Page 1

Glass Thermovec

Installation and Maintenance Manual

Page 2

CONTENTS

1.Preface

2.Safety precautions

2.1 Mark Notes

2.2 Icon Notes

2.3 Warning

2.4 Attention

3 Specifications

3.1 Parameter list

3.2 Working condition

3.3 Overall dimensions

3.4 The working principle of units

3.5 Unit characteristics

4 Installation

4.1 Installation precautions

4.2 Installation note places

4.3 Install note schemes

4.4 Conduit connections

5 Usage

5.1 Function description of wire controller

5.2 Usage of wire controller

6 Maintenance and Overhaul

6.1 Maintenance

6.2 Common fault and the solving methods

7 Appendix

7.1 Net control diagram

7.2 PCB I/O port

7.3 Wire Connection

Page 3

1. Preface

Thank you for choosing Earth Save Products Limited’s Glass Thermovec. Please read this installation

and maintenance manual carefully before attempting to install, use or maintain your Thermovec.

Your Thermovec must be installed by a suitably qualified and experienced technician to ensure that

it is installed safely and correct and also to comply with warranty requirements. Likewise, in the

unlikely event of a repair being necessary, it should only be carried out by a qualified technician

using genuine spare parts supplied by Earth Save Products Limited. Your Thermovec must be

installed, used and maintained in accordance with these instructions to ensure safety and comply

with warranty requirements.

Once your Thermovec is installed, these instructions should be kept in a safe place for reference. A

replacement can be obtained from Earth Save Products Limited.

V1.0

1 of 16

Page 4

Safety Precautions

Symbol

Meaning

Caution

Compulsory

Prohibited

Installation

Installation must be carried out by a qualified technician due to risk of leakage,

electrical shock or fire.

The Thermovec must be correctly earthed due to risk of electrical shock and

installed to comply will all electrical regulations

Ensure that the wall on which the Thermovec is to be mounted is structurally

sound and can take the weight of the unit

The Thermovec must be connected to the power supply via a fused spur with a

correctly rated fuse

If you need your Thermovec moved, a qualified technician must be engaged to do

so

Using the Thermovec

Do not put fingers or any object into any opening in the Thermovec

If your Thermovec emits unusual odours or sounds, turn the unit off immediately

and seek advice from your installer or ESP Ltd

Switch off your Thermovec before cleaning the case or the filters

Switch off your Thermovec before carrying out any maintenance

Do not modify or change any of the internal devices without consulting ESP Ltd.

To ensure the safe operation of your Thermovec please note the following:

Symbols used:

General Precautions:

Some basic safety rules should be followed when using any product that uses electricity and water,

such as:

Do not touch the appliance with wet skin.

Turn off the unit before cleaning it.

Do not damage or modify the power supply cord.

Do not place anything on the Thermovec nor climb upon it.

Ensure that all packing materials are disposed of safely and/or recycled.

