Page 1

1 of 42

V 1.9

www.esavep.com PASHW-003-100LD

ESP ECOCENT 100L

Installation and

Operation Manual

Page 2

2 of 42

V 1.9

www.esavep.com PASHW-003-100LD

WARNING !

READ THIS BEFORE INSTALLING

THE

UNIT.

All un-vented water heating systems above 15 litres (this includes the ESP E c o c e n t

Hot Water ASHP’s) MUST be installed to meet the requirements of the local area

Building Regulations. It is a legal requirement that the local Building Control Officer

be notified of any proposed installation of un-vented water heating systems over 15

litre capacity.

Furthermore, it must be fitted by an installer who has successfully completed a

recognised course in the installation of un-vented heating systems such as CITB and

be familiar with installing the Ecocent unit. Failure to properly fit the unit may affect

its safety, efficiency and invalidate any guarantee.

Safety requirements in the UK call for an expansion space (internal or external),

safety devices to prevent the stored water exceeding 100°C, and pipe work to convey

discharged hot water safely away from the safety devices.

THE UNIT MUST BE INSTALLED, COMMISSIONED AND MAINTAINED BY A COMPETENT

INSTALLER IN ACCORDANCE WITH BUILDING REGULATION G3 (ENGLAND AND WALES),

TECHNICAL STANDARD P3 (SCOTLAND) OR BUILDING REGULATION P5 (NORTHERN

IRELAND) AND THE WATER FITTING REGULATIONS (ENGLAND AND WALES) OR WATER

BYELAWS (SCOTLAND). FOLLOWING INSTALLATION AND COMMISSIONING, THE

OPERATION OF THE UNIT SHOULD BE EXPLAINED TO THE USER AND THESE

INSTRUCTIONS LEFT WITH THEM FOR FUTURE REFERENCE.

Page 3

3 of 42

V 1.9

www.esavep.com PASHW-003-100LD

Contents Page 1.0 Preface

2.0 General Notes

2.1 Safety Precautions

2.2 Installation Notes

2.3 Operating Notes

2.4 Moving and Repair Notes

2.5 Siting and Safety Notes

2.6 General Requirements

3.0 Siting the Unit

3.1 Heat Source

3.2 Dehumidification

3.3 Cooling

3.4 Siting Guidance

4.0 Installation

4.1 Ducting

4.2 Water Supply

4.3 Outlet Fittings

4.4 Limitations

4.5 Regulations

4.6 Package Contents

5.0 Specifications

5.1 Appearance

5.2 Features

6.0 Technical Specifications

7.0 Performance

7.1 Technical Performance

7.2 Standing Heat Losses

7.3 DHW Recovery Times

7.4 Performance Graphs

8.0 Functions

9.0 Physical Installation

Page 4

4 of 42

V 1.9

www.esavep.com PASHW-003-100LD

9.1 Schematic Diagram

9.2 Pipe Fittings

9.3 Cold Water Supply

9.4 G3 Requirements

9.5 G3 Guidance

10.0 Moving the unit

10.1 Storage and Transport

10.2 Using a Forklift

10.3 Transporting for Installation

11.0 Hydraulic Connection

11.1 Connection Diagram

12.0 Wiring

12.1 Wiring Diagram

12.2 Earthing

13.0 Operating the Unit

14.0 Troubleshooting

15.0 Maintenance

15.1 The Cylinder

15.2 Safety Valves

15.3 The Strainer

15.4 Draining The Unit

15.5 Descaling the Immersion

15.6 Refilling the Unit

15.7 Log Book

15.8 Maintenance Requirements.

16.0 Fault Finding

17.0 Guarantee

17.1 Guarantee Terms

18.0 Environmental Information

19.0 Spare Parts

Page 5

5 of 42

V 1.9

www.esavep.com PASHW-003-100LD

1.0 PREFACE

This manual includes the necessary information about installation

and maintenance of the Ecocent. Please read this manual carefully

before you install or carry out maintenance on the unit.

When installing the unit, please carry out the work strictly in

accordance with the manual, relevant Regulations and good practice.

Please do not switch the unit on until you are sure that it has been

properly installed, electrically and mechanically and there is water in

the system.

The installer should explain to the end user how to operate and

maintain the unit before handing over the unit to the end user. Also,

the installer should advise the end user to read the manual fully

before operating the unit.

Further, improper installation, operation and/or maintenance, and

failure to maintain the unit as per this manual will invalidate any unit

warranty or guarantee.

The manual may be altered and/or updated in any way at the sole

discretion of the supplier and/or ESP without notice.

2.0 GENERAL NOTES

2.1 Safety Precautions

Below you will find information that is critical for the safe and proper

installation and use of the unit. Please make sure that you understand the

contents because it is written to help avoid the risk of injury or damage to the

unit/other property.

Page 6

6 of 42

V 1.9

www.esavep.com PASHW-003-100LD

2.2 Installation Notes

Professional

& qualified

installer

is required

The heat pump must only be installed by a suitably qualified

engineer. Failure to ensure this can cause damage to the unit and

may cause serious injury. The warranty on the unit will also be

invalidated if a suitably qualified engineer is not engaged to install

it.

Earthing

required

Please make sure that the unit and power supply are properly

earthed.

Refrigerant

If you are installing the unit in a small room, please give full

consideration to adequate ventilation being available in the event

of a refrigerant leak.

Installation

Site

Do not install the unit near a gas installation. This unit is

designed to be installed inside a building.

Site

consideration

Ensure that this unit is fixed securely to a suitable wall that is

capable of taking the load of the unit when full of water. Make

sure that you have a suitable facility to cater for the disposal of

condensate from the condensate drain on the unit.

Circuit

Breaker

Make sure that this unit is connected to the power supply via a

fused switched spur and a 13A Type C MCB.

Unit Upright

The unit must be installed level across the whole diameter.

Failure to install the unit level will mean that condensate can spill

over the lip of the cylinder.

Do NOT

Do not push anything into the fan blades when running and make

sure that children cannot access the unit or play close to the unit.

Shut off the

power supply

If there is an unusual sound or smell coming from the unit, shut

off the power supply immediately and call your installation

engineer.

Caution

This unit has a high centre of gravity. This unit must be strapped

down to prevent it falling over when in transit.

