Page 1

AIRTRONIC D2/D4

Installation, Troubleshooting & Parts Manual

AIRTRONIC

For Heater Models Release period

AIRTRONIC D2 - 12 volt 25 2069 05 00 00 November 2001

AIRTRONIC D2 - 24 volt 25 2070 05 00 00 November 2001

AIRTRONIC D4 - 12 volt 25 2113 05 00 00 November 2001

AIRTRONIC D4 - 24 volt 25 2114 05 00 00 November 2001

Espar

P/N: 610-103-0901 November 2001

Page 2

Table of Contents Page

Introduction Heater Warnings ........................................................ 3

Introduction ........................................................ 4

Specifications ........................................................ 5

Principal Dimensions ........................................................ 6

Heater Components ........................................................ 7

Installation Procedures Heater Location ........................................................ 8

Heater Mounting ........................................................ 8

Heater Plate installation ........................................................ 8

Mounting Pattern ........................................................ 9

Ducting Components ........................................................ 9

Heater Air Ducting ........................................................ 9

Fuel System ........................................................ 10

Electrical Connections ........................................................ 12

Exhaust/Intake Connections ........................................................ 13

Operating Switches ........................................................ 13

Heater Operation Switch on ........................................................ 14

Start-Up ........................................................ 14

Temperature setting ........................................................ 14

Temperature Control ........................................................ 15

Switching Off ........................................................ 15

Controls & Safety Equipment ........................................................ 15

Operational Flow Chart ........................................................ 15

Function Diagrams ........................................................ 16

Schematic AIRTRONIC D2/D4 ........................................................ 17

Maintenance, Periodic Maintenance ........................................................ 18

Troubleshooting & Basic Troubleshooting ........................................................ 18

Repairs Self Diagnostic Troubleshooting ....................................................... 18

Fuel Quantity Test ........................................................ 23

Overheat/Flame sensor values ........................................................ 23

Control and Resistance values ........................................................ 24

Repair Steps ........................................................ 25

Heater Parts AIRTRONIC D2/D4 ........................................................ 30/32

-Service Parts Diagram

AIRTRONIC D2/D4

-Parts List ........................................................ 31/33

Special Notes

Note: Highlight areas requiring special attention or clarification.

Caution: Indicates that personal injury or damage to equipment may occur unless specific guidelines are followed.

Warning: Indicates that serious or fatal injury may result if specific guidelines are not followed.

This publication was correct at the time of going to print. However, Espar Inc. has a policy of continuous improvement

and reserves the right to amend any specifications without prior notice.

Page 3

Heater Warnings

3

Warning To Installer:

Correct installation of this heater is necessary to ensure

safe and proper operation.

Read and understand this manual before attempting to

install a heater.

Warning - Explosion Hazard

1. Heater must be turned off while re-fueling.

2. Do not install heater in enclosed areas where

combustible fumes may be present.

3. Do not install heaters in engine compartments of

gasoline powered boats.

Warning - Fire Hazard

1. Install heater so it will maintain a minimum distance of

2” from any flammable or heat sensitive material.

2. Install the exhaust system so it will maintain a

minimum distance of 2” from any flammable or heat

sensitive material.

3. Ensure that the fuel system is intact and there are no

leaks.

Failure to follow these instructions could cause fire resulting in serious or fatal injury.

Warning - Asphyxiation Hazard

1. Route the heater exhaust so that exhaust fumes can

not enter any passenger compartments.

2. Ensure an air tight seal will be maintained between

the heater and mounting surface and at any exhaust

connection points.

3. Ensure that heating air supply is taken from an area

where poisonous gases will not be present.

4. If running exhaust components through an enclosed

compartment, ensure that it is vented to the outside.

ATTENTION

Operation with bio-diesel

AIRTRONIC D2

AIRTRONIC D2 is not certified for use with bio-diesel.

Admixtures of bio-diesel up to a magnitude of approx. 10%, as

in some countries, are allowed.

AIRTRONIC D4

AIRTRONIC D4 is certified for operation with bio-diesel as per

DIN V 51606 in free-flowing state when installed in “normal

horizontal position (exhaust pipe downwards)”; bio-diesel is not

permitted for any other installation positions.

When using 100% bio-diesel, AIRTRONIC D4 should be operated with pure diesel fuel twice per year, preferably in the middle and at the end of a winter period, to burn off any possible

PME residues: For this purpose, drain your vehicle tank as far

as possible (caution: do not forget to leave enough fuel in the

tank to get to the next fuel station!) and then fill the tank with

pure diesel fuel without bio-admixture.

While using this tank filling, let AIRTRONIC D4 run at the maxi-

mum temperatures pre-selection stage at least twice or three

times for 30 minutes at a time. You can use this for example to

pre-heat your vehicle before setting off. After this “diesel operation” of your AIRTRONIC D4, you can use bio-diesel again as

required.

When using mixtures of diesel / bio-diesel with up to 50% bioshare, it is not necessary to use pure diesel fuel now and then.

ATTENTION

Heating at high altitudes

Up to 1500 meters - unrestricted heating operation is possible

Above 1500 meters - heating operation is in principle possible

for short periods, e.g. when crossing a mountain pass of during

a brief stop. In cases of extended stays , the fuel supply at the

fuel metering pump has to be adapted to high altitude conditions. Please call

Failure to follow these instructions could cause oxygen

depletion resulting in serious or fatal injury.

Direct questions to Espar Heater Systems

USA 1-800-387-4800

CDA 1-800-668-5676

USA 1-800-387-4800

CDA 1-800-668-5676

for special circumstances.

Page 4

Introduction

Espar ‘s AIRTRONIC bunk heaters

The AIRTRONIC D2 is a compact diesel-fired 7,500 BTU/hr air

heater, quality engineered to provide a dependable means of

space heating. This heater is uniquely designed for inside

mounting and ease of installation. The AIRTRONIC D4 is a

12,000 BTU/hr air heater for larger bunks.

These heater provide hot air to the interior of vehicles

for passenger comfort. Since the heater runs on diesel

fuel and 12 or 24 volt power, it is able to provide space

heat completely independently of the vehicle engine.

The heater is operated by a rheostat switch or room thermo-

stat. It cycles through four temperature settings (boost-high-

medium-low) in order to maintain the desired temperature.

If, in special cases, less heating capacity is required than

the heater supplies in the “Low” setting, the heater switches to

a “stand-by” setting. Temperature and overheat sensors, and a

specially designed heat exchanger are among the safety features which make this heater a safe and dependable unit.

4

For illustration purposes only

Page 5

5

Specifications

AIRTRONIC D2 AIRTRONIC D4

Heat Output (±10%) 7,500 BTU/hr Boost (2.2 kW) 13,650 BTU/hr Boost (4.0 kW)

6,150 BTU/hr High (1.8 kW) 10,200 BTU/hr High (3.0 kW)

4,100 BTU/hr Medium (1.2 kW) 6,800 BTU/hr Medium (2.0 kW)

2,900 BTU/hr Low (0.85 kW) 3,400 BTU/hr Low (1.0 kW)

Current at 12v (±10%) 8.3 amps - Start 8.3 amps - Start

2.8 amps - Boost 3.3 amps - Boost

1.9 amps - High 2.0 amps - High

1.0 amps - Medium 1.1 amps - Medium

0.7 amps - Low 0.6 amps - Low

Current at 24v (±10%) 4.2 amps/hr - Start 4.2 amps/hr - Start

1.4 amps/hr - Boost 1.7 amps/hr - Boost

1.0 amps/hr - High 1.0 amps/hr - High

0.5 amps/hr - Medium 0.5 amps/hr - Medium

0.3 amps/hr - Low 0.3 amps/hr - Low

Fuel Consumption (±10%) U.S. Litre/hr U.S. Litre/hr

Gal/hr Gal/hr

Boost 0.07 0.28 Boost 0.13 0.51

High 0.06 0.23 High 0.10 0.38

Medium 0.04 0.14 Medium 0.07 0.25

Low 0.03 0.10 Low 0.03 0.13

Air Flow (±10%) 48 cfm Boost 85 cfm Boost

40 cfm High 69 cfm High

27 cfm Medium 50 cfm Medium

19 cfm Low 30 cfm Low

Operating Voltage Range 10.5 - 16 vdc at 12 vdc 10.5 - 16 vdc at 12 vdc

21 - 32 vdc at 24 vdc 21 - 32 vdc at 24 vdc

Overheat Temperature 240°F (115°C) 240°F (116°C)

Shutdown (±10%)

Ambient Operating -40°F to 158°F (-40°C to 70°C) -40°F to 158°F (-40°C to 70°C)

Temperature

Weight 6.0 lbs. (2.7 kg) 9.9 lbs. (4.5 kg)

Note: The heater control unit is equipped with a low

voltage cutout to prevent vehicle battery drain and

a high voltage cutout to protect heater electrical

parts.