V1.0

2 of 16

Page 5

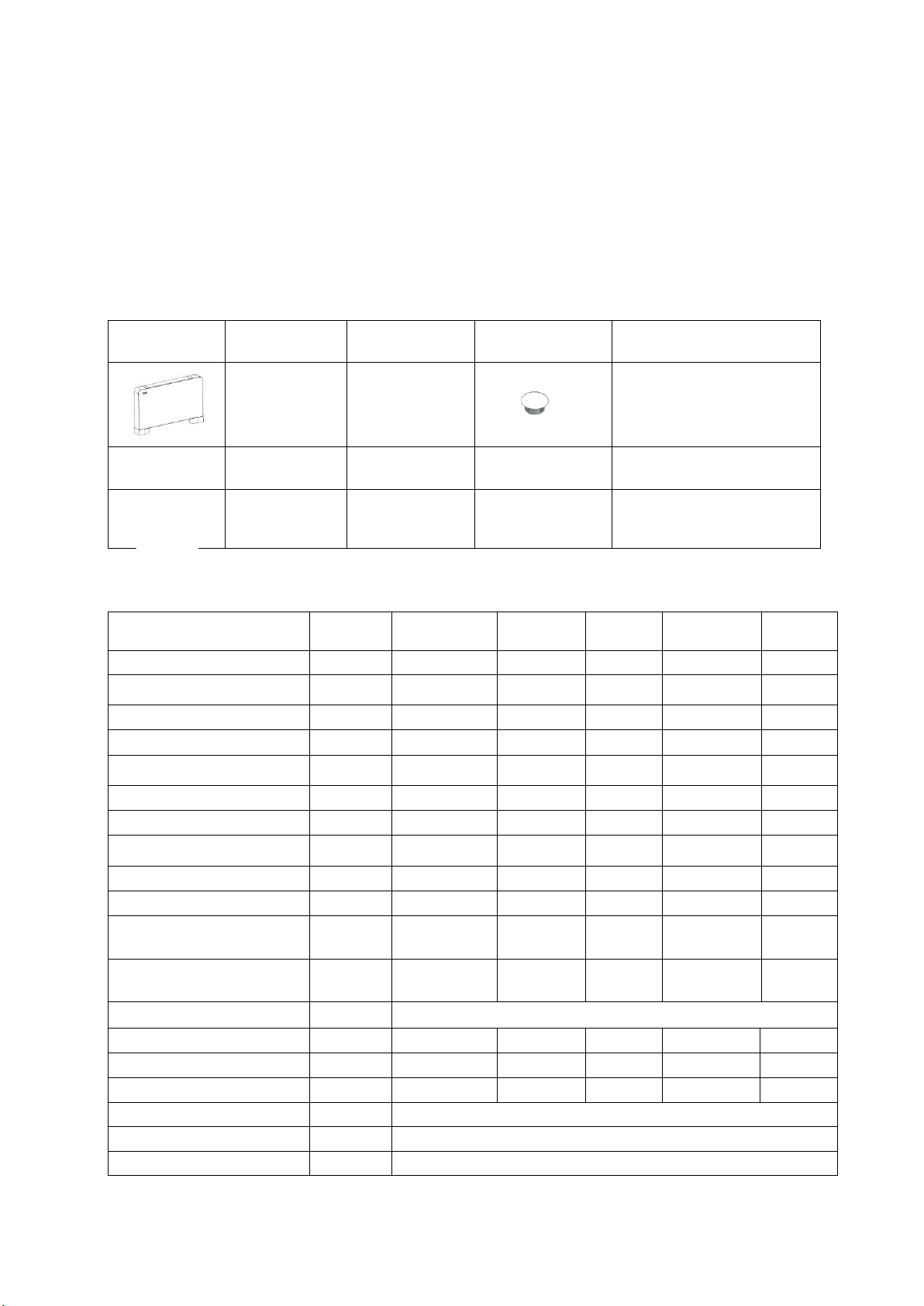

This appliance is not intended for use by persons (including children) with reduced physical,

