Page 1

www.esavep.com

Air source heat pumps

Installation and user

manual

ESP HT 9kW

ESP HT 12kW

ESP HT 15kW

Page 2

1.0 Preface

2.0 System Overview

2.1 General Information

2.2 Specification Table

2.3 Dimensions and Scale

2.4 Performance Graph (COP)

3.0 Installation & Maintenance

3.1 Cautions & Warnings

3.2 Transit

3.3 Installation Position

3.4 Securing the Unit

3.5 Water Loop Connection

3.6 Water Pump

3.7 Power Supply Connection

3.8 Power Cable and Switch

3.9 Normal Heating and Cooling

3.10 Unit Commissioning Checks

3.11 General Maintenance

3.12 Operating notes for end user

3.13 After sales service & Information

4.0 Controls and Operation

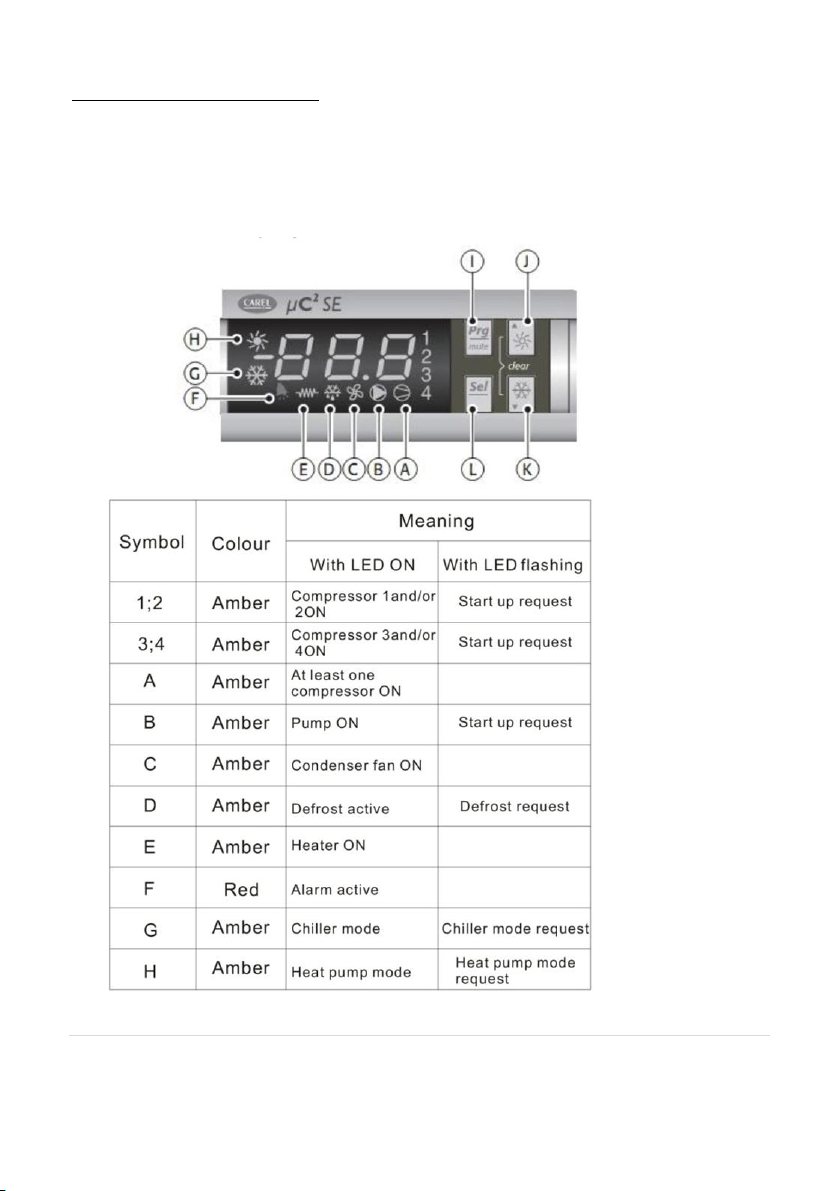

4.1 The Unit controller display

4.2 Functions and associated buttons

4.3 Saving Controller Parameters

4.4 Installing a remote control

4.5 Symbol meanings

4.6 Parameters

4.7 Weather Compensation Data

5.0 FAQ & Troubleshooting

5.1 Support

6.0 Appendices

Appendix 1 Wiring Diagrams

Appendix 2 Installation Engineer’s Details.

Appendix 3 Installation and Commissioning Certificate

2 of 52| Earth Save Products-ASHP PASRW030B-D-PS

V 1.8 PASRW040B-D-PS

PASRW050B-D-PS

Page 3

WARNING !

READ THIS BEFORE

INSTALLING

THE UNIT.

The installation of all un-vented water heating systems above 15

litres (this includes the ESP Hot Water ASHP’s) MUST

comply with local area Building Regulations. It is a legal

requirement that the local Building Control Officer be notified

of any proposed installation.

UK regulations require an appropriately sized expansion vessel

(internal or external) to be incorporated, safety devices to prevent

the stored water exceeding 100°C, and pipe work to convey

discharged hot water safely away from the safety devices.

Furthermore, the installation must be carried out in

accordance with this manual and by an engineer who has

successfully completed a recognised course in the

installation of un-vented heating systems such as CITB. The

guidance contained in the Good Practice Guide should be

followed. Failure to fit the unit correctly and in accordance

with regulations may affect its safety, efficiency and WILL

invalidate any guarantee.

THE UNIT MUST BE INSTALLED, COMMISSIONED AND

MAINTAINED BY A COMPETENT INSTALLER IN ACCORDANCE

WITH BUILDING REGULATION G3 (ENGLAND AND WALES),

TECHNICAL STANDARD P3 (SCOTLAND) OR BUILDING

REGULATION P5 (NORTHERN IRELAND) AND THE WATER FITTING

REGULATIONS (ENGLAND AND WALES) OR WATER BYELAWS

(SCOTLAND). FOLLOWING INSTALLATION AND COMMISSIONING,

THE OPERATION OF THE UNIT SHOULD BE EXPLAINED TO THE

3 of 52| Earth Save Products-ASHP PASRW030B-D-PS

V 1.8 PASRW040B-D-PS

PASRW050B-D-PS

Page 4

1.0 Preface

Congratulations on purchasing your ESP air source heat pump (ASHP). It will

give you years of trouble free heating and help reduce your carbon footprint.

ESP ASHP units are built using the highest quality components and the latest

design and technology.

Please read this manual:

It is important that you read this manual and familiarise yourself with the

technology and controls so that you can get the best out of your unit. You

should keep this manual safe and ensure that it is available to engineers that

perform any installation works or maintenance.

Installation:

Please make sure that your ASHP is only installed by a suitably qualified

engineer and in accordance with this manual. If this is not done, it may

invalidate your warranty.

Warranty:

All ESP ASHPs are covered by the warranty contained in the ESP Terms and conditions

of Business a copy of which will have been provided to you prior to your purchase.

YOUR INSTALLATION ENGINEER MUST COMPLETE THE TABLE IN APPENDIX 2

– PLEASE ENSURE THAT THIS IS DONE AND THAT CONTACT DETAILS ARE

CORRECT AND CLEAR.

YOUR INSTALLATION ENGINEER SHOULD ALSO COMPLETE AND SIGN

APPENDIX 3 AND THIS INSTALLATION AND COMMISSIONING CERTIFICATE

SHOULD BE PROVIDED BY THE INSTALLATION ENGINEER AS PART OF THE

HANDOVER PACKAGE. THE CERTIFICATE SHOULD BE KEPT WITH THE UNIT

DOCUMENTATION AND ALWAYS HANDED TO ANY NEW OWNER OR

OCCUPIER OF THE INSTALLATION ADDRESS.

4 of 52| Earth Save Products-ASHP PASRW030B-D-PS

V 1.8 PASRW040B-D-PS

PASRW050B-D-PS

Page 5

Pictures and Drawing:

The pictures and drawings in this manual are for information only. The

manufacturer reserves the right to make modifications to the product

without prior notification to the end users.

Children:

You should not let children operate the unit or play close to it when in

operation. The unit has a fast moving fan and, whilst every effort has been

made to ensure that it is not accessible, children may try to put objects in to

it – this can cause injury and seriously damage the unit.

Check on delivery:

On taking delivery of your ASHP, please check for any signs of damage. If you

are not happy with the condition of the unit on delivery, please advise Earth

Save Products (ESP) immediately and point out any damage to the delivery

driver and request that he take notes of your concerns.

Storage:

If put in to storage, the unit must be covered to keep it free from dust build

up and away from direct sunlight.

2.0 System Overview

2.1 General Information

Air source heat pumps are similar in operation to ground source heat pumps,

except that heat is extracted from the air rather than the ground. Air source

heat pumps are classified as either air to air or air to water depending on

whether the heat distribution system in the building uses air or water.

The main advantage of air source heat pumps over ground source heat

pumps is their lower installation cost. A ground source heat pump requires a

network of underground coils that is used to extract heat from the ground. By

comparison, air source heat pumps extract the heat directly from outside air

and so avoid these potential problems.

5 of 52| Earth Save Products-ASHP PASRW030B-D-PS

V 1.8 PASRW040B-D-PS

PASRW050B-D-PS

Page 6

Benefits of air source heat pumps over conventional boilers include the fact

there is no combustion and no explosive gases within the building, no need

for flues or ventilation, no local pollution, long life expectancy with minimal /

no annual maintenance, simple engineering/fitting and lower running costs.

Depending on the comparison fuel and heating system being compared to

the ASHP, savings can be up to 75% and the units are designed to have a life

span of 20 years with no substantial annual required or recommended

maintenance.

Component parts of ESP ASHP units are from industry leading manufacturers

such as the Danfoss heat exchanger, Wilo water pump, Copeland compressor

and Carel controller, so reliability and longevity is ensured.