Page 6

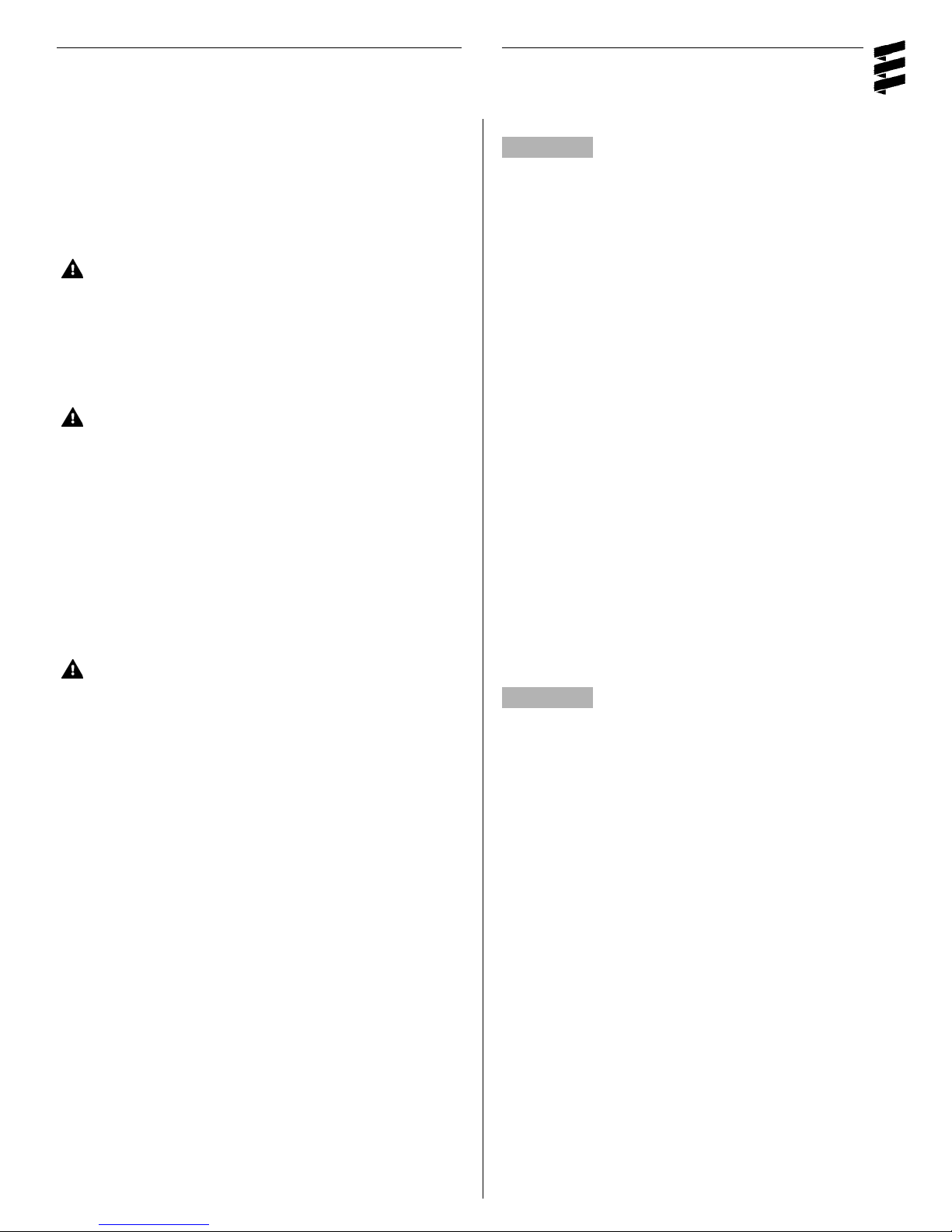

Principal Dimensions AIRTRONIC D2

6

* All measurements in millimeters

25.4 mm = 1”

Minimum installation distance

(clearance) to open the lid and to

dismount the glow pin and the

control unit.

Minimum installation distance

(clearance) to take in heating air.

Principal Dimensions AIRTRONIC D4

(12.2 inches)

(4.5 inches)

(14.8 inches)

(5.5 inches)

Page 7

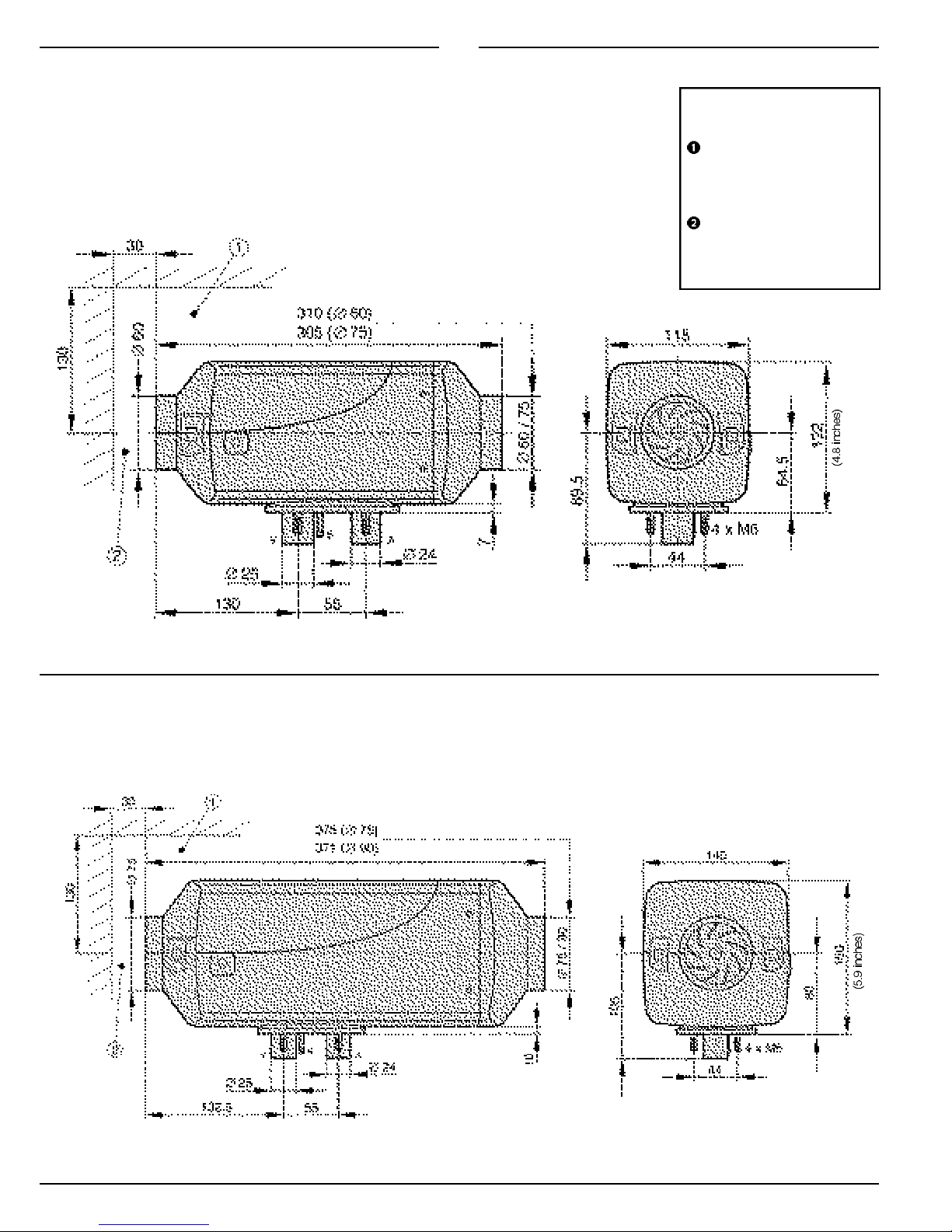

Heater Components

7

1 Hot Air Blower Wheel

2 Control Unit

3 Combustion Air Blower Wheel

4 Glow Pin

5 Cover

6 Heat Exchanger

7 Overheat/Flame sensor

8 7 Day Timer with thermostat (optional)

9 Operating Unit (Thermostat)

10 Operating Unit (Rheostat)

11 Blower Motor

12 Fuel Connection

13 Flange Seal

14 Combustion Chamber

15 Hot Air Outlet Hood

16 Combustion Air Intake Hose

17 Fuel Metering Pump

18 Fuel Filter built into FMP

19 Hot Air Output Deflector

20 Flexible Exhaust Pipe

21 Main Fuse: -

AIRTRONIC D2 - 20 A

AIRTRONIC D4 - 10 A

C = Combustion Air

D = Fuel Intake from tank

E = Exhaust

F = Fresh Air Intake

H = Hot Air Output

Page 8

8

Installation Procedures

Heater Location

Depending on the type of vehicle, the best location for mounting the heater will vary. Typically, air heaters are mounted

inside tool or luggage compartments. However, the heater may

be mounted anywhere inside the vehicle provided you adhere

to the following conditions:

• Combustion air intake, exhaust and fuel inlet must be

located outside of the vehicle.

