Page 1

INSTALLATION

AND PROGRAMMING

MANUAL

Intelligent Interactive Analogue Addressable

Fire Alarm Control Panel

MAGPRO16

Attention:

This manual contains information on limitations regarding product use and

function and information on the limitations as to liability of the manufacturer.

The entire manual should be carefully read.

The information in this manual is a subject to change without notice!

Page 2

MAGPRO16 Addressable Fire Alarm Panel – Installation and Programming Manual

Table of Contents

1. INTRODUCTION ........................................................................................................................................................... 5

1.1. General Description....................................................................................................................................... 5

1.2. General Specifications .................................................................................................................................. 5

1.2.1 General Technical Specifications .................................................................................................... 5

1.2.2 Possible Hardware Configurations .................................................................................................. 6

1.2.3 Environment ..................................................................................................................................... 6

1.2.4 Electrical Characteristics ................................................................................................................. 6

2. INSTALLATION ............................................................................................................................................................. 8

2.1. Wall Mounting ................................................................................................................................................ 8

2.2. System Components ..................................................................................................................................... 9

2.2.1 Front panel ....................................................................................................................................... 9

2.2.2 Configuration of the basic modules ............................................................................................... 11

2.2.3 Description of the main PCB (control panel) ................................................................................. 11

2.3. Connection of Signaling Devices ................................................................................................................ 13

2.3.1 Connecting of Sounders ................................................................................................................ 13

2.3.2 Connecting of Signaling Devices ................................................................................................... 13

2.3.3 Connecting to the Specialized Inputs ............................................................................................ 13

2.3.4 Loop Controller .............................................................................................................................. 14

2.3.5 Maximum Permissible Cable Length ............................................................................................. 15

2.4. Connecting to the Main Power Source........................................................................................................ 16

2.5. Connecting the Accumulator Battery........................................................................................................... 16

2.6. Connecting a Heat Printer ........................................................................................................................... 17

2.7. Connecting a Network Interface Card (MAGPRO-NIC) .............................................................................. 17

2.8. Connecting an AJAX LAN Communication Module .................................................................................... 17

3. PROGRAMMING TYPES ............................................................................................................................................ 18

3.1. Programming via MAGPRO Programming Software .................................................................................. 18

3.2. Programming via Panel’s Keyboard ............................................................................................................ 18

3.3. Firmware Update ......................................................................................................................................... 18

3.3.1 Firmware Update from Computer .................................................................................................. 18

3.3.2 Firmware Update from USB Drive ................................................................................................. 19

3.3.3 Copying Image File from the Panel to USB Drive ......................................................................... 19

4. FULL HARDWARE RESET ......................................................................................................................................... 19

5. PROGRAMMING OF MAGPRO16 FIRE ALARM PANEL ..................................................................................... 20

5.1. General Information for Programming and Operation ................................................................................. 20

5.2. Codes and Access Levels ........................................................................................................................... 20

6. DESCRIPTION OF THE OPERATION MODES ......................................................................................................... 22

6.1. Review of Alarm Events .............................................................................................................................. 22

6.2. Review of Fault Events................................................................................................................................ 22

6.3. Review of Disablements .............................................................................................................................. 23

6.4. Review of Running Tests ............................................................................................................................ 23

6.5. Review of Warning Messages ..................................................................................................................... 24

6.6. Silencing the Internal Buzzer ...................................................................................................................... 25

6.7. Silencing the Sounders ............................................................................................................................... 25

6.8. Activate Evacuation ..................................................................................................................................... 25

6.9. Resetting the Panel ..................................................................................................................................... 25

6.10. Indication Test ........................................................................................................................................... 25

7. DESCRIPTION OF THE PROGRAMMING MENUS ................................................................................................... 26

7.1. View History Log Menu ............................................................................................................................... 26

7.1.1 Review of Full Events List ............................................................................................................. 26

7.1.2 Review of List of Events by Date ................................................................................................... 27

7.1.3 Deleting the Events in the LOG file ............................................................................................... 27

7.1.4 Printing Events ............................................................................................................................... 27

7.1.5 Printer Settings .............................................................................................................................. 27

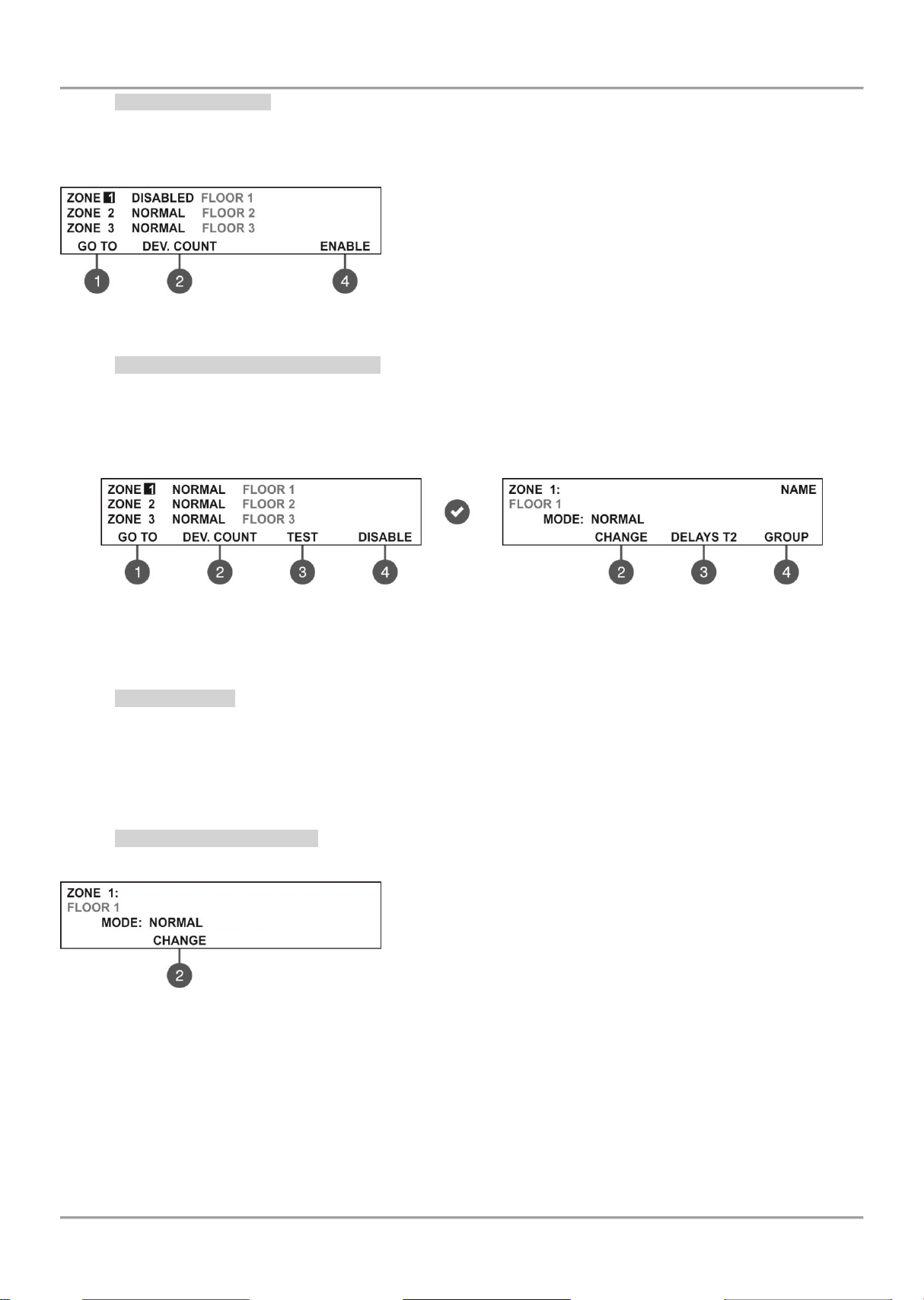

7.2. Zones Menu ................................................................................................................................................ 28

7.2.1 General Submenus ........................................................................................................................ 28

7.2.2 Zones Testing ................................................................................................................................ 28

7.2.3 Disabling Zones ............................................................................................................................. 29

7.2.4 Programming Zone Parameters .................................................................................................... 29

2

Page 3

MAGPRO16 Addressable Fire Alarm Panel – Installation and Programming Manual

7.2.5 Zone Name .................................................................................................................................... 29

7.2.6 Zone Operation Modes .................................................................................................................. 29

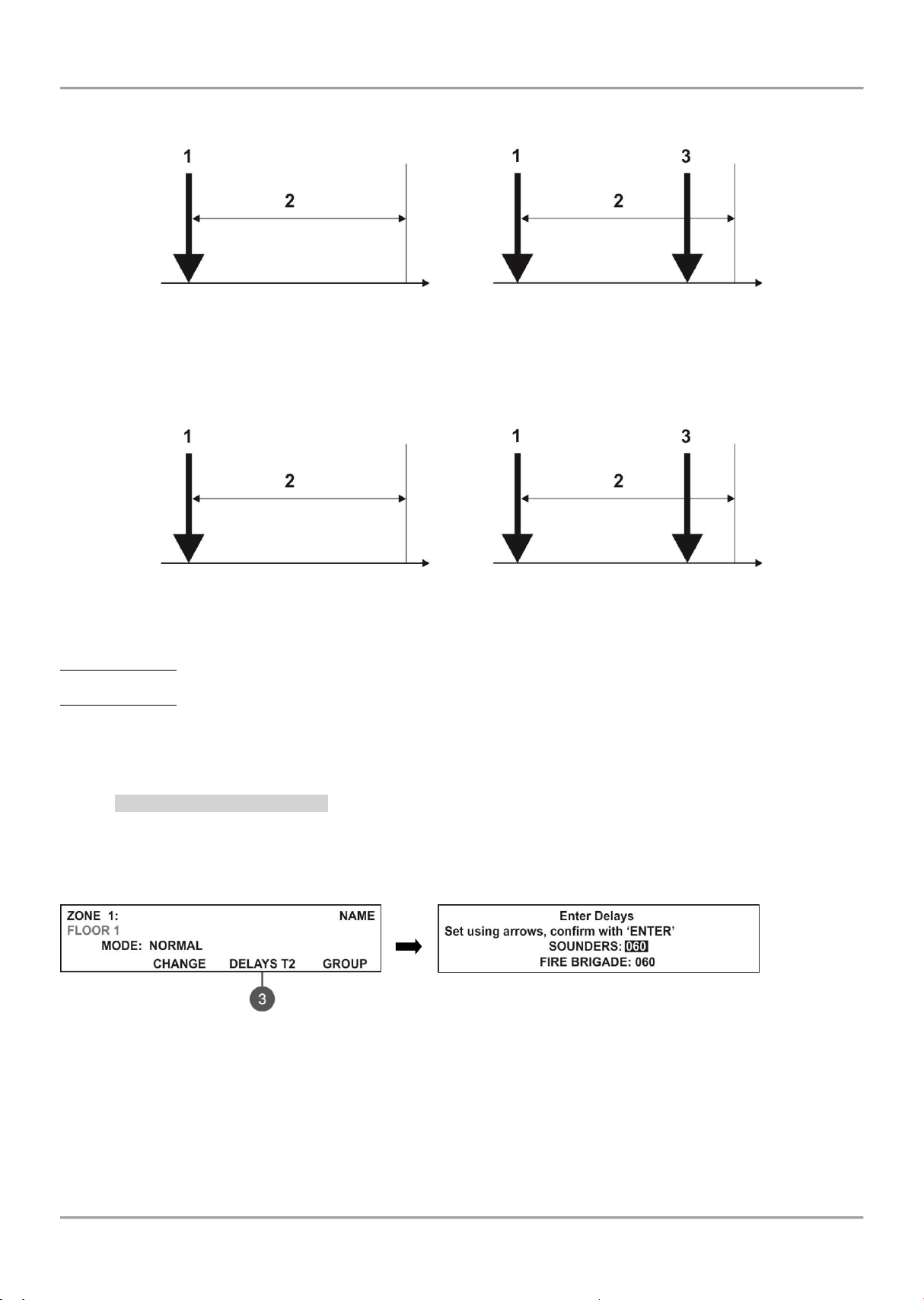

7.2.7 Programming Delays Т2 ................................................................................................................ 30

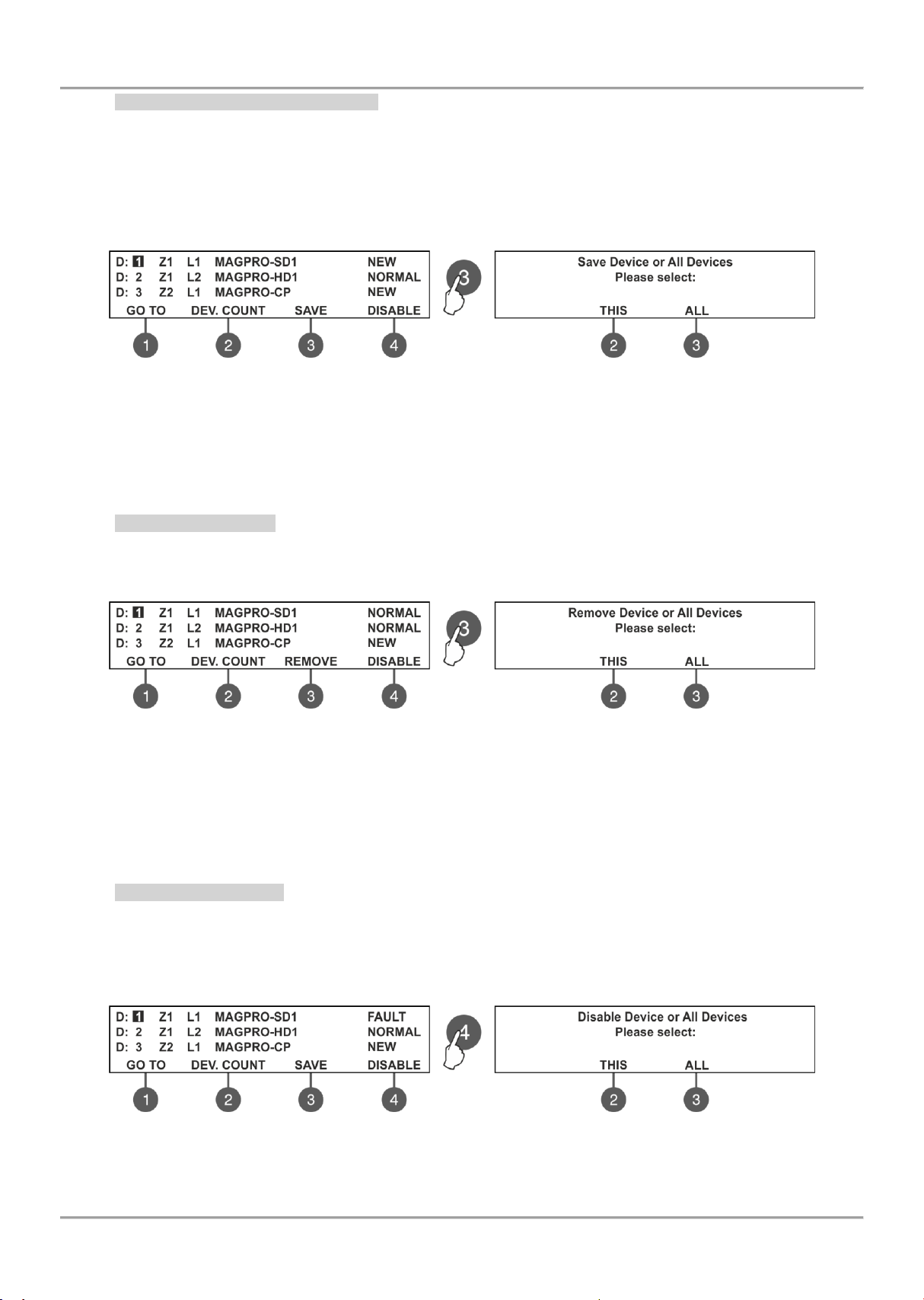

7.2.8 Arranging Zones in Groups ........................................................................................................... 31