Suitably

qualified

engineer

When moving the unit or carrying out repair work please be sure

to use only a suitably qualified engineer.

2.3 Operating Notes

2.4 Moving and Repair Notes

Page 7

7 of 42

V 1.9

www.esavep.com PASHW-003-100LD

Do NOT

Do NOT try to install, move or repair the unit yourself – it is NOT

worthwhile running the risk of injury.

Transporting

the Unit

The unit must be transported in the vertical position. It can be

tilted up to 60° from the horizontal axis (see section 11.3).

Siting the

Unit

The unit must only be installed indoors – the unit is not

designed for, or suitable for installation outside. The Unit

needs to be sited where the ambient temperature never

goes below 5 degrees. If the unit is to be left unused for any

significant period of time during which the ambient

temperature could cause the unit or pipe work from the unit

to freeze, it should be drained down.

Shut off the

power

When cleaning the unit, shut off the power supply.

You MUST

You must use a suitable power supply that is appropriately

fused.

2.5 Siting and Safety Notes

2.6 General Requirements

IMPORTANT: PLEASE READ AND ENSURE THAT YOU UNDERSTAND

THESE INSTRUCTIONS BEFORE INSTALLING THE ESP Ecocent (“DHW

ASHP” or “unit”). INCORRECT INSTALLATION WILL INVALIDATE ANY

GUARANTEE.

PLEASE NOTE THAT THERE ARE ESSENTIALLY 2 UNITS COMBINED INTO

ONE IN THE ESP ECOCENT AND YOU MUST BE SURE TO

UNDERSTAND BOTH ELEMENTS - THE INDIRECT HOT WATER

CYLINDER AND THE AIR SOURCE HEAT PUMP. PLEASE ALSO NOTE THE

ECOCENT CAN BE INSTALLED IN EITHER A VENTED OR UNVENTED

SYSTEM

IMPORTANT NOTE: DO NOT SITE THE UNIT IN THE SAME ROOM AS AN

APPLIANCE WITH AN OPEN FLUE OR IN A ROOM FROM WHICH AN

OPEN FLUED APPLIANCE TAKES ITS COMBUSTION AIR, UNLESS THE

Page 8

8 of 42

V 1.9

www.esavep.com PASHW-003-100LD

MATTER HAS BEEN CAREFULLY CONSIDERED AND ADEQUATE DUCTING

AND VENTILATION HAS BEEN PROVIDED FOR THE UNIT (THE DHW

ASHP) AND THAT THE OPEN FLUED APPLIANCE IS FULLY CATERED FOR

IN TERMS OF SUITABLE AIR SUPPLY.

Please be sure to use appropriate lifting equipment when moving the unit.

3.0 SITING THE UNIT

The unit is designed to be wall mounted. It can be placed anywhere

convenient provided the discharge pipe(s) from its safety valves and air

handling duct work can be correctly installed. Areas that are subject to

freezing must be avoided. Ensure that the wall is of sufficient strength

to support the weight of the unit when full with water. Pipe run

lengths should be kept as short as possible for maximum economy and

efficiency: the use of secondary returns should be avoided. Access to

associated controls and indirect controls must be possible for servicing

and maintenance of the unit. Please do not install valves or pipe work

(except discharge pipe) within 50mm (2”) of the T&P relief valve to

allow insulation to be fitted. The insulation is important to avoid heat

loss.

Consideration must be given to the use of insulated ducting to carry air

to and from the unit. Insulated ducting must be used where

condensate may form on the duct work.

Page 9

9 of 42

V 1.9

www.esavep.com PASHW-003-100LD

3.1 Heat Source

The Ecocent can receive ducted waste heat from another area in the

building – duct work can be fixed to the top of the unit and may be up to

8m long without an additional in-line fan in the ductwork being needed.

The Ecocent can also draw heat from the room in which it is sited. (See

Picture 1)

Always be sure to site the unit and arrange duct work to allow adequate

heat availability to allow the Ecocent to operate efficiently (inlet air should

not be below 8° C.)

The secondary coil in the Ecocent enables direct connection to a second

stable heat source, e.g. a solar heating system or a boiler.

Under no circumstances is the Ecocent to be installed onto an uncontrolled

heat source e.g wood burner or back boiler

Page 10

10 of 42

V 1.9

www.esavep.com PASHW-003-100LD

Picture 1

3.2 Dehumidification – The Ecocent can be used to dehumidify rooms that

are hot and damp – e.g. Laundry room (See Picture 2). The unit is equipped

with a condensate drain that must be properly directed to a suitable waste

pipe where the condensate water (non acidic) can drain away. If the drain is

into a main sewer it must have a trap installed to prevent back smell through

the Ecocent.

Picture 2

3.3 Cooling (picture 3)

The Ecocent can extract warm air and place cooled, dehumidified, outlet air

back in to the same room – this is perfect for cellars and gymnasiums. Any

cold air exhaust air ducting must be lagged when passing through a warmer

Page 11

11 of 42

V 1.9

www.esavep.com PASHW-003-100LD

area to prevent the formation of condensate. All ducting should be 150mm

or split into two 75-80mm ducts.

Picture 3

3.4 Siting Guidance

1. Decide upon the right route to be taken to move the unit in to the chosen

position.

2. Try to move the unit in its original case to avoid damage.

3. Be sure to have the unit and electrics fitted by qualified electrician.

4. Ensure that no building materials or debris are allowed to enter the air

ducts at the top of the unit or any extension of the ducts.

4.0 INSTALLATION

4.1 Ducting

Air ducts to and from the heat pump should be 150mm pipe.

The outlets should be fitted with a suitable gravity vent to prevent rain,

debris, animals and plants entering the ducts.

You can use rigid or flexible ducting. It is always best to use insulated ducting

so that condensation is avoided.

Page 12

12 of 42

V 1.9

www.esavep.com PASHW-003-100LD

When servicing the unit, ducting should be checked to make sure that it is

clear and obstructions removed.

4.2 Water Supply

Bear in mind that the mains water supply to the property will be supplying

both the hot and cold water requirements simultaneously. Therefore, it is

important that the maximum water demand be assessed and the water

supply checked to ensure that it can meet peak demand.

