Page 1

1 of 41

V 1.0

www.esavep.com PASRW060-D-BP

ESP VARIMAX 20 ASHP

Installation and

Operation Manual

Page 2

2 of 41

V 1.0

www.esavep.com PASRW060-D-BP

WARNING !

READ THIS BEFORE

INSTALLING

THE UNIT.

The installation of all un-vented water heating systems above 15 litres

MUST comply with local area Building Regulations. It is a legal

requirement that the local Building Control Officer be notified of any

proposed installation.

UK regulations require an appropriately sized expansion vessel

(internal or external) to be incorporated, safety devices to prevent the

stored water exceeding 100°C, and pipe work to convey discharged hot

water safely away from the safety devices.

Furthermore, the installation must be carried out by an engineer who

has successfully completed a recognised course in the installation of

un-vented heating systems such as CITB. Failure to fit the unit

correctly and in accordance with regulations may affect its safety,

efficiency and WILL invalidate any guarantee.

THE UNIT MUST BE INSTALLED, COMMISSIONED AND MAINTAINED BY A

COMPETENT INSTALLER IN ACCORDANCE WITH BUILDING REGULATION

G3 (ENGLAND AND WALES), TECHNICAL STANDARD P3 (SCOTLAND) OR

BUILDING REGULATION P5 (NORTHERN IRELAND) AND THE WATER

FITTING REGULATIONS (ENGLAND AND WALES) OR WATER BYELAWS

(SCOTLAND). FOLLOWING INSTALLATION AND COMMISSIONING, THE

OPERATION OF THE UNIT SHOULD BE EXPLAINED TO THE USER AND

THESE INSTRUCTIONS LEFT WITH THEM FOR FUTURE REFERENCE.

Page 3

3 of 41

V 1.0

www.esavep.com PASRW060-D-BP

Contents:

1.0 Preface

1.1 Features of the Varimax 20 ASHP

2.0 Safety Precautions

3.0 Varimax 20 Specifications

3.1 Appearance

3.2 Dimensions

4.0 Choosing the right heat pump

4.1 Heat Load Calculation

4.2 Varimax 20 Output Statistics

4.3 Emitter systems

5.0 Installation

5.1 Where to use and Where to Site the unit

5.2 Location of the Unit

5.3 Transporting the Unit

5.4 Plumbing Considerations

6.0 Hydraulic Connection

6.1 Expansion vessels

6.2 Flow Switch

6.3 Flexi Hoses

6.4 Automatic bleed valves

6.5 Transit Bung

6.6 In-Line Filter

6.7 Flow Setter

6.8 TRVs

6.9 Distribution Water Pump

6.10 Glycol

7.0 Electrical Connection

7.1 Warning Notes

7.2 Before You Start

7.3 MCB

7.4 Isolation Switch

7.5 Cable Routing

Page 4

4 of 41

V 1.0

www.esavep.com PASRW060-D-BP

7.6 Wiring-in The Unit

8.0 Unit Specifications

9.0 Commissioning

9.1 Pre-Start Checks

9.2 Switching on the Unit

10.0 UNIT CONTROLLER

10.1 main Interface

10.2 Basic Operation

10.3 Start-UP and Shut-Down

10.4 Setting the Target Temperature

10.5 Using the Premium User Interface

10.6 Setting the Time

10.7 Setting the Timers

10.8 Cancelling the Timers

10.9 Checking the Status of the ASHP

10.10 Locking the Display

10.11 Fault Displays

11.0 Maintenance

11.1 Essential Checks

11.2 Advisory Checks

12.0 Trouble Shooting

12.1 Error Codes

12.2 Simple Faultfinding

13.0 Wiring Diagram

14.0 Guarantee

14.1 Guarantee Terms

15.0 Environmental Information

16.0 Weather Compensation

17.0 Performance

18.0 Parameter List

Page 5

5 of 41

V 1.0

www.esavep.com PASRW060-D-BP

1.0 Preface:

This manual includes important information about the installation and

maintenance of the ESP Varimax 20 inverter driven air source heat pump

(ASHP) unit. Please read this manual carefully before installing or carrying

out maintenance works on the unit. Please note that, failure to observe the

provisions in this manual will invalidate any warranty on the unit and may

lead to loss and/or damage to people and/or property for which ESP will not

be liable. All ESP ASHPs are covered by the warranty contained in the ESP

Terms and conditions of Business a copy of which will have been provided to

you prior to your purchase.

The Varimax 20 must only be installed by suitably qualified personnel.

The Varimax 20 air source water heat pump is a high efficiency, energy

saving and environmentally friendly unit that should be used primarily for

space heating. It can work with any kind of heat emitter scheme such as

under floor heating, the ESP Thermovec fan coil unit or traditional radiators.

The Varimax 20 can also be used to generate domestic hot water (DHW) for

sanitary purpose although ESP strongly recommend that space heating is

achieved with an ASHP and the DHW requirement be met by an ESP Ecocent

unit. PLEASE NOTE that operating conditions, such as ambient air

temperature, required water flow temperatures, target room temperatures

and humidity will influence the operating efficiency of the unit.

1.1 Features of the Varimax 20 ASHP:

1. Advanced controls

All user set parameters can be controlled via A PC based

controller that can control several units simultaneously.

2. Appearance

The Varimax 20 is designed to be attractive and discrete.

3. Compact design

Our Varimax 20 units have a built-in water pump and are

stand-alone units (monobloc) to make installation simple and quick.

4. Quiet running

Page 6

6 of 41

V 1.0

www.esavep.com PASRW060-D-BP

High quality and efficient compressors, fans, water pumps and sound

insulation combine to ensure a very low running noise of 59 dBa.

5. Efficiency

The Varimax20 unit is equipped with a highly efficient heat exchanger

to deliver exceptional efficiency.

6. Wide operating temperature capability

The Varimax I unit is designed to work effectively and efficiently

down to -10°C ambient air temperature.

2.0 SAFETY PRECAUTIONS

It is important to take the following precautions when planning your

installation, installing and operating the Varimax 20: Failure to observe these

points could lead to loss or damage to property and/or injury/death of

installers/operators and will invalidate the warranty.

The unit must only be installed, moved and/or repaired by a suitably

qualified and experienced engineer. If you are in doubt about who is

qualified to carry out such works on the Varimax 20 unit, please call

ESP.

The Unit MUST be properly earthed.

Do not put fingers or other objects into the grill covering the fan and

make sure that children do not play close to the unit. The grills are

there for a good reason.

If you hear abnormal noises, or smell strange odours, coming from

the unit, switch it off immediately and call your installer or ESP.

Do NOT install the unit close to any gas fired appliance, heater or fire.

Ensure that the base on which the unit is secured is both large and

strong enough to take the weight of the unit comfortably and will not

subside. The base should also be at least 150mm above the

surrounding ground level and you should check the base periodically

to ensure that there is no subsidence of the base or the immediate

surrounds. In areas prone to flooding, care should be taken to

Page 7

7 of 41

V 1.0

www.esavep.com PASRW060-D-BP

ensure that the unit is elevated to avoid flood damage.

Ensure that you use a suitably rated circuit breaker. If in doubt, have

your electrician call ESP Technical Support.

Switch off the power before carrying out any cleaning and/or

maintenance of the unit.

