Page 1

Page 2

Safety Considerations--------------------------------------------------------------3

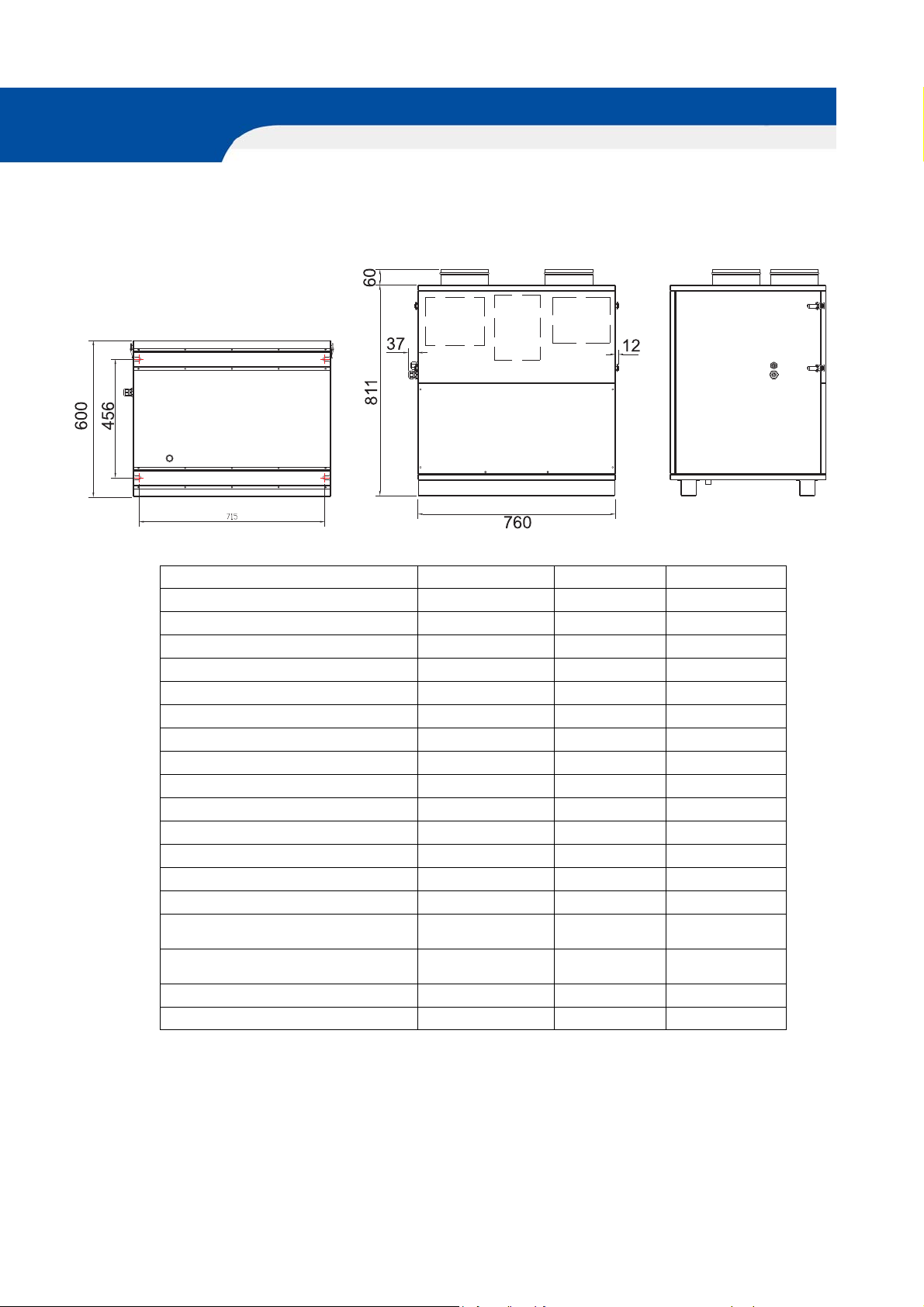

Unit Specifications----------------------------------------------------------------- 4

Dimensioned Drawings------------------------------------------------------------4