NOTE: A high mains water pressure will not always guarantee high flow rates.

The main supply pipe to the unit must be in 22mm. The minimum mains water

supply requirements should be 0.15 MPa (1.5 bar) working pressure and 20

litres per minute flow-rate at the unit. At these levels, outlet flow rates may

be poor if several outlets are used simultaneously - the higher the available

pressure and flow-rate the better the system performance will be.

The unit has a design operating pressure of 3 bar which is controlled by

the Cold Water Combination Valve on the cold water feed pipework. The

Cold Water Combination Valve can be connected to a maximum mains

supply pressure of 1.6 MPa (16 bar). The water supply must be of wholesome

water quality (Fluid Category 1 as defined by the Water Supply Regulations

1999).

The unit MUST be level horizontally, and vertically upright, otherwise this

could cause problems with condensate draining from the heat pump section

of the unit into the condensate drain.

An inline strainer (if open vented) and scale inhibitor (WRAS approved) must

be fitted “in line” on the water supply to the unit. Failure to fit these will

invalidate the unit warranty/guarantee. All fittings must be WRAS approved.

Page 13

13 of 42

V 1.9

www.esavep.com PASHW-003-100LD

If installing the unit in unvented configuration, an “unvented Pack”,

containing the required safety valves must be supplied with the unit and

there is likely to be an additional cost for this.

4.3 Outlet Fittings

The unit can be used in conjunction with most types of terminal fittings. It is

helpful in many mixer showers to have balanced hot and cold water supplies;

in these instances the balanced cold water supply can be taken from the

tapping on the combination valve. Branches to cold drinking water outlets

should be taken before the combination valve.

NOTE: Accessories should have a rated operating pressure of at least

0.8 MPa (8 bar).

4.4 Limitations

The unit should not be used in any of the following instances:

• With a water supply from solid fuel boilers or any other boiler in which

the energy input is not under effective thermostatic control, unless

additional, necessary and appropriate safety measures are installed.

• With gravity circulation primaries unless a good head of pressure is

available.

• With a steam heating plant unless additional and appropriate safety

devices are installed.

• With ascending spray type bidets or any other facility where there is a

Class 5 back-siphoning risk requiring that an appropriate air gap be

employed.

• With water supplies that have either inadequate pressure or where

the supply may be intermittent.

• In situations where it is not possible to pipe away any discharge from

the safety valves safely.

Page 14

14 of 42

V 1.9

www.esavep.com PASHW-003-100LD

• In areas where the water contains a high proportion of solids, e.g.

suspended matter that could block the strainer, unless adequate

filtration can be ensured.

• Where another appliance in the room is vented by way of an open flu.

The installation must be carried out in accordance with the relevant

requirements of:

A) The appropriate Building Regulations: either The Building

Regulations (England and Wales), The Building Regulations (Scotland) or

Building Regulations (Northern Ireland).

B) The Water Fittings Regulations (England and Wales) or Water By-laws

(Scotland).

C) Any other applicable Regulations.

Failure to observe any of the above conditions will invalidate the

warranty/guarantee.

4.5 Package Contents

Where the unit is to be installed as an unvented system it will be supplied

with the fittings needed to allow installation to comply with G3 Regulations –

This means that the supply cost for the unvented configuration unit will be

higher than when installed as a vented system as additional fittings are

required. Where the unit is to be installed in a vented system, such fittings

will not be necessary.

Page 15

15 of 42

V 1.9

www.esavep.com PASHW-003-100LD

5.0 SPECIFICATIONS

Air Inlet

Air Outlet

5.1 Appearance

5.2 Features

Good Looking and Efficient

The attractive design allows the unit to be placed in the open in finished

utility spaces and basements; depending on ambient conditions, the cost of

operation can be up to 75% less of that of an electric water heater, and can

be used in locations unsuitable for solar hot water heating.

Environmentally friendly and safer

The unit produces no harmful emissions locally; there is no combustion of oil,

coal, or natural gas. No carbon monoxide is produced and there is no open

flame.

Easy to operate and multiple heat sources

The Ecocent is equipped with a timer for automatic start-up and stop and an

adjustment for setting of water temperature easily. The unit can take heat

from a number of sources in domestic installations, or from hot areas in light

industrial environments.

Page 16

16 of 42

V 1.9

www.esavep.com PASHW-003-100LD

6.0 TECHNICAL SPECIFICATIONS

Page 17

17 of 42

V 1.9

www.esavep.com PASHW-003-100LD

Model

ESP400-003-10 0L(D)

Heating ca pa city

kW

1.0

Wa ter tank capa city

L

100L

Power input

kW

0.27

Ru nning curren t

A

1.2

Power supp ly

230V~/50H z

Compressor num be r

1

Compressor Type

Rotary

Rated out let water temp.

°C

55

No ise

dB(A)

45

Water in let /o utlet size

inch

1/2

Net d imensio ns

mm

see the d ia gr am

Shipping dimen si ons

mm

see package label

Net weight

kg

see nameplate

Shipping w eight

kg

see package label

7.0 PERFORMANCE

7.1 Technical Performance

Standard working conditions:

Ambient temperature of dry bulb/wet bulb: 15° C /13° C

Rated water outlet temperature: 45° C.

Working scope: Peak water outlet temperature: 60° C

Running Current is quoted without Immersion Heater.

Immersion heater is rated at 1kW

Operating parameters:

Acceptable scope of water setting temperature: 9° C ~70° C

Acceptable running pressure of the water tank: 0.1~1.0MPa

Maximum inlet water pressure: 0.7MPa

Page 18

18 of 42

V 1.9

www.esavep.com PASHW-003-100LD

Volume

Time

10l

32 mins

15l

47 mins

20l

63 mins

30l

95 mins

40l

126 mins

65l

205mins

7.2 Standing Heat Losses

The amount of heat that the Ecocent loses through convection to the

surrounding area (standing heat loss) is dependent on a number of things

including, for example, the target temperature and the ambient air

temperature surrounding the unit. The target temperature is an end user

choice and the ambient temperature will depend on location; clearly if the

unit is in an ‘airing cupboard’, the ambient temperature will be higher than

if it is located in, say, a utility room; the higher the ambient air

temperature, the lower the rate of heat loss. However, an illustrative heat

loss for the Ecocent is 1.09 kWh per 24hrs in an ‘average’ location of 20°C

and a target temperature of 55°C.

