking of the hot

air ducts). After the cause of overheating has been

eliminated and a new 8 Amp fuse installed, the heater is

again ready to operate.

3. The static pressure in the hot air ducts is higher than in

the combustion cham ber and heàt exchanger. Owing to

this no exhaust gages can penetrate the hot air even if the

exchanger should be leaking.

~

12 13 ~.

I

~II;II.P415

L

140 Il ~

C" .111'-"~

'-'-'-'l

1-'

~

\ \ \

20 19 18 17

j

~

29 28

\

27

.~8

26

~

F = Fresh Air

W = Warm Air

A = Exhaust

V = Combustion Air

B = Fuel

1 Electric motor

2 Breaker 33: 1

3 Relais

4 Connector

5 Glowsparkplug

6 Coil

7 Condensor

8 Safety switch

9 8 AMP fuse (24V lA)

10 Thermoswitch

Il Overheat switch

12 Temp. regulator switch

13 Bowden cable

14a Off/On switch

14 Controllamp

15 Button for regulator switch

16 Outlet

17 Housing

18/19 Heatexchanger

20 Exhaust pipe

21 Combustion chamber

22 Impeller

23 Combustion air pipe

24 Breaker 1:1

25 Blower

26 Fuel fiUer

27 Suction line

28 Fuel dosing pump

29 Pressure line

~

2

Page 3

~

OPERATION

SwitchingOn Heater

Pullout the pull-pushswitch. The pilot light corneson and

indicates that the heater is switched on.

SwitchingOff Heater

Pushin the pull-push switch. The pilot light goesout. The

2 - 3 minute cleaningcycle ends automatically.

Operatingwith Room Thermostat

To keep the passengercompartment temperature constant

a room thermostat cao be installed.

The heater is started by pulling the pu11-push switch. The

pilot light then cornes on. As soon as the temperature which

bas been set at the thermostat bas been reached, it switches

the heater off. After the temperature bas dropped, the

thermostat switches the heater on again.

The heater remains off when the push-pull switch is pushed

in and the pilot light is extinguished. The cleaning cycle

always follows to cool the heating system down and to

clean out a11residue gages.

~

MAINTENANCE

Please switch the heater on during the warm season (once a

mon th) for a short period to avoid gumming,up of the fuel

line.

