Page 1

Part

Number:

10060-001

Rev:

03

Description:

SSS-903 TG-E

Install Guide

Date:

08/15/2017

Page: 1 of 53

Date

Revision

Description

Approved

3/21/13

02

Addition; Appendix II

Warranty & Return Policy

A. Burgos

Revision History

Information and technical data disclosed in this document

may be used and distributed only for the purposes and to

the extent specifically authorized by ESP Safety Inc.

ESP Safety Inc. Reserves the right to change published

specifications and designs without prior notice

OPERATING MANUAL

SSS-903 Toxic Gas Detection System

Model SSS-903 Transmitter and Controller

Model PGU-IR Infrared Optical Gas Sensor

Model PGU-P Photo Ionization Gas Sensor

Model PGU-E Electrochemical Gas Sensor

Model PGU-C Catalytic Bead Gas Sensor

Page 2

Part

Number:

10060-001

Rev:

03

Description:

SSS-903 TG-E

Install Guide

Date:

08/15/2017

Page: 2 of 53

General Information .............................................................................................................. 3

Specifications of SSS-903 with PGU Sensors ........................................................................ 4

SSS-903 Theory of Operation .............................................................................................. 11

Data Communication ........................................................................................................... 17

IMPORTANT SAFETY INFORMATION................................................................................... 18

Physical Installation Procedure .......................................................................................... 19

Physical Installation Quick Guide........................................................................................ 20

Wiring Requirements .......................................................................................................... 24

Power up and Stand Alone Operation of the SSS-903 ........................................................ 31

RS-485 Modbus Digital Communication and Operation ...................................................... 32

Calibration Procedures ........................................................................................................ 33

Non-Invasive Calibration Magnet Procedure ...................................................................... 33

Non-Invasive Calibration Procedure with HART Communicator……………………………..….33

Bench Test Calibration Procedure with ESP Commander ................................................. 438

Unpacking A New SSS-903 .................................................................................................. 44

Appendix 1 Explosion Proof Design……………………………………………… .............. …………45

Appendix 2 Warranty & Return Policy .............. ……………………………………………………46

Page 3

Part

Number:

10060-001

Rev:

03

Description:

SSS-903 TG-E

Install Guide

Date:

08/15/2017

Page: 3 of 53

This instruction guide details the specification, application and operation of the ESP Safety Inc. SSS-903 with an included

sensor. The SSS-903 System consists of two components, a receiver and gas specific sensor that have been factory

configured and calibrated to provide detection of toxic, flammable and combustible gases in open or closed environments. The product

includes multiple features required to report alarms when the toxic gas concentrations in the environment

reach three independently programmed levels. Each alarm also triggers a relay that is provided as a standard feature,

which can be used to operate warning devices, sirens, valves or switches.

The SSS-903 receiver is a versatile product that can be used in a specific proximity or in a decoupled mode with the sensor

and receiver head located up to 500 feet apart. Furthermore, any SSS-903 can be reconfigured in the field to detect toxic

gases using optional sensor replacements.

The SSS-903 system is recommended for applications that require a gas detector with localized digital readout of detected

gas levels. It comes factory standard for with Analog 4-20mA output with embedded HART, an independent HART connector

that is conveniently located on the SSS-903 enclosure able, relay contacts, and Modbus RS485. The system is comprised of an

SSS-903 Receiver and plug-in universal PGU sensors for electrochemical (PGU-E) , infrared (PGU-IR) ,photo-ionized (PGU-P) and

catalytic bead (PGU-C)detection. Power is supplied from an external 24 VDC nominal power source (source can range 18-3VDC). In

operation the

SSS-903 system has been designed for operation in temperature ranges from minus 40 to 75 °С (without internal heated option

activation) and minus 60 to 75 °С (with activated internal heated option) and relative humidity of up to 100 % (non-condensing)

The SSS-903 receiver includes 5 LED annunciators plus an easily readable LCD display. On the display an operator can determine

information of alarm status, gas detected, current level detected and view a Time Weighted Average (TWA) run time graphic

showing each event and level detected during a user programmed time from 3 to 30 minutes. The design of the SSS-903 is an

approved product for use in control monitoring of gas contamination levels with flammable and toxic gases present in the

working area environment of oil, gas and chemical industries All electronics are enclosed in explosion-proof aluminum or

stainless steel housings that have been certified by FM-Approvals for use in explosive areas pertinent to classes 1 and 2 with the

potential hazard of forming explosive gas mixtures attributed to the subgroup IIС and to explosion hazard categories Т1–Т6,

inclusive of the following zones, premises and facilities:

Drilling and production platforms

Refineries

Bulk terminals and tank farms

Compressor stations

Pipelines

Transportation facilities

Petrochemical facilities

Paint Manufacturing

Fertilizer plants

Fuel loading facilities

Residential areas

Boiler stations

Non-invasive calibrations can be performed in the field using an included magnetic wand or a HART communicator.

A device descriptor file is available from ESP Safety for use with a HART communicator. Calibration can also be performed with an

included Windows PC application, ESP Commander. Both HART and ESP Commander applications can supply real time output of

current operational data plus access a non-volatile memory in the SSS-903 for further diagnostic analysis.

General Information

Applications

Page 4

Part

Number:

10060-001

Rev:

03

Description:

SSS-903 TG-E

Install Guide

Date:

08/15/2017

Page: 4 of 53

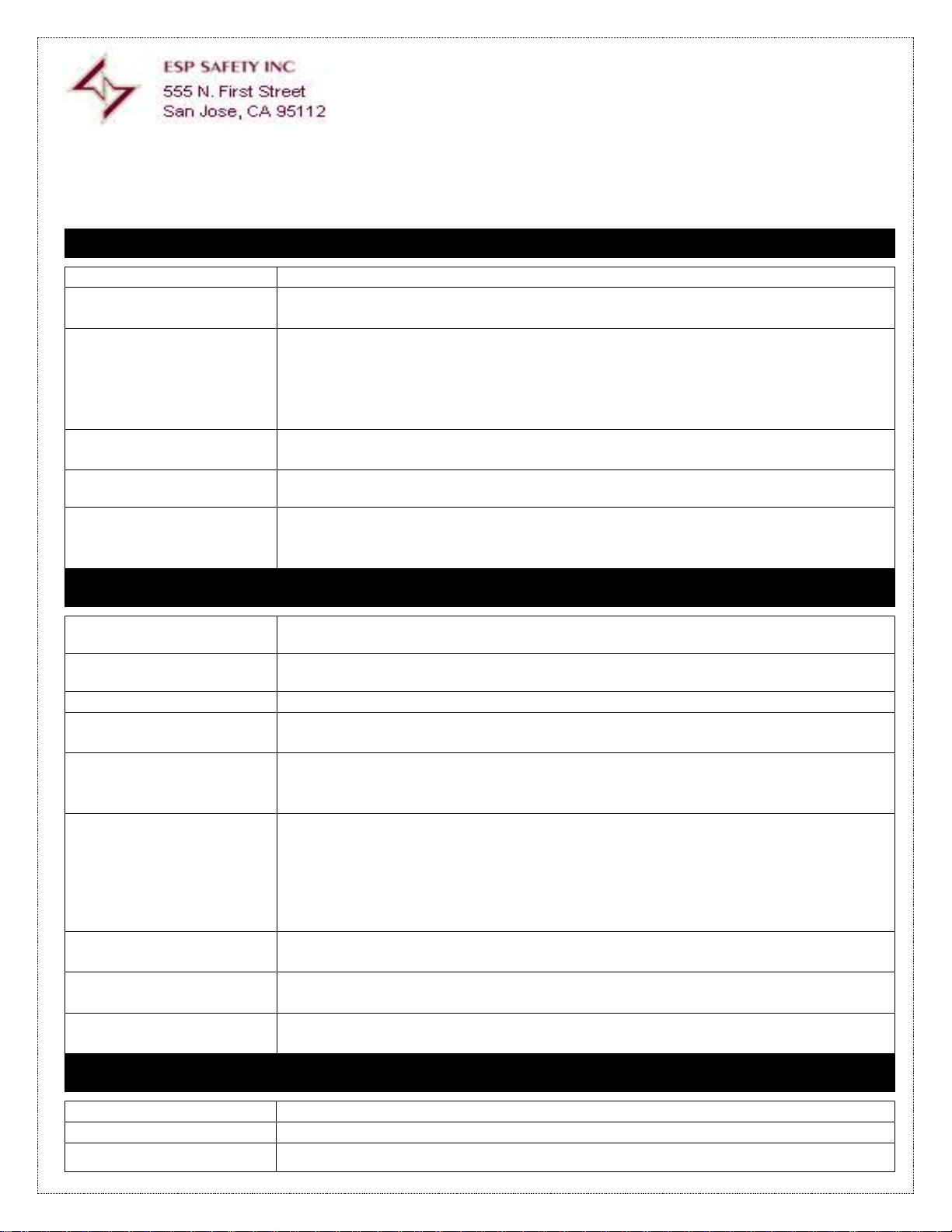

Electrical Characteristics

Operational Characteristics

Mechanical Characteristics

Input Voltage

+24VDC Nominal (+18 to 32VDC)

Power Consumption

2 W-standby

5 W-during alarms

Output From SSS-903

+4-20mA industry standard analog with embedded HART

Digital RS-485 Modbus RTU

HART interface with easy access dedicated connector

4 “Dry Contact” relays (NO/Form-A)

All Relays Contact Rating 1Amp@125VAC/30VDC

Alarm Relays

3 User Programmed Alarm Relays

1 Fault Condition Relay

GT Sensor Interface to SSS903 Receiver

Digital RS-485 Modbus RTU

*Note All ESP Safety gas detector products can be interfaced with the SSS-903

Sensor Types / Model

Electrochemical: PGU-E

Infrared: PGU-IR

Photo Ionized: PGU-P

Humidity Range

Up to 100%, non-condensing

(Withstands up to 100% RH for short periods)

Operating Temperature

Standard Operation: -40oF to +167oF (-40oC to +75oC)

With Optic Heater Enabled: –76oF to +167oF (-60oC to +75oC)

Ingress Protection

IP66

RFI/EMI Protection

EN50081-1 / Class B E> 50270

*Operates with no interference from a 5 watt walkie talkie keyed (transmitting) at 1 meter

Annunciators (LED)

Tri-color status LED indicates operational mode, fault, and gas presence.