3.0 VARIMAX 20 SPECIFICATIONS

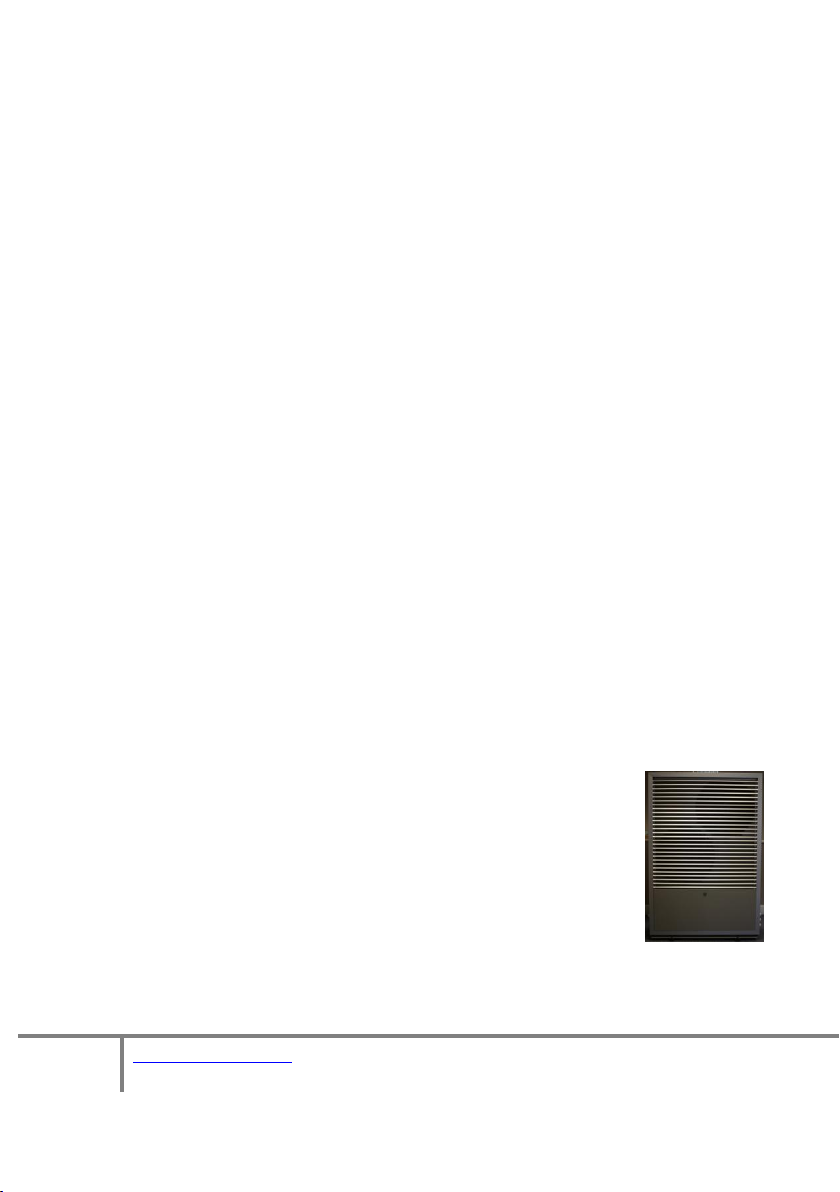

3.1 APPEARANCE

The Varimax 20 is designed to be stylish but

unobtrusive. It can be installed with or

without the front louvre covering the fans.

The cabinet is weather resistant and designed

to look good throughout the life of the unit.

Page 8

8 of 41

V 1.0

www.esavep.com PASRW060-D-BP

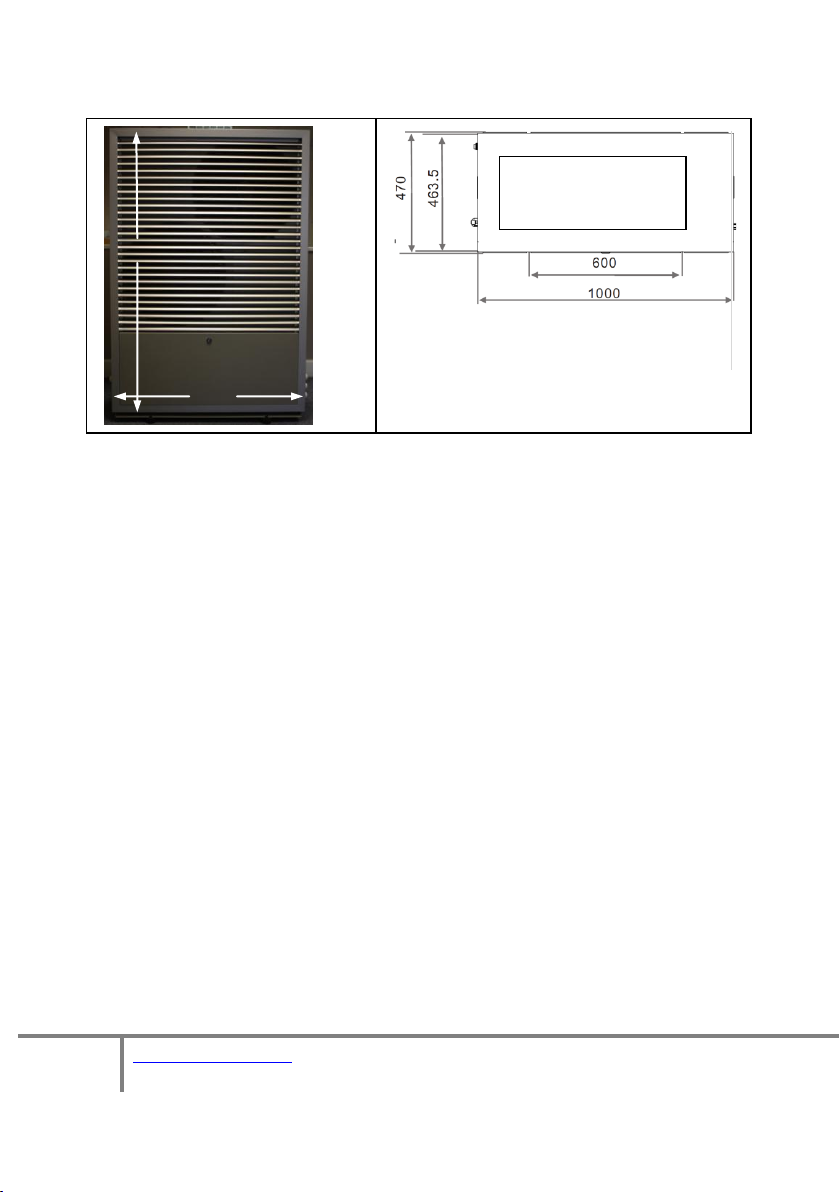

1475

1000

Unit viewed from the

top

3.2 Dimensions

4.0 Choosing the right heat pump

4.1 Heat Load Calculation

Based on the local climatic conditions, construction features and insulation

levels, your system designer will calculate the heat load of your building and,

therefore, the appropriate unit size for your building. ESP can provide a

heat load calculation that conforms to MIS 3005. For new builds, meeting

the requirements of current building regulations for insulation (or better)

will help ensure that the heat load of the dwelling is kept to a minimum. For

existing buildings, insulation should be improved as much as possible to

minimise the heat load.

4.2 Varimax Output Statistics

The Varimax 20 has been tested according to BS EN 14511, EN 14825 and

12102. Additionally it has been tested in accordance with EU Directive

813/2013 to prove the ErP rating. The choice of ASHP for your purposes

should be based upon the output proven by these tests and the conditions

stated in MIS 3005. Performance graphs are included in section 18.

Make sure that your supplier/installer is familiar with the most recent

requirements of MIS 3005.

Page 9

9 of 41

V 1.0

www.esavep.com PASRW060-D-BP

The Varimax 20 unit is MCS Certified and, if you wish to take advantage of

certain funding that may be available, your unit MUST BE INSTALLED BY AN

MCS ACCREDITED INSTALLER – please consult your supplier or ESP should

you require further clarification.

4.3 Emitter system.

The Heat pump must be matched to a suitable emitter system. The

Microgeneration Certification Scheme website offers guidance on pipe

spacing for UFH systems together with sizing consideration for fan coil units

such as the ESP Thermovec and traditional wet radiators can be found.

Please note that, in the case of an UFH system, the floor coverings must be

chosen very carefully to ensure that the heat is not ‘trapped’ in the floor by

laying the wrong floor covering for the individual room heat load. Again,

guidance is available from the MCS website.