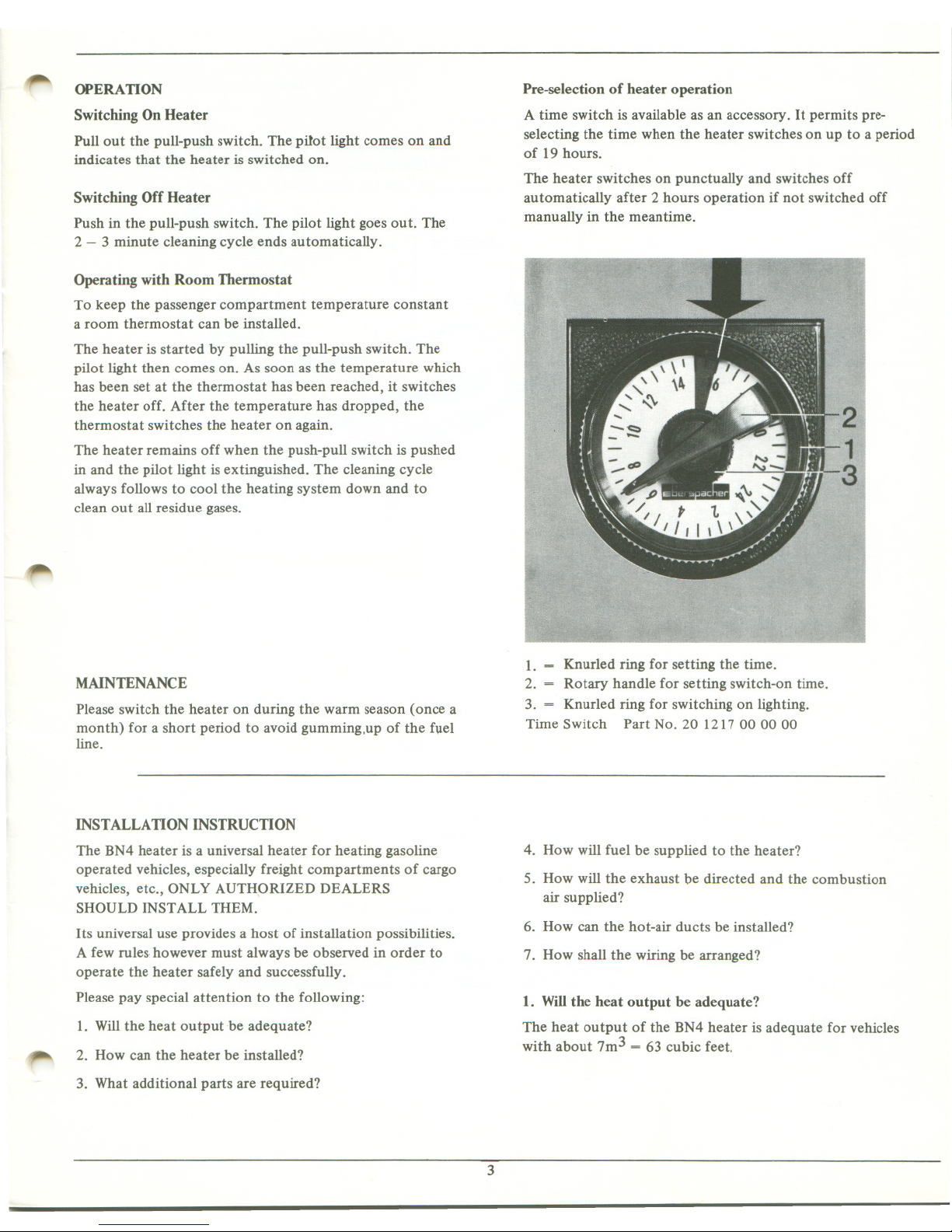

Pre-selection of heater operation

A time switch is available as an accessory. It permits pre-

selecting the time when the heater switches on up to a period

of 19 houes.

The heater switches on punctually and switches off

automatically after 2 houes operation if Dot switched off

manually in the meantime.

1. = Knurled ring for setting the time.

2. = Rotary handle for setting switch-on time.

3. = Knurled ring for switching on lighting.

Time Switch Part No. 201217000000

INSTALLATIONINSTRUCTION

The BN4 heater is a universal heater for heating gasoline

operated vehicles, especially freight compartments of cargo

vehicles, etc., ONLy AUTH9RIZED DEALERS

SHOULD INSTALL THEM.

Its universal use provides a host of installation possibilities.

A few mIes-however must always be observed in order to

operate the heater safely and successfu11y.

Please pay special attention to the fo11owing:

1. Will the heat outputbe adequate?

~

2. How cao the heater be installed?

3. Whatadditional parts are required?

4. How will fuel be supplied to the heater?

5. How will the exhaust be directed and the combustion

air supplied?

6. How cao the hot-air ducts be installed?

7. How shall the wiring be arranged?

1. Willthe beat output be adequate?

The heat output of the BN4 heater is adequate for vehicles

with about 7m3 = 63 cubic feet.

3

Page 4

.