7.3 DHW Recovery times

The recovery time of your 100ltr Ecocent (the time it takes to return to fully

hot) depends on the storage temperature (normally 55°C), the temperature

of your cold water supply (normally taken to be 10°C), the temperature of

the air supply (at least 15°C) and the amount of water you use. Typically, a

single person uses about 45l of hot water per day. However, it would be

unusual to use all this hot water at the same time. A shower uses around 30l

and a bath uses around 65l. The recovery times based on proscribed test

data are as follows:

Page 19

19 of 42

V 1.9

www.esavep.com PASHW-003-100LD

But, because the Ecocent unit uses waste heat, the expected recovery times

Volume

Time

10l

24 mins

15l

36 mins

20l

48 mins

30l

72 mins

40l

97 mins

65l

157mins

are likely to be much shorter and the following table is indicative of more

normal recovery times:

In fact, the recovery times could well be even better than this because the air

source will probably warmer than used to calculate the above tables.

Your Ecocent unit will have been sized based upon normal DHW use profiles

and volumes and, save in exceptional circumstances (e.g. visitors using

shower/bath), you should not run out of hot water. Should your usage

exceed normal expectation, the immersion heater can be used to provide a

boost by selecting the rapid heating mode. In fact, in the unusual event that

the target temperature (normally 55°C) is not reached within 45 mins, the

immersion heater will automatically provide that boost.

Page 20

20 of 42

V 1.9

www.esavep.com PASHW-003-100LD

7.4 Performance Graphs

Page 21

21 of 42

V 1.9

www.esavep.com PASHW-003-100LD

8.0 FUNCTIONS

Heating Capacity

The unit absorbs energy from the air taken in through the inlet ductwork. If

the air inlet temperature is low, heating capacity will show a variation from

standard conditions.

3 Minutes Protection

When the unit stops, if you try to immediately restart the unit or turn on the

manual switch, the unit will not run for 3 minutes. This is built in protection

for the compressor.

Heating Mode Operating

If the ambient temperature is very high, to protect the unit, the fan motor

will stop running.

Defrosting

When in heating mode, the unit will defrost automatically, if required . The

fan motor will stop running when the unit is defrosting.

Working Conditions

The unit should be run in ambient temperatures of 0-40 deg. The unit

includes sophisticated electronic devices - do not fill the Ecocent with water

from a lake, river water or groundwater and be sure to put an inline strainer

(open vented) and scale inhibitor in the cold water feed - failure to do so

will invalidate the warranty/guarantee.

Page 22

22 of 42

V 1.9

www.esavep.com PASHW-003-100LD

9.0 PHYSICAL INSTALLATION

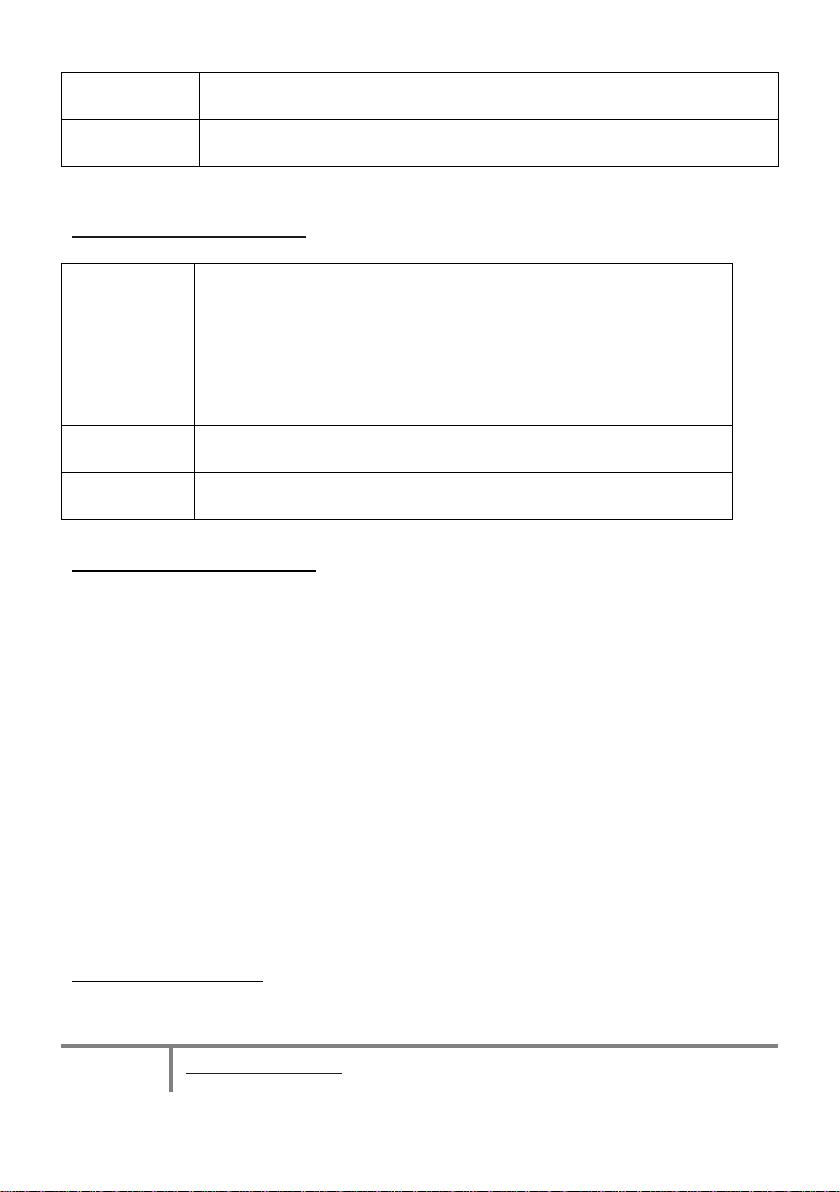

9.1 Schematic Diagram

9.2 Pipe Fittings

Air ducts must be at least 150mm in internal diameter. It is recommended

that you use insulated ducting on both inlet and outlet ducts.