Three LED indicators for Alarms activation

A fourth LED indicates the unit is in calibration mode

Displayed Information

(Illuminated LCD Display)

Continuous sensor data

Gas Type

Measuring Units

Three Fixed Alarm Thresholds

Graphic display of trending data for Peak Readings and Time-Weighted Average (TWA) of gas

concentration 3-30 minutes

Explosion Proof Labels for SSS903 & PGU Sensors

Ex d [ia Ga] IIC T6 Gb

Ex d ia IIC T6

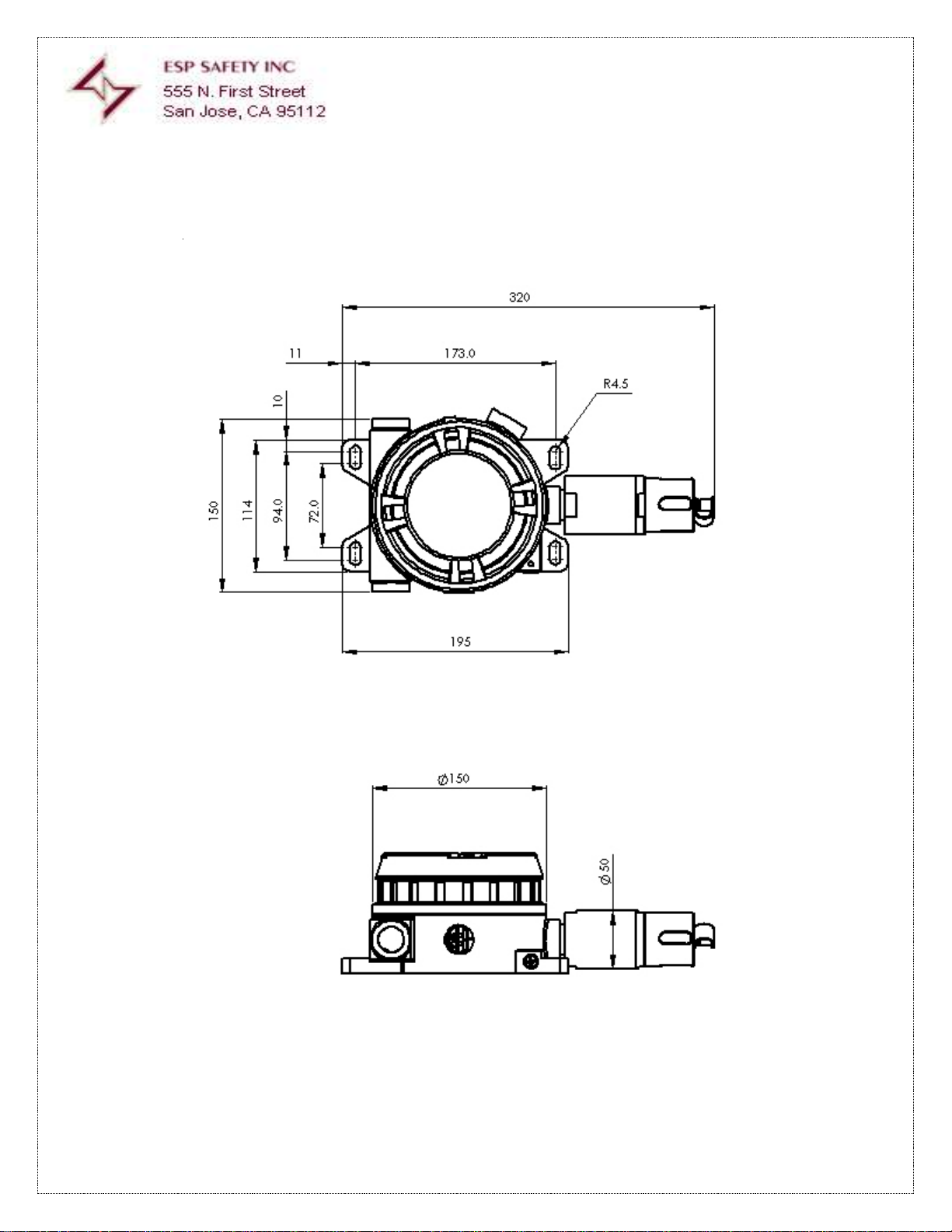

Dimensions of SSS-903

Receiver

270x150x120mm

10.63”x5.9”x4.73”

Dimensions of PGU Sensors

94x50mm

3.7”x1.97”

SSS-903 and PGU

Stainless Steel Grade-316

Cable Entry

2 Cable Entries ¾” NPT

Weight

5.5kg / 11lbs

Specifications of SSS-903 with PGU Sensors

Page 5

Part

Number:

10060-001

Rev:

03

Description:

SSS-903 TG-E

Install Guide

Date:

08/15/2017

Page: 5 of 53

Dimensions Diagram of SSS-903 Receiver

All dimensions are in mm

Page 6

Part

Number:

10060-001

Rev:

03

Description:

SSS-903 TG-E

Install Guide

Date:

08/15/2017

Page: 6 of 53

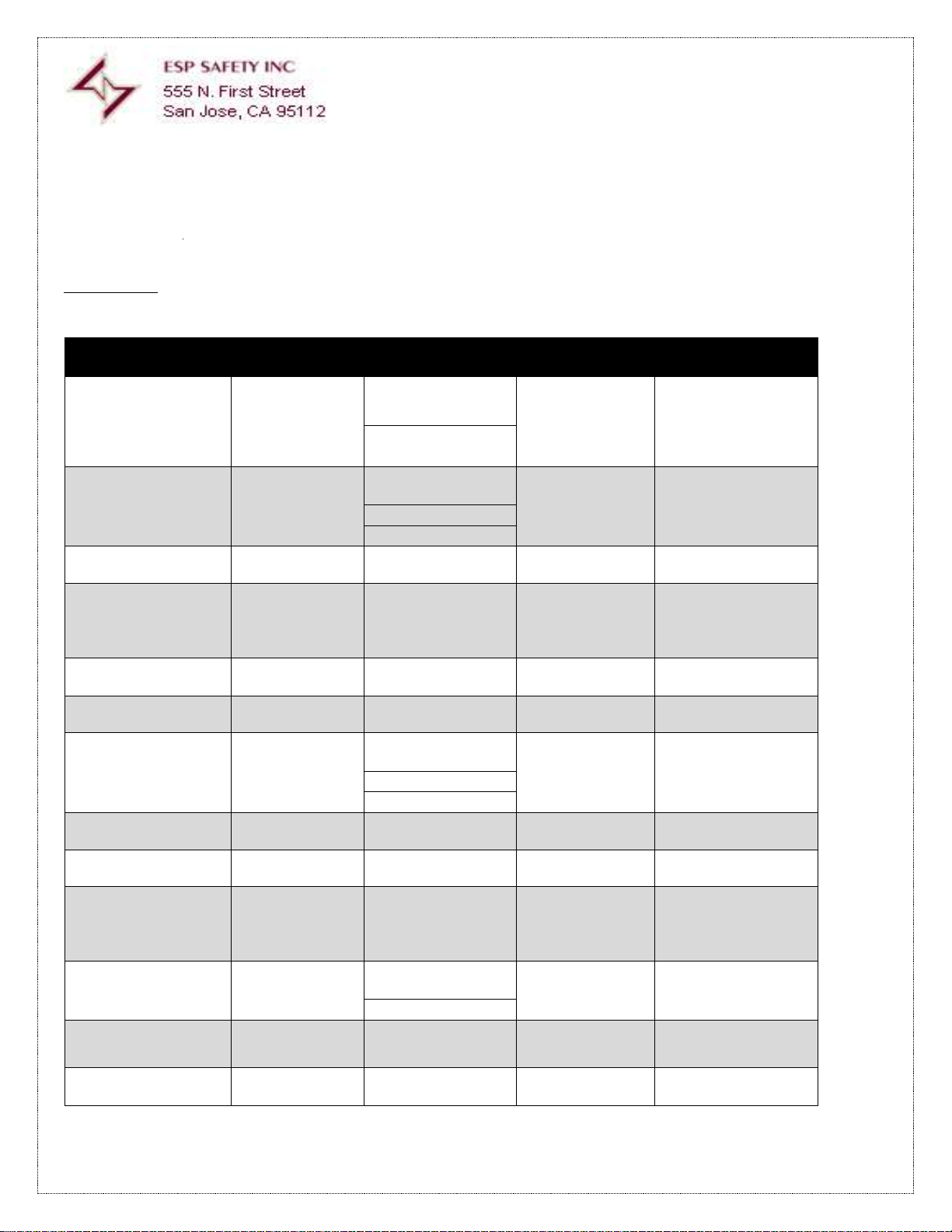

Table 1: SSS-903 with PGU-E Electrochemical Gas Sensor Range, Accuracy and

Response Times

Using Gas Specific Electrochemical Detectors

*Response Time is the time to reach a percentage of final reading when gas concentration is equal to full scale of the sensor

range of detection. (i.e. T50=50% 0f Range)

**Some sensors have multiple ranges one of which is determined by the user during setup or calibration

Gas Formula

Range of Detection**

Accuracy

Response Time*

Hydrogen

(H2)

0 to 4 % vol (100%

LEL)

±2% full scale

T50 < 40 seconds

Т90 < 60 seconds

0 - 1% vol (0 - 100)

ppm

Carbon Monoxide

(CO)

(0 - 100) ppm

±2% full scale

T20 < 10 seconds

Т90 < 25 seconds

(0 - 500) ppm

(0 – 1000)ppm

Ammonia

(NH3)

(0 - 1000) ppm

±2% full scale

Т90 < 90 seconds

Hydrogen Fluoride

(HF)

(0 - 10) ppm

±2% full scale

T50 < 30 seconds

Т90 < 90 seconds

Methanol

(CH3OH)

(0 – 100)ppm

± 2% full scale

Т90 < 90 seconds

Oxygen

(O2)

(0 - 30) % vol

±2% full scale

Т90 < 11 seconds

Hydrogen Sulfide

(H2S)

(0 - 20) ppm

±2% full scale

T20 < 10 seconds

T50 < 12 seconds

Т90 < 25 seconds

(0 - 50) ppm

(0 - 100) ppm

Chlorine

(CI2)

(0 - 20) ppm

±2% full scale

Т90 < 25 seconds

Formaldehyde

(CH2O)

(0 - 10) ppm

± 2% full scale

Т50 < 20 seconds

Nitrogen Dioxide

(NO2)

(0 - 20) ppm

±2% full scale

T50 < 12 seconds

Т90 < 25 seconds

Sulfur Dioxide

(SO2)

(0 - 20) ppm

±2% full scale

T50 < 12 seconds

Т90 < 25 seconds

(0 - 100) ppm

Hydrogen Chloride

(HCI)

(0 - 30) ppm

±2% full scale

T50 < 30 seconds

Т90 < 90 seconds

Vinyl Acetate

(C4H6O2)

(0 - 100)ppm

± 2% full scale

Т90 < 90 seconds

Page 7

Part

Number:

10060-001

Rev:

03

Description:

SSS-903 TG-E

Install Guide

Date:

08/15/2017

Page: 7 of 53

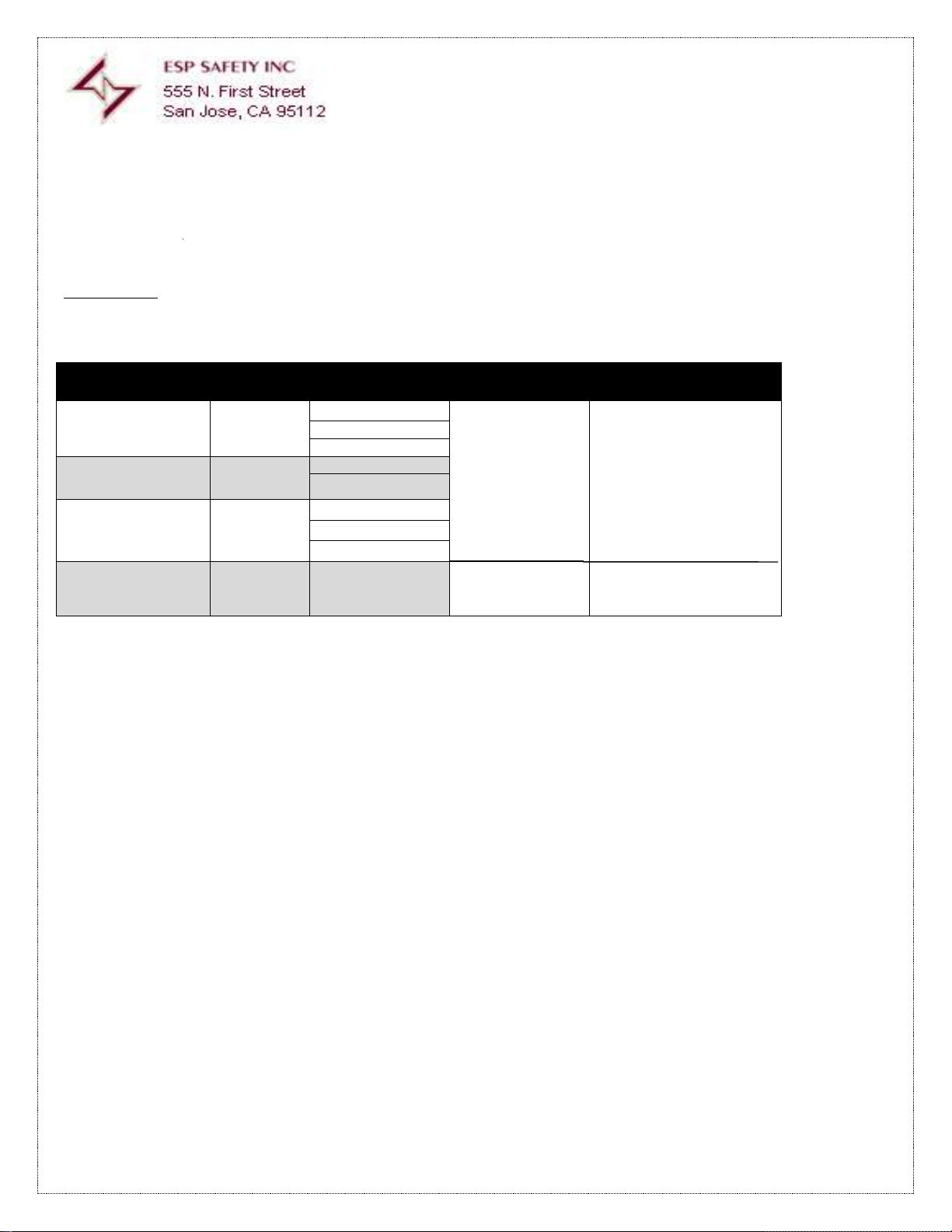

Using Gas Specific Photoionized Detectors

*Response Time is the time to reach a percentage of final reading when gas concentration is equal to full scale of the sensor

range of detection. (i.e. T50=50% 0f Range)

**Some sensors have multiple ranges one of which is determined by the user during setup or calibration

Note: All gases with ionization potential <10.6 eV

Gas

Formula

Range of

Detection**

Accuracy

Response Time*

Benzene

C6H6

(0 - 100) ppm

± 2% full scale

± 2% full scale

Т50 < 9 seconds

Т90 <25 seconds

Т90 <25 seconds

(0 - 1000) ppm

(0-10000) ppm

Ethylene

C2H4

(0 - 20) ppm

(0 - 2000) ppm

Isobutylene

C4H8

(0 - 20) ppm

(0 - 200) ppm

(0 - 2000) ppm

Methyl Mercaptan

СH3SH

(0 - 100) ppm

Other ranges per

request

Table 2: SSS-903 with PGU-P Photo Ionization Gas Sensor:

Range, Accuracy and Response Times

Page 8

Part

Number:

10060-001

Rev:

03

Description:

SSS-903 TG-E

Install Guide

Date:

08/15/2017

Page: 8 of 53

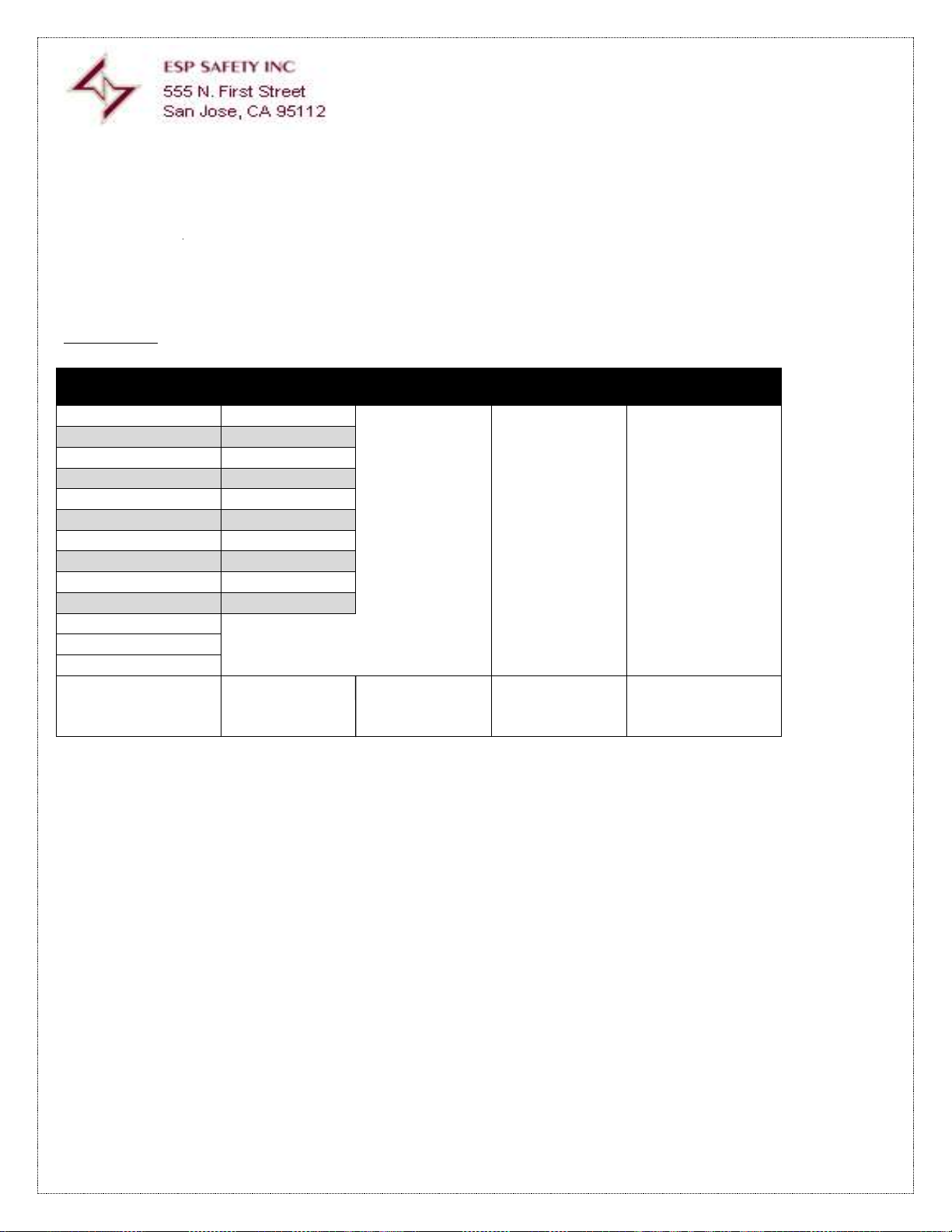

Using Gas Specific IR Detectors

*Response Time is the time to reach a percentage of final reading when gas concentration is equal to full scale of the sensor

range of detection. (i.e. T50=50% 0f Range)

Gas

Formula

Range of

Detection**

Accuracy

Response Time*

Methane

CН4

(0 -100) % LEL

± 3% to 50% LEL

± 5% from 51%

to 100% LEL

T20 < 5 seconds

Т90 < 25 seconds

Propane

C3Н8

Ethylene

C2Н8

Hexane

C6Н14

Butane

С4H10

Isobutane

l-С4Р10

Ethanol

C2H5OH

Cyclopentane

C5H10

Propylene

C3H6

Methanol

CH3OH

Gasoline Vapor

Diesel Vapor

JP4 Fuel Vapor

Carbon Dioxide

CO2

(0 to 2) % Vol

(0 to 5 ) % vol

( 1 – 3000) ppm

± 2% full scale

Т90 <25 seconds

Table 3: SSS-903 with PGU-IR Infrared Optical Detection:

Range Accuracy and Response Times

Page 9

Part

Number:

10060-001

Rev:

03

Description:

SSS-903 TG-E

Install Guide

Date:

08/15/2017

Page: 9 of 53

Using Catalytic Bead (pellisor) sensor specifically for detection of hydrogen

*Response Time is the time to reach a percentage of final reading when gas concentration is equal to full scale of the sensor

range of detection. (i.e. T50=50% 0f Range)

** All data refers to catalytic bead sensor as tested with H2 gas from an approved source. The sensor data listed is based on ideal test

environment with no interference from other gases

Gas

Formula

Range of

Detection**

Accuracy

Response Time*

Hydrogen

H2

0-100 % LEL

< ± 10% of

measured value

T 90 < 10 seconds

Table 4: SSS-903 with PGU-C Catalytic Bead Sensor:

Range Accuracy and Response Times

Page 10

Part

Number:

10060-001

Rev:

03

Description:

SSS-903 TG-E

Install Guide

Date:

08/15/2017

Page: 10 of 53

CE 0539 II 2 G

Ex d[ia] IIC T4 (Tamb 75°C)

IP 66

Ex d [ia] IIC T4

(Tamb 75°C)

IP 66

1 Ex d [ia] IIC T4 X T= -60°C....75°C

IP 66

EN Standards

EN 60079-0: 2006

EN 60079-1: 2007

EN 61779-1: 2000

EN 60529: 1991+A1: 2000

EN 50270: 2006.

94/9/EC ATEX:

IECEx:

Certifications

Page 11

Part

Number:

10060-001

Rev:

03

Description:

SSS-903 TG-E

Install Guide

Date:

08/15/2017

Page: 11 of 53

The SSS-903 is physically designed to perform in a wide range of hazardous environments and harsh weather conditions.

Employing a durable enclosure that can withstand these conditions and even explosion is key to the operation and function

of the device.

The SSS-903 is an elegant design that uses only two printed circuit board assemblies (PCBA) that have also been designed to

resist the effects of environmental challenges. The PCBAs are installed in a layered fashion with a single interconnection for easy

removal.

The Controller PCBA provides all information to the user via LED and LCD display. A micro controller with embedded software

performs all functions used in communication and control. As noted the controller card also functions as the driver for the

LCD display and performs all calculations used for the timed graphic HART. Event information displayed on the graphic cHART

is also stored in a Non-Volatile memory within the PGU sensor that can be accessed using ModBus or a HART communicator.

The second module is the Power PCBA. This PCBA accepts and regulates the externally supplied power source in addition to

all signal connections. Four solid state-sealed relays are also located on the Power PCBA eliminating the potential of electronic

discharge associated with mechanical relays.

All signals enter and exit the enclosure via ¾” threaded female attachments for conduit as required by the user application

and local regulations.