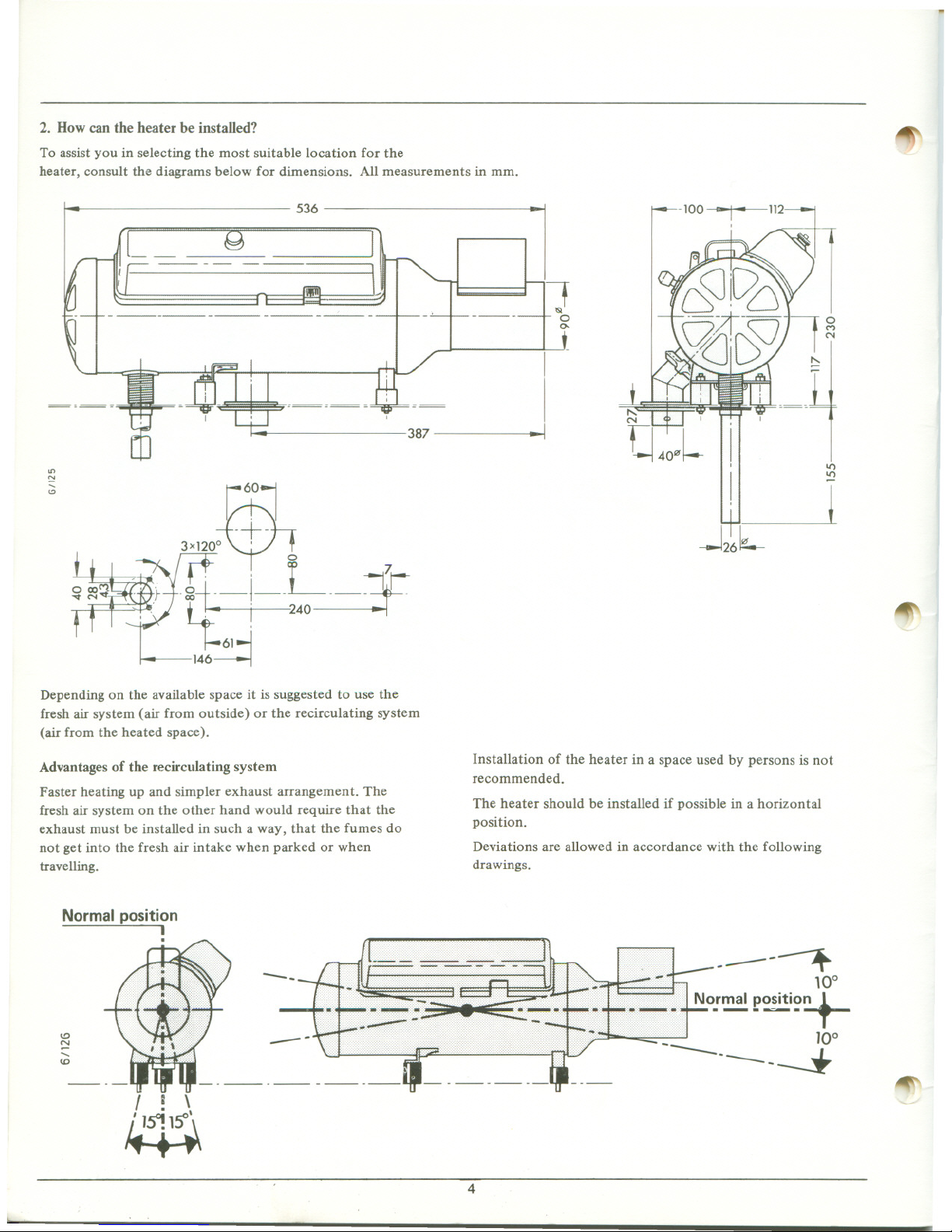

2. Dow can the heater be instaUed?

To assist you in selecting the most suit able location for the

heater, consult the diagrams below for dimensions. AlI measurements in mm.

536

----

----

----

387

on

N

Depending on the available space it is suggested to use the

fresh air system (air from outside) or the recirculating system

(air from the heated space).

Advantages of the recirculating system

Faster heating up and simpler exhaust arrangement. The

fresh air system on the other hand would require that the

exhaust must be installed in such a way, that the fumes do

Hot get into the fresh air intake when parked or when

travelling.