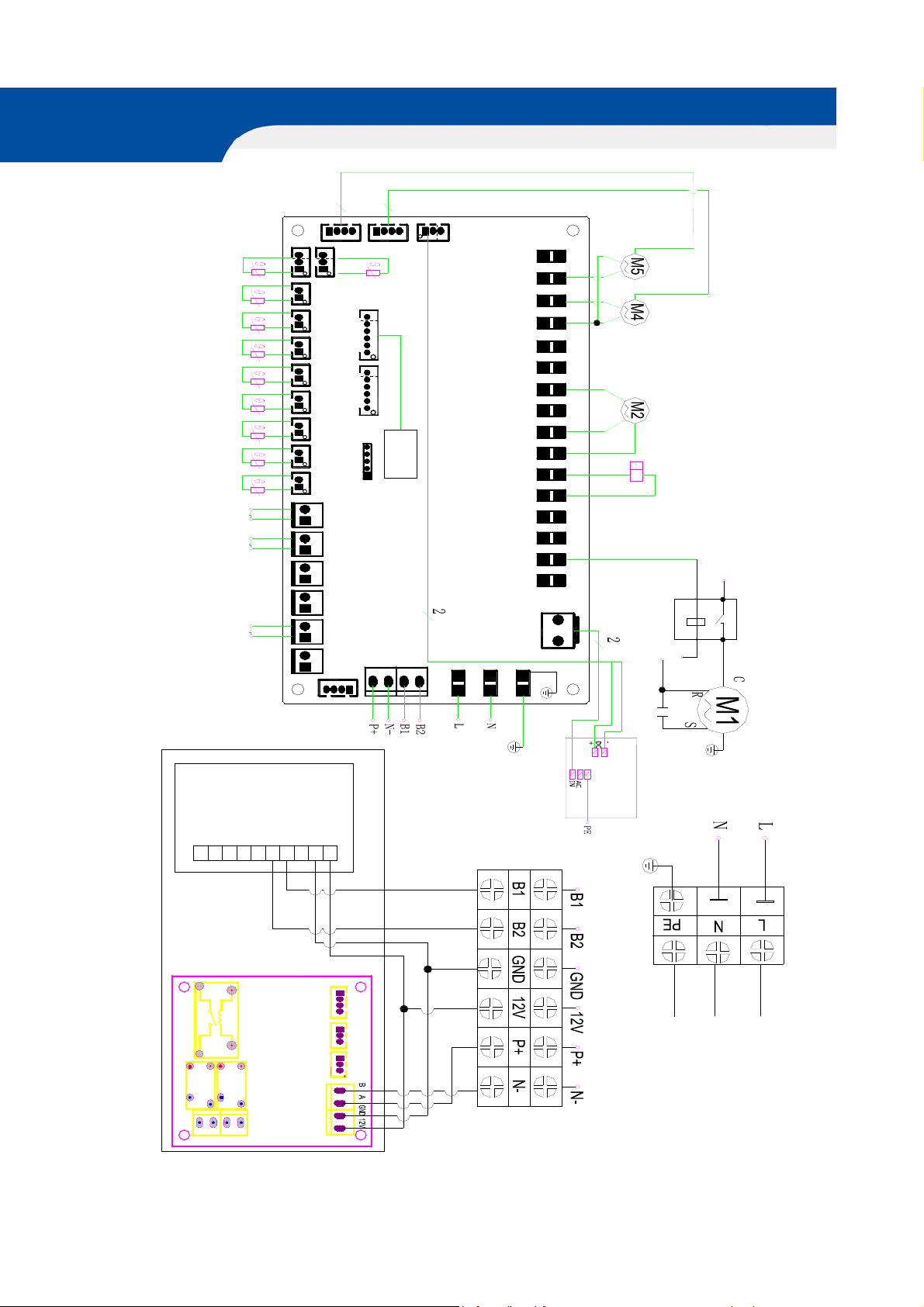

Wiring Diagrams--------------------------------------------------------------------5

Installation Considerations----------------------------------------------------6 to 8

Controller Introduction ------------------------------------------------------9 to 13

Contents

Page 3

Safety Considerations

1.Safety marks contained in these instructions

1. If the safety precautions marked by this symbol are not complied with, injuries to persons may

be caused.

