Page 1

©ESP Ltd. Sept 2008

Operation &Installation

Manual

The ESP Ecocent

Model:

ESP 400-200Ltr

ESP 400-250Ltr

ESP 400-300Ltr

Please keep this manual safely and read

it carefully before installation or operation

Page 2

2 ©ESP Ltd. Sept 2008

Contents

Warning!!!!

READ THIS BEFORE INSTALLING THE

UNIT.

All un-vented water heating systems above 15 litre (this includes the ESP Hot Water ASHP‟s) MUST be installed to

meet the requirements of the Building Regulations. It is a

legal requirement that the local Building Control Officer be

notified of any proposed installation of un-vented water

heating systems over 15 litre capacity.

Furthermore, it must be fitted by an installer who has successfully completed a recognised course in the installation

of un-vented heating systems such as CITB. Failure to properly fit the unit may affect its efficiency and invalidate any

guarantee.

Safety requirements in the UK call for an expansion space

(internal or external), safety devices to prevent the stored

water exceeding 100°C, and pipework to convey discharged

hot water safely away from the safety devices.

Preface………………………………………………………………..3

General Requirements………………………………………………..4

Specs…………………………………………………………………6

Function Presentation………………………………………………..8

Installation…………………………………………………………...9

Commissioning……………………………………………………...18

Maintenance…………………………………………………………19

User Instructions…………………………………………………….22

Safety Precautions…………………………………………………...24

Guarantee……………………………………………………………26

Spare Parts…………………………………………………………...27

Appendix 1…………………………………………………………..27

Appendix 2…………………………………………………………..36

Page 3

3 ©ESP Ltd. Sept 2008

Preface Hot water air source heat pump

PLEASE NOTE FOR TRANSPORT AND STORAGE!!!:

Storage

The unit must be stored and/or transported in its shipping container in an

upright position and kept dry. For transport over short distance, and provided

due care is exercised, an inclination angle of up to 60 degree is permitted.

Both during transport and storage, ambient temperatures of - 20 to +70 are

the limits.

Transport using a forklift

When transporting by fork lift, the unit must remain mounted on the pallet.

The lifting height should be kept to a minimum. Due to its top-heaviness, the

unit must be secured against tipping over. To prevent any damage, the unit

must be placed on a level surface!

Manual transportation

For the moving the unit by hand, the wooden pallet can be used for bottom

lifting. Using ropes or carrying straps is permissible with great care being

taken not to damage the unit.

With all manual handling, care must be taken that the max. permissible inclination angle of 60 degree is not exceeded. If transport in an inclined position

cannot be avoided, the unit MUST be left upright for at least 90 mins. in the

planned installation position before being installed. Failure to do this may

cause serious damage to the unit during and following installation.

This manual includes the necessary information about installation, and

maintenance of the Ecocent. Please read this manual carefully before

you install or carry out maintenance on the unit.

When installing the unit , please carry it out strictly according to the man-

ual.

Please do not switch the unit on until you are sure that it has been properly installed.

The installer should explain to the end user how to operate and maintain

the unit before handing over the unit to the end user. Also, the installer

should advise the end user to read the manual fully before operating the

unit.

The supplier and/or manufacturer of the unit will not be responsible if

someone is injured or the unit is damaged, as a result of installation, operation and/or maintenance that is not in line with this manual. Further,

improper installation, operation and/or maintenance, and failure to maintain the unit as per this manual will invalidate any unit warranty or guarantee.

The manual may be altered and/or updated in any way at the sole discretion of the supplier and/or ESP without notice.

Page 4

4 ©ESP Ltd. Sept 2008

1. General Requirements

IMPORTANT : PLEASE READ AND UNDERSTAND THESE INSTRUCTIONS BEFORE INSTALLING THE ESP Ecocent (“DHW ASHP” or “unit”).

INCORRECT INSTALLATION WILL INVALIDATE ANY GUARANTEE.

THIS UNIT IS NOT INTENDED FOR USE BY PERSONS (INCLUDING

CHILDREN) WITH REDUCED PHYSICAL, SENSORY OR MENTAL CAPABILITIES, OR LACK OF KNOWLEDGE AND EXPERIENCE, UNLESS

THEY HAVE BEEN GIVEN SUPERVISION OR INSTRUCTION CONCERNING THE USE OF THE UNIT BY A PERSON RESPONSIBLE FOR

THEIR SAFETY.

THE UNIT MUST BE INSTALLED, COMMISSIONED AND MAINTAINED BY A COMPETENT INSTALLER IN ACCORDANCE WITH

BUILDING REGULATION G3 (ENGLAND AND WALES), TECHNICAL STANDARD P3 (SCOTLAND) OR BUILDING REGULATION P5

(NORTHERN IRELAND) AND THE WATER FITTING REGULATIONS (ENGLAND AND WALES) OR WATER BYELAWS

(SCOTLAND). FOLLOWING INSTALLATION AND COMMISSIONING, THE OPERATION OF THE UNIT SHOULD BE EXPLAINED TO

THE USER AND THESE INSTRUCTIONS LEFT WITH THEM FOR

FUTURE REFERENCE.

PLEASE NOTE THAT THERE ARE ESSENTIALLY 2 UNITS COMBINED

INTO ONE IN THE ESP DHW ASHP AND YOU MUST BE SURE TO UNDERSTAND BOTH ELEMENTS—THE INDIRECT PRESSURIZED CYLINDER AND THE AIR SOURCE HEAT PUMP.

1.1 COMPONENT CHECK LIST

Before commencing installation check that all the components for your unit

are contained in the package. The following components are supplied as standard with the unit :

• Factory fitted immersion heater (s) and thermal controls

• Cold Water Combination Valve (comprises Pressure Reducing Valve,

Strainer, and Check Valve)

• Expansion Core Unit (comprises Check Valve and Expansion Valve)

• Temperature/Pressure Relief Valve (set at 90 - 95°C/1 Mpa (7bar))

• Tundish (included in Cold Water Combination Valve pack)

• Factory fitted Indirect Thermostat and Thermal Cut-out

Further detail is provided on the above at Appendix 1 and you should make

sure that you read the Appendix thoroughly before undertaking any installation or other work on the unit.

1.2 SITING THE UNIT

The unit must be vertically floor mounted. It can be placed anywhere convenient provided the discharge pipe(s) from its safety valves can be correctly

installed. Areas that are subject to freezing must be avoided. Ensure that the

floor is of sufficient strength to support the weight of the unit when full with

water. Pipe run lengths should be kept as short as possible for maximum

economy and efficiency. Access to associated controls, immersion heaters

and indirect controls must be possible for servicing and maintenance of the

unit. Please do not install valves or pipework (except discharge pipe) within

50mm (2”) of the T&P relief valve to allow insulation to be fitted. The insu-

lation is important to ensure heat and energy conservation.

IMPORTANT NOTE: DO NOT SITE THE UNIT IN THE SAME ROOM

AS AN OPEN FLUED APPLIANCE OR A ROOM WHERE AN OPEN

FLUED APPLIANCE TAKES ITS COMBUSTION AIR FROM UNLESS

THE MATTER HAS BEEN CAREFULLY CONSIDERED AND ADEQUATE DUCTING AND VENTILATION HAS BEEN PROVIDED FOR

THE UNIT (THE DHW ASHP).

.

1. General Requirements

Hot water air source heat pump Hot water air source heat pump

Page 5

5 ©ESP Ltd. Sept 2008

Please be sure to use appropriate lifting equipment when moving the unit.

1.3 WATER SUPPLY

Bare in mind that the mains water supply to the property will be supplying both

the hot and cold water requirements simultaneously. Therefore, it is important

that the maximum water demand be assessed and the water supply checked to

ensure this demand can be met.

NOTE: A high mains water pressure will not always guarantee high flow rates.

Wherever possible the main supply pipe to the unit should be in 22mm. The

minimum mains water supply requirements should be 0.15 MPa (1.5 bar)

working pressure and 20 litres per minute flow-rate. At these values outlet flow

-rates may be poor if several outlets are used simultaneously, the higher the

available pressure and flow-rate the better the system performance will be.

The unit has a design operating pressure of 3 bar which is controlled by the

Cold Water Combination Valve. The Cold Water Combination Valve can be

connected to a maximum mains supply pressure of 1.6 MPa (16 bar). The water

supply must be of wholesome water quality (Fluid Category 1 as defined by the

Water Supply Regulations 1999).

The unit MUST be sited on a level surface, otherwise this could cause problems with condensate draining from the heat pump section of the unit in to the

condensate drain.

An inline strainer and scale inhibitor (WRAS approved) must be fitted “in line”

on the water supply to the unit. Failure to fit these will invalidate the unit warranty/guarantee. All fittings must be WRAS approved.

1.General Requirements

Hot water air source heat pump Hot water air source heat pump

1.General Requirements

1.4 OUTLET/TERMINAL FITTINGS (TAPS, ETC.)

The unit can be used in conjunction with most types of terminal fittings. It is

helpful in many mixer showers to have balanced hot and cold water supplies;

in these instances the balanced cold water supply should be tee‟d off the sup-

ply to the unit immediately after the Cold Water Combination Valve (see Figures 4 and 5). Branches to cold drinking water outlets should be taken before

the valve.

NOTE: Accessories should have a rated operating pressure of at least 0.8 MPa (8 bar).

1.5 LIMITATIONS

The unit should not be used in any of the following instances:

Solid fuel boilers or any other boiler in which the energy input is not under

effective thermostatic control, unless additional and appropriate safety

measures are installed.

Gravity circulation primaries.

Steam heating plant unless additional and appropriate safety devices are

installed.

Ascending spray type bidets or any other Class 5 back syphonage risk re-

quiring that a appropriate air gap be employed.

Water supplies that have either inadequate pressure or where the supply

may be intermittent.

Situations where it is not possible to safely pipe away any discharge from

the safety valves.

Areas where the water contains a high proportion of solids, eg. suspended

matter that could block the strainer, unless adequate filtration can be ensured.

Where another appliance in the room is vented by way of an open flu.