Normal position

1

.

~

l

If

'IS!

0

0.

1

1

-j

"

b:tli

1

1

~-

-J26 L

l

1/")

~

~

Installation of the heater in a space used by persons is Hot

recommended.

The heater should be installed if possible in a horizontal

position.

Deviations are allowed in accordance with the following

drawings.

10

~

.....

(j)

1 1 \

. ,

~

:t

10°

No!~ po~iti~~

10°

*

~

4

Page 5

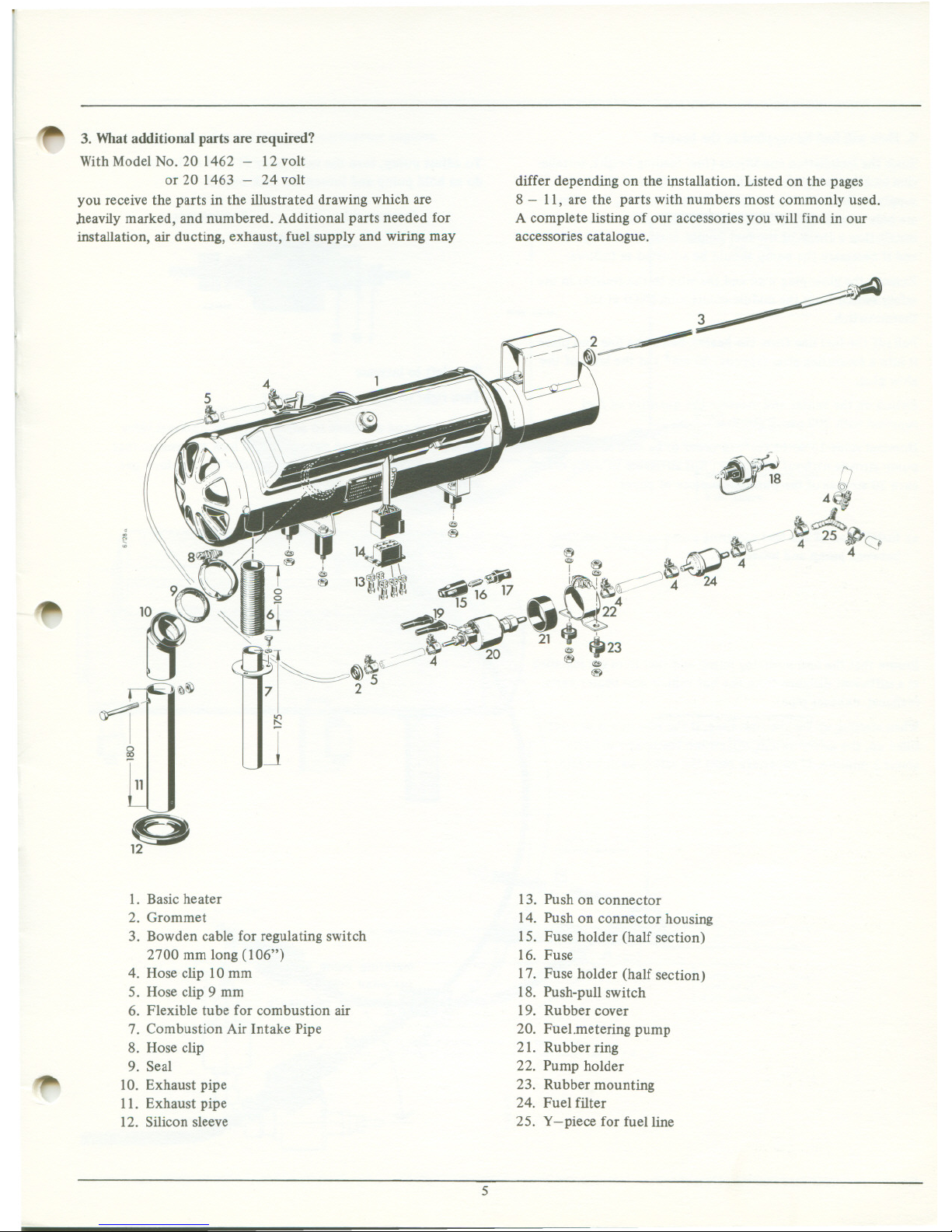

~ 3. Whatadditionalparts are required?