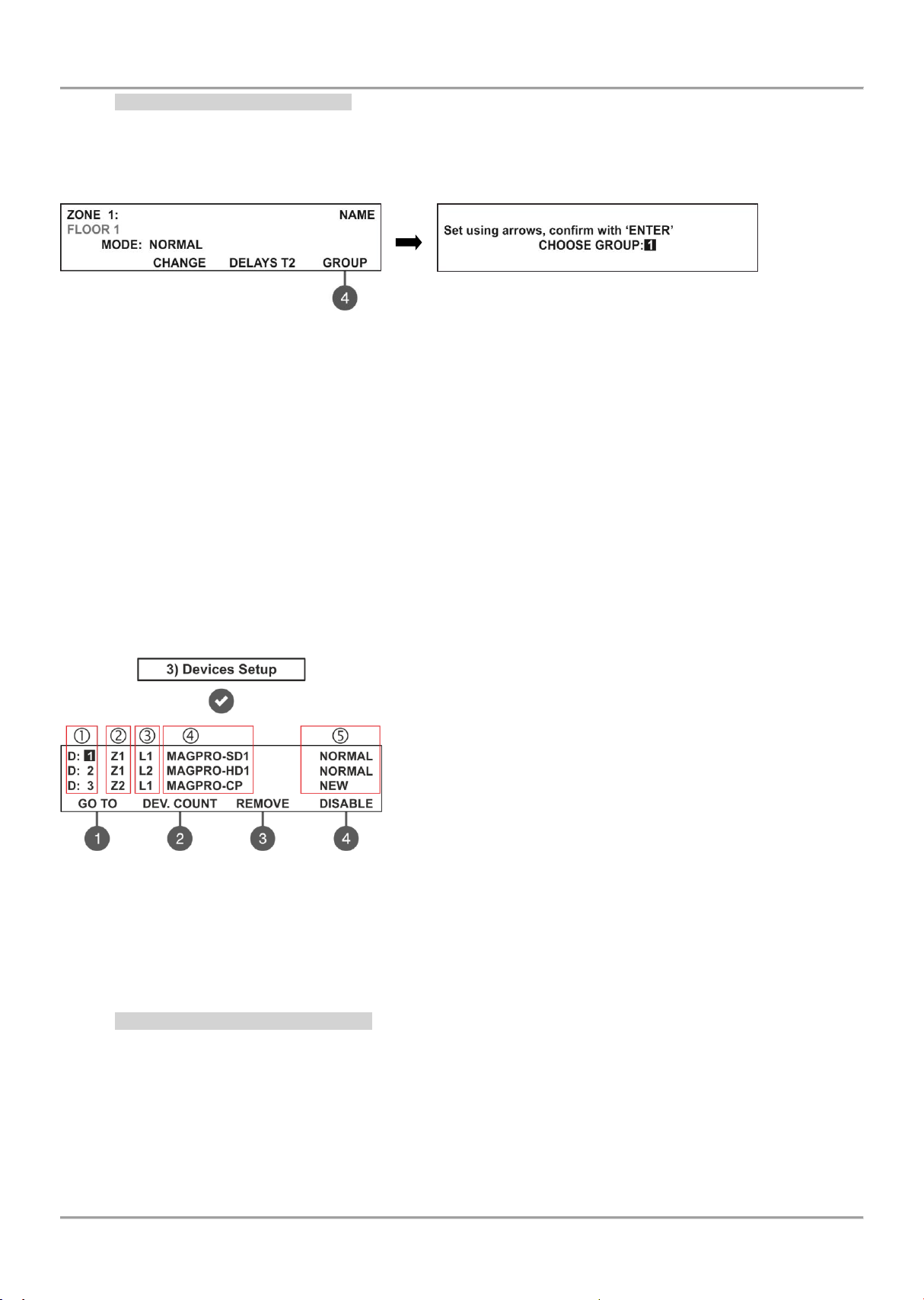

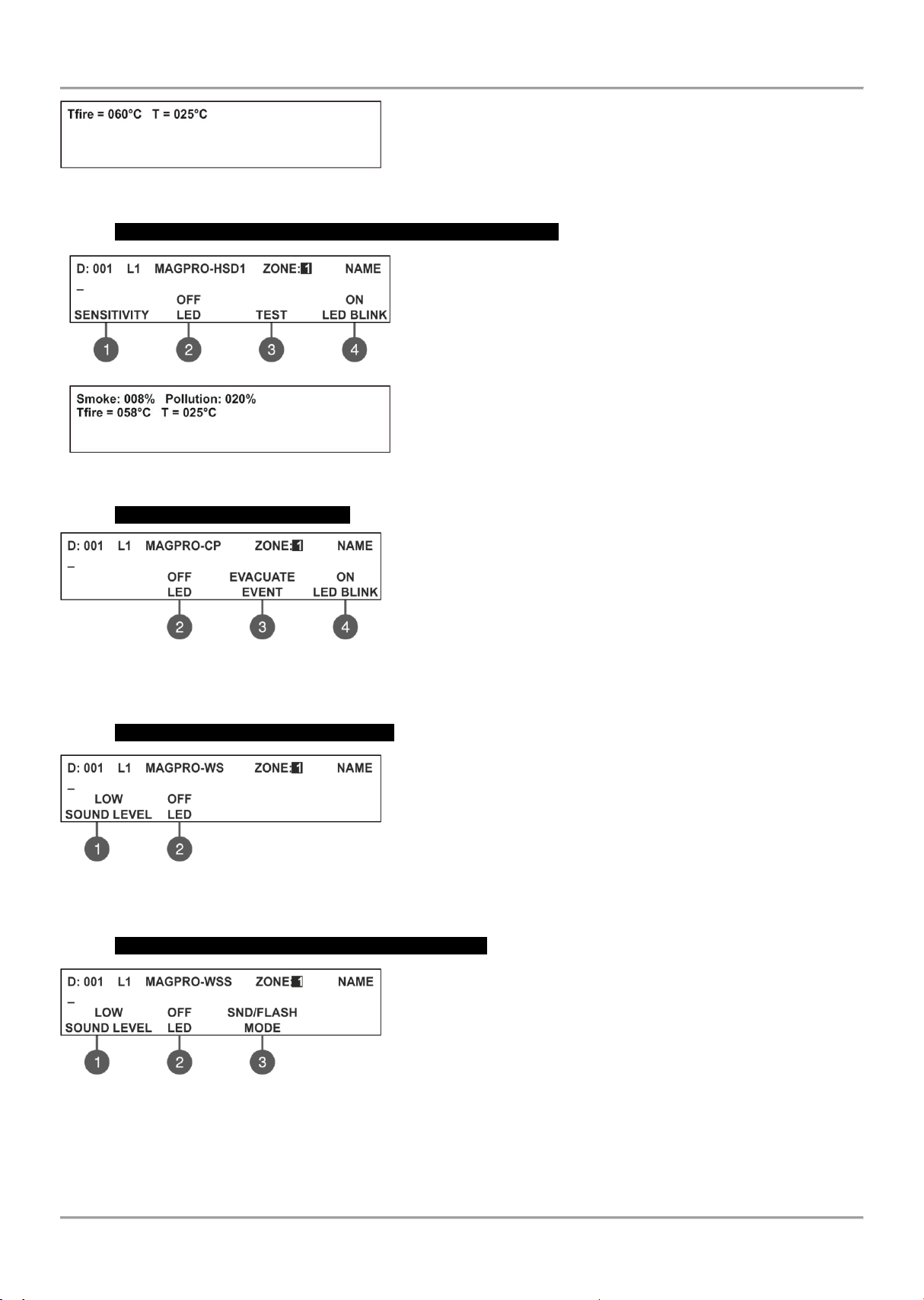

7.3. Devices Setup Menus ................................................................................................................................. 31

7.3.1 Submenus for General Setting ...................................................................................................... 31

7.3.2 Saving the New Found Devices .................................................................................................... 32

7.3.3 Deleting Devices ............................................................................................................................ 32

7.3.4 Disabling Devices .......................................................................................................................... 32

7.3.5 Programming of Device Parameters ............................................................................................. 33

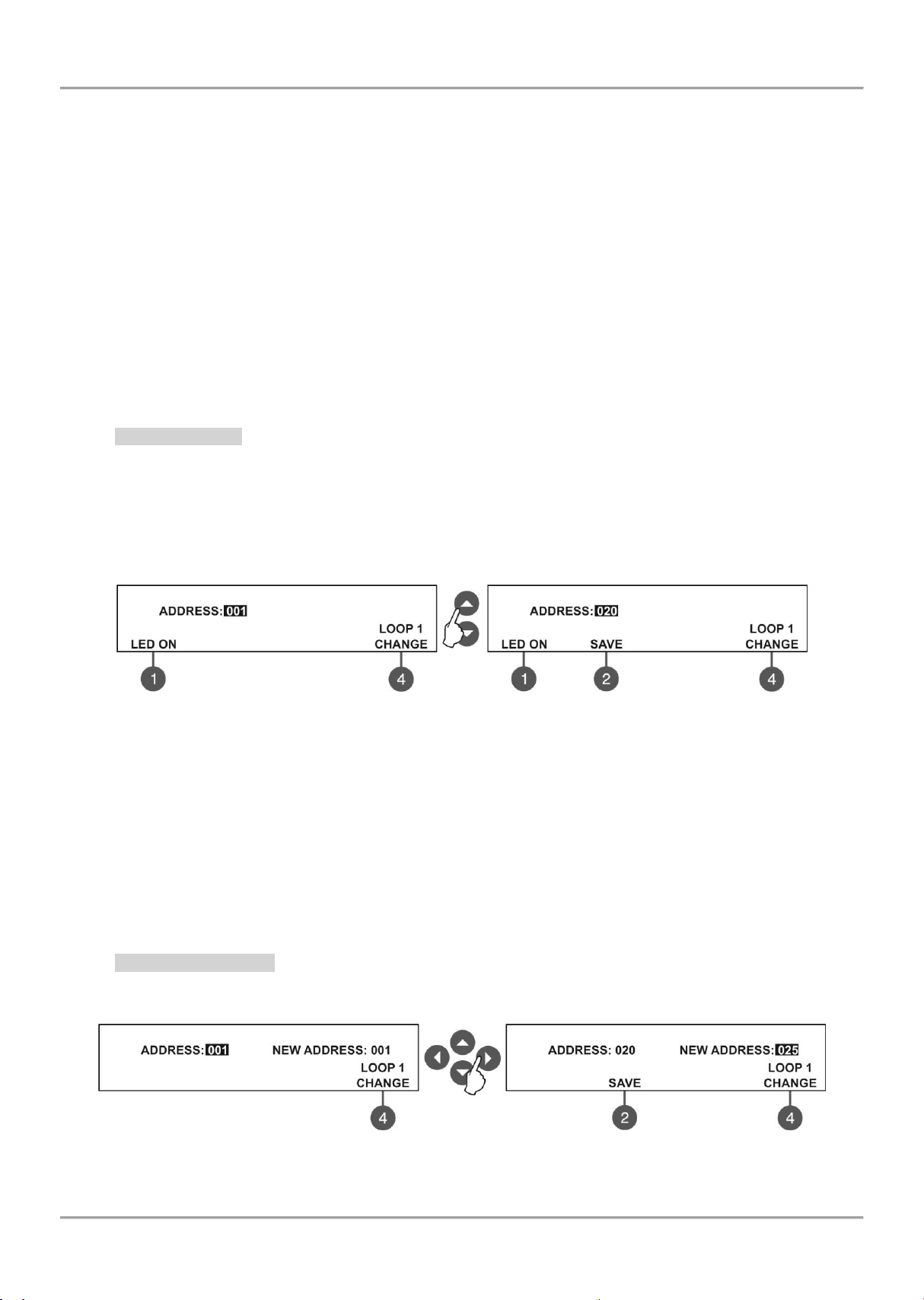

7.4. Addressing Menus ....................................................................................................................................... 39

7.4.1 Set Address ................................................................................................................................... 39

7.4.2 Change Address ............................................................................................................................ 39

7.4.3 Self-Addressing ............................................................................................................................. 40

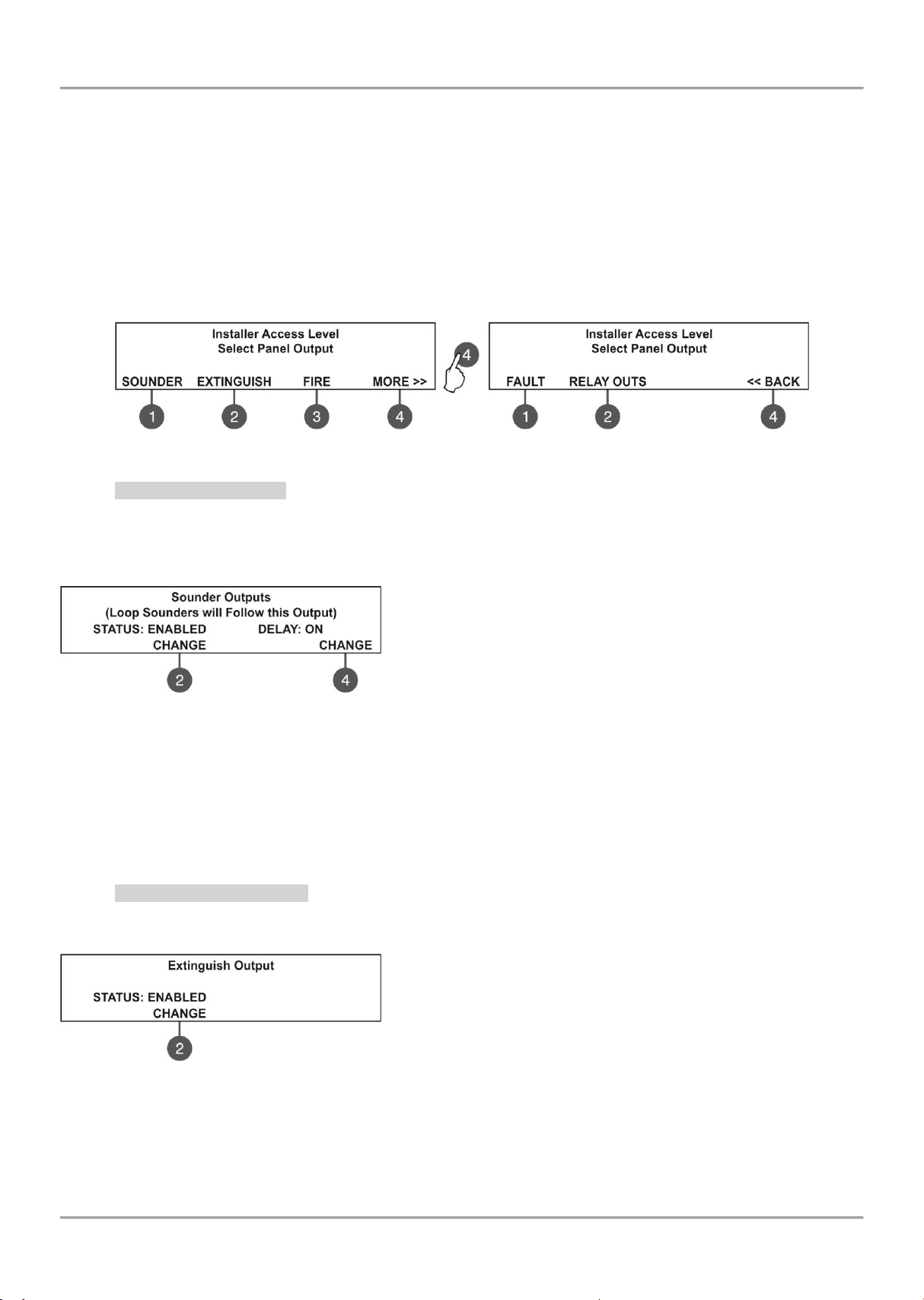

7.5. Panel Outputs Menus .................................................................................................................................. 41

7.5.1 Sounders Outputs .......................................................................................................................... 41

7.5.2 Extinguishing Output...................................................................................................................... 41

7.5.3 Fire Output ..................................................................................................................................... 42

7.5.4 Fault Output ................................................................................................................................... 42

7.5.5 Relay Outputs ................................................................................................................................ 42

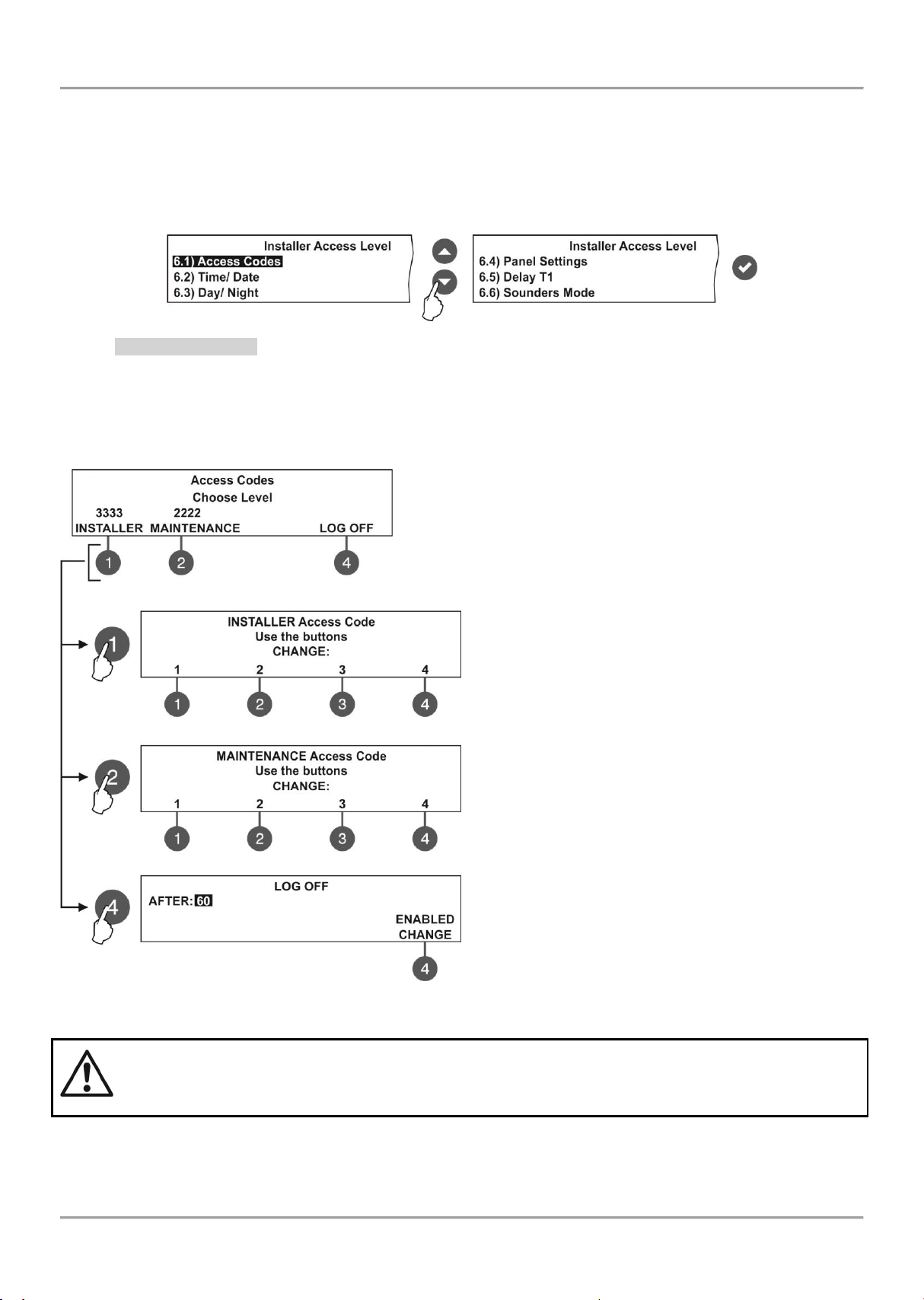

7.6. General Settings Menu ............................................................................................................................... 43

7.6.1 Access Codes ................................................................................................................................ 43

7.6.2 Setting the Date and Time ............................................................................................................. 44

7.6.3 Setting Day/ Night Alarm Modes ................................................................................................... 44

7.6.4 Panel General Settings .................................................................................................................. 45

7.6.5 Delay Т1 ........................................................................................................................................ 45

7.6.6 Sounders Mode ............................................................................................................................. 45

7.7. Save Configuration Menu ............................................................................................................................ 46

7.8. Restore Defaults Menu................................................................................................................................ 46

7.9. Software Revision ....................................................................................................................................... 46

7.10. Network ..................................................................................................................................................... 47

7.10.1 Network Settings .......................................................................................................................... 47

7.10.2 Panels Settings ............................................................................................................................ 47

7.11. Active Isolators Menu ................................................................................................................................ 48

7.12. Access Level 1 .......................................................................................................................................... 48

APPENDIX А ................................................................................................................................................................... 49

APPENDIX B ................................................................................................................................................................... 50

APPENDIX C ................................................................................................................................................................... 51

APPENDIX D ................................................................................................................................................................... 52

APPENDIX E ................................................................................................................................................................... 53

3

Page 4

MAGPRO16 Addressable Fire Alarm Panel – Installation and Programming Manual

STANDARDS AND CONFORMITY

The addressable fire alarm control panel MAGPRO16 is designed and certified according and with conformity to

EN 54 – 2/4 standard. Conforms and approved in accordance with CPR (Construction Products Regulation).