Thermovec

Installation

Template

Manual

Screw Cap

Remote

X 2

Mounting

Brackets

Wall Plugs

Screws

Condensate

Drain Pipe

Feet

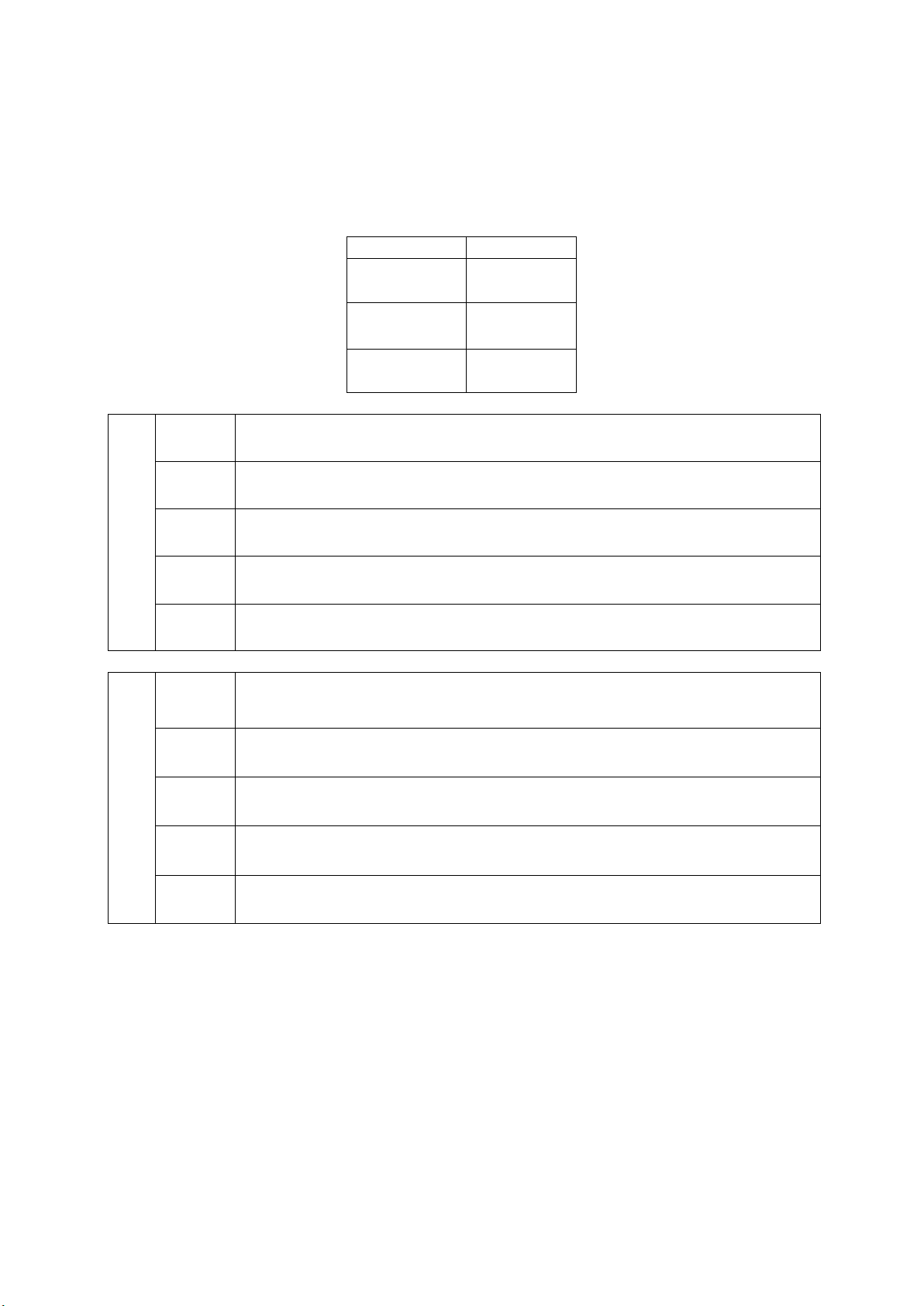

Unit Model

Units

ESP VFC

2.55G

ESP VFC

3.95G

ESP VFC

5.75G

ESP VFC

7.2G

ESP VFC

9.4G

Heating Capacity①

W

2550

3950

5750

7200

9400

Water flow rate①

m3/h

0.22

0.34

0.49

0.62

0.81

Pressure drop①

kPa

10.6

12.2

26.2

27.5

28.2

Heating capacity②

W

1350

2500

3350

4300

5200

Water flow rate②

m3/h

0.23

0.43

0.58

0.74

0.89

Pressure drop②

kPa

10.8

13.1

27.5

27.9

28.5

Cooling capacity③

W

1000

1900

2500

3500

4350

Water flow rate③

m3/h

0.17

0.33

0.43

0.60

0.75

Pressure drop③

kPa

11.1

13.3

27.7

28.3

30.6

Air volume

m3/h

160

320

460

580

650

Noise pressure at max air

flow

dB(A)

30

32

37

39

41

Noise pressure at min air

flow

dB(A)

24

27

28

28

30

Power Supply

V/Hz

220-240V~/50Hz

Power Input

W

15

20

23

25

32

Water In/Out tapping size

inch

3/4

3/4

3/4

3/4

3/4

Condensate Drain size

mm

16

16

16

16

16

Net Dimensions(L/W/H)

mm

See below

Shipping Dimensions(L/W/H)

mm

See package label

Net weight

kg

See nameplate

sensory or mental capabilities, or lack of experience and knowledge, unless they have been

given supervision or instruction concerning use of the appliance by a person responsible for

their safety.

Specifications.

Packing List.

