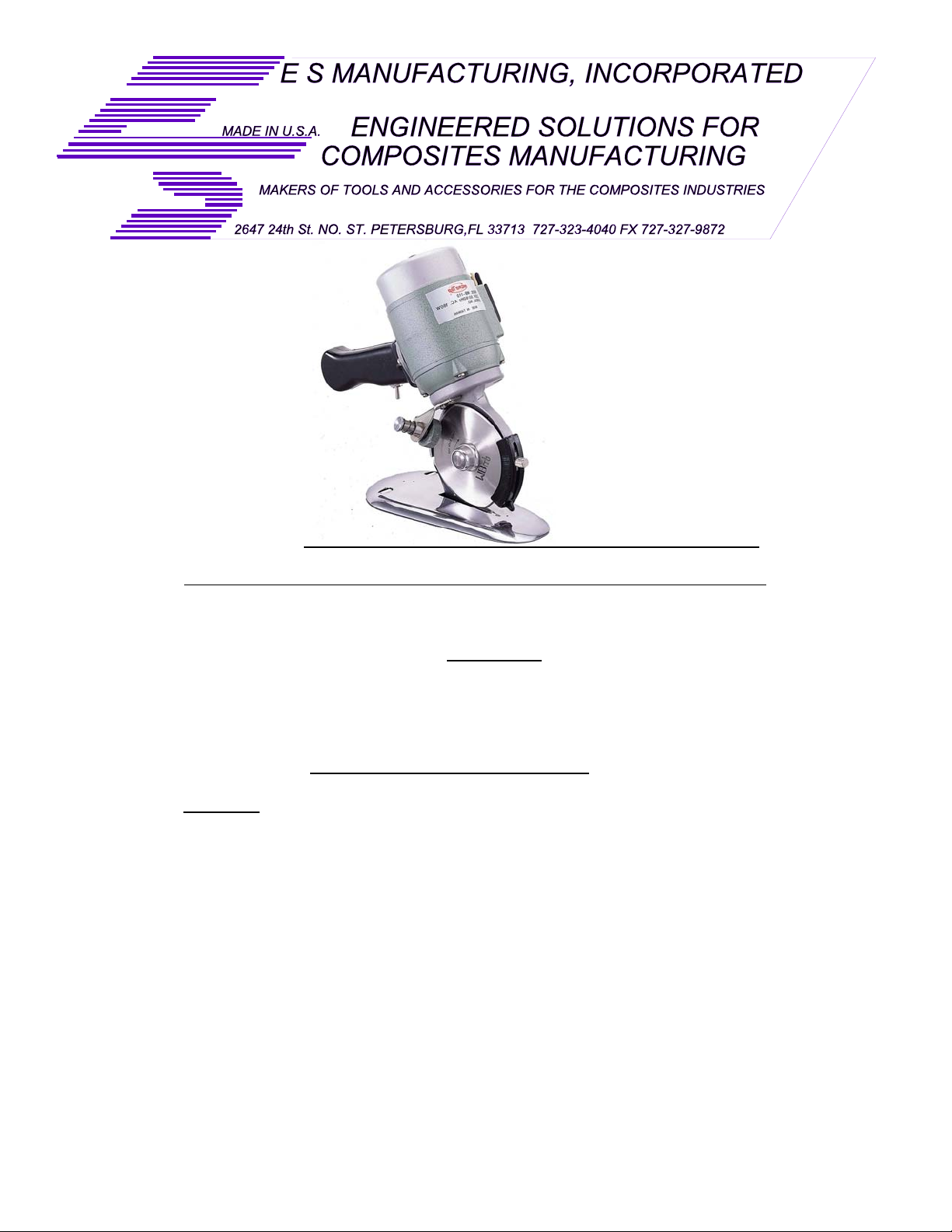

ES manufacturing MB110 Series, MB110-220V, MB110-115V Operating Instructions, Maintenance & Safety

e-mail sales@esmfg.com US/Canada 800-55ES-MFG

______

Documentation & Warranty Packet

MB110 ( 600 rpm’s)

Thank you for purchasing the MB110 If properly operated and

maintained, this Heavy Duty Fiber Cutter will provide years of

trouble free service.