Distributor: Elite Security Products Ltd, Unit 7 Target Park, Shawbank Road Lakeside, Redditch B98 8YN, UK

http://www.espuk.com

Manufacturer: Teletek Electronics JSC, 14 Srebarna Str., 1407 Sofia, Bulgaria

DoP No: 002

EN 54-2:1997/A1:2006/AC:1999; EN 54-4:1997/A2:2006/AC:1999

MAGPRO16

Intended for use in fire detection and fire alarm systems in and around buildings.

Essential Characteristics

Performance

Performance under fire conditions

Pass

Response delay (response time to fire)

Pass

Operational reliability

Pass

Durability of operational reliability and response delay: temperature resistance

Pass

Durability of operational reliability: humidity resistance

Pass

Durability of operational reliability: vibration resistance

Pass

Durability of operational reliability: electrical resistance

Pass

4

Page 5

MAGPRO16 Addressable Fire Alarm Panel – Installation and Programming Manual

1. INTRODUCTION

1.1. General Description

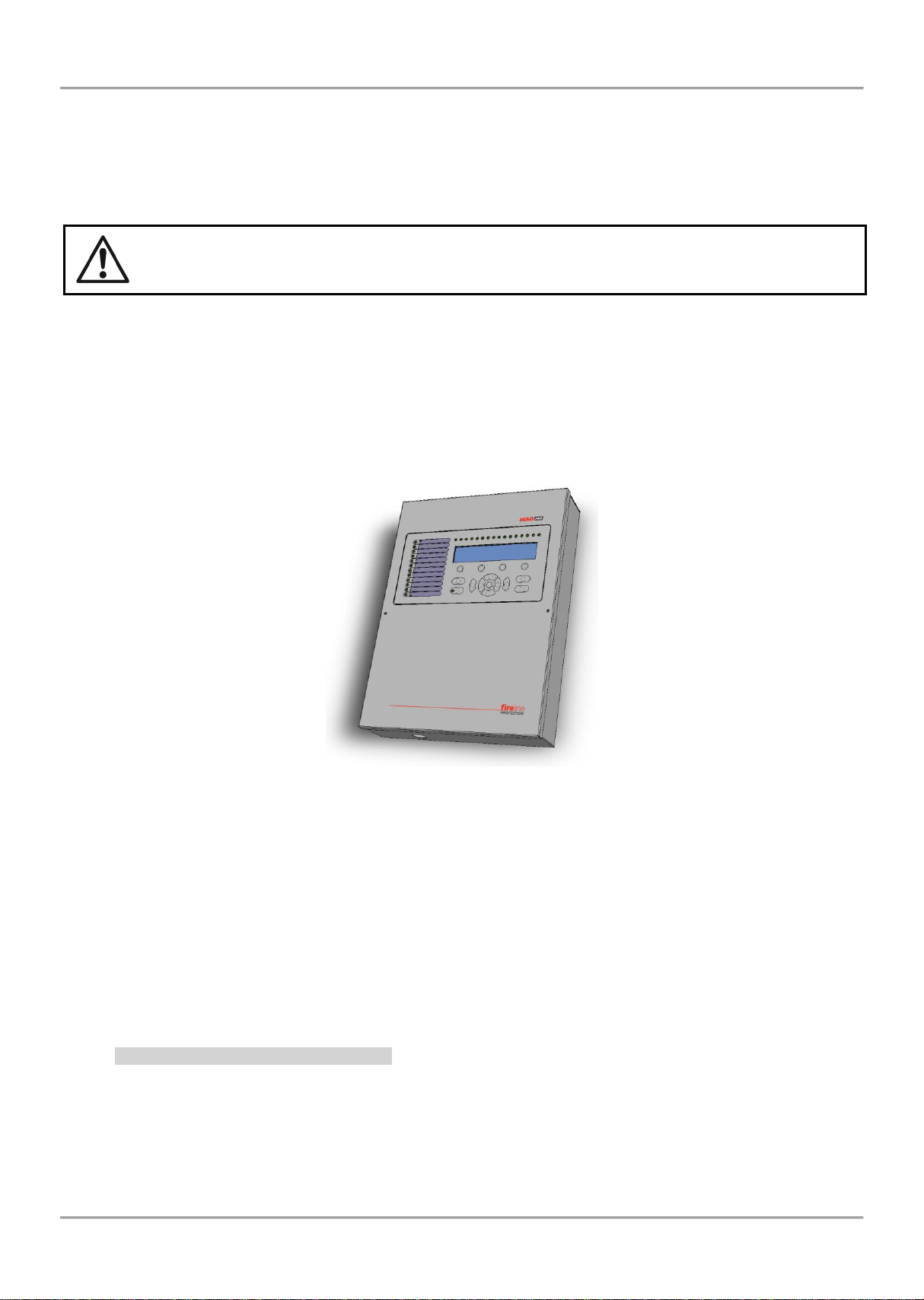

MAGPRO16 is an addressable fire panel with maximum coverage of 16 zones and connecting and up to 2 loops. The

panel supports communication protocol MAGPRO (MAGPRO16-L250 Loop) and operation with MAGPRO

addressable device series.

Every MAGPRO16-L250 Loop provides up to 250 devices (detectors and modules, regardless of the

type).

An arbitrary number of devices can be added to each zone thus ensuring the easy adaptation of the system to any type

of configuration.

To avoid or significantly diminish problems when mounting the system it must be carefully planned prior to installation.

This includes: setting an address for every device and planning a name of maximum 40 digits (including the

spaces) for each address, thereby ensuring easy access to the device.

According to the acting standards for establishing fire systems and the plan of the building, the devices must

be grouped in zones.

1.2. General Specifications

The front panel consists of LCD module (4 rows x 40 symbols), functional buttons and system status LED indication.

Separate access level passwords provide access to the functions of the panel.

The fire alarm panel is designed on module structure as in the metal cabinet there are provided additional places for

mounting of a second loop controller for Loop 2 (Loop 1 is built-in the main PCB), LAN module and redundant network

module.

The panel has a built-in real time clock and calendar, allowing day and night time modes of work.

Switching over between the two modes can be automatic or manual. Events like FIRE, RESET, FAULT, etc., are saved

in the memory, thereby creating an event log-file. It contains the time and date, the address of the device, the name of

the device, the zone number, the name of the zone, etc.

1.2.1 General Technical Specifications

Loops - 1 to 2:

o Loop 1 is built-in in the main board

o Loop 2 – optional, separately mounted to the main control panel

Number of loop devices:

o Up to 250 devices (modules and/ or detectors regardless of the type) for every loop (max. 500 for the

entire system)

16 operation zones

5

Page 6

MAGPRO16 Addressable Fire Alarm Panel – Installation and Programming Manual

16 groups for zones’ organization

5 monitored potential outputs:

o SND1 (Sounder 1)

o SND2 (Sounder 2)

o FIRE

o FAULT (In case of Fault event the output is deactivated.)

o EXT (Extinguishing/ Fire Protection – An output for sending an fire alarm signal to automatic fire

extinguishing system)

3 specialized inputs:

o In AmC* (Input Alarm Confirmation)

o In PC* (Input Protection Alarm Confirmation)

o In FP* (Input Fault Protection Panel)

* Covers the requirements on standard VdS 2540

4 non-monitored, programmable relay outputs with parameters: 15A@24VDC

Display – letter and digits LCD module (4 rows х 40 symbols)

Built-in real time clock, supported from integrated lithium battery - 3V, CR3032 type

Memory log file for up to 10240 system events

Comprehensive day/night mode facility

2 Steps of alarm levels (T1 and T2)

Supports external thermo printer

Multilanguage support for operation menus

Easy software update via computer or USB drive

Designed according the requirements of EN54-2/4

Metal box cabinet for wall mounting: bottom (306х412х81mm) and cover (310х416mm)

1.2.2 Possible Hardware Configurations

Minimal Configuration

o Control panel (main PCB with one built-in loop controller)

o Indication (indication PCB with mounted LCD module)

o Power supply source

Maximal Configuration

o Control panel (main PCB with one built-in loop controller)

o Indication (indicator PCB with mounted LCD module)

o Power supply source

o MAGPRO16-L250 Loop controller (for the second loop)

o LAN Communication module

o RS485 Redundant Network controller

1.2.3 Environment

Degree of protection: IP30

Operation temperature: -5ºС up to +40ºC

Relative humidity: up 95% (without condense)

Storage temperature: -10ºС up to +60ºC

Weight (without the battery): ~ 4.2 kg.

1.2.4 Electrical Characteristics

Earth Connection

The earth connection has to be realized in accordance with the rules for the electrical safety with the total resistance in

the circuit lower than 10Ω. It is mandatory to connect the main power supply cable to the middle input of the fire panel

terminal – see also item 2.4 Main power connection.

ATTENTION: Do not instal the fire panel near power electromagnetic fields (radio equipment,

electric motors, etc.)!

6

Page 7

MAGPRO16 Addressable Fire Alarm Panel – Installation and Programming Manual

1 Resistor 10k ± 5%, 0.25W

6 pcs

2

Resistor 47k ± 5%, 0.25W

4 pcs

3

Resistor 20k ± 5%, 0.25W

3 pcs

4

Screw 4.2х38, cross slot DIN7981

4 pcs

5

Anchor 6х30mm

4 pcs

6

Fuse 4А, glass time-delay type 5x20mm

(for the power supply)

4 pcs

Main power supply

In normal operating conditions, the fire panel is powered from the mains voltage line. In case of mains voltage line loss

the fire panel is equipped with one rechargeable battery. The characteristics of the main power supply are as follows:

Main power supply: 90 264 VAC

Frequency: 47 440 Hz

Electrical output: 4.2 А

Backup (accumulator) power supply

Voltage output (U): 13,65V

Accumulator battery: 1 x 12V / 18Ah, sealed lead-acid type rechargeable battery

Internal resistance of the accumulator battery Ri: < 0.3Ω

Max. dimensions of the accumulator battery: 167х181х76mm

Type of the battery connection: with a cable lug, Ø5mm (M5) or cable shoe (according the type of the battery

terminals)

Loading capacity

Max. loading capacity of one loop: 500 mA DC

Max. loading capacity of AUX output: 500 mA DC

Max. loading capacity of outputs SND1 and SND2: 500 mA DC

Max. loading capacity of outputs FIRE, FAULT and EXT: 300 mA DC

Max. total loading capacity (sum of the four mentioned above): 2.0 A DC

Programmable relay outputs: 15A@24VDC

Consumption

From the main power supply in standby mode:

o For a minimum configuration: 60 mA AC

o With mounted second loop controller: 65 mA AC

From the backup power supply in FAULT mode and generated message ‘AC loss’:

o For a minimum configuration: 125 mA DC

o With mounted second loop controller: 213 mA DC

List of the used fuses

Main power supply: 4А, Т type, glass time-delay fuse, size 5х20mm

AUX output: 0,5А, PTC type, resettable fuse

Outputs: 0.3А, PTC type, resettable fuse

Accumulator: 7.0А, PTC type, resettable fuse

List of spare parts kit:

ATTENTION!

Qualified specialists only should install the panel.

The electronic components of the panel are vulnerable to electrostatic discharge.

Never add or turn off components which are being power supplied!

7

Page 8

MAGPRO16 Addressable Fire Alarm Panel – Installation and Programming Manual

2. INSTALLATION

2.1. Wall Mounting

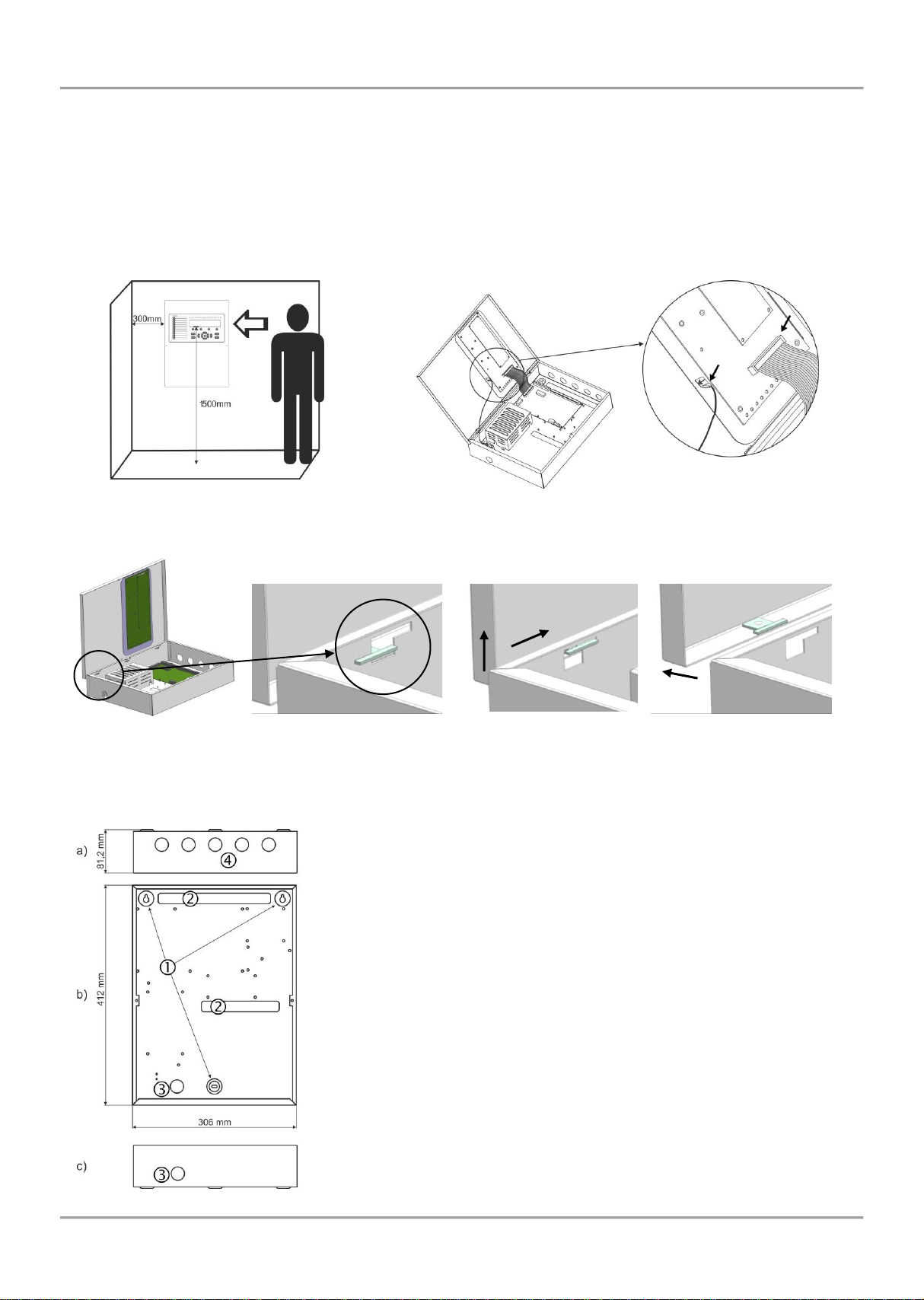

• The panel must be installed in a clean dry place and must not be subjected to impact or vibrations (Figure 1). It must

be situated far from heating appliances. The temperature must be within -5ºС and + 50ºC. The fire panel is not

waterproof!

• Unpack the panel and observe for visible damages due to bad transport or incorrect storing.

• Open the front cover and disconnect the flat indication cable and the earthling point (Figure 2).

Figure 1 Figure 2

• Remove the front cover as dismount the side hinges (Figure 3).

Figure 3

• Choose inlets for the main power supply cable, loops, sounders, control devices, etc. Remove the metal cap element

just from those holes for cable running (Figure 4).

Figure 4 – Elements of the metal bottom:

а) View from above;

b) Front view;

c) View from below.

1 – Main mounting holes.

2 – Holes for cable running.

3 – Holes for main power supply cable running, protected with a metal cap

element.

4 – Additional holes for cable running, protected with a metal cap element.

8

Page 9

MAGPRO16 Addressable Fire Alarm Panel – Installation and Programming Manual

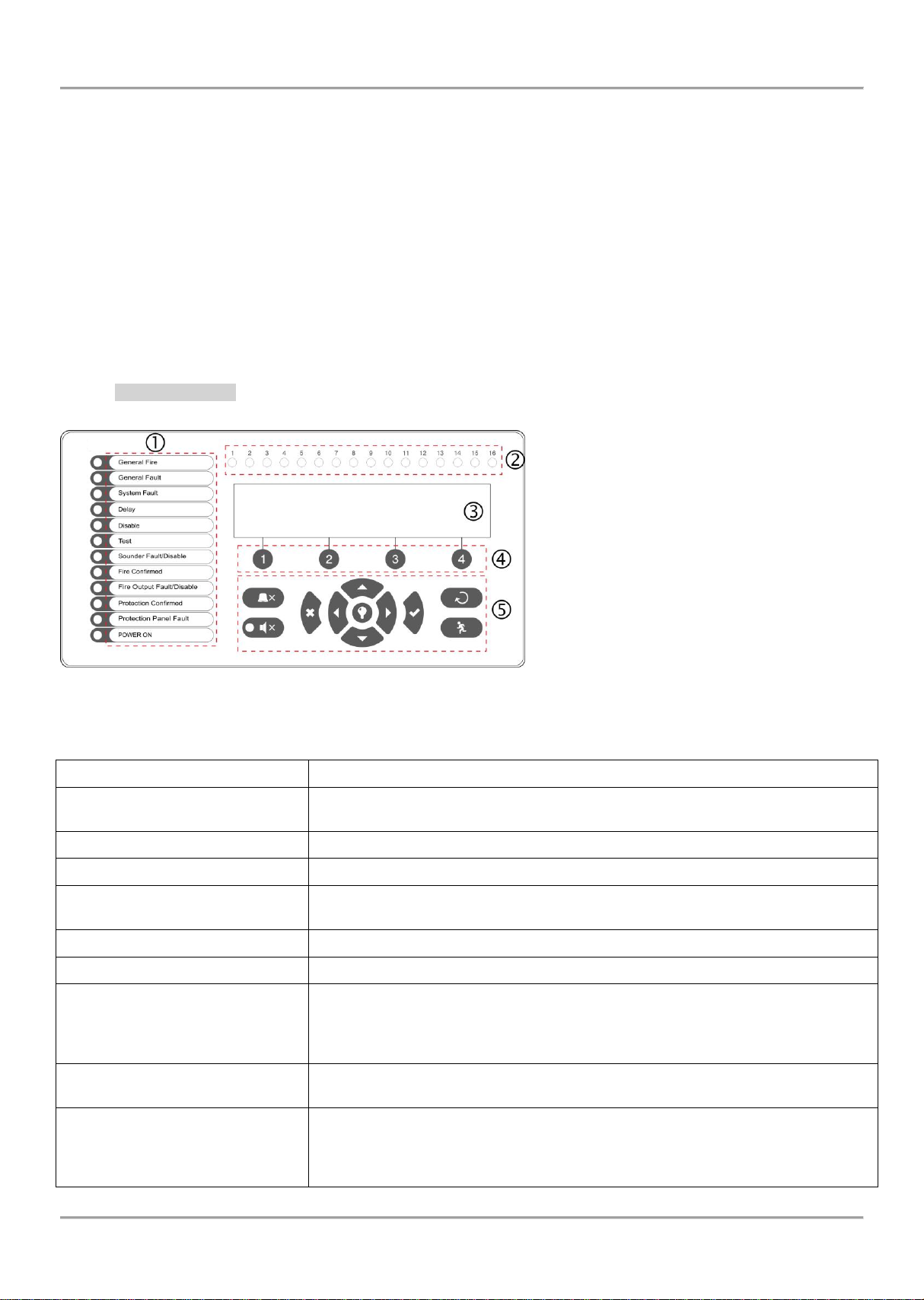

LED

Indication/ Description

GENERAL FIRE (red)

Lights on permanently in case of fire alarm event – fire alarm signal from an

automatic or manual call point, or other auxiliary device connected to a panel input.