9.3 Cold Water Supply

Because water composition can vary greatly, it is not ESP’s policy to issue

recommendations relating to water treatment. The user or the owner is

responsible for contacting a specialised water treatment company to obtain

water treatment advice appropriate to your location. Appropriate water

treatment processes/devices must be fitted to ensure the longevity of the

unit and its proper operation.

Page 23

23 of 42

V 1.9

www.esavep.com PASHW-003-100LD

A 22mm cold water supply is recommended, however, if a 15mm (1/2”)

supply exists which provides sufficient flow it may be used. More flow noise

may be experienced from small bore pipes due to the increased water

velocity through them.

The Cold Water should be fitted with a full flow isolation valve which will

enable the unit to be isolated from the mains supply for maintenance or

servicing.

An inline filter (open vented) and an effective scale prevention device should

be fitted.

9.4 G3 Requirement

G3 (ENGLAND AND WALES), TECHNICAL STANDARD P3 (SCOTLAND) OR BUILDING

REGULATION P5 (NORTHERN IRELAND) AND THE WATER FITTING REGULATIONS

(ENGLAND AND WALES) OR WATER BYELAWS (SCOTLAND).

There shall be precautions to ensure that the hot water discharged from

safety devices is safely conveyed to where it is visible but will not cause

danger to persons in or about the building.

9.5 G3 Guidance

The installation should include the discharge pipe(s) (D1) from the safety

device(s). In either case the tundish should be vertical, located in the same

space as the unvented hot water storage system and be fitted as close as

possible and within 500mm of the safety device(s) e.g. the TPRV.

The discharge pipe (D2) from the tundish should terminate in a safe place

where there is no risk to persons in the vicinity of the discharge, and be of

metal

a) be at least one pipe size larger than the nominal outlet size of the

safety de- vice unless its total equivalent hydraulic resistance exceeds

that of a straight pipe 9m long i.e. discharge pipes between 9m and

18m equivalent resistance length should be at least two sizes larger

Page 24

24 of 42

V 1.9

www.esavep.com PASHW-003-100LD

than the nominal outlet size of the safety device, between 18 and

27m at least 3 sizes larger, and so on. Bends must be taken into

account in calculating the flow resistance. Refer to Diagram 7 and

Table 1 below. An alternative approach for sizing discharge pipes

would be to follow BS6700:1987 Specification for design,

installation, testing and maintenance of services supplying water for

domestic use within buildings and their curtilages, Appendix E,

section E2 and table 21.

b) have a vertical section of pipe at least 300mm long below the

tundish before any elbows or bends in the pipe work.

c) be installed with a continuous fall, and in a frost free environment.

d) have discharges visible at both the tundish and the final point of

discharge, but where this is not possible or is practically difficult

there should be clear visibility at one or other of these locations.

Page 25

25 of 42

V 1.9

www.esavep.com PASHW-003-100LD

Examples of acceptable discharge arrangements are:

i. ideally below a fixed grating and above the water seal in a trapped

gully.

ii. downward discharges at low level; i.e. up to 100mm above

external surfaces such as car parks, hard standings, grassed areas etc.

are acceptable providing that where children may play or otherwise

come into contact with discharges a wire cage or similar guard is

positioned to prevent contact, whilst maintaining visibility.

iii. discharges at high level; e.g. into a metal hopper and metal down

pipe with the end of the discharge pipe clearly visible (tundish

visible or not) or onto a roof capable of withstanding high

temperature discharges of water and 3m from any plastic guttering

system that would collect such discharges (tundish visible).

Page 26

26 of 42

V 1.9

www.esavep.com PASHW-003-100LD

iv. where a single pipe serves a number of discharges, such as in

blocks of flats, the number served should be limited to not more than

6 systems so that any installation discharging can be traced

reasonably easily. The single common discharge pipe should be at

least one pipe size larger than the largest individual discharge pipe

(D2) to be connected. If unvented hot water storage systems are

installed where discharges from safety devices may not be apparent

i.e. in dwellings occupied by blind, infirm or disabled people,

consideration should be given to the installation of an electronically

operated device to warn when discharge takes place.

10.0 MOVING THE UNIT

10.1 Storage and Transportation

Generally, it's better to use a container to transport hot water heat pumps

and store them in a suitable and dry place.

10.3 Using a Forklift

When using forklift to carry the unit it must be on a pallet and the operator

should try to keep the height of forklift at the lowest possible level because

unit is top-heavy.

10.3 Transportation for Installation

The unit must be kept at vertical for at least 1 hour before you attempt to

start it.

DO NOT TURN UPSIDE DOWN

Page 27

27 of 42

V 1.9

www.esavep.com PASHW-003-100LD

11.0 Hydraulic Connection

Handle

Drainage Pipe

Please bear the following points in mind when connecting the water pipes:

The inner surface of all pipes should be clean, with no oxidization or

dirt to restrict flow. After connecting pipes, please check the whole

system for leaks before applying insulation.

Install one-way valves and safety valves in the distribution system.

All pipework must be installed in accordance with DIN1988. To avoid

too high a water pressure, please install a discharge valve.

Ensure that debris does not enter the distribution pipework during

installation.

The drain valve should be operated periodically (using the handle) to

ensure that it does not jam and is free of sediment. Care should be

taken as the discharge water will be hot. The drainage pipe should be

well insulated and checked periodically to minimise the risk of blockage.

Blockage could lead to a system failure.

Page 28

28 of 42

V 1.9

www.esavep.com PASHW-003-100LD

11.1 Installation Diagram

Accessories provided: safety release valve.

ATTENTION !

After installing the pipework in accordance with the above diagram, open the closest

hot water tap and stop valve to fill the vessel. This will purge the system of air and the

process can take up to 20mins. When no more air escapes from the hot water tap, the

tap can be turned-off and the system should have been fully purged.