6 of 52| Earth Save Products-ASHP PASRW030B-D-PS

V 1.8 PASRW040B-D-PS

PASRW050B-D-PS

Page 7

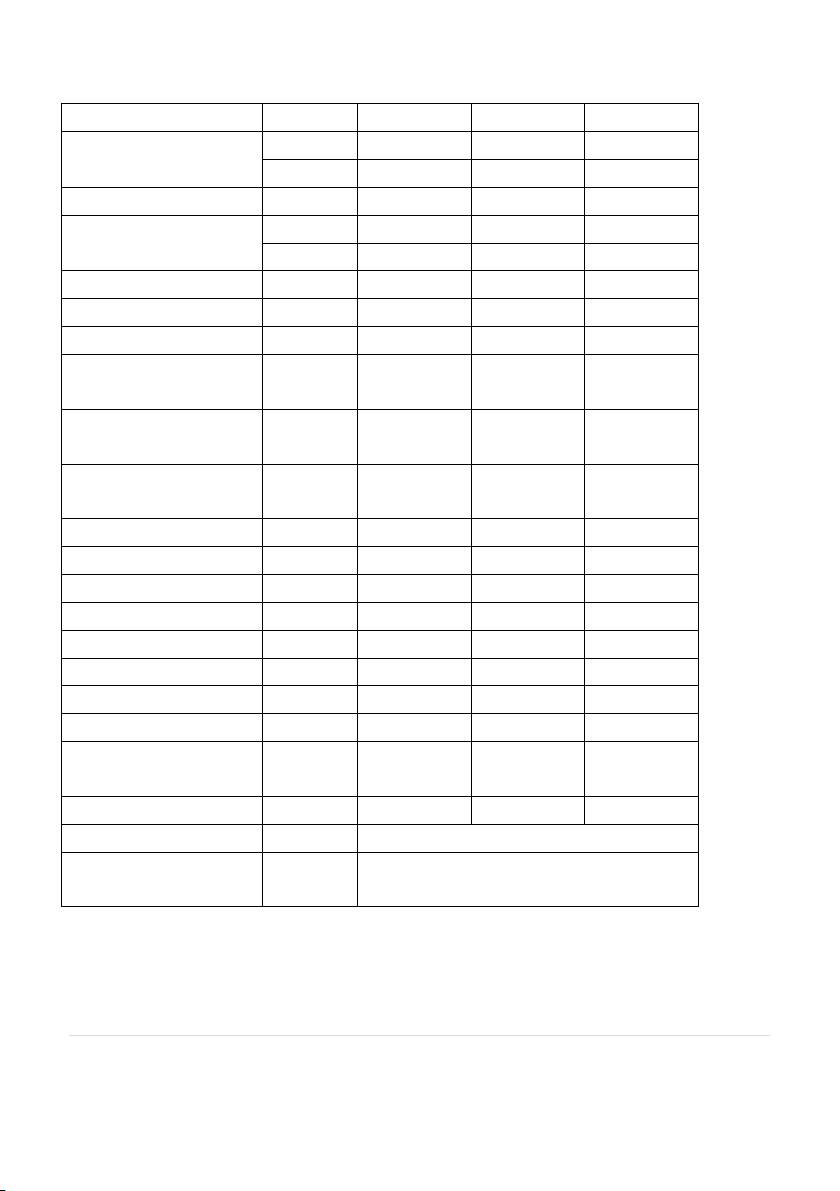

2.2 Specification Table.

Units

9kW

12kW

15kW

Heating Capacity

1

kW

9.2

12.0

14.5

BTU/h

31409

40968

49503

COP1 W/W

3.58

3.6

3.6

Heating Capacity2

kW

9.5

12.9

15.0

BTU/h

32300

43800

51000

COP2 W/W

2.4

2.6

2.6

Power Supply

V/Ph/Hz

230/1/50

230/1/50

230/1/50

Electrical Heater

kW

1.5

3.0

3.0

Electrical Heater

Running Current

A

6.8

13

13.5

Max Running

Current

A

27

42.9

45.2

Number of

Compressors

1 1

1

Compressor Type

Scroll

Scroll

Scroll

Number of Fans

1 2

2

Fan power input

W

120

2X120

2X120

Fan Direction

Horizontal

Horizontal

Horizontal

Water Pump Power

kW

0.2

0.6

0.6

Water Head

M 8 22

22

Water Connection

Inch 1 1

1

Water Flow Rate

m3/h

1.5

2.1

2.6

Water Pressure

Drop

kPa

17

34

34

Noise

dB(A)

46

48

50

Net Dimensions

See Diagrams Below

Shipping

Dimensions

See Shipping Label

Notes:

1. Flow temp 45°C, return temp 40°C

2. Flow temp 60°C, return temp 55°C

7 of 52| Earth Save Products-ASHP PASRW030B-D-PS

V 1.8 PASRW040B-D-PS

PASRW050B-D-PS

Page 8

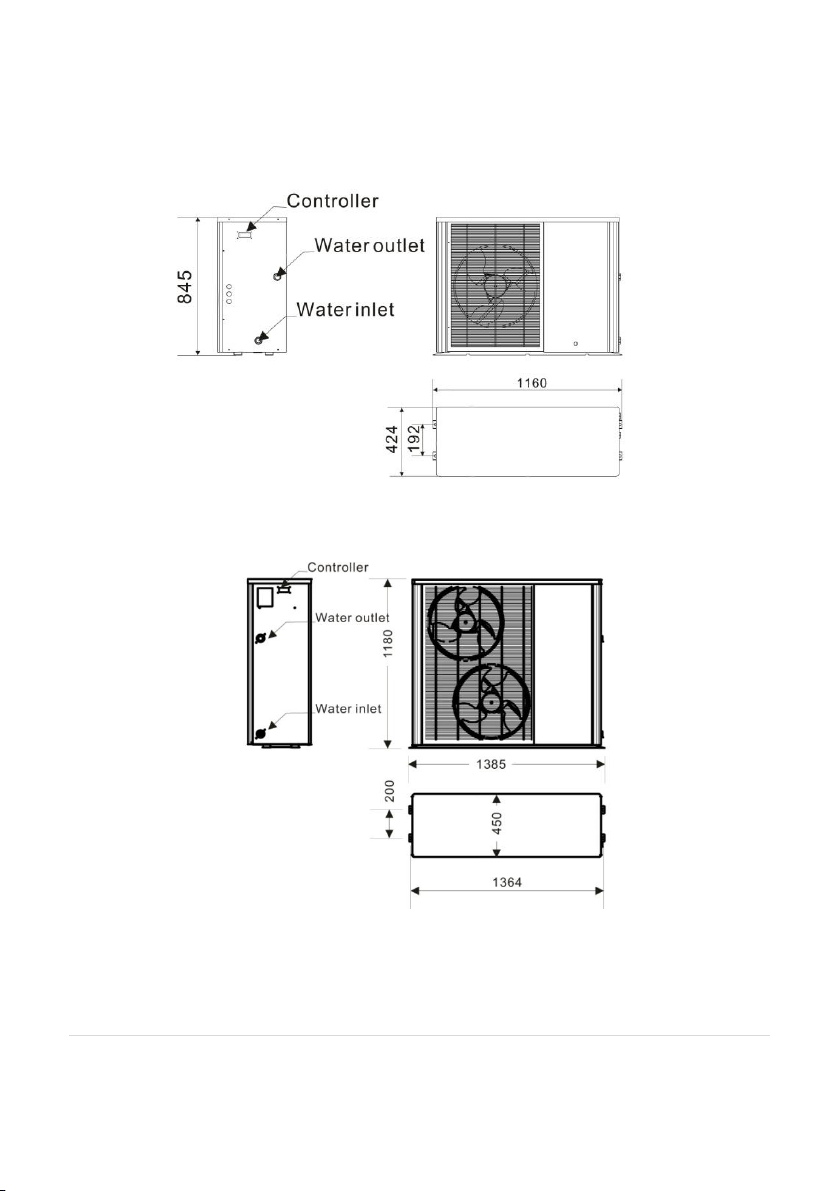

Dimensions and Scale

ESP HT 9KW

ESP HT 12KW/15KW

8 of 52| Earth Save Products-ASHP PASRW030B-D-PS

V 1.8 PASRW040B-D-PS

PASRW050B-D-PS

Page 9

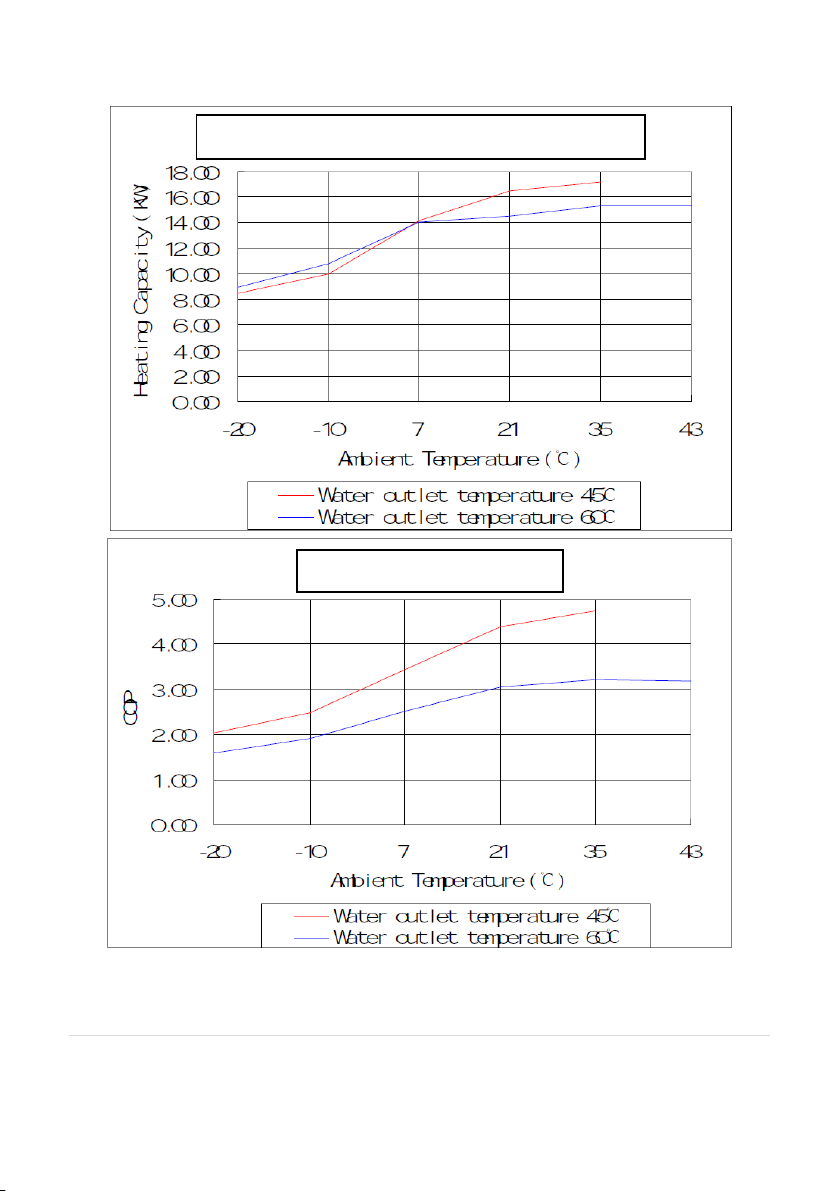

2.4 Performance Graphs

15kW HT Heat Output Curve

15Kw HT COP Curve

9 of 52| Earth Save Products-ASHP PASRW030B-D-PS

V 1.8 PASRW040B-D-PS

PASRW050B-D-PS

Page 10

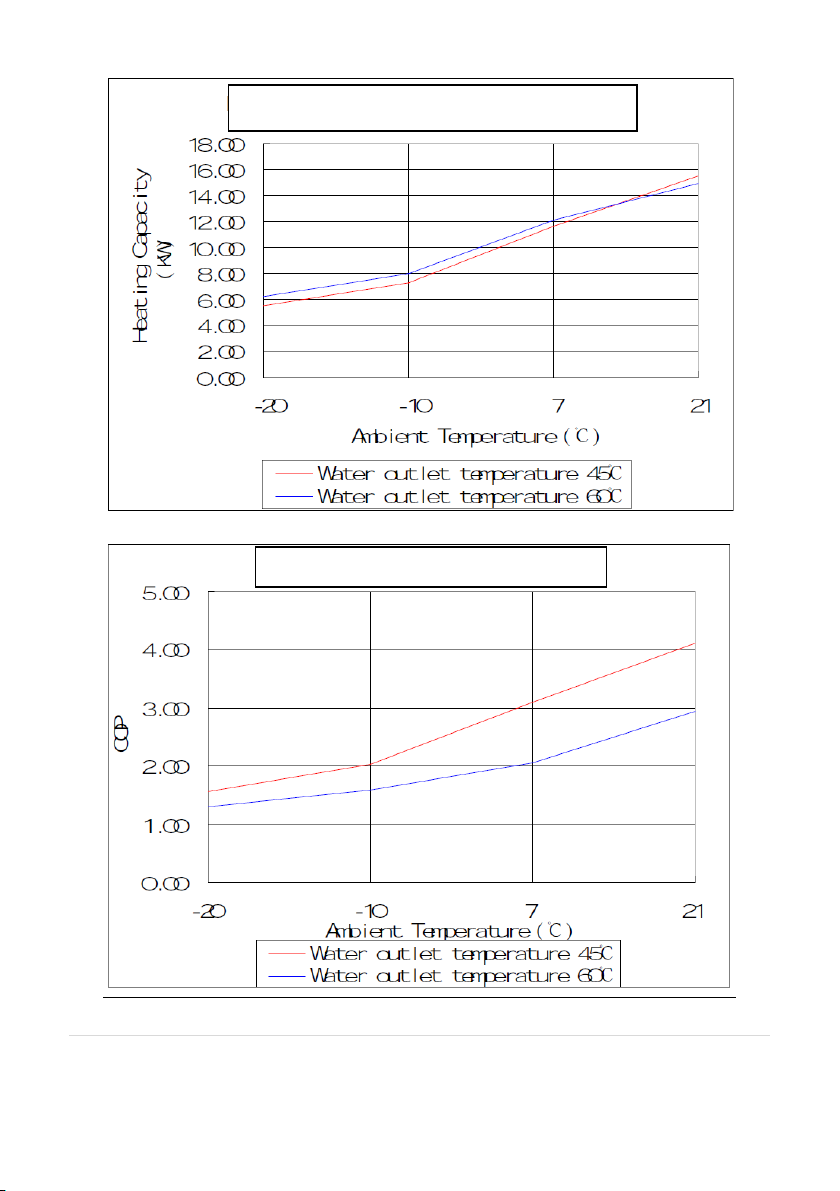

12kW HT Heat Output Curve

12kW HT COP Curve

10 of 52| Earth Save Products-ASHP PASRW030B-D-PS

V 1.8 PASRW040B-D-PS

PASRW050B-D-PS

Page 11

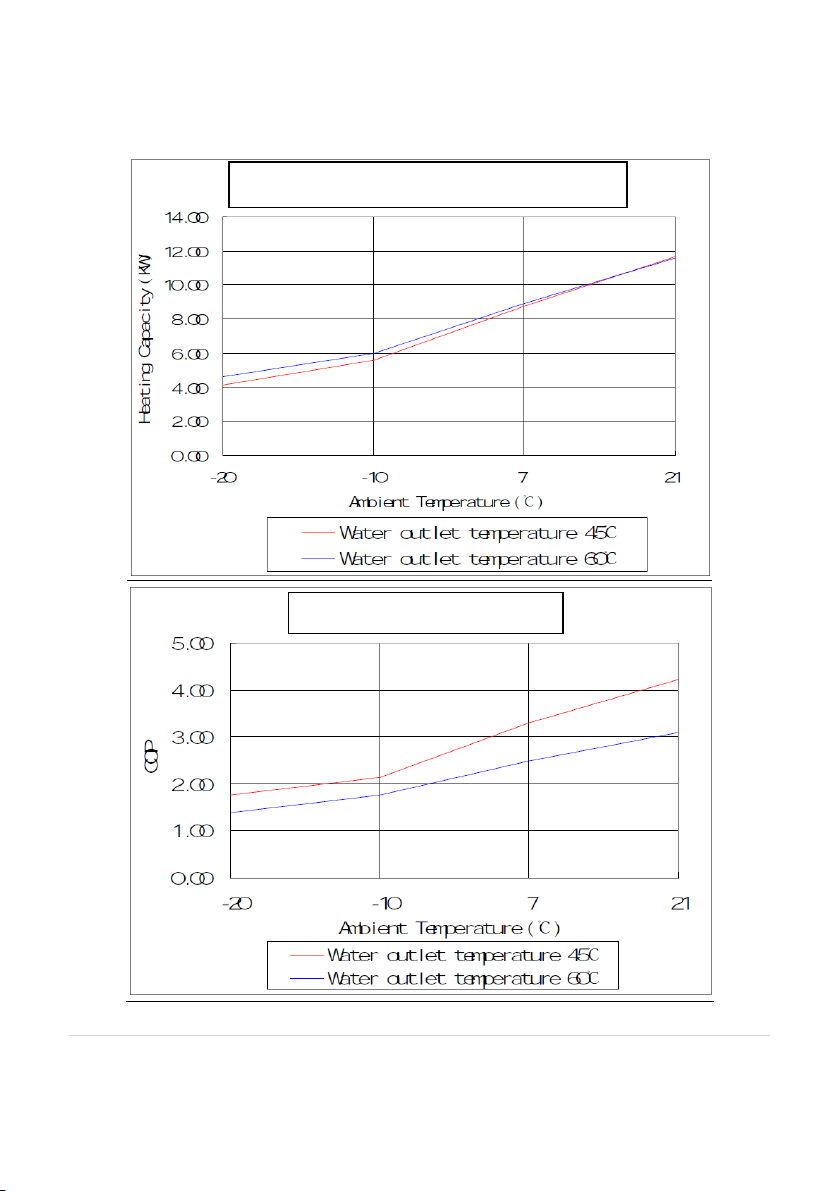

9 kW HT COP Curve

9kW HT Heat Output Curve

11 of 52| Earth Save Products-ASHP PASRW030B-D-PS

V 1.8 PASRW040B-D-PS

PASRW050B-D-PS

Page 12

3.0 Installation and Maintenance

Professional

installer

is required

The heat pump must be installed by a suitably qualified engineer.

Failure to ensure this can cause damage to the unit and may

cause serious injury. The unit’s warranty will also be invalidated if

a suitably qualified engineer is not engaged to install it.

Earthing

required

Please make sure that the unit and power supply are soundly

earthed.

3.1 Cautions and Warnings.

It is of the highest importance that you read and understand this manual and

that the unit is installed in accordance with it. The manual is here to help

with installation and to ensure that damage to people or property is avoided.

INCORRECT INSTALLATION WILL INVALIDATE ANY GUARANTEE.

THE UNIT MUST BE INSTALLED, COMMISSIONED AND MAINTAINED BY

A COMPETENT INSTALLER/ENGINEER IN ACCORDANCE WITH LOCAL

REGULATIONS AND BY-LAWS. FOLLOWING INSTALLATION AND

COMMISSIONING, THE OPERATION OF THE UNIT SHOULD BE

EXPLAINED TO THE END USER BY THE INSTALLER/ENGINEER AND THESE

INSTRUCTIONS LEFT WITH THEM FOR FUTURE REFERENCE.

All plumbing works and electrical works must be carried out by a suitably

qualified plumber and electrician respectively. This is mandated by English

law and there are severe penalties if works are carried out by unqualified, or

not suitably qualified, engineers and tradesmen.

IMPORTANT NOTES:

Below you will find information that is critical for the safe and proper installation

and use of the unit. Please make sure that you understand the contents as it is

written to help avoid injury to end users, installer and the unit itself.

12 of 52| Earth Save Products-ASHP PASRW030B-D-PS

V 1.8 PASRW040B-D-PS

PASRW050B-D-PS

Page 13

Refrigerant

Please give full consideration to adequate ventilation being

available in the event of a refrigerant leak- this unit must be

installed outdoors.

Installation

Site

Do not install the unit near to a gas installation.

Anchor the

Unit

Make sure that the unit is secured a base that is capable of taking

the weight of the unit.

Circuit

Breaker

Make sure that the unit is connected to the power supply via a

suitably sized type C MCB.

Unit Upright

The unit must be installed level across the whole width. See

section 3.4 for further details.

Do NOT

Do not push anything through the grills protecting the unit, or into

the fan blades when they are running and make sure that children

cannot access the unit or play close to the unit.

Shut off the

power supply

If there is an unusual sound or smell coming from the unit,

immediately shut off the power supply and call your installation

engineer.

Suitably

qualified

engineer

The unit should only be moved and/or repaired by a suitably

qualified engineer.

Do NOT

Do NOT try to install, move or repair the unit yourself – it is NOT

worthwhile running the risk of injury.

Transporting

the Unit

The unit must be transported in the vertical position.

Where to site

the unit

The unit must only be installed outdoors – the unit is not

designed, nor suitable for, installation ANYWHERE inside the

house. The Unit needs to be sited where it can receive and expel

large volumes of ambient air and condensate from the unit must

be drained away to a suitable point to avoid water running from

the unit on to walkways where ice may form. If the unit is to be

left unused for any significant period of time, it should be drained

OPERATING NOTES:

MOVE AND REPAIR NOTES:

OPERATION NOTES:

13 of 52| Earth Save Products-ASHP PASRW030B-D-PS

V 1.8 PASRW040B-D-PS

PASRW050B-D-PS

Page 14

down. Make sure that the flow and return pipework from/to the

unit have a full flow level valve fitted in-line so that the unit may be

isolated from the complete system before draining it down – this

avoids the waste of glycol if the whole system were to be drained

down. Make sure that pipework outside is properly lagged so that

it will not freeze in cold weather when the unit is not in use.

Shut off the

power

When cleaning or working on the unit, shut off the power supply.

You MUST

You must use a suitable power supply that is appropriately fused.

IMPORTANT SAFETY INFORMATION FOR THE END USER

− Installation of the heat pump must only be carried out by persons with

suitable engineering qualifications and experience.

− Do not attempt to modify, repair or service the heat pump yourself,

unless you have been appropriately trained and are suitably

qualified.

− Do not insert body parts or any other items into the air inlet or air outlet;

the fans are provided with a guard for good reason!

− Save in emergencies, do not start or stop the unit by switching the power to

the unit on or off; always use the controls provided on the unit/controller.

Starting/stopping the heat pump using mains power is dangerous for you and

may damage the unit.

− Ensure that the heat pump is protected from prolonged exposure to

large quantities of water (e.g. leaking gutters). Failure to do so may

damage the unit.

− Do not operate the unit or the programmer with wet hands/fingers.

− Upon replacement of any fuse in any part of the power feed to the unit,

ensure a correct replacement is used. Do not, under any circumstances,

use a fuse that is too large or bridge the fuse with silver paper, nails,

wire, or anything similar.

− Keep the programmer for the unit out of reach of children.

14 of 52| Earth Save Products-ASHP PASRW030B-D-PS

V 1.8 PASRW040B-D-PS

PASRW050B-D-PS

Page 15

− The electrical supply must be isolated during a heightened risk of lightning

strikes.

− Do not attempt to move the appliance once installed; this must be carried

out by a qualified engineer.

− Isolate the electrical supply to the appliance if you detect an odor from

the unit, or scorching is detected anywhere in or on the unit.

− Only use the unit for the purpose intended and in accordance with this

manual.

− Ensure the area around the unit is clean, well-ventilated and kept free of all

obstructions.

− Do not keep items on top of the unit or use it to support other appliances.

− Do not under any circumstances stand on the unit - it is dangerous for you

and will damage the unit.

− Isolate the electrical supply to the unit if it is to be switched off for a period

of more than a week.

− Drain the water from the water circuit if power to the unit is to be switched

off during very cold weather.

− Periodically check the condition of any supports or wall brackets for

deterioration - have these replaced immediately if any deterioration is

evident.

− Do not wash the unit with water, alcohol, benzene, thinners, glass cleaner,

polish or powders.

− Before cleaning, isolate the electrical supply to the unit. If cleaning of any

internal part of the unit is required, this should only be done by an

appropriately qualified engineer.

- If you have any questions about the operation and maintenance of the

unit that are not addressed in this manual, or if you feel that

something in the manual is unclear, please call the seller, distributor or

ESP.

15 of 52| Earth Save Products-ASHP PASRW030B-D-PS

V 1.8 PASRW040B-D-PS

PASRW050B-D-PS

Page 16

3.2 Transit

The unit must be kept upright during transit and securely fastened so that it

does not rock, slide or fall over.

Ensure suitable lifting equipment is available to move the unit around the site

and into position, whilst maintaining a vertical position. Using unsuitable

lifting gear or equipment to move the unit around can cause significant

damage to the unit externally and internally.

When using lifting gear, an 8m cable is needed and the cable should not

touch the surface of the unit – use soft packing between the lifting gear and

the unit to prevent damage to the unit.