GENERAL FAULT (yellow)

Lights on permanently in case of fault event in the system.

SYSTEM FAULT (yellow)

CPU FAULT. Lights on permanently in case of main microprocessor fault.

DELAY (yellow)

Lights on permanently in daytime mode and set time delay for one or several

outputs.

DISABLE (yellow)

Light on permanently in active disablement in the system.

TEST (yellow)

Light on permanently in system test mode.

SOUNDERS FAULT/ DISABLED

(yellow)

The LED will be active in case of fault or disablement of the sounders circuits. The

indication is as follows:

- Blinking in case of fault event in the sounder circuits.

- Lighting on when the sounder circuits are disabled.

FIRE CONFIRMED (yellow)

FIRE ALARM CONFIRMATION. Lights on permanently in activation of the

specialized “In AmC” input – see the description on page 12.

FIRE OUTPUT FAULT/ DISABLED

(yellow)

The LED will be active in case of fault or disablement of the FIRE relay output. The

indication is as follows:

- Blinking in case of fault event.

- Lighting on when the output is disabled.

• Use the template in the set to fix the mounting holes of the metal box on the wall.

• Drill holes (suitable for anchors Ø6mm) on the wall and fix the metal box.

• Route the external cables onto the back box, make off connection glands etc., BUT DO NOT make any connections

at this stage. ENTER THE MAINS CABLE THROUGH ITS OWN CABLE ENTRY POINT AND KEEP MAINS WIRING

AWAY FROM SYSTEM AND OTHER LOW VOLTAGE WIRING.

• Connect the mains supply and earth to the power supply terminal (see Figure 16), BUT DO NOT apply the main

electrical supply at this stage.

• Place the battery in an upright position.

• Mount the front cover back to the bottom as mount the hinges in the reverse order of that described on Figure 3.

• Connect back the flat cable for the indication and the earthling point (Figure 2).

• Proceed with initial power up of the system and testing.

• When you finish with power up and testing steps and the panel is normal operation mode you must fix the front cover

to the bottom with the two screws for the spare parts kit.

2.2. System Components

2.2.1 Front panel

Description of the front panel elements:

1 – LED indication for the system status. The

descriptions are printed on the paper label and

can be changed if needed, including for

language change. The paper label is placed in a

special opening on the inner side of the

indicator PCB, over the flat cable for the

indication.

2 – LED indication for the used zones

3 – Letters and digits LCD-module (4х40)

4 – Functional digits buttons

5 – Control and navigation buttons

Figure 5

1 – Description of system status LED indication:

9

Page 10

MAGPRO16 Addressable Fire Alarm Panel – Installation and Programming Manual

PROTECTION CONFIRMED

(yellow)

EXTINGUISHING STARTED CONFIRMATION. Lights on permanently in

activation of the specialized “In PC” input – see the description on page 12.

PROTECTION PANEL FAULT

(yellow)

EXTINGUISHING SYSTEM FAULT. Lights on permanently in activation of the

specialized “In FP” input – see the description on page 12.

POWER ON (green)

MAIN POWER SUPPLY ON. Lights on permanently in presence of 230V main

power supply.

SILENCE ALARM (yellow)

THE SOUNDERS ARE SILENCED. Lights on permanently when the sounders are

silenced (the LED is situated next to the button).

LED

Indication/ Description

Zone indicators (red)

1 - 16

FIRE IN A ZONE. Lights on permanently in case of fire alarm in a zone. Blinking

when the zone is in fire test mode.

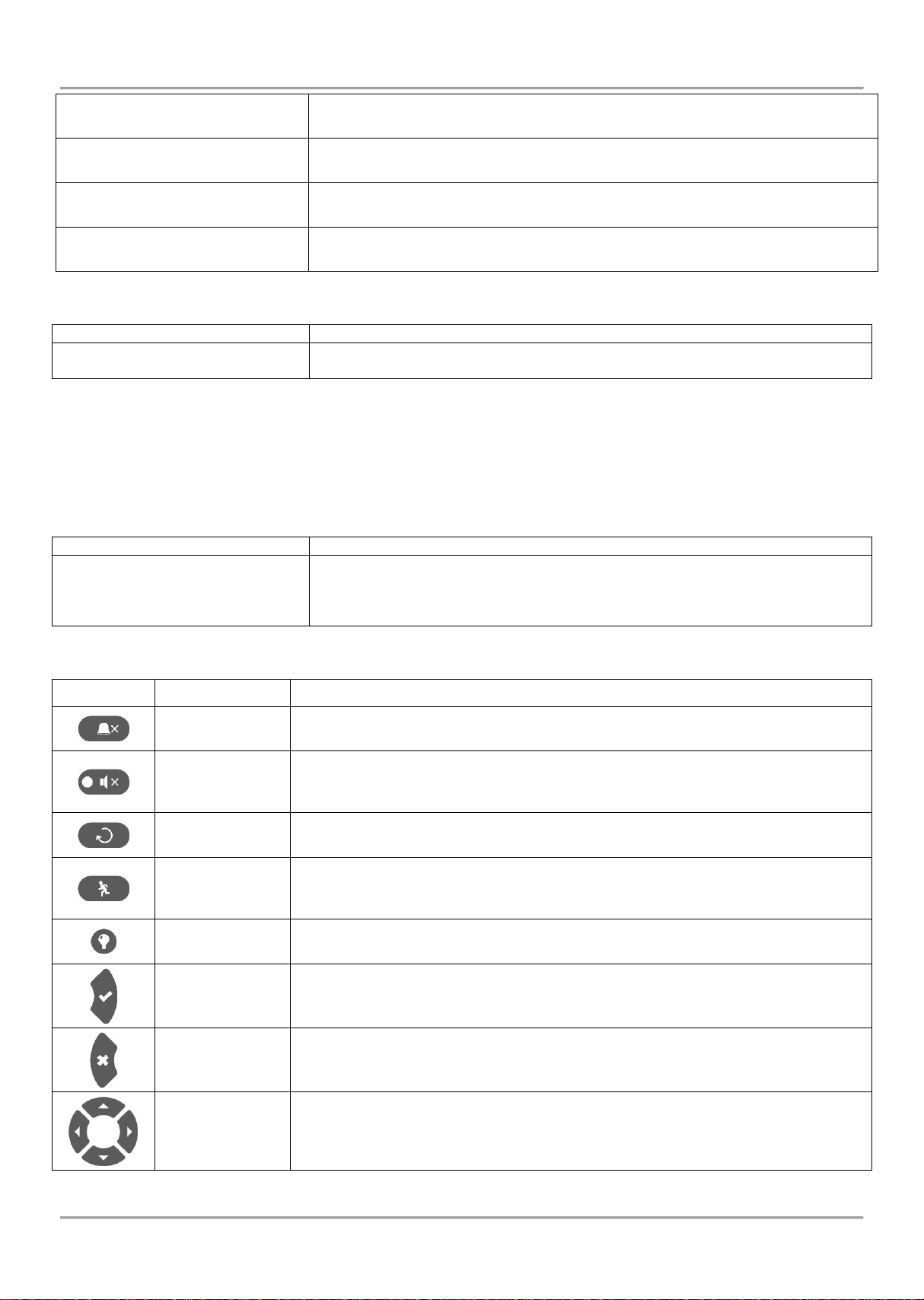

Button

Description

Functional digit buttons

1 - 4

The buttons are active at access levels 2 and 3, and have the following meaning:

- Introducing of access codes.

- Functional submenu entry.

- Changing of value or parameter status.

Button

Action

Description

Silence Buzzer

The button is active at access levels 1, 2 and 3. The button functionality is

deactivation of the internal buzzer (except for the “Protection Panel Fault” event).

Silence

Sounders

The button is active at access levels 2 and 3. The button functionality is

deactivation of the sounders in case of fire alarm event. After pressing the button

the LED next to it is lighting in yellow.

Reset

The button is active at access levels 2 and 3. The button functionality is resetting

the panel without switching off the main power supply.

Evacuation

The button is active at access levels 1*, 2 and 3. The button immediately activates

the sounders – the sounder delay is ignored if present.

* In case of fire alarm event in a zone and set sounder delay.

Buzzer and LED

general test

The button will activate all LEDs on the front panel – for events and zones, as and

the internal buzzer. The next pressing of the button deactivates the test.

ENTER

(Confirmation)

The button is active at access levels 1, 2 and 3. Use the button to confirm the

entered values and parameters; in the devices and zones menus use the button to

enter in a submenu for name and status changing.

CANCEL

(Rejection)

The button is active at access levels 1, 2 and 3. Use the button to reject the entered

values and parameters; one step back to the previous menu.

Navigation

buttons

The button is active at access levels 2 and 3. Use the arrows to scroll over the

menus; in the programming menus the buttons has a specific function for changing

values and switching between the editable fields.

2 – Description of the zone LED indication:

3 – Description of the LCD-module

The MAGPRO16 fire alarm addressable panel is equipped with letter-digit LCD-module (4 rows x 40 symbols). The

user can enter device and zone names using the navigation and control buttons. The display has an adjustable

backlight with 20 levels of intensity.

4 – Description of the functional digit buttons:

5 – Description of control and navigation buttons:

10

Page 11

MAGPRO16 Addressable Fire Alarm Panel – Installation and Programming Manual

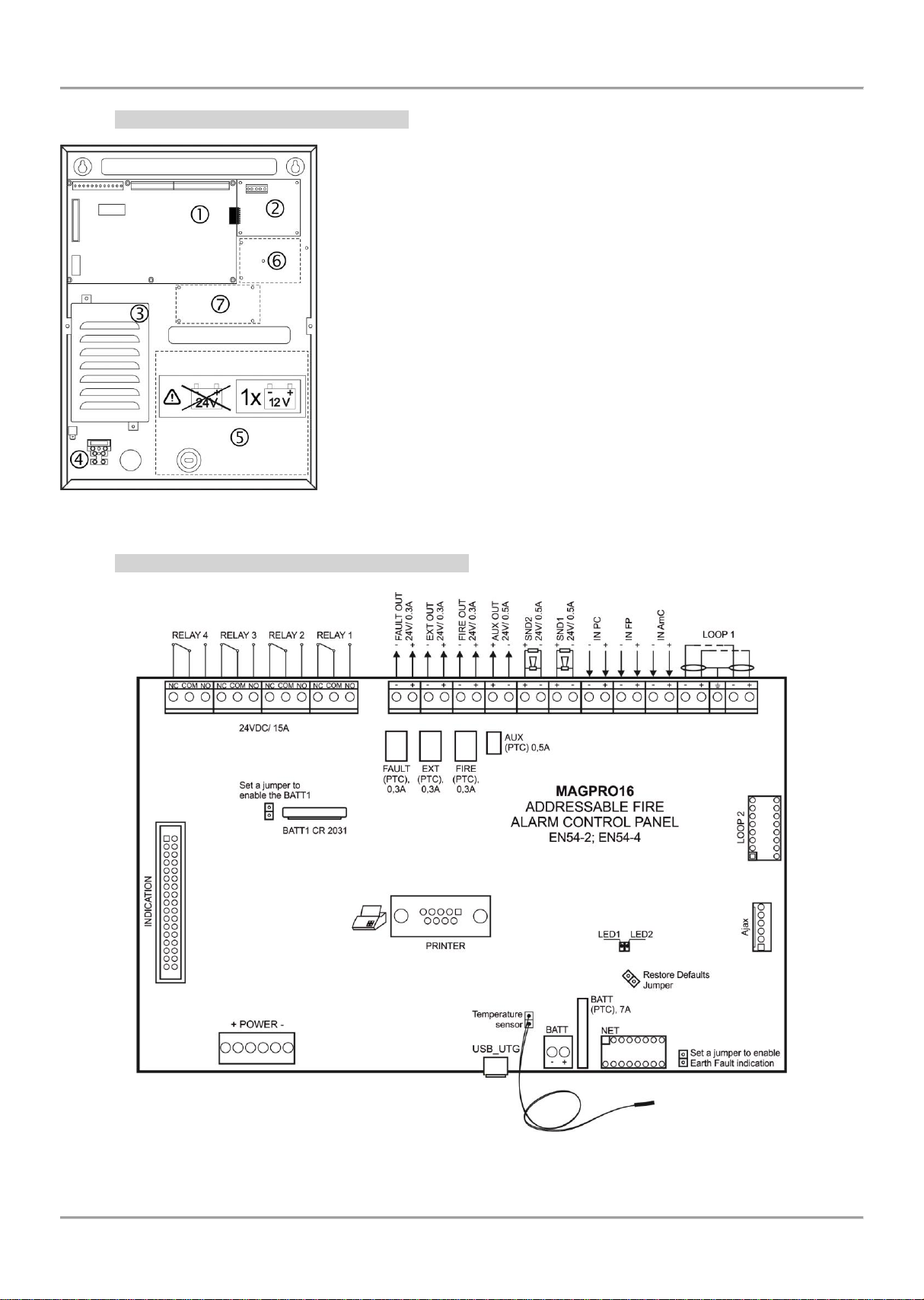

2.2.2 Configuration of the basic modules

Figure 6 – Configuration of the modules in the box:

1 – Main PCB (control panel)

2 – Second loop controller (optional, it may not be present in your

system configuration)

3 – Power supply unit

4 – Terminal 230V for connection of the main power supply cable

5 – Place for accumulator battery, 1 х 12V/ 18Ah

6 – Place for mounting of AJAX LAN communication module

7 – Place for mounting of redundant network module

2.2.3 Description of the main PCB (control panel)

Figure 7 – Main PCB of the MAGPRO16 fire alarm panel

11

Page 12

MAGPRO16 Addressable Fire Alarm Panel – Installation and Programming Manual

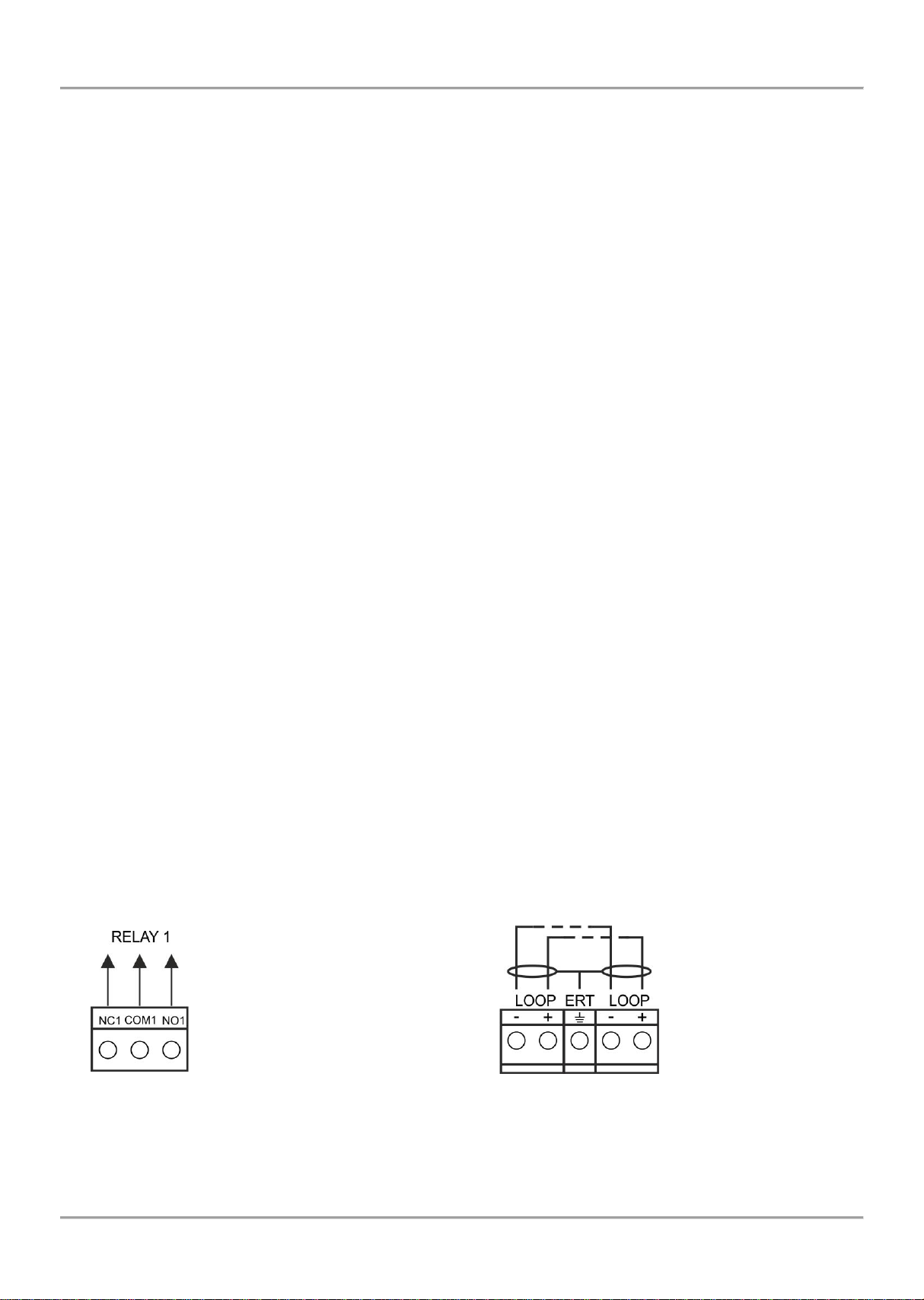

Figure 8 – Internal structure

of relay output

Figure 9 – Connection to the

loop controller

Description of the terminal row (left to right):

RELAY 1 - 4 – Programmable volt free change over relay contacts each, 24VDC@15A. Each relay has one

NO (normal open) and one NC (normal closed) contact with common lead on a terminal. When a relay output

is activated the NO contact is closed and the NC contact is opened.