¾ Inch Inlet/Outlet Receptacles

For Explosion Proof Conduit and

Cabling

Dedicated HART Device

Communication Connector

with Protective Cover

Installed

.35” Diameter Surface

Mount (Left and Right)

Screw On Explosion Prove Housing Cover with

Shatter Proof Glass Window

Physical Earth

Ground Clamp

Housing Cover Lock

Screw

Removable PGU Sensor

Splash Guard and Gas Collector

Removable Detector Module Housing

cover with Lock Screw

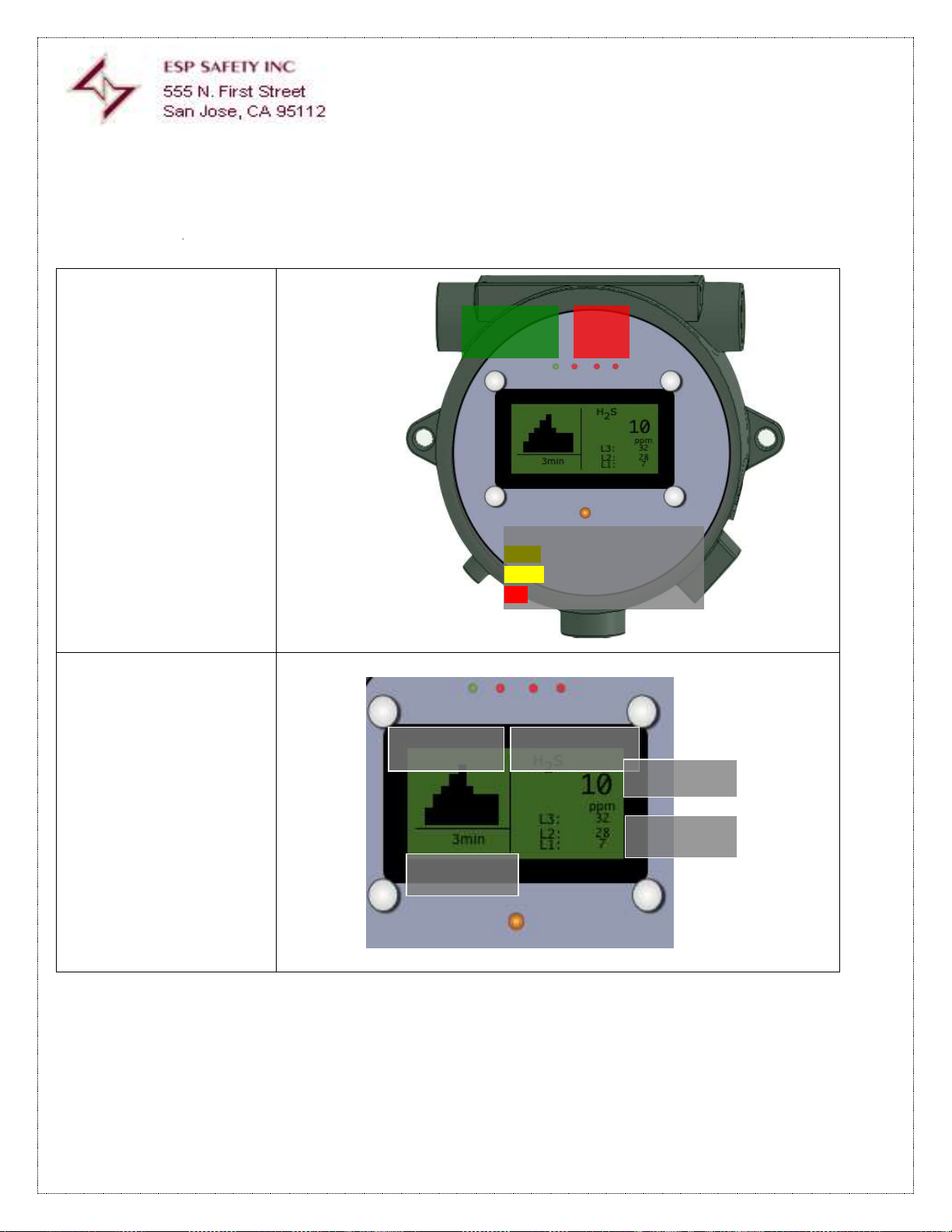

SSS-903 Receiver Operation

Figure 1 SSS-903 Receiver with PGU Sensor Installed

Page 12

Part

Number:

10060-001

Rev:

03

Description:

SSS-903 TG-E

Install Guide

Date:

08/15/2017

Page: 12 of 53

Figure 2- SSS-903 LED

Indicators

Figure 3 -

SSS-903 LCD Display

Detected Gas

Current Value

Alarm Preset

Values

Time Value of

Graphic Display

Graphic Display

Green

Calibration

Mode

Red

Alarm

1 2 3

Operational Status

Green – Normal Operation

Yellow – Alarm Active

Red – Fault Condition

Page 13

Part

Number:

10060-001

Rev:

03

Description:

SSS-903 TG-E

Install Guide

Date:

08/15/2017

Page: 13 of 53

The PGU-P performs selective detection of hydrocarbon molecules using infrared light and

photo ionization detectors (PID). Air containing molecules of the selected combustible gas

passes into a collection chamber that has an IR source and detector. The molecules containing

the combustible gas absorb the IR photons and become ionized. Ionized molecules create an

electric current that is measured by the detector. The electric current increases as the amount

of gas molecules in the chamber increases. The current is measured and processed by the

PGU-P sensor, generating the signals that are passed to the SSS-903 receiver via RS-485. Each

detector is factor programmed for the gas requested by the customer at the time of purchase.

Operation the PGU-IR is based on selective signal disruption by hydrocarbon molecules when an

infrared light source is projected to an optical detector. Measurement for a specific gas is

determined by passing the IR energy through a filter placed between the source and a chamber

where the gas is collected. If nogas is present, the detector will receive all of the energy

radiated by the IR source and generating an electrical current. When gas molecules enter the

collection chamber, each molecule of the gas blocks the IR energy reducing the output of the

detector, which is then processed by the PGU-IR sensor. Each detector is delivered preset for a

specific gas, in the example shown, the gas is Methane (CH4), which ionizes at two points on the

light spectrum, one for each Atomic Element, and are measured as wave numbers (cm-1).

Figure -5 TG-IR Detector

PGU-P Photo Ionization Gas Sensor Theory of Operation

Figure-4 PGU-P Detector

PGU-IR Infrared Optical Gas SensorTheory of

Operation

Page 14

Part

Number:

10060-001

Rev:

03

Description:

SSS-903 TG-E

Install Guide

Date:

08/15/2017

Page: 14 of 53

The PGU-P sensor contains electrode in contact with an electrolyte. The target gas

diffuses into the sensor through a membrane and comes into contact with electrodes

where it is oxidized. The electrochemical reaction results in an electric current that passes

to PGE-P microcontroller and from there to the SSS-903 receiver. The magnitude of the

current is controlled by how much of the target gas is oxidized by the electrode. Output

current from the sensor is also linearly proportional to the gas concentration. A linear

output allows for more precise measurement of low concentrations and much simpler

calibration.

Figure6 – TG-E Detector

PGU-E Electrochemical Gas Sensor Theory of Operation

Page 15

Part

Number:

10060-001

Rev:

03

Description:

SSS-903 TG-E

Install Guide

Date:

08/15/2017

Page: 15 of 53

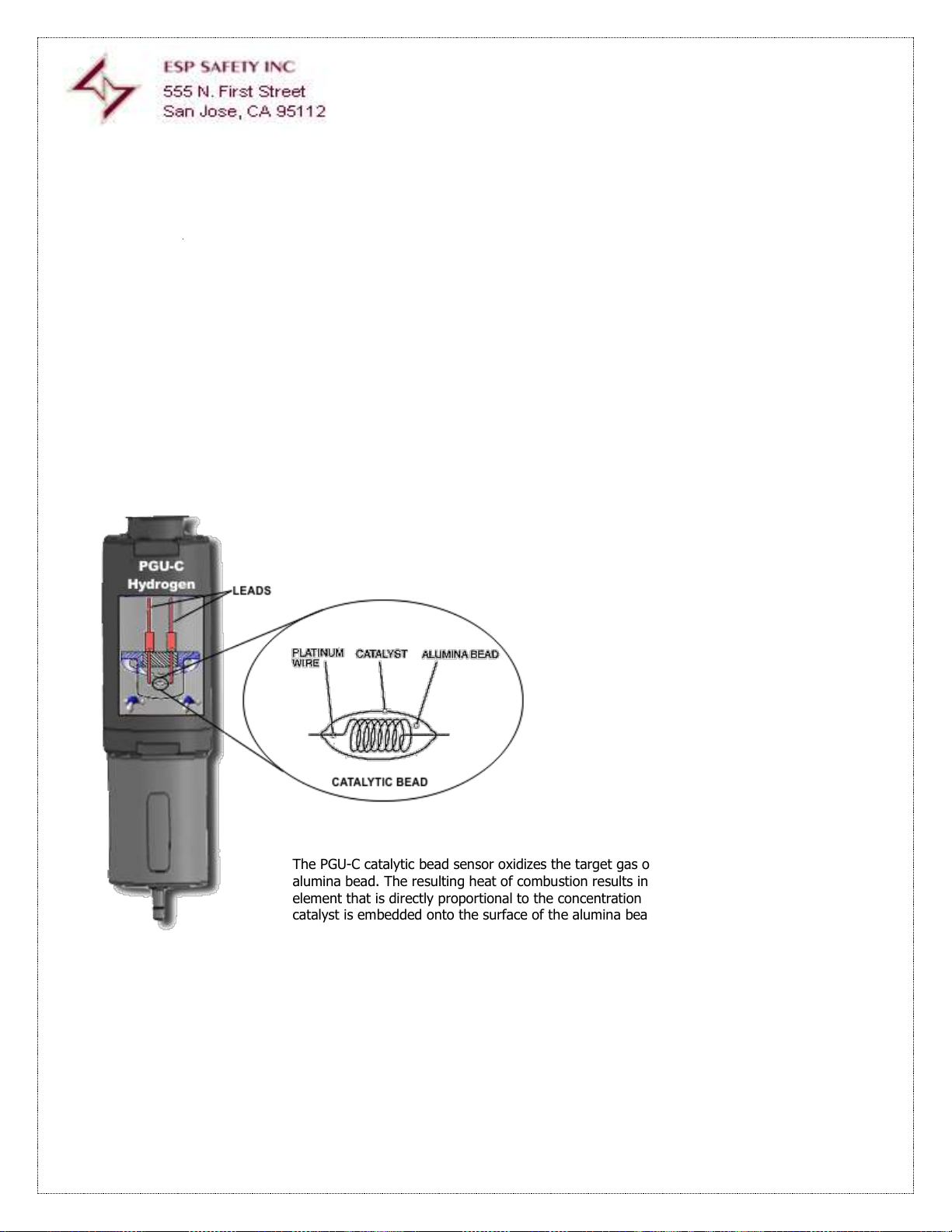

The PGU-C catalytic bead sensor oxidizes the target gas on the surface of a heated

alumina bead. The resulting heat of combustion results in a change in resistivity of the

element that is directly proportional to the concentration of the gas. A precious metal

catalyst is embedded onto the surface of the alumina bead to lower the oxidation

temperature. Two platinum wire leads are embedded in the alumina bead and connected

electrically in a Wheatstone bridge circuit. Heat is generated by passing current through

the leads.