WARRANTY

This model MB110 is warranted against defects for a period of 90 days. Keep your

original sales receipt for proof of purchase. ES Mfg., Inc. will replace or repair any

defective part, either directly, or through the distributor, at the option of ES Mfg.

Warranty shall not cover mis-use or damaged caused by the user. ES Mfg. Reserves

the right to inspect the merchandise at our facility, and is not responsible for

transportation cost to ES Mfg. ES Mfg. Is not responsible for damage, loss, lost

production or any other expenses due to the failure of this product. No other warranty

is expressed or implied.

Copyright 2007 ®

ES Manufacturing, Inc.

2647 24th Street North

St. Petersburg, FL 33713

US / Canada: 800-55ES-MFG Local / International: 727-323-

4040 Fax: 727-327-9872

OPERATING INSTRUCTIONS, MAINTENANCE & SAFETY

MB110-115V

600 rpms

Cutters are precision tools made by master

creaftsman.

In order to maintain this precision and the

adjustments which are essential to satisfactory

operation of your cutter, it is important to

conscientiously follow these instructions.

1.In General

Handle cutter with great care. Do not drop it or

handle it roughly as this will change its

adjustments and may cause serious damage

mechanism.

2.Prior to Starting the Cutting Operation

Firstly set the “ON/OFF” switch to the “off”

position, connect the female plug of the electric

cord with the machine terminal and then tighten

the screw on the female lug. Now connect the

male plug of the electric cord to the electrical

outlet. Prior to starting the cutting operation

remove any obstacle from the path of the base

plate.

3.Cutting Operation

Do not force cutter through material. By nature of

their texture and because of the properties of their

fibers, not all materials can be cut with the same

speed or ease. Trail cutting will readily let you

find the best speed at which the machine is to be

advanced through the material.

4.Sharpening the Blade

1. Connect the plug of the electric cord to the

Power supply.

2. Push the switch to start the machine.

3. Pressing the Push Knob (#21) down for a few

seconds so that the sharpening stone lightly

touches and grinds the blade several times.

5. How to replace Blade

1. Make sure the electrical cord is disconnected

from power source.

2. Turn the screw for finger guard (#4) and

remove finger guard (#5).

3. Remove the blade lock nut (#1) by turning it

(#61,28,29,30).

4. Remove blade (#27) clean and dust or dirt

from machine.

5. Replace dirt blade.

6. How to Replace Carbon Brush

1. While the machine is unplugged.

Remove the two screw (#57) &

pull the cover (#54) upward.

2. Remove the screw cap (#49)

Over the carbon brush and replace the carbon brush (#50-1).

3. Put the cover (#54) back into its

original position and tighten the

screw.

4. Check the right and left carbon

brushes from time to time and

always replace both right and left

carbon brushes when worn out.

7. Lubrication and Maintenance

1. Turn the grease cup (#7) clockwise a

little bit to inject the grease into gear

box.

2. Make sure to add grease supplied

with the machine to the grease cup

(#6) when the grease cup is screwed

down to clean the bottom.

3. Always keep the machine clean

and free from remnants.

8. Maintenance and Inspection

1. Keep machine clean by removing all

accumulations of lint, thread and

cuttings from around the knife itself

to clean away from behind it, any

accumulated matter.

2. In addition, add grease to the

grease cup monthly using the

special grease the is supplied

with the machine.

3. From time to time, check the

right and left carbon brushes

and replace when necessary.

4. It is recommended that the

machine be turned off when not in

use.

5. Never put your hands in front of the

blade when operating.

6. Before doing any work on the

machine, be sure to disconnect the

machine from the electrical

outlet.

Loading...

Loading...