FAULT – Potential, monitored output for connection of auxiliary devices, 24 VDC/ 0.3А. This output is

deactivated in case of system trouble or fault.

EXT - Potential, monitored output for fire extinguishing, 24 VDC/ 0.3А. This output is activated in case of a fire

alarm condition.

FIRE – Potential, monitored output for connection of auxiliary devices (signaling devices for example), 24 VDC/

0.3А. This output is activated in case of fire in the premises.

AUX – Potential output for power supply of auxiliary devices, 24 VDC/ 0.5А.

SND 1, SND 2 – Potential, monitored outputs for connecting sounders, 24 VDC/ 0.5А.

IN PC (Input Protection Alarm Confirmation) – Input for monitoring of signal „Confirmation for extinguishing

started in the site“ sent by extinguishing control panel.

IN FP (Input Fault Protection Panel) – Input for monitoring of signal „Fault“ sent by extinguishing control panel.

IN AmC (Input Alarm Confirmation) – Input for monitoring of signal „Alarm confirmation“ sent by extinguishing

control panel.

LOOP 1 (-LOOP+ / +ERT / -LOOP+) – Terminal row for connecting Loop 1 in the system.

LOOP 2 – Interface connector for adding MAGPRO16-L250 loop (for Loop 2) in the system configuration.

INDICATION – Interface connection for the indication module.

POWER – Interface connection for the main power supply unit.

JP7 – Jumper for enable/ disable the built-in battery for supporting the real time clock in case of main and

backup power supply failure.

PRINTER - RS232 interface connector for heat-printer.

USB UTG – Micro USB A/B connector for firmware update of the main microprocessor via PC or USB flash

drive; suitable also for programming via MAGPRO programming software.

BATT – Connector with wires (red and black) for connection to the accumulator battery. The type of connection

is according the battery terminals – to every cable shoe is added a separate cable lug connector Ø5mm (M5).

Restore Defaults – Jumper for full hardware reset of the panel and restoring the factory default settings.

Earth Fault – Jumper for enable/disable indication for earth fault.

Example: If you want to enable the earth fault indication set a jumper on Earth Fault terminals.

NET – Interface connector for a redundant network module to the system configuration.

Ajax – Interface connector for adding of AJAX LAN communication module to the system configuration.

Fuses:

AUX – 0.5А, PTC type, resettable

FAULT, EXT, FIRE – 0.3A, PTC type, resettable

BATT – 7A, PTC type, resettable

LED indication:

LED 1 (red) – Indication for scanning the devices connected to Loop1. In normal operation mode the LED

lights on continuously in 10 seconds intervals.

LED 2 (green) – Indication for data transfer between the main microprocessor of the panel and the controller

for Loop 1.In normal operation mode is constantly blinking.

Temperature sensor:

The temperature sensor is used for measurement of the battery temperature. The sensor is mounted at the end of the

wires couple factory connected to “Temperature sensor” terminal on the panel’s PCB.

The temperature sensor should be places behind or under the accumulator battery.

12

Page 13

MAGPRO16 Addressable Fire Alarm Panel – Installation and Programming Manual

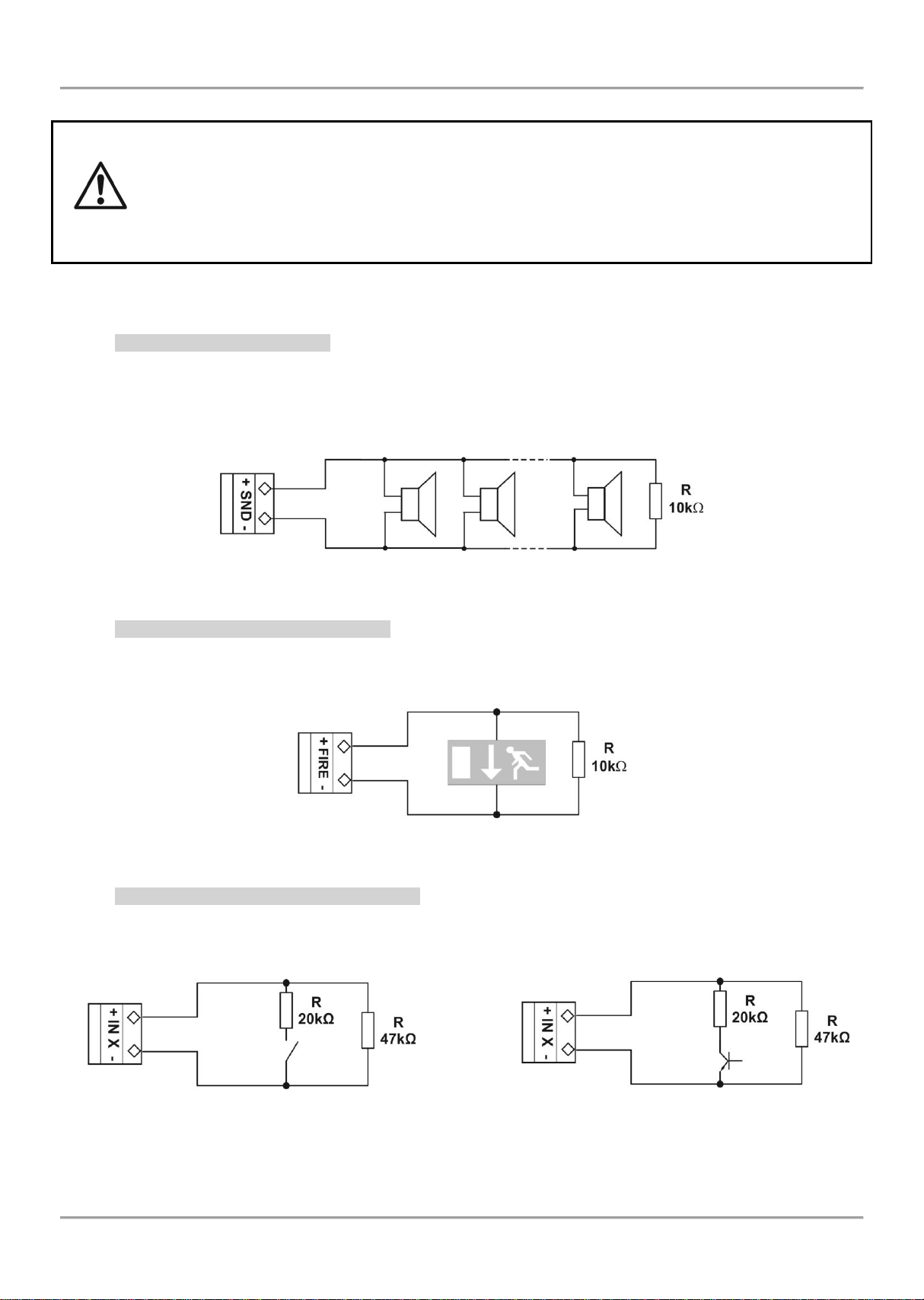

The monitored outputs SND, at activation, provide 24VDC@0,5A to the load connected between

them and GND*.

The monitored outputs FAULT, EXT and FIRE, provide 24VDC@0,3A to the load connected

between them and GND*.

It is necessary to connect in parallel to the last device in the loop a 10k terminate resistor,

so to ensure that the panel is able to detect any break or short circuit in the loop – see Figures 10

and 11!

Sounder 1

Sounder 2

Sounder N

а) Connecting diagram of relay

contact to the input

b) Connecting diagram of open

collector to the input

2.3. Connection of Signaling Devices

* The grounding point of the panel.

2.3.1 Connecting of Sounders

To every monitored output SND could be connected several sounders - Figure 10. The maximum number of sounders

that could be connected in the circuit depends on their total current consumption, which must not exceed 0,5A.

Before connecting the last sounder in the circuit, parallel to it must be added resistor 10k.

Figure 10 – Connecting sounders to SND output

2.3.2 Connecting of Signaling Devices

To every monitored output FAULT, EXT and FIRE could be connected signaling and other control devices – Figure 11.

The maximal consumption of the devices should not exceed 0.3А.

Before connecting the last device in the circuit, parallel to it must be added resistor 10k.

Figure 11 – Example for connecting of end device (an illuminated exit sign) to the Monitored FIRE Output.

2.3.3 Connecting to the Specialized Inputs

The specialized inputs of MAGPRO16 fire alarm panel are designed for operation with an extinguishing control panel.

The example connection diagrams are presented on Figures 12 а) and b).

Figure 12 – Examples of connections to the specialized input IN XX

13

Page 14

MAGPRO16 Addressable Fire Alarm Panel – Installation and Programming Manual

Detector 1

Detector 2

Detector N

MAGPRO16

Main Board

MAGPRO16-L250

Loop controller

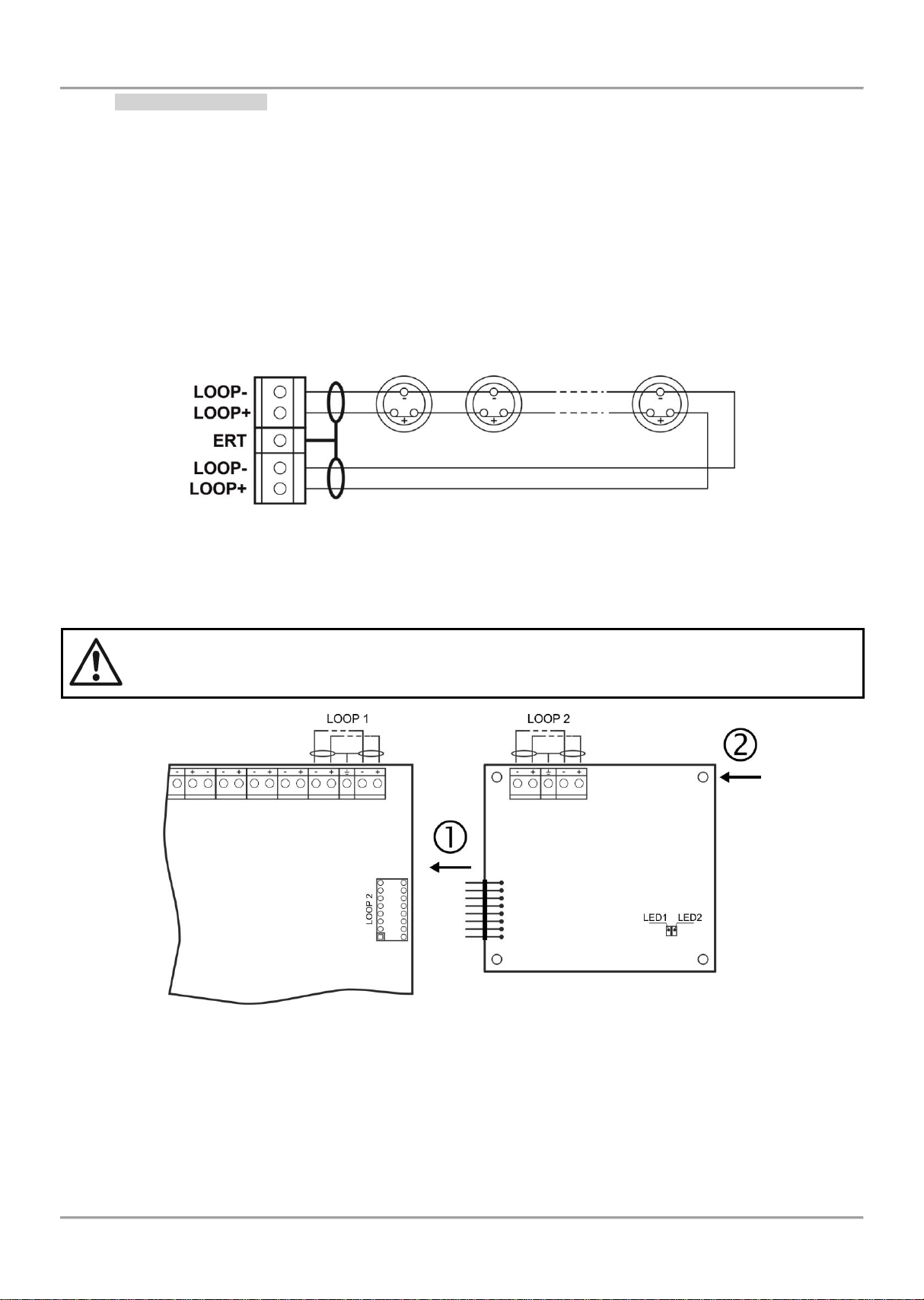

2.3.4 Loop Controller

The MAGPRO16 fire alarm panel supports operation with MAGPRO16-L250 loop controller via communication protocol

MAGPRO.

The Loop Controller realizes the connection between the I/O Module and devices connected to the communication

line. The Loop Expander has two basic functions:

Gathers data from the devices in the communication line and transfers it to the main microcontroller;

Receives commands from the main microcontroller and transfers them to the devices connected in the

communication line.

Up to 250 MAGPRO devices can be connected to MAGPRO16-L250 loop controller. The general connection

diagram of devices to the loop controller is shown on Figure 13.

The maximum current consumption of the devices in the communication line is Imax = 500mA. If the consumption

exceeds this value an over-load protection would be turned on.

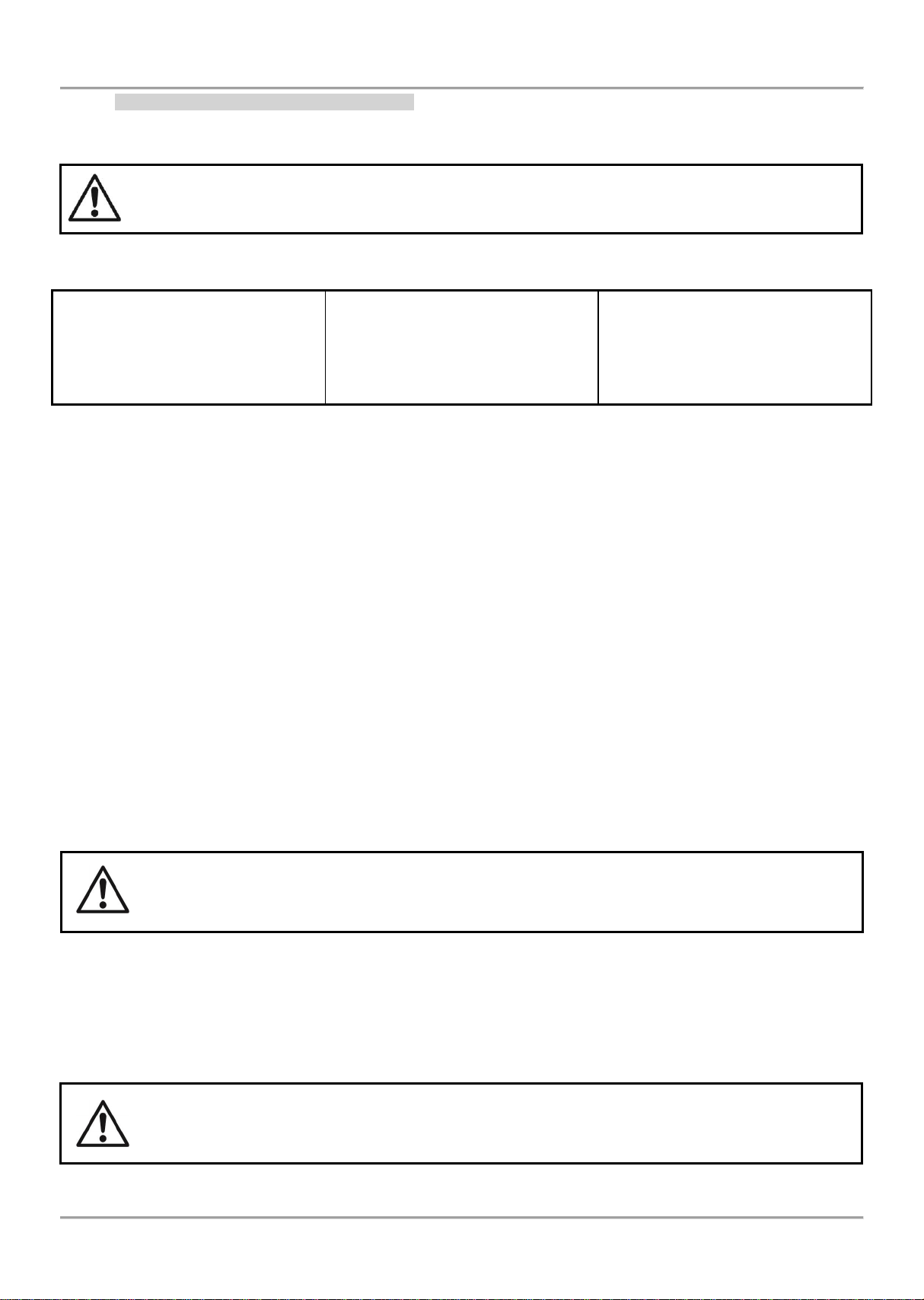

Figure 13 – Connecting of detectors to a loop controller

In the configuration of addressable fire alarm panel MAGPRO16 could be mounted a second loop controller as a

separate module – see Figure 14.

ATTENTION! Do not add or remove loop expanders to the fire panel configuration when

the main and backup power supplies are on!

- Connect the connectors: LOOP 2 of the main control panel and LOOP of the second loop controller.

- Fix the second loop expander to the metal box of the fire panel using the supplied bolts in the spare parts

kit.