Figure7 – TG-C Detector

PGU-C Catalytic Bead Gas Sensor Theory of Operation

Page 16

Part

Number:

10060-001

Rev:

03

Description:

SSS-903 TG-E

Install Guide

Date:

08/15/2017

Page: 16 of 53

Field Replaceable Detector

Module

Housing Label Must

Match with Detector

Gas.

Removable Housing

Cover with Filter

Each PGU sensor consists of PGU module with imbedded processing and a single gas specific plug-in

electrochemical, infrared (optical) or photo-ionized detector. There is a filter located between the

collection chamber and the detector to minimize potential contamination from dust or moisture. The

collection chamber is covered by a splashguard, which also serves as the gas collector. The

splashguard also has an inlet nipple for calibration purposes.

Each PGU detector internally stores the data reported to the SSS-903, HART, or Modbus. All

calibration information is also stored in the PGU module processor, thus any PGU module can be

moved to another SSS-903 receiver and resume data collection from the time of removal.

The detector module may be replaced in the field with a one that is intended for use to detect the

same gas. If a different gas is required a replacement PGU module must be ordered from ESP Safety

or their representative. Aside from detector or filter replacement there are no user serviceable parts

in the PGU sensor.

Figure 7 – PGU Detector Module

Page 17

Part

Number:

10060-001

Rev:

03

Description:

SSS-903 TG-E

Install Guide

Date:

08/15/2017

Page: 17 of 53

The SSS-903 provides three digital communication methods:

HART (Highway Addressable Remote Transducer) accessible via a dedicated connector that is located on the SSS-903 housing.

Digital RS-485 ModBus-RTU (Remote Terminal Unit)

HART over +4 to 20 mA output

HART is a bi-directional communication protocol that provides data access between

Intelligent field instruments and host systems. In most applications for the

SSS-903 the host is an ESP-Safety specific software application available from

the HART Foundation for use on a technician's hand-held HART communicator

device.A HART system in considered non-invasive in that the SSS-903 does not

have to be opened or removed from a field installed location.

HART communicators and RS-485 devices can access:

Information detected gas type

The measuring range in PPM or LEL%

Value of current gas concentration

State and programming of fixed alarm thresholds

Calibration Zero Cal Address of the SSS-903 as used by RS-485

Download of Non-Volatile Memory of event occurrence from a 60 day history

Modbus is an interface structure that is used for communication to control devices (PLC) or computers. Modbus is a similar

to HART but has been adapted as the industry standard for communication to multiple devices with a single cable run.

(Series or “Daisy Chain” connection) Unlike HART, RS-485 must be considered and designed into the installation of the SSS-903.

All of the same functions available with HART can also be accessed remotely with this system.

Modbus is available for use as a dedicated communication system with High Speed data communication.

ESP-Safety provides a Windows compatible computer application, ESP Commander, that provides all access to the

SSS-903 functions, and is often used for bench calibration of units removed from the field or prior to new installations.

ESP-Commander may require a customer provided translation device. All ESP Safety gas detector models have the ability

to interface with ESP Commander in RS-485 “daisy chain” networked installations. Modbus is also available in a single

point to point interface (one SSS-903 to One port of a control system as a data signal

that is imbedded in the +4 to 20mA analog output. In this application the data rate is significantly slower at 1200kb/s.

ESP-Safety has an available rack mounted control system that can

be used with all ESP devices along with those of other manufacturers.

Explosion proof integrity of SSS-903 units installed and in operation it is must not be modified in any form. All labeling must be

intact and visible. All surfaces that are subject to disassembly or removal during installation or maintenance must be installed as

detailed in Appendix I (Explosion Proof Diagram)

Emerson 475 Shown

Figure 8 - SSS-903 with

HART Communicator

Figure 9 - UPES Controller

Digital Data Communication

HART Dedicated Connector

Digital RS-485 Modbus

UPES Controller

Explosion Proof Integrity

Page 18

Part

Number:

10060-001

Rev:

03

Description:

SSS-903 TG-E

Install Guide

Date:

08/15/2017

Page: 18 of 53

Caution: The installation of SSS-903 must comply with relevant requirements of the latest edition

of the national Electri Code (ANSI/NFPA 70)

Caution: Connection Conduit, Barrier Glands, and Epoxy Sealants are to meet

EN-50018/IEC 60079-1 Standards

Caution: ESP Safety Inc. Recommends use of shielded cable with 14AWG conductors reaching a span

no greater than 3,900 ft. (1200 meter)

Be sure to read and understand the entire instruction manual before installing or operating the gas detection system. The products

described in this document can be used with a variety of ESP-Safety gas detector models to provide earlywarning of the presence of a

toxic or explosive gas mixture. Proper device installation, operation, and maintenance is required to ensure safe and effective

operation. If this equipment is used in a manner not specified in this manual, safety protection may be impaired.

Caution: The installation of SSS-903 must comply with relevant requirements of the latest edition of the national

Electric Code (ANSI/NFPA 70)

Caution: Connection Conduit, Barrier Glands, and Epoxy Sealants are to meet EN-50018/IEC

60079-1 Standards

Caution: ESP Safety Inc. Recommends use of shielded cable with 14AWG conductors reaching a span no greater

than 3,900 ft. (1200 meter)

Cautions and Warnings

This user guide includes numerous cautions and warnings that are specifically included to prevent injury to

personnel and prevent damage to equipment. Care is also taken to include notation of all applicable

standards and best practices as appropriate information that may apply to any use or procedure associated

with the product.

WARNING: TOXIC, COMBUSTIBLE, AND FLAMMABLE GASES OR VAPORS ARE VERY

DANGEROUS. USE EXTREME CAUTION WHEN THESE HAZARDS ARE PRESENT.

WARNING: Take appropriate precautions, including wearing and use of protective clothing and

devices when servicing the SSS-903 as they may have remnants of corrosive solutions.

IMPORTANT SAFETY INFORMATION

Page 19

Part

Number:

10060-001

Rev:

03

Description:

SSS-903 TG-E

Install Guide

Date:

08/15/2017

Page: 19 of 53

Physical Installation Procedure

Preparing For

Installation

The SSS-903 has unique installation procedures for either local or remote hardware

configurations. Before installation, evaluate the gas leak locations and other

conditions at the test site and configure the unit for that particular need.

PGU sensor Location

Selection of PGU sensor location is critical to the overall performance of the product.

Five factors play an important role in the selection of PGU sensor locations:

Density of the gas to be detected

Most probable leak sources within the industrial process

Ventilation and prevailing wind conditions

Personnel exposure

Maintenance access

*Note the PGU Sensor must be pointed down.

Density of detected

gas

If the target gas is heavier than air, the sensor should be located within 4 feet of

grade. Heavier than air gases will tend to settle in low-lying areas. For gases lighter

than air, PGU sensor placement should be 4-8 feet above grade in open areas or in

pitched areas of enclosed spaces.

Probable leak

sources

Leak sources include flanges, valves, and tubing. Connections of the sealed type

where seals may either fail or wear. All potential leak sources and SSS-903 mounting

locations are best determined by facility engineers with experience in similar

processes.

Ventilation and

Prevailing Winds

Normal ventilation or prevailing wind conditions can dictate efficient location of gas

PGU sensors so that migration of potential gas clouds is quickly detected.

Personnel exposure

If an undetected migration of gas clouds should approach concentrated personnel

areas such as control rooms, maintenance or warehouse buildings. Selection of PGU

sensor location should include the potential leak source and perimeter of personnel.

Use of ESP Safety PGUAES open field detectors should be considered for these areas.

Maintenance Access

Consideration should be given to providing easy access for maintenance personnel.

PGU sensor location should also take into account the proximity to contaminants that

may foul the PGU sensor prematurely.

SSS-903 Receiver

and PGU Sensor

Location Guidelines

There are no standard rules for placement since the optimum PGU sensor location is

unique for each application. Before installing the SSS-903, check the conditions at the

installation site to make a placement determination. The following guidelines can

assist in determining the best possible placement of the SSS-903:

Locate the SSS-903 near potential gas leak sources and away from excessive heat,

light, wind, dust, water, vibration, shock, and radio frequency interference (RFI).

Ensure the installation location has sufficient space to accommodate the SSS-903

housing, PGU sensor, and all necessary cabling.

Mount the SSS-903 with the PGU sensor pointing down.

Mount the SSS-903 housing in an easily accessible location for reading the digital

display and calibration checks

Page 20

Part

Number:

10060-001

Rev:

03

Description:

SSS-903 TG-E

Install Guide

Date:

08/15/2017

Page: 20 of 53

Physical Installation Quick Guide

Page 21

Part

Number:

10060-001

Rev:

03

Description:

SSS-903 TG-E

Install Guide

Date:

08/15/2017

Page: 21 of 53

Tools Required

18-Inch Adjustable Crescent (Spanner Wrench) with 2-inch or greater span for installation

and removal of PGU sensor/Sensors

2-MM “Flat Head” screwdriver for protective cover lock screw and wire terminal block clamps

#2 Phillips Head Screwdriver for Ground Connector

Physical

Installation/

mounting

The SSS-903 can be physically mounted in a number of ways.

The surface mount “ears” can be used for a wall mount.

Figure 10 – Mounting To Pole (Local Configuration)

Figure 11- Mounting

with PGU Sensor in

local configuration

Local configuration refers to the

configuration where the SSS-903 housing

and the pre-calibrated PGU PGU sensor

are attached and placed in the same

location. This is also commonly referred

to as a stand-alone configuration.

Install explosion proof conduit or cable or

conveying appropriate cabling using into a ¾” Male NPT fitting using an explosion proof

cable gland.

Mount the SSS-903 vertically with the Smart PGU sensor pointing down to reduce the

possibility of dirt and dust building up on the window.

Ensure that the open slots of the gas passage are straight up and down to enable the gas to

rise up and through the PGU sensor’s cell.

Using the two surface mounting holes, attach the SSS-903 to a pole bracket or a surface

mount to a wall.

Caution: The SSS-903 with TG Sensor installed must

always be installed in a vertical orientation with the TG

Sensor pointing down. This will minimize collection of

contaminates in the TG sensor.

Page 22

Part

Number:

10060-001

Rev:

03

Description:

SSS-903 TG-E

Install Guide

Date:

08/15/2017

Page: 22 of 53

Mounting in

Remote

configuration

Figure 13 –

Sensor removal

In addition to the standard local configuration, the SSS-903 also supports remote placement

of the PGU sensor up to 500 feet away from the housing.

Mount the SSS-903 housing vertically to reduce the possibility of dirt and dust building up on

the window.

Using an optional bracket or the two surface mounting holes, attach the SSS-903 to a stable

surface or wall.

Mount the PGU sensor to a stable surface or wall with user supplied clamps.

Connect the explosion proof conduit or cable to the SSS-903 housing.

Connect the explosion proof conduit or cable to the PGU sensor.

Ensure that the PGU sensor is pointing down for maximum exposure.

All connections require explosion proof and sealed cable glands.

FIGURE 12 - REMOTE CONFIGURATION

Note: The SSS-903 remote configuration option can be utilized with any gas analyzer

equipped with the standard RS-485 (Modbus RTU) output and a power consumption of 24

VDC. This includes all of ESP Safety’s toxic gas PGU sensors and ESP’s SGOES Combustible

Gas Detector.