The installation must be carried out in accordance with the relevant re-

quirements of:

Page 6

6 ©ESP Ltd. Sept 2008

2.1 APPEARANCE

2.2 CHARACTERISTICS

Good looking and efficient

The attractive design allows the unit to be placed in the open in finished

utility spaces and basements; depending on ambient conditions, the cost

of operation can be 25% of that of an electric water heater, and can be

used in locations unsuitable for solar hot water heating.

Environmentally friendly and safer

Produces no harmful emissions locally; there is no combustion of oil,

coal, or natural gas. No carbon monoxide is produced and there is no

open flame.

Easy to operate and multiple heat sources

Contains a timer for start and stop and an adjustment dial for easy setting

of the water temperature; the unit can take heat from a number of sources

- the outside environment, from an attic space, or from hot areas in light

industrial environments.

2.Specs

A) The appropriate Building Regulations: either The Building Regula-

tion (England), The Building Regulations (Scotland) or Building

Regulations (Northern Ireland).

B) The Water Fittings Regulations (England and Wales) or Water Bye

laws (Scotland).

C) Any other applicable Regulations.

Failure to observe any of the above conditions will invalidate the warranty/gurantee.

1.6 HOT WATER AIR SOURCE HEAT PUMP PACKAGE

The unit will be supplied with the fittings detailed in section 1.1 above.

Hot water air source heat pump

1.General Requirements

Hot water air source heat pump

Page 7

7 ©ESP Ltd. Sept 2008

2.3 DIMENSIONS

ESP 400 SERIES—150L/200L/250L/300LD

Unit/mm

2.4 PERFORMANCE PARAMETER

Measuring conditions

Instant heating: Ambient temperature 20/19,Water outlet 55°C

Operating range

(1).Ambient temperature range is 0-40°C

(2). The max water temperature is 60°C

2. Specs

2. Specs

Hot water air source heat pump

Hot water air source heat pump

Please note - Stabbings may vary by model.

Model

ESP400 010-150L(D) 010-200L(D) 010-250L(D) 010-300L(D)

Heating capacity

kW 2.6 2.6 2.6 2.6

Water tank capacity

L 150 200 250 300

Power input

W 810 810 810 810

Running current

A 3.7 3.7 3.7 3.7

Power supply

V/PH/ 220/1/50 220/1/50 220/1/50 220/1/50

Compressor Number

1 1 1 1

Compressor

Rotary Rotary Rotary Rotary

Rated outlet water tempera-

°C 55 55 55 55

Max. outlet water tempera-

°C 60 60 60 60

Air volume

M³/h 450 450 450 450

Air pressure

Pa 60 60 60 60

Duct diameter

Mm Φ200 Φ200 Φ200 Φ200

Noise

dB(A) 49 49 49 49

Water inlet size/outlet size

Inch ¾" ¾" ¾" ¾"

Auxiliary electrical heating

kW 1.5 1.5 1.5 1.5

Net dimensions

mm φ470≠1830 φ560≠1700 φ560≠1950 φ640≠1750

Net weight

Kg 63 81 81 88

Shipping weight

kg 68 78 86 93

Page 8

8 ©ESP Ltd. Sept 2008

3.Function presentation

3.1 PLEASE NOTE:

Heating capacity

The unit absorbs energy from the air inlet location ambient conditions. If the

air inlet temperature is low, heating capacity will show variation from standard

conditions.

3 minutes protection

When the unit stops, if you restart the unit or turn on the manual switch, the

unit will not run for 3 minutes. This is built in protection for the compressor.

Heating mode running

If the ambient temperature is too high, to protect the unit, the fan motor will

stop running.

Defrosting

When in heating mode, the unit will defrost automatically. The fan motor will

stop running when the unit is defrosting.

Working condition

The unit should be run at ambient temperatures of 0-40 deg. The unit includes

sophisticated electronic devices - do not fill the heating system with water

from lake, river water or groundwater and be sure to put an inline strainer and

scale inhibitor in the cold water feed - failure to do so will invalidate the warranty/guarantee.

Power off

If the power supply is off, the unit will stop running. If operation is disturbed

by lightning, power grid fluctuations or similar, please turn the power supply

off manually and then power on again to reset.

3.Function presentation

Hot water air source heat pump

Hot water air source heat pump

Earthing

The unit MUST be earthed and facility is provided for this in the unit design

- be sure to have the unit properly earthed during installation. You must have

the unit fitted by a suitably qualified installer - we accept no responsibility for units that are not fitted by fully qualified installers. Also, failure

to have the unit fitted by a suitably qualified installer will invalidate the

warranty/guarantee of the unit.

Page 9

9 ©ESP Ltd. Sept 2008

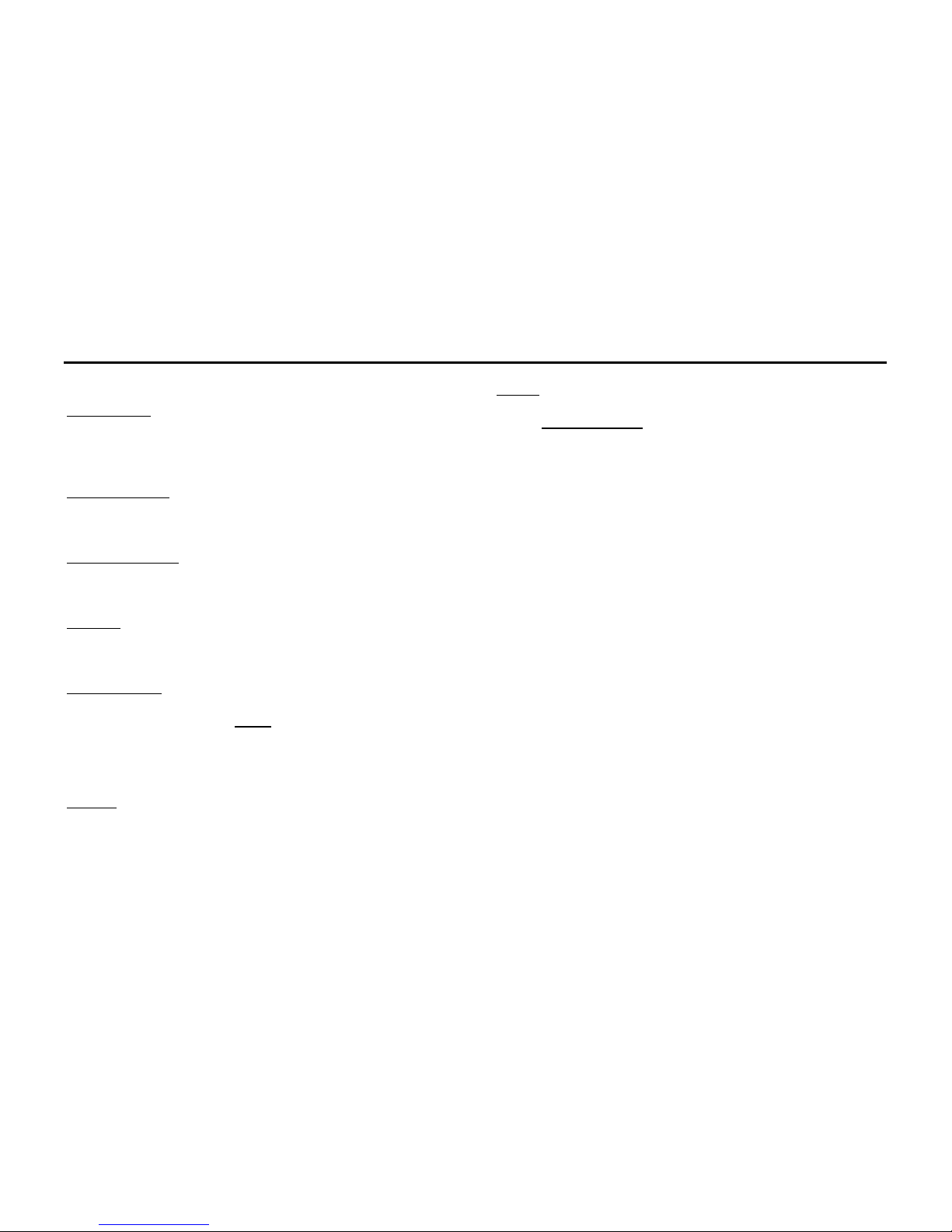

4.1 INSTALLATION DIAGRAM

Please note: Circulation of the hot water, solar and heat reclaims is optional.

Please contact Earth Save Products before using the primary coil.

ATTENTION

The one-way safety valve attached with the unit must be installed or it will

cause damage to the unit and can cause injury in certain circumstances.

Ensure that any damage to the unit caused prior to delivery is notified to the

Supplier within 5 days of delivery. Failure to notify the Supplier within this

time period will mean that any claims relating to damage will be rejected.

4.2 PIPE FITTINGS

All pipe connections to the unit are 22mm. The fittings are also threaded

3/4” BSP male should threaded pipe connections be required.

Air ducts must be at least in 6 inch rigid pipe.

4.3 COLD WATER SUPPLY

A 22mm cold water supply is recommended, however, if a 15mm (1/2”) sup-

ply exists which provides sufficient flow (see section 2.3) this may be used.

More flow noise may be experienced from small bore pipes due to the increased water velocity through them.

The Cold Water Combination Valve supplied with the unit incorporates a

full flow isolating valve which will enable the unit to be isolated from the

mains supply for maintenance or servicing. To close the valve the black handle should be turned so that it lies at 90°C to the direction of flow. To open

turn the handle so that it lies parallel to the direction of flow.

An inline filter and an effective scale prevention device must be fitted to the

cold feed.