• Heater must be mounted on flat horizontal surface

providing an air tight seal between heater and vehicle.

• Do not mount the heater outside the vehicle, unless care is

taken to protect the heater from the weather. When selecting

the location, consider the following:

• Combustion air and exhaust connections.

• Ducting.

• Fuel line connections.

• Electrical connections.

Heater Mounting

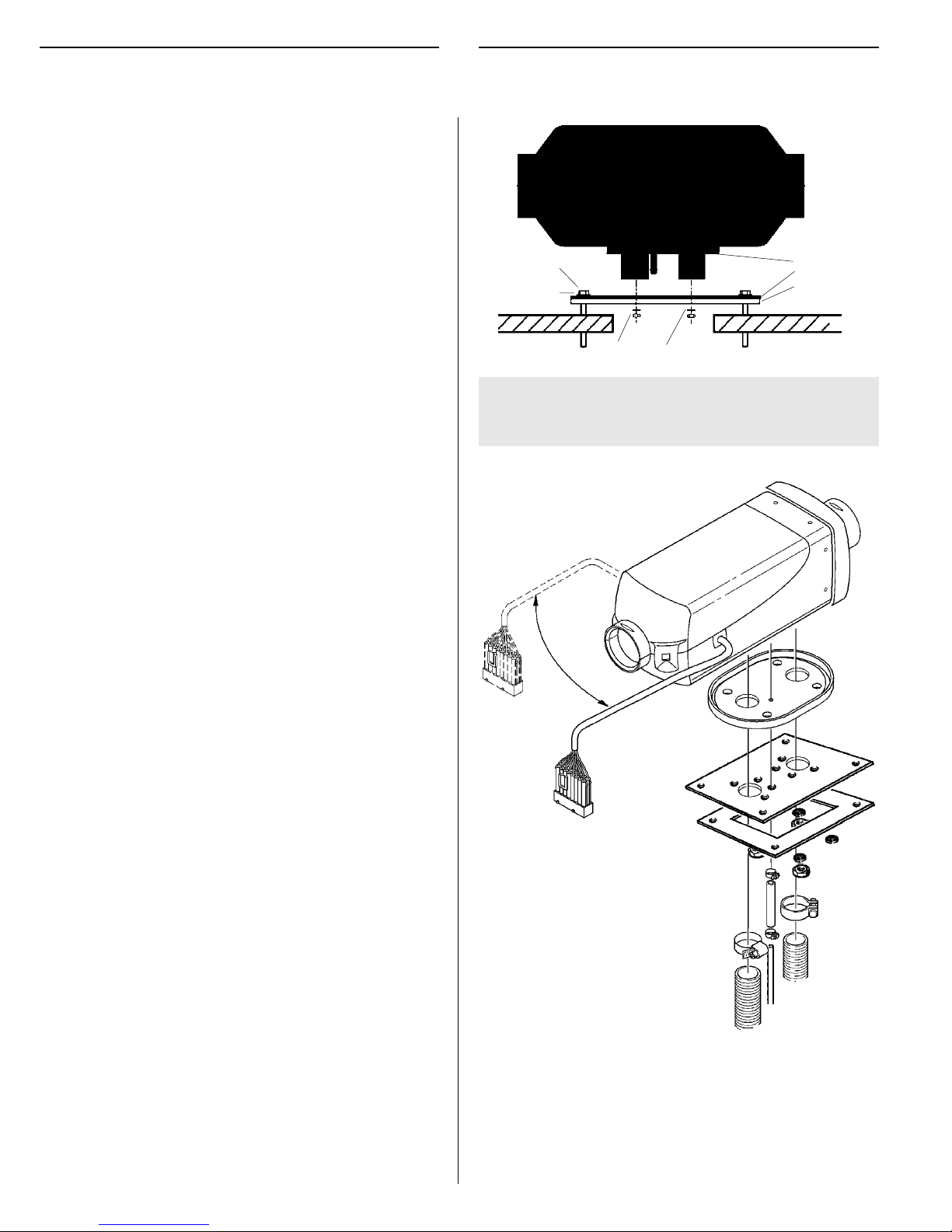

Heater Mounting Plate Installation

Hex Head Tek Screw

Flat washer

Nut

Spring Washer

Cab Floor

Note: Tighten screws sufficiently to ensure positive seal

between mounting plate and mounting surface.

Do not over tighten.

Silicon gasket (flange)

Stainless Steel Plate

Plate seal

A mounting plate and hardware are provided with the truck

heater kit.

• Choose heater location.

• Using template provided, drill and cut center hole. Cut (1)

four and one half inch (4 1/2”) diameter hole or one rectangular hole four (4”) by five (5”) inches to accommodate

mounting plate and seal. Secure mounting plate to vehicle

floor with “Tek” screws provided.

• Use Heater flange as a template if not using mounting plate

and seal

• Mount heater on mounting plate with nuts and spring

washers provided.

• For ease of installation make the exhaust, combustion air

intake and fuel connections at base of heater before mounting the heater into the vehicle. See following pages for

instructions and restrictions on exhaust, combustion and fuel

hook-ups.

Wiring harness connection, right or left

Wiring harness can be converted to the opposite side of the

heater if it makes the installation more practical. To do this you

must remove the AIRTRONIC cover and then the control unit.

On the control unit (underneath) is a semicircular clip protecting the harness. This must be removed. The harness should be

moved to the other side of the control unit then reassembled.

The grommet on the heater casing (side) must also be taken

out and secured into the opposite lower side of heater casing.

Wiring Harness

Right or Left

Stainless Steel

Mounting Plate

and seal

Combustion

Air intake

Fuel line

Heater

Flange

Exhaust

Tubing

Page 9

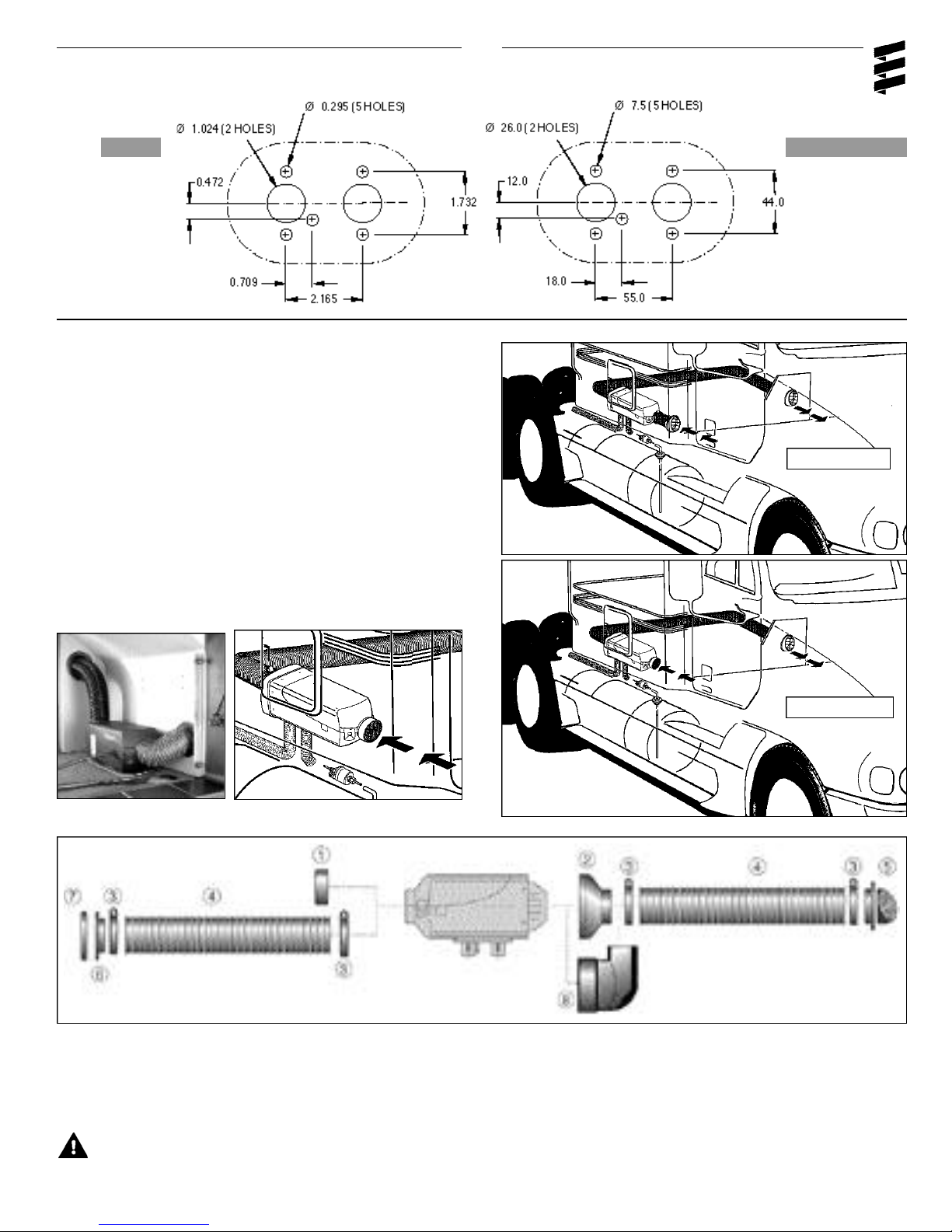

Mounting Pattern

inches millimeters

Heater Air Ducting Installation

A 60mm flexible duct 40 inches long, hot air outlet and clamps

are provided with the heater kit. In routing and installing the

ducting the following criteria must be observed:

9

• Route ducting with smooth bends. Avoid crushing duct.