Page 29

29 of 42

V 1.9

www.esavep.com PASHW-003-100LD

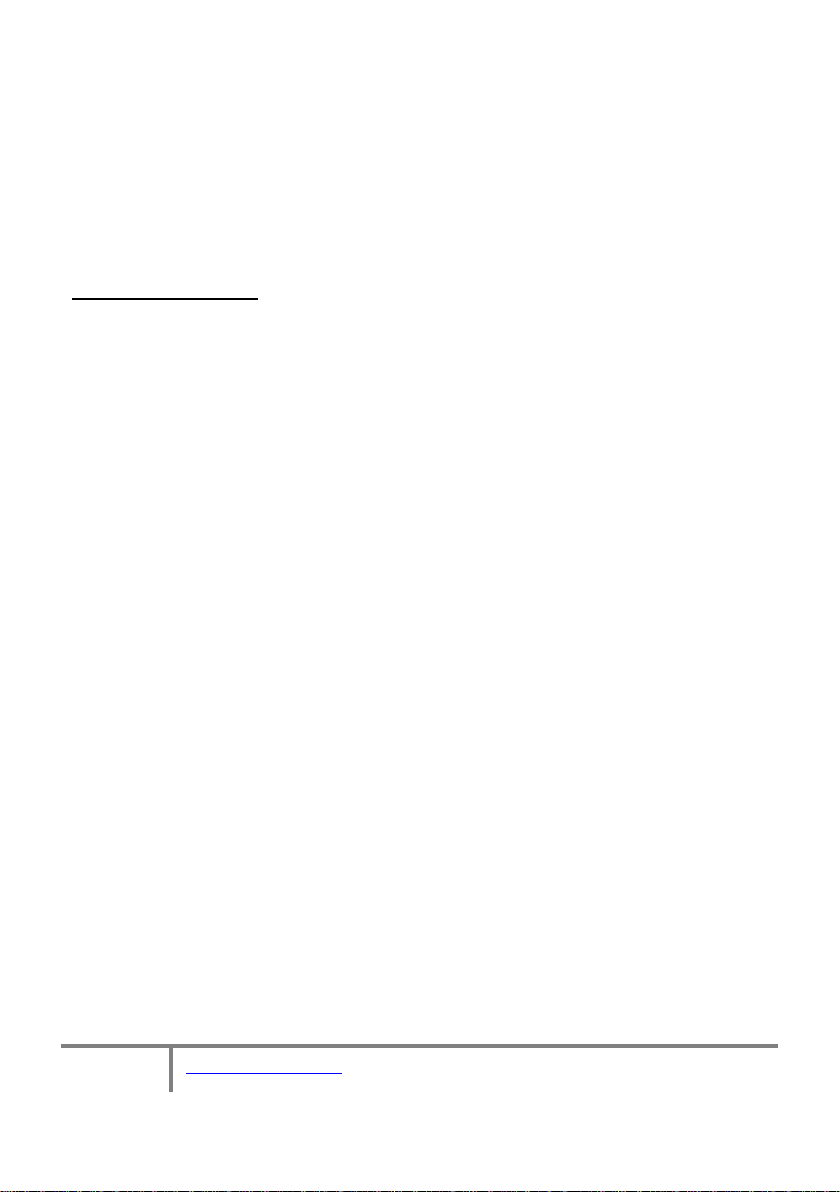

12.0 WIRING

Diagram 14

12.1 Wiring Diagram

All electrical wiring MUST be carried out by a qualified electrician and

conform to the latest I.E.E. Wiring Regulations. The wiring block diagram is

set out below in diagram 14.

Great care should be taken to ensure that the unit is properly wired to the

mains electricity and any auxiliary components. The mains wire connection

will be found towards the top of the unit. The power supply MUST be a fused

switched spur.

12.2 Earthing

The unit MUST be earthed and a facility is provided for this in the design. The

unit MUST be installed by qualified engineers and electricians. ESP will not

accept responsibility for units that are not fitted by appropriately qualified

Page 30

30 of 42

V 1.9

www.esavep.com PASHW-003-100LD

installers. Failure to have the unit fitted by a suitably qualified installer will

invalidate the warranty/guarantee of the unit.

13.0 OPERATING THE UNIT

Control Panel

Power On

When the unit is powered on, the unit will either be in stand-by or running

depending upon the state when it was turned-off. When the unit is in standby mode, the red light is off.

Viewing Modes

Repeatedly pressing the Mode Button will allow you to toggle between

different energy modes.

Page 31

31 of 42

V 1.9

www.esavep.com PASHW-003-100LD

Red and yellow

lights Illuminated

Green and Red

lights Illuminated

Two Red lights

illuminated

The three different modes operate as following:

1 Standard mode: When the ‘running’ and the ‘hybrid’ lights are

illuminated, the unit is in the standard mode. This is the recommended mode

and should be suitable year-round.

2 Energy saving mode: When the ‘running’ and the ‘economic’ lights are

illuminated, the unit is in energy saving mode. In this mode, water is being

heated by the heat pump alone. This setting is suitable when the ambient air

temperature is above 10°C.

3 Rapid heating mode: When the ‘running’ and the ‘H Demand’ lights are

illuminated, the unit is in high demand mode. In this mode, both the heat

pump and the 1kW immersion heater are used. This mode is suitable for

urgent hot water needs only.

Page 32

32 of 42

V 1.9

www.esavep.com PASHW-003-100LD

Green Light

Illuminated

Green and Red lights

illuminated

Modes can be selected according to the actual demand but it is strongly

suggested that standard mode is used the majority of the time.

Power on/Power off

is the power switch. When the unit is operating, the indicator light is

illuminated.

Parameter setting

Power on and press " " to rise the set point (the target water

temperature), press the " " to decrease the set point. The factory setting

for the water temperature is 55°C and you are advised not to change it.

Page 33

33 of 42

V 1.9

www.esavep.com PASHW-003-100LD

Set point automatic regulation

The default setting is automatic mode during which the unit will change the

set point to follow the ambient air temperature automatically to account for

seasonal variations. Decreasing the set point can save energy in summer and

the set point will rise automatically in winter. The set point can also be

changed manually. Use the up or down arrow keys to set the hot water

temperature. The automatic mode is disabled by changing the set point

manually. Press the mode key for 10 seconds will re-enable automatic mode.

The unit is pre-set to the recommended setting for all parameters. Should

you wish to change these settings, you would be advised to discuss your

decision with the ESP technical team. The default settings are as follows:

Page 34

34 of 42

V 1.9

www.esavep.com PASHW-003-100LD

Function Parameter Default

Target set point

0 55

℃

Return temperature difference

1 5

℃

Set point for elec. Heater

2 55

℃

If temp is not reached within this time, elec heater will boost.