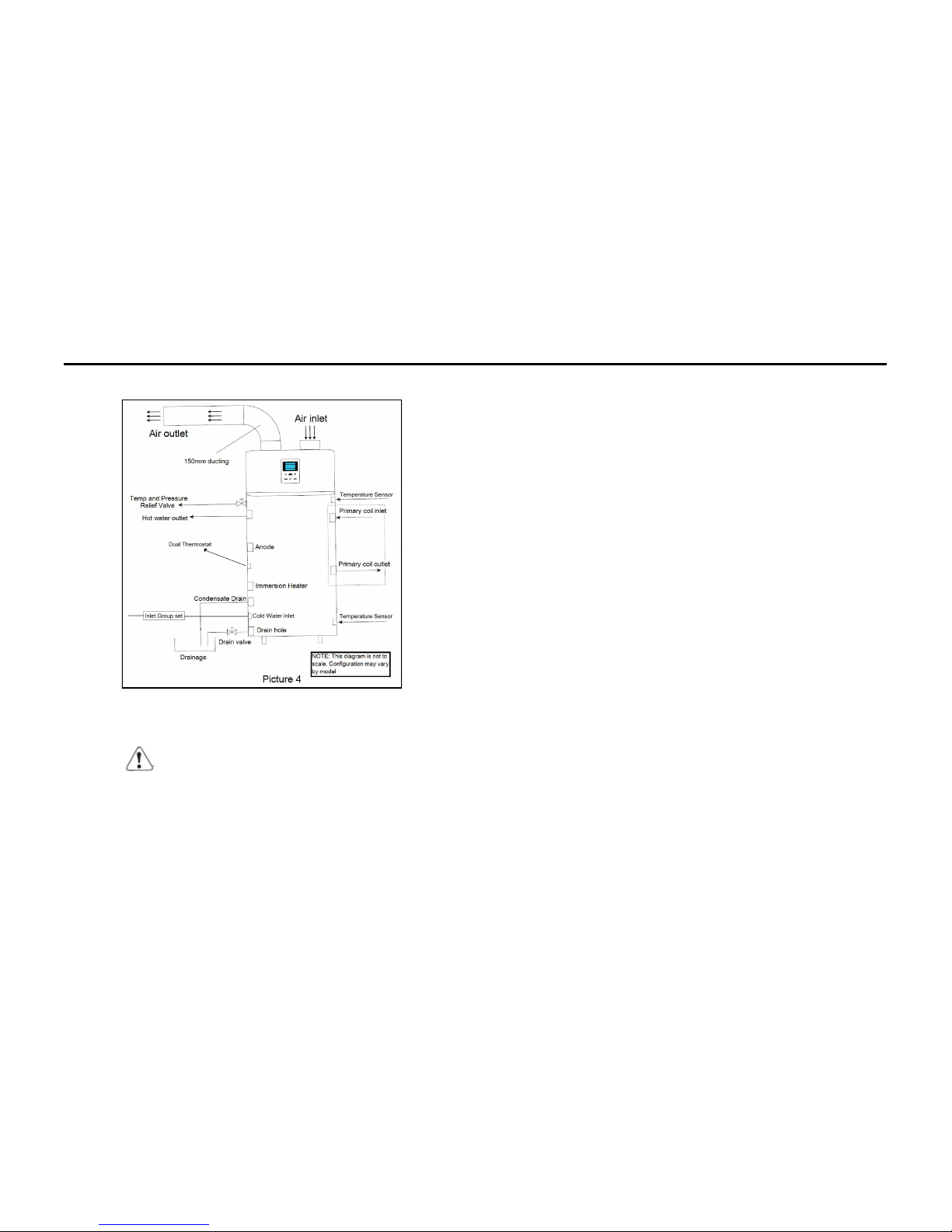

4.4 COLD WATER COMBINATION VALVE (see Figure 2)

The Cold Water Combination Valve must be sited close to the unit to allow

the safety discharge pipe to run in to the tundish, in line with appropriate

Regulations. The Expansion Valve connection must not be used for any

other purpose.

The Cold Water Combination Valve can be installed as a complete one-piece

unit. The valve incorporates a factory set, non-adjustable Pressure Reducer/

Strainer, an Expansion Valve connection and a single Check Valve. The

valve can be fitted in any orientation to suit the installation, however, ensure

that the Valve is installed with the direction of flow arrows (stamped on the

side of the brass body) pointing towards the unit.

4. Installation 4. Installation

Hot water air source heat pump

Hot water air source heat pump

Page 10

10 ©ESP Ltd. Sept 2008

4 . Installation 4 . Installation

Should you wish to site the Expansion Valve on the Cold Water Combination

Valve this can be done by unscrewing the connection nut beneath the Expansion Valve on the Expansion Core Unit and removing the Expansion Valve.

The connecting nut and blanking plug should then be unscrewed from the Cold

Water Combination Valve and replaced with the Expansion Valve. Note: if the

Expansion Valve is fitted to the Cold Water Combination Valve the Expansion

Core Unit should not be used as the Check Valve within it will prevent free

passage of expanded water to the Expansion Valve. Ensure the discharge from

the Expansion Valve can be correctly installed.

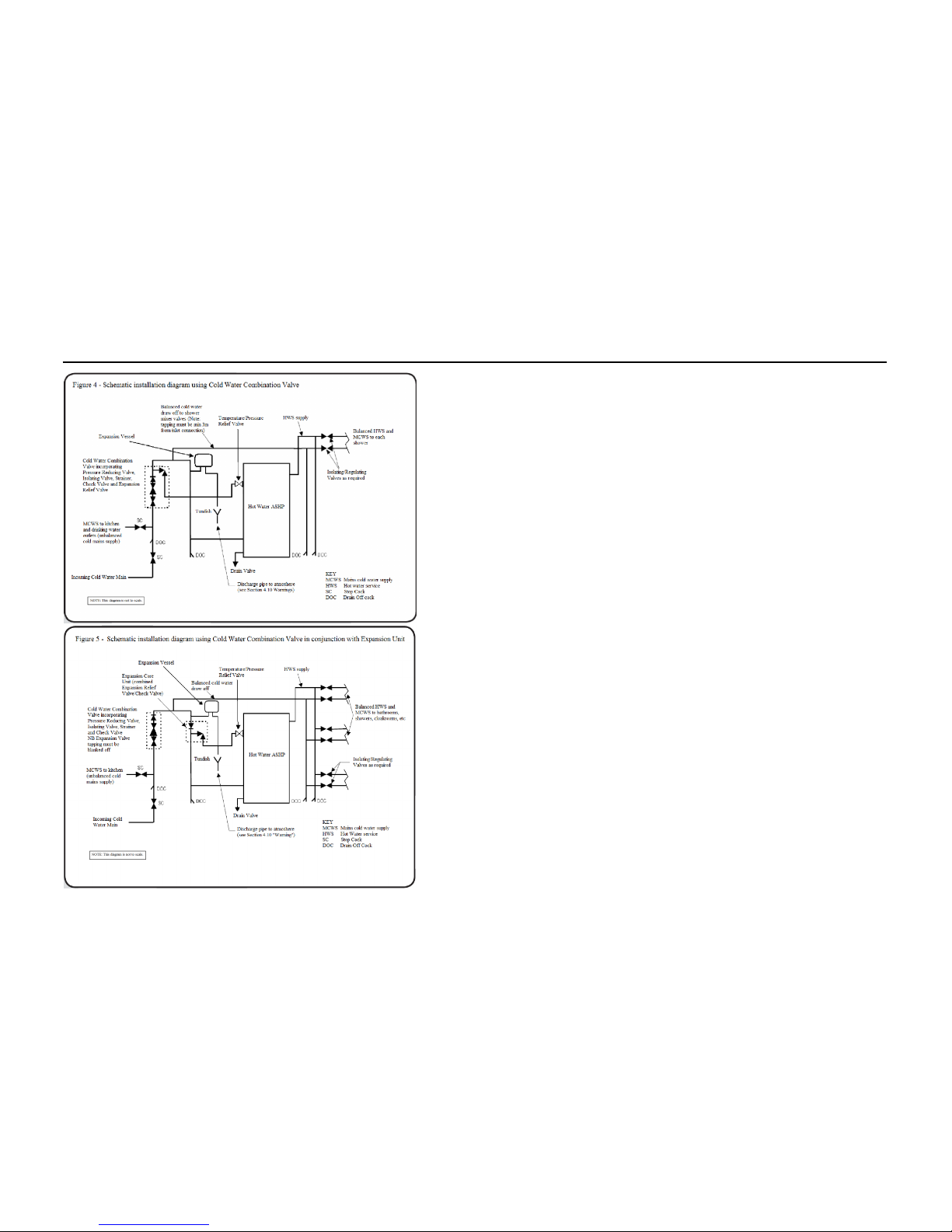

If a balanced pressure cold water supply is required to a thermostatic shower

mixer valve this may be tee‟d off the supply to the unit immediately after the

Cold Water Combination Valve (see Figure 4). Branches to drinking water outlets should be taken before the valve to avoid the possibility of warm expanded

water being drawn from the tap.

4.5 EXPANSION CORE UNIT (see Figure 3)

Should a balanced pressure cold water supply be required for other cold water

outlets the Expansion Core Unit supplied should be used. The Core Unit should

be fitted into the pipework between the Cold Water Combination Valve and the

unit (note direction of flow arrows). The cold water balanced draw off connection should be taken from between the Cold Water Combination Valve and the

Expansion Core Unit (see Figure 5). The Expansion Valve connection on the

Cold Water Combination Valve should remain blanked off using a blanking nut

and seal. Ensure the discharge from the Expansion Valve can be correctly installed.

Hot water air source heat pump Hot water air source heat pump

Page 11

11 ©ESP Ltd. Sept 2008

4.6 DRAIN TAP

A draining tap should be installed in the cold water supply to the unit between the Cold Water Combination Valve (or Expansion Core Unit if being

used) and the heater at as low a level as possible It is recommended that the

outlet point of the drain pipe work be at least 1 metre below the level of the

heater (this can be achieved by attaching a hose pipe to the drain tap outlet

spigot).

4.7 OUTLET PIPEWORK

Ideally the pipework from the unit to the outlet fittings should be in 22mm

pipe with short runs of 15mm pipe to showers and basin taps. Small bore pipe

can also be used to suit some taps, but runs should be of minimum length.