With Model No. 20 1462 - 12 volt

or 20 1463 - 24 volt

fOU receive the parts in the illustrated drawing which are

heavily marked, and numbered. Additional parts needed for

installation, air ducting, exhaust, fuel supply and wiring may

differ depending on the installation. Listed on the pages

8 - Il, are the parts with numbers most commonly used.

A complete listing of our accessories fOU will find in our

accessories catalogue.

~

~

--

"~

11

p

~

1. Basicheater

2. Grommet

3. Bowdencablefor regulating switch

2700 mm long (106")

4. Hose clip 10 mm

5. Hoseclip 9 mm

6. Flexible tube for combustion air

7. Combustion Air Intake Pipe

8. Hose clip

9. Sea1

10. Exhaust pipe

11. Exhaust pipe

12. Siliconsleeve

13. Push on connector

14. Push on connector housing

15. Fuse holder (half section)

16. Fuse

17. Fuse holder (half section)

18. Push-pull switch

19. Rubber cover

20. Fuel.metering pump

21. Rubber ring

22. Pump holder

23. Rubber mounting

24. Fuel filter

25. y -piece for fuelline

5

Page 6

4. How will fuel be supplied to the heater?

Since the installation conditions (fuel feeding height, installa-

tion location, length of fuellines etc.) influence the fuel

supply to the metering pump to a certain extent, the pumps

are only preadjusted by the manufacturer. After successful

installation a check of the fuel supply must be carried out

and if necessary thè pump should be adjusted as follows:

Remove the glow plug wire and the wire to the resistor in the

safety switch from the middle connection (NO) at the

thermoswitch.

Pull off the fuelline from the heater, bleed the line and place

it into a measuring glass (approx. 20 cm3.) at the level of the

glow plug.

Switch on the heater and measure the quantity of fuel

supplied with 200 pump strokes.

Nominal value 13 to 15 cm3. ln order to be able to count the

pump strokes without difficulty, it is advisable to mark off

each 20 strokes of the pump on a piece of paper.

a) Installation of the fuel metering pump and the fuelline

between pump and heater.

Ensure that the fuel metering pump and fuellines are installed

at a sufficient distance from the hot vehicle and heater parts.

(exhaust, exhaust pipe).

When starting up for the first time, if the fuelline is not yet

filled op, the safety-switch will switch the heater off after

about 3 minutes. If necessary reset the safety-switch again.

~

To adjust pump, tum the valve body (1) 1/4 to 1/2 tom. To

do so hold pump and loosen the lock nut (2).

Pressure side Suction side

Tum left to increase

Tum right to decrease the quantity

Remeasure and continue to adjust until the nominal value

has been reached. When tightening the lock nut ensure that

the valve body is not also tumed. Finally geai the lock nut

with paint.

~

~

~+ .

.~

'.s-~ .

r.s-

"

'..I~

".9

~

a.

c

~

6

Page 7

~

b) Fuel connection for vehicles with carburetor engines.

---------

---------

---------

---------

---------

- - - - - - - --

max. 20 in. ---------

- - - - - - ---

---------

---------

---------

- - - - - - - --

~'O healer

~ '" "';d. ."'~ ~

1 -~ -.~-~-

~--------

-------

pump below min. fuel

level or al max. of

4 in. above

max. 17 fI. long, if pump below min. fuel level

max. 4 fI. long, if pump above min. fuel level (al max.4 in.l

~

c) Fuel connection for vehicles with fuel injection engines.