5.0 Installation

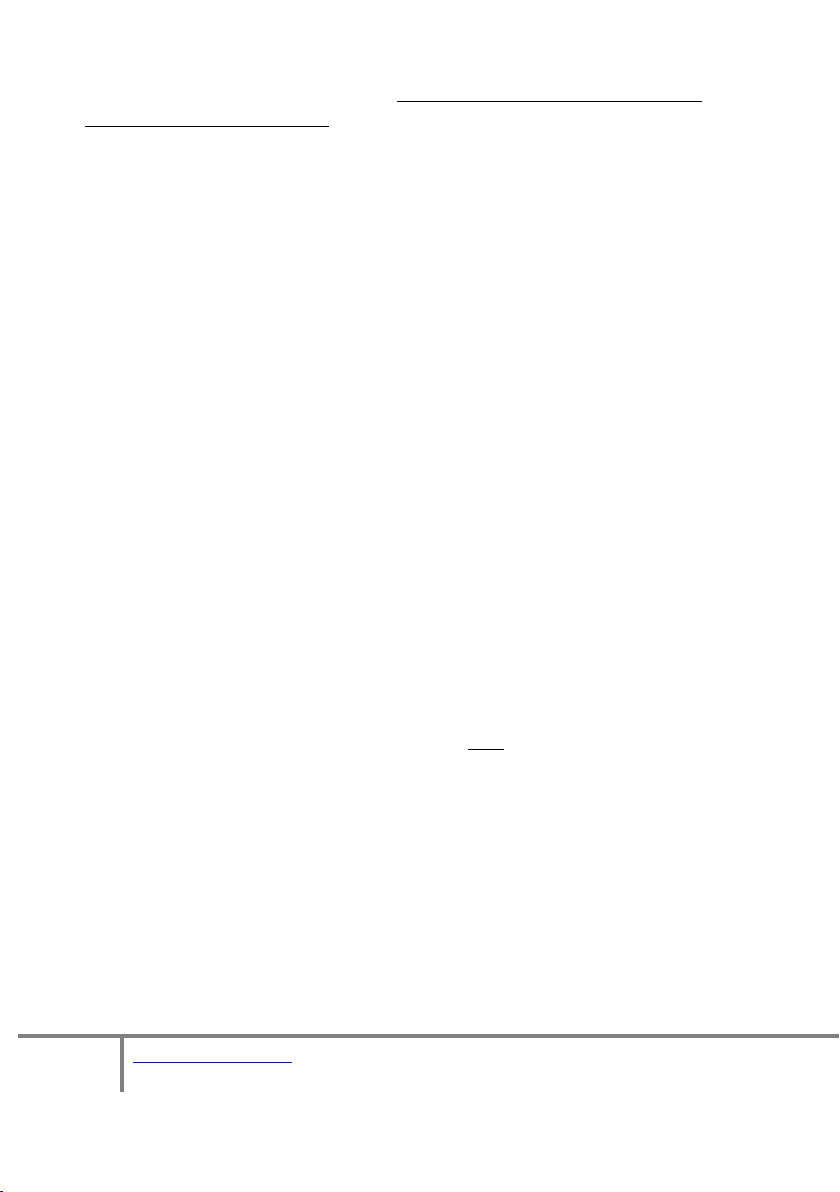

5.1 Where to use and Where to Site the unit

The Varimax 20 can be used for domestic or commercial premises and

consideration should be given to the following when choosing an installation

site:

The unit must be installed in an outdoor location on a solid base

that can carry the weight of the unit. This can be on the ground, a

roof or balcony. If it is to be installed on a roof or balcony, a steel

frame must be used. Please contact ESP for further details.

The site must be well ventilated but NOT windy.

The site should be away from sources of high heat.

The unit must be sited away from any obstacles to the rear and

sides. There must be enough space around the unit for plumbing and

maintenance works as detailed in the diagram below. Care should

also be given to ensure that any overhead obstacles cannot create a

re-circulating air flow (where air exhausted from the ASHP is sucked

back in).

Further information is included in the section below entitled

Page 10

10 of 41

V 1.0

www.esavep.com PASRW060-D-BP

“Location of Unit”.

Clearances:

A. >500mm B. >1500mm

C. > 1000mm D. > 500mm

The unit generates condensate and this should be piped away

from the unit and into a suitable drain to prevent ice forming on the

area around the unit. This also applies to the water resulting from a

defrost cycle.

The unit MUST be firmly fixed to a secure base using the rubber

anti-vibration feet using suitable fixings. Failure to secure the unit

properly using the rubber feet will mean that it will fail MCS

Certification and cannot be registered on the MCS database.

To allow precipitation to run off the unit and to ensure that any

water entering the unit can drain through the holes in the bottom of

the unit, allow a 3mm fall left to right as you look at the fan.

5.2 Location of the Unit

5.3 Transporting the Unit

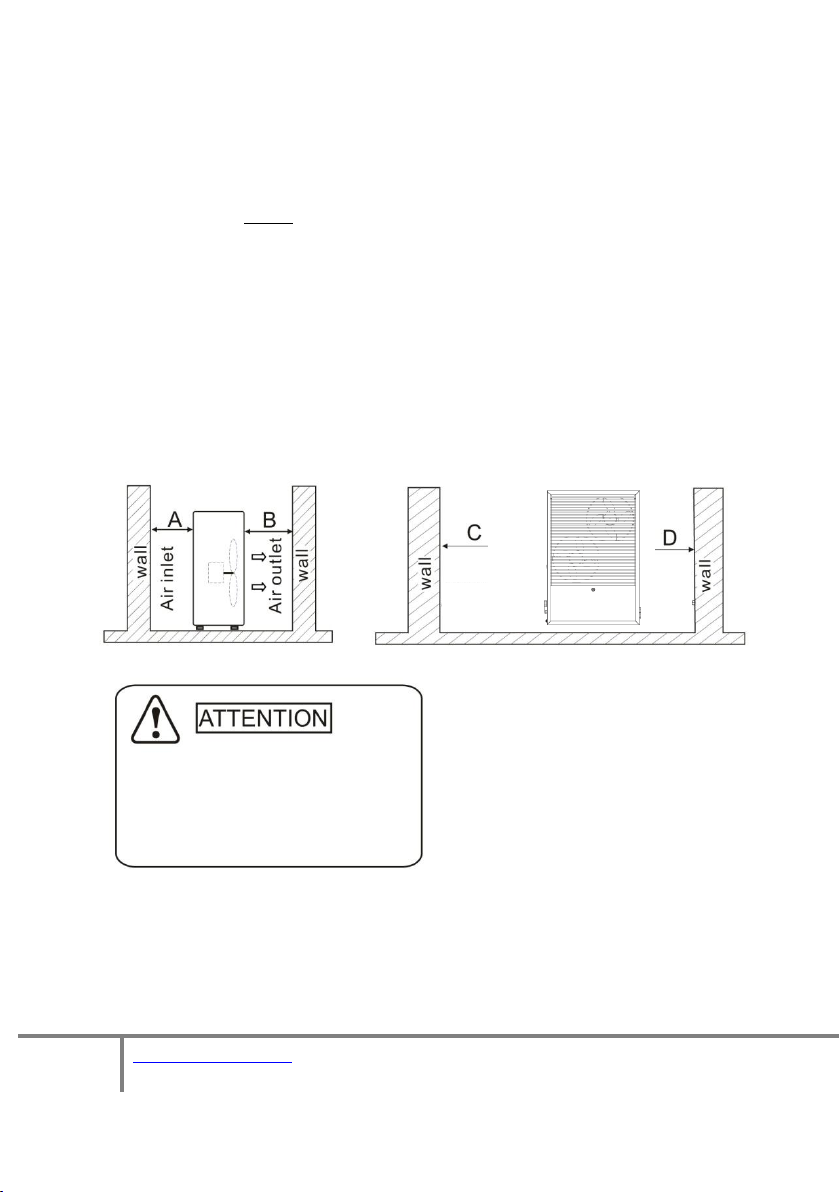

When lifting the unit during installation and transportation, an 8 meter strap

must be used and the unit protected by soft material placed between the

Page 11

11 of 41

V 1.0

www.esavep.com PASRW060-D-BP

lifting strap and the unit to prevent damage. (See picture below).

8m lifting web

Soft Protection

5.4 Plumbing Considerations

When planning the plumbing for the unit, please take the following into account:

Whenever possible, limit the number of bends in pipework.

The pipework must be clear and free from debris and blockages.

Pipework should be hot flushed before the unit is connected. Failure to

observe this precaution will invalidate the warranty.

Pipework must be pressure tested for leaks and this must be

carried before the unit is connected to avoid damage to the unit. Failure

to observe this precaution will invalidate the warranty.

It is highly recommended that a suitably sized buffer tank be

installed between the unit and the heating distribution system. Please

consult your installer or ESP when considering this system design

point – the right sized buffer tank can make a significant difference to

the economy and efficiency of the unit and the heating effectiveness.

6.0 Hydraulic Connection

6.1. Expansion vessels.

An expansion vessel must be installed where the heating system is unvented. The

size of the vessel(s) must be determined by the installer on site and take into

account the entire volume of water/glycol mix being heated including the volumes

contained in the Unit, the buffer tank, the distribution system, emitters and any

other system connected to the unit. For this reason, they are not included as part

of the optional ASHP installation pack. Expansion vessels can, however, be

provided by ESP as an additional optional extra.

6.2 Flow Switch

Page 12

12 of 41

V 1.0

www.esavep.com PASRW060-D-BP

The unit is fitted with a water flow switch that will pause the unit operation if

Transit Bung

water flow is not continuous (this includes where there is air in the system). The

flow switch is there to protect the unit and the setting should not be altered. If

the flow of water is insufficient, an error code will be displayed on the controller.