Pipe sizes may vary due to system

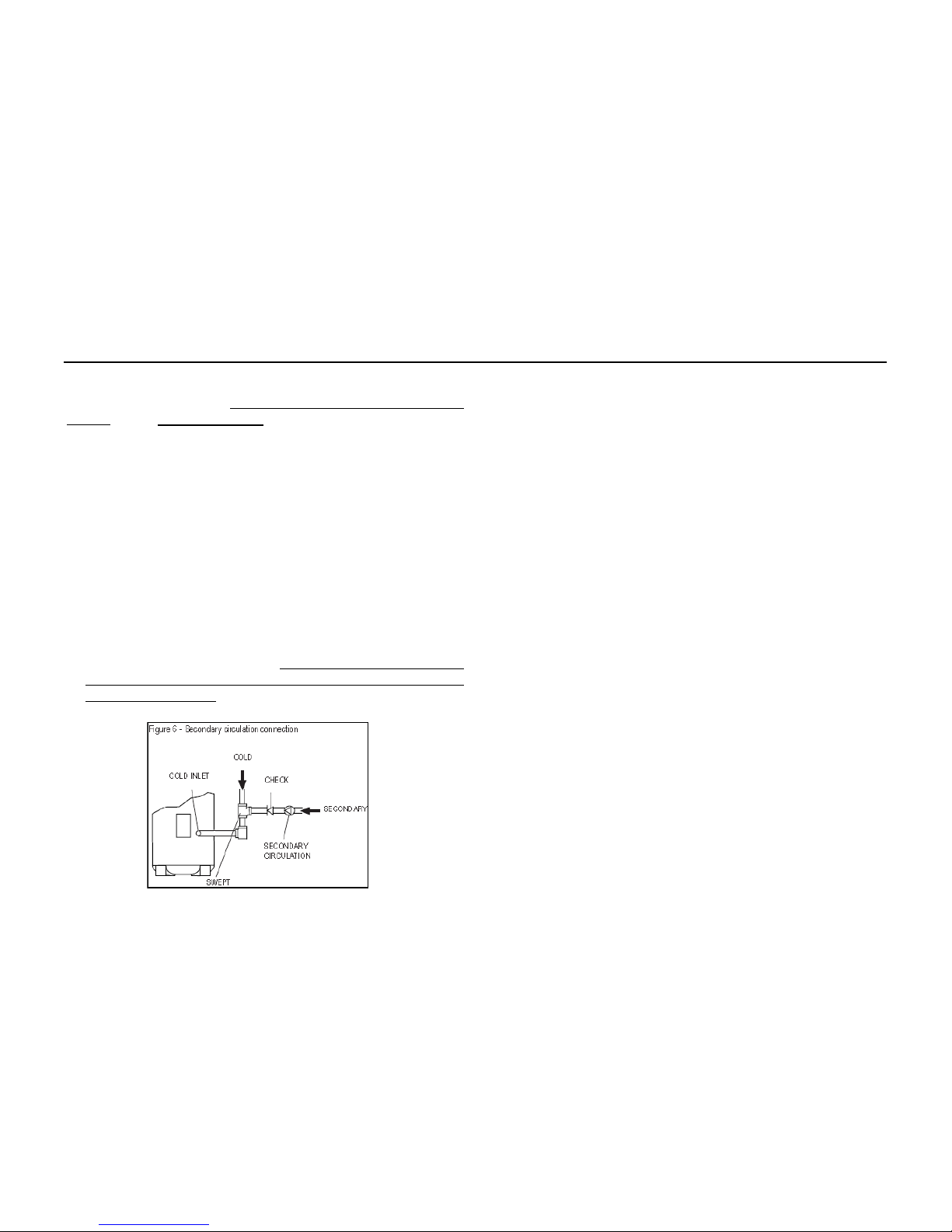

4.8 SECONDARY CIRCULATION

If a secondary circulation system is required it should be installed as per Figure 6. The secondary return pipe should be in 15mm pipe and incorporate a

check valve to prevent backflow. A suitable WRAS approved bronze circulation pump will be required with appropriate unions. On large systems, due to

the increase in system water content, it may be necessary to fit additional expansion volume to the system by fitting an external expansion vessel to the

secondary circuit. This should be done if the capacity of the secondary circuit

exceeds 10 litres.

Pipe capacities (copper)

15mm o/d = 0.13 litres per metre run (10 litres = 77m)

22mm o/d = 0.38 litres per metre run (10 litres = 26m)

28mm o/d = 0.55 litres per metre run (10 litres = 18m)

Secondary circulation is NOT recommended for units being used on “Off

Peak” electricity tariffs.

4 . Installation 4 . Installation

Hot water air source heat pump Hot water air source heat pump

Page 12

12 ©ESP Ltd. Sept 2008

4 . Installation 4 . Installation

4.11 DISCHARGE PIPEWORK

It is a requirement of Building Regulations that any discharge from an unvented system is conveyed to where it is visible, but will not cause danger to

persons in or about the building. The tundish and discharge pipes should be

fitted in accordance with the requirements and guidance notes of Building

Regulations. Building Regulation G3 Requirements and Guidance section

4.10 are reproduced in the following sections.

Information Sheet No. 33 available from the British Board of Agrément gives

further advice on discharge pipe installation. For discharge pipe arrangements

not covered by G3 Guidance or BBA Info Sheet No.33 advice should be

sought from your local Building Control Officer. Any discharge pipe connected to the pressure relief devices (Expansion Valve and Temperature/ Pressure Relief Valve) must be installed in a continuously downward direction

and in a frost free environment.

The water may drip from the discharge pipe of the pressure relief device and

that this pipe must be left open to the atmosphere. The pressure relief device

is to be operated regularly to remove lime deposits and to verify that it is not

blocked.

Please see figure 7 for typical discharge arrangement.

EXPANSION VESSEL

An appropriately sized expansion vessel must be fitted to the system in which

the unit is incorporated and it should discharge in to the tundish. The Expansion vessel can be fitted to the cold feed in to the unit (see Figures 4 and 6).

G3 REQUIREMENT

“...there shall be precautions...to ensure that the hot water discharged from

safety devices is safely conveyed to where it is visible but will not cause danger to persons in or about the building.”

Hot water air source heat pump Hot water air source heat pump

4.9 T&P RELIEF VALVE (“TPRV”)

The TPRV is factory fitted and must not be interfered with in any way and/or

removed - under NO circumstances should the installer or end user tamper

with the TPRV or the warranty/guarantee will be invalidated and serious damage may occur. You will find detailed information on this safety device at Appendix 2.

4.10 WARNINGS

i) Under no circumstances should the factory fitted TPRV be removed other

than by approved, fully trained and experienced fitters. To do so will invalidate any warranty/guarantee or claim.

ii) The Cold Water Combination Valve, in line strainer and scale inhibiting de-

vice must be fitted to the mains water supply to the unit.

iii) No control or safety valves should be tampered with.

iv) Water may drip from the discharge pipe of the pressure relief device

(Expansion Valve) and this pipe must be left open to atmosphere. The dis-

charge pipe should not be blocked or used for any other purpose.

v) For units with primary coil facilities, please discuss use of the coil, and a

suitable configuration for use, with ESP before proceeding to add a heat

source to the primary coil.

Page 13

13 ©ESP Ltd. Sept 2008

G3 GUIDANCE SECTION 4.10

The discharge pipe (D1) from the vessel up to and including the tundish is

generally supplied by the manufacturer of the hot water storage system. Where

otherwise, the installation should include the discharge pipe(s) (D1) from the

safety device(s). In either case the tundish should be vertical, located in the

same space as the unvented hot water storage system and be fitted as close as

possible and within 500mm of the safety device e.g. the TPRV.

The discharge pipe (D2) from the tundish should terminate in a safe place

where there is no risk to persons in the vicinity of the discharge, preferably be

of metal and:

a. be at least one pipe size larger than the nominal outlet size of the safety de-

vice unless its total equivalent hydraulic resistance exceeds that of a straight

pipe 9m long i.e. discharge pipes between 9m and 18m equivalent resistance

length should be at least two sizes larger than the nominal outlet size of the

safety device, between 18 and 27m at least 3 sizes larger , and so on. Bends

must be taken into account in calculating the flow resistance. Refer to Diagram 7 and Table 1 below.

An alternative approach for sizing discharge pipes would be to follow BS

6700:1987 Specification for design, installation, testing and maintenance of

services supplying water for domestic use within buildings and their curtilages, Appendix E, section E2 and table 21.

b. have a vertical section of pipe at least 300mm long below the tundish before

any elbows or bends in the pipe work.

c. be installed with a continuous fall, and in a frost free environment.

d. have discharges visible at both the tundish and the final point of dicharge,

but where this is not possible or is practically difficult there should be clear

visibility at one or other of these locations.

Examples of acceptable discharge arrangements are:

i. ideally below a fixed grating and above the water seal in a trapped gully.

ii. downward discharges at low level; i.e. up to 100mm above external sur-

faces such as car parks, hard standings, grassed areas etc. are acceptable

providing that where children may play or otherwise come into contact

with discharges a wire cage or similar guard is positioned to prevent contact, whilst maintaining visibility.

iii. discharges at high level; e.g. into a metal hopper and metal down pipe

with the end of the discharge pipe clearly visible (tundish visible or not)

or onto a roof capable of withstanding high temperature discharges of water and 3m from any plastics guttering system that would collect such discharges (tundish visible).

iv. where a single pipe serves a number of discharges, such as in blocks of

flats, the number served should be limited to not more than 6 systems so

that any installation discharging can be traced reasonably easily. The single common discharge pipe should be at least one pipe size larger than the

largest individual discharge pipe (D2) to be connected. If unvented hot

water storage systems are installed where discharges from safety devices

may not be apparent i.e. in dwellings occupied by blind, infirm or disabled

people, consideration should be given to the installation of an electronically operated device to warn when discharge takes place.

Note: The discharge will consist of very high temperature water and steam.

Asphalt, roofing felt and non-metallic rainwater goods may be damaged by

such discharges and you must take this in to account when fitting the unit.

Should such damage be caused, ESP will accept no liability for any consequent damage caused.