Parameters

V1.0

3 of 16

Page 6

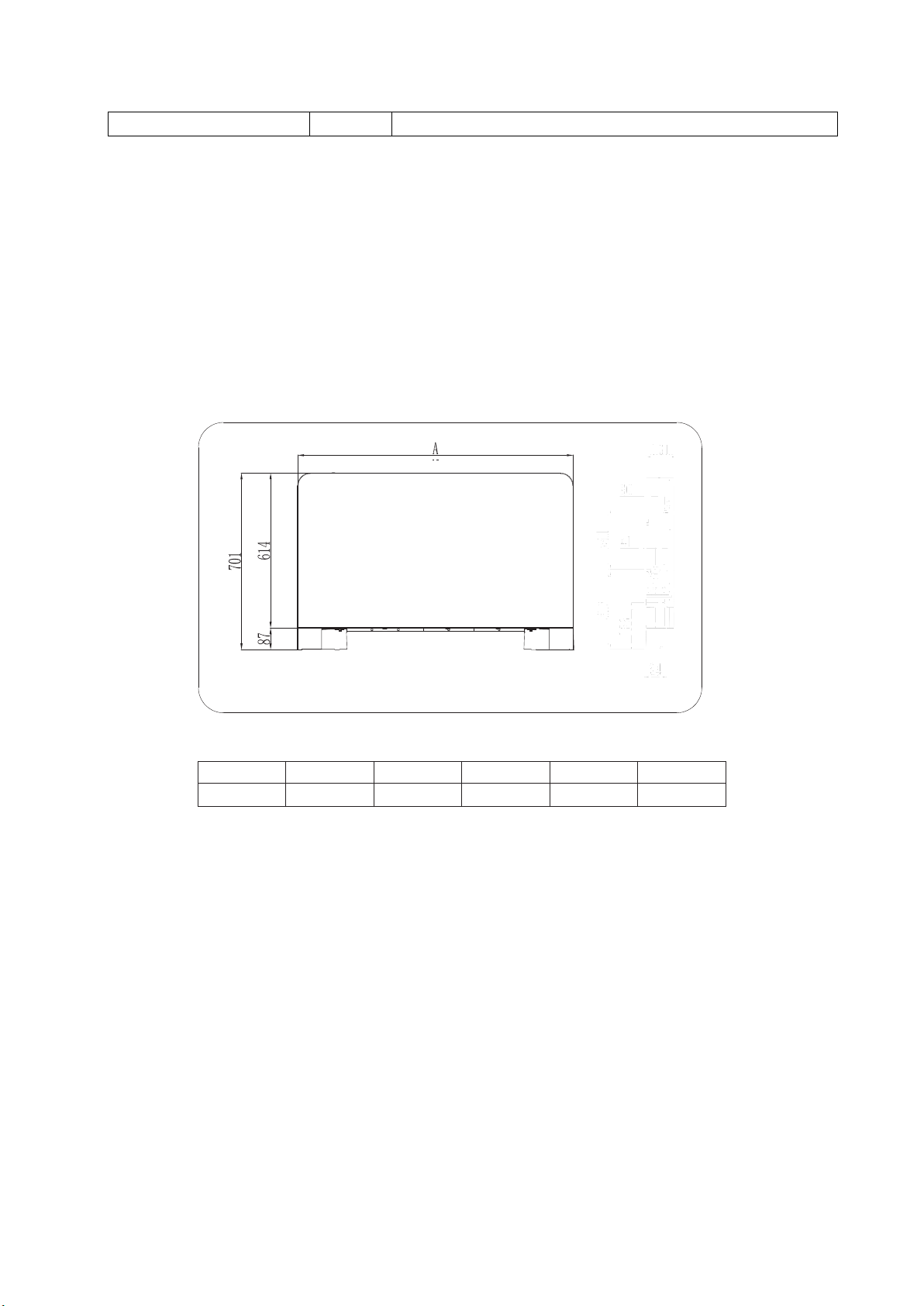

Gross weight

kg

See package label

Notes

Unit Model

VFC2.55G

VFC 3.95G

VFC5.75G

VFC 7.2G

VFC 9. 4G

A

695

895

1095

1295

1495

1. Supply flow temperature of 70°C, return temperature of 60°C and 20°C ambient air temperature.

2. Supply flow temperature of 50°C, return temperature of 45°C and 20°C ambient air temperature.

3. Supply flow temperature of 7°C, return temperature of 13°C and 27°C ambient air temperature.

4.Noise level is measured in the standard anechoic chamber<17dB(A)

5. Above data is subject to change without prior notification.

Working conditions

Heating ambient temperature: 5-29℃, flow water temperature: 35-70℃.

Cooling ambient temperature: 9-35℃, return water temperature: 5-20℃.