3 40

Target temp. for weekly sterlilization

4 60

℃

Time for sterilization

5 0min

Defrosting time

6 45min

Evaporator Trigger Temp. For defrost cycle

7

-3

℃

Trigger temp to end defrost cycle.

8 13

℃

Defrost cycle period.

9 8min

Adjustment for the elec. Expansion valve

10

1

Target degree of superheat

11

5

℃

Steps of elec. Expansion valve

12

35

Use elec. Heater instead of compressor

13

0

Temp. to use elec. Heater instead of compressor

14 5

℃

Energy saving defrosting

15

0

Min. time for energy saving defrosting

16 3min

Power off memory

17

1

Time to start sterilization (Midnight)

18 Oh

Days to start sterilization (Weekly)

19 7d

Temperature compensation

20

0

Ambient temp. to start temperature compensation

21 15

℃

Max. error for temperature compensation

22 5

℃

Coefficient for temperature compensation

23 0.8

℃

Notes:

Engineer Only Setting

Page 35

35 of 42

V 1.9

www.esavep.com PASHW-003-100LD

Fault

Display

Code

Reason

So lut io n

Turn on

Ru nning

Bot tom sens or failur e

P 01

The sensor is open or short circuit

Chec k and rep lace the botto m temp. sens or

Upp er s ens or f ailur e

P 02

The sensor is open or short circuit

Ch eck and rep la ce the u pp er te mp. se ns or

Co il s ens or f ai lur e

P 03

The sensor is open or short circuit

Ch eck and rep la ce the co il

tem p. sens or

Suc ti on s ensor fai lur e

P 04

The sensor is open or short circuit

Che ck and r epl ace the suctio n t emp .sen sor

Ambient s ens or f ail ur e

P 05

The sensor is open or short circuit

Ch ec k and r ep la ce the a mbi ent t em p. se nso r

High pr essure prot ection

E 01

The high pressure is over 21bar or

pressure switch is open.

Ch eck co nne cti on and r efr ige ran t

sy ste m.

Low pre ss ure pro tec tio n

E 02

The low pressure switch is open.

Ch eck co nne cti on and r efr ige ran t

sy ste m.

Therm al pr otect ion

E 03

Water temperature is more than

85°C.

Ch eck if the vessel is full.

Com mun icat ion failure

E 08

Communication cable is disconnected or

there is strong interference near the unit.

Ch eck the c onn ect io n of th e pc b.

Defrosting

Flash

14.0 TROUBLESHOOTING

15.0 MAINTENANCE REQUIREMENTS

15.1 The Cylinder

To ensure the continued optimum performance of the Ecocent, it should be

regularly maintained. This is of particular importance in hard water areas or

where the water supply contains particulate matter. Maintenance should be

carried out by a suitably qualified plumber/engineer and any replacement

parts used must only be ESP recommended spare parts. It is recommended

that maintenance is carried out every 12 months on the cylinder and includes

the checks detailed in this manual. If you are in a hard water area, you

should check the magnesium sacrificial anode deterioration within 6 months

of commissioning of the unit and annually 12 months after. You will be able

to see the rate at which deterioration is happening and set a date for a full

inspection when it is clear that a new magnesium anode is likely to be

needed. Keeping a functioning magnesium anode is critical to the longevity

of the unit. If you run the unit without the anode you will invalidate the

Page 36

36 of 42

V 1.9

www.esavep.com PASHW-003-100LD

warranty/guarantee and the stainless steel cylinder may be seriously

damaged.

In hard water areas consideration should be given to periodically descaling

the immersion heater elements. To do this the unit will need to be drained;

Paragraphs 16.4 to and 16.6 below detail how to drain the unit and remove

the immersion heater(s).

Please check the condition on the magnesium anode during any

servicing/maintenance and fit a new anode, if required.

15.2 Safety Valves

Slowly open the Temperature and Pressure Relief Valve by twisting its cap

for a few seconds. Check that water is discharged and that it flows freely

through the tundish and discharge pipework. Check valve reseats correctly

when released.

NOTE : The water discharged may be very hot.

Repeat the procedure for the Expansion Relief Valve (located on the Cold

Water Combination Valve or Expansion Valve Core Unit).

15.3 The Strainer

The in line strainer must be cleaned periodically by a suitably qualified

engineer. The in-line strainer can be found inside the cold water combination

group valve on unvented systems or alternatively a Y strainer on open vented

systems. The engineer should:

i) Wash any particulate matter from the inline strainer under clean

running water.

ii) Refit the inline strainer once totally clean or install a new one

where necessary.

Page 37

37 of 42

V 1.9

www.esavep.com PASHW-003-100LD

15.4 Draining the Unit

Switch off the electrical supply to the unit. Turn off the mains water supply

to the unit. Attach a hosepipe to the drain cock having sufficient length to

take waste water to a suitable discharge point below the level of the unit, at

least one metre below the unit is recommended. Open the hot water tap

nearest to the unit to relieve the system pressure. Open the drain cock. If

water fails to drain from the unit, vent it by manually opening the

Temperature/ Pressure Relief Valve or “crack a joint” in the unit plumbing to

prevent the creation of a vacuum that may prevent effective draining.

15.5 Descaling the Immersion Heater

Once the unit has been drained and the power supply disconnected, open the

cover to the immersion heater housing and disconnect wiring from

immersion heater. Remove the thermostat by carefully pulling it outwards

from the immersion heater. Unscrew t h e immersion heater back nut and

remove the immersion heater from the unit. Over time the immersion

heater gasket may become stuck to the mating surface. To break the seal

insert a round bladed screwdriver into one of the pockets on the immersion

heater and gently lever up and down.

Carefully remove any scale from the surface of the element. DO NOT use a

sharp implement as damage to the element surface could be caused. Ensure

that all sealing surfaces are clean and that the seals are undamaged; if in

doubt fit a new gasket.