4 . Installation 4 . Installation

Hot water air source heat pump Hot water air source heat pump

Page 14

14 ©ESP Ltd. Sept 2008

Table 1 - Sizing of copper discharge pipe (D2) for common T&P relief

valve sizes

4.12 HOW TO CONNECT TO THE HEAT PUMP

As the heat pump is an integral part of the unit, please contact the manufacturer for additional information where required.

PLEASE NOTE that only manufacturer approved engineers should carry out

any work on the heat pump. Call the manufacturer for the name of an approved engineer in your area.

THE FOLLOWING IS FOR REFRIGERANT ENGINEER ONLY:

1) Vacuum and filling Refrigerants.

The unit is supplied pre-gassed. Should a refrigerant fill be required at any

point, please note the following:

When you have finished the connection between the heat pump and the hot

water unit, you must create a vacuum in the hot water unit. See below pictures 6 & 7 below:

A. Unscrew the screw cap of the high pressure valve on the heat pump, and

connect the multiplex manometer to the check valve.

B. Connect the vacuum pump to the multiplex manometer, then open them to

create a vacuum in the hot water unit, making sure the absolute pressure is

less than 70Pa, and lasts for 60 minutes.

C. When you have finished the vacuum test, open the check valve to let the

refrigerant go into the ASHP part of the unit.

4 . Installation 4 . Installation

Hot water air source heat pump Hot water air source heat pump

Page 15

15 ©ESP Ltd. Sept 2008

D. When you need to add the refrigerant, please do so as follows:

2) Controller system test

Switch on the power to the unit, check the display of the wire controller-it

will display the water temperature when the unit is on standby mode. If

the wire controller display is showing an incorrect reading or an error

code, please refer to Section 6.9.

3) Debug the cooling system

a) On completing wiring of the unit, please release a little refrigerant from

the low pressure side, or use the vacuum pump to create the vacuum in

the system, until the pressure is below 70Pa.

b) Once the unit is in vacuum, please open the high pressure valve and the

low pressure valve until the pressure is balanced, then check the joints

for leaks.

c) Ducting—Please ENSURE that ducting is safely and appropriately fitted.

IMPORTANT Do not allow any impurities to enter the refrigerant system

4) Insulation treatment

As per the below picture, you must insulate all connecting pipes and you

must use good quality, non flammable, PVC insulating material, of 15mm20mm thickness.

(a) To keep the pipes in a tidy state, you may wrap the pipes together after

being separately insulated.

(b) Under no circumstances should you let electric wires come in to con-

tact with the plumbing.

NOTE: With the 400 Series, the ASHP and the cylinder are one unit and

the above should be interpreted accordingly.

4 . Installation 4 . Installation

4.13 INDIRECT THERMAL CUT-OUT AND 2-PORT MOTORISED

VALVE

To comply with Building Regulations and to prevent the unit from overheating a 2-port motorised valve MUST be fitted to the primary flow to the indirect coil—See Figure 11 below Please note that this diagram may vary from

model to model, but the principle does not.

4.14 WIRING

All electrical wiring MUST be carried out by a competent electrician and be

in accordance with the latest I.E.E. Wiring Regulations. The wiring block

diagram is set out below in Picture 14.

Hot water air source heat pump Hot water air source heat pump

Page 16

16 ©ESP Ltd. Sept 2008

4.Installation 4. Installation

Great care should be taken to ensure that the unit is properly wired to the

mains electricity and any auxiliary components.

The mains wire connection will be found towards the bottom of the unit. The

power supply MUST be switched.

The 2-port motorised valve MUST be wired in series with the Indirect controls

(for the unit Indirect Thermostat and Thermal Cut-Out) such that the power

supply to the valve is interrupted should either the Thermostat or Thermal CutOut operate. Wiring to external controls is made via the terminal block fitted.

The cable should be routed through the aperture in the terminal cover and secured using cable grips. The Indirect Thermal Cut-out MUST NOT be bypassed.

4.15 UNIT/SYSTEM CONTROLS

The controls either supplied with the unit or to be purchased from reputable

suppliers, must be properly installed to ensure the safe operation of the unit.

Other controls/zone valves will be necessary to control solar (or other) auxiliary requirements.

4.16 IMMERSION HEATER(S)

The unit is supplied with an immersion heater which can be used as an alternative and/or complementary heat source to raise the temperature of the water in the unit to above 60°C once a week to remove any risk from legionella

bacteria. The immersion heater is located in the side of the unit

Hot water air source heat pump Hot water air source heat pump

Page 17

17 ©ESP Ltd. Sept 2008

Some things to be considered in positioning the unit:

(1) Waste heat is useful heat (picture 10)

The standard heat exchanger of the hot-water heat pump enables direct connection to a second stable heat generator, e.g. a solar heating system or a boiler.

(2) Dehumidification in the re-circulating air mode (picture 11)

Dehumidified air in the laundry room supports laundry drying and prevents

moisture-induced damage.

Picture 10

Picture 11

(3) Cooling in the re-circulating air mode (picture 12)

Room air can be extracted from a storage room or a wine cellar, subsequently

cooled and dehumidified in the heat pump and finally re-introduced into the

room. Recreation rooms, boiler rooms or utility rooms are ideal installation

sites. The air ducts leading through warm sections must be insulated to prevent the formation of condensation. All ducting must not restrict airflow.

Therefore, 6 inch

Picture 12

(4) variable change over of intake air

A duct system with integrated bypass flaps can be installed to utilise the cold

air produced by the unit.

Picture 13

4. Installation 4. Installation

Hot water air source heat pump Hot water air source heat pump

Page 18

18 ©ESP Ltd. Sept 2008

4 . Installation

1. Decide upon the right route to be taken to move the unit;

2. Try to move the unit in its original case;

3. Be sure to have the unit and electrics fitted by qualified tradesmen.

4. Ensure that no building materials or debris are allowed to enter the air ducts

at the top of the unit or any extension thereof. NOTE: Ducting must be 6

inches in size.

Check for obvious signs of damage to the cylinder and controls before undertaking commissioning work.

Ensure that the Drain Cock at the base of the appliance is closed before

commencing.

1) Open all outlet taps;

2) Turn on mains water supply and allow the unit to fill;

3) Ensure that the hot water system is flushed in accordance with BS 6700;

4) Close taps in turn after having purged the system of air;

5) Check for leaks around the controls and immersion heaters and again

after the unit has heated up;

6) Check that no water is passing to waste through the relief valves;

7) Ensure that the line strainer (situated in the pressure reducing valve) is

clear of installation debris and clean if necessary;

8) Test the operation of the temperature & pressure relief and expansion

valves by lifting/turning the manually operated test lever/cap and

observing that water flows through freely and safely to waste;

9) Turn on electricity (and check for any wiring errors);

10) Check that the discharge pipe is plumbed to Local Regulations so that it

falls continuously and that no taps, valves or other shut off devices are

installed in the pipe;

11) Check that all thermostats are set appropriately;

12) Fill the indirect/solar (primary) circuit (if used). Allow unit to heat up

and check operation of indirect thermostat on motorised valve(s);

13) Check the temperature of the hot water at the nearest outlet and record

in any Log Book provided with the unit (if any);

14) Demonstrate operation to end user, including operation of temperature &

pressure relief valve and what to do if it operates

Hot water air source heat pump

5. Commissioning

Hot water air source heat pump

SOME NOTES ON DUCTING

Air ducts to and from the heat pump should be in 6 inch (preferably rigid) pipe.

The outlets should be fitted with a suitable “flap” or “guard” device to prevent

rain, debris, animals and plants entering the ducts.

When servicing the unit, ducting should be checked to make sure that it is

clear and obstruction removed.

Installation points

Page 19

19 ©ESP Ltd. Sept 2008

5. Commissioning 6. Maintenance

6.1 MAINTENANCE REQUIREMENTS (The Cylinder)

To ensure the continued optimum performance of the unit it should be regularly maintained. This is of particular importance in hard water areas or

where the water supply contains particulate matter. Maintenance should be

carried out by a competent person and any replacement parts used should be

supplier recommended spare parts. It is recommended that maintenance is

carried out every 12 months on the cylinder and includes the checks detailed

in this manual.

In hard water areas consideration should be given to periodically de-scaling

the immersion heater elements. To do this the unit will need to be drained;

6.4 and 6.5 below detail how to drain the unit and remove the immersion

heater(s).

Please check the condition on the magnesium anode on any servicing/

maintenance and fit a new anode, if required.

6.2 CHECK OPERATION OF SAFETY VALVES

Slowly open the Temperature and Pressure Relief Valve by twisting its cap

for a few seconds. Check water is discharged and that it flows freely through

the tundish and discharge pipework. Check valve reseats correctly when released.

NOTE : The water discharged may be very hot.

Repeat the procedure for the Expansion Relief Valve (located on the Cold

Water Combination Valve or Expansion Valve Core Unit).

6.3 CLEAN THE STRAINER

The in line strainer must be cleaned periodically by a suitably qualified engineer. The engineer should:

i) Wash any particulate matter from the inline strainer under clean running

water.

ii) Refit the inline strainer once totally clean or install a new one.

15) Give this manual along with the completed Log Book (if any) to the end

user to retain for future reference and make the customer aware that periodic checks of the equipment are essential for safety.

PLEASE NOTE that

you must have the unit fitted and commissioned by a suitably qualified engi-

neer ; and,

installation instructions must be followed;

Failure to do so will invalidate any unit warranty/guarantee.

Hot water air source heat pump

Hot water air source heat pump

Page 20

20 ©ESP Ltd. Sept 2008

6.4 DRAINING THE UNIT

Switch off the electrical supply to the immersion heater(s) and heat pump. Turn

off the mains water supply to the unit. Attach a hosepipe to the drain cock having sufficient length to take water to a suitable discharge point below the level

of the unit, at least one metre below the unit is recommended. Open hot water

tap nearest to the unit to relieve the system pressure. Open drain cock. If water

fails to drain from the unit vent the unit by manually opening the Temperature/

Pressure Relief Valve or “crack a joint” in the unit plumbing to prevent the

creation of a vacuum that may prevent effective draining.