• Position hot air outlet so that it cannot be obstructed.

• When not using return ducting. Use a protective air intake

grille on air inlet side of heater to prevent objects from

being sucked in.

• Ensure provisions are made for proper air return ventilation.

• Use return air ducting for best heating efficiency.

Ducting Components

Return Ducting

For illustration

purposes only

No Return Ducting

For illustration

purposes only

1. Protective Grill 5. Air Outlet - Rotatable

2. Air Outlet Hood AIRTRONIC D2 - ø60 or75mm 6. Connection Piece

AIRTRONIC D4 - ø75 or 90mm 7. Protective Grill

3. Hose Clamp 2-2 3/4” 8. 90° Bend Ducting 2 3/8”

4. Flex Duct 2 3/8” (ø60 or 75mm) (ø90mm on D4)

Warning: Do not use existing vehicle ducting or outlets.

Ducts and outlets must be capable of withstanding a minimum of 300°F operating temperatures.

Caution: Do not over tighten duct clamps.

Do not position outlet so that it will blow hot air

directly at operator or at room thermostat.

Page 10

Fuel System

The fuel metering pump is the heart of the system and must be

installed properly to ensure a successful heater operation.

Fuel System Overview

10

7

6

Max. 2’6”

Fuel

Tank

1

1. Fuel Pick-Up Pipe

2. 5.0 Rubber Connector

3. 11mm Clamp

2

3

Max. 6’6”

Fuel

Tank

Optional

Max. 6’6”

4

2

3

Max. 2’

Max. 20’

6

5

3

9

3

1

4. 2.0mm Black Plastic Fuel Line

5. Fuel Metering Pump

6. 9mm Clamp

8

7

5

Note: Butt joints and clamps on all connections.

7. 3.5mm Rubber Connector

8. 1.5mm White Plastic Fuel Line

9. 5mm Rubber Fuel Line

Fuel Pick-Up Pipe Installation (Standard Pick-Up)

• Choose a protected mounting location close to the fuel

pump and heater.A spare fuel sender gauge plate provides an ideal mounting location.

• Drill the mounting holes as shown

• Cut the fuel pick-up pipe to length.

• Mount the fuel pick-up pipe as shown.

• Lower the fuel pick-up pipe (with reinforcing washer) into

the tank using the slot created by the two 1/4” holes.

• Lift the assembly into position through the 1” hole.

• Assemble the rubber washer, metal cup washer and nut.

Note: Drill the two 1/4” holes first.

Optional

Page 11

Custom Pick-Up Pipe with NPT fitting - optional

• Remove an existing plug from the top of the fuel tank.

• Cut the fuel pick-up pipe to length.

• Secure the fuel pick-up pipe into position using the

combined NPT compression fitting

11

NPT fitting and pipe

optional

Note: NPT fittings are available in various sizes (Refer

to parts section).

Fuel Metering Pump

• Choose a protected mounting location close to the fuel

pick-up pipe and heater if not using standard assembly as

shown on right.

• Using the bracket and rubber mount provided, install fuel

pump as shown

Note: Proper mounting angle of the fuel pump is

necessary to allow any air or vapor in the fuel

lines to pass through the pump rather than cause

a blockage.

Fuel Line

• Route fuel lines from the fuel pick-up pipe to the fuel

metering pump then to the heater.

• Use fuel lines provided.

• Other sizes or types of fuel lines may inhibit proper

fuel flow.

• Make proper butt joints using clamps and connector

pieces as shown on previous page

• Use a sharp utility knife to cut plastic

fuel lines to avoid burrs and pinching

fuel line shut.

Typical standard assembly, if

not using this format please

adhere to specifications on

pg.10

Page 12

12

Electrical Connections

Main Harness....................................................................... 16 pin connector with 10 terminated wires at 8 terminals.

(green/red, blue/white (2), red, grey/red, grey, brown,

brown/white and yellow (2)).

Connect to the heater’s 16 pin connector

Connect other harnesses as described below

Power Harness..................................................................... 2 core harness (red and brown).

Route power harness to batteries, cut to length and terminate

as described below. Install 20 amp fuse last. (10 amp on 24V).

Connect red wire to fuse holder near battery.

Connect fuse link wire directly to battery positive post using

ring terminal.

Connect brown wire directly to battery negative post using ring

terminal.

Switch Harness.................................................................... 7 core harness (red, brown/white, yellow, grey, brown, grey/red and

b l u e / w h i t e )

Route this harness the length required to reach thermostat

installed in bunk compartment. Do not cut this harness, wires have

been soldered at ends for convenience of terminating to terminals

on thermostat. Coil up excess harness and secure in safe location.

Connect to thermostat or rheostat switch (refer to switch connection section).

Fuel Metering Pump Harness............................................. 2 core harness (green/red and brown).

Route this harness from heater to fuel metering pump. Cut to

length and connect to fuel metering pump using single terminals and connector provided with kit. (no polarity required).

Diagnostic Harness............................................................. 4 pin on 8 pin connector.(red, brown, yellow, blue/white

For diagnostic purposes only.

Caution: Install power 20 amp fuse only after all electrical

connections are complete. 10 amp on 24V.

Note: All exposed electrical connections should be coat-

ed with protective grease, (petroleum gel,

Vaseline, etc.).

Fuel Metering Pump Harness

Fuse and holder

Main Harness

Connector for Diagnostics

Switch Harness

Thermostat

Power Harness

Page 13

13

Exhaust and Combustion Air Intake Connections

A 24mm flexible stainless steel exhaust pipe (39”long) and a

25mm flexible plastic tube (39” long) for combustion air intake

are included with the heater kit. Exhaust clamps and holders

are also provided.

Caution: Route exhaust and combustion air intakes so they

cannot be plugged by dirt, water or snow.Ensure the

outlets do not face into the vehicle slip stream.

Keep exhaust and combustion air intake a minimum

of 12” apart.

Drill 1/8” holes in exhaust pipe if necessary to allow

water drainage.

Combustion air intake and exhaust lengths can be

shortened to a minimum of 8”.

• Attach the exhaust pipe to the exhaust outlet of the heat

exchanger

• Route exhaust pipe to an open area to the rear or side of

the vehicle so that fumes cannot build up and enter the

cab or the combustion air inlet to the heater.

• Install protective cap.

• Attach the combustion air intake tube to the combustion

air inlet of the heater

• Once secure to the heater inlet, the intake pipe must be

routed to the underside of the vehicle where it will pick up

clean, fresh, moisture free air.

Operating Switches

The heater can be controlled using a Thermostat or Rheostat

type switch. It can also be controlled by a 7 day timer with thermostat. See schematic pg. 17.

Thermostat

• Select a mounting location which will be representative of

the average temperature of the area being heated. Avoid

mounting near heater outlets, windows, doors, electrical

appliances or in areas receiving direct sunlight.

• Route the switch harness from the heater to the thermostat mounting location.

• Mount the thermostat as shown using proper mounting

hardware and the slots provided on the thermostat base.

Pull the switch harness through the

thermostat base access hole.

• Connect the six core switch harness to the thermostat as

shown

Mounting slots

End Cap

Exhaust ( min. 8” - max. 6.5’).

Combustion Air Intake

( min. 8” - max. 6.5’).

End Cap

Warning: The exhaust is hot, keep a minimum of 2”

clearance from any heat sensitive material

Thermostat base

access hole

This wire is “optional”

• It is recommended that when using return ducting, not to

use this wire. See illustration on pg. 9 for ducting.

• Not using the grey wire defaults the heater to use the temperature sensor on the control unit of the heater.

• Use of the grey wire defaults the heater to use the sensor

on the thermostat.

• The sensor on the control unit provides a more accurate

reading of the overall air temperature, whereas the sensor

in the thermostat gives more of a spot reading of the air

surrounding the thermostat.

Temperature sensor on

AIRTRONIC control unit.

Warning: Route exhaust so that the exhaust fumes

cannot enter the passenger compartment.

Page 14

Rheostat Switch

Note: When using Rheostat switch, the Return Ducting

method must be used as shown on page 9. This

allows the AIRTRONIC heater’s internal sensor to

properly monitor cab temperature.