2. If the safety precautions marked by this symbol are not complied with, damage to the machine

or to its functions may be caused.

2.Please read the label on the machine carefully

When abnormal conditions happen, like abnormal noise, smell, smoke, temperature rise, leakage or fire,

please cut off power immediately. And contact our customer service department or distributor. Don’t repair

it by yourself. Please contact fire and rescue department if necessary.

3.For your safety, please read carefully the cautions before installation or use

• Strictly follow the instructions and safety attentions before installation and usage.

• All the electric works and piping should be done by qualified professionals.

• Keep the electrical parts away from water to maintain good electric insulation.

• Complete the grounding engineering according to the Electrical Safety Regulations to avoid leakage.

• The machine needs to be used with special power supply. Don’t share the circuit with other equipment.

• The machine should be fastened at the place of flatness and good ventilation and keep proper distance

with surrounding.

• Keep the machine away from fire and pollutant.

• It is not recommended to place the machine under the sun and rain.

• Keep the children away from the machine.

• Random change of specification by user is not allowed.

• It is prohibited to us e the volat ile s ol vent , volat ile oi l, tolu ene an d ot her c hemic als be sid es or ab ove the

machine.

• Make sure the machine doesn’t put on the cable, and the cable is comp lete ly f ine , in case of a ny d ang er

of leakage and fire.

• Don’t operate or repair the machine with wet hands.

• Under no conditions should users repair the machine by themselves. Only the professionals are au-

thorized to repair the machine, it may result in personal injury or more serious problem to the equipment.

• Don’t wash the machine directly with water or cleanser. Need to scrub by cloth with water or mild de-

tergent.

• For avoiding machine breakdown or any danger, it is prohibited to insert objects into the air outlet.

• Users could not modify or repair the power wire.

• It is prohibited to p ut anything on th e machine, in case it fa lls down du ring the op eration of t he machine

and cause danger.

3

Page 4

Specifications and Dimension

HPERV-300/V2, HPERV-400/V2 Fresh Air Heat Pump (Air conditioner)

RA

filter

Controller

box

OA

filter

Specifications Unit HPERV-300/V2 HPERV-400/V2

Rated cooling capacity W 2000 2300

Rated heating capacity W 2500 2800

Rated cooling power W 550 630

Rated cooling current A 2.6 3.0

Rated heating power W 610 685

Rated heating current A 2.9 3.3

Maximum operating power W 750 800

Maximum operating current A 3.6 3.8

Power type

/

220V~50Hz 220V~50Hz

Fresh air/Exhaust air capacity m3/h 300/220/150 400/320/240

External static pressure Pa 80 80

Noise dB(A) 35 37

Outlet dimension mm 184 184

Condensation drainage dimension inch (BSP) 1/2" 1/2"

Machine overall dimension (length/

with/height)

Packing dimension (length/width/

height)

mm 810*600*870 810*600*870

mm 866*662*986 866*662*986

Net/Gross weight Kg 92/110 92/110

Refrigerant

/

R410A R410A

Test conditions:

Heating conditions: Ambient dry bulb / wet bulb temperature7℃/6℃

Room dry bulb / wet bulb temperature20℃/15℃

Cooling conditions: Ambient dry bulb / wet bulb temperature35℃/24℃

Room dry bulb / wet bulb temperature27℃/19℃

Fresh Air Heat Pump only handles fresh air.

4

Page 5

SA temp

compressor discharge temp

OA temp

compressor suction temp

SA sid e D X co ils in -tub e tem p

EA side DX coils in-tube temp

SA side DX coils inlet air temp

SA side DX coils outlet air temp

EA side DX coils inlet air temp

Fire alarm

HP

LP

Control System Wiring Diagram

44

FG

10V

SPD

J5

GND

J4

5V

CT2

RT1

RT2

RT7RT6RT5RT4RT3

RT8

X1

X2

X4X3

X5

X6

CN22

CN21

CN17

CN20

CN19

CN18

CN16

CN28

CN1

CN2

CN3

CN5

CN6

CN7

J1

TX RX GND5V

CT1

EA side DX coils

outlet air temp.