6.5 DESCALING IMMERSION HEATER(S)

Open the cover(s) to the immersion heater housing(s) and disconnect wiring

from immersion heater(s). Remove the thermostat by carefully pulling outwards from the immersion heater. Unscrew immersion heater backnut(s) and

remove immersion heater from the unit. Over time the immersion heater gasket may become stuck to the mating surface. To break the seal insert a round

bladed screwdriver into one of the pockets on the immersion heater and gently

lever up and down.

Carefully remove any scale from the surface of the element(s). DO NOT use a

sharp implement as damage to the element surface could be caused. Ensure

sealing surfaces are clean and seals are undamaged, if in doubt fit a new gasket.

Replace immersion heater(s) ensuring (where appropriate for the unit being

worked upon) the lower (right angled) element hangs vertically downwards

towards the base of the unit. It may be helpful to support the immersion heater

using a round bladed screwdriver inserted into one of the thermostat pockets

whilst the backnut is tightened. Replace the thermostat(s) by carefully plugging

the two male spade terminations on the underside of the thermostat head into

the corresponding terminations on the element.

Rewire the immersion heater(s). Close and secure terminal cover(s).

6. Maintenance

6.6 REFILLING SYSTEM

DO NOT switch on the immersion heater(s) or heat pump part of the unit

until the system has been completely refilled.

Close the drain tap. With the hot tap open, turn on mains water supply. When

water flows from the hot tap allow to flow for a short while to purge air and

to flush through any disturbed particles. Close hot tap and then open successive hot taps in system to purge any air. The electrical supply can now be

switched on.

6.7 LOG BOOK

Please complete any log book supplied with the unit stating what has been

done, the date of the service and the name/contact details of the servicing

engineer.

6.8 MAINTENANCE REQUIREMENTS (For Heat Pump)

Check the water supply and air vent frequently, to avoid lack of water or

air in the water loop. Clean the inline strainer regularly to maintain water

quality and check that the scale inhibitor is still working effectively. Replace as appropriate. Lack of water and dirty water can damage the unit.

The heat pump will start the water pump every 72 hours when it is not

running, to avoid freezing.

Keep the unit in a place which is dry and clean, and has good ventilation.

Clean the heat exchanger every 1 or 2 months to maintain a good heat

exchange rate.

Check each part of the unit and the pressure of the system. Replace any

failing part, and recharge the refrigerant if it is necessary.

Check the power supply and the electrical system to ensure that all is in

order. If any part has failed replace it. Check for any unusual smells that

may indicate parts about to fail.

6. Maintenance

Hot water air source heat pump Hot water air source heat pump

Page 21

21 ©ESP Ltd. Sept 2008

6. Maintenance 6. Maintenance

If the heat pump is not to be run for a long time, please drain out all the

water in the unit and seal the unit to protect it. Please drain the water from

the lowest point of the heat exchanger to avoid freezing in winter when not

being used. Water recharge and full inspection of the heat pump is needed

before it is restarted.

Don't power off the unit when you use it regularly.

Check the air ducting for any obstruction and clear as required. The air

ducts MUST be totally cleared of any obstructions or it will adversely impact upon the efficiency of the unit.

6.9 FAULT FINDINGS AND SOLUTIONS

6.9.1 The Heat Pump

Failure Display Indicator Cause Solutions

Power on Off

Unit running On

Lower tank water

temp. sensor failure

PP1 1 on 1 off The temp. sensor is open or short

circuit

Check and replace the temp. sensor for the

upper tank water

Upper tank water

temp. sensor failure

PP2 2 on 1 off The temp. sensor is open or short

circuit

Check and replace the temp. sensor for the

lower tank water

Evaporator coil

temp. sensor failure

PP3 3 on 1 off The temp. sensor is open or short

circuit

Check and replace the temp. sensor for the

evaporator inlet

Elec. Heater temp.

sensor failure

PP4 4 on 1 off The temp. sensor is open or short

circuit

Check and replace the temp. sensor for the

elec. heater

High pressure

protect

EE1 6 on 1 off 1. too much refrigerant

2. Bad air-side heat

exchange

1. Discharge the redundant gas (qualified

fitter required)

2. Clean the air-side heat exchanger

Low pressure pro-

tect

EE2 7 on 1 off 1. Insufficient refrigerant

2. Block on the filter or capillary

3. Inadequate water flow

4. Expansion sensor is broken

1. Check if there is any leaks and refill gas

2. Replace the filter or capillary

3. Clean the water side exchanger or dis-

charge the air in the water loop

4. Use new expansion valve

AUX heating

thermal protect

EE3 8 on 1 off Water level in tank too low Check the water supply or tank to see

whether there is adequate water

Exhaust temp.

protect

EE4 9 on 1 off 1. Shortage of refrigerant

2. Out of temp. setting too high

1. Check the gas pressure to see whether or

not it has enough refrigerant

2. Check the setting temp.

Communication

failure

EE8 On Communication failure between

wire controller and main board;

Check the wire connection between the

wire controller the main board

Defrosting Defrosting

indicate

Flash

Hot water air source heat pump Hot water air source heat pump

Page 22

22 ©ESP Ltd. Sept 2008

7. User Instructions

7.1 FUNCTION OF THE CONTROLLER

Use of controller is as follows:

6.9.2 The Cylinder

Hot water air source heat pump Hot water air source heat pump

6. Maintenance

Page 23

23 ©ESP Ltd. Sept 2008

7.2 USE OF THE CONTROLLER

1)Start up.

After checking everything is OK, switch on the unit and enter into

standby state, with the screen showing as follows:

2) Turn-on.

Press “ “ to turn on the unit with the screen showing as follows:

3) Turn-off

Press “ “ to turn off the unit with the screen showing as follows:

7. User Instructions

4) Check parameters

During running or standby state, press or to check the related parameters with the screen showing as follows:

5) Check and change the set parameters (Note: you can check and change

the set parameters during standby state but you can only check (not change)

the set parameters when the unit running ).

1. Press repeatedly to check the related set parameters;

2 . Then press ELEC. HEATING at the same time to change these

parameters; If you do not press the control for 6 secs, it will exit the

setting;

7. User Instructions

Hot water air source heat pump Hot water air source heat pump

Page 24

24 ©ESP Ltd. Sept 2008

7. User Instructions

6) Malfunction Display

During standby or running state, if the unit malfunctions, the system will

stop and display the malfunction code as follows:

8. Safety Precautions

SAFETY PRECAUTION

The following are some safety tips to observe, but they are no substitute for

the use of common sense! Please use the unit for the purpose intended

and be sure to read, understand and follow the provisions of this manual.

These units can cause serious damage to property and people if installed/

used improperly or inappropriately. The units can cause broken bones

when improperly handled, burns and electric shock when improperly

installed and/or operated.

Please be sure to install and operate the unit with great care and in accordance with this manual.

Hot water air source heat pump Hot water air source heat pump

7) Controller Parameter

Page 25

25 ©ESP Ltd. Sept 2008

INSTALLATION WARNING

8. Safety Precautions 8. Safety Precautions

OPERATION WARNING

MOVE AND REPAIR

OPERATION ATTENTION

Hot water air source heat pump Hot water air source heat pump

IMPORTANT: The unit warranty/guarantee will be invalidated if all work on installing, commissioning and maintaining it is not carried out by suitably qualified engineers.

Page 26

26 ©ESP Ltd. Sept 2008

9. Guarantee

9.1 GUARANTEE

!!!!!WARNING!!!!!

Should any factory fitted Temperature and/or Pressure Relief Valve(s) or other

safety devices be tampered with or removed or any recommended Temperature

or Pressure Relief Valves/safety devices not be fitted, your warranty/guarantee

will be invalidated. Neither the Distributor nor Manufacturer shall be responsible for any damage resulting from the tampering, howsoever caused., save

where such an exclusion is unlawful.

9.2 GUARANTEE TERMS

ESP warrants/guarantees the electrical parts, thermal controls and valves relating to the cylinder for a period of one year from the date of purchase, with the

exception of normal ware and tear including any damage caused as a result of

limescale deposits.

The stainless steel vessel forming part of the cylinder is warranted/guaranteed

for a period of five years against faulty manufacture or materials provided that :

-

i) It has been properly installed by a competent installer as per the instructions

and recommendations contained in this manual and all relevant Codes of

Practice and Regulations in force at the time of installation.

ii) Any disinfection has been carried out in accordance with BS 6700.

iii) It has not been modified in any way other than by ESP.

iv) It has only been used for the storage of wholesome water.

v) It has not been installed in a location liable to be subjected to frost, nor has it

been tampered with or been subjected to misuse or neglect.

vi) No factory fitted parts have been removed for unauthorised repair or re-

placement

vii) Within 45 days of purchase the user completes and returns the certificate

supplied to register the product.

The compressor in the heat pump is warranted/guaranteed for 2 years from

the date of purchase. Remaining parts of the heat pump are warranted/

guaranteed for 1 year from the date of purchase.

Evidence of purchase and date of supply must be submitted with any wattanty/guarantee claim.

This warranty/guarantee is not valid for installations outside the United Kingdom or the Republic of Ireland.

Any warranty/guarantee is for replacement parts only.

The purchaser of the unit acknowledges that it has seen ESP‟s conditions of

supply and has understood them.

This guarantee does not affect your statutory rights.

ENVIRONMENTAL INFORMATION

This product is made from many recyclable materials, therefore at the end of

its useful life, it should be disposed of at a Local Authority Recycling Centre

in order to realise the full environmental benefits.

Please note:

The pace of product development is such that we reserve the right to

change product specifications without notice. We do, however, strive to ensure that all information in this leaflet is accurate at the time of publication.

9. Guarantee

Hot water air source heat pump Hot water air source heat pump

Page 27

27 ©ESP Ltd. Sept 2008

10. Spare Parts

Hot water air source heat pump

10.1 SPARE PARTS

Please be advised that Earth Save Products Limited carries spare parts for all

the units that it supplies. We strive to ensure that spare parts are readily available at competitive prices.