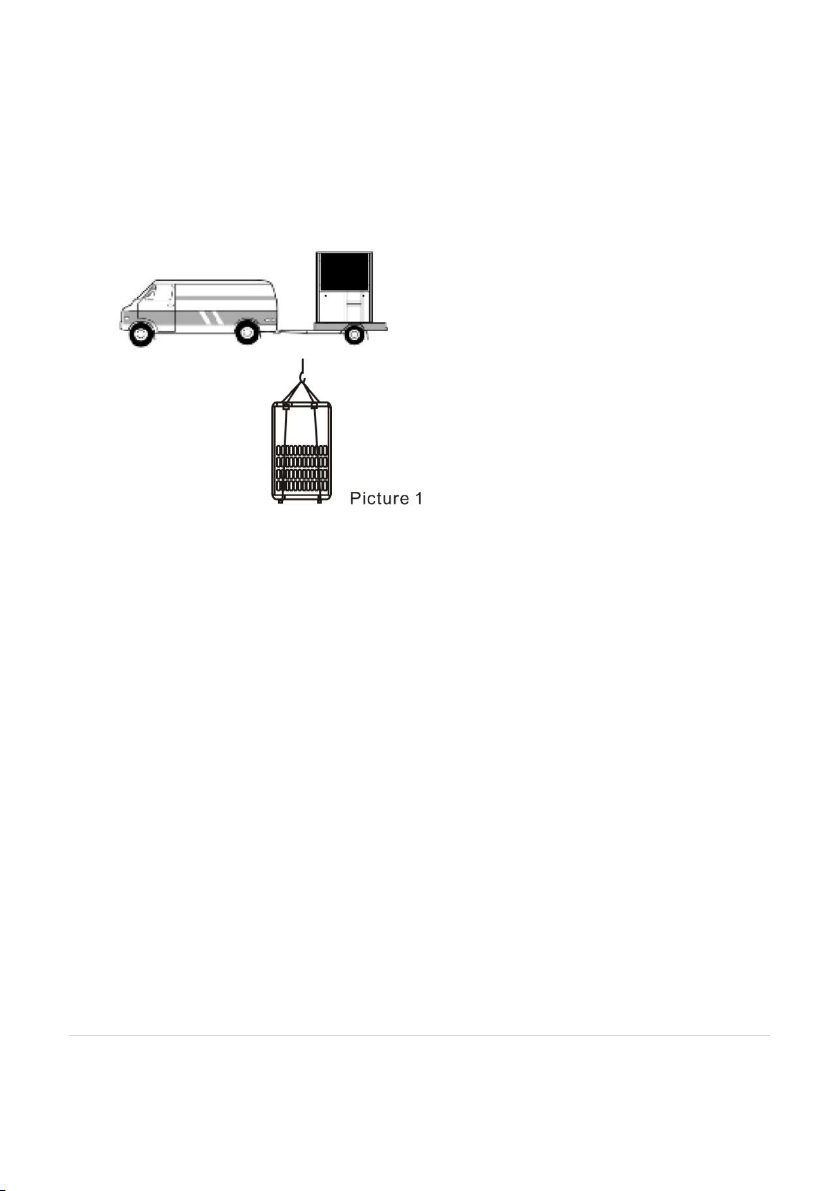

3.3 Installation Position

Please note the following important points:

The unit can be installed in any outside location that can support

heavy machinery i.e. balcony, roof terrace or on the ground.

If possible, the unit should be sited on a south facing wall to maximise

solar gain.

Circulation of air around the unit must not be impeded and the

minimum recommended clearances are shown in the diagram below.

16 of 52| Earth Save Products-ASHP PASRW030B-D-PS

V 1.8 PASRW040B-D-PS

PASRW050B-D-PS

Page 17

However, PLEASE NOTE that the unit should be positioned away from

strong winds blowing directly on to/through the unit as this can also

impair unit performance.

The unit must be kept a good distance from other heat sources and

any fuel storage.

A cover is needed in the winter to protect the unit from heavy

snowfall.

The unit should be positioned so that it is easily accessible for

maintenance and servicing.

The unit needs to be sited near a water drainage facility to allow the

safe drainage of condensing water that is produced during normal

unit operation.

3.4 Securing the Unit

The unit must be placed upon a level and firm base that is suitable to carry

the weight of the unit e.g. a 100mm concrete base. The base must provide

for the unit to be sitting at least 150mm above the surrounding ground. Allow

for a slight tilt of the unit (3mm across the width running from right to left as

17 of 52| Earth Save Products-ASHP PASRW030B-D-PS

V 1.8 PASRW040B-D-PS

PASRW050B-D-PS

Page 18

you face the fan(s)) to allow rain water run-off and any water entering the

unit to drain through the holes in the bottom of the unit.

The unit must be secured to its base using suitable fixings through the unit

feet. The rubber feet supplied with the unit must be used. Alternatively,

there are proprietary unit fixings available that include an adjustable steel

frame and legs with rubber mounting pads. Please consult ESP if you have

any questions on the use of such fixing methods; failure to comply with these

instructions will mean that the unit will not meet certification requirements.

The unit must be fixed, stable and kept vertical during operation.

3.5 Water Loop Connection

Please pay special attention to the following points when installing the unit:

I. Keep pipework as free from bends as possible to keep back pressure

in the system to a minimum. Make sure that fittings, manifolds, water pumps

and valves in the system are designed for full flow as restrictions in the

system from these can materially and adversely impact upon the

performance of the unit and effectiveness of the overall heating system.

II. The piping must be clear and free from debris. Leak testing the heat

distribution system must be carried out before connecting the unit to the

system and repairs made where required.

III. Pressure testing of the distribution and emitter system must be done

BEFORE the unit is connected to the system. If the unit is connected while

pressure testing is carried out, it will damage the unit.

IV. An expansion vessel must be installed where the heating system is

unvented/pressurised. If installing the unit in an unpressurised system, feed

and expansion tanks must be provided and they should be positioned at least

0.5 metre higher than the highest point in the heat distribution system.

18 of 52| Earth Save Products-ASHP PASRW030B-D-PS

V 1.8 PASRW040B-D-PS

PASRW050B-D-PS

Page 19

V. The unit is fitted with a water flow switch that will pause the unit

operation if water flow is not continuous (this includes where there is air in

the system). The flow switch is there to protect the unit and the setting

should not be altered. You should check that the switch is working

properly before running the unit for any sustained period. If the flow of

water is insufficient, an error code of “Flow Level” will be displayed on the

controller.

VI. The final connection to the heat pump flow and return must be made

with suitable flexible pipes to prevent vibration in to the system pipework.

Please ensure that two wrenches are employed to take up the torque created

in tightening the fittings to avoid damage to both fittings and heat pump.

VII. These flexible hoses are available from ESP as part of an Installation

Pack or individually.

VIII. Make sure that you fit automatic air vents at high points in the

system. The unit will shut down if air is in the system because the water

flow switch will recognise air in the system as no water flow and a system

alarm/protection code will appear on the unit controller. The Error Message

“Flow Level” will appear on the controller display.

IX. You must fit a pressure gauge and suitable blow off valve at the unit

inlet/outlet where it can be seen from the unit.

X. The unit is supplied with a bung below the flow/return pipes. This

bung must be removed and replaced with a drain-off- cock (DOC). There

must also be a DOC at any lower point in the system, to allow for effective

drain-down of the system as and when required. Please note that, if the

system is to be left idle for a long period in winter, the system should be

drained down. You should fit full flow lever valves on the flow and return to

19 of 52| Earth Save Products-ASHP PASRW030B-D-PS

V 1.8 PASRW040B-D-PS

PASRW050B-D-PS

Page 20

the unit so that the unit can be quickly and effectively drained down where

required for maintenance.

XI. You must fit a Y-strainer on in-line on the return pipe to the unit. This

is normally fitted in an external location and must have a full flow lever valve

side either side of the strainer to minimise glycol loss during maintenance.

Due to the mix of metals on many systems it is both advisable and preferable

to install a Spirotrap Magnabooster 2 ® rather than the minimum standard Y

strainer. Failure to fit a good quality strainer in the return flow to the unit will

invalidate the warranty on the unit.

XII. Where standard steel radiators are to be fitted, careful consideration

should be given before fitting Thermostatic Radiator Valves (TRVs) because

they are not designed to be used with low temperature systems. If the

decision is taken to use TRVs, one must not be fitted in the same room as a

room thermostat.

3.6 Water Pump

If using a buffer tank in the system, you will need to fit a suitably sized water

pump on the water distribution side of the system. This water pump will

need to be wired to receive an appropriate signal from the heating system.

The ASHP-fitted water pump performance parameters are as follows:

20 of 52| Earth Save Products-ASHP PASRW030B-D-PS

V 1.8 PASRW040B-D-PS

PASRW050B-D-PS

Page 21

3.7 Power Supply Connections

9 kW HT

40amp

12 kW HT

40amp

15kW HT

50amp

Before starting to wire in the power supply to the unit, please check that the

power supply is suitable for the unit (e.g. single or three phase, correct size

cable, MCB etc. is available) having taken into account the requirements of

the entire site.

The unit power specification is stated on a label on the side of the unit.

We recommend the use of a dedicated Type C MCB of appropriate rating (See

below) for connection of the power supply via the consumer unit.

Important:

All electrical work MUST be carried out by a suitably qualified electrician.

The heat pump MUST be installed with an isolation switch adjacent to the

unit and suitably positioned for general and emergency use. The isolation

switch must be suitable for the unit electrical duty and comply with

applicable Regulations.

The connection to the electrical consumer unit in the property must comply

with current electrical standards and Regulations and be done via a fused

supply/breaker that corresponds to the unit electrical capacity. Failure to do

this correctly can result in fire and/or permanent damage to the unit. If the

unit is not appropriately wired in to a suitable supply, the warranty on the

unit will be voided.

IMPORTANT! We know that suitably qualified electricians charge

professional level fees for work that they carry out, but it is better to pay a

professional/fully qualified electrician to connect your unit in to an

21 of 52| Earth Save Products-ASHP PASRW030B-D-PS

V 1.8 PASRW040B-D-PS

PASRW050B-D-PS

Page 22

appropriate power supply in the correct way, than for you to die trying or as a

result of a fire in your property caused by inappropriate or incorrect electrical

works. Also, it is law that only qualified electricians should install, repair or

maintain electrical connections and, if you do not kill yourself installing the

unit, you run the risk of prosecution if you do not comply with the law. It is

not an exaggeration to say that, if you install/connect your unit to a power

supply and that installation/connection causes injury to, or death of someone

(even years after installation), you can be prosecuted under criminal law for

murder, manslaughter or bodily harm and spend many years in prison as a

result. IT IS NOT WORTHWHILE RUNNING THIS RISK.

SO, GET YOUR UNIT WIRED IN BY A PROFESSIONALLY QUALIFIED

ELECTRICIAN IF YOU DO NOT KNOW SOMEBODY THAT IS QUALIFIED TO DO

THE WORK, FIND SOMEONE AND DO NOT BREAK THE LAW BY DOING THE

WORK YOURSELF.

The unit must be connected to the power supply through a two port rotary

isolation switch, fixed in close proximity to the unit and as required by

relevant Regulations.

The following points should be noted in relation to power supply wiring and

system components:

Open the front and side panels to access the power supply terminal.

The power supply must go through the protective wire accesses and

be connected to the terminals in the control box.

Connect the 3 core signal wire plugs into the main controller

terminals.

If an additional water pump is being used (e.g. on the heating system

side of a buffer tank) the additional water pump will need to be

connected to the same power supply as the water pump located

inside the unit so that they operate at the same time.

In the Appendices to this manual you will find wiring diagrams for the units.

Please use these diagrams when introducing power or other wiring into the

22 of 52| Earth Save Products-ASHP PASRW030B-D-PS

V 1.8 PASRW040B-D-PS

PASRW050B-D-PS

Page 23

unit. You should also use these diagrams to check the installation through

before starting it up.

3.8 Power Cable and Switch

The unit must have its own independent power supply from the

consumer board. This power supply must be equipped with a

suitable ampere rated MCB.

The power supply must be equipped with a two port rotary isolation

switch that has at least a 3mm contact separation at all poles.