Earth Grounding

The enclosure of the SSS-903 Reciever must be

earthed/grounded for for electrical safety and to limit the

effects of radio frequency interference. An earth/ground

point is provided on the outside of the SSS-903 Explosion

Proof enclosure

Use 14 AWG copper, (Stranded or Solid), wire.

Loosen the screw sufficiently to enable wrapping the wire

around the screw in a “U” shape. Raise the flat and lock

washers and place the wire between the flat washer and

ground base.

Tighten the screw to10.4lb-in torque.

Figure 14 – Ground

Page 23

Part

Number:

10060-001

Rev:

03

Description:

SSS-903 TG-E

Install Guide

Date:

08/15/2017

Page: 23 of 53

Step 1- Remove

Protective Cover

Figure 15 - Cover Removal

Loosen the Protective Cover Lock Screw

approx. one turn.

Remove the explosion proof protective

cover by

turning counter

clockwise. The handle

of a Crescent or

Spanner Wrench can

be used as a lever

with the cover removal tabs.

Step 2- Remove

Control PCBA

Module

Figure 16 - Remove Module

Un-plug the control circuit by grasping two of the

thumbscrews surrounding the display and pulling outwards.

Step 3- Wire

Preparation

Figure 17 –Wire

Prep

Use a stripping tool for the selected wire gauge to remove ¼-inch

(6mm) of the insulating jacket for each conductor to be inserted in the

terminal blocks of the Connector PCBA.

Step 4- Electrical

Connections

Figure 18 - Spring Clamp Terminal Block

Use a 2MM Flathead screwdriver or Spring Actuation Tool to

engage spring connector slots when installing or removing

wires.

Step 5-

Re-assemble the

SSS-903

After wiring is completed insert the control module with the 4 LED lights at the top then

attach the Explosion Proof protective cover onto the SSS-903 and secure by tightening the

housing cover lock screw.

Paladin Model GripP – 1117

Multi-gauge wire stripper

shown above

¼” (6mm)

Shielded 14 AWG Stranded wire

(Recommended)

6mm Insulated Crimp On Ferrule

ESP safety recommends a Ferrule

that is crimped onto the wire for

better connectivity and ease of

insertion into the terminal block.

Insert wire

Use tool to lever the

spring open

Remove

Cover

Lock

Screw

Removal

Page 24

Part

Number:

10060-001

Rev:

03

Description:

SSS-903 TG-E

Install Guide

Date:

08/15/2017

Page: 24 of 53

Caution: All cable/conduit entries must be sealed with an appropriate and certified sealing plug and cable gland. The use of

industrial grade, armored field cable is recommended. If installing the PGU sensor in a hazardous area using remote

configuration, armored cabling is required for the Probe/Sensor connection to the SSS-903 receiver.

Cabling Guidelines

If installing connection cables in an explosion proof conduit, do not use the same conduit to carry wiring for any other purpose

or equipment.

If installing the PGU sensor in a hazardous area using remote configuration armored cabling is required for the PGU Sensor

connection to the SSS-903 Receiver

Minimum 14 AWG (2.08 mm2) shielded cable conductors are required for optimal performance. The gauge of the wire used

determines the maximum distance between the controller and the PGU SENSOR.

When using Modbus power and signal must be separate shielded twisted pair conductors

CAUTION: System Power / Digital Ground

System ground must be provided at the point

of origination for 24VDC. Failure to do this

may result in loss of range and/or signal

integrity.

General Wiring Requirements

Page 25

Part

Number:

10060-001

Rev:

03

Description:

SSS-903 TG-E

Install Guide

Date:

08/15/2017

Page: 25 of 53

Terminal Block X-3

Terminal Block X-1

Terminal Block X-2

Terminal Block X-4

J1

Figure 19 - Power Board Connecting Terminal Block Locations

Page 26

Part

Number:

10060-001

Rev:

03

Description:

SSS-903 TG-E

Install Guide

Date:

08/15/2017

Page: 26 of 53

Connection

Label

Function

Terminal Block X1

SCR

Not Used

RS485B

ModBus RTU Interface

RS485A

ModBus RTU Interface

GND

Digital Ground

+24V

+24 VDC Power (From External Source)

Terminal Block X2

SCR

Bridge from X1 SCR for Daisy Chain configuration

RS485B

Bridge from X1 RS-485B for Daisy Chain configuration

RS485A

Bridge from X1 RS-485A for Daisy Chain configuration

GND

Bridge from X1 GND

+24V

Bridge from X1 +24 VDC

Terminal Block X3

+4 to 20 mA

Analog status system with embedded HART

communication data

GND

Digital Ground

Fault Relay In

Normally Open Relay closes when the SS-903 detects

a fault condition.

Fault Relay Out

Closed condition output of Fault Relay

Level 1 Relay In

Normally Open Relay closes when the SS-903 detects

a pre-programmed level condition determined by +4

to 20 mA.

Level 1 Relay Out

Closed condition output of Level 1 Relay

Level 2 Relay In

Normally Open Relay closes when the SS-903 detects

a pre-programmed level condition determined by +4

to 20 mA.

Level 2 Relay Out

Closed condition output of Level 1 Relay

Level 3 Relay In

Normally Open Relay closes when the SS-903 detects

a pre-programmed level condition determined by +4

to 20 mA.

Level 3 Relay Out

Closed condition output of Level 1 Relay

Terminal Block X4

SCR

RS-485B

Probe

RS-485a

GND

+24V

Jumper 1

J1

Termination Jumper For “Daisy Chain” RS-485

configuration of Multiple SSS-903 Units.

Table 6 SSS-903 Connections

Page 27

Part

Number:

10060-001

Rev:

03

Description:

SSS-903 TG-E

Install Guide

Date:

08/15/2017

Page: 27 of 53

Installation Wiring

There are several methods of wiring connections for the SSS-903 Receiver. To accommodate this variety and provide ease of

installation, the SSS-903 includes all hardware and connections for any configuration determined by the user making it well suited for

new and replacement applications.

Caution: The installation of SSS-903 must comply with relevant requirements of the latest edition of the national

Electric Code (ANSI/NFPA 70)

Caution: Connection Conduit, Barrier Glands, and Epoxy Sealants are to meet EN-50018/IEC

60079-1 Standards

Caution: ESP Safety Inc. Recommends use of shielded cable with 14AWG conductors reaching a span no greater

than 3,900 ft. (1200 meter)

Caution: All cable/conduit entries must be sealed with an appropriate and certified sealing plug and

cable gland. The use of industrial grade, armored field cable is recommended. If installing the TG

sensor in a hazardous area using remote configuration, armored cabling is required for the Sensor

connection to the SSS-903 receiver.

Remote PGU Sensor Wiring to SSS-903

Figure 20 –PGU Connection to Terminal Block X-4

Page 28

Part

Number:

10060-001

Rev:

03

Description:

SSS-903 TG-E

Install Guide

Date:

08/15/2017

Page: 28 of 53

Figure 21 - Comprehensive Wiring Diagram for Multiple use Configuration

Page 29

Part

Number:

10060-001

Rev:

03

Description:

SSS-903 TG-E

Install Guide

Date:

08/15/2017

Page: 29 of 53

Figure 22 - Connecting the SSS-903 to ESP Safety UPES Multichannel Controller

Figure 23 - Connecting the SSS-903 Using 3 Wire Analog Interface Method

Page 30

Part

Number:

10060-001

Rev:

03

Description:

SSS-903 TG-E

Install Guide

Date:

08/15/2017

Page: 30 of 53

Figure 24 - Connecting the SSS-903 Using 4 Wire Analog Interface Method

Page 31

Part

Number:

10060-001

Rev:

03

Description:

SSS-903 TG-E

Install Guide

Date:

08/15/2017

Page: 31 of 53

Installation

Review Prior to

Startup

Once the mounting, cabling, and alarm relay installation has been completed, the SSS903 is ready to begin the power-on sequence.

Before applying power to the system for the first time, review the steps below:

Verify that the SSS-903 has been properly mounted. Ensure that all conduit / cable

gland entries have been tightened and sealed if necessary.

Verify that all of the signal wires have been installed correctly.

Verify connection or earth/ground to the enclosure.

Verify connections between the SSS-903 housing and the PGU sensor if in remote

configuration.

Verify the connections between the SSS-903 housing and any control room devices and

alarm systems.

Make sure that the SSS-903 cover is securely installed and locked with the housing

cover lock screw.

Make sure to turn off or disconnect any external devices, such as Trip Amplifiers, PLC

devices or DCS systems, until after the startup sequence has been completed.

Once you are ready to begin startup, verify that the power supply is connected properly

and verify input voltage with the SSS-903 disconnected at the source. The SSS-903 is

powered by 24 VDC (12 to 36 VDC voltage range).

After completing the above, the SSS-903 is ready to be powered on.

Startup Procedure

Before the initial power up,

remove power from or

disconnect all output devices

and alarms to prevent actuation.

Apply power to the

system. Upon first

power-up, the SSS-903

should be allowed to

stabilize and allow the

sensor to initialize

Figure 25 - Initialization Screen

After 15 seconds, the

Operational Status indicator

diode will glow green and all

information will be available on

the display.

Figure 26 - Operation Screen

Power up and Stand Alone Operation of the SSS-903

Page 32

Part

Number:

10060-001

Rev:

03

Description:

SSS-903 TG-E

Install Guide

Date:

08/15/2017

Page: 32 of 53

The Modbus interface is used for communication to all ESP Safety Detector models. Up to 480 devices can be connected in

a Daisy Chain method. Modbus® RTU protocol uses ASCII/Hex data for communication and allows all SSS-903 functions to be

transmitted using this method.Modbus protocol is a Master-Slaves protocol. ESP-Safety provides a communication program,

ESP Commander that uses a PC as a Master Device

controlling all connected Detectors as Slave devices.

The ESP Commander master initiates all communication to the devices. The slave detectors

cannot transmit data without receiving a request

from the master. The slave detectors cannot communicate with each other.

MODBUS® is a registered trademark of Schneider

Automation Inc.ESP Commander can perform real

time monitoring, control operations, adjustment of

function, and download of the non-volatile flash

memory on the SSS-903.

ESP Safety manufactures a variety of detection devices for fire, explosive and toxic gas detection. Up to eight detectors, of any

mix, can be connected in a string, or daisy chain. When using this configuration, Jumper J-1 must be used for the last unit in

the chain, providing signal termination. All other units must have J1 removed.

RS-485 Modbus Digital Communication and Operation

Figure 27 - Modbus Connection with Analog and Alarm

RS-485 Modbus Daisy Chain Digital Data Loop

Figure 28 - Modbus Daisy Chain

Page 33

Part

Number:

10060-001

Rev:

03

Description:

SSS-903 TG-E

Install Guide

Date:

08/15/2017

Page: 33 of 53

There are three methods available to perform calibration of the SSS-903 with Smart Probe:

Using RS-485 Modbus with the ESPCommander control Program (Bench Test Method A)

Using a HART Communicator (Non-invasive In Field or Bench Test Method B) HART Communicator required

Using a Magnetic “Wand” (Non-invasive In Field or Bench Test Method C) No Instrument or tools required

Non-Invasive Zero set up can be performed on SSS-903 detectors when installed in the permanent

location by using a magnetic Wand that is included with every SSS-903 unit.

Required Equipment For

Non-Invasive

Calibration

.

¼” PVC Tubing

ESP Safety Zero Gas and Span

Gas disposable canister for

the appropriate gas.