• Mount the rheostat switch in a location

where it is easily accessible.

• Route the switch harness from the

heater to the Rheostat mounting location.

• Connect the six core switch harness

as shown

Temperature sensor on

AIRTRONIC control unit.

14

Heater Operation

Warning: To prevent fire, the heater must be switched

off while filling fuel tanks.

To prevent asphyxiation, the heater must not

be operated in enclosed areas unless heat

exhaust is routed to outside of garage bay.

1 Switch On

• Switch the heater on using the room thermostat’s, On/Off

switch (1=On, 0=Off ) or the rheostat switch.

2 Start Up

On start up the indicator light illuminates and the following

sequences take place:

• Control unit does a systems check of the glow pin, flame

sensor/temperature sensor, fuel metering pump and control unit.

• Blower starts slowly and begins to accelerate.

• Glow pin is energized and starts preheating the combustion chamber.

• After a delay (approx. 60 seconds) the fuel pump delivers

fuel.

• Ignition will take place as the fuel/air mixture contact the

glow pin.

• Blower speed and fuel delivery are slowly increased.

• Once flame sensor has detected a flame the glow pin will

switch off, after approx. 60 secs.

• After another 120 secs., heater will have reached maximum power.

3 Temperature Setting

Using the adjusting dial, set the desired temperature range.

• Lowest Setting - approx. 10°C (50˚F)

• Mid - Setting - approx. 20°C (68˚F)

• Highest Setting - approx. 30°C (86˚F)

On/Off switch

Green diagnostic light

Red operating light

On OEM installs the ‘red” & “green” indicator lights illuminate.

On after market installs only the “Red” light illuminates.

Operation indicating light

Low

High

Page 15

15

4. Temperature Control

• The temperature is monitored constantly at the heater’s

process air inlet or thermostat.

• This temperature is compared to the set temperature on

the adjusting dial.

• The heater cycles through Boost, High, Medium and Low

heat modes to maintain the desired temperature.

• If the desired temperature is exceeded while the heater is

operating in low heat mode the heater will switch into

“standby” mode. This is a comfort feature.

• The heater will re-start in once heat is again required.

5 Switch Off

Once switched off either manually or automatically, the heater

begins a controlled cool down cycle.

• Indicating light(s) on switch will go off

• Fuel pump stops delivering fuel.

• The glow pin is re-energized for a 40 second after-glow to

burn off any combustion residue.

• The blower continues to run for 4 minutes and automatically switches off.

6 Controls and Safety Equipment

• If the heater fails to ignite within two 90 second start

attempts, a "no start" shut down occurs.

• If a flame out occurs after the heater has started, the

heater will attempt to restart.

• If repeated flame outs occur within 15 minutes the heater

will not restart.

• Overheat shut down will occur if there is a restriction of the

heating air flow (i.e. blocked inlet or outlet). The overheat

sensor will automatically reset once the heater has cooled

down.

• Once the air flow restriction is removed, the heater can be

re-started by switching the heater off then back on.

• If the voltage drops below 10.5 volts or rises above 16

volts the heater will shut down (21 volts and 28 volts for 24

volt systems).

• If the glow pin circuit or fuel metering pump circuit are

interrupted the heater will not start.

• The blower motor is checked on start

up and continuously during operation.

Shut down will occur if the blower does

not start or maintain proper speed.

Operational Flow Chart

Page 16

Function diagram AIRTRONIC D2

16

Function diagram AIRTRONIC D4

Page 17

Schematic AIRTRONIC D2 / AIRTRONIC D4

17

Wire color key Designation

for switches

red = power (+)

yellow = switch

brown = ground (-)

grey = temperature sensor

on thermostat

*vehicle dimmer switch

for light display on

grey/red = temperature setting

blue/white = diagnostic

brown/white = ground

7-day timer

blue = diagnostic

from heater

from heater

black = to vehicle ignition

accessories for continuous

operation of heater

1.1 Blower Motor

1.2 Glow Pin

1.5 Overheat and Flame sensor

2.1 Control Unit

2.2 Fuel Metering Pump

2.7 Main Fuse

12Volt - 20 amp / 24 volt - 10 amp

3.1.11 Rheostat

3.2.8 7 Day Timer

3.5 Thermostat

5.1 Battery

6.1 Diagnostic Pigtail

(for connection to Fault code retrieval device)

Page 18

18

Maintenance

Recommended Periodic Maintenance

• Remove the glow pin and inspect for carbon build up.

Clean or replace.

• Remove the glow pin screen and inspect for carbon build

up. Clean or replace.

• Make sure vent hole is open. Espar recommends the use

of non detergent 100% volatile carburetor cleaner, an air

gun will also help. Remove loose carbon from the glow pin

chamber.

• Inspect the ducting, the air intake screen and air outlet for

restriction or blockage.

• Inspect combustion air intake and exhaust for blockage.

• Operate your heater for a minimum of 20 minutes each

month

• Maintain your batteries and all electrical connections in

good condition. With insufficient power the heater will not

start. Low and high voltage cutouts will shut the heater

down automatically.

• Use fuel suitable for the climate (see engine manufacturers recommendations). Blending used engine oil with

diesel fuel is not permitted.

Basic Troubleshooting

Check LIst:

What happens when the heater is switched on and ....

Heater does not ignite

1 Blower motor does not run

Check: - Fuse in power harness.

- Power to control unit.

- Power to and from switch.

- Electrical connections.

2 Blower motor runs approximately 20 seconds and then

shuts off

Check: - Ensure voltage at control unit remains

above 10 volts during start up with glow

plug circuit on.

3 Blower motor runs/fuel metering pump starts and then

shuts down after two start up attempts

Check: - Fuel lines and fuel filter.

- Fuel quantity. Pg. 23

- Combustion air or exhaust tube blockage.

4 Blower motor runs/ no fuel metering pump

Check: - For electrical pulses at fuel metering

pump.

- If pump is frozen.

- Blocked fuel line.

Heater ignites

1 Shuts down at random

Check: - Fuel metering pump quantity. Pg. 23

- Possible overheat.

- Control unit input voltage.

2 Heater smokes and carbons up

Check: - Exhaust pipe blocked.

- Combustion air intake blocked.

- Exhaust entering combustion air intake

pipe.

- Short cycling, rapid on/off operation.

- Fuel system.

- Fuel metering pump quantity.

- Motor rpm.

Page 19

Self Diagnostics

The heater is equipped with self diagnostic capability. To

retrieve information on the heater’s last 5 faults, a retrieval

device is required (part # CA1 05 020). There is a pig tail to

accommodate the connector on the main harness from

heater. If wire pigtail is not present, a wiring

adapter (P/N: 22 1000 31 86 00) must be used.

Connect the fault code retrieval device as shown. This device

enables these four functions to be performed.

1. Access the current fault which is affecting the heater

2. Access the four previous faults which affected the heater.

3. Clear the fault memory to erase previous fault history

4. Unlock “lockout features” which exist for some control

units.

Equipment Face and Controls

Symbols that are seen on the display face are as follows:

19

AF Actual fault.

F1-F5 Up to five stored faults can be accessed.

The AF and F1 are the same number.

This sign is displayed when the heater is in

operation.

DIAG The word (DIAG) nostic will come on when

the diagnostic number is requested.

000 Three digit diagnostic fault code number.

On/Off switch

• Switch the fault code retrieval device on and wait 10

seconds.

• Press the "D" button.

• Wait 3-5 seconds for the current fault code to appear (AF).

• To review the previous faults use the arrow buttons

(F1= Most Recent, F5= Oldest).

• Consult the fault code chart for code number descriptions.

• To erase the faults that are in memory press both "L" keys

at the same time for 5 seconds. This will also a unlock the

control unit.

On/Off

Retrieval Device

Page 20

20

Note: If there are no heater faults, the heater will go through

a normal start cycle and regulate based on thermostat

See schematic

pg. 17

setting.

Fault Code Fault Description Causes / Repair

000 Normal Operation

004 Warning - short circuit in controller, fresh air-outlet Disconnect connection S1/B1 at AIRTRONIC. At connector B1, pin 16

check for short between pin and blower relay. If no short exists replace

control unit.

005 Warning - short circuit at controller - anti-theft alarm output Disconnect connection S1/B1 at AIRTRONIC. At connector B1, pin 16

check the line through to the relay isolating switch or theft warning in

line for short circuit to chassis. If no short exists replace control unit.

009 TRS - shut down Switch off due to signal change.Check for change of signal from (+) to

(-) at pin 13 (S1) or a (+) signal at pin 14 (S1).

010 Overvoltage Start vehicle motor. Check voltage at (B1) between terminals 1 and 10.

This must be less than 16 volts (15.2 volts with glow plug on). Check

vehicle charging system.

AIRTRONIC 24 volt - voltage must be less than 32 volts

011 Undervoltage shut down Start vehicle motor. Check voltage at connector (B1) between terminals

1 and 10. This must be more than 10 volts. Check vehicle charging

system. Check batteries and connections.