Please call us should you need any spare parts and we will be pleased to give

you a quotation.

For spare parts please contact us on ++ 44 (0) 844 414 2345 / ++ 44

(0)1235 815569 or ++ 44 (0)1865 40 72 70 .

Appendix 1

UNVENTED HOT WATER STORAGE

SYSTEMS AND CONTROLS

Uses

Page 28

28 ©ESP Ltd. Sept 2008

The purpose of this guide is to provide useful information on Unvented Hot

Water Storage Systems and their benefits, the features and functions of the

typical controls used.

Unvented Hot Water Storage Systems are subject to the legal requirements of

Building Regulation G3 and can only be installed by an “approved installer” in

strict accordance with the relevant manufacturer‟s Instruction Manual, Building

Regulation G3 and the current Water Byelaws.

Reputedly devised by an Englishman as far back as 1861, Unvented Systems

are commonplace throughout Europe, South Africa, North America and Australia, although the UK remains one of the last bastions of the traditional low

pressure vented system. However, times are changing. The demands from discerning householders for increased performance, sophisticated continental-style

taps and showers and pleasing aesthetic looks, has seen a growing trend towards the installation of Unvented Systems in the UK, which will continue to

rise at an increasing rate.

How the Unvented System Works

The basic difference between the high pressure Unvented Systems and a traditional low pressure vented system is that we no longer require the cold water

storage cistern, open vent pipe or cold feed pipe.

Instead, the unvented unit is fed direct from the mains cold water supply via

an inlet control group preset to the relevant manufacturers specified pressures.

Hot water drawn from the unit is then replenished from the mains supply.

As water expands when heated and, as the name implies, there is no vent pipe

(or cold feed pipe), the expanded water within the system is accommodated

by either an external expansion vessel or, in the case of bubble-top units, an

internal air bubble within the unit which is generated when the system is commissioned.

To maximise the benefits of the Unvented System, a sealed heating system, if

applicable, can also be installed providing the boiler used is compatible.

UNVENTED HOT WATER STORAGE SYSTEMS AND CONTROLS

Page 29

29 ©ESP Ltd. Sept 2008

The significant benefits to be gained from the installation of an Unvented Hot

Water Storage System can be divided into two categories; benefits to the Specifier/Installer and benefits to the householder.

Specifier / Installer Benefits

• Choice of location - unit can be installed virtually anywhere within the build-

ing structure allowing greater flexibility of house and system design Reduces

costs.

• Superior performance - ensures constant high flow rates at all outlets and al-

lows rapid filling of baths.

• No Cold Water Storage Cistern - Reduces pipework. No requirement for tank

stand or pipework/tank insulation - reduces costs. Roof space can be utilised

for additional living accommodation.

• Balanced pressures - far wider choice of sophisticated continental style taps

and showers can be used.

• Quicker to install - reduces pipework and installation costs.

• Reduces noise in system - no filling of Cold Water Storage Cistern.

• Smaller diameter pipework can be used - reduces costs.

• Eliminates risk of freezing and burst pipes in roof space.

• No shower pump required - reduces costs.

• Eliminates risk of contamination - no Cold Water Storage Cistern in roof

space.

• Superior performance and flow rates - ideal for multi-bathroom dwellings.

• Energy efficient - reduces fuel costs.

• Ease of maintenance - no access to roof space required.

• Frees roof space - can be utilised for loft conversions.

Aesthetic looks - „white goods‟ casing

Householder Benefits

• Superior performance - ensures constant high flow rates at all outlets and

allows rapid filling of baths.

• Balanced pressures - far wider choice of continental style taps and showers

can be used.

• Reduces noise in system - no filling of cold water storage cistern.

• Eliminates risk of freezing and burst pipes in roof space.

• Eliminates risk of contamination - no cold water storage cistern in roof

space.

• Frees roof space - can be utilised for loft conversions.

• Energy efficient - reduces fuel costs.

• Aesthetic looks - „white goods‟ casing.

Choosing an Unvented System

From the early Unvented Systems of the seventies, the continued growth of

installations in the UK has now produced the sophisticated, high performance

units demanded by today‟s householder and, the availability of Unvented Sys-

tems from manufacturers in the UK, Europe, South Africa and North America, now offers the specifier/installer an unparalleled choice to suit virtually

any application.

Manufactured from either copper, glass-lined steel or stainless steel, almost

all of the Unvented Systems available in the UK are supplied with a white

goods easy clean finish. Using inlet pressures ranging from 1.5 Bar to 3.5 Bar,

depending on the relevant manufacturer‟s specification, and available in both

direct and indirect form, today‟s Unvented Systems can be divided into three

main categories; Bubble-Top unit, External Expansion units and Direct Gas or

Oil Fired units.

UNVENTED HOT WATER STORAGE SYSTEMS AND CONTROLS

Page 30

30 ©ESP Ltd. Sept 2008

Bubble-Top Units

Bubble-Top Units

Bubble-Top units, manufactured from either copper or stainless steel, accommodate the expansion

of the heated water by using an internal air-bubble

which is generated and trapped at the top of the

unit during commissioning.

External Expansion Unit

As the name implies, External Expansion units

utilise an expansion vessel to contain the expanded

heated water. The expansion vessel can be installed

directly onto the unit, or, if required remotely sited

with the Inlet Control Group. These units are

manufactured from copper, glass-lined steel or

stainless steel.

The Direct-Fired Unit, normally manufactured

from glass-lined steel or stainless steel, again uses

an expansion vessel to accommodate the increased

volume of the heated water. Predominantly installed in larger domestic or commercial premises,

these units can be either gas or oil fired.

A recent development now available in the UK

is the Combi Storage unit. This type of unit incorporates the benefits, features and controls

associated with Unvented Systems but has a

limited storage capacity of hot water.

Ideally, the mains supply pressure to the premises should be a minimum of 2 Bar to ensure

the superior performance associated with the

Unvented System and, although all Unvented

Systems will operate at supply pressures as low

as 1 Bar, the benefits will be reduced.

External Expansion Unit

Direct-Fired Unit

Unvented Systems can also be used in conjunction with tank fed supplies and

booster pump sets, although these installations are usually confined to commercial premises. Unvented Systems are suitable for use in conjunction with

electric, gas, LPG or oil heating appliances but MUST NOT be used with

solid fuel appliances.

The majority of Unvented units available today are certified to comply with

the requirements of Building Regulation G3, either by the BBA (British

Board of Agrément) or the WRc (Water Research Evaluation and Testing

Centre) and are supplied with a complete package of controls - either factory

fitted or supplied as an Unvented Kit - which must be installed in strict accordance with the relevant manufacturer‟s instructions.

UNVENTED HOT WATER STORAGE SYSTEMS AND CONTROLS

Page 31

31 ©ESP Ltd. Sept 2008

Installation, Commissioning and Maintenance of Unvented Systems

Although the basic principles are similar, the installation, commissioning and

maintenance of an Unvented System must be in strict accordance with the rele-

vant manufacturer‟s instructions and, all installations must be carried out by a

“competent person” approved to install Unvented Systems.

As the dominant supplier and, pioneers in the development of controls for

Unvented Systems, the Reliance range of controls incorporate unique features

to ensure superior performance; ease of installation; long, trouble-free service

and ease of maintenance and replacement.

In this part of the Guide, we look at the different controls used on the majority

of Unvented Systems in the UK. These controls fall into two specific groups Functional Controls and Safety Controls.

Functional Controls

Required to protect the mains water supply from contamination and the unvented unit from over pressure, these controls consist of the following components:-

• Line Strainer - filters debris from the water supply to reduce the risk of

damage to downstream controls.

• Pressure Reducing Valve - reduces the mains water pressure to the specified

cold working pressure of the unit.

• Single Check Valve - prevents contamination of the mains water supply from

backflow and, crossflow between hot and cold distribution pipes.

• Expansion Valve - protects unit from over pressure caused by failure of pres-

sure reducing valve, failure of expansion vessel or loss of internal air bubble.

Originally supplied as separate components, Reliance have developed and

engineered these controls to form a one piece or two piece Inlet Control

Group for units requiring DN20 Nominal size controls and, a three piece Inlet

Control Group for units requiring DN25 size controls.Inlet Control Group One Piece (Multibloc).

Originally developed for use on Bubble-To units - there is no provision for an

integral expansion vessel connection - this control is now found on all types

of Unvented Systems and offers the following features.

Inlet Control Group - One Piece (Multibloc)

Originally developed for use on “Bubble-Top” units

- there is no provision for an integral expansion vessel connection - this control is now found on many

types of Unvented Systems and offers the following

features.

• Integral coaxial stainless steel strainer

• Drop tight balanced seat Pressure Reducing Valve

- very stable under fluctuating inlet pressure conditions.

• Unique one piece Pressure Reducing Cartridge

with noise reduction comb - facilitates ease of

maintenance, reduces system noise further and

prevents cavitation.

• Balanced cold water connection - equal pressures to mixer taps/showers.

• Unique stainless steel seat Expansion Valve - dramatically reduces prema-

ture failure from seat erosion - Particularly in hard water areas.

• Superior flow rates - up to 55 l/m.

• Multi-orientational - installation flexibility.

UNVENTED HOT WATER STORAGE SYSTEMS AND CONTROLS

Page 32

32 ©ESP Ltd. Sept 2008

Inlet Control Group - Two Piece (Core Unit)

Forerunner of the Multibloc one piece control, this Inlet Control Group is again

used on all types of Unvented Systems and comprises of a separate Pressure

Reducing Valve/Strainer and combined Check/Expansion Valve core unit offering the following features.

• Separate Pressure Reducing Valve with integral coaxial stainless steel strainer

-enables remote siting of the Pressure Reducing Valve if required.

• Droptight balanced seat Pressure Reducing valve - very stable under fluctuat-

ing inlet pressure conditions.

• Unique one piece Pressure Reducing Cartridge with noise reduction comb -

facilitates ease of maintenance, reduces system noise further and prevents

cavitation.

• Balanced cold water connection - equal pressures to mixer taps/showers.

• Separate Check/Expansion Valve core unit with integral Expansion Vessel

connection.