SWCLK

SWDAT

GND

EXV2EXV1

GND

RST

5V

FG

SPD

SPD

GND

10V

10V

12V GND

J2

J2

EC2

EC2

D1

CN11

CN14

expansion

valvetemp

DC IN

J6

EC1

EA

FAN

Y7Y8Y9

P17P18

P16 P12P13P14P15 P10 P9 P4P11 P8 P5P6P7P19

NNNNNNN

FAN

SA

Y6

Y5

onoff

electronic

170623 V2.0

E4A60000FF

Y4

Y3

Bypass

Valve

Four-way

valveK

Y2

Y1

L

AC OUT

N

CN4

RS485

L

CN23

P+

N-

B1

B2

N

P1

P2

CN15

PE

P3

N

K1

Compressor

power supply

switching

M1

Touch screen con troller

HG1

HG2

RY2

CN6

O2 IN2 O1 IN1

484B2

485A2

RY1

RY3

2014-11-06

CN7

GND

485B1

485A1

Monitor board

12V

0V

GND

CN1

V4

GND

V3

VCC

VCC

GND

V2

VCC

V1

GND

CN3

CN8 CN9

220V/50HZ

Power supply

1) Wiring should be done by professional people. Power supply 1-1.5mm²,other wires 0.5-0.75mm²

2) Wires of the controller and monitor board should be shielded twisted pair wires

5

Page 6

Engineering Installation

Installation site

A. Should be capable of providing sufficient installation and maintenance space.

B. Should be no barrier in the inlet and outlet where would avoid the strong wind.

C. Should be dry and well ventilated.

D. Should have even supporter and strong enough to bear the weight of the machine, where the machine

can be installed horizontally, creating no extra noise and vibration.

E. Should be where the neighbor can’t be disturbed by running noise and discharge air.

F. Should be where no flammable air leakage.

G. Should have easy access for piping and electrical connection.

Attention

1.Cautions for installation

Don’t install the system at the following places, which may cause system failure (please consult our service

team if necessary).

A. Places with mineral oil like cutting machine oil

B. Places with salty air

C. Places with corrosive gas, such as sulfur.

D. Places with fluctuant power supply and voltage

E. Vehicle or cabin

F. Places like kitchen where full of oil ,Places with strong electromagnetic waves

G. Places with flammable gas and materials

H. Places with acidic or alkaline gas

I. Other special places

2.Attention before installation

A. Choose the correct transportation way.

B. Keep the original packing during transportation.

C. If the mac hine is ins ta lle d o n th e m eta l ba se of t h e construction, the electrical insulation must be done

well and strictly

according to the technical standards of electrical equipment.

3.Installation attention

Please reserve enough room for maintenance, refer to below picture

Compressor

80mm reserved 50mm reserved

SA EA

RA OA

Front of the

ventilator (white)

6

300mm reserved

Page 7

Engineering Installation

4.Installation of drainpipe

Connect the soft pipe to the drainpipe connector (1/2”),

gradient should be over 1/100, to avoid the condensate water on surface of the drainpipe, the drainpi pe

should be thermal insulated.

Drainpipe connector

5.Electric wiring

Power Terminal

Monitoring Board

TerminalTouch Screen

control modul e

Touch screen

controller

Terminal

Note:

1) The dotted line area wiring connection should be operated by a professional.

2) The wiring for connecting monitoring board, touch screen with terminals should be used with shielded

wire to prevent interference.

7

Page 8

Engineering Installation

6.Power cord requirement

Type No. HPERV-300/V2, HPERV-400/V2

Power cord

Specification 3 X 1.5 mm

Model No. 60245 IEC57(YZW)

7.Grounding requirements

1)It is a Class I appliances, be sure to take a reliable grounding.

2)The yellow-green wire is the grounding wire. It must not be used for other purposes and can not be cut.

Do not use

self-tapping screw to prevent the risk of electric shock.

3)Grounding resistance should be in line with the national standard requirement of GB17790.

4)User must provide a reliable grounding power supply. Please do not connect grounding wire to the places

like Water pipe, gas canisters, drain outlet and other unreliable places recognized by professionals.

8.User’s attention

• Set appropriate indoor temperature The indoor temperature should not be set too hi gh or too low, to

make most people feel comfortable. Recommended temperature for cooling is 26-28

heating.