AIRTRONIC 24 volt - voltage must be more than 21 volts.

012 Overheat at overheating sensor Sensor has detected excessive temperatures. Check for clogged hot air

ducting. Check that the the total number of ducting pieces in unison is

not too large. Re-route if necessary. Check overheat sensor resistance

values. (see component value chart pg 23). If O.K. Measure fuel quantity. See page 23.

013 Overheat at flame sensor Flame sensor detects excessive temperature at heat exchanger. Check

for clogged hot air ducting. Check that the the total number of ducting

pieces in unison is not too large. Re-route if necessary. Measure fuel

quantity. See page 22. Check flame sensor resistance. (see component

value chart pg 22)

014 Temperature difference between flame sensor and Check for clogged hot air ducting. Check that the the total number of

overheating sensor too large ducting pieces in unison is not too large. Check flame sensor, if O.K.,

check overheating sensor. If over-heating sensor defective replace

combi-sensor. If over-heating sensor O.K. measure fuel quantity. See

page 23. If fuel quantity O.K. replace control unit.

015 Overheat with excessive temperatures Fault code 015 is shown when the AIRTRONIC is switched on again

after fault code 017. The hardware limit value for the overheating sensor, has been exceeded - control unit is damaged. Check sensor.

Replace control unit.

017 Overheat with excessive temperature The hardware limit value for the overheating sensor, has been exceed-

ed, because the control unit has not detected fault code 012, 013.The

control unit is locked. If AIRTRONIC is switched on again, fault code

015 is displayed. Replace control unit. Check sensor.

020 Open circuit - glow pin Check continuity of glow pin.

AIRTRONIC 12 volt - approx. 0.5 Ω ± 0.05 Ω

AIRTRONIC 24 volt - approx. 2 Ω ± 0.2 Ω

021 Short circuit - glow pin Check functions of glow pin in installed condition, to do so disconnect

Caution!

For AIRTRONIC 12 volt, check functions with max. 8 volt

For AIRTRONIC 24 volt, check functions with max. 18 volt.

if voltage values are exceeded the component is destroyed.

Check sort-circuit resistance of mains unit: min. 20 Amp.

connector from controller. AIRTRONIC 12 Volt and 24 Volt. Apply voltage of 8 / 18 volts to glow pin respectively, and measure current

intensity after 40 seconds. Glow in is O.K. for the following values:

glow pin 8 volt - current = 9 amps + 1.5 / - 1.2 amps

glow pin 18 volt - current = 4 amps ± 0.5 amps

If the values differ, replace glow pin. If the values of the continuity test

and function test are O.K., check glow pin cable harness for damage

and continuity. If O.K., replace control unit.

Page 21

21

Fault Code Fault Description Causes / Repair

031 Blower motor interrupted Check blower motor cable harness for correct routing and damage. If

032 Blower motor, short circuit Check functions of blower motor, to so so, disconnect connector from

Caution!

For AIRTRONIC 12 volt, check functions with max. 8 volt

For AIRTRONIC 24 volt, check functions with max. 18 volt.

if voltage values are exceeded the component is destroyed.

Check sort-circuit resistance of mains unit: min. 20 Amp.

033 Blower motor does not turn Motor speed varies from specification by more than 10% for longer than

047 Short circuit - fuel metering pump Disconnect connector from fuel metering pump, if fault code 048 (inter-

048 Open circuit - fuel metering pump Disconnect connector from fuel pump and measure resistance value of

O.K., disconnect cable harness from control unit and check for continuity, if O.K., replace control unit.

control unit. Apply voltage of 8 volts or 18 volts ± 0.1 to blower motor

and measure current intensity after 40 seconds.

Current < 6.5 amp - blower motor O.K., replace controller

Current > 6.5 amp, replace blower.

30 seconds.

If too slow, check for restriction, and check for short in motor circuit or

control unit. If none found, replace blower.

If too fast, check for damage or missing magnetic sensor on control

unit. Replace blower motor if damaged.

Replace control unit otherwise.

ruption) is displayed then the fuel metering pump is defective, replace

FMP.

If fault code 047 is still displayed, then disconnect connection S1/B1. At

connector B1, Pin 5, check line1(green/red) through to FMP for short

circuit to (pin 10), if O.K. replace control unit

fuel pump (see values, pg 22). If resistance values O.K., then reconnect cable harness to the fuel pump. Disconnect connection S1/B1,

and measure the resistance value between pin 5 and pin 10. If O.K.,

replace control unit.

050 Too many no start attempts Control unit is locked after too many unsuccessful start attempts. Check

051 Faulty flame recognition If the resistance value of flame sensor is 1274 Ω after switching on (>

052 No start safety time exceeded No flame detected on start attempt.Check exhaust and combustion air

053 Flame cutout in boost mode Heater has started successfully the flame has extinguished.

054 Flame cutout in high mode Check exhaust and combustion air lines. Check fuel

055 Flame cutout in medium mode supply/measure fuel quantity, see values, pg 23. Check flame

056 Flame cutout in low mode sensor, diagram and values table on following pages, if O.K., replace

060 Open circuit - external temperature Temperature sensor detects a value beyond it's range sensor

061 Short circuit - external temperature Disconnect connection S1/B1 (main harness), measure resistance

fuel, glow plug, combustion air and exhaust flow. Use control unit

tester or fault code retrieval device to unlock control unit. Maximum 255

70°C), then the blower of the AIRTRONIC runs for approx. 15 minutes

to cool down. If resistance does not fall below the above value within

15 mins.., this is followed by fault shut down. Check flame sensor, diagrams and values, pg 23. If O.K., replace control unit.

lines. Check fuel supply/measure fuel quantity, see following pages.

Check glow pin (see fault code 020 and 021). Check flame sensor, diagram and values table on following pages, if O.K., replace control unit.

control unit.

Disconnect connection S1/B1 (main harness), measure resistance

value at connector B1, pins 6 & 12. Refer to the values table on pg 23.

If there is an open circuit, the ohmic value between the pins is > 7175

Ω. If the resistance value is O.K., then the control unit is defective.

value at connector B1, between pins 6 & 12., see values on pg 23. If

there is a short circuit, the ohmic value between the pins is < 486 Ω. If

fault 061 continues to be displayed, then the control unit is defective.

Page 22

22

Fault Code Fault Description Causes / Repair

062 Thermostat/Rheostat/Timer, open circuit Potentiometer values outside of range on Thermostat (switch)

063 Switch control - short circuit If a ventilating switch has been built in, disconnect and check function.

Fault recognition only works in heating mode. However, if

a short circuit already exists and the AIRTRONIC is subsequently switched on, ventilating mode will be active (no

fault code).

064 Open circuit - flame sensor Sensor is sensing value outside of range. Open Airtronic shell and

065 Short circuit - flame sensor Open Airtronic shell and remove control unit from casing. Disconnect

Check resistance between pins 6 and 7 at B1.

Resistance value for interruption between pins > 7175 Ω

Normal value: 1740 Ω - 2180 Ω (± 80 Ω )

If resistance value is O.K., replace control unit. If not replace thermostat/(switch).

If faulty, replace switch. Disconnect wires from thermostat or switch. If

fault code 062 is displayed, replace switch. If switch is O.K., check connection lines grey/red and brown/white for short-circuit. If O.K., reconnect wires to thermostat/switch. Disconnect connection B1. If fault 063

is still displayed, replace control unit. Resistance value for short circuit

between pins 6 and 7 < 486 Ω. Normal value: 1740 Ω - 2180 Ω (± 80

Ω).

remove control unit from casing. Disconnect green connector from control unit. At green connector measure resistance value at green wire

and brown/white wire. Check flame sensor, diagram and values on pg.

23. If flame sensor is O.K., replace control unit. Resistance value for

interruption > 7175 Ω

green connector from control unit. If fault 064 is displayed, replace

combination sensor (flame/temperature). If fault 065 is still displayed,

replace control unit. Resistance value for shot circuit < 486 Ω, see val-

ues on following pages.

071 Open circuit - overheat sensor Open Airtronic shell and remove control unit from casing. Disconnect

072 Short circuit - overheat sensor Open Airtronic shell and remove control unit from casing. Disconnect

090 Control unit defect Internal failure. Replace control unit.

091 External voltage disturbance Check vehicle charging system. Poor battery, battery charger, eliminate

092 Control unit defective (ROM fault) Internal failure. Replace control unit.

094 Control unit defective (EEPROM fault) Replace control unit

096 Internal temperature sensor defect Replace control unit or use external temperature sensor.

097 Control unit defective (power failure) Internal failure. Replace control unit.

blue and green connectors from control unit. Measure the resistance

value at blue connector(pin 1- blue wire) and at green connector pin 2

(brown/white wire). See values on following pages. If O.K., replace control unit. Resistance value for interruption > 223 Ω.

blue connector from control unit. If fault 071 displayed, replace combination sensor (flame/temperature). If fault 072 is still displayed, replace

control unit. Resistance value for short circuit < 183 Ω, see following

pages for values.

fault.