Replace immersion heater ensuring that the lower (right angled) element

hangs vertically downwards towards the base of the unit. It may be helpful to

support the immersion heater using a round bladed screwdriver inserted

into one of the thermostat pockets whilst the back nut is tightened. Replace

the thermostat(s) by carefully plugging the two male spade terminations on

the underside of the thermostat head into the corresponding terminations

on the element.

Rewire the immersion heater. Close and secure terminal cover.

Page 38

38 of 42

V 1.9

www.esavep.com PASHW-003-100LD

15.6 Refilling the System

DO NOT switch on the immersion heater or heat pump part until the

system has been completely refilled. Close the unit drain tap. With the hot

tap open, turn on the mains water supply. When water flows from the hot

tap allow time to purge all th e air and to flush through any disturbed

particles. Turn off the hot tap and then open successive hot taps in system

to purge any air. The electrical supply can now be switched on.

15.7 Log Book

Please complete the log book supplied with the Ecocent, stating what has

been done, the date of the service and the name/contact details of the

servicing engineer.

15.8 Maintenance Requirements

There are no formal annual maintenance requirements. However, it is

advisable to check annually that:

a) The pressure and temperature relief valve is still functioning properly

by turning the plastic black cap around to make sure that water

comes out of the valve when the black cap is turned.

b) All filters are clear of debris.

c) The air outlet to outside to make sure that it is clear from foliage,

nests, etc. and that the gravity vent is working.

Please note that the top can be removed (by a suitably qualified engineer/

plumber) so that the evaporator can be cleaned of dust and any debris.

Page 39

39 of 42

V 1.9

www.esavep.com PASHW-003-100LD

16.0 FAULT FINDING

Fault Possible Causes Remedy

1) Mains cold water supply shut

Check and open isolation

No hotwater flow

2) Line strainer blocked

Turn off mains water

supply, remove and clean

inline strainer

or reduced flow rate

3) Cold water combination

valve fitted incorrectly

Check direction flow arrows

on valve and correc in

4) Size of service pipe too small

Upgrade service pipe to

correct size

5) Low mains water pressure

Check water pressure.

Consult with local water

authority if necessary

1) Unit is turned off Ensure unit us turned on.

2) Unit is in holiday mode

Reset programmer to

standard running parameter

Water from hot taps is

cold

3) Check for error codes on

Ecocent controller

Refer to manual error code

sheet

4) Parameter zero set to low

Reset parameter zero with

up arrow to a max of 60°C

5) All hot water has been

exhausted

Turn on immersion heater

manually to boost recovery

time

1) Pressure above 7bar. Failure

of pressure reducing set

Replace cold water

combination group set

Discharge from TPRV

2) Temperature above 90-95°C

thermal probe activated

Ascertain reason for high

temp and replace TPRV

3) Water dripping from TPRV,

Expansion vessel failure or

discharged

Recharge expansion vessel

or replace

Discharge from cold

1) Pressure above 6bar. Failure

of pressure reducing set

Replace cold water

combination group set

water combination

group set (CWCGS)

2) Water dripping from CWCGS

safety valve, Expansion vessel

failure or discharged

Recharge expansion vessel

or replace

Cloudiness in water

In some areas a cloudiness may

be noticed in the hot water.

This is due to aeration of

the water, is quite normal

and will quickly clear.

The following table lists simple faults and actions that can be attempted to

clear the fault. Please ensure that a suitably qualified and experienced

engineer/plumber makes any diagnoses and carries out any testing and

repair.

Page 40

40 of 42

V 1.9

www.esavep.com PASHW-003-100LD

17.0 GUARANTEE

Should any factory fitted Temperature and/or Pressure Relief Valve(s) or

other safety device be tampered with or removed, or any recommended

Temperature or Pressure Relief Valves/safety device be omitted, your

warranty/guarantee will be invalidated. ESP will not take responsibility for

any damage resulting from the tampering, howsoever caused, save where

such exclusion is unlawful.

17.1 Guarantee Terms

ESP warrants/guarantees the electrical parts, thermal controls and valves

relating to the cylinder for a period of one year from the date of purchase,

with the exception of normal wear-and-tear including any damage caused as

a result of lime scale deposits.

The stainless steel vessel forming part of the cylinder is warranted/

guaranteed for a period of five years against faulty manufacture or materials

provided that:

i) It has been properly installed by a qualified installer as per the

instructions and recommendations contained in this manual and all

relevant Codes of Practice and Regulations in force at the time of

installation.

ii) Any disinfection has been carried out in accordance with BS 6700.

iii) It has not been modified in any way other than by ESP.

iv) It has only been used for the storage of wholesome water.

v) It has not been installed in a location liable to be subjected to

frost, nor has it been tampered with or been subjected to misuse or

neglect.

Page 41

41 of 42

V 1.9

www.esavep.com PASHW-003-100LD

vi) No factory fitted parts have been removed for unauthorised repair

or replacement.

vii) Within 45 days of purchase the user completes and returns the

certificate supplied to register the product.

The compressor in the heat pump is warranted/guaranteed for 2 years

from the date of purchase. Remaining parts of the heat pump are

warranted/ guaranteed for 1 year from the date of purchase.

Evidence of purchase and date of supply must be submitted with any

warranty/guarantee claim.

This warranty/guarantee is not valid for installations outside the United

Kingdom or the Republic of Ireland.

Any warranty/guarantee is for replacement parts only.

The purchaser of the unit acknowledges that he/she has seen ESP’s

conditions of supply and has understood them.

All of our units are RoHS approved units.

This guarantee does not affect your statutory rights.

18.0 ENVIRONMENTAL INFORMATION

This product is made from many recyclable materials, therefore at the end of

its useful life, it should be disposed of at a Local Authority Recycling Centre

in order to realise the full environmental benefits.

Please note:

The pace of product development is such that we reserve the right to

change product specifications without notice. We do, however, strive to

ensure that all information in this leaflet is accurate at the time of

publication.

Page 42

42 of 42

V 1.9

www.esavep.com PASHW-003-100LD

19.0 SPARE PARTS

Earth Save Products Limited carries spare parts for all the units that it

supplies. We strive to ensure that spare parts are readily available at

competitive prices. Please call on 00 44 (0)1865 40 77 69 us should you need

any spare parts and we will be pleased to give you a quotation.

Loading...

Loading...