• The window and door should be closed, otherwise, it will affect the effectiveness of air conditioning.

• Equipment like TV, radio and Hi-Fi etc. should be at least one meter away from the indoor machine,

otherwise, they will interfere the image and make noise.

• The power of the machine should be shut down if it is not used for a long time. To protect the machine,

the power should be connected for 24 hours before it is used. If it is shut down in winter, please clean the

machine and dry it. For dustproof, please cover the machine, open the outlet valve to drain out the water

in the heat exchanger and pipes, to prevent frosting. It is recommended to inject antifreeze into the pipes.

• The window should hang up curtains or shutters, to avoid the sun shine directly to the house.

• Dry articles should not be put under the machine, because when the ambient temperature is high or the

drainage is blocked, the machine may drip.

2

℃, and 18-23℃for

If any abnormity is found (like scorching smell), shut down the power, and contact our

service team, if it is still using in that case, the m achine may be dam aged and cause e lectric

shock or fire, maintenance can only be conducted by professional. The power should be

disconnected before touching the wiring device

The machine can be cleaned only when the power is disconnected, otherwise, it may cause

electric or injury. Don’t wash the machine with water, or it may cause electric shock, Stand

on a firm platform when cleaning ceiling air conditoner

8

Page 9

Controller Introduction

1. Homepage

Fresh Air Heat Pump is with intelligent touch screen controller to monitor indoor air quality (IAQ), including index of indoor temperature, humidity, VOC concentration, CO2 concentration and PM2.5 value.

Timer on/off

Mode switch

On/off button

On/off button, to turn on or turn off the ventilator.

Mode switch, to switch heating mode, cooling mode, ventilation mode and auto mode.

Setting button, to set the parameters of the ventilator.

Timer on/off, after activate the timer on/off function, a “CLOCK” displayed on the top left corner.

When there is system error, there will be messages displayed on the top left corner.

Setting button

2. Mode switch

Press Mode switch button to enter the modes setting as below

Cooling mode, to set the cooling temperature and fan speed, then to confirm.

Heating mode, to set the heating temperature and fan speed, then to confirm.

Ventilation mode, to set the fan speed, then to confirm.

Auto mode, to set cooling and heating temperature, then to confirm.

9

Page 10

Controller Introduction

3. Setting button

Press setting button to enter basic setting, advanced setting, data query or maintenance setting.

A) Press basic setting to enter the basic setting page.

Under basic setting page, press PM2.5 or CO2 value to set the targeted value, these 2 values will

influence the SA fan and

EA fan speed after setting temperature achieved (compressor off).

10

Page 11

Controller Introduction

Press screen lock at the top right corner to enter the screen lock time setting.

Press time setting to enter the system time setting and timer on/off setting

a) press system time at the top right corner to set the system time

b) after setting the timer on and timer off time, then to click the “

√“ to activate timer on/off

Press filter life to check the filters life, after cleaning or replacing the filters then can reset the life time.

11

Page 12

Controller Introduction

B) Press advanced setting and enter the password 3333 to turn to advanced setting page. Through

advanced setting to set filter life, correction value and return difference value, also the defrost value.

ADVANCED SETTING ONLY FOR ADMINISTRATOR, INCORRECT

SETTING MAY INFLUENCE THE VENTILATOR NORMAL WORK.

Press filter life to set different filters life alarm

Press correction value & return difference to check and set the value

12

Page 13

Controller Introduction

Press defrost setting to enter defrost duration time and defrosting interval time setting.

C) Press data query to enter the data checking, it is for administrator ONLY, if there is error displayed

on the homepage, then can enter this page to check the details, password is 5555, if the ventilator

works fine, then no need to enter this page.

D) Maintenance page, THIS PAGE IS FOR DEVELOPER OPTIONS, ANY NOT PROFESSIONALS ARE

NOT ALLOWED TO ENTER THIS PAGE, INCORRECT SETTING WILL RUIN THE VENTILATOR

SYSTEM, PLEASE CONTACT THE MANUFACTURE FOR THE PASSWORD IN CASE OF NECESSARY.

13

Page 14

Loading...

Loading...