LED 1/ LED 2 – LED indication for the loop controller status, analogical to that for the main control panel – see

the description on page 12.

Figure 14 – Adding of second loop controller MAGPRO16-L250 Loop

14

Page 15

MAGPRO16 Addressable Fire Alarm Panel – Installation and Programming Manual

1. To ensure the ability of the fire

panel to receive the signals from the

devices in the loop, calculate:

L

C1max

≤ 123 / R

C

2. To ensure the ability of the fire

panel to recognize the double

addresses in the system, calculate:

L

C2max

≤ 62 / RC

3. To ensure the ability of the devices

in the loop to receive command

signals from the panel, calculate:

L

C3max

≤ (12 / Imax - Ri) / RC

2.3.5 Maximum Permissible Cable Length

The maximum length of the loop in the system could vary according to the cross-section and the ohmic resistance of

the used cable.

ATTENTION! MAGPRO16-L250 Loop controller supports up to 250 devices, regardless of the type!

To ensure the correct operation of the system is necessary to make some calculations in advance:

where:

L

R

, L

C1max

- is total ohm resistance of the two wires of the used able; its value shows the magnitude of the cable resistance at

C

C2max

, L

- are maximum permissible length of the used cable, [km];

C3max

length 1km [Ω/km];

R

- is the total resistance of the isolator modules in the loop;

i

I

- is the maximum current consumption in the loop - total amount of the current consumption of all devices in the

max

loop *.

*Note, In case of using one or more from the following devices MAGPRO Series: SD1, HD1, HSD1, CP, CZM, WS,

WSS, DBS, DBSS.

Then the total amount for I

includes: the maximal current consumption in alarm mode of these 15 devices with

max

highest consumption, and for the rest of the devices - the total consumption in stand-by mode.

L

- is the necessary length of the cable for the loop.

C

After calculating, the maximal length of the cable is determined according:

• If L

≤ L

C

C2max

and L

≤ L

C

- the fire pane will be able to communicate with the devices in the loop and

C3max

also will be able to identify the presence of double addresses.

• If L

C2max

< LC ≤ L

C1max

and L

≤ L

C

- the fire panel will be able to communicate with the devices in

C3max

the loop but will not be able to identify the presence of double addresses.

ATTENTION! Always calculate the maximal cable length according the mentioned above formulas!

If L

> L

C

C1max

or L

> L

C

- the fire panel would not be able to communicate with the devices.

C3max

The connection diagram shown on Figure 15, gives the possibility to protect devices against opening and short circuit.

For example, short-circuit in section 2 will not influence the operation of sections 1 and 3. The isolator modules at the

both ends of section 2 will isolate it, and section 1 and 3 will continue working properly, as section 1 will operate by

supply from the channel “A” and section 3 - by supply from channel “B”. Since the fire panel will not be able to

communicate with the devices from section 2, it will generate an alarm signal for lost devices and open circuit.

The maximum recommended number of devices between two isolator modules (module isolator

device or using the built-in module isolator in a device) is 30!

15

Page 16

MAGPRO16 Addressable Fire Alarm Panel – Installation and Programming Manual

Device with isolator

Device with isolator

Section 1

Section 3

Section 2

Channel А

Channel В

Main

Power

Source

Fuse 4А

Type: glass time-delay

MAGPRO16

Main Board

Figure 15 – Example for connecting of detectors and call points to a loop expander

(the built-in in the main control panel or MAGPRO16-L250 Loop)

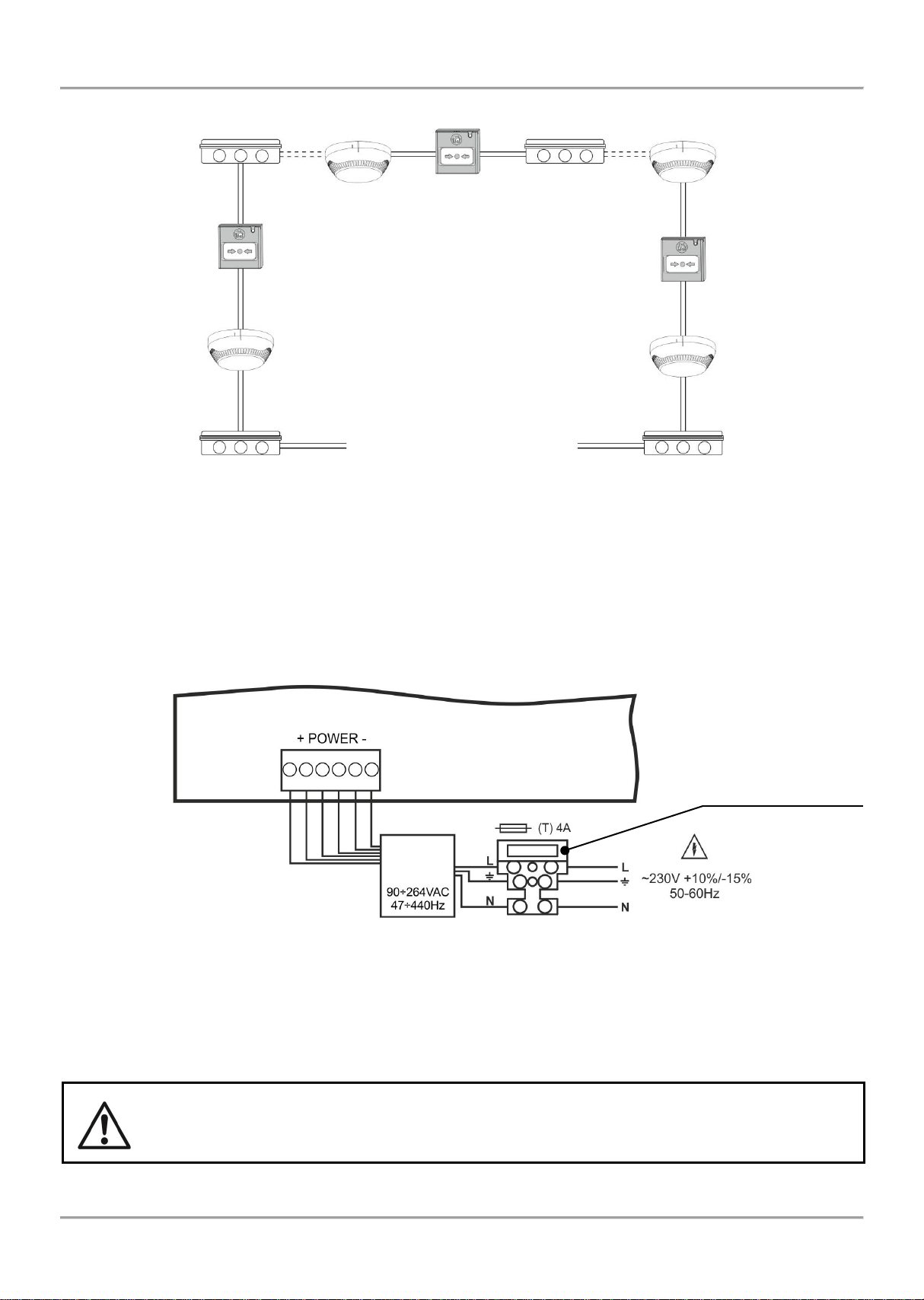

2.4. Connecting to the Main Power Source

The mains power supply of MAGPRO16 fire alarm panel is realized with connection of the main power cable to the

230V terminal, mounted in the metal box under the powers source. The connection between the 230V terminal and the

main power source is done from the manufacturer. The connection of the main power supply cable to the 230V

terminal is shown on Figure 16.

Before the mains supply is switched on, check the correct connection of each loop, sounder or any other input

or output!

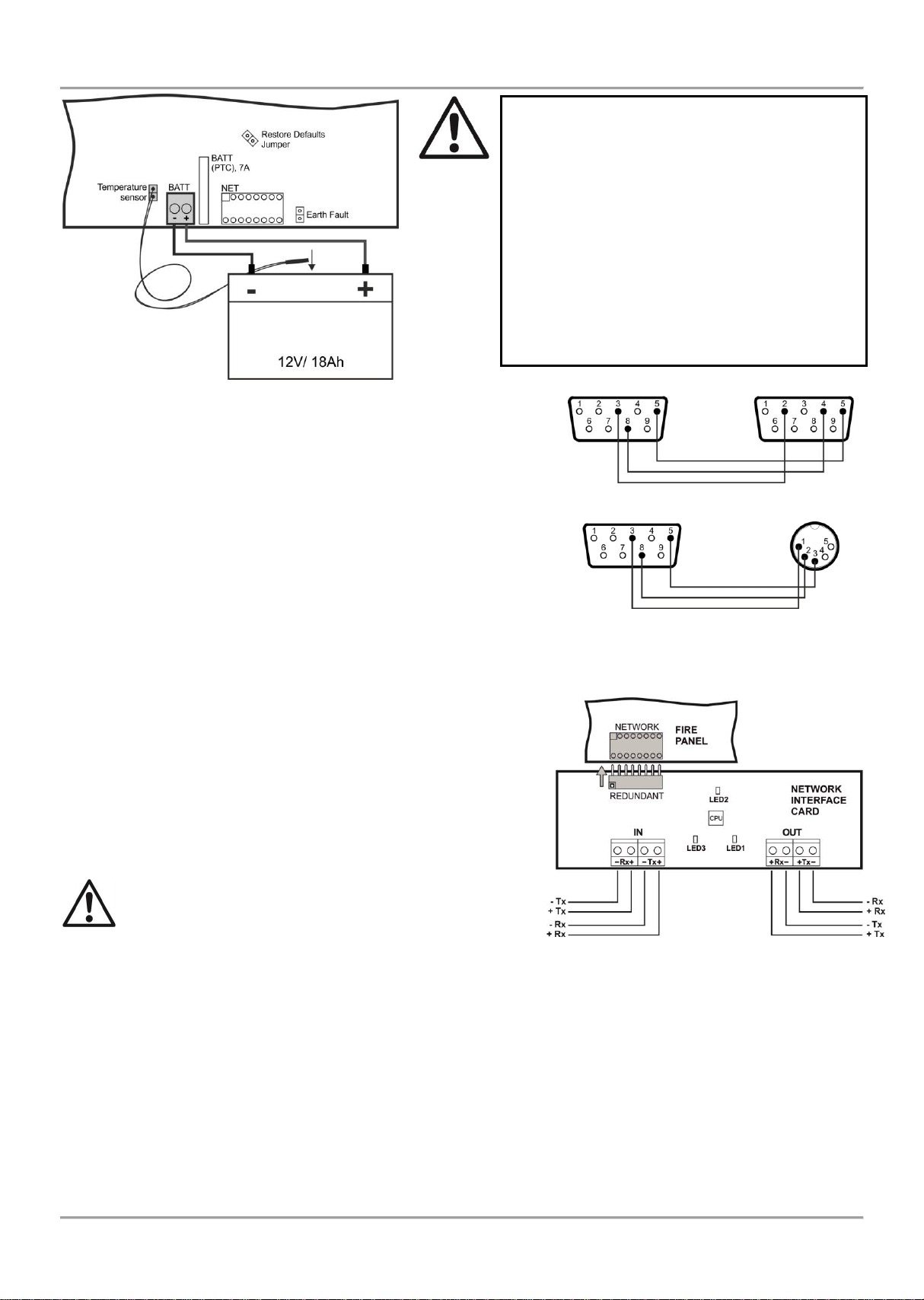

2.5. Connecting the Accumulator Battery

The accumulator battery leads are mounted on a terminal at the bottom of main control panel. Connect the battery

leads to the accumulator terminal as observe the polarity - see Figure 17.

The battery cannot power up the panel before the mains supply has been switched on!

The charging of the accumulator battery is done at maximum current I = 2A and charging voltage U

≤ 13.65V.

Figure 16. Connecting the main power supply cable to the 230V terminal

16

Page 17

Attention: The connection between the

accumulator battery and the main power

source has some special features.

It is strongly recommended to use only

battery with electrical characteristics and

dimensions pointed from the manufacturer.

Before connecting to the power source

check the polarity of the battery. Connect the

battery after the mains supply is turned on.

If the battery is new it will take a few hours

before its complete charging!

Black

Red

Accumulator

Battery

Figure 17. Connecting

the accumulator battery

MAGPRO16

Main Board

To control panel

To Kafka printer

Figure 18

Figure 19

DB9

DB9

DB9

DIN5

Attention: The connection between the

accumulator battery and the main power

source has some special features.

It is strongly recommended to use only battery

with electrical characteristics and dimensions

pointed from the manufacturer.

Before connecting to the power source check

the polarity of the battery. Connect the battery

after the mains supply is turned on.

If the battery is new it will take a few hours

before its complete charging!

To measure the current temperature of the

battery, place the temperature sensor behind

or under the battery.

2.6. Connecting a Heat Printer

The addressable fire alarm panel MAGPRO16 is equipped with RS232

interface connector, situated in the middle of the main PCB, for

connecting a heat printer. The heat printer allows the technician to print

the log file for the alarm and fault events, warnings and changes during

programming. The capacity of log file is 10 240 events, which are

saved with date and time of occurring – see also item 7.1.4.

The addressable fire alarm panel MAGPRO16 supports Canon 9 type

external printers, models Kafka and Datecs. For connecting the

MAGPRO16 panel to the heat printer you have to prepare a special

cable for the purpose – connect two male DB9-DB9 (Datecs printer) or

DB9-DIN5 (Kafka printer) type connectors as shown on Figure 18.

Before printing (access levels 2 and 3) make sure that the heat printer

is connected to the ‘PRINTER’ interface connector on the main PCB

and the printer is powered on.

2.7. Connecting a Network Interface Card (MAGPRO-NIC)

The addressable fire alarm panel MAGPRO16 is designed with option

for connection in a Ethernet network with other MAGPRO16 or

MAGPRO96 addressable panels (up to 32). The network interface

card is mounted under the main PCB and is connected to ‘NET’

connector – Figure 19. The card should be fixed with screws to the

metal bottom. The maximum cable length between two network

interface cards is 1000m.

Attention: NEVER add or remove the network interface

card to the fire panel configuration WHEN THE MAIN

AND BACKUP POWER SUPPLIES ARE ON!

2.8. Connecting an AJAX LAN Communication Module

The addressable fire alarm panel MAGPRO16 is designed for monitoring via serial interface connection using

specialized AJAX communication module. The monitoring could be realized over LAN network, according the type of

the used module. The communication module is mounted on the place under the second loop controller and it is fixed

with suitable screws to the metal bottom. The connection is realized with interface flat cable between the ‘AJAX’

connector on the main PCB and the interface connector on the communication module itself.

Attention: NEVER add or remove the communication module to the fire panel configuration WHEN THE MAIN

AND BACKUP POWER SUPPLIES ARE ON!

MAGPRO16 Addressable Fire Alarm Panel – Installation and Programming Manual

17

Page 18

MAGPRO16 Addressable Fire Alarm Panel – Installation and Programming Manual

MAGPRO16

Main Board

MAGPRO

Programming

Software

3. PROGRAMMING TYPES

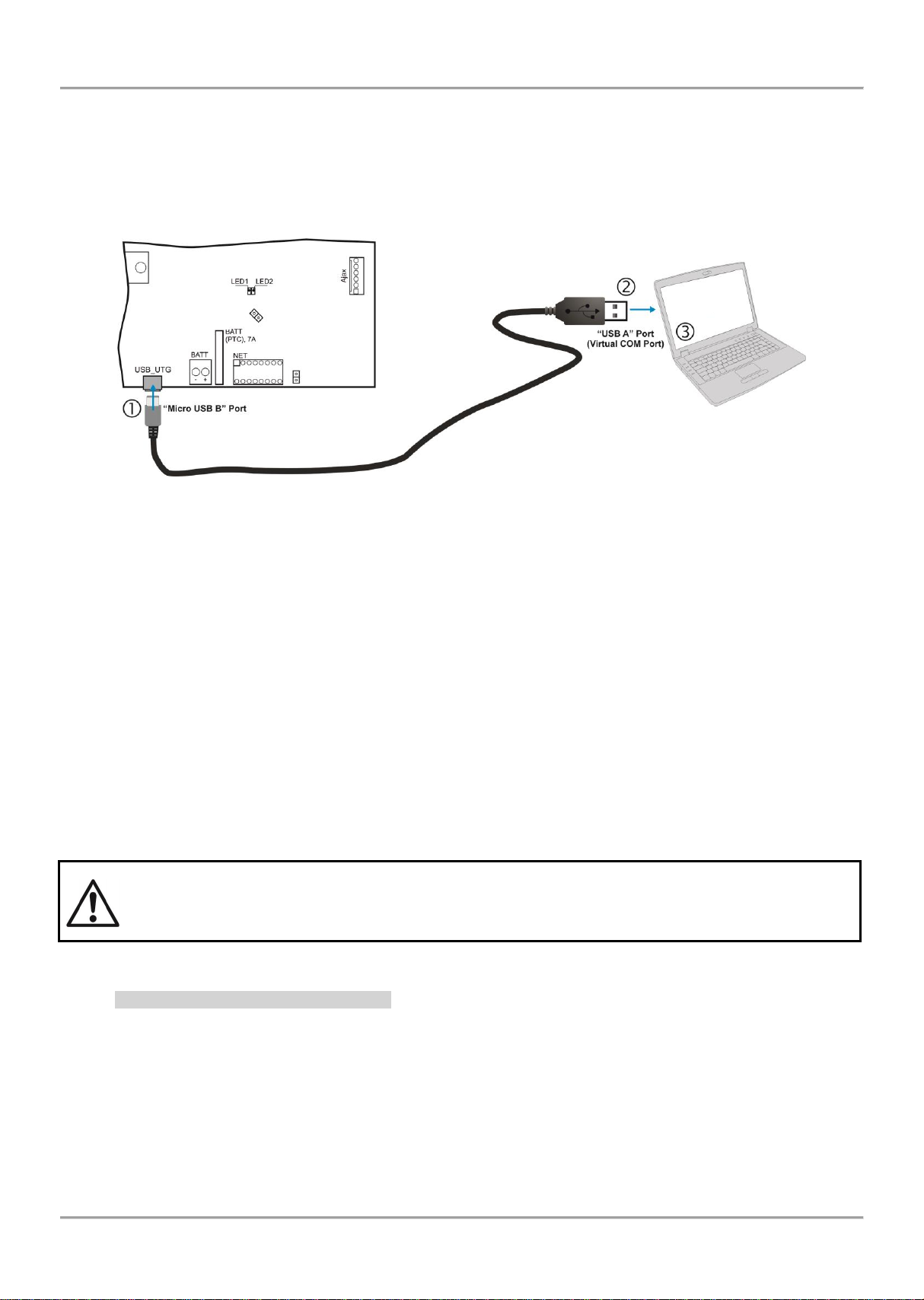

3.1. Programming via MAGPRO Programming Software

The specialized MAGPRO programming software is designed for programming of MAGPRO16/ 96 fire alarm panels.