ESP Safety Magnetic Wands

Figure 29 - Equipment for Magnetic Wand Calibration

Magnetic Wand

Warning: Trained staff must perform all calibration procedures.

The calibration procedure work area must be located a safe distance from any hazardous zone.

Follow all site safety operating procedures before removing any detector from service.

Warning: All alarms must be disconnected to eliminate the possibility of erroneous alarm

activation when performing this procedure.

Calibration Procedures

Methods of Performing Calibration

Page 34

Part

Number:

10060-001

Rev:

03

Description:

SSS-903 TG-E

Install Guide

Date:

08/15/2017

Page: 34 of 53

Non-Invasive Magnetic Wand Calibration Procedure

Page 35

Part

Number:

10060-001

Rev:

03

Description:

SSS-903 TG-E

Install Guide

Date:

08/15/2017

Page: 35 of 53

Purging

The working area must be

free of any Gas or

contaminants.

Connect the nipple of Sensor’s

collection chamber to the Zero

Gas Cylinder with PVC tubing.

1. Apply magnetic wand to

SSS-903 calibration point.

CAL LED will turn solid

green and ‘CALIBRATION’

message is displayed

2. Apply zero gas for at least

1 minute at 0.3 LPM flow

rate. Ensure reading

displayed on SSS-903 is a

stable value (should be

zero).

Figure 30 – Purge for Wand Calibration

Wand Zero Cal

Apply magnetic wand to

SSS-903 calibration point.

CAL LED will start to flash

green. Displayed value

should be zero (zero

calibration is now

complete).

Figure 31 - Zero Cal with Wand

Page 36

Part

Number:

10060-001

Rev:

03

Description:

SSS-903 TG-E

Install Guide

Date:

08/15/2017

Page: 36 of 53

Wand Span Cal

1. Apply calibration gas for 1

minute at 0.3 LPM flow

rate. Reading displayed

should increase to near

calibration gas value.

Ensure reading is stable

value.

2. Apply magnetic wand to

SSS-903 calibration point.

The CAL LED will start

rapidly flashing green.

The magnetic calibration

gas value is now set,

displayed value should

equal magnetic

calibration gas value.

3. Remove the calibration

cup, once calibration gas

is clear of the sensor

(readings approach zero)

CAL LED will turn off and

‘CALIBRATION’ message

turns off indicating

calibration is complete.

Figure 32 – Span Cal with Wand

Caution: Factory calibration of the PGU sensor is performed using a gas flow rate of 0.3 LPM

(Litres Per Minute). ESP Safety recommends that field calibration of PGU sensors is performed at

the same flow rate. Using non-recommended flow rates may result in calibration errors.

Page 37

Part

Number:

10060-001

Rev:

03

Description:

SSS-903 TG-E

Install Guide

Date:

08/15/2017

Page: 37 of 53

Non-Invasive field calibration can be performed on SSS-903 detectors with a HART communicator.

Establish communication between the HART Communicator and

the SSS-903 by attaching the ESP Safety-supplied cable to the

HART connection port of the SSS-903

Zero Calibration using a HART Communicator

Step 1:

From the Online Display, select 1 Device Setup

Step 2:

Highlight and select the 2 Detailed Setup item.

Figure x-xx: Device Setup

Figure x-xx: Online Display

Non-Invasive Calibration Procedure w HART Communicator

Page 38

Part

Number:

10060-001

Rev:

03

Description:

SSS-903 TG-E

Install Guide

Date:

08/15/2017

Page: 38 of 53

Page 39

Part

Number:

10060-001

Rev:

03

Description:

SSS-903 TG-E

Install Guide

Date:

08/15/2017

Page: 39 of 53

Step 3:

Highlight and select the 6 Sensor Trim item.

Step 4:

From the Sensor Trim Display, highlight and select 3

Zero Trim

Warning Message 1:

Note the warning message. As a safety precaution,

any alarms or devices controlled by the gas sensor

output should be disabled at this time.

Warning Message 2:

Note the warning message. The user may abort the

calibration sequence at this point if calibration is not

desired at this time.

Step 5:

Apply the zero gas to the sensor and wait for the

reading to stabilize. Press “OK” to complete the

sensor zero calibration. Press “ABORT” to cancel the

calibration sequence. Remove the zero gas from the

sensor.

Warning Message 3:

Figure x-xx: Warning Message 2

Figure x-xx: Warning Message

Figure x-xx: Sensor Trim Select

Figure x-xx: Detailed Setup

Figure X-XX: Sensor Zero Calibration

Figure x-xx: Warning Message

Page 40

Part

Number:

10060-001

Rev:

03

Description:

SSS-903 TG-E

Install Guide

Date:

08/15/2017

Page: 40 of 53

Span Calibration using a HART Communicator

Step 1:

From the Online Display, select 1 Device Setup

Step 2:

Highlight and select the 2 Detailed Setup item.

Step 3:

Highlight and select the 6 Sensor Trim item.

Step 4:

From the Sensor Trim Display, highlight and select 4

Device Variable Trim

Figure X-XX: Sensor Zero Calibration

Step 5:

Apply zero gas to sensor. When the displayed gas is

stable, select OK

Step 5a:

The SSS-903 display will show ‘Calibration’ message

and green CAL LED will flash.

Figure x-xx: Device Setup

Figure x-xx: Online Display

Figure x-xx: Sensor Trim Select

Figure x-xx: Detailed Setup

Page 41

Part

Number:

10060-001

Rev:

03

Description:

SSS-903 TG-E

Install Guide

Date:

08/15/2017

Page: 41 of 53

Step 6:

Select gas calibration.

1. Lower Concentration (choose for mid-span)

2. Upper Concentration (choose for full-scale)

Step 7:

Apply concentration gas. When the displayed gas

value is stable, select ‘OK’.

Step 8:

Enter the span gas concentration in the units

specified. Press ‘ENTER’ to complete

Step 8a:

The value of the gas displayed on the SSS-903 should

now equal the reference gas concentration.

Figure x-xx: Warning Message 2

Figure X-XX: Sensor Zero Calibration

Figure x-xx: Warning Message

Page 42

Part

Number:

10060-001

Rev:

03

Description:

SSS-903 TG-E

Install Guide

Date:

08/15/2017

Page: 42 of 53

Step 9:

Reapply zero gas. The green ‘CAL’ LED on the SSS903 will flash for approximately three minutes as the

readings stabilize. When calibration is complete, the

green ‘CAL’ LED will turn off and the ‘ON/FAULT’ LED

will display solid green, indicating normal function.

Page 43

Part

Number:

10060-001

Rev:

03

Description:

SSS-903 TG-E

Install Guide

Date:

08/15/2017

Page: 43 of 53

Warning: SSS-903 Receivers and PGU Sensors may be used in conditions where Toxic gasses may have been

present. The customer must follow their defined and regulatory procedures, including protective clothing and

or breathing apparatus for safe handling of these toxic substances, as residual of amounts of the toxic

substance may be present in the Detector units being calibrated.

Caution: Before the calibration and verification procedure, inspect the SSS-903 for any mechanical damages to

the enclosure and/or sensor elements. Please contact the ESP Safety Inc. service department for further

information

Bench Test Calibration Procedure with ESP Commander

The bench test procedure requires the SSS-903 and PGU sensor to be removed from a field

installation for testing in an area designated by the user. Site safety procedures should designate

the location, configuration, and safety requirements.

The user may also choose to perform a bench calibration as part of a commissioning procedure

for a new (out of the box) unit prior to installation.

Page 44

Part

Number:

10060-001

Rev:

03

Description:

SSS-903 TG-E

Install Guide

Date:

08/15/2017

Page: 44 of 53

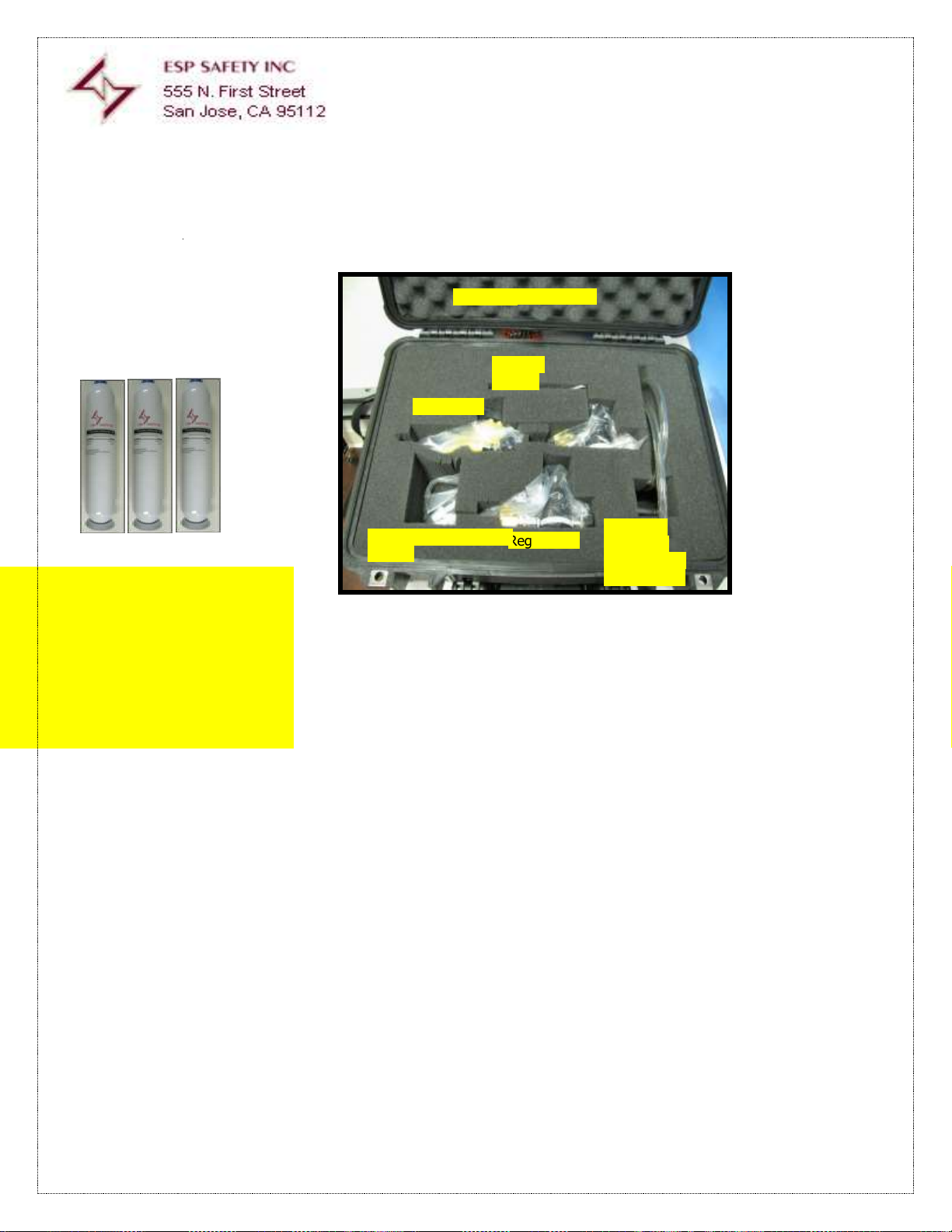

ESP Safety Inc. SSS-903 Calibration Kit for Methane Gas (Part Number 24011-xxx)

Power supply: output voltage 0-30VDC with adjustable current limit (no less than .05mA)

Digital Multimeter (Optional)

Plastic or vinyl tube – 3 pieces of 59.06 inches (1.5M) in lenPGUh

Four control lamps (24VDC) for relay operation verification (Optional)

PC With Windows operating System

Convertor RS232/485 (Or USB to RS-485 Adapter Cable)

ESP Safety Inc. “ESP Commander Program”

ITEM

PART NUMBER

DESCRIPTION

QTY 1 50016-xxx

ZERO GAS CALIBRATION CYLINDER

1 2 50021-xxx

MID-SPAN CALIBRATION GAS CYLINDER (50% LEL)

1 3 50022-xxx

SPAN GAS CALIBRATION CYLINDER (50% LEL)

1

4

40072-xxx

REGULATOR, SINGLE STAGE, FIXED ORIFICE, 500 SCCM

3

5

40074-xxx

CUP, CALIBRATION, SSS-903

1 6 40076-xxx

CASE, TRAVEL, CALIBRATION KIT

1

Crescent

Wrench

Regulator 1

Regulator 3

TG Sensor

Calibration

Cup with ¼”

Tygon tubing

Extra Fittings for Teflon

gaskets

Hard Shell Travel Case

Calibration Gas Cylinders

Zero Gas (0% LEL)

Mid Span Gas (typically 50%LEL)

Span Gas (typically 90% LEL)

Cylinders are supplied with 1 cubic liter of

gas at 1600-1800 PSIG. Replace cylinders

when the internal pressure is lower than

200PSIG

Note: User supplied tanks and

regulators may be employed.