Page 23

23

Fuel Quantity Test

The fuel quantity should be tested if the heater has difficulty

starting or maintaining a flame. Check the following before

measuring fuel quantity.

• Check the filter in the fuel pump

• Check that the fuel lines are correctly routed

• Check that the fuel lines don’t leak.

• Check and tighten hose connections

• Does fuel withdrawal comply with the data in the technical

description.

Preparation

• Detach the fuel line from the AIRTRONIC.

• Insert the fuel line into a measuring glass (25 cm3).

• Switch the AIRTRONIC on and allow fuel system to bleed

out air for approx. 60 seconds.

• Switch the AIRTRONIC off and drain the measuring glass.

Measurement

• Switch the AIRTRONIC on

• The fuel is pumped approx. 60 seconds after switching on.

• Hold the fuel line in the measuring glass level with the

glow pin while fuel is being delivered.

• The pump will stop automatically after delivering fuel for 90

seconds. (110 seconds for AIRTRONIC 4)

• Once fuel pump stops, switch off the heater.

Evaluation

• Read out the quantity of fuel in measuring glass.

• Fuel quantity should be between

3.7 ml and 4.3 ml. on AIRTRONIC 2

5.4 ml and 6.3 ml. on AIRTRONIC 4

• If the fuel quantity is outside this range, check for and

remove any restriction in fuel system or replace the fuel

metering pump.

Values for Overheat sensor

Temperature (°C)

Temperature °C Resistance kΩ min. max.

-40 1597.0 1913.0

-20 458.80 533.40

0 154.70 175.50

20 59.30 65.84

40 25.02 28.04

60 11.56 13.16

80 5.782 6.678

100 3.095 3.623

120 1.757 2.081

140 1.050 1.256

160 0.6654 0.792

180 0.4253 0.5187

200 0.2857 0.3513

Values for Flame sensor

Note: The fuel quantity is not affected by voltage vari-

ances.

Temperature (°C)

Temperature °C Resistance kΩ min. max.

-40 825.90 859.60

0 980.00 1020.00

40 1132.30 1178.50

80 1282.80 1335.10

120 1431.50 1489.90

160 1578.30 1642.80

200 1723.40 1793.70

240 1866.60 1942.80

280 2008.10 2090.00

320 2147.70 2235.40

360 2285.50 2378.80

400 2421.50 2520.30

Page 24

24

Control values

Motor speed

Control stage AIRTRONIC D2 AIRTRONIC D4

• Power 4800 U/min ± 140 U/min 4400 U/min ± 130 U/min

• Fast 4000 U/min ± 120 U/min 3600 U/min ± 100 U/min

• Medium 2800 U/min ± 80 U/min 2800 U/min ± 80 U/min

• Slow 2000 U/min ± 60 U/min 1600 U/min ± 50 U/min

• Adjustment

- in circulation mode with temperature sensor, internal 600 U/min ± 20 U/min 600 U/min ± 20 U/min

- In fresh air mode with temperature sensor, external 0 U/min 0 U/min

• Ventilation 4800 U/min ± 140 U/min 3600 U/min ± 100 U/min

Resistance values

Component AIRTRONIC D2 -12V AIRTRONIC D2 -24V AIRTRONIC D4 -12V AIRTRONIC D4 -24V

Blower motor 0.6 Ω ± 0.1 Ω 2 Ω ± 0.4 Ω 0.4 Ω ± 0.1 Ω 1.5 Ω ± 0.3 Ω

Glow plug 0.5 Ω ± 0.05 Ω 2 Ω ± 0.2 Ω 0.5 Ω ± 0.05 Ω 2 Ω ± 0.2 Ω

Fuel metering pump 10 Ω ± 0.5 Ω 36 Ω ± 1.8 Ω 10 Ω ± 0.5 Ω 36 Ω ± 1.8 Ω

Operator control unit

set value potentiometer 1750 - 2080 Ω ± 80 Ω 1750 - 2080 Ω ± 80 Ω 1750 - 2080 Ω ± 80 Ω 1750 - 2080 Ω ± 80 Ω

Switching value

Component AIRTRONIC D2 / D4

Overheating sensor 160°C - 170°C

measured in the control

stage “power”and at a

clearance of 300 mm

from the hot air outlet

Exhaust value

AIRTRONIC D2 / D4

CO2 in exhaust in control stage “fast” 7.5 -12.5 Vol. %

Soot number as per Bacharach <6

300 mm

Page 25

Repair Instructions

25

Removing the cover

Removing and checking the control unit

Removing the glow pin

Removing the lining

Removing and checking the overheating and flame sensor

Installing the overheating and flame sensor

Dismantling the heat exchanger

Removing the combustion air blower

Removing the combustion chamber

Removing the cover form the AIRTRONIC

Unlock both seal plates, lift cover and pull to the front.

Note:

The cover must always be removed from the AIRTRONIC for

all repair stages. You may have to wait for the device to cool

down.

The cable harness can exit from the left or right of heater shell.

Caution: Remove power from the heater prior to any disas-

sembly by unplugging main connection or removing

main fuse.

Carefully check all seals and O-rings and replace

where necessary

Clean all parts before reassembly and check for

any signs of damage, replace where necessary

1.

2.

Cover

Seal Plates

Removing the control unit

Remove the AIRTRONIC cover

Unscrew fastening screw, press retaining brackets together, lift

out control unit. Unclip the lines from the holder of the control

unit (observe the positions of the lines). Remove the bushing

(lower part) from the outer case. Disconnect the control unit

from the controller. The control unit can now be removed.

Note:

When reassembling the control unit, ensure that the lines are

correctly clipped in the holder of the control unit, and that the

connectors are plugged into the control unit (non-interchangeable).

Fastening screw

Retaining brackets

Control unit

Bushing

Checking the control unit.

A test instrument is necessary to check the control unit in a dis-

mantled state. The test instrument is connected up to the PC

and with special software can display run times on certain

parts and give a visual of heater in operation.

Part number 22 1524 89 00 00

Adapter P/N: 22 1000 3186 00

Page 26

Heater Casing Disassembly

• remove the AIRTRONIC cover

• remove the control unit.

Disconnect the connector of the glow pin cable harness from

the controller.

Remove the rubber bush and use the special tool (SW 12) to

unscrew the glow pin.

The special tool is included with the glow pin.

Tighten torque of the glow pin : 6

+0.5

Nm

Note:

When the glow pin has been removed, check the lining of the

support in installed state for any contamination. The lining must

be replaced if the surface is covered with dirt.

26

Glow Pin

Connector of glow pin cable harness

Rubber bushing

Removing the lining

Pull the lining out of the support with pointed pliers. Blow out

the support with compressed air.

If necessary, carefully pierce with a wire.

The special tool has to be used to install the new lining. The

special tool is included with the lining. Push the lining onto the

special tool, watching the position of the recess. The recess

must be position at right angles (90°) to the axis of the heater

Push the tool with the lining carefully as far as it will go, ensuring that the bore (ø 2.7 mm) for the glow plug ventilation is

free. See illustration 1

Bore (Ø 2.7 mm) for glow pin ventilation

Lining

Special tool with lining

Position of recess

illustration 1

Page 27

Removing the overheating sensor / flame sensor

• Remove the AIRTRONIC cover

• Remove the control unit

Disconnect both connectors of the overheating / flame sensor

cable harness from the control unit.

Unlock clip from sensor.

Remove overheating/flame sensor.

Cable harness for overhear/flame sensor

clip

Checking the overheating / flame sensor

Observe a maximum temperature of 320° C for checking the

sensor

Overheating sensor

Check the overheating sensor with a digital multimeter. If the

resistance value is outside the set point indicated in the values,

on pg.22 then the sensor must be replaced

27

Flame Senor

Check the flame sensor with ta digital multimeter. If the resis-

tance value is outside the set point indicated by the values

table on pg 22, then the sensor must be replaced.

Installing the overheating / flame sensor

For AIRTRONIC D2 (Assembly without using purpose made

tool)

Mount the special tool on the sensor

Place the sensor on the heat exchanger using the special tool.

The special tool slides on the heat exchanger until the sensor

meets the collar (installation site of the sensor)

Lock the sensor in place and remove the purpose made tool. It

is then vital to check that the sensor sits flat on the heat

exchanger. If necessary use a mirror and lamp to aid correct

assembly.

Route the cable harness sensor along the clip eyelet to the

control unit and connect.

Connector blue

Connector green

NTC 50Ω = overheating sensor

PT=flame sensor

Special tool - only for AIRTRONIC D2

Overheating sensor / flame sensor

Special tool - only for AIRTRONIC D2

Overheating sensor / flame sensor

Clip

Overheat sensor / flame sensor

Clip

Cable harness -overheat/ flame sensor

Special tool - only necessary for the AIRTRONIC D2

Page 28

Dismantling the heat exchanger

Removing the combustion air blower

• remove the AIRTRONIC cover

• remove the control unit.