The wiring must be completed by a suitably qualified and accredited

electrician

All wiring should be routed neatly, be kept as far away as possible

from the units water pipes and valves and comply with relevant

Regulations. High voltage and low voltage wiring should be clearly

separated.

Part L2 of The Building Regulations requires that the heating system

be fitted with a 7 day programmer. However, the most efficient way

of running an ASHP system is to program is to ALWAYS On. An L2

compliant programmer may be used but it is very IMPORTANT that

any signal going back to the heat pump from the heating system

thermostat and/or programmer must be VOLT FREE ! The heating

system thermostat/ programmer controller is wired to terminals

25&26 inside the heat pump (these connections are not polarized) –

see appendices. If you do not use a volt free programmer you WILL

damage the ASHP unit.

3.9 Normal Heating Water Flow Temperatures

The heat pump should be installed with a buffer tank of suitable size (consult

your supplier). The buffer tank will store water at a constant temperature

and the stored water may be used for heating or cooling. Typically, for under

floor heating the water flow temperature should be 35 °C, for Thermovec (fan

coil) units 45-50 °C and for radiators 35-50 °C. For under floor heating, you

must consider and take account of the floor finish/covering to be used as this

23 of 52| Earth Save Products-ASHP PASRW030B-D-PS

V 1.8 PASRW040B-D-PS

PASRW050B-D-PS

Page 24

may impact upon the performance of the system and the transfer of heat in

to the area to be heated. Guidance on emitter systems can be found at

www.microgenerationcertification.org/admin/documents/MIS%203005%20S

upplementary%20Information%202%20%20Heat%20Emitter%20Guide%20v2.0.pdf where guidance can be found on

pipe spacing for under floor heating and sizing fan coil units (such s the ESP

Thermovec unit) and wet radiators. It should be noted that TRVs

(Thermostatic Radiator Valves) are not designed for use with low temperature

systems and, if the decision is taken to use them, one should not be fitted in

any room where a room thermostat is fitted.

Simple heating and hot water system configuration:

Since the heat pump can comfortably heat the system water to 60 deg C, it is

capable of supplying hot water by way of a suitable hot water cylinder (to

taps, showers, etc). However, ESP strongly recommends that the Space

Heating and Domestic Hot Water (DHW) systems are kept separate; the space

heating to be provided by an ASHP and the DHW to be provided by an

Ecocent to achieve maximum efficiency and economy.

Because water composition can vary greatly, it is not ESP’s policy to issue

recommendations relating to water treatment. The user or the owner is

responsible for contacting a specialised water treatment company to obtain

water treatment advice appropriate to your location. Appropriate water

treatment processes/devices must be fitted to ensure the longevity of the

unit and its proper operation.

The unit system must have a water glycol mix in it to protect the unit/system

in cold weather - the mix is stated on the label on the side of the unit. Units

in certain colder locations may need more glycol in the mix and you should

consult your installation engineer or ESP to ensure that you use an

appropriate mix. WARNING!! - GLYCOL CAN BE POISONOUS - PLEASE BE SURE

TO USE A NON-TOXIC BRAND AS VERY LITTLE GLYCOL NEEDS TO BE

INGESTED TO BE FATAL. ESP/YOUR INSTALLATION ENGINEER CAN SUPPLY

NON-TOXIC GLYCOL UPON REQUEST.

24 of 52| Earth Save Products-ASHP PASRW030B-D-PS

V 1.8 PASRW040B-D-PS

PASRW050B-D-PS

Page 25

3.10 Unit Commissioning Checks

Please carry out the checks noted below before commissioning and starting

up the unit. These checks are not exhaustive & should be used a startingpoint; your installer will use experience and Best Practice when

commissioning the unit:

Make sure that the fan(s) rotate freely.

Check the buffer tank, manifolds, under floor heating system,

radiators, fan coils (as appropriate) and make sure that the pipe work

is securely connected and the relevant valves are open and that there

are no leaks. Also, make sure that fittings that have operating flow

directions are, indeed, fitted so that the water flows in the right

direction.

Check that there is adequate water in the system and that it is clean.

Make sure that you have vented all air from the system – air in the

system will cause the unit to shut down shortly after starting up as air

passing the flow switch in the unit will be recognised by the flow

switch as a flow problem.

Check that the system is pressurised to the correct level (0.2MPa).

Check the wiring to make sure that the system wiring conforms to the

diagrams and Regulations and that it is properly and securely

earthed. Also, make sure that electrical connections are tight.

Visually inspect the heat pump to make sure there are no loose parts.

When the power is first turned on to the unit, immediately inspect

the controller to make sure there are no error messages or warnings

showing. Because it can be difficult to purge a system of air

immediately, it is not uncommon to see an error message of “FL”

(meaning Flow Level) on the controller display indicating residual air

in the system.

25 of 52| Earth Save Products-ASHP PASRW030B-D-PS

V 1.8 PASRW040B-D-PS

PASRW050B-D-PS

Page 26

Once you have turned on the heat pump, check the water pressure

gauge and it should be running at 0.2 MPa when the water pump is

running.

After the water pump has been running for approx. 1 minute, the

compressor will start. When the compressor starts up, listen carefully

for any strange or abnormal noises coming from the unit. If you hear

anything that is unusual, switch off the unit immediately and consult

your supplier.

Check whether the power input and running current is in line with the

information in this manual.

When using under floor heating, adjust the actuators on the water

loops to make sure that the water supply to each valve is operating

and that the water is heating and cooling, as required.

Once the system has reached its required running temperature, check

that the output temperature is stable.

PLEASE NOTE – Control settings are factory set for UK conditions and will NOT

need alteration– PLEASE DO NOT TRY TO CHANGE THE CONTROL SETTINGS. If

you are having control issues, check with the unit supplier or ESP.

Upon completion of commissioning and when the unit is running correctly in

a steady state, the installation engineer must complete an Installation and

Commissioning certificate in the template found in Appendix 3.

3.11 General Maintenance

Whilst no formal maintenance is required, you should note the following:

Monitor the air and water supply frequently to ensure it is clean –

check and clean the in-line water filter periodically.

Please note that the unit, when left idle, will automatically start up

every 72 hours to carry out a short maintenance cycle to prevent the

water pump sticking.

Clean the evaporator to the rear of the unit as and when required –

this will depend upon the site of the unit and may need cleaning as

26 of 52| Earth Save Products-ASHP PASRW030B-D-PS

V 1.8 PASRW040B-D-PS

PASRW050B-D-PS

Page 27

often as once per month. Maintaining the evaporator will keep heat

exchanging efficiently and will save you money. Do not power-wash

the evaporator.

Make regular checks of the system pressure. If the pressure drops

significantly make sure the fault is diagnosed quickly and repaired

accordingly – it is possible that the system has a leak and this must be

found and repaired.

If the pump is to be unused for any protracted period, it is important

to drain down the unit. When fitting the unit, install a full flow lever

valve on both the flow and return pipes so that the unit may be

isolated from the rest of the system and drained down easily, without

losing all water and glycol from the system. A water recharge and

inspection will be necessary before restarting the unit.

The unit and the water distribution system must be protected in the

winter to avoid freezing – this means using glycol in the system and

ensuring that water pipes are properly lagged with waterproof high

grade lagging with a wall thickness of at least 30mm. See further

notes below - these points must be observed to avoid the warranty

being invalidated:

a. Do not shut of the power supply to the heat pump in the

winter, when the air temperature is below 0°C. If the inlet water

temperature is above 2°C and below 4°C, the water pump will

automatically start to prevent the system from freezing. If the inlet

water temperature is below 2°C the system will automatically heat

the water to 2°C+.

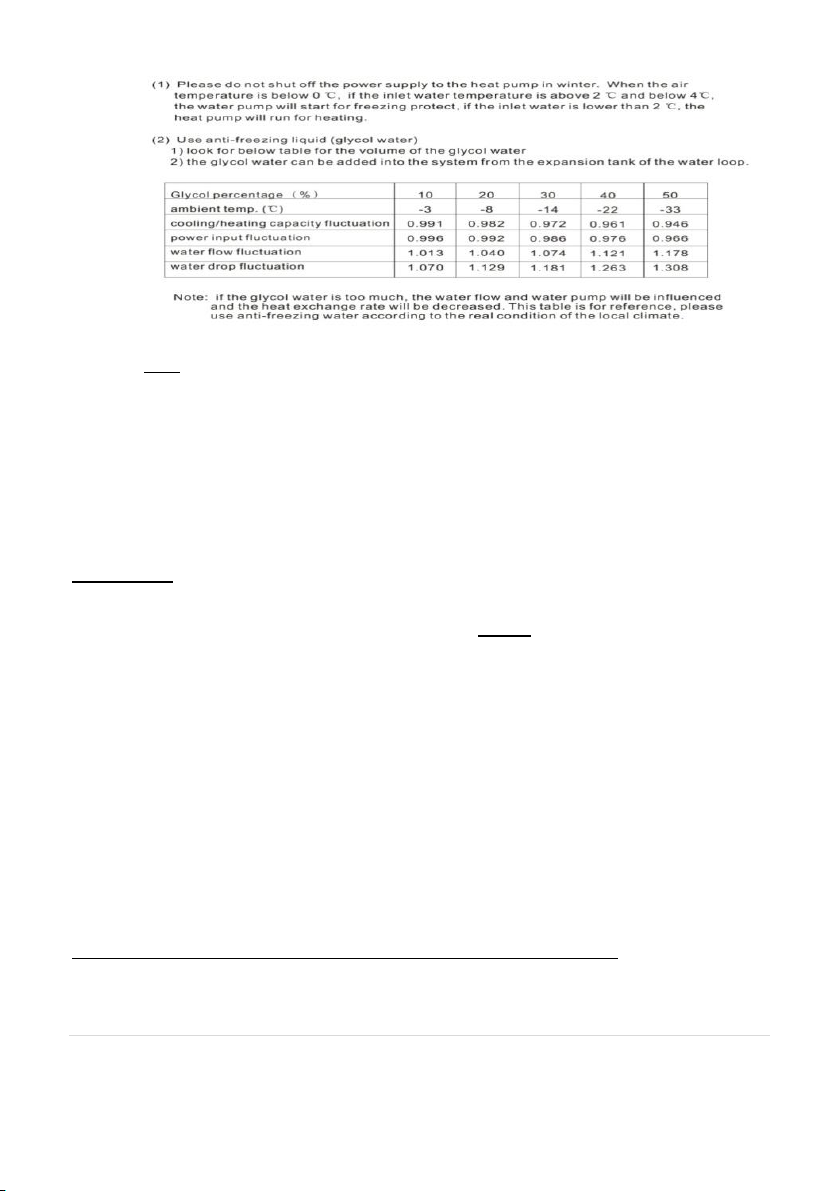

b. Use anti-freeze (Glycol water) Follow the guidelines below to

ensure you have the correct amount of anti-freeze in system:

27 of 52| Earth Save Products-ASHP PASRW030B-D-PS

V 1.8 PASRW040B-D-PS

PASRW050B-D-PS

Page 28

Note: Too high a concentration of the anti-freeze will affect the performance of the

heat pump.

PLEASE NOTE – ESP CAN PROVIDE AN ANNUAL INSPECTION/MAINTENANCE

PACKAGE, IF REQUIRED.

3.12 Operating notes for the end user

WARNING!

Before doing any work on the heat pump you MUST switch off power to the

unit at the twin port isolator switch (that should be installed next to the unit).

Servicing and maintenance of the unit must only be carried out by qualified

technicians. ESP can provide a full inspection and maintenance service, if

required.

Repeated triggering of safety and control devices must be thoroughly

investigated and any fault causing the triggering corrected before further use

of the unit. Please call your service engineer/installer should safety or control

devices be triggered.