Flow rates must be limited to

10 LPM as measured on a

rotameter.

The following equipment is required for ESP Commander calibration of the SSS-903:

Figure 39- ESP

Safety Inc.

calibration Kit

Methane Gas

Calibration Kit Components

Page 45

Part

Number:

10060-001

Rev:

03

Description:

SSS-903 TG-E

Install Guide

Date:

08/15/2017

Page: 45 of 53

Figure 40 - Wiring Diagram for Bench Calibration

Page 46

Part

Number:

10060-001

Rev:

03

Description:

SSS-903 TG-E

Install Guide

Date:

08/15/2017

Page: 46 of 53

Figure 41 -Launch ESP Commander

Software Program on the user supplied PC

interfaced to the user supplied RS-485 to

USB converter.

Select The COM port for the link between

the PC and converter

ESP Commander will scan for all devices

connected (via MODBUS communication

protocol)

Select the device to be calibrated by “double

clicking”

Page 47

Part

Number:

10060-001

Rev:

03

Description:

SSS-903 TG-E

Install Guide

Date:

08/15/2017

Page: 47 of 53

Device Model

Device relay state

Device Address

Version

Serial Number

Device Address Assignment

Detection Gas

Calibration Values

Alarm Values

Graph of Alarm events

Recording of Real Time Data

Polling Interval

After connecting the SSS gas analyzer to the

PC, ensure that the digital interface is

functional by comparing the SSS-903

settings with those display by ESP

Commander.

REAL TIME ALARM STAUS & DATA FROM SSS-903

ENTER & SET NEW THRESHOLD VALUES

ALARM THRESHOLDS AT SSS-903

Figure 42 -ESP Commander Operating Screen Display and Function:

Page 48

Part

Number:

10060-001

Rev:

03

Description:

SSS-903 TG-E

Install Guide

Date:

08/15/2017

Page: 48 of 53

Figure 43 –Cal Gas Selection

Use the pull down to select the gas to match

the labeling on the sensor.

The gas pull down is pre-programmed with

the required LEL/ppm for the selected gas.

Connect tubing between the gas cylinder

and PGU sensor inlet nipple.

Using the Zero Gas Cylinder, purge the the

cup and PGU sensor by inserting the tubing

from the Zero Gas Cylinder and passing

approximatly one Liter of Gas into the

sensor.

Figure 44- Zero Cal Purge

using ESP Commander

Page 49

Part

Number:

10060-001

Rev:

03

Description:

SSS-903 TG-E

Install Guide

Date:

08/15/2017

Page: 49 of 53

Figure 45- Zero Cal

When measured gas level has stopped

changing, Zero or close to it, Click on Zero.

Current loop out put will equal 4.0mA

The SSS-903-903 will show Zero

Attached the Span Gas Cylinder with the

mixture value as required.

Start a flow into the Calibration cup. After

about 60 seconds, the count will top out. Set

this as Span or the user selected Max % of

the LEL.

Current loop output will equal 20ma.

Hydrogen Sulfide is measured as ppm the

setting for 100%LEL is equal to the screen

value.

Figure 46 -Span Cal with ESP Commander

A second gas with a mixture equal to 50%

LEL may be used for calibration of span or

mid span.

Figure 47 – 50% Span

Level 1,2,3 Alarm levels can now be entered

to the SSS-903 by entering the value and

clicking set.

Stop the flow and remove the Span gas hose

and Cal Cup at this point.

The SSS-903 can now be reassembled and

returned to service.

Note that in the SSS-903 Screen (left) the

Alarm 1, Alarm 2, are RED and the Tri Color

LED Alarm Status is YELLOW.

When the Span gas is removed, the ppm

value will drop to zero and alarms will turn

off when thresholds are crossed.

Figure 48- Setting Alarm Thresholds

Page 50

Part

Number:

10060-001

Rev:

03

Description:

SSS-903 TG-E

Install Guide

Date:

08/15/2017

Page: 50 of 53

Field Repair

The SSS-903 detector has no user serviceable parts. If a problem

should develop, refer to the Troubleshooting information. If it is

determined that the problem is caused by a manufacturing defect,

please return the device to the factory for repair or replacement.

Return

Material

Authorization

(RMA)

Contact ESP Safety Inc at 408-886-9746 to obtain a Return Material Authorization

(RMA) number. In the call, provide the following information:

- Company Name

- Serial Number

- Date of Commissioning

- A brief explanation of malfunction

Pack the unit properly to ensure that no shipping damage occurs and ship prepaid

to:

ESP Safety Inc

555 North First Street

San Jose, CA 95112

Write the RMA number on the front of the shipping carton.

The contents should be carefully removed and verified against the packing list. If any damage has occurred or there is any

discrepancy in the order, please notify ESP Safety Inc. customer service department as soon as possible at (408) 886-9746

or via Email mailto:info@espsafetyinc.com

Warranty

: ESP Safety Inc, 555 North First Street San Jose, CA 95112 USA, guarantees the SSS-903 will be free of manufacturing

defects

for 5 years after date of commissioning, provided the customer follows all guidelines pertaining to installation, operation, and

maintenance detailed in this Operating Manual.During this warranty period, the manufacturer will correct any failures detected

in the SSS-903 or replace any damaged unit

free of charge.

The technical maintenance for the SSS-903 systems consists of periodical external examination and zero setup. The inspection

interval is set by the based upon their operating procedures. Physical inspections of the detector installation should be

performed at regular intervals as determined by customer procedure.Detectors used in corrosive environments should be

replaced at regular intervals. Contact ESP Safety to order replacement

PGU Sensors.

Malfunction / Problem

Possible Cause

Troubleshooting Method

Unit does not perform self test on

power up

Low Power supplied.

Check input voltage to be 18 to 36

VDC range

Following power-up of and self testing

mode completion some functions fail

Microprocessor error

Return to ESP Safety for repair

Unpack A New SSS-903

Maintenance

Troubleshooting

Page 51

Part

Number:

10060-001

Rev:

03

Description:

SSS-903 TG-E

Install Guide

Date:

08/15/2017

Page: 51 of 53

Appendix I: Explosion Proof Design

Page 52

Part

Number:

10060-001

Rev:

03

Description:

SSS-903 TG-E

Install Guide

Date:

08/15/2017

Page: 52 of 53

Appendix II: Warranty & Return Policy

ESP Safety, Inc. (“ESP”) warrants the

under normal use and service for a period of five (5) years, beginning on the date of shipment to the buyer. This

warranty extends only to the sale of new and unused products to the original buyer. ESP’s warranty obligation is

limited, at ESP’s option, to refund of the purchase price, repair, or replacement of a defective product or a component

thereof, to the extent that the product is properly returned to ESP within the warranty period.

This warranty does not include:

a) fuses, disposable batteries or the routine replacement of parts due to the normal wear and tear of the

product arising from use;

b) any product or component which in ESP’s opinion, has been misused, altered, abused, tampered with,

improperly maintained or used, neglected or otherwise damaged by accident or abnormal conditions of

operation, handling or use, or to have deteriorated due to aging of any component made of rubber or any

other elastomer; or

c) any damage or defects attributable to repair of the product by any person other than an authorized dealer,

or the installation of unapproved parts on the product.

The obligations set forth in this warranty are conditional on:

a) proper storage, installation, calibration, use, maintenance and compliance with the product manual

instructions and any other applicable recommendations of ESP;

b) the buyer promptly notifying ESP of any defect and, if required, promptly making the product available for

correction. No goods shall be returned to ESP until receipt by buyer of shipping instructions from ESP. A

return authorization number must be obtained from ESP prior to shipment; and

c) all warranty returns to be shipped pre-paid by buyer.

d) the right of ESP to require that the buyer provide proof of purchase such as the original invoice, bill of sale

or packing slip to establish that the product is within the warranty period.

THE BUYER AGREES THAT THIS WARRANTY IS THE BUYER’S SOLE AND EXCLUSIVE REMEDY AND IS IN LIEU OF ALL

OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED TO ANY IMPLIED WARRANTY OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. ESP SHALL NOT BE LIABLE FOR ANY SPECIAL,

INDIRECT, INCIDENTAL OR CONSEQUENTIAL DAMAGES OR LOSSES. ESP WILL NOT BE LIABLE FOR LOSS OR

DAMAGE OF ANY KIND CONNECTED TO THE USE OF ITS PRODUCTS OR FAILURE OF ITS PRODUCTS TO FUNCTION

OR OPERATE PROPERLY. IN NO EVENT SHALL ESP’S LIABILITY HEREUNDER EXCEED THE PURCHASE PRICE

ACTUALLY PAID BY THE BUYER FOR THE PRODUCT.

To the extent any provision of this warranty is held invalid or unenforceable by a court of competent jurisdiction, such

holding will not affect the validity or enforceability of any other provision.

Field Repair

The SSS-903 Gas Detector is not intended to be repaired in the field. If a pro b l e m should develop, refer to the

troubleshooting section of this manual. If it is determined that the problem falls within this warranty, please

return the product to ESP as instructed hereunder.

SSS-903 Gas Detector

to be free from defects in material and workmanship

Page 53

Part

Number:

10060-001

Rev:

03

Description:

SSS-903 TG-E

Install Guide

Date:

08/15/2017

Page: 53 of 53

Return Material Authorization (RMA) Number

Contact ESP Safety Inc. at +1-408-886-9746 to obtain a Return Material Authorization (RMA) n umber. Please

provide the following information during your call:

-Company Name

-Product Type

-Serial Number

-Date of Shipment

-Brief explanation of malfunction

Pack the unit properly to ensure that no shipping damage occurs and ship pre-paid to:

ESP Safety Inc.

555 North First Street

San Jose, CA 95112 USA

Write the RMA number on the front of the shipping carton.

Loading...

Loading...