To program the fire alarm panel MAGPRO16 you should first to install the MAGPRO programming software on your

computer.

To program the MAGPRO16 panel you have to use cable type USB Micro B - USB A – Figure 20.

Figure 20. Programming via MAGPRO programming software

3.2. Programming via Panel’s Keyboard

The addressable fire alarm panel MAGPRO16 can be programmed directly using the keyboard on the front panel. The

programming and settings are accessed from levels 2 (Maintenance) and 3 (Installer). The buttons on the front panel

are organized in three main groups

Functional digit buttons – used for entry in submenus, changing parameter status, entering of new combination

for Maintenance and Installer access codes.

Navigation buttons – arrows for moving the cursor on the screen and switching over the editable fields,

confirmation of entered parameters, cancelation of entered parameters and step back in the menu

programming structure.

Specialized buttons for User operation – Silence buzzer, Silence sounders, Reset, Evacuation, General test of

the LEDs, buzzer and screen.

The detailed description of all buttons on the front panel is presented in item 2.2.1 – 5, page. 9

The detailed description of Maintenance and Installer programming access levels is presented in item 5.

3.3. Firmware Update

ATTENTION!

The firmware update of the main microprocessor of fire alarm panel MAGPRO16 should be

performed by qualified personnel only and after held training program by distributer or

manufacturer!

3.3.1 Firmware Update from Computer

To start a firmware update from a computer you should first to have a copy of an image update file (with *.bin

extension) saved on your computer. For firmware updates use the USB_UTG connector on the main PCB:

Connect the panel to the computer using USB cable: Normal A to Micro B type.

Enter access code for level 2 or 3 and choose menu 9) SOFT. REVISION.

Wait for the message from Windows Explorer for found new Removable Disk.

The panel will display automatically on the screen:

USB Host Detected

1. Copy image file to Removable Disk

2. Make Eject at Removable Disk

> Panel is configured

18

Page 19

MAGPRO16 Addressable Fire Alarm Panel – Installation and Programming Manual

Use the Windows Explorer file manager to copy the new image update file (with *.bin extension) in Removable

Disk directory.

When the copying of the image file completes, remove the Removable Disk, as select Eject option from its

dialogue box (right click with the mouse over it).

If the data in the image file are correct, the panel starts the firmware update procedure of the main

microprocessor accompanied with short beeps.

Disconnect the USB cable.

The panel will reset itself automatically after a successful firmware update.

3.3.2 Firmware Update from USB Drive

To start a firmware update from a USB drive you should first have to copy the new image update file (with *.bin

extension) in the main directory of the USB removable disk. The name of the file must be short – up to 8 symbols.

Connect the panel to the computer using USB cable: USB Micro А - USB A type.

Enter access code for level 2 or 3 and choose menu 9) SOFT. REVISION.

Connect the USB drive, with the new image file (with *.bin extension).

Notes:

1. The panel will scan the files copied only in the main directory and these files in the first subfolders in the tree

hierarchy of the USB drive.

2. It is obligatory the name of the file to be up to 8 symbols long.

Wait until the polling procedure is complete - USB drive will be displayed with its name and manufacturer. On

the last row of the screen will start blinking the notice Push 'Enter' to continue.

Press Enter button and wait for a message for the USB drive capacity. On the last row of the screen will be

active two buttons (2) To Panel and (3) From Panel.

Press (2) To Panel button. A list with the present image files (with *.bin extension) copied to USB drive is

displayed on the screen, as the software revision is displayed on the right side, for example:

0:/MAGPRO16/MAGPRO162_0.BIN v 2.00

Scroll through the listed files using the buttons with up and down arrows – the currently selected file is blinking.

Select the file and press Enter button.

The panel starts uploading the file from the USB drive to the external Flash memory of the panel. The running

process is displayed with a progress bar.

If the data in the image file are correct, the panel starts the firmware update procedure of the main

microprocessor accompanied with short beeps.

Disconnect the USB cable.

The panel will reset itself automatically after a successful firmware update.

3.3.3 Copying Image File from the Panel to USB Drive

Connect the panel to the computer using USB cable: USB Micro B - USB A type.

Enter access code for level 2 or 3 and choose menu 9) SOFT. REVISION.

Connect the USB drive.

Wait until the polling procedure is complete - USB drive will be displayed with its name and manufacturer. On

the last row of the screen will start blinking the notice Push 'Enter' to continue.

Press Enter button and wait for a message for the USB drive capacity. On the last row of the screen will be

active two buttons (2) To Panel and (3) From Panel.

Press (3) From Panel button – the panel will download a copy of its own image file to the USB drive and saves

the file in MAGPRO16 folder.

4. FULL HARDWARE RESET

The full hardware reset of MAGPRO16 addressable fire alarm panel allows the engineer to restore all factory settings

and access code combinations for level 2 (Maintenance) and 3 (Installer).

To perform full hardware reset, follow the steps:

1. Disconnect the mains and backup power supplies.

2. Set a jumper on ‘RESTORE DEFAULTS’ terminal on the PCB.

3. Connect mains and after that the backup power supply.

4. Wait the procedure for initialization to complete.

5. Remove the jumper from ‘RESTORE DEFAULTS’ terminal.

6. Proceed with save system configuration and other settings.

19

Page 20

MAGPRO16 Addressable Fire Alarm Panel – Installation and Programming Manual

Indication - Groups

Priority

ALARMS

The highest

FAULTS

High

DISABLEMENTS

Normal

TESTS

Normal

WARNINGS

Low

Level

Description

Code

Combination

Access

1

User

-

Only Silence buzzer and Evacuation* buttons are active. It is not allowed to

enter Maintenance and Programming access levels.

* Just for that cases, when the fire alarm signal is received from a device

2

Maintenance

2222

Silence buzzer, Silence sounders, Reset and Evacuation buttons are active.

Maintenance access level entry, which allows partial programming and menu

settings.

3

Installer

3333

Silence buzzer, Silence sounders, Reset and Evacuation buttons are active.

Installer access level entry, which allows full programming and settings.

5. PROGRAMMING OF MAGPRO16 FIRE ALARM PANEL

5.1. General Information for Programming and Operation

Addressable fire alarm panel MAGPRO16 can be programmed directly through the navigation and functional digit

buttons on the front panel. The programming menus are organized in a text tree-structure and are viewed on the LCDdisplay (4 rows x 40 symbols). The access to the programming menus is organized in three levels – see items 5.2.

When turned on, the panel always runs a procedure of loading the parameters, which usually takes about 5-6 sec.

There is no access to the menus of the panel during that procedure.

Upon the initial startup, the panel does not hold any configurations. Initialization may take several minutes. The

initialization time needed depends on the number of periphery and loop devices – for Loop 1 and Loop 2. After the

panel has been turned on, it performs a procedure for detecting newly installed loop devices – see also APPENDIX C,

page 48.

During the procedure the symbol “ ” is blinking in the up right corner of the screen. This symbol will appear always

when running similar procedures like resetting of devices or recognized new devices connected to the loop.

Right after the initial startup of the mains power supply and initialization completed the panel turns to normal operation

mode. If there are any active alarm and fault messages they are displayed on the screen, as the indication follows the

priority:

The name of the current active indication group is blinking together with the number of the first message. Press the

ENTER button to review some additional information for the respective message as data and time of occurring, device

address, zone number or other, according the trouble type.

The indication for the active ALARMS in the system is viewed with highest priority.

The addressable fire alarm panel MAGPRO16 supports different languages for the programming menus.

The factory default setting of the language is in English. You can change the language after the initial powerup as enter in sequence:

Press CANCEL – enter code 3333 – select menu 6) GENERAL SETTINGS – menu 6.4) PANEL SETTINGS –

Button 1 – Button ENTER

Use the ENTER button to enter in programming menus and confirmation of entered values and

parameters; the functional digit buttons are used for entering of access codes and changing the

current status; the navigation buttons (up/ down and left/ right arrows) are used for scrolling

through the menus and for changing the editing field.

5.2. Codes and Access Levels

There are three access levels in MAGPRO16 panel: User, Maintenance and Installer. Every level comprises different

functions and operations. To enter Maintenance and Installer levels is necessary to enter valid access code:

The introduced code combinations are visualized with “ “ symbol. The entry is automatic.

20

Page 21

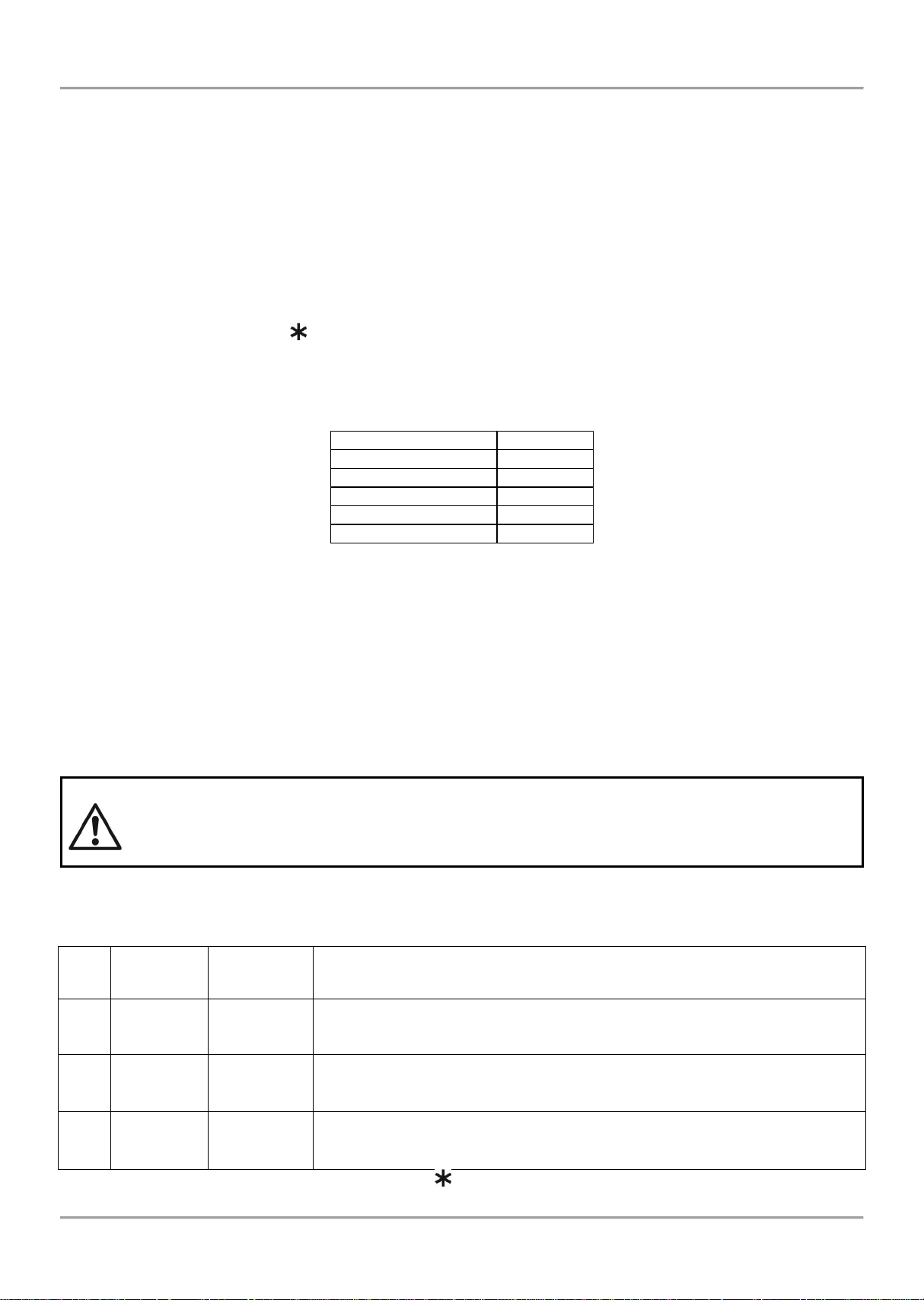

MAGPRO16 Addressable Fire Alarm Panel – Installation and Programming Manual

Mode/ Menu

Description

Access Level

1 2 3

Operation modes

ALARMS

Viewing the Alarms Messages in the system.

FAULTS

Viewing the Faults Messages in the system.

DISABLEMENTS

Viewing the active disablements in the system.

TESTS

Viewing the running tests in the system.

WARNINGS

Viewing the Warnings Messages in the system.

Silence buzzer

Deactivating Internal Buzzer.

Silence Sounders

Deactivating the Sounders.

During active fire alarms and deactivated/ silenced

sounders the LED next the button is lighting up.

Reset

Resetting the panel without switching off the main and

backup power supplies.

Evacuation

Activating Evacuation alarm signal; the sounders will

activate immediately overriding all introduced delays.

*

Test

General test for operability of all LEDs and internal buzzer.

Programming menus

View history LOG

Viewing the LOG file for all events; printing of all or

separate events; clear the log file.

Zones

Zones status; setting a zone name; parameter

programming; zone test for operability.

Device Setup

Setting a device name; parameter programming.

Addressing:

Menus for addressing devices.

-

Set address

Setting an address for single devices.

Change address

Changing device address.

Self-addressing

Automatic self-addressing mode.

Panel outputs

Parameter programming for the built-in panel outputs:

SOUNDERS, EXTINGUISHING, FIRE, FAULT, RELAY

OUTPUTS.

General Settings:

General settings common for the panel.

-

Access codes

Changing the code combinations for levels Maintenance

and Installer; enable/ disable the automatic exit from the

installer programming menus.

Time/ Day

Setting the current time and date.

Day/ Night alarm mode

Setting Day/ Night alarm mode or operation on schedule.

Panel settings

Changing the menu language, setting the backlight

brightness; entering disablements.

Delay Т1

Setting the Delay Т1.

Sounders mode

Programming the operation of SOUNDER outputs.

Save configuration

Saving the set system configuration.

Restore defaults

Restoring the factory default settings.

Software revision

Reviewing the current software revision.

Network

Setting the redundant network parameters

Active isolators

Reviewing the activated isolators in the system.

Access level 1

Return to Access Level 1.

The access codes could be changed only from level Installer - menu 6) General Settings - submenu 6.1) Access

codes.

There are different restrictions on the panel functions in the relative access levels, which are shown in the table below:

* Just for that cases, when the fire alarm signal is received from a device

- The operation modes and the menus are not supported for that access level

- The operation modes and the menus can be reviewed or are allowed for partial programming for that access level.

21

Page 22

MAGPRO16 Addressable Fire Alarm Panel – Installation and Programming Manual

6. DESCRIPTION OF THE OPERATION MODES

In this section you can find detailed descriptions of all operation modes of MAGPRO16 addressable fire alarm panel.

The modes for reviewing of system events are accessible only from level 1 without entering access code. If no alarm,

fault or warning messages, active tests and disablements are present, then the panel is in normal operation mode and

only the current day and time are displayed. In case of alarm, fault or warning situation is occurred the panel will

display information and text messages for the events. A list of all types of event messages is presented with details in

APPENDIX A, page 46.

6.1. Review of Alarm Events

The messages for alarm events are displayed with the highest priority in the system. In case of alarm in the system the

panel will show a list with active alarms at the moment, and ALARMS mode is blinking together with the number of the

first alarm message. Over the button (1) is displayed the total number of the active alarms. The LED ‘General Fire’

lights on together with the number of the zone in alarm. The panel is signaling with continuous sound signal, which can

be stopped with pressing the ‘Silence buzzer’ button. The activated sounders could be stopped after entering access

level 2 or 3 and pressing the ‘Silence sounders’ button.

Example:

The User can review also some additional information for every of the alarm events. For this, select the number of the

alarm message using up/ down arrow buttons (the number of the selected event is blinking) and press ENTER button.

On the screen is displayed information for the loop number and the address of the device sensed the alarm event. At

the bottom of the screen is displayed the day and time of occurring of the respective event. Note that the additional

information is different according the type of the alarm event. To exit the review alarm events mode, press CANCEL

button.

6.2. Review of Fault Events

The messages for fault events are displayed with high priority. If no alarm events are present, and there are active

faults in the system, the FAULTS mode is blinking together with the number of the first fault event. The LED ‘General

Fault’ lights on. The faults messages are cleared automatically after the fault condition is restored.

Example:

The User can review also some additional information for every of the faults events. For this, select the number of the

fault message using up/ down arrow buttons (the number of the selected event is blinking) and press ENTER button.

In case, there are active alarms in the system, but you want to review the fault messages, press button (2) – FAULTS

mode. The present faults in the system are displayed with serial numbers. The reviewing is the same as described in

item 6.1. The total number of active faults is displayed at the bottom right corner of the screen. Use button (1) to go

back to ALARMS mode and reviewing the alarm messages.

To review the FAULTS at active alarms in the system:

To exit the review fault events mode, press CANCEL button.

22

Page 23

MAGPRO16 Addressable Fire Alarm Panel – Installation and Programming Manual

6.3. Review of Disablements

The messages for disablements are displayed with normal priority. If no alarm or fault events are present, and there

are active disablements in the system, the DISABLEMENTS mode is blinking together with the number of the first

disablement. The LED ‘Disable’ is lighting on.

Example:

The User can review also some additional information for each of the disablements. For this, select the number of the

disablement message using up/ down arrow buttons (the number of the selected event is blinking) and press ENTER

button.

In case, there are active alarms and/ or faults in the system, but you want to review the disablements, press button (3)

– DISABLEMENTS mode. The disablements in the system are displayed with serial numbers. The reviewing is the

same as described in item 6.1. The total number of the introduced disablements is displayed at the bottom right corner

of the screen. Use button (1) to go back to ALARMS mode and reviewing the alarm messages.

To review the DISABLEMENTS at active alarms and/ or faults in the system:

To exit the review fault events mode, press CANCEL button.

6.4. Review of Running Tests

The messages for running tests are displayed with normal priority. If no alarm or fault events or disablements are

present, and there are active tests in the system, the TESTS mode is blinking together with the number of the first

running test. The LED ‘Test’ is lighting on.

The numbers of the zones in test mode with activated detectors are blinking.