This will occur on initial start-up if the installer has failed to purge all the air from

the system.

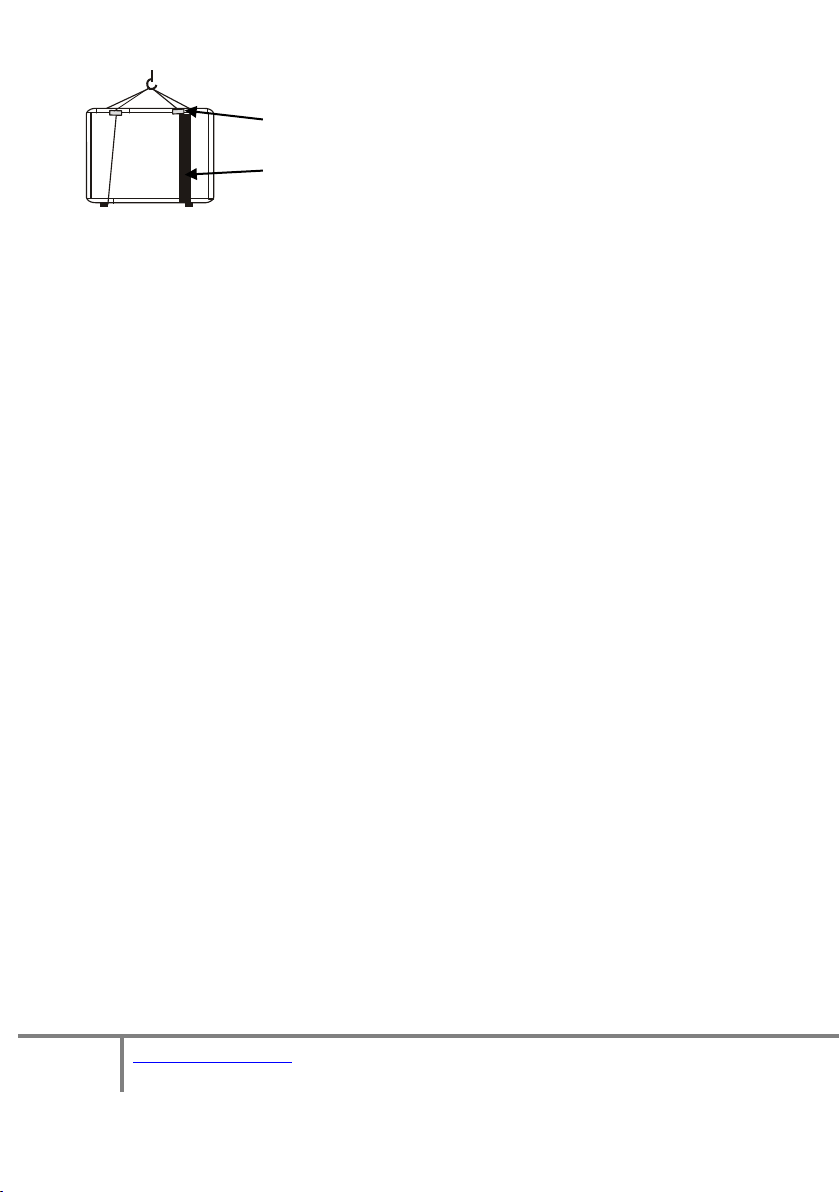

6.3 . Flexi Hoses

The final connection to the heat pump flow and return must be made with suitable

flexible pipes to prevent vibration in to the system pipework. Please ensure that

two wrenches are employed to take up the torque created in tightening the fittings

to avoid damage to both the fittings and the heat pump.

These flexible hoses are available from ESP as part of an optional ASHP Installation

Pack or individually.

6.4 Automatic bleed valves

Make sure that you fit automatic bleed valves (air vent)s at high points in the

system. The unit will shut down if air is in the system because the water flow

switch will recognize air in the system as no water flow and a system

alarm/protection code will appear on the unit controller.

6.5 Transit Bung

The unit is supplied with a transit bung below the flow/return

pipes.

This bung must be removed and replaced with a drain-off- cock (DOC). There must

also be a DOC at any lower point in the system, to allow for effective drain-down of

the system as and when required. Please note that, if the system is to be left idle

for a long period in winter, the system should be drained down. You must fit full

flow lever valves on the flow and return to the unit so that the unit can be quickly

and effectively drained down where required for maintenance.

Page 13

13 of 41

V 1.0

www.esavep.com PASRW060-D-BP

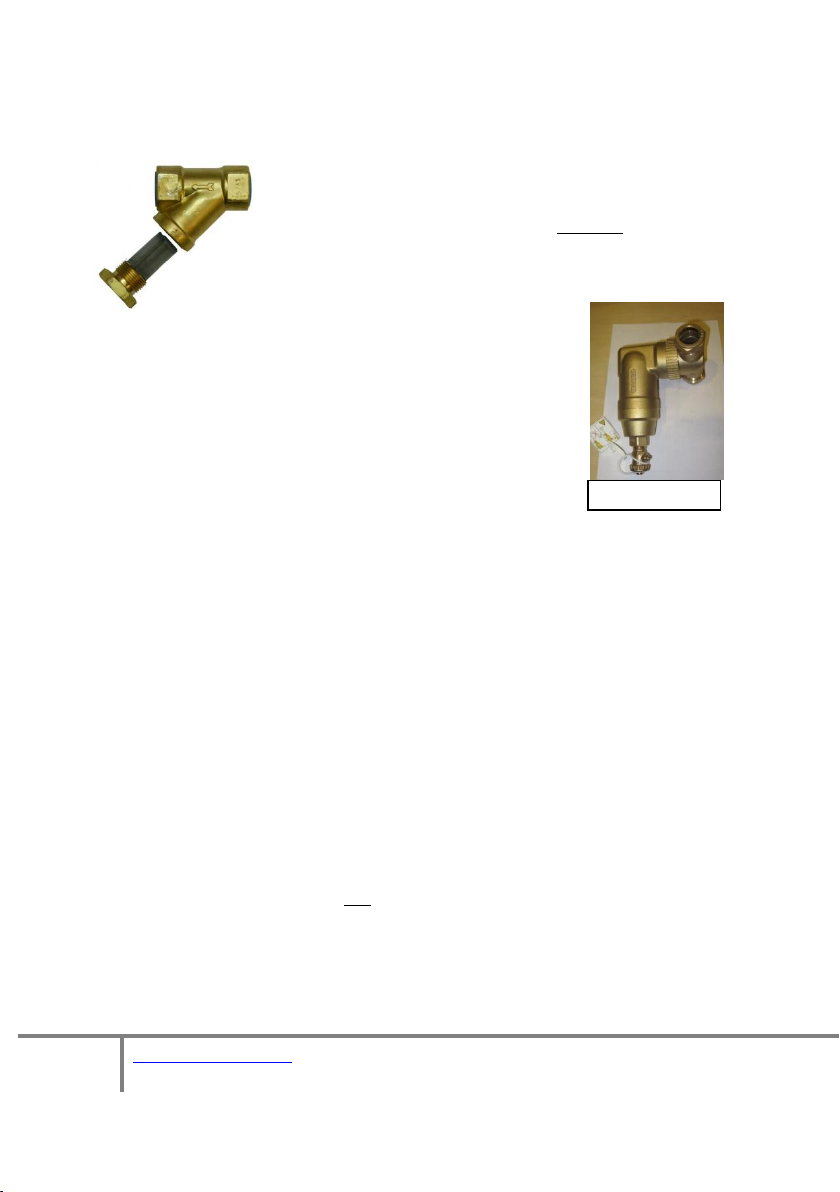

Spirotrap Strainer

6.6 In-Line Filter

You must fit a Y-strainer in-line on the return pipe between

the buffer tank and the ASHP. This is normally fitted in an

external location and must have a full flow lever valve side

either side of the strainer to minimise glycol loss during

maintenance. Due to the mix of metals in the Varimax

it is both advisable and preferable to install a

Spirotrap ® rather than the minimum standard Y

strainer. Failure to fit a good quality strainer in the

return flow to the unit will invalidate the warranty on

the unit.

6.7 Flow Setter

ESP Strongly recommend the use of a flow setter in the return pipework from the

buffer to the ASHP. This will allow the system flow rate to be optimised for the

individual project.

6.8 TRVs

Where Thermostatic Radiator Valves (TRVs) are fitted to radiators in the system,

one should NOT be fitted to any radiator in the same room as a room thermostat.