1

maximum----.

,--_~-_~fuellevel- --

------

---------

----

---------

-------

- - - - --

max. 20 in.

---------

- - - - - - ---

---------

---------

-~-----

--- -------

pump below min. fuel

level or al max. of

4 in. above

max. 17 fI. long, if pump below min. fuel level

max. 4 fI. long, if pump above min. fuel level (al max.4 in.l

~

7

Page 8

d) Fuel connection for a very high tank (level regulator

necessary).

~

---------

---------

to tank vent

---------

~---

if

------

- - - - - - - --

-------

------

--------

-------

over 20 in.

------

--------

-------

--------

minimum

fuel level - 7" -::

- .--=-=-= :-_-

~toheater

1

1

. L.~" ~

~

.

--~ --

1

evel regulator always

-. ..1 below the minimum

-- fuel level

t fi) max.4 in.;..

~ ~11ti---1~

~ max.4ft.long

r:

e) Fuel connectiQn if the metering pump has to be installed

higher than lOOmm above the minimum fuellevel, or if the

suction Hne is longer than 1.2 m.

ç8~---

~

...L ~

L-:::;:~~: ---1

:s:z.maximum -

=- -= fuel level --

- --- - - - - --

- - - - ---

max.40in.

- ------

--------

t

~

l

- --- - - - - --

- - - - - ~ --

- - - - - ---

tr

",-,

1--2.. minimum

- :-=- = !.u~1'~vel~

------

-- --

8

Page 9

~

f) Accessories for Fuel Supply

O

~

~

Ventmg

""

"".""

Pipe .'

-"

4 --

... ,,',

~S.c: ~~ r- ~

.J-o_~~:::]~ ) , Ir~~

- [cc;:~;;#;;~ .,: &1 ~ "

f(fJf!À'

~

\) / "\\-~! lA.

I~~Y::

,

'~

,

. \ \ , ,.J;P&«iP ~ 1it' _01\\

,

7

,

, 13

2\\~~

~

(~, 1 <8>

,

~

&

~

~

,

'- &

~

,'!&"!J,' , ' ..~~"' "' ' 10.,.-,

~ '~"

11 tn>

V,nting ~ 1

12 ~ Pipo U

3& ~

12&~ ~ \

,..----

f

~

DiagramNo.

1

2

3

4

5

5a

6

7

8

9

10

~

Il

12

13

14

15

16

Name

fuelline

stee1line

fuelline

1eve1regulator

y piece (for vehicle fuelline)

y piece (for vehicles with fuel injection)

y piece (for vehicle fue1line)

pump bracket

hose fitting straight

capnutM10X1

fuel pump

hose fitting 90° with capnut M 10 X 1

hose clamp

fuel tank connection

fuel tank

fuel tank

fuel tank

15

Dimensions etc.

5/16 aD, 1/8 i.d. 9'>lin. H.

5/32 ID, 1.16 i.d. 9'>lin. H.

3/8 aD, 3/16 i.d. 9'>lin. H.

12 V. 0.1 aille = 1.411bs. psi

24 V. 0.1 aille ~ 1.411bs. psi

15/32" 9'>

7 liter ca 1 1/2 gallons

7 liter ca 1 1/2 gallons

4 liter ca 1 gallon

Part No.

36075 110

049 10 004

36075 130

25 85~5 360000

20 1307 02 06 00

20 1316 02 01 00

25 1202 03 01 00

20 8546 07 00 27

250187000000

116 10002

201122040100

201123040100

25 1156200300

102061 01 0090

25 1156270000

20 1462 89 10 00

20 146289 20 00

20146289 1500

9

Page 10

S. Dow will the exhaust be directed and the

combustion air supplied?

Exhaust and combustion air intake must be balanced to ensure

a smooth, soot-free combustion process. Make sure that no

combusted air enfers the fresh air intake while fOU are

driving or parked. It is important that the heater does not

interfer with vital parts of the vehicle, (brake lines, fuel

lines etc.). The combustion air must be picked up from the

outside.