Dimensions

3.3.1 Product model: VFC 2.55/3.95/5.75/7.2/9.4G

V1.0

4 of 16

Page 7

Heated or Cooled air is

distributed evenly

How it works

Ambient air is drawn in

Return

Flow

The Thermovec is supplied by hot or cold water from your ASHP. It draws air in from the room in

which it is installed, blows that air over a heat exchanger and exhausts the air into that room. The

temperature of the room is controlled by the Thermovec and the water flow is controlled by a

three-way valve. The air is distributed across the room in a much more efficient manner than a

traditional radiator.

Note: if the Thermovec is used for cooling, the condensate drain must be connected.

Unit characteristics:

Whisper Technology

The use of a cross-flow fan combined with wind-guiding technology make the

Thermovec quiet as a whisper.

Slimline

The Thermovec is only 130mm thick – thinner than traditional radiators of similar

output saving space.

Elegant Design

The rounded and clean outline ensures that the Thermovec will blend into any room.

Easy to use

With a simplified control menu, the Thermovec can be controlled via the touchscreen panel or the remote control. Note: if you are using a high-temperature

source, the Thermovec should be controlled with the remote control because the

glass whole unit can achieve a temperature of up to 70°C to the touch.

Installation

Installation precautions

To ensures that the installation is performed correctly and safely and to conform to the warranty

conditions the Thermovec must be installed by a suitably qualified technician and in accordance

with this manual.

The electrical aspects of the installation must be carried out in accordance with current regulations.

The Thermovec must be correctly earthed.

The unit must be installed in a position that allows routine maintenance such as cleaning the filter.

V1.0

5 of 16

Page 8

22mm

22mm

90mm

140 mm

400mm

Positioning the unit

Avoid installing the unit in proximity to other heat sources, in direct sunlight, in damp areas

or where it is likely to come into contact with water. Areas contaminated with combustible

fumes and high frequency radio signals should also be avoided.

Ensure that:

The wall on which the unit is to be installed is strong enough to support the weight.

You are not going to drill through wires, pipes or anything else important when

securing the brackets.

The mounting wall is perfectly flat.

There is nothing to interfere with the airflow around the Thermovec (see below).

If using the Thermovec for cooling, the condensate drain can be routed

satisfactorily.

Minimum Clearances:

Installation

Side opening

Lift the screw cap (A) and undo the screw (B) beneath it. Move the side panel (c) slightly and lift it

out.

6 of 16

V1.0

Page 9

First, lay the unit down

carefully to protect both

the Thermovec and the

surface on which it is

placed. Line up both

feet with the four screw

holes for each foot.

Next, using the 8

screws provided

attach the feet

securely, taking care

not to over tighten

the screws.

Mounting the Thermovec

Using the paper template, trace the position of the bracket holes.

Thermovec Feet.

If you are going to use the Thermovec feet, they must be attached before installation as shown in

the following two diagrams.

V1.0

7 of 16

Page 10

Fix the two brackets to the wall using suitable fixings: the supplied wall plugs are only suitable for

Flow

Return

The distribution pipework should be hot

flushed and pressure tested before the

Thermovec is connected. The distribution

pipework should be designed to reduce

resistance and automatic air bleed valve

incorporated at key points. The flow and

return should then be connected to the 3way valve as shown (Thermovec shown

from the back of the unit)

If the Thermovec is to be used for cooling, a

condensate drain pipe must be fitted to take

resulting condensate away from the unit and

dispose of it safely. The condensate will drip from

aperture A, collect in tray B and the pipe should be

connected at C. If the pipe is to be connected to a

drain, a waterless trap should be used.

certain types of walls. Do not tighten until final adjustment to ‘level’ has been made and checked.

4.Installation

Connecting the Pipework.

V1.0

8 of 16

Page 11

Bleeding the Thermovec

Power on/off. Also used to cancel an action or to return to the previous menu

Air Vent or Time. Used to display time settings, set the timer and to turn the air vent on

or off.

Fan Speed. Used to set the fan speed.

Up. Used to increase a value or to go up a menu level.

Down. Used to decrease a value or to go down a menu level.

The Thermovec must be bled before power is

applied i.e. before it is switched on. Use a

screwdriver to open the bleed valve on the

side of the Thermovec until all air is expelled

from the unit then close the valve again taking

care not to over-tighten it. It is

recommended that each Thermovec be bled

again one it has been running for a few hours.

If the unit is powered-up before it is bled, the

3-way valve will have closed and it must be

opened manually.