6.9 Distribution Water Pump

If, as advised, you are using a buffer tank in the system, you will need to fit a

suitably sized water pump on the water distribution side of the system. This water

pump will need to be wired to receive an appropriate signal from the heating

system. Because the pump must be sized according to the requirements of the

distribution system, this item is not provided by ESP as part of any installation pack

but can be provided as an optional extra.

6.10 Glycol

The system must be protected from freezing by using a glycol solution in the water

circuits. The glycol/water should be added into the system from the expansion

Page 14

14 of 41

V 1.0

www.esavep.com PASRW060-D-BP

tank of the water loop or via the top of the buffer tank. The Glycol must be suitable

% Glycol

10

20

30

40

50

Ambient Temp

-3

-8

-14

-22

-33

Heating Capacity Fluctuation

.991

.982

.972

.961

.946

Power Input Fluctuation

.996

.992

.986

.976

.966

Water Flow Fluctuation

1.013

1.040

1.074

1.121

1.178

Water Drop Fluctuation

1.070

1.129

1.181

1.263

1.308

for the whole system which is why ESP can supply the ideal glycol for the Varimax

as an optional extra. The following table details the volume of the glycol/water

solution mix:

Note: if the glycol/water mix is too strong, the water flow and water pump

will be affected and the efficiency of the unit will be decreased. The above

table is for reference only and you should use a glycol/water solution that is

suited to local conditions. Using an incompatible Glycol may invalidate your

warranty.

7.0 Electrical Connection

7.1 Warning Notes

IMPORTANT! All electrical work MUST be carried out by a suitably qualified

electrician. It is not an exaggeration to say that, if you install/connect your unit to a

power supply and that installation/connection causes injury to, or death of

someone (even years after installation), you may be subject to prosecution under

the provisions of criminal law – some of the provisions carry very heavy custodial

sentences. IT IS NOT WORTHWHILE RUNNING THIS RISK.

PLEASE GET YOUR UNIT WIRED IN BY A PROFESSIONALLY QUALIFIED ELECTRICIAN

TO REMAIN SAFE AND COMPLY WITH THE LAW.

The remained of section 7 is intended as guidance for qualified electricians:

7.2 Before You Start

Before starting to wire in the power supply to the unit, please check that the power

supply is suitable for the unit (e.g. single phase, correct size cable, MCB etc. is

available) having taken into account the requirements of the entire site. All

electricity generating installations that are connected to the grid must be notified

to the Distributed Network Operator (DNO). The DNO requirements vary between

Page 15

15 of 41

V 1.0

www.esavep.com PASRW060-D-BP

the regions and details of the different Network Operators and you will need to

Typical Isolation Switch

follow the instruction of your local DNO. The unit power specification is stated on

a label on the side of the unit. We recommend the use of a dedicated 32 Amp Type

C or D MCB for connection of the power supply to the consumer unit.

7.3 MCB

The connection to the electrical consumer unit in the property must comply with

current electrical standards and Regulations and be done via a dedicated breaker

on the consumer unit that corresponds to the heat pump electrical capacity.

Failure to do this correctly can result in fire and/or permanent damage to the unit.

If the unit is not appropriately wired in to a suitable supply, the warranty on the

unit will be voided.

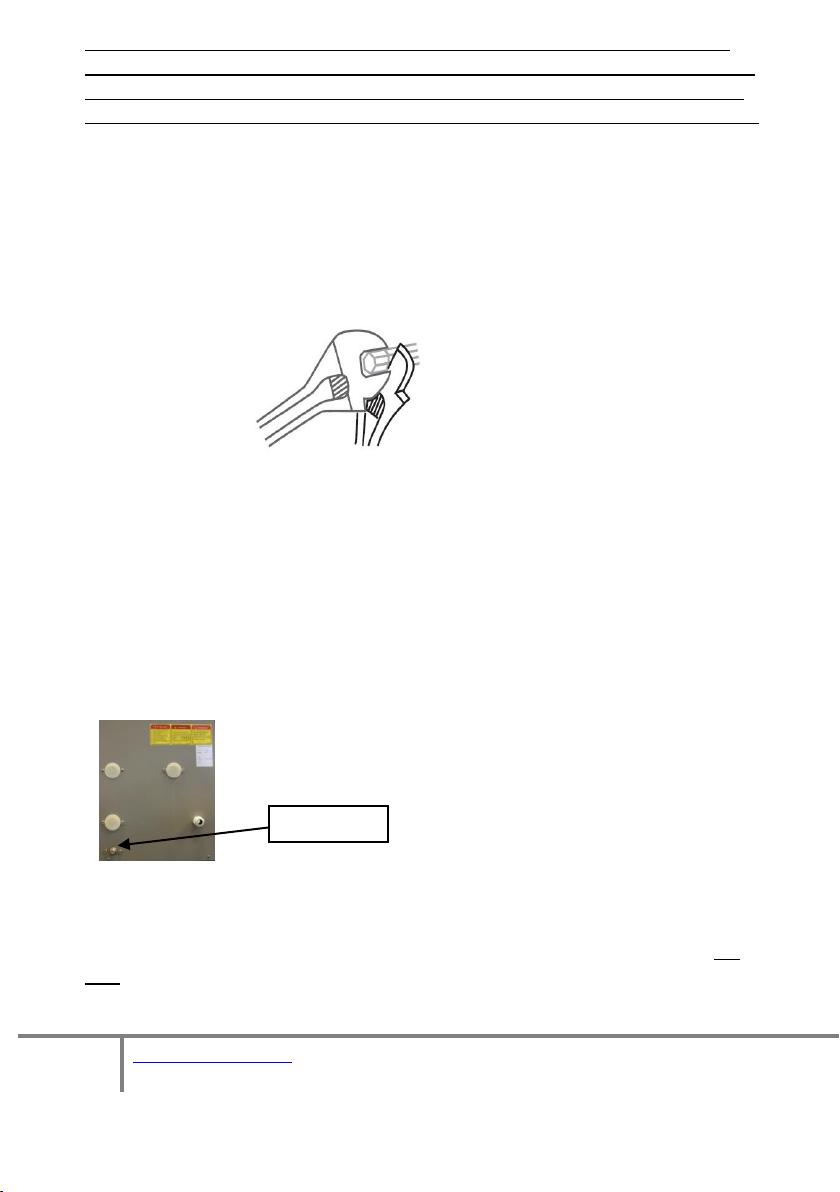

7.4 Isolation Switch

The heat pump MUST be connected to the power supply through a

two port rotary isolation switch that has at least a 3mm contact

separation at all poles, fixed in close proximity to the unit and

suitably positioned for general and emergency use as required by

relevant Regulations. The switch must NOT be attached to the unit

itself. The isolation switch must be suitable for the unit electrical

duty and comply with applicable Regulations.

7.5 Cable Routing

All wiring should be routed neatly, be kept as far away as possible from the units

water pipes and valves and comply with relevant Regulations. High voltage and low

voltage wiring should be clearly separated.

The maximum length of cable for the unit controller is 200 metres from the heat

pump and in order to get better signal quality over long distances, all the wires

should be twisted pair + Shield.

7.6 Wiring-in the Unit

The following points should be noted in relation to power supply wiring and system

components:

Remove the front louvred grill then remove the access panel to access

the electrical connection terminals.

Page 16

16 of 41

V 1.0

www.esavep.com PASRW060-D-BP

The control wire must be passed through the

Mains power

Connector Block

Controller

Connector

protective wire aperture in the unit casing and

plugged into the controller socket.

The power supply must go through the

protective wire aperture in the unit casing and

be connected securely to the terminals in the

control box. There is an alternate access

grommet in the casing near to the drain-off point.

In section 13 you will find wiring diagrams for the. Please refer to these

diagrams when introducing power or other wiring into the unit. You

should also use these diagrams to check the installation through before

starting the unit for the first time.

If the Building Regulations in your area require a 7-day programmer,

please note that the most efficient way of running an ASHP heating

system is to set the programmer to ALWAYS ON. A programmerthat

meet current building regulations may be used but it is very IMPORTANT

that any signal going back to the heat pump from the heating system

thermostat and/or programmer must be VOLT FREE ! The heating

system thermostat/ programmer controller is wired to terminals 45&46

inside the heat pump (these connections are not polarized) If you do not

use a volt free programmer you WILL damage the ASHP unit.