You should carry out some basic checks on your unit regularly to maintain it in

optimum working order - these consist of standard checks (look at the

operating temperature settings, checking water flow and temperatures, see if

28 of 52| Earth Save Products-ASHP PASRW030B-D-PS

V 1.8 PASRW040B-D-PS

PASRW050B-D-PS

Page 29

there is scorching visible on the unit, make sure that the unit surroundings are

free from debris and growth of foliage from plants) and should be carried out

every 3 months and after the unit has been out of service for any prolonged

periods.

The inline filter/strainer should be cleaned regularly for the first six months

and at least once a year there after. It is recommended that you use a high

performance filter/strainer such as the Spirotech Magna-booster 2 ® rather

than a basic “Y” strainer/filter. Please discuss this with your installer.

WARNING!

The grills on the unit are intended to protect installation engineers from injury

from the evaporator during handling and installation work.

However, the grills located over the evaporator can create a risk of clogging

with a frost or ice during very cold weather. You may remove the grills over

the evaporator during periods of very cold weather but, if you do this, you

must make sure that the evaporator is not damaged while the grills are

removed and it is therefore advisable to keep people and pets away from the

unit. Please also note that the metal "fins" on the evaporator are sharp and

you should not touch them and also prevent others touching them - they can

cause serious cuts. The fins are also fragile and you should avoid bending

them.

If in any doubt about what to do, please call your installation engineer or ESP.

WARNING!

Very important:

The 3 phase model has built-in set phase protection. If the phase

sequence is wrong or there is a phase is missing, the controller will

29 of 52| Earth Save Products-ASHP PASRW030B-D-PS

V 1.8 PASRW040B-D-PS

PASRW050B-D-PS

Page 30

prevent the unit from starting up. Once the fault has been corrected,

the unit will start.

Delivery:

The ESP range of high temperature ASHP units can provide domestic hot

water and space heating by extracting heat energy from the surrounding air

and transferring it in to the system water.

Please note, any ESP ASHP is fully checked before delivery to make sure

that it is operating as it should. Any visible damage should be reported to

your supplier immediately and noted on any delivery note – if you are able

to photograph damage, please do so. The delivery driver should be

informed and any damage shown to him. Make sure that the delivery

driver notes your concerns on the delivery record.

The ESP Classic range of ASHP's is designed and built to give years of

trouble-free service and the content of this manual is important to

ensuring the maximum life span is achieved and performance delivered

with the least difficulty and cost.

If you are seeking any Government support for the cost of purchase,

installation and/or operating the ASHP, please ensure that you understand

fully what is required to enable you to access that support. ESP accepts no

responsibility or liability for any failure to obtain the support that you may

be seeking and complying with any rules or requirements to obtain any such

support is solely your responsibility.

30 of 52| Earth Save Products-ASHP PASRW030B-D-PS

V 1.8 PASRW040B-D-PS

PASRW050B-D-PS

Page 31

Some Important Additional Information:

FROST PROTECTION

As the ASHP will be fi tted exte rnally to the property being heated, the

water in the system could freeze up, if not protected. The unit should have

glycol mixed with the system water to prevent freezing and the required

mix of glycol/ water is stated on the label on the unit. Failure to use the

correct mix for the environment will invalidate the warranty.

DEFROST MODE

If the temperature is cold enough for ice to develop on the evaporator at the

rear of the unit and the unit has failed to reach the target system

temperature within the pre-set period of time, the unit will automatically

enter defrost mode. This will divert heat from the heating circuit back to the

evaporator until the ice has melted. The DEFROST symbol will appear above

the temperature display and will flash during the defrost operation. When

defrosting, the unit can give off a lot of steam and this is normal.

SERVICING

While it is not necessary to carry out an annual service on the appliance

like that for a gas/oil boiler, regular inspections are advisable. Remove

leaves, debris, moss, etc. from the evaporator at the rear of the unit. Also,

certain Government grant/support Schemes require that, for grant/support

funding to be payable, the unit be inspected and that inspection recorded in

a unit i ns p e ct io n lo g . It is YOUR responsibility to ensure that the rules

of any such Scheme are complied with. ESP offers a planned inspection

service and, if required, you should enquire about this by calling us.

31 of 52| Earth Save Products-ASHP PASRW030B-D-PS

V 1.8 PASRW040B-D-PS

PASRW050B-D-PS

Page 32

COIL TEMPERATURE CUT OUT

Should the coil reach too high a temperature, the unit will automatically

switch off until the temperature has reduced sufficiently. Please note that

the unit may take several minutes to restart. This is normal.

COMPRESSOR OUTLET TEMPERATURE CUT-OUT

Should the compressor outlet reach too high a temperature, the unit will

automatically switch off until the temperature has reduced. Please note that

the unit may take several minutes to restart.

GOING ON HOLIDAY?

If power to the heat pump is to be shut down for a long period during very

cold weather (and when the glycol in the system water will not offer

adequate protection – NOTE - the system must have glycol in it to the

required mix), it is advisable to completely drain the system. However,

frequent draining of the system should be avoided, especially in hard water

areas, as this can lead to the build-up of scale in the heating circuit. To avoid

draining down the whole system, the flow and return pipework (to and from

the unit) should have full flow lever valves fitted on each port so that

minimum drain-down is needed to protect the unit. However, you should

also have regard to protecting the pipework leading up to the unit and in the

house. Suitable waterproof lagging and/or other protection should be

installed.

FAILURE TO START UP

If the unit fails to start for no apparent reason, carry out the following checks

before making changes to running parameters on the controller or calling in a

service engineer:

The unit may be running through a process that deals with temporary out of

specification operating conditions to clear an operating parameter. In most

32 of 52| Earth Save Products-ASHP PASRW030B-D-PS

V 1.8 PASRW040B-D-PS

PASRW050B-D-PS

Page 33

cases, this will be cleared automatically within minutes. If it persists, check

the programmer display to see if there is a fault/protection message showing.

Refer to the guide in section 5 for basic fault finding and remedial actions.

2. Ensure there is a current ‘heat demand’ from the programmer (that the

programmer is in a heating period and that the inside temperature is below

the required temperature). Ensure that the programmer clock and timer

controls (and any auxiliary room stat controller/programmer fitted) have

been set in accordance with the instructions and that they are calling for

heat from the system. If the house is not calling for heat, the unit will not be

run.

3. Check for failure in the electrical supply. Please do not attempt to deal

with any electrical faults yourself - call in a suitably qualified electrician.

4. Check for a blown fuse. If the fuse has blown and the replacement also

fails, switch off the main electrical supply to the unit and contact your

service engineer.

5. Check the circuit breaker. If this has “tripped out”, reset and restart the

unit. If the circuit breaker trips for a second time soon after, switch off the

mains electrical supply to the unit and contact your service engineer.

Note: If the unit has been shut down due to a failure of the power supply,

the programmer contains a battery backup which will mai n ta in all settings

while the battery is charged. Make sure that you do not leave the system

water to freeze while the unit is switched off (you must have glycol in the

system to protect the unit from frost at all times).

If the unit is operating, but the system water temperature is not reaching the

target operating temperature:

1. Check that all isolation valves are fully open.

2. Check the water temperature setting is not lower than you think it

is set!

33 of 52| Earth Save Products-ASHP PASRW030B-D-PS

V 1.8 PASRW040B-D-PS

PASRW050B-D-PS

Page 34

3. Check that the vents on the back of the unit and the evaporator

have not become blocked, thereby impeding the air flow through the

unit.

4. Check the unit has not entered in to defrost mode (the DEFROST

symbol will appear above the temperature display and flash). Should

this occur, the heat output from the unit will be diverted to the

evaporator until any ice build up has been removed from the

evaporator. When in defrost mode the system water temperature will

fall and the lower system temperature will show on the unit

controller.

5. If you hear water “gurgling” in the unit, most of the time this will

not be a problem and is just the normal movement of refrigerant in

the unit. In exceptional circumstances, it could mean that you have

air in the water system that is likely to be cleared by the auto airbleeding vents on the system pipework. If it persists, it could indicate

that there is a leak in the water system that needs attention. Check

the system pressure to see if it has fallen. If it has, call your service

engineer/plumber.

6. If there is power to the unit and the programmer is calling for

heat, but the unit is not running, it could be that one of the safety

cut-out facilities has operated. This can take several minutes to clear

before the unit restarts.

You can also refer to the table in section 5 for more detailed fault

finding. If ever in doubt, or if you are concerned in any way, call your

service engineer/plumber and discuss the problems that you are

having. If you cannot contact your service engineer/plumber, please

call ESP for assistance.

34 of 52| Earth Save Products-ASHP PASRW030B-D-PS

V 1.8 PASRW040B-D-PS

PASRW050B-D-PS

Page 35

TIPS FOR LOWERING ENERGY USAGE

1) General unit maintenance can have a significant impact upon system

performance and service life. Ensure regular inspections are carried out over

the lifetime of the appliance. ESP offers a planned maintenance service, so

please ask us about this, if required.

2) Dirty evaporators and fans reduce airflow through the system, resulting in

decreased performance. Regular checks should be carried out to ensure that

these are kept clean – don’t forget to turn the unit off when working on it.

3) The unit should be protected from high winds as this can lead to reduced

airflow and efficiency as well as out of specification running.

4) While the unit should be protected from high winds, avoid siting in areas

where the airflow is restricted, resulting in recirculation of cold air over the

evaporator.

5) Insulate the pipe work and fittings to and from the unit to avoid unwanted

heat loss from the system. Use the highest quality waterproof insulation with

a wall thickness of at least 30 mm – it will pay for itself very quickly – poor

quality insulation will mean that you have a poor quality system performance

and that you are wasting a lot of money. For new builds, the requirements of

Part L of The Building Regulations (or better) for insulation will help ensure

that the heat load of the dwelling is kept to a minimum. For existing

buildings, insulation should be improved as much as possible to minimise the

heat load.

6) Do not power wash the evaporator!

7) Set the room stat temperatures as low as you can.

35 of 52| Earth Save Products-ASHP PASRW030B-D-PS

V 1.8 PASRW040B-D-PS

PASRW050B-D-PS

Page 36

8) Do not over fill the unit with glycol - see required water/glycol mix on the

label on the unit - using too much glycol alters the thermal properties of the

system water.

9) Ensure that the unit is properly installed! Poor quality, or inappropriate,

installation of the unit can dramatically reduce the performance, life span and

efficiency of the unit.

3.13 AFTER SALES SERVICE INFORMATION

A qualified service engineer is available to attend a breakdown or

manufacturing fault occurring while the appliance is under guarantee.

Please note, upon attendance by an Earth Save Products Ltd. (ESP) service

engineer, a charge may applied for any service/site visit where:

- The service engineer finds no fault with the unit.

- The cause of a breakdown is due to components not supplied by ESP.

- The cause of the breakdown is due to incorrectly installed parts within the

heating system.

- The unit has not been correctly installed (in accordance with this manual and

good installation practice) by a suitably qualified engineer.

- The breakdown occurs outside the guarantee period.

- The unit has not been properly maintained.

- The breakdown occurs due to use of unit not for the purpose designed.

- The breakdown occurs as a result of unauthorized third-party work on the

unit

36 of 52| Earth Save Products-ASHP PASRW030B-D-PS

V 1.8 PASRW040B-D-PS

PASRW050B-D-PS

Page 37

TECHNICAL ASSISTANCE

Technical advisors are available to discuss any problem with the unit. In many

cases the problem can be solved over the telephone, eliminating the need for

a service visit.

HOW TO REPORT A FAULT

Contact your installer/supplier, who should thoroughly check the installation

and/or all recent work before the attendance of an ESP service engineer is

requested.

If your own installer/supplier is unavailable, contact ESP. Please be aware that

a charge may be made for any visit not covered by the unit guarantee.

Before contacting ESP about a problem with the unit, it would help us if you

have the following information ready:

1) Appliance serial number, account number or invoice number.

2) Description of fault, including any operating parameter code which

may be displayed on the programmer.

3) Date of delivery/installation. Please note that the warranty starts

from the date of delivery.