Example:

The User can review the number of the zone in test mode. For this, select the number of the zone using up/ down

arrow buttons (the number of the selected event is blinking) and press ENTER button.

If, there are active alarms and/ or faults in the system and you want to review the running tests, press button (4)

MORE>> – TESTS mode is blinking. The tests running in the system are displayed with serial numbers. The reviewing

is the same as described in item 6.1. The total number of the running tests is displayed at the bottom right corner of the

screen. Use button (1) to go back to ALARMS mode and reviewing the alarm messages.

23

Page 24

MAGPRO16 Addressable Fire Alarm Panel – Installation and Programming Manual

After choosing the button (2) TESTS the screen displays:

To exit the review of running tests mode, press CANCEL button.

6.5. Review of Warning Messages

The messages for warnings are displayed with low priority. If no alarm or fault events or disablements and tests are

present, and there are active warnings in the system, the WARNINGS mode is blinking together with the number of the

first message. There is no LED indication on the front panel.

Example:

The User can review also some additional information for every warning message. For this, select the number of the

message using up/ down arrow buttons (the number of the selected event is blinking) and press ENTER button. On the

screen is displayed information for the loop number and the address of the device. At the bottom of the screen is

displayed the day and time of occurring of the warning. Note that the additional information is different according the

type of the warning event.

In case, there are active alarms and/ or faults in the system, but you want to review the warnings, press button (4)

MORE>> – (3) WARNING mode. The warning messages in the system are displayed with serial numbers. The

reviewing is the same as described in item 6.1. The total number of the warnings is displayed at the bottom right corner

of the screen. Use button (1) to go back to ALARMS mode and reviewing the alarm messages.

To review the WARNINGS at active alarms and/ or faults in the system:

After choosing the button (3) WARNINGS the screen displays:

To exit the review warning messages mode, press CANCEL button.

NOTE: If you are programming parameters at Access Level 2 (Maintenance) or Access Level 3 (Installer) and there is

an alarm or fault event in the system, the panel will automatically display a list with messages. After reviewing the

events, you can return to the programming mode with single pressing the CANCEL button.

24

Page 25

MAGPRO16 Addressable Fire Alarm Panel – Installation and Programming Manual

Maintenance Code – 2222

Installer Code – 3333

Maintenance Code – 2222

Installer Code – 3333

Maintenance Code – 2222

Installer Code – 3333

6.6. Silencing the Internal Buzzer

The internal buzzer of addressable fire alarm panel MAGPRO16 is signaling in case of activated alarm or fault events

in the system. The buzzer silencing is available from every access level without code entry.

To silence the internal buzzer press button.

6.7. Silencing the Sounders

The sounders silencing is available from access levels 2 and 3 after code entry.

To silence the sounders enter in sequence:

The LED ‘Silence sounders’ right to the button is lighting up.

To reset the panel in normal operation mode press ‘Reset’ button.

6.8. Activate Evacuation

The evacuation alert is available for activation from every access level regarding the following:

Level 1: Just for that cases, when the fire alarm signal is received from a detector in a zone.

To start the sounders for evacuation alert, the user has to press the button.

Levels 2 and 3: In case there is no fire alarm signal from a detector in a zone.

To start the sounders for evacuation alert, the user has to enter in sequence:

6.9. Resetting the Panel

The resetting of the panel’s current state is available from access levels 2 and 3 after code entry. The resetting function

is used for initializing the panel and return to normal operation mode after alarm or fault restoring.

To reset the panel enter in sequence:

After resetting are cleared also all introduced earlier test in zones and disablements. The introduced delays are not

cleared. The panel returns to normal operation mode.

6.10. Indication Test

The indication test could be started at any time regardless of the access level. The general test allows the user to

review the correct operation of the LED indication on the front panel, the sound signal of the internal buzzer, and the

visualization on the LCD display.

To start the general test press button – all LEDs must light on and the internal buzzer starts sounding. On the

LCD module every one position is displayed with 5x8 dots. The panel will automatically exit the general test mode after

6 seconds. The general test can be stopped also with next pressing of the same button.

25

Page 26

MAGPRO16 Addressable Fire Alarm Panel – Installation and Programming Manual

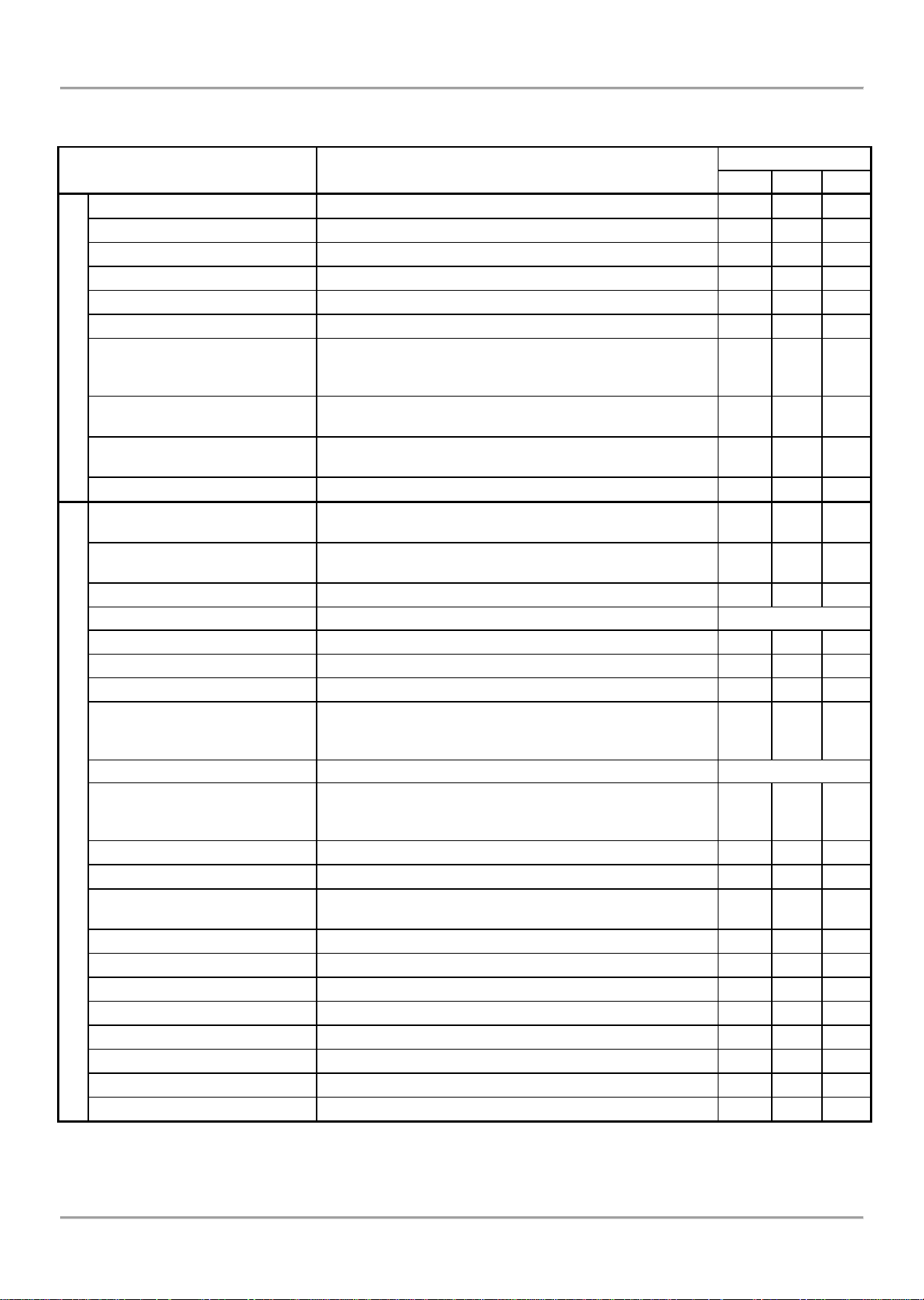

Button

Functions

Menu entry; Confirmation of entered parameters and settings.

Cancelation of entered parameters and settings; Step back in the menu structure.

Scrolling between menus; Increasing values; Text entering.

Scrolling between menus; Decreasing values; Text entering.

Changing the editing fields.

7. DESCRIPTION OF THE PROGRAMMING MENUS

The programming menus are accessible from level 2 (Maintenance) and level 3 (Installer) after entering a valid access

code.

In level 2 could be realized partial programming of parameters, and some values are accessible only for reviewing.

In level 3 could be realized full programming and settings, and also to restore the factory default settings, including

access codes. For details see the descriptions in the tables in item 5.2 for the rights and limitations for every access

level.

The navigation buttons have the following functionalities in operation:

7.1. View History Log Menu

This menu allows the installer to review and print the system events recorded in the panel memory log file. The

capacity of the panel memory log file is 10 240 events. The installer can clear also all panel’s memory or to extract a

list of events by date. The menus are accessible from levels 2 and 3.

After entering the menu the screen displays:

The following general information is displayed in the main screen of

VIEW LOG menu:

Total Entries - Shows the total number of the recorded events in the

memory log file.

Total Alarms Count - Shows the total number of the registered

alarm events.

Use the functional digit buttons to enter the respective submenu.

7.1.1 Review of Full Events List

From the main screen of VIEW LOG menu press (1) VIEW ALL button. The last (newest) event is displayed on the

screen. Use the buttons with up and down arrows to review all recorded events one-by-one, as everyone is displayed

with date and time of occurring.

Press a functional button for entry in the respective submenu:

1 – NEWEST: Shows the last recorded event.

2 – OLDEST: Shows the first recorded event.

3 – CLEAR: See the description of item 7.1.3

4 – PRINT: See the description of 7.1.4

Exit to the main screen of VIEW LOG menu is realized with CANCEL button.

26

Page 27

MAGPRO16 Addressable Fire Alarm Panel – Installation and Programming Manual

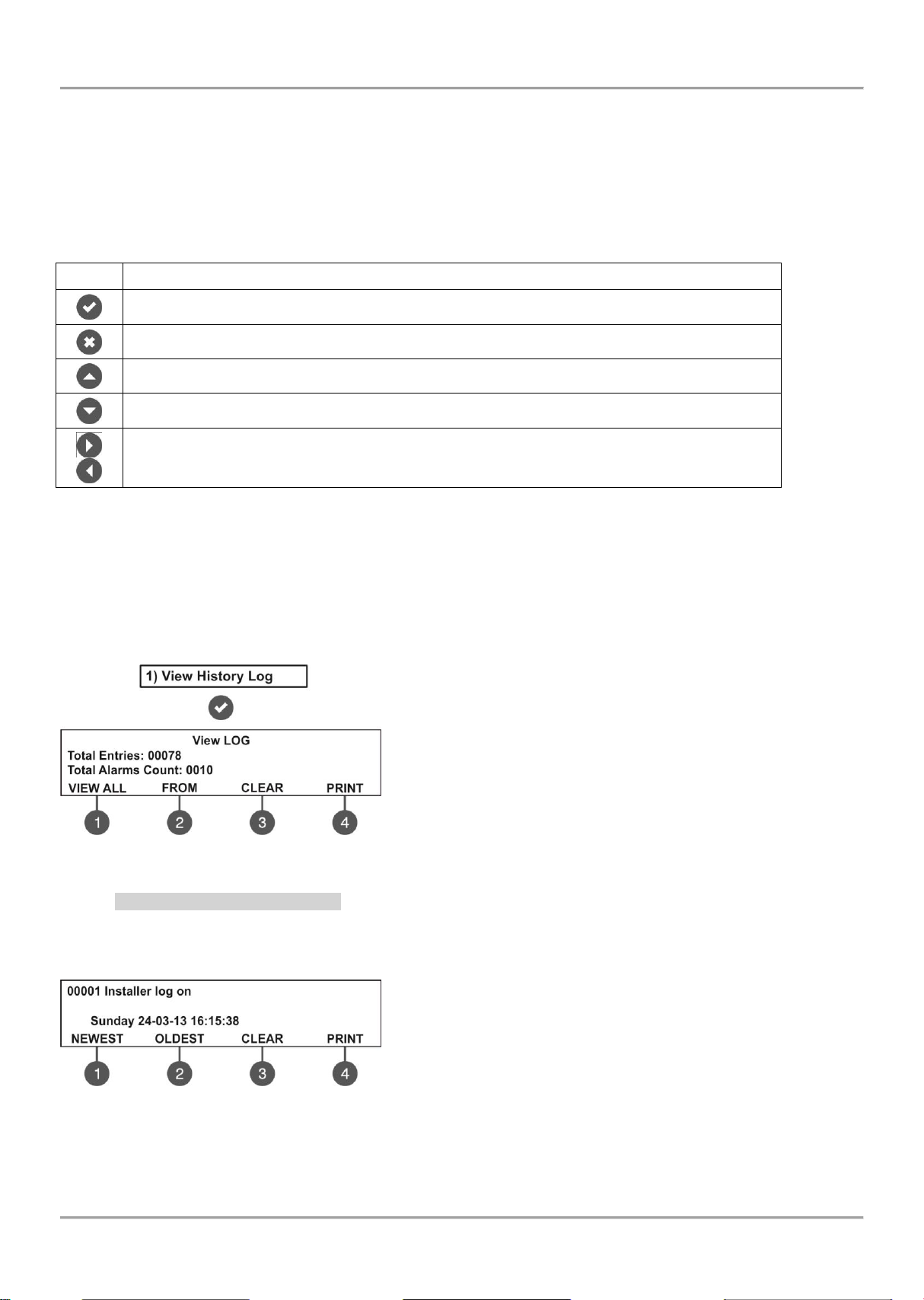

7.1.2 Review of List of Events by Date

From the main screen of VIEW LOG menu press (2) FROM button. In “FROM” submenu the installer can extract a list

of events by date. Set in sequence the day, the month and the last two digits of the year. The edited digit is flashing.

Scroll between the fields using the left and the right arrows.

In “From date” field enter the new date using the buttons:

- UP arrow for increasing the number

- DOWN arrow for decreasing the number

- LEFT/ RIGHT arrows for changing the editing field

Then press the ENTER button – at the screen is displayed the first event for the entered date with time.

Exit to the main screen of VIEW LOG menu is realized with CANCEL button.

7.1.3 Deleting the Events in the LOG file

From the main screen of VIEW LOG menu press (3) CLEAR button. In “CLEAR”* menu the installer can delete the

entire system events list. The screen displays the total number of recorded events.

The system will ask for confirmation.

To delete all records in the LOG file press (2) YES button.

Exit to the main screen of VIEW LOG menu is realized with CANCEL

or (3) NO button.

Note: The ‘CLEAR’ submenu is not available in the Maintenance access level (2).

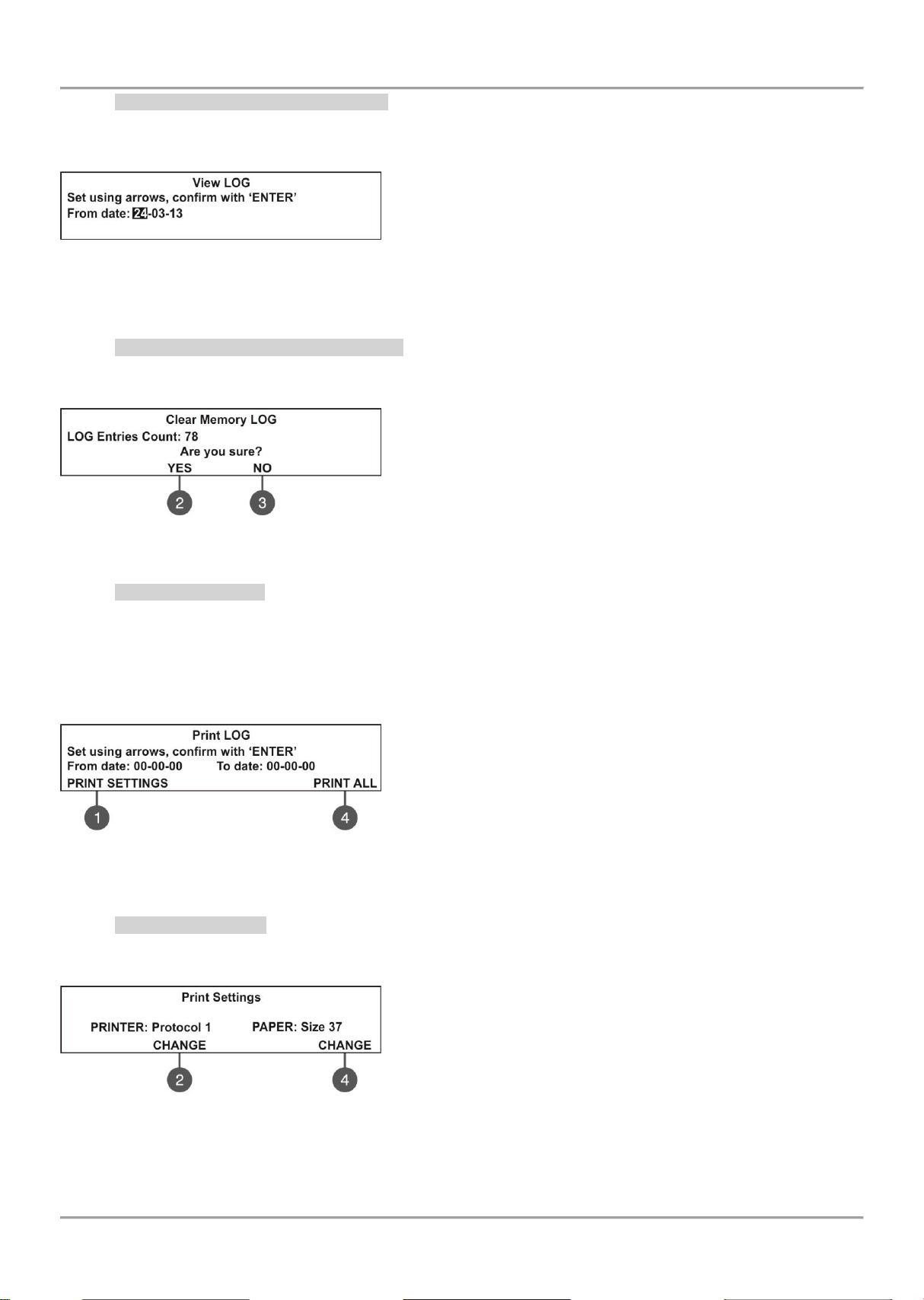

7.1.4 Printing Events

Attention: To print the system events you have to connect printer to the ‘PRINTER’ terminal on the main board.

Check your printer connection before entering this menu!

Use only printer models recommended from the manufacturer!