Page 17

17 of 41

V 1.0

www.esavep.com PASRW060-D-BP

Model Designation

PASRW060B-D-BP

Heating Capacity Range

Kw

6.0~15.0

BTU/h

20500~51000

Heating Power Input

Kw

1.6~7.0

Max. Running Power

Consumption

A

12.0/12.2

Power Supply

V/Ph/Hz

230/1/50

Number of Compressors

1

Compressor Type

Scroll

Number of Fans

2

Refrigerant

R410a

3.1kg

Compressor Oil

FV50S

1700cc

Fan Power Input

W

110 X 2

Fan Speed

RPM

850

Noise

dB(A)

59

Water Pump Power Input

Kw

.18

Max Water Head

M

12.5

Water Connection

Inch

1 1/4

Water Flow Volume

m3/h

2.5

Terminals 45/46

for volt free

connection

Mains power

Connection

Socket for

Wire

Controller

The unit MUST be connected to the master thermostat within the

building that controls the call for heat. If you do not have a master

thermostat connected to the unit from the building, you will not meet

Building Regulations.

8.0 Unit Specifications

Page 18

18 of 41

V 1.0

www.esavep.com PASRW060-D-BP

Water Pressure Drop

KPa

34

Water Capacity

Ltr

2.44

Unit Dimensions

mm

See Drawings

Unit Shipping

Dimensions

mm

1050 X 510 X 1475

Net Weight

Kg

See Unit Label

Shipping Weight

Kg

See Package Label

9.0 Commissioning

9.1 Pre-Start Checks

The following checks must be made prior to starting up the unit for the first

time:

Check that all relevant lever valves are open.

Check the water loop and expansion tank to ensure that both have

adequate water in them to allow the system to operate at 1 – 1.5

bar.

Ensure that all air has been purged from the system.

Ensure that pipes are well insulated using waterproof lagging, with at

least 30mm wall thickness.

Check the electrical wiring is correct in every respect. In particular,

make sure that the system is properly earthed.

Inspect the heat pump to ensure that all the cover screws have been

replaced and secured properly.

Check that the fan rotates freely.

When you switch on the power to the unit at the rotary isolation

switch, check the controller on the unit casing to see if there is an

error code being displayed.

9.2 Switching on the Unit

Please familiarise yourself with the unit controller and the

instructions in section 10 so that you can check various parameters as

the unit starts.

Start the heat pump by pressing the key on the unit controller

(see section 10). This will start the water pump. Check that the

water pump is running - there should be a reading of 0.2 MPa on the

Page 19

19 of 41

V 1.0

www.esavep.com PASRW060-D-BP

water pressure gauge.

When the water pump has been running for 1 minute, the

compressor will start up. Make sure that there are no strange noises

coming from it

immediately and check the compressor. If the

compressor runs well please check the pressure of the refrigerant.

Following the above, check whether the power input and running

current being drawn by the unit is in line with this manual. If not

please stop the unit and check for any problems.

If the unit is supplying a heating manifold, adjust the actuators on the

manifold(s) to balance the heating being received in all areas of the

system.

Check that the outlet water temperature is stable and increasing

smoothly towards the target temperature. The return water

temperature should move in line with the flow temperature with

around a 4 deg C. difference between the flow and return water

temperatures.

The parameters of the unit controller are factory set and you must

not change them without consulting your installer or ESP. The

exceptions to this are the running temperature (or flow temperature)

of the system and the time. However, changing the flow

temperature will affect the efficiency of your system and may affect

your ability to claim/continue to claim any Government grant.

Section 10 explains how to view the various parameters although the

default view will show the current status of the system.

. If the compressor sounds abnormal, stop the unit

Page 20

20 of 41

V 1.0

www.esavep.com PASRW060-D-BP

10.0 Unit Controller

Icon

Key

Meaning

Cooling Mode

Indicates that the unit is in cooling

mode.

Heating Mode

Indicates that the unit is in Heating

mode.

Boost Mode

Indicates that the unit is in Boosted

Heating mode.

Hot Water Mode

Indicates that the unit is in Hot Water

mode.

Number

Icon

Key

Function

①

On-Off

This is a multi-function button used to start the units, turn it

off, cancel a current operation and to return to the previous

menu page.

②

Time

Used to set the time and the optional timers.

③

Timers

Used to set the optional timers.

④

Check

To check current load (power) and temperatures.

⑤

Setting

Used to set various functions.

⑥

Up

Used to move ‘up’ in menus and to increase values.

⑦

Down

Used to move ‘down’ in menus and to decrease values.

⑧

Modes

Used to change between modes.

10.1 Main Interface

10.2 Basic operation

Page 21

21 of 41

V 1.0

www.esavep.com PASRW060-D-BP

Defrost Mode

Indicates that the unit is defrosting.

Inlet temperature

Indicates that the inlet temperature is

being displayed.

Outlet Temperature

Indicates that the outlet temperature is

being displayed.

Setting Mode

Indicates that the control is in setting

mode.

Value

Indicates that the basic display area is

displaying a parameter value.

Parameters

Indicates that the auxiliary display area

is displaying a parameter category.

Degrees Centigrade

Indicates that a value displayed in the

basic or auxiliary area is a temperature.

Kilowatts

Indicates that a value displayed in the

auxiliary area is a power value.

Hour

Indicates that the basic display area is

displaying an hour value.

Minute

Indicates that the basic display area is

displaying a minute value.

Second

Indicates that the basic display area is

displaying a second value.

Cubic Meters Per

Hour

Indicates that the basic display area is

displaying a flow rate.

Bars

Indicates that the basic display area is

displaying a pressure value.

Compressor

Indicates that the compressor is

running.

Pump

Indicates that the pump is running.

Fan

Indicates that the fans are running.

Lock

Indicates that the control pad is locked.

Fault

Indicates that a fault has been detected.

Start Time

The start time in timer mode (timer 2

illustrated)

Finish Time

The finish time in timer mode (timer 1

illustrated)

Page 22

22 of 41

V 1.0

www.esavep.com PASRW060-D-BP

10.3 Start-up and Shut Down

When the unit is in stand-by mode or has

automatically gone ‘blank’, the screen is

activated by pressing the on-off button.

When the unit is in stand-by mode, press the

on-off key and hold it for 0.5 seconds to start

the unit. When the unit is running, pressing

(and holding) the same button for the same

time will put the unit into stand-by mode.

When running, the display will show the inlet

temperature and the outlet temperature

NB. The screen will return to blank

automatically.

Page 23

23 of 41

V 1.0

www.esavep.com PASRW060-D-BP

10.4 Setting the target temperature

This symbol indicates that the unit is in heating mode

Press the up button once will show the

target temperature as set.

Symbol indicates that the target temperature can be set

Current Target Temperature

Pressing the up arrow will

increase the target

temperature, the down arrow

will decrease the target

temperature. Press the

key to save the setting or the

to cancel the change. If no

key is pressed within 20

seconds, the new setting will automatically be saved.

N.B. Your installer will have set the target temperature to

optimise the flow temperature for your building. Changing this

setting from the recommended temperature will decrease the

efficiency of your system. If you are considering changing this

setting from that set by your installer, you should consult your

installer or the ESP Technical Team first.

Page 24

24 of 41

V 1.0

www.esavep.com PASRW060-D-BP

10.5 Using the Premium User Interface

The Premium User Interface is used to change the time, set (or

change) timers, change from a Centigrade to a Fahrenheit

display, mute the interface and check the status of the ASHP.

Pressing the set button to

change to the Premium

User Interface. If the on-off

button is pressed or no

button is pressed within 20

seconds, the display will

revert to the start screen.

The Premium User Interface

has three additional buttons

on the left hand side of the

display.

Page 25

25 of 41

V 1.0

www.esavep.com PASRW060-D-BP

10.6 Setting the time:

Minute Segment

The display will change and

using the up and down buttons

will change the ‘hours’ setting.

Press the set key to save the

change.

First, press the time button.

Use the up and down

buttons to change the

‘minutes’ segment of the

clock. Press the set key to

save the change.

Page 26

26 of 41

V 1.0

www.esavep.com PASRW060-D-BP

Timer time

N.B. pressing the on-off button at any stage will cancel

the changes to that stage or not pressing a button within

20 seconds will save any changes made.

10.7 Setting the timers

The ASHP can be set to come on and go off again for two

periods per day. However, the most efficient way to run

an ASHP is to leave the unit running ‘always on’ and not to

set the timers.

Should you wish to set the timers against this advice, the

procedure is as follows:

Press and hold the time button for 2

seconds.