Using the Thermovec

The Control Panel – what the symbol mean

V1.0

9 of 16

Page 12

Mode. Used to toggle between modes.

Pressing the on/off button

for 0.5Secs will power the

unit on/off.

Press to

toggle between

modes.

Press to

toggle between

modes

In Auto, Heating or Cooling modes,

the target temperature will show for

5 secs after the mode is selected.

The display will then revert to

ambient temp.

In Dehumidifying and Ventilation

modes, the display will only show the

ambient temperature.

Changing the Target Temperature

To Change the target temperature, simply press the up or down buttons once, then use the up

or down buttons to select the required temperature. Once you have done so, the display will

return to the default display and save the target temperature after 5 Secs:

Note: If no button has been pressed for 1 min, the control panel will be hidden. Simply touch the

control panel area to display the controls.

Using the Control Panel

Turning the Thermovec on/Off

10 of 16

V1.0

Page 13

After 5 secs, the changed

setting will be saved and the

display will revert to the

default.

To Switch on Boost mode:

Press and hold

for 5 secs

Press to revert

to previously set fan

speed

Please note that the fan speed in Auto and Dehumidifying modes will be set automatically

and cannot be altered.

Changing the Fan Speed

To change the fan speed, simply press the fan speed button to toggle between 3 fan speed or

‘auto’. For ‘boost mode’, press and hold the fan speed button for 5 seconds. In boost mode, press

the fan speed button once to revert to the previously set fan speed:

11 of 16

V1.0

Page 14

Setting the Sleep Mode

From the main display

press to start

setting sleep mode

Use and to

select a value from 1 to

11 (hours before

switch-off)

Press again to set the ‘power on’

delay time

Use and to

select a value from 1

to 11 (hours before

switch-on)

Press again to enter sleep

mode

Press one last time to save

and exit

Note, if no button is pressed for 5 secs at any time during the setting process, whatever

settings have been made will be saved and the display will return to the default display

Sleep mode can be used to turn the Thermovec off after a period from 1-11 hours then back on

again after a period of 1-11 hours:

V1.0

12 of 16

Page 15

Checking the Coil temperature

After 3 Secs, the

display will revert to

the default.

To check the coil temperature, press the and buttons simultaneously. This will display the

coil temperature for 3 secs before the display reverts to the default display. This isfor information

only and cannot be changed.

Turning the Air Vent on/off.

To turn the air vent on/off simply press the button:

V1.0

13 of 16

Page 16

Locking the Control Panel

Code

Fault

Cause

Remedy

P4

Ambient Temperature Sensor

Ambient Temperature Sensor

failed or open circuit.

Check or replace

sensor.

P5

Coil Temperature Sensor

Coil Temperature Sensor failed

or open circuit

Check or replace

sensor.

E0

Motor Feedback Signal

Motor or signal wire failure.

Check motor and

signal wire. Replace as

necessary

E8

Communications

Communication fault.

Check the control

wires.

Press and hold for 5 secs to lock/unlock

Symbol signifies that

control panel is locked

Press or to

toggle between fault

codes

Press to toggle

between fault codes and

the default display.

Symbol indicates a

fault

To lock the control panel, press and hold the power button for 5 seconds. Repeat to unlock the

panel:

Fault Display

In the unlikely event that your Thermovec develops a fault, it will be displayed as a code. Pressing

the up or down buttons will toggle through the codes and the power button will return you to the

main display:

Fault Codes

V1.0

14 of 16

Page 17

Cleaning and Maintenance.

Filter replacement order

When removing the filters, treat the catches

gently as they do not require much pressure and

the lugs can be broken. To replace, locate

carefully in the square apertures.

There is very little to be done to maintain the Thermovec. Please turn the unit off before cleaning it

and use a clean, damp cloth but no abrasives or solvents as these could damage the finish. The

three filters underneath the unit should be cleaned periodically by removing them, rinsing them

under clean running water, drying and replacing them:

Any repairs should be undertaken by qualified technicians using genuine spare parts supplied by

Earth Save Products Ltd. Should a leak develop, the unit should be switched off and advice sought

from your installer or the ESP Ltd Technical Department.

Correct Disposal of this product

This product should not be disposed of with other household waste but recycled in accordance with

current Government policy.

V1.0

15 of 16

Page 18

Wiring Details

Thermovecs can be connected together and incorporated into a building management system:

PCB I/O Ports

V1.0

16 of 16

Loading...

Loading...