• Unique replacement Expansion Valve cartridge

and seat - enables refurbishment of existing valve

without removal.

• Superior flow rates - up to 55 l/m.

Multi-orientational - installation flexibility.

In addition to the standard specification DZR brass

Expansion Valve seat of the core unit, Reliance

have developed a stainless steel seat version for the

exclusive use of one Unvented Systems manufac-

turer, proving Reliances‟ commitment to continual

development to offer the best available control

package.

Inlet Control Group - Three Piece (Check Valve Manifold)

Used on all types of Unvented System, this Inlet Control Group is for larger

domestic and commercial installations where a high flow rate is required to

satisfy peak demand.

• Separate Pressure Reducing Valve with integral coaxial stainless steel

strainer, droptight balanced seat design and one piece cartridge with unique

noise reduction comb.

• Check valve manifold with Integral connections for Expansion Valve, Ex-

pansion Vessel and Balanced cold water supply.

• High discharge capacity Expansion Valve with replaceable cartridge and

seat feature.

• High Flow rates - up to 77 l/m.

Multi-orientational - installation flexibility.

Although the various Inlet Control

Grou ps are t he most c ommon

“functional controls” supplied with

today‟s units, some Unvented Systems

still use individual, separate controls.

All controls supplied by Reliance in

this format offer similar technical features to the Inlet Control Groups but

do not allow provision for a balanced

cold water connection or integral expansion vessel connection - these must

be supplied by the “approved” in-

staller, using additional fittings in the

pipework.

UNVENTED HOT WATER STORAGE SYSTEMS AND CONTROLS

Page 33

33 ©ESP Ltd. Sept 2008

All Reliance Inlet Control Groups are supplied with comprehensive Installation

and Maintenance instructions to supplement the relevant Unvented System

manufacturer‟s Instructions.

The final “functional control” - a means to accommodate the expanded water to

prevent waste of water - is also supplied with the Unvented System. This is

achieved in two ways - either by using an external Expansion Vessel or an internal air bubble generated within the unit.

External Expansion Vessel

Supplied in various sizes, dependent on the water capacity of the Unvented System, the Expansion Vessel has an inner butyl rubber membrane which is surrounded by a cushion of air, the pressure of this air cushion corresponding to the

set pressure of the relevant manufacturer‟s Pressure Reducing Valve. When the

water is heated, the additional volume flows into the bag-type membrane, compressing the air cushion and accommodating the expanded water. On cooling

down, the volume of water decreases, thereby “deflating” the inner membrane.

The Expansion Vessel must be sited

either directly on the Unvented unit

or, as in most Unvented Systems utilising this method to accommodate the

expanded water, the Inlet Control

Group.

The RWC range of Expansion Vessels

used on domestic Unvented Systems

are supplied in a white finish to com-

pliment the “white goods” image of

the Unvented unit.

All potable Expansion Vessels with a nominal capacity of 16 litres or greater

incorporate a replaceable membrane to facilitate replacement in the unlikely

event of failure.

Internal Air Bubble

In this type of Unvented System, the expanded water is accommodated by

compressing the internal air bubble generated when the unit is commissioned.

Again, on cooling down, the volume of water contained within the unit decreases and the internal air bubble returns to it‟s nominal capacity.

This type of Unvented System is commonly known as a Bubble-Top unit.

Safety Controls

Required to protect the householder and prevent the temperature of the water

in the Unvented System exceeding 99°C, these controls provide a three tier

level of protection.

• Control thermostat - usually set between 60-65°C.

• Energy cut out device with manual reset - usually set between 85-89°C.

Temperature & Pressure Relief Valve - set to 90°C + 5°C.

Both the Control Thermostat and Energy cut out device are supplied by the

manufacturer, the Control Thermostat offering the first level of protection

against over temperature of the water. The Energy cut out device will offer

the second level of protection in the event of Control Thermostat failure. The

Energy cut out device must incorporate a manual reset feature and must not

be self-resetting.

UNVENTED HOT WATER STORAGE SYSTEMS AND CONTROLS

Page 34

34 ©ESP Ltd. Sept 2008

The Temperature & Pressure Relief Valve is the third and final level of protection. Although this valve does incorporate a pressure relief function, the sole

purpose of this control is to prevent the system water temperature exceeding 99°

C - the pressure relief function is not used.

The Reliance Temperature & Pressure Relief Valves are supplied in two de-

signs, Lever Type or “Twist Top” (Lever Type valves are being phased out)

and, are available in DN15, DN20 and DN25 nominal sizes. These can be supplied with an extended temperature sensor probe, depending on the relevant

manufacturer‟s design and specification.

All Temperature & Pressure Relief Valves should be factory fitted to the Unvented unit by the relevant manufacturer.

Lever Type Temperature & Pressure Relief Valve

Originally specified for use with the first generation

systems installed in the UK, these valves incorporate

lever type easing gear. With over 20 Million valves

manufactured and, although still used in Australia and

the Far East, the demands of both the UK and European

manufacturers has seen this valve being replaced by the

“twist-top” version as the standard fitment on today‟s

units.

“Twist-Top” Temperature & Pressure Relief Valve

Developed following the demands of manufacturers for a more aesthetic,

modern design to compliment the “white goods” image of today's unvented

units, the “twist-top” valve is now becoming the standard fitment, superseding

the “old fashioned” lever type valve, and has the added benefit of direct com-

pression connections for the discharge pipework. The twist-top Temperature

& Pressure Relief Valve has also been designed to conform to the requirements of the latest European Standard.

Under fault conditions, the Temperature & Pressure

Relief Valve will discharge water to prevent over

temperature of the system. The drain pipework from

the valve must discharge through a Tundish, positioned within 500mm of the Temperature & Pressure

Relief Valve, to a safe and visible position to alert the

householder of a fault condition with the Unvented

System and to prevent damage to the property.

The drain discharge pipework must comply with the

relevant manufacturer‟s instructions and the require-

ment of Building Regulation G3. The Expansion

Valve will also discharge water under fault conditions

and it is acceptable practice to allow the drain pipework from the Expansion Valve to discharge into the

same Tundish used for the Temperature & Pressure

Relief Valve provided the requirements of both the relevant manufacturer's

instructions and Building Regulation G3 are maintained.

UNVENTED HOT WATER STORAGE SYSTEMS AND CONTROLS

Page 35

35 ©ESP Ltd. Sept 2008

UNVENTED HOT WATER STORAGE SYSTEMS AND CONTROLS

Spare Components

The Inlet Control Groups supplied by Reliance for use with Unvented Systems

have proven to be extremely reliable in field service but, in the unlikely event

of failure, the following spare components are available from the relevant

manufacturer of the Unvented System in question.

Products Illustrated

Pressure Reducing Valve cartridge - supplied at the manufacturer‟s required

setting. One piece design facilities replacement. Supplied complete with integral strainer.

Replacement Expansion Valve cartridge and seat - the unique design enables

damaged valves to be refurbished in situ without need for their removal.

Problems and Remedial Action

All manufacturers of Unvented Systems which are available in the UK today,

supply a comprehensive Instruction Manual with each unit, giving full details

of fault diagnosis and remedial action required.

Summary

There are no mysteries to Unvented Hot Water Storage Systems and their

installation. The continual development of both Unvented units and their associated controls together with the superiority of these units in comparison

to their traditional vented “cousins”, will undoubtedly see the Unvented Hot

Water Storage System as the preferred solution to Hot Water Storage

requirements in the UK.

Page 36

36 ©ESP Ltd. Sept 2008

Appendix 2

Product Specification Sheet

TPR15 Pressure and Temperature Relief Valves

A compact, cartridge type pressure and temperature safety relief valve for use

on unvented hot water systems.

Product Features and Benefits

• Fully approved by WRAS for use on unvented hot water systems.

• Available in a wide range of relief pressures between 4.0 and 10 bar.

• Provides protection to EN1490 from the dangerous build of pressure

which can be caused by overheating within an unvented hot water system.

• Cartridge construction of the pressure relief function and silicone rubber

seals provide a long lifespan and easy servicing.

• PTFE impregnated inlet threads for faster, easier installation.

• Integrated twist top lifting mechanism to check the valve functionality.

TPR15 Pressure and Temperature Relief Valves

Uses

Page 37

37 ©ESP Ltd. Sept 2008

Standards

Complies with EN1490

Approvals

WRAS Certificate No. 0412080

Description

The new Reliance compact pressure and temperature relief valve has been designed to provide protection against over pressurisation which can occur within

an unvented hot water system if the input temperature controls fail. The valve

is designed to be fitted in the upper portion of the cylinder as this is where the

hottest system temperatures will be found. If the system temperature rises beyond 95° C the wax mixture within the element of the temperature probe will

expand and this will lift the valve off of it‟s seat and relieve water to waste and

therefore reducing the pressure inside the cylinder. If the water pressure increases (without temperature increase) the valve will stay closed until the set

pressure of the relief mechanism is reached at which point the valve will open

to relieve the excess pressure build-up. The PTEM valve is supplied with PTFE

coated inlet threads for fast installation, twist top easing gear for testing the

valve function and comes with 1/2” MBSP inlet connections and 15mm com-

pression outlet connections.

Product Range

PTEM 550 852: 1/2” x 15mm 7 Bar P&T valve

PTEM 550 853: 1/2” x 15mm 10 Bar P&T valve

PTEM 550 855: 1/2” x 15mm 4 Bar P&T valve

PTEM 550 856: 1/2” x 15mm 4.5 Bar P&T valve

Materials

Body: Brass

Seal: ABS

Lever: Polyamide

Diaphragm: EPDM

Compression nut: Brass

Compression olive: Brass

TPR15 Pressure and Temperature Relief Valves

Dimensions

All dimensions in mm unless stated.

Page 38

38 ©ESP Ltd. Sept 2008

Model No:

Date of Purchase:

Any work carried out post commissioning:

Date Nature of work carried out

Specifications

Pressure relief tolerance: +/- 5%

Temperature relief: 90°C - 95°C

Discharge capacity: 10Kw