The display will change and the ‘on’

time of ‘timer 1’ can be set using

the up and down arrows to set the

hour. Press set to save the ‘hour’

and move to ‘minutes’. Us the up

and down arrows to set the minutes

then press set again to save the minutes. The display will

automatically move to ‘timer 1 off’. Use the same method

to set the desired ‘off’ time. At the end of that process, the

display will change to ‘timer 2 on’ and once that has been

set, ‘timer 2 off’.

Page 27

27 of 41

V 1.0

www.esavep.com PASRW060-D-BP

‘On 1’ time will flash

‘On 1’ time will stop flashing

Timer has been cancelled

10.8 Cancelling timers

To cancel a timer, enter the

Premium User Interface then

press the time button for 2

seconds. This will display the

current ‘Timer 1 on’ setting and

the time will flash. Press the

set button and the

Pressing the set button will

stop the time flashing.

Pressing the on-off button at

this stage will cancel the timer.

Press the on-off button once

more to return to the premium

user interface.

Page 28

28 of 41

V 1.0

www.esavep.com PASRW060-D-BP

Parameter Value

Parameter Number

10.9 Checking the Status of the ASHP

To Check the status of a

parameter, press the check

button whilst in the Premium

User Interface.

The display will change to

parameter 1. The

parameter value, the ‘val’

symbol, the parameter

number and ‘param’

symbols will be displayed.

Press the up and down

arrows to toggle through the

parameter list and the on-off

button to return to the

Premium User Interface.

The complete list of

parameters is in section 18

for information only;

changing any parameter other than the time/timers could

invalidate the warranty, the MCS registration and any

Government grants claimed.

Page 29

29 of 41

V 1.0

www.esavep.com PASRW060-D-BP

Indicates that the

display is locked

Fault Code

Serial

Number

Number of faults reported

10.10 Locking the Display

To lock the display, simply

press and hold the on/off

button for 5 seconds.

The ‘lock’ symbol will appear.

To unlock the display, press

and hold the on-off button for 5

seconds. However, the display

will automatically unlock if the

unit restarts after a power

failure or if a fault is reported.

10.11 Fault Displays

Should the ASHP develop a fault, a fault code will be

displayed in the following format:

The fault code will be

displayed, together with the

number of faults reported

and the serial number of the

fault. Use the up and down

arrows to scroll through

reported faults. A table of

fault and meanings is in

section 12.1.

Page 30

30 of 41

V 1.0

www.esavep.com PASRW060-D-BP

11 Maintenance

11.1 Essential Checks

Periodically clean the in-line filter (Y strainer or Spirotrap); this will need to be every

month for the first 6 months following start up of the system to allow installation

debris to be extracted. NOTE that a lack of water in the system or debris/dirt

entering the system can damage the unit.

11.2 Advisory Checks

Although there is no formal requirement for annual maintenance of the unit, the

following checks are strongly suggested:

Check the grill and evaporator for debris and remove before cleaning the evaporator.

Check the water supply and air vents frequently, to ensure that there is adequate

water within the system and that air is kept out of the system.

Check each part of the unit and the pressure within the system.

If any component has failed, replace it (and recharge refrigerant, if any has been

lost).

Check over the power supply and the electrical system generally to make sure that

no wires are lose or degrading. You must investigate any scorching visible or unusual

smells coming from the unit or the wiring.

Replace any part that may be malfunctioning; it is better to replace a part early (to

practice good preventative maintenance) than await failure.

If the heat pump is not to be used for a long period of time, please drain it down and

seal the unit to keep it safe for recharging and restarting when needed.

If a period of non use will include any possibility of the unit freezing, isolate the unit

and drain the water from the lowest point of the heat exchanger. Recharge the

water/glycol and carry out a full inspection of the unit before it is restarted.

The water loop of the heat pump MUST be protected from freezing in winter.

Please NOTE THE FOLLOWING – failure to observe the following requirements

WILL invalid the warranty for the heat pump.

Page 31

31 of 41

V 1.0

www.esavep.com PASRW060-D-BP

Please do not shut off the power supply to the heat pump in winter unless

Code

Malfunction

Reason

Resolution

P01

Inlet probe error

Short-circuit/Open-circuit

Check and change the

temp.

Sensor

P02

outlet probe error

Short-circuit/Open-circuit

Check and change

the

temp.

Sensor

P04

Ambient probe

error

Short-circuit/Open-circuit

Check and change the

temp.

Sensor

P07

Suct. temp. prb.

Error

Short-circuit/Open-circuit

Check and change

the

temp.

Sensor

P08

Disc. temp. prb.

Error

Short-circuit/Open-circuit

Check and change

the

temp.

Sensor

PP1

Disc. press prb.

Error

Short-circuit/Open-circuit

Check and change

the sensor

PP2

Suct. press prb.

error

Short-circuit/Open-circuit

Check and change

the sensor

E01

High pressure

High pressure switch off

Check cooling system

and pressure switch

E02

Low pressure

Low pressure switch off

Check cooling system

and pressure switch

E03

Flow switch alarm

No water or little

water

Check water flow and

water pump

E07

Freeze alarm

Inadequate water

Check water flow

and clear blockages

E19

Freeze alarm1

Low environment temp.

E29

Freeze alarm2

Low environment temp.

P181

High disc. temp

Overload of compressor

Check compressor

E21

Inv. Input

Lessvolt.

Low voltage leads the

overlarge current

Check the input

voltage

E22

Inv. Input

Overvolt

Input current over

protection current

Check input current

it is to be drained-down. When the air temperature is below 0°C, if the

inlet water temperature is above 2°C and below 4°c, the water pump will

start automatically once in every 72 hrs to provide frost protection.

12.0 Troubleshooting

12.1 Error Codes:

Page 32

32 of 41

V 1.0

www.esavep.com PASRW060-D-BP

E23

Input Over Cur.

War n

Input current over

protection current

Check input current

E24

Inv. DC

Overvoltage

DC bus voltage >DC

protection bus volt

Check bus

voltage

E25

Inv. DC

Lessvoltage

DC bus voltage<DC

protection bus volt

Check bus

voltage

E27

IPM Overcurrent

Overlarge current of the

IPM

Check current

E28

IPM Overheating

Over Temp. of the IP M

Module

Check current

E29

Inv. Temp. Probe

Fail

Short-circuit or ope n circuit

of sensor

Check and change

the sensor

E30

Inv. Input

Overvolt

Over Temp. of the parts

Lower the

temperature and

check

E31

Input Over Cur.

War n

Over Temp. of the parts

Lower the

temperature and

check

E32

IPM Sampling

Cur

Fault of current sampling

E33

Comp.

Overcurrent

Overlarge current of

compressor

Check the current

E34

Comp. Over Cur.

War n

Overlarge current of

compressor

Check the current

E35

Inv. Input Out

Phase

Lack of phase in input

voltage

Check the voltage

E36

Comp. Driver

Failure

Lack of phase or

breakdown of driver

Check the voltage

E37

Comm. Err DSPMCU

Fault of DSP or

communication board

Check

communication

connection

E38

Comm. Err DSPPFC

Fault of DSP and PFC

Check

communication

connection

E39

Inv. Sampling Volt

Fault of current sampling

Page 33

33 of 41

V 1.0

www.esavep.com PASRW060-D-BP

E40

EEPROM Error

Warn

Chip error

Check and change

the chip

E41

Weak Magnetic

Warn

Comm

Weak Magnetic

Problem

Possible Causes

Suggested Solutions

Heat pump will

not start

1 Incorrect power supply.

2 Power cable is loose.

3 MCB Tripped.

1 Shut off th e power and check power supply.

2 Check power cable is correctly connected.

3 Check for the cause an d reset MCB.

Water pump is

running but

noisy or without

water

1 Lack of water in the pipes.

2 Air in pipes.

3 Isolation water valves closed.

4 Blocked water filter

1 Check the water supply and fill pipes.

2 Bleed the system.

3 Open the valves.

4 Clean the water filter.

The compressor

runs

continuously or

the output is

low

1 Refrigerant leaking.

2 Inadequate insulation on ASHP flow and

return pipes.

3 Low heat exchange rate on air side

Exchanger.

4 lack of water flow

1 check for the gas leakage an d recharge the refrigerant.

2 make good insulation on water pipe.

3 clean the ai r side heat exchanger.

4 clean the water filter.