Therefore, please observe the following:

a) Should the supplied exhaust pipes have to be extended, an

elbow with an injector should be installed first. You can

then connect a pipe up to 3 ft. to if. A further extension

requires the installation of an exhaust blower, to which

a pipe up to 6 ft. can be attached. The cross section

(55 mm 1/>,2 5/32") of the pipe must not be reduced.

b) The maximum permissible length of the combustion air

intake pipe is 600 mm. (23.4").

c) Exhaust and combustion air intake must be located in

such a way that no exhaust fumes can be sucked in by

the combustion air intake.

d) The exhaust pipe and combustion air intake pipe must be

located in a similar pressure area. At aIl speeds the

differential pressure between the combustion air intake

and exhaust outlet must not exceed +4 mm WC(5/32")

(max. over pressure at exhaust pipe) and - 4 mm WC

(5/32") (max. under pressure). Solder close to the heater

one tube 1/16" 1/>i.d. to the combustion air pipe and one

1/16 1/>i.d. to the exhaust pipe.

At least 2" of pipe must be allowed beyond 'the measuring

point. Drill a 1/16" hole through both pipes and deburr them.

The tubes are connected by hoses to a manometer (e.g. U-tube)

at which the differential pressure can be read off. By moving

the exhaust pipe and the combustion air intake pipe to

another location or by cutting the pipes diagonally the

pressure differential can be influenced due to a change of

speed. Do not install the exhaust pipe facing the direction

of trave!.

~

N

~

(0

0 Desirable value

~

-4mmWS

0

Maximum allowable

vacuum at exhaust pipe

Maximum allowable

over pressure at exhaust pipe

~

10

Page 11

.

~

Accessories for exhaust and combustion air intake.

?\

5

~

~

~

p

Diagram No.

1

2

3

3a

4

5

6

Name

Flexible Combustion Air Intake Pipe

Seal

Combustion air intake pipe

Dimensions etc.

1 1/32" If>I.D. in fi.

Part No.

102112020000

20 1282 20 00 00

047 05 023

20 1121 07 01 00

25 8585 33 03 00

047 05 069

25 1202 24 00 00

25 1202 25 00 00

1 1/32" If>O.D. in fi.

Exhaust Elbow with Injector

Exhaust Pipe

Exhaust Blower

25/32" If>I.D.

12 volt

24 volt

,.,...

Il

Page 12

6. How can the hot air ducts be installed?

The resistance of the hot air ducts (wall friction and losses

due to variation in direction) and the outlet and intake hood

should Dot exceed a static pressure of 6mm WC 0/4" WC).

This resembles a 9ft. flexible pipe with 90mm = 3 9/16" i.d.

with 1 or 2 bends and with an outlet and intake hood. Hot

air ducts should Dot exceed the above 1engths (minimum

cross section 64 cm2 = 90 mm i.d. = 3 9/16" i.d.)

1"

Witha fresh air system draw in the fresh air from a level as

lllgh as possible, Dot in the region of the exhaust, and Dot

from a location which is un der ram-air pressure or vacuum.

With a recirculation system, locate the circulating air intake

so that the outflowing hot air cannot be directly drawn in

again.

Insulate hot air ducts installed in the open against heat loss.

3~

+-'-'-'

" i i

! i

! i

1 i _.~ ,

. .

~

l

! ! i

'1 1 ~." "~~" ~"

-

1

~ '. \\;/1

.

' \-

. ~ 1

i \

~

,!\v,lj

~

! \, \_~

\ \ \

2 - - \.

1

""

90 mm I.D. in ft.

Part Number

20 1127 010101

25 8585 29 00 00

la 2060 09 51 52

10 2112 15 00 00

20 1297 00 00 al

20 1297 00 0100

20 146289 06 00

20 146289 02 00

~

No.