Remove the flange seal.

Take the AIRTRONIC out of the outer case (lower part).

Unscrew the 4 fastening screws from the combustion air blower.

Remove the combustion air blower and the seal from the heat

exchanger.

Important!

When reassembling the combustion air blower, a new seal is

always required.

Tighten the 4 fastening screws of the combustion air blower in

the series shown in the drawing, with a tightening torque of 4

+0.5

Nm.

28

Combustion Air blower

Heat Exchanger

Fastening screws

- Tighten the fastening screws in this sequence with a

tightening torque of 4

+0.5

Nm

Always replace the seal between combustion air

blower and heat exchanger

Page 29

Removing the combustion chamber

• remove the AIRTRONIC cover

Remove the flange seal.

Take the AIRTRONIC out of the outer case (lower part).

• remove control unit (

see previous pages)

• remove glow pin (see previous pages)

• remove combustion air blower (see previous pages)

Unscrew the fastening screws.

For AIRTRONIC D2 = 3 fastening screws

For AIRTRONIC D4 = 4 fastening screws

Pull the combustion chamber out to the front and remove the

seal from the heat exchanger.

Note!

When reassembling the combustion chamber, the seal, which

has been enclosed with the spare part, must always be

replaced.

Tighten the fastening screws of the combustion chamber with a

torque of 5

+0.5

Nm.

Note:

If the heat exchanger is being replaced, the over heat sensor /

flame sensor must be dismantled and mounted to the new heat

exchanger. (

see previous pages)

29

Combustion chamber

Heat Exchanger

Fastening screws

AIRTRONIC D2 = 3 fastening screws

AIRTRONIC D4 = 4 fastening screws

Combustion chamber

Seal between combustion chamber and heat exchanger -

must always be replaced.

Heat exchanger

Fastening screws

AIRTRONIC D2 = 3 fastening screws

AIRTRONIC D4 = 4 fastening screws

Page 30

AIRTRONIC D2/D4

Service Parts Diagram

12

30

18

17

16

19

11

2

10

4

3

6

1

5

9

7

14

8

13

15

20

Page 31

31

Parts List AIRTRONIC D2/D4

Ref. No. Description Part Number

1 Heat exchanger with burner (full assembly) 25 2069 99 06 00 • •

25 2113 99 06 00 • •

2 Heat exchanger 25 2069 06 01 00 • •

25 2113 06 01 00 • •

3 Burner 25 2069 10 01 00 • •

25 2113 10 01 00 • •

4 Gasket seal 25 2069 06 00 01 • •

25 2113 06 00 01 • •

5 Grommet 25 2069 06 00 02 • • • •

6 Fillister head bolt, M 5 x 12 103 10 348 • • • •

7 Blower motor 12V 25 2069 99 20 00 •

24V 25 2070 99 20 00 •

12V 25 2113 99 20 00 •

24V 25 2114 99 20 00 •

8 Fillister head bolt, M 5 x 25 103 10 462 • • • •

9 Gasket , blower 25 2069 01 00 03 • •

25 2113 01 00 03 • •

10 Control unit 22 5101 00 10 01 •

22 5102 00 10 01 •

22 5101 00 10 05 •

22 5102 00 10 03 •

11 Fillister head bolt, M 4 x 10q 103 10 349 • • • •

12 Upper casing 25 2069 01 06 00 • •

25 2113 01 00 01 • •

13 Lower casing 25 2069 01 01 00 • •

25 2113 01 01 00 • •

14 Grommet 25 2069 01 00 01 • • • •

15 Flange seal 25 2069 01 00 02 • • • •

16 Overheating sensor / Flame sensor 25 2069 01 02 00 • • • •

17 Clip 25 2069 01 02 02 • •

25 2113 01 02 02 • •

18 Glow pin with socket wrench 25 2069 01 03 00 • •

25 2070 01 03 00 • •

19 Glow pin strainer 25 2069 10 01 02 • • • •

20 Mounting plate with hardware and seal CA0 00 019 • • • •

Page 32

AIRTRONIC D2/D4

Service Parts Diagram

32

4

5

2

3

3

30

2a

42

43

29

1

22

21

22

27

22

31

24

9

10

25

20

32

26

11

6

7

8

34

41

35

19

13

28

10

18

18

12

17

23

44

16

39

37

38

17

33

36

38a

40

14

15

17

16

Page 33

33

Parts List AIRTRONIC D2/D4

Ref. No. Description Part Number

1 Safety screen ø 60 25 1688 80 06 00 • •

ø 75 25 1552 05 01 00 • •

2 Warm air deflector ø 60 20 1577 89 06 00 • •

2a ø 90 20 1609 80 09 00 • •

3 Clamp ø 50-70 10 2064 05 00 70 • •

ø 70-90 10 2064 07 00 90 • •

4 Flexible air hose ø 60 10 2114 31 01 00 • •

ø 90 10 2114 37 00 50 • •

5 Straight outlet hood ø 60 22 1000 01 00 16 • •

ø 90 22 1000 01 00 19 • •

6 Main harness CA1 60 201 • • • •

• short harness CA1 60 205 • • • •

7 Cable ties CA1 00 005 • • • •

8 Air intake ø25 mm 360 00 006 • • • •

9 Flexible exhaust ø24 mm 25 1774 80 01 00 • • • •

10 Fuel hose 3.5 mm 360 75 300 • • • •

11 Plastic fuel line 1.5 mm 090 31 118 • • • •

12 Fuel metering pump 12V 22 4519 01 00 00 • •

24V 22 4518 01 00 00 • •

13 Clamp for fuel metering pump 22 1000 50 03 00 • • • •

14 Plastic fuel line 2 mm 090 31 125 • • • •

15 Angle bracket CA0 10 105 • • • •

16 Fuel hose 5 mm 360 75 350 • • • •

17 Clamp 11 mm 10 2063 01 10 98 • • • •

18 Clamp 9 mm 10 2063 00 90 98 • • • •

19 End sleeve with cross bar 25 1729 89 00 02 • • • •

20 Grommet 20 1280 09 01 03 • • • •

21 Intake hose clamp ø 20-32 10 2064 02 00 32 • • • •

22 Clamp 26 mm 152 61 102 • • • •

23 Fuel screen 20 1280 09 01 03 • • • •

24 Blade fuse 20 amp CA1 07 005 • •

10 amp CA1 07 006 • •

25 Plug connector 22 1000 31 80 00 • • • •

26 Housing 22 1000 31 81 00 • • • •

*27 Muffler 25 1864 81 01 00 • • • •

28 Connectors for fuel metering pump 22 1000 31 87 00 • • • •

*29 90° Air outlet hood ø 60 22 1000 01 00 20 • •

ø 75 22 1000 01 00 22 • •

ø 90 22 1000 01 00 23 • •

*30 90° Bend ø 60 25 1688 89 00 01 • •

ø 75 25 1482 89 00 05 • •

31 Fuse holder with terminals CA1 07 001 • • • •

32 Terminals CA1 90 043 • • • •

33 3/8’ Ring terminals 10-12 G CA1 90 014 • • • •

*34 7 day timer with thermostat 12V CA1 00 210 • •

24V CA1 00 211 • •

35 Thermostat 12V 301 00 154 • •

24V 301 00 153 • •

Page 34

34

Parts List AIRTRONIC D2 / D4

Ref. No. Description Part Number

*36 Operating switch (rotary) 12V 25 1895 71 00 00 • •

24V 25 1896 71 00 00 • •

37 Standard fuel pick up pipe 2 mm CA0 12 056 • • • •

* 38 Fuel pick up pipe (Compression fitting type) CA0 12 042 • • • •

* 38a Compression fittings 1/4” NPT CA0 12 044 • • • •

3/8” NPT CA0 00 031 • • • •

1/2” NPT CA0 12 005 • • • •

*39 Rubber hose 5 mm CA3 00 103 • • • •

40 C-clamp 10 mm 152 00 139 • • • •

41 C-clamp 25 mm 152 10 048 • • • •

42 C-clamp 28 mm 152 10 051 • • • •

43 End-sleeve 24 mm 25 1482 80 00 01 • • • •

Operators tape (not shown) 625 101 0102 • • • •

AIRTRONIC D2/D4 manual (not shown) 610 103 0901 • • • •

Operators guide (not shown) 615 103 0901 • • • •

Fault code retrieval device CA1 05 020 • • • •

* indicates optional features

44 Bezel kit for 7 day timer 25 1482 70 01 00 • • • •

Page 35

1st. Printing - November 2001

Printed in Canada

P/N: 610-103-0901

A member of the Worldwide Eberspächer Group of Companies

Espar Products, Inc.

6435 Kestrel Road

Mississauga, Ontario

Canada L5T 1Z8

Canada (Tel): 905-670-0960

800-668-5676

Fax: 905-670-0728

U.S. (Tel): 800-387-4800

Loading...

Loading...