4) Name of the company that installed the unit and when it was

installed.

37 of 52| Earth Save Products-ASHP PASRW030B-D-PS

V 1.8 PASRW040B-D-PS

PASRW050B-D-PS

Page 38

4.0 Controls and Operation

4.1 The unit controller display

Please see below a picture of the unit controller with key controls and

functions identified.

38 of 52| Earth Save Products-ASHP PASRW030B-D-PS

V 1.8 PASRW040B-D-PS

PASRW050B-D-PS

Page 39

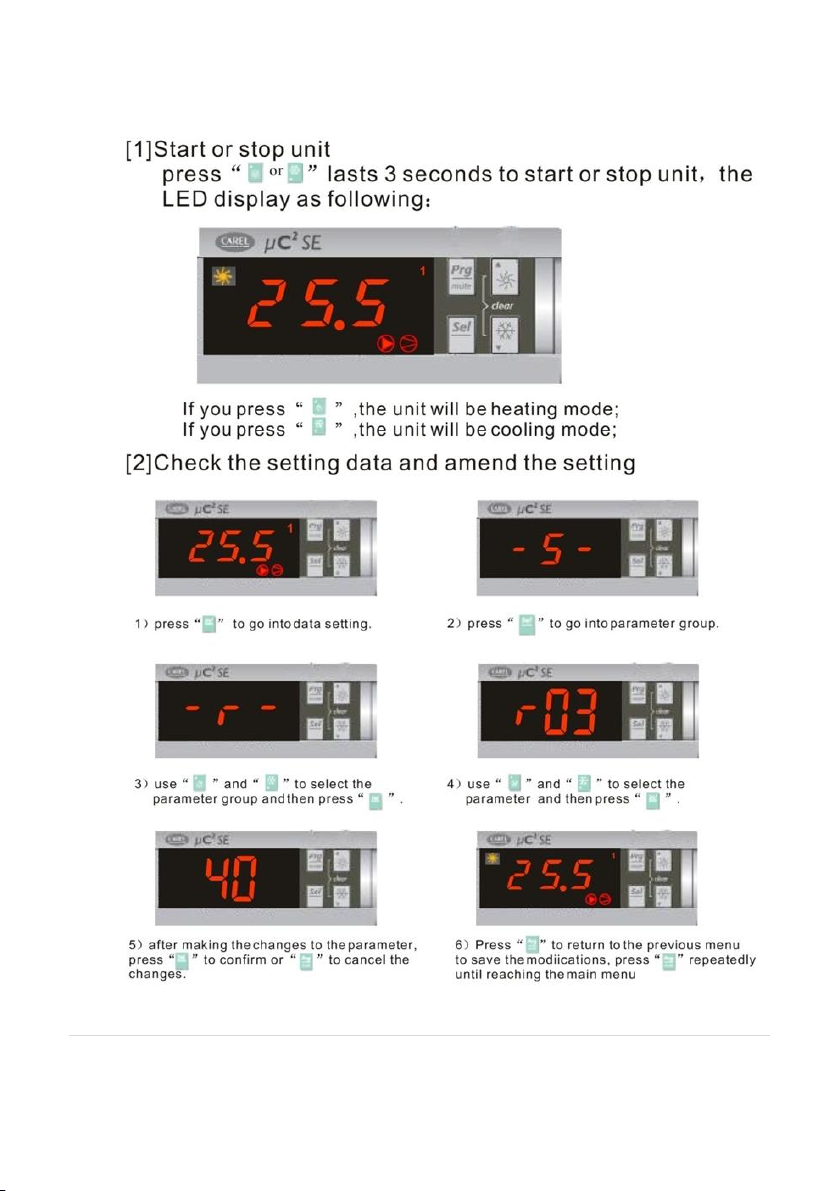

4.2 Functions associated with the buttons

The following table gives a description of what each of the buttons on the

unit controller will do. Please familiarise yourself with them as they are

important to the operation of your unit. They are also important for the

installer:

39 of 52| Earth Save Products-ASHP PASRW030B-D-PS

V 1.8 PASRW040B-D-PS

PASRW050B-D-PS

Page 40

4.3 Saving Controller Parameters

(This example illustrates changing the “set point” or “flow” temperature)

40 of 52| Earth Save Products-ASHP PASRW030B-D-PS

V 1.8 PASRW040B-D-PS

PASRW050B-D-PS

Page 41

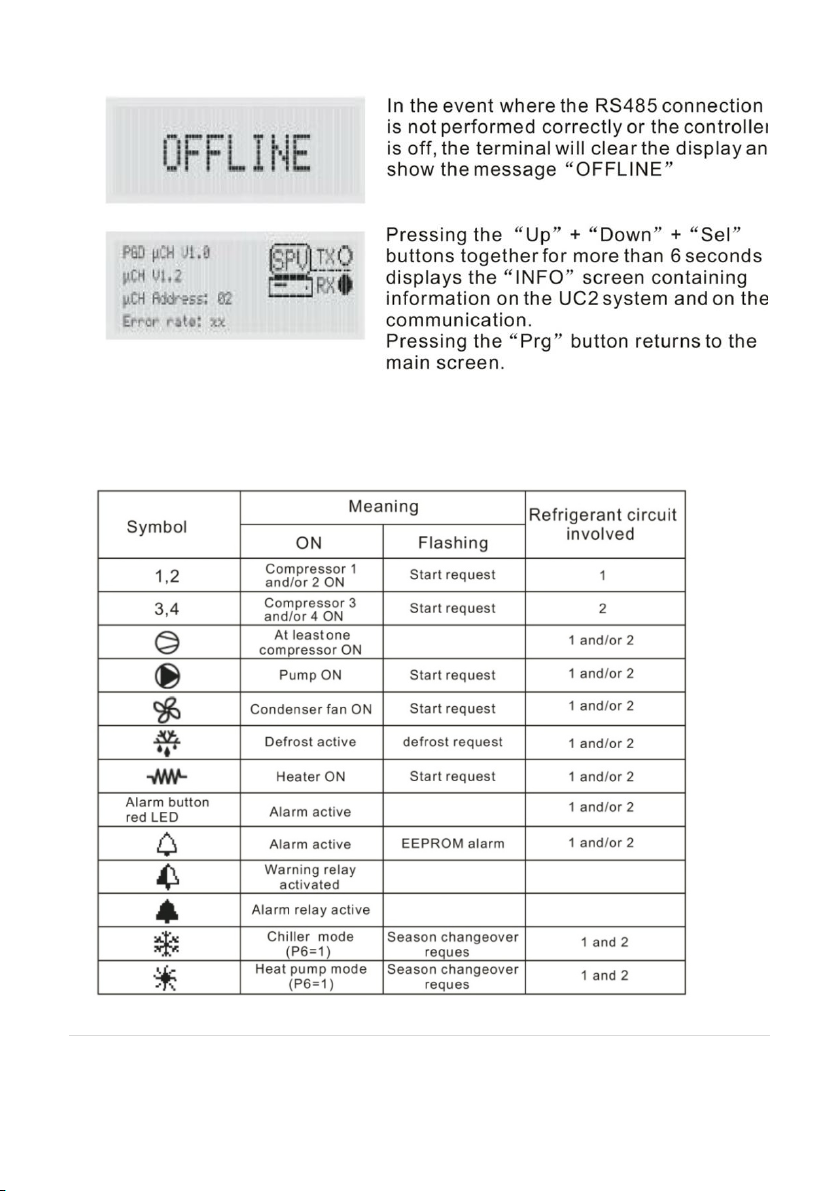

4.4 Installing a Remote Control

41 of 52| Earth Save Products-ASHP PASRW030B-D-PS

V 1.8 PASRW040B-D-PS

PASRW050B-D-PS

Page 42

4.5 Symbol Meaning

Please note below the function(s) that each of the identified symbols

performs:

42 of 52| Earth Save Products-ASHP PASRW030B-D-PS

V 1.8 PASRW040B-D-PS

PASRW050B-D-PS

Page 43

4.6 Parameters

The operating parameters are set as follows and the advice of the ESP

Technical team should be sought before changing them:

43 of 52| Earth Save Products-ASHP PASRW030B-D-PS

V 1.8 PASRW040B-D-PS

PASRW050B-D-PS

Page 44

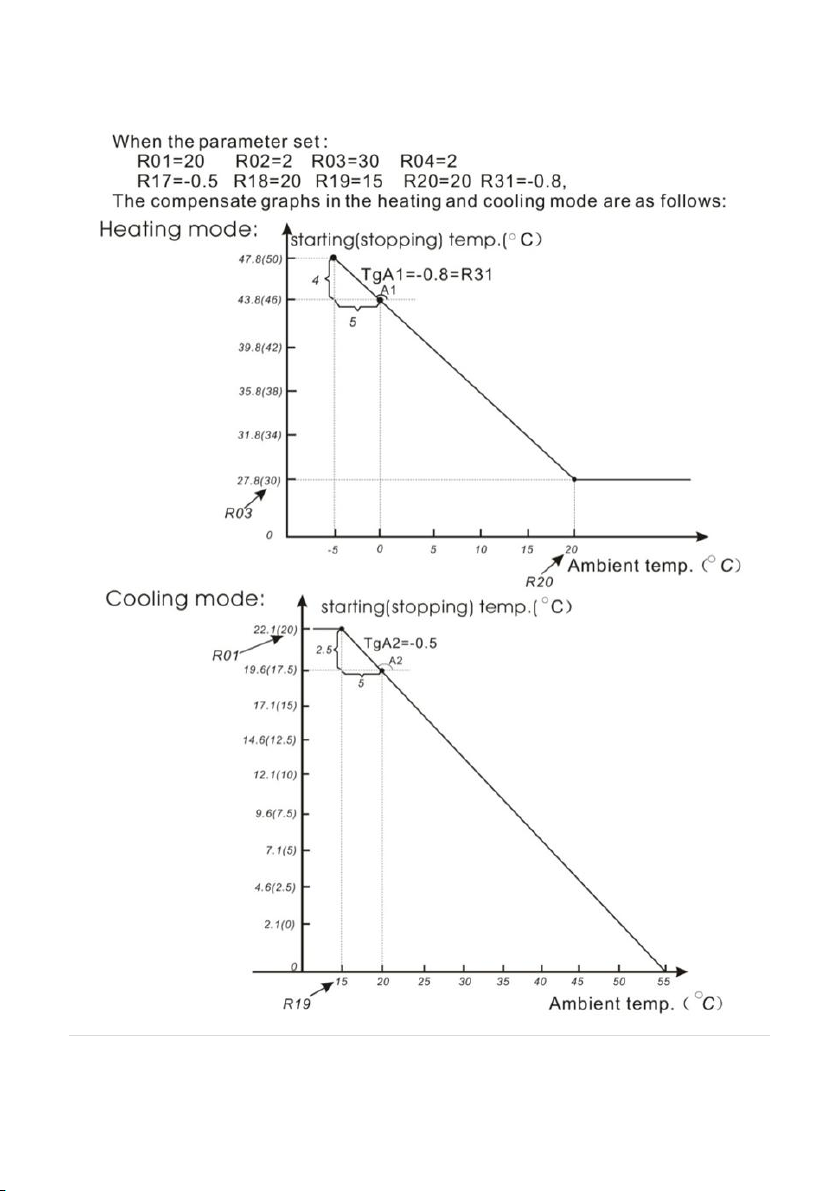

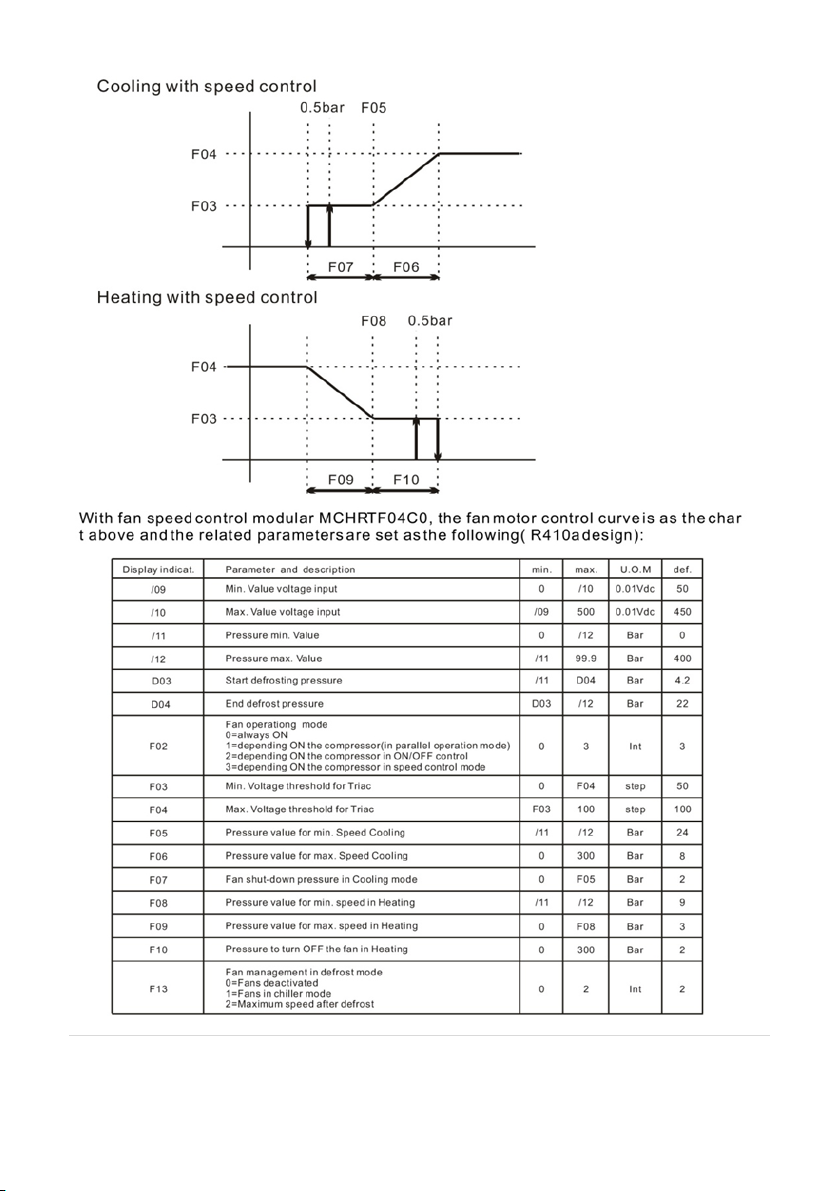

4.7 Weather Compensation Data

44 of 52| Earth Save Products-ASHP PASRW030B-D-PS

V 1.8 PASRW040B-D-PS

PASRW050B-D-PS

Page 45

45 of 52| Earth Save Products-ASHP PASRW030B-D-PS

V 1.8 PASRW040B-D-PS

PASRW050B-D-PS

Page 46

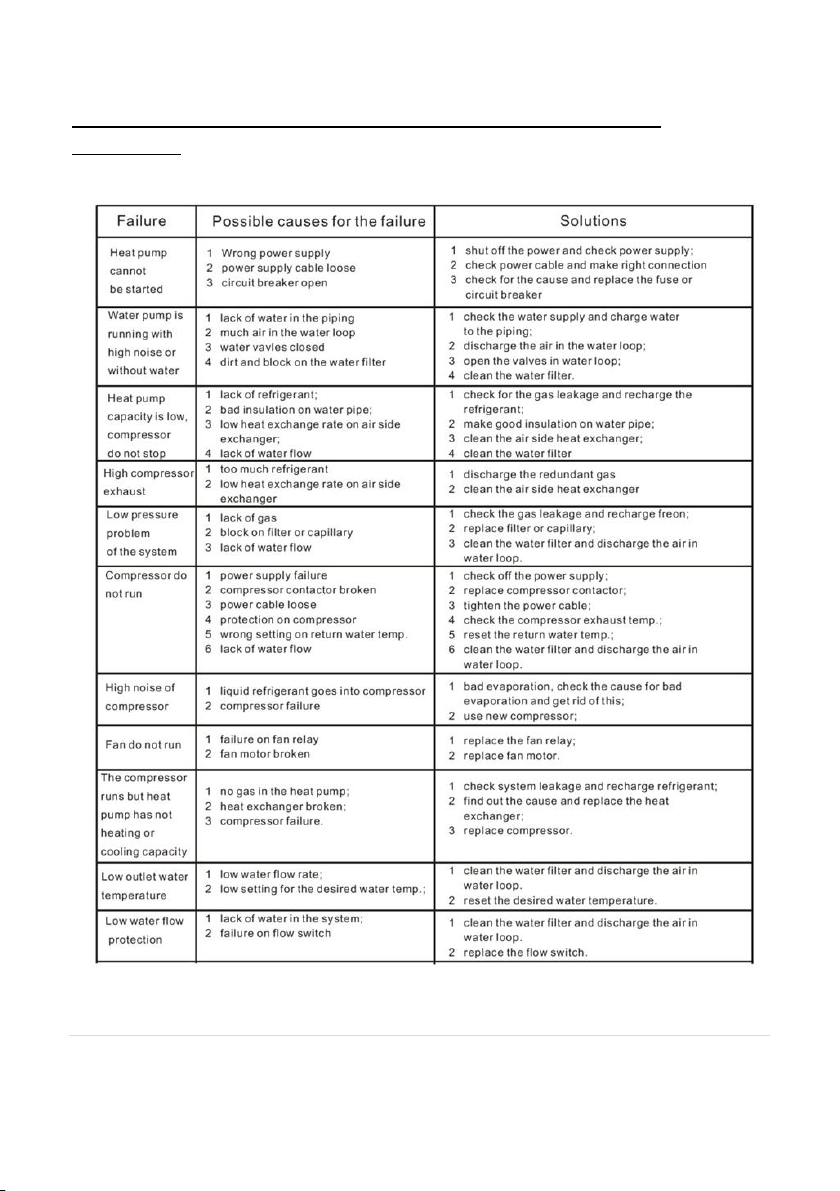

5.0 Frequently Asked Questions: Troubleshooting and Additional

Information

46 of 52| Earth Save Products-ASHP PASRW030B-D-PS

V 1.8 PASRW040B-D-PS

PASRW050B-D-PS

Page 47

5.1 Support

If you have trouble with your ESP High Temp ASHP, the ESP technical team or

your engineer will be willing to assist you.

47 of 52| Earth Save Products-ASHP PASRW030B-D-PS

V 1.8 PASRW040B-D-PS

PASRW050B-D-PS

Page 48

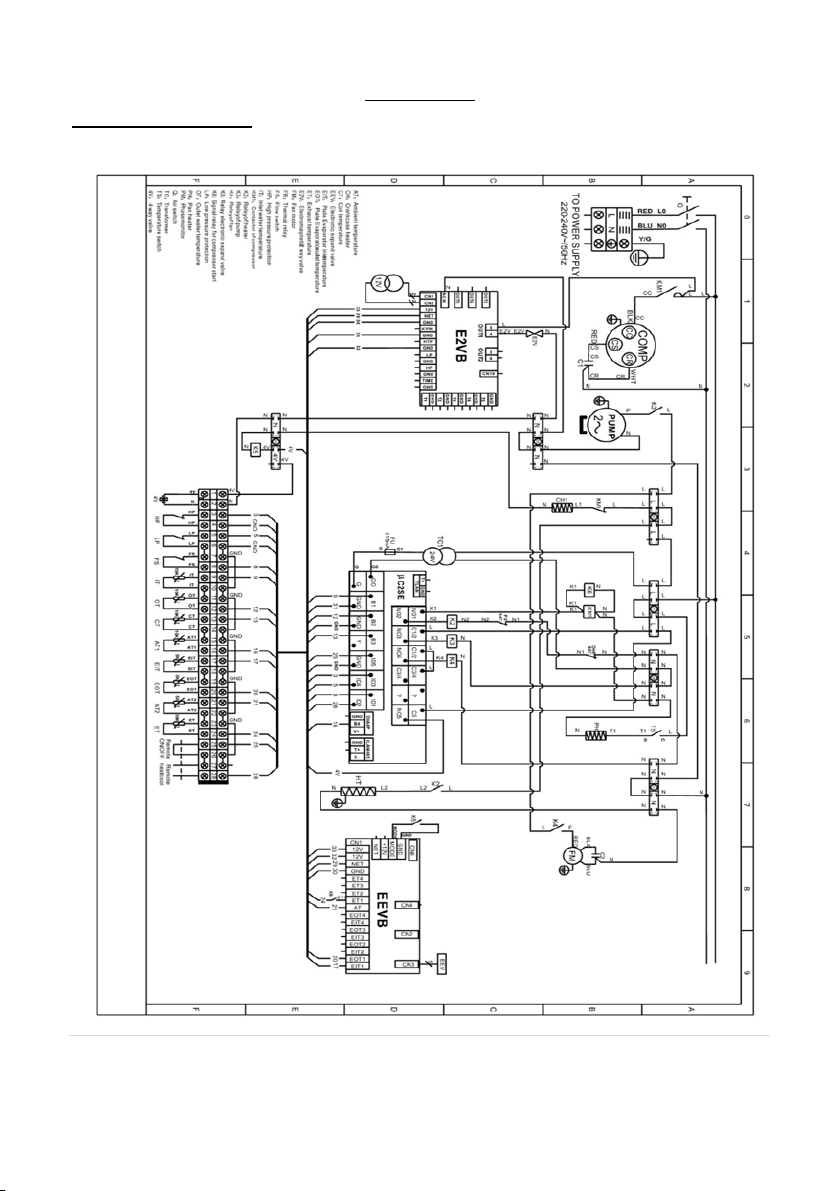

WIRING DIAGRAMS

ESP HT 9kW

APPENDIX 1

48 of 52| Earth Save Products-ASHP PASRW030B-D-PS

V 1.8 PASRW040B-D-PS

PASRW050B-D-PS

Page 49

ESP HT 12kW & 15kW

49 of 52| Earth Save Products-ASHP PASRW030B-D-PS

V 1.8 PASRW040B-D-PS

PASRW050B-D-PS

Page 50

Installation engineer's signature

Company Name (if applicable)

Company address

Company Tel No

Email address

APPENDIX 2

INSTALLATION ENGINEER’S DETAILS

50 of 52| Earth Save Products-ASHP PASRW030B-D-PS

V 1.8 PASRW040B-D-PS

PASRW050B-D-PS

Page 51

Customer Details:

Name:

Correspondence Address:

Installation Postcode:

Installer Details:

Installer Company Name:

Accreditation no. (MCS)

Address:

Postcode:

Telephone:

Emergency Telephone (if different):

Email Address:

Website:

Installation carried out by:

(if different from above)

APPENDIX 3

Installation and Commissioning Certificate

This should be completed in full and left with the customer.

51 of 52| Earth Save Products-ASHP PASRW030B-D-PS

V 1.8 PASRW040B-D-PS

PASRW050B-D-PS

Page 52

System Details

Heat Pump Manufacturer: ESP

Unit size:

Heat Pump Model and Serial no:

We have inspected the installation of the Air Source Heat Pump and can

advise that the unit has been correctly installed.

We have not inspected the system or reviewed its design.

I confirm that we are responsible for the installation, commissioning and

handover of the above Air Source Heat Pump and the same has been

carried out (so far as we are aware) in accordance with the manufacturer's

Documentation and MCS requirements

Signed: Print Name: .

Date (of commissioning): _

52 of 52| Earth Save Products-ASHP PASRW030B-D-PS

V 1.8 PASRW040B-D-PS

PASRW050B-D-PS

Loading...

Loading...