1

2

3

4

5

6

7

8

Description

Hood

E1bow

Clamp

Flexible duct for hot air

F1ange for flexible duct

Screen

Spherica1 E1bow .Left

Spherical Elbow Right

Measurements and other Data

12

Page 13

,..

7. How shaHthe wiring be arranged?

CORRectthe heater to the power supply according to the

wiringdiagram(check the voltage).

1

1:-

Ir--

- --

The additional coRRection of a time switch and a room

thermostat is indicated by dotted liRes.

1

1

\

\ 1

I~

.j:

~~

","

~;-:-

Ground strap with ...;-..,-='

radio supressor ,,;',~--

models only ,"'di

d:'

À

"..

Wiringdiagramfor BN4 heater

WITHOUTventilation

~

1

1

1 1

3

) !

,/' 1

/ 1

i 7

Ground

',5(4)' ,od ('2."5(4)"Od--O +Batte"l

12red .r ,

4~:

.,.,.,.} ... ~.. c.. 'i :

;;;~' 1

l',' lighting 1

--j/l~

~

.~',\~

5

\~~1~JJJ

~--1

"

~

Cross sections in 0 for duct lengths over 4 m ~ feet

~

To CORRectthe room thermostat rem ove wire 0.5 grey

between switch and Six-coRRection plug.

AlI diameters given in sq. mm.

1

l

,

l

,

L-

6

1

2.5(4)2 brown

0 -Battery

0.52 grey

[Q]2

1) Multi connector

2) Fuse holder

3) Fuel metering pump

4) Off/On Switch

5) Timer (accessory)

6) Room thermostat (accessory)

13

Page 14

Wiringdiagram for BN4 heater WITH ventilation

1"

-

- -

Ground strap with

radio suppressor ,

models only '"

~

1

0 -Battery

~

:b

.

1 1

1 1

3

J l

, 1

~

/ l

,/'

.<f~

(/~

1 7

lGround

'"

Il'I

ci

1

1

.

1

.

L-

6

[92

'~4

0.5black/whiteB ' 1 Il "-

1 l "-

/,. -1 ,

, ( Lighting 1

/I~I

-_/ ~~

O,S2grey

f8'Iit

14

Page 15

~ Accessoriesfor electrical installation and controls

A

~

DiagramNo.

1

2

3

4

~

,~

~

2

---~

3

4

JJO~)

';;';é"-'

Dimensions etc. Part No.

Name

Room thermostat

Timer

Bowden cab1e for temperature contro1 switch

Off/On Switch

25 1179320000

20 134803 1600

13 ft. 20 1104260001

12 volt (heating & ventilatiOn)

}

20 1121 090001

24 volt (heating & ventilation)

15

Page 16

BN4 - Compact Heater - l2V Model No. 20 1547

24V Model No. 20 1548

...-

These heaters are already equipped with the following

accessories: Metering pump, electric fuel pump to overcome

greater suction heights, fuel fiUer, and rubber mounting, all

premounted. ln addition the following parts are inc1uded:

2. Grommet (2) for fuelline and wiring harness

3. Bowden cable for regulating with 2700'

4. Clamps (39/16" - 4 5/16")

5. Clamp

6. Gasket

7. Exhaust Elbow

8. Exhaust pipe

9. Silicon geai

10. Flexible combustion air intake pipe

Il. Combustion air intake pipe

12. Hexagon nuts & washers

13. Wiring harness 15 feet with 16 Amp fuse

14. Push-pull switch

00

~ -Battery

~ +B_~

,..

,

b

@

12

~

Operation

The wiringharness has to be installed according to the above

diagram.

90

To bleed the fuelline proceed as follows:

Unscrew the hollow screw at the outlet of the electric fuel

pump (Arrow). Start heater. As soon as fuel emerges tighten

hollow screw again.

~

16

.

Loading...

Loading...