High

compressor

exhaust

1 System refrigerant overcharged.

2 Low heat exchange rate on air side

exchanger

1 Reduce refrigerant.

2 Clean the air side heat exchanger.

Low pressure

problem

of the system

1 Insufficient refrigerant.

2 Blocked filter or capillary.

3 Low water flow.

1 Check for refrigerant leaks and recharge.

2 Replace filter or capillary.

3 Clean the water filter and bleed the system.

Compressor will

not run

1 Power supply failure

2 Compressor contactor broken

3 Power cable loose

4 Protection on compressor has tripped

5 Incorrect return water temp setting.

6 Low water flow.

1 Check power supply;

2 Replace compressor contactor;

3 Tighten the power cable;

4 Check the compressor exhaust temp.

5 Reset the return water temp.

6 Clean the water filter and bleed the system.

Compressor

unusually noisy

1 Liquid refrigerant getting into

Compressor.

2 Compressor failure.

1 Check the cause of poor evaporation an d clear fault.

2 Replace compressor.

Fan does not run

1 Fan relay failure.

2 F an motor failure.

1 Replace th e fan relay;

2 Replace fan motor.

The compressor

runs but heat

pump has no

heating or

cooling capacity

1 No refrigerant in the heat pump.

2 Heat exchanger failure.

3 Compressor failure.

1 Check for leaks, cure the fault and recharge refrigerant.

2 Investigate the cause and replace the heat exchanger;

3 Replace compressor.

Low outlet water

temperature

1 Low water flow rate.

2 Low target temperature set.

1 Clean the water filter and bleed the system.

2 Check the target temperature setting and reset if

necessary.

Low water flow

reported

1 Lack of water in the system;

2 Flow switch failure.

1 Clean the water filter and bleed the system.

2 Replace th e flow switch.

12.2 Simple Faultfinding

The following is a list of some basic faults and solutions.

Page 34

34 of 41

V 1.0

www.esavep.com PASRW060-D-BP

13.0 Wiring Diagram

For zero volt connection

from Controller

Page 35

35 of 41

V 1.0

www.esavep.com PASRW060-D-BP

14.0 Guarantee

14.1 Guarantee Terms

Should any factory fitted Temperature and/or Pressure Relief Valve(s) or

other safety devices be tampered with or removed or any recommended

Temperature or Pressure Relief Valves/safety devices not be fitted, your

warranty/guarantee will be invalidated. Neither the Distributor nor

Manufacturer shall be responsible for any damage resulting from the

tampering, howsoever caused, save where such exclusion is unlawful.

ESP warrants/guarantees the electrical parts, thermal controls and valves

relating to the cylinder for a period of one year from the date of purchase, with

the exception of normal wear and tear including any damage damage caused as a result

of lime scale deposits.

The stainless steel vessel forming part of the cylinder is

warranted/guaranteed for a period of five years against faulty manufacture

or materials provided that:

i) It has been properly installed by a competent installer as per the

instructions and recommendations contained in this manual and all relevant

codes of Practice and Regulations in force at the time of installation.

ii) It has not been modified in any way other than by ESP.

iii) It has only been used for the storage of wholesome water.

iv) It has not been installed in a location liable to be subjected to frost, nor ha

s it been tampered with or been subject to misuse or neglect.

v) No factory fitted parts have been removed for unauthorised repair or repla

cement.

Page 36

36 of 41

V 1.0

www.esavep.com PASRW060-D-BP

vi) Within 45 days of purchase the user completes and returns the

registration certificate.

The compressor in the heat pump is warranted/guaranteed for 2 years

from the date of purchase. Remaining parts of the heat pump are

warranted/ guaranteed for 1 year from the date of purchase.

Evidence of purchase and date of supply must be submitted with any

warranty/guarantee claim.

This warranty/guarantee is not valid for installations outside the United

Kingdom or the Republic of Ireland.

Any warranty/guarantee is for replacement parts only.

The purchaser of the unit acknowledges that he/she has seen ESP’s conditions of

supply and has understood them.

All of our units are RoHS approved units.

This guarantee does not affect your statutory rights.

15.0 Environmental Information

This product is made from many recyclable materials, therefore at the end of

its useful life, it should be disposed of at a Local Authority Recycling Centre

in order to realise the full environmental benefits. The R410a gas contained in the unit

should be reclaimed, recycled or destroyed, in accordance with current Government

regulations covering F-Gas available from WWW.Gov.UK and should only be attempted

by a qualified technician. For disposal of the glycol added to the system, the glycol

supplier should be contacted. For ESP glycol, the disposal instructions are supplied with

the non-toxic glycol sold by ESP.

Please note:

The pace of product development is such that we reserve the right to

change product specifications without notice. We do, however, strive to

ensure that all information in this leaflet is accurate at the time of

publication.

Page 37

37 of 41

V 1.0

www.esavep.com PASRW060-D-BP

The Varimax 20 has built-in weather compensation to ensure that that maximum

efficiency is maintained and that output is matched to the load of the building and

the external ambient temperature. With factory defaults set (it is unwise and,

possibly, dangerous to change these – see warning in section 10.9) the compensation

is as follows:

16.0 Weather Compensation

Page 38

38 of 41

V 1.0

www.esavep.com PASRW060-D-BP

Frequency (HZ)

Frequency (HZ)

Frequency (HZ)

17.0 Performance

Page 39

39 of 41

V 1.0

www.esavep.com PASRW060-D-BP

Frequency (HZ)

Frequency (HZ)

Frequency (HZ)

Page 40

40 of 41

V 1.0

www.esavep.com PASRW060-D-BP

Parameter

Number

Description

Default

Value

Units

A01

High Pressure protection delay

0

Secs

A01

Low Pressure protection delay

300

Secs

A03

Outlet water antifreeze

5

°C

A04

Return differential antifreeze

2

°C

A05

Exhaust temperature maximum

105

°C

A06

Frequency reduction of exhaust overtemp

10

Hz

A07

Frequency reduction cycle for exhaust overtemp

60

Secs

A08

Return differential of exhaust over temp

25

°C

C01

Compressor on-delay

180

Secs

C02

Compressor off-delay

120

Secs

C04

Minimum compressor frequency

30

Hz

C05

Maximum compressor frequency

90

Hz

D01

Defrost start trigger pressure

5.0

bar

D02

Defrost end trigger pressure

27

bar

D03

Defrost cycle

45

mins

D04

Defrost maximum

8

mins

D05

4-way valve switching delay

55

Secs

D06

Slide defrosting set on

1

(logic)

D07

Slide defrosting trigger temp

2

°C

D08

Ambient temp defrosting trigger

17

°C

D09

Pressure differential for defrost

2.7

bar

E01

Manual mode for EEV set on

0

(logic)

E02

Overtemp protection for EEV (Heating)

1

°C

E03

Overtemp protection for EEV (Cooling)

0.5

°C

E04

Opening of EEV Valve during heating

250

Steps

E05

Opening of EEV Valve during cooling

250

Steps

E06

Opeinging of EEV Valve during defrost

450

Steps

F01

Max fan speed trigger (Cooling)

27

bar

F02

Min fan speed trigger (Cooling)

15

bar

F03

Max fan speed trigger (Heating)

4

bar

F04

Min fan speed trigger (Heating)

3

bar

F05

Air valve voltage min

3 V F06

Air valve voltage max

10 V F07

Pressure differential fan trigger (Cooling)

3

bar

F08

Pressure differential fan trigger (Heating)

2

bar

F09

Rated rotate speed

6.5 V H01

Power-off memory set on

1

(logic)

18.0 Parameter List:

Please note that the changing any one of the parameters in this list may:

1. Be dangerous.

2. Invalidate the warranty on the unit.

3. Invalidate the MCS registration (where applicable).

4. Invalidate any Government grant claimed for the installation.

Page 41

41 of 41

V 1.0

www.esavep.com PASRW060-D-BP

H02

4-way valve on when heating set

1

(logic)

H03

Oil return for compressor set

1

(logic)

H04

Frequency protection on compressor overtemp set

1

(logic)

P01

Water pump intermittent set

1

(logic)

P02

Water pump interval

30

mins

P03

Water Pump duration

2

mins

P04

Compressor delay after water pump start

1

mins

P05

Target temp differential (Heating)

1

°C

P06

Target temp differential (Cooling)

1

°C

R01

Target set temp (Cooling)

12

°C

R02

Target set temp (Heating)

40

°C

R03

Trigger differential for electric heater

2

°C

R04

Use electric heater set

0

(logic)

R05

Ambient temp electric heater start

9

°C

R06

Electric heater delay

30

mins

You are strongly recommended to contact the ESP technical

support team before changing any of these parameters.

CONTACT DETAILS

Earth Save Products Technical Team – 01865 598158